Bosch PVA-4CR12 Operation Manual

PAVIRO Controller

PVA-4CR12

en Operation manual

Table of contents

1

Safety 4

2

Short information 8

3

System overview 9

3.1 Rear 11

3.2 Front 13

4

Parts included 15

5

Installation 16

5.1 OM-1 Module installation 17

6

Connection 18

6.1 Audio input 18

6.1.1 Line level signal 18

6.1.2 Amplifier inputs 19

6.2 Audio output 21

6.2.1 Line level signal 21

6.2.2 Loudspeaker outputs 22

6.3 Call station 23

6.4 Ethernet 24

6.5 Supply voltage 24

6.6 CAN BUS 25

6.7 Slave clocks 27

6.8 DCF77 28

6.9 Ready relay 28

6.10 Control input 29

6.10.1 CONTROL IN 29

6.10.2 ANALOG CONTROL IN 31

6.11 Control output 32

6.11.1 CONTROL OUT 32

6.11.2 CONTROL OUT HP 34

7

Configuration 35

7.1 Network configuration 35

7.2 Displaying the CAN baud rate 35

8

Operation 37

8.1 Line supervision 37

8.1.1 Impedance measurement 37

8.1.2 EOL slave module 38

8.1.3 Plena EOL 39

8.2 Pilot tone 39

9

Maintenance 40

10

Technical data 41

10.1 Standards 43

10.2 Dimensions 44

PAVIRO Controller Table of Contents | en 3

Operation manual 08-May-2017 | 04 | F01U306900

Safety

Danger!

High risk: This symbol indicates an imminently hazardous situation such as "Dangerous

Voltage" inside the product.

If not avoided, this will result in an electrical shock, serious bodily injury, or death.

!

Warning!

Medium risk: Indicates a potentially hazardous situation.

If not avoided, this could result in minor or moderate bodily injury.

!

Caution!

Low risk: Indicates a potentially hazardous situation.

If not avoided, this could result in property damage or risk of damage to the unit.

1. Read these instructions. – All the safety and operating instructions should be read

before the apparatus or system is operated.

2. Keep these instructions. – The important safety instructions and operating instructions

should be retained for future reference.

3. Heed all warnings. – All warnings on the apparatus and in the operating instructions

should be adhered to.

4. Follow all instructions. – All instructions for installation or use/operating should be

followed.

5. Do no use this apparatus near water. – Do not use this apparatus near water or a moist

environment - for example, near a bath tub, wash bowl, kitchen sink, or laundry tub, in a

wet basement, near a swimming pool, in an unprotected outdoor installation, or any area

which is classified as a wet location.

6. Clean only with dry cloth. – Unplug the apparatus from the outlet before cleaning. Do

not use liquid cleaners or aerosol cleaners.

7. Do not block any ventilation openings. Install in accordance with the manufacturer’s

instructions. – Openings in the enclosure, if any, are provided for ventilation and to

ensure reliable operation of the apparatus and to protect it from overheating. These

openings must not be blocked or covered. This apparatus should not be placed in a builtin installation unless proper ventilation is provided or the manufacturer’s instructions

have been adhered to.

8. Do not install near any heat sources such as radiators, heat registers, stoves, or other

apparatus (including amplifiers) that produce heat or in direct sunlight.

9. No naked flame sources, such as lighted candles, should be placed on the apparatus.

10. Do not defeat the safety purpose of the polarized or ground-type plug. – A polarized

plug has two blades with one wider than the other. A grounding type plug has two blades

and a third grounding prong. The wider blade or the third prong are provided for your

safety. If the provided plug does not fit into your outlet, consult an electrician for

replacement of the obsolete outlet.

11. Protect the power cord from being walked on or pinched particularly at plug,

convenience receptacles, and the point where they exit from the apparatus.

12. Only use attachments/accessories specified by the manufacturer. – Any mounting of the

apparatus should follow the manufacturer’s instructions, and should use a mounting

accessory recommended by the manufacturer.

1

4 en | Safety PAVIRO Controller

08-May-2017 | 04 | F01U306900 Operation manual

13. Use only with the cart, stand, tripod, bracket or table specified by the manufacturer, or

sold with the apparatus. – When a cart is used, use caution when moving the cart/

apparatus combination to avoid injury from tip-over. Quick stops, excessive force, and

uneven surfaces may cause the appliance and cart combination to overturn.

14. Unplug this apparatus during lighting storms or when unused for long periods of time.

– Not applicable when special functions are to be maintained, such as evacuation

systems.

15. Refer all servicing to qualified service personnel. – Servicing is required when the

apparatus has been damaged in any way, such as power-supply cord or plug is damaged,

liquid has been spilled or objects have fallen into the apparatus, the apparatus has been

exposed to rain or moisture, does not operate normally, or has been dropped.

16. The apparatus shall not be exposed to dripping or splashing and that no objects filled

with liquid, such as vases, shall be placed on the apparatus.

17. Batteries (battery pack or batteries installed) shall not be exposed to excessive heat

such as sunshine, fire or the like.

!

Caution!

Danger of explosion if battery is incorrectly replaced. Replace only with the same or

equivalent type. Dispose of used batteries according to the environmental law and

procedures.

18. Professional installation only – Do not use this equipment in residential applications.

19. Condensation – In order to avoid condensation; wait a few hours before turning on the

equipment when it is transported from a cold to a warm space.

20. Hearing damage – For apparatus with audio output, to prevent possible hearing damage,

do not listen at high volume levels for long periods.

21. Replacement parts – When replacement parts are required, be sure the service

technician has used replacement parts specified by the manufacturer or having the same

characteristics as the original part. Unauthorized substitutions may result in fire, electric

shock or other hazards.

22. Safety check – Upon completion of any service or repairs to this apparatus, ask the

service technician to perform safety checks to determine that the apparatus is in proper

operating condition.

Danger!

Overloading – Do not overload outlets and extension cords as this can result in a risk of fire or

electric shock.

23. Power sources – This apparatus should be operated only from the type of power source

indicated on the marking label. If you are not sure of the type of power supply you plan to

use, consult your appliance dealer or local power company. For apparatuses intended to

operate from battery power, or other sources, refer to the operating instructions.

24. Power lines – An outdoor system should not be located in the vicinity of overhead power

lines or other electric light or power circuits, or where it can fall into such power lines or

circuits. When installing an outdoor system, extreme care should be taken to keep from

touching such power lines or circuits, as contact with them might be fatal. U.S.A. models

only – refer to the National Electrical Code Article 820 regarding installation of CATV

systems.

PAVIRO Controller Safety | en 5

Operation manual 08-May-2017 | 04 | F01U306900

Danger!

Object and Liquid entry – Never push objects of any kind into this apparatus through

openings as they may touch dangerous voltage points or short-out parts that could result in a

fire or electric shock. Never spill liquid of any kind on the apparatus.

25. Coax grounding – If an outside cable system is connected to the apparatus, be sure the

cable system is grounded. U.S.A. models only: Section 810 of the National Electrical

Code, ANSI/NFPA No.70-1981, provides information with respect to proper grounding of

the mount and supporting structure, grounding of the coax to a discharge apparatus, size

of grounding conductors, location of discharge unit, connection to grounding electrodes,

and requirements for the grounding electrode.

26. Protective grounding – An apparatus with class I construction shall be connected to a

power outlet socket with a protective grounding connection.

Protective earthing – An apparatus with class I construction shall be connected to a

mains socket outlet with a protective earthing connection.

Note for power connections

– For permanently connected equipment, a readily operable mains plug or all-pole mains

switch shall be external to the equipment and in accordance with all applicable

installation rules.

– For pluggable equipment, the socket-outlet shall be installed near the equipment and

shall be easily accessible.

This label may appear on the bottom of the apparatus due to space limitations.

!

Caution!

To reduce the risk of electrical shock, DO NOT open covers. Refer servicing to qualified

service personnel only.

!

Warning!

To prevent fire or shock hazard, do not expose units to rain or moisture.

!

Warning!

Installation should be performed by qualified service personnel only in accordance with the

National Electrical Code or applicable local codes.

!

Warning!

Power disconnect: If the apparatus is mains powered and a power supply cord set is

provided, the disconnect device is the mains plug of the power cord set.

If an AC‑DC adapter is provided and the mains plug that is part of the direct plug‑in device,

the AC‑DC adapter is the disconnect device.

The socket outlet shall be near the apparatus and shall be easily accessible.

6 en | Safety PAVIRO Controller

08-May-2017 | 04 | F01U306900 Operation manual

!

Warning!

To avoid electric shock, do not connect safety extra-low voltage (SELV) circuits to telephone-

network voltage (TNV) circuits. LAN ports contain SELV circuits, and WAN ports contain TNV

circuits. Some LAN and WAN ports both use RJ‑45 connectors. Use caution when connecting

cables.

Old electrical and electronic appliances

Electrical or electronic devices that are no longer serviceable must be collected separately and

sent for environmentally compatible recycling (in accordance with the European Waste

Electrical and Electronic Equipment Directive).

To dispose of old electrical or electronic devices, you should use the return and collection

systems put in place in the country concerned.

Only used at

altitude not

exceeding 2000m.

Only used in non-

tropical climate

regions.

PAVIRO Controller Safety | en 7

Operation manual 08-May-2017 | 04 | F01U306900

Short information

The PVA-4CR12 controller is the central paging manager for the PAVIRO system. Eight local

audio inputs can be switched to four audio outputs. A two channel message manager is

integrated. The controller provides all the audio processing, supervision and control functions

for a complete PAVIRO system. A single controller supports up to 16 call stations and 492

paging zones. The controller is equipped with 12 zones, 18 GPIs and 19 GPOs. One controller

can handle up to 2000 W loudspeaker load. Additional zones and power can be added by

using up to 20 external routers and 40 amplifiers with each 2 ✕ 500 W. The zone indicator

lights on the front indicate the current status of every zone:

– Green: Zone in use for non emergency purpose

– Red: Zone in use for emergency purpose

– Yellow: Zone fault detected

– Off: Zone in idle condition

2

8 en | Short information PAVIRO Controller

08-May-2017 | 04 | F01U306900 Operation manual

System overview

This chapter explains the basic features of the PAVIRO system and its most important

functions.

General overview

The PVA-4CR12 is the controller of the PAVIRO system. The controller contains all necessary

audio functions and is responsible for controlling and monitoring the complete PAVIRO

system. The type and number of connected audio sources, amplifiers, and relays are extremely

variable, and can be adjusted to individual requirements. A single controller can manage up to

16 call stations and up to 492 loudspeaker zones. Control inputs and outputs can be used for

controlling and monitoring functions. Both logic level and the analog level signals can be

processed. Configuration is performed on a PC using the IRIS-Net software, which also

provides access to system documentation and the required user interface. A configuration can

be changed at any time, and adjusted to new circumstances without having to modify the

system installation. A PC is required only for loading or changing the configuration; it does not

need to be connected during live operation. In many cases, however, a permanently connected

PC is helpful; for example, to provide detailed status displays and log reports, real-time

loudspeaker and sound control, or for remote diagnosis and maintenance via the network. The

user interface can be individually tailored, and up to 32 password levels can be assigned.

Audio routing

A digital audio matrix is integrated into the controller. Up to 8 local audio inputs, 2 message

playback channels, and 4 internal generators are available. The 4 audio output channels are

connected to the amplifiers via a 4-channel audio bus. The amplifiers include an audio input

router where the correct input signal is selected automatically. Each loudspeaker circuit can

be connected with amplifier outputs via a relay matrix, which allows for 492 loudspeaker

zones. The controller manages the audio signals, and distributes them according to priority. In

addition to the call stations, other audio sources can also be connected to the audio inputs

such as microphones, mixing desks, CD players, MP3 players, tuners, and so on. A number of

different connections are available for optimum adjustment.

Audio processing

The controller provides separate volume controls with a mute function for each audio input

and audio output. Each audio input has a 3-band equalizer and a compressor for optimal

sound adjustment of the audio sources. All outputs are fitted with a 5-band equalizer and a

limiter. For the equalizers, the operator can select from five different filter types for each band

filter (peak, low-shelving, high-shelving, high pass, low pass). Volume levels, filter parameters,

and so on are set on the PC during configuration. However, these can also be changed in realtime during operation using the graphical user interface, the special keys for the call stations,

or external operating controls.

Signal generators

The controller provides four signal generators: Two independent generators for generating

alarm signals and two independent generators for generating chime signals. Operators can

choose between 24 alarm types and six chime types that are available ex-works.

Message manager

The integrated message manager is for EVAC messages and alarm signals, as well as

commercial messages and chime/pre-chime signals. The message manager allows easy

configuration of EVAC and commercial messages, and other customized audio signals by using

the IRIS-Net software.

3

PAVIRO Controller System overview | en 9

Operation manual 08-May-2017 | 04 | F01U306900

Call stations

The call stations are used mainly for announcements, but are also used for manual control of

the PAVIRO system. Possible call station functions include zone/group selection,

announcements, program allocation, triggering chime and alarm signals, and message

playback. However, special commands such as volume control, light control, function displays,

and much more are also possible. The call stations can therefore also be configured for

general control tasks. If an announcement is to be routed through a loudspeaker zone that is

already occupied, the system issues an occupied notification (i.e., the talk button indicator

light flashes). If the call station concerned has a higher priority, it can interrupt the lowerpriority call from the other call station/signals. The system is configured to indicate the

conditions: The user is notified that the system is occupied when selecting the zone/group

(before the interruption) by the flashing talk button indicator light. The user can now decide

whether to interrupt the signal immediately, or whether to wait until the end of the active

announcement. Each zone selection key has two indicator lights: A green indicator light shows

the current selection, and a red indicator light shows if the zone is occupied with an

emergency signal. System information or error messages can be displayed on the call station's

illuminated graphic display.

Control inputs and outputs

The PAVIRO system has analog and logic control inputs and logic control outputs. The control

inputs allow a connection to be established to fire alarm systems, intruder alarm systems, or a

control desk. However, it is also possible to connect external switches, controllers, or rotary

potentiometers, or triggers from external equipment (power supply, power amplifiers, and so

on). The control outputs allow the user to activate/deactivate external devices, trigger signals

and events, remotely control doors, gates, and roller blinds, and much more.

Automatic control

The controller contains a quartz-controlled real-time clock that can be switched to DCF77

radio clock operation via an optional antenna. The system clock automatically recognizes leap

years; in DCF77 mode, it also automatically switches to daylight-saving time. Up to 80 external

slave clocks (max. 1 A) can be controlled by the system clock. A special output for polarity

switching pulse, which is protected against short circuits, is integrated in the controller for

this purpose. Slave clocks are automatically adjusted if a time difference between the slave

clocks and the system clock is detected, for example after a power failure or in the event of

manual input. Together with the calendar function, the system clock can be used to execute

functions such as a break chime, music, gate control, light control, and so on. These functions

can be programmed for specific days, but can also be implemented on an hourly, daily,

weekly, monthly, and annual basis. Up to 500 time-controlled events can be entered.

Functions and parameters can be connected in an internal sequence. The TaskEngine in the

controller GUI provides a graphic way to combine processes individually. One example would

be a chime signal to be transmitted at a certain volume and with a specific priority in specific

call groups, and which simultaneously activates a control output. In this case, the process

consists of the “chime” and “analog output” function blocks combined with the parameters of

chime type, volume, priority number, call group number, as well as the type and number of the

control output. The processes can be triggered via special function keys on the call stations or

via control inputs, but can also be linked to clock or calendar dates.

Interfaces

In addition to the control inputs and outputs, the PAVIRO system also includes other

interfaces:

– The call stations are connected to the controller via the CST bus (CAN bus standard). Up

to four call stations can be connected via one CST bus.

10

en | System overview PAVIRO Controller

08-May-2017 | 04 | F01U306900 Operation manual

– The power amplifiers and the routers are controlled and monitored by the controller via

an additional, independent CAN bus interface.

– The connection to a PC is established via an Ethernet interface.

– An optional OM-1 Module can be installed at the rear of the device.

The OM‑1 is a compact interface module which is prepared for a connection to an OMNEO

network. It can send and receive Dante audio to and from up to four other PAVIRO controllers

with an OM‑1 Interface Module.

Monitoring

The controller monitors all internal functions itself, and the connected call stations, routers

and power amplifiers including their connection lines are also monitored by polling and pilot

tone. Loudspeaker lines can be monitored by impedance measurement or end-of-line modules

installed at the last speaker. The PAVIRO system also supports emergency power operation –

in the event of a power failure, the controller can assume all power management functions,

that is, all unnecessary internal and external consumers switch to standby mode, or are

deactivated and only reactivated again when required. This greatly reduces power

consumption, and ensures maximum operating time on battery power. Error messages can be

displayed on the call station displays in plain text. The status of the “combined fault” is

available via the floating READY contact on the controller.

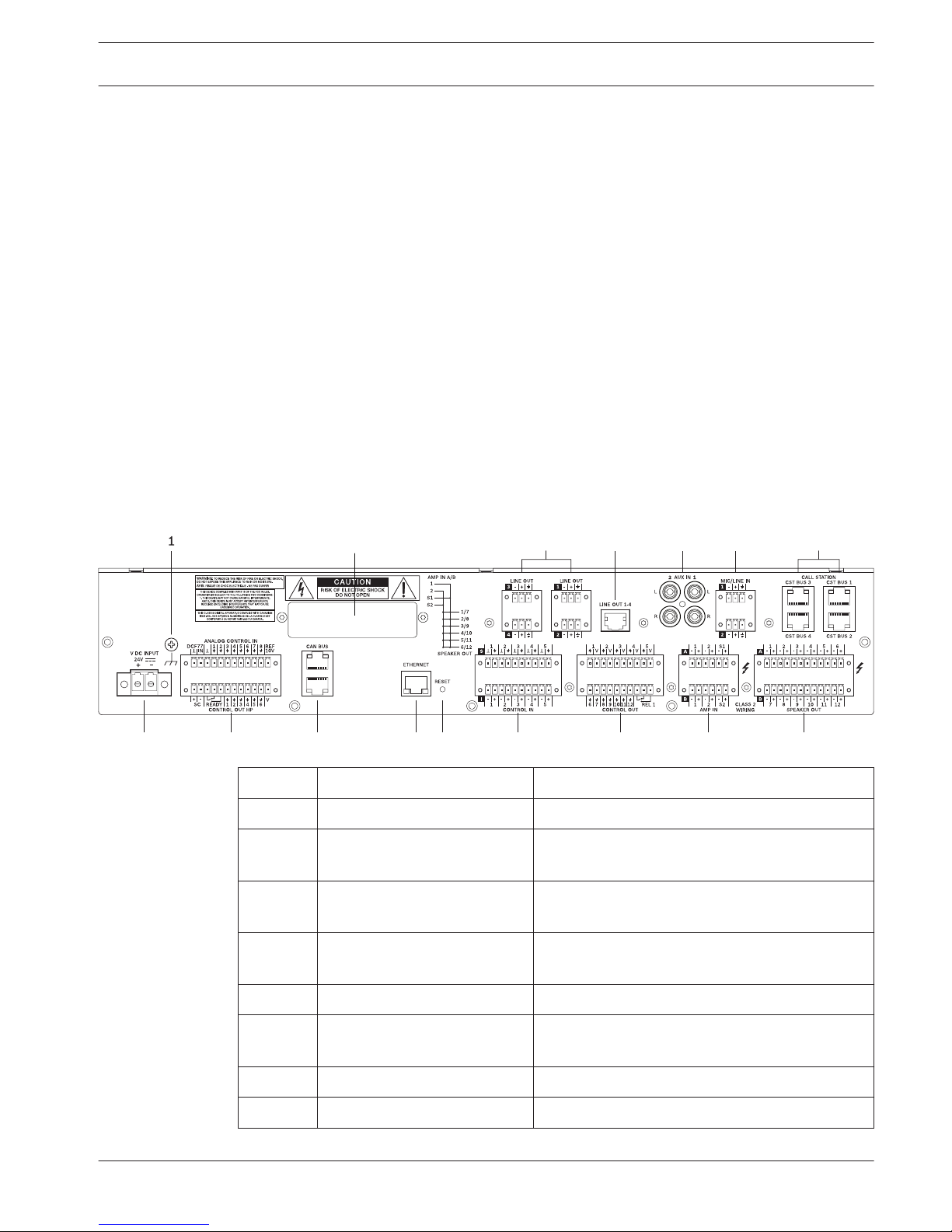

Rear

2

3 4 5 6 7

8 9 10 11 12 13 14 15 16

Number Element Description

1 Grounding screw Ground connection

2 Blind cover for optional OM-1

Module

Blind cover with slot for installing OM-1 Module.

3 LINE OUT 1-4 ports

(Euroblock)

Balanced line level audio outputs for channel 1

to 4 (parallel to RJ-45 port).

4 LINE OUT 1-4 port (RJ-45) Balanced line level audio output for channel 1 to

4 (parallel to Euroblock port).

5 AUX IN 1/2 ports (RCA) Stereo audio input for line level signals.

6 MIC/LINE IN 1/2 ports

(Euroblock)

Audio input for microphone or line level signals.

7 CST BUS 1-4 ports (RJ-45) Ports for connecting call stations.

8 DC power input

3.1

PAVIRO Controller System overview | en 11

Operation manual 08-May-2017 | 04 | F01U306900

Number Element Description

9 CONTROL IN/OUT port Control port with analog/logic inputs, high

power outputs and pins for DCF77 or slave

clocks.

10 CAN BUS port Port for connecting power amplifiers or routers.

11 ETHERNET port with status

indicator lights

Port for connecting to a PC or other network

devices.

12 Reset button Reset of the device: Briefly press this button to

reset the device.*

13 CONTROL IN port Control port with isolated or supervised inputs.

14 CONTROL OUT port Control port with open collector outputs.

15 AMP IN port Input for 100 V (or 70 V) audio signal from power

amplifier.

16 SPEAKER OUT port Output for speaker zones.

* If the reset button is pressed too long (e.g. > 4 seconds), the device enters the service

mode. Press the reset button again to exit the service mode.

12

en | System overview PAVIRO Controller

08-May-2017 | 04 | F01U306900 Operation manual

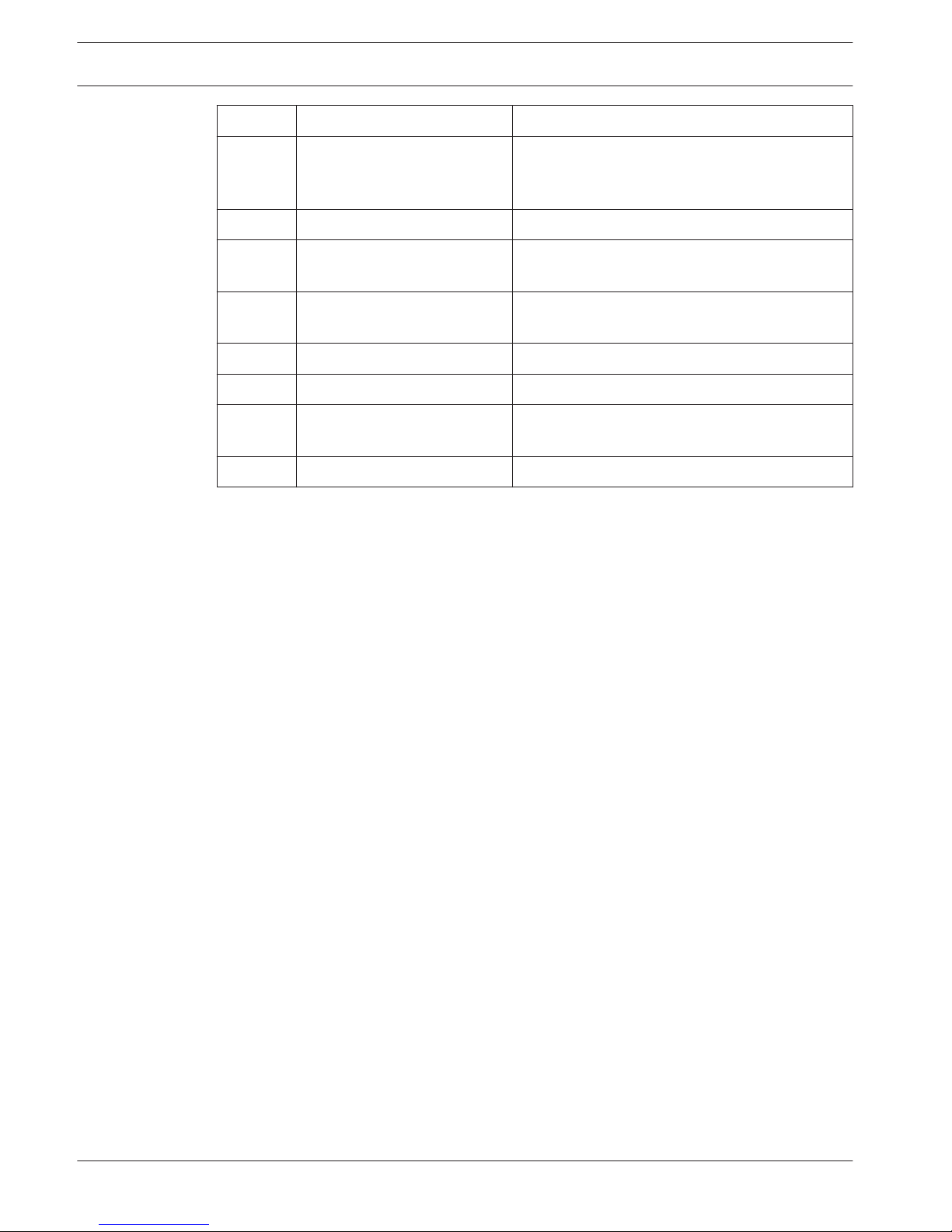

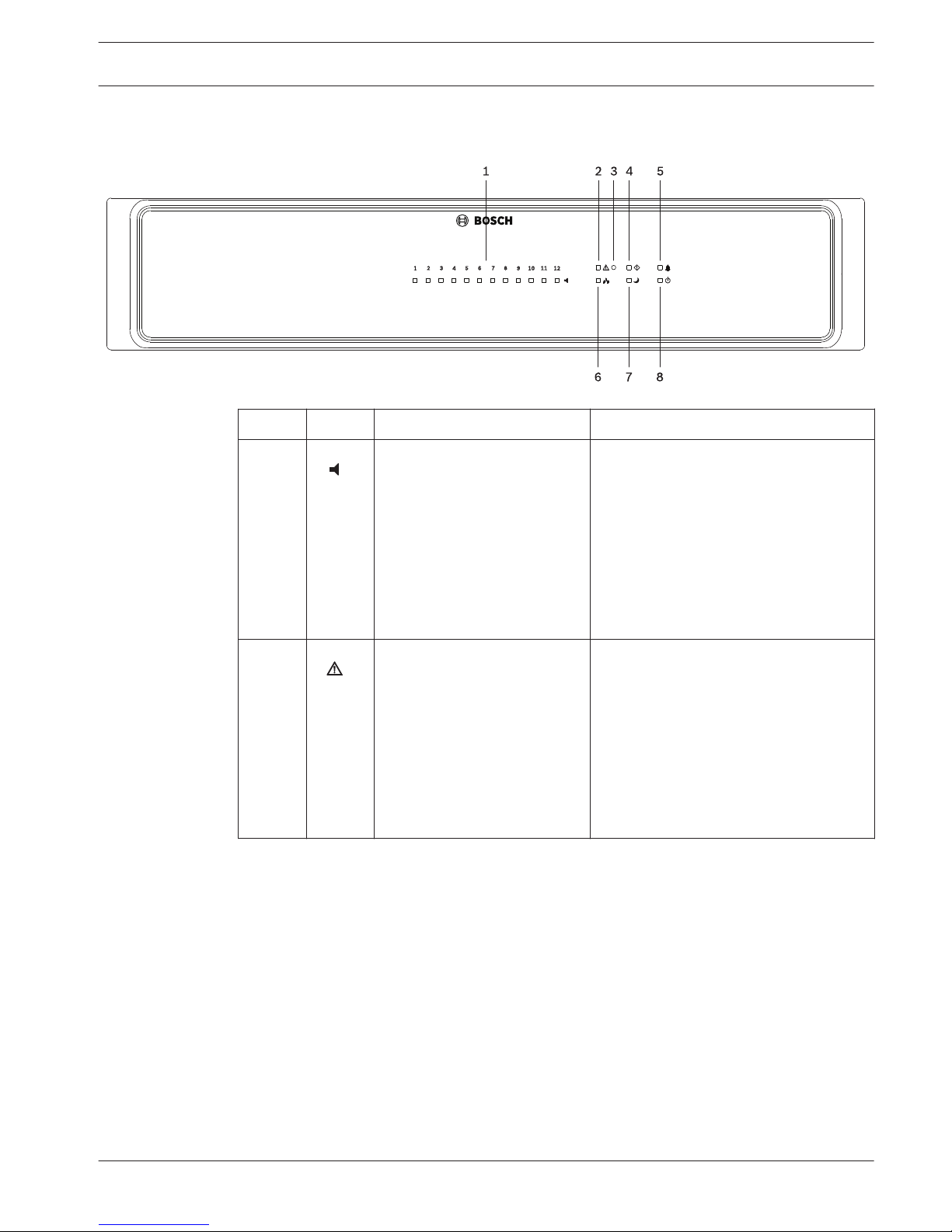

Front

Number Symbol Element Description

1 Zone status indicator light Indicates the status of the zone:

– Green = Zone is in use for non-

emergency purpose

– Yellow = Zone fault detected (Note:

The indication of this status has the

highest priority)

– Red = Zone is in use for emergency

purpose

– Off = Zone in idle condition

2 Combined fault warning

indicator light

This indicator lights yellow if a fault in

the system is detected. The indicator is

coupled with the READY contact (see

section Ready relay, page 28) on the

rear of the device, which allows any

faulty system behavior to be reported

externally.

Note: The fault types to be indicated via

this indicator can be configured.

3.2

PAVIRO Controller System overview | en 13

Operation manual 08-May-2017 | 04 | F01U306900

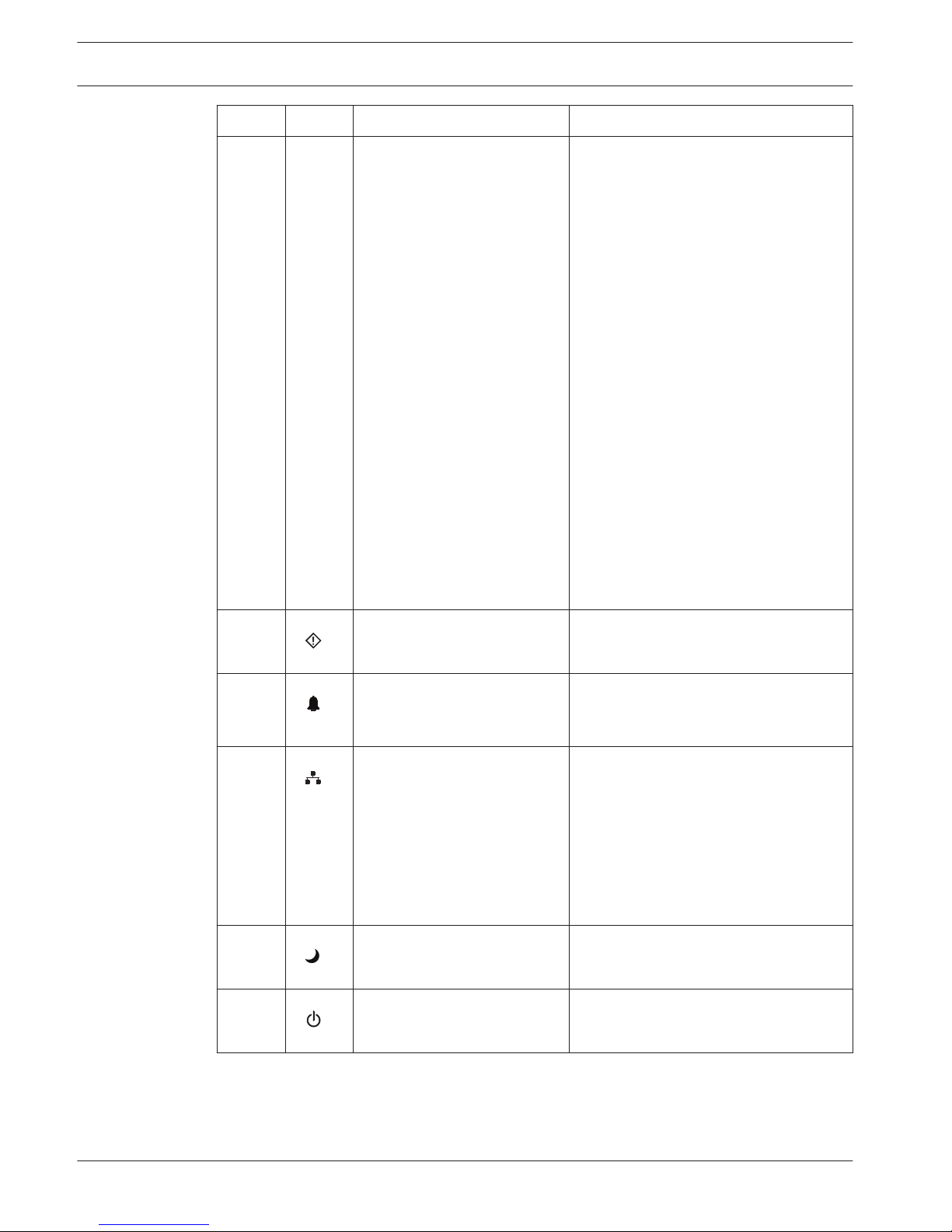

Number Symbol Element Description

3 Recessed button The button is protected to prevent it

from being pressed accidentally. Use a

pointed object (such as a ballpoint pen)

to press the button.

This button has the following functions:

– Silencing of the buzzer: If the

buzzer is active, press the button

briefly to deactivate the warning

tone.

– Find function: If the find function of

the device is activated, press this

button to deactivate the indicators.

– Displaying the CAN baud rate: Press

this button for at least one second.

Please refer to section Displaying

the CAN baud rate, page 35

– Indicator test: Press this button for

at least three seconds to activate all

indicators. All indicators (LEDs) at

the front panel light up as long as

the button is pressed (“LED test”)

and the internal buzzer is activated.

4

System fault indicator light This indicator lights yellow if a system

fault according EN 54-16 was detected.

5 Voice alarm indicator light This indicator lights red if the controller

is in voice alarm state according EN

54-16.

6 Network indicator light Indicates the Ethernet network status:

– Illuminated green: Successful data

communication to all configured

Ethernet devices has been

established.

– Flashing green: Ethernet connection

to at least one Ethernet device lost.

– Off: No Ethernet connection.

7 Standby indicator light This indicator lights up green when the

device is in standby mode.

8 Power indicator light This indicator lights up green when the

power supply is OK.

14

en | System overview PAVIRO Controller

08-May-2017 | 04 | F01U306900 Operation manual

Loading...

Loading...