Bosch SE 320 Lsni User Manual

SE 320 LSNi SmartKey Arming Device

Installation Manual

EN

SE 320 LSNi

Table of Contents

System Description

System Overview with Functional Variants................................................................................... 3

Description of the Connections on the Control Unit...................................................................... 6

Installation Instructions

Installing System Components...................................................................................................... 8

Installing the Magnetic Contact and Bolt Contact......................................................................... 9

Connection, Switch-Point Control, Address Switches ................................................................ 10

Connecting the Control Panel and Optional Components.......................................................... 11

Connecting for Operation Without an SPE Blocking Element .................................................... 12

Connecting for Operation with SmartKey Code Keypad Only.................................................... 13

Connecting the SmartKey Code Keypad with Integrated Reader .............................................. 14

Connecting a Lockable Code Keypad......................................................................................... 15

Connecting a Door Opener Relay............................................................................................... 16

Connecting an E4.4 Blocking Element for Vault Doors .............................................................. 17

Connecting an E4.3 Blocking Element for Vault Doors .............................................................. 18

Function Test for SPE Blocking Element and Reader................................................................ 20

Reading In Keys and Programming the System......................................................................... 21

Starting up the SmartKey Code Keypad with Reader................................................................. 26

(or changing user codes)

Starting up the SmartKey Code Keypad Without Reader........................................................... 28

(or changing user codes)

Starting up a Lockable Code Keypad ......................................................................................... 30

(or changing user codes)

Concluding System Installation................................................................................................... 32

Operating the System

Viewing the System Status from the Reader.............................................................................. 33

Arming the System from the Reader or Code Keypad ............................................................... 34

Disarming the System from the Reader or Code Keypad........................................................... 35

Operation with SmartKey Code Keypad Only: Viewing the System Status................................ 36

Operation with SmartKey Code Keypad Only: Arming the System with the Code Keypad........ 36

Operation with SmartKey Code Keypad Only: Disarming the System with the Code Keypad... 37

Example of Operation with 4 SmartKeys/Code Keypads ........................................................... 38

Disarming for "Forced Unlocking and Alarm Display"................................................................. 38

Fault Elimination

Problems with Installation and Reading In Keys......................................................................... 39

Diagnostics Options on the Open Control Unit........................................................................... 39

Operating Problems During Normal Operation........................................................................... 40

Replacing the Bolt in the SPE Blocking Element........................................................................ 42

Notes for Maintenance and Service

General........................................................................................................................................ 43

Inspection and Maintenance....................................................................................................... 43

Loss of Keys................................................................................................................................44

Ordering Additional Keys ............................................................................................................44

Loss of the Security Card......................................................................................................

Restoring the Default Settings .................................................................................................... 45

...... 45

Technical Data........................................................................................................................... 46

2

System Description

r

y

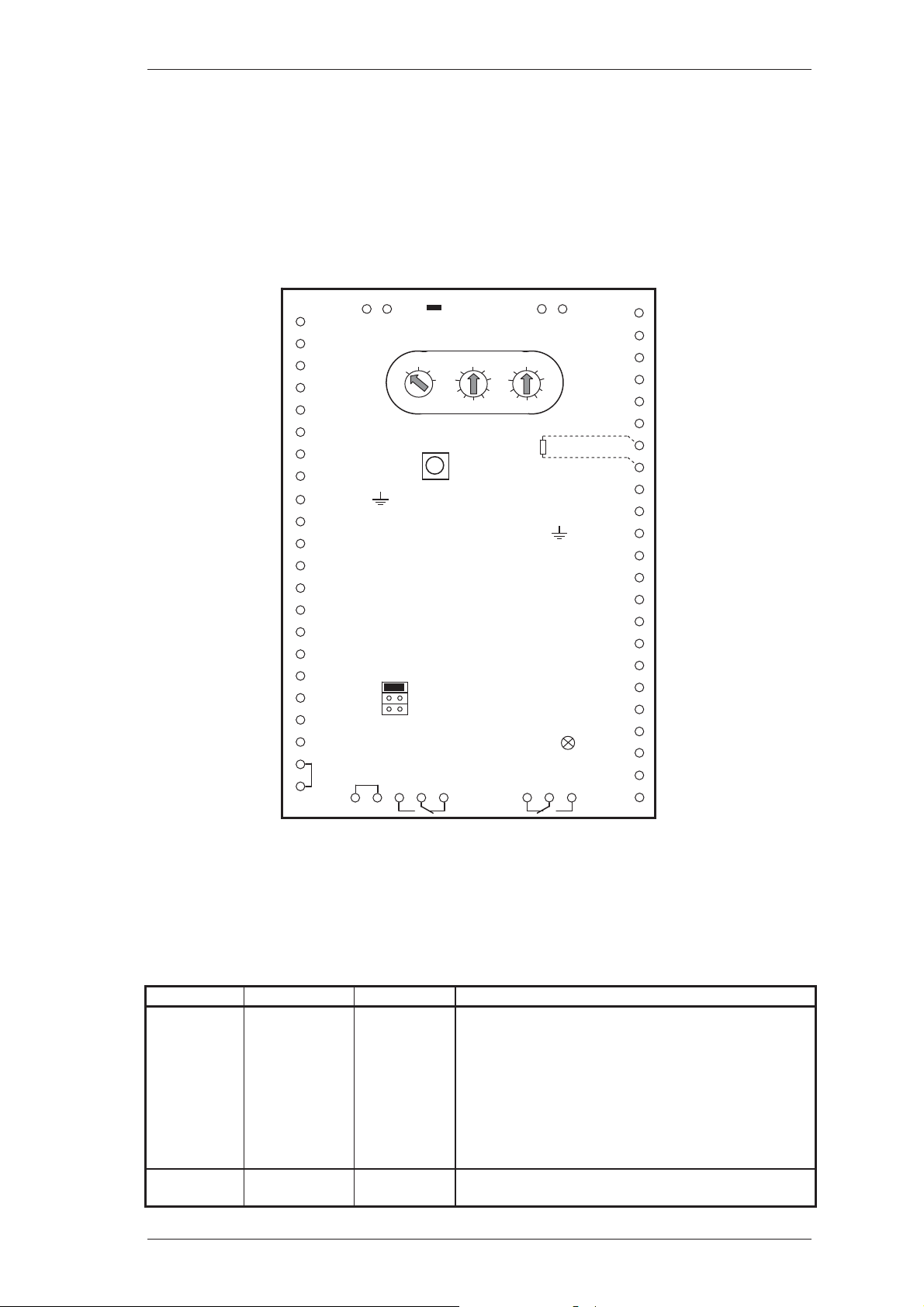

System Overview with Functional Variants

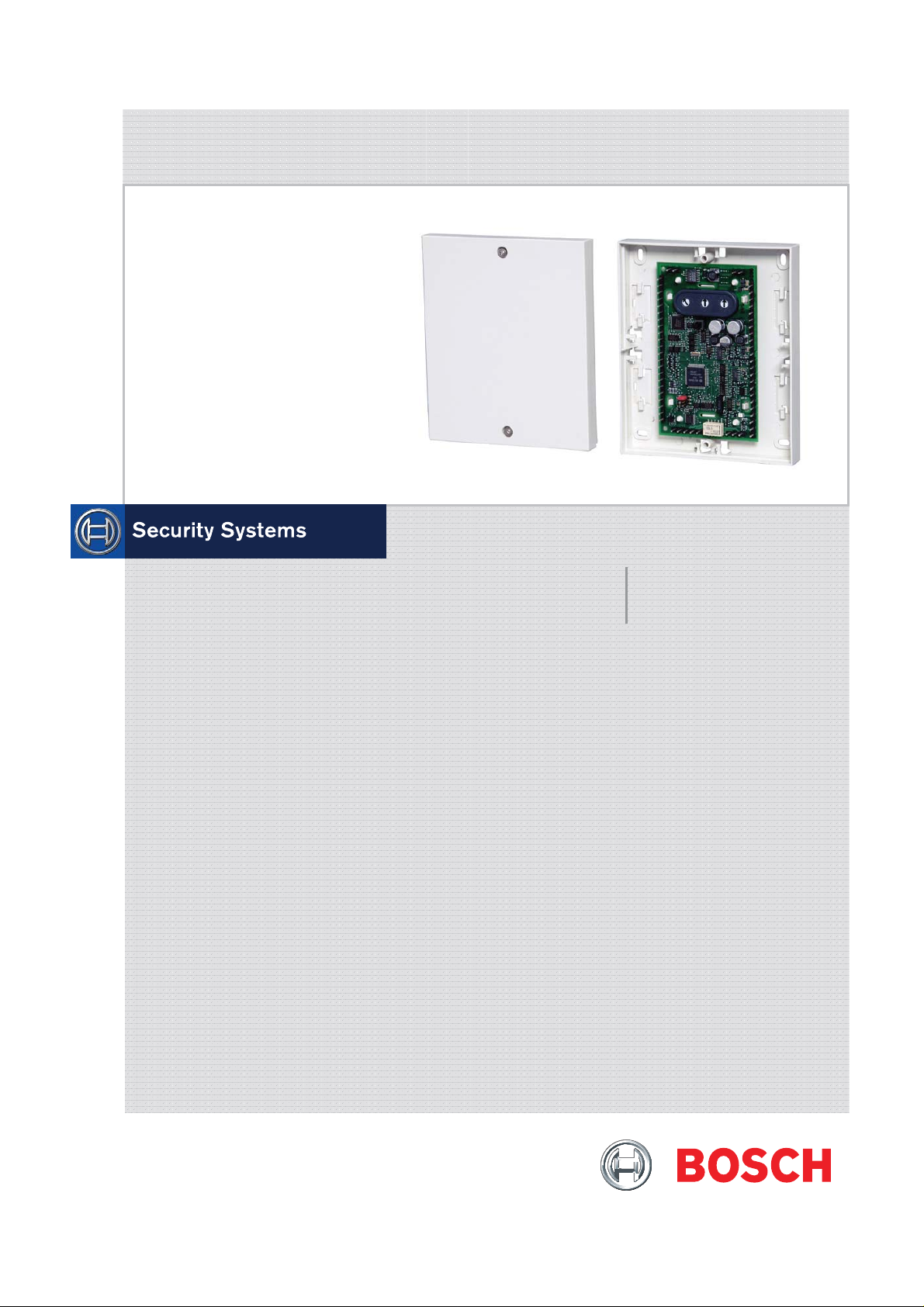

The SE 320 LSNi SmartKey Arming Device is a system solution for arming and disarming intrusion alarm systems. The individual components of the system can be put together as required for

the intended usage. Operation types with or without the SPE blocking element are possible. Control authorizations for arming/disarming are defined during control panel programming. The system is programmed using an appropriate programming program. All the information and explanations you need to program the system can be found in the online help, i.e. directly on the screen.

SPE blocking element

The SPE blocking element is an additional lock

for the door and is meant to prevent unauthorized entry to the armed area. The SPE blocking element is always installed in conjunction

with a kit in the secure area to enable it to accommodate different doors. The figure shows a

door-mounted installation; see installing the

SPE blocking element for other variants. A

conventional magnetic contact can be used

with the door-mounted installation kit. Operation types with and without blocking elements

are possible.

Control unit

SE 320 LSNi

SPE blocking

element

SmartKe

Key

Bolt

contact

Reade

Code

keypad

SE 320 LSNi control unit

The control unit processes the status reports of all components in the system,

communicates these reports to the intrusion alarm system and controls the

blocking element. The control unit is installed in the secure area.

Reader

The system is armed and disarmed by

holding an electronic key up to the reader. The LED and buzzer provide information about the status of the system as

well as operation.

The reader can be surface

mounted or recessed mounted (outside the secure area).

Door opener relay

or blocking element for

vault doors

Bolt contact: a conventional bolt contact can be connected to the

control unit. The bolt contact is not included in the scope of delivery.

Magnetic contact: a conventional standard magnetic contact can

be connected to the control unit. The magnetic contact is not included in the scope of delivery.

Note: Conventional contacts are the recommended contact type as

they can be processed directly by the control unit.

Notes on bolt contacts and door openers

x A bolt contact is mandatory for VdS systems.

x A bolt contact is optional for systems that are not compliant with VdS.

x Door openers on doors fitted with bolt contacts will not be activated when the door is locked.

3

System Description

)

System Overview with Functional Variants

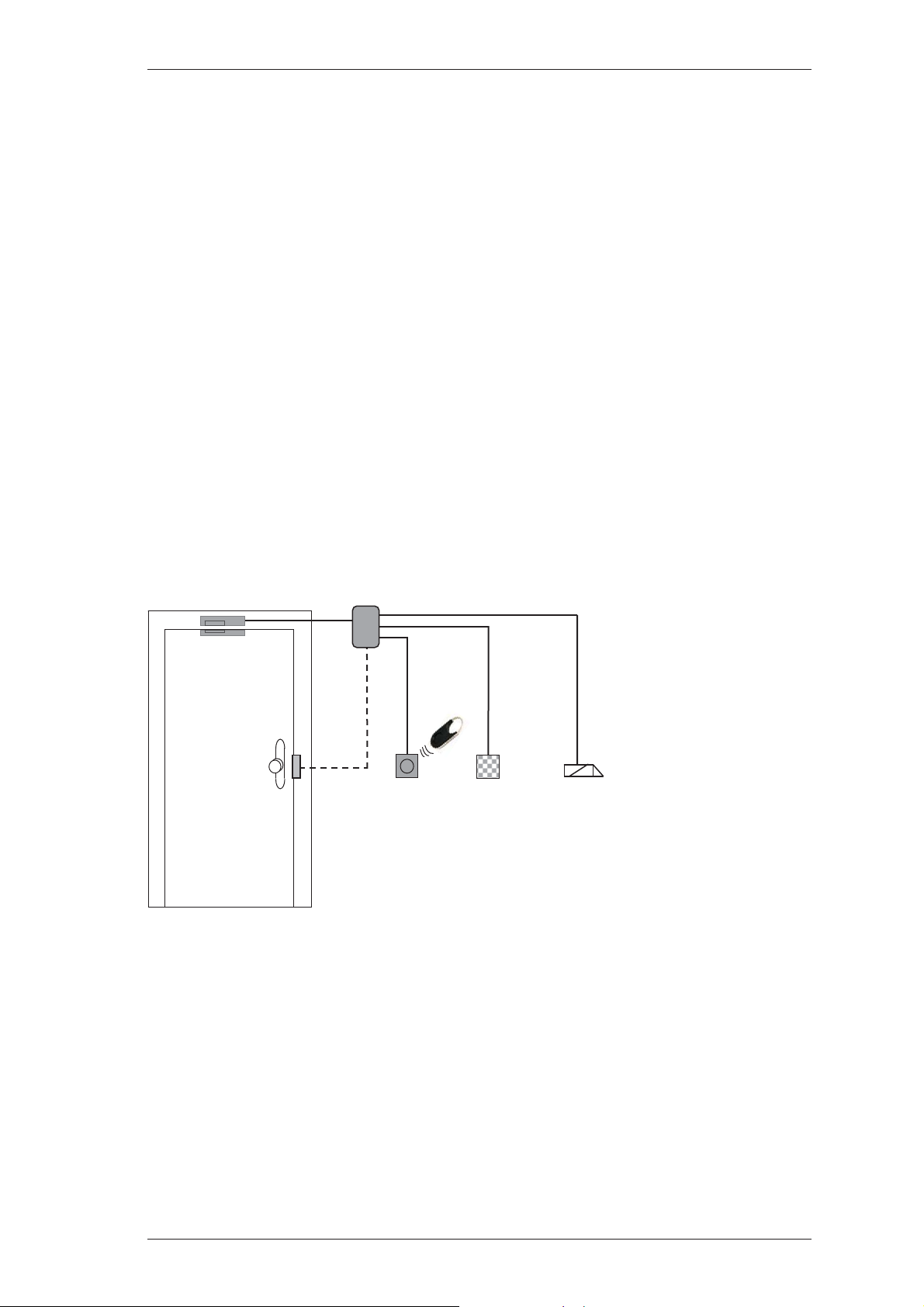

Code keypads

There are two types of code keypads: SmartKey code keypads and lockable code keypads.

The code keypad, used in conjunction with the reader, allows arming and disarming of the in-

trusion alarm system only after the correct combination of numbers has been entered on the

keypad.

Holdup alarm: if someone is forced to disarm the intrusion alarm system under duress, a silent

alarm (hold-up alarm) can be set off remotely via the code keypad.

The code keypad can be surface mounted or recessed mounted (outside the secure area).

SmartKey code keypad with integrated reader

The SmartKey code keypad with integrated reader combines

the function of the reader + the SmartKey code keypad in one

unit.

Initial set-up and operation is the same as with one reader + one

code keypad. Instructions for start-up and operation are enclosed with the corresponding device, reader or SmartKey code

keypad.

Function variants

n

o

p

q

The reader for the SmartKey key is located in the middle of the

device (not visible from the outside). To operate, hold the SmartKey up to the center of the code keypad at a maximum distance

of 2 cm and press the button on the key.

Reader

Non-contact reader for surface-mounting or recessed-mounting (IP55 junction box).

SmartKey code keypad with integrated reader

Code keypad with integrated non-contact reader for

surface or recessed mounting (IP55 junction box).

SmartKey code keypad

Code keypad for surface mounting or recessed mounting (IP55 junction

box

.

Reader + lockable code keypad

Non-contact reader for surface mounting or recessed

mounting (IP55 junction box). Lockable code keypad

for surface mounting or recessed mounting (recessed

mounting with mounting kit).

4

System Description

System Overview with Functional Variants

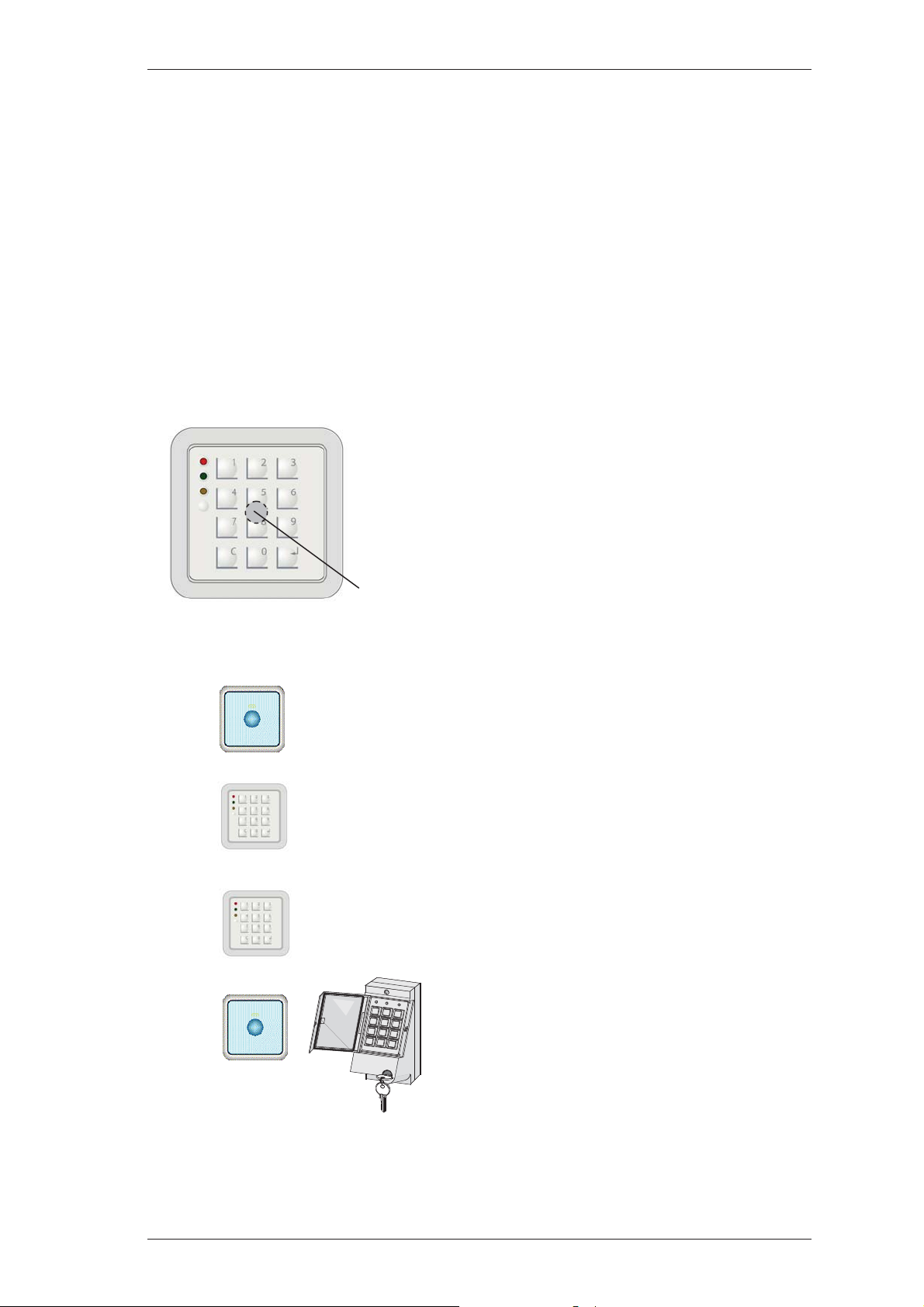

SmartKey keys

There are two types of SmartKey keys

x Keys with a security card

x Standard key (without security card)

Key with security card: the system operates like a locking device. The key kit consists of a set

number of valid keys and a security card. The control unit is initialized using the security card,

and accepts only the keys of the key kit. To order additional keys, the security card must be sent

to the manufacturer together with the order. The keys are labeled with a consecutive key number, a security card number and an 8-digit identification number.

Standard key (without security card): the keys are not numbered and can be programmed in

any way. The keys are labeled with an 8-digit identification number.

Note: All the SmartKeys can share the same code (programmable). Every code change made on

the code keypad will immediately apply to every SmartKey.

Further connection options

Blocking elements for vault doors: The blocking elements E4.4 and E4.3 (E4.3 available as

E4.4 + conversion kit for installation on left or right) are electromagnetic blocking systems designed for installation in vault or safe doors and cash dispensers. The blocking elements are not

used as arming devices; arming is performed via SmartKeys. The blocking element for vault

doors is included in the arming's forced actuation system.

Important note: Do not connect an SPE blocking element or a door relay

if you are connecting an E4.4/E4.3 blocking element.

!

Door opener relay: There is a relay for activating a door opener relay on the control unit (2 A, 30

V DC). A door opener connection will require programming. Activation is only possible when the

control panel is disarmed and the bolt contact open. Setting of a time-delay and an activation

time is programmable. The door opener relay can also be activated using a push-button on PL2.

Important note: Do not connect an E4.4/E4.3 blocking element for safe doors if a

door opener relay is connected.

!

Switch-point control (C-Point): a freely programmable C-point switching output (open-collector

output) 12 V, max. 80 ma, is located on the control unit. Connect only one cable with a maximum

length of 3 m.

The yellow LED on the SmartKey code keypad is connected to the C-point by default. An appropriate series resistor is fitted to enable the C-point to be connected to the yellow LED on the

SmartKey code keypad. Solder a bridge across the solder points on BR2 (circuit board reverse)

to bridge the series resistor if the C-point is used for a different purpose and not connected to the

yellow LED on the SmartKey code keypad.

5

System Description

A

,

A

C

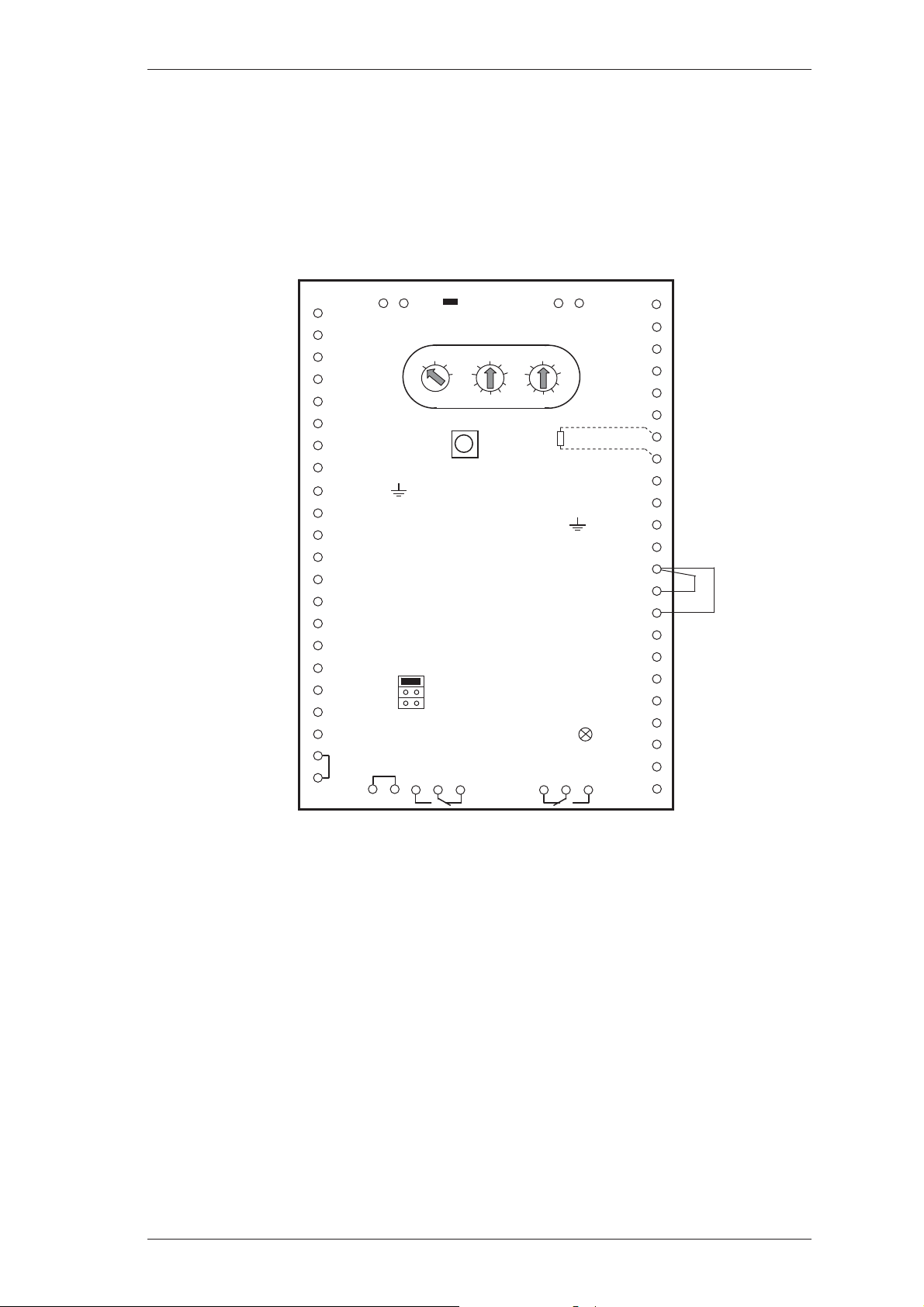

Description of the Connections on the Control Unit

The control unit connections have different functions. There are inputs, outputs and plug-in terminals. Inputs and outputs have to be assigned according to a specific schema with regard to the

scope of basic functions.

, B, C or D is equipped with an SMD re-

sistor

depending on the control unit.

57 56

Free Free

1 +U

2 0V

3 aLSN1

4 bLSN1

5 +U

6 0V

7 aLSN2

8 bLSN2

9 Ground

10 T7

11 T6

12 T5

13 T4

14 T3

15 T2

16 T1

17 Test

18 C-Pt.

19 Detec +

20 Detec -

21 Free

22 Free

o

23 24

0

L

0

1

9

1

2

8

7

4

6

5

DK

BR1

B1 Operation

B2 Programming

B3 Bolt test

25 26 27 28 29 30

B

C

D

2

3

8

7

9

6

0

REEG

55 54

Free Free

1

2

3

4

5

+12V SPE 42

LED

PL2 53

0V 52

PL1 51

0V 50

Free 49

Free 48

EW1a 47

EW1b 46

VÜ 45

0V 44

Ground 43

0V 41

HALL1 40

HALL2 39

MOT1 38

MOT2 37

ANT1 36

ANT2 35

+12V 34

SU 33

LED1 32

LED2 31

Free

RK2

Free

R

EG 12K1 already installed

n

o

Points 21/22 and 23/24 are connected internally.

RK3

RK1

RK6

RK5

RK4

Description of the Connections on the Control Unit

Connection Name Function Description

1

2

3

4

5

6

7

8

9

+ U

0V

aLSN1

bLSN1

+ U

0V

aLSN2

bLSN2

Ground

Input

Input

Input

Input

Output

Output

Output

Output

Distributor

10 - 16 T7 - T1 Code key-

pad

6

Power supply 9.6 - 30V

Power supply 0V

LSN incoming

LSN incoming

Power supply 9.6 - 30V

Power supply 0V

LSN outgoing

LSN outgoing

Operating ground

Code keypad connection

System Description

Description of the Connections on the Control Unit

Connection Name Function Description

17 Test Input This input is for test purposes only, i.e. a line

should only be connected temporarily to perform a

test. The SPE blocking element's bolt will engage

when 0V is connected.

18 C-Point Output Freely programmable switching output (open-

collector output) 12V, max. 80 mA. Connect only

one cable with a maximum length of 3 m. The yellow LED on the SmartKey code keypad is connected to the C-point by default. An appropriate

series resistor is fitted to enable the C-point to be

connected to the yellow LED on the SmartKey

code keypad. Solder a bridge across the solder

points on BR2 (circuit board reverse) to bridge the

series resistor if the C-point is used for a different

purpose and not connected to the yellow LED on

the SmartKey code keypad.

19/20 Detec +

Detec 21/22

23/24

25/26/27

28/29/30

31

32

33

34

35/36

37/38

39

40

41

42

43 Ground Distributor Operating ground

44/45 0V/VÜ Input Connection option for conventional bolt contact

46/47

50/51

Free

Free

RK1 - RK3

RK6 - RK4

LED 2

LED 1

SU

+12V

ANT2/ANT1

MOT2/MOT1

HALL2

HALL1

0V

+12V SPE

EW1b/EW1a

0V/PL 1

Input Blocking element (lock) detection output for safe

doors (E4.3/E4.4), optocoupler input

Distributor

Distributor

Relay contact

Relay contact

Output

Output

Output

Output

Input

Output

Input

Input

Output

Output

Input

Input

Free plug-in terminals, 21 and 22 connected

Free plug-in terminals, 23 and 24 connected

Changeover contact, programmable for door open-

ers

(2 A, 30 V DC)

Changeover contact switches at the same time as

RK1 – RK3

Green LED reader

Red LED reader

Buzzer reader

Power supply 12V reader

Antenna reader

SPE blocking element motor control

Detection of initial bolt position

Detection of final bolt position

Power supply 0V for SPE blocking element

Power supply 12V for SPE blocking element

Connection option for magnetic contact

Connection option for magnetic contact

51

REEG is

permanently built-in

REEG

48/49 Free Distributor Free plug-in terminals

52/53 0V/PL 2 Input Primary line usable depending on connection

54 - 57 Free Distributor Free plug-in terminals

Note: The primary lines PL 1, PL 2 and VÜ are evaluated by the control unit.

7

50

47

46

Conventional magnetic contact

Installation Instructions

Installing System Components

Note the following during installation:

x Used shielded cables only.

!

x The usual precautionary measures for C-MOS technology apply to handling the cir-

cuit boards and to soldering work. Wear a grounded wrist strap when working on the

control panel.

Mounting the control unit

x Mount the control unit to the wall. When choosing a position to mount the unit,

please note that the reader and SPE blocking element are equipped with a 6 m molded

!

Mounting the reader

cable that must not be lengthened.

x Mount the reader according to the enclosed instruction leaflet.

If you have to install the reader close to other systems with proximity readers, please

!

Installing the code keypad

x The code keypad must be installed outside of the security area close to the assigned door

!

make sure that you leave a distance of at least 0.5 m.

The reader should be installed at a height of at least 1.2 m and preferably recessed

mounted. The reader is molded and completely resistant to environmental influences.

Do not fit the reader cover until you have performed all the function tests. Removing the

cover after it has been fitted will cause damage to the cover. The reader is equipped

with a 6 m molded cable that must not be lengthened.

(next to the reader because of the LED and buzzer) and protected from atmospheric

conditions. Make sure that the code keypad is not visible to other persons during use.

Install the code keypad in accordance with the installation instructions enclosed with

the device. Make sure the membrane supply line does not get broken when fitting the

membrane keypad. The SmartKey keypad unit is equipped with a 6 m molded cable

that must not be lengthened.

Important information for lockable code keypad: Connect points LF1 and LF2 with a

solder bridge as described in the code keypad installation instructions if you want to

enable user codes to be changed using the keypad.

8

Installation Instructions

A

Installing System Components

Installing the SPE blocking element

x Install the SPE blocking element using the appropriate kit and in accordance with the en-

closed installation note.

Make sure the door cannot slam shut. The bolt of the SPE blocking element could oth-

!

SPE blocking element variants and kits

erwise be damaged during start-up by a slamming door.

Installation on the door or on the frame Installation on the door or on the frame

Kit for on-the-door installation. In

the kit, a conventional magnet

contact can be used.

Bolt piece (installed on the frame)

Sleeve piece (installed on the door)

Installation example:

Spacers

Fastening

bar of the

kit

Door

Bushing

glass doors

Counterpiece

Normal collar

ngled collarKit for

Installation example: Installation example:

Glass

Bolt piece of the

blocking element

Sleeve piece of the

blocking element

Counterpiece/bushing

Door

Frame

Blocking

element

Collar

Installing the Magnetic Contact and Bolt Contact

Install the magnetic contact or bolt contact in accordance with the manufacturer's instructions.

The control unit will serve as a distributor for the contacts.

9

Installation Instructions

C

Connection, Switch-Point control, Address Switches

Connection

Make sure the control panel is disconnected from the power supply.

!

Connect the control unit and the optional components

as shown in the connection diagram on the following page.

Switch-point control

(18 C point): a freely programmable C-point switch output (open-collector output) 12 V, max. 80

mA, is located on the control unit. Connect only one cable with a maximum length of 3 m.

The yellow LED on the SmartKey code keypad is connected to the C-point by default. An appropriate series resistor is fitted to enable the C-point to be connected to the yellow LED on the

SmartKey code keypad. Solder a bridge across the solder points on BR2 (circuit board reverse)

to bridge the series resistor if the C-point is used for a different purpose and not connected to the

yellow LED on the SmartKey code keypad.

Address switch

The address switch is used for LSN panels in the planning stage.

The address switch does not need to be adjusted on any of the currently available LSN panels.

The address switch should remain in the positions CL 0 0. Default setting.

Preliminary information on the address switch:

CL 0 0 = "Classic" LSN mode (standard setting)

001 – 254 = LSNi mode with manual addressing of the control unit

0 0 0 = LSNi mode with automatic addressing of the control unit

The control unit address is set by positioning the three rotatable switches. Use a flat-head screwdriver to adjust each switch. The switches will click when turned. The valid range is from 1 to

254. Any settings between 255 and 299 will cause an error message to be displayed on the control panel.

0

L

Setting in Hundreds Tens Units

0

1

9

2

8

7

6

5

0

1

2

3

4

1

9

2

8

3

7

4

6

5

10

Installation Instructions

p

gr-p

r

A

C

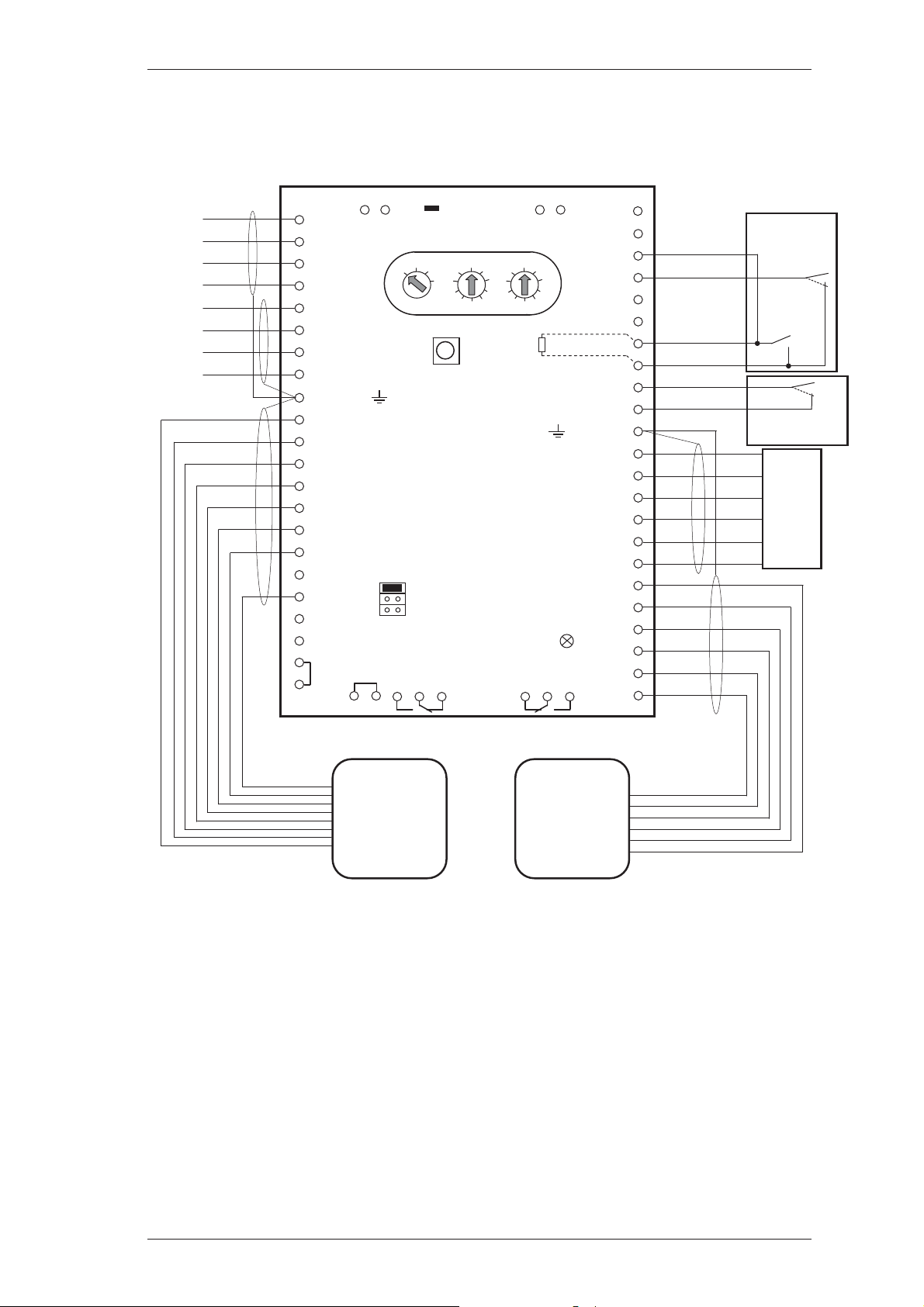

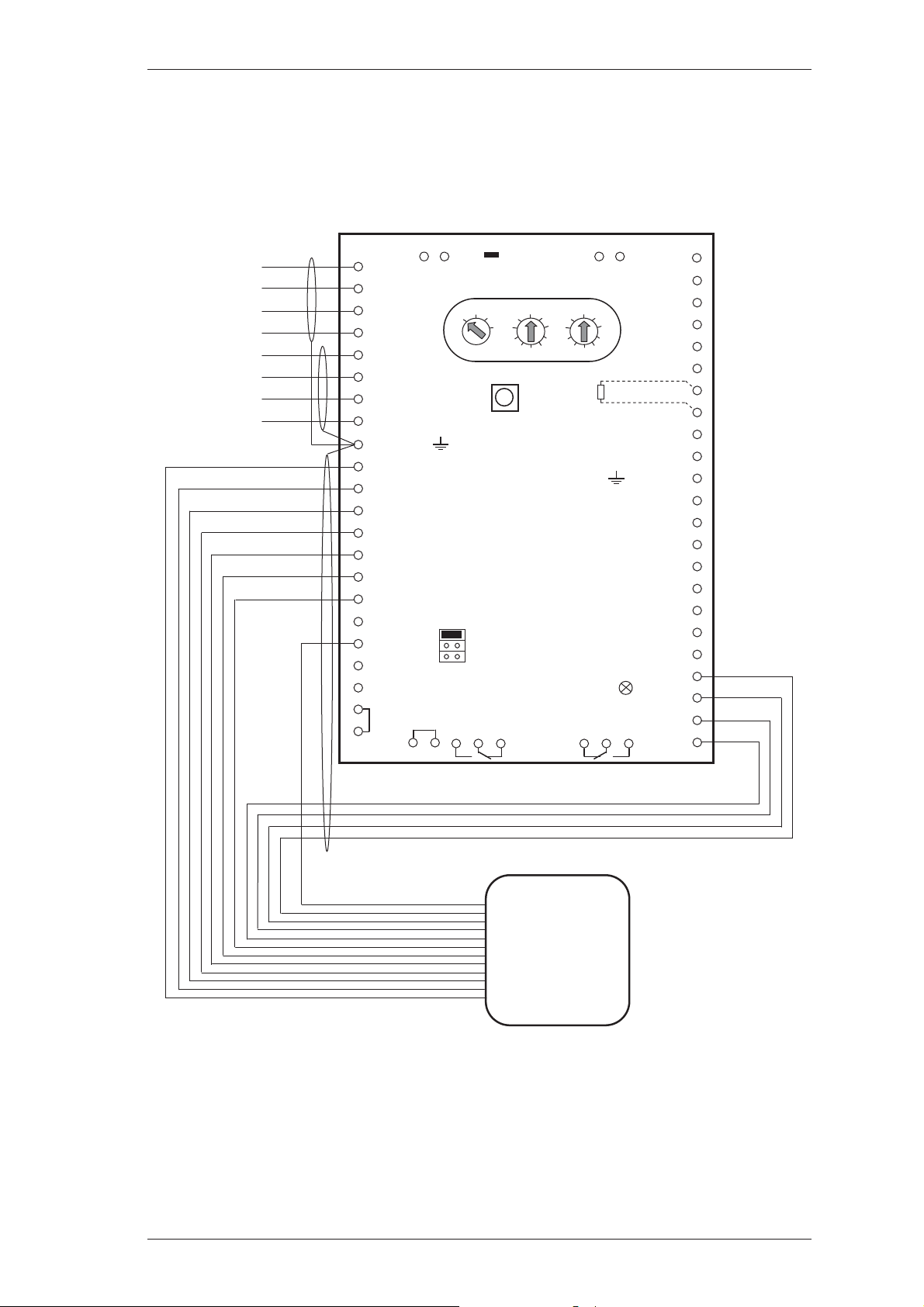

Connecting the Control Panel and Optional Components

LSN

0V

aLSN1

bLSN1

0V

aLSN2

bLSN2

rd

+

bk

wt

yl

rd

+

bk

wt

yl

r

-

l

bn-gn

i

wt-gn

g

bl

wt

vi

o

1 +U

2 0V

3 aLSN1

4 bLSN1

5 +U

6 0V

7 aLSN2

8 bLSN2

9 Ground

10 T7

11 T6

12 T5

13 T4

14 T3

15 T2

16 T1

17 Test

18 C-Pt.

19 Detec +

20 Detec -

Free Free

21 Free

22 Free

p

23 24

57 56

0

L

0

1

9

1

2

8

7

4

6

5

DK

BR1

B1 Operation

B2 Programming

B3 Bolt test

25 26 27 28 29 30

B

C

D

2

8

3

7

55 54

Free Free

0

1

9

4

6

5

REEG

PL2 53

PL1 51

2

3

Free 49

Free 48

EW1a 47

EW1b 46

Ground 43

+12V SPE 42

HALL1 40

HALL2 39

MOT1 38

MOT2 37

ANT1 36

ANT2 35

+12V 34

LED

LED1 32

LED2 31

0V 52

0V 50

VÜ 45

0V 44

0V 41

SU 33

2

Line length <3m

1

4

3

Line length <3m

rd

or

yl

gn

bn

bk

yl

gn

rd

bk

or

bn

Magnetic

contact

Switch part

Tamper

rotection

Bolt contact

Blo-

cking

element

SPE

Free

Free

SmartKey

Code

keypad

Cable length d6 m

REEG 12K1 already installed

n

Yellow LED on code keypad

o

Points 21/22 and 23/24 are connected internally.

p

RK1

RK2

RK3

RK6

Reader

RK5

RK4

Cable length d6 m

11

Installation Instructions

A

C

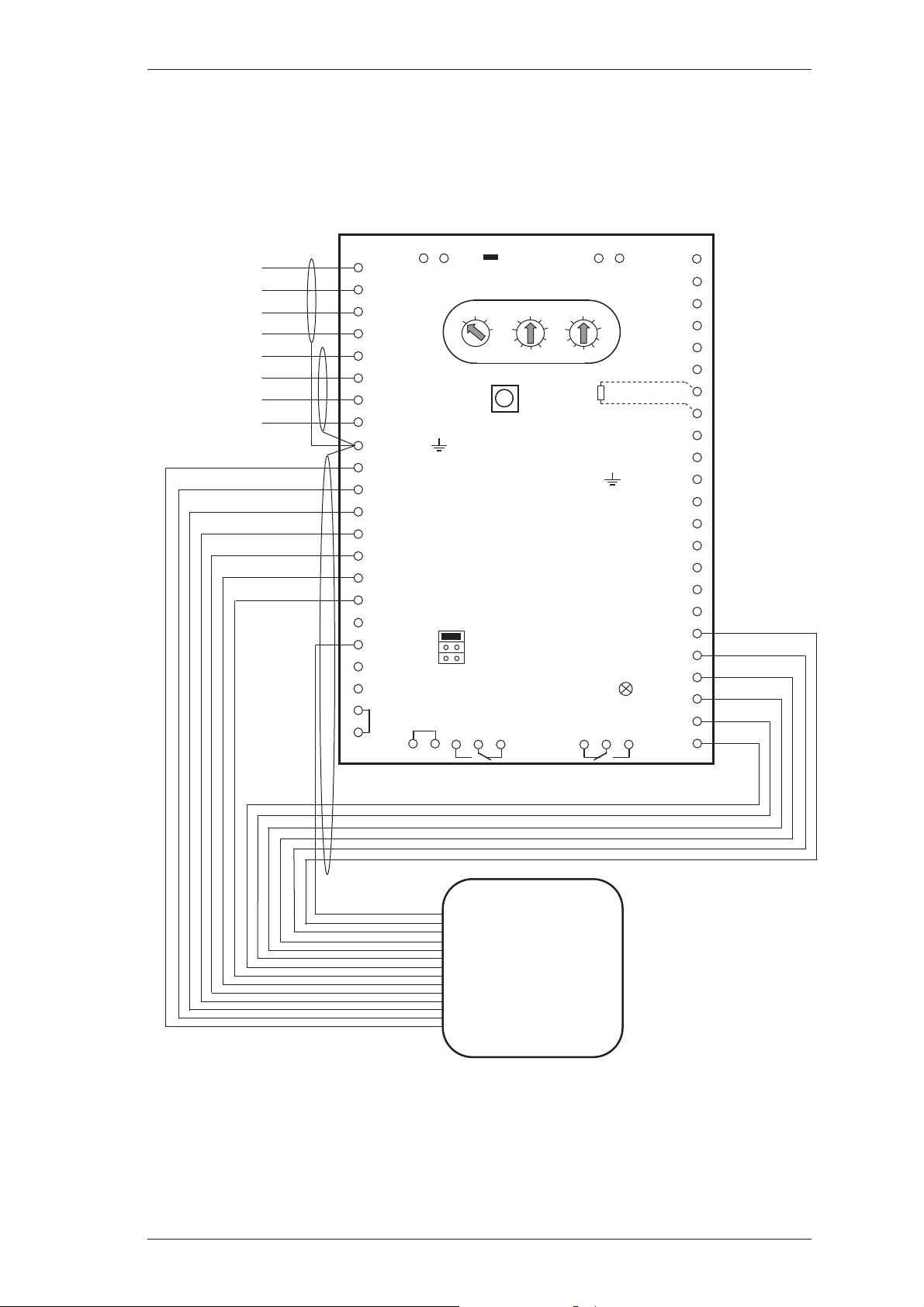

Connecting for Operation Without an SPE Blocking Element (37

to 42)

Use the following switching arrangement on the control unit to set the operating mode "Without

SPE blocking element". Connect the inputs HALL1 and HALL2 to 0V.

57 56

1 +U

Free Free

2 0V

3 aLSN1

4 bLSN1

5 +U

6 0V

7 aLSN2

8 bLSN2

9 Ground

10 T7

11 T6

12 T5

13 T4

14 T3

15 T2

16 T1

17 Test

18 C-Pt.

19 Detec +

20 Detec -

21 Free

22 Free

23 24

55 54

B

Free Free

C

D

0

L

0

9

1

2

8

7

6

5

0

1

2

3

4

1

9

8

3

7

4

6

5

DK

REEG

BR1

B1 Operation

B2 Programming

B3 Bolt test

25 26 27 28 29 30

PL2 53

0V 52

PL1 51

0V 50

Free 49

Free 48

EW1a 47

EW1b 46

VÜ 45

0V 44

Ground 43

+12V SPE 42

0V 41

HALL1 40

HALL2 39

MOT1 38

MOT2 37

ANT1 36

ANT2 35

+12V 34

SU 33

LED

LED1 32

LED2 31

Free

Free

RK1

RK2

RK3

RK6

RK5

RK4

12

Installation Instructions

d-b

r

r

A

C

Connecting for Operation with SmartKey Code Keypad Only

For information about connecting all other components, see "Connecting the Control Panel and

Optional Components".

LSN

0V

aLSN1

bLSN1

0V

aLSN2

bLSN2

rd

+

bk

wt

yl

rd

+

bk

wt

yl

1 +U

2 0V

3 aLSN1

4 bLSN1

5 +U

6 0V

7 aLSN2

8 bLSN2

Free Free

0

L

0

1

9

1

2

8

7

4

6

5

DK

9 Ground

57 56

r

bn-gn

-pi

g

wt-gn

g

bl

wt

o

l

vi

10 T7

11 T6

12 T5

13 T4

14 T3

15 T2

16 T1

17 Test

18 C-Pt.

19 Detec +

20 Detec -

BR1

B1 Operation

B2 Programming

B3 Bolt test

21 Free

22 Free

p

25 26 27 28 29 30

23 24

B

C

D

2

8

3

7

55 54

Free Free

0

1

9

4

6

5

REEG

PL2 53

PL1 51

2

3

Free 49

Free 48

EW1a 47

EW1b 46

Ground 43

+12V SPE 42

HALL1 40

HALL2 39

MOT1 38

MOT2 37

ANT1 36

ANT2 35

+12V 34

LED

LED1 32

LED2 31

0V 52

0V 50

VÜ 45

0V 44

0V 41

SU 33

rd

bk

pi

bn

Free

Cable length d6 m

REEG 12K1 already installed

n

Yellow LED on code keypad

o

Points 21/22 and 23/24 are connected internally.

p

Free

RK1

RK2

RK3

SmartKey

code

keypad

RK6

RK5

RK4

13

Installation Instructions

d-b

r

r

A

C

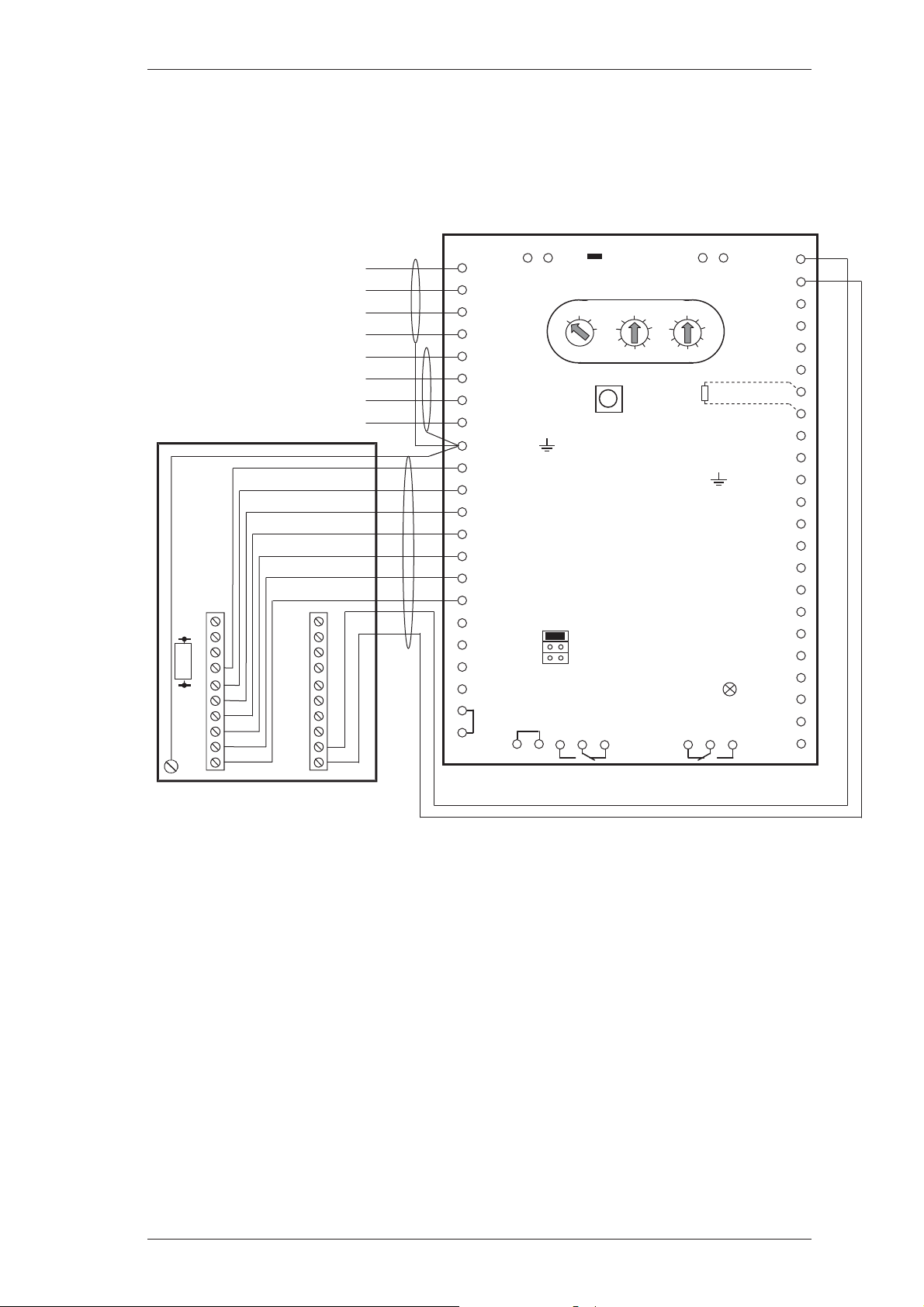

Connecting the SmartKey Code Keypad with Integrated Reader

For information about connecting all other components, see "Connecting the Control Panel and

Optional Components".

LSN

0V

aLSN1

bLSN1

0V

aLSN2

bLSN2

21 Free

22 Free

p

57 56

Free Free

0

L

0

9

1

2

8

7

6

5

DK

BR1

B1 Operation

B2 Programming

B3 Bolt test

25 26 27 28 29 30

23 24

1

4

rd

+

bk

wt

yl

rd

+

bk

wt

yl

r

l

bn-gn

g

-pi

wt-gn

g

bl

wt

vi

o

1 +U

2 0V

3 aLSN1

4 bLSN1

5 +U

6 0V

7 aLSN2

8 bLSN2

9 Ground

10 T7

11 T6

12 T5

13 T4

14 T3

15 T2

16 T1

17 Test

18 C-Pt.

19 Detec +

20 Detec -

2

3

B

C

D

9

8

7

6

55 54

Free Free

0

1

2

3

4

5

REEG

+12V SPE 42

LED

PL2 53

0V 52

PL1 51

0V 50

Free 49

Free 48

EW1a 47

EW1b 46

VÜ 45

0V 44

Ground 43

0V 41

HALL1 40

HALL2 39

MOT1 38

MOT2 37

ANT1 36

ANT2 35

+12V 34

SU 33

LED1 32

LED2 31

yl

gn

rd

bk

pi

bn

Free

Free

Cable length d6 m

REEG 12K1 already installed

n

Yellow LED on code keypad

o

Points 21/22 and 23/24 are connected internally.

p

RK1

RK2

RK3

SmartKey

code keypad

with

integrated

reader

RK6

RK5

RK4

14

Installation Instructions

r

A

C

Connecting a Lockable Code Keypad

For information about connecting all other components, see "Connecting the Control Panel and

Optional Components".

Code keypad

10

9

8

RE

7

6

5

4

3

2

1

Cable length (T1-T7) <10m

10

1

2

3

4

5

6

7

8

9

LSN

0V

aLSN1

bLSN1

0V

aLSN2

bLSN2

Tamp

21 Free

22 Free

o

57 56

Free Free

0

L

0

9

1

2

8

7

6

5

DK

BR1

B1 Operation

B2 Programming

B3 Bolt test

25 26 27 28 29 30

23 24

RK1

RK2

Free

Free

RK3

1

4

rd

+

bk

wt

yl

rd

+

bk

wt

yl

1+U

20V

3 aLSN1

4 bLSN1

5+U

60V

7 aLSN2

8 bLSN2

9 Ground

10 T7

11 T6

12 T5

13 T4

14 T3

15 T2

16 T1

17 Test

18 C-Pt.

19 Detec +

20 Detec -

B

C

D

2

8

3

7

55 54

Free Free

0

1

9

4

6

5

REEG

RK6

PL2 53

PL1 51

2

3

Free 49

Free 48

EW1a 47

EW1b 46

Ground 43

+12V SPE 42

HALL1 40

HALL2 39

MOT1 38

MOT2 37

ANT1 36

ANT2 35

+12V 34

LED

LED1 32

LED2 31

RK5

RK4

0V 52

0V 50

VÜ 45

0V 44

0V 41

SU 33

Terminating resistor RESG tampe

in code keypad 12K1

Important notice: Connect points

REEG 12K1 already installed

n

Points 21/22 and 23/24 are connected internally.

o

LF1 and LF2 with a solder bridge

as described in the installation instructions for the code keypad.

15

Loading...

Loading...