Bosch MIC440AXWUP14636N, MIC440AXBUP14636N, MIC440AXBUD14636N, MIC440AXBUD14618N User Manual

Page 1

MIC440 Explosion-protected Camera

MIC440

en Operation Manual

Page 2

Page 3

MIC440 Explosion-protected Camera Table of Contents | en 3

Table of contents

1

2

2.1 Safety Precautions 6

2.2 Important Safety Instructions 6

2.3 Important Notices 7

2.4 Safety Information Specific to Explosion Protection 11

2.5 Customer Support and Service 12

3

3.1 Parts List 13

3.2 Additional Products Required 13

3.3 Additional Tools Required 14

4

5

5.1 Mounting the Conduit Gland and Cable 16

5.2 PSU Installation and Setup in a Non-Hazardous Area 17

5.3 PSU Installation and Setup in a Hazardous Area 17

5.4 MIC Power Supply Unit Extension 19

6

6.1 About the MIC Shielded Composite Cable 21

6.2 Composite Cable Color-coding 21

7

7.1 Mounting Location Overview 23

7.2 Select the Mounting Location 25

7.3 Mounting Orientation 25

8

9

10

11

11.1 MIC PSU Overview 30

11.2 Earth Link on PCB 30

11.3 Fuse Ratings 31

11.4 Alarm Inputs 31

11.5 Layout of MIC Power Supply Units (PSUs) 31

11.6 Installation Instructions (Power Supply) 33

12

13

13.1 Connection Overview 42

13.2 Connecting the USB to RS-485 Converter 42

14

14.1 Addressing the Camera 44

14.2 Configuring the Camera for Inverted Operation 44

15

16

16.1 Cleaning MIC440 54

About this Manual 5

Safety 6

Unpacking 13

Product Description 15

Installation of a MIC440 Camera 16

Electrical Connections 21

Select the Mounting Location and Orientation 23

Mount the Camera 27

Earthing the Camera 28

Finalize Camera Mounting 29

Install the MIC Power Supply Unit (PSU) 30

Fit the Optional Sunshield (MIC440) 40

Connection 42

Configuration 44

Operation 45

Maintenance and Troubleshooting 53

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 4

4 en | Table of Contents MIC440 Explosion-protected Camera

17

18

Technical data 57

Appendices 58

18.1 MIC440 Common Features by Protocol 58

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 5

MIC440 Explosion-protected Camera About this Manual | en 5

1

About this Manual

This user manual has been compiled with great care and the information it contains has been

verified thoroughly. The text was complete and correct at the time of printing. The ongoing

development of products means that the content can change without notice. Bosch Security

Systems accepts no liability for damage resulting directly or indirectly from faults,

incompleteness or discrepancies between the user guide and the product described.

Copyright

This user manual is the intellectual property of Bosch Security Systems, Inc. and is protected

by copyright. All rights reserved.

Trademarks

All hardware and software product names used in this document are likely to be registered

trademarks and must be treated accordingly.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 6

!

!

!

!

6 en | Safety MIC440 Explosion-protected Camera

2

2.1

Safety

Safety Precautions

In this manual, the following symbols and notations are used to draw attention to special

situations:

Danger!

High risk: This symbol indicates an imminently hazardous situation such as “Dangerous

Voltage” inside the product. If not avoided, this will result in an electrical shock, serious bodily

injury, or death.

Caution!

Medium risk: Indicates a potentially hazardous situation. If not avoided, this may result in

minor or moderate injury. Alerts the user to important instructions accompanying the unit.

Caution!

Low risk: Indicates a potentially hazardous situation. If not avoided, this may result in

property damage or risk of damage to the unit.

Notice!

This symbol indicates information or a company policy that relates directly or indirectly to the

safety of personnel or protection of property.

2.2

Important Safety Instructions

Read, follow, and retain all of the following safety instructions. Heed all warnings on the unit

and in the operating instructions before operation.

Caution!

TO REDUCE THE RISK OF ELECTRIC SHOCK, DISCONNECT THE POWER SUPPLY BEFORE

OPENING THE POWER SUPPLY UNIT.

POWER DISCONNECT: POWER SUPPLY UNITS HAVE POWER SUPPLIED WHENEVER THE

POWER CORD IS INSERTED INTO THE POWER SOURCE.

Caution!

Installation must be made by qualified personnel and conform to ANSI/NFPA 70 (the National

Electrical Code® (NEC)), Canadian Electrical Code, Part I (also called CE Code or CSA C22.1),

and all applicable local codes. Bosch Security Systems, Inc. accepts no liability for any

damages or losses caused by incorrect or improper installation.

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 7

!

!

!

MIC440 Explosion-protected Camera Safety | en 7

Warning!

INSTALL EXTERNAL INTERCONNECTING CABLES IN ACCORDANCE TO NEC, ANSI/NFPA70

(FOR US APPLICATION) AND CANADIAN ELECTRICAL CODE, PART I, CSA C22.1 (FOR CAN

APPLICATION) AND IN ACCORDANCE TO LOCAL COUNTRY CODES FOR ALL OTHER

COUNTRIES. BRANCH CIRCUIT PROTECTION INCORPORATING A 20 A, 2-POLE LISTED

CIRCUIT BREAKER OR BRANCH RATED FUSES ARE REQUIRED AS PART OF THE BUILDING

INSTALLATION. A READILY ACCESSIBLE 2-POLE DISCONNECT DEVICE WITH A CONTACT

SEPARATION OF AT LEAST 3 mm MUST BE INCORPORATED.

Warning!

ROUTING OF EXTERNAL WIRING MUST BE DONE THROUGH A PERMANENTLY EARTHED

METAL CONDUIT.

Warning!

THE CAMERA MUST BE MOUNTED DIRECTLY AND PERMANENTLY TO A NON-COMBUSTIBLE

SURFACE.

2.3

– Ensure that the unit case is properly earthed. If the product is likely to be struck by

lightning, ensure that earth bonding connections are made correctly to the mounting of

the base of the unit.

– Do not point the camera at the sun. Bosch Security Systems will not be liable for any

damage to cameras that have been pointed directly at the sun.

– Do not back drive the pan or tilt axis of the camera. Doing so will damage the motor drive

gear train and will invalidate the warranty.

– For transportation, rotate the ball so that the window points toward the base. This will

protect the wiper and the window during transit.

Important Notices

Notice!

This device is intended for use in public areas only.

U.S. federal law strictly prohibits surreptitious recording of oral communications.

Accessories - Do not place this unit on an unstable stand, tripod, bracket,

or mount. The unit may fall, causing serious injury and/or serious damage to

the unit. Use only with the cart, stand, tripod, bracket, or table specified by

the manufacturer. When a cart is used, use caution and care when moving

the cart/apparatus combination to avoid injury from tip-over. Quick stops,

excessive force, or uneven surfaces may cause the cart/unit combination to

overturn. Mount the unit per the manufacturer's instructions.

All-pole power switch - Incorporate an all-pole power switch, with a contact separation of at

least 3 mm in each pole, into the electrical installation of the building.If it is needed to open

the housing for servicing and/or other activities, use this all-pole switch as the main

disconnect device for switching off the voltage to the unit.

Camera grounding - For mounting the camera in potentially damp environments, ensure to

ground the system using the ground connection of the power supply connector (see section:

Connecting external power supply).

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 8

en | Safety MIC440 Explosion-protected Camera

8

Camera signal - Protect the cable with a primary protector if the camera signal is beyond 140

feet, in accordance with NEC800 (CEC Section 60).

Cleaning - Unplug the device before cleaning. Generally, using a dry cloth for cleaning is

sufficient, but a moist, fluff-free cloth may also be used. Do not use liquid cleaners or aerosol

cleaners.

– Do not use caustic or abrasive cleaning products on the camera.

Coax grounding:

– Ground the cable system if connecting an outside cable system to the unit.

– Connect outdoor equipment to the unit's inputs only after this unit has had its grounding

plug connected to a grounded outlet or its ground terminal is properly connected to a

ground source.

– Disconnect the unit's input connectors from outdoor equipment before disconnecting the

grounding plug or grounding terminal.

– Follow proper safety precautions such as grounding for any outdoor device connected to

this unit.

U.S.A. models only - Section 810 of the National Electrical Code, ANSI/NFPA No.70, provides

information regarding proper grounding of the mount and supporting structure, grounding of

the coax to a discharge unit, size of grounding conductors, location of discharge unit,

connection to grounding electrodes, and requirements for the grounding electrode.

Disposal

Your Bosch product has been developed and manufactured using highquality materials and components that can be reused.

This symbol means that electronic and electrical devices that have reached

the end of their working life must be disposed of separately from

household waste.

In the EU, separate collecting systems are already in place for used

electrical and electronic products. Please dispose of these devices at your

local communal waste collection point or at a recycling center.

Environmental statement - Bosch has a strong commitment towards the environment. This

unit has been designed to respect the environment as much as possible.

Electrostatic-sensitive device - Use proper CMOS/MOS-FET handling precautions to avoid

electrostatic discharge. NOTE: Wear required grounded wrist straps and observe proper ESD

safety precautions when handling the electrostatic-sensitive printed circuit boards.

Fuse rating - For security protection of the device, the branch circuit protection must be

secured with a maximum fuse rating of 16A. This must be in accordance with NEC800 (CEC

Section 60).

Heat sources - Do not install unit near any heat sources such as radiators, heaters, or other

equipment (including amplifiers) that produce heat.

Moving - Disconnect the power before moving the unit. Move the unit with care. Excessive

force or shock may damage the unit.

Outdoor signals - The installation for outdoor signals, especially regarding clearance from

power and lightning conductors and transient protection, must be in accordance with NEC725

and NEC800 (CEC Rule 16-224 and CEC Section 60).

Permanently connected equipment - Incorporate a readily accessible disconnect device in the

building installation wiring.

Power lines - Do not locate the camera near overhead power lines, power circuits, or

electrical lights, nor where it may contact such power lines, circuits, or lights.

Ventilation - The camera is a completely sealed device and requires no special consideration

as regards to ventilation.

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 9

MIC440 Explosion-protected Camera Safety | en 9

Water - Do not install the camera power supply near water for example near a bathtub,

washbowl or swimming pool. The power supplies have an IP65 rating and are suitable for

outside installation; however, for security reasons, Bosch recommends that they are installed

in a suitable equipment cabinet. The camera is sealed to IP68 and can be used safely in damp

environments or outdoors, as long as the base cable connector is suitably sealed.

Object and liquid entry - With the exception of the base connector, the camera can be

exposed to non-corrosive liquids without damage. Never push objects into the base connector

as this may damage the connection pins and prevent the camera from operating correctly.

Lightning – For added protection during a lightning storm, or when leaving the device

unattended and unused for long periods, unplug the device and disconnect the cable system.

This will prevent damage to the device from lightning and power line surges.

Adjustment of controls - Adjust only those controls specified in the operating instructions.

Improper adjustment of other controls may cause damage to the unit.

Power sources - Use only the power source indicated in this manual / on the device label.

Ensure that the rating of current of the supply cable is adequate for the device. Before

proceeding, disconnect the power from the cable to be installed into the device.

- For external-power-supplied devices, use only the recommended or approved power

supplies.

- For limited power source devices, this power source must comply with EN 60950.

Substitutions may damage the device or cause fire or shock.

- For 24 VAC devices, voltage applied to the device’s power input should not exceed ±10% (or

28 VAC). User-supplied wiring must comply with local electrical codes (Class 2 power levels).

Do not ground the supply at the terminals or at the device’s power supply terminals.

- If unsure of the type of power supply to use, contact your dealer or local power company.

Damage requiring service – Unplug the device from the main AC power source and refer

servicing to qualified service personnel whenever any damage to the device has occurred,

such as:

- the power supply cord or plug is damaged;

- liquid has been spilled into the device;

- an object has fallen into the device;

- the device has been dropped, or its enclosure or the equipment cabinet in which it is located

has been damaged;

- the device exhibits a distinct change in performance;

- the device does not operate normally when the user follows the operating instructions

correctly

Servicing - Do not attempt to service this device yourself. Refer all servicing to qualified

service personnel.

This device has no user serviceable parts.

Replacement parts - Use only replacement parts specified by the manufacturer. Unauthorized

substitutions may cause fire, electrical shock, or other hazards.

Safety check – Safety checks should be performed upon completion of service or repairs to

the device to ensure proper operating condition.

Notice!

This is a class A product. In a domestic environment this product may cause radio

interference, in which case the user may be required to take adequate measures.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 10

10 en | Safety MIC440 Explosion-protected Camera

Notice!

Ce produit est un appareil de Classe A. Son utilisation dans une zone résidentielle risque de

provoquer des interférences. Le cas échéant, l’utilisateur devra prendre les mesures

nécessaires pour y remédier.

FCC & ICES Information

(U.S.A. and Canadian Models Only)

This device complies with part 15 of the FCC Rules. Operation is subject to the following

conditions:

– this device may not cause harmful interference, and

– this device must accept any interference received, including interference that may cause

undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules and ICES-003 of Industry Canada. These

limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and

radiates radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference, in which case the

user will be required to correct the interference at his expense.

Intentional or unintentional modifications, not expressly approved by the party responsible for

compliance, shall not be made. Any such modifications could void the user's authority to

operate the equipment. If necessary, the user should consult the dealer or an experienced

radio/television technician for corrective action.

The user may find the following booklet, prepared by the Federal Communications

Commission, helpful: How to Identify and Resolve Radio-TV Interference Problems. This

booklet is available from the U.S. Government Printing Office, Washington, DC 20402, Stock

No. 004-000-00345-4.

Informations FCC et ICES

(modèles utilisés aux États-Unis et au Canada uniquement)

Ce produit est conforme aux normes FCC partie 15. la mise en service est soumises aux deux

conditions suivantes :

– cet appareil ne peut pas provoquer d'interférence nuisible et

– cet appareil doit pouvoir tolérer toutes les interférences auxquelles il est soumit, y

compris les interférences qui pourraient influer sur son bon fonctionnement.

AVERTISSEMENT: Suite à différents tests, cet appareil s’est révélé conforme aux exigences

imposées aux appareils numériques de Classe A en vertu de la section 15 du règlement de la

Commission fédérale des communications des États-Unis (FCC). Ces contraintes sont

destinées à fournir une protection raisonnable contre les interférences nuisibles quand

l'appareil est utilisé dans une installation commerciale. Cette appareil génère, utilise et émet

de l'energie de fréquence radio, et peut, en cas d'installation ou d'utilisation non conforme aux

instructions, générer des interférences nuisibles aux communications radio. L’utilisation de ce

produit dans une zone résidentielle peut provoquer des interférences nuisibles. Le cas

échéant, l’utilisateur devra remédier à ces interférences à ses propres frais.

Au besoin, l’utilisateur consultera son revendeur ou un technicien qualifié en radio/télévision,

qui procédera à une opération corrective. La brochure suivante, publiée par la Commission

fédérale des communications (FCC), peut s’avérer utile : How to Identify and Resolve Radio-TV

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 11

!

MIC440 Explosion-protected Camera Safety | en 11

Interference Problems (Comment identifier et résoudre les problèmes d’interférences de radio

et de télévision). Cette brochure est disponible auprès du U.S. Government Printing Office,

Washington, DC 20402, États-Unis, sous la référence n° 004-000-00345-4.

UL Disclaimer

Underwriter Laboratories Inc. ("UL") has not tested the performance or reliability of the

security or signaling aspects of this product. UL has only tested fire, shock and/or casualty

hazards as outlined in Standard(s) for Safety for Information Technology Equipment, UL

60950-1 . UL Certification does not cover the performance or reliability of the security or

signaling aspects of this product.

UL MAKES NO REPRESENTATIONS, WARRANTIES, OR CERTIFICATIONS WHATSOEVER

REGARDING THE PERFORMANCE OR RELIABILITY OF ANY SECURITY OR SIGNALING-RELATED

FUNCTIONS OF THIS PRODUCT.

2.4

Safety Information Specific to Explosion Protection

Warning!

DO NOT OPEN PRODUCT HOUSING!

No repairs requiring opening the product housing are permitted.

Failure to observe this precaution will void the certification and the warranty.

The product is certified for use within the ambient temperature range of -20 °C to +60 ºC and

must not be used outside this range.

The certification of this equipment depends upon the maintenance of the flamepaths and the

use of the following materials in the construction of exposed parts: Aluminum (BS-EN755 1997

6082T6); Stainless Steel (BS-EN10088 No.1.4404). The maximum constructional gaps (Ic) of

the cylindrical flamepaths are less than that required by Table A of EN 60079-1:2007, as

detailed below:

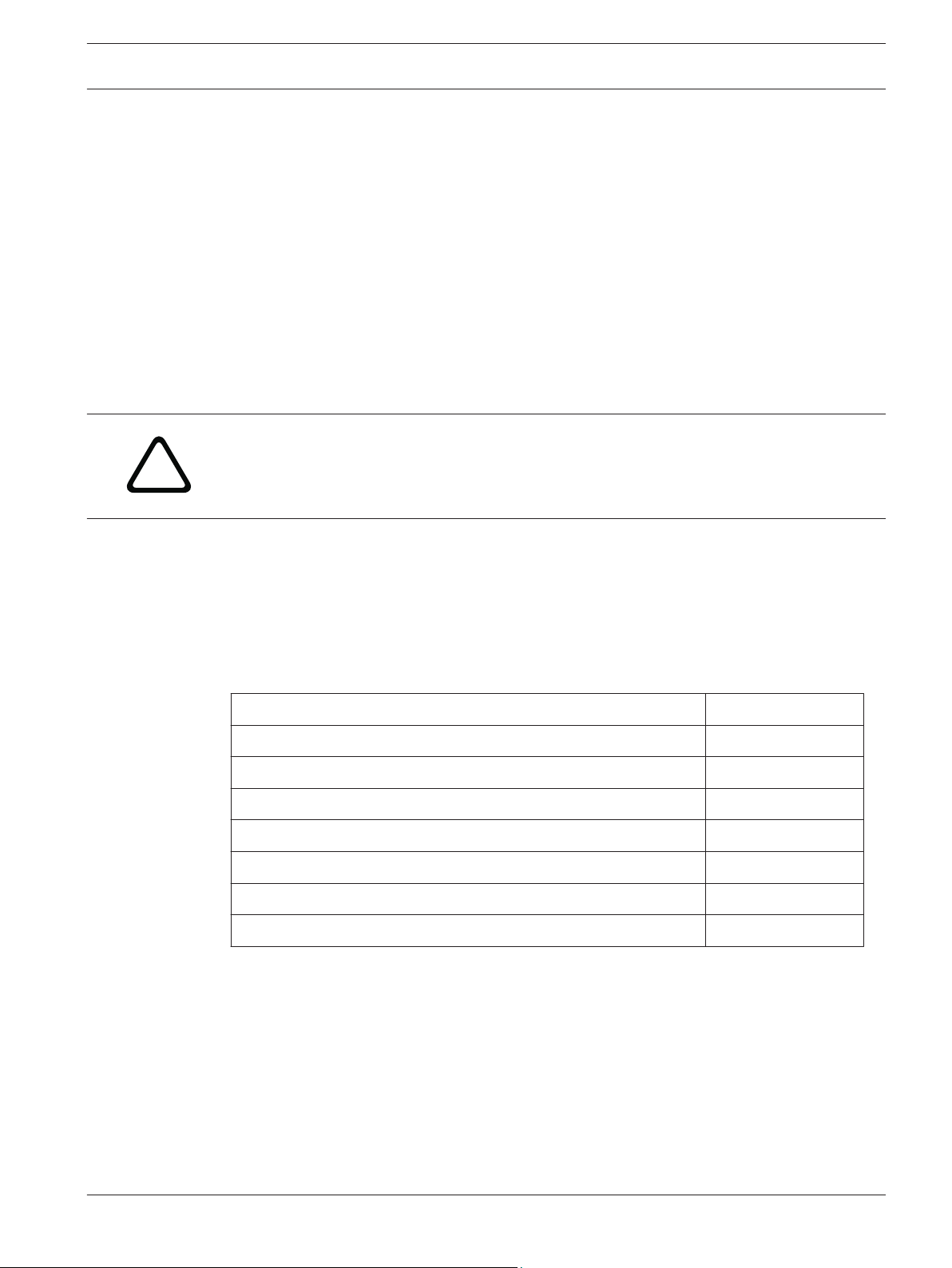

Flamepath Maximum Gap (mm)

Between the tilt center bore and tilt bearing housing shaft (2 off) 0.089

Between the yoke arm bore and tilt resolver shaft 0.061

Between the yoke arm bore and yoke arm blanking cap shaft 0.061

Between the yoke arm bore and yoke spigot shaft 0.061

Between the pan body top bore and yoke spigot shaft (2 off) 0.061

Between the upper cover bore and wiper motor mount shaft 0.060

Between the wiper motor mount bore and base flange shaft 0.100

The pan body to pan body top are to be secured with cap head M5 - 0.8 x 10 mm long S316

stainless steel grade A4/70 special fasteners.

If the equipment is likely to come into contact with aggressive substances (for example, acidic

liquids or gases that may attack metals, or solvents that may affect polymeric materials), then

the user is responsible for taking suitable precautions that prevent it from being adversely

affected, thus ensuring that the type of protection provided by the equipment is not

compromised. “Suitable precautions” include regular checks as part of routine inspections or

establishing from the material’s datasheets that it is resistant to specific chemicals.

The camera is designed for use with flammable gases and vapors covered by apparatus groups

IIA, IIB, and IIC, and with temperature classes T1 to T6.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 12

12 en | Safety MIC440 Explosion-protected Camera

Units must carry the following certification marking: SIRA05ATEX1300X Exd IIC T6 Ta –20ºC

to +60ºC Gb.

EC Directives

This MIC camera complies with the following EC directives:

– EMC Directive (2011/108/EC)

– Machinery Directive (2006/42/EC)

– Low Voltage Directive (2006/95/EC)

– RoHS (Restriction of Hazardous Substances) 2011/65/EC

– WEEE (Waste Electrical and Electronic Equipment) 2002/96/EC

2.5

Customer Support and Service

If this unit needs service, contact the nearest Bosch Security Systems Service Center for

authorization to return and shipping instructions.

Service Centers

USA

Telephone: 800-366-2283 or 585-340-4162

Fax: 800-366-1329

Email: cctv.repair@us.bosch.com

Customer Service

Telephone: 888-289-0096

Fax: 585-223-9180

Email: security.sales@us.bosch.com

Technical Support

Telephone: 800-326-1450

Fax: 585-223-3508 or 717-735-6560

Email: technical.support@us.bosch.com

Repair Center

Telephone: 585-421-4220

Fax: 585-223-9180 or 717-735-6561

Email: security.repair@us.bosch.com

Canada

Telephone: 514-738-2434

Fax: 514-738-8480

Europe, Middle East & Africa Region

Please contact your local distributor or Bosch sales office. Use this link:

http://www.boschsecurity.com/startpage/html/europe.htm

Asia Pacific Region

Please contact your local distributor or Bosch sales office. Use this link:

http://www.boschsecurity.com/startpage/html/asia_pacific.htm

More Information

For more information please contact the nearest Bosch Security Systems location or visit

www.boschsecurity.com

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 13

!

MIC440 Explosion-protected Camera Unpacking | en 13

3

3.1

Unpacking

– This equipment should be unpacked and handled with care. Check the exterior of the

packaging for visible damage. If an item appears to have been damaged in shipment,

notify the shipper immediately.

– Verify that all the parts listed in the Parts List below are included. If any items are

missing, notify your Bosch Security Systems Sales or Customer Service Representative.

– Do not use this product if any component appears to be damaged. Please contact Bosch

Security Systems in the event of damaged goods.

– The original packing carton is the safest container in which to transport the unit and must

be used if returning the unit for service. Save it for possible future use.

Caution!

Take extra care lifting or moving MIC440 cameras because of their weight (15.5 kg (34.17

lb)).

Parts List

Quantity Part

1 MIC440 with Exd DCA attached

1 Quick Installation Guide

1 MIC Series 440 Installation Manual

1 USB to RS-485 converter kit

4 M3 x 25 mm stainless screws

1 Nebar gasket

3.2

Quantity Product Part Number Size

1 per camera Shielded Composite Cable for MIC cameras

Quantity Product Part Number

Additional Products Required

Mounting accessories are sold separately by Bosch. (Refer to the chapter Product Description

for a list.) Users must supply all wiring/cabling for power, video, and telemetry.

The following table lists additional products, sold separately by Bosch, required to operate

each MIC camera:

MIC-CABLE-2M 2 m

(See the model numbers and lengths at right.)

MIC-CABLE-10M 10 m

MIC-CABLE-20M 20 m

MIC-CABLE-25M 25 m

MIC-240PSU-2,

1 per camera Power Supply Unit (PSU) for MIC cameras

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

MIC-115PSU-2,

MIC-24PSU-2

Page 14

!

14 en | Unpacking MIC440 Explosion-protected Camera

Warning!

These power supply units are NOT explosion-proof and must be installed outside of the

hazardous environment.

3.3

Additional Tools Required

The following table lists additional tools (not supplied by Bosch) that are or may be required

to install a MIC camera:

Quantity Part

1 13 mm wrench for the mounting bolts

1 3 mm screwdriver for the terminal blocks in the MIC PSU

1 8 mm screwdriver for captive screws for the MIC PSU enclosure

1 Silicone sealant for ensuring a water tight seal [if not using the Nebar gasket]

1 Roll of PTFE tape

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 15

MIC440 Explosion-protected Camera Product Description | en 15

4

Product Description

MIC Series 440 cameras are high-specification, weatherproof, ruggedized, fully functional day/

night PTZ cameras that have been designed to offer a reliable, robust, and high-quality

surveillance solution for extreme security applications.

MIC440 models have a 18x or 36x optical zoom (12x digital) and flexible mounting options

(upright or inverted) to achieve the perfect field of view.

MIC440 cameras meet the requirements of ATEX Directive 94/9/ EC Exd IIC T6 and CSA Class

I, Division 1, Groups CD, Class II, Division 1, Groups EFG, T6 for safe use in explosive

atmospheres such as those found in oil, gas, chemical processing sites, and petrochemical

refineries.

Precision-engineered to exacting standards, MIC cameras offer numerous benefits over

traditional dome and PTZ cameras. Rated to an industry-leading IP68, the compact, vandalresistant, 6 mm thick aluminum camera housing is pre-treated and then painted with polyester

powder coat paint (Jet black (RAL 9005) or Signal white (RAL 9003)). Brushless motor

technology ensures ultra-reliable, whisper quiet operation with full 360° continuous pan and

320° tilt control. The optically perfect, flat viewing window and integrated wiper ensure that

razor-sharp images are captured in even the most demanding conditions.

The following table identifies the mounting accessories for MIC440 cameras. Refer to the

datasheet MIC Series Mounting Brackets and Other Accessories for details.

MIC-SCA

Shallow Conduit Adapter

MIC-CMB Corner Mount Bracket

MIC-PMB Pole Mount Bracket

MIC-WMB Wall Mount Bracket

MIC-SPR Spreader Plate

A long-life silicone wiper blade mounted on a spring-loaded arm is standard on all MIC

cameras.

The following table identifies the accessories (not including mounting brackets) for MIC440

cameras.

Accessories

MIC-ALM Alarm and washer pump drive card for non-IR PSU; 8 inputs.

MIC-WKT Washer kit, containing mounting bracket, nozzle, and washer pump

drive card.

MIC-BP4 Bosch Biphase converter card for MIC power supplies with an

available expansion slot.

MIC440SUNSHIELD

A two-part plastic sunshield to provide additional protection in sunny

climates for MIC cameras Comes with stainless steel bosses, washers,

and retaining screws.

Description

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 16

!

!

!

16 en | Installation of a MIC440 Camera MIC440 Explosion-protected Camera

5

5.1

Installation of a MIC440 Camera

This chapter provides an overview for the installation of a MIC440 camera.

Caution!

The MIC440 camera is designed for use with flammable gases and vapors covered by

apparatus groups IIA, IIB and IIC and with temperature class T6. The product is certified for

use within the ambient temperature range of -20 °C to +60 ºC and must not be used outside

this range.

While a MIC440 camera is certified for installation in a hazardous area, its power supply unit

(PSU) is not. The PSU itself can be installed in either a non-hazardous area or in a hazardous

area. If installed in a hazardous area, the PSU must be placed inside a certified enclosure that

is certified for use in hazardous areas.

Warning!

ROUTING OF EXTERNAL WIRING MUST BE DONE THROUGH A PERMANENTLY EARTHED

METAL CONDUIT.

Mounting the Conduit Gland and Cable

The MIC composite cable (8 mm) required to connect the MIC440 to its power supply consists

of two pairs (24AWG) plus 4 cores of (22 AWG), 2 cores of (24 AWG), and one coax core for

the video signal to a maximum distance of 25 m.

Warning!

Bosch recommends connecting the cable to the unit before taking the unit for mounting onsite.

To mount the conduit gland and cable, follow these steps:

1. Remove the 4 x M8 Hexagon bolts holding the conduit adapter (DCA) to the MIC440 unit.

Remove the DCA.

2. Fit the unterminated ends of the composite cable through the 20 mm threaded gland hole

in the DCA. Allow approximately 100 mm of free cable on the inside to connect to the 12-

way cable connector.

3. Screw the Exd conduit gland into the DCA, maintaining approximately 100 mm of cable

on the inside of the DCA to enable the cable connector to be inserted freely into the MIC

unit base connector.

4. Connect the 12-way cable connector into the matching connector in the base of the MIC

unit.

5. Ensure that the connector is fitted properly in the camera’s integral plug. Turn the socket

thread ring approximately two and a half turns to fasten the two halves of the connectors

together properly.

6. Bolt the DCA onto the MIC440 unit; tighten the 4 x M8 hexagon bolts.

7. Ensure that there are no trapped cables.

8. Ensure that there is some slack cable in the DCA, then tighten and seal the Exd barrier

gland per the instructions included with the gland. The unit with the cable tail is now

ready for on-site installation.

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 17

!

MIC440 Explosion-protected Camera Installation of a MIC440 Camera | en 17

5.2

PSU Installation and Setup in a Non-Hazardous Area

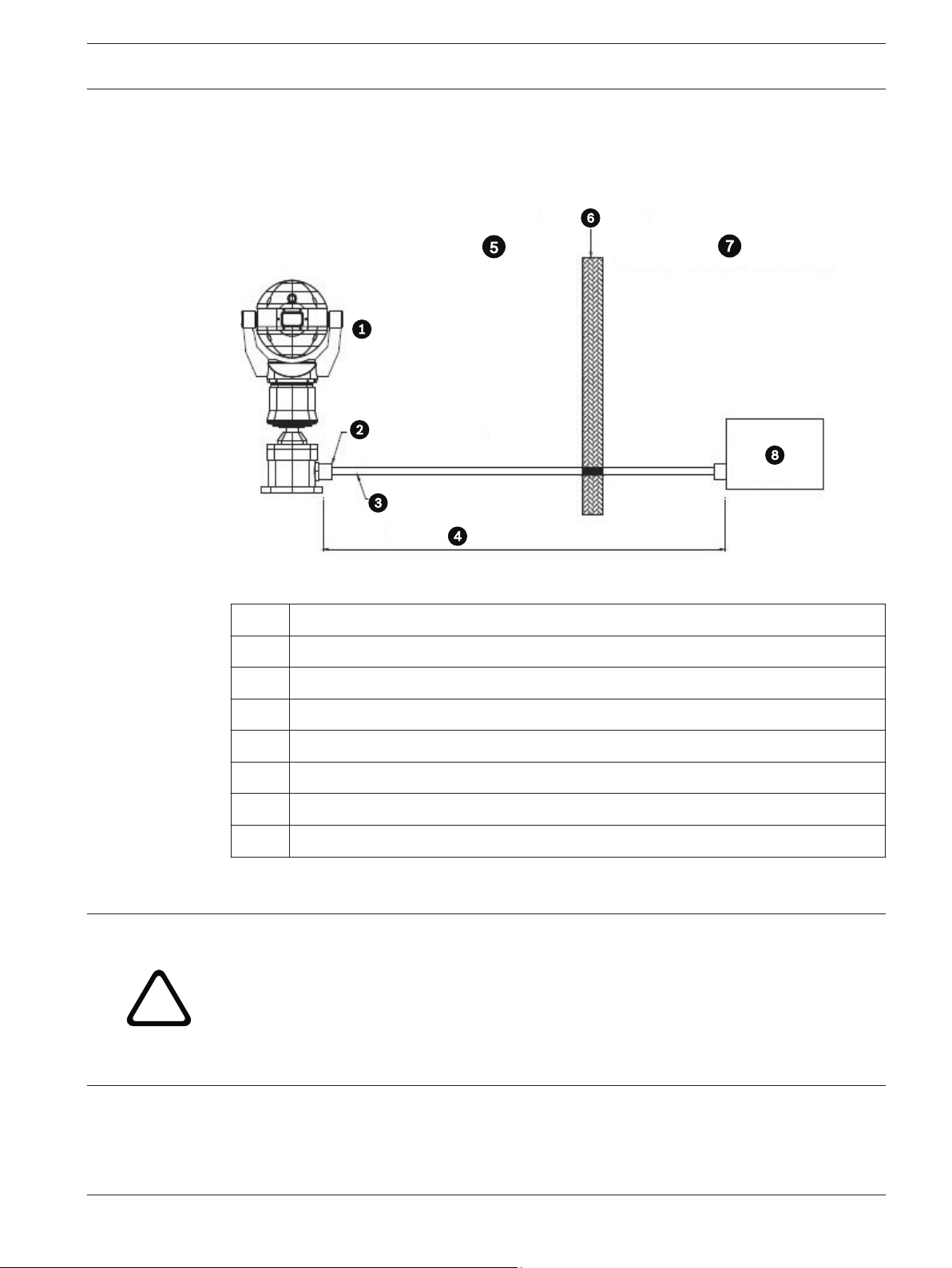

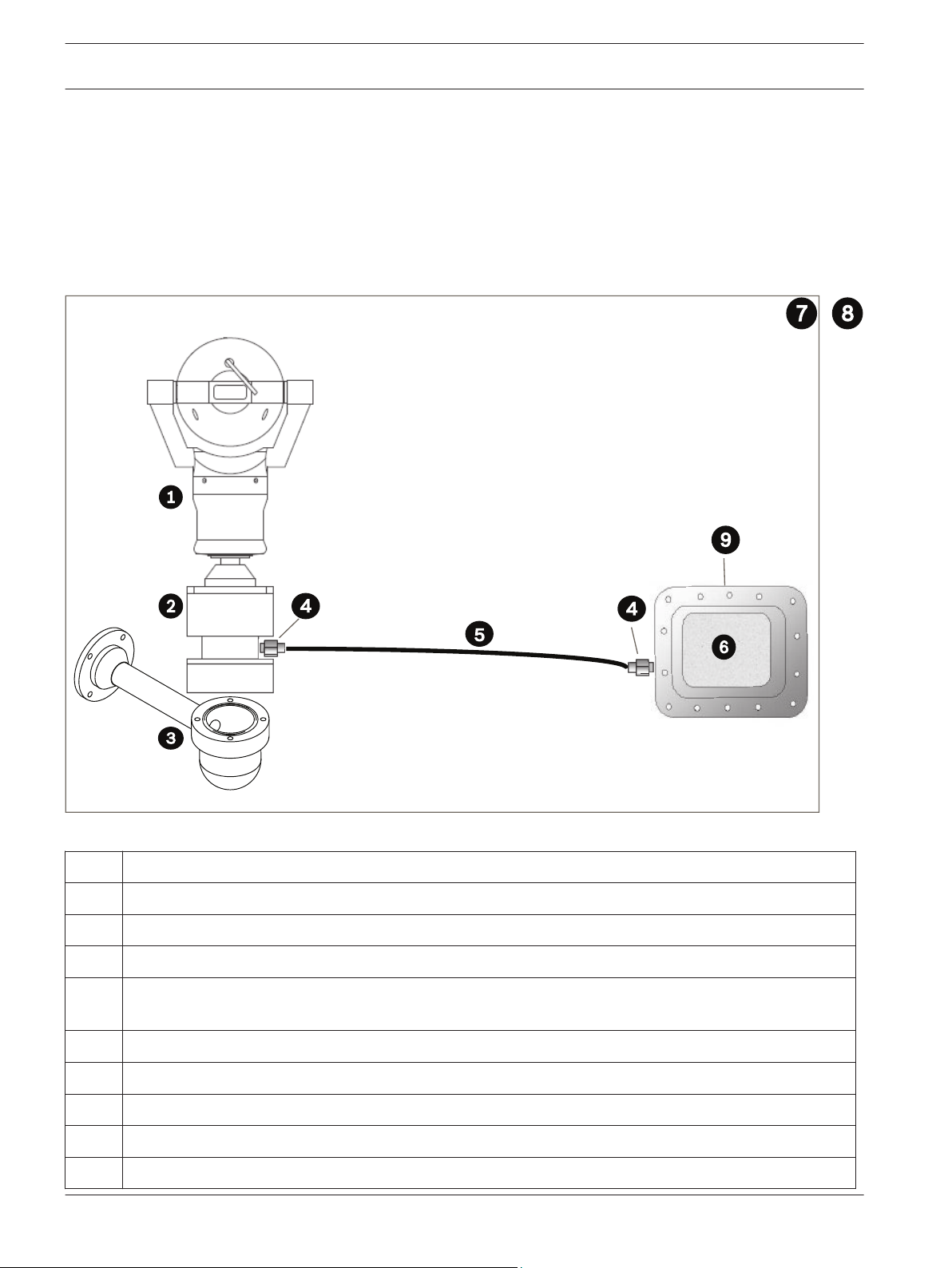

The figure below illustrates an installation of a MIC PSU for MIC440 in a non-hazardous area.

Note that the camera itself is installed in a hazardous area.

Figure 5.1: Installation of MIC PSU in Non-Hazardous Area

5.3

1

2 Exd conduit gland

3 Composite cable inside metal conduit

4 Distance of 25 mm maximum

5 Hazardous area

6 Exd Barrier

7 Non-hazardous Area

8 Standard MIC PSU

MIC440 camera

PSU Installation and Setup in a Hazardous Area

Caution!

Any junction box or enclosure used for mounting the power supply or separating cable cores

MUST BE appropriately rated for the installation. MIC PSU enclosures are not Exd rated and

must be placed inside a certified enclosure if installed within a hazardous area.

For additional protection in hazardous area installations, suitable metal conduit must be used

externally for the composite cable run to connect the power supply to the Exd conduit gland

(not supplied) in the Deep Conduit Adapter (MIC-DCA).

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 18

18 en | Installation of a MIC440 Camera MIC440 Explosion-protected Camera

Installation of the PSU within a hazardous area must have the standard PSU enclosure placed

inside an appropriate certified enclosure and four (4) Exd conduit glands (NOT supplied). The

power supply PCB is usually re-housed, by a third party company, within an Exd enclosure

which is then factory certified and shipped to site. Follow all manufacturers’ instructions when

installing a third party Exd enclosure.

The figure below illustrates a typical installation of both a MIC440 and a MIC PSU in a

hazardous area. Note that the PSU is installed inside an enclosure that is certified for use in

hazardous areas.

Figure 5.2: Installation of MIC PSU in Hazardous Area

No. Description

1 MIC440 camera

2 MIC440 DCA

3 MIC Wall Mount Bracket (not supplied)

4 Exd conduit gland

Exd Barrier Gland (not supplied; to be specified by installer to match incoming conduit)

5 MIC composite cable (length to be specified; 25 m maximum) inside metal conduit (not supplied)

6 MIC PSU

7 Hazardous area

8 Non-Hazardous area

9 Exd Enclosure certified for hazardous areas (not supplied)

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 19

MIC440 Explosion-protected Camera Installation of a MIC440 Camera | en 19

5.4

MIC Power Supply Unit Extension

Users can extend the distance between their MIC camera and the MIC PSU by using two

junction boxes (user-supplied). The boxes must be weatherproof or explosion-proof,

depending on the model and the physical location of the box. The second junction box is

required to reduce the size of the cable and to reduce the amount of conduit connections to

the MIC PSU.

All cables used outdoors must have a UV-resistant outer jacket, or must be installed inside

permanently earthed metal conduit. See the table below for the maximum distance and wire

gauge recommended for each camera. The maximum distance is the distance between the two

user-supplied junction boxes.

Wire Gauge

18 AWG 16 AWG 14 AWG 12 AWG

Maximum Distance in Meters (feet) 46 (151) 73 (240) 116 (381) 185 (606)

Maximum Watts, MIC440 = 25.2.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 20

20 en | Installation of a MIC440 Camera MIC440 Explosion-protected Camera

Figure 5.3: MIC PSU Extension with two (2) user-supplied junction boxes (weatherproof or explosion-proof, depending on model

and physical location)

1 Head-end control system

2 Standard cables and power

3 MIC PSU

4 Standard MIC composite cable (2 meters MAXIMUM)* inside metal conduit

5 First user-supplied Junction Box (weatherproof or explosion-proof).

See the Caution boxes at the beginning of the subchapter.)

6 RG59U Coax

7 RS-485 (2- or 4-wire shielded twisted pair with ground)

8 Power wires, which control the maximum distance.

See the table below for limitations.

9 Second user-supplied Junction Box (weatherproof or explosion-proof).

See the Caution boxes at the beginning of the subchapter.)

This second box is required to reduce the size of the cable and to reduce the

amount of conduit connections to the MIC PSU.

10 Standard MIC composite cable (2 meters MAXIMUM)* inside metal conduit

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 21

!

MIC440 Explosion-protected Camera Electrical Connections | en 21

6

6.1

Electrical Connections

About the MIC Shielded Composite Cable

All connections (power, telemetry, video) to the MIC camera are provided through the screw

terminal connections in the MIC power supply. MIC shielded composite cables are multiconductor cables of various lengths (and gauges ranging from 14 - 18) that provide all power,

video, and telemetry connections between the MIC PSU and the MIC camera. The cables are

pre-made with a female terminated connector (12-pin) at one end for attachment to the male

connector installed into the base of the camera. The other end of the cables has free (nonterminated) wires for wiring into terminals in the MIC PSU. The composite cable consists of

two pairs (24AWG) plus 4 cores of (22 AWG), 2 cores of (24 AWG), and one coax core for the

video signal to a maximum distance of 25 m.

Notice!

Bosch Security Systems does not recommend using the shielded composite cable for

distances greater than 25 m between the MIC camera and the MIC power supply.

For installations that require the camera to be more than 25 m from the power supply, Bosch

recommends that a 2 m cable be connected to a junction box (Exd rated for MIC440) from

which telemetry, video, and power can be broken out into separate cables and appropriate

wiring used to extend the distance to suit.

6.2

Warning!

Bosch recommends connecting the cable to the unit before taking the unit for mounting onsite.

MIC shielded composite cable before connection to a MIC440 camera

MIC shielded composite cable connected to a MIC440 camera

Composite Cable Color-coding

The standard color coding used in MIC composite cables is as follows:

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 22

en | Electrical Connections MIC440 Explosion-protected Camera

22

Figure 6.1: Exploded View of Composite Cable Connections

Camera

Cable

Signal Name Description Cable Wire

Color

Connector

Pin

1 Washer Drive Rtn Auxiliary Connection Grey

2 Tamper Sw Rtn Auxiliary Connection Brown

3 Washer Drive Wash Signal Orange

4 Tamper Sw Alarm Communications Black

5 Video Return Video Signal Ground Coax

Screen

6 Video Output Video Output to Control Room Coax Core

7 Full Duplex Tx B+ Telemetry I/O to RS-422/485 Violet

8 Full Duplex Tx A- Telemetry I/O to RS-422/485 Blue

9 0v Ground Shield

10 Full Duplex Rx A-

Telemetry I/O to RS-422/485 Yellow

Half Duplex Tx/Rx A

11 Full Duplex Rx B+

Telemetry I/O to RS-422/485 White

Half Duplex Tx/Rx B

12 Power Input 2 Low Voltage Power Input Green

13 Power Input 1 Low Voltage Power Input Red

Video output signal conforms to CCIR PAL or NTSC 1V Composite format. Telemetry signals all

conform to the RS-485 / RS-422 standard. The unit continuously monitors incoming telemetry

whether in full or half duplex mode.

In full duplex mode, the Tx pins are tri-state except during transmission times. This may cause

problems when interfacing to some fiber optic converter units. Check out the Commissioning

notes for ways of overcoming these problems. In 2 wire Half Duplex mode (RS-485), the Rx

pins are used to transmit data to the MIC440.

The washer connections can be used to operate a relay in the power supply unit, which in turn

can activate a pump.

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 23

MIC440 Explosion-protected Camera Select the Mounting Location and Orientation | en 23

7

7.1

Select the Mounting Location and Orientation

Mounting Location Overview

MIC Series cameras are designed for easy installation in various locations such as directly onto

buildings and dedicated CCTV poles. Bosch sells a complete series of mounting brackets

designed to allow the camera to achieve the optimal field of view.

The most common type of mounting location is the top of a dedicated CCTV pole that provides

a robust mounting platform that minimizes camera motion and typically has a large base

cabinet for mounting ancillary equipment such as power supplies.

The camera can also be mounted on the side of a lamp post, pole, or similar column using the

Pole Mount Bracket (MIC-PMB). Be aware that lamp posts can often be subject to movement

and are not suitable platforms in all conditions or for all applications.

Other locations for mounting the camera include the top of a building, the side (wall) of a

building, the corner of a building, and under the eave of a building.

The three figures directly below illustrate the arrangement of mounting brackets for installing

a MIC camera. The camera (not shown) is attached to the bowl of the MIC-WMB.

Figure 7.1: Typical pole mount (from left: Pole Mount Bracket (MIC-PMB) [2 mounting blocks, 2 pole bands,

and 1 mounting plate], Shallow Conduit Adapter (MIC-SCA), and Wall Mount Bracket (MIC-WMB))

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 24

24 en | Select the Mounting Location and Orientation MIC440 Explosion-protected Camera

Figure 7.2: Typical wall mount (from left: Wall Mount Bracket (MIC-WMB), Shallow Conduit Adapter (MIC-

SCA), and Spreader Plate (MIC-SPR))

Figure 7.3: Typical corner mount (from left: Wall Mount Bracket (MIC-WMB), Shallow Conduit Adapter (MIC-SCA), and Corner

Mount Bracket (MIC-CMB))

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 25

!

MIC440 Explosion-protected Camera Select the Mounting Location and Orientation | en 25

7.2

Select the Mounting Location

1. Select the mounting location.

Select a secure installation location and mounting position for the device. Ideally, this is a

location where the device cannot be interfered with either intentionally or accidentally.

Ensure that the location has the appropriate clearance from power and lightning conductors,

in accordance with NEC725 and NEC800 (CEC Rule 16-224 and CEC Section 60).

Do not install the device near:

– Any heat sources

– Any overhead power lines, power circuits, or electrical lights, or where the device may

contact power lines, circuits, or lights

4 Ensure that the selected mounting surface is capable of supporting the combined weight

of the camera and mounting hardware (sold separately) under all expected conditions of

load, vibration, and temperature.

Notice!

MIC cameras must be secured to one of the following surfaces:

- Concrete (Solid/Cast)

- Concrete Masonry Unit (Concrete Block)

- Brick (all types)

- Metal (Steel/Aluminum, minimum 1/8-in. thick)

7.3

Caution!

Risk of lightning strikes

If the camera is installed in a highly exposed location where lightning strikes may occur, then

Bosch recommends installing a separate lightning conductor within 0.5 m (1.6 ft) of the

camera and at least 1.5 m (4.9 ft) higher than the camera. A good earth bonding connection

to the camera housing itself will provide protection against damage from secondary strikes.

The camera housing itself is constructed to cope with secondary strikes. If the correct

lightning protection is applied, then no damage to the internal electronics or camera should

result.

Mounting Orientation

2. After selecting the mounting location, select the appropriate mounting orientation.

MIC Series cameras are designed to be mounted upright (straight up, 90°) or inverted

(straight down, 90°). See the figures below for illustrations of the correct and the incorrect

mounting orientations of MIC cameras.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 26

26 en | Select the Mounting Location and Orientation MIC440 Explosion-protected Camera

Correct mounting orientation of

Incorrect mounting orientation of MIC camera

MIC camera - upright, inverted

3. Install the mounting brackets.

Observe all appropriate safety precautions and local building regulations.

Refer to the MIC Series Mounting Brackets Installation Guide for installation instructions.

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 27

!

MIC440 Explosion-protected Camera Mount the Camera | en 27

8

Mount the Camera

To mount a MIC Series camera, follow these steps:

Warning!

Ensure not to damage the paint work on the housing of the camera or the mount.

1. Carefully lift the camera to the mounting location.

2. Connect the female cable connector end (12-pin) of the shielded composite cable to the

male plug in the base of the camera. Screw the cable connector sleeve onto the plug until it is

secured firmly (approximately four (4) turns from the start of thread engagement).

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 28

!

28 en | Earthing the Camera MIC440 Explosion-protected Camera

9

Earthing the Camera

Earth the MIC Camera to metal on or attached to the mount.

Warning!

The camera must be earthed / grounded to meet EMC immunity standards.

Earth the camera using one of the supplied securing bolts. Only earth the camera at a single

point to prevent earth loops and video distortion (hum bars), caused by electrical

interference, from appearing on the camera picture in the control room. Please note:

– The camera module and housing are electrically isolated, so the housing should be safety

earthed regardless. The safety earth should be a bonding connection (for example, one of

the securing bolts) to the camera housing, or should be attached to the Earth terminal

post on the PCD base of the camera.

– If the system is copper throughout and the camera pictures are fed back to the control

room via coaxial copper cable, then the camera should be earthed only at the video

termination point in the control room. In this case, the "Earth Link" on the PCB should be

broken. Refer to Earth Link on PCB, page 30.

– If the video is transmitted back to the control room via some non-electrical connecting

medium (for example, fiber optic, radio, or microwave link), then the camera should be

earthed at the transmitter point in the power supply unit. The PSU "Earth Link" may be

used for this purpose.

– If dual earthing is unavoidable, then a video isolation transformer should be fitted

between the two earths.

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 29

!

!

MIC440 Explosion-protected Camera Finalize Camera Mounting | en 29

10

Finalize Camera Mounting

Finalize Camera Mounting

Warning!

It is essential that the connections and the base of the camera are completely sealed from

water ingress. Any water getting into the connector is liable to cause corrosion to the

connector pins, leading to unreliable operation of the camera unit. This is especially

imperative for a camera mounted in inverted orientation.

1. To prevent water ingress, seal the threads of the securing bolts using PTFE tape (not

supplied). An additional gasket or suitable silicone sealant can be applied liberally to the

threads prior to final tightening to ensure a watertight seal between the base of the camera

and the mounting surface.

2. Use M8 x 20 mm stainless steel nuts, bolts, and washers to secure the base of the camera

to the mounting surface.

3. Tighten all bolts securely.

4. Secure all cabling and conduit.

Caution!

The upright unit can be mounted either with the camera ball up or down. So that the picture

from a camera installed with the camera ball down appears properly, rotate the camera tilt

axis 180°. For more information, see Configuring the Camera for Inverted Operation, page 44.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 30

!

!

30 en | Install the MIC Power Supply Unit (PSU) MIC440 Explosion-protected Camera

11

11.1

Install the MIC Power Supply Unit (PSU)

MIC PSU Overview

Caution!

Use only the power supply specified for your specific model of camera.

Bosch provides a range of power supply units (PSUs) for MIC Series cameras. These units

have a variety of common voltages and provide all the connections needed for power,

telemetry and video.

Warning!

These power supply units are NOT explosion-proof and must be installed outside of the

hazardous environment.

Each MIC PSU provides all of the connections needed for power, video, and telemetry for a

single MIC camera. Each MIC PSU has CE and FCC approval and has a cast-aluminum

enclosure that is weather-resistant (rated IP65). Features include:

– A provision for driving various optional interface cards mounted internally to the MIC

power supply enclosure (for example, an 8-input alarm card (MIC-ALM))

– A provision for a signal interface card (MIC-BP4) to connect telemetry to Bosch Biphase

equipment

– Screw termination of all cables (composite, telemetry, and ancillary) into and out of the

enclosure

– Earth isolation and termination within the unit to control video earthing correctly and

thus prevent earth loops

Each MIC PSU ships with the following parts:

– Three (3) M12 cable glands for telemetry, video and ancillary equipment

– One (1) M16 gland for connection of the shielded composite cable to the MIC camera

– One (1) 1/2 in. NPT cable gland for the power cable connection

– One (1) 1/2 in. NPT and one (1) M12 blanking plug

The transformer fitted to these designs is thermally protected and automatically cuts out if the

transformer core temperature exceeds 40 degrees C. On cooling, the transformer will become

operational again. In addition, the unit provides all the terminations required to connect a

MIC440 camera to third party equipment. A second, independent 12v (600mA) power supply

is also included to drive any internally fitted optional interface cards.

11.2

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Earth Link on PCB

The printed circuit board (PCB) of each MIC PSU (IR and non-IR) has one Earth Link option,

near terminal block HD1, to allow the PSU to be set up for different earthing schemes:

– If there is a separate connection between video screen and earth, the Earth Link should

be broken. This usually occurs on copper-connected systems where all of the copper

video coaxes are taken back to the control room to be connected to a central earth point.

– If fiber optics or other indirect connections are used to get data and video to and from

the control room, then the Earth Link should be left intact, as long as it is the only

camera-end earth reference point.

Page 31

MIC440 Explosion-protected Camera Install the MIC Power Supply Unit (PSU) | en 31

11.3

Fuse

ID

FS 1 MIC camera

FS 2 Primary protection Glass 200 mA quick blow 500 mA quick blow 2.5 A quick blow

FS 3 Heater protection 1 Glass 1.6 A anti-surge (T) 1.6 A anti-surge (T) 1.6 A anti-surge (T)

FS 5 Heater protection 2 Glass 1.6 A anti-surge (T) 1.6 A anti-surge (T) 1.6 A anti-surge (T)

Fuse Function Type Rating for 240 V

protection

11.4

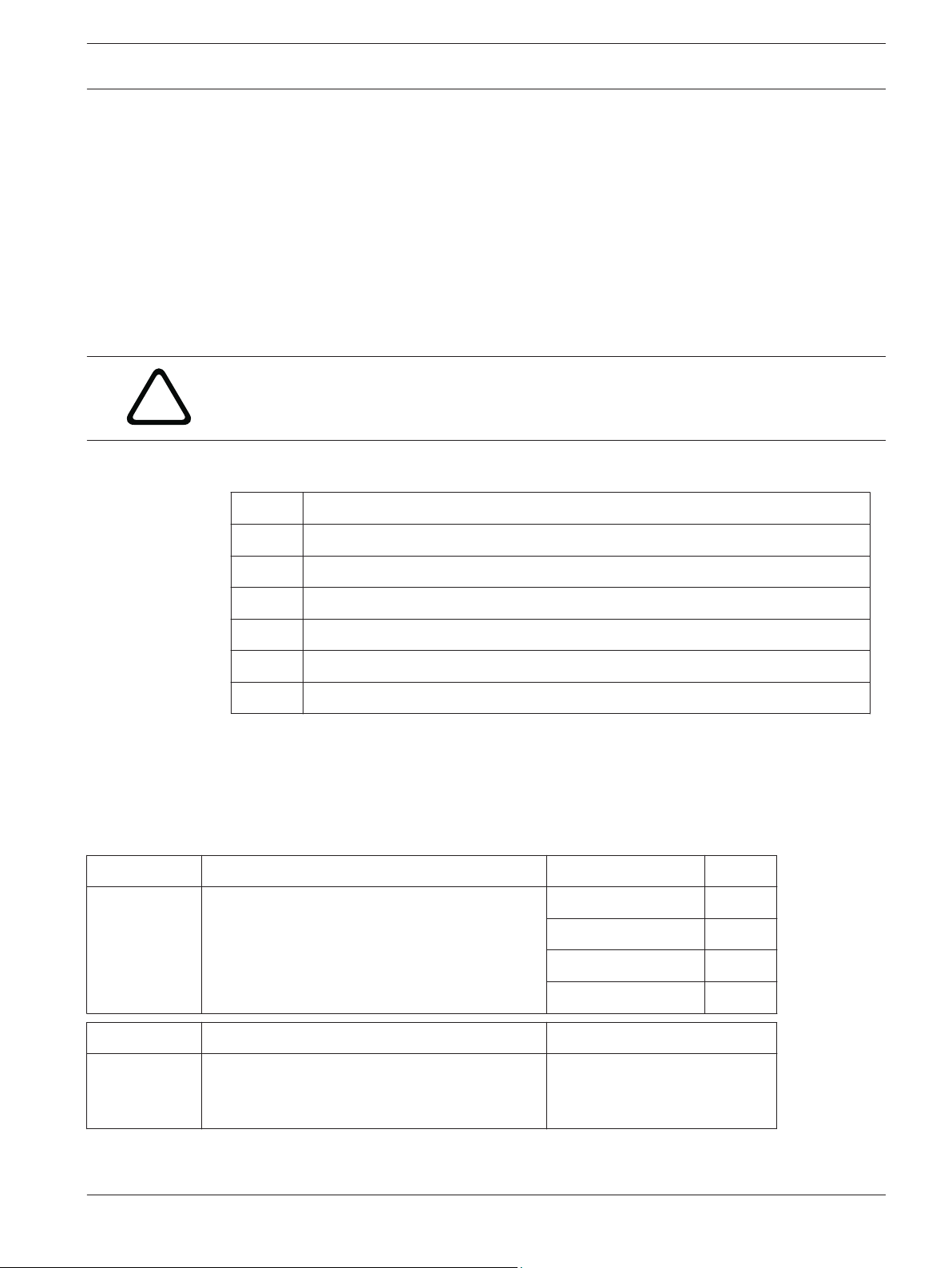

Fuse Ratings

The MIC PSUs for MIC440 cameras have four (4) off 20 mm fuses (numbers 13 - 16 in the

figure “Layout of MIC-240PSU-2 and MIC-115PSU-2”) in fuse holders. The ratings for these

fuses are fixed on the low voltage secondary side but change with input voltage on the high

voltage primary side. The following table shows the fuse values that should be fitted to

provide proper protection for the MIC-240PSU-2 and MIC-115PSU-2 power supplies. Note: FS

4 does not exist.

Rating for 115 V

Primary

Glass 1.6 A anti-surge (T) 1.6 A anti-surge (T) 1.6 A anti-surge (T)

Primary

Rating for 24 V

Primary

Alarm Inputs

The table below identifies the number of alarm inputs and outputs available in MIC power

supply units, depending on whether or not an 8-input alarm card is installed.

MIC PSU 8-input Alarm Card

(MIC-ALM)?

MIC-24PSU-2,

MIC-115PSU-2,

MIC-240PSU-2

Table 11.1: Number of alarm inputs and outputs in MIC PSUs

11.5

Layout of MIC Power Supply Units (PSUs)

Layout of MIC-240PSU-2 and MIC-115PSU-2

The figure below displays the layout of the PCB in the MIC PSUs for non-IR cameras, with callout numbers to the side of or below the connection/terminal ID or the terminal, and ’on’ the

fuses. The table below the figure identifies the connections.

Number of

Alarm Inputs

No 1 0

Yes 8 2

Number of

Alarm Outputs

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 32

32 en | Install the MIC Power Supply Unit (PSU) MIC440 Explosion-protected Camera

Figure 11.1: Layout of MIC-240PSU-2 and MIC-115PSU-2

No. PCB

Marking

1 HD1 AC Power input connector

Description/Function of

Connection / Terminal

Type of Connection/

Terminal

Screw terminal

Live (HD1-1); Neutral (HD1-2)

[Ground wire connects to earth termination post

2 HD3 Shielded composite cable header (connections to camera) Screw terminal

3 HD5 RS-485 control header Screw terminal

4 HD4 Telemetry header Molex connector

5 HD8 USB to RS-485 converter

Molex connector

[Not used for MIC440.]

6 HD6 [Optional] Auxiliary, heater

Screw terminal

[Not used for MIC440.]

7 HD7 Video (composite cable) Screw terminal

8 HD2 Tamper switch header Screw terminal

9 CN3

Video Switched

Coax connection (Switched visible/thermal video out)

[Not used for MIC440.]

BNC socket

10 CN1

Video Out

Coax connection header

(Visible video out)

BNC socket

11 CN2 Auxiliary / add-on card terminal Plug in

12 Earth Link Earth Link

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 33

!

!

!

MIC440 Explosion-protected Camera Install the MIC Power Supply Unit (PSU) | en 33

No. PCB

Marking

13 FS2 Fuse 2 - Primary protection --

14 FS1 Fuse 1 - MIC camera protection --

15 FS3 Fuse 3 - Heater protection 1 --

16 FS5 Fuse 5 - Heater protection 2 --

17 -- Earth termination post Ring terminal

11.6

Installation Instructions (Power Supply)

Danger!

ELECTRICAL SHOCK HAZARD

To reduce the risk of electrical shock, disconnect power before opening or working on any

power supply unit. Power must be disconnected before replacing any fuse in the MIC PSU.

Power supply units have power supplied whenever the power cord is inserted into the power

source.

MIC PSUs have a separate internal shield covering the power cable input terminal block

(HD1). Only suitably qualified persons should remove this shield and connect the mains power

cable. The shield MUST be re-installed and fully secured before connecting the power.

The power supply cable shall have conductors of a maximum size of 12 AWG.

Branch circuit protection incorporating a 15 A, 2-pole, listed circuit breaker or branch rated

fuses are required. A readily accessible 2-pole disconnect device with a contact separation of

at least 3mm must be incorporated externally to the equipment.

Description/Function of

Connection / Terminal

Type of Connection/

Terminal

Warning!

To meet UL standards and ratings, all external wires for installation applications must be

routed through a permanently earthed metal conduit.

Caution!

Except for the Earth Link, heater links, and applicable fuses, the MIC PSUs have no useradjustable parts. MIC cameras have no user-serviceable parts.

Caution!

Bosch recommends using an uninterruptible power supply (UPS) in connection with a MIC

camera/PSU installation.

Notice!

To maintain the IP rating of the power supply enclosure, install only listed or recognized

conduit hubs or fittings with the same environmental rating as the enclosure in compliance

with the installation instruction of the hub or fitting.

Notice!

Refer to the MIC Series Power Supply Installation Manual included with the PSU for full details

on installing a MIC Series PSU and connecting to a MIC Camera.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 34

34 en | Install the MIC Power Supply Unit (PSU) MIC440 Explosion-protected Camera

To install the power supply unit (PSU), follow these steps:

1. Select a secure installation location for the PSU. Ideally, this is a location where the device

cannot be interfered with either intentionally or accidentally.

Bosch recommends using an environmentally suitable, lockable equipment cabinet.

2. Locate the four (4) mounting holes of the power supply enclosure.

3. Drill four (4) holes in the mounting surface for the mounting anchors appropriate for M6

screws (not supplied).

4. Loosen the four (4) captive Phillips head screws on the top of the lid of the power supply

enclosure. Lift the lid and set it upside down next to the enclosure.

Notice!

Do not stretch or cut, or otherwise disturb, the earth core cable (shown in the figure below)

to the inside of the lid and to the earth termination post.

Figure 11.2: Holes for screws for mounting enclosure mounting; holes for screws for enclosure lid

Number Description

1 Hole for mounting screw in enclosure

2 Hole for lid screw in enclosure

5. Secure the enclosure to the mounting surface using four (4) M6 stainless steel screws and

washers (not supplied), which fit through the large holes in the enclosure.

Notice!

If you are securing the power supply enclosure in a vertical position (for example, on a wall),

one person should hold the enclosure lid while another secures the enclosure body in place,

to avoid damage to any part of the enclosure, and/or injury to the installer(s).

6. Unscrew the two (2) M3 screws on the internal high voltage input head-end shield (marked

with "Danger") covering the mains cable terminal HD1; retain the screws.

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 35

!

MIC440 Explosion-protected Camera Install the MIC Power Supply Unit (PSU) | en 35

Figure 11.3: Enclosure showing shield and earth core cable between earth terminal post and enclosure lid

Number

1 Earth core cable to enclosure lid

2 Internal shield

3 Earth termination post

7. Remove the internal shield and set it nearby, outside of the PSU enclosure. You can now

access the hole for the power cable and the M20 blanking plug covering the hole.

8. Remove the blanking plug. Install suitable (metal) conduit in place of the blanking plug.

Secure the conduit as recommended by the conduit manufacturer.

Caution!

Only installations with conduit meet UL standards. If you choose to use a power cord without

conduit (not recommended), fit the 1/2 in. NPT cable gland (supplied) in place of the

blanking plug. Note: It is easier to fit the power cord through the cable gland outside of the

enclosure, and then attach the gland to the enclosure. Ensure that the cable glands have

sufficient room to allow for the cables to enter (approximately 60 mm on either side of the

enclosure).

9. Prepare the power cable as need, and then feed the cable into the enclosure.

10. Connect the Live and Neutral cores to the correct screw terminals on terminal block HD1

as identified in the table below and printed on the PCB. Observe polarity and voltage.

Description

PCB Marking Description

L Live

N Neutral

Earth / Ground

11. Remove the brass nut and copper washer from the earth termination post (item 3 in the

figure “Mains input with shield removed…”); set these aside.

12. Remove the ring terminal (supplied).

13. Insert the earth core from the mains cord (item 2 in the figure “Mains input with shield

removed…”) into the crimp portion (size M6, UL-certified) of the ring terminal and crimp it in

place.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 36

en | Install the MIC Power Supply Unit (PSU) MIC440 Explosion-protected Camera

36

14. Place the ring terminal onto the earth termination post.

15. Replace the copper washer. Secure with the brass nut.

Figure 11.4: Mains input with shield removed, showing terminal block HD1 before wiring

Number

Description

1 Earth core cable to enclosure lid

2 Earth core cable to power supply PCB

3 Earth termination post

16. Replace the internal shield, taking care to avoid pinching the cables. Tighten the screws.

17. Feed the unconnected end of the shielded composite cable through the top-right M16

cable gland (item 2 in the figure “MIC PSU Enclosure, with cable glands identified”).

Figure 11.5: MIC PSU Enclosure, with cable glands identified

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 37

MIC440 Explosion-protected Camera Install the MIC Power Supply Unit (PSU) | en 37

Number Description Cable Gland Size

1 Optical Video out M12

2 Composite cable M16

3 Optional switched video output M12

4 Head-end / Telemetry controls M12

18. Connect the shielded composite cable to terminal block HD3 (and, if necessary, HD6 and

HD7) following the color coding as shown in the figure below, and printed on the PCB.

No.ID, Connection/

Terminal + Pin

PCB Mark,

Signal

Description/Function of Connection PCB Mark,

Cable Color

1 HD3-1 Power Low Voltage Power (Input 1) / AC supply Red

2 HD3-2 Power Low Voltage Power (Input 2) / AC supply return Green

3 HD3-3 RxB Telemetry I/O to RS-422/485 [Rx +]

White

Full Duplex RxB/Half Duplex Tx/RxB

4 HD3-4 RxA Telemetry I/O to RS-422/485 [Rx -] Full Duplex

Yellow

RxA/Half Duplex Tx/RxA

5 HD3-5 0v Ground [Drain Wire / Shield] Screen (Black)

6 HD3-6 TxA Telemetry I/O to RS-422/485 [Tx -] Full Duplex

Blue

TxA

7 HD3-7 TxB Telemetry I/O to RS-422/485 [Tx +] Full Duplex

Violet

TxB

8 HD3-8 Video Video output of optical camera to Control Room

Core

(Coax - BNC CN1)

9 HD3-9 Video 0V Video signal return (optical camera) (ground to

Screen

Control Room) (Coax - BNC CN1)

10 HD3-10 Tamp Sw [Optional] Tamper Switch Black

11 HD3-11 Wash [Optional] Washer Drive Signal Orange

12 HD6-1 AUX1 [Optional] Auxiliary Connection (heater) Brown

13 HD6-2 AUX2 [Optional] Auxiliary Connection (heater) Grey

14 HD7-1 -- Video Switched Output to Control Room

Core (Black)

(Switched visible/thermal video out signal)

15 HD7-2 -- Switched video signal ground Screen (Black)

Notice!

MIC440 cameras do not have an internal heater.

19. Slide back the cable so that the shield is in the middle of the gland.

20. Tighten the cable gland so that it grips firmly the shielded composite cable. It is important

that the braided cable screen engages with the internal clamps of the cable gland to ensure

correct EMC protection.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 38

38 en | Install the MIC Power Supply Unit (PSU) MIC440 Explosion-protected Camera

21. If necessary, connect a tamper switch to terminal block HD2.

22. Make the necessary video connections. Feed the coaxial cable of your choice--see the table

below to identify the recommended cable types, maximum distance, and other specifications

for the coax video connection between the MIC power supply and the head-end control

system--through the top-left M12 cable gland (item 1 in the figure “MIC PSU Enclosure, with

cable glands identified”).

Cable Type; Maximum

Distance

RG-59/U; 300 m (1000 ft)

RG-6/U; 450 m (1500 ft)

RG-11/U; 600 m (2000 ft)

Size O.D. between 4.6 mm (0.181 in.) and 7.9 mm

(0.312 in.)

Shield Copper braid: 95%

Central Conductor Standard copper center

23. Crimp the end of the cable with a BNC terminal connector.

24. Connect the Video Out cable to BNC socket CN1.

25. Feed telemetry cable through the bottom-right M12 cable gland (item 4 in the figure “MIC

PSU Enclosure, with cable glands identified”).

26. Connect head-end RS-485 control to terminal block HD5, as indicated in the table below:

PCB Marking

Telemetry Signal Name Connection Description / Function Pin Number

(non-IR PCBs)

RxB Rx + RS485+ to camera 1

RxA Rx - RS485- to camera 2

0V Ground 0V from control room 3

TxA Tx - RS485- to control room 4

Note: The terminal block is positioned with the screw terminals on the left, next to the fuses.

Pins are numbered from top to bottom in that orientation. Non-IR PSU PCBs are marked.

27. If connecting to additional add-on cards (for example, a card for 8-input alarms (MICALM), and/or a Biphase card (MIC-BP4)), remove the second blanking plug that covers one of

the holes for an M12 cable gland (item 3 in the figure “MIC PSU Enclosure, with cable glands

identified”). Attach the supplied M12 gland. Make the appropriate connections to plug-in

terminal CN2.

Notice!

For installation of the MIC 8-input Alarm Card (MIC-ALM) or Biphase converter (MIC-BP4),

please refer to their respective manuals.

TxB Tx + RS485+ to control room 5

28. After wiring is complete, connect the power supply to the power source.

29. Verify that the following LEDs are lit:

LED Description

LED 2 18 VAC power on to camera

LED 4 Power on for optional heater

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 39

MIC440 Explosion-protected Camera Install the MIC Power Supply Unit (PSU) | en 39

LED Description

LED 3 18 VAC power on camera

LED 5 Power on for optional heater

30. Re-attach the enclosure lid and tighten the four (4) captive screws on the cover to ensure

that the enclosure is watertight.

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 40

!

40 en | Fit the Optional Sunshield (MIC440) MIC440 Explosion-protected Camera

12

Fit the Optional Sunshield (MIC440)

The MIC440 Sunshield is designed to provide additional protection against direct solar

radiation by reflecting solar exposure and creating an insulating gap between the environment

and the surface of the camera. It is a two (2) part moulding and comes supplied with four (4)

stainless steel set screws.

Caution!

DO NOT REMOVE the lid from the camera, and do not back drive the pan or tilt axis manually.

Doing so will void the warranty. Back driving may also strip teeth off the internal gears.

To fit the sunshield, follow these steps:

1. Turn on the power to the camera so that you can rotate the camera head up to fit the

bottom half of the sunshield (steps 2 through 4).

2. Rotate the camera under power--do not rotate by hand--until the bottom of the camera

head is facing up.

3. Align the 4 posts/alignment tabs and the two screw holes of one piece of the sunshield

with the corresponding posts and holes on the camera head. Push the sunshield until it

fits snugly onto the camera head.

4. Place two of the socket head screws into the screw holes. Fasten the screws with a Torx

wrench.

5. Rotate the camera under power--do not rotate by hand--until the top of the camera head

is facing up.

6. Repeat steps three and four for the second half of the sunshield. When fitted properly,

both halves of the sunshield should align and meet at the back of the camera head.

Figure 12.1: Sunshield and Screws being placed

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 41

MIC440 Explosion-protected Camera

Fit the Optional Sunshield (MIC440) | en 41

Figure 12.2: Side View of Fitted Sunshield

Figure 12.3: Back View of Fitted Sunshield

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 42

42 en | Connection MIC440 Explosion-protected Camera

13

13.1

13.2

Connection

Connection Overview

Connecting and configuring MIC cameras

To configuration and operate/control the camera, you will need a computer, either an RS-232

to RS-485 adapter or a USB to RS-485 adapter, and the MIC Series Universal Camera Setup

Software (“Camset”). The Camset software is provided on the CD that comes with each

camera. Refer to the Universal Camera Setup Software User Guide for details.

Typically the RS-232/RS-485 adapter is connected to a serial port on a computer. The port will

generally be assigned to Comm Port 1.

If your computer does not have a serial port, you can use the MIC-USB485CVTR2 converter to

connect to the MIC power supply, or you can use the camera’s on-screen menu function.

Connecting the USB to RS-485 Converter

Connecting the USB to RS-485 Converter

Figure 13.1: MIC-USB485CVTR2 (USB to RS-485 signal converter)

The MIC-USB485CVTR2 is a USB to RS-485 signal converter that allows computers without a

serial port to connect directly to the MIC camera via the telemetry header connection (HD4) in

the power supply using standard twisted pair cable such as Belden 8760. The MICUSB485CVTR2 can also be used to connect a PC to any other RS-485 device. The converter is

usually mapped to Comm port 3 or 4.The MIC-USB485CVTR2 has been designed to work with

all functions in Universal Camset and to be backwards-compatible with legacy versions of

Camset, although full compatibility is not guaranteed. Refer to the MIC Series USB485CVTR2

User Guide for more details.

The figure below illustrates how the screw terminal connections on the MIC-USB485CVTR2

connect to the MIC power supply. Depending on the protocol and selected communication

mode, you may only need a 2-wire configuration.

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 43

MIC440 Explosion-protected Camera Connection | en 43

Figure 13.2: MIC-USB485CVTR2 to MIC Series Power Supply Unit Telemetry Header Cable

Number Color Converter

Output

Number Color Telemetry Header

(HD4 or HD5)

Communication Mode

in Power Supply

1 Black RxB/Rx - 6 Black TxB

2 Red RxA/Rx + 7 Red TxA

Full Duplex (4-wire only)

3 (Shield) GND/0V 8 (Shield) GND Shield (always)

4 Green TxA/Tx - 9 Green RxA Simplex

5 White TxB/Tx + 10 White RxB

Hall Duplex (2-wire)

Full Duplex (4-wire)

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 44

44 en | Configuration MIC440 Explosion-protected Camera

14

14.1

Configuration

Addressing the Camera

Addressing the camera using Bosch protocol with Camset 4.12.00.06

The camera accepts a custom string of commands that change the camera address. The

following procedure uses hexadecimal numbers to identify the camera address. Bosch

recommends using a calculator with a decimal to hexadecimal converter to obtain the correct

hexadecimal value for the address. (The Calculator included with Microsoft Windows

operating systems contains a converter in the Programmer mode).

1. Launch Camset 4.12.00.06 and ensure that you can control camera.

2. Select Send Custom Command from the Advanced Setup menu.

3. Type the following string to send the AUX ON 14 command: 07,01,0E

4. Click the Send Now button.

5. Type the following string to send the AUX ON 21 command: 07,01,15

6. Click the Send Now button.

7. Type the following string to send the AUX OFF 21 command: 07,02,15

8. Click the Send Now button.

9. Type the following string to send the AUX OFF “new address” command and to set the

camera address: 07,02,xx

where “xx” is the hexadecimal address for the camera. For example, use “AB” to set the

camera address to 171.

4 Click the Send Now button. The camera address is set.

14.2

Configuring the Camera for Inverted Operation

The video display from a camera installed in inverted position will appear upside down until

you set the video orientation to “Inverted position.” Follow these steps:

1. Access the main Setup Menu of the on-screen display (OSD). The screen Setup Menu

appears.

2. Select the submenu “PTZ Setup.” The screen PTZ Setup appears.

3. Select the option “Orientation.”

4. Select the value “Inverted,” which rotates the video 180°. The video should now appear

upright.

2013.11 | 8.1 | Operation Manual Bosch Security Systems, Inc.

Page 45

MIC440 Explosion-protected Camera Operation | en 45

15

Aux Function Description (MIC function)

1 Focus Control On: Enables Manual Focus

2 Digital Zoom Enable On: Digital Zoom is enabled

3 Iris Control On: Enables Manual Iris

4 Auto Lowlight On: Enables Auto Lowlight, Decrease frame rate for low light conditions

5 Wiper On: Wiper On

6 Washer On: Washer On

7 Proportional PTZ On: Enabled, Pan and Tilt Speed is scaled according to Zoom position

Operation

For operation of the MIC440, refer to the tables below for the list of support protocols and

commands.

Off: Disables Manual Focus => Auto Focus

Off: Digital Zoom is disabled

Off: Disables Manual Iris => Auto Iris

Off: Disables Auto Lowlight, Returns to Auto Iris

Off: Wiper Off

Off: Washer Off

Off: Disabled, Normal PTZ

8 IR Lamps On: Switches IR Cut Filter & Lamps On

Off: Switches IR Cut Filter & Lamps Off

9 Camera Power On: Video Output from Sony Camera module is enabled

Off: Video Output from Sony Camera module is disabled

10 Backlight On: Backlight On

Off: Backlight Off

11 B&W On: Black & White Mode

Off: Color Mode

12 OSD On: Shows Sony camera module On-Screen-Display

Off: Hides Sony camera module On-Screen-Display

13 Shutter Speed (1/2 s) On: Sets Shutter Speed to 1/2 s (fixed)

Off: Returns to Auto Iris

14 Address Change Stage1On: Sets variable for Address Changing -> must call Aux 21 On, to continue

Off: Clears variable for Address Changing

SEE NOTE 1.

15 Pan Reverse On: Pan direction is reversed

Off: Pan direction is normal

16 Auto Alarm On: Enables Auto Alarm

Off: Disables Auto Alarm

Bosch Security Systems, Inc. Operation Manual 2013.11 | 8.1 |

Page 46

46 en | Operation MIC440 Explosion-protected Camera

17 Preset Tour On: Starts Preset Tour (Either 5 or 10 Presets & dwell time as programmed)

Off: Programs Preset Tour to include Presets 1 to 5 with a 5 sec dwell time

Presets must be individually saved using either Camset LEARN or controller

SET.

18 Preset Tour On: Programs Preset Tour to include Presets 1 to 5 with a 15 sec dwell

Off: Programs Preset Tour to include Presets 1 to 5 with a 60 sec dwell

19 Preset Tour On: Programs Preset Tour to include Presets 1 to 10 with a 5 sec dwell

Off: Programs Preset Tour to include Presets 1 to 10 with a 15 sec dwell

20 Preset Tour On: Programs Preset Tour to include Presets 1 to 10 with a 60 sec dwell

Off: Same as On.

21 Address Change Stage

2&3

On: Sets variable for Address Changing -> must call Aux 21 Off, to continue

Off: Sets variable for Address Changing -> next Aux {A} Off, {A} is new

address.

SEE NOTE 1.

22 Auto Home (Inactivity) On: Auto home enabled, will return to home position after idle for 300

seconds.

Off: Auto home disabled

23 White Balance On: Auto White balance

Off: Outdoor White balance

24 Auto IR On: Enables Auto IR, camera module switches to IR mode automatically

(Auto Night Mode)

Off: Disables Auto IR

25 Washwipe On: Enables Washwipe, camera moves to Washwipe position on Washer On