LTC 8900 Series

en Installation Manual

LTC 8900 Series Table of Contents | en 3

Table of contents

1

1.1 About this Manual 8

1.2 Legal Information 8

1.3 Safety Precautions 8

1.4 Important safety instructions 8

1.5 Important notices 10

1.6 FCC & ICES compliance 13

1.7 UL certification 14

1.8 Warranty / Limitation of Liability 14

1.9 Customer Support and Service 15

2

2.1 Parts List 16

3

3.1 Description 17

3.2 Features 17

4

4.1 LTC 8904 Series CPU Bay 18

4.2 LTC 8901 Series CPU Bay 18

4.3 LTC 8902 Series Output Bay 18

4.4 LTC 8903 Series Input Bay 18

4.5 LTC 8934/00 Video Output Modules 19

4.6 LTC 8921/00 Video Input Modules 19

4.7 LTC 8943/95 System Controller PC 19

4.8 LTC 8944/93 and LTC 8945/93 LAN Switches 19

4.9 LTC 8946/93 LAN Switches 19

4.10 LTC 8809/00 Video Ribbon Cable 19

4.11 LTC 8808/00 Video Interconnect Panel 20

4.12 LAN Cables 20

4.13 Security Key for PC-based Software 20

4.14 Miscellaneous Components 20

5

5.1 General Installation Considerations 21

5.2 LTC 8904 Series CPU Bay Installation 22

5.3 LAN Switch Installation 23

5.4 LTC 8902 Series Output Bay and LTC 8903 Series Input Bay Installation 23

5.5 Module Insertion 24

5.6 Data Receiver Modules 24

5.7 LTC 8916/01 Data Receiver Modules 24

5.8 LTC 8918/01 Data Receiver Modules 25

5.9 LTC 8934/00 Video Output Modules 26

5.10 LTC 8921/00 Video Input Modules 27

5.11 System Video Connections 28

5.11.1 Camera Input Connections 28

5.11.2 System Connections over 1024 Cameras 28

5.11.3 Camera Bays to Monitor Bay Video Connections 29

5.11.4 Multiple Monitor Bay Consideration 29

5.11.5 Monitor Output Connections 29

Safety 6

Unpacking 16

Introduction 17

System Components 18

Hardware Installation Procedure for Standard Systems Utilizing LTC 8904 Series CPU 21

Bosch Security Systems, Inc. Installation Manual 2016.04 | 10.7 | F.01U.323.096

4 en | Table of Contents LTC 8900 Series

5.11.6 System Video Looping Connections 29

5.12 Termination Practices 30

5.12.1 LTC 8903 Series Terminations 30

5.12.2 Second Level LTC 8903 Series Terminations 30

5.12.3 LTC 8902 Series Terminators 30

5.13 System Data Connections 31

5.13.1 LTC 8904 Series CPU Data Connections 31

5.13.2 LTC 8902 Series and LTC 8903 Series Data Connections 31

5.13.3 Multiple LTC 8946/93 LAN Switch Connections 31

5.14 Main Power Connections 31

6

Hardware Installation Procedure for Redundant System Configuration Utilizing LTC

33

8901 Series CPU

6.1 System Redundancy Considerations 33

6.1.1 General Information 33

6.1.2 LTC 8901 Series CPU Design Features 34

6.1.3 LTC 8943/95 System Controller PC Functions 34

6.1.4 LTC 8901 Series CPU Design Features 35

6.1.5 Video Bay Redundancy Considerations 36

6.1.6 General Installation Considerations 37

6.2 Main CPU Bay Installation 39

6.3 LAN Switch Installation 40

6.4 LTC 8943/95 System Controller PC Installation 40

6.4.1 PC Installation 40

6.4.2 PC Monitor Installation 41

6.4.3 Keyboard/Mouse Rack Installation 41

6.4.4 Final Installation 41

6.5 LTC 8902 Series Output Bay and LTC 8903 Series Input Bay Installation 41

6.6 Module Insertion 42

6.7 Data Receiver Modules 43

6.8 LTC 8916/01 Data Receiver Modules 43

6.9 LTC 8918/01 Data Receiver Modules 44

6.10 LTC 8934/00 Video Output Modules 45

6.11 LTC 8921/00 Video Input Modules 46

6.12 System Video Connections 47

6.12.1 Camera Input Connections 47

6.12.2 System Connections over 1024 Cameras 47

6.12.3 System Connections over 1024 Cameras 47

6.12.4 Multiple Monitor Bay Considerations 48

6.12.5 Monitor Output Connections 48

6.12.6 System Video Looping Connections 48

6.13 Termination Practices 48

6.13.1 LTC 8903 Series Terminators 48

6.13.2 Second Level 8903 Series Terminations 49

6.13.3 LTC 8902 Series Terminations 49

6.14 System Data Connections 49

6.14.1 LTC 8901 Series CPU Data Connections 49

6.14.2 LTC 8902 Series and LTC 8903 Series Data Connections 50

6.14.3 LTC 8944/93 LAN Switch to LTC 8945/93 LAN Switch Connections 50

6.14.4 LTC 8946/93 LAN Switch Connections 50

2016.04 | 10.7 | F.01U.323.096 Installation Manual Bosch Security Systems, Inc.

LTC 8900 Series Table of Contents | en 5

6.14.5 LTC 8943/95 PC to LTC 8945/93 LAN Switch Connectors 50

6.15 Main Power Connections 50

6.16 LTC 8901 Series CPU Relay Outputs and Buzzers 52

6.17 LTC 8901 Series CPU Selection Switch 53

7

Camera Phasing and Accessory Installation 54

7.1 Camera Phasing Information 54

7.2 External Sync Information 54

7.3 System Keyboard Installation 54

7.4 Signal Distribution Unit Hookup 55

7.5 Alarm Interface Unit Hookup 55

7.6 External Computer Interface Connections 55

7.7 Logging Printer Option Installation 55

8

Satellite System Configuration Installations 57

8.1 Allegiant Satellite System Configuration Installations 58

8.2 Satellite Site “Trunk Line” Monitor Outputs 64

8.3 Main Site “Trunk Line” Video Inputs 64

8.4 Control Data Lines in Satellite Systems 64

8.5 Satellite Sites Programming Requirements 64

8.6 Main Site Programming Requirements 65

8.7 Special Programming for “Cascaded” Satellite System Configurations 67

8.8 Alarm Inputs in Satellite Systems 68

9

10

Troubleshooting Guide 100

Maintenance Information 103

10.1 Cleaning System Keyboard(s) 103

10.2 Matrix Bay AC Line Voltage Input Selection 103

10.3 Matrix Bay AC Line Fuse Replacement 104

10.4 Matrix Bay Power Supply Fuse Replacement 105

10.5 Replacing LTC 8901 or LTC 8904 Series CPU Parts 105

10.6 LTC 8943/95 System Controller PC 106

10.7 Replacement of Memory Backup Batteries 106

11

Pinouts 108

Bosch Security Systems, Inc. Installation Manual 2016.04 | 10.7 | F.01U.323.096

Sécurité

Attention : l'installation doit exclusivement être réalisée par du

personnel qualié, conformément au code national

d'électricité américain (NEC) ou au code d'électricité local en

vigueur.

Coupure de l'alimentation. Qu'ils soient pourvus ou non d'un

commutateur ON/OFF, tous les appareils reçoivent de

l'énergie une fois le cordon branché sur la source

d'alimentation. Toutefois, l'appareil ne fonctionne réellement

que lorsque le commutateur est réglé sur ON. Le

débranchement du cordon d'alimentation permet de couper

l'alimentation des appareils.

ATT EN TIO N : P O UR É VIT ER T OU T R I SQ UE D 'É LE CT RO C UTI ON,

N'E S S AYEZ P AS DE R E TIR E R L E C AP OT ( O U L E P ANNE AU

AR RI ÈR E) . C ET AP P ARE IL N E C ON TIE NT AU CU N C O MP OS AN T

S US CE P TIB L E D 'Ê TR E R ÉP AR É P AR L 'U TIL IS ATE UR . C ON FIE Z

LA R ÉP AR ATIO N D E L 'AP PAR E IL À D U P ER S ONN EL Q UAL IF IÉ .

Ce symbole signale que le produit renferme une « tension

potentiellement dangereuse » non isolée susceptible de

provoquer une électrocution.

Ce symbole invite l'utilisat eur à consulter les instructions

d'utilisation et d'entretien (dépannage) reprises dans la

documentation qui accompagne l'appareil.

Sicherheitshinweise

Achtung! Die Installation sollte nur von qualiziertem

Kundendienstpersonal gemäß jeweils zutreender

Elektrovorschriften ausgeführt werden.

Unterbrechung des Netzanschlusses. Geräte mit oder

ohne Netzschalter haben Spannung am Gerät anliegen,

sobald der Netzstecker in die Steckdose gesteckt wird.

Das Gerät ist jedoch nur betriebsbereit, wenn der

Netzschalter (EIN/AUS) auf EIN steht. Wenn das N etzkabel

aus der Steckdose gezogen wird, ist die

Spannungszuführung zum Gerät vollkommen

unterbrochen.

VOR S ICH T: U M E I NEN E L EK TR IS CHE N S C HL AG Z U

VER ME IDE N, I S T D IE AB DEC KU NG ( O DE R R ÜC KS EI TE)

NIC HT ZU E NT FE RNE N. E S B E FIND EN S IC H K EI NE T E ILE IN

DIE S EM B E R EIC H, D IE VO M B E NUTZ ER G EWAR TE T W ER DE N

KÖ NNE N. L AS S EN S I E W ART UNG SAR BE IT EN N UR VO N

QU ALIF IZIE RT EM W AR TUNG S PE RS ONAL AU SF ÜHR EN.

Das Symbol macht auf nicht isolierte „gefährliche

Spannung" im Gehäuse aufmerksam. Dies kann zu

einem elektrischen Schlag führen.

Der Benutzer sollte sich ausführlich über Anweisungen

für die Bedienung und Instandhaltung (Wartung) in den

begleitenden Unterlagen informieren.

Precauciones de Seguridad

Atención: la instalación la debe realizar únicamente

personal cualicado de conformidad con el National

Electric Code o las nor mas aplicables en su país.

Desconexión de la alimentación. Las unidades con o sin

interruptores de encendido/apagado reciben alimentación

eléctrica siempre que el cable de alimentación esté

conectado a la fuente de alimentación. Sin embargo, la

unidad sólo funciona cuando el interruptor está en la

posición de encendido. El cable de alimentación es la

principal fuente de desconexión de todas las unidades.

PR E CAU CI ÓN : P AR A D IS MI NUIR E L R IE S GO D E D E S CAR G A

E LÉ CT RI CA, N O R E TI RE L A C U BI ER TA ( N I L A P AR TE

PO S TE RI OR ) . N O E XIS T EN P IEZ AS DE R E CA MB IO E N E L

INT ER IO R DE L E QU IPO . E L P E R SO NAL D E S E RVI CI O

C UALI FI CAD O S E E NC ARG A D E R EAL IZAR L AS

R EP ARAC IO NE S .

Este símbolo indica que existen puntos de tensión peligrosos

sin aislamiento dentro de la cubierta de la unidad. Estos

puntos pueden constituir un riesgo de descarga eléctrica.

El usuario debe consultar las instrucciones de

funcionamiento y mantenimiento (reparación) en la

documentación que se suministra con el aparato.

Safety Precautions

Attention: Installation should be performed by

qualied service personnel only in accordance

with the National Electrical Code or applicable

local codes.

Power Disconnect. Units with or without

ON-OFF switches have power supplied to the

unit whenever the power cord is inserted into the

power source; however, the unit is operational

only when the ON-OFF switch is in the ON

position. The power cord is the main power

disconnect for all

units.

C A U T IO N : T O R E D U C E T H E R I S K O F

E L E C T R IC S H O C K , D O N O T R E M O V E C O V E R

( O R B A C K ) . N O U S E R S E R V I C E A B L E P A R T S

IN S I D E . R E F E R S E R V IC IN G T O Q U A L I F IE D

S E R V IC E P E R S O N N E L .

This symbol indicates the presence of

uninsulated dangerous voltage wit hin the

product s enclosure. This may constitute a

risk of electric shock.

The user should consult the operating and

maintenance (servicing) instructions in the

literature accompanying the appliance.

6 en | Safety LTC 8900 Series

1

Safety

2016.04 | 10.7 | F.01U.323.096 Installation Manual Bosch Security Systems, Inc.

Veiligheidsmaatregelen

Attentie: het apparaat mag alleen door gekwaliceerd

personeel wor den ge ïnst alleerd. De installatie dient in

overeenstemming met de nationale elektrische richtlijnen

of de van toepassing zijnde lokale richtlijnen te worden

uitgevoerd.

Spanning uitschakelen. Apparatuur met of zonder

aan-uitschakelaar staat onder spanning zolang de stekker

is aangesloten op de wandcontactdoos. De apparatuur is

uitsluitend in werking als de aan-uitschakelaar aan staat.

Het netsnoer is de "hoofdschakelaar" voor alle apparatuur.

VO OR ZIC HT IG : O P EN D E B E HU IZIN G O F D E

AC HTE R KANT V AN H ET AP P ARAAT N IE T. ZO VE R MIN DE RT

U H E T R I SI CO O P E LE KT RI SC HE S C HO KK EN . I N H E T

AP PAR AAT B EVI NDE N Z IC H G E E N O ND ER DE LE N D IE U

ZE LF K UNT R E PAR ER E N. L A AT S E R VIC E E N O NDE R HO UD

UI TVO ER EN D OO R G E KW ALIF IC E ER D P E RS O NE EL .

Dit symbool geeft aan dat er binnen in het apparaat

ong eïsol eer de, gevaarlijke spanning aanwezig is die

mogelijk elektrische schokken kan veroorzaken.

De gebruiker dient de bedienings- en

onderhoudsvoorschriften te raadplegen in de

documentatie die werd meegeleverd met het apparaat.

Sicurezza

Attenzione: l'installazione deve essere eettuata

esclusivamente da personale tecnico qualicato in

confor mità con il N ational Electrical Code o con le

normative locali vigenti.

Scollegamento dell'alimentazione. Le unità dotate o

sprovviste di interruttori ON-OFF vengono alimentate

quando si inserisce il cavo nella presa dell'alimentazione.

L'unità è tutta via in funzione solo quando l'interruttore ONOFF si trova nella posizione ON. Il cavo di alimentazione

costituisce il dispositivo di scollegamento dell'alimentazione

principale per tutte le unità.

ATT ENZI ONE : P E R R ID URR E I L R ISC HI O D I S C OS S E

EL ET TR ICH E N ON R IMUO VER E L A C O PE RT URA ( O I L

PAN NEL LO P OS TE RI OR E) . L 'UNI TÀ N ON C O NTI ENE

C OMP ONE NTI IN TER NI R I PAR ABIL I D ALL 'UTE NTE . P E R

QU ALS IAS I I NTE RVE NTO , R IVO LG ER S I A P E RS ON ALE

TE CN ICO Q UALI FIC ATO .

Questo simbolo indica la presenza di "tensione pericolosa"

non isolata all'interno del contenitore del prodotto. Ciò

comporta un potenziale rischio di scosse elettriche.

Si consiglia di consultare le istruzioni operative e di

manutenzione (interventi tecnici) contenute nella

documentazione fornita con il dispositivo.

Medidas de Segurança

Atenção: a instalação deve ser executada apenas por

técnicos qualicados da assistência, de acordo com o

código eléctrico nacional ou os códigos locais aplicáveis.

Corte de corrente. As unidades com ou sem interruptores

ON-OFF (ligar/desligar) recebem corrente sempre que o o

de alimentação está introduzido na fonte de alimentação;

contudo, a unidade apenas está operacional quando o

interruptor ON-OFF está na posição ON. O o de

alimentação destina-se a desligar a corrente em todas as

unidades.

C UID ADO : P AR A R E DUZI R O R IS CO D E C HO QUE

E LÉ CT RI CO , NÃO R E TIR E A T AM PA ( O U A P AR TE

P OS TE RI OR ) . N O IN TE RIO R , N ÃO E XIS TE M P E Ç AS Q UE

P OS S AM S E R R EP AR ADAS P E LO U TIL IZAD OR . R EM ET A A

AS S IS TÊ NC IA P AR A O S T ÉC NI CO S Q UAL IFI CAD OS .

Este símbolo indica a presença de "tensão perigosa" não

isolada dentro da estrutura do produto, o que pode

constituir risco de choque eléctrico.

O utilizador deve consultar as instruções de

funcionamento e manutenção (assistência) nos

documentos que acompanham o aparelho.

LTC 8900 Series Safety | en 7

Bosch Security Systems, Inc. Installation Manual 2016.04 | 10.7 | F.01U.323.096

!

!

!

8 en | Safety LTC 8900 Series

1.1

1.2

1.3

About this Manual

This manual has been compiled with great care and the information it contains has been

thoroughly verified. The text was complete and correct at the time of printing. Because of the

ongoing development of products, the content of the manual may change without notice.

Bosch Security Systems accepts no liability for damage resulting directly or indirectly from

faults, incompleteness, or discrepancies between the manual and the product described.

Legal Information

Copyright

This manual is the intellectual property of Bosch Security Systems, Inc. and is protected by

copyright. All rights reserved.

Trademarks

All hardware and software product names used in this document are likely to be registered

trademarks and must be treated accordingly.

Safety Precautions

Danger!

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

1.4

Warning!

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Caution!

Indicates a hazardous situation which, if not avoided, could result in minor or moderate

injury.

Notice!

Indicates a situation which, if not avoided, could result in damage to the equipment or

environment, or data loss.

Important safety instructions

Read, follow, and retain for future reference all of the following safety instructions. Heed all

warnings on the unit and in the operating instructions before operating the unit.

Warning!

For Indoor Use Only!

If this unit connects to outdoor equipment, ensure that the system is grounded.

1. Cleaning - Unplug the unit from the outlet before cleaning. Follow any instructions

provided with the unit. Generally, using a dry cloth for cleaning is sufficient but a moist,

fluff-free cloth or leather shammy may also be used. Do not use liquid cleaners or aerosol

cleaners.

2. Heat Sources - Do not install the unit near any heat sources such as radiators, heaters,

stoves, or other equipment (including amplifiers) that produce heat.

2016.04 | 10.7 | F.01U.323.096 Installation Manual Bosch Security Systems, Inc.

LTC 8900 Series

Safety | en 9

3. Ventilation - Any openings in the unit enclosure are provided for ventilation to prevent

overheating and ensure reliable operation. Do not block or cover these openings. Do not

place the unit in an enclosure unless proper ventilation is provided, or the manufacturer's

instructions have been adhered to.

4. Water - Do not use this unit near water, for example near a bathtub, washbowl, sink,

laundry basket, in a damp or wet basement, near a swimming pool, in an outdoor

installation, or in any area classified as a wet location. To reduce the risk of fire or

electrical shock, do not expose this unit to rain or moisture.

5. Object and liquid entry - Never push objects of any kind into this unit through openings

as they may touch dangerous voltage points or short-out parts that could result in a fire

or electrical shock. Never spill liquid of any kind on the unit. Do not place objects filled

with liquids, such as vases or cups, on the unit.

6. Lightning - For added protection during a lightning storm, or when leaving this unit

unattended and unused for long periods, unplug the unit from the wall outlet and

disconnect the cable system. This will prevent damage to the unit from lightning and

power line surges.

7. Controls adjustment - Adjust only those controls specified in the operating instructions.

Improper adjustment of other controls may cause damage to the unit. Use of controls or

adjustments, or performance of procedures other than those specified, may result in

hazardous radiation exposure.

8. Overloading - Do not overload outlets and extension cords. This can cause fire or

electrical shock.

9. Power supply cord and plug protection - Protect the power supply cord and plug from

foot traffic, being pinched by items placed upon or against them at electrical outlets, and

its exit from the unit. For units intended to operate with 230 VAC, 50 Hz, the power

supply cord must comply with the latest versions of IEC 60227. For units intended to

operate with 120 VAC, 60 Hz, the power supply cord must comply with the latest versions

of UL 62 and CSA 22.2 No.49.

10. Power disconnect - Units have power supplied to the unit whenever the power cord is

inserted into the power source. The power cord plug is the main power disconnect device

for switching off the voltage for all units.

11. Power sources - Operate the unit only from the type of power source indicated on the

label. Before proceeding, be sure to disconnect the power from the cable to be installed

into the unit.

– For battery powered units, refer to the operating instructions.

– For external power supplied units, use only the recommended or approved power

supplies.

– For limited power source units, this power source must comply with EN60950.

Substitutions may damage the unit or cause fire or shock.

– For 24 VAC units, voltage applied to the unit's power input should not exceed ±10%,

or 28 VAC. User-supplied wiring must comply with local electrical codes (Class 2

power levels). Do not ground the supply at the terminals or at the unit's power

supply terminals.

– If unsure of the type of power supply to use, contact your dealer or local power

company.

12. Servicing - Do not attempt to service this unit yourself. Opening or removing covers may

expose you to dangerous voltage or other hazards. Refer all servicing to qualified service

personnel.

Bosch Security Systems, Inc. Installation Manual 2016.04 | 10.7 | F.01U.323.096

10 en | Safety LTC 8900 Series

13. Damage requiring service - Unplug the unit from the main AC power source and refer

servicing to qualified service personnel when any damage to the equipment has occurred,

such as:

– the power supply cord or plug is damaged;

– exposure to moisture, water, and/or inclement weather (rain, snow, etc.);

– liquid has been spilled in or on the equipment;

– an object has fallen into the unit;

– unit has been dropped or the unit cabinet is damaged;

– unit exhibits a distinct change in performance;

– unit does not operate normally when the user correctly follows the operating

instructions.

14. Replacement parts - Be sure the service technician uses replacement parts specified by

the manufacturer, or that have the same characteristics as the original parts.

Unauthorized substitutions may cause fire, electrical shock, or other hazards.

15. Safety check - Safety checks should be performed upon completion of service or repairs

to the unit to ensure proper operating condition.

16. Installation - Install in accordance with the manufacturer's instructions and in accordance

with applicable local codes.

This unit should not be located in the vicinity of electrical lights or power circuits, or

where it may contact such lights or circuits.

U.S.A. models only – refer to the National Electrical Code Article 820 regarding

installation of CATV systems.

17. Attachments, changes or modifications - Only use attachments/accessories specified by

the manufacturer. Any change or modification of the equipment, not expressly approved

by Bosch, could void the warranty or, in the case of an authorization agreement, authority

to operate the equipment.

1.5

Important notices

Accessories - Do not place this unit on an unstable stand, tripod, bracket, or mount. The

unit may fall, causing serious injury and/or serious damage to the unit. Use only with the

cart, stand, tripod, bracket, or table specified by the manufacturer. When a cart is used, use

caution and care when moving the cart/apparatus combination to avoid injury from tip-over.

Quick stops, excessive force, or uneven surfaces may cause the cart/unit combination to

overturn. Mount the unit per the manufacturer's instructions.

All-pole power switch - Incorporate an all-pole power switch, with a contact separation of at

least 3 mm in each pole, into the electrical installation of the building. If it is needed to open

the housing for servicing and/or other activities, use this all-pole switch as the main

disconnect device for switching off the voltage to the unit.

Battery replacement - A lithium battery is located inside the unit enclosure. To avoid danger

of explosion, replace the battery as per instructions. Replace only with the same or equivalent

type recommended by the manufacturer. Refer all servicing to qualified service personnel.

Notice!

Batteries must not be disposed of in household waste. Dispose of batteries only at suitable

collection points and, in the case of lithium batteries, mask the poles.

For further information refer to: http://www.BoschSecurity.com/standards

2016.04 | 10.7 | F.01U.323.096 Installation Manual Bosch Security Systems, Inc.

LTC 8900 Series Safety | en 11

Camera signal - Protect the cable with a primary protector if the camera signal is beyond 140

feet, in accordance with NEC800 (CEC Section 60).

Disposal - Your Bosch product was developed and manufactured with high-quality material

and components that can be recycled and reused. This symbol means that electronic and

electrical appliances, which have reached the end of their working life, must be collected

and disposed of separately from household waste material. Separate collecting systems are

usually in place for disused electronic and electrical products. Please dispose of these units

at an environmentally compatible recycling facility, per European Directive 2002/96/EC.

Electronic Surveillance - This unit is intended for use in public areas only. U.S. federal law

strictly prohibits surreptitious recording of oral communications.

Environmental statement - Bosch has a strong commitment towards the environment. This

unit has been designed to respect the environment as much as possible.

Electrostatic-sensitive device - Use proper CMOS/MOS-FET handling precautions to avoid

electrostatic discharge. NOTE: Wear required grounded wrist straps and observe proper ESD

safety precautions when handling the electrostatic-sensitive printed circuit boards.

Fuse rating - For protection of the unit, the branch circuit protection must be secured with a

maximum fuse rating of 16A. This must be in accordance with NEC800 (CEC Section 60).

Grounding - For mounting the unit in potentially damp environments, ensure to ground the

system using the ground connection of the power supply connector (see section: Connecting

external power supply).

Coax grounding:

– Ground the cable system if connecting an outside cable system to the unit.

– Connect outdoor equipment to the unit's inputs only after this unit has had its grounding

plug connected to a grounded outlet or its ground terminal is properly connected to a

ground source.

– Disconnect the unit's input connectors from outdoor equipment before disconnecting the

grounding plug or grounding terminal.

– Follow proper safety precautions such as grounding for any outdoor device connected to

this unit.

U.S.A. models only - Section 810 of the National Electrical Code, ANSI/NFPA No.70, provides

information regarding proper grounding of the mount and supporting structure, grounding of

the coax to a discharge unit, size of grounding conductors, location of discharge unit,

connection to grounding electrodes, and requirements for the grounding electrode.

Grounding and polarization - This unit may be equipped with a polarized alternating current

line plug (a plug with one blade wider than the other blade). This safety feature allows the

plug to fit into the power outlet in only one way. If unable to insert the plug fully into the

outlet, contact a locally certified electrician to replace the obsolete outlet. Do not defeat the

safety purpose of the polarized plug.

Alternately, this unit may be equipped with a 3-pole grounding plug (a plug with a third pin for

earth grounding). This safety feature allows the plug to fit into a grounded power outlet only.

If unable to insert the plug into the outlet, contact a locally certified electrician to replace the

obsolete outlet. Do not defeat the safety purpose of the grounding plug.

Moving - Disconnect the power before moving the unit. Move the unit with care. Excessive

force or shock may damage the unit and the hard disk drives.

Outdoor signals - The installation for outdoor signals, especially regarding clearance from

power and lightning conductors and transient protection, must be in accordance with NEC725

and NEC800 (CEC Rule 16-224 and CEC Section 60).

Permanently connected equipment - Incorporate a readily accessible disconnect device

external to the equipment.

Bosch Security Systems, Inc. Installation Manual 2016.04 | 10.7 | F.01U.323.096

!

12 en | Safety LTC 8900 Series

Pluggable equipment - Install the socket outlet near the equipment so it is easily accessible.

Rack-mount

– Elevated Operating Ambient - If installed in a closed or multi-unit rack assembly, the

operating ambient temperature of the rack environment may be greater than room

ambient. Therefore, consideration should be given to installing the equipment in an

environment compatible with the maximum ambient temperature (Tma) specified by the

manufacturer.

– Reduced Air Flow - Installation of the equipment in a rack should be such that the amount

of air flow required for safe operation of the equipment is not compromised.

– Mechanical loading - Mounting of the equipment in the rack should be such that a

hazardous condition is not achieved due to uneven mechanical loading.

– Circuit Overloading - Consideration should be given to the connection of the equipment

to the supply circuit and the effect that overloading of the circuits might have on

overcurrent protection and supply wiring. Appropriate consideration of equipment

nameplate ratings should be used when addressing this concern.

– Reliable Earthing - Reliable earthing of rack-mounted equipment should be maintained.

Particular attention should be given to supply connections other than direct connections

to the branch circuit (e.g. use of power strips).

System ground/Safety ground

System (video) ground is indicated by the symbol .

Safety (power) ground is indicated by the symbol

.

The system ground is only used to comply with safety standards or installation practices in

certain countries. Bosch does not recommend connecting system ground to safety ground

unless it is explicitly required. However, if the system ground and safety ground are connected

and grounding loops are causing interference in the video signal, use an isolation transformer

(available separately from Bosch).

Caution!

Connecting System ground to Safety ground may result in ground loops that can disrupt the

CCTV system.

Video loss - Video loss is inherent to digital video recording; therefore, Bosch Security

Systems cannot be held liable for any damage that results from missing video information. To

minimize the risk of lost digital information, Bosch Security Systems recommends multiple,

redundant recording systems, and a procedure to back up all analog and digital information.

2016.04 | 10.7 | F.01U.323.096 Installation Manual Bosch Security Systems, Inc.

LTC 8900 Series Safety | en 13

1.6

FCC & ICES compliance

FCC & ICES Information

(U.S.A. and Canadian Models Only)

This device complies with part 15 of the FCC Rules. Operation is subject to the following

conditions:

– this device may not cause harmful interference, and

– this device must accept any interference received, including interference that may cause

undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules and ICES-003 of Industry Canada. These

limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and

radiates radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference, in which case the

user will be required to correct the interference at his expense.

Intentional or unintentional modifications, not expressly approved by the party responsible for

compliance, shall not be made. Any such modifications could void the user's authority to

operate the equipment. If necessary, the user should consult the dealer or an experienced

radio/television technician for corrective action.

The user may find the following booklet, prepared by the Federal Communications

Commission, helpful: How to Identify and Resolve Radio-TV Interference Problems. This

booklet is available from the U.S. Government Printing Office, Washington, DC 20402, Stock

No. 004-000-00345-4.

Informations FCC et ICES

(modèles utilisés aux États-Unis et au Canada uniquement)

Ce produit est conforme aux normes FCC partie 15. la mise en service est soumises aux deux

conditions suivantes :

– cet appareil ne peut pas provoquer d'interférence nuisible et

– cet appareil doit pouvoir tolérer toutes les interférences auxquelles il est soumit, y

compris les interférences qui pourraient influer sur son bon fonctionnement.

AVERTISSEMENT: Suite à différents tests, cet appareil s’est révélé conforme aux exigences

imposées aux appareils numériques de Classe A en vertu de la section 15 du règlement de la

Commission fédérale des communications des États-Unis (FCC). Ces contraintes sont

destinées à fournir une protection raisonnable contre les interférences nuisibles quand

l'appareil est utilisé dans une installation commerciale. Cette appareil génère, utilise et émet

de l'energie de fréquence radio, et peut, en cas d'installation ou d'utilisation non conforme aux

instructions, générer des interférences nuisibles aux communications radio. L’utilisation de ce

produit dans une zone résidentielle peut provoquer des interférences nuisibles. Le cas

échéant, l’utilisateur devra remédier à ces interférences à ses propres frais.

Au besoin, l’utilisateur consultera son revendeur ou un technicien qualifié en radio/télévision,

qui procédera à une opération corrective. La brochure suivante, publiée par la Commission

fédérale des communications (FCC), peut s’avérer utile : How to Identify and Resolve Radio-TV

Interference Problems (Comment identifier et résoudre les problèmes d’interférences de radio

et de télévision). Cette brochure est disponible auprès du U.S. Government Printing Office,

Washington, DC 20402, États-Unis, sous la référence n° 004-000-00345-4.

Bosch Security Systems, Inc. Installation Manual 2016.04 | 10.7 | F.01U.323.096

14 en | Safety LTC 8900 Series

Notice!

This is a class A product. In a domestic environment this product may cause radio

interference, in which case the user may be required to take adequate measures.

1.7

1.8

UL certification

UL Disclaimer

Underwriter Laboratories Inc. ("UL") has not tested the performance or reliability of the

security or signaling aspects of this product. UL has only tested fire, shock and/or casualty

hazards as outlined in Standard(s) for Safety for Information Technology Equipment, UL

60950-1 . UL Certification does not cover the performance or reliability of the security or

signaling aspects of this product.

UL MAKES NO REPRESENTATIONS, WARRANTIES, OR CERTIFICATIONS WHATSOEVER

REGARDING THE PERFORMANCE OR RELIABILITY OF ANY SECURITY OR SIGNALING-RELATED

FUNCTIONS OF THIS PRODUCT.

Disclaimer

Underwriter Laboratories Inc. (“UL”) has not tested the performance or reliability of the

security or signaling aspects of this product. UL has only tested fire, shock and/or casualty

hazards as outlined in UL's Standard(s) for Safety for Closed Circuit Television Equipment, UL

2044. UL Certification does not cover the performance or reliability of the security or signaling

aspects of this product.

UL MAKES NO REPRESENTATIONS, WARRANTIES, OR CERTIFICATIONS WHATSOEVER

REGARDING THE PERFORMANCE OR RELIABILITY OF ANY SECURITY OR SIGNALING RELATED

FUNCTIONS OF THIS PRODUCT.

Warranty / Limitation of Liability

The unit has a 3 year warranty.

BOSCH Security Systems warrants that its products, at the time of shipment by BOSCH

Security Systems, are free from defect in material or workmanship under normal use and

service for the respective warranty periods specified in the applicable Price Schedule or as

otherwise published.

To assure conformance with operating limitations, Buyer should refer to the applicable data

sheet.

The warranty is void (i) if the Product is not operated in conformance with installation,

environmental, mechanical or electrical requirements, or within thermal stress limits, or (ii) to

the extent that any malfunction is the result of misuse, abuse, vandalism, neglect, improper

installation or application, alteration, accident, or negligence in use, storage, transportation,

or handling or if the original identification markings on the product have been removed,

defaced or altered, lightning, electricity, water, fire, environment or other hazard, or act of

God, or other impact outside of normal operating guidelines.

The foregoing warranty is subject to Buyer’s (i) promptly written claim and (ii) timely provision

to BOSCH Security Systems of an opportunity to inspect and test the Product claimed to be

defective. Such inspection may be on Buyer’s premises and/or BOSCH Security Systems may

request the return of the Product at Buyer’s expense. However, BOSCH Security Systems shall

not be responsible for packing, inspection, or labor costs in connection with the return of

Product. No Product shall be accepted for warranty service that is not accompanied by a

Return Authorization issued by BOSCH.

2016.04 | 10.7 | F.01U.323.096 Installation Manual Bosch Security Systems, Inc.

LTC 8900 Series Safety | en 15

The liability of BOSCH Security Systems hereunder or otherwise is solely and exclusively

limited to replacement (new or refurbished Product), repair, or credit of the amortized

purchase price, as BOSCH Security may elect, for any Product which is returned by Buyer

during the applicable warranty period, or services for which timely notice of defect has been

given by Buyer, and which are found by BOSCH Security to be subject to adjustment under

this warranty.

BOSCH Security System’s warranty shall not be enlarged, diminished, or affected by, and no

obligation or liability shall arise or grow out of BOSCH Security’s rendering or technical

advice, facilities, or services in connection with Buyer’s order to the products furnished

hereunder.

Some non-Bosch manufactured products supplied in this kit may be factory refurbished by

original equipment manufacturer. Irrespective of OEM’s warranty, Bosch standard warranty

still applies to all items supplied.

For more information about the warranty on this product, see the Warranty Repair section on

Bosch’s Customer Care web page at www.boschsecurity.us/en-us/Service/CustomerCare.

1.9

Customer Support and Service

If this unit needs service, contact the nearest Bosch Security Systems Service Center for

authorization to return and shipping instructions.

Service Centers

USA

Telephone: 800-366-2283 or 585-340-4162

Fax: 800-366-1329

Email: cctv.repair@us.bosch.com

Customer Service

Telephone: 888-289-0096

Fax: 585-223-9180

Email: security.sales@us.bosch.com

Technical Support

Telephone: 800-326-1450

Fax: 585-223-3508 or 717-735-6560

Email: technical.support@us.bosch.com

Repair Center

Telephone: 585-421-4220

Fax: 585-223-9180 or 717-735-6561

Email: security.repair@us.bosch.com

Canada

Telephone: 514-738-2434

Fax: 514-738-8480

Europe, Middle East & Africa Region

Please contact your local distributor or Bosch sales office. Use this link:

http://www.boschsecurity.com/startpage/html/europe.htm

Asia Pacific Region

Please contact your local distributor or Bosch sales office. Use this link:

http://www.boschsecurity.com/startpage/html/asia_pacific.htm

More Information

For more information please contact the nearest Bosch Security Systems location or visit

www.boschsecurity.com

Bosch Security Systems, Inc. Installation Manual 2016.04 | 10.7 | F.01U.323.096

16 en | Unpacking LTC 8900 Series

2

2.1

Unpacking

– This equipment should be unpacked and handled with care. Check the exterior of the

packaging for visible damage. If an item appears to have been damaged in shipment,

notify the shipper immediately.

– Verify that all the parts listed in the Parts List below are included. If any items are

missing, notify your Bosch Security Systems Sales or Customer Service Representative.

– Do not use this product if any component appears to be damaged. Please contact Bosch

Security Systems in the event of damaged goods.

– The original packing carton is the safest container in which to transport the unit and must

be used if returning the unit for service. Save it for possible future use.

Parts List

Part

LTC 8901 or LTC 8904 Series Unit

LTC 8902 Series and LTC 8903 Series Matrix Bays

LTC 8943/95 PC System Controller PC (Redundant Configurations Only)

LTC 8944/93, LTC 8945/93, LTC 8946/93 LAN Switches

2016.04 | 10.7 | F.01U.323.096 Installation Manual Bosch Security Systems, Inc.

LTC 8900 Series Introduction | en 17

3

3.1

3.2

Bosch Security Systems, Inc. Installation Manual 2016.04 | 10.7 | F.01U.323.096

Introduction

This manual covers the installation of the Allegiant® LTC 8900 Series systems. Information on

system operation and information on the PC software package (if applicable) are covered in

their own respective manuals. Keep these and other manuals which are supplied along with

the various accessory devices available for reference during system installation and

configuration.

Description

The Allegiant LTC 8900 Series is a state-of-the-art video switching and control system for

indoor use only. It is the highest-capacity system in the Allegiant family. The system can switch

and control up to 4096 cameras to 512 monitors. It is also compatible with all the existing

accessories currently available in the Allegiant product line. Various system capacity

configurations are illustratedin , page 68 through , page 68.

Features

The LTC 8900 system can be purchased in either one of two design configurations: standard

and redundant. The standard configuration includes the LTC 8904 Series type CPU, which

contains a single CPU module and a single power supply. If maximum reliability is required,

the system can be purchased to include the LTC 8901 Series CPU which contains dual CPU

modules and dual power supplies. This redundant system design option includes an industrial

model PC, which enables the system to provide automatic switchover in case of failure of the

primary CPU module or of the CPU power supply.

The LTC 8900 Allegiant series systems can accommodate multiple operator keyboards and a

computer system console. They can also accommodate 2048 alarm points. All 2048 alarm

points are available through RS-232 command input; up to 1024 alarm points are available

through contact closure inputs using LTC 8540/00 alarm units and LTC 8713/00 Series port

expander units. In addition, the Allegiant Series have a Satellite configuration capability

through which the system can communicate with up to 256 remote combinations of Allegiant

Series switchers. In standard system configurations, the user can add a Windows®-based PC

to simplify programming of the system using either the supplied LTC 8059 Master Control

Software for Windows package or the optional LTC 8850 GUI software package. In the

redundant design configuration, the system is programmed and continuously monitored using

the supplied LTC 8943/95 System Controller Pentium® PC.

Using the PC-based software, user passwords can be utilized, providing an added measure of

system security; various lockout tables restricting user access to cameras, monitors,

keyboards, and remote camera control are easily programmed using the PC-based software

package. The PC software also supports up to 128 different time-activated events, providing

automated control of video sequencing, monitor message broadcasts, receiver/driver

functions, sophisticated alarm control, powerful system macro capabilities, and several other

functions.

Even with its sophistication, the Allegiant LTC 8900 system is designed for the novice user.

The ergonomic keyboard design contains many user-friendly but powerful functions. A user

can choose from up to 256 sequences that are stored in memory, select any of the cameras to

view on any of the monitors, and take exclusive control of remote pan/tilt camera functions

right from the keyboard. Each monitor can display a system status overlay showing alarm

status, sequence conditions, time/date, and camera information.

The Allegiant LTC 8900 Series systems represent a dramatic breakthrough in CCTV switcher/

controllers, and are backed by years of expertise in designing and manufacturing closed circuit

video equipment.

18 en | System Components LTC 8900 Series

4

4.1

4.2

System Components

LTC 8904 Series CPU Bay

This unit provides central control for the entire system. It contains all the system's

configuration information such as camera tables, alarm tables, sequences, etc. It is also the

connection interface to the various external Allegiant Series accessory products such as

keyboards, alarm interfaces, signal distribution units, etc. One LTC 8904 Series CPU bay per

system is required. An LTC 8904 Series CPU bay includes one power supply (LTC 8905), one

CPU module (LTC 8910), and a relay module (LTC 8917).

LTC 8901 Series CPU Bay

(Applicable to redundant system configurations only.)

This unit is similar to the standard LTC 8904 Series CPU, except it utilizes a redundant design

architecture. The LTC 8901 Series provides hot standby features with redundant power

supplies and CPU boards. In conjunction with the supplied System Controller PC, the LTC

8901 Series system is capable of automatic detection of a main power supply or CPU fault and

automatic switch over to the backup.

The unit also features the patented data mirroring technology, which allows the backup CPU

to constantly maintain the same state as the main CPU. Downloaded tables into the primary

CPU are automatically transferred to the backup CPU. Unlike competitive systems, data

transfers to the backup LTC 8901 Series CPU are automatically verified to ensure accuracy.

With this feature, if the main CPU fails, the backup CPU will be in the exact same state that

the main CPU was in prior to failure - all appropriate video will be on the monitors, sequences

will be running, alarms will be active, etc. One LTC 8901 Series CPU bay per system is

required. An LTC 8901 Series CPU bay includes two power supplies (LTC 8905), two CPU

modules (LTC 8910), and a relay module (LTC 8917).

4.3

4.4

2016.04 | 10.7 | F.01U.323.096 Installation Manual Bosch Security Systems, Inc.

LTC 8902 Series Output Bay

The LTC 8902 Series Output Bays generate the text overlays for the video monitors. Each bay

accepts up to 8 LTC 8934/00 Video Output Modules providing output for up to 64 monitors.

For more outputs, additional output bays can be used up to a maximum of 8 bays providing

512 monitor outputs. Each LTC 8902 Series Input Bay includes one Data Receiver module

(LTC 8916) and a power supply (LTC 8906).

LTC 8903 Series Input Bay

The LTC 8903 Series Input Bays provide the video switching functions. Each bay accepts up to

16 LTC 8921/00 Video Input Modules providing up to 256 camera inputs. Because of it’s

unique video bus design, the LTC 8903 Series bay is capable of switching 256 cameras to a

group of 32 monitors using only 8 LTC 8921/00 Video Input modules. When 16 LTC 8921/00

modules are installed in a LTC 8803 Series bay, 256 cameras can be switched to up to 64

monitors.The Input Bay provides full matrix switching – any input can be connected to any

output. Up to 4 LTC 8903 Series Input Bays can be connected directly to a LTC 8902 Series

Output Bay. This configuration can handle up to 1024 camera inputs.

To handle a greater number of cameras, a second stage of LTC 8903 Series bays can be used.

In this configuration, the outputs of up to 4 LTC 8903 Series Input Bays are connected to the

camera inputs of another LTC 8903 Series Input Bay. The outputs of this second-stage bay are

then connected to an LTC 8902 Series Output Bay. Up to 4 second-stage LTC 8903 Series

Input Bays can connect to the LTC 8902 Series Output Bay, for a total capacity of 4096

camera inputs. When multiple LTC 8902 Series Output Bays are used in a system, the LTC

LTC 8900 Series System Components | en 19

8903 Series Input Bay configuration must be duplicated for each output bay. The camera

signals to the first input bay configuration are looped using video ribbon cables to the next

group of input bays. This sequence continues for each LTC 8902 Series Output Bay in the

system.Each LTC 8903 Series Input Bay includes one Data Receiver module (LTC 8918) and a

power supply (LTC 8805).

4.5

4.6

4.7

LTC 8934/00 Video Output Modules

The LTC 8934/00 Video Output modules are installed into LTC 8902 Series Output Bays to

provide video output to monitors and DVR/VCRs. Each output module handles 8 outputs. Up

to 8 modules can be installed in each LTC 8902 Series Output Bay.

LTC 8921/00 Video Input Modules

The LTC 8921/00 Video Input modules are installed into LTC 8903 Series Input Bays to accept

input from cameras and other video sources. Each input modules accepts 32 video inputs. Up

to 16 modules can be installed in each LTC 8903 Series Input Bay.

LTC 8943/95 System Controller PC

(Applicable to redundant system configurations only.)

The LTC 8943/95 Series System Controller is an industrial grade PC system supplied in a rackmountable enclosure and includes a rack-mounted monitor, a rack-mounted keyboard,

Windows operating system and preloaded configuration software. The LTC 8943/95 PC is

supplied only if the system is purchased in the redundant design configuration.

The PC runs the System Supervisor Software that manages the CPU data mirroring and

automatic switchover functions. Since the PC is intended to configure and monitor the

operation of the LTC 8900 system, Bosch strongly recommends using the PC solely for this

purpose, not as an operator’s workstation or for any other purpose which could interfere with

its ability to provide automatic switchover functions.

4.8

4.9

4.10

LTC 8944/93 and LTC 8945/93 LAN Switches

(Applicable to redundant system configurations only.)

The LTC 8944/93 and LTC 8945/93 units are 10/100Base-T Ethernet LAN switches that

provide a communication link between the LTC 8901 Series main CPU bay and the system’s

LTC 8902 Series and LTC 8903 Series matrix bays. In redundant system configurations, the

LTC 8944/93 and LTC 8945/93 switches are factory-configured to communicate directly with

the LTC 8943/95 System Controller PC.

LTC 8946/93 LAN Switches

The LTC 8946/93 is a 10/100Base-T Ethernet LAN switch that provides a communication link

between the LTC 8904 Series main CPU bay and up to 11 of the system’s LTC 8902 Series and

LTC 8903 Series matrix bays. LTC 8946/93 switches can be cascaded together for use in large

systems to provide additional LAN ports when the number of LTC 8902 Series and LTC 8903

Series matrix bays exceed a combined quantity of 11 in standard configuration systems or 18

in redundant design system configurations.

LTC 8809/00 Video Ribbon Cable

The LTC 8809/00 are 16-channel ribbon cables used to provide video connections between

various system components. They are specifically designed for use with video signals and are

equipped with locking keyed connectors on each end.

Bosch Security Systems, Inc. Installation Manual 2016.04 | 10.7 | F.01U.323.096

20 en | System Components LTC 8900 Series

4.11

4.12

4.13

4.14

LTC 8808/00 Video Interconnect Panel

This patch panel contains 32 BNC connectors on its front for external video connections and

two 16-contact ribbon connectors on its rear. Two LTC 8809/00 16-conductor ribbon cables

are included for interfacing the patch panel to the video input or video output connectors on

the LTC 8902 Series Output Bays and LTC 8903 Series Input Bays.

LAN Cables

Three types of LAN cables are supplied with the system. The first type has a length of 8 m (25

ft). The second type is 3 m (10 ft) long. The third type is 2 m (6 ft) long and contain reversed

data connections. These shorter LAN cables are used exclusively for crossover connections

between the LTC 8944/93, LTC 8945/93, and LTC 8946/93 LAN switches.

Security Key for PC-based Software

The Master Control Software for Windows (MCSW) or the Graphical User Interface (GUI) PCbased software programs can only be accessed when a Security Key is attached to the PC.

This key is used to prevent unauthorized access to the system software, and it should be kept

in a safe place if the need to remove it from the PC occurs. In redundant design system

configurations, a Security Key is supplied along with the preloaded MCSW software for use on

the LTC 8943/95 PC. In standard system configurations, the MCSW and its Key are included

for use on a user-supplied PC.

Miscellaneous Components

The system is supplied with other miscellaneous components including power cords for both

110V and 220 V outlets. The unused cords can be discarded. Figure 31 illustrates some of

these components along with other cables noted elsewhere in this manual.

2016.04 | 10.7 | F.01U.323.096 Installation Manual Bosch Security Systems, Inc.

LTC 8900 Series

Hardware Installation Procedure for Standard Systems Utilizing LTC 8904 Series CPU |

en

21

5

5.1

Hardware Installation Procedure for Standard Systems Utilizing LTC 8904 Series CPU

General Installation Considerations

(Refer to Hardware Installation Procedure for Redundant System Configuration Utilizing LTC 8901

Series CPU, page 33, for Installation Procedure for redundant system configurations using

LTC 8901 Series CPU.)

Notice!

Do Not Apply power to equipment until instructed to do so.

To facilitate system installation, it is highly recommended to install the system components

using these guidelines: �

1. The main system components are designed to be rack-mounted into standard 19in. EIA

racks. Remove the 4 rubber bumper foot pads found on the bottoms of the bays before

installing them. Four (4) holes are provided for mounting the bays in the rack. Rack-

mounting screws and associated hardware are NOT included.

2. If possible, rack the LTC 8902 Series bays so they are in a central location with respect to

the LTC 8903 Series bays. This is especially important in large system configurations

where many LTC 8903 Series Input Bays will be feeding video to a single or a few LTC

8902 Series Output Bays.

NOTE: Interconnecting LTC 8902 Series bays and LTC 8903 Series bays must be located

close enough together that the supplied 2 m (6 ft) video interconnect cables can be used.

Although it is not an absolute requirement, the matrix bay video interconnect cabling will

be easier to manage if the LTC 8902 Series Bays are mounted higher up in the rack above

any LTC 8903 Series Input Bays.

3. Camera and monitor video connections are NOT made directly to the LTC 8902 Series

and LTC 8903 Series matrix bays. All external video connections are made to LTC

8808/00 Video Interconnect Panels. Each LTC 8808/00 panel accepts up to 32 video

connections and interfaces to the various matrix bays using 2 LTC 8809/00 video ribbon

cables. The LTC 8808/00 panels can be mounted wherever convenient as long as they are

within 2 m (6 ft) of the matrix bay that they are being used with 2 m (6 ft) is the length of

the LTC 8809/00 ribbon cable).

4. Install the LTC 8902 Series and LTC 8903Series matrix bays close enough to the systems

LTC 8946/93 LAN switch(es) so that the supplied 8 m (25 ft) LAN cables can be used. If

necessary due to unusual installation conditions, longer standard 10/100 Base-T LAN

cables should be obtained from a local computer hardware supplier.

5. Once installed, some care is necessary to avoid damage to the connectors on the matrix

bays to which the LTC 8809/00 ribbon cables are attached. The ribbon cable connectors

contain locking hooks which can be damaged if too much strain is put on the ribbon

cables. If necessary, support the LTC 8809/00 cables to eliminate excessive loading force

on the locking hooks.

Bosch Security Systems, Inc. Installation Manual 2016.04 | 10.7 | F.01U.323.096

LTC 8902

Monitor Bay

LTC 8946 LAN Switch LTC 8904 CPU Bay

LTC 8902

Monitor Bay

LTC 8903

Camera Bay

LTC 8903

Camera Bay

LTC 8903

Camera Bay

LTC 8903

Camera Bay

LTC 8903

Camera Bay

LTC 8903

Camera Bay

LTC 8903

Camera Bay

LTC 8903

Camera Bay

AL LE G IA NT M at rix C P U

Powe r

CPU A C T IV IT Y

BOSCH

en | Hardware Installation Procedure for Standard Systems Utilizing LTC 8904 Series

22

CPU

LTC 8900 Series

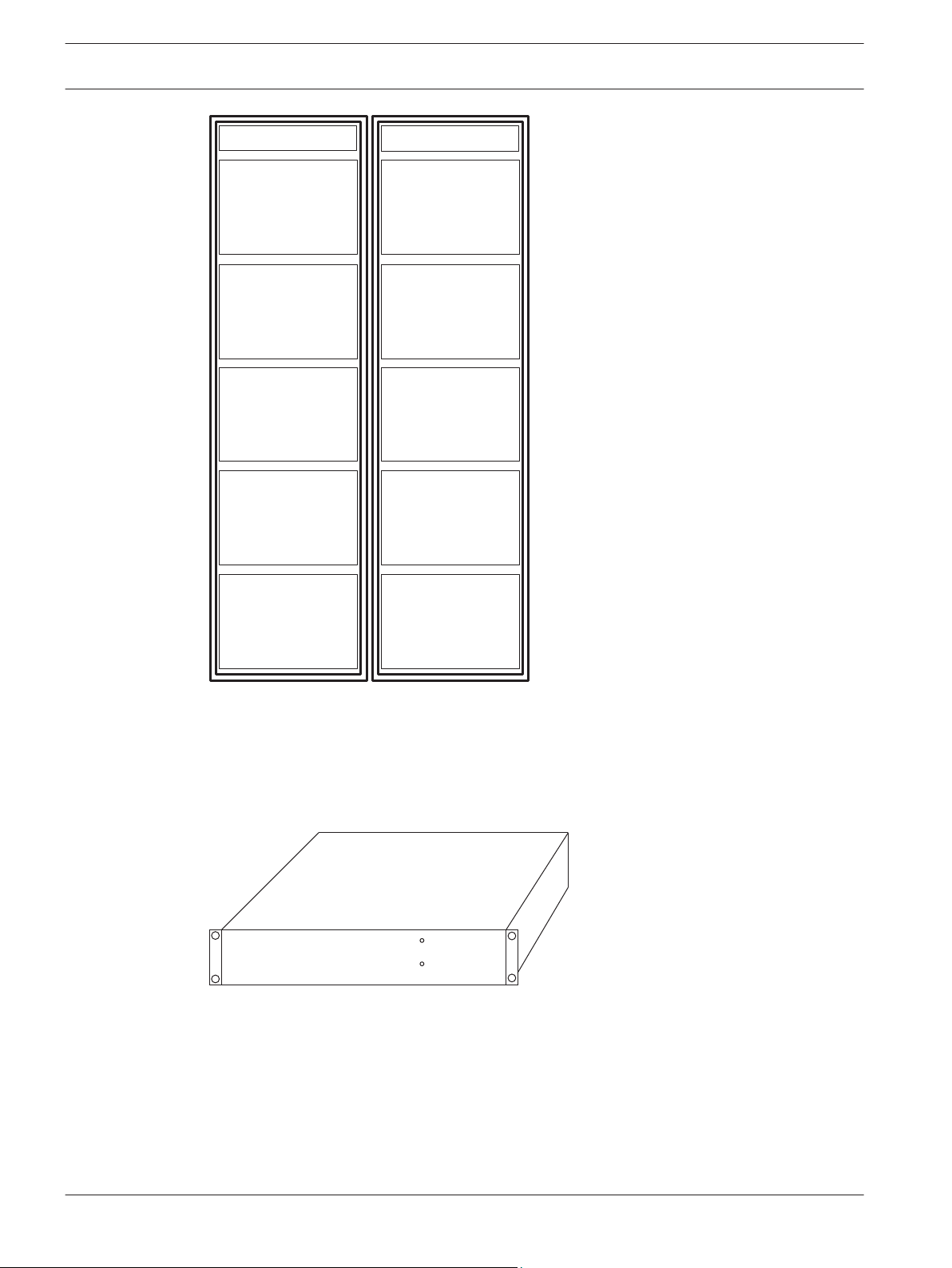

Figure 5.1: LTC 8900 1024 Camera by 128 Monitor System Installed in Two 72 in. EIA Mounting Racks

5.2

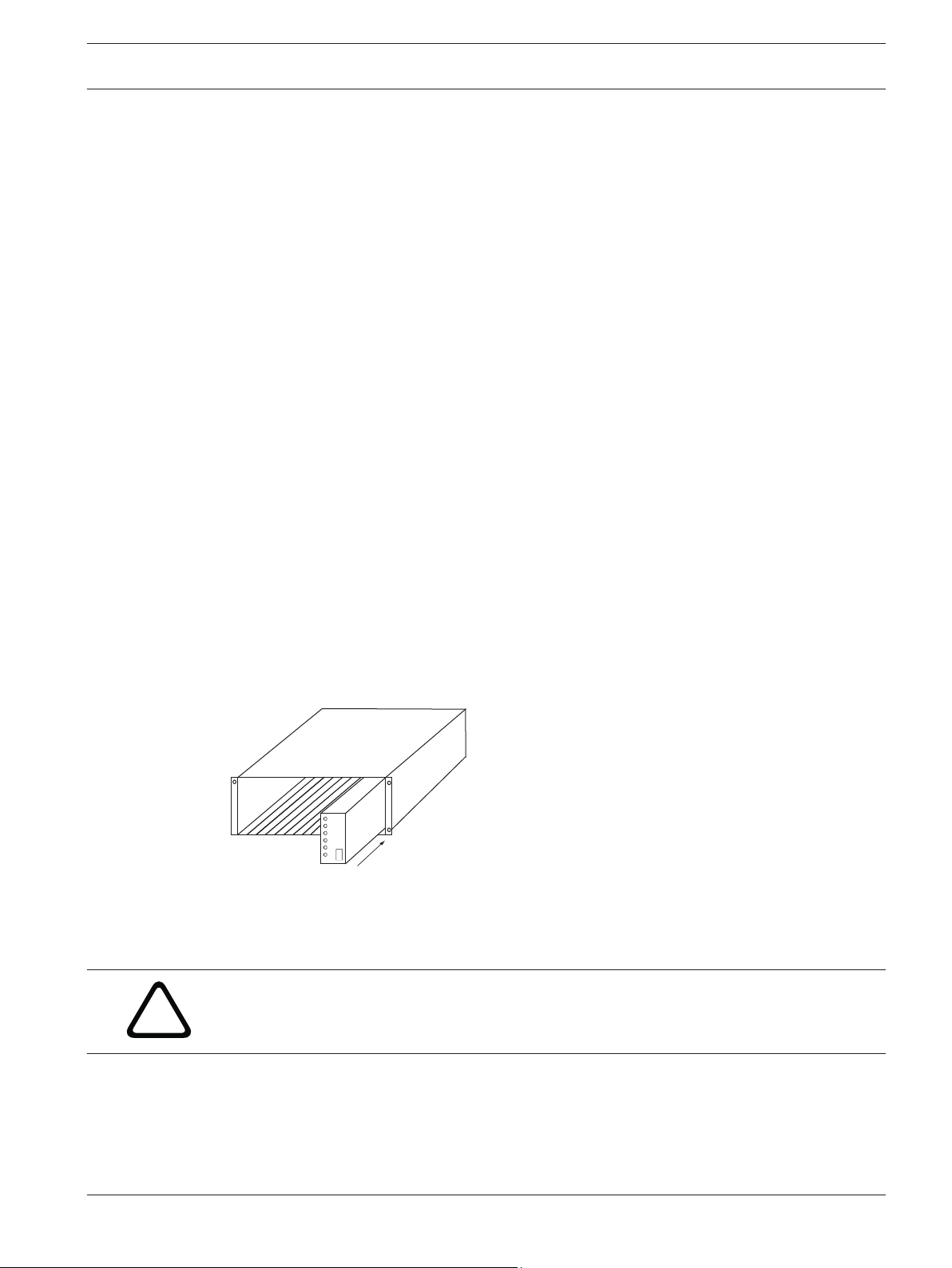

LTC 8904 Series CPU Bay Installation

The LTC 8904 Series Main CPU Bay is supplied fully assembled and requires no user

adjustments. Install the CPU bay into the mounting rack.

NOTE: Rack-mounting screws and associated hardware are NOT included.

Figure 5.2: LTC 8904 Series CPU Bay

It is recommended that the CPU bay be mounted so that a 9 cm (3-1/2 in.) rack space is

available either above or below the enclosure. In sites where the system can not be taken

out of operation for a period of time, this will leave a mounting space available for a

replacement CPU in the unlikely event that the original CPU must be removed for servicing.

Do not attach line cord to AC power source until instructed to do so.

2016.04 | 10.7 | F.01U.323.096 Installation Manual Bosch Security Systems, Inc.

!

LTC 8900 Series

Hardware Installation Procedure for Standard Systems Utilizing LTC 8904 Series CPU |

en

23

5.3

5.4

LAN Switch Installation

The LTC 8946/93 is a standard 10/100 Base-T network switch. Disregard the original

manufacturers instructions supplied with the LAN switch(es). To use the switch(es) in the LTC

8900 system, follow the directions supplied in this manual ONLY.

The software supplied with the switch(es) is not used. The switch(es) for the LTC 8900

systems are used in a network dedicated to only the LTC 8900 system. The switch(es) must

not be connected to a computer network or any other network.

All of the LAN data cables going to the switch(es) will connect to the front panel ports. The

main AC linecord is connected to the rear panel of the switch. If desired, switch(es) can be

mounted so that the front panel is facing into the rack. Determine which orientation is most

suitable for your application, then attach the supplied racking ears to the side mounting holes

accordingly.

Attach the AC line cords to the switches, but do not attach the line cord to the AC power

source until instructed to do so.

LTC 8902 Series Output Bay and LTC 8903 Series Input Bay Installation

The LTC 8902 Series and LTC 8903 Series bays require insertion of the power supply, data

receiver module, and the video modules.

Remove the front panel of the bay (LTC 8902 Series or LTC 8903 Series) by loosening the 4

corner fasteners.

LTC 8902 Series Video Output bays are supplied with LTC 8906 Series power supplies. LTC

8903 Series Video Input bays are supplied with LTC 8805 Series power supplies.

Install the power supply in the far right position of the bay ensuring proper alignment and

seating of the supply into the rear mating connector.

Verify that the power supply ON/OFF switch is in the OFF position.

Figure 5.3: Typical Power Supply Insertion

Install four (4) supplied screws and star washers on the rear panel of the bay(s) surrounding

the power supply line cord. This fastens the power supply securely in place.

Repeat this procedure for all LTC 8902 Series and LTC 8903 Series bays.

Caution!

If the LTC 8902 Series or LTC 8903 Series bays are to be transported, the main power

supplies should be removed to prevent possible damage to the bays internal parts.

Bosch Security Systems, Inc. Installation Manual 2016.04 | 10.7 | F.01U.323.096

Install the matrix bays into the mounting rack.

Place the bays in the racks as described in General Installation Considerations within his

manual.

Note that rack-mounting screws and associated hardware are NOT included.

Attach the AC line cord, but do not power up the bay until instructed.

IN SR - T OL

en | Hardware Installation Procedure for Standard Systems Utilizing LTC 8904 Series

24

CPU

NOTE: The LTC 8902 Series and LTC 8903 Series bays should be installed so there is at least

4.5 cm (1-3/4 in.) of clearance above and below the bay, to allow for proper cooling. Failure to

provide proper clearance may cause the equipment to exceed its recommended operating

temperature range.

DO NOT install the LTC 8934/00 Video Output modules or the LTC 8921/00 Video Input

modules into the matrix bays at this time.

LTC 8900 Series

5.5

Module Insertion

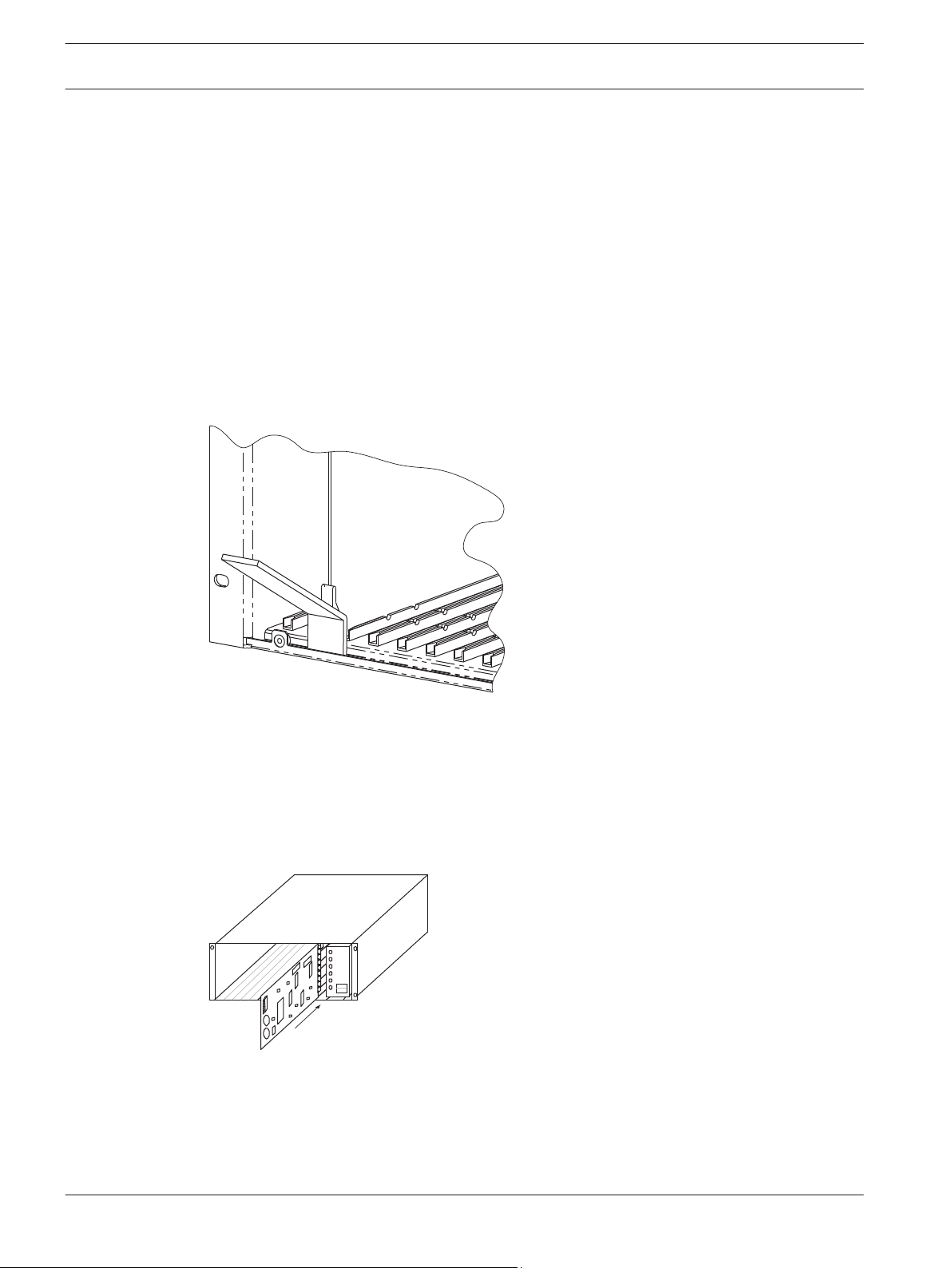

A special tool is supplied with the system components, for insertion of the Data Receiver,

Video Input Module, and Video Output Module boards into LTC 8902 and LTC 8903 Series

equipment bays. The tool is a simple lever (an angled piece of aluminum), used as follows:

Insert the board fully into the slot, ensuring proper alignment with the connectors. Insert the

short end of the lever into the groove in the front of the bay so the tool is aligned with the

card ejectors on the card, then push the lever to force the card into the slot.

Figure 5.4: Example of Insertion Tool Use

5.6

5.7

2016.04 | 10.7 | F.01U.323.096 Installation Manual Bosch Security Systems, Inc.

Data Receiver Modules

LTC 8902 Series Video Output bays are supplied with LTC 8916/01 Data Receiver modules.

LTC 8903 Series Video Input bays are supplied with LTC 8918/01 Data Receiver modules. Data

Receiver Modules are installed into the right most slot (adjacent to the power supply) of the

matrix bays as shown below:

Figure 5.5: Typical Data Receiver Module Insertion

LTC 8916/01 Data Receiver Modules

The LTC 8916/01 Data Receiver modules (installed in LTC 8902 Series bays) contain three (3)

8-position dip switches.

LTC 8900 Series

Hardware Installation Procedure for Standard Systems Utilizing LTC 8904 Series CPU |

en

25

For system configurations of up to 2048 cameras and 512 monitors, , page 68 can be used as

a guide for setting the Data Receiver DIP switches. Otherwise, follow the procedure described

below.

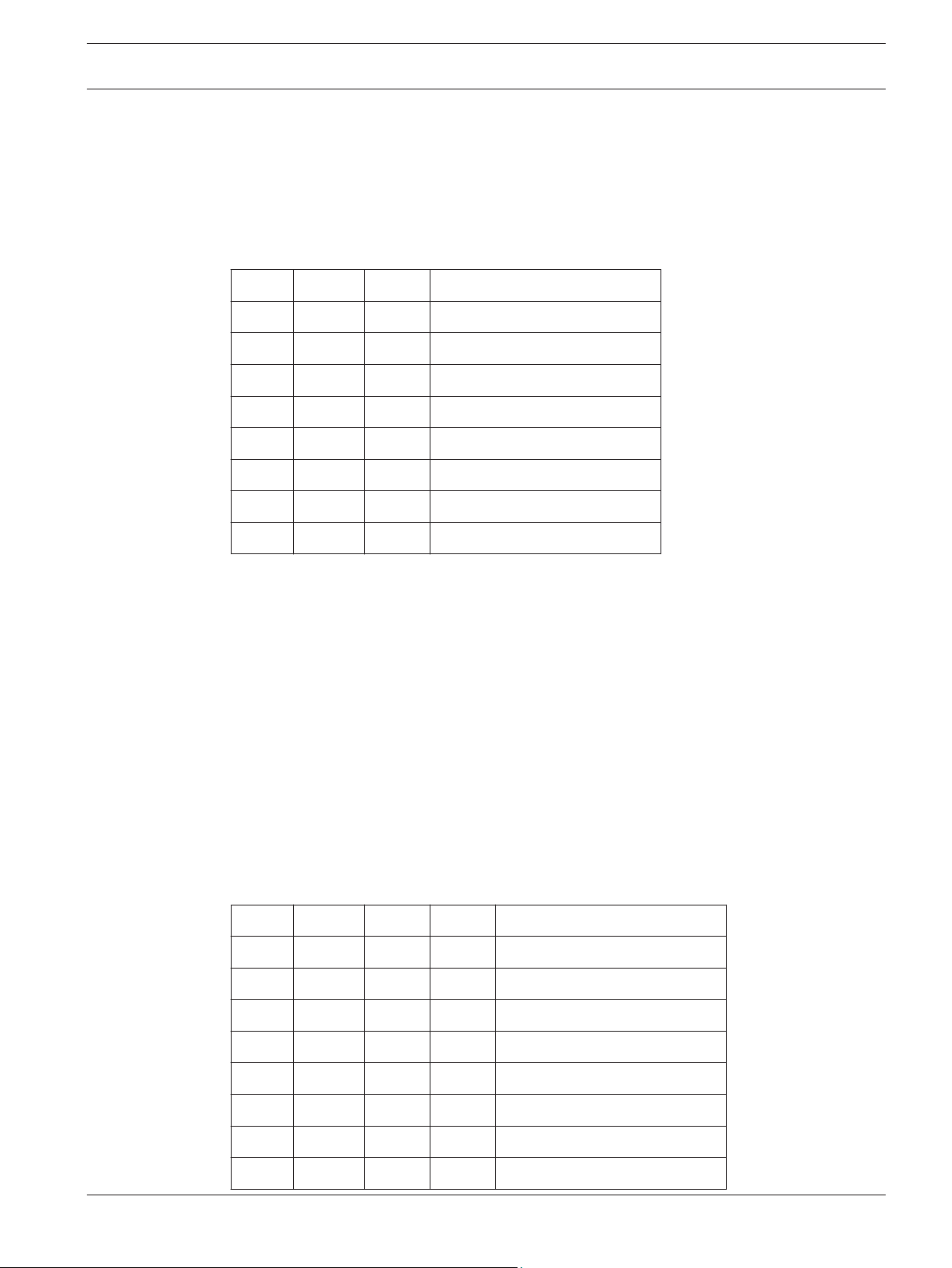

Verify that switches located on dipswitch S1 and S3 are all OFF.On dipswitch S2 of the LTC

8916/01, verify that switches 1 to 4 are OFF. Switch 8 should be in the ON position. Switches

5 through 7 determine the monitor number range that the bay will be used for and must be set

according to the table below:

5 6 7 Monitor Range

OFF OFF OFF 1 to 64

OFF OFF ON 65 to 128

OFF ON OFF 129 to 192

OFF ON ON 193 to 256

ON OFF OFF 257 to 320

ON OFF ON 321 to 384

ON ON OFF 385 to 448

5.8

ON ON ON 449 to 512

Table 5.1: LTC 8916/01 Data Receiver Module Switch Positions (used in LTC 8902 Service Bays)

LTC 8918/01 Data Receiver Modules

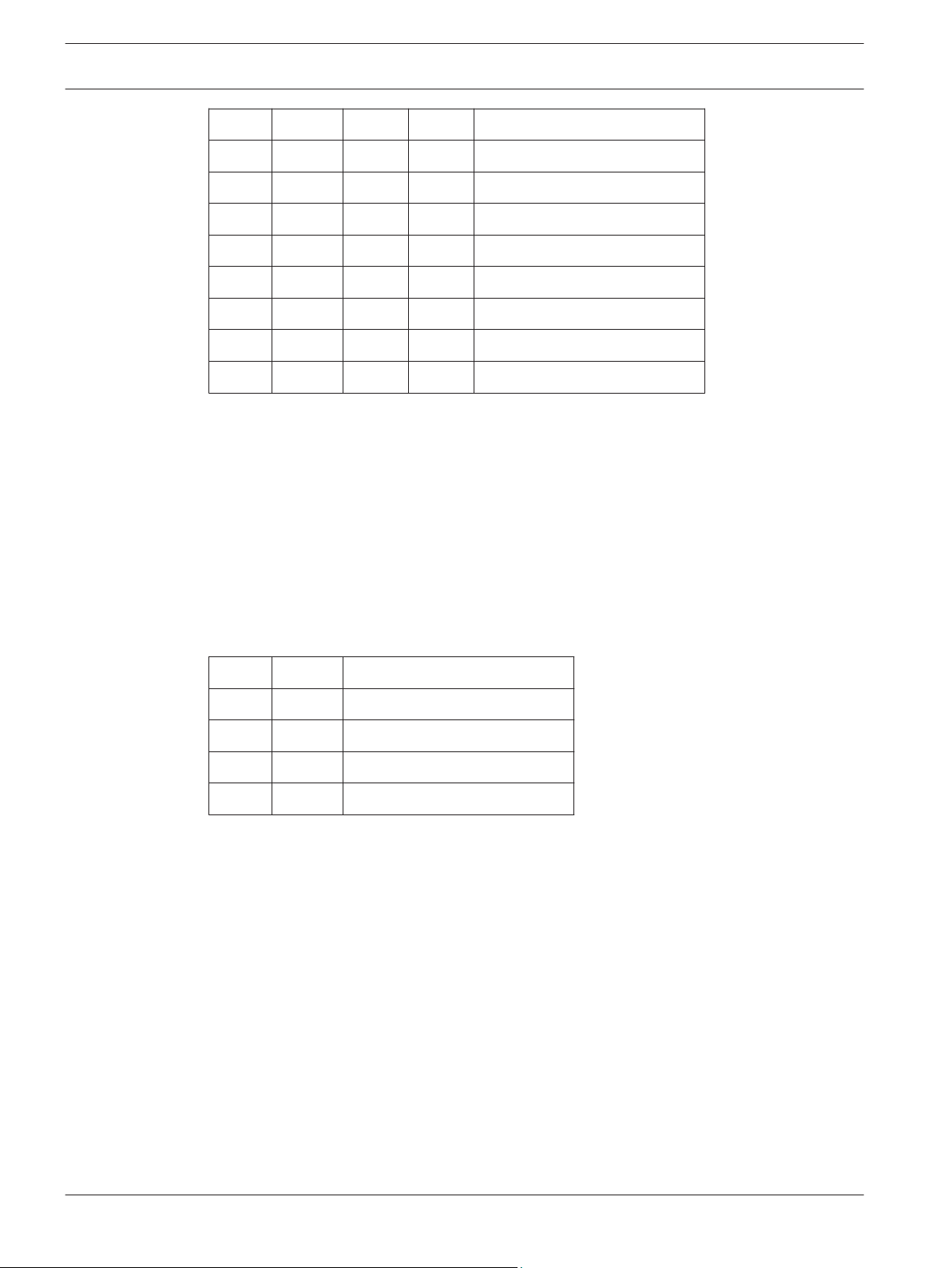

The LTC 8918/01 Data Receiver modules (installed in LTC 8903 Series bays) contain three (3)

8-position dip switches. For system configurations of up to 2048 cameras and 512 monitors, ,

page 68 can be used as a guide for setting the Data Receiver DIP switches. Otherwise, follow

the procedure described below.

Verify that switches 1 to 3 and 5 to 8 on dipswitch S1 are OFF.

If the LTC 8903 Series bay will be used as a primary camera bay (one that will have cameras

directly connected to it), place switch 4 on S1 in the OFF position.

If the LTC 8903 Series bay will be used as a secondary camera bay (one that will have other

LTC 8903 Series bays connected to its inputs), place switch 4 on S1 in the ON position.

If switch 4 on S1 has been set to the OFF position (for use as a primary camera bay as

described previously), set switches 1 to 4 on S2 according to the Primary Camera Bay Range

in , page 25 shown below:

1

OFF OFF OFF OFF 1 to 256

OFF OFF OFF ON 257 to 512

2 3 4 Camera Number Range

OFF OFF ON OFF 513 to 768

OFF OFF ON ON 769 to 1024

OFF ON OFF OFF 1025 to 1280

OFF ON OFF ON 1281 to 1536

OFF ON ON OFF 1537 to 1792

OFF ON ON ON 1793 to 2048

Bosch Security Systems, Inc. Installation Manual 2016.04 | 10.7 | F.01U.323.096

en | Hardware Installation Procedure for Standard Systems Utilizing LTC 8904 Series

26

CPU

1 2 3 4 Camera Number Range

ON OFF OFF OFF 2049 to 2304

ON OFF OFF ON 2305 to 2560

ON OFF ON OFF 2561 to 2816

ON OFF ON ON 2817 to 3072

ON ON OFF OFF 3073 to 3328

ON ON OFF ON 3329 to 3584

ON ON ON OFF 3585 to 3840

ON ON ON ON 3841 to 4096

Table 5.2: LTC 8918/01 Data Receiver Module (used in LTC 8903 Series bays) S2 positions 1 through 4

LTC 8903 Series Camera bays will always be providing video signals (either directly, or via a

second LTC 8903 Series bay) to a specific LTC 8902 Series Monitor bay. Determine the

applicable LTC 8902 Series Monitor bay, then set switches 5 through 7 on dipswitch S2 to the

same settings as switches 5 through 7 on S2 of the Data Receiver module installed in the

corresponding LTC 8902 Series bay. These will be the same settings as listed in the Monitor

Number Range shown in , page 24.

On dipswitch S2 of the LTC 8918, verify that switch 8 is ON.

If switch 4 on S1 has been set to the ON position (for use as a secondary camera bay as

described above), set switches 3 and 4 of S2 OF. Set switches 1 and 2 of S2 according to

which primary camera bays it will be connected per , page 25 below:

LTC 8900 Series

5.9

1

2 Primary Camera Bay Range

OFF OFF 1 to 4

OFF ON 5 to 8

ON OFF 9 to 12

ON ON 13 to 16

Table 5.3: LTC 8918 Data Receiver Module (used in LTC 8903 bays) S2 Positions 1 and 2

LTC 8934/00 Video Output Modules

The appropriate number of LTC 8934/00 Video Output Modules should be installed in the LTC

8902 Series main bay starting with the left most slot. Each output module handles 8 outputs.

If fewer than the maximum number of Video Output Modules are installed, they should be

installed from left to right, with empty spaces on the right.

In some system configurations, 8 or less LTC 8934/00 modules may be distributed between

two (2) LTC 8902 Series Video Output bays. This configuration assures partial system

operation in the unlikely event of an LTC 8902 Series failure. Since this creates a gap in the

monitor number order, the optional Allegiant PC-based system software allows renumbering

of the logical monitor numbers. For example, if the system was designed for 64 monitor

outputs, four LTC 8934/00 modules (handling monitors 1 to 32) would be installed in the first

LTC 8902 Series bay. Another four LTC 8934/00 modules would be installed in a second LTC

8902 Series bay.

2016.04 | 10.7 | F.01U.323.096 Installation Manual Bosch Security Systems, Inc.

LTC 8900 Series

Hardware Installation Procedure for Standard Systems Utilizing LTC 8904 Series CPU |

en

27

The default monitor number range for this second module would be 65 to 96. Since this would

be inconvenient to operators of the system, the logical numbers of the monitor numbers in the

second bay can be renumbered to range from 33 to 64 using the optional Allegiant PC-based

system software. , page 37 shows an example of this type of configuration. It is also possible

to number the monitors so that one bay contains the odd numbered monitors and the other

bay contains even numbered monitors. This way, a viewing location containing an even mix of

monitors from each bay would lose every other one in the unlikely event of a LTC 8902 Series

bay failure.

Figure 5.6: Typical Video Output Module Insertion

The LTC 8934/00 Video Output Modules contain five (5) 8-position dip switches. DIP switch

S1001 is reserved and all switches should be left in the ON position.

Dip switches S1002, S1003, S1004, and S1005 are video termination switches for each of the

video bus inputs. All of these switches should be set to ON (terminated). This is the factory

default.

All LTC 8934/00 Video Output Modules are identical and can be swapped anywhere within the

bay without changing the module.

5.10

LTC 8921/00 Video Input Modules

For the LTC 8903 Series Bays, termination switches (S1001 through S1004) on the LTC

8921/00 Video Input Modules must be set to the correct position prior to installation. Read

the Termination Practices section prior to actually installing the Video Input Modules on these

systems. As shipped from the factory, all terminated switches are in the ON (terminated)

position.

Locate and use the diagram(s) that best fit your system configuration (, page 68 to , page

68 in this manual). The appropriate number of Video Input Modules (LTC 8921/00) should be

installed in the LTC 8903 Series main bay, starting with the left most slot. Each input module

handles 32 inputs by 32 outputs.

Since the LTC 8903 Series supplies 64 outputs, two (2) LTC 8921/00 input cards are required

for each set of 32 cameras. Odd numbered slots provide video for monitors 1-32, and even

numbered slots provide video for monitors 33-64. If 32 or less monitors are being served by

the LTC 8903 Series bay, the Video Input Modules are not required in the even numbered

slots. This concept is shown in , page 68 and examples of system configurations are shown

in , page 68.

Cards in even numbered slots should have all termination switches OFF. If looping is not being

used, cards in odd numbered slots should have the termination switches ON. See Termination

Practices for more details.

Bosch Security Systems, Inc. Installation Manual 2016.04 | 10.7 | F.01U.323.096

en | Hardware Installation Procedure for Standard Systems Utilizing LTC 8904 Series

28

CPU

Figure 5.7: Typical Video Input Module Insertion

All LTC 8921/00 Video Input Modules are identical and can be swapped anywhere within the

bay without making any changes to the module except to maintain proper termination

settings.

LTC 8900 Series

5.11

5.11.1

System Video Connections

Camera Input Connections

Camera connections to the LTC 8903 Series Input Bays require LTC 8808/00 Video

Interconnect (Patch) Panel. Each patch panel provides 32 BNCs for video input or video

looping connections to the system. Patch panels are connected to the rear of the LTC 8903

Series Input Bay using the supplied LTC 8809/00 ribbon cables. Each cable can carry video for

up to 16 cameras. Two cables can be attached to each patch panel to support up to 32

cameras per panel. Each ribbon cable should be attached to the appropriate VIDEO IN

connector on the rear of the LTC 8903 Series bays. A rear panel diagram of the LTC 8903

Series bay is shown in , page 68. Refer to , page 68 to , page 68 to review typical system

connections.

The LTC 8809/00 ribbon cables have keyed connectors on each end. Maintain correct

polarity when connecting system components.

Although attaching a ribbon cable with reversed polarity will not cause permanent damage,

it can cause all video functions within the bay to cease until corrected. Double-check ribbon

cable connections to avoid this condition.

, page 68 illustrates the polarity key orientations on the LTC 8902 and LTC 8903 Series video

matrix bays.

The LTC 8808/00 panels are typically installed on the rear of the mounting rack, behind the

applicable matrix bay. They can be mounted elsewhere as long as the 2 m (6 ft) LTC 8809/00

ribbon cables can reach the applicable matrix bay. Note that rackmounting screws and

associated hardware are NOT included.

The Video Input connectors are labeled with multiple levels. If more than 256 cameras are

used in a system, multiple levels of input bays are used. These system configurations are

shown in , page 68 through , page 68.

5.11.2

2016.04 | 10.7 | F.01U.323.096 Installation Manual Bosch Security Systems, Inc.

System Connections over 1024 Cameras

If more than 1024 cameras are used, a second stage of LTC 8903 Series Video Input Bays are

required. These system configurations are shown in , page 68, , page 68 to , page 68, ,

page 68 and , page 68. In this configuration, the VIDEO OUT connectors from the first stage

LTC 8903 Series bays are connected to the VIDEO IN connectors on the second stage bays

using LTC 8809/00 ribbon cables.

The LTC 8809/00 ribbon cables have keyed connectors on each end. Maintain correct

polarity when attaching between the bays.

LTC 8900 Series

Hardware Installation Procedure for Standard Systems Utilizing LTC 8904 Series CPU |

en

The VIDEO OUT connectors are labeled A through D. These connectors must be connected to

corresponding VIDEO IN connectors labeled A through D.

29

5.11.3

5.11.4

Camera Bays to Monitor Bay Video Connections

The VIDEO OUT connectors from LTC 8903 Series input bays are connected to the VIDEO BUS

connectors on the LTC 8902 Series output bays using LTC 8809/00 ribbon cables. Rear panel

diagrams of the LTC 8902 Series and LTC 8903 Series bays are shown in , page 68.

The LTC 8809/00 ribbon cables have keyed connectors on each end. Maintain correct

polarity when attaching between the bays.

, page 68 shows the polarity key of the ribbon cable connectors on the LTC 8902 Series and

LTC 8903 Series matrix bays.

The LTC 8903 Series bay s VIDEO OUT connectors are labeled A through D, and the Monitor

Bay VIDEO BUS connectors are labeled CAMERA BAY OUTPUT A through CAMERA BAY

OUTPUT D.

The input bay A-D connectors must be connected to corresponding A-D connectors on the

output bay using LTC 8809/00 coax ribbon cables. , page 68 and , page 68 demonstrate

these connections.

Multiple Monitor Bay Consideration

If multiple monitor bays are used in the system, the LTC 8903 Series Input Bay configuration

must be duplicated for each output bay. This is illustrated in system configuration diagrams ,

page 68 through , page 68. The video inputs from the first set of LTC 8903 Series Input

Bays must be looped through to the second set of input bays using LTC 8809/00 coax ribbon

cables.

The LTC 8903 Series bays provide looping connectors for these connections. The supplied

ribbon cable connectors are connected from the LOOP outputs of the first set of input bays to

the corresponding VIDEO IN connectors on the next set of input bays using LTC 8809/00

ribbon cables. This looping can continue as needed. The termination switches on the LTC

8921/00 Video Input Cards must be turned OFF in all LTC 8903 Series Input bays except those

in the last set (assuming the system will NOT have video looping connections).

5.11.5

5.11.6