Bosch SHS5AV56UC/01, SHS5AVF2UC/01, SHS5AV55UC/01, SHS5AV52UC/01, SHS5AVF6UC/01 Installation Guide

...

o

o_

o_

o

o

_m

0

0

Important Safety instructions:

Please READ and SAVE this information

To avoid possible injury or property damage, OBSERVE ALL WARNINGS

AND CAUTIONS.

These instructions are intended for use by qualified installers only. The

dishwasher must be installed by a qualified service technician or installer.

• in addition to these instructions, the dishwasher shall be installed to

meet all electrical and plumbing codes and ordinances (both national

and local).

Read these installation instructions completely and follow them

carefully. They will save you time and effort and help to ensure safety and

optimum dishwasher performance.

iMPORTANT

• The dishwasher drain hose must be installed with a portion of it at least

20" (508 ram) off the cabinet floor; otherwise the dishwasher may not

drain properly.

• This dishwasher is intended for indoor residential use only, and should

not be used in commercial food service establishments.

• This dishwasher is designed to be enclosed on the top and both sides

by cabinetry.

• NEW INSTALLATION - If the dishwasher is a new installation, ensure

all connections are properly made before the dishwasher is moved into

place.

• REPLACEMENT - If the dishwasher is replacing another dishwasher,

check the existing dishwasher connections for compatibility with the

new dishwasher, and replace parts as necessary.

This appliance has been found to be in compliance with CAN/CSA-C22.2

No. 167/UL 749. It is the responsibility of the owner and the installer

to determine if additional requirements and standards apply in specific

installations.

• Not for outdoor use.

Avoiding General Hazards

Do not use the dishwasher until it is completely installed. When opening

the door on an uninstalled dishwasher, carefully open the door while

supporting the rear of the unit. Failure to follow this warning can cause the

dishwasher to tip over and result in serious injury.

Before installing the "L"-shaped supplied countertop mounting brackets

(select models), decide which method will be used to secure the dish-

washer into its opening. Once these mounting brackets are installed on

the dishwasher, removing them is difficult and will damage the mounting

brackets and the dishwasher.

In some conditions, hydrogen gas can form in a hot water system that

has not been used for weeks. Hydrogen gas is explosive. Before filling a

dishwasher from a system that has been off for weeks, run the water from

a nearby faucet in a well ventilated area until there is no sound or evidence

of gas.

Temperatures required for soldering and sweating will damage the

dishwasher's base and water inlet valve. If plumbing lines are to be

soldered or sweated, keep the heat source at least 6 inches (152.4 mm)

away from the dishwasher's base and water inlet valve.

Removing any cover or pulling the dishwasher from the cabinet can

expose hot water connections, electrical power and sharp edges or points.

Handle with care.

Avoiding Electrical Shock/Fire Hazards

Do not allow the electrical and water supply lines to touch.

Do not work on an energized circuit. Doing so could result in serious

injury or death. Only qualified electricians should perform electrical work.

Do not attempt any work on the dishwasher electric supply circuit until

you are certain the circuit is de-energized.

Make sure electrical work is properly installed. There should be no loose

electrical connections. Ensure all electrical connections are properly

made.

Thecustomerhasthe responsibilityof ensuringthat the dishwasher

electricalinstallationisincompliancewithallnationalandlocalelectrical

codesandordinances.Thedishwasherisdesignedforanelectricalsupply

of 120V, 60 Hz,AC,connectedto a dishwasher-dedicated,properly

groundedelectricalcircuitwitha fuse or breakerratedfor 15 amps.

Electricalsupplyconductorsshallbea minimum#14AWGcopperonly

wireratedat75°C(167°F)orhigher.

Thisappliancemustbeconnectedtoagroundedmetal,permanentwiring

system,oranequipment-groundingconductormustberunwiththecircuit

conductorsandconnectedtotheequipment-groundingterminalorleadon

theappliance.Donotuseextensioncords. A

Avoiding Plumbing/Scalding Hazards

Do not perform any work on a charged hot water line. Serious injury could

result. Only a qualified plumber should perform plumbing work. Do not

attempt any work on the dishwasher hot water supply plumbing until you

are certain the hot water supply is shut off.

Do not over tighten the 90 ° elbow. Doing so may damage the water inlet

valve and cause a water leak.

Check local plumbing codes for approved plumbing procedures and ac=

cessories. All plumbing should be done in accordance with national and

local codes.

These instructions depict an installation method for stainless steel braided

hose or PEX hot water supply lines, If using copper tubing or other material

for water supply, defer to a licensed plumber for proper installation.

3

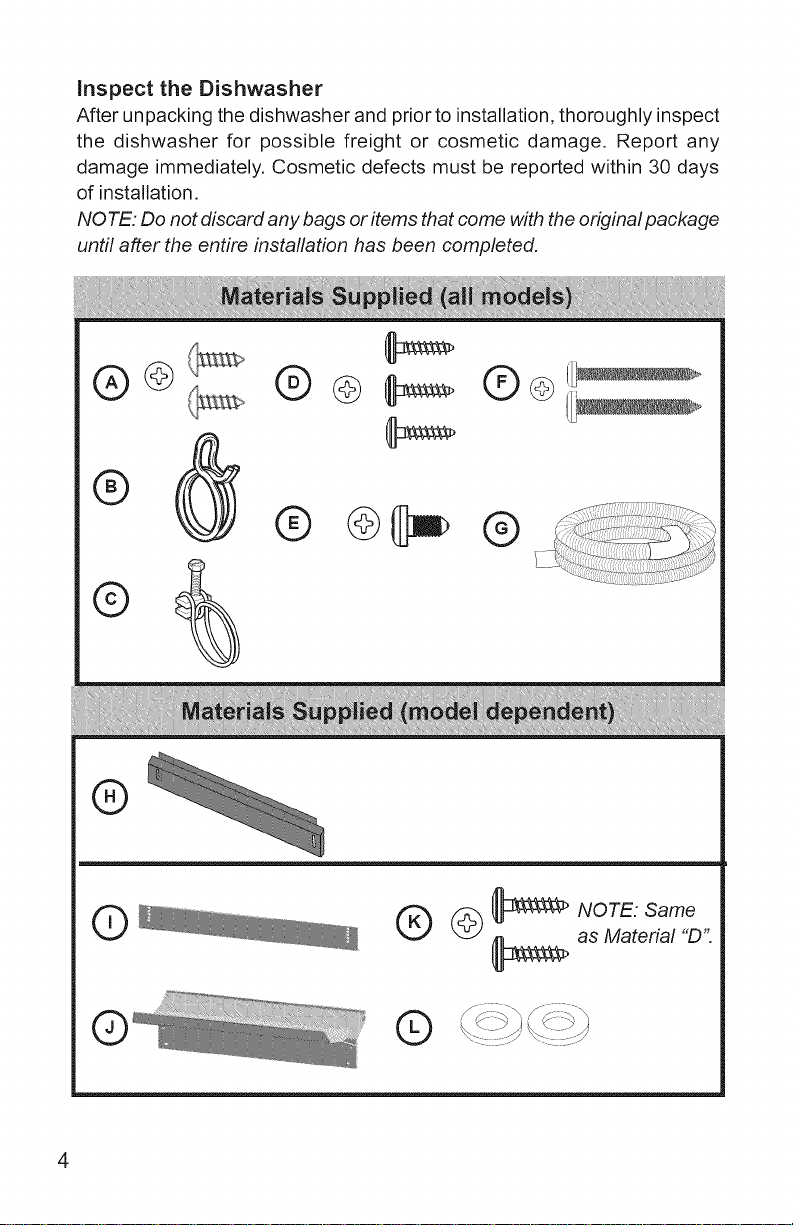

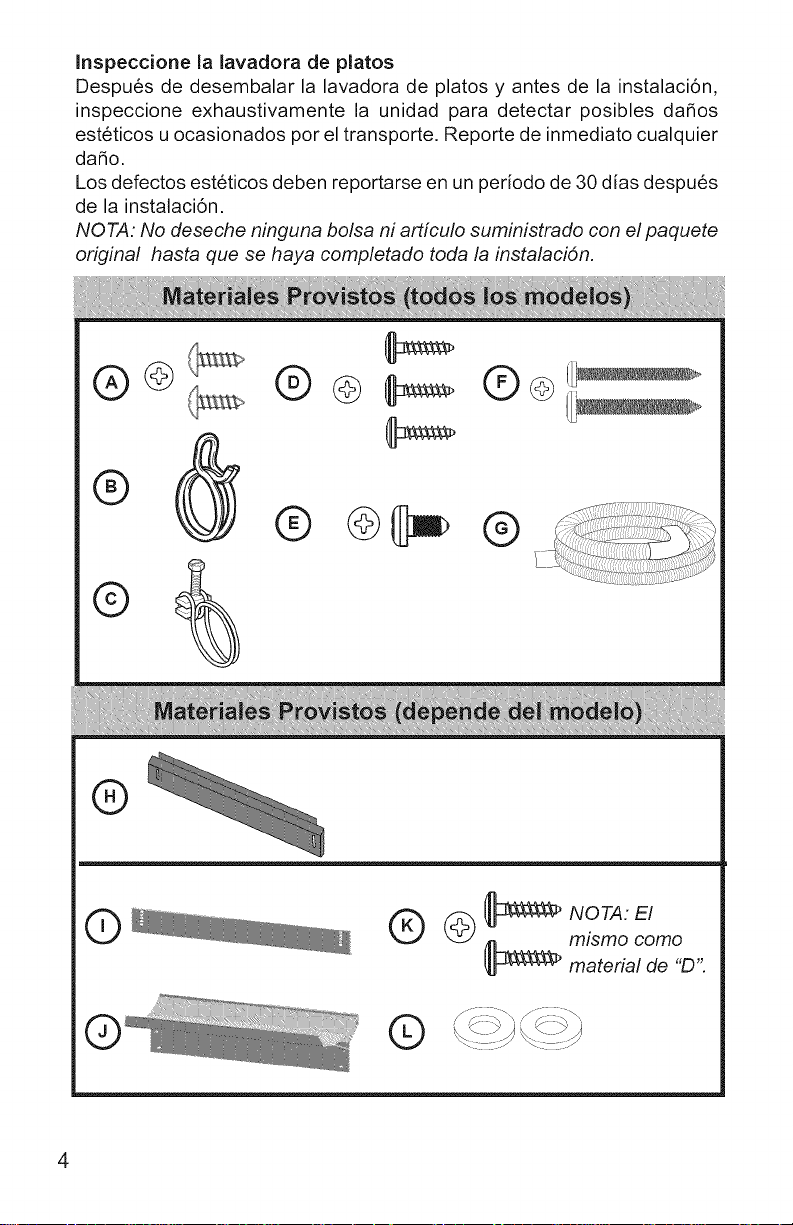

Inspect the Dishwasher

After unpacking the dishwasher and prior to installation, thoroughly inspect

the dishwasher for possible freight or cosmetic damage. Report any

damage immediately. Cosmetic defects must be reported within 30 days

of installation.

NOTE: Do not discard any bags or items that come with the original package

until after the entire installation has been completed.

®@

®@t_@

®

@ _ NOTE: Same

_ as Material "D".

©

E]

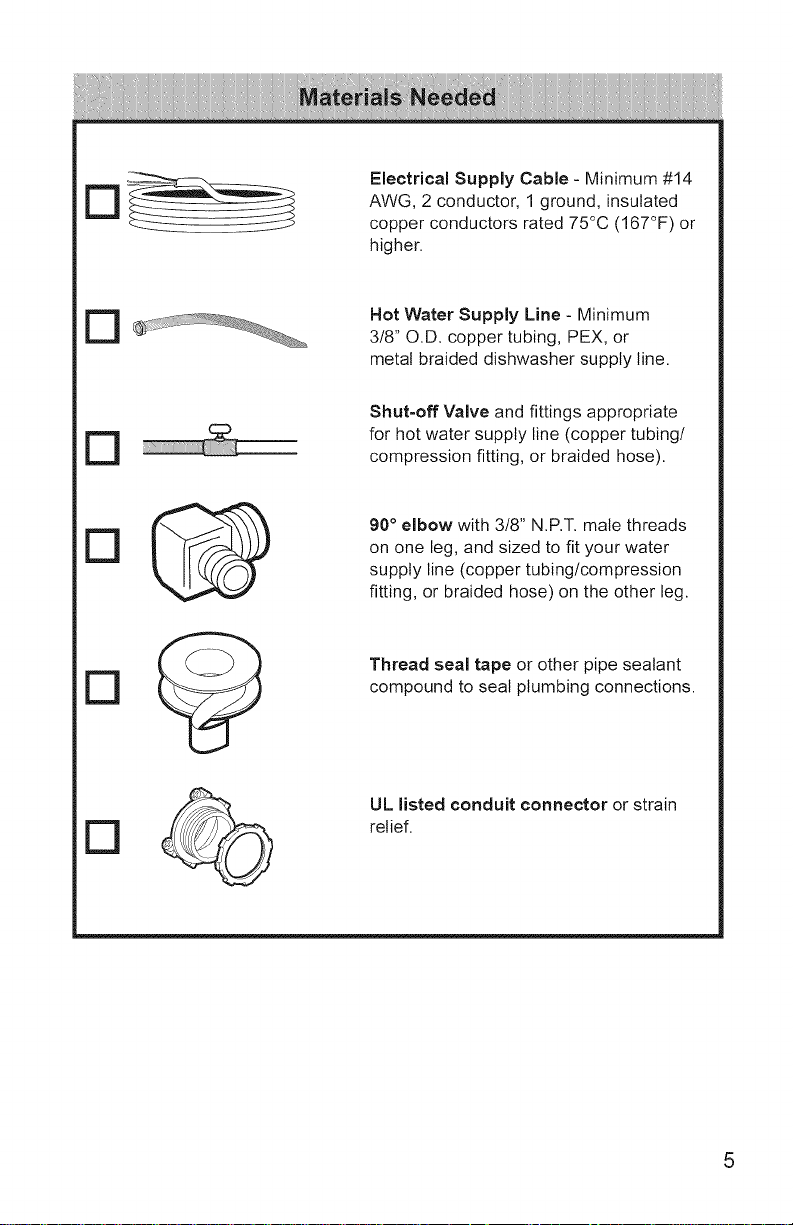

Electrical Supply Cable - Minimum #14

AWG, 2 conductor, 1 ground, insulated

copper conductors rated 75°C (167°F) or

higher.

[3

[3

[3

Hot Water Supply Line - Minimum

3/8" O.D. copper tubing, PEX, or

metal braided dishwasher supply line.

Shut=off Valve and fittings appropriate

for hot water supply line (copper tubing/

compression fitting, or braided hose).

90° elbow with 3/8" N.P.T. male threads

on one leg, and sized to fit your water

supply line (copper tubing/compression

fitting, or braided hose) on the other leg.

Thread seal tape or other pipe sealant

compound to seal plumbing connections.

UL listed conduit connector or strain

relief.

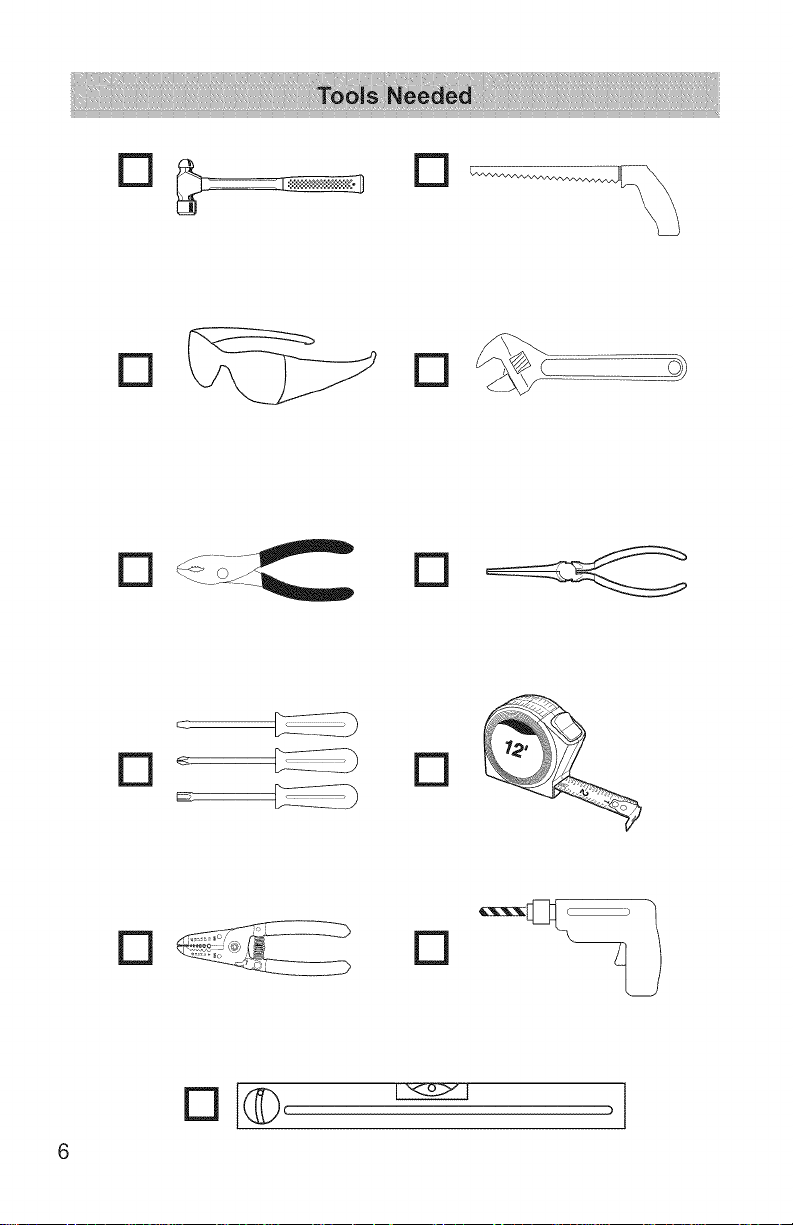

D

D

D

D

D _

D

D I©_

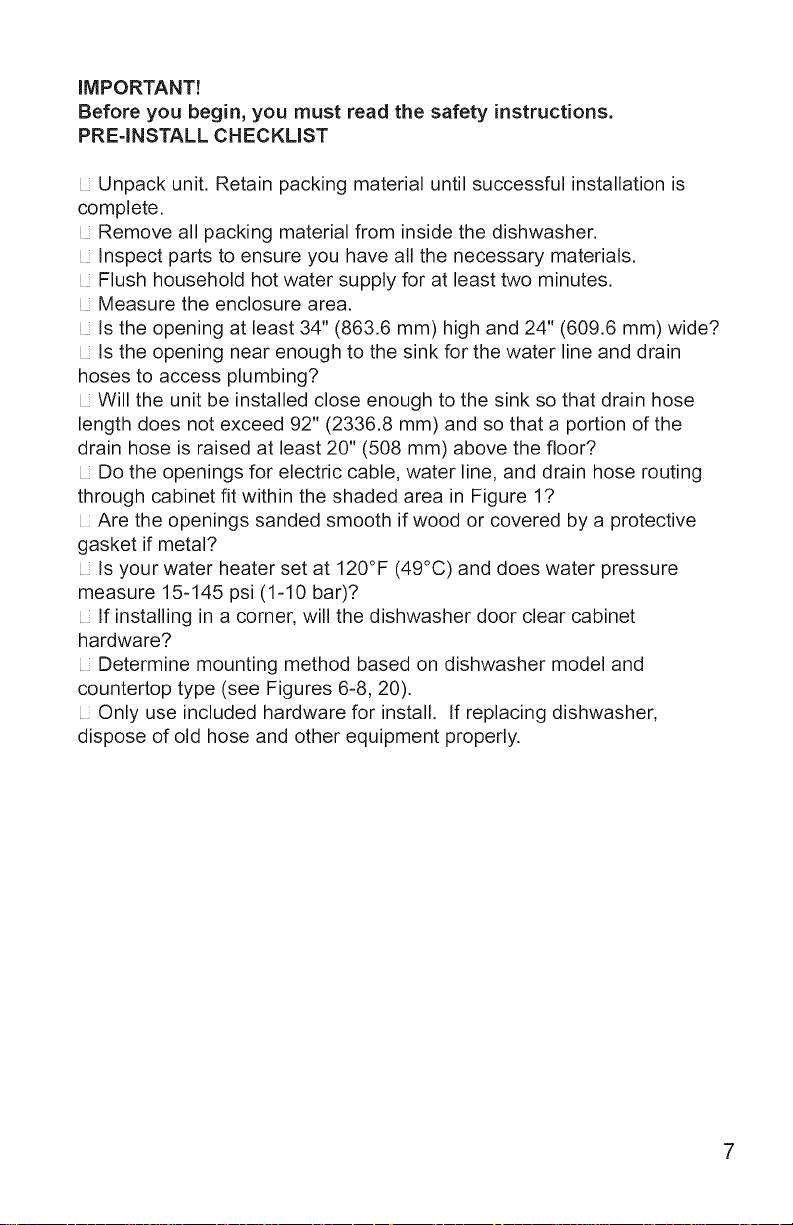

IMPORTANT!

Before you begin, you must read the safety instructions.

PRE=INSTALL CHECKLIST

Unpack unit. Retain packing material until successful installation is

complete.

Remove all packing material from inside the dishwasher.

Inspect parts to ensure you have all the necessary materials.

Flush household hot water supply for at least two minutes.

Measure the enclosure area.

Is the opening at least 34" (863.6 mm) high and 24" (609.6 mm) wide?

Is the opening near enough to the sink for the water line and drain

hoses to access plumbing?

Will the unit be installed close enough to the sink so that drain hose

length does not exceed 92" (2336.8 mm) and so that a portion of the

drain hose is raised at least 20" (508 mm) above the floor?

Do the openings for electric cable, water line, and drain hose routing

through cabinet fit within the shaded area in Figure 1?

Are the openings sanded smooth if wood or covered by a protective

gasket if metal?

Is your water heater set at 120°F (49°C) and does water pressure

measure 15=145 psi (1-10 bar)?

If installing in a corner, will the dishwasher door clear cabinet

hardware?

Determine mounting method based on dishwasher model and

countertop type (see Figures 6-8, 20).

Only use included hardware for install. If replacing dishwasher,

dispose of old hose and other equipment properly.

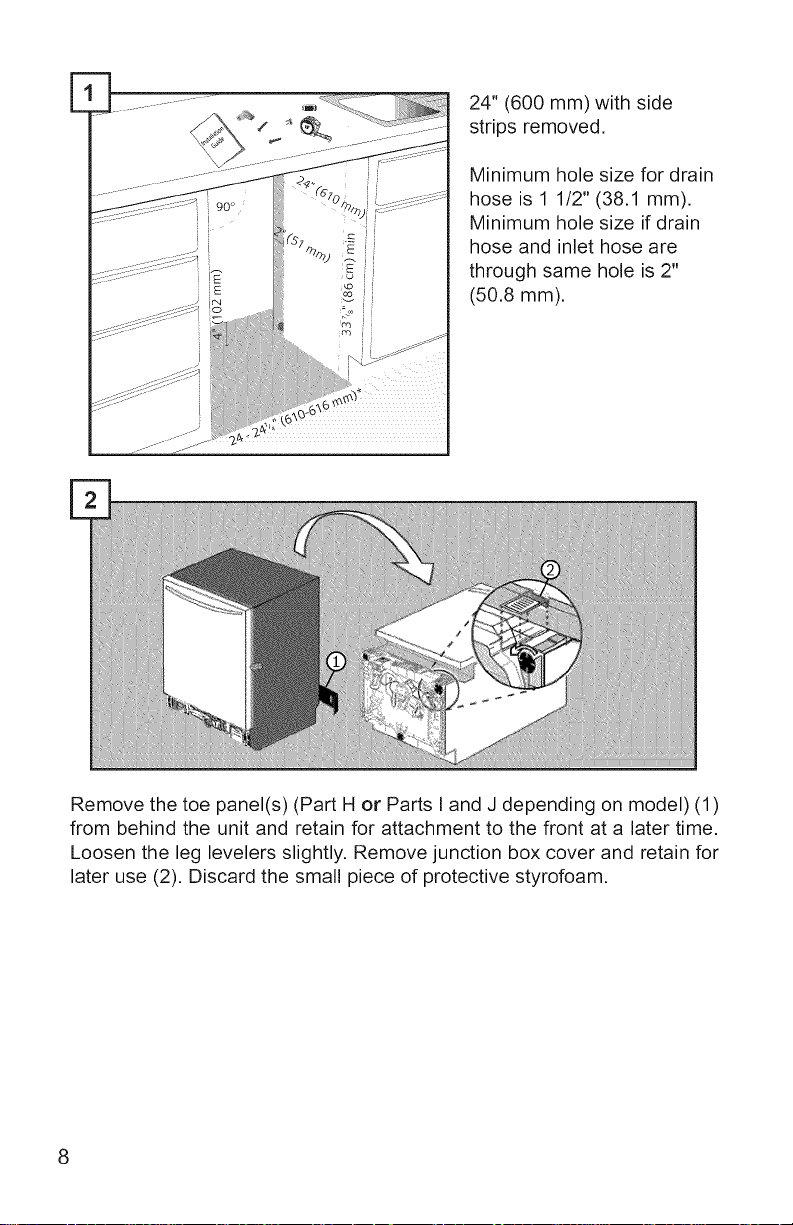

24" (600 mm) with side

strips removed.

Minimum hole size for drain

90 °

hose is 1 1/2" (38.1 mm).

Minimum hole size if drain

hose and inlet hose are

through same hole is 2"

(50.8 mm).

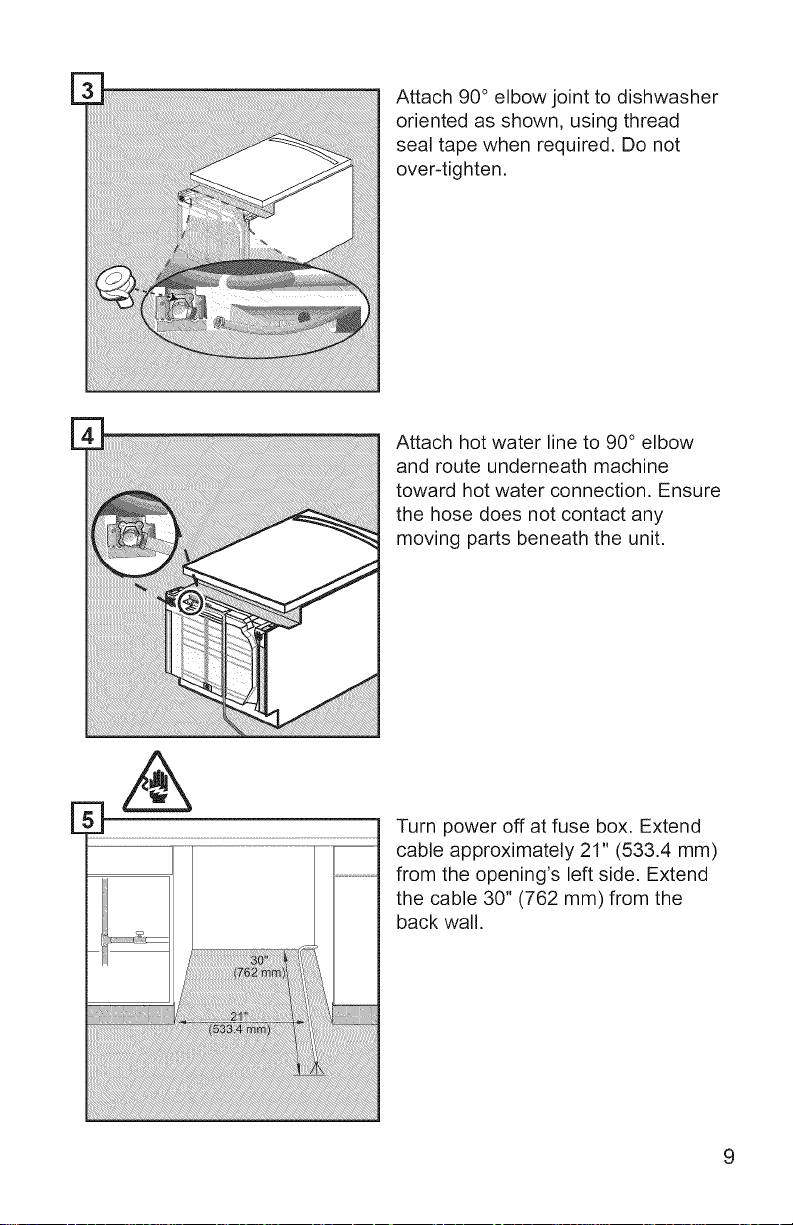

Remove the toe panel(s) (Part H or Parts I and J depending on model) (1)

from behind the unit and retain for attachment to the front at a later time.

Loosen the leg levelers slightly. Remove junction box cover and retain for

later use (2). Discard the small piece of protective styrofoam,

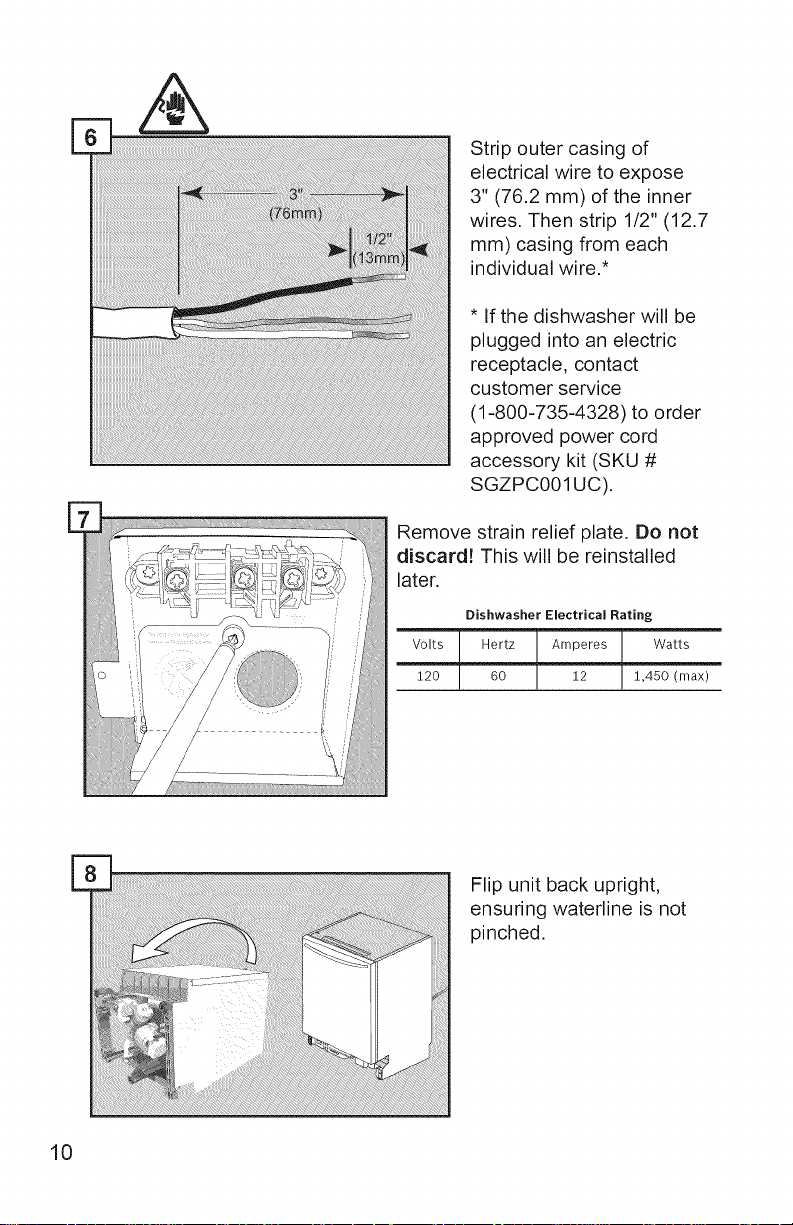

Attach90°elbowjointtodishwasher

orientedasshown,usingthread

sealtapewhenrequired.Donot

over-tighten.

Attachhotwaterlineto90°elbow

androuteunderneathmachine

towardhotwaterconnection.Ensure

thehosedoesnotcontactany

movingpartsbeneaththeunit.

Turnpoweroffatfusebox.Extend

cableapproximately21"(533.4mm)

fromtheopening'sleftside.Extend

thecable30"(762mm)fromthe

backwall.

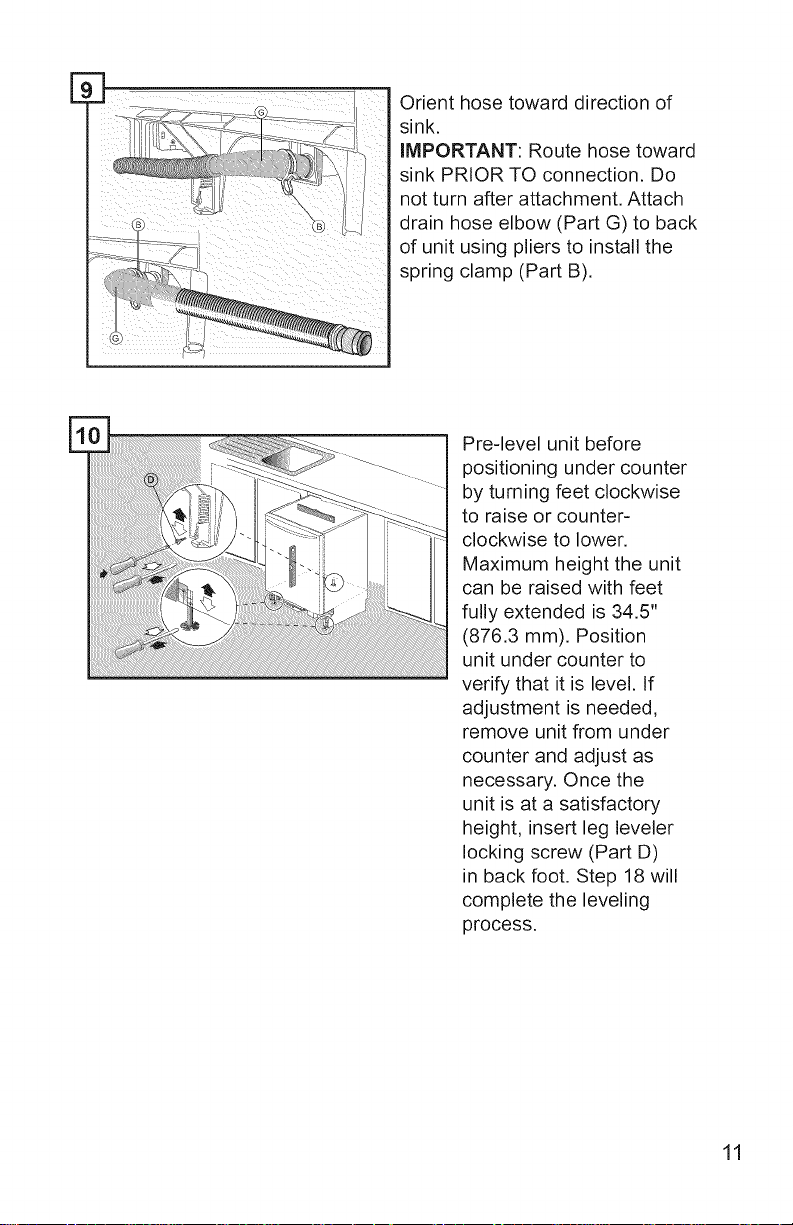

Stripoutercasingof

electricalwiretoexpose

3"(76.2mm)oftheinner

wires.Thenstrip1/2"(12.7

mm)casingfromeach

individualwire.*

*Ifthedishwasherwillbe

pluggedintoanelectric

receptacle,contact

customerservice

(1-800-735-4328)toorder

approvedpowercord

accessorykit(SKU#

SGZPC001UC).

Removestrainreliefplate.Donot

discard!Thiswillbereinstalled

later.

Dishwasher Electrical Rating

Volts Hertz Amperes Watts

120 60 12 1,450 (max)

10

Flip unit back upright,

ensuring waterline is not

pinched.

E

Orient hose toward direction of

sink.

IMPORTANT: Route hose toward

sink PRIOR TO connection. Do

not turn after attachment. Attach

drain hose elbow (Part G) to back

of unit using pliers to install the

spring clamp (Part B).

Preqevel unit before

positioning under counter

by turning feet clockwise

to raise or counter-

clockwise to lower.

Maximum height the unit

can be raised with feet

fully extended is 34.5"

(876.3 mm). Position

unit under counter to

verify that it is level. If

adjustment is needed,

remove unit from under

counter and adjust as

necessary. Once the

unit is at a satisfactory

height, insert leg leveler

locking screw (Part D)

in back foot. Step 18 will

complete the leveling

process.

11

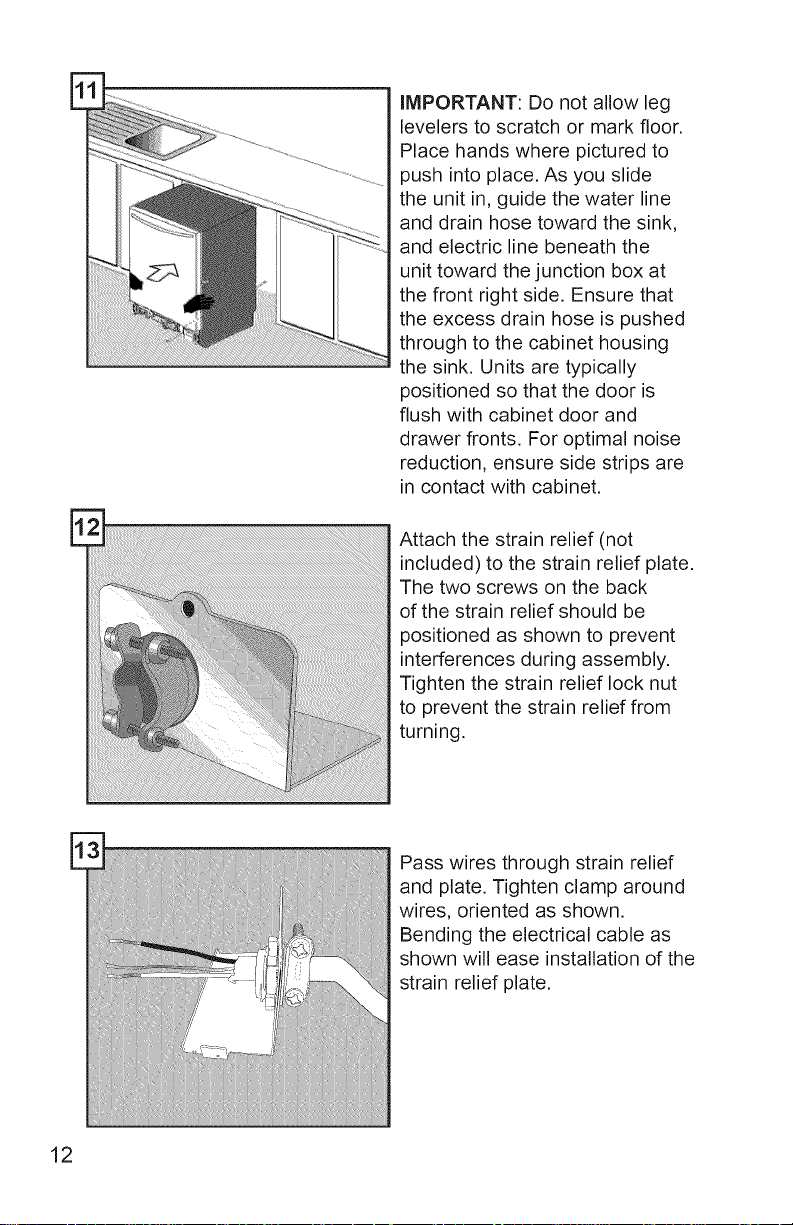

IMPORTANT: Do not allow leg

levelers to scratch or mark floor.

Place hands where pictured to

push into place. As you slide

the unit in, guide the water line

and drain hose toward the sink,

and electric line beneath the

unit toward the junction box at

the front right side. Ensure that

the excess drain hose is pushed

through to the cabinet housing

the sink. Units are typically

positioned so that the door is

flush with cabinet door and

drawer fronts. For optimal noise

reduction, ensure side strips are

in contact with cabinet.

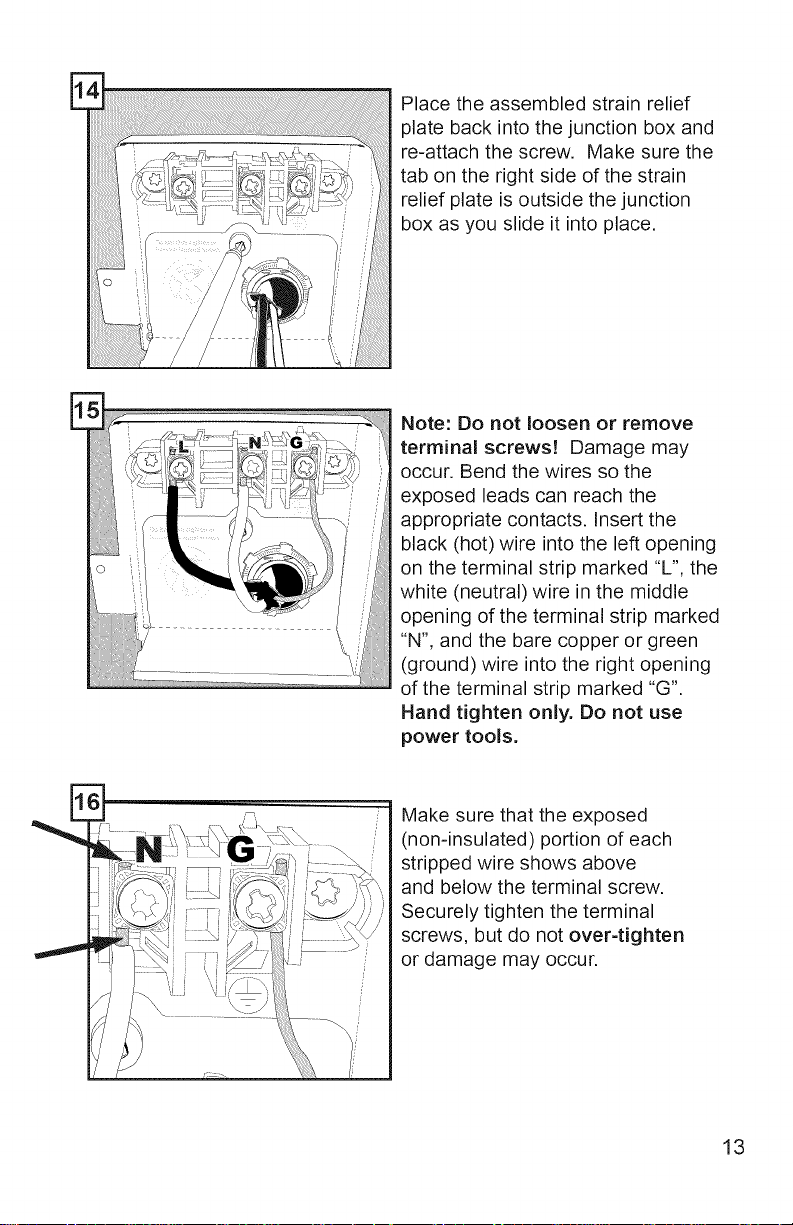

Attach the strain relief (not

included) to the strain relief plate.

The two screws on the back

of the strain relief should be

positioned as shown to prevent

interferences during assembly.

Tighten the strain relief lock nut

to prevent the strain relief from

turning.

12

Pass wires through strain relief

and plate. Tighten clamp around

wires, oriented as shown.

Bending the electrical cable as

shown will ease installation of the

strain relief plate.

Place the assembled strain relief

plate back into the junction box and

re-attach the screw. Make sure the

tab on the right side of the strain

relief plate is outside the junction

box as you slide it into place.

E

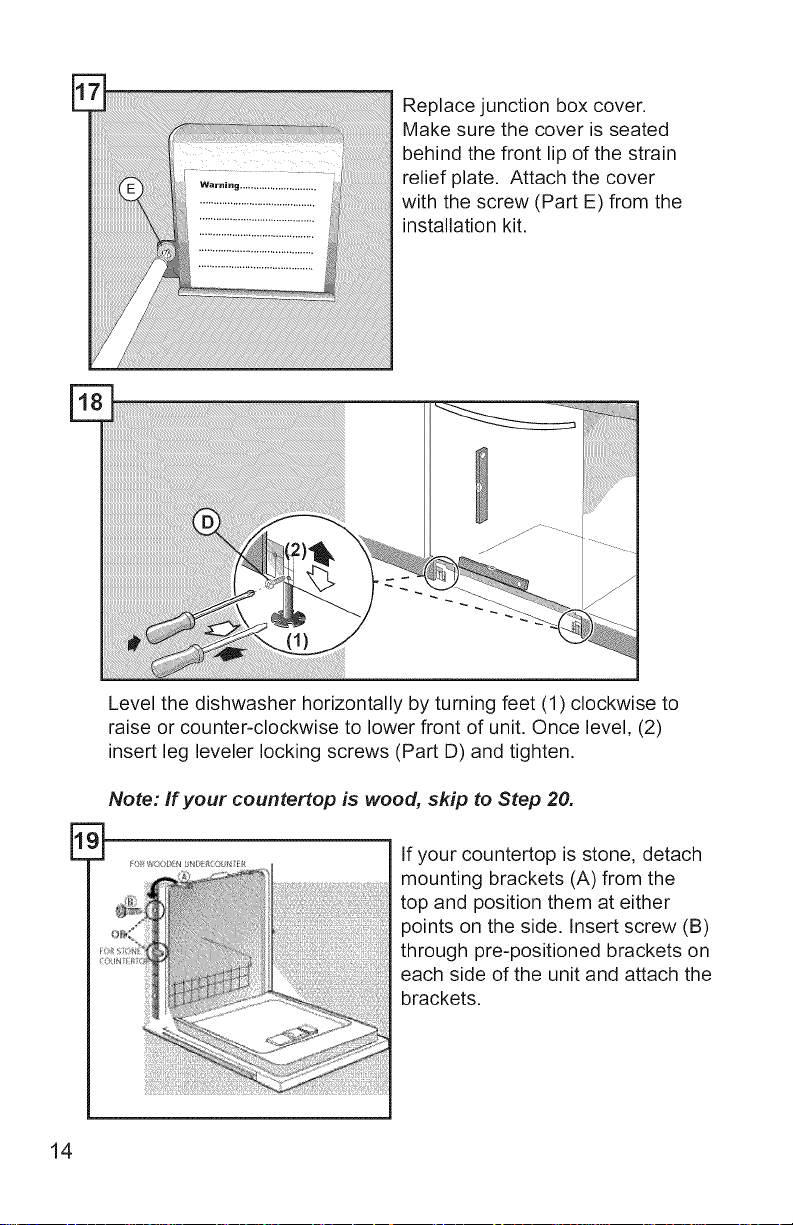

Note: Do not loosen or remove

terminal screws! Damage may

occur. Bend the wires so the

exposed leads can reach the

appropriate contacts. Insert the

black (hot) wire into the left opening

on the terminal strip marked "L", the

white (neutral) wire in the middle

opening of the terminal strip marked

"N", and the bare copper or green

(ground) wire into the right opening

of the terminal strip marked "G".

Hand tighten only. Do not use

power tools.

Make sure that the exposed

(non-insulated) portion of each

stripped wire shows above

and below the terminal screw.

Securely tighten the terminal

screws, but do not over-tighten

or damage may occur.

13

Replace junction box cover.

Make sure the cover is seated

behind the front lip of the strain

relief plate. Attach the cover

with the screw (Part E) from the

installation kit.

Level the dishwasher horizontally by turning feet (1) clockwise to

raise or counter-clockwise to lower front of unit. Once level, (2)

insert leg leveler locking screws (Part D) and tighten.

Note: If your countertop is wood, skip to Step 20.

E

14

If your countertop is stone, detach

mounting brackets (A) from the

top and position them at either

points on the side. Insert screw (B)

through pre-positioned brackets on

each side of the unit and attach the

brackets.

Insert screws (Part A) through

pre-positioned mounting brackets

on each side of the unit and attach

to enclosure (pre-drilling of holes

recommended). Remove upper rack

before inserting screws.

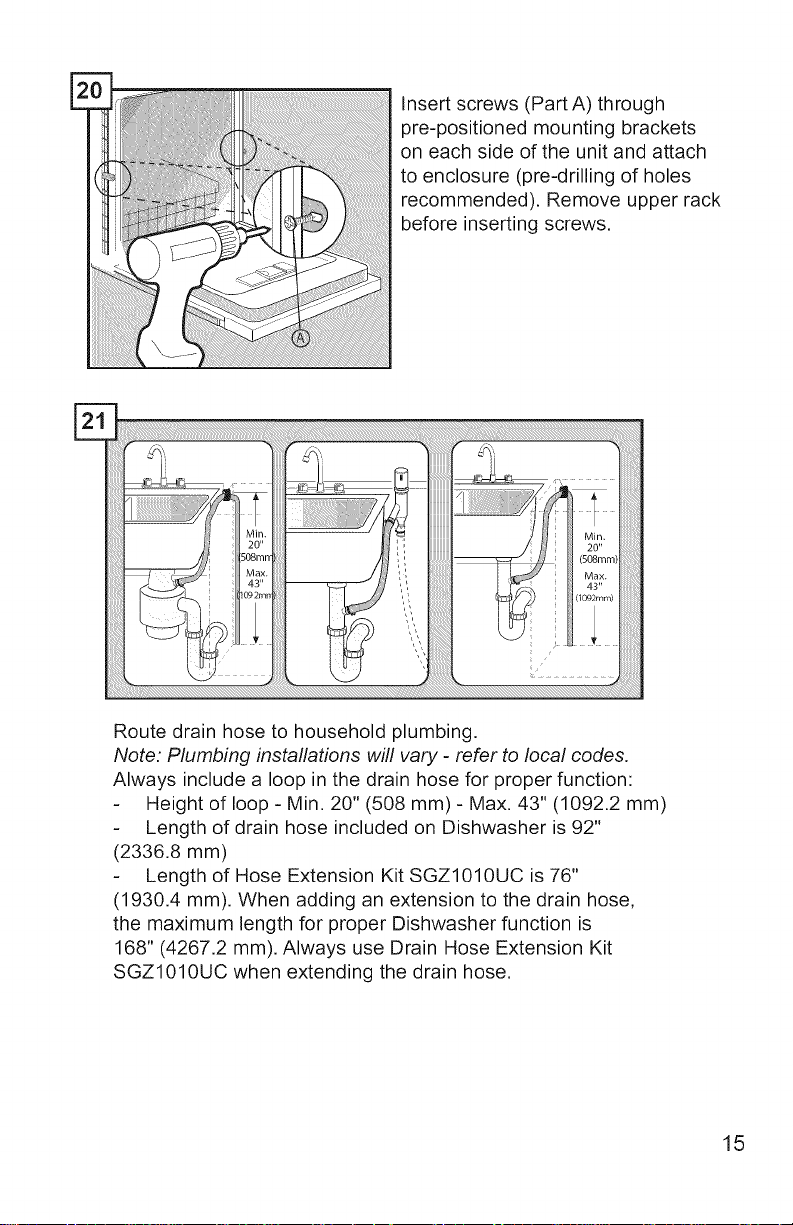

Route drain hose to household plumbing.

Note: Plumbing installations will vary - refer to local codes.

Always include a loop in the drain hose for proper function:

Height of loop - Min. 20" (508 mm) - Max. 43" (1092.2 mm)

Length of drain hose included on Dishwasher is 92"

(2336.8 mm)

Length of Hose Extension Kit SGZl010UC is 76"

(1930.4 mm). When adding an extension to the drain hose,

the maximum length for proper Dishwasher function is

168" (4267.2 mm). Always use Drain Hose Extension Kit

SGZ1010UC when extending the drain hose.

15

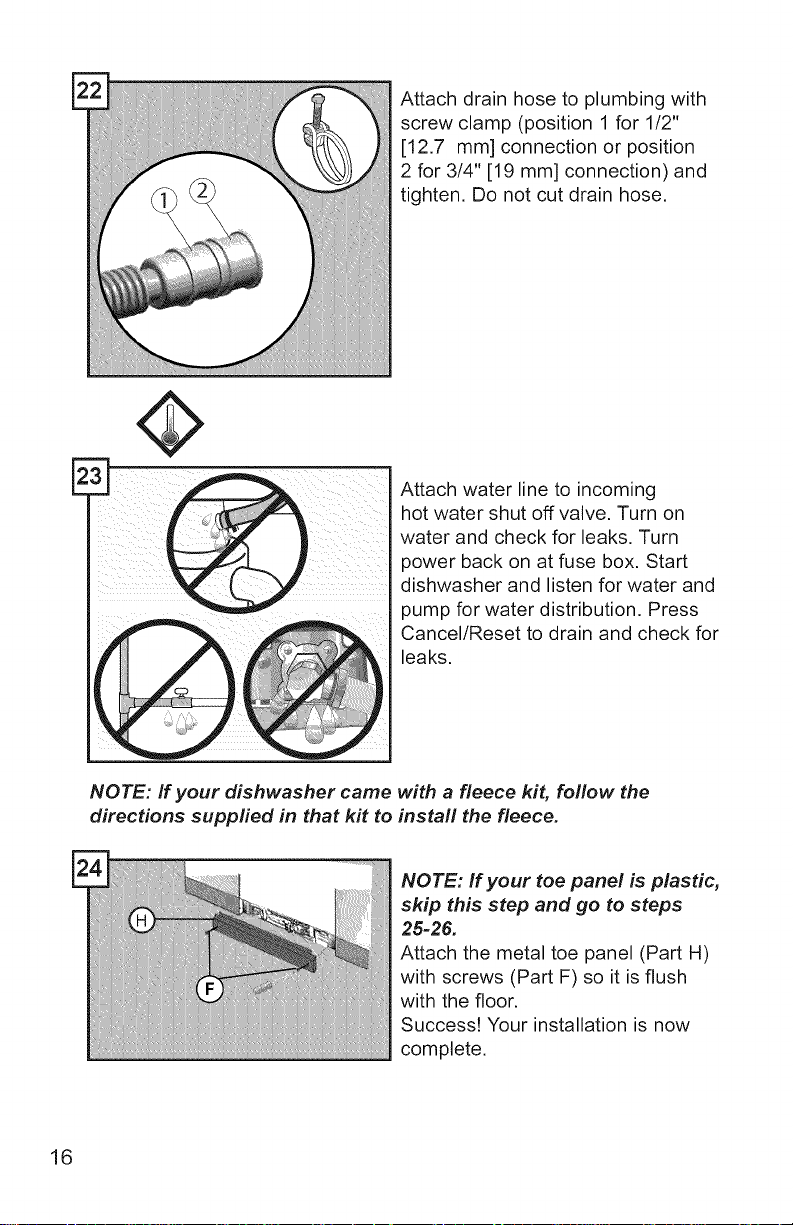

Attach drain hose to plumbing with

screw clamp (position 1 for 1/2"

[12.7 mm] connection or position

2 for 3/4" [19 mm] connection) and

tighten, Do not cut drain hose,

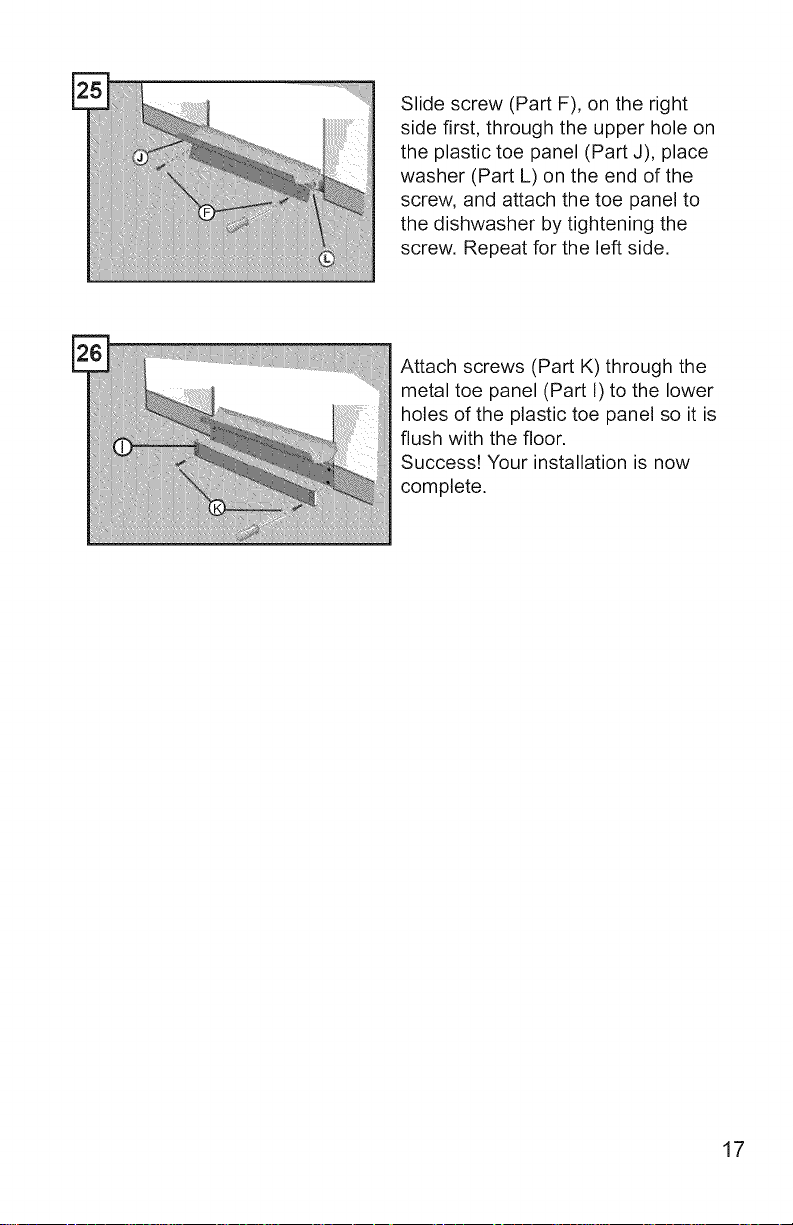

Attach water line to incoming

hot water shut off valve. Turn on

water and check for leaks. Turn

power back on at fuse box. Start

dishwasher and listen for water and

pump for water distribution. Press

Cancel/Reset to drain and check for

leaks,

NOTE: If your dishwasher came with a fleece kit, follow the

directions supplied in that kit to install the fleece.

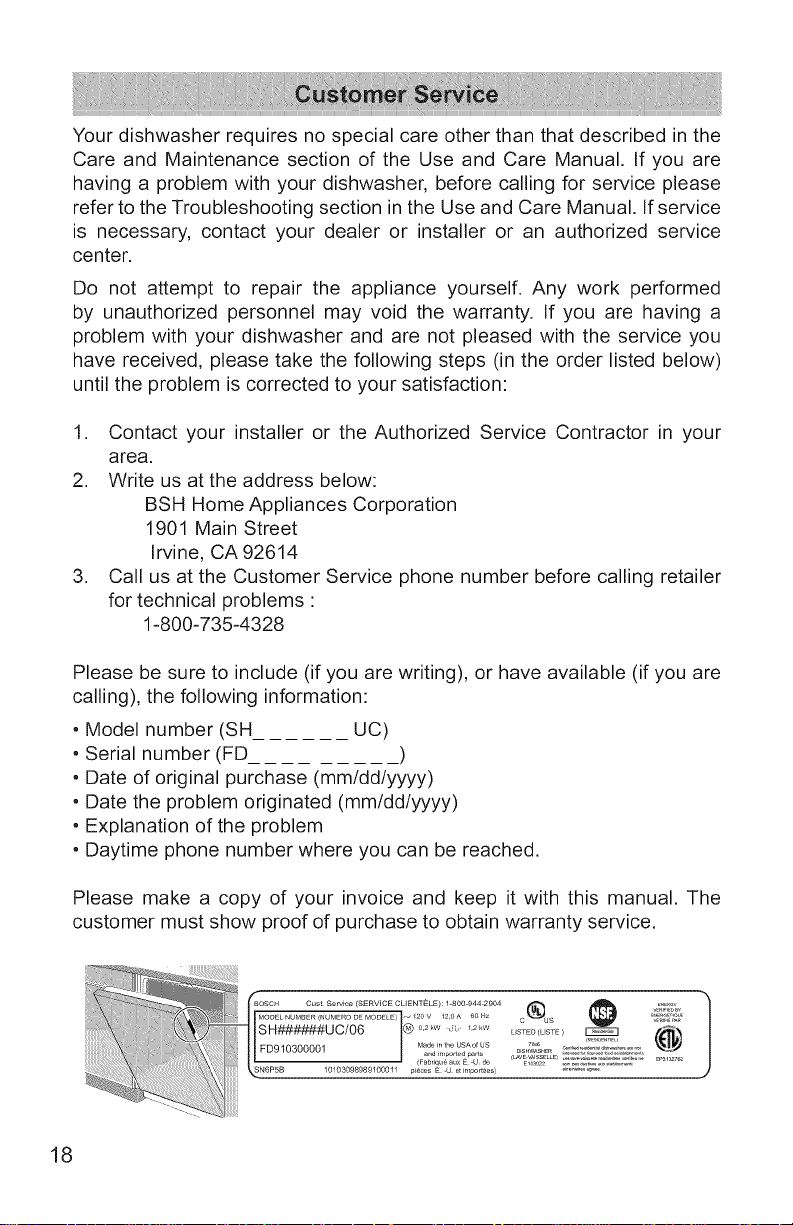

NOTE: If your toe panel is plastic,

skip this step and go to steps

25-26.

Attach the metal toe panel (Part H)

with screws (Part F) so it is flush

with the floor.

Success! Your installation is now

complete.

16

Slide screw (Part F), on the right

side first, through the upper hole on

the plastic toe panel (Part J), place

washer (Part L) on the end of the

screw, and attach the toe panel to

the dishwasher by tightening the

screw. Repeat for the left side.

Attach screws (Part K) through the

metal toe panel (Part I) to the lower

holes of the plastic toe panel so it is

flush with the floor.

Success! Your installation is now

complete.

17

Your dishwasher requires no special care other than that described in the

Care and Maintenance section of the Use and Care Manual. If you are

having a problem with your dishwasher, before calling for service please

refer to the Troubleshooting section in the Use and Care Manual. If service

is necessary, contact your dealer or installer or an authorized service

center.

Do not attempt to repair the appliance yourself. Any work performed

by unauthorized personnel may void the warranty. If you are having a

problem with your dishwasher and are not pleased with the service you

have received, please take the following steps (in the order listed below)

until the problem is corrected to your satisfaction:

1. Contact your installer or the Authorized Service Contractor in your

area.

2. Write us at the address below:

BSH Home Appliances Corporation

1901 Main Street

Irvine, CA 92614

3. Call us at the Customer Service phone number before calling retailer

for technical problems:

1-800-735-4328

Please be sure to include (if you are writing), or have available (if you are

calling), the following information:

• Model number (SH UC)

• Serial number (FD )

• Date of original purchase (mm/dd/yyyy)

• Date the problem originated (mm/dd/yyyy)

• Explanation of the problem

• Daytime phone number where you can be reached.

Please make a copy of your invoice and keep it with this manual. The

customer must show proof of purchase to obtain warranty service.

_BOSCH C t S (SERVICE CLIENTELE) 1 8OO 944 29O4 E.Ea¥

--'':}k::2:A--,:!io®US@ ,,:,s,:.<.

SH######U C/06 I@ ...... " L............ )

,i } }:ii1 ,,_ FD910300001 Mad_ in the USA°f US ...... L..............................

i _N6P5B 10103098989100011 pieces E -U et importees) _'_"_'_

18

Instrucciones de seguridad importantes"

Pot favor lea y guarde esta informaci6n

Para evitar posibles lesiones o da_os materiales, RESPETE TODAS LAS

ADVERTENCIAS Y PRECAUCIONES. Estas instrucciones estan dise_adas

para set usadas Onicamente pot instaladores calificados. La lavadora de

platos debe set instalada pot un t6cnico de servicio t6cnico o instalador

calificado.

• Ademas de estas instrucciones, la lavadora de platos debe insta-

larse de conformidad con todos los c6digos y las ordenanzas de

electricidad y de plomeda (nacionales y locales).

Lea estas instrucciones de instalaci6n completamente y sigalas

con cuidado. Le ahorraran tiempo y esfuerzo, y le ayudaran a asegura-

rse de que el rendimiento de la lavadora de platos sea 6ptimo y seguro.

IMPORTANTE

• La manguera de drenaje de la lavadora de platos debe instalarse

manteniendo una parte de esta, al menos, a una distancia de 20" (508

mm) del piso del gabinete; de Io contrario, es posible que la lavadora

de platos no drene correctamente.

• Esta lavadora de platos ha sido dise_ada para uso residencial en inte-

riores Onicamente y no debe usarse en establecimientos comerciales

de servicios de comidas.

Este lavavajillas esta disedado para ser cerrado en la parte superior y

ambos lados pot los gabinetes.

NUEVA INSTALACION: si la lavadora de platos es una instalaci6n

nueva, la mayoria del trabajo debe realizarse antes de que la lavadora

de platos sea colocada en su lugar.

REEMPLAZO: si la lavadora de platos reemplaza a otra lavadora de

platos, verifique las conexiones de la lavadora de platos existente para

ver la comp,atibilidad con la nueva lavadora de platos y reemplace las

piezas segun sea necesario.

• Este electrodom6stico cumple con la norma CAN/CSA-C22.2 n.° 167/

UL 749. Es responsabilidad del propietario y del instalador determinar

si se aplican otros requisitos y normas en instalaciones especificas.

• Esta unidad no esta destinada para uso en exteriores.

Cdmoevitarpeligros generales

Use la lavadora de platos _nicamente cuando est6 completamente

instalada. AI abrir la puerta de una lavadora de platos que no esta

instalada, abra la puerta con cuidado mientras sostiene la parte posterior

de la unidad. No seguir esta advertencia puede provocar que la lavadora

de platos se caiga, Io que ocasiona lesiones graves.

Antes de instalar los soportes de montaje en "L" para la encimera sumi-

nistrados con la unidad (solo en algunos modelos), decida qu6 m6todo

se usara para asegurar la lavadora de platos en su abertura. Una vez

que estos soportes de montaje est_n instalados en la lavadora de platos,

es dificil retirarlos, y esto dafia los soportes de montaje y la lavadora de

platos.

En algunas condiciones, se puede formar gas hidr6geno en un sistema

de agua caliente que no se ha utilizado durante semanas. El gas hi-

dr6geno es explosivo.

Antes de Ilenar una lavadora de platos con un sistema que ha estado

apagado durante semanas, deje correr agua de un grifo cercano en un

_rea bien ventilada hasta que no haya sonido ni evidencia de gas.

Las temperaturas requeridas para soldar y fundir dafian la base y la

valvula de entrada de agua de la lavadora de platos. Si se van a soldar o

fundir las tuberias para plomeria, mantenga la fuente de calor, al menos,

a 6" (152.4 mm) de distancia de la base y de la valvula de entrada de

agua de la lavadora de platos.

Retirar cualquier cubierta o jalar la lavadora de platos del gabinete

puede hacer que queden expuestas las conexiones de agua caliente, la

alimentaci6n el6ctrica, y puntas o bordes filosos. Manipule la unidad con

cuidado.

C6mo evitar peligros de descarga el_ctrica/incendio '_

No permita que las lineas de electricidad ni las tuberias de suministro de

agua entren en contacto. Se suministran canales separados debajo de la

lavadora de platos.

No trabaje en un circuito energizado. Hacerlo podria ocasionar lesio-

nes graves o la muerte. 0nicamente los electricistas calificados pueden

realizar la instalaci6n el6ctrica. No intente realizar ningOn trabajo en el

circuito de suministro el6ctrico de la lavadora de platos hasta que est6

seguro de que el circuito se encuentra desenergizado.

Aseg0resedequelainstalaci6nel6ctricasehayarealizadocorrecta-

mente.Nodebehaberconexionesel6ctricassueltas.Aseg0resedeque

todaslasconexionesel6ctricassehayanrealizadocorrectamente.

Elclientetienelaresponsabilidaddeasegurarsedequelainstalaci6n

el6ctricadelalavadoradeplatoscumplacontodoslosc6digosylasor-

denanzasdeelectricidadnacionalesylocales.Lalavadoradeplatosesta

dise_adaparaunsuministroel6ctricodeCAde120V,60Hz,conectadoa

uncircuitoel6ctricoconunaconexi6natierraadecuada,exclusivoparala

lavadoradeplatos,conunfusibleodisyuntorconcapacidadnominalpara

15A.Losconductoresdelsuministroel6ctricodebensetdealambre,Oni-

camentedecobre,conuncalibredealambreestadounidense(American

WireGauge,AWG)n.°14comominimo,concapacidadnominalparauso

entemperaturasde75°C(167°F)omasaltas.

Esteelectrodom6sticodebeconectarseaunsistemadecableadometalico

y permanente,conconexi6natierra,o debeinstalarseunconductorde

conexi6na tierraparaequiposjuntoconlosconductoresde circuitos

y conectarloalterminalde conexi6natierraparaequiposo al hilode

conexi6natierradelelectrodom6stico.Nousecablesdeextensi6n.

C6moevitarpeligrosenlastuberiasy peligros A

deescaldadura

NorealiceningOntrabajoenunatuber[adeaguacalientequetengacarga.

Podriaocasionarlesionesgraves.0nicamentelosplomeroscalificados

puedenrealizartrabajosdeplomer[a.NointenterealizarningOntipodetrabajo

enlastuber[asdesuministrodeaguacalientedelalavadoradeplatoshasta

queest6segurodequeelsuministrodeaguacalienteestacerrado.

Noaprieteenexcesoelcodode90°.Hacerlopuededa_arlavalvulade

entradadeaguay provocarunap6rdidadeagua.

Lastemperaturasrequeridasparasoldary fundirda_anla valvulade

entradadeaguadelalavadoradeplatos.Sisevanasoldarofundirlas

tuberiasparaplomeria,mantengalafuentedecalor,almenos,a6"(152.4

mm)dedistanciadelav_lvuladeentradadeaguadelalavadoradeplatos.

Consultelosc6digosdeplomerialocalesparaconocerlosprocedimientos

y losaccesoriosdeplomeriaaprobados.Todoslostrabajosdeplomer[a

debenrealizarsesegQnlosc6digosnacionalesylocales.

Estasinstruccionesdescribenunm6tododeinstalaci6nparamangueras

trenzadasdeaceroinoxidableo tuberiasdesuministrodeaguacaliente

depolietilenoreticulado(Cross-linkedpolyethylene,PEX).Siusatubosde

cobreo deotromaterialparaelsuministrodeagua,hagaqueunplomero

autorizadorealicelainstalaci6ncorrespondiente.

3

Inspeccione la lavadora de platos

Despu6s de desembalar la lavadora de platos y antes de la instalaci6n,

inspeccione e×haustivamente la unidad para detectar posibles dafios

est6ticos u ocasionados por el transporte. Reporte de inmediato cualquier

dafio.

Los defectos est6ticos deben reportarse en un periodo de 30 d[as despu6s

de la instalaci6n.

NOTA: No deseche ninguna bolsa ni articulo suministrado con el paquete

original hasta que se haya completado toda la instalaci6n.

®@

® @l]_ @

®

Q_

®

©

_ mlsmo como

material de "D".

Loading...

Loading...