Bosch MIC440AXWUW14636N, MIC440AXWUW14618N, MIC440AXWUP14618N, MIC440AXWUL14636N, MIC440AXWUA14636N User Manual

...Page 1

MIC440 Explosion Protected

CCTV Camera System

Bosch Security Systems

EN Installation and Operation Manual

Page 2

MIC440 Explosion Protected CCTV

Camera System

Installation and Operation Manual

For the MIC440 Camera System

Chapters

1. Introduction

2. Hardware Installation

3. Power Supply Installation & Setup

4. Configuring the MIC440 Camera

5. Technical Specifications

Page 3

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 3

Introduction............................................................... 1-6

MIC440 Camera Options..................................................................... 1-7

MIC440 Power Supply Versions……………………………………….... 1-7

Unpacking............................................................................................ 1-8

Package Contents............................................................................... 1-8

Installation Accessories....................................................................... 1-9

Hardware Installation................................................ 2-10

Preinstallation Preparation in the Workshop……………………..…….. 2-11

Cable Gland and Cable Mounting Instructions………..……………….. 2-11

Camera Installation Instructions........................................................... 2-11

Electrical Connections to the MIC440.................................................. 2-12

Earthing Instructions............................................................................ 2-13

Lightning Protection............................................................................. 2-13

Maintenance….……………..……………………………………….…….. 2-13

Onsite Inspection..…………………….................................................. 2-13

Power Supply Installation and Setup…..................... 3-14

Hazardous Area Power Supply Installation………..…………………… 3-14

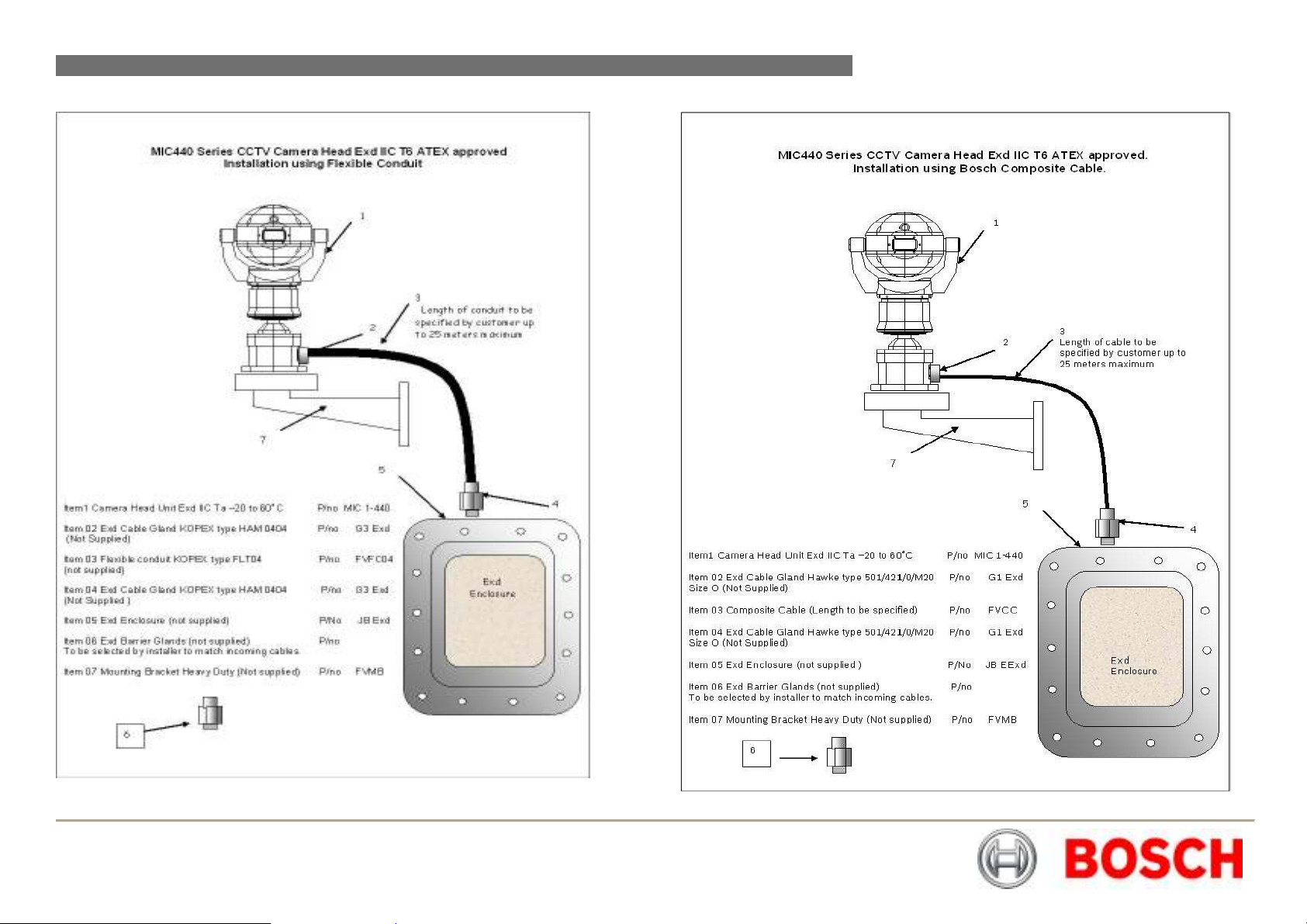

Diagrams of example Hazardous Area Installations…………………... 3-15

Non Hazardous area Power Supply Installation........................……… 3-16

Connecting the MIC-240, MIC-24 and MIC115PSU….……………….. 3-17

Power Supply Layout and Connections............................................... 3-18

PCB Earth Link………......................................................................... 3-18

Fuse Ratings………………………………………….............................. 3-18

MIC-12PSU….…………………………................................................. 3-19

MIC-12PSU Power Supply Layout and Connections........................... 3-19

Optional Cards and Kits for the MIC440………………………………... 3-20

Configuring the MIC440 Camera……………………. 4-20

Connecting the MIC440 to a PC.......................................................... 4-20

Connecting the Greenwich adaptor……………………………………... 4-20

Connecting the K2-ADE Adaptor………………………………………... 4-21

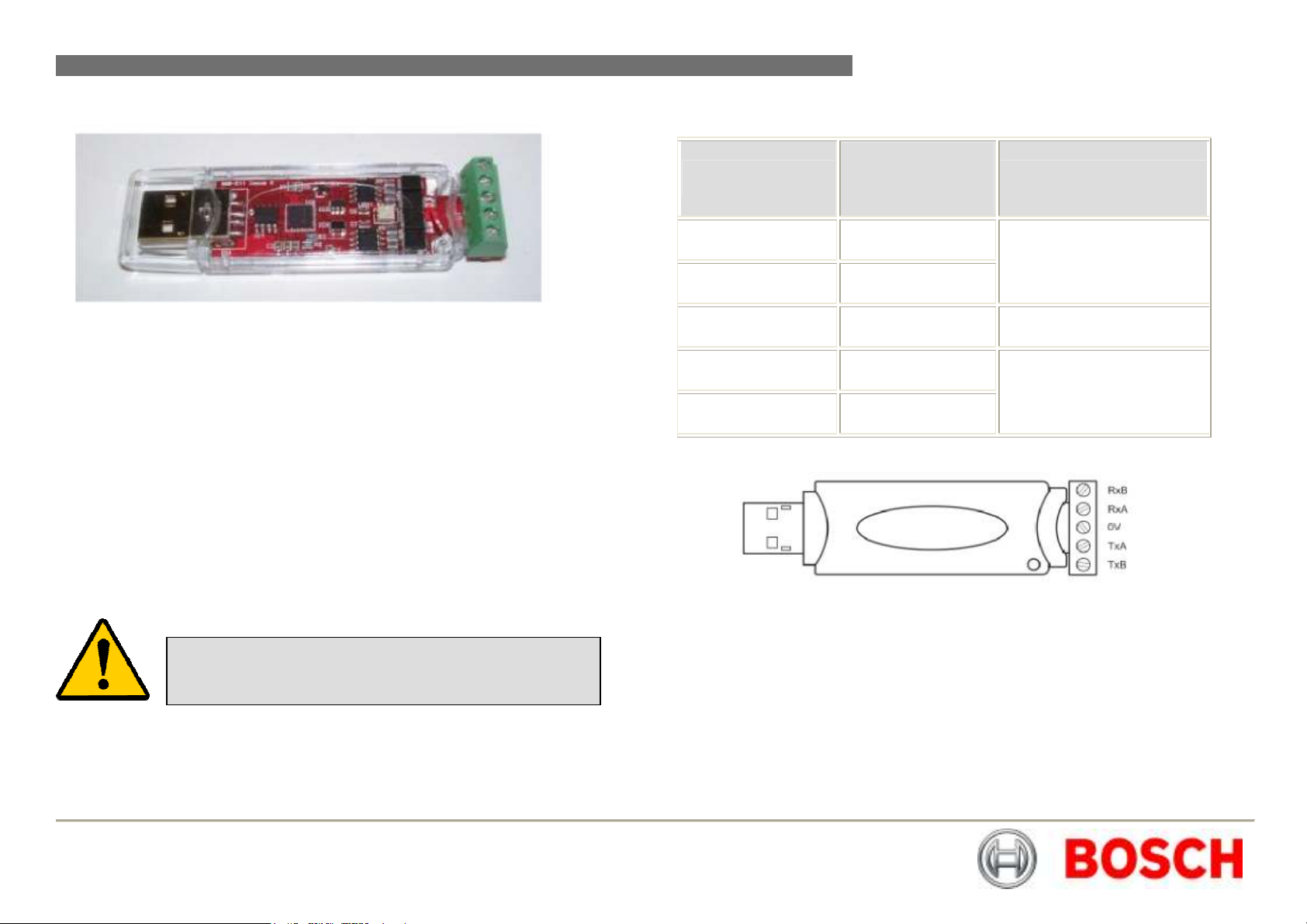

Connecting the MIC-USB485 Converter……………………………….. 4-22

MIC-USB485 Converter and Universal Camset Software Installation. 4-22

Commissioning the MIC440 camera with Universal Camset………… 4-23

Standard Controls

Boot Messaging…………………………………………………………… 4-24

.

………………………………………………………… 4-23

MIC Settings……………………………………………………………….. 4-24

Camset Settings…………………………………………………………… 4-25

Manual Control.…………………………………………………………… 4-26

Pan, Tilt and Zoom Controls…………………………………………….... 4-26

Iris Controls………………………………………………………………… 4-26

Focus Controls…………………………………………………………….. 4-26

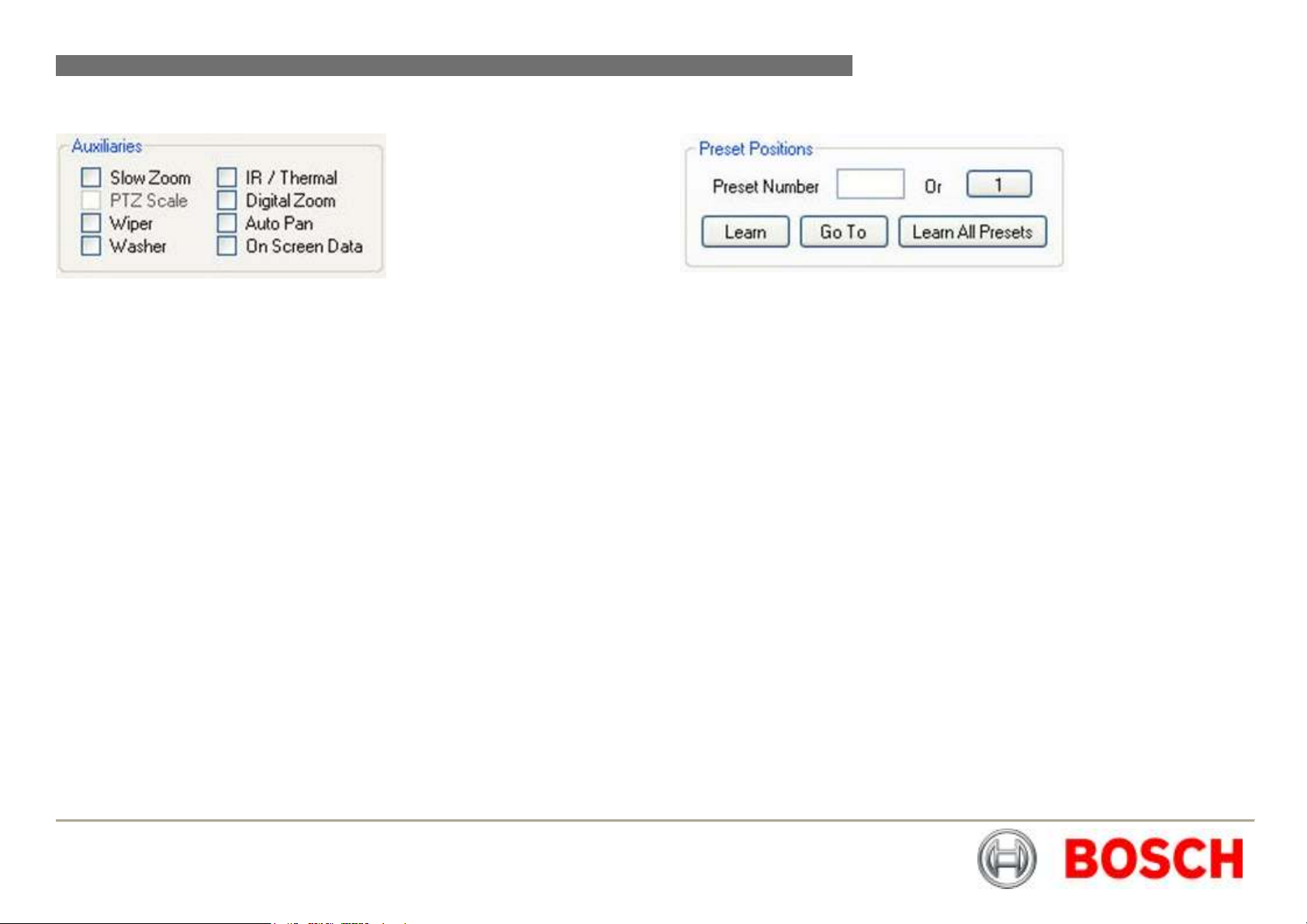

Auxiliaries………………………………………………………………….. 4-27

Preset Positions…………………………………………………………… 4-27

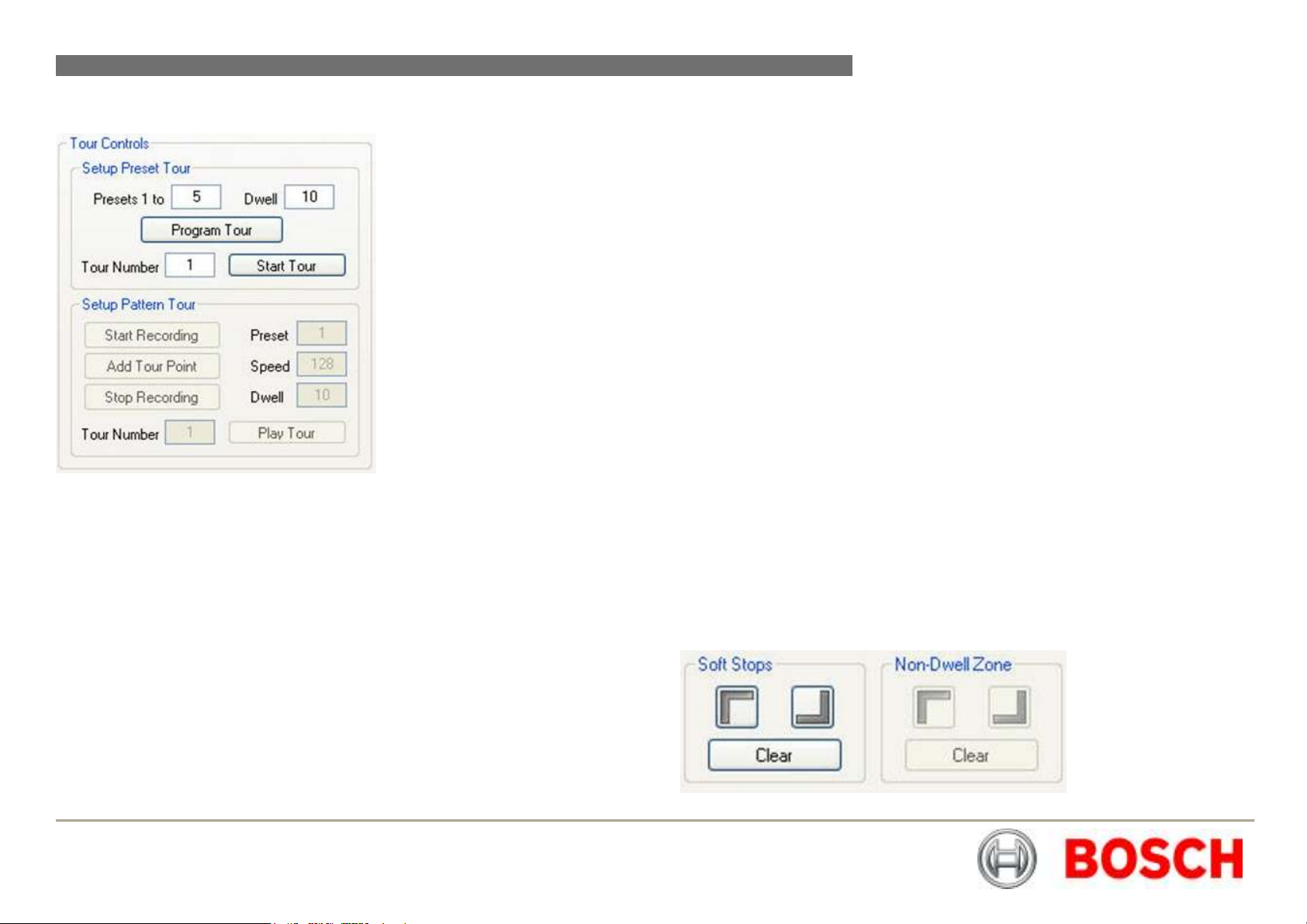

Tour Controls………………………………………………………………. 4-28

Softstops and No Dwell Zones…………………………………………… 4-28

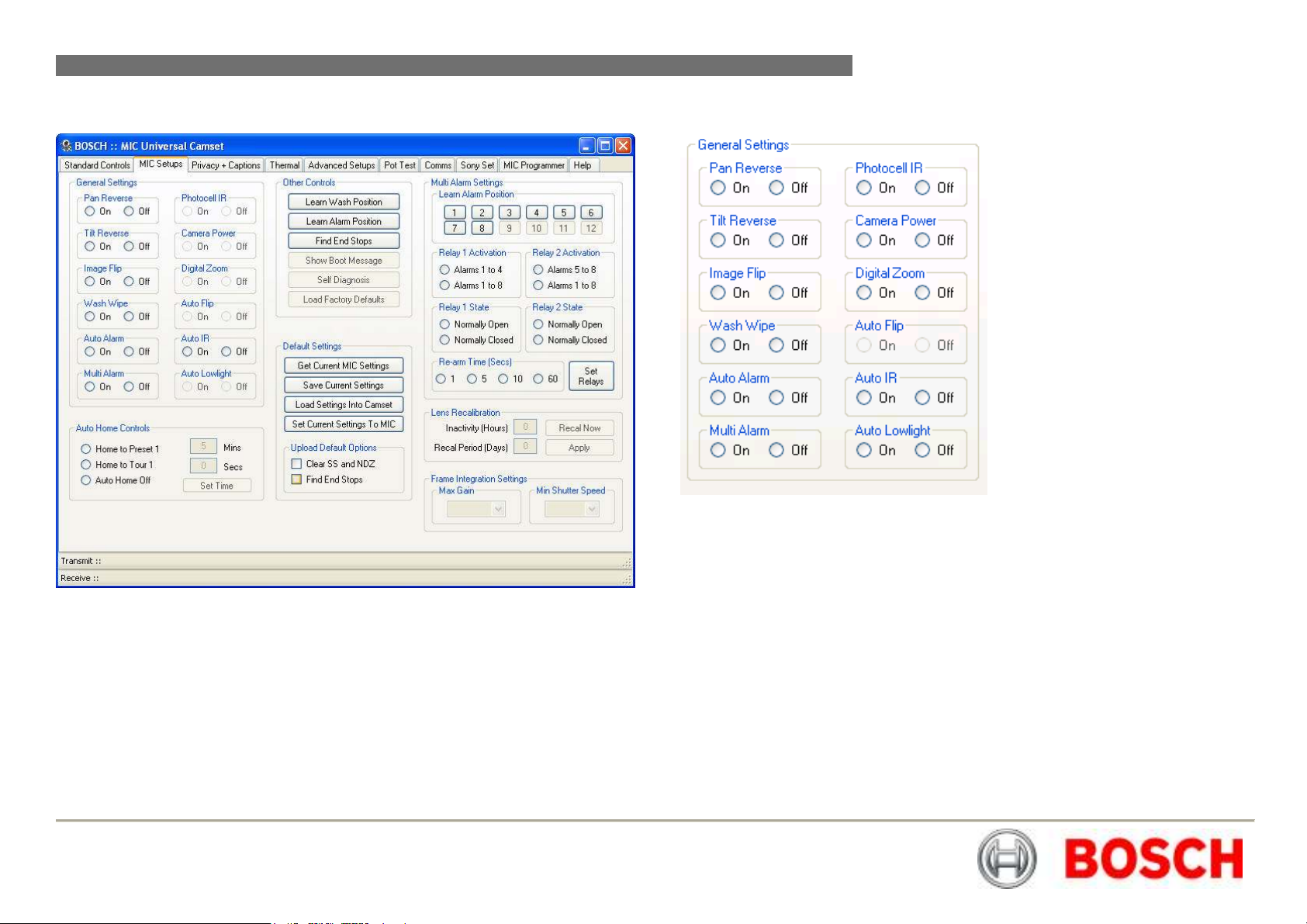

MIC Setups………………………………………………………………… 4-29

General Settings…………………………………………………………… 4-29

AutoHome Controls……………………………………………………….. 4-30

Other Controls……………………………………………………………… 4-31

Default Settings……………………………………………………………. 4-31

MultiAlarm Settings……………………………………………………….. 4-32

Lens Recalibration and Frame Integration……………………………… 4-33

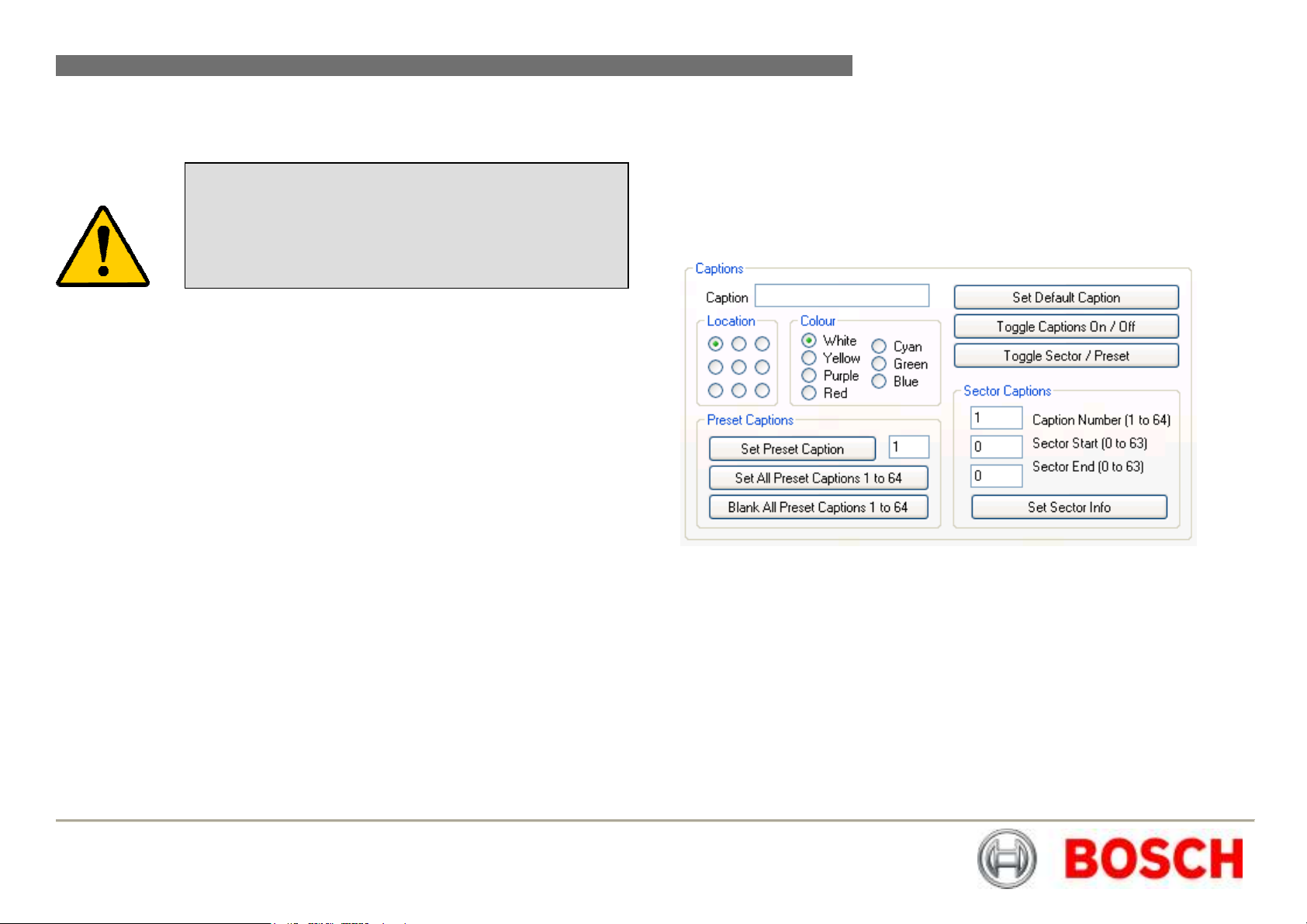

Privacy and Captions……………………………………………………… 4-33

Privacy Controls…………………………………………………………… 4-34

Captions……………………………………………………………………. 4-35

Thermal…………………………………………………………………….. 4-36

Advanced Settings………………………………………………………… 4-37

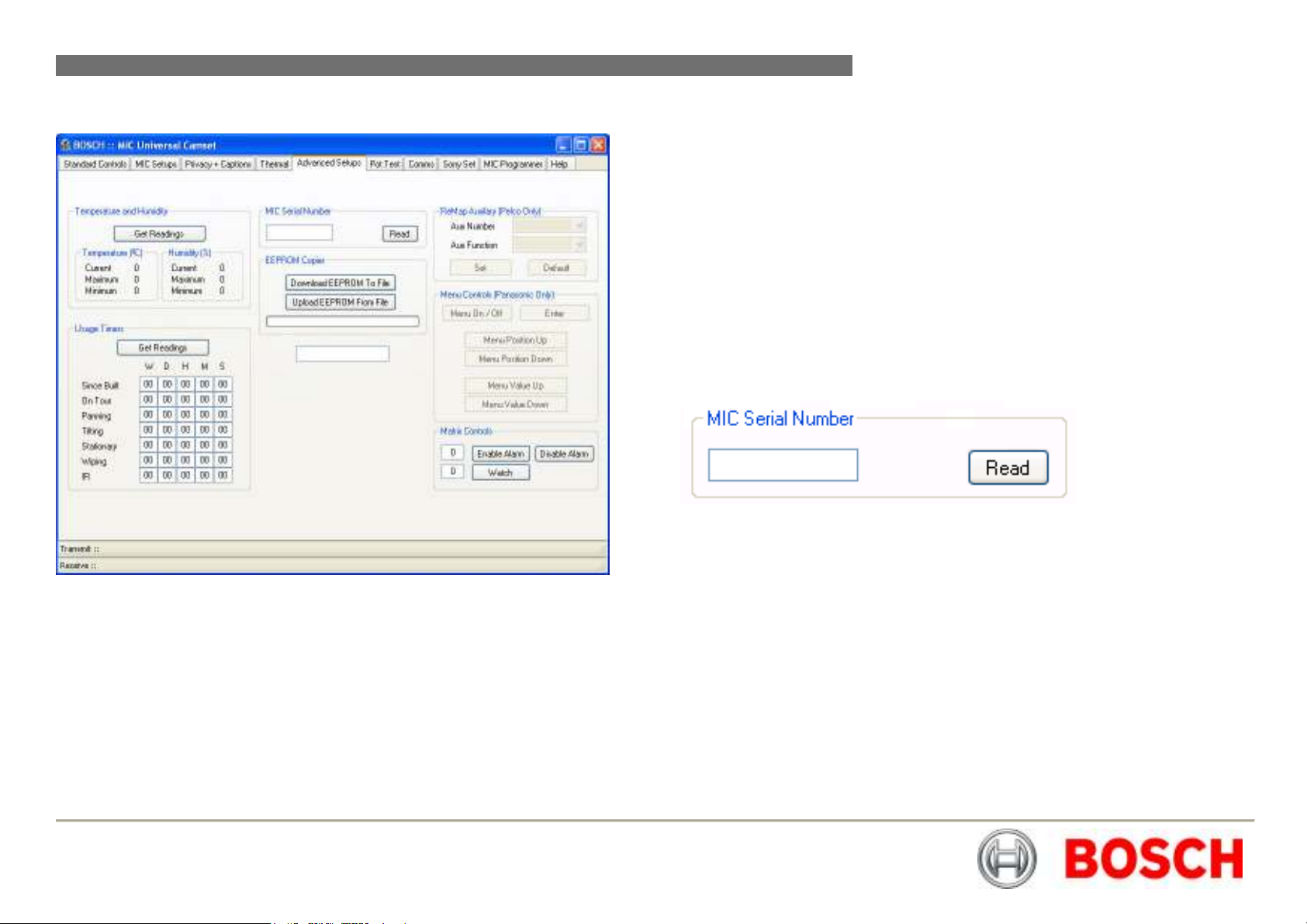

MIC Serial Number………………………………………………………… 4-37

EEPROM Copier…………………………………………………………… 4-38

Re-Map Auxiliary (Pelco Protocol Only)…………………………………. 4-38

Menu Control (Panasonic Protocol Only)……………………………….. 4-39

Matrix Controls……………………………………………………………… 4-39

POT Test……………………………………………………………………. 4-39

POT Test Controls…………………………………………………………. 4-40

POT Test Results…………………………………………………………. 4-41

Comms…………………………………………………………………….. 4-41

Send Direct Command…………………………………………………… 4-42

Communications Testing…………………………………………………. 4-42

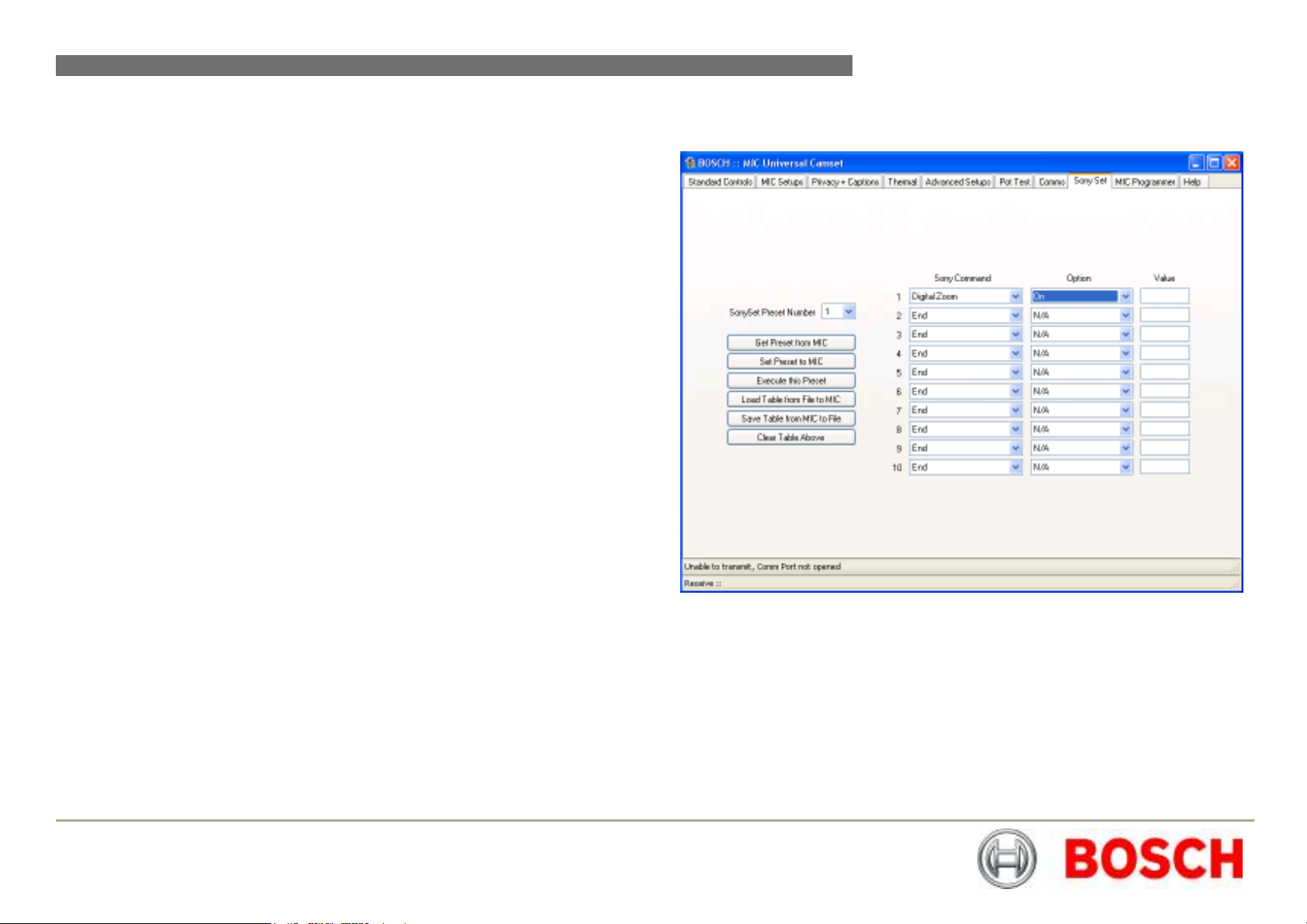

SonySet…………………………………………………………………….. 4-43

SonySet Controls………………………………………………………….. 4-44

The SonySet Table………………………………………………………... 4-45

MIC Programmer…………………………………………………………... 4-46

Technical Specifications.......................................... 5-47

Technical Specifications…………………………………………………. 5-47

Bosch Security Systems Issue 6

Page 4

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 4

The following symbols are used throughout this manual please pay careful

attention to their meaning.

Safety Precautions

The lightning flash with an arrowhead symbol within a triangle

is intended to alert the user to the presence of non-insulated

“dangerous voltage” within the product’s enclosure that may

be of sufficient magnitude to constitute a risk of electric shock

The exclamation point within a triangle is intended to alert the

user to the presence of important safety, operating and

maintenance (servicing) instructions in the literature

accompanying the appliance.

Important Safety Instructions

CAUTION

TO REDUCE THE RISK OF ELECTRICAL SHOCK,

DISCONNECT POWER SUPPLY BEFORE OPENING THE

POWER SUPPLY UNIT.

POWER DISCONNECT: POWER SUPPLY UNITS HAVE

POWER SUPPLIED WHENEVER THE POWER CORD IS

INSERTED INTO THE POWER SOURCE

WARNING

INSTALLATION SHOULD BE CARRIED OUT BY QUALIFIED

PERSONNEL ONLY IN ACCORDANCE WITH THE

APPLICABLE LOCAL CODES.

BOSCH SECURITY SYSTEMS ACCEPT NO LIABILITY FOR

ANY DAMAGES OR LOSSES CAUSED DUE TO

INCORRECT OR IMPROPER INSTALLATION

Bosch Security Systems Issue 6

Page 5

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 5

recycling this equipment.

IMPORTANT SAFETY INSTRUCTIONS

1. Read and keep these instructions

2. Heed all warnings and Follow all instructions

3. Do not install near any strong heat sources such as furnaces

4. Do not back-drive the pan or tilt axis of the camera. To do so will damage

the motor drive gear chain and will invalidate the warranty

5. Do not use caustic or abrasive cleaning products on the unit

6. Do not point the MIC440 camera at the sun. BOSCH Group will not be liable

for any damages to cameras which have been directly pointed at the sun

7. In situations where there could be a risk of injury should any part of the

assembly become detached for any reason and fall, normal common sense

safety precautions should be employed; a strong safety chain between the

camera pan shaft and the mounting surface is recommended

8. For transportation please rotate the ball so the window points towards the

base, this helps to protect the wiper & windows during transit

9. Ensure that the product case is properly earthed. If the product is likely to

be struck by lightning, ensure that earth-bonding connections are made

correctly to the mounting base of the unit

10. Use only the power sources indicated in this user guide and ensure that the

current rating of supply cables, fuses and overload protection devices are

adequate for the product.

11. The product is certified for use within the ambient temperature range of

-20C to +60º C and must not be used outside this range.

12. This product must only be installed by suitably trained personnel in

accordance with the relevant code of practice (e.g. EN60079-14:1997).

These instructions are intended for their sole use.

13. All installation work should be carried out in accordance with the relevant

local and national standards.The unit shall only be installed and brought into

service using the operating parameters defined in these instructions and in

the technical specifications.

14. There are no user serviceable parts and on line maintenance is not required

for this product.

15. Inspection and maintenance of this equipment must be carried out by

suitably trained personnel in accordance with the applicable code of

practice e.g. EN 60079-17.

16. Repair of this equipment must be carried out by suitably trained personnel

in accordance with the applicable code of practice e.g. EN 60079-19.

17. Units must carry the following certification marking.

WARNING

NO REPAIRS REQUIRING OPENING THE PRODUCT

CASING WHILST IN A HAZARDOUS AREA ARE

ALLOWED.

FAILURE TO OBSERVE THIS PRECAUTION WILL VOID

THE CERTIFICATION AND WARRANTY.

BOSCH SECURITY SYSTEMS ACCEPTS NO LIABILITY

FOR LOSSES CAUSED BY INCORRECT INSTALLATION

Please contact BOSCH Security Systems for details of approved repair centres.

This product complies with the following EC directives:-

EMC Directive (89/336/EC as amended)

Machinery Directive (98/37/EC)

LV Directive (73/23/EC)

RoHS (Restriction of Hazardous Substances) 2002/95/EC

WEEE (Waste Electrical & Electronic Equipment) 2002/96/EC

This equipment contains electrical or electronic

components that must be recycled properly to comply with

Directive 2002/96/EC of the European Union regarding the

disposal of waste electrical and electronic equipment

(WEEE). Contact your local supplier for procedures for

This product is designed for use with flammable gases and vapors

covered by apparatus groups IIA, IIB and IIC and with temperature

classes T1 to T6.

SIRA05ATEX1300X Exd IIC T6 Ta –20ºC to +60ºC Gb

Bosch Security Systems Issue 6

Page 6

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 6

Reference

Glossary of Terms

PTZ - Pan/Tilt/Zoom

Bi-phase - Bosch Bi-phase telemetry protocol

PSU - Power Supply Unit

IR - Infra Red

BP 4 - Bi-phase converter cards for MIC400 cameras

STP - Shielded Twisted Pair cable

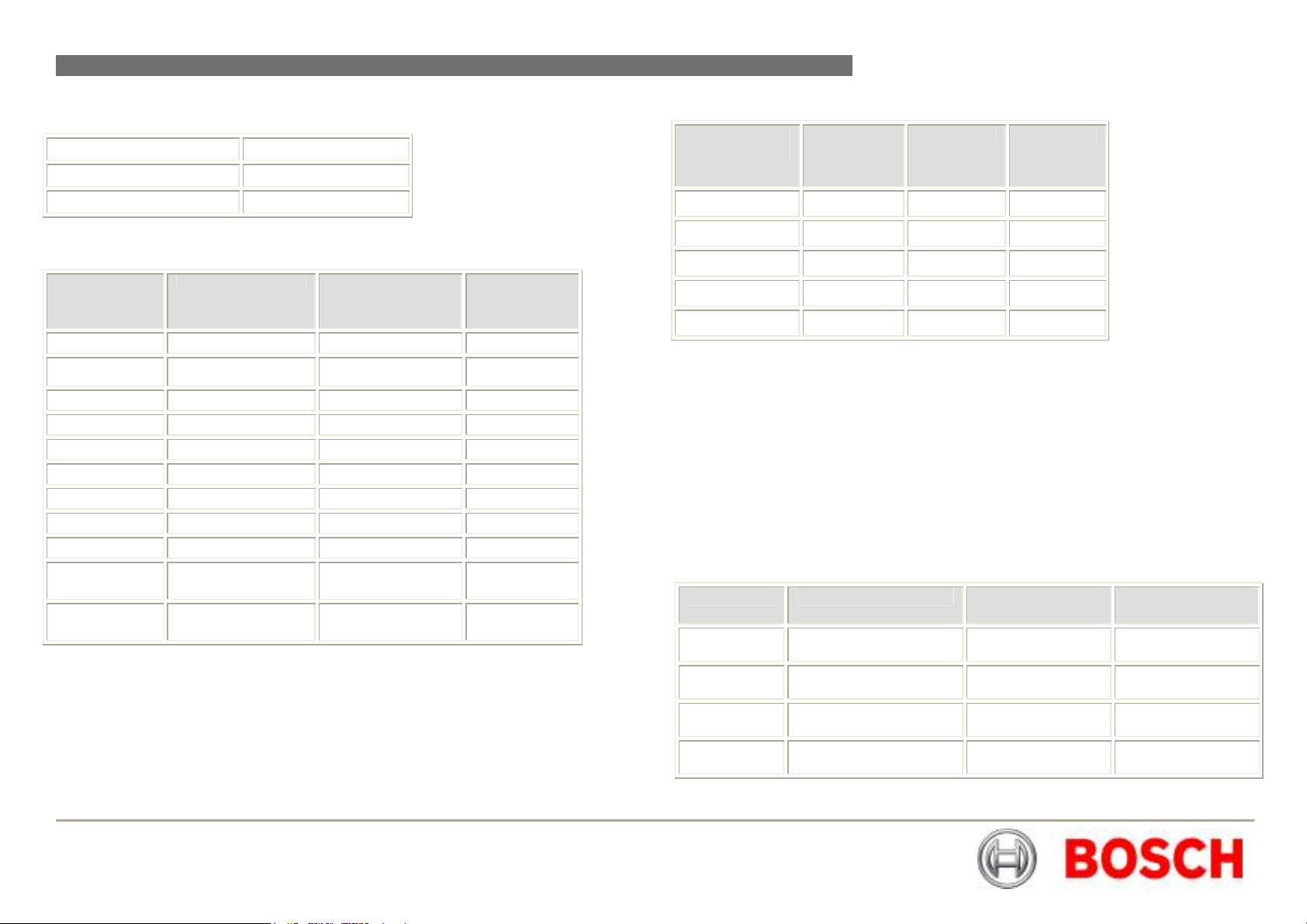

Glossary of Tables

Table A (Pg7) - Flamepath Tolerance table

Table B (Pg12) - MIC composite cable pin table

Table C (Pg18) - Power connection to Header HD1

Table D (Pg18) - Composite cable to Power Supply HD-3

Table E (Pg18) - Telemetry Connections to HD3, HD4 and HD5

Table F (Pg18) - Fuse ratings for MIC-240PSU, MIC-24PSU, MIC-115PSU

Table G (Pg19) - Power Input wiring connections for MIC-12PSU - HD1

Table H (Pg20) - Connecting the Greenwich Adaptor

Table I (Pg21) - DIP Switch Settings for K2-ADE 2 wire mode

Table J (Pg 21) - K2-ADE Adaptor Connection

Table K (Pg21) - Camera Interface Control Settings

Table L (Pg22) - MIC-USB485CVTR Connection table and Diagram

Table M (Pg45) - Sony Set Commands

Appendices

Appendix A (Pg49) - Protocol Preset Commands

CHAPTER 1

The MIC440 is a complete PTZ camera head system specifically designed for use

in hazardous areas and is rated up to IIC T6 classification. The robust construction

in aluminium makes it ideally suitable for the petrochemicals industry and other

demanding environments.

The unit is designed to be plug and play making it easy to install, giving

considerable reductions in installation and maintenance costs.

To bring the unit into service, use only assembling, and adjustment equipment as

described in the text and diagrams contained in this instruction manual.

The certification of this equipment depends upon the maintenance of the

flamepaths (see note and table) and the use of the following materials in the

construction.

The maximum constructional gaps (Ic) of the cylindrical flamepaths are less than

that required by Table A of EN 60079-1:2007 are as detailed below:

The pan body to pan body top are to be secured with cap head M5 - 0.8 x 10 mm

long S316 stainless steel grade A4/70 special fasteners.

All exposed parts: Aluminium (BS-EN755 1997 6082T6)

Stainless Steel (BS-EN10088 No.1.4404)

If the equipment is likely to come into contact with aggressive substances, then it is

the responsibility of the user to take suitable precautions that prevent it from being

adversely affected, thus ensuring that the type of protection provided by the

equipment is not compromised.

Aggressive substances: e.g. acidic liquids or gases that may attack metals, or

Suitable precautions: e.g. regular checks as part of routine inspections

Units must carry the following certification marking.

Introduction

solvents that may affect polymeric materials.

or establishing from the material’s data sheets

that it is resistant to specific chemicals.

SIRA05ATEX1300X Exd IIC T6 Ta –20ºC to +60ºC Gb

Bosch Security Systems Issue 6

Page 7

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 7

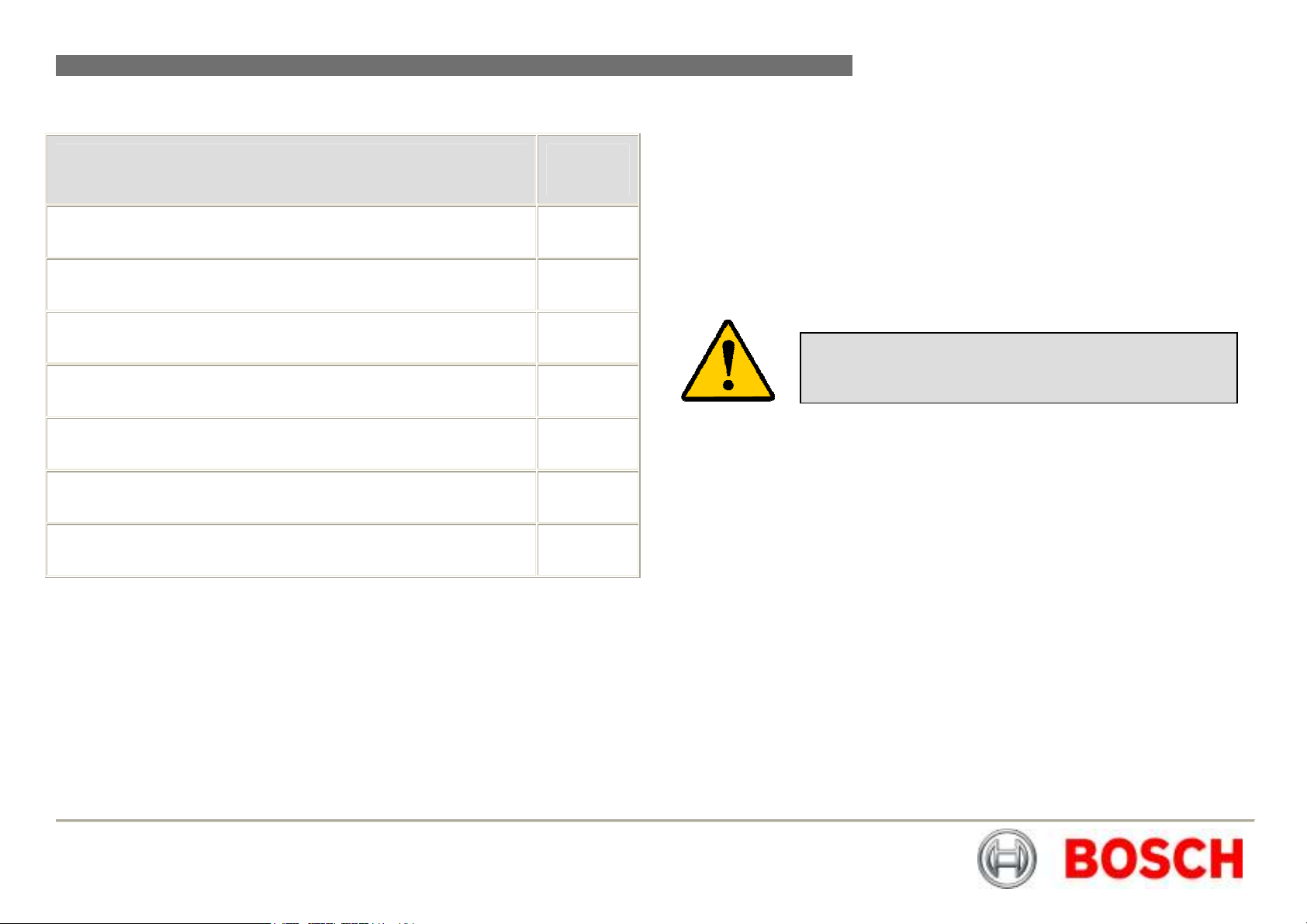

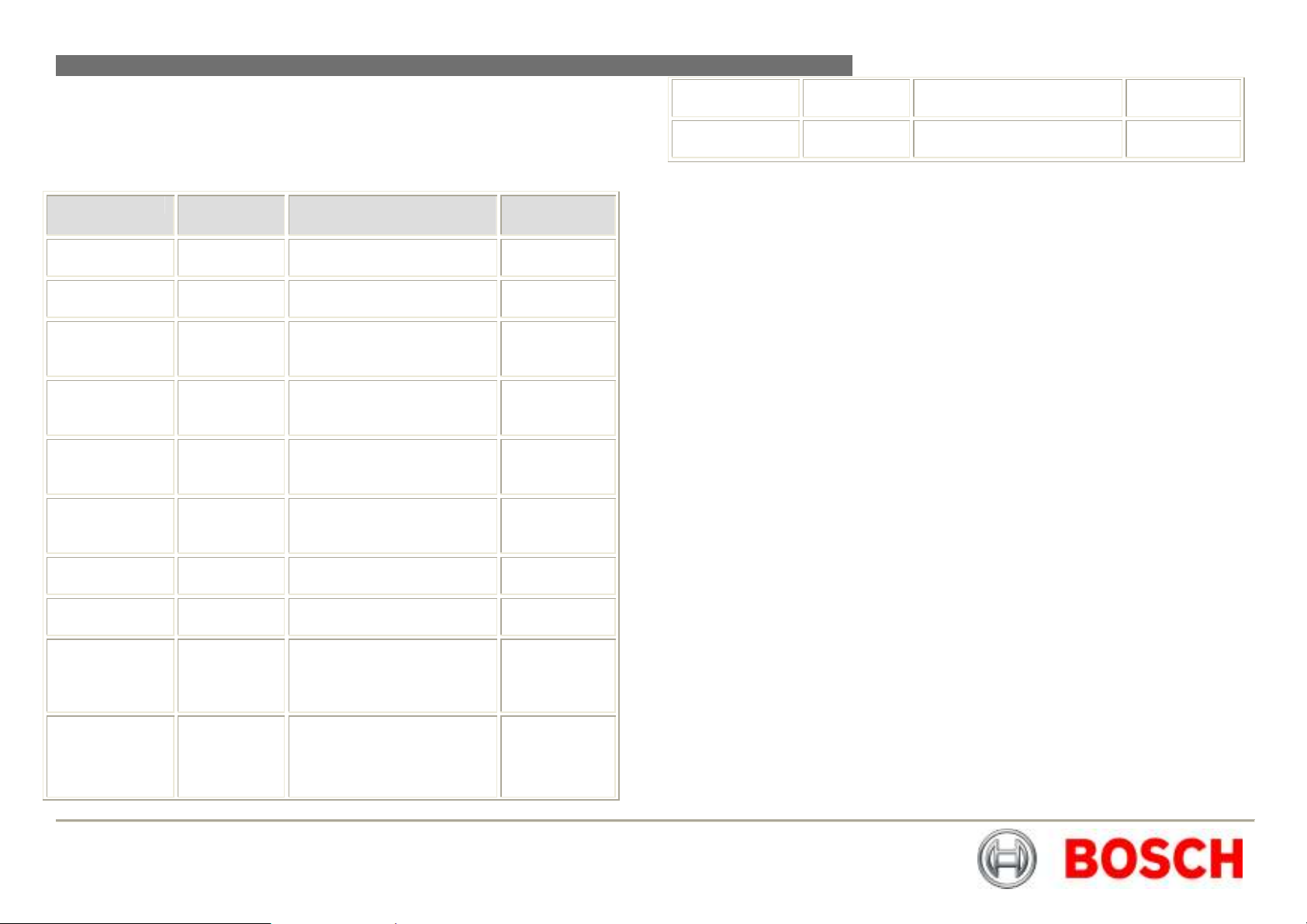

Table A – Constructional Flamepath Tolerances

Flamepath Maximum

Gap (mm)

Between the tilt centre bore and tilt bearing housing shaft (2 off) 0.089

Between the yoke arm bore and tilt resolver shaft. 0.061

MIC440 Camera Options

The MIC440 Camera has available the following optional extras:-

MIC-ALM - 8 input Alarm card (Fits in PSU).

MIC-WKT - Washer pump drive card (fits in MIC-PSU), washer

nozzle and bracket.

MIC-BP4 - Bosch Bi-phase converter card for power supplies with an

expansion slot available.

MIC440 Power Supply Unit Versions

Between the yoke arm bore and yoke arm blanking cap shaft. 0.061

Between the yoke arm bore and yoke spigot shaft 0.061

Between the pan body top bore and yoke spigot shaft (2 off) 0.061

Between the upper cover bore and wiper motor mount shaft. 0.060

Between the wiper motor mount bore and base flange shaft. 0.100

CAUTION: The PSU enclosures are not Exd rated and must

be replaced with a certified enclosure if installed within a

hazardous area.

Bosch Security Systems has designed a range of power supplies for the MIC440

camera to cater for a variety of common voltages and provide all the connections

needed for power, telemetry and video. The power supply units and options are

detailed below.

MIC-240PSU - 240Vac input Power Supply Unit

MIC-115PSU - 115Vac input Power Supply Unit

MIC-24PSU - 24Vac Input Power Supply Unit

MIC-12PSU - 12 to 24Vdc Input Power Supply Unit

Bosch Security Systems Issue 6

Page 8

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 8

Unpacking

CAUTION: Take extra care lifting or moving MIC440 units

due to their weight.

• Check the exterior of the packaging for visible damage. If any items

appear to have been damaged in transit please inform the shipping

company.

• Unpack the power supply unit carefully; although ruggedized this is

electronic equipment & should be handled with care.

• Do not use if any component appears to be damaged. Please contact

Bosch Security Systems in the event of damaged goods.

• The shipping cartoon is the best way to transport the unit, save it & all

other packaging materials for future use. If the unit must be returned, use

the original packing materials.

Package Contents

Please check for the following contents

• MIC440 Installation & Operation manual (this guide)

• Installation & Configuration CD

• Quick start reference sheet

Bosch Security Systems Issue 6

Page 9

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 9

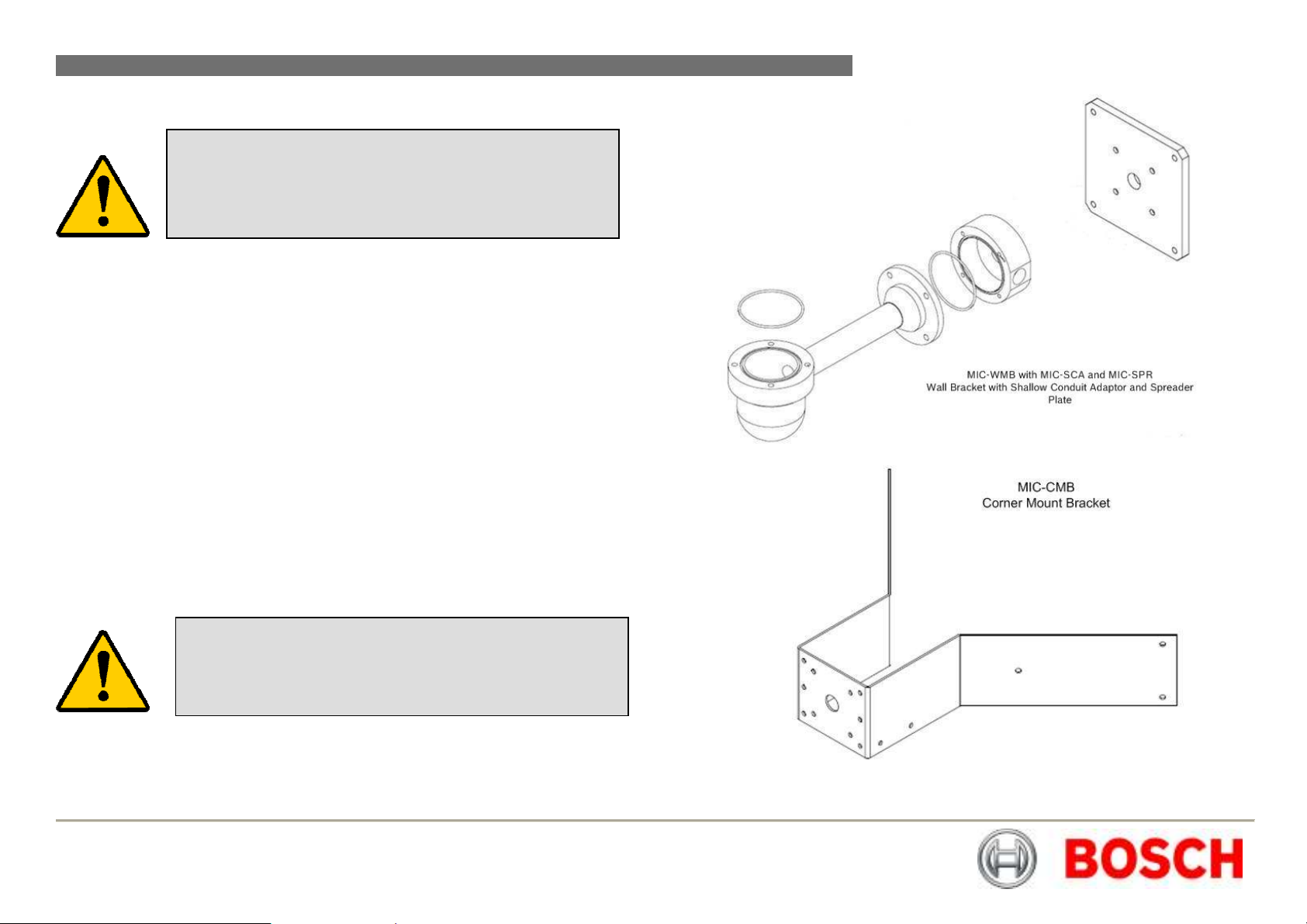

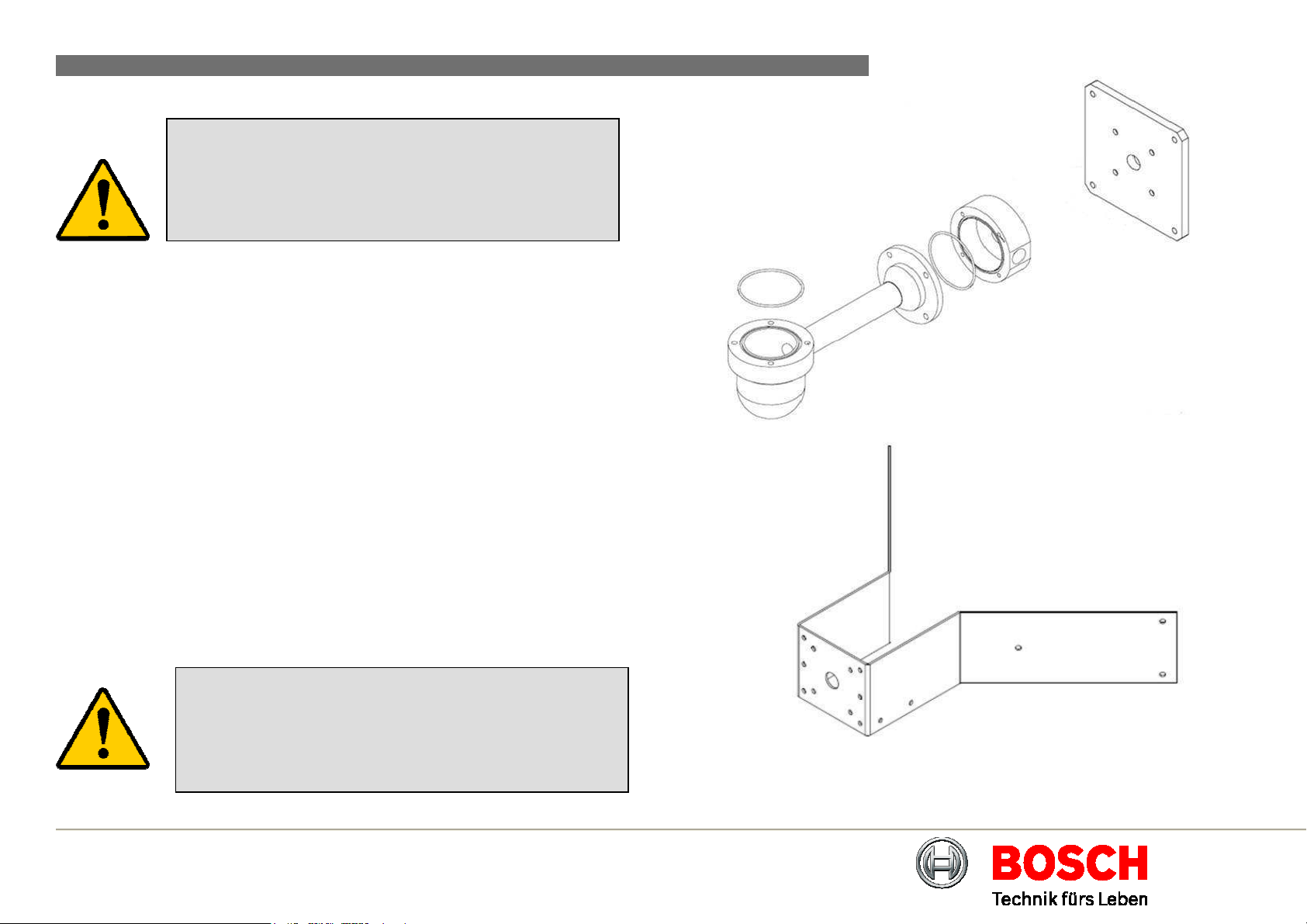

Installation Accessories

The MIC440 Camera has been designed to be easily installed on a variety of

common fittings. The MIC440 comes with an integrated Deep Conduit Adaptor

with an M20 threaded hole for a suitable Exd cable gland (Not supplied).

The MIC440 cameras can be mounted on lamp post column/scaffolding pole or

similar using the Pole Mount Bracket (MIC-PMB) however users should be aware

that lamp posts can often be subject to movement and are not suitable platforms in

all conditions or for all applications.

For mounting directly onto buildings Bosch Security Systems manufacture a range

of brackets suitable for all typical building installations for upright (90°) or Inverted

camera positions, examples are shown below.

MIC-CMB - Corner Mount Bracket

MIC-WMB - Wall Mount Bracket

MIC-SCA - Shallow Conduit Adaptor

MIC-DCA - Deep Conduit Adaptor (Included)

MIC-PMB - Pole Mount Bracket

CAUTION: Ensure all local safety codes are observed when

installing this product; ensure a strong safety chain is used to

secure the MIC440 camera to prevent any danger of dropping

the product during installation. Particular care should be taken

with MIC440 models due to the additional weight.

CAUTION: For additional protection in hazardous area

installations suitable flexible conduit can be used externally for

the composite cable run to connect the power supply to the

Exd Cable Gland (Not supplied) in the MIC440 Deep Conduit

Bosch Security Systems Issue 6

Page 10

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 10

CHAPTER 2

Hardware Installation

CAUTION: Ensure all local safety codes are observed when

installing this product; ensure a strong safety chain is used to

secure the MIC440 camera to prevent any danger of dropping

the product during installation.

This product is designed for use with flammable gases and

vapors covered by apparatus groups IIA, IIB and IIC and with

temperature classes T1 to T6.

The product is certified for use within the ambient temperature

range of -20C to +60º C and must not be used outside this

range.

This product must only be installed by suitably trained personnel

in accordance with the relevant code of practice (e.g. EN6007914:1997). These instructions are intended for their sole use.

The MIC440 uses a composite cable to carry all power & telemetry between the

camera head and the MIC power supply unit this cable can be a maximum of 25m

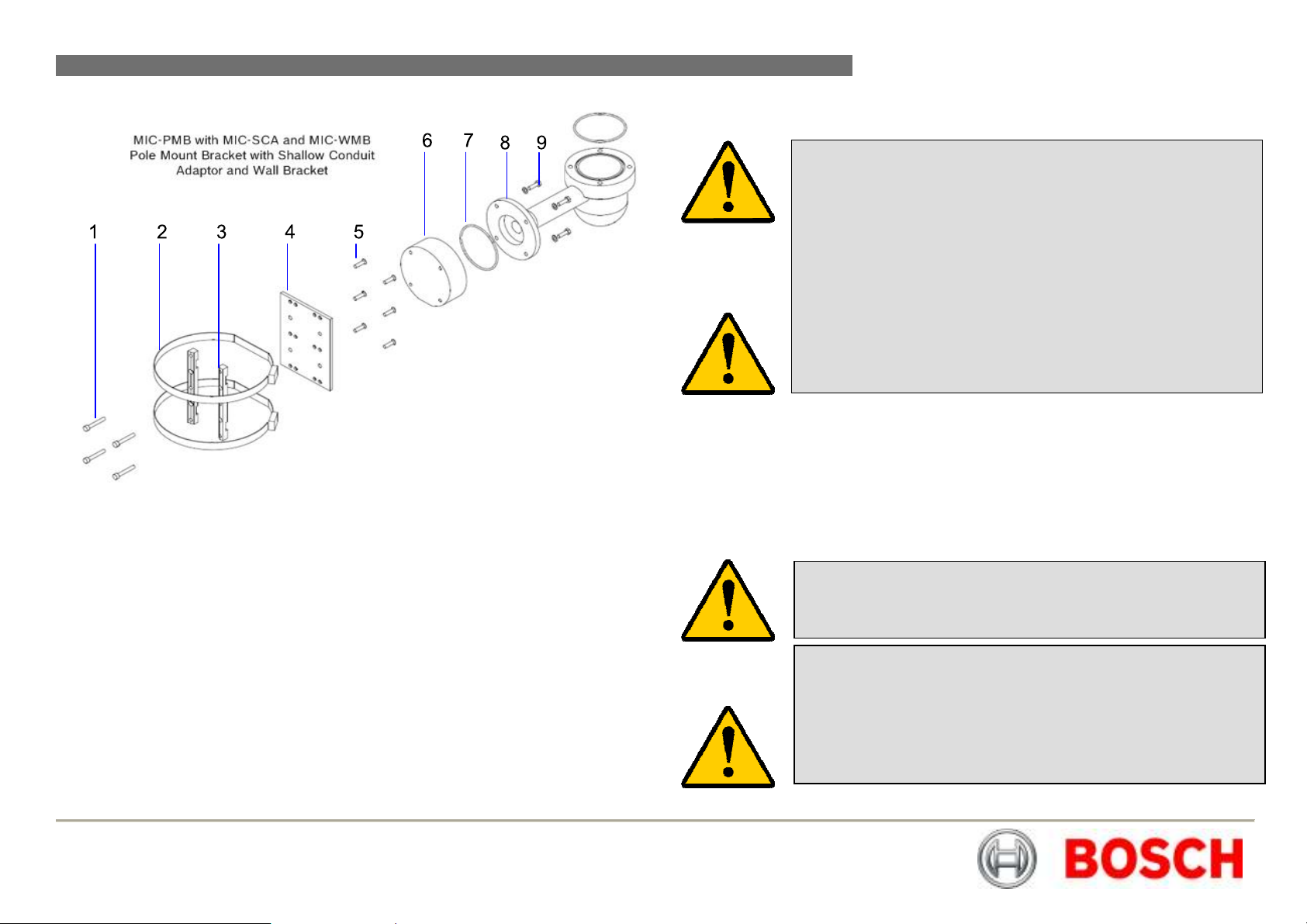

Key to MIC-PMB drawing

1. Securing bolts for MIC-SCA

2. 90mm stainless steel pole banding

3. Pole mount bracket blocks

4. Pole mount bracket plate

5. Pole mount block securing securing bolts

6. Shallow conduit adaptor

7. “O”-ring

8. Wall mount bracket

9. Wall mount bracket securing bolts

long, for installations which require the camera head to be more than 25m from the

power supply then it is recommended that a 2m cable be connected to an Exd

rated junction box from which telemetry; video and power can be broken out into

separate cables with appropriate wiring to extend the distance to suit.

CAUTION: Any junction box or enclosure used for mounting the

power supply or separating cable cores must be Exd rated to the

appropriate rating for the installation.

CAUTION: If the camera is mounted ball down it is essential

that the connector and base area of the camera are completely

sealed from water ingress.

CAUTION: Any water getting into the connector is liable to

cause corrosion to the connector pins leading to unreliable

operation of the camera unit.

Bosch Security Systems Issue 6

Page 11

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 11

Pre installation Preparation in the Workshop

The unit is NOT supplied with a external Exd cable gland. A suitable sized Exd

barrier gland to match the composite cable diameter is required. For the Bosch

composite cable (8mm); use a Hawke cable gland type 501/421 Size 0.

The composite cable is required to connect the MIC440 to its power supply it

consists of two pairs (24AWG) plus 4 cores of (22 AWG), 2 cores of (24 AWG) and

one coax core for the video signal to a maximum distance of 25m as per Table B.

CAUTION: It is recommended that the cable and connector

should be made up, connected to the unit and sealed with the

Exd barrier gland in a workshop before taking the unit for

All connections to the unit are made via the single 12 way connector mounted on

the base of the camera unit and accessible through the base conduit adaptor.

Cable Gland and Cable Mounting instructions

1. Remove the 4 x M8 Hexagon bolts holding the base conduit adaptor to the

MIC440 unit and remove the base conduit adaptor.

2. Fit the composite cable through the Exd barrier gland.

3. Fit the composite cable through the 20mm threaded gland hole in the base

conduit adaptor and allow approx 100mm of free cable on the inside to

connect to the 12 way cable connector.

4. Screw the Exd barrier gland into the base conduit adaptor maintaining

approx 100mm of cable on the inside of the adaptor to enable the cable

connector to be freely inserted into the MIC unit base connector.

5. Connect the 12 way cable connector into the matching connector in the

base of the MIC unit.

6. Make sure the connector is fitted home properly in the camera integral

plug (requires approx. two and a half turns of the socket threaded ring to

fasten the two halves of the connectors together properly).

7. Fit the base conduit adaptor back to the MIC440 unit and fasten using the

4 x M8 hexagon bolts.

8. Ensure that there are no trapped cables.

9. Ensure there is some slack cable in the base conduit adaptor then tighten

up and seal the Exd barrier gland as per the instructions included with the

gland.

10. The unit with the cable tail is now ready for on site installation

Camera Installation Instructions

1. Locate the mounting position of the camera so that it cannot be interfered

with either intentionally or accidentally.

2. Ensure the mounting surface is capable of supporting the combined weight

of the camera and mounting hardware under all expected conditions of

load, vibration and temperature.

3. Fit the mounting brackets (if used) securely, observing all appropriate

safety precautions & local building regulations.

4. Earth the camera using one of the securing bolts. Only earth the camera at

a single point to prevent earth loops & hum bars.

5. M8 x20mm Stainless steel nuts, bolts and washers should be used to

secure the camera’s base conduit adaptor to the mounting point.

6. Secure all cabling & conduit.

Bosch Security Systems Issue 6

Page 12

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 12

Electrical Connections to the MIC440

The MIC440 base connector pin allocations are as follows:

Table B – MIC Connector Pin Table

Connector Pin Signal

Name

A Video

Output

B Video

Return

C Tamper

Switch

D Tamper

Switch

return

E Washer

drive return

F Washer

drive

G Full Duplex

Tx A

H Full Duplex

Tx B

J Full Duplex

Rx A

Half Duplex

Tx/Rx A

K Full Duplex

Rx B

Half Duplex

Tx B

Description Cable Wire

Video Signal output to

control room

Video Signal Ref output to

control room

Connection C to D will

provide an alarm to the

control

room via telemetry 24 AWG core

TTL ref output can be used

to drive external relay for

wash operation option

TTL output can be used to

drive external relay for

wash operation option

Telemetry Output RS 485 Pair 1 - Blue

Telemetry Output.RS485 Pair 1 - Violet

Telemetry I/O to RS485 Pair 2 -

Telemetry I/O to RS485 Pair 2 - White

Type/Colour

Coax core

Coax screen

24 AWG core

- Black

- Brown

22 AWG core

- Grey

22 AWG core

- Orange

Yellow

L Power input 1 Low volt AC or DC power

input 15 Volts AC or DC

M Power input 2 Low volt AC or DC power

input 15 Volts AC or DC

Video output signal conforms to CCIR PAL 1V Composite format. (NTSC format is

available on request).

Telemetry signals all conform to the RS485 / RS422 standard.

The unit continuously monitors incoming telemetry whether in full or half duplex

mode.

In full duplex mode, the Tx pins are tri-state except during transmission times.

This may cause problems when interfacing to some Fibre Optical converter units.

Check out the Commissioning notes for ways of overcoming these problems.

In 2 wire Half Duplex mode (RS485), the Rx Pins are used to transmit data to the

MIC440 unit.

The washer connections can be used to operate a relay in the power supply unit,

which in turn can activate a pump.

22 AWG core

- Red

22 AWG core

- Green

Bosch Security Systems Issue 6

Page 13

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 13

Earthing of the MIC440 Camera

1. The camera module & housing are electrically isolated so the housing

should be safety earthed regardless. The safety earth should be a bonding

connection to the cameras outside case for example one of the securing

bolts.

2. The camera should be earthed at one point only to prevent earth loops &

thus hum bars showing on the control room monitor.

3. If the system is copper throughout & the camera pictures are fed back to

the control room coaxial copper cable, then the camera should be earthed

at the video termination point in the control room & nowhere else. In this

case the PCB “Earth Link” should be broken.

4. If the video is transmitted back to the control room via some non electrical

connecting medium, e.g. fibre optic, radio or microwave link, then the

camera should be earthed at the transmitter point in the psu. The PSU

“Earth Link” may be used for this purpose.

5. If dual earthing is unavoidable then a video isolation transformer should be

fitted between the two earths.

Lightning Protection

If the camera is fitted in a highly exposed place then consideration should be given

to lightning protection. A good earth bonding connection to the case itself will

provide protection against damage from secondary strikes.

Where there is a risk of a primary strike hitting the camera housing directly, it is

recommended that a separate lightning conductor be fitted within 0.5m of the

camera and at least 1.5m higher than the camera.

The construction of the housing itself is very capable of coping with secondary

strikes and no damage to the internal electronics or camera should result if correct

lightning protection is applied.

Maintenance

The unit contains no maintainable parts and in the event of failure should be

removed from site for repair.

Maintenance and repair of this equipment shall only be carried out by suitably

trained personnel in accordance with the applicable code of practice (e.g.

EN60097-19)

To maintain the validity of the certification only components supplied by Bosch

Security Systems shall be used.

On Site Inspection

It is recommended that the equipment be inspected on site every six months to

check mounting bolts for tightness, security and any signs of physical damage.

Inspection of this equipment shall only be carried out by suitably trained personnel

in accordance with the applicable code of practice (e.g. EN60097-17)

Bosch Security Systems Issue 6

Page 14

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 14

MIC440

CHAPTER 3

The Power Supply Units provide all the support functions for connecting the

MIC440 cameras to third party equipment, they comprise of the following products:

MIC-12PSU, MIC-240PSU, MIC-24PSU and MIC-115 PSU

The power supply provides power for a single MIC440 camera unit from a 12v DC

source (MIC-12PSU), a 240v AC source (MIC-240PSU), a 24v AC source (MIC24PSU) or a 115v AC source (MIC-115PSU). The transformer fitted to these

designs is a thermally protected and automatically cuts out if the transformer core

temperature exceeds 40 Degrees C. On cooling the transformer will become

operational again.

In addition the unit provides all the terminations required to connect a MIC440

camera to third party equipment.

A second independent 12v (600mA) power supply is also included to drive any

internally fitted optional interface cards.

Power Supply Installation & Setup

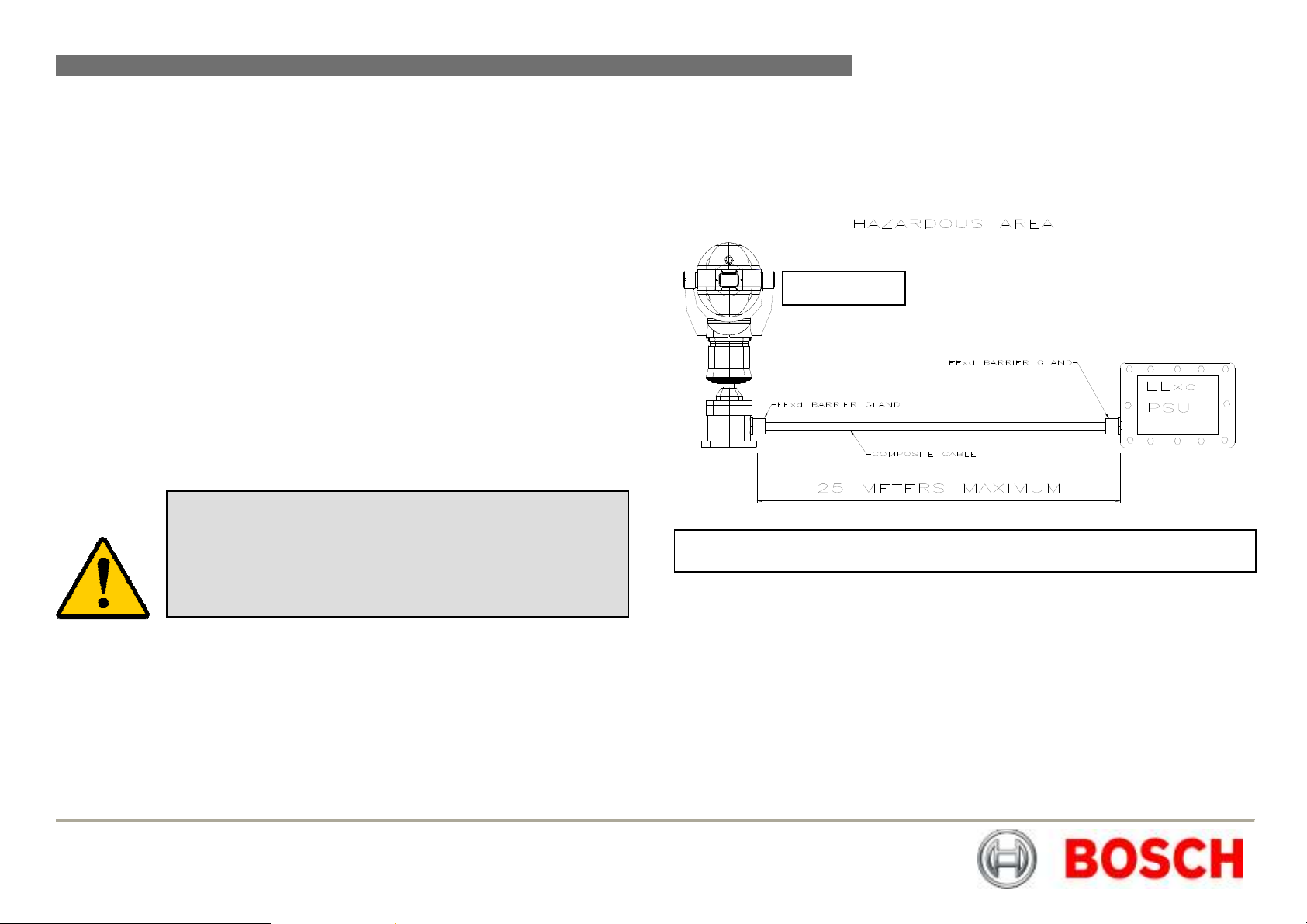

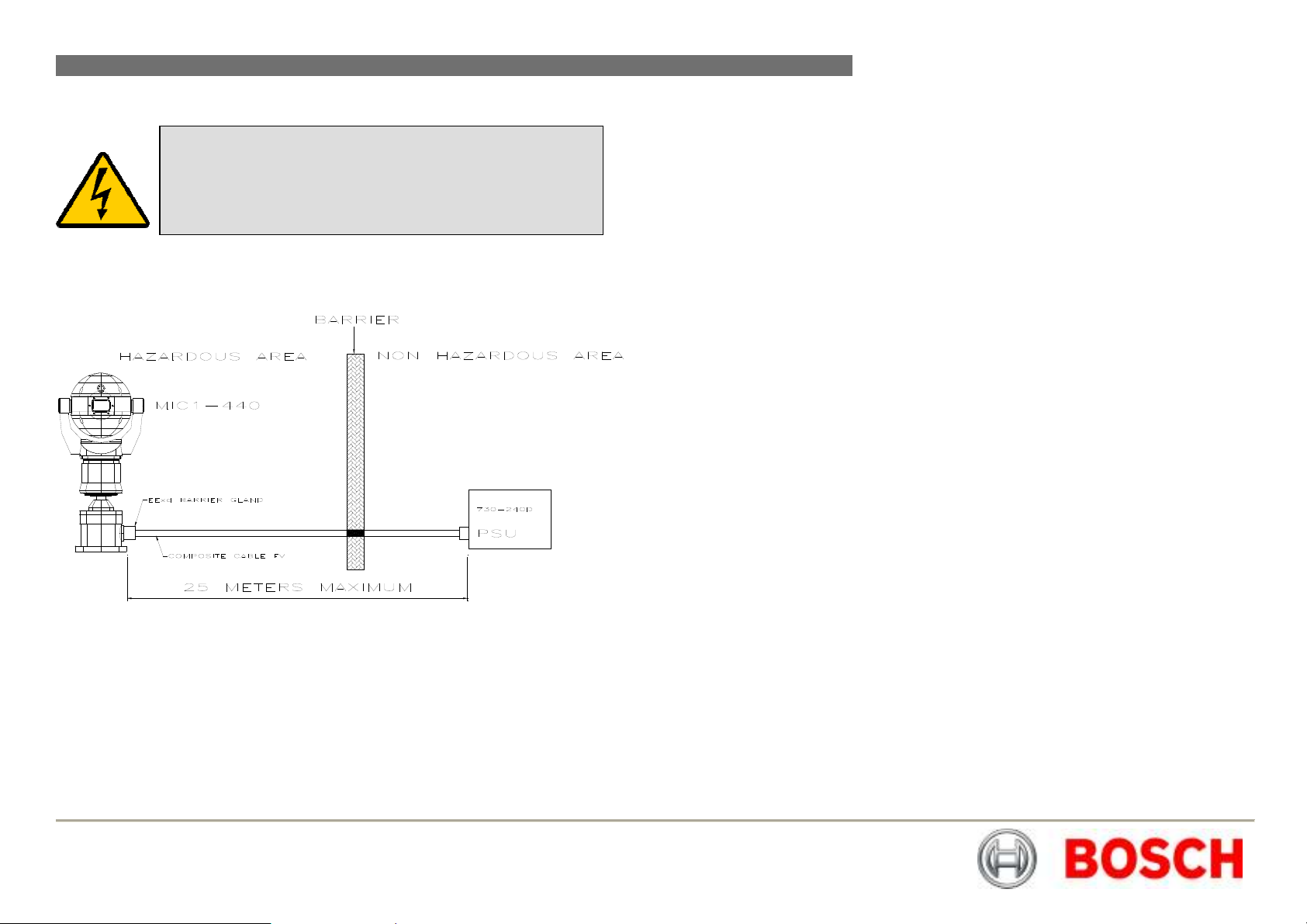

A maximum cable length of 25m is permitted as shown overleaf in Fig A, if the

PSU can be located in a Non-hazardous area near to the camera installation then

an Exd enclosure for the PSU may not be required as shown in Figure B on page

15.

Hazardous Area Power Supply Installation Instructions

Installation of the PSU within a hazardous area must have the standard PSU

enclosure replaced with an appropriate certified enclosure and four (4) Exd cable

glands (NOT Supplied), the power supply PCB is usually re-housed, by a third

party company, within an Exd enclosure which is then factory certified and shipped

to site. Follow all manufacturer’s instructions when installing a third party Exd

enclosure, examples are shown on Page 15.

CAUTION: The PSU enclosures are not Exd rated and must be

replaced with a certified enclosure if installed within a

hazardous area.

This product must only be installed by suitably trained

personnel in accordance with the relevant code of practice (e.g.

EN60079-14:1997).

Figure A – Installation using Exd junction box

Bosch Security Systems Issue 6

Page 15

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 15

Bosch Security Systems Issue 6

Page 16

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 16

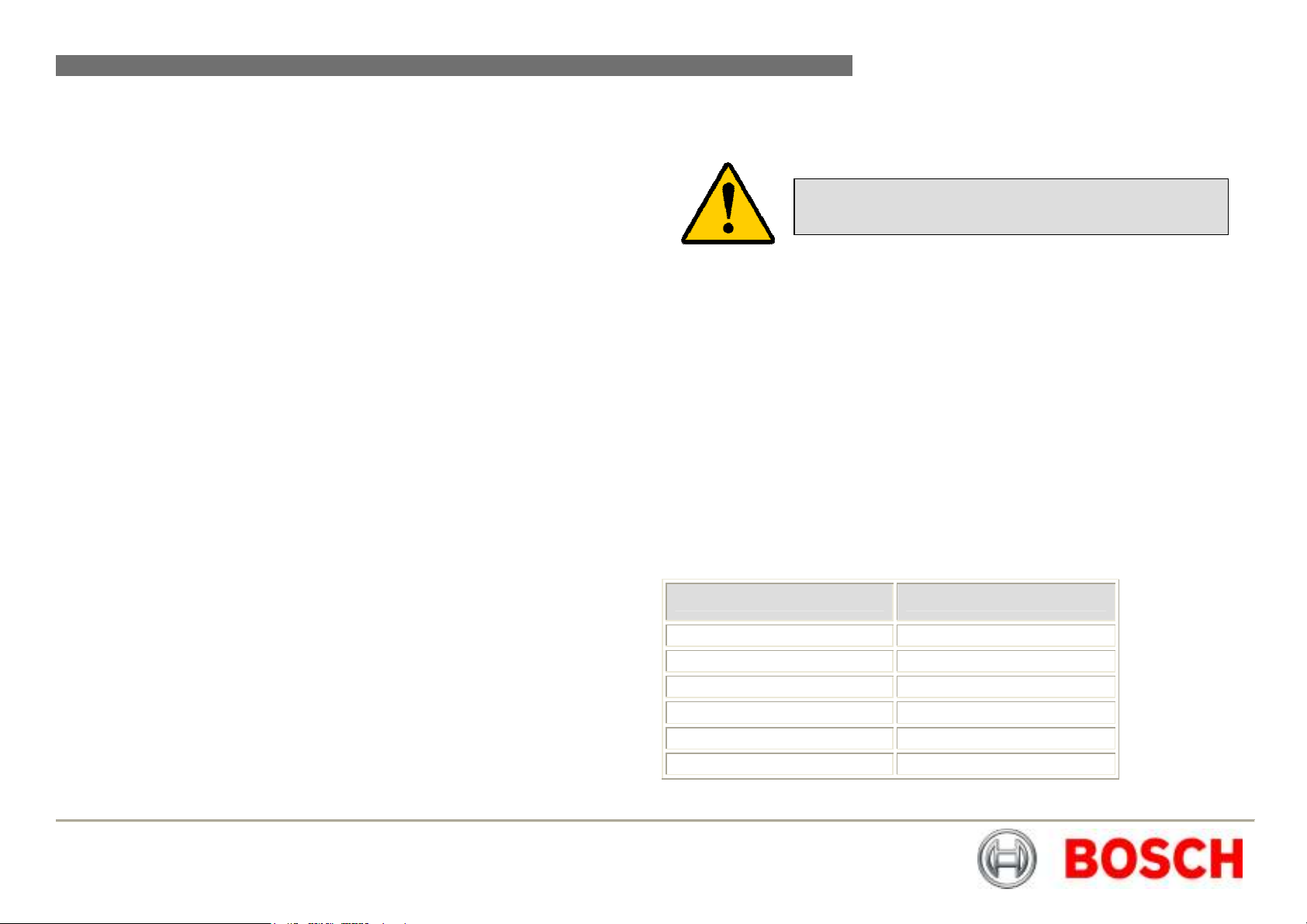

Non Hazardous Area Power Supply Installation Instructions

Figure B – Installation of the PSU in a Non-Hazardous area

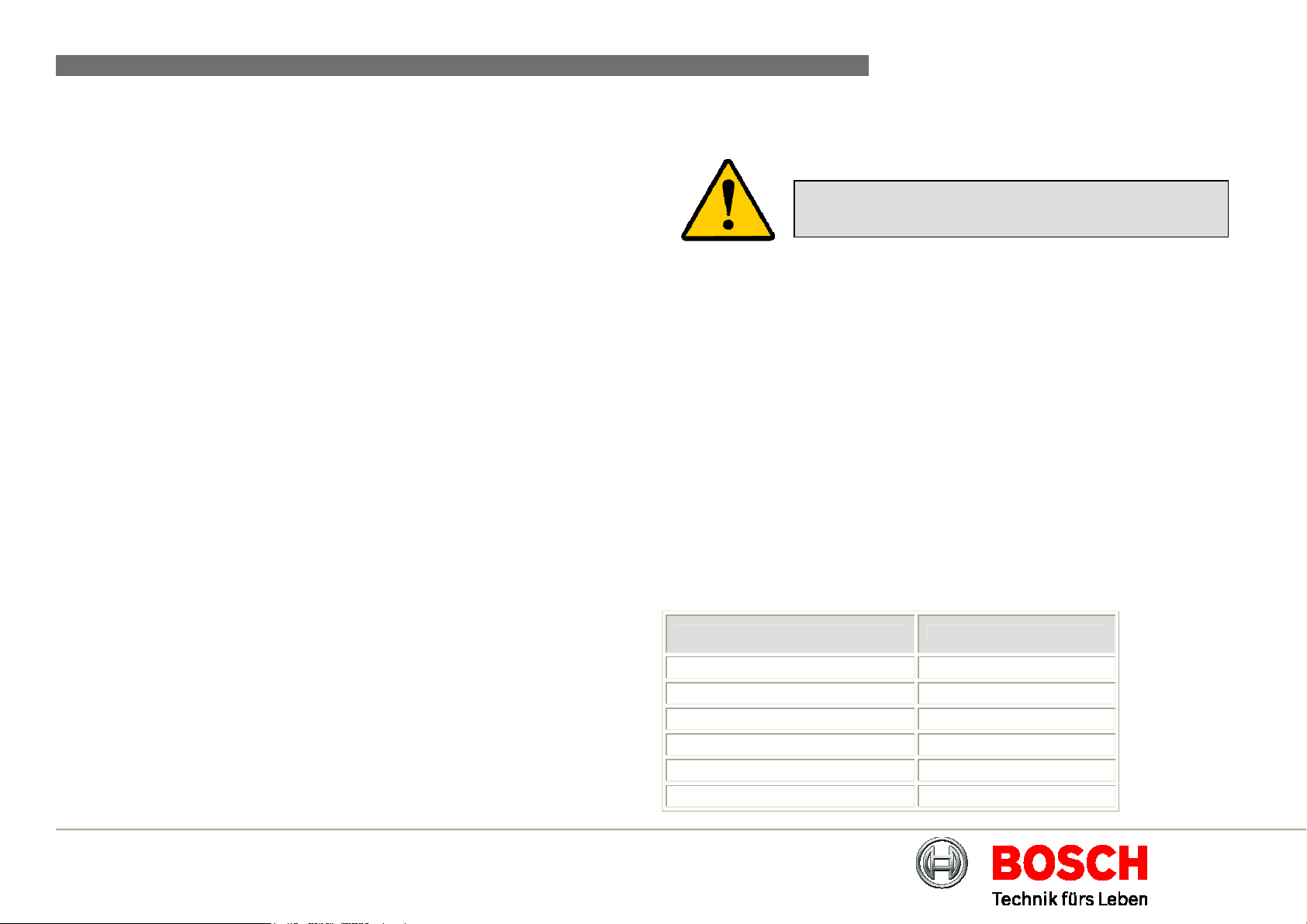

WARNING: Electrical Danger: Ensure all power is

disconnected before opening or working upon any Power

Supply Unit.

Installation must be carried out by suitably qualified persons

& all local safety regulations should be followed.

Installation of the MIC-PSU

To install the MIC-PSU in a Non-Hazardous area please do the following.

1. Locate the mounting position of the MIC-PSU outside the hazardous area

so that it cannot be interfered with either intentionally or accidentally, a

lockable cabinet is recommended.

2. Securely fix the MIC-PSU using M4 stainless steel screws & washers;

ensure the cable glands have sufficient room to allow for the cables to

enter.

3. Feed all cabling through the appropriate sized gland holes.

4. Connect the composite cable to HD3 following the colour coding as shown

in the Table D & printed on the PCB.

5. If a tamper switch relay is to be used, connect this at HD2.

6. Connect the Coaxial video cable to the CN1 header.

7. CN2 is for additional add on cards such as alarm inputs, video processors,

Bi-phase cards etc.

8. Telemetry connections are provided by headers HD3, HD4 and HD5 which

respectively enable crimp or screw terminations for connecting the MIC440

to the control room as per Table E.

9. Connect the power to HD1 carefully observing the polarity and voltage as

per Table C.

10. When wiring is complete, apply power & check the all four (4) LED’s are lit.

11. Following Installation when power is applied the following LEDs will light to

indicate:-

LED1 – 15vAC power on to camera

LED2 – 15vAC power on to camera

LED4 – Power on for optional heater/speaker (Not MIC440)

LED5 – Power on for optional heater/speaker (Not MIC440)

12. Re-attach the enclosure lid & screw down until tight.

13. For installation of the MIC-WKT-KIT, MIC-ALM or MIC-BP-4 Bi-phase card

please refer to their respective manuals.

Bosch Security Systems Issue 6

Page 17

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 17

Connecting the MIC-24PSU, MIC-240PSU or MIC-115PSU

Once installed on site please connect the composite cable from the MIC440 to the

MIC-PSU as per the following instructions.

WARNING: Electrical Danger: Ensure all power is disconnected

before opening or working upon any Power Supply Unit.

Installation must be carried out by suitably qualified persons & all

local safety regulations should be followed.

Dimensions

Power supply enclosure:-225mm (W) x 70mm (H) x 195mm (D)

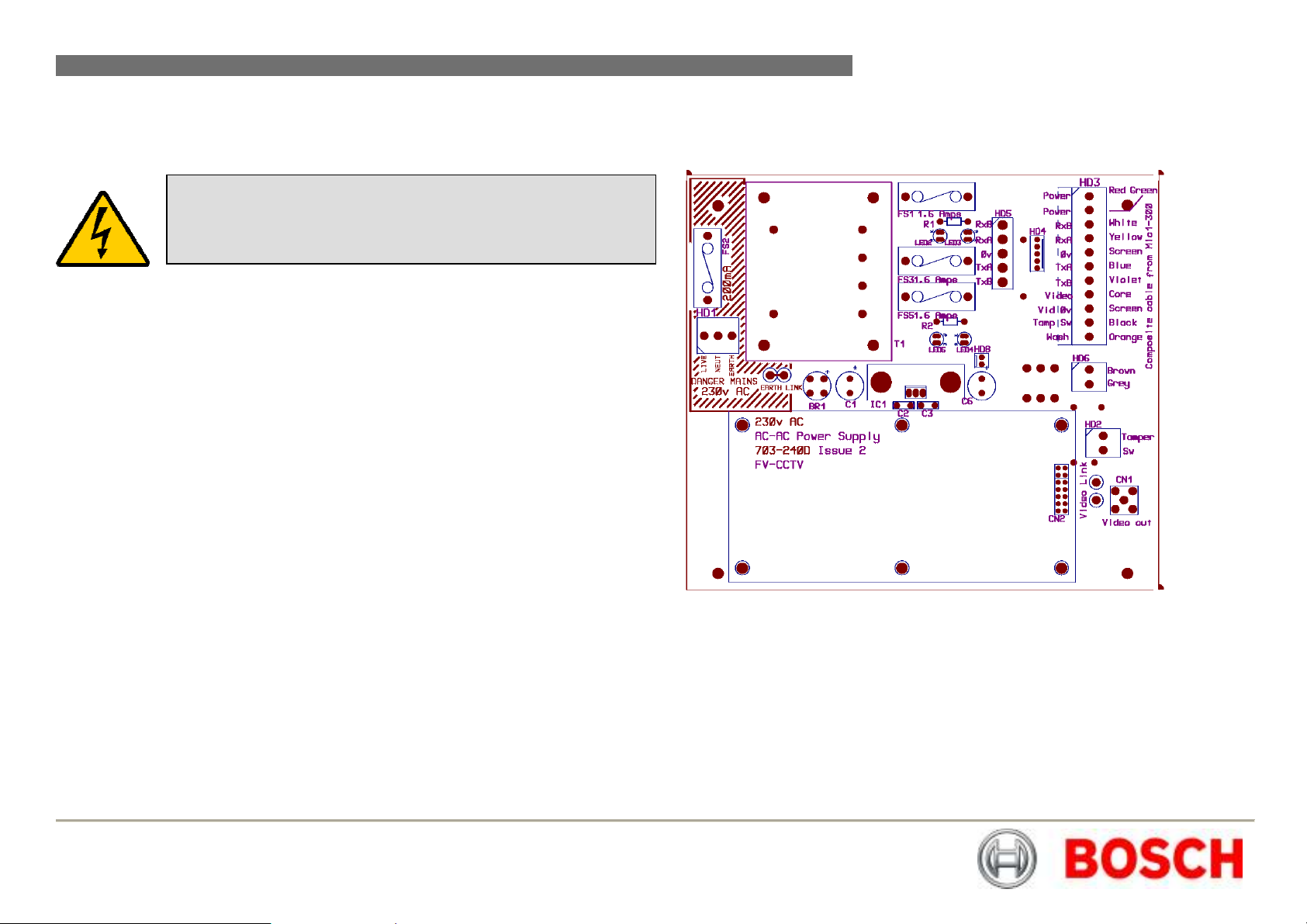

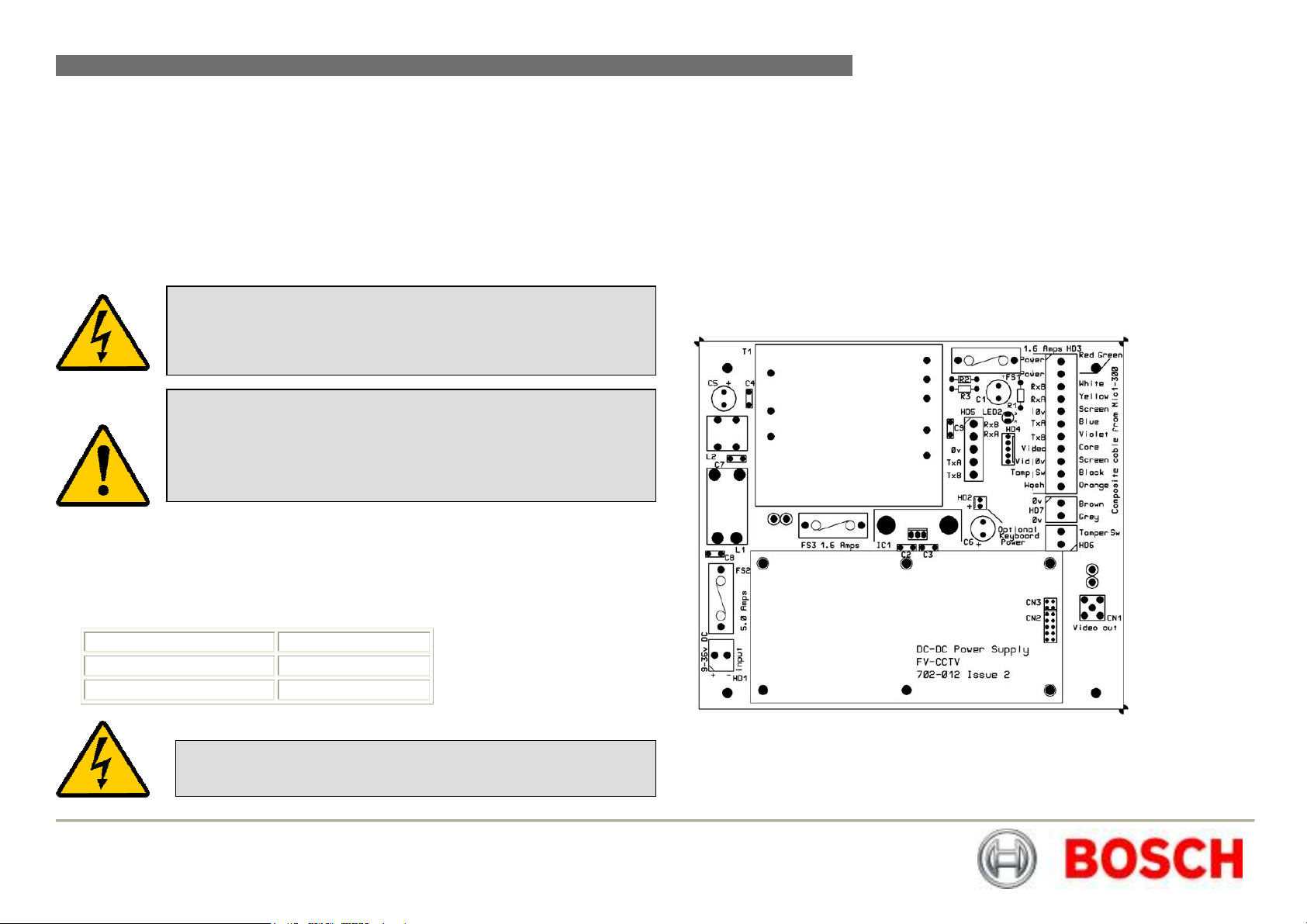

Figure C - MIC24PSU/MIC-240PSU/MIC-115PSU Layout

The Power Supply Unit comprises of the following:

1) A weather resistant (IP55) plastic box fitted with four cable glands.

2) A power supply for the MIC440 camera.

3) A second power supply for driving various interface cards mounted internally

to the power supply box. e.g. washer drive card, alarm interface card.

4) Provision for a signal interface card, to connect telemetry to third party

equipment.

5) Screw termination of all cable into and out of the box.

6) Correct video termination for the camera coaxial cable.

7) Earth isolation and termination within the unit to correctly control Video

earthing and thus prevent Earth loop.

Power Supply Layout and Connections

The Power supply PCB has the following connections as shown overleaf on Figure

C:-

HD1 – Power Input Connector (screw terminal)

HD2 - Tamper Switch header (screw terminal)

HD3 - Composite cable header (Connections to camera head, screw terminal)

HD4 - Telemetry header (Molex Connection)

HD5 - Telemetry header (screw terminal)

HD6 - Washer pump header (screw terminal)

HD8 - Keyboard power connector (demo purposes only, not normally fitted)

CN1 - Video out connection header (BNC)

CN2 - Add on card header (plug in)

PCB Earth Link

The PCB has one link option next to HD1 to allow the power supply to be set up for

different earthing schemes: The Earth Link should be broken if there is a separate

connection between video screen and earth. Usually occurs on copper connected

systems where all the copper video coaxes are taken back to the control room to

be connected to a central earth point. If fibre optics or other indirect connections

are used to get data and video to and from the control room then the earth link

should be left intact provided it is the only camera end earth reference point.

Bosch Security Systems Issue 6

Page 18

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 18

Table C – Power Connection to Header HD1

Live HD1-1

Neutral HD1-2

Earth HD1-3

Table D - Composite cable to Power Supply HD-3 Connection Table

Composite

Cable Wire

Colour

Red AC supply HD3-1 Power

Green AC supply rtn. HD3-2 Power

White Rx + HD3-3 RxB

Yellow Rx - HD3-4 RxA

Drain Wire Gnd HD3-5 GND

Blue Tx - HD3-6 TxA

Violet Tx + HD3-7 TxB

Coax Core Video HD3-8 Video

Coax Screen Video Return HD3-9 Vid 0v

Black

(Optional)

Orange

(Optional)

Function Terminal Box

Connector

Tamper Switch HD3-10 Tamp Sw

Wash drive HD3-11 Wash

Terminal

Box ID

Marking

Table E - Telemetry Connections to HD3, HD4 and HD5

Telemetry

Signal Name

RXB or Rx + Pin 3 Pin 1 Pin 1

RXA or Rx - Pin 4 Pin 2 Pin 2

GND Pin 5 Pin 3 Pin 3

TXA or Tx - Pin 6 Pin 4 Pin 4

TXB or Tx + Pin 7 Pin 5 Pin 5

HD3 HD4 HD5

Fuse ratings

The power supply houses 4 off 20mm fuses in fuse holders. The ratings for these

fuses if fixed on the low voltage secondary side but changes with input voltage on

the high voltage primary side.

The following table shows the fuse values fitted for the different supplies for

operating the power supply:

Note FS 4 does not exist

Table F – Fuse Ratings for MIC-240PSU, MIC-24PSU and MIC-115PSU

Fuse ident Fuse function. Rating for 240v

primary

FS 1 MIC400 protection 1.6A glass Anti

surge (T)

FS 2 Primary protection. 800mA ceramic

quick blow

FS 3 Heater protection 1 1.6A glass Anti

surge (T)

FS 5 Heater protection 2 1.6A glass Anti

surge (T)

Rating for 115v

primary

1.6A glass Anti

surge (T)

800mA ceramic

quick blow

1.6A glass Anti

surge (T)

1.6A glass Anti

surge (T)

Bosch Security Systems Issue 6

Page 19

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 19

MIC-12PSU Power Supply Unit

The power supply provides power for a single MIC440 camera unit from a 9v DC to

29v DC source for installations using low voltage systems.

Dimensions

Power supply enclosure – 225mm (W) x 70mm (H) x 195mm (D)

This is connected as per the MIC-240PSU as shown previously with the exception

of the following changes:-

WARNING: Electrical Danger: Ensure all power is disconnected

before opening or working upon any Power Supply Unit.

Installation must be carried out by suitably qualified persons & all

local safety regulations should be followed.

This should be fed in to connection HD1 nominally marked as mains input,

connections should be as follows:-

Table G – Power Input wiring connections for MIC-12PSU

CAUTION: It is extremely important to observe the correct polarity,

failure to do so will result in the destruction of the DC-DC power

supply.

CAUTION: This power supply was designed for negative earthed

systems only it is not suitable for use with positive earth systems.

Positive HD1-1

Negative HD1-2

Earth and Negative HD1-3

WARNING: The rating of fuse FS2 should be changed to a 2A

quickblow as opposed to the rating shown on the PCB.

Power Supply Layout and Connections

HD1 – Power Input Connector (screw terminal)

HD2 - Keyboard power connector (demo purposes only, not normally fitted)

HD3 - Composite cable header (Connections to camera head, screw terminal)

HD4 - Telemetry header (Molex Connection)

HD5 - Telemetry header (Screw terminal)

HD6 - Tamper Switch header (Screw terminal)

HD7 – Washer Pump Drive header (Screw terminal)

CN1 - Video out connection header (BNC)

CN2 - Add on card header (plug in)

Figure C – MIC-12PSU Layout

For 12V installations the composite cable wiring is identical to that shown earlier in

this manual on Table D.

Bosch Security Systems Issue 6

Page 20

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 20

Optional Cards and Kits for MIC440 Cameras

The MIC440 has several optional cards and kits as described earlier.

Please refer to the respective manuals for details on their installation and

operation.

MIC-WKT Washer bracket, nozzle and pump card kit

MIC-ALM 8-input alarm card includes washer pump drive

function

MIC-BP4 Bosch Bi-phase converter card for MIC power supplies with an

available expansion slot.

CHAPTER 4

Configuring the MIC440 Camera

Connecting the MIC440 to the PC

CAUTION: This procedure must be carried out in a non

hazardous area only.

The MIC can be connected to a PC’s serial port via a RS232/RS422 adaptor unit;

this will generally be assigned to Comm Port 1.

Suitable serial port adaptor units are the Greenwich RS232/RS422 adaptor unit

(Farnell 778-758, RS No: 201-758), the KK systems K2-ADE RS232 to RS485/422

adaptor or the MIC-USB485CVTR (485 to USB Converter) for PC’s without a serial

port.

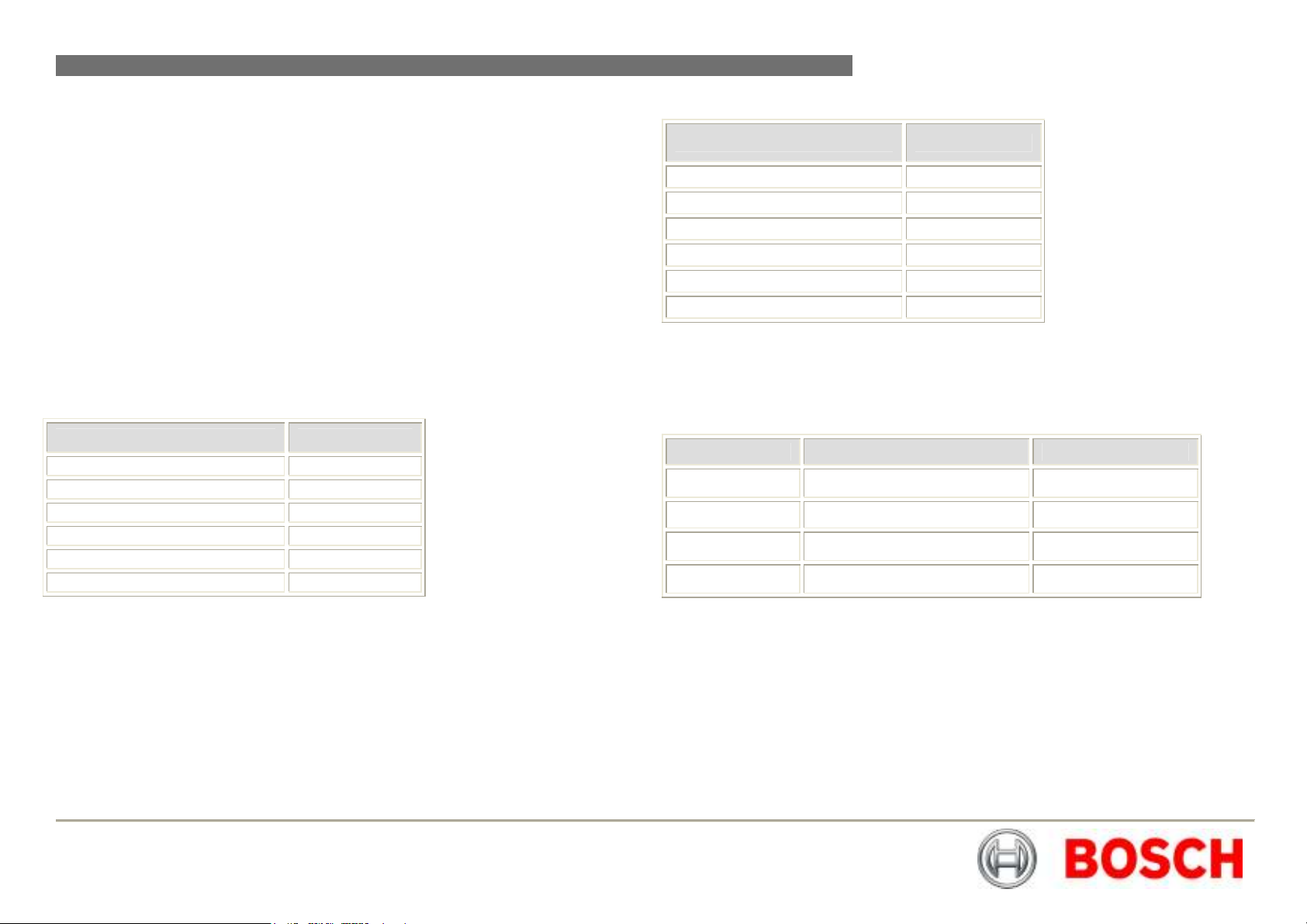

Connecting the Greenwich Adaptor

To connect the Greenwich serial adaptor to the PC you will also need a 9 pin D

female to 25 pin D male RS232 compatible adaptor cable. A suitable cable is

Farnell 960-573 or RS Part No: 202-644. The adaptor should be set to DCE mode

and the power supply connected.

Connections from the Greenwich adaptor to the power supply are shown below

Table H – Connecting the Greenwich Adaptor

Adaptor Connections HD4

F 778-758. Connection and wire colour.

DATA OUT 6-3+ RXB White

DATA OUT 5-4- RXA Yellow

SCREEN 0v

DATA IN 4-5- TXA Blue

DATA IN 3-6+ TXB Violet

Bosch Security Systems Issue 6

Page 21

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 21

The connections can be tested by selecting the DETECT button in Camset and

checking to see if the window below this button displays the address and software

version No of the camera being tested.

Should a problem be encountered then connect the MIC440 screen wire (0v) to the

pc chassis with a separate piece of wire to ensure 0v continuity

Connecting the KK systems K2-ADE RS232 to RS485/422

Adaptor

This unit is self powered and can be plugged directly into the PC serial port.

RS485 two wire mode.

Connections and Dip switches settings for 2-wire mode should be made as

follows:-

Table I – DIP Switch Settings for K2-ADE 2 wire mode

DIP Switch Setting

Sw 1 OFF

Sw 2 OFF

Sw 3 OFF

Sw 4 ON

Sw 5 OFF

Sw 6 ON

Table J – K2-ADE Adaptor connections

Adaptor Connections HD4

K2-ADE Connection.

Pin 3 RXB White

Pin 9 RXA Yellow

Pin 5 0v

Not required TXA Blue

Not required TXB Violet

With all the above set up, when Camset is running and the serial port selected, set

the Camera Interface Controls to the following:-

Table K – Camera interface control settings

Camset Tabs 2 Wire RS485 4 Wire RS422

Comms 1 Selected Selected

Interface 2 Wire 4 Wire

RTS Off On

Baud 9600 9600

If a notebook PC is used, which sometimes lacks a serial port, then a RS485 to

USB converter such as the MIC-USB485CVTR can be used instead, this would

typically be mapped to Comms port 3 or 4.

Bosch Security Systems Issue 6

Page 22

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 22

Connecting the MIC-USB485CVTR, USB to RS485 Converter

Table L – MIC-USB485CVTR Connection Table and Diagram

MIC Power Supply

Converter Output

RxB / Rx - TxB

RxA / Rx + TxA

Telemetry Header

(HD4 or HD5)

Communication Mode

Full Duplex (4-wire only)

The MIC-USB485CVTR is a USB to RS485 signal converter that allows PCs

without a serial port to connect directly to the MIC440 camera via the telemetry

connection (HD4) in the power supply, the MIC-USB485CVTR can also be used to

connect a PC to any other RS485 device.

The MIC-USB485CVTR has been designed to work with all functions in Universal

Camset and to be backwards compatible with legacy version of Camset although

full compatibility is not guaranteed.

The MIC-USB485CVTR should be connected to the telemetry header (HD4) of the

MIC440 power supply with Standard Twisted Pair cable such as Belden 8760.

The table overleaf shows how the screw terminal connections on the MICUSB485CVTR connect to the MIC power supply depending upon the protocol and

selected communication mode you may only need a 2 wire configuration.

CAUTION: Should be taken to avoid earth loops when

connecting 0v from the converter to GND terminal in the

MIC power supply

Bosch Security Systems Issue 6

GND / 0V GND Shield (always)

TxA / Tx - RxA

TxB / Tx + RxB

Simplex

Half Duplex (2-wire)

Full Duplex (4-wire)

Page 23

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 23

MIC-USB485CVTR and Universal Camset Software Installation

Universal Camset comes with WHQL certified drivers for the MIC-USB485CVTR

that must be installed prior to connecting the converter to the PC.

To install the drivers please do the following:-

1. Locate the

click to begin and follow the on screen instructions to install; these are the

required drivers for using the MIC-USB485CTR.

2. Locate the CAMSET INSTALLER.MSI and then double click to begin,

follow the on screen instructions to install.

3. Once installed a Universal Camset Icon will appear on your PC Desktop.

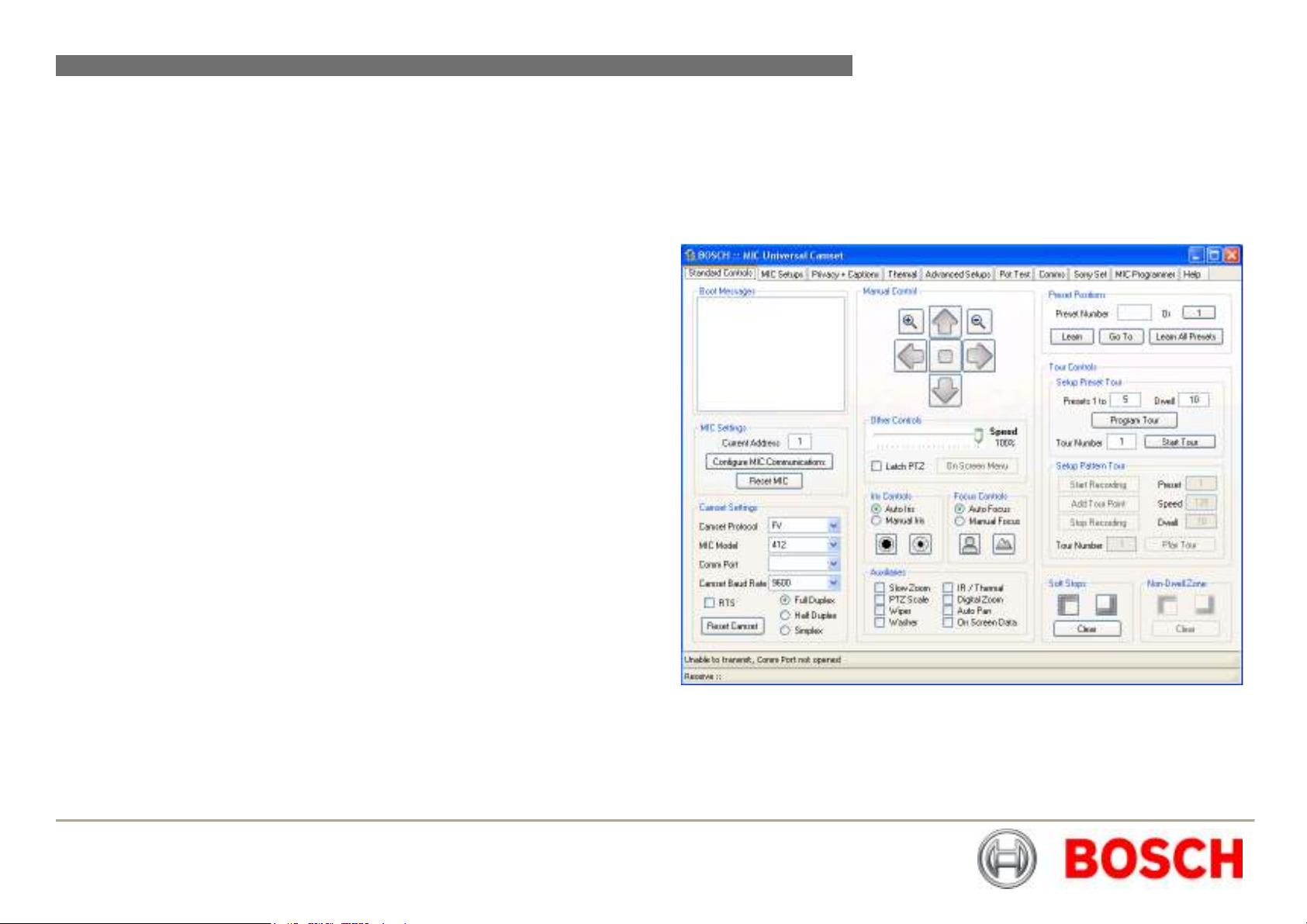

4. When opened the Universal Camset will display the Standard Controls

Tab as shown overleaf.

Providing the USB drivers have been installed successfully, you can then plug the

MIC-USB485CVTR into a PC via the USB port. If your converter is being plugged

in for the first time your system should recognise the device and inform you that

the hardware has been installed successfully.

The MIC-USB485CVTR should appear in the Comm Port selection list as USB and

as a virtual Comm Port, e.g “comm2” (for legacy support). Universal Camset has

been optimised to work with this converter in USB mode; therefore users should

select “USB” for maximum functionality and reliability.

The MIC-USB485CVTR has a status LED indicating its current state, by sending a

manual command e.g. Left or Right, you should see the LED flash. Transmitted

data from the converter is indicated by a

data a

green LED will flash.

USB DRIVERS.EXE in the Universal Camset Folder, double

red flashing LED flash and upon receiving

Commissioning the MIC440 using Universal Camset

Universal Camset is a Windows PC based configuration software from BOSCH

Security Systems; it is issued free on the CD that comes with each MIC camera.

Universal Camset supersedes all previous versions of Camsets used.

Standard Controls

Universal Camset opens on the

highlighted area contains the Boot messaging, MIC settings and Camset Settings

controls.

Standard Controls tab as shown above; the

Bosch Security Systems Issue 6

Page 24

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 24

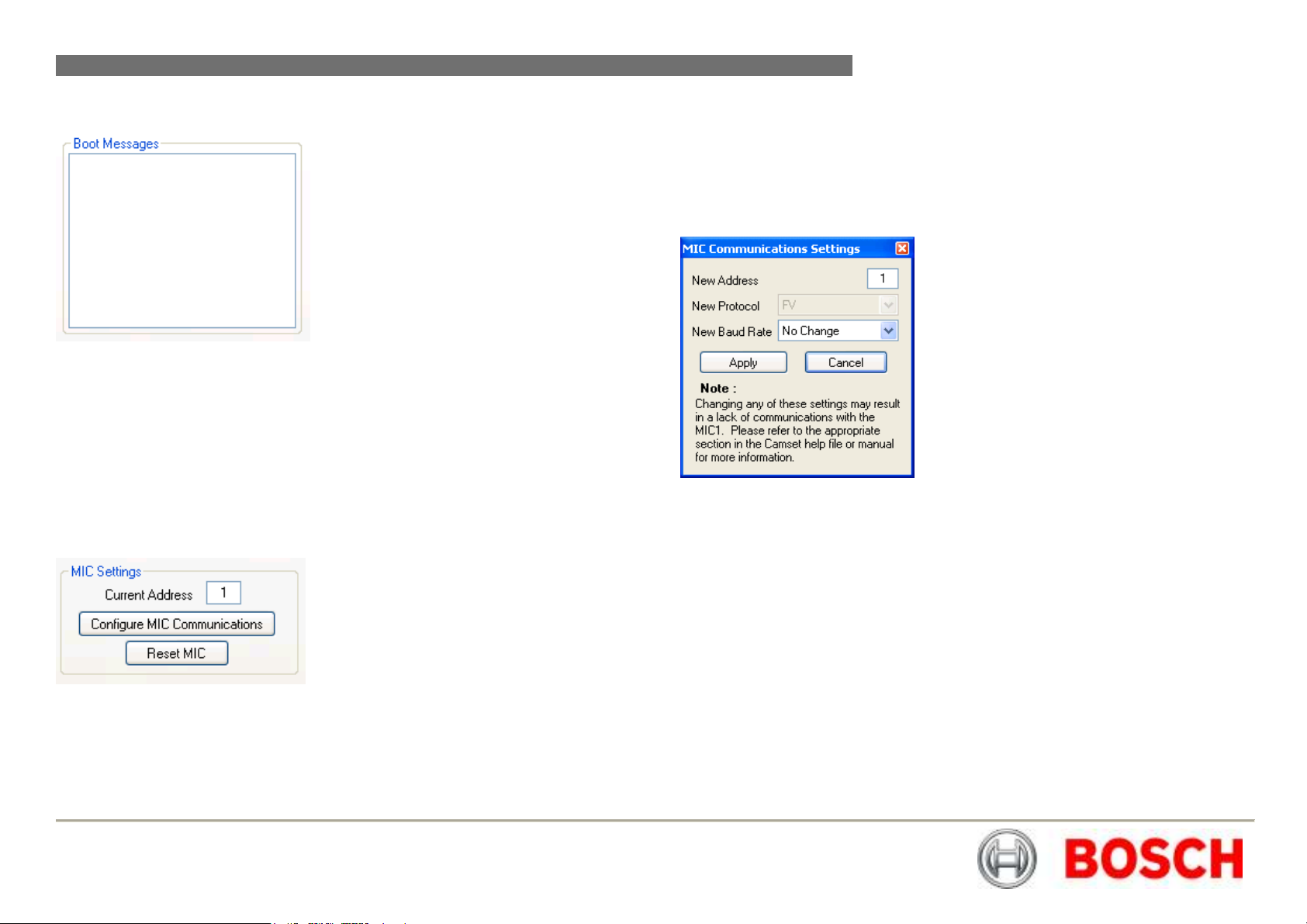

Boot Messages

When the MIC is booted the first line of the messages it sends is the address,

which is read and put into this box automatically.

Configure MIC Communications

This button opens up a new window which provides the options to reconfigure the

MIC communications settings. These options will depend on the MIC model

connected.

The large square text box in this area will display boot messages coming from the

MIC. One of the first lines contains the MIC address which is decoded and entered

into the

card serial number, MIC Software etc.

At the same time, a boot message is displayed on the video indicating similar

information, which may be helpful if return comms should fail or be incorrectly

connected.

Address line. The rest of the lines indicate the MIC model number, control

MIC Settings

Current Address

This box indicates the address to which commands are sent from Camset. This

therefore needs to match the address of the MIC that needs to be controlled.

In order for any of these modifications to work, Camset must have full

communications with the MIC. Ensure this by performing a simple manual control

test (Up, Down, etc). To store the new settings press

have been made or alternatively press

New Address

This input box defines the new address the MIC should change to once Apply has

been clicked. The value will also be copied over into Current Address on the main

form to provide continual control.

New Protocol

The drop down list here provides a full list of the protocols available in Camset.

Control depends upon selecting the correct protocol in the drop down list to match

the protocol that is loaded onto the MIC400; if the incorrect protocol is selected in

Camset the MIC may not respond. To regain control should this happen, reset the

Camset Protocol back to what the MIC originally was.

Bosch Security Systems Issue 6

Apply once the modifications

Cancel to discard any changes.

Page 25

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 25

New Baud Rate

This drop down list will provide the valid baud rates for the chosen protocol. The

baud rate options reflect the protocol as set on the main form for Camset itself. In

FV protocol the option is a toggle which simply switches the MIC between 4800

and 9600. If control is not present after the window is closed, try changing the

Camset Baud Rate.

Reset MIC

This sends out a command to reboot the software. This is not a hardware reboot;

the only way to do that is to remove the power supply to the MIC.

Camset Settings

Camset Settings section as shown above control the Protocol, MIC model,

The

Baud Rate and Comm Port used; select the appropriate parameters for your

MIC440 from the dropdown menus.

Some functions in Universal Camset may not be supported by particular protocols;

any incompatible functions will be greyed out if it is not supported in a given

protocol.

The communication settings will be set to the default for the chosen protocol,

indicating this on the Camset Baud Rate drop down list.

Reset Camset

This re-initialises all of the controls for the software to the state it would be on boot.

MIC Model

This provides a list of all the available MIC Models. This should be set to the type

of camera being controlled as Camset is then set up accordingly to provide more

or less options dependant upon the combination of this setting with the Camset

Protocol above.

Comm Port

This provides a list of the available Comm Ports detected by the software on the

PC. If a comm port is in use when it is selected the user will be prompted with an

error, and should either select another port or close the application currently using

it. If the MIC-USB485CTR, USB to RS485 convertor is being used, when plugged

in this will show on the Comm Port drop down menu as USB, simply select to use.

The final option is close which will close any open communications port meaning

that other applications can then use the port for other purposes.

Camset Baud Rate

This displays the current Baud Rate at which outgoing messages are sent, and the

other options available for the given protocol above. Changing this without first

changing the MIC baud rate will cause a loss of communications.

RTS

This defines the state of the RTS line on the serial port which can be used power

in line RS232 to 485 adapters.

Comms Mode

There are 3 available options for comms modes:

Full Duplex: Full 2 way 4 wire communications connection. Messages are

transmitted and received on separate comms pairs.

Half Duplex: 2 way, 2 wire communications connection. Messages are transmitted

and received on the same pair of wires. The 485 drivers deal wih the switching of

the line directions automatically.

Simplex: 1 way 2 wire communications connection. Messages are only transmitted

to the camera. This will work for most manual controls, but anything that requires a

response, such as Pot Test, Exact Positioning, Programming etc will fail.

Bosch Security Systems Issue 6

Page 26

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 26

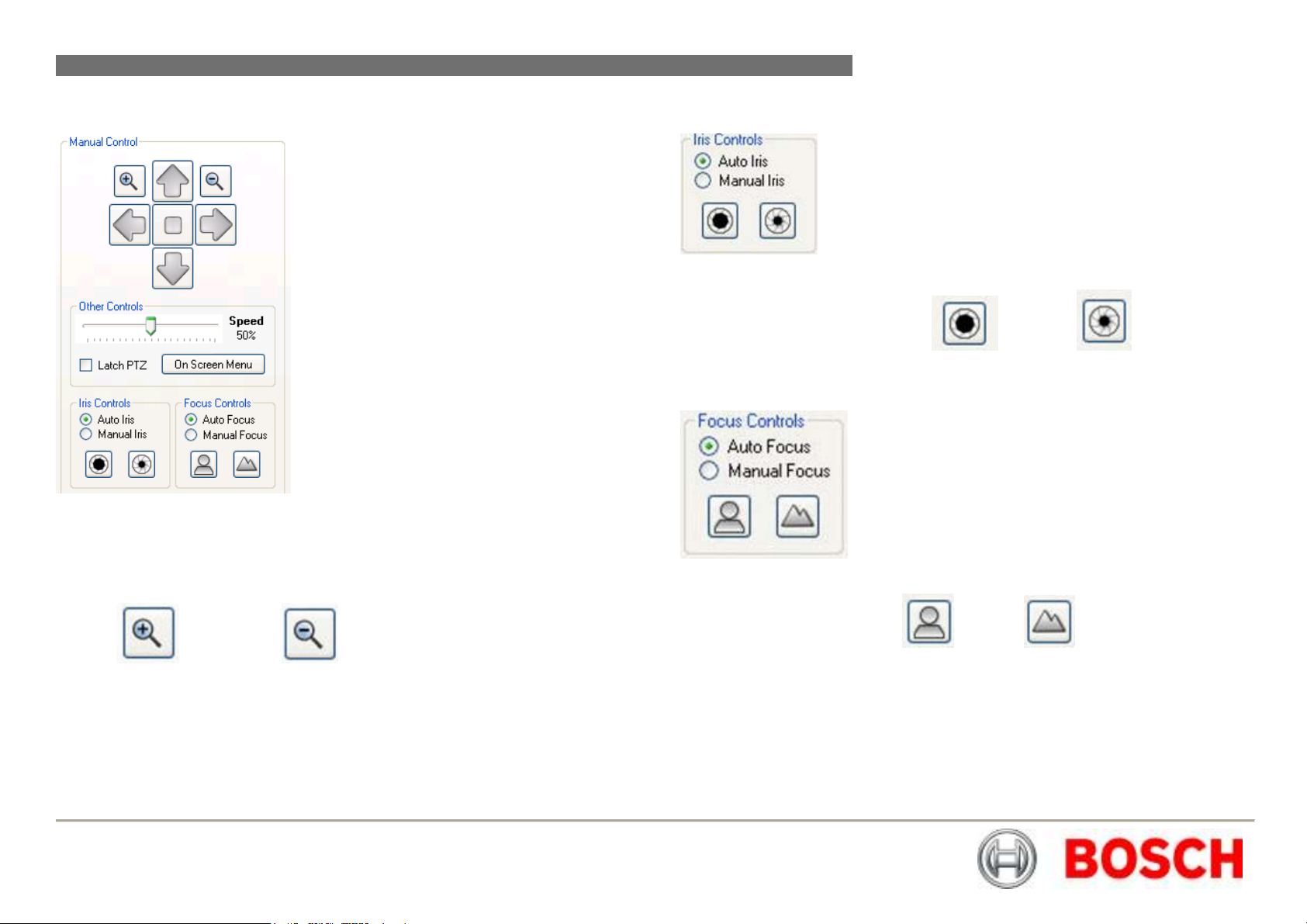

Manual Control

Iris Controls

Pan, Tilt and Zoom Controls

The Up, Down, Left and Right buttons send commands to the MIC to move in the

selected direction at the speed indicated by the

Zoom In and Zoom Out control the zoom position of the camera

lens at a fixed rate.

Latch PTZ: This tickbox will Latch the PTZ controls for continuous tilt or rotation

as required.

Speed Slider.

Auto Iris lets the MIC automatically adjust to changing light levels, where Manual

Iris

gives the user control with Open and Close buttons.

Focus Controls

Auto Focus

gives the user control with Near and Far buttons.

lets the MIC automatically focus on a changing scene, Manual Focus

Bosch Security Systems Issue 6

Page 27

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 27

Auxiliaries

Preset Positions

Slow Zoom

PTZ Scale: Scales the MIC speed dependant on zoom position.

Wiper: Turns on or off the MIC wiper if fitted.

Washer: Activates the washer relay on the MIC-WKT card or the MIC-ALM card if

fitted in the PSU. This also moves the MIC to the stored

turns on the wiper. Once de-activated the MIC will return to its original position and

turn off the wiper.

IR / Thermal: Dependant on the MIC this will do one of 3 things, for a Non-IR

Standard MIC the IR cut filter will come in and the image will go black and white.

For a twin IR MIC, the cut filter will come in and the lamps will turn on.

Note: If the lamps do not turn on, ensure the power supply is an IR version and

that Auto Alarm and Multi Alarms in the MIC Setup tab are both turned on.

For a MIC412, the video output will switch from the Sony module to the thermal

module; the controls on the

Digital Zoom: This will enable the MIC to continue into the digital zoom once the

optical limit has been reached. This also needs to have

under the

Auto Pan: This will start the MIC panning between left and right defined limits.

On Screen Data: This activates the Sony modules on screen icons.

: Reduces the speed at which the MIC zooms.

Thermal tab will also now function.

MIC Setup tab.

WashWipe position and

Digital Zoom Enabled

Preset positions are locations stored by the MIC in Pan, Tilt and Zoom, Focus etc,

which can be either called back manually, or returned to as part of a preset

position tour.

To learn a position move the MIC to the desired location and then either enter in

the preset number in the box available or press the

displays the desired value. Then press the

value in the input box will be cleared.

Returning to a position uses the same number entry method and then press the

Go To instead.

The Learn All Presets button will set every preset position available for the given

protocol to the current position. This may take a few seconds.

Learn button to store. Once stored the

Preset Number button until it

Bosch Security Systems Issue 6

Page 28

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 28

Tour Controls

The

Tour Number selects the tour to which you save and also play from. The Start

Tour button initiates the current programmed sequence for the given Tour Number.

Pattern Tours

Depending on the protocol, the controls for these vary. Some fully implement the

recording functionality and in these cases the

buttons are used, with user manual control in between. This is again stored to the

Tour Number as set.

Other protocols use an add point method, where Start Recording and

Stop Recording are used in the same way, but instead of manual control in the

middle

Preset, Dwell and Speed.

Add Tour Point is used to insert a preset position with the options specified

Start Recording and Stop Recording

Soft Stops and Non Dwell Zones

This feature offers a method of restricting the MIC's movements to a certain area.

A "box" is defined using the Top Left and Bottom Right buttons which provides the

area within which the MIC is allowed to move. To clear the area set both corners to

the same location.

Tours provide a way of making a MIC continually move to points of interest within

its visible range. There are 2 different methods to enable this;

preset positions in the set order waiting at each for a desired dwell time while

Pattern Tours mimic the operator’s movements whilst recording so it can follow a

defined path.

Access to these methods is entirely protocol specific, meaning if it is shaded out,

the feature is not supported. In some cases there are up to 6 tours available.

Preset Tours

To save a preset tour, simply enter the end preset number into the input box and a

corresponding dwell time and press

each steps preset position being fixed and the dwell time constant across the tour,

stored to the Tour Number. More comprehensive program methods are normally

available through the control system.

Program Tour. This initiates a simple tour with

Preset Tours recalls

Non-Dwell Zone

This provides the opposite of Soft Stops, in that an area can be defined within

which the MIC cannot stop. The area is defined and cleared in the same way using

the Top Left and Bottom Right buttons. Once the MIC enters the area it passes

straight through to the opposite edge.

Clear

This button clears both the Soft Stops and the Non-Dwell Zone, which is required

after a MIC has its protocol re-flashed (see Programming section).

Bosch Security Systems Issue 6

Page 29

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 29

MIC Setups

General Settings

MIC Setups tab contains the basic camera controls such as General Settings,

The

Multi alarms (if MIC-ALM card is fitted), Relays, AutoHome options and the Default

Settings.

Bosch Security Systems Issue 6

Pan Reverse

This will invert the pan rotation of the MIC compared to the commands from the

controller. This would be used if a MIC was inverted to regain logical control.

Tilt Reverse

This will invert the tilt rotation of the MIC compared to the commands from the

controller.

Image Flip

This manually inverts the image from the camera module, which may be used on

an inverted camera where the head cannot be rotated through 180 degrees.

Inverting the image would normally also require some modification of the control

directions.

Page 30

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 30

Wash Wipe

If Wash Wipe is On then, when the Wash auxiliary is set the MIC will return to a

preset Wash Position activate the washer relay in the PSU and turn on the wiper.

When the auxiliary is turned off again, the MIC will return to its prior position and

turn the wiper off. If Wash Wipe is Off then when the aux is activated the MIC will

simply close the washer relay and remain in its current position.

Auto Alarm

This is used for both single and multi alarm functionality. With Auto Alarm on and

Multi Alarm off, the MIC will monitor the tamper switch line, moving to the

programmable Alarm Position when the connection is grounded. If Auto Alarm is

turned off the MIC will ignore any change in status of the tamper line.

Multi Alarm

With this the user can setup a separate position for each of the 8 alarm inputs. Any

given alarm input will trigger the MIC to move to the position with which it is

associated. To get this functionality working both Auto Alarm and Multi Alarm

should be turned on.

Photocell IR

This mode enables the user to attach an external photocell to the power supply to

control the IR lamps. The device is connected to alarm input 4, meaning that when

the light levels drop sufficiently alarm 4 is triggered, and instead of moving the MIC

detects this as an activation signal for the lamps. When the light levels pick up

again, the alarm will deactivate and the lamps will be turned off. This mode can

enable the user to hide the sensor away from any large external lighting which may

cause the camera to flick in and out of IR mode under Auto conditions.

Camera Power

This can be used to turn the camera module inside the MIC off as required.

Digital Zoom

This is an override for the Digital Zoom Auxiliary, meaning that if On this will allow

digital zoom to be controlled by the aux state, but if off, will never allow digital

zoom no matter what the state of the aux.

Auto Flip

With this enabled the MIC will pan through 180 degrees as it reaches the vertical

position so the user can then tilt down the other side meaning the MIC video is

never inverted. Once the rotation is complete the controls are reversed until a stop

command is received, at which point they are returned to normal.

Auto IR

In this mode the camera module is monitored for its current IR state, as soon as

the light drops sufficiently, the module will automatically put the cut filter in place

and switch to black and white, at which point the MIC will turn on the IR lamps.

Auto Lowlight

If this is turned on, the MIC will decrease its shutter speed as the light levels drop,

rather than increasing the gain. Motion blur on the video can occur if the frame rate

drops sufficiently low, which may not be ideal for a camera which is continually

moving. However if motionless, the images will not have the grain associated with

lowlight conditions. The gain at which a change is made and the lowest frame rate

can be controlled under the Frame Integration section.

Auto Home Controls

After a programmable time with no manual control the MIC can be configured to

either, move to the home position (Preset 1) or start tour / pattern 1. With

turned off the MIC will simply remain stationary until the next user input.

Home

The amount of time before this takes place can be set using the input boxes and

the Set Time button.

Auto

Bosch Security Systems Issue 6

Page 31

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 31

Other controls

Default Settings

Learn Wash Position

This is the position that the MIC will return to when the Washer Auxiliary is

activated and

nozzle.

Learn Alarm Position

This is the alarm position for the tamper switch. The MIC will return to this position

Auto Alarm is turned on, Multi Alarm is turned off and the tamper line in the PSU

if

is pulled to ground.

Find End Stops

This will get the MIC to rotate in the tilt axis first down then up to its mechanical

limit stops. It will then store a "soft" limit a few units back from these for normal

use. During this process manual control is not available.

Show Boot Message

This will display the boot message that appears on the video for a few seconds,

this may be helpful to determine the current software of the MIC, without having to

do a full reboot.

Self Diagnosis

This function is for future products and does not work with the MIC400 or MIC412.

Wash Wipe is turned on. This should point towards the washer jet

The Default Settings tab reads and sets settings from the following sections:

- Manual Control Auxiliaries

- General Settings

- Auto Home Controls

- Multi Alarm Settings

- Lens Recalibration

- Frame Integration Settings

- All Thermal controls

All other settings will not be saved, loaded, downloaded or set through the

following controls.

Get Current MIC Settings

This downloads the current status of each of the settings from the MIC and loads it

into the text boxes and radio buttons on Camset. This provides an easy way of

viewing the current setup of each MIC and also a way of copying the settings from

one into the next.

Bosch Security Systems Issue 6

Page 32

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 32

Save Current MIC Settings

This option will first prompt for a file location and then store the current state of all

the options outlined above to an XML file which can then be loaded at a later date

back into Camset as a standard for a specific site.

Load Settings into Camset

This will prompt to open an XML file as saved above. Only valid Camset Default

XML files will work.

Set Current Settings to MIC

This will go through each of the settings above except for thermal, and send out

the commands to the MIC to set it up as Camset displays. This may take a few

seconds as there are several commands involved in this process.

Upload Default Options

At the end of this there are 2 extra options for defaults,

clear any saved Soft Stops and Non-Dwell Zones and then

options may be used to completely set up a MIC after it has been reprogrammed

to a new protocol.

Clear SS and NDZ will

Find End Stops. These

Multi Alarm Settings

Learn Alarm Positions

Simply point the MIC400 at the position you would like it to cover when each

numbered alarm is triggered and press

Relay State

This function is available only to MIC cameras with the MIC-ALM card fitted into

the MIC PSU or the MIC400IR Power Supply which has Four (4) Alarm Inputs built

in.

The MIC-ALM multi alarm card provides 2 output relays which can be configured to

close or open on given alarm inputs. Relay 1 can be activated from either alarm

inputs 1 to 4 or 1 to 8 and relay 2 with alarm inputs 5 to 8 or 1 to 8.

, Activation and Re-arm

Learn Alarm Position to set this.

Bosch Security Systems Issue 6

Page 33

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 33

The re-arm time is a time in seconds before the MIC returns to its current position

and returns the relay to its prior state. The options for this are 1, 5, 10 or 60

seconds. To send the settings to the MIC select the desired options and then press

Set Relays.

Privacy and Captions

Due to space limitations within the MIC440 camera a privacy card cannot be

fitted hence the privacy function does not function, captions are unaffected.

Lens Recalibration and Frame Integration

This section defines when and how often the Sony Optical Camera block should

perform a recalibration process. The first field Inactivity defines how long in hours it

should be after the last manual control command before the first recalibration

should take place, and the second is a time in days between each successive

recalibration from then on.

To set these enter the appropriate values in the text boxes provided and press

Apply. Alternatively the Recall Now button will perform a manual recalibration.

Frame Integration Settings

This section defines the

MIC when in Auto Lowlight mode. The drop down lists provides the actual settings

available in dB for gain and FPS for shutter speed. The On Screen Data auxiliary

command will indicate the current frame rate if required. The values are set by

simply selecting the desired option from the drop down lists.

Max Gain and Min Shutter Speed parameters used by the

The

Privacy and Captions tab allows the user to define and set the privacy mask

function if the optional privacy card is fitted; this is not applicable to the MIC400 as

the privacy card cannot be used with the thermal imager.

Bosch Security Systems Issue 6

Page 34

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 34

Privacy Controls

For MIC400 Cameras with the optional privacy card fitted (Not MIC412 or MIC440)

Masks On / Off

This is an override setting to turn masks completely On or Off. This will not clear

each individual masks settings, so when

re-appear with

Crosshair On / Off

This setting makes a crosshair appear on the video display centered on the middle

of the video. This can then be used to set individual mask pixels with the

appropriate command from below.

Show / Clear Mask Style

This setting provides a preview of the current mask style. This will only work if the

Crosshair is turned

crosshair center. If nothing appears, the mask may be clear, so use the

Style

to change to a visible setting. Once the required style has been selected;

press

Clear Mask Style and Crosshair Off, to return to the normal state.

Mask / Clear Whole Screen

These functions will add or remove a privacy mask the size of the entire current

view. Moving the MIC in Pan or Tilt should then indicate the zone clearly. This

would most commonly be used in conjunction with zoom where a window can be

made full frame and then the whole thing masked as apposed to the method below

which may take significantly longer.

Mask / Clear Pixel

This is a more accurate way of creating privacy masks one pixel at a time. The

Pixel is created at the center of the image, or where the crosshair points if it is

visible.

Set Crosshair

This will create a pixel sized mask as with the function above, and will also bring

up the crosshair. Press again to remove the crosshair or use Crosshair Off.

On, in the same positions.

On. It will show a small privacy block to the right of the

Off is sent they will disappear and then

Set Mask

Set Mask Type

If Crosshair and Mask Style are both turned On this function can be used to step

through each of the available mask types one at a time. This will not update all the

masks to the same type, only the ones that are created subsequent to the change.

Load Factory Defaults

Clears the current Privacy masks and resets the privacy card to the factory

defaults.

MIC Configuration

These options define the MIC's orientation, which defines how the masks track. for

Inverted MICs, the head would normally be rolled around through 180 degrees,

with Pan Reverse On to regain sensible control. However, with inverted IR MICs,

the head cannot be rotated around due to the IR Lamp arms, and therefore the

video must be inverted, and both controls reversed.

Basic Calibration

This sends a set of default commands to the MIC to initialize the privacy for an

upright MIC. This will not be perfect as each board needs fine individual calibration

but provides a good starting point.

Zoom Alignment

The zoom alignment buttons provide accurate calibration of the mask tracking.

This would normally be carried out by using a vertical line of mask on along a

known straight edge. If this line then moves as the MIC pans and tilts, it can be

corrected using the appropriate arrow. The labels indicate the current value in both

the Vertical and Horizontal planes, which will be incremented or decremented

dependant upon the direction pressed.

Direct Command

All privacy commands consist of 2 Hex bytes, a command byte and a data byte.

These perform all of the privacy functions available. To enter commands, enter the

2 bytes in Hex, into the boxes provided and press Send Command. Entering

random commands here may result in very odd results so please do not use

unless under specific instruction.

Save Current Settings

Once any calibration changes are made, this button should be pressed to save the

new values permanently.

Bosch Security Systems Issue 6

Page 35

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 35

Privacy Calibration

Disabled for cameras without a privacy card fitted

Privacy Calibration section deals with the calibration settings of the privacy

The

masking. I.e. how the masks track as the MIC is moved in Pan, Tilt or Zoom.

MIC Configuration

These options define the MIC's orientation, which defines how the masks track. for

Inverted MICs, the head would normally be rolled around through 180 degrees,

with Pan Reverse On to regain sensible control. However, with inverted IR MICs,

the head cannot be rotated around due to the IR Lamp arms and therefore the

video must be inverted and both controls reversed.

Basic Calibration

This sends a set of default commands to the MIC to initialise the privacy for an

upright MIC. This will not be perfect as each board needs fine individual calibration

but provides a good starting point.

Zoom Alignment

The zoom alignment buttons provide accurate calibration of the mask tracking.

This would normally be carried out by using a vertical line of mask on along a

known straight edge. If this line then moves as the MIC pans and tilts, it can be

corrected using the appropriate arrow. The labels indicate the current value in both

the Vertical and Horizontal planes, which will be incremented or decremented

dependant upon the direction pressed.

Direct Command

All privacy commands consist of 2 Hex bytes, a command byte and a data byte.

These perform all of the privacy functions available. To enter a command, enter

the 2 bytes, in Hex, into the boxes provided and press

CAUTION: The privacy calibration settings should be

configured at manufacture and should therefore not need to

be changed on site.

Any changes to these settings may be difficult to correct, so

please do not attempt to change anything unless under

instruction from Bosch.

Send Command. Entering

random commands here may result in very odd results so please do not use

unless under specific instruction.

Save Current Settings

Once any calibration changes are made, this button should be pressed to save the

new values permanently.

Captions

Captions tab allows the user to set up captions, Sector or Preset Captions;

The

Screen Location and Caption Colour are all user definable.

The MIC has 3 different caption options available. On the MIC 400 model range

only one line of text is available and therefore a Preset Caption will overwrite a

Default Caption.

The

Default Caption can be treated as the name of the camera. It will appear on

the video whenever it can, i.e. when no Preset or Sector captions are selected.

Preset Captions can be used to display a different title for each of the preset

positions available. This will be loaded once the MIC has reached the position.

Bosch Security Systems Issue 6

Page 36

MIC440 Explosion Protected CCTV Camera System| Installation and Operation Manual EN | 36

As an alternative, the same 64 captions can be used, not for preset positions but

for rotational sectors. The MIC’s pan is split into 64 segments and a different

caption can be assigned to each or to a group. Using this option can result in an

occasional slight control lag.

Whatever caption is being set the writing must be entered into the

Box

. The caption will be displayed in block capitals and only certain extra

characters are recognised. Unknown characters will be displayed as "?".

Location and Colour

These options define where on the video and in what colour the caption will be.

Set Default Caption

This programs the current caption (if valid), position and colour settings to the

default caption. If captions are turned on this should appear immediately on the

video.

Toggle Captions On / Off

This setting is a global On / Off setting for captions. If Off then no captions will be

displayed, Default, Preset or Sector.

Toggle Sector / Preset