Page 1

chheat

ing

ing

inginging

in

coocoo

coo

coo

coo

iii

g.c

g.cg.c

g.c

g.c

c

omom

om

jejejec

c

c

c

c

c

c

c

c

c

ct

ge

ge

ge

e

wit

wit

wi

ittt

ou

t t ppppt

t

t

oti

oti

ce.

LV Model

Water Source Heat Pump

1/2 to 6 ton

The option-rich, water-to-air

LV offers one of the smallest

cabinets in the industry,

making it a great choice for

replacement and new

construction projects.

boschheatingandcooling.com | 1bos

LV

MODEL

UP TO

P TO

16.9

EER

GLHP

UP TO

5.3

COP

WSHP

Commercial Sales Catalog

boschheatingandcooling.com

Page 2

1 | LV Model | Commercial Geothermal Heat Pumps

.

Table of Contents

MODEL NOMENCLATURE ..............................................2

CERTIFIED PERFORMANCE DATA .................................2

FHP EQUIPMENT ............................................................3

ADVANTAGES OF FHP’s TECHNOLOGY ........................3

LV MODEL 007-070 .........................................................3

FEATURES, FUNCTIONS AND BENEFITS .................. 3-5

Cabinet ......................................................................3

Quiet Operation .......................................................4

Serviceability ...........................................................4

Unit Confi gurations ...................................................4

Filter Racks and Options ..........................................4

Optional MERV-8 and -13 Filter.................................4

FAN MOTOR ....................................................................5

Permanent Split Capacitor Motors (PSC) ................5

ECM Constant Torque Motor (Optional) ..................5

ECM Constant Airfl ow Motor ...................................5

Hanging Brackets ......................................................5

Water Connections ...................................................5

Two-Position Water Valve..........................................5

Refrigerant Circuit ....................................................5

Evaporator Coil and DuoGuard

TM

.............................6

Blower Housing .........................................................6

Unit Protection Module ......................................... 6-7

UPM CONTROL BOARD FEATURES ...........................7-8

ADDITIONAL OPTIONS ................................................. 8

Hot Gas Reheat ........................................................ 8

Hot Gas Reheat Control Options .............................9

Special Considerations .............................................9

Low Temperature Well Water ...................................9

Indoor Pool Dehumidifying During Winter Months .....9

Sequence of Operation - Modulating

Hot Gas Reheat (MHGRH) ........................................9

Hot Gas Bypass .........................................................9

Psychrometric Chart ............................................... 10

DDC Controls ................................................................10

DDC Room Sensors ................................................ 10

DDC Zone Sensors ..................................................11

Waterside Economizer Common Waterside

Economizer Applications .........................................11

Fluid Flow ................................................................11

Aquastat .................................................................. 12

Air Side Pressure Drop ........................................... 12

Fluid Differential Pressure Switch .......................... 12

Energy Management Switch (EMS) ....................... 12

OTHER OPTIONS ..........................................................13

ACCESSORIES .............................................................13

Thermostats ............................................................ 13

Hose Kits ................................................................. 13

UNIT CONFIGURATION DIAGRAMS ........................... 14

SYSTEMS .......................................................................15

Water Source Cooling Tower/Boiler Systems ........ 15

Geothermal Systems .............................................. 15

Earth Coupling Options ......................................15-16

Vertical Ground Loop System.................................16

Horizontal Ground Loop System ............................ 16

Surface Water, Lake or Pond System ......................17

Well Water System ...................................................17

TYPICAL HEAT PUMP OPERATION.............................. 17

Cooling Mode ...........................................................17

Heating Mode ...........................................................17

TYPICAL UNIT INSTALLATION .....................................18

Water-to-Air Heat Pump Cycle - Cooling ................. 18

Water-to-Air Heat Pump Cycle - Heating................. 18

Unit Location...........................................................18

Vertical Unit Installation .........................................18

Horizontal Unit Installation .................................... 19

Ductwork & Sound Attenuation Considerations .... 19

Piping ......................................................................20

Condensate Drain Piping ........................................20

Operating Limits – Cooling & Heating .............. 20-21

EQUIPMENT SELECTION.............................................. 21

ANTIFREEZE CORRECTION DATA ...............................22

WATERSIDE PRESSURE DROP ....................................22

CAPACITY DATA ..................................................... 23-35

LV007 (300 CFM) ....................................................23

LV009 (350 CFM) ...................................................24

LV012 (400 CFM) ....................................................25

LV015 (500 CFM) ....................................................26

LV018 (650 CFM) .................................................... 27

LV024 (850 CFM) ....................................................28

LV030 (950 CFM) ...................................................29

LV036 (1200 CFM) ................................................. 30

LV041 (1150 CFM) ................................................... 31

LV042 (1500 CFM) ..................................................32

LV048 (1600 CFM) ..................................................33

LV060 (2000 CFM) .................................................34

LV070 (2200 CFM) ..................................................35

UNIT ELECTRICAL DATA .............................................. 36

Standard Blower Motor ..........................................36

ECM Constant Torque ............................................37

ECM Constant Airfl ow (Variable Speed) ............... 38

BLOWER PERFORMANCE CFM .................................. 39

Standard Blower Motor ..........................................39

ECM Constant Torque ........................................... 40

ECM Constant Airfl ow (Variable Speed) ................ 41

PHYSICAL DATA ........................................................... 42

HORIZONTAL CABINET CORNER WEIGHTS .............. 43

VERTICAL UNIT DIMENSIONS .................................... 44

HORIZONTAL UNIT DIMENSIONS ............................... 45

COUNTERFLOW UNIT DIMENSIONS .......................... 46

GUIDE SPECIFICATION .......................................... 47-50

Subject to change without prior notice

Page 3

.

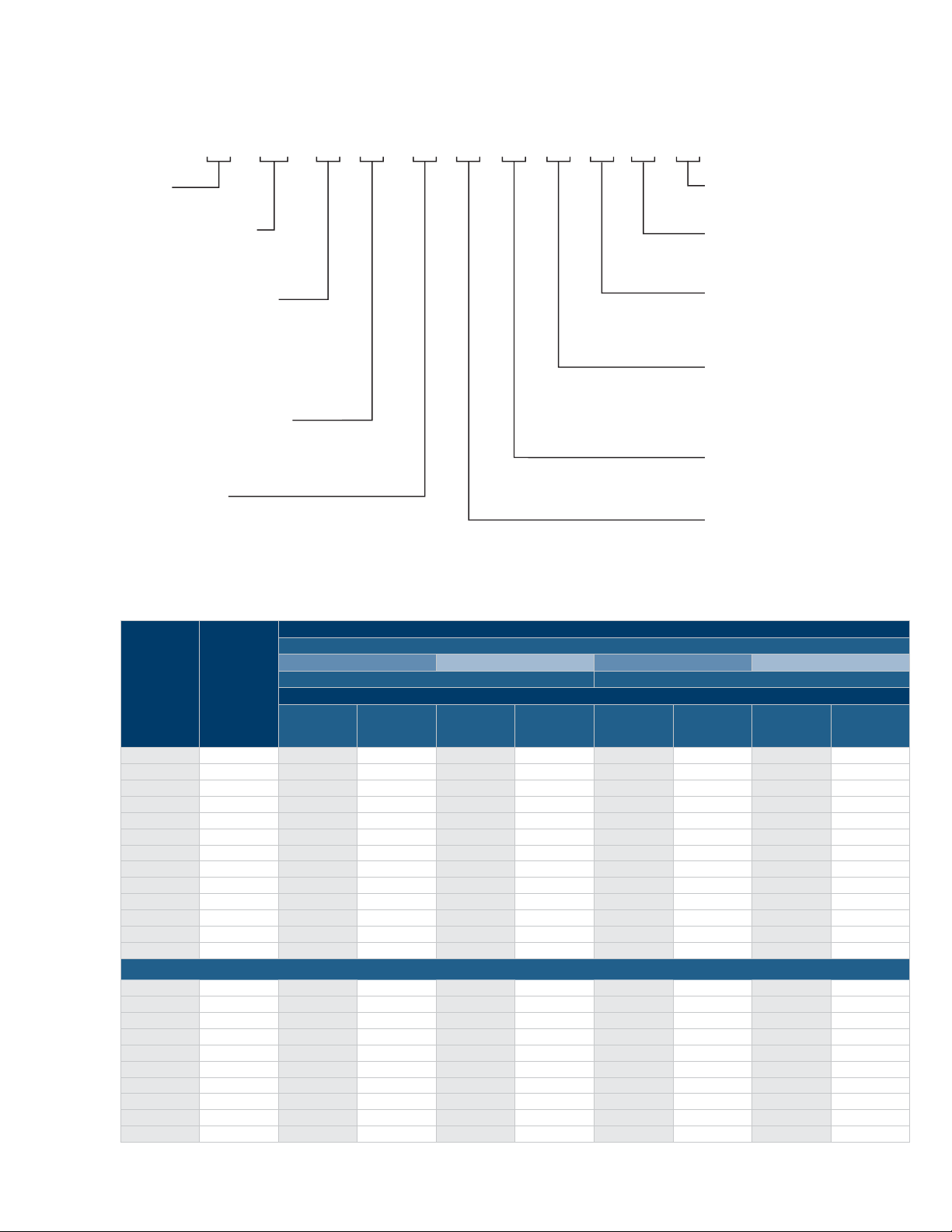

Model Nomenclature

LV 036 1 VT C F L T P U A

boschheatingandcooling.com | 2

MODEL:

LV

NOMINAL CAPACITY:

007, 009, 012, 015, 018,

024, 030, 036, 041, 042,

048, 060, 070

VOLTAGE DESIGNATION:

0 - 115/60/1 (LV012 only)

1 - 208/60/1 & 230/60/1

2 - 265/60/1

3 - 208/60/3 & 230/60/3

4 - 460/60/3

5 - 575/60/3

CABINET CONFIGURATION:

VT - Vertical

HZ - Horizontal

CF - Counterfl ow (Downfl ow)

COAX OPTIONS:

C - Copper

N - Cupro-Nickel

REVISION LEVEL:

A - Current

AIR COIL OPTIONS:

U - Uncoated Air Coil

D - DuoGuard™ Air Coil

FAN/MOTOR OPTIONS:

P - Standard PSC

A - ECM Constant Airfl ow

T - ECM Constant Torque

DISCHARGE AIR CONFIGURATION:

T - Top

S - Straight

E - End

B - Bottom

RETURN AIR CONFIGURATION:

L - Left

R - Right

WATER CONNECTIONS:

F - Front

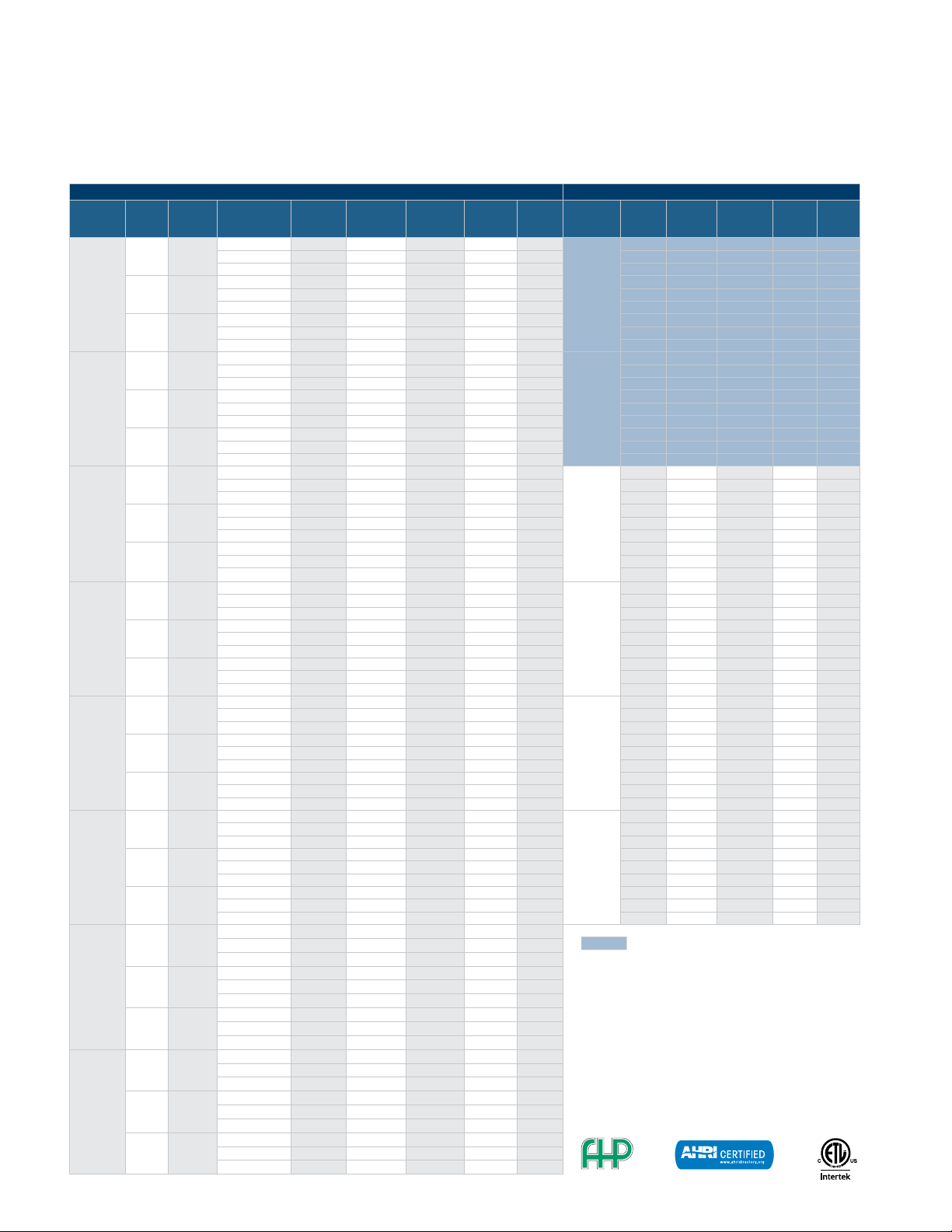

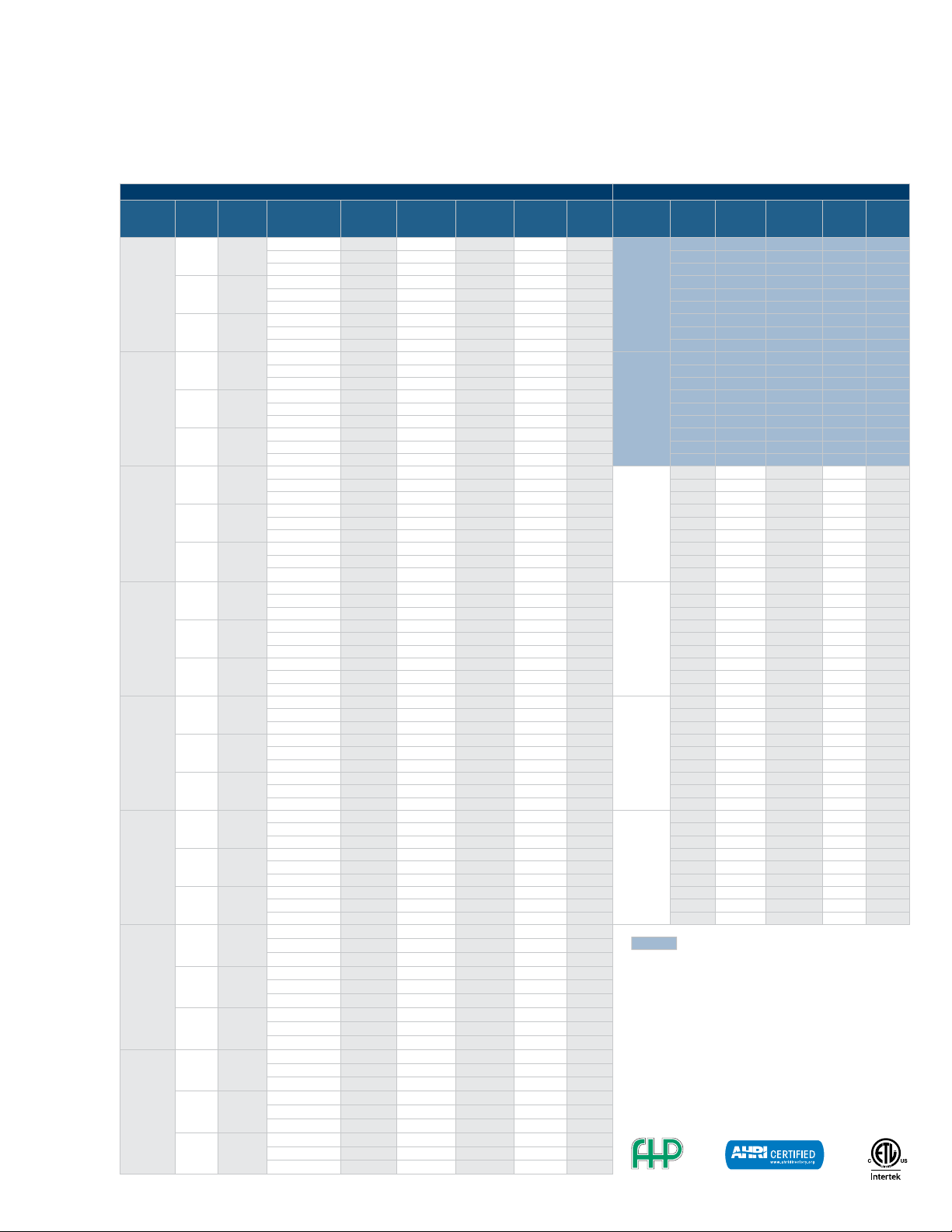

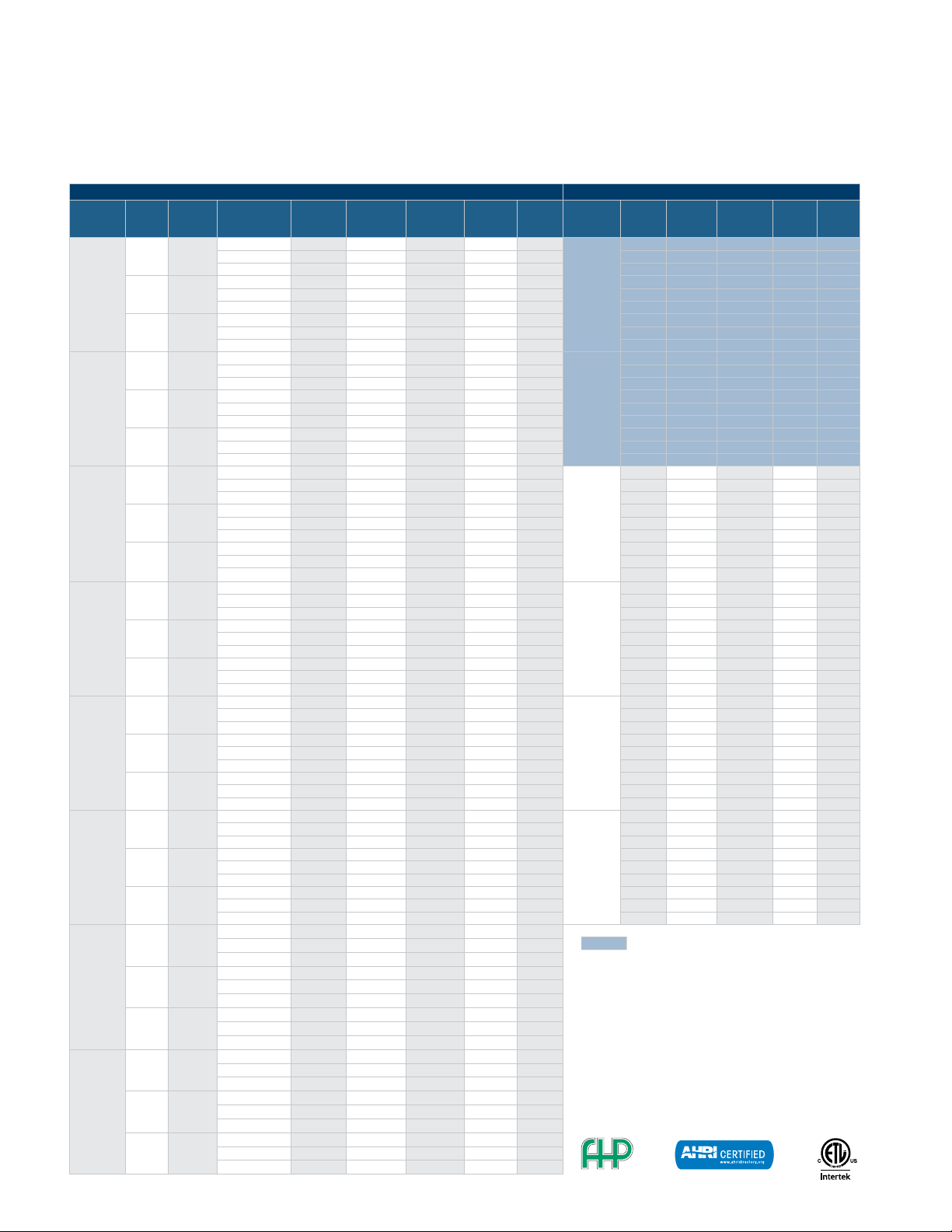

Certifi ed Performance Data

AHRI/ANSI 13256-1 Performance Data

Entering Water Temperatures

Model

LV007 2.0 6,100 12.20 7,800 5.30 6,800 15.10 4,900 3.40

LV009 2.5 8,200 12.40 9,900 4.70 8,700 14.60 5,740 3.20

LV012 3 10,900 12.20 13,000 4.30 11,800 14.10 8,700 3.20

LV015 4 14,200 12.80 16,100 4.40 14,200 14.60 11,300 3.30

LV018 5.0 19,400 13.40 22,200 4.60 21,200 15.80 14,300 3.50

LV024 6 23,400 13.40 26,600 4.40 25,000 15.50 17,000 3.40

LV030 7 29,200 13.20 33,400 4.30 31,000 14.70 20,900 3.30

LV036 9 37,900 14.70 41,800 4.60 39,900 16.90 26,900 3.50

LV041 9 39,500 13.10 44,600 4.30 41,200 14.30 29,400 3.20

LV042 10 40,000 13.70 46,300 4.30 42,600 14.80 31,000 3.30

LV048 12 45,900 13.00 56,400 4.30 48,800 14.90 35,400 3.40

LV060 15 57,900 13.00 67,200 4.30 60,100 14.10 46,900 3.20

LV070 16 64,000 13.30 72,800 4.40 66,400 15.00 50,800 3.40

LV015 4 13,700 13.90 15,500 4.40 14,400 16.20 10,700 3.30

LV018 5.0 19,700 14.40 21,900 4.80 21,500 15.90 14,100 3.70

LV024 6 23,800 14.50 26,200 4.60 25,400 16.80 16,700 3.60

LV030 7 30,000 15.00 32,800 4.60 31,600 17.50 20,400 3.40

LV036 9 38,200 15.40 41,400 4.70 40,200 17.70 26,500 3.60

LV041 9 40,500 13.60 43,700 4.40 42,200 15.90 28,500 3.60

LV042 10 40,900 14.10 45,300 4.40 43,500 16.30 30,100 3.50

LV048 12 46,800 14.20 55,600 4.50 49,600 16.30 34,600 3.60

LV060 15 59,000 14.30 66,400 4.30 61,100 16.40 46,200 3.30

LV070 16 65,200 14.60 71,800 4.60 67,600 16.60 50,000 3.50

Tabulated performance data is at noted water temperatures and entering air conditions of 80.6°F DB/66.2°F WB at AHRI/ANSI 13256-1 rated CFM with 1"

disposable fi lter.

GLHP ratings require an extended range option. ECM motors can be either constant torque or constant CFM.

Fluid Flow

Rate

Cooling

Capacity

(WLHP)

86˚F68˚F77˚F32˚F

Water Loop Ground Loop

Capacity and Effi ciency Data – PSC Motor (Standard)

EER

(WLHP)

Heating

Capacity

(WLHP)

ECM Motor (Option)

(WLHP)

COP

Cooling

Capacity

(GLHP)

EER

(GLHP)

ubject to change without prior notice

Heating

Capacity

(GLHP)

COP

(GLHP)

Page 4

3 | LV Model | Commercial Geothermal Heat Pumps

FHP Equipment

Specializing in effi cient green technology for commer-

cial heating and cooling products. FHP products are

one of the leading Geothermal and Water Source heat

pumps in the market, which assures that you are buying

a unit that you can trust. Bosch Thermotechnology

Corp. is dedicated to providing highly effi cient heating

and cooling solutions to the private and public sectors.

Bosch Thermotechnology Corp. is always on the

forefront of product development and innovative

design to optimize the performance of FHP units.

Our products are designed and manufactured to the

highest quality, refl ecting the no-compromise stan-

dards for which FHP and Bosch are renowned in order

to provide our customers with the highest level of

satisfaction and comfort. The variety of options,

energy effi ciency, and uncompromising quality of all

FHP products makes them the ideal choice for the

commercial new construction market and the ease of

designing into tight retrofi t spaces of buildings.

Advantages of FHP Technology

Low installation costs

Lower operating costs

Flexibility and comfort

Energy effi ciency

Space savings

Superior quality

Quiet operation

LV Model 007 - 070

13 Models from 1/2 through 6 tons

Horizontal, Vertical, and Counterfl ow Confi gurations*

The LV Model is a cost-effective, single stage water

source heat pump designed for commercial retrofi t

and new construction applications.

*Not all model sizes are available in all confi gurations. Consult the charts

found in this catalog for details.

Features, Functions and Benefits

Cabinet

The LV unit cabinetry is constructed using heavy-gauge,

galvanized steel. This steel provides superior corrosion

protection for units located indoors.

All interior surfaces are lined with 1/2" thick, 1.5 lb./

cu.ft. density, Micromat insulation for thermal insulation and acoustical attenuation. This insulation is

non-combustible, non-hydroscopic and does not

support fungal growth. Insulation meets NFPA 90A and

90B for fi re protection and is certifi ed to meet the

GREENGUARD® Indoor Air Quality Standard for Low

Emitting Products.

Protection against corrosion is a feature in the LV unit.

A stainless steel drain pan will last the lifetime of the

unit and resist corrosion and cracking that may occur

with steel or plastic materials.

Subject to change without prior notice.

Page 5

boschheatingandcooling.com | 4

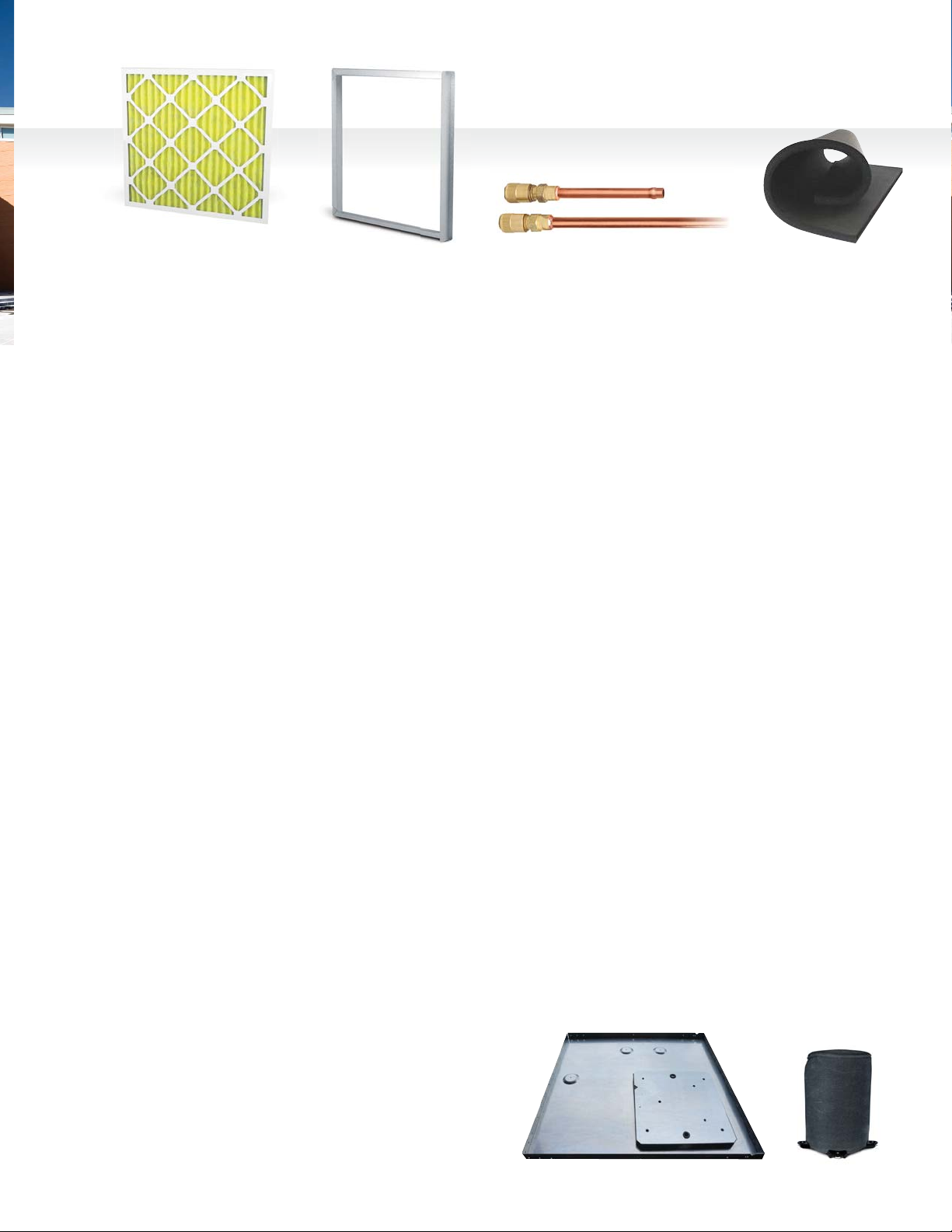

MERV-8 or MERV-13

Filter Option

2" 4-Sided Filter

Rack Option

Quiet Operation

Noise reduction is a critical consideration of the

unit design. All LV units have a distinct fl oating base

pan; the compressor is mounted on a heavy steel

plate which rests on a high density rubber pad on

the base of the unit. In addition, compressors are

mounted on rubber grommets. This double isolation, distinct to FHP equipment, is standard in all

LV units preventing vibration and noise transmission

from the compressor to the unit structure, resulting

in exceptionally quiet operation.

The LV offers optional 1/2" thick, closed cell foam

insulation to help aid indoor air quality (IAQ) and to

further attenuate low frequency noise from the

compressor compartment. The closed cell foam

insulation option is available in all unit sizes. For

additional sound attenuation, an optional compressor

blanket is available on unit sizes 024 and above.

Serviceability

All units are designed to be serviced from the front of

the unit. Schrader valves for high and low pressure

gauges and the electrical box components are easily

accessible for diagnosing and servicing the unit.

Insulated bulkheads in all units, separate the compressor section from the blower section, allowing the

unit to be serviced during operation.

Schrader

Charging Valves

Closed Cell Foam

Insulation (Optional)

Unit Confi gurations

All units are available in horizontal, vertical and

counterfl ow confi gurations. Additionally, several

options of return air and supply air are offered as

standard, providing confi guration fl exibility.

Filter Racks and Options

Units come standard with a 1" fi lter rack and construc-

tion fi lter. A 2" four-sided fi lter rack and pleated fi lter is

optional and greatly improves air fi ltration. Filter doors

allow for easy routine maintenance and changing of the

air fi lter. A 1" return duct collar is integral to the fi lter

rack eliminating the need for fi eld mounted duct collars.

MERV-8 and MERV-13 Filters

The optional MERV-8 or -13 fi lter is most advantageous

for premium air fi ltration on commercial HVAC

projects. High effi ciency fi ltration is a cost-effective

way of upgrading air quality while maintaining low

pressure drop and sustaining long service life. These

fi lters effectively remove up to 98% of airborne

matter, such as fi ne particulates, bacteria, smoke,

gases and allergens including dust mites, pollen, mold

spores, dust and smog. MERV-8 and MERV-13 rated

fi lters are a minimum requirement for EQ credits 3.1

and 5 on LEED projects. With the standard ECM

constant airfl ow motor the LV is prepared to handle

higher external pressure drops when utilizing the

higher effi ciency MERV-13 fi lters.

Large removable panels aid in servicing the unit, when

necessary. Separate electrical knockouts in the unit

corner post allow for easy and safe routing of high and

low voltage lines to the inside of the cabinet.

Standard

Optional

Subject to change without prior notice.

Page 6

5 | LV Model | Commercial Geothermal Heat Pumps

.

Constant Airfl ow

ECM Option

Constant Torque

ECM Option

Fan Motor

Permanent Split Capacitor Motors (PSC)

The standard motor for all LV model heat pumps is a

PSC motor. For all models other than 575 V units, the

supplied motor is a three speed motor. 575 V motors

are single speed.

ECM Constant Torque Motor (Optional)

The LV’s constant torque blower motor option offers

improved effi ciency (up to 33%) over the standard

PSC motor. This motor is similar in function to a PSC,

but can handle up to 1 in.w.g. external static pressure

making it a wise choice for high fi ltration applications.

These motors are available in unit sizes 015 to 070.

This ECM motor option is an excellent choice for

retrofi t. The constant-torque motors do not require a

neutral wire for 460/3 power.

ECM Constant Airfl ow Motor

The LV’s new high effi ciency ECM motor option,

available in 1/3hp to 1hp, provides constant airfl ow in

a wide static pressure range up to 1 in.w.g. Available in

unit sizes 015 to 070, this motor is a great choice in

high fi ltration applications, such as MERV-13. The

motor has a soft start/stop feature, keeping noise to a

minimum. LV units outfi tted with any ECM motor can

see an effi ciency boost with up to 1.8 additional points

of EER.

Passive dehumidifi cation can be achieved with the

constant airfl ow ECM by reducing nominal airfl ow by

15%. This control feature lowers air coil temperature and

prevents over-cooling of the space when in dehumidifi -

cation mode. IMPORTANT NOTE: The constant airfl ow

ECM requires a neutral wire in a 460V application.

2-Way Valve with

Actuator

Coax Coil

Hanging Brackets

All horizontal units come standard with hanging

bracket kits for suspending the unit from fi eld

supplied hanger rods. These kits include heavy-duty

steel brackets and rubber grommets for sound and

vibration isolation from the building structure.

Water Connections

All water connections are heavy-duty bronze FPT

fi ttings securely fastened to the unit corner post.

This allows connecting to a fl exible hose kit without

the use of a backup wrench making for easier,

faster installation.

Two-Position Water Valve

The two-position motorized water valve is optional

on all unit sizes and is a great energy savings

option. The valve opens to allow 100% fl uid fl ow

through the coaxial heat exchanger only when

there is a call for cooling or heating. Closing off

fl uid fl ow to the unit when there is no call for

cooling or heating reduces system operating costs,

when using variable speed pumping, by reducing

the speed of the primary loop pumps.

Refrigerant Circuit

LV units are designed using the optimum

combination of compressor, water and air coils to

provide peak performance. LV units are rated to

withstand 600 PSIG working refrigerant pressure

and 400 PSIG working water pressure.

Heavy-duty heat pump compressors are used in all

units. Rotary, reciprocating and scroll compressors

offer optimum performance for each unit size.

Subject to change without prior notice

Page 7

boschheatingandcooling.com | 6

.

Compressors Tin Plated with Coated Fin

Evaporator Coil (Optional)

Refrigerant to water heat exchangers are coaxial tube-intube type providing a robust construction, ensuring years

of trouble free operation. Coaxial coils are selected and

designed for peak performance, offering the best combination of low water pressure drop and maximum heat

transfer in both the cooling and heating modes. Standard

coaxial coils have a copper interior water tube and a steel

outer shell. Optional Cupro-Nickel coils are available for

applications where the water is of lower quality.

In geothermal applications where fl uid temperatures

can drop below the dew point of the surrounding air,

optional insulation is available to prevent water coils

and refrigerant piping from sweating.

Air side refrigerant coils have copper tubes, aluminum

fi ns and side plates to prevent corrosion.

Air coils are state of the art, employing lanced fi n and

rifl ed tubing for maximum heat transfer. Large face

areas result in lower face velocity reducing sound

while ensuring high latent heat removal for maximum

dehumidifi cation in the cooling mode.

A pilot operated four-way reversing valve in the refrigeration circuit allows the unit to operate in either the

heating or cooling mode. All FHP units have the

reversing valve energized in cooling mode. This will

ensure you are not left without heat in the middle of

winter, should the reversing valve coil fail.

Refrigerant fl ow to the air coil is metered by capillary

tubes as standard in LV units. Thermal Expansion

Valves come with the optional Extended Range LV and

are designed to vary the fl ow of refrigerant depending on

the load. TXV’s provide unit optimization and a more

stable control over a wider range of operating conditions.

Blower Housing

(with Removable Inlet Ring)

Evaporator Coil and DuoGuardTM (Option)

Air handling sections come standard with a copper

tube aluminum fi n evaporator coil. Available as an

option is the DuoGuardTM evaporator coil protection

system. DuoGuardTM Protection® - Tin Electro-Plated

Copper Tubing with High-Tech Polymer Coated

Aluminum Fins will aid in protecting the evaporator

coil from most forms of corrosive elements in the

airstream. The tin plating provides a best-in-class

protection of the copper tubing from formicary

corrosion while the fi n coating provides protection

against salt spray and other corrosive elements.

DuoGuardTM protected coils are able to exceed 1000

hours salt spray per ASTM standard B-117.

Blower Housing

A removable inlet ring is a standard feature of the

blower housing on all unit sizes. The removable inlet

ring helps facilitate motor removal without having to

remove the fan housing from the cabinet.

Unit Protection Module

Each LV Model is factory provided with a Unit

Protection Module (UPM) that controls the unit

operation and monitors the safety controls that protect

the unit. The UPM interfaces with the thermostat or

direct digital controller. The main purpose of the UPM

is to protect the compressors by monitoring the

different states of switches and sensors. This module

provides time delays and protects the unit against

freezing of the water to refrigerant and air to refrigerant

heat exchangers as well as condensate overfl ow.

ubject to change without prior notice

Page 8

7 | LV Model | Commercial Geothermal Heat Pumps

.

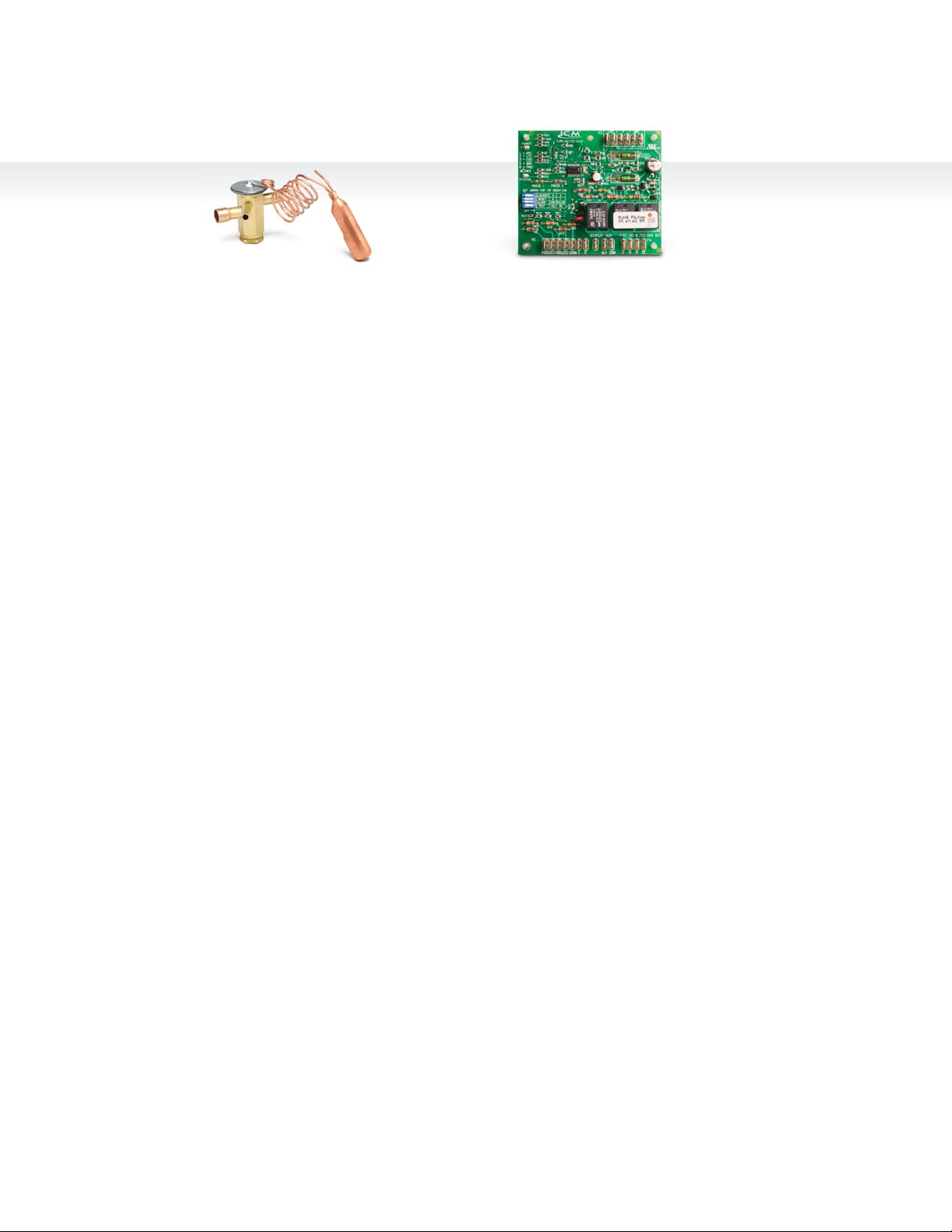

TXV Valve (Optional)

Safety controls include the following as standard:

High pressure switch located in the refrigerant

discharge line.

Low pressure switch located in the unit refrigerant

suction line.

Standard low fl uid temperature (freeze) protection

sensor. The freeze protection sensor, located on the

refrigerant liquid line entering the coaxial heat

exchanger, is designed to disable compressor

operation when the unit is in the heating mode,

should the refrigerant temperature fall below either

26°F (-6.6°C) or 15°F (-9.4°C).

Condensate overfl ow protection sensor is standard

and factory mounted in the drain pan of the unit.

Low air coil temperature (freeze) protection sensor

disables the compressor when the refrigerant

entering the air coil drops below 30°F (-1.1°C).

UPM Control Board Features

Condensate Overfl ow Protection — The UPM

controller continuously monitors the drain pan for

high condensate water level, and if this exceeds

normal operating levels, the compressor operation

is interrupted to protect against drain pan overfl ow.

Anti-Short Cycle Timer — 5 minute delay on break

timer to prevent compressor short cycling.

UPM Control Board

Low Pressure Bypass Timer — The low pressure

switch is bypassed for 120 seconds after a call for

compressor operation to prevent nuisance low

pressure lockouts during cold start-up in the

heating mode.

Brownout/Surge/Power Interruption Protection

— Prevents compressor operation should the voltage

drop below 10% of unit rated value. The unit will

restart once the voltage is within tolerance and the

random start has timed out.

Malfunction (Alarm) Output — The controller has a

set of contacts for remote fault indication. This can

be either a steady output or can be set to pulse with

the fault code. Two connections are available - one

to provide a 24 volt output, the other to provide a

dry contact.

Test Service Mode — A dip switch setting is provid-

ed to reduce all time delay settings to 10 seconds

maximum during troubleshooting for verifi cation of

unit operation.

LED Fault Indication — Two LED indicators are

provided as follows:

Green: Power LED indicates 18 – 30 VAC present

at the board.

Red: Fault indicator with blink codes identifying

the particular fault. This information is available

via the malfunction (alarm) output contacts.

Random Start — Each controller has a unique

random start delay ranging from 270 to 300 seconds

after power is applied to the board. This will prevent

the simultaneous start of multiple units after a

power outage.

Subject to change without prior notice

1 Blink - High Pressure

2 Blinks - Low Pressure

3 Blinks - Low Fluid Temperature (Freeze Protection)

4 Blinks - Condensate Overfl ow

5 Blinks - Brownout condition

Page 9

boschheatingandcooling.com | 8

.

Intelligent Reset—If a fault condition is initiated, the

5 minute delay on break time period is initiated and

the unit will restart after this delay expires. The UPM

is confi gurable for either 2 or 4 fault occurrences

before going into a hard lockout. The selection is

made through a dip switch setting on the board. If

the fault condition still exists or reoccurs twice or

four times within one hour, the unit will go into a

hard lockout and requires a manual lockout reset. A

condensate overfl ow fault will, however, put the unit

into a hard lockout immediately.

Lockout Reset—A hard lockout can be reset by

turning the unit thermostat off and then back on or

by shutting off unit power at the circuit breaker. The

method of reset is selectable by the dip switch on

the board.

Additional Options

Blower monitor relay

Typical unit control is by a wall mounted thermostat that

senses temperature in the occupied space. By utilizing a

humidistat in addition to the thermostat, LV units with

Hot Gas Reheat are able to control the humidity levels in

the space as well. The Hot Gas Reheat option allows

cooling and dehumidifi cation to satisfy both the thermo-

stat and humidistat while preventing over-cooling of the

space while in the dehumidifi cation mode.

Once the thermostat reaches set point temperature, the

humidity is above set point, the unit controller will

energize the reheat valve operating the unit in hot gas

reheat mode, fi rst cooling and dehumidifying, then

reheating the air (using hot refrigerant gas) before delivering it to the space, usually 2° to 5°F below room temperature. The unit operates like a dehumidifi er by reheating

the air along a constant sensible heat line, while the

relative humidity of the leaving air is reduced.This option

offers signifi cant energy savings over reheating air with

electric heating coils.

Compressor monitor relay

Phase monitor

Pump relay

Fire alarm relay

Fault LED light

50, 75 or 100 VA transformer option

40 Amp disconnect switch

Single and three phase

Hot Gas Reheat

Hot gas reheat (HGR) allows the user to not only control

space temperature, but also humidity levels within the

conditioned space. Excessive moisture in the space can

promote mold growth leading to damage in the structure

or interior surfaces, as well as reducing the air quality

and creating an unhealthy environment.

Possible causes of excess humidity could be a byproduct

of the unit having to operate under a widely varying load,

an oversized short cycling unit, a high percentage of

unconditioned outside air being introduced into the

space, a high latent load in the space or any location

where humidity infi ltration is a problem.

The moisture removal capacity of a specifi c heat pump

is determined by the unit latent capacity rating. A heat

pump’s latent capacity can be determined by reviewing the heat pump specifi cation data sheets. Depend-

ing upon the entering water and air conditions, a total

and sensible capacity can be interpolated from the

data sheets. Subtracting sensible capacity from total

capacity yields latent capacity. Dividing the latent

capacity by 1069 converts the amount of moisture

removal from BTU/Hr. to Pounds Per/Hr.

A hot gas reheat valve and a reheat coil are included in

the refrigerant circuit. The refrigerant circuit in the

cooling and heating mode is identical to a standard

heat pump.

In the reheat mode, the compressor discharge gas is

diverted through the reheat valve to the reheat coil

which is located downstream of the cooling coil.

The superheated refrigerant gas reheats the air

leaving the cooling coil. The hot refrigerant gas then

passes though the water to refrigerant coil where it

is condensed to a liquid. From this point the rest of

the cooling cycle is completed as in a regular heat

pump. There are check valves to prevent refrigerant

fl ow into the reheat coil during standard cooling/

heating cycles.

ubject to change without prior notice

Page 10

9 | LV Model | Commercial Geothermal Heat Pumps

.

Hot Gas Reheat Control Options

There are several ways to control heat pumps with hot

gas reheat. You should choose the means that best

suits your specifi c application. Please refer to the Hot

Gas Reheat wiring diagrams for typical thermostat

wiring. Most heat pump compatible thermostats in

conjunction with a humidistat are acceptable for use,

(Note: “O” output for reversing valve energized in

cooling mode is required.) Combination thermostat/

humidistats are also available.

Special Considerations

Some applications require special attention to

maximize the performance of the hot gas

reheat function:

Low Temperature Well Water

Indoor Pool Dehumidifying During Winter Months

(Re: Heating Mode)

Consult the factory for special application considerations.

the pool water temperature. If this is not done the

warm pool water attempts to heat the space and the

humidity levels increase exponentially. The heat pump

is normally sized to handle the design latent load

moisture removal. A second heat pump or resistance

heat should be provided to handle the structure’s shell

loss load. DuoGuard™ evaporator coil option is required for this application.

Protective coatings are highly recommended for

all pool applications, due to the highly corrosive

chemical environment.

Sequence of Operation - Modulating Hot

Gas Reheat (MHGRH)

Modulating Hot Gas Reheat differs from On/Off in that

the reheat function is always active. The purpose of

Modulating Hot Gas Reheat is to deliver supply air at or

close to neutral conditions.

Low Temperature Well Water

When low temperature well water is utilized as the water

source (below 55°F), a means of establishing two fl ow

rates, one for the cooling/reheat mode and one for

heating mode is recommended. In the cooling mode at

low entering water temperatures and standard fl ow

rates, discharge pressures and corresponding discharge

gas temperatures are relatively low. At these conditions,

when the reheat mode is initiated, the low temperature

discharge gas can reduce reheat capacity. A means to

reduce the water fl ow rate and elevate the discharge

pressure/temperature in cooling/reheat mode should be

provided. Conversely, at low entering water temperatures in the heating mode, system suction pressure is

reduced causing a loss in heating capacity. A means of

providing higher fl ow in the heating mode should be

supplied. The simplest way to accomplish the above is to

install water regulating valves.

Indoor Pool Dehumidifying

During Winter Months

It is important to remember that when in the reheat/

dehumidifi cation mode the heat pump is cooling and

reheating. A secondary means of heating the space during the dehumidifi cation mode should be provided. For

indoor pool environments, the indoor space temperature should be kept at least two (2) degrees F above

Subject to change without prior notice

Air is cooled and dehumidifi ed by the cooling coil to

around 55°F DB/54°F WB. A sensor located in the supply

air stream is set at the required leaving dry bulb temperature and will send a signal to the modulating hot gas

reheat valve to direct the fl ow of hot gas to maintain that

temperature. A typical application for this would be in

treating 100% outside air. This air would be ducted

directly into the space relieving the unit handling the

zone of any outside air load. This can result in a smaller

zone unit, less airfl ow and a savings in both initial and

operating cost.

Control of the hot gas modulation is by the thermostat

in the supply air duct or through a building management system. A separate controller is used to control

the unit itself.

Hot Gas Bypass

The function of the hot gas bypass valve is to prevent

icing of the air coil when the unit is operating at low

cooling load conditions. This situation could arise if the

space experiences widely different loads, for example a

conference center or if a unit is sized for

be oversized for cooling. Without a hot gas bypass

circuit the evaporating temperature could fall and ice

could form on the coil restricting airfl ow and aggravating

the situation. Eventually the heat pump could lock out

on air coil freeze protection.

heating, it could

Page 11

boschheatingandcooling.com | 10

.

The hot gas bypass valve located in the compressor

discharge line diverts hot gas to the inlet of the air coil.

The valve is factory set to open when the evaporating

pressure falls to 90 PSI and will modulate to prevent the

pressure falling any lower. This setting is fi eld adjustable

and this set point may be adjusted as required.

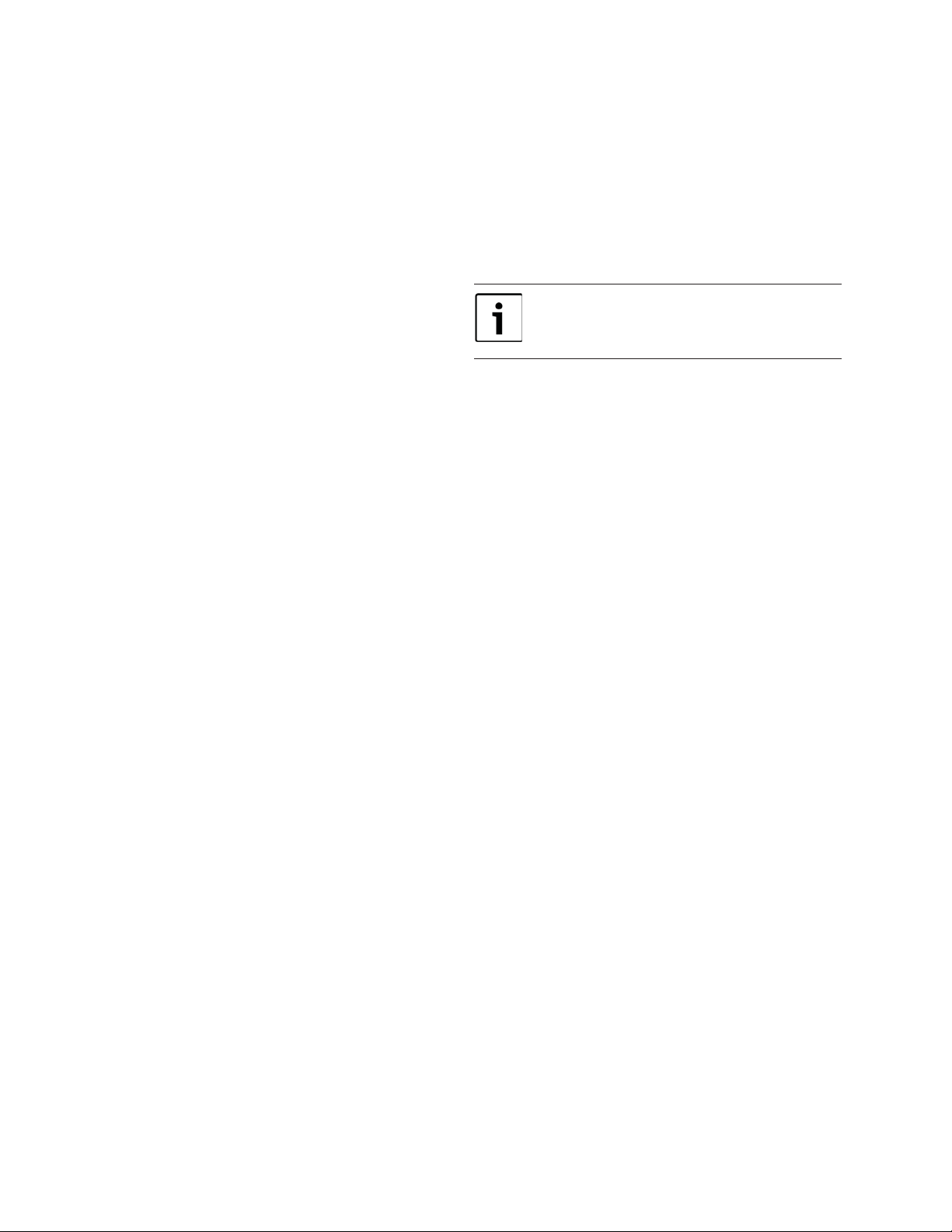

Psychrometric Chart

8

5

8

0

8

7

5

7

0

6

5

6

0

%

0

9

%

0

8

Lvg. Coil Reheat

5

5

5

0

55 60 65 70 75 80 85 90 95 100

.com

%

0

7

%

55

0

6

%

0

5

%

0

4

%

0

3

%

20

R

%

10

MI

U

H

E

V

I

T

A

L

E

6

0

Y

T

I

D

DRY BULB TEMPERATURE - °F

7

0

6

5

0

7

5

%

5

2

%

5

1

H

E

V

I

T

LA

E

R

%

8

%

6

%

4

%

2

Figure 1

M

U

Entering

Y

T

I

D

I

85

8

5

W

E

T

B

U

L

B

T

80

E

M

P

E

R

A

T

U

R

E

75

70

65

DEW POINT TEMPERATURE - °F

60

55

50

45

40

35

30

25

20

10

0

Night setback status

Percent of units cooling

Percent of units heating

Cooling set point

Heating set point

Status of all the alarms

Space temperature

Occupied heating and cooling set points

Continuous or cycle fan during occupied mode

Command for occupied or unoccupied mode

Command for override of the unoccupied mode

(unit resorts to occupied set points)

-

°

F

Set point adjustment

DDC Room Sensors

To complement the controller, Bosch offers a line of

intelligent space sensors, which provide precision

measurement and communication capabilities in an

attractive low profi le enclosure. A hidden

communications jack provides access to the HVAC

control system for commissioning and maintenance.

Models available include:

The RS Pro has a large LCD display and easy-to-

use occupant controls for set point adjustment.

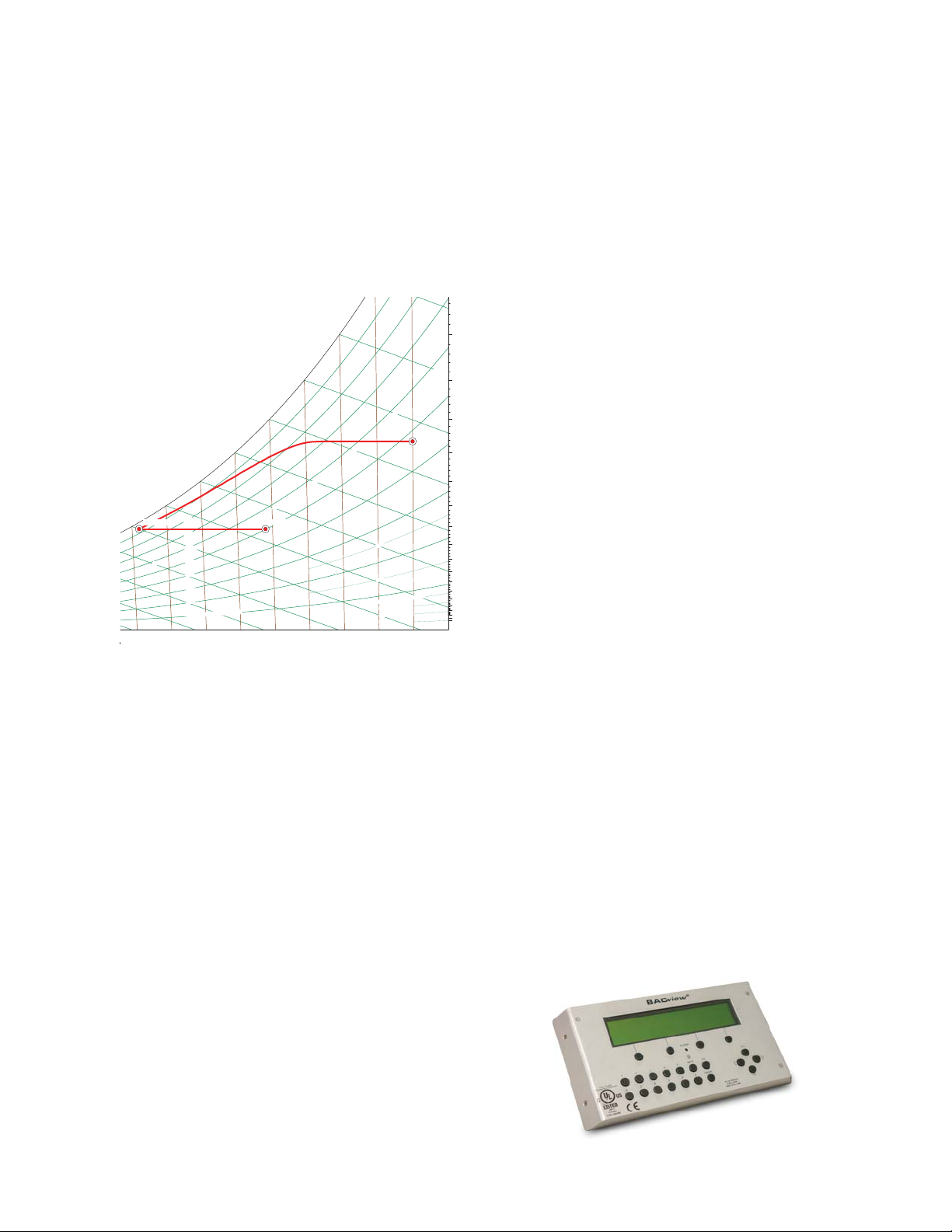

DDC Controls

The optional factory mounted DDC Controller is

preprogrammed and installed on the unit with the Unit

Protection Module (UPM) to be job site ready. The unit

will operate in a 100% stand-alone control mode or

connect to a Building Automation System (BAS) using

open protocols BACnetTM, Modbus, N2 or LonWorks®

(with an optional Lon card). Stand-alone DDC modules

must use remote intelligent sensors and are to be

programmed by the BACview® controller only.

Zone temperatures, leaving air temperatures and

water temperatures can be monitored from the central

control computer and unit fault indication displayed.

Available inputs/outputs include:

Discharge air temperature

Leaving water temperature

Fan run time

Override time remaining

The RS Plus offers a local set point adjustment

and override to an occupied mode and LED

indication of current status.

The RS Standard which has no local temperature

set point adjustment.

A BACview® hand held diagnostic tool is available to

allow local access to display and modify user

defi ned properties without any computer software.

These space sensors will monitor, sense and provide

local control for the room.

BACview® Hand Held

Diagnostic Tool

ubject to change without prior notice

Page 12

11 | LV Model | Commercial Geothermal Heat Pumps

.

DDC Control Board

DDC Zone Sensors*

RS Base

DDC Sensor

The Pro Zone Sensor (ZS) has an LCD screen that can

display the current temperature and set temperature.

It can also display relative humidity and CO2 settings as

well as their current readings. It comes with a button for

additional information that can be displayed.

The Pro ZS can be ordered in any of the

following combinations:

Temperature setting only

Temperature with relative humidity settings

Temperature, relative humidity, and CO2 settings

The Plus Zone Sensor (ZS) has a little different look to

it. It has a occupied indicator that identifi es the sensor

to be operating in occupied conditions. It comes with

a slide bar of for some manual temperature control in

the occupied mode +/- setting can be adjusted

during commissioning.

The Plus ZS can be ordered in any of the

following combinations:

Temperature setting only

RS Plus

DDC Sensor

RS Pro

DDC Sensor

Waterside Economizer

Common Waterside Economizer Applications

Commercial application where perimeter heating is

taking place while core cooling is required. Perimeter heat pumps operating in the heating mode

extract heat from the building loop, thus dropping

the building loop fl uid temperature. Internal core

cooling requirements are usually high even in the

winter months due to people, lighting, and equipment loads. The moderate temperature loop water

circulated through a core heat pump’s waterside

economizer coil can provide free-cooling without

the use of mechanical cooling (Compressors). Also,

in many areas code requires some type of economizer cycle. Waterside Economizers in lieu of air

side economizers are an inexpensive way to satisfy

code requirements in commercial applications.

Can also be sized up for preheating.

Tenant build out commercial applications where the

central chilled water fl uid loop serves as a individual

zoned heat pump condenser water. In this application low temperature fl uid is always available for

free-cooling.

The Base Zone Sensor (ZS) is limited to only sensing

capabilities without local controllability. This zone

sensor offers a basic look and blends into most decors.

The Base ZS can be ordered in any of the

following combinations:

Temperature sensor

Temperature and relative humidity sensor

* DDC Zone Sensors available through Applications Special

Handling Sheet. When the Zone Sensors (ZS) are available as

a standard option they will replace the Room Sensors (RS).

Subject to change without prior notice

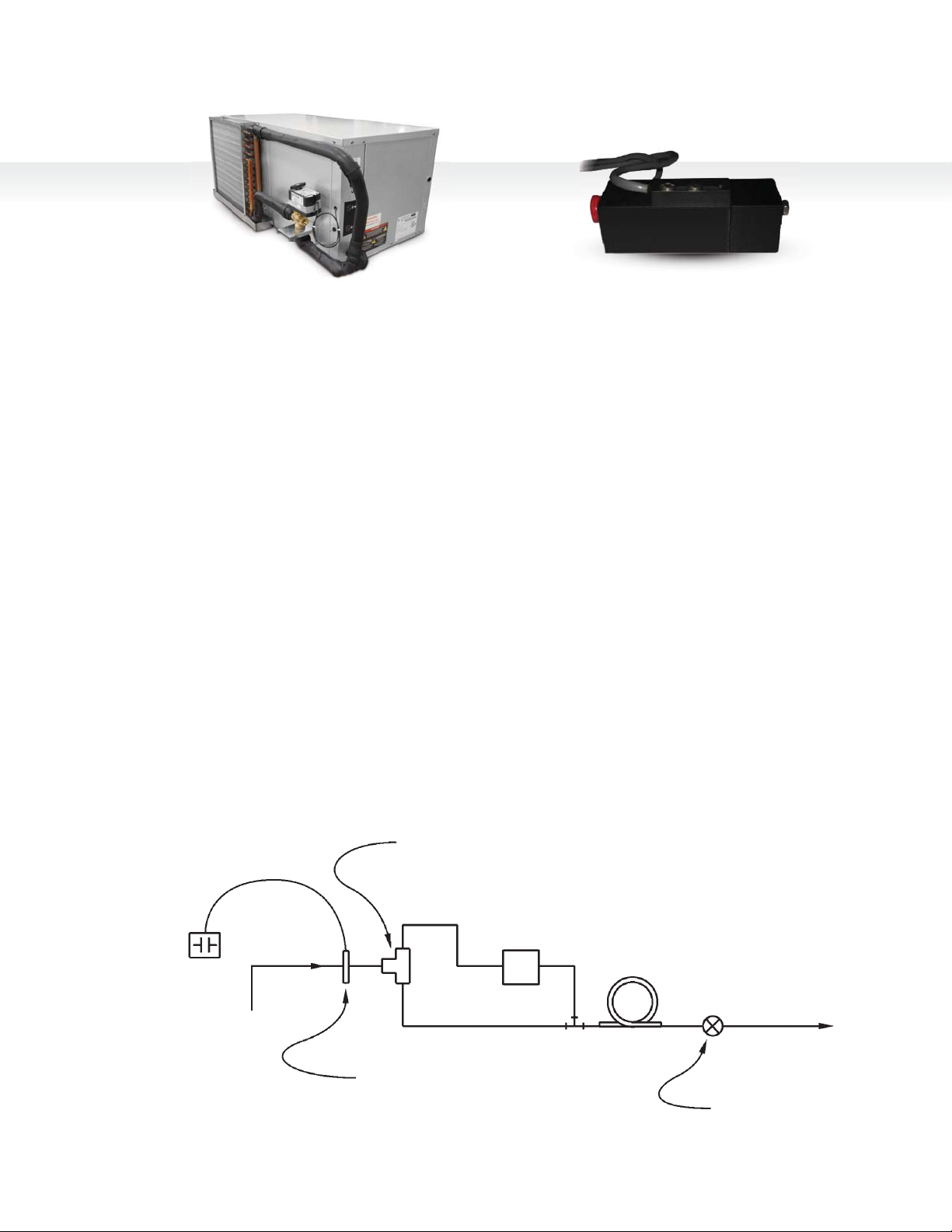

Fluid Flow

Fluid fl ow through heat pumps equipped with wa-

terside economizer coils is directed by the use of a

single three-way motorized ball valve. Flow is either

through the waterside economizer coil and then

through the condenser or through the condenser

only. When applying these units to a variable speed

pumping system, a separate fi eld provided means

of positive fl ow shut-off is required. (Re: A positive

shut-off solenoid valve located down stream of the

heat pump. See fi gure 2 on next page).

Page 13

boschheatingandcooling.com | 12

.

Waterside

Economizer (Optional)

Aquastat

The aquastat controller is mounted to the heat pump

electrical control box. All electrical control wiring is

factory installed. The controller is supplied with an

external range adjustment and screwdriver slot.

Actual range is -30° to 100°F and requires fi eld setting.

The remote bulb stored inside the heat pump for

shipping requires fi eld mounting.

Recommended settings: 45° F Cool, 90° F Heat

Air Side Pressure Drop

The air side pressure drop shown on the waterside

economizer performance tables is considered as

additional heat pump external static pressure. Refer

to Bosch Select Tools selection software for blower

performance and to determine if the unit requires an

optional fan upgrade.*

*See fhp-mfg.com for BST Software.

Fluid Differential

Pressure Switch (Optional)

Fluid Differential Pressure Switch

The function of the differential pressure switch is to

prevent or stop compressor operation should the

water supply fail. This will prevent the unit from

locking out on a safety requiring a manual reset to

restart. This optional control is internally mounted

and factory installed.

The switch is piped between the water entering and

leaving connections. Should the pressure drop across

the water to refrigerant heat exchanger and fall below

set value, the switch will open de-energizing the

compressor. The blower operation will not be affected

by this option.

Energy Management Switch (EMS)

This switch allows you to connect to an energy management system that can turn the unit off and on.

Figure 2

Aquastat

N.O.

Fluid in

3-Way motorized ball valve

N.C.

MBV

N.O.

“Bulb Strapped to Fluid”

in Line (field installed)

Waterside

economizer coil

Fluid to refrigerant

heat exchanger

Positive shut-off solenoid

valve for variable speed

pumping system

(field installed)

ubject to change without prior notice

Page 14

13 | LV Model | Commercial Geothermal Heat Pumps

.

Thermostats Hose Kit

Accessories

Thermostats

The unit control may be as simple as a single stage

thermostat or the unit may have a DDC controller

integrated into the building management system.

Kit 1: Hoses only. 3/4" through 2" diameter hoses are

available with 24" and 36" hose lengths. 1/2" diameter hose kits are available only with 12" long hoses.

All external low voltage control wiring is made to the

thermostat terminal located in the unit electrical box.

Thermostats may be manual change over, auto change

over, programmable or non-programmable depending

on the requirements of the project. A full line of

thermostats are available as an accessory.

Hose Kits

Hose kits are recommended between the unit and

system loop piping. This will help eliminate the transmission of vibration and noise from the unit to the space.

Hoses are fi re rated fi ber reinforced EPDM Stainless

Steel braid hoses with swivel connections.

Maximum working pressure 400 PSI for sizes 1/2" – 1"

diameter and 300 PSI for sizes 1 1/4" – 2".

A variety of hose kits are available depending on the

job requirement.

Kit 2: Hose kit 1 with ball valves on the supply and

return hoses. Valves have P/T (pressure/temperature)

ports to facilitate pressure and temperature readings.

Kit 3: Hose kit 2 with an automatic fl ow control

valve. The design fl ow rate is preset at the factory

per the design conditions and will automatically

limit the fl ow to this value. This will greatly facilitate

balancing of the fl uid loop and ensuring each unit

gets the required fl ow.

Kit 4: Hose kit 3 with a Y-strainer and blow down

valve on the supply side. The fi lter screen is 20

mesh, 304 stainless steel to help prevent dirt and

debris from entering the water coil.

Kit 5: Hose kit 3 with a 24 v 2 position solenoid

valve. This could be used to shut off fl ow to the unit

when there is not a call for heating or cooling. A typical application would be with VFD pumping.

Kit 6: Hose kit 4 with a 24 v 2 position solenoid

valve. Hose kit options are available in the accessories section of the BST selection software.

Subject to change without prior notice

Page 15

.

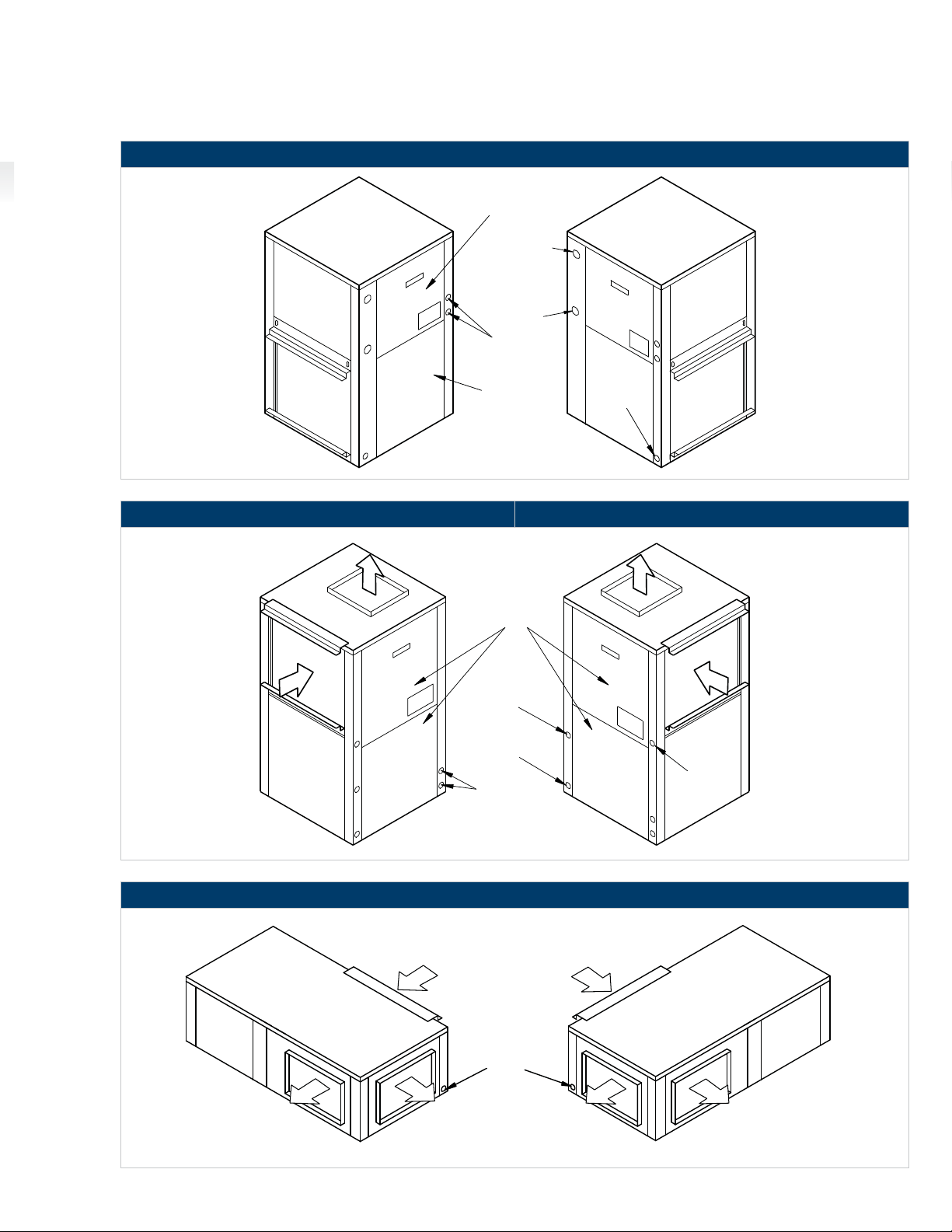

Unit Confi guration Diagrams

Counterfl ow

Compressor Access

Condenser

Water Out

Condenser

Water In

Electrical

Knock-Outs

boschheatingandcooling.com | 14

Figure 3

Blower Access

Condensate

Drain

Left Hand Return Top Discharge FLT Right Hand Return Top Discharge FRT

Access

Panels

Condenser

Water Out

Condenser

Water In

Condensate

Electrical

Drain

Connections

Figure 4

Figure 5

Front

Straight Through FLS

Typical Horizontal Unit Confi gurations

Return Air RightReturn Air Left

Condensate

Drain

End Blow FLE

End Blow FRE

Front

Straight Through FRS

ubject to change without prior notice

Page 16

15 | LV Model | Commercial Geothermal Heat Pumps

.

Systems

LV Models may be used in a variety of different

applications depending on the system design. An

overview of tower/boiler and geothermal systems is

given below. There could be several variations and

combinations of these systems.

Cooling Tower/Boiler Systems

will keep the fl uid within certain temperature limits

typically 70°F in winter and 85°F in summer by cycling

either the cooling tower or boiler.

In today’s modern buildings the interior core usually

has a net cooling requirement year round irrespective

of the outside temperature. This is due to the internal

heat gains from people, offi ce equipment and lighting.

The heat from heat pumps operating in cooling is

rejected to the common water loop and is absorbed

by heat pumps on the building’s perimeter that are in

the heating mode. In effect the system is transferring

energy around the building areas from where it is in

excess to those areas where it is needed. In many

instances we fi nd a balanced system where the heat

generated in the interior space is suffi cient to heat the

perimeter, resulting in neither the cooling tower nor

boiler operating. This concept, unique to a water

source system, provides the most energy effi cient

system on the market.

Water source heat pumps with cooling tower/boiler

systems have been used for many years and are

recognized as having a low installation cost and

providing more energy effi cient operation than most

other systems on the market.

In a typical building, each offi ce or space would

receive its own heat pump. This ensures that the unit

will independently satisfy the heating or cooling

requirements for that space irrespective of the requirements of any other space. Unlike some other

systems, this offers individual control and enhanced

comfort in all areas.

All the units are connected to a common water loop

containing, in addition to the heat pumps, a cooling

tower, boiler, a primary and standby pump and a loop

water temperature controller. In the summer cooling

mode, the units are cooling and rejecting heat to the

water loop. This heat is then rejected to the atmosphere through a cooling tower. In winter, heat is

taken from the loop and, together with the compressor’s heat of compression, used to heat the space.

The heat removed from the loop is then replenished

by the boiler. The loop water temperature controller

Geothermal Systems

The earth has a tremendous capacity of storing thermal

energy, which can be utilized to heat or cool a building.

A geothermal system offers all the benefi ts of a

cooling tower and boiler system with the additional

advantage of having overall greater energy effi ciency.

As the cost of energy increases, geothermal installations are becoming the system of choice by developers and design engineers.

There are several alternative methods of utilizing the

energy contained in a geothermal system, giving the

design engineer several options for selecting the one

that is right for a particular application.

Earth Coupling Options

Ground Loop Systems (Closed Loop)

Lengths of high density polyethylene piping are buried

in the earth either in vertical bore holes or horizontal

trenches depending on the space available.

Subject to change without prior notice

Page 17

boschheatingandcooling.com | 16

.

Fluid from the loop inside the building circulates

through these pipes either rejecting heat to the

ground when there is a net cooling requirement or

absorbing heat from the ground when heating is the

dominant requirement.

The temperature of the earth below 6 feet is relatively

constant and is not affected by the ambient temperature. For this reason, the ground temperature is cooler

than the summer ambient and warmer than the winter

ambient in most regions. Geothermal systems are able

to operate effectively in extreme ambient conditions

exceeding 100°F in summer and -30°F in winter. This

is one of the reasons why geothermal systems have

such an advantage over other systems. An additional

advantage is that no fossil fuels are used, reducing the

carbon emission of the building.

Even in areas which are cooling or heating dominant a

hybrid system can be used with a downsized cooling

tower or boiler. This system will reduce the installed

cost signifi cantly with only a modest impact on overall

operating effi ciency.

This method is used mainly in commercial buildings or

where space for a loop fi eld is limited. Vertical holes

100 to 400 feet deep are drilled in the ground, and a

single loop of high density polyethylene pipe with a

U-tube at the bottom is installed. The bore hole is then

sealed with grout to ensure good contact for heat

transfer with the soil. The size of the project will

determine how many bore holes are required. The

vertical ground loops are then connected to a horizontal header pipe that carries fl uid to the building and

circulated to each heat pump. The Earth’s temperature is stable below the surface which is an advantage

for this system and provides for the greater effi ciency.

Vertical ground loop fi elds may be located under

buildings or parking lots. The life expectancy is in

excess of 50 years.

Horizontal Ground Loop System

Geothermal systems may cost more to install but the

savings in energy and low maintenance costs more

than off set this with payback times typically fi ve years

or even less.

Vertical Ground Loop System

This type is cost effective on smaller projects or where

there is suffi cient space for the loop fi eld. Trenches,

three to six feet deep are dug in which a series of high

density polyethylene pipes are laid. These loops are

manifolded and connected to the loop inside the

building which feeds the heat pumps. The fl uid is then

circulated, absorbing or rejecting heat to the earth

depending on the requirement for heating or cooling.

ubject to change without prior notice

Page 18

17 | LV Model | Commercial Geothermal Heat Pumps

.

Typical Heat Pump System

Surface Water, Lake or Pond System

This type of design is economical when a project is

located near a body of water. Fluid circulates through

polyethylene piping in a closed system, just as it does

through ground loops, but in this case, underwater. The

pipes may be coiled in a slinky to fi t more surface into a

given amount of space. The lake needs to be a minimum

size and depth depending on the building load. Lake

loops have no adverse impact on the aquatic system.

Specialized lake heat exchangers are also available for

this application. New technology is emerging for stainless steel and titanium heat exchangers.

Well Water System

is pumped directly from the source into the geothermal unit and then discharged either into a return well

or a body of water. The water quality is unaffected

other than a change in the temperature. Refer to the

installation manuals for water quality guidelines.

Typical Heat Pump Operation

Cooling Mode

In the cooling mode, hot high pressure refrigerant gas

is pumped from the compressor to the water-to-refrigerant heat exchanger via the reversing valve. Water, or

an anti-freeze solution, fl owing through the water-to-

refrigerant heat exchanger transfers heat from the

refrigerant to the fl uid raising the fl uid temperature

while condensing the hot gas into a liquid. This liquid

refrigerant then fl ows through a metering device,

where the refrigerant is expanded to a cold liquid, to

the air-to-refrigerant heat exchanger coil.

The air-to-refrigerant heat exchanger cools and dehumidifi es air by evaporating the liquid refrigerant. The

cooling cycle is completed when the refrigerant fl ows

as a low pressure gas through the reversing valve and

back to the suction side of the compressor. Cool

dehumidifi ed air is circulated to the space maintaining

comfort conditions.

This type of installation is only possible if there is

suffi cient ground water available in a well. The water

must be of good quality. Local codes may limit the use

of this system in certain areas. The arrangement is

referred to as an open system which means that water

Subject to change without prior notice

Heating Mode

During the heating mode, the high pressure refrigerant

gas is pumped from the compressor to the air-to-refrigerant heat exchanger coil via the reversing valve. In the

air-to-refrigerant heat exchanger coil, the heat is

removed by the air that passes over the coil surface,

and the hot gas condenses into a liquid.

The heated air is ducted to the space and provides

heating for the building. The refrigerant liquid then

fl ows through a metering device to the water-to-refrigerant heat exchanger.

tion, circulates through this heat exchanger and is

cooled by the evaporating refrigerant which evaporates into a gas. The heating cycle is completed

when the refrigerant fl ows as a low pressure gas

through the reversing valve and back to the suction

side of the compressor.

Water, or an anti-freeze solu-

Page 19

.

Typical Unit Installation

r

boschheatingandcooling.com | 18

Water-to-Air Heat Pump Cycle — Cooling

Cool Refrigerant Gas

Air to

Refrigerant

Loop Fluid

Loop Fluid

Figure 6

Loop Fluid

Thermal

Expansion

Valve

Warm Liquid Refrigerant

Water to

Refrigerant

Heat

Exchanger

Hot Refrigerant Gas

Heat

Exchanger

Cold Liquid Refrigerant

Hot Refrigerant Gas

Cool

Refrigerant Gas

ReversingValve

Hot

Refrigerant

Gas

Cool

Refrigerant

Gas

Compressor

Water-to-Air Heat Pump Cycle — Heating

Hot Refrigerant Gas

Air to

Refrigerant

Loop Fluid

Loop Fluid

Figure 7

Loop Fluid

Thermal

Expansion

Valve

Cold Liquid Refrigerant

Water to

Refrigerant

Heat

Exchanger

Cool Refrigerant Gas

Heat

Exchanger

Warm Liquid Refrigerant

Refrigerant Gas

Refrigerant

Hot Refrigerant Gas

Refrigerant

Cool

ReversingValve

Hot

Gas

Hot

Gas

Compresso

Vertical Unit Installation

Vertical units are normally installed in a closet or

mechanical plant room.

If installed in a closet or other confi ned space,

ensure adequate space for return air to the unit.

Suffi cient space must be provided for fi lter re-

placement and access to the compressor and

blower for service.

Units should be set on a piece of rubber, neoprene or

other vibration absorbing material at least 1/3" to 1/2"

thick. The pad should extend 3/4" over the entire base of

the unit.

Avoid direct line of sight to the unit. Install a sound

baffl e over any door that has a return air grille.

Unit Location

Any mechanical device will, at some point in time

require servicing and repair.

With this in mind suffi cient space must be provided

around the unit for service personnel to perform

maintenance or repair.

Units are not designed for outdoor installation. Avoid

locations where the unit may be exposed to freezing

conditions or where the humidity levels could cause

condensation on the unit panels, for example, when

exposed to outdoor ambient conditions.

Figure 8

ubject to change without prior notice

Page 20

19 | LV Model | Commercial Geothermal Heat Pumps

.

Typical Unit Installation

Horizontal Unit Installation

Figure 9

Horizontal units are typically suspended above the

ceiling by four (fi eld supplied) 3/8" threaded rods

fastened to the unit by the factory supplied hanger

bracket kits. The kits include rubber isolators to help

prevent transmission of vibration and noise to the

building structure. Units should be located directly below

a structural member, so that it is securely anchored.

A horizontal unit should be positioned to allow for

removal of the fi lters and access panels. Allow at least

18" clearance on each side of the unit for service and

36" in front of the unit for maintenance access. The

fi lter needs to be slid out and suffi cient space must

be provided to allow this.

Ductwork and

Sound Attenuation Considerations

Lining the fi rst fi ve feet of

supply duct reduces noise

Take-offs should be at

least fi ve feet away from

the plenum

Figure 10:

Supply Air Ducting

Sound is becoming an increasingly important factor in all

HVAC installations. The LV models has been designed to

minimize sound, but sound acoustical design plays an

important part of the sound level in the space.

Most of the problems associated with HVAC generated

sound can be avoided by paying close attention to

duct design and equipment placement.

A discharge fl ange is provided on all horizontal unit

models for fastening of ductwork. We recommend

using a fl exible collar between the discharge fl ange

and the duct transformation to reduce vibration

transmission from the cabinet and to simplify

disconnection of the unit from the ceiling ductwork.

Flex

duct

Turns attenuate

blower noise

Flex

duct

Do not install the unit above any piping or electrical

raceways. The unit should be able to be removed to

the fl oor without major rearrangement of other

mechanical or ceiling components.

Consideration needs to be made as to the location of

the units. Avoid installing units directly above occupied spaces (e.g. above offi ce desks or classrooms).

This will minimize possible disruption to the occupants if maintenance or service is required as well as

keeping a potential source of noise out of the area. If

possible, units should be installed above the hallway

drop ceiling in schools, and the supply and return air

is routed directly into classrooms. Local code may

require fi re dampers to be used in this application.

Subject to change without prior notice

Return air

fi lter and grill

Figure 11:

Return Air Ducting

Return air to the unit could be either free return or

ducted. The fi lter rack is provided with a 1" fl ange

should a ducted return be used. We recommend using

a fl exible collar between the return fl ange and the

duct transformation to reduce vibration transmission

from the cabinet and to simplify disconnection of

the unit from the ductwork.

Page 21

boschheatingandcooling.com | 20

.

Sound is transmitted down the ductwork and it is

important to avoid direct line of sight between the unit

and the space, both on the return or supply side. To

accomplish this, design the duct runs with two 90° turns.

As a general recommendation, duct interiors should have

1

an acoustic / thermal lining of least

/2" thick over the

entire duct run or a minimum of the fi rst 5 feet of the

supply trunk.

Line the last fi ve diameters of duct before each outlet

with a 1" thick sound blanket. Line elbows and transition

pieces, as well as a short distance upstream and downstream of the fi ttings.

Elbows, tees and dampers can create turbulence or

distortion in the airfl ow. Using aerodynamic fi ttings will

help in reducing this effect. Place a straight length of

duct, 5 to 10 times the duct width, before the next fi tting

to smooth out airfl ow.

Diffusers that are located in the bottom of a trunk duct

can also produce noise.Balancing dampers should be

located several duct widths upstream from an air outlet.

Ductwork should be mounted and supported using

isolation devices that absorb vibration.

Applications such as Hotel, Motel, Dormitory or Nursing

Home that use a single duct discharge are susceptible to

noise. These applications typically have low static

pressures and short duct lengths. In these applications

the discharge duct must be fully lined and have a square

elbow without turning vanes. A velocity not exceeding

500 to 600 fpm is recommended. Return air for these

applications should enter through a sidewall grille and

route up the stud space to a ceiling plenum.

For horizontal heat pumps mounted in the ceiling plenum, an insulated return plenum is sometimes placed at

the return air opening to further attenuate line-of-sight

sound transmission through return openings.

A high pressure stainless steel fl exible hose kit is recom-

mended to connect the unit to the building’s hard piping

and acts as a sound attenuator for both the unit operating

noise and hydraulic pumping noise. One end of the hose

has a swivel fi tting to facilitate removal of the unit for

replacement or service.

Hose kits come in several confi gurations, but in all cases

should include supply and return shutoff ball valves to

allow removal of a unit without the need to shut down the

entire heat pump system. The hose kit may contain either

a manual or automatic fl ow control that may be preset to

ensure correct water fl ow to the unit.

Pressure / Temperature ports should be included in these

fi ttings to allow the service technician to measure water

fl ow and temperatures when checking unit operation.

Condensate Drain Piping

Condensate piping can be made of steel, copper or PVC

pipe. In most cases, PVC pipe eliminates the need to wrap

insulation around the pipe to prevent sweating.

A 3/4" FPT condensate drain connection is installed in the

unit. The condensate piping must be trapped at the unit

and pitched away from the unit not less than 1/4" per foot.

A vent is required after the trap so that the condensate

will drain away from the unit. The vent can also act as a

cleanout if the trap becomes clogged. The condensate

drain should not be directly piped to a drain/waste/vent

stack. See local codes for the correct application of

condensate piping to drains.

Operating Limits

LV Models are capable of operating over a wide range of

conditions. For operation in a geothermal application or

any other installation where the loop fl uid temperature

may drop below the ambient dew point, the extended

range option is recommended. This consists of TXV in

lieu of capillary tubes and additional insulation on the

piping and wax exchanger to prevent condensation.

Piping

The water loop system is typically designed using a

“reverse return” piping system which includes a fl ow

control device so that fl ow requirements are met for

each zone.

Maximum and minimum fl uid conditions are at unit

rated fl ow rate.

Maximum and minimum operating limits may not be

combined. If one value is at either maximum or minimum,

the other two should be at normal operating range.

Entering fl uid temperatures below 45°F in the

heating mode requires antifreeze.

ubject to change without prior notice

Page 22

21 | LV Model | Commercial Geothermal Heat Pumps

.

Equipment Selection

To ensure that you get the optimal performance

from your FHP heat pump it is important that

they be selected accurately to match your

design conditions.

Prior to making equipment selections the

zone conditions need to be determined.

Bosch Thermotechnology Corp. recommends

using a building load program to determine the

heating and cooling loads.

The catalog provides a wide range of entering air and

water conditions that will meet most applications. The

unit performance can be determined by referring to

the data tables from page 23 to 35.

Our Bosch Select Tools Selection Software (BST)

is designed to provide you with a fast and accurate

selection based on your specifi c conditions. This soft-

ware is available through the commercial website. You

may click on the BST link and request an account.

Unit Operating Limits —LV Model

Operating Limits – Cooling & Heating Standard Unit Extended Range Option

Cooling

Minimum ambient air temperature °F 50 50

Maximum ambient air temperature °F 100 100

Minimum evaporator entering air db/wb °F 68/57 68/57

Rated air coil entering air db/wb °F 80/67 80/67

Maximum evaporator entering air db/wb °F 95/85 95/85

Minimum water coil entering fl uid temperature °F 50 50

Water loop typical coil entering fl uid range temperature °F 70/90 70/90

Maximum water coil entering fl uid temperature °F 110 110

Heating

Minimum ambient air temperature °F 50 40

Maximum ambient air temperature °F 100 85

Minimum evaporator entering air db °F 50 50

Rated air coil entering air °F 68 68

Maximum evaporator entering air db °F 80 80

Normal water coil entering fl uid range °F 50-80 25-80*

Minimum water coil entering Fluid °F 50 20*

* Antifreeze solution is required at these fl uid temperatures.

Subject to change without prior notice

Page 23

.

Antifreeze Correction Data

Antifreeze Type Antifreeze %

Total Cap. Sens. Cap Power Htg. Cap Power

Water

Propylene Glycol

Methanol

Ethanol

Ethylene Glycol

0 1.000 1.000 1.000 1.000 1.000 1.000

5 0.997 0.997 1.004 0.989 0.997 1.060

10 0.994 0.994 1.006 0.986 0.995 1.125

15 0.990 0.990 1.009 0.978 0.988 1.190

25 0.983 0.983 1.016 0.960 0.979 1.300

5 0.997 0.997 1.003 0.990 0.997 1.060

10 0.996 0.996 1.005 0.979 0.993 1.100

15 0.994 0.994 1.008 0.970 0.990 1.140

5 0.998 0.998 1.002 0.981 0.994 1.160

10 0.996 0.996 1.004 0.960 0.988 1.230

15 0.992 0.992 1.006 0.944 0.983 1.280

25 0.986 0.986 1.009 0.917 0.974 1.400

5 0.997 0.997 1.003 0.993 0.998 1.060

10 0.995 0.995 1.004 0.986 0.996 1.120

15 0.992 0.992 1.005 0.980 0.993 1.190

25 0.988 0.988 1.009 0.970 0.990 1.330

30 0.985 0.985 1.012 0.965 0.987 1.400

Antifreeze Correction

Cooling Heating

EWT 90 °F EWT 30 °F

boschheatingandcooling.com | 22

WPD Correction

Factor

EWT 30 °F

Waterside Pressure Drop

Model

LV007

LV009

LV012

LV015

LV018

LV024

LV030

Based on 70° F

Wtr. Flow

Rate (GPM)

1.0 0.3 0.5

2.0 1.1 1.8

3.0 2.3 3.8

1.0 0.5 0.6

2.0 1.7 2.3

3.0 3.5 5.0

1.5 1.0 1.4

2.5 2.6 3.6

3.5 4.8 6.7

2.0 1.9 2.5

3.0 3.9 5.3

4.0 6.5 9.1

2.5 1.1 2.1

4.0 2.7 5.2

5.0 4.0 8.0

3.0 1.7 2.0

4.0 2.8 3.4

6.0 5.8 7.2

4.0 2.0 2.6

6.0 4.2 5.6

8.0 7.0 9.6

Wtr. PD w/o

Int. Valve

(psi)

Mixture of 15% methanol / water solution.

Wtr. PD w/

Int. Valve

(psi)

Model

LV036

LV041

LV042

LV048

LV060

LV070

Wtr. Flow

Rate (GPM)

4.5 1.6 2.4

6.0 2.6 4.0

9.0 5.4 8.6

5.0 2.0 3.0

8.0 4.6 7.2

11.0 8.2 13.1

5.0 2.0 3.0

8.0 4.6 7.2

11.0 8.2 13.0

6.0 0.8 1.4

8.0 1.4 2.5

12.0 2.8 5.4

7.5 1.4 2.4

10.0 2.3 4.1

15.0 4.8 8.8

9.0 2.0 3.4

12.0 3.4 5.9

18.0 7.0 12.7

Wtr. PD w/o

Int. Valve

(psi)

ubject to change without prior notice

Wtr. PD w/

Int. Valve

(psi)

Page 24

23 | LV Model | Commercial Geothermal Heat Pumps

.

Capacity Data

LV007 (300 CFM)

Entering

Fluid Temp

(°F)

50

60

70

80

85

90

100

110

Water

Flow

(GPM)

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

Pressure

Drop PSI

(FOH)

0.3

(0.6)

1.2

(2.77)

2.5

(5.77)

0.3

(0.6)

1.2

(2.77)

2.4

(5.54)

0.3

(0.6)

1.1

(2.54)

2.3

(5.31)

0.3

(0.6)

1.1

(2.54)

2.3

(5.31)

0.3

(0.6)

1.1

(2.54)

2.2

(5.07)

0.3

(0.6)

1.1

(2.54)

2.2

(5.07)

0.3

(0.6)

1

(2.31)

2.1

(4.84)

0.3

(0.6)

1

(2.31)

2.1

(4.84)

Cooling Heating

Entering Air

Temp (db/wb) °F

Total Capaci-

ty (MBTUH)

Sensible

Capacity

(MBTUH)

Heat of

Rejection

(MBTUH)

Power Input

(kW)

75/63 7.0 6.3 8.3 0.42 16.9

EER

Entering

Fluid Temp

(°F)

(°F)

Total

Capacity

(MBTUH)

Entering

Air Temp

60 4.5 3.2 0.42 3.1

Heat of

Absorption

(MBTUH)

80/67 7.5 6.5 8.8 0.42 18.1 70 4.4 3.0 0.45 2.8

85/71 7.9 6.7 9.2 0.42 19.0 80 4.3 2.8 0.48 2.6

75/63 7.5 6.5 8.6 0.37 20.3 60 4.9 3.6 0.43 3.3

80/67 8.0 6.7 9.1 0.37 21.9 70 4.8 3.4 0.46 3.0

30

85/71 8.5 6.9 9.7 0.36 23.5 80 4.6 3.1 0.49 2.7

75/63 7.6 6.5 8.8 0.35 21.6 60 5.1 3.8 0.43 3.4

80/67 8.1 6.8 9.3 0.35 23.4 70 5.0 3.5 0.46 3.2

85/71 8.7 7.0 9.8 0.34 25.5 80 4.8 3.2 0.49 2.8

75/63 6.6 6.1 8.0 0.45 14.6

60 5.3 3.9 0.43 3.6

80/67 7.1 6.3 8.5 0.46 15.7 70 5.1 3.7 0.46 3.2

85/71 7.5 6.6 8.9 0.46 16.5 80 5.0 3.4 0.50 2.9

75/63 7.1 6.3 8.3 0.41 17.4 60 5.8 4.4 0.44 3.9

80/67 7.5 6.5 8.8 0.41 18.4 70 5.6 4.1 0.47 3.5

40

85/71 8.0 6.8 9.3 0.41 19.8 80 5.4 3.8 0.50 3.1

75/63 7.2 6.4 8.5 0.40 18.3 60 6.0 4.6 0.44 4.0

80/67 7.7 6.6 9.0 0.39 19.8 70 5.8 4.3 0.47 3.6

85/71 8.2 6.8 9.5 0.39 21.3 80 5.6 4.0 0.51 3.2

75/63 6.2 6.0 7.7 0.49 12.7

60 6.0 4.7 0.44 4.0

80/67 6.7 6.2 8.2 0.50 13.6 70 5.9 4.4 0.47 3.6

85/71 7.1 6.5 8.6 0.50 14.3 80 5.7 4.1 0.51 3.3

75/63 6.6 6.1 8.0 0.45 14.7 60 6.7 5.3 0.44 4.4

80/67 7.1 6.4 8.5 0.45 15.8 70 6.5 4.9 0.48 4.0

50

85/71 7.6 6.6 9.0 0.45 17.0 80 6.3 4.6 0.52 3.6

75/63 6.8 6.2 8.1 0.44 15.6 60 6.9 5.5 0.44 4.5

80/67 7.3 6.4 8.6 0.44 16.8 70 6.7 5.2 0.48 4.1

85/71 7.8 6.7 9.1 0.43 18.1 80 6.5 4.8 0.52 3.7

75/63 5.9 5.6 7.4 0.53 11.2

60 6.9 5.5 0.44 4.5

80/67 6.3 6.1 7.8 0.54 11.8 70 6.7 5.2 0.48 4.1

85/71 6.7 6.3 8.3 0.54 12.5 80 6.5 4.9 0.52 3.7

75/63 6.2 6.0 7.7 0.50 12.6 60 7.6 6.2 0.45 5.0

80/67 6.7 6.2 8.2 0.50 13.6 70 7.4 5.8 0.49 4.4

60

85/71 7.1 6.5 8.6 0.50 14.4 80 7.1 5.4 0.53 3.9

75/63 6.4 6.0 7.8 0.48 13.4 60 7.9 6.5 0.45 5.2