Bosch UPH-C630N-L8585, UPH-C630N-L86154, UPH-C610N-L8120, UPH-C630N-L8120, UPH-C498N-L8585 Operation Manual

...Page 1

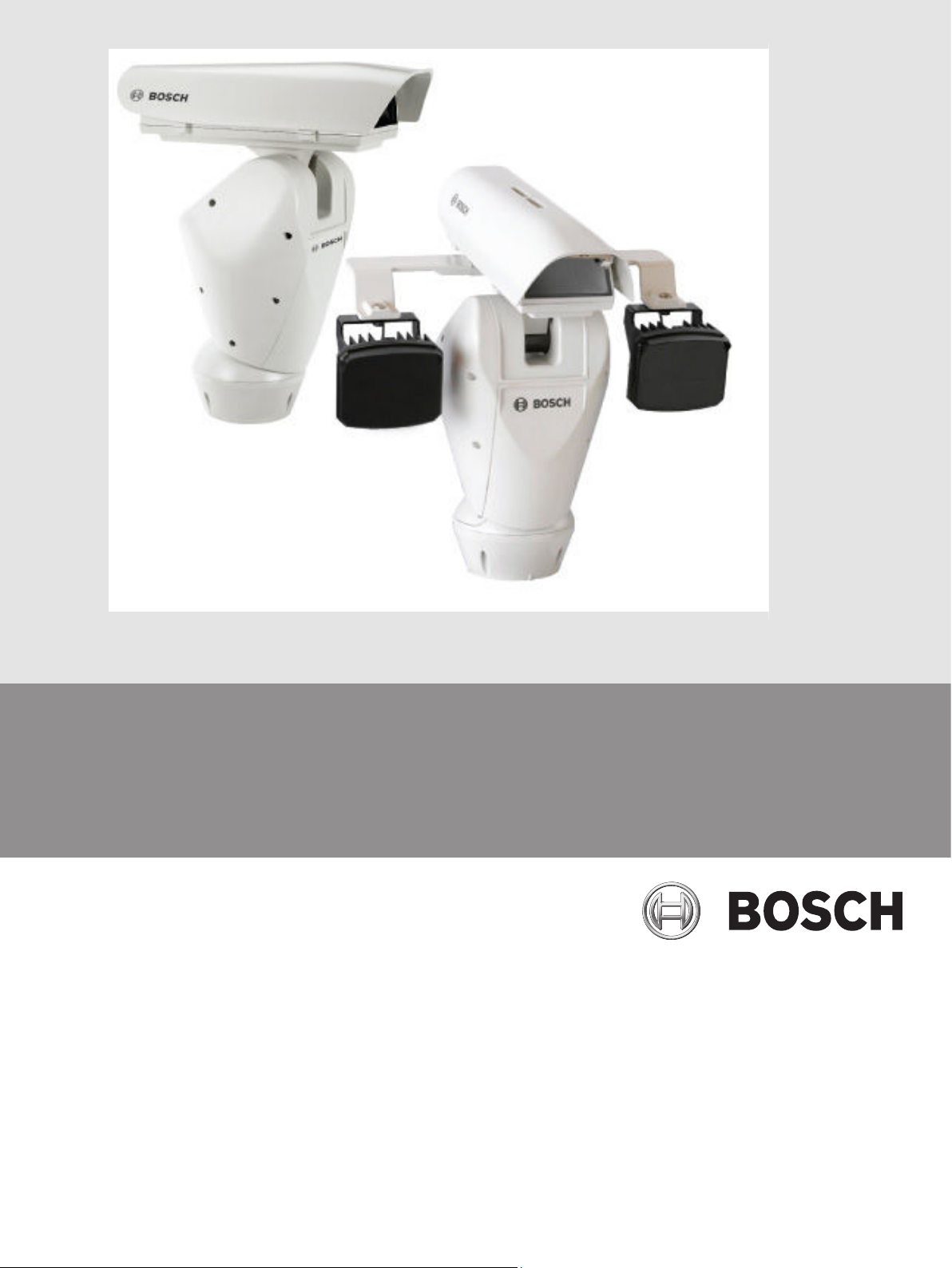

High-Speed Positioning System (HSPS)

UPH Series

Page 2

en Operation Manual

Page 3

High-Speed Positioning System

(HSPS)

Table of contents

Table of Contents | en 3

1

1.1 About this Manual 5

1.2 Legal Information 5

1.3 Safety precautions 5

1.4 Important safety instructions 5

1.5 Important Notices 7

1.6 Customer Support and Service 11

2

2.1 Parts List 12

2.2 Tools Required 12

2.3 Safety Rules 12

3

4

4.1 Installing the Camera/Lens Mounting Tray 15

4.2 Preparing the Camera 17

4.3 Connecting the Camera and Motorized Lens 18

5

5.1 Mounting the High Speed Positioning System 20

5.2 Wiring the Device 24

5.3 Wiring the Video Cable 25

5.4 Connecting the Power Supply 26

6

7

8

9

9.1 Fitting the Bracket 34

9.2 Assembling the Spotlights 34

9.3 Fitting the Spotlights on the Bracket 35

9.4 Connecting the Spotlights 36

10

11

11.1 Pelco D Baud Rate 43

11.2 Protocol 43

11.3 Setting the Address 43

11.4 RS485 Line Termination 44

11.5 Biphase/Bilinx Termination 44

11.6 Connections 45

12

12.1 Language Menu 48

12.2 Display Setup Menu 48

12.2.1 Area Parameters Menu 49

12.2.2 Changing the Edit Text Menu 51

12.2.3 Display Parameters 52

12.3 Motion Parameters Menu 53

12.3.1 Speed Menu 53

12.3.2 Limits 55

12.3.3 Preset/Patrol/Autopan 56

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Safety 5

Unpacking 12

Description 14

Installing the Camera/Lens 15

Installing the High Speed Positioning System 20

Connecting to the Standard Base 30

Connecting to the IR360 Base 31

Fixing the Top Unit 32

Assembling and Connecting IR360 Models (optional) 34

Making Connections for the Pump of the Washer Kit (Optional) 41

Configuring the Device 42

Configuring the System 48

Page 4

4 en | Table of Contents

High-Speed Positioning System

(HSPS)

12.3.4 Wiper-Washer 62

12.3.5 Alarms 63

12.4 Camera/Infrared Parameters 64

12.4.1 Lens Modules Parameters and Area Masking 64

12.4.2 Infrared Parameters 66

12.4.3 Illuminator/Dinion Configuration 66

12.5 Load Default Configuration 67

12.6 Setup Info Menu 68

13

Keyboard Commands List - Bosch 69

13.1 Keyboard Commands List - Pelco 69

13.2 Changing the Settings 70

13.3 Changing the Numeric Fields 70

14

15

On-screen Display (OSD) 71

Troubleshooting 73

15.1 Low and High Temperatures 74

15.2 Dimensions and Range of Movement 75

16

Maintenance 77

16.1 Cleaning 77

16.2 Replacing the Fuses 77

17

Appendix A: Wiring Summary 78

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 5

!

!

High-Speed Positioning System

(HSPS)

Safety | en 5

1

1.1

1.2

1.3

Safety

About this Manual

This manual has been compiled with great care and the information it contains has been

thoroughly verified. The text was complete and correct at the time of printing. Because of the

ongoing development of products, the content of the manual may change without notice.

Bosch Security Systems accepts no liability for damage resulting directly or indirectly from

faults, incompleteness, or discrepancies between the manual and the product described.

Legal Information

Copyright

This manual is the intellectual property of Bosch Security Systems, Inc. and is protected by

copyright. All rights reserved.

Trademarks

All hardware and software product names used in this document are likely to be registered

trademarks and must be treated accordingly.

Safety precautions

Danger!

High risk: This symbol indicates an imminently hazardous situation such as “Dangerous

Voltage” inside the product. If not avoided, this will result in an electrical shock, serious bodily

injury, or death.

1.4

Warning!

Medium risk: Indicates a potentially hazardous situation. If not avoided, this may result in

minor or moderate injury.

Caution!

Low risk: Indicates a potentially hazardous situation. If not avoided, this may result in

property damage or risk of damage to the unit.

Notice!

This symbol indicates information or a company policy that relates directly or indirectly to the

safety of personnel or protection of property.

Important safety instructions

Read, follow, and retain all of the following safety instructions. Heed all warnings on the unit

and in the operating instructions before operation.

1. Cleaning - Unplug the unit from the outlet before cleaning. Follow any instructions

provided with the unit. Generally, using a dry cloth for cleaning is sufficient but a moist,

fluff-free cloth or leather shammy may also be used. Do not use liquid cleaners or aerosol

cleaners.

2. Heat Sources - Do not install the unit near any heat sources such as radiators, heaters,

stoves, or other equipment (including amplifiers) that produce heat.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 6

6 en | Safety

High-Speed Positioning System

(HSPS)

3. Ventilation - Any openings in the unit enclosure are provided for ventilation to prevent

overheating and ensure reliable operation. Do not block or cover these openings. Do not

place the unit in an enclosure unless proper ventilation is provided, or the manufacturer's

instructions have been adhered to.

4. Object and liquid entry - Never push objects of any kind into this unit through openings

as they may touch dangerous voltage points or short-out parts that could result in a fire

or electrical shock. Never spill liquid of any kind on the unit. Do not place objects filled

with liquids, such as vases or cups, on the unit.

5. Controls adjustment - Adjust only those controls specified in the operating instructions.

Improper adjustment of other controls may cause damage to the unit. Use of controls or

adjustments, or performance of procedures other than those specified, may result in

hazardous radiation exposure.

6. Overloading - Do not overload outlets and extension cords. This can cause fire or

electrical shock.

7. Power sources - Operate the unit only from the type of power source indicated on the

label. Before proceeding, be sure to disconnect the power from the cable to be installed

into the unit.

– For battery powered units, refer to the operating instructions.

– For external power supplied units, use only the recommended or approved power

supplies.

– For limited power source units, this power source must comply with EN60950.

Substitutions may damage the unit or cause fire or shock.

– For 24 VAC units, voltage applied to the unit's power input should not exceed ±10%,

or 28 VAC. User-supplied wiring must comply with local electrical codes (Class 2

power levels). Do not ground the supply at the terminals or at the unit's power

supply terminals.

– If unsure of the type of power supply to use, contact your dealer or local power

company.

Notice!

Installation category (also called Overvoltage Category) specifies the level of mains voltage

surges that the equipment will be subjected to. The category depends upon the location of

the equipment, and on any external surge protection provided. Equipment in an industrial

environment, directly connected to major feeders/short branch circuits, is subjected to

Installation Category III. If this is the case, a reduction to Installation Category II is required.

This can be achieved by use of an isolating transformer with an earthed screen between

primary and secondary, or by fitting listed Surge Protective Devices (SPDs) from live to

neutral and from neutral to earth. Listed SPDs shall be designed for repeated limiting of

transient voltage surges, suitable rated for operating voltage and designated as follows:

- Type 2 (Permanently connected SPDs intended for installation on the load side of the

service equipment overcurrent device)

- Nominal Discharge Current (In) 20 kA min.

For example: FERRAZ SHAWMUT, STT2240SPG-CN, STT2BL240SPG-CN rated 120/240 VAC,

(In=20 kA)

8. Servicing - Do not attempt to service this unit yourself. Opening or removing covers may

expose you to dangerous voltage or other hazards. Refer all servicing to qualified service

personnel.

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 7

High-Speed Positioning System

(HSPS)

9. Damage requiring service - Unplug the unit from the main AC power source and refer

10. Replacement parts - Be sure the service technician uses replacement parts specified by

11. Safety check - Safety checks should be performed upon completion of service or repairs

12. Installation - Install in accordance with the manufacturer's instructions and in accordance

Safety | en 7

servicing to qualified service personnel when any damage to the equipment has occurred,

such as:

– the power supply cord or plug is damaged;

– exposure to moisture, water, and/or inclement weather (rain, snow, etc.);

– liquid has been spilled in or on the equipment;

– an object has fallen into the unit;

– unit has been dropped or the unit cabinet is damaged;

– unit exhibits a distinct change in performance;

– unit does not operate normally when the user correctly follows the operating

instructions.

the manufacturer, or that have the same characteristics as the original parts.

Unauthorized substitutions may cause fire, electrical shock, or other hazards.

to the unit to ensure proper operating condition.

with applicable local codes.

1.5

Notice!

This product must only be used with a UR marked camera, rated 6-12 VDC with a maximum

power consumption of 5 W and a flammability class V-0 and Product Category NWGQ2,8.

13. Attachments, changes or modifications - Only use attachments/accessories specified by

the manufacturer. Any change or modification of the equipment, not expressly approved

by Bosch, could void the warranty or, in the case of an authorization agreement, authority

to operate the equipment.

Important Notices

Disclaimer

Underwriter Laboratories Inc. (“UL”) has not tested the performance or reliability of the

security or signaling aspects of this product. UL has only tested fire, shock and/or casualty

hazards as outlined in UL's Standard(s) for Safety for Closed Circuit Television Equipment, UL

2044. UL Certification does not cover the performance or reliability of the security or signaling

aspects of this product.

UL MAKES NO REPRESENTATIONS, WARRANTIES, OR CERTIFICATIONS WHATSOEVER

REGARDING THE PERFORMANCE OR RELIABILITY OF ANY SECURITY OR SIGNALING RELATED

FUNCTIONS OF THIS PRODUCT.

FCC & ICES Information

(U.S.A. and Canadian Models Only)

This device complies with part 15 of the FCC Rules. Operation is subject to the following

conditions:

– this device may not cause harmful interference, and

– this device must accept any interference received, including interference that may cause

undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules and ICES-003 of Industry Canada. These

limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and

radiates radio frequency energy and, if not installed and used in accordance with the

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 8

8 en | Safety

High-Speed Positioning System

(HSPS)

instruction manual, may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference, in which case the

user will be required to correct the interference at his expense.

Intentional or unintentional modifications, not expressly approved by the party responsible for

compliance, shall not be made. Any such modifications could void the user's authority to

operate the equipment. If necessary, the user should consult the dealer or an experienced

radio/television technician for corrective action.

The user may find the following booklet, prepared by the Federal Communications

Commission, helpful: How to Identify and Resolve Radio-TV Interference Problems. This

booklet is available from the U.S. Government Printing Office, Washington, DC 20402, Stock

No. 004-000-00345-4.

Informations FCC et ICES

(modèles utilisés aux États-Unis et au Canada uniquement)

Ce produit est conforme aux normes FCC partie 15. la mise en service est soumises aux deux

conditions suivantes :

– cet appareil ne peut pas provoquer d'interférence nuisible et

– cet appareil doit pouvoir tolérer toutes les interférences auxquelles il est soumit, y

compris les interférences qui pourraient influer sur son bon fonctionnement.

AVERTISSEMENT: Suite à différents tests, cet appareil s’est révélé conforme aux exigences

imposées aux appareils numériques de Classe A en vertu de la section 15 du règlement de la

Commission fédérale des communications des États-Unis (FCC). Ces contraintes sont

destinées à fournir une protection raisonnable contre les interférences nuisibles quand

l'appareil est utilisé dans une installation commerciale. Cette appareil génère, utilise et émet

de l'energie de fréquence radio, et peut, en cas d'installation ou d'utilisation non conforme aux

instructions, générer des interférences nuisibles aux communications radio. L’utilisation de ce

produit dans une zone résidentielle peut provoquer des interférences nuisibles. Le cas

échéant, l’utilisateur devra remédier à ces interférences à ses propres frais.

Au besoin, l’utilisateur consultera son revendeur ou un technicien qualifié en radio/télévision,

qui procédera à une opération corrective. La brochure suivante, publiée par la Commission

fédérale des communications (FCC), peut s’avérer utile : How to Identify and Resolve Radio-TV

Interference Problems (Comment identifier et résoudre les problèmes d’interférences de radio

et de télévision). Cette brochure est disponible auprès du U.S. Government Printing Office,

Washington, DC 20402, États-Unis, sous la référence n° 004-000-00345-4.

Notice!

This is a class A product. In a domestic environment this product may cause radio

interference, in which case the user may be required to take adequate measures.

Accessories - Do not place this unit on an unstable stand, tripod, bracket,

or mount. The unit may fall, causing serious injury and/or serious damage to

the unit. Use only with the cart, stand, tripod, bracket, or table specified by

the manufacturer. When a cart is used, use caution and care when moving

the cart/apparatus combination to avoid injury from tip-over. Quick stops,

excessive force, or uneven surfaces may cause the cart/unit combination to

overturn. Mount the unit per the manufacturer's instructions.

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 9

!

High-Speed Positioning System

(HSPS)

All-pole power switch - Incorporate an all-pole listed circuit breaker, with a contact separation

of at least 20A, 3 mm (400 V not essential) in each pole, into the electrical installation of the

building.If it is needed to open the housing for servicing and/or other activities, use this allpole switch as the main disconnect device for switching off the voltage to the unit.

Warning!

For the standard models with 120/230 VAC power, an external junction box with a readily

accessible 2-pole disconnect device must be incorporated.For the IR model UPH-H-WDIR-24,

the 24 VAC power must be provided by a UL listed power supply with a double insulation

transformer.

Camera grounding - For mounting the camera in potentially damp environments, ensure to

ground the system using the ground connection of the power supply connector (see section:

Connecting external power supply).

Camera lens - An assembled camera lens in the outdoor housing must comply and be tested in

accordance with UL/IEC60950. Any output or signal lines from the camera must be SELV or

Limited Power Source. For safety reasons the environmental specification of the camera lens

assembly must be within the environmental specification of -10 °C (14 °F) to 50 °C (122 °F).

Camera signal - Protect the cable with a primary protector if the camera signal is beyond 140

feet, in accordance with NEC800 (CEC Section 60).

Coax grounding:

– Ground the cable system if connecting an outside cable system to the unit.

– Connect outdoor equipment to the unit's inputs only after this unit has had its grounding

– Disconnect the unit's input connectors from outdoor equipment before disconnecting the

– Follow proper safety precautions such as grounding for any outdoor device connected to

U.S.A. models only - Section 810 of the National Electrical Code, ANSI/NFPA No.70, provides

information regarding proper grounding of the mount and supporting structure, grounding of

the coax to a discharge unit, size of grounding conductors, location of discharge unit,

connection to grounding electrodes, and requirements for the grounding electrode.

Electronic Surveillance - This device is intended for use in public areas only. U.S. federal law

strictly prohibits surreptitious recording of oral communications.

Environmental statement - Bosch has a strong commitment towards the environment. This

unit has been designed to respect the environment as much as possible.

Safety | en 9

Disposal

Your Bosch product has been developed and manufactured using highquality materials and components that can be reused.

This symbol means that electronic and electrical devices that have reached

the end of their working life must be disposed of separately from

household waste.

In the EU, separate collecting systems are already in place for used

electrical and electronic products. Please dispose of these devices at your

local communal waste collection point or at a recycling center.

plug connected to a grounded outlet or its ground terminal is properly connected to a

ground source.

grounding plug or grounding terminal.

this unit.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 10

!

!

!

10 en | Safety

High-Speed Positioning System

(HSPS)

Electrostatic-sensitive device - Use proper CMOS/MOS-FET handling precautions to avoid

electrostatic discharge. NOTE: Wear required grounded wrist straps and observe proper ESD

safety precautions when handling the electrostatic-sensitive printed circuit boards.

Fuse rating - For protection of the device, the branch circuit protection must be secured with

a maximum fuse rating as indicated in the manual. This must be in accordance with NEC800

(CEC Section 60).

Caution!

For continued protection against risk of fire, replace, only with same type and rating of fuse.

Grounding and polarization - This unit may be equipped with a polarized alternating current

line plug (a plug with one blade wider than the other blade). This safety feature allows the

plug to fit into the power outlet in only one way. If unable to insert the plug fully into the

outlet, contact a locally certified electrician to replace the obsolete outlet. Do not defeat the

safety purpose of the polarized plug.

Alternately, this unit may be equipped with a 3-pole grounding plug (a plug with a third pin for

earth grounding). This safety feature allows the plug to fit into a grounded power outlet only.

If unable to insert the plug into the outlet, contact a locally certified electrician to replace the

obsolete outlet. Do not defeat the safety purpose of the grounding plug.

Caution!

The separate protective earthing terminal provided on this product shall be permanently

connected to earth.

Moving - Disconnect the power before moving the unit. Move the unit with care. Excessive

force or shock may damage the unit and the hard disk drives.

Outdoor signals - The installation for outdoor signals, especially regarding clearance from

power and lightning conductors and transient protection, must be in accordance with NEC725

and NEC800 (CEC Rule 16-224 and CEC Section 60).

Permanently connected equipment - Incorporate a readily accessible disconnect device

external to the equipment.

Power resupply - If the unit is forced to power down due to exceeding the specified operating

temperatures, disconnect the power cord, wait for at least 30 seconds, and then reconnect

the power cord.

Power lines - Do not locate the camera near overhead power lines, power circuits, or

electrical lights, nor where it may contact such power lines, circuits, or lights.

System ground/Safety ground

System (video) ground is indicated by the symbol

Safety (power) ground is indicated by the symbol .

The system ground is only used to comply with safety standards or installation practices in

certain countries. Bosch does not recommend connecting system ground to safety ground

unless it is explicitly required. However, if the system ground and safety ground are connected

and grounding loops are causing interference in the video signal, use an isolation transformer

(available separately from Bosch).

Caution!

The separate protective earthing terminal provided on this product shall be permanently

connected to earth.

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

.

Page 11

!

High-Speed Positioning System

(HSPS)

Caution!

Connecting System ground to Safety ground may result in ground loops that can disrupt the

CCTV system.

Video loss - Video loss is inherent to digital video recording; therefore, Bosch Security

Systems cannot be held liable for any damage that results from missing video information. To

minimize the risk of lost digital information, Bosch Security Systems recommends multiple,

redundant recording systems, and a procedure to back up all analog and digital information.

Safety | en 11

1.6

Customer Support and Service

If this unit needs service, contact the nearest Bosch Security Systems Service Center for

authorization to return and shipping instructions.

Service Centers

USA

Repair Center

Telephone: 800-566-2283

Fax: 800-366-1329

E-mail: repair@us.bosch.com

Customer Service

Telephone: 888-289-0096

Fax: 585-223-9180

E-mail: security.sales@us.bosch.com

Technical Support

Telephone: 800-326-1450

Fax: 585-223-3508 or 717-735-6560

E-mail: technical.support@us.bosch.com

Canada

Telephone: 514-738-2434

Fax: 514-738-8480

Europe, Middle East, Africa Region

Repair Center

Telephone: 31 (0) 76-5721500

Fax: 31 (0) 76-5721413

E-mail: RMADesk.STService@nl.bosch.com

Asia Region

Repair Center

Telephone: 65 63522776

Fax: 65 63521776

E-mail: rmahelpdesk@sg.bosch.com

Customer Service

Telephone: 86 (0) 756 7633117 or

86 (0) 756 7633121

Fax: 86 (0) 756 7631710

E-mail: customer.service@cn.bosch.com

Warranty and additional information

For additional information and warranty queries, please contact your Bosch Security Systems

representative or visit our website at www.boschsecurity.com.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 12

!

12 en | Unpacking

High-Speed Positioning System

(HSPS)

2

2.1

Unpacking

This equipment should be unpacked and handled with care. If an item appears to have been

damaged in shipment, notify the shipper immediately.

Verify that all the parts listed in Parts List, page 12 are included. If any items are missing,

notify your Bosch Security Systems Sales or Customer Service Representative.

The original packing carton is the safest container in which to transport the unit and must be

used if returning the unit for service. Save it for possible future use.

Parts List

The High Speed Positioning System includes the following components:

– One (1) Unitized Pan Head (UPH) device

– One (1) Camera/Lens Mounting Tray

– The following Accessory Bags

– Cable and Screws:

One (1) coaxial termination cable

One (1) coaxial cable

Four (4) M4 x 10 mm screws; for tray mounting

Four (4) 4 mm washers; for tray mounting

Two (2) tie wraps, 102 x 2.5 mm

One (1) tie wrap, 180 x 3.5 mm

– Power Connection:

One (1) 3 mm Allen wrench

Two (2) tie wraps, 102 x 2.5 mm

One (1) plastic tube (power wiring cover)

Two (2) conduit plugs for cable glands

One (1) safety label

– Desiccant:

One (1) desiccant bag

One (1) mounting plate

Two (2) M4 x 10 mm screws self-tapping, galvanized (Zn)

One (1) 4 mm Allen wrench

– One (1) instruction manual

– One (1) box containing:

– One (1) PTZ base with power supply and one (1) desiccant bag

– Four (4) M5 x 20 mm screws, hexagonal head;

– Four (4) washers/gaskets (2015 O-ring)

– IR bracket with four (4) M5 x 14 mm screws, hexagonal head; four (4) M5 lock washers

UNI 1751; IR model only

2.2

2.3

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Tools Required

– Small, straight-blade screwdriver - 2.5 mm (0.1 in.)

– Calibrated torque wrench – 4 mm

– Thread locker (such as Loctite 243) (to ensure watertight seals)

Safety Rules

Warning!

Installation and maintenance must be performed by skilled personnel only.

Page 13

!

!

High-Speed Positioning System

(HSPS)

Warning!

The building installation must include a 20A max. Branch Circuit Protection.

Unpacking | en 13

To ensure safety, the following warnings are specified:

– Connect the device to a power source corresponding to the indications given on the

marking label.

– The device has been designed for permanent installation in a building or other suitable

structure.

– Moving parts may result in risk of injury, therefore, the device should be mounted so that

it is accessible only to the technician/installer.

– Place the safety warning label near the UPH.

– Before carrying out any technical work on the UPH, tilt the UPH all the way up or all the

way down, then disconnect the power supply and cables from all other devices.

– Do not use power cables with signs of wear or aging.

– Do not use the device in the presence of inflammable substances.

– Do not allow children or unauthorized personnel to use the device.

– The device should be switched OFF when the power supply has been disconnected and

the connecting cables to other devices have been removed.

Caution!

Before disconnecting the power supply to the UPH, tilt the device either all the way up or all

the way down. When the UPH loses power, depending on how it is positioned, the unit may

drop slightly forward or backward. Therefore, failure in correctly positioning the UPH before

disconnecting the power supply may result in personal injury or possible damage to the

device.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 14

14 en | Description

High-Speed Positioning System

(HSPS)

3

Description

The Bosch High-Speed Positioning System is a complete, high-performance, high quality

solution that can pan 360 degrees continuously at speeds of up to 100 degrees per second. An

extensive range of options lets you tailor the system to your specific requirements. For

example, a wide variety of video cameras and lenses, including the optimized Dinion 2X

camera and zoom lens combinations, are available.

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 15

!

High-Speed Positioning System

(HSPS)

Installing the Camera/Lens | en 15

4

4.1

Installing the Camera/Lens

This chapter outlines the procedures needed to install the camera/lens inside the UPH

housing.

Caution!

Installation must be made by qualified personnel and conform to ANSI/NFPA 70 (the National

Electrical Code® (NEC)), Canadian Electrical Code, Part I (also called CE Code or CSA C22.1),

and all applicable local codes. Bosch Security Systems, Inc. accepts no liability for any

damages or losses caused by incorrect or improper installation.

Note: For models that already have the camera/lens installed, go to Installing the High Speed

Positioning System, page 20.

Notice!

This product must only be used with a UL-marked camera, rated 6-12 VDC with a maximum

power consumption of 5 W and a flammability class V-0 and Product Category NWGQ2,8.

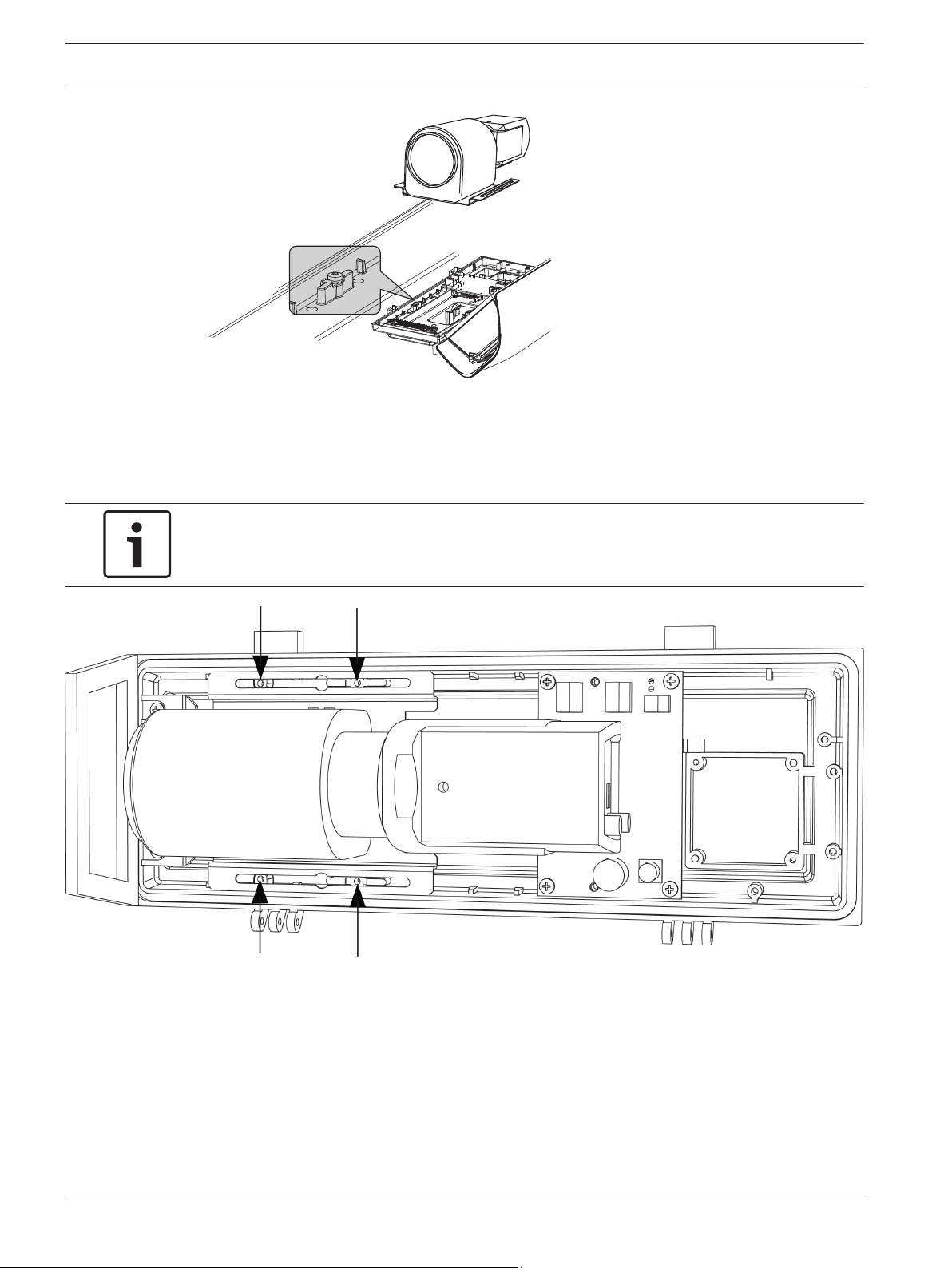

Installing the Camera/Lens Mounting Tray

For some models of the High Speed Positioning System, the customer is responsible for

installing the camera and lenses.

To install the camera, follow these steps:

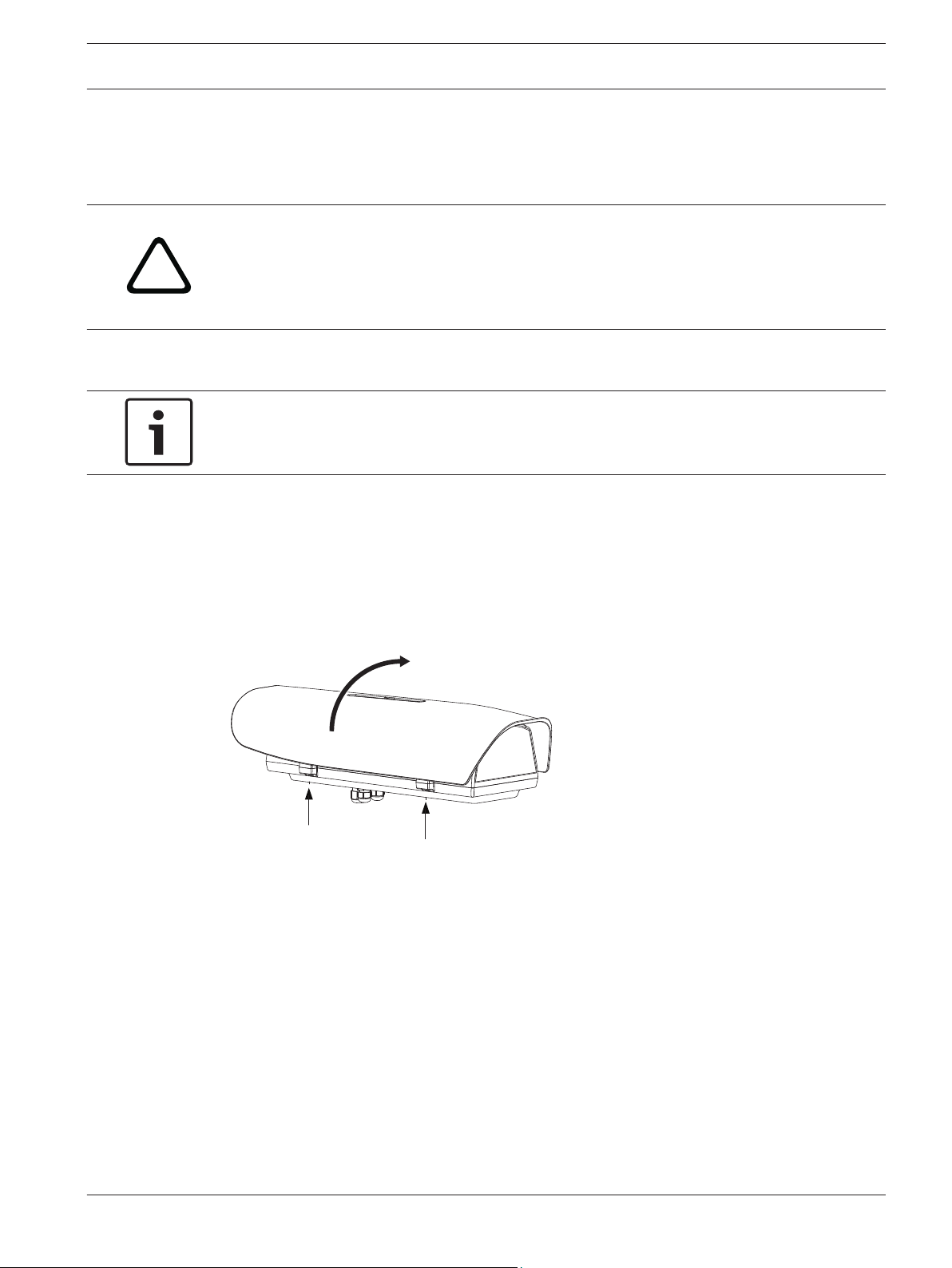

1. Open the housing by loosening the captive screws on the side and swivel the upper body

until it is completely open (do not remove screws completely).

Figure 4.1: Loosen Screws and Open Lid of Housing

2. Remove the camera/lens mounting tray from the packing box.

3. Install the camera/lens mounting tray attached in the correct position inside the housing

at the location shown below.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 16

16 en | Installing the Camera/Lens

Figure 4.2: Install Camera/Tray

4. Reposition the camera/lens mounting tray by sliding it forward so that the lens is as close

to the front window as possible. Insert and tighten the four M4 x 10 screws and the four

washers (contained in the Cable and Screws accessory bag) as shown in the figure

“Attach Camera to Housing” below.

High-Speed Positioning System

(HSPS)

Notice!

A partially blocked view may result if the camera is not pushed up close to the front of the

housing.

Figure 4.3: Attach Camera to Housing

5. Locate the sealed plastic bag containing the desiccant bag.

6. Place the desiccant bag inside the housing as shown in the figure below, with the

desiccant bag secured into position by the metal fixing accessory and two fixing screws

(supplied in the Desiccant accessory bag).

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 17

High-Speed Positioning System

(HSPS)

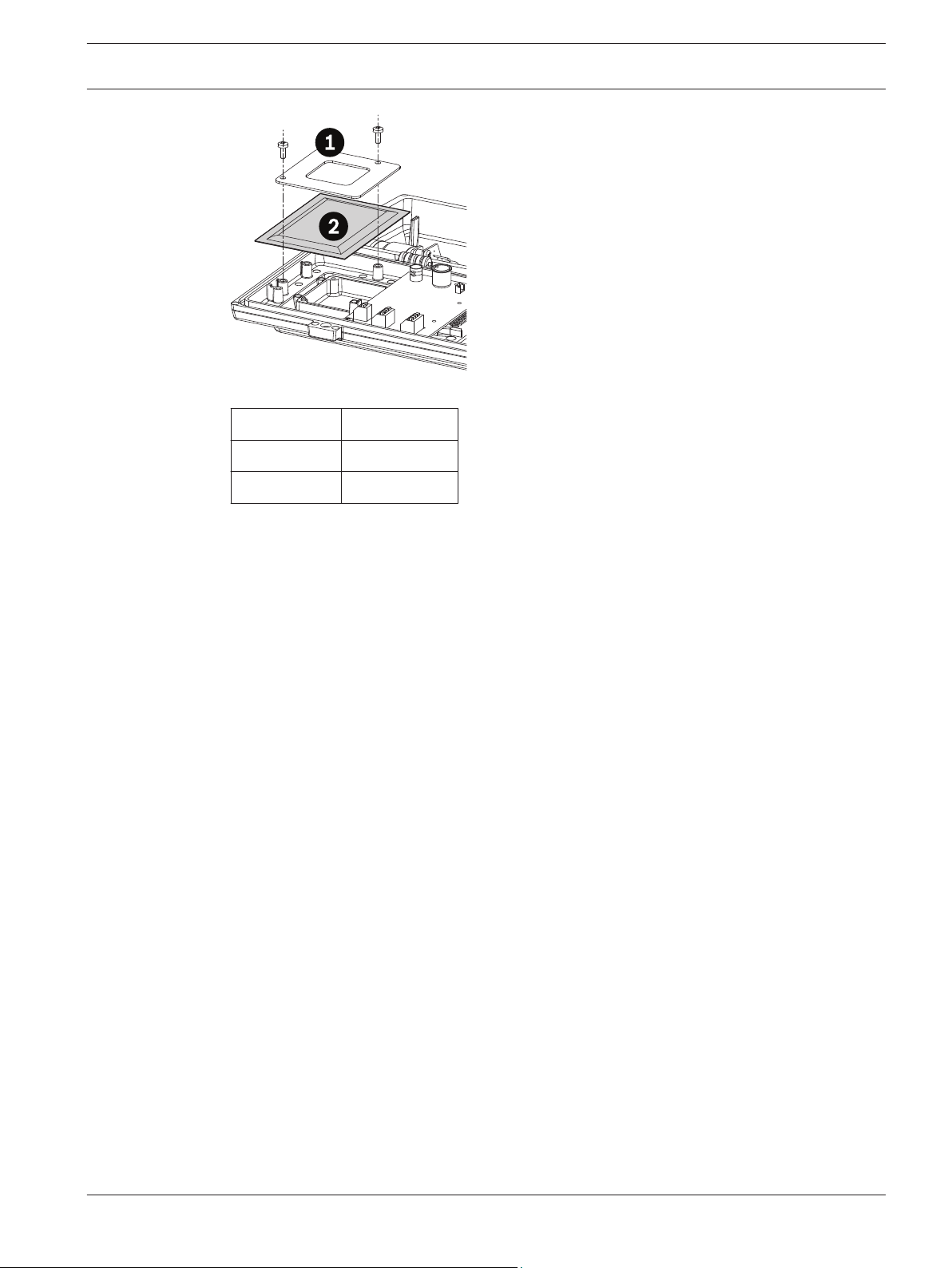

Figure 4.4: Attach Desiccant Bag

Installing the Camera/Lens | en 17

4.2

Reference #

1 Bracket

2 Desiccant Bag

Description

Preparing the Camera

1. Remove the camera packaging material.

2. Make sure that the gasket is present and in good condition.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 18

J22

J27

J26

J5

J2

J7

J1

18 en | Installing the Camera/Lens

High-Speed Positioning System

(HSPS)

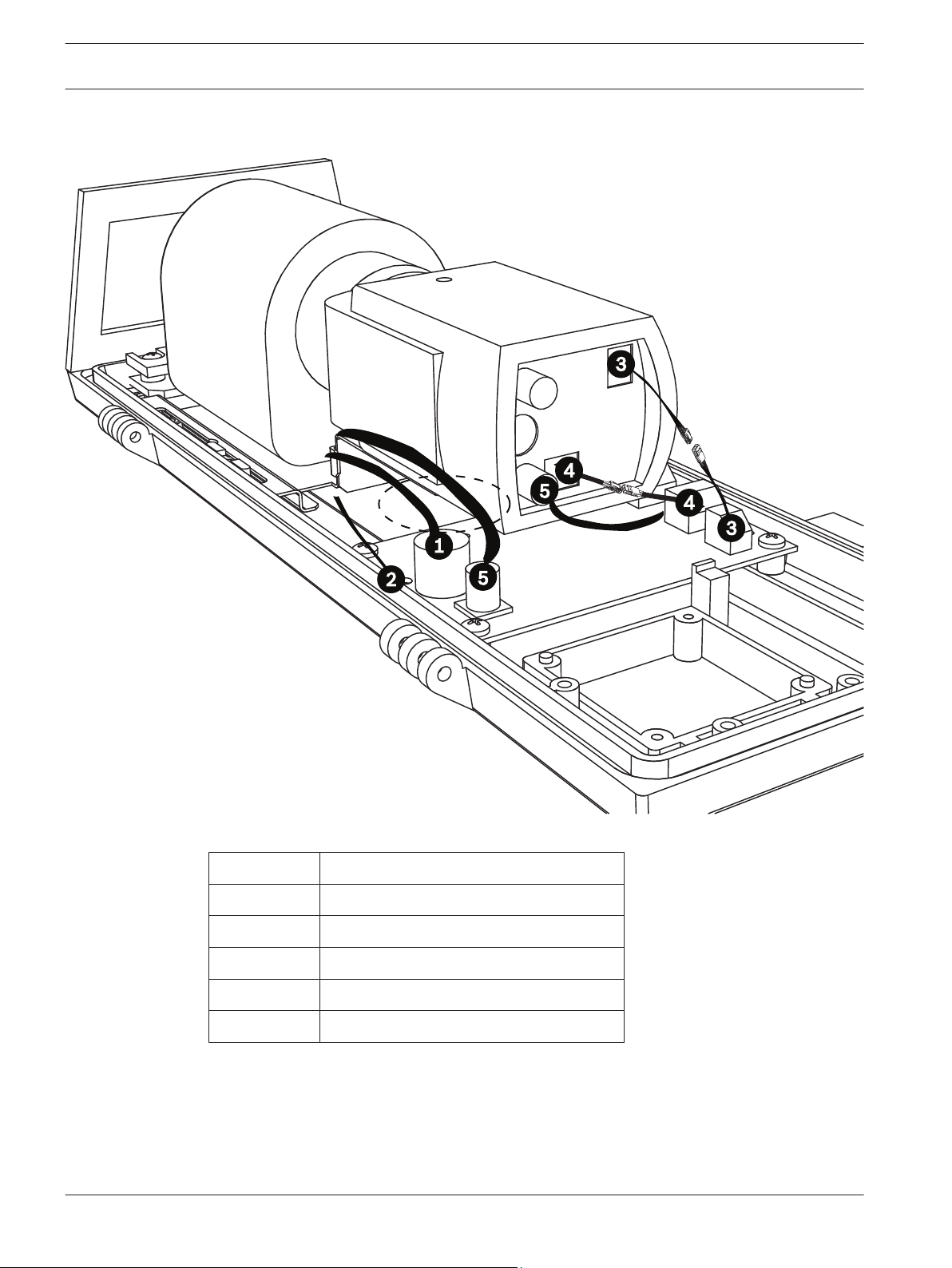

4.3

Connecting the Camera and Motorized Lens

Figure 4.5: Make Connections (LTC 0498 Dinion 2X camera shown)

Reference Description

1 8-pin DIN connector

2 4-pin iris override connector

3 2-pin power cable

4 4-pin alarm cable

5 VIDEO IN connector

1. Connect the 8-pin DIN connector zoom and focus control cable from the camera to the J5

location on the board. Secure cable in up-right position by using supplied tie wrap.

2. If applicable (LTC 3293/30 manual override units only), connect the 4-pin iris override

connector from the camera to the J2 location on the board.

3. Connect the 2-pin power cable from the camera to the mating connector from the J26

location on the board.

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 19

High-Speed Positioning System

(HSPS)

4. Connect the 4-pin alarm cable from the camera to the mating connector from the J27

5. Connect the “L” adapter end of the coax cable (supplied in the Cable and Screw

6. Route the other end of the coax cable along the right side (looking from behind) of the

7. Wrap one of the 102 x 2.5 mm tie wraps around the zoom and focus cable and the coax

8. Close and secure the housing lid.

Installing the Camera/Lens | en 19

location on the board.

accessory bag) to the coax connector on the back of the camera. VIDEO IN connector

from the camera to the J1 location on the board.

camera and under the camera tray. Then, connect the coax cable to the J1 location on the

board.

cable, near the location where the cables connect to the board.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 20

!

!

!

20 en | Installing the High Speed Positioning System

High-Speed Positioning System

(HSPS)

5

Installing the High Speed Positioning System

This chapter outlines the procedures needed to mount the High Speed Positioning System.

Caution!

Installation must be made by qualified personnel and conform to ANSI/NFPA 70 (the National

Electrical Code® (NEC)), Canadian Electrical Code, Part I (also called CE Code or CSA C22.1),

and all applicable local codes. Bosch Security Systems, Inc. accepts no liability for any

damages or losses caused by incorrect or improper installation.

Notice!

The High-speed Positioning System device cannot be mounted upside down! This

configuration stresses bearings and mechanical components; no liabilities are accepted and

all warranties are void.

Notice!

In accordance with NEC laws, you may be required to install an external power junction box.

The following warnings apply to the device itself, the video cable, and the connections for

Biphase and for RS-422/Pelco D.

5.1

Warning!

The installation is type TNV-1. Do not connect it to SELV circuits.

Warning!

The installation is type CDS (Cable Distribution System). Do not connect it to SELV circuits.

In order to reduce the risk of fire, only use UL Listed or CSA certified telecommunication line

cord sizes greater than or equal to 26 AWG.

Mounting the High Speed Positioning System

The High Speed Positioning System can be mounted with either a wall mount (MTC-WUPH,

sold separately) or a pole mount (MTC-PUPH, sold separately).

The figure below illustrates the configuration of the mount, the support for the washer pipe

for the optional washer kit, and the base of the device.

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 21

!

High-Speed Positioning System

(HSPS)

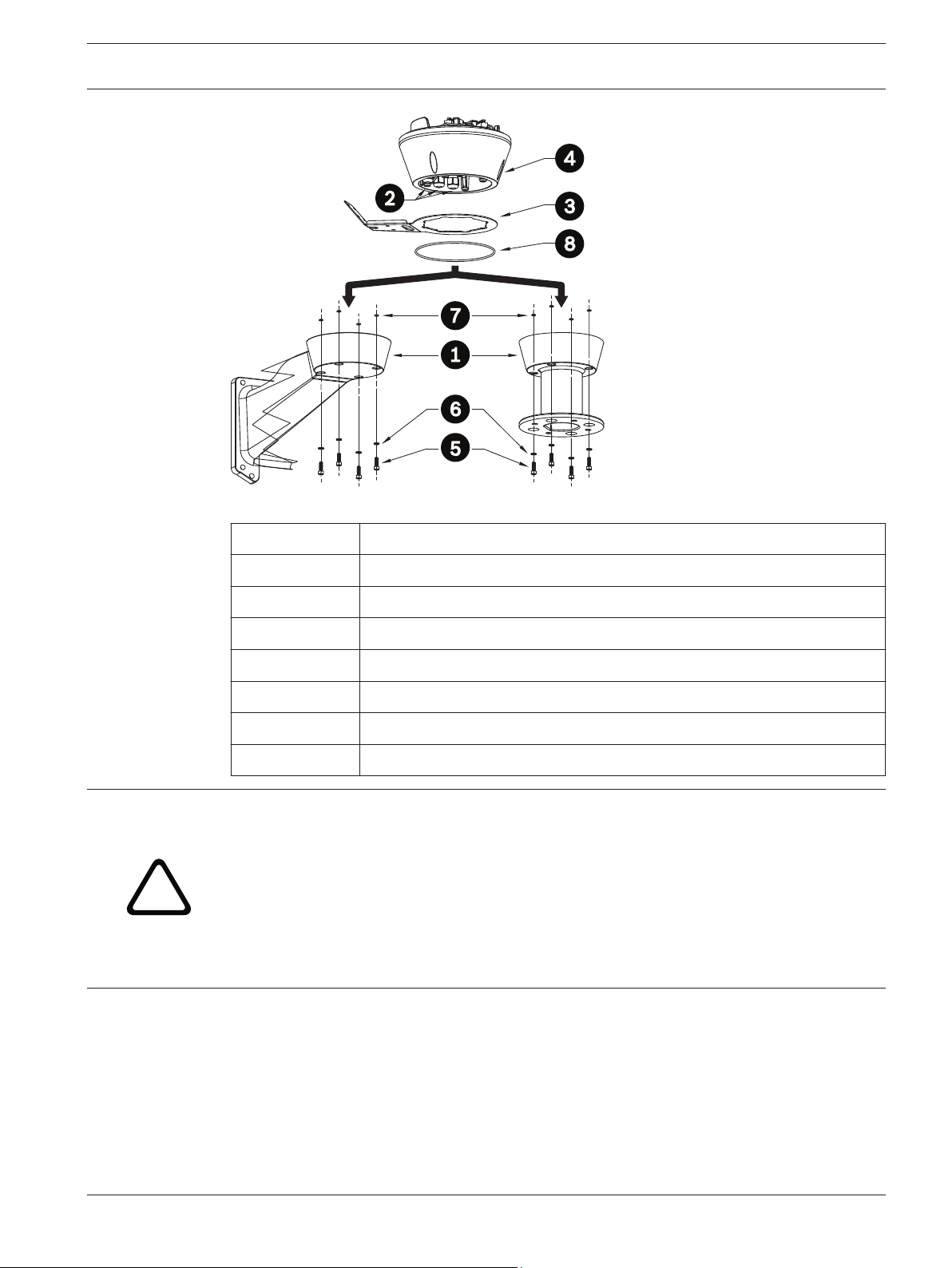

Figure 5.1: Diagram of mount, washer support, base

Installing the High Speed Positioning System | en 21

1

2 Cable glands

3 Support for the washer pipe for the optional washer kit

4 Base

5 Screws (4)

6 Washers (4)

7 Screw seals (4)

8 Gasket

Warning!

Take special care when attaching and fastening down the device.

Fixing dowel pins with a traction torque rating/load of at least 300 dN each are required:

- When the MTC-WUPH Wall Mount is fixed to a wall.

- If the mount is to be attached to a concrete surface.

For a metal surface, use screws/bolts with a diameter of at least 8 mm and of an appropriate

length. The clamping system must support at least four times the weight of the entire

equipment, including the pan and tilt head, lenses, and camera.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Installing the mount

To install the device, follow these steps:

1. Determine the location to install the device.

When selecting a location, a minimum clearance of 300 mm (12 in.) in front of the device

and 300 mm (12 in.) in back of the device is required to facilitate component removal and

installation.

The device should be installed vertically. Any other position could impair the performance

of the device.

Do not attach the device upside down.

Support for MTC-WUPH (wall mount) or MTC-PUPH (pole mount)

Page 22

1

2

(1 9.7 in.)

0.53 m

(1 9.7 in.)

0.53 m

MTC-WUPH

MTC-PUPH

!

!

22 en | Installing the High Speed Positioning System

2. Insert the cables into the optional wall or pole mount so that they protrude approximately

0.5 m (19.7 in.).

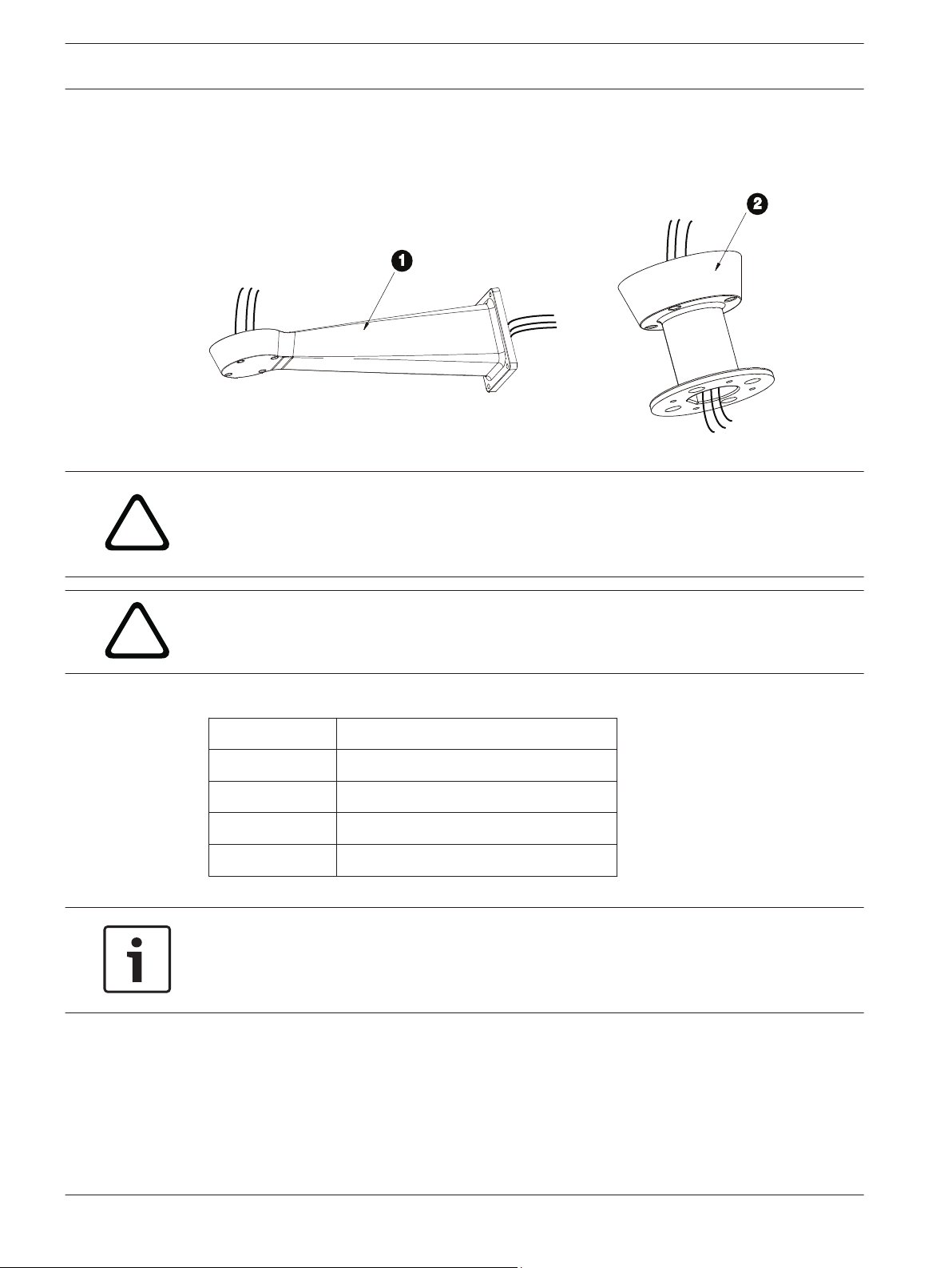

Figure 5.2: Optional Wall Mount (1) or Pole Mount (2)

Warning!

The cables should not be accessible by unauthorized personnel; cables should be secured to

fixed locations at appropriate intervals to bare the weight of the cables, for example, cables

running inside a tall camera pole.

High-Speed Positioning System

(HSPS)

Warning!

Be sure to use appropriately strong and load-bearing bolts and other fixing materials when

installing any UPH mountings to any surface.

3. Attach the optional wall or pole mount according to the specific mounting manual.

Part Description

MTC-PUPH Outdoor Pole Mount for UPH Series

MTC-WUPH Outdoor Wall Mount for UPH Series

MTC-POLE-W Pole Adapter for MTC-WUPH

MTC-CORN-W Corner Adapter for MTC-WUPH

Installing the optional washer kit

Notice!

If using a washer kit (optional, sold separately), you must install the support for the washer

pipe before positioning and wiring the pan/tilt. Refer to the Installation Manual for the Washer

Kit.

Installing the HSPS base on the mount

1. Remove the desiccant bag from inside the base and discard.

2. Remove the cable glands from the base and fit the gasket / seal ring.

3. Insert the cables into the cable glands while holding the base approximately 20 cm from

the bracket. Note that there are three glands; one for power, one for video, and one for

data / IO cables.

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 23

7

1

2

3

4

5

6

1

2

3

4

5

High-Speed Positioning System

(HSPS)

4. Securely lock the cable glands into place, using a gland closing torque of 5 N m. Use a

5. Position the base on the optional wall or pole mount, guiding the cables so that they are

Installing the High Speed Positioning System | en 23

calibrated torque wrench to ensure closure.

Note: The cable glands accept cables 5-10 mm (0.2-0.39 in.) in diameter. They can be

changed to accept smaller 3-7 mm diameter cables by using the two (2) conduit plugs

(supplied).

positioned inside the wall or pole mount (see the figure Schematic Diagram below).

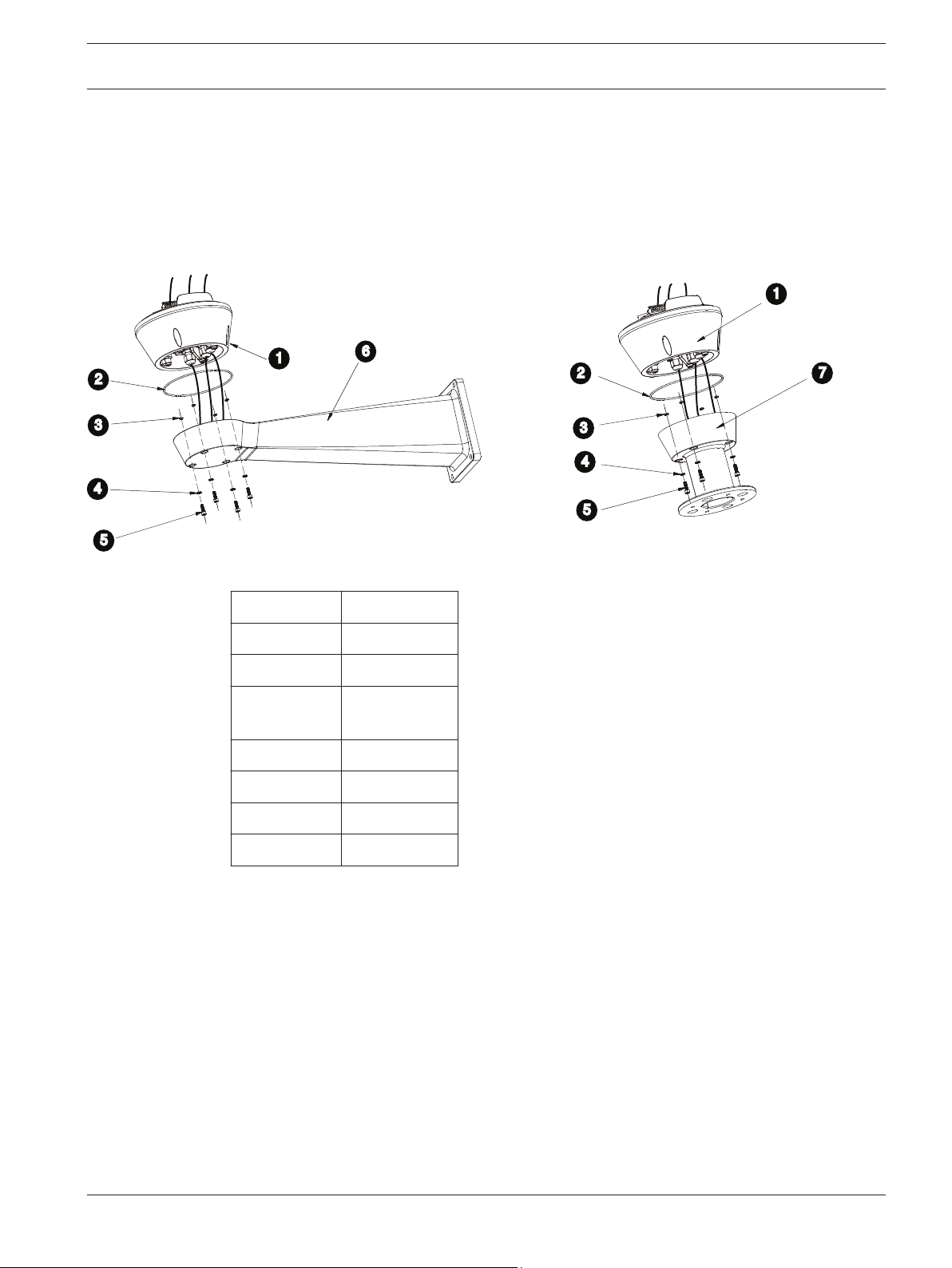

Figure 5.3: Schematic Diagram

Reference Description

1 Base

2 Gasket

3 Screw seals

4 Washers (4)

5 Screws (4)

6 Bracket

7 Support

Securing the base to the mount

1. Apply thread locker (such as Loctite 243) on the holes of the screws.

2. Secure the base to the wall or pole mount with the screws and washers (supplied).

3. Tighten the screws to 4 N m using a calibrated torque wrench.

(4)

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 24

24 en | Installing the High Speed Positioning System

High-Speed Positioning System

(HSPS)

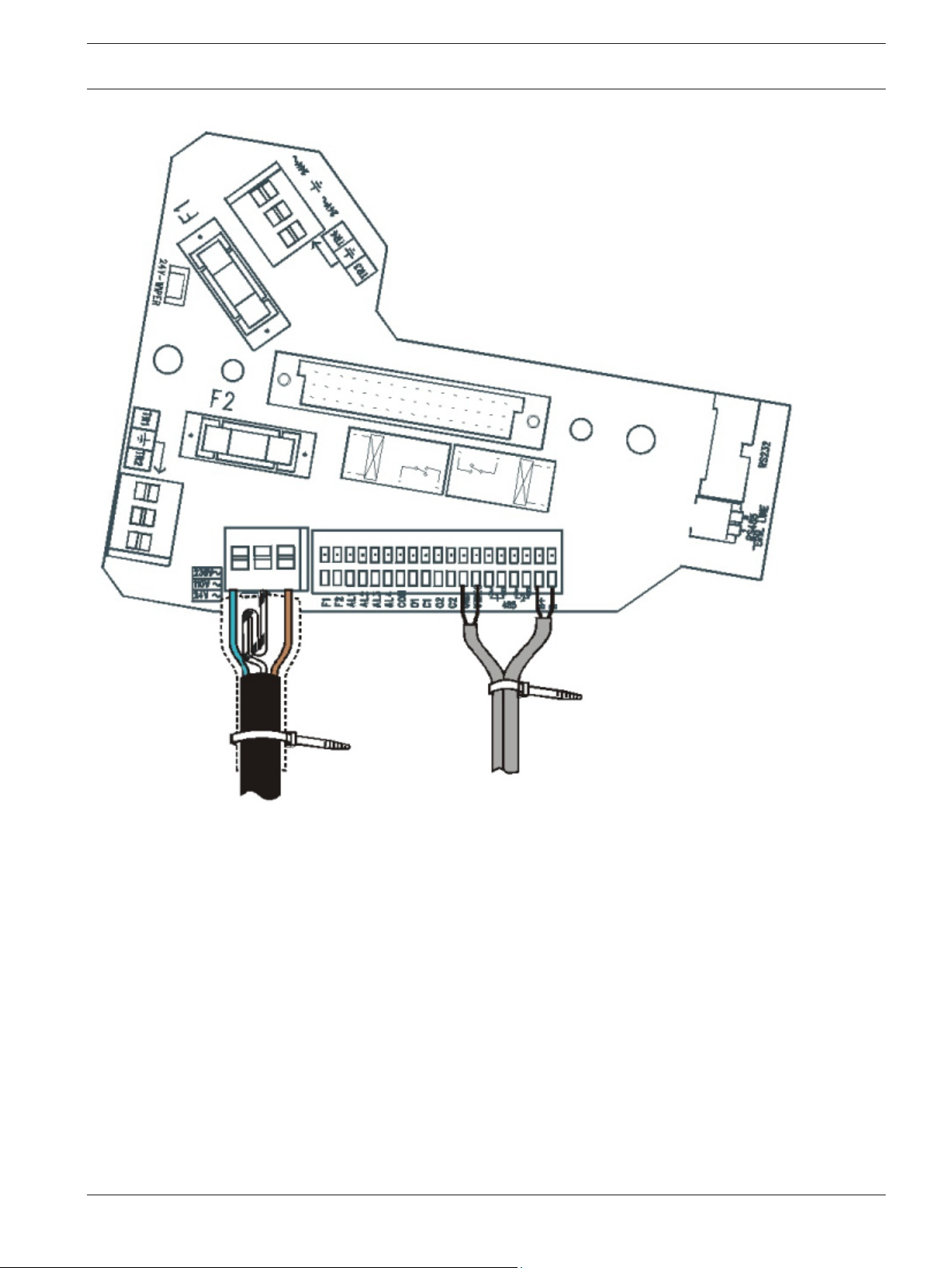

5.2

Wiring the Device

Figure 5.4: Preparing the Cables for Wiring

1. Cut the cables to approximately 152.4 mm (6 in.) (see the figure Preparing the Cables for

Wiring, above). The earth cable must be longer than the power wires by approximately 10

mm or more to prevent disconnection.

2. Cover the power cable with the plastic tube supplied. Fix it with the tie thread.

3. Make a group with all signal cables and fix them with the tie thread. See the illustration

below for a proper cable connection.

Note: IR360 version boards will vary slightly because the signals connector has 16 lines as

instead of 19, as shown below.

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 25

High-Speed Positioning System

(HSPS)

Installing the High Speed Positioning System | en 25

Figure 5.5: Tie Threads used to Group and Secure Cables

5.3

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Wiring the Video Cable

Note: The terminals support AWG 20 (0.5 mm2) to AWG 28 (0.08 mm2) cables.

To wire the video cable, follow these steps:

1. Locate the coaxial termination cable that is in the Cable and Screws accessory bag.

2. Use a small screwdriver to press down on the GND push latch (see the figure) and attach

the black ground wire to the GND terminal.

3. Use a small screwdriver to press down on the VIDEO push latch (see group 101) and

attach the clear coaxial conductor to the VIDEO terminal.

4. Retract the shield covering the female BNC connector and route the coaxial termination

cable into the base of the device.

5. Route the incoming coaxial cable with a male BNC connector into the base and connect

to the female BNC connector on the coaxial termination cable.

6. Move the shield to cover the coaxial connection.

Page 26

J7

VIDEO

VIDEO

GND

GND

J7

VIDEO

VIDEO

GND

GND

!

26 en | Installing the High Speed Positioning System

Figure 5.6: Wiring the Terminals

High-Speed Positioning System

(HSPS)

5.4

Reference

Description

1 Standard - 19 pin

2 IR - 16 pin

3 GND

4 Video

Connecting the Power Supply

Caution!

The separate protective earthing terminal provided on this product shall be permanently

connected to earth.

Notice!

Installation category (also called Overvoltage Category) specifies the level of mains voltage

surges that the equipment will be subjected to. The category depends upon the location of

the equipment, and on any external surge protection provided. Equipment in an industrial

environment, directly connected to major feeders/short branch circuits, is subjected to

Installation Category III. If this is the case, a reduction to Installation Category II is required.

This can be achieved by use of an isolating transformer with an earthed screen between

primary and secondary, or by fitting listed Surge Protective Devices (SPDs) from live to

neutral and from neutral to earth. Listed SPDs shall be designed for repeated limiting of

transient voltage surges, suitable rated for operating voltage and designated as follows:

- Type 2 (Permanently connected SPDs intended for installation on the load side of the

service equipment overcurrent device)

- Nominal Discharge Current (In) 20 kA min.

For example: FERRAZ SHAWMUT, STT2240SPG-CN, STT2BL240SPG-CN rated 120/240 VAC,

(In=20 kA)

The base with power supply box is available in three (3) power supply voltages (24 VAC,

120 VAC, or 230 VAC). To connect the power supply, follow these steps:

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 27

!

!

J6

L

N

High-Speed Positioning System

(HSPS)

1. Before proceeding with the installation, check the identification label of the product to

Caution!

When connecting the base, make sure the external power source is disconnected (the

disconnecting switch is open).

2. When the base is opened, the power supply board appears as shown below. To connect

Warning!

For 24 VAC models intended for UL markets, use only a Class 2 UL listed power supply for all

models except the UPH-H-WDIR-24 (compliant with the local electrical codes). For UPH-HWDIR-24, the power must be provided by a UL listed power supply with a double insulation

transformer.

Installing the High Speed Positioning System | en 27

verify that the device coincides with the power supply requirements.

the power supply, make the connections as seen in figure Power Supply Connections

below.

Figure 5.7: Power Supply Connections

3. To wire the power cable (not supplied), attach the appropriate colored wire to the

appropriate terminal. Use the tables below for reference.

Wire Color

Reference 24 VAC1 Terminal Connection

Per local Installer N Neutral

Per local Installer L Live/Active

Green/Yellow G Earth

1. For 24 VAC models intended for UL markets, use only a Class 2 UL listed power supply for all models except the UPH-H-WDIR-24 (compliant with the local

electrical codes). For UPH-H-WDIR-24, the power must be provided by a UL listed power supply with a double insulation transformer.

Wire Color 120 / 230 VAC2 Terminal Connection

Blue Neutral

Brown Live/Active

Green/Yellow Earth

2. Use the appropriate junction box to connect the power supply line. Use a Class 2, UL listed power supply

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 28

!

!

!

28 en | Installing the High Speed Positioning System

Warning!

For the standard models with 120/230 VAC power, an external junction box with a readily

accessible 2-pole disconnect device must be incorporated. For the IR model UPH-H-WDIR-24,

the 24 VAC power must be provided by a UL-listed power supply with a double insulation

transformer.

Note: The power cable must be double-insulated. Each separate cable is individually insulated,

then contained in an outer insulated cover. The cable type must be chosen in accordance with

local and national wiring rules.

Warning!

The device must be wired by skilled technical personnel. Never make any changes or

connections that are not described in this manual. Failure to follow the instructions indicated

in this manual may result in system or safety hazards, thus invalidating the guarantee.

Warning!

When wiring for external/outdoor environments, be sure to use appropriately rated cables.

High-Speed Positioning System

(HSPS)

Wiring Biphase

4 To wire for Biphase, connect the C+ terminal wire to the B+ terminal and the C- terminal

wire to the B- terminal respectively.

Figure 5.8: Wiring for Biphase

Wiring RS-422/Pelco D

4 In order to change the Baud Rate, the 4-way dip switch must be used. Refer to Pelco D

Baud Rate, page 43.

Figure 5.9: Connecting for RS-422

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 29

High-Speed Positioning System

(HSPS)

Reference Description

1 Pelco D connections

2 RS485-2 A, connect to Pelco controller out Tx +

3 RS485-2 B, connect to Pelco controller out Tx -

4 RS485-1 A, connect to Pelco controller input Rx +

5 RS485-1 B, connect to Pelco controller input Rx -

Installing the High Speed Positioning System | en 29

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 30

!

30 en | Connecting to the Standard Base

High-Speed Positioning System

(HSPS)

6

Connecting to the Standard Base

The standard base has a 19-pin connector for which the following connections are illustrated:

Figure 6.1: Base with 19-pin Connector for Connecting Peripherals

Reference

F1 and F2 Feed 1, 24 VAC for optional washer; Feed 2, 24 VAC for

Description

optional washer

O1-C1 and O2-C2

(O=Output, C=Common)

AL1, AL2, AL3, and AL4, COM Alarm inputs 1-4, voltage-controlled (10-35 VDC supplied

Warning!

The installation is type TNV-1. Do not connect it to SELV circuits.

Dry contact output that can be activated by alarm or by user

(50 VDC or 30 VAC @ 1A)

externally), referred to common COM

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 31

High-Speed Positioning System

(HSPS)

Connecting to the IR360 Base | en 31

7

Connecting to the IR360 Base

The IR360 base has a 16-pin connector for which the following connections are illustrated:

Reference Description

F1 and F2 Feed 1, 24 VAC for optional washer; Feed 2, 24 VAC for optional

washer

O1 and C1

(O=Output, C=Common)

Dry contact output that can be activated by alarm or by user (50

VDC or 30 VAC @ 1A)

AL1 and AL2 Alarm inputs 1-2, voltage-controlled (10-35 VDC supplied

externally), referred to AGND

AGND Alarm Ground & External IR probe common

LNO External photosensor/IR probe

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 32

!

2

3

4

5

32 en | Fixing the Top Unit

High-Speed Positioning System

(HSPS)

8

Fixing the Top Unit

Warning!

Hazardous Moving Parts. Keep Fingers and Other Body Parts Away.

To attach the top of the unit to the base, follow these steps. If re-assembling after repair, be

sure to replace the screw seals. This will ensure that the device remains watertight.

Figure 8.1: Attaching the Top Unit

Reference

1 Base

2 Gasket

3 Screw seals (4)

4 Washers (4)

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

5 Screws (4)

6 Configuration Window

1. Align the tabs on the top unit with the tabs on the base so that both parts are positioned

correctly.

2. Push down to snap into place.

3. Apply thread locker (such as Loctite 243) on the holes of the screws.

4. Attach the top unit to the base using the attachment screws and screw seals (supplied).

Description

Page 33

High-Speed Positioning System

(HSPS)

5. Tighten the base screws to 4 N m using a 4 mm calibrated torque wrench.

6. Place on or near the device the safety label (supplied) that warns of moving parts.

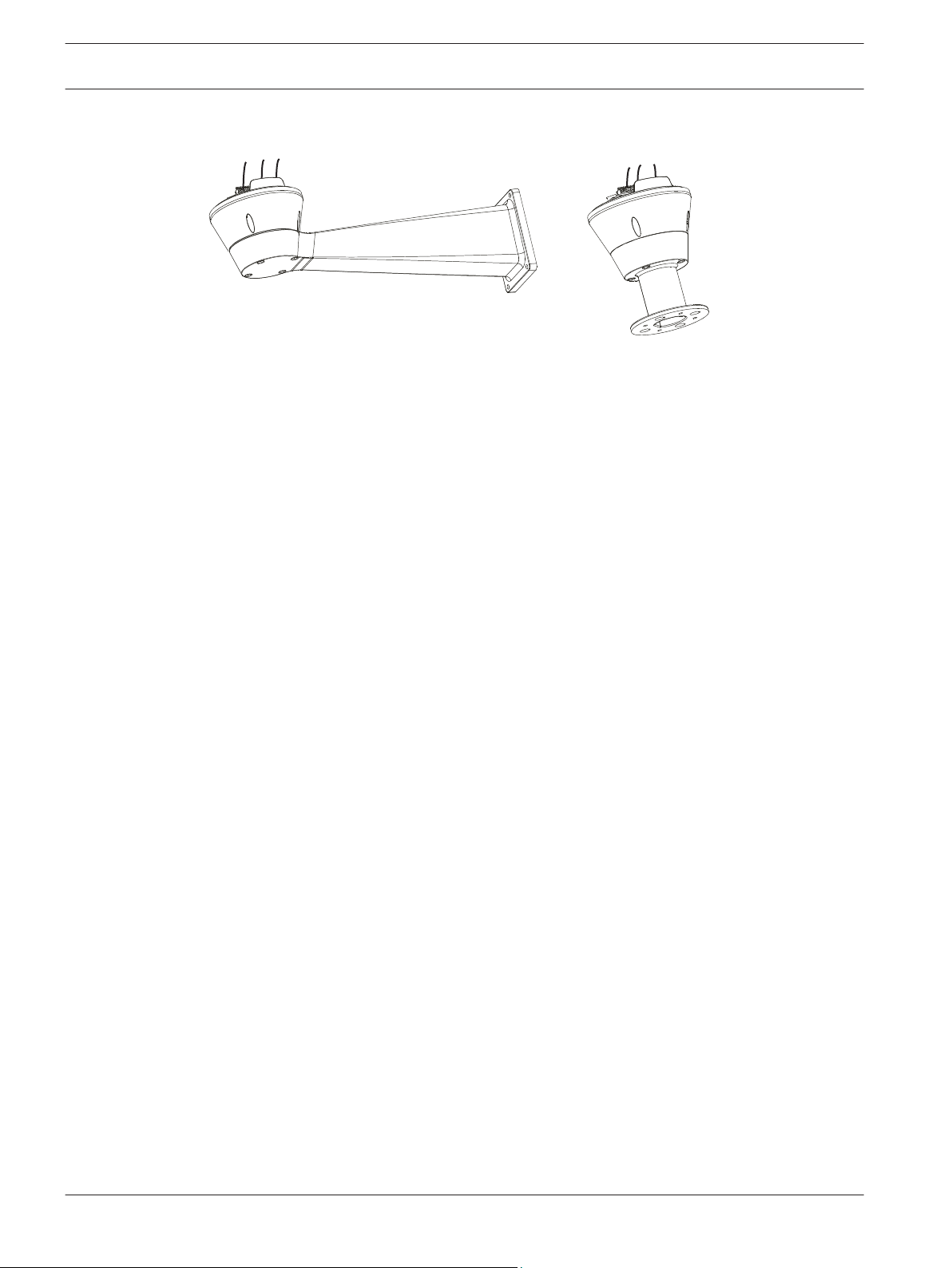

The camera should appear as in the figure below.

Fixing the Top Unit | en 33

Assembled High Speed Positioning System (with tabs aligned)

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 34

!

34 en | Assembling and Connecting IR360 Models (optional)

High-Speed Positioning System

(HSPS)

9

9.1

Assembling and Connecting IR360 Models (optional)

The device must be configured to mount two of the Bosch UFLED illuminators. The

illuminators are connected to the bracket supplied with the pan and tilt motor.

Caution!

For operational reasons, both spotlights must be fitted.

When turning on, the device looks for the angular reference.

Fitting the Bracket

Fitting the Bracket

Note: Use only the material supplied with the kit.

1. Position the bracket on the bottom of the housing as shown in the illustration.

2. Insert the screws with the washers into the respective holes and tighten.

3. Make sure the bracket is secured firmly.

Figure 9.1: Fitting the Bracket

Reference

1 Screws

2 Washers

3 Bracket

4 Holes

9.2

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Assembling the Spotlights

Assembling the Spotlights

1. Position the bracket so that the threaded holes are on the same axis as the holes on the

body of the spotlight.

2. Fix the two components using the screw, the crinkle washer, and the plane washer.

Description

Page 35

High-Speed Positioning System

(HSPS)

Figure 9.2: Assembling the Spotlight

Assembling and Connecting IR360 Models (optional) | en 35

9.3

Reference

1 Bracket

2 Spotlight holes

3 Plane washer

4 Crinkle washer

5 Screw

Description

Fitting the Spotlights on the Bracket

Fitting the Spotlight on the Bracket

1. Position the gasket between the bracket and the spotlight.

2. Place the crinkle washer and the nut in the respective hexagonal seat.

3. Fix the assembly using the screw and it washer.

4. Make sure the spotlight is secured firmly to the bracket.

5. Complete the necessary wiring.

6. Configure the on-screen menu to disable complete rotation of the pan and tilt.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 36

36 en | Assembling and Connecting IR360 Models (optional)

Figure 9.3: Fitting the Spotlight on the Bracket

High-Speed Positioning System

(HSPS)

9.4

Reference

1 Gasket

2 Bracket

3 Spotlight

4 Crinkle washer

5 Nut

6 Screw

7 Washer

Danger!

During normal operation, the surface of the spotlight can reach very high temperatures. Do not

allow direct contact. Ensure to position the product where it is inaccessible to unauthorized

persons.

Description

Connecting the Spotlights

Connecting the Infrared LED Spotlights

1. Open the housing.

2. Extract the support plate from the housing.

3. Disconnect the flat cable.

4. Disconnect the relay power supply connector.

5. Remove the screws.

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 37

High-Speed Positioning System

(HSPS)

Figure 9.4: LED Connections

Assembling and Connecting IR360 Models (optional) | en 37

Reference

Description

1 Flat cable

2 Power supply connector

3 Screws

Connecting the Power Cable

1. Connect the power cable to each spotlight.

Figure 9.5: Connecting the Power Cable to the Spotlight

2. Thread the cable through the holes in the pan and tilt bracket.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 38

en | Assembling and Connecting IR360 Models (optional)

38

Figure 9.6: Threading the Cable through the Bracket

3. Insert the cable in the cable glands mounted in the lower part of the housing so that they

protrude about 20 cm.

High-Speed Positioning System

(HSPS)

Figure 9.7: Inserting the Cable through the Cable Glands

4. Place the desiccant bag in the housing.

Figure 9.8: Inserting the Desiccant Bag

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 39

1

2

3

4

1

2

3

4

High-Speed Positioning System

(HSPS)

Reference Description

1 Flat cable

2 Relay power supply connector

Completing Assembly

1. Secure the support plate to the housing.

2. Reconnect the flat cable and the relay power supply connector previously disconnected,

3. Connect the cables as illustrated.

Assembling and Connecting IR360 Models (optional) | en 39

in order to complete the operation.

Figure 9.9: Connecting the IR Cables

Reference

Color Description

1 Brown 24 VAC1

2 White 24 VAC1

3 Black 24 VAC2

4 Blue 24 VAC2

Notice!

The day/night mode relay is pre-wired. The figure below is for reference only. For more

information on how to operate the day/night mode, please call Technical Support at

1-800-326-1450.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 40

40 en | Assembling and Connecting IR360 Models (optional)

Figure 9.10: Switching Day and Night Mode

High-Speed Positioning System

(HSPS)

Reference

Description

1 Night Mode

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 41

!

High-Speed Positioning System

(HSPS)

Making Connections for the Pump of the Washer Kit (Optional) | en 41

10

Making Connections for the Pump of the Washer Kit (Optional)

The Bosch Washer Kit (pump and water reservoir tank) is an optional product, available

separately from Bosch, that connects directly to the High Speed Positioning System in order

to clean dirt and debris that accumulates on the glass in front of the lens of the camera,

improving visibility through the camera.

The figure below identifies the O1 and C1 connections on terminal block J7 on the connector

board in the base of the device. All models have these connections to activate the pump

contact and start the washer pump (using maxinum 50 VDC/30 VAC, 1 A), even if not all

models will have a Washer Kit attached.

For specifics about the Washer Kit itself, see the Installation Manual of the Washer Kit.

Warning!

These connections should be made only by skilled installers who comply scrupulously with all

the wiring and power supply instructions. Failure to do so could create serious risks for the

operator and would invalidate the warranty.

Figure 10.1: Terminal block J7 on the connector board in the base

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 42

42 en | Configuring the Device

High-Speed Positioning System

(HSPS)

11

Configuring the Device

Before powering the High Speed Pan/Tilt, it must be properly configured. To configure the DIP

switches inside the configuration window, proceed as follows:

1. Open the configuration window (as seen in , page 42) by unscrewing the screws with a

3 mm Allen wrench.

2. Verify that the position of the DIP switches are the same as in, page 42.

Figure 11.1: Positioning the DIP Switches

Reference Description

1 Pelco D Baud Rate

2 Not Used, All Off

3 Address

4 RS485 Terminations

5 Biphase + Bilinx

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 43

High-Speed Positioning System

(HSPS)

– For DIP switches (Reference 1-3 , page 42), when the rocker is down the switch is OFF or

– For DIP switches (Reference 4-5 , page 42), when the rocker is up the switch is OFF or

Configuring the Device | en 43

represents the logical value “0”; when the rocker is up, the switch is ON, with logical

value “1.”

represents the logical value “0”; when the rocker is down, the switch is ON, with logical

value “1.” The white rectangle represents the position of the rocker.

11.1

11.2

Pelco D Baud Rate

Dip switches 4, 3, and 2 are used to set the communication rate of the device according to the

table below:

Dip Switch 4 Dip Switch 3 Dip Switch 2 Dip Switch 1 Baud Rate

Off Off Off Off 300 Baud

On Off Off Off 600 Baud

Off On Off Off 1200 Baud

On On Off Off 2400 Baud

Off Off On Off 4800 Baud

On Off On Off 9600 Baud

Off On On Off 19200 Baud

Protocol

There is no need to set any particular protocol, the UPH is auto-sensing. The protocols

supported are:

Protocol Baud Rate Menu Setup (OSD)

11.3

Pelco D Selectable (8N 1) Preset 95

Biphase and Bilinx Auto AUX-On 200

Setting the Address

You can set the address for the UPH address using the Address switched (see item 3 in , page

42).

Notice!

The highest addres using the Bosch OSRD protocol is 998. The highest address using the

Pelco D protocol is 255.

Binary code is used to select the address using the 10 DIP switches. The up position

represents binary value “1”, while the down position represents binary value “0”.

To convert a decimal address to a binary address, use the following technique.

– Assign a binary value to each DIP switch, starting with a binary value of “1” for DIP switch

1. If the DIP switch is “on” then the number associated with the switch is stored.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 44

44 en | Configuring the Device

– Consider the decimal address and start adding the DIP switch values from the left,

skipping a DIP switch value that is higher than the decimal address.

– Turn a DIP switch to “on” if its associated value is used for the address. Keep the DIP

switch “off” if its associated value is too high or is not needed to add up to the decimal

address.

For example, to convert the decimal address 237 to binary:

Flag each binary digit needed to add up to 237 starting from the left. Do not flag 512 and 256

since these values are larger than 237. The first binary value to flag is 128; then flag 64 and 32

adding up to 224. Do not flag 16 because that puts the decimal value over 237. The next digit

to flag is 8, then skip 4 (too large), and flag the 2 and 1. The flagged numbers should equal

237: 128+64+32+8+2+1=237.

The following table lists DIP switch positions for various decimal addresses:

High-Speed Positioning System

(HSPS)

11.4

512 256 128 64 32 16 8 4 2 1

Decimal Address Binary Value

1 1 OFF OFF OFF OFF OFF OFF OFF OFF OFF ON

2 10 OFF OFF OFF OFF OFF OFF OFF OFF ON OFF

4 100 OFF OFF OFF OFF OFF OFF ON OFF OFF OFF

8 1000 OFF OFF OFF OFF OFF OFF ON OFF OFF OFF

143 1000 1111 OFF OFF ON OFF OFF OFF ON ON ON ON

299 1 0010 1011 OFF ON OFF OFF ON OFF ON OFF ON ON

998 11 1110 0110 ON ON ON ON ON OFF OFF ON ON OFF

DIP Switch Positions

10 9 8 7 6 5 4 3 2 1

RS485 Line Termination

Serial Lines Termination Switches (refer to item 4 in , page 42):

– Dip-switch 1 is not used (the RS485-1 line is not available).

– Dip-switch 2 is used to enable the line termination of RS485-2 serial line (Pelco D only).

– Down/On = terminated

– Up/Off = Open

11.5

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Biphase/Bilinx Termination

Bilinx and Biphase Switches (refer to item 5 in , page 42):

– Dip-switch 1 is used to enable the line termination of a Biphase serial line.

– Down/ON = terminated. Up/OFF = open (daisy chain).

– Dip-switch 2 is used to select the video format (Down/ON = PAL, Up/OFF = NTSC).

Page 45

High-Speed Positioning System

(HSPS)

Configuring the Device | en 45

11.6

Connections

All versions support Bilinx and Biphase telemetry control, i.e.: PTZ.

The PTZ menu setup of UPH Series is done via the AUX ON - 200 - Enter. The camera menu

setup is done via two different AUX commands, i.e.: AUX ON - 46 - Enter (Dinion main menu)

and AUX ON - 801 - Enter (Dinion installation menu). See 9 Keyboard Commands List - Bosch

for more information about keyboard commands.

Bilinx is a Bosch two-way communication protocol that allows remote control, configuration,

and updates over a video coax cable. Bilinx is available on all UPH models.

Biphase is used for communicating telemetry (control) and set up information with the

UPH‑Series units over a shielded twisted pair. Biphase does not pass the video signal from the

UPH-Series units, so a separate video coax cable is required. Biphase should be wired with

Belden 8760 or equivalent. Biphase is available on all UPH models.

Note: If the UPH is the only Biphase unit connected, or the last unit in a daisy chain

configuration, then turn ON dip-switch 1 of Biphase + Bilinx to terminate the data line. Turn

OFF dip-switch 1 of Biphase + Bilinx for each UPH in a daisy chain (i.e. unterminated). A

maximum of four (4) UPH units can be daisy chained together.

Figure 11.2: Typical Setup via an Interface Box

LTC 5136 or equivalent 5 UPH Series: unitized pan/tilt head

1

2 RS-232 6 Video out, coax

3 LTC 8786 7 CCTV Monitor

4 Biphase

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 46

1

2

3

4 5

6

7 8 9

0

Shot

MonProd

Clr

BOSCH

46 en | Configuring the Device

Figure 11.3: Typical Setup via an Allegiant with Biphase

High-Speed Positioning System

(HSPS)

1

IntuiKey Keyboard 4 Biphase

2 RS-485 5 UPH Series: unitized pan/tilt head

3 Allegiant Matrix Switcher 6 Video out, coax

Figure 11.4: Typical Setup via an Allegiant + LTC 8016

IntuiKey Keyboard 4 LTC 8016 Bilinx Data Interface

1

2 RS-485 5 Bilinx/Video

3 Allegiant Matrix Switcher 6 UPH Series: unitized pan/tilt head

Figure 11.5: Typical Connections to a DiBos

1

DiBos 8

2 Biphase

3 UPH Series: unitized pan/tilt head

4 Video output coax

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 47

High-Speed Positioning System

(HSPS)

Figure 11.6: VIPX1 Connection Diagrams

1 Vidos, IE, DiBos 8, Bosch VMS or equivalent 5 RS-485-2

2 Ethernet 6 Video

3 LAN 7 UPH Series: unitized pan/tilt head

4 VIP X1

Configuring the Device | en 47

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 48

48 en | Configuring the System

High-Speed Positioning System

(HSPS)

12

12.1

Configuring the System

The UPH High Speed Pan/Tilt can be configured through the on-screen display (OSD). Open

the main menu by pressing AUX ON - 200 - Enter. Use the joystick to move up and down

through the menus. Press focus to select the sub-menu.

MAIN MENU

1 - LANGUAGE >

2 - DISPLAY SETUP >

3 - CAMERA PARAMETERS >

4 - LENS PARAMETERS >

5 - LOAD DEFAULT CONF. >

6 - SETUP INFO >

Language Menu

12.2

This menu is used to select and set the desired language. The default setting is English.

LANGUAGE MENU

1 - ITALIANO

> 2 - ENGLISH OK

3 - FRANCAIS

4 - DEUTSCH

Table 12.1: Language Menu with English Selected

Display Setup Menu

The Display Setup menu is used to define settings for the information that is permanently

displayed on the screen.

DISPLAY SETUP MENU

> 1 - PAN/TILT POSITION : Y

2 - PRESET TITLE : Y

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 49

High-Speed Positioning System

(HSPS)

3 - PRESET POSITION : Y

4 - TILT LIMIT TITLE : Y

5 - VIDEO SIGNAL : PA

6 - INTERLACED VIDEO : Y

7 - AREA PARAMETERS >

8 - DISPLAY PARAMETERS >

Table 12.2: Display Setup Menu

Configuring the System | en 49

L

Feature

PAN/TILT

POSITION

Description Default Options

Shows the current position of the device (in

degrees) with reference to the home position.

PRESET TITLE Enables or disables the preset title on the

display.

PRESET POSITION Enables or disables the preset number reached

on the display.

TILT LIMIT TITLE Enables or disables displaying if the tilt limit is

reached.

VIDEO SIGNAL Type of video signal. Select to automatically

adjust position of OSD.

INTERLACED

VIDEO

AREA PARAMETERS

(sectors)

DISPLAY

PARAMETERS

Enables or disables the display for interlaced

video.

Information about area (or sector) that the unit is

pointing towards.

Setup of location of text position/type on the

display.

Y YES, NO

Y YES, NO

Y YES, NO

Y YES, NO

PAL PAL,

NTSC

Y YES, NO

12.2.1

Area Parameters Menu

The Area Parameters menu enables the user to show a message on the screen, depending on

the horizontal position reached by the device; this is sometimes known as sector information.

From this menu, it is possible to enter two (2) lower menus that are used to set the text for

each area, and the start and end positions (in degrees) of these areas. It is possible to set up

to eight (8) areas with their own title, start, and end positions.

For example, to activate the first title and obtain a message when the device is between +80 °

and +120 ° in the horizontal (pan) direction, proceed as follows:

1. Enter the Position Area menu.

2. Select Area 1 by pressing Focus; an arrow starts blinking next to the start position. Press

Focus again, use the joystick to enter the value +080.00 in the left column (start position

of text coming on screen), then press Focus to store that value. Repeat the process, but

put +120.00 in the right column (stop position of text removed from the screen).

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 50

50 en | Configuring the System

3. In the Text (String) Area menu, select the first line and enter the desired text.

Note! If the area position start and end values are set to +0.00, this disables the text

display (defaults are all set to +0.00).

AREA PARAMETERS MENU TEXT AREA MENU

1 > AREA TITLE : N > 1 - AREA 1

2 -STRING AREA MENU > 2 - AREA 2

3 - POISTION AREA MENU > 3 - AREA 3

4 - AREA 4

5 - AREA 5

6 - AREA 6

7 - AREA 7

8 - OFFSET PAN: + 0.0 8 - AREA 8

Test area 1

AREA POSITION MENU

1 > AREA 1 + 0.00 + 0.00

2 - AREA 2 + 0.00 + 0.00

3 - AREA 3 + 0.00 + 0.00

4 - AREA 4 + 0.00 + 0.00

5 - AREA 5 + 0.00 + 0.00

6 - AREA 6 + 0.00 + 0.00

7 - AREA 7 + 0.00 + 0.00

8 - AREA 8 + 0.00 + 0.00

Test area 1

High-Speed Positioning System

(HSPS)

Feature Description Default Options

AREA TITLE Enables / disables the on-screen message

NO YES, NO

depending on the horizontal position reached

by the device.

STRING AREA MENU Enables the user to edit a customized, on-

screen text message that is activated when

N/A Area 1 to

Area 8

the device reaches a defined, horizontal

position.

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 51

80°

120°

0°

+/-180°

High-Speed Positioning System

(HSPS)

Configuring the System | en 51

Feature Description Default Options

POSITION AREA

MENU

The horizontal position reached by the device

that prompts a customized on-screen text

message.

OFFSET PAN Adds a corresponding value (offset) in

degrees to the pan references used for

displaying the area text. For example, if this

value is set to +45.0 ° then all references will

be shifted in PAN by +45 ° with respect to the

system’s physical reference.

Table 12.3: Area Parameters Menu

N/A Area 1 to

Area 8

+0.00 -180.00to

+180.00

Figure 12.1: Setting the Area Position Values

12.2.2

Changing the Edit Text Menu

To change the text within the Edit Text menu, proceed as follows:

1. Upon accessing the Edit Text menu, select String Edit. The first field flashes a “v”,

indicating it is in Edit mode.

2. Press the Focus button. The cursor flashes at the bottom of the screen, corresponding to

the groups of alpha/numeric characters. Operate the joystick (up, down, left, and right)

to select a group of characters.

3. Press the confirmation (Focus) button to confirm the alpha/numeric group containing the

character to be added. The first value in the sequence you selected starts flashing.

4. Move the joystick up or down to choose a value.

5. When finished, press the Focus button to confirm your choice. The “v” automatically

moves to the right.

6. Repeat steps 2-5 until finished.

7. When finished, press the Iris button to exit the menu.

Note: To skip a space while in edit mode, press the Iris button, then move the joystick to the

right past the number spaces you would like to skip. Press the Focus button to resume adding

values.

The character being edited flashes and the joystick (up and down) can be used to change it.

After making the change, confirm and continue to edit the text, or else exit with the Iris

button.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 52

52 en | Configuring the System

EDIT TEXT MENU

v _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ __

Test Area 1

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

> 1ABC 2DEF 3GHI 4JKL

5MNO6PQR 7STU 8VWX

9YZ 0()* +,-.

High-Speed Positioning System

(HSPS)

12.2.3

Table 12.4: Edit Text Menu

Offset Pan

By default, the offset pan is +0.00. The value can be changed to move the default pan position

of the unit to wherever is convenient. For example, if the installation requires that the NORTH

position should be at 0.00 ° (pan), then an offset pan can be entered to compensate for any

deviation from NORTH. After mounting, the NORTH position was found to be +41.37 ° (pan

position); therefore, the offset pan should be set to - 41.37 ° to make the pan +0.00 ° position

point to NORTH.

This has an effect on the Area Title as defined in the Area Position menu. In the above

example, after the offset pan has been set to -41.37 °, the Area Text Menu “1 - Area” could be

changed to “1 - NORTH” to display NORTH on the screen at pan +0.00 ° position.

Display Parameters

The Display Parameters menu is used to enter the settings menus for the device movement

parameters.

DISPLAY PARAMETERS

> 1 - OSD VIDEO ENABLING : Y

2 - VIDEO CHAR TYPE : 000

3 - HORIZONTAL DELTA : 000

4 - VERTICAL DELTA : 000

5 - ADDRESS NUMBER Y

2013.11 | 5.2 | F.01U.291.981 Operation Manual Bosch Security Systems, Inc.

Page 53

High-Speed Positioning System

(HSPS)

OSD Video Enabling Set to YES to superimpose the menu text over the video signal

Video Character Type Set to 0 to make the background of the text to transparent; set

Configuring the System | en 53

from the camera. Set to NO to have a blue screen behind the

menu TEXT.

to 1 to make it black.

12.3

Horizontal Delta/Vertical

Delta

Address Number If enabled, the address number of the unit is shown at the top

These set the position of reference to the title so that the text

can be centralized. 0 (left, up) and 6 (right, down).

left of the screen during normal operation. Yes/No.

Motion Parameters Menu

The Motion Parameters menu is used to control the speed, limits, preset/patrol/autopan,

wiper-washer, and the alarm settings of the UPH.

MOTION PAR MENU

> 1 - SPEEDS >

2 - LIMITS >

3 - PRESET/PATROL/PAN >

4 - WIPER-WASHER >

5 - ALARMS >

12.3.1

Speed Menu

The Speed menu is used to control the pan and tilt movement of the UPH in manual control

mode using the joystick. See Speed Menu, page 53 for setting pan and tilt speeds for the

presets, patrols, and scans.

PAN SPEED MENU

SPEED MENU 1 > SPEED 1... 1.0

> 1 - PAN SPEED > 2 - SPEED 2... 2.0

2 - TILT SPEED > 3 - SPEED 3... 5.0

3 - ZOOM PROP. SPEED :N 4 - SPEED 4... 10.0

5 - SPEED 5... 20.0

6 - SPEED 6... 30.0

Bosch Security Systems, Inc. Operation Manual 2013.11 | 5.2 | F.01U.291.981

Page 54

54 en | Configuring the System

7 - SPEED 7... 40.0

8 - DEFAULT

TILT SPEED MENU

" 1 > SPEED 1... 1.0

2 - SPEED 2... 2.0

3 - SPEED 3... 3.0

4 - SPEED 4... 5.0

5 - SPEED 5... 8.0

6 - SPEED 6... 10.0

High-Speed Positioning System

(HSPS)

7 - SPEED 7... 20.0

8 - DEFAULT

Feature Description Default Options

PAN SPEED 1 Correspondence between

PAN SPEED 2 2.0 0.1-100.0

PAN SPEED 3 5.0 0.1-100.0