Page 1

Video | MIC Series 412TI Thermal Camera

MIC Series 412TI Thermal Camera

www.boschsecurity.com

u Dual thermal/optical operation

u Brushless motor technology

u Robust design

The MIC Series 412 thermal camera has been designed

to offer an extremely reliable, robust, and high quality

surveillance solution for security applications that

demand the very best performance. Precision

engineered to exacting standards, the device offers

the most ruggedized dual optical/thermal image

capture solution available on the market today.

Containing both a high quality optical day/night

camera module and a thermal imaging module that sit

side-by-side within the housing, the compact MIC

Series 412 thermal camera switches between a high

resolution optical camera and a high performance

thermal camera at the press of a button on the control

keyboard.

A 36x day/night camera is paired with the latest

50 mm un-cooled thermal imager to provide a range of

enhanced viewing options, such as spectral heat

variance, and hot and cold spot highlights. The thermal

imager has built-in sun protection that allows the

camera to self-heal should it be pointed directly at the

sun.

Brushless motor technology ensures ultra-reliable,

whisper‑quiet operation while groundbreaking resolver

technology provides pinpoint accuracy, affording the

user full 360° continuous rotation pan and 260° tilt

control.

u Integrated wiper unit

u Host of mounting and viewing options

The MIC Series 412 thermal camera is compatible with

all MIC Series connection cables, brackets, control

equipment, and non-IR power supply units for ease of

installation, integration, and operation.

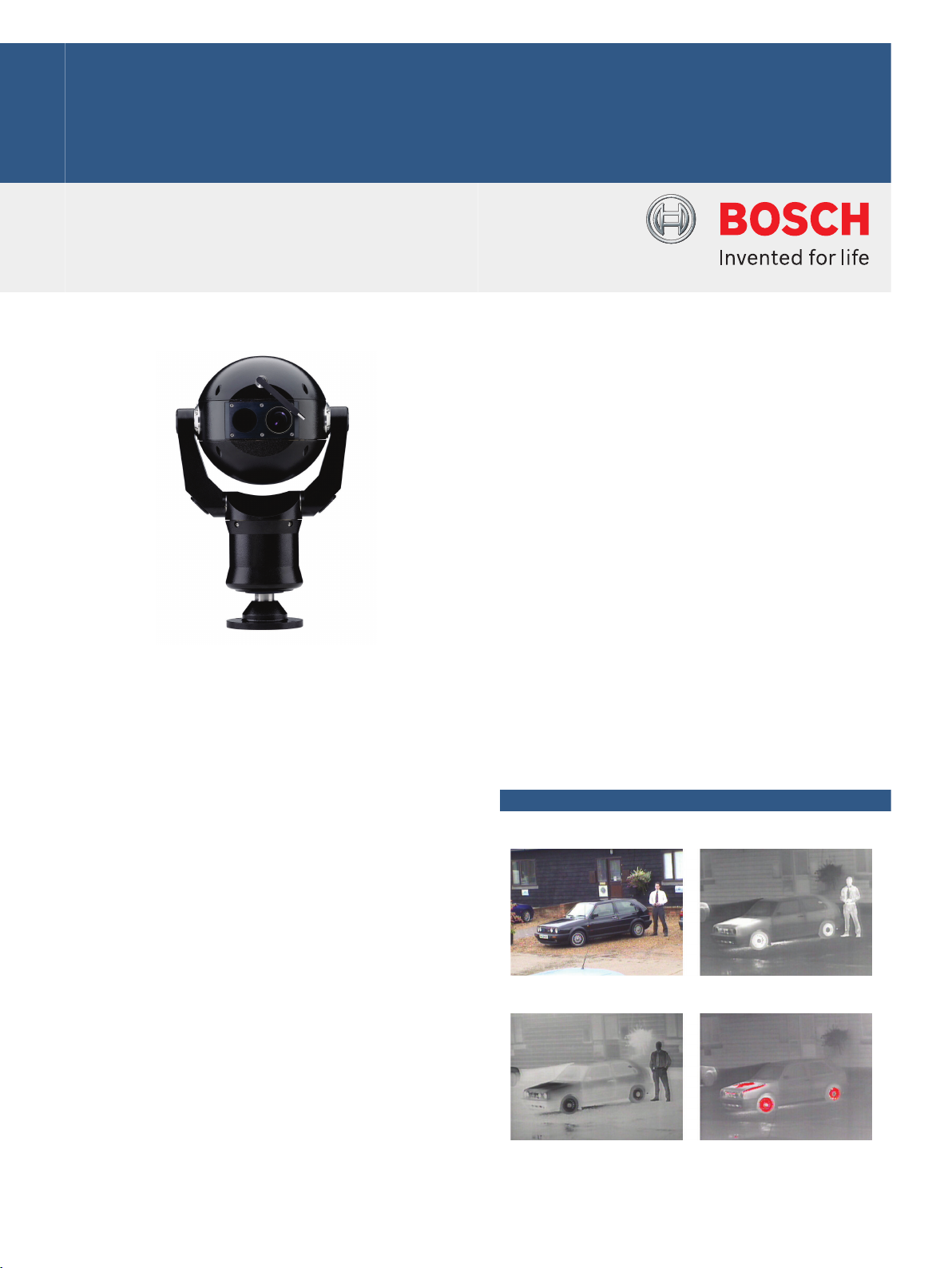

System overview

Examples of optical and thermal modes

Optical image / Thermal image in white hot spot mode

Page 2

2 | MIC Series 412TI Thermal Camera

Thermal image in black hot spot mode / Thermal image

in ice and fire mode

Thermal image in glow bow mode / Thermal image in

iron bow mode

Functions

Separate optical and thermal cameras

Switch between optical camera and thermal imager at

the press of a single button.

Brushless motor technology

Whisper‑quiet operation and smooth control is

provided through use of ultra-reliable brushless

motors.

Robust design

Machined from solid aluminum, the MIC Series 412

thermal camera ensures corrosion protection by using

two different processes; first an Alocrom 1200

coating, then a robust, powder paint coating. Alocrom

1200 is a chromate conversion coating of aluminum,

used in the aerospace and defense industries where a

protective layer is required to improve corrosion

resistance. Sealed with 'O'-rings, the device can

operate submerged up to 1 meter (3.3 feet)

underwater by virtue of its design and construction.

Notice

The thermal camera will show no detail if

submerged.

Integrated long-life silicone wiper and heater

Thanks to its integrated wiper and heater, the MIC

Series 412 thermal camera is able to capture the

highest possible quality image all year round,

regardless of the weather.

Host of mounting and viewing options

Faultless operation, either upright or inverted, gives

the user a host of mounting and viewing possibilities

Easy to use

Provides the same easy to use functionality of all MIC

series cameras, including the same connection cables,

brackets, control equipment, and non-IR power supply

units.

Certifications and approvals

Electromagnetic

Compatibility (EMC)

Safety Complies with CE regulations, UL, EN, and IEC

Weatherproofing IP68 (1 m submersion for 24 hrs)

Complies with FCC Part 15, ICES-003, and

CE regulations, including EN50130-4,

EN61000-3-2 & 3-3, EN55022 and

EN50121-4

Standards 60950-1 & 22

Technical specifications

Camera Module (optical)

Image sensor 1/4‑inch EXview CCD

Horizontal resolution (WDR) 36x module, 530 TVL NTSC/PAL

Filter Automatic mechanical IR cut filter

Focus system Auto or manual

Iris Auto or manual with slow shutter integration

Synchronization Internal / External (V‑Lock)

Signal-to-Noise ratio

(SNR)

Back Light

Compensation (BLC)

White balance Automatic

Automatic Gain Control

(AGC)

Aperture control 16 Steps

typical

modes

50 dB or more

On/Off

-3 to -28 dB, 2 dB steps

36x optical zoom module

Lens F=3.4 mm (WIDE) to 122.4 mm (TELE), F1.6

Zoom 36x optical (12x digital)

Angle of view 57.8º (WIDE end) to 1.7º (TELE end)

Minimum illumination 1.4 lux (1/60 s NTSC, 1/50 s PAL, typical,

Shutter speed 1/4 to 1/10,000s (20 steps) NTSC, 1/3 to

to F4.5

F1.6, 50IRE)

0.1 lux (1/4 s NTSC, 1/3 s PAL, typical, F1.6,

50IRE)

ICR-ON mode: 0.01 lux (1/4 s NTSC, 1/3 s

PAL)

1/10,000s (20 steps) PAL

Camera Module (thermal)

Lens 50 mm

Image sensor Focal Plane Array (FPA), un-cooled Vanadium

Picture elements 324(H) x 256(V)

Oxide microbolometer

7.5 Hz NTSC, 8.3 Hz PAL

Page 3

3 | MIC Series 412TI Thermal Camera

Spatial resolution 0.760 mrad with 50 mm lens

Field of view 14°(H) x 11°(V) with 50 mm lens

Focus Factory-set at infinity focus

Spectral response 7.5 to 13.5 μm

Thermal sensitivity <85 mK at F1.6

Electronic zoom 2X

Features White hot, black hot, and false color modes

Performance Range Human 1.8 x 0.5 m

(5.9 x 1.6 ft)

Detection 780 m (2559 ft) 2.2 km (2200 m)

Recognition 200 m (656 ft) 590 m (1,936 ft)

Object 2.3 x 2.3 m

(7.5 x 7.5 ft)

(7218 ft)

Operational

E-flip Yes, E-flip enables the optical camera to invert the

Manual flip Yes

Presets 64 telemetry presets accurate to less than

Preset tours 6 tours each with up to 32 presets

Sector titles Yes (64 sectors) 20 characters per title

Preset titles 20 character caption for each of the 64 presets

Home position Yes (preset 1 or tour)

image

0.1°utilising resolver technology (using FV protocol,

10 camera set-up presets to allow ANPR, color

correction etc.)

Communication and Protocols

Communication RS485 / RS422

Control protocol Bosch or FV protocol cameras available;

additional protocols supported are Pelco D, Kalatel,

Panasonic, and VCL. These can be loaded using the

MIC-USB485CVTR signal converter and Cam-set

via a PC.

Biphase control requires a Biphase to RS485

converter (MIC-BP4, available separately) installed

in the MIC Series PSU to connect to Biphase

equipment.

Connectivity

Video Single co-axial via composite cable (optical/

Telemetry Twisted pair; Simplex, half and full duplex

MIC Universal Camera

Setup Software Utility

(Camset)

thermal cameras, user switchable)

operation via composite cable

Supplied with each camera, Cam-set allows

direct connection to a USB-equipped PC via

the MIC Series PSU over a full duplex or IP

network to provide access to all camera

functions and useful diagnostic tools

USB to RS485 signal

converter

Power Via composite cable

Allows MIC Series cameras to connect to a

PC (supplied free with camera, or available

separately)

Alarms

Alarm inputs 1 tamper input (additional inputs possible

Alarm communication Tamper switch (ground connection)

with optional alarm card in MIC Series PSU)

Mechanical

Drive unit Brushless integral pan/tilt motor drive

Pan angle 360° continuous rotation

Pan speed Up to 72° per second (variable)

Tilt angle 260°

Tilt speed 0.2° to 90° per second (variable)

Speed control Closed loop electronics

Preset accuracy ±0.30° (typical)

Proportional Pan/Tilt to

Zoom

Yes

Electrical

Input voltage (dual

source)

Input current Camera: 2 A

18VAC, +/-10%, 50/60 Hz

Heater: 1 A

Environmental

Operating temperature -40 °C to +50 °C (-40 °F to +122 °F)

Weatherproofing IP68 (1m submersion for 24 hrs)

MTBF 53,817 hours

Construction

Dimensions (W x H x D) 267 x 445 x 200 mm

Weight 9.5 kg (20.94 lb)

Viewing window Tempered flat glass (optical) and

Construction material Machined aluminum

Standard colors Black( RAL9005), Grey (RAL7001), or

Standard finish Alocrom 1200 surface treatment with

Window wiper Standard, long-life silicone wiper

(10.51 x 17.52 x 7.87 in.)

(including 4-in. PCD base)

germanium covering (thermal)

White (RAL9003)

powder coat paint

Page 4

4 | MIC Series 412TI Thermal Camera

Heater Standard

Configurations available Upright mount or inverted (Inverted mount

is possible using software setting and

upright camera.)

Ordering information

MIC412TIBUP13636N 9Hz, 36X NTSC Thermal Camera,

Black

9 Hz Thermal, 36X, NTSC, PTZ camera, Black, Bosch

Protocol with integrated wiper and heater

Order number MIC412TIBUP13636N

MIC412TIGUP13636N 9Hz, 36X NTSC Thermal Camera,

Grey

9 Hz Thermal 36X, NTSC, PTZ camera, Grey, Bosch

Protocol with integrated wiper and heater

Order number MIC412TIGUP13636N

MIC412TIWUP13636N 9Hz, 36X NTSC Thermal Camera,

White

9 Hz Thermal 36X, NTSC, PTZ camera, White, Bosch

Protocol with integrated wiper and heater

Order number MIC412TIWUP13636N

MIC412TIBUW13636P 9Hz, 36X PAL Thermal Camera,

Black

9 Hz Thermal, 36X, PAL, PTZ camera, Black, FV

Protocol with integrated wiper and heater

Order number MIC412TIBUW13636P

MIC412TIGUW13636P 9Hz, 36X PAL Thermal Camera,

Grey

9 Hz Thermal 36X, PAL, PTZ camera, Grey, FV Protocol

with integrated wiper and heater

Order number MIC412TIGUW13636P

MIC412TIWUW13636P 9Hz, 36X PAL Thermal Camera,

White

9 Hz Thermal 36X, PAL, PTZ camera, White, FV

Protocol with integrated wiper and heater

Order number MIC412TIWUW13636P

Accessories

MIC-24PSU-UL 24 VAC Camera Power Supply

24 VAC, 50/60 Hz power supply for MIC Series

cameras

Order number MIC-24PSU-UL

MIC-BP4 Biphase Converter

Biphase converter for non-IR versions of MIC series

power supply units

Order number MIC-BP4

MIC‑DCA‑B Deep Conduit Adapter, Black

Deep conduit adapter for 4 in. PCD base - black

leatherette finish, RAL9005

Order number MIC-DCA-B

MIC‑DCA‑G Deep Conduit Adapter, Grey

Deep conduit adapter for 4 in. PCD base - grey

leatherette finish, RAL9010

Order number MIC-DCA-G

MIC‑DCA‑W Deep Conduit Adapter, White

Deep conduit adapter for 4 in. PCD base - white

leatherette finish RAL9003

Order number MIC-DCA-W

MIC‑SCA‑G Shallow Conduit Adapter, Grey

Shallow conduit adapter for 4 in. PCD base - grey,

leatherette finish, RAL7001

Order number MIC-SCA-G

MIC‑SCA‑B Shallow Conduit Adapter, Black

Shallow conduit adapter for 4 in. PCD base - black,

leatherette finish, RAL9005

Order number MIC-SCA-B

MIC‑SCA‑W Shallow Conduit Adapter, White

Shallow conduit adapter for 4 in. PCD base - white,

leatherette finish, RAL9003

Order number MIC-SCA-W

MIC-SPR Spreader Plate

Aluminum spreader plate suitable for brickwork

surface mounting – black leatherette finish RAL9005

Order number MIC-SPR

MIC-SPR-G Spreader Plate, Grey

Aluminum spreader plate suitable for brickwork

surface mounting, grey leatherette finish (RAL7001)

Order number MIC-SPR-G

MIC-SPR-W Spreader Plate, White

Aluminum spreader plate suitable for brickwork

surface mounting, white leatherette finish (RAL9003)

Order number MIC-SPR-W

MIC-115PSU-UL 115 VAC Camera Power Supply

115 VAC, 60 Hz power supply for MIC Series cameras

Order number MIC-115PSU-UL

MIC-240PSU-UL 240 VAC Camera Power Supply

240 VAC, 50 Hz power supply for MIC Series cameras

Order number MIC-240PSU-UL

MIC-ALM Alarm and Washer Pump Drive Card

8 Input alarm and washer pump drive card for PSU

(Not for IR PSU)

Order number MIC-ALM

MIC‑CMB‑B Corner Mount Bracket, Black

Corner mount bracket, black leatherette finish

(RAL9005)

Order number MIC-CMB-B

MIC‑CMB‑G Corner Mount Bracket, Grey

Corner mount bracket, grey leatherette finish (RAL

7001)

Order number MIC-CMB-G

Page 5

5 | MIC Series 412TI Thermal Camera

MIC‑CMB‑W Corner Mount Bracket, White

Corner mount bracket, white leatherette finish

(RAL9003)

Order number MIC-CMB-W

MIC-PMB Pole Mount Bracket

Pole mount bracket (includes 2 x 455 mm stainless

steel banding straps for pole diameters 75 to 145 mm)

Order number MIC-PMB

MIC‑WMB‑B Wall Mount Bracket, Black

Wall mount bracket, black leatherette finish (RAL9005)

Order number MIC-WMB-B

MIC‑WMB‑G Wall Mount Bracket, Grey

Wall mount bracket, grey leatherette finish (RAL7001)

Order number MIC-WMB-G

MIC‑WMB‑W Wall Mount Bracket, White

Wall mount bracket, white leatherette finish

(RAL9003)

Order number MIC-WMB-W

MICUSB485CVTR2 USB to RS485 Signal Converter

USB to RS485 signal converter to allow MIC Series

cameras to connect to a PC, supplied with each

camera

Order number MICUSB485CVTR2

MIC-25M-S 25 m Shielded Composite Cable

Shielded Composite 25 m cable that provides power,

telemetry and video connection from a MIC Series

camera to a MIC Series power supply

Order number MIC-25M-S

HAC-WAS05-20 24 VAC Washer

24 VAC washer inst. 4M 25L

Order number HAC-WAS05-20

HAC-WAS05-50 230 VAC Washer

230 VAC washer inst. 4M 25L

Order number HAC-WAS05-50

HAC-WAS30-50 230 VAC Washer

230 VAC washer inst. 30M 25L

Order number HAC-WAS30-50

MIC-WKT Washer Kit

Washer kit for non infrared MIC models (includes

washer pump drive card, washer nozzle and mounting

brackets for wall and 4 in. PCD base)

Order number MIC-WKT

UPA-2450-50 Power Supply, 220 V, 50 Hz

220 VAC, 50 Hz, 24 VAC, 50 VA Out

For use with certain 24 VAC camera models.

Order number UPA-2450-50

UPA-2450-60 Power Supply, 120 V, 60 Hz

120 VAC, 60 Hz, 24 VAC, 50 VA Out

Order number UPA-2450-60

MIC-2M-S 2 m Shielded Composite Cable

Shielded Composite 2 m cable that provides power,

telemetry and video connection from a MIC Series

camera to a MIC Series power supply

Order number MIC-2M-S

MIC-10M-S 10 m Shielded Composite Cable

Shielded Composite 10 m cable that provides power,

telemetry and video connection from a MIC Series

camera to a MIC Series power supply

Order number MIC-10M-S

MIC-20M-S 20 m Shielded Composite Cable

Shielded Composite 20 m cable that provides power,

telemetry and video connection from a MIC Series

camera to a MIC Series power supply

Order number MIC-20M-S

Page 6

6 | MIC Series 412TI Thermal Camera

Represented by:

Americas: Europe, Middle East, Africa: Asia-Pacific: China: America Latina:

Bosch Security Systems, Inc.

130 Perinton Parkway

Fairport, New York, 14450, USA

Phone: +1 800 289 0096

Fax: +1 585 223 9180

security.sales@us.bosch.com

www.boschsecurity.us

Bosch Security Systems B.V.

P.O. Box 80002

5617 BA Eindhoven, The Netherlands

Phone: + 31 40 2577 284

Fax: +31 40 2577 330

emea.securitysystems@bosch.com

www.boschsecurity.com

Robert Bosch (SEA) Pte Ltd, Security

Systems

11 Bishan Street 21

Singapore 573943

Phone: +65 6571 2808

Fax: +65 6571 2699

apr.securitysystems@bosch.com

www.boschsecurity.asia

Bosch (Shanghai) Security Systems Ltd.

201 Building, No. 333 Fuquan Road

North IBP

Changning District, Shanghai

200335 China

Phone +86 21 22181111

Fax: +86 21 22182398

www.boschsecurity.com.cn

Robert Bosch Ltda Security Systems Division

Via Anhanguera, Km 98

CEP 13065-900

Campinas, Sao Paulo, Brazil

Phone: +55 19 2103 2860

Fax: +55 19 2103 2862

latam.boschsecurity@bosch.com

www.boschsecurity.com

© Bosch Security Systems 2013 | Data subject to change without notice

2316894731 | en, V5, 04. Oct 2013

Loading...

Loading...