Bosch Climate 5000, MAHUP(C)-32.40, MAHUP(C)-06.07 Installation, Operation And Maintenance Manual

Modular Air Handling Unit

MAHUP(C)-06.07~ MAHUP(C)-32.40

en Installation, Operation and Maintenance Manual

8736862495 (2015/0

7)CN

Read the manual carefully prior to installation and operation the unit!

Observe the warnings in the manual!

Installation by an authourised person only!

Climate 5000

WELCOME

Distinguished users:

Thank you for choosing and using Bosch products!

For ease of use, please read the Manual carefully

and operate as per the steps as described in the

Manual. We will be with you all along. Please feel

free to contact us at the number and address on

the Warranty Card whenever you have any problems. We are ready to serve you.

Due to product improvement, the product you

have purchased may be slightly different from

those introduced in the Manual. We hereby apologize for the inconvenience we cause.

Important notice:

• Modular air handling unit is the air side of air

conditioning system for water chiller, which

requires expertise and has strict specifications

and requirements. Therefore, it must be

installed, commissioned, operated and managed (by professionally trained technical

personnel).

• The product can be used widely, except damp

environment, outdoors, the environment with

blowing dust and corrosion, and the site with

explosion hazard.

• Operating conditions:

- Power supply: 3N~/380V/50Hz

- Maximum operating pressure: ≤1.6Mpa

Our company adheres to the principle of commitment to excellence, and may not inform you of

certain improvement in specification, performance, material and structure of such products.

Sorry for the inconvenience. Please contact us for

obtaining the latest information.

Table of Contents

1 Key to symbols and safety introductions ... 3

1.1 Explanation of symbols ................................ 3

1.2 Safety information ...................... 3

1.3 Delivery, handling and storage ........... 4

1.3.1 Delivery inspection ................. 4

1.3.2 Way of transport.................... 4

1.3.3 Storage of the unit .................. 4

2 Unit introduction............................................ 6

2.1 Type introduction ....................... 6

2.2 Product introduction .................... 6

2.3 Left/ right Hand pipe connection .......... 6

2.4 Unit symbols........................... 7

2.4.1 Safety symbols..................... 7

2.4.2 Functional section and symbols ...... 7

3 Unit installation.............................................. 8

3.1 Product introduction .................... 8

3.2 Equipment assembly.................... 9

3.3 Installation and connection of air duct ......10

3.4 Installation and connection of water coil pipe 10

3.5 Installation and connection of steam coil pipe 11

3.6 Installation of siphon ....................11

3.7 Electrical wiring of motors ...............12

3.8 Electrical wiring of electrical heater .......12

3.9 Electrical wiring of humidifier .............12

4 Unit commissioning ..................................... 13

4.1 Preparations before commissioning .......13

4.2 Starting and operating ..................13

4.3 Specific Prohibitions ....................13

5 Unit maintenance ......................................... 14

5.1 Maintenance and inspection ............. 14

5.2 Storage measures for the unit long-time

shutdown .................................16

5.3 Inspection and maintenance intervals .....16

6 Fault analysis and troubleshooting............ 20

6.1 Abnormal noise ........................20

6.2 Vibration ..............................20

6.3 Overcurrent............................20

6.4 Air flow insufficient ......................21

6.5 Cooling capacity too small ...............21

6.6 Leakage ..............................21

7 Packing list ................................................... 22

8 Notes ............................................................. 23

Any figures and information in this

instruction are only for reference.

8736862495(2015/07) Climate 5000

2 | Table of contents

Climate 5000 8736862495(2015/07)

1.1 Explanation of symbols

Warnings

Keywords indicate the seriousness of the hazard

in terms of the consequences of not following the

safety instructions.

• Notice Indicates that material damage may

occur.

• Caution Indicates that minor to medium injury

may occur.

• Warning Indicates that serious injury may

occur.

• Danger Indicates possible risk to life.

Important information

Additional symbols

Tab. 1 Additional symbols

1.2 Safety information

Warnings in this document are framed

and identified by a warning triangle

which is printed on a grey background. The signal word attached

indicates the type and severity of

consequence due to nonobservance of

danger prevention measures.

Important information in cases where

there is no risk of personal injury or

material losses is identified by the symbol

shown on the left. It is bordered by

horizontal lines above and below the text.

Notice: Risk of frostbite the coil!

Please make anti-freezing preparations

and drain off the water during the winter

and in low temperature.

Symbol Definition

a step in an action sequence

a reference to a related part in the document or to other related documents

· a list entry

– a list entry (second level)

►

Key to symbols and safety instructions | 3

1 Key to symbols and safety introductions

Caution: Risk of falling!

Pay attention to the center of gravity

and weight when move in and out.

Notice:

Carry out electrical work as per relevant

electrical standards and rules for

electrical works.

Notice: Risk of loosing!

Tighten the bolt for connection and

assembling.

Notice:

Pay attention to the gravity center and

weight when moving the unit.

Notice: Risk of the fan damage!

In case of unusual event (e.g. sound,

vibration and smell), stop the unit

immediately and carry out inspection.

Notice: Risk of the motor burned!

Please use the rated volt.

Notice:

Please fix on the firm foundation.

Caution:

Do not use or inspect the machine by

non-profession operator.

Caution: Risk of scalding!

Any alteration, fixing and removal

without permission are forbidden.

Warning: Risk of scalding!

Any alteration, fixing and removal

without permission are forbidden.

Warning:

Close the access door when the unit is

running.

Caution:

Ware safety gloves and safety helmet

when inspecting. The inner part of the

unit may be very hot, so it cannot be

inspected by naked hands. Attention is

to be paid that the vane may be rotated

by wind from the duct even though the

machine is powered off.

Warning: Risk of strangulation injury!

Do not put fingers into rotating parts!

1.3 Delivery, handling and storage

Each Bosch Climate 5000 modular air handling

unit (Abbreviation: MAHU)may be delivered as an

integral whole, in segments or in separate units.

1.3.1 Delivery inspection

• Bosch Climate 5000 MAHU, although have been

experienced strict factory inspection, considering

abnormal conditions may have been occurred

during transportation, please carry out inspection

and confirmation according to following items.

• Check if piping connection ports and headers

are damaged.

• Check if coils and fins are damaged.

• Manually rotating the vane to check the abnor-

mal belt and pulley (only for the unit using belt

for driving the fan).

• Check if the vane has abnormal facts (by

manually rotating the vane).

• Check if there are obvious damages of the

outer appearance of unit body and motors.

• Verify if the product specification is conformed

to the order (please verify the nameplate).

• Check the units according to the detailed list

attached to the out-of-box form.

• Check if the bolts and nuts are loosened.

If any damages and abnormals are found, please

contact to the distributor immediately. If there is an

obvious damage, please make note on the waybill

and attach the evidence, and then carry out claim

according to the instructions on the waybill.

1.3.2 Way of transport

Prior to transport the unit, please verify there are

suitable devices and tools for handling the unit,

and they shall bear the weight of unit and all the

accessories.

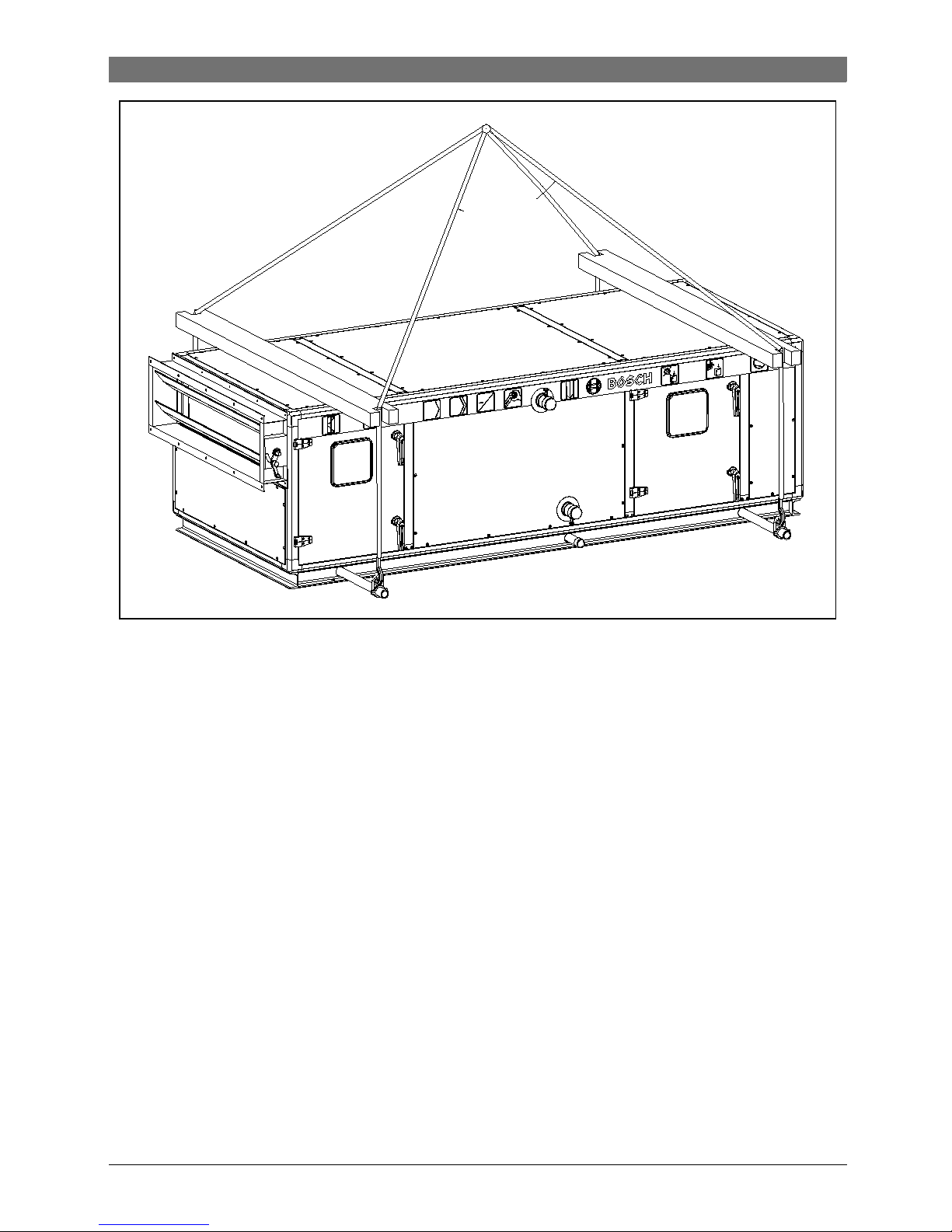

Use lifting frame for unit lifting, and length design

of lifting frame shall be capable of avoiding all

lifting loads to prevent severe damage. Each

lifting appliance shall be capable of bearing the

overall weight of the unit and maintaining sufficient weight allowance( →Page5,Fig. 1, Schematic diagram of unit lifting).

Use lifting steel pipe for unit lifting. When the

delivery weight is within 2000kg, use steel pipe

with caliber and wall thickness ≥ Φ 48×6; when

the delivery weight is within 4000kg, use steel

pipe with caliber and wall thickness ≥ Φ 48×10.

Load must be carried by base, and the suspension angle must not exceed 60°.

1.3.3 Storage of the unit

If the unit can not be installed after being delivered into the site, following protections shall be

applied:

• Put the goods on the flat plate with base down-

wards, and the shell cannot be stressed directly.

• Ensure the unit is isolated from outdoor envi-

ronment, wind and rain.

• Ensure all the orifices are equipped with

protective blind plate or closing plate.

• Put the unit away from human activity place to

avoid machinery crush.

• It is suggested to close the access door and

take off the access door key to deliver it to

responsible personnel.

• It is suggested to carry out regular inspection

for the unit during the storage.

8736862495(2015/07) Climate 5000

4 | Key to symbols and safety instructions

Danger: Beware of electric shock!

During inspection, unit must be powered off!

Danger: Beware of electric shock!

Grounding is necessary.

Notice: Risk of unit damage!

Do not put the unit on rollers!

Do not use forklift to lift the unit!

Caution: Risk of falling!

Both sides of lifting steel bar shall be

applied anti-sliding pins or fixed by pipe

clamps, to avoid slip and tilt due to

shifting of gravity center.

Key to symbols and safety instructions | 5

Climate 5000 8736862495(2015/07)

Max. 60°

Fig. 1 Schematic diagram of unit lifting

2 Unit introduction

2.1 Type introduction

Fig. 2 Type introduction drawing

2.2 Product introduction

Bosch Climate5000 modular air handling unit

manufactured by Bosch Thermal Technology(

Shandong) CO., Ltd. certified by ISO 9000

authorization, applies to strict design and manufacturing standard, meet any limits specified by

this manual, and is able to ensure the quality, and

its liability and flexibility of each type of air handling unit. The unit can be connected to water

chiller and heat pumps, and is not suitable for

other applications not specified by the manual.

The manual includes all for correct installation

and commissioning information, and operating

and maintenance instructions of the unit.

Prior to operating and maintenance of the unit,

please carefully read the manual. Any work

described in the manual including installation,

commissioning and maintenance can only be

conducted by trained and qualified professional

technicians.

Any damage and broken due to incorrect installation, operation, commissioning and maintenance,

because of failure to comply steps and instructions

specified by this manual shall be free of any

responsibilities of the manufacture.

2.3 Left/ right Hand pipe connection

( →Page 7, Fig. 3, Schematic diagram of distinguishing left and right type)

• For MAHU with Mono structure, Left or Right

Hand pipe connection is decided by judging the

relative position of Air Inlet to the Water pipe

position. (Air inlet is Left to the water pipe

position, or Right to the water pipe position).

• For MAHU with double deck or side by side

structure, Left or Right Hand pipe connection is

decided by judging the relative position of Air Inlet

to the water pipe position of the single Mono part

which contain Coil Section. See below graph.

As default, the access door is on the same side as

pipe connection.

6 | Unit introduction

8736862495(2015/07) Climate 5000

BOSCH Climate 5000

MAHU

P - 06

. 07 M

L

E

Category: Climate

Value Level: 1000~9000

Modular Air Handling Unit

P: Series Professional

C: Series Comfort

can be extended...

Type of structure:

M=Mono

S=Side by side

D=Double deck

Pipe connection:

L= Left Hand, R=Right Hand

Export(Out of CN)

Internal Width=07×Modulus(100mm)

Internal Height=06×Modulus(100mm)

Brand

Unit introduction | 7

Climate 5000 8736862495(2015/07)

2.4 Unit symbols

2.4.1 Safety symbols

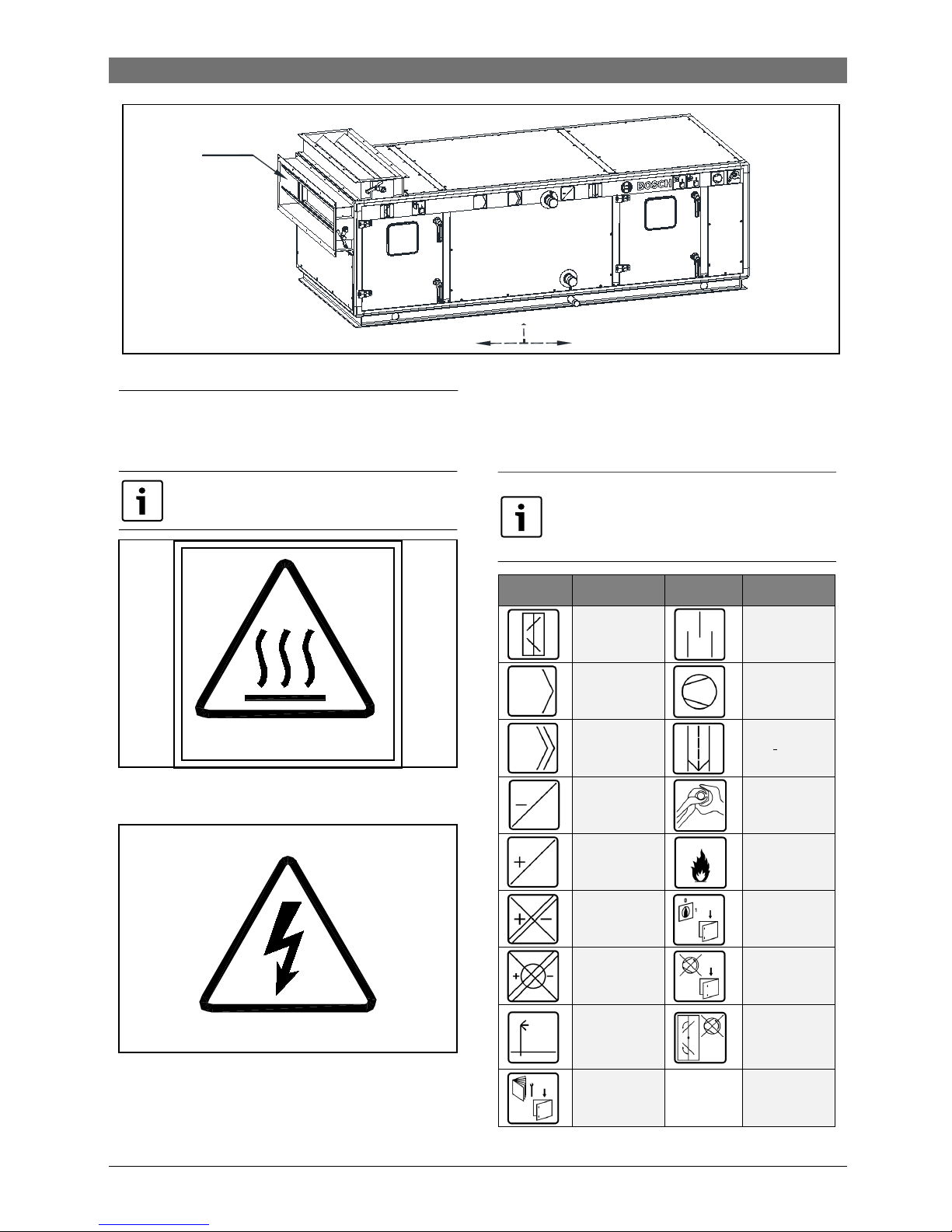

Fig. 4 Black symbol with yellow background ,

which warns high temperatureof the surface.

Fig. 5 Black symbol with yellow background,

which requires cutting off the main power before

dissembling of the machine/opening up the high

voltage electrical control box or it may cause

lethal hazard.

2.4.2 Functional section and symbols

Tab. 2 List of functional section symbols

The following symbols are attached on

each unit for the possible risks.

The following symbols are the unit

functional section or warning symbols,

the color of which is coal ash color, and

shadow of the lines is industrial gray.

高温!

HIGH TEMPERATURE!

Left

Right

Left type unit

Air inlet

Fig. 3

Schematic diagram of distinguishing left and right type

Symbols Instruction Symbols Instruction

Air damper

Muffler

Pre-filter

Fan

Medium filter

Drip eliminato

r

Cooling coil

Use a pipe

clamp when

installing coils

Heating coil

No flame

Heating and

cooling coil

Electric shock

when opening

the door

Rotary wheel

heat

exchanger

Do not open

the door when

fan operating

Humidifier

Do not start

when the air

damper is

closed

Indoor

attached

information

3 Unit installation

Find installation instruction , assembling

spare parts and accessories on place for storing

the documents and accessories. Before installation, transportation safety device with yellow

symbols shall be removed especially the safety

device for fan. Any abovementioned works must

be operated by professional personnel.

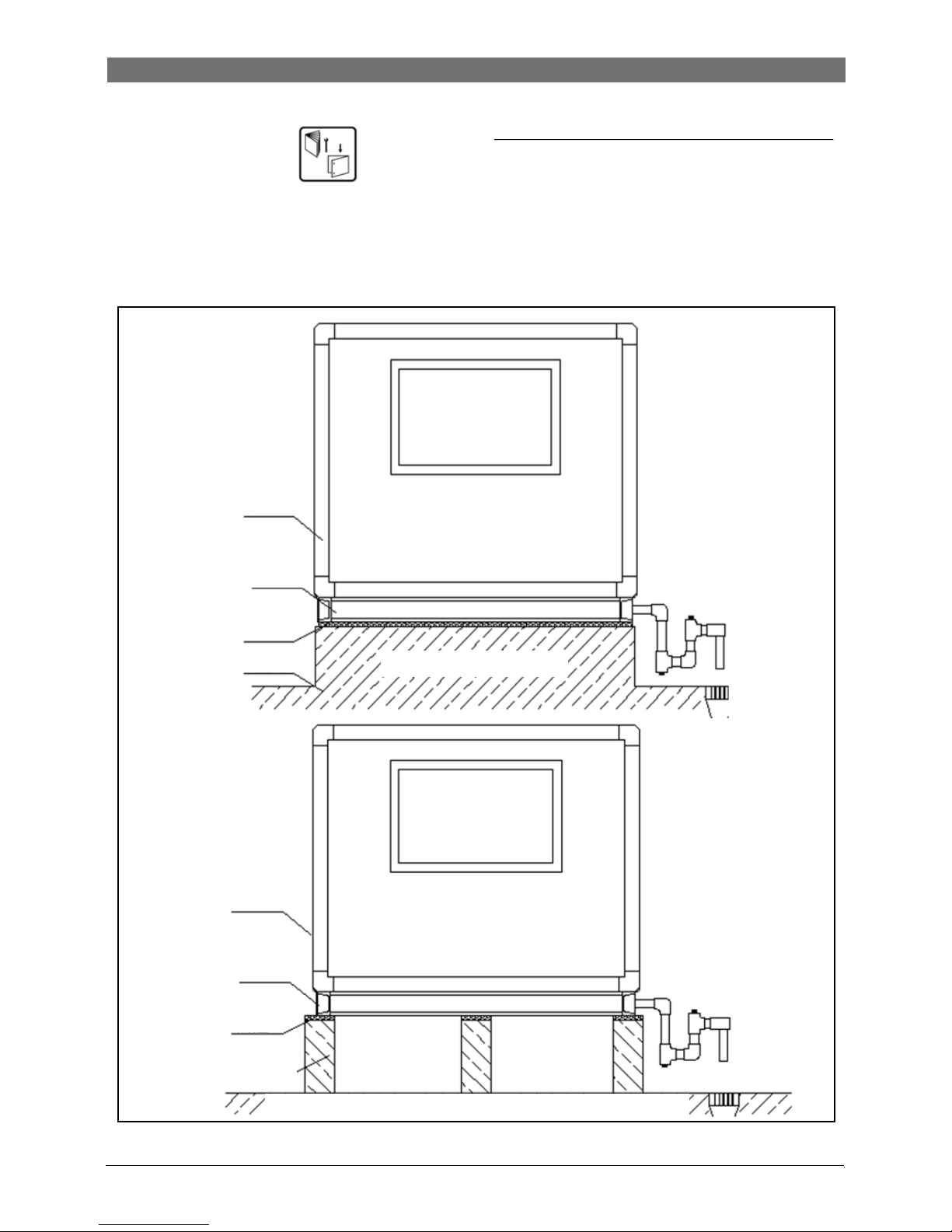

Fig. 6 Schematic diagram of base installation

3.1 Product introduction

• To prevent vibration and noise transmission,

anti-vibration pads shall be applied between

equipment and foundation; foundation levelness should be 1/1000. After placement, the

tolerance of entire unit in height and width shall

be controlled within 3mm. For the details of

foundation installation→Fig. 6.

8 | Unit installation

8736862495(2015/07) Climate 5000

Flat face foundation

Concrete or steel support strap footing foundation

Unit body

Unit body

Channel

Channel

Absorption gasket

Absorption gasket

Flat face foundation

Concrete or steel-frame

strip foundation

Loading...

Loading...