Page 1

Hood

Installation Manual

Models:

HCP36E52UC, HCP30E52UC, HCP34E52UC

Page 2

Table of

Safety

CONTENTS

Safety .................................................................................. 2

Important Safety Instructions ..................................... 2

General Notes ............................................................ 3

Electrical Connection................................................... 5

Before you begin ............................................................... 6

Safety Clearances ....................................................... 7

Ventilator Performance Calculation ........................... 8

Installation Procedure......................................................... 9

Preparing the Installation ........................................... 9

Mounting the extractor hood on the wall.................. 10

Connect Electrical Supply .......................................... 11

Attaching Flue Duct..................................................... 12

DEFINITIONS

WARNING

This indicates that death or serious injuries may occur as a

result of non-observance of this warning.

CAUTION

This indicates that minor or moderate injuries may occur

as a result of non-observance of this warning.

NOTICE: This indicates that damage to the appliance or

property may occur as a result of non-compliance with this

advisory.

Note: This alerts you to important information and/or tips.

Page 2

This Bosch appliance is made by

BSH Home Appliances Corporation

1901 Main Street, Suite 600

Irvine, CA 92614

Questions?

1-800-735-4328

www.bosch-home.com/us

We look forward to hearing from you!

Page 3

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

General Notes

WARNING

Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer.

WARNING

• When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

• Ducted fans must always be vented to the outdoors.

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE

APPLIANCE AFTER INSTALLATION IS COMPLETE.

IMPORTANT: SAVE FOR THE LOCAL INSPECTOR’S USE.

WARNING

When properly cared for, your new appliance has been

designed to be safe and reliable. Read all instructions carefully before use. These precautions will reduce the risk

of burns, electric shock, re, and injury to persons. When

using kitchen appliances, basic safety precautions must

be followed, including those in the following pages.

Proper Installation and Maintenance

WARNING

Remove all tape and packaging before using the appliance. Destroy the packaging after unpacking the appliance.

Never allow children to play with packaging material.

This appliance is intended for normal family household

use only. It is not approved for outdoor use. Refer to the

Statement of Limited Warranty in the Use and Care Manual. If you have any questions, contact the manufacturer.

Do not store or use corrosive chemicals, vapors, ammables

or nonfood products in or near this appliance. It is spe-

cically designed for use when heating or cooking food.

The use of corrosive chemicals in heating or cleaning will

damage the appliance and could result in injury.

Do not operate this appliance if it is not working properly,

or if it has been damaged. Contact an authorized servicer.

Do not repair or replace any part of the appliance unless

specically recommended in this manual. Refer all servicing to a factory authorized service center.

CAUTION

WARNING

Hidden surfaces may have sharp edges. Use caution when

reaching behind or under appliance.

Fire Safety

WARNING

Use this appliance only for its intended use as described

in this manual.

Always have a working smoke detector near the kitchen.

In the event that personal clothing or hair catches re,

drop and roll immediately to extinguish ames.

Have an appropriate re extinguisher available, nearby,

highly visible and easily accessible near the appliance.

Smother ames from food res other than grease res

with baking soda. Never use water on cooking res.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN

THE EVENT OF A RANGE TOP GREASE FIRE,

OBSERVE THE FOLLOWING:

• SMOTHER FLAMES with a close tting lid, cookie

sheet, or metal tray, then turn off the burner. BE

CAREFUL TO PREVENT BURNS. If the ames do not

go out immediately, EVACUATE AND CALL THE

FIRE DEPARTMENT.

• NEVER PICK UP A FLAMING PAN - you may get

burned.

• DO NOT USE WATER, including wet dishcloths or

towels - a violent steam explosion will result.

• Use an extinguisher ONLY if:

a) You know you have a class ABC extinguisher,

and you already know how to operate it.

b) The re is small and contained in the area where

it started.

c) The re department is being called.

d) You can ght the re with your back to an exit.

a

Based on “Kitchen Fire Safety Tips” published by NFPA.

Whenever possible, do not operate the ventilation system

during a cooktop re. However, do not reach through re to

turn it off.

a

Grease left on lters can melt and move into the vent.

Page 3

Page 4

WARNING

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

WARNING

RISK OF FIRE

Hot oil and fat catch re fast. Never leave hot oil and fat

unsupervised.

Never extinguish a re with water. Switch off the cooking

position.

Suffocate ames carefully with a lid, a re blanket or similar.

WARNING

RISK OF FIRE

Grease deposits in the grease lter can ignite.

Clean the grease lter at least every two months or as

frequently as necessary.

Never operate the appliance without the grease lter.

WARNING

RISK OF FIRE

Grease deposits in the grease lter can catch re. Never

work with a naked ame near the appliance (e.g. am-

béing). Install the unit near a heat-producing appliance

for solid fuels (e.g. wood or coal) only if there is a closed,

non-detachable cover. There must be no ying sparks.

WARNING

RISK OF FIRE

Use only metal ductwork.

WARNING

RISK OF BURNS

The accessible parts get hot during operation.

Never touch hot parts.

Keep children away.

CAUTION

It is recommended to wear gloves and long sleeves to

protect hands and forearms from abrasion and potential

scratches during the installation process.

Child Safety

When children become old enough to use the appliance,

it is the responsibility of the parents or legal guardians to

ensure that they are instructed in safe practices by qualied

persons.

Do not allow anyone to climb, stand, lean, sit, or hang on

any part of an appliance. This can damage the appliance or

cause injury.

Be sure the entire appliance (including the grease lters

and light bulbs, if applicable) has cooled and grease

has solidied before attempting to clean any part of the

appliance.

Do not use steam cleaners to clean the appliance.

Proposition 65 Warnings

This product may contain a chemical known to the State

of California, which can cause cancer or reproductive

harm. Therefore, the packaging of your product may

bear the following label as required by California:

STATE OF CALIFORNIA PROPOSITION 65 WARNING:

WARNING

Cancer and reproductive harm - www.P65Warnings.ca.gov.

Protecting The Environment

Unpack the appliance and dispose of the packaging in line

with environmental requirements.

NOTICE

Risk of damage due to corrosion. Always turn appliance

on when cooking to avoid condensation buildup. Condensation can lead to corrosion damage.

Risk of damage due to moisture entering into the electronic

circuitry.

Never clean operator controls with a wet cloth.

Surface damage due to incorrect cleaning. Clean stainless

steel surfaces in the grind direction only. Do not use any

stainless steel cleaners for operator controls. Never use

strong or abrasive cleaning agents, since they can cause

surface damage.

Risk of damage from condensation back ow. Install exhaust

vent at a slight downward slope away from the appliance (1°

slope).

Page 4

Page 5

General Notes

Fan operation

Note: Ventilation may not exit through an already

operational smoke or exhaust chimney, nor a duct used

for ventilating furnace installation areas.

• If the ventilation is intended to pass through smoke

or exhaust that is not in operation, the responsible area

heating inspector must give approval.

• If the ventilation passes through an external wall, use a

telescope wall sleeve.

Electrical Connection

WARNING

RISK OF ELECTRIC SHOCK

Parts inside the appliance can have sharp edges.

The connection cable can be damaged. Do not

bend or pinch connection cables during installation.

Before connecting the appliance, check the household

installation. Ensure sufcient fuse protection of the household installation. Turn off power circuit at service panel and

lock out panel before wiring this appliance. Requirement:

120 VAC, 60 Hz 15 A (see rating plate).

The appliance complies with protection class 1 and must

only be operated in conjunction with a protective conductor terminal.

An all-pole isolating switch with at least a 3 mm contact

gap must be tted in the installation. This must remain

accessible after installation.

Only a qualied electrician who takes the appropriate

regulations into account may lay or replace the

connecting cable.

Ventilation line

Note: The manufacturer is not responsible for the operation

or complaints associate with the pipe section.

• The device achieves its optimum performance by

means of a short, straight exhaust air pipe and as large

a pipe diameter as possible.

• The optimum extraction performance is not achieved

and fan noise is increased if exhaust air pipes are long

and rough and if there is a large number of pipe bends

or diameters less than 8” (200 mm).

• The pipes or hoses for laying the exhaust air line must

consist of non-combustible material.

Round pipes

An inner diameter of 8” (200 mm) is necessary.

Follow all standards, regulations, and laws.

Ensure that the electrical connection meets the requirements of the latest version of all applicable standards.

regulations, and laws in the appropriate country, especially

the following standards: National Electrical Code, ANSI/

NFPA 70*, or CSA Standards C22.1-94, Canadian

Electrical Code, Part 1 and C22.2 No.0-M91**.

Have a qualied electrical technician check the grounding

of the appliance.

Do not ground with a gas line.

No fuse protection in the neutral or grounding circuit.

Keep these installation instructions. Only connect the

appliance with a copper conductor. If possible, connect

the appliance to a metal cable guide directly to the fuse

box.

Ensure that the wire diameter meets the requirements of

the latest version of all applicable standards, regulations,

and laws in the appropriate country, especially the following

standards: National Electrical Code, ANSI/NFPA 70*, or

CSA Standards C22.1-94, Canadian Electrical Code, Part

1 and C22.2 No.0-M91**.

For copies of the standards listed, contact:

* National Fire Protection Association Batterymarch Park

Quincy, Massachusetts 02269

** CSA International 8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

Page 5

Page 6

Before you begin

Tools and Parts Needed

• Measuring tape

• Pencil

• Phillips screwdriver (Posidrive) #2

• Drill with the following bits:

(9.5 mm)

• Spirit-level

• Aluminum tape (DO NOT use insulating tape)

• Exhaust channel (conguration depends on the

installation situation)

• Additional sheet metal screws (if necessary for

installation of the exhaust air duct)

• Saw

Parts Included

5

⁄16” (7.9 mm) and 3⁄8”

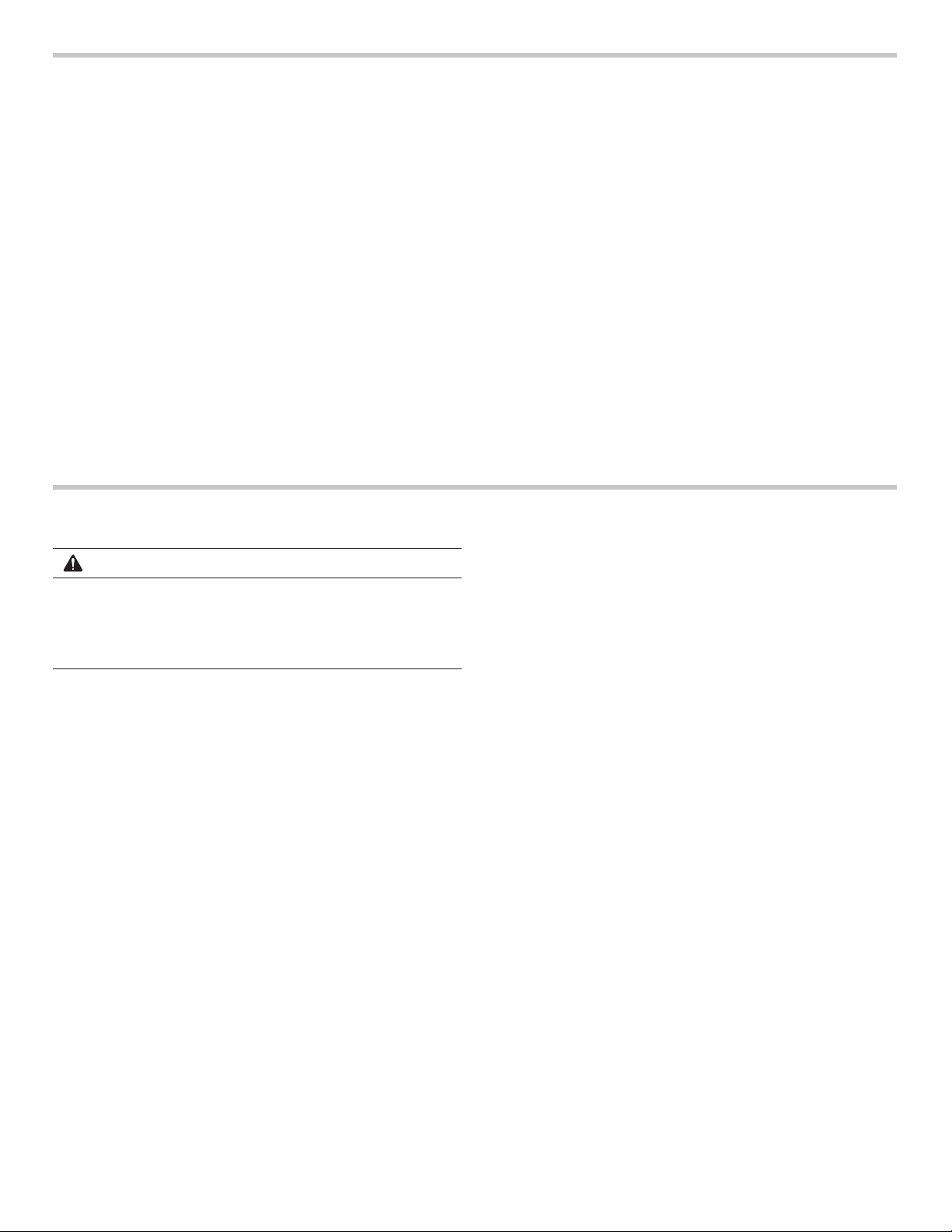

Appliance Dimensions

3

/4"

10

(273 mm)

3

/16"

13

(335 mm)

7

7

/8"

(200 mm)

5

4

/8"

(118 mm)

5"

(126 mm)

A

• Extractor hood with fan, back-pressure ap

• Lamp, already installed

• Metal grease lter

• Flue duct

• Drill template

• 1x angle bracket for the ue duct

• Installation manual and instructions for use

• 6x screws, 5x45 mm

• 8x screws, 4x8 mm

• 2x washers

• 2x hollow wall plugs, 8x40 mm

• 4x hollow wall plugs, 10x50 mm

• Torx adapter, 10 & 20

24" (610 mm) or

30" (762 mm) or

36" (914 mm)

A Only for circulating-air mode:

*Max. 42 9/16” (1081 mm)

*Min. 28 1/4” (718 mm)

Only for ducted operation:

*Max. 38 7/8” (988 mm)

*Min. 24 9/16” (625 mm)

11

19

/16"

(500 mm)

Page 6

Page 7

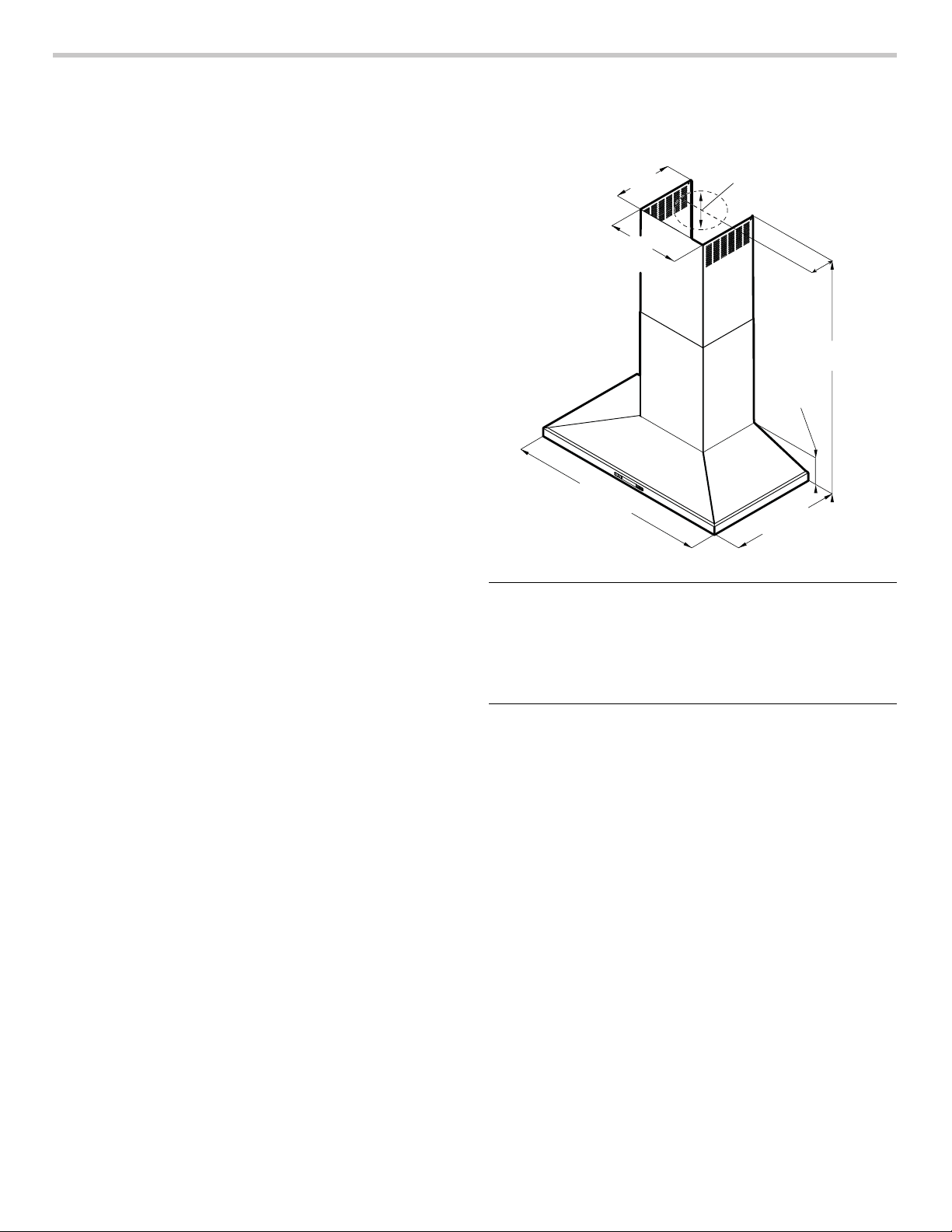

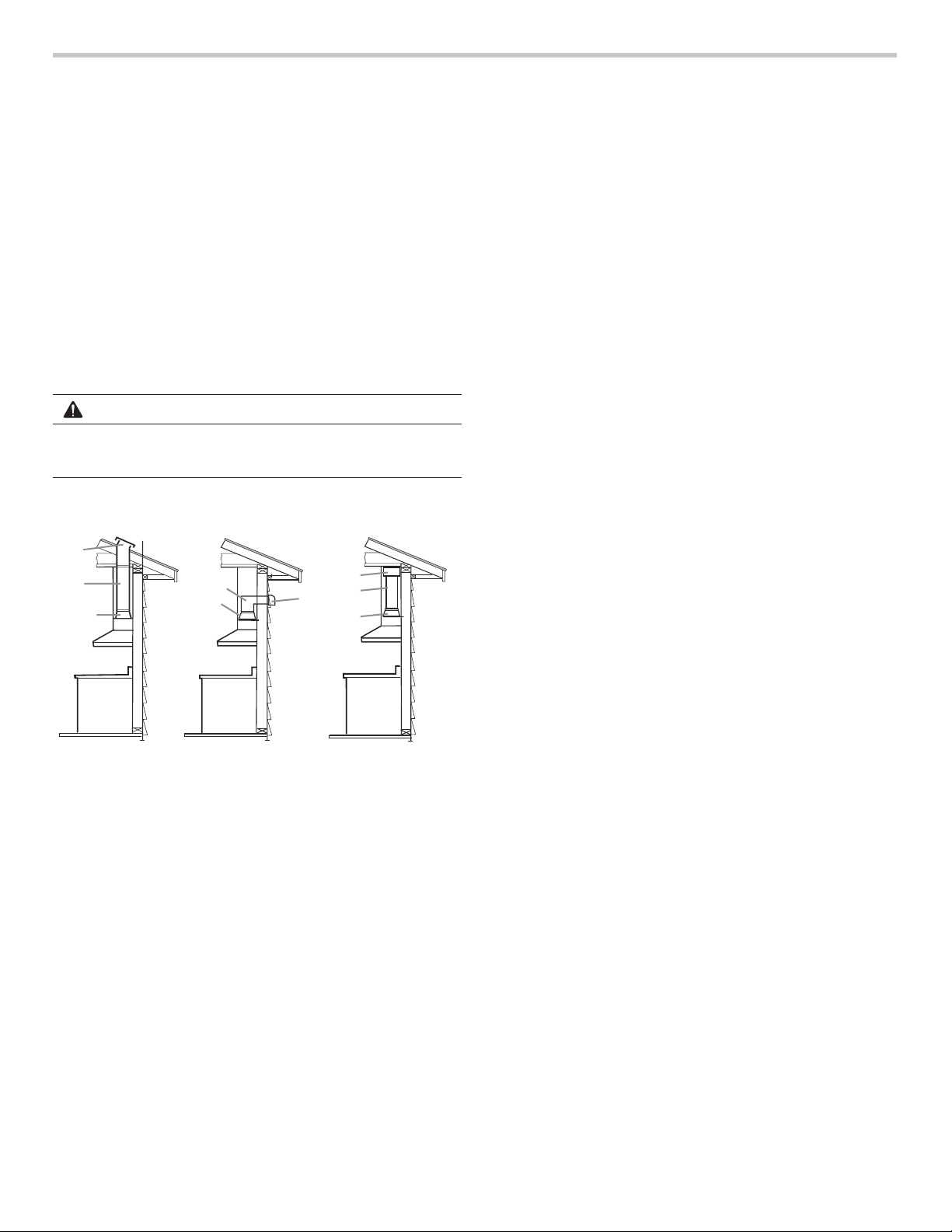

Safety clearances

WARNING

RISK OF FIRE

Grease deposits in the grease lter can catch re.

The given safety clearance must be observed to avoid

heat buildup. Observe the specications for your cooking

appliance. If gas and electric cooktops are used together,

the largest given clearance applies.

The appliance may only be installed directly next to a

cabinet or wall on one side. The wall or cabinet clearance

must be at least 2” (50 mm).

The clearance between the shelf on the cooktop and the

bottom of the extractor hood may not be less than 24”

(610 mm) in the case of electric cooktops and 27”

(686 mm) in case of gas or combined ranges.

If the installation instructions for the gas cooking appliance

specify a larger distance, this must be taken into account.

Electrical cooktops

min. 24" (610 mm)

Gas cooktops

Fan operation

Note: Ventilation may not exit through an already

operational smoke or exhaust chimney, nor a duct used

for ventilating furnace installation areas.

• If the ventilation is intended to pass through smoke

or exhaust chimney that is not in operation, the

responsible area heating inspector must give approval.

• If the ventilation passes through an external wall, use a

telescope wall sleeve.

Ventilation line

Note: The device manufacturer is not responsible for the

operation or complaints associated with the pipe section.

• The ventilation opening and the exhaust air ducts must

be made according to the local requirements.

• The device achieves its optimum performance by

means of a short, straight exhaust air pipe and as

large a pipe diameter as possible.

• As a result of long rough exhaust air pipes, many pipe

bends or too-small diameters, the optimum extraction

performance is not achieved and fan noise is increased.

• The pipes or hoses for laying the exhaust air line must

consist of non-combustible material.

• Smooth the connection area of the pipes before

installation.

• Seal the connection points of the pipes appropriately.

Round pipes

An inner diameter of Ø 8” (200 mm) is recommended.

Checking the wall

• The wall must be level, vertical and adequately load

bearing.

• The depth of the bore holes must be the same length

as the screws. The wall plugs must have a secure grip.

• The enclosed screws and wall plugs are suitable for

solid brickwork. Suitable fasteners must be used for

other structures.

min. 27" (686 mm)

Page 7

Page 8

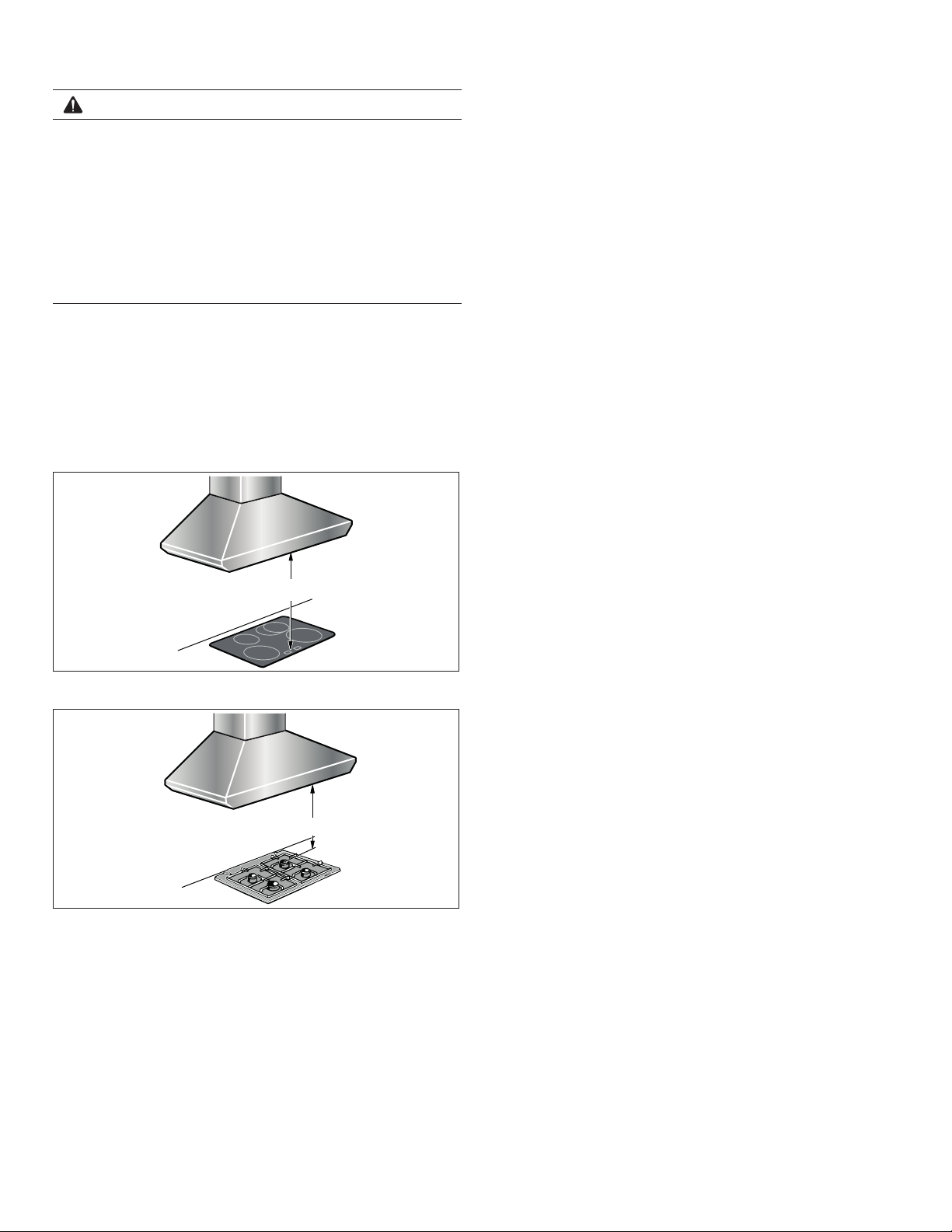

Ventilator Performance Calculation

61

A2

A1

A2

62

82

62

82

61

local hardware store. Bosch does not manufacture all these parts.

Duct Piece

Smooth, straight

3¼" x 10", straight N/A1

3¼" x 14", straight N/A0.7

90° elbow, round

45° elbow, round

3¼" x 10",

90° elbow, round

3¼" x 10",

45° elbow, round

Size (in)

61.2

80.7

10 0.6

612

86

10

65

83

10

N/A5

N/A15

Eq uivalent

Length (ft)

5

2

Duct Piece

Round to 3¼" x 10"

90° elbow,

3¼" x 10" to round

90° elbow,

3¼" x 10" Center

reverse elbow, left

3¼" x 10", Center

reverse elbow, right

3¼" x 10", Left

reverse elbow

3¼" x 10", Right

reverse elbow

Round wall cap

Size (in)

N/

N/

N/

10 2

Eq uivalent

Length (ft)

0

0

15N/A

5

5

5

3¼" x 10", Flat elbowN/A 20

61

Round to 3¼" x 10"

3¼" x 10" to round

810

65

82

Round roof cap

10

2’ long, 3¼" x 10" flexN/A 20

3¼" x 10", Roof jack

and shutter

NOTE: These commonly used installation parts can be purchased at a

N/A

2

2

Page 8

Page 9

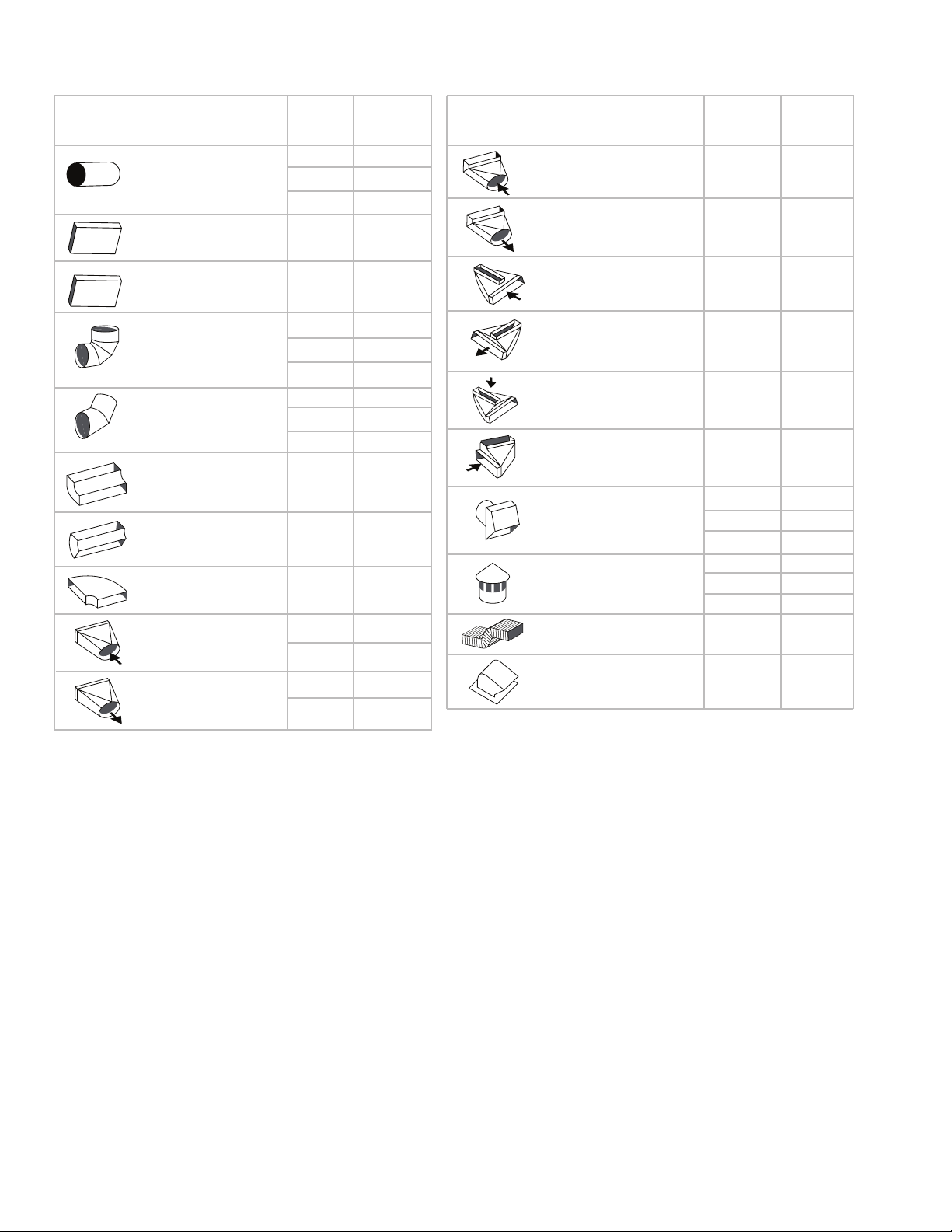

Installation Procedure

Roof

Wall

Non Vented

A. Roof ca

B. 8" (20.3 cm)

C. Seal duct joints

caulk

caulk

caulk

The ducting from this fan to the outside of the building has

a strong effect on the air ow, noise and energy use of the

fan. Use the shortest, straightest duct routing possible for

best performance, and avoid installing the fan with smaller

ducts than recommended. Insulation around the ducts can

reduce energy loss and inhibit mold growth. Fans installed

with existing ducts may not achieve their rated airow.

Ensure duct joints and exterior penetrations are sealed

with caulk or other similar material to create an air-tight

path and to minimize building heat loss and gain, and

reduce the potential for condensation.

Place/wrap insulation around duct and/or fan in order to

minimize possible condensation buildup within the duct,

building heat loss and gain.

CAUTION

Ensure that there are no electric wires, gas or water pipes

in the area where holes are to be made.

A

B

Venting

C

Venting

B

C

A

(Recirculating)*

A

B

C

Preparing the installation

1. Mark a vertical center line on the wall from the ceiling

to the lower edge of the extractor hood.

2. Align the drill template on the center line and the

bottom edge of the extractor hood and glue on.

3. Mark positions for the screws and the contour of the

attachment area.

4. Mark holes for the ue’s angle brackets. The center of

the angle bracket is marked with a hole. Place the

angle brackets in the center of the center line, align

them horizontally and mark the positions of the holes.

Fitting the wall retainer

1. Drill holes with Ø 5/16” (7.9 mm) for the angle bracket.

2. Press in the wall plugs ush with the wall.

3. Screw screws (5x34 mm) into the wall plugs by hand

in order to spread the plugs apart.

4. Unscrew screws.

5. Screw on the angle bracket for the ue duct.

Making the ceiling breakthrough

p

round vent

with duct tape/

*The recirculating version are neither Energy Star nor HVI certied.

Ensure duct joints and exterior penetrations are sealed

A. Wall cap

B. 8" (20.3 cm)

round vent

C. Seal duct joints

with duct tape/

A. Diverter

B. 8" (20.3 cm)

round vent

C. Seal duct joints

with duct tape/

with caulk or other similar material to create an air-tight

path and to minimize building heat loss and gain, and

reduce the potential for condensation.

Place/wrap insulation around duct and/or fan to in order to

minimize possible condensation buildup within the duct,

building heat loss and gain.

1. Using a spirit level, extend the center line of the drill

template to the ceiling.

2. Mark the ceiling breakthrough (Ø 8 1/2” (216 mm)) at

least 4 5/8” (117 mm) away from the wall.

Making the wall breakthrough

1. Using a spirit level, extend the center line of the drill

template to the ceiling.

2. Depending on the curved section of the wall

breakthrough (Ø 8 1/2” (216 mm) mark at least

26 1/2” (660 mm) above the bottom edge of the

extractor hood.

Page 9

Page 10

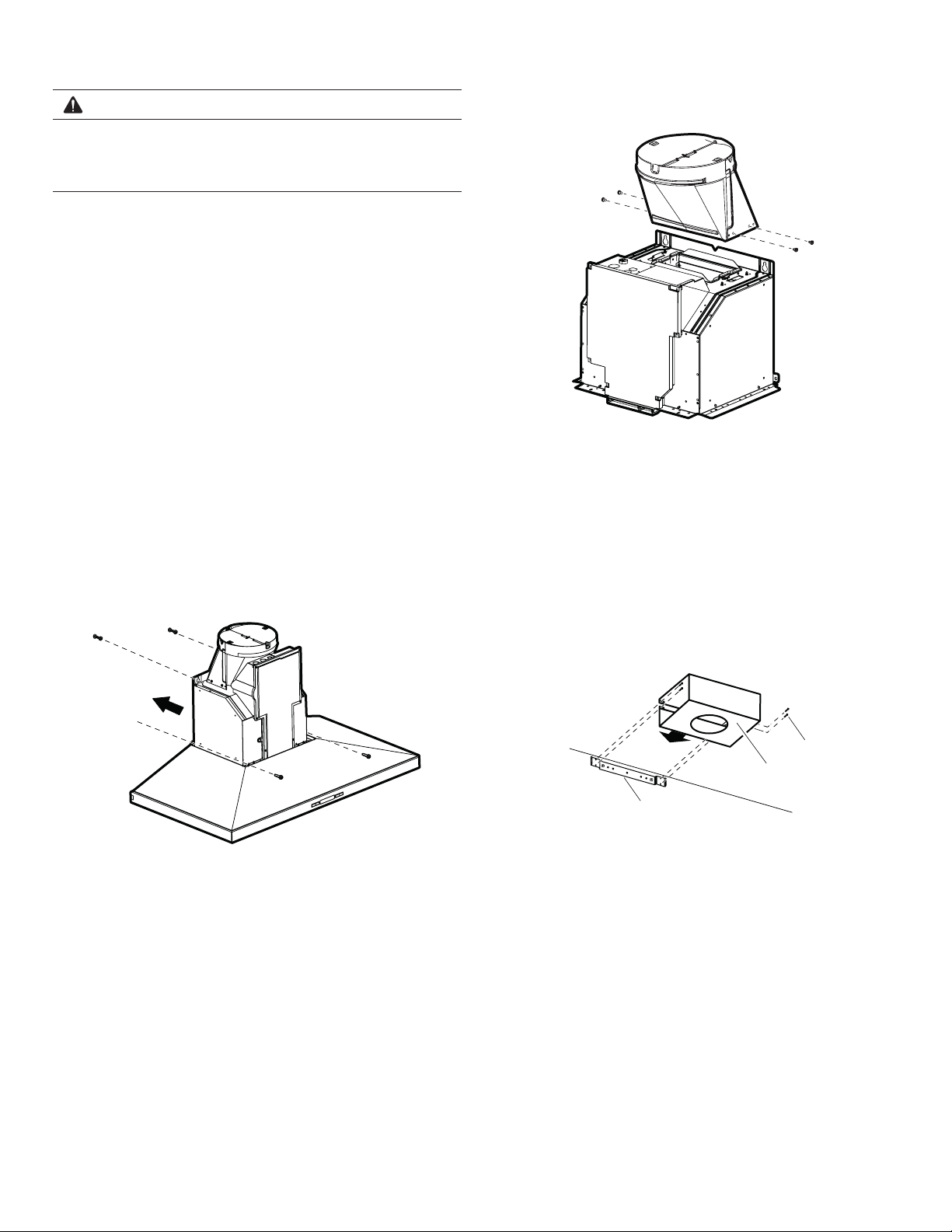

Mounting the extractor hood on the wall

C

WARNING

RISK OF INJURY

The appliance is heavy. To move the appliance, 2 people

are required. Use only suitable tools and equipment.

1. Initially remove the protective foil from the back of the

appliance and, following installation, remove foil

completely.

2. Mark the upper holes on the wall.

Note: Ensure that the holes are horizontal and aligned

centered on the center line.

3. Drill the upper holes. Adhere to a distance of 1/4”

(6 mm) between the wall and screw head.

4. Remove grease lters.

Mounting the back-pressure flap

Using 4 screws (4x8 mm), attach the back-pressure ap

to the extractor hood.

5. Hang the extractor hood on the upper screws on the

wall.

6. Mark holes for the lower holes.

7. Remove the extractor hood from the wall.

8. Drill the lower holes.

9. Hang the extractor hood on the upper screws on the

wall.

10. Tighten the upper and lower screws by hand.

Connecting the air extractor (only for ducted operation)

Note: If an aluminum pipe is used, smooth the connection

area beforehand.

1. Attach exhaust air pipe and seal.

2. Check whether the back-pressure ap works.

Mounting the recirculation model

(only for circulating-air mode)

1. Use 4 screws (4x8 mm) to screw the housing to the

angle bracket.

A

B

A Screws

B Recirculation module

C Angle bracket

Page 10

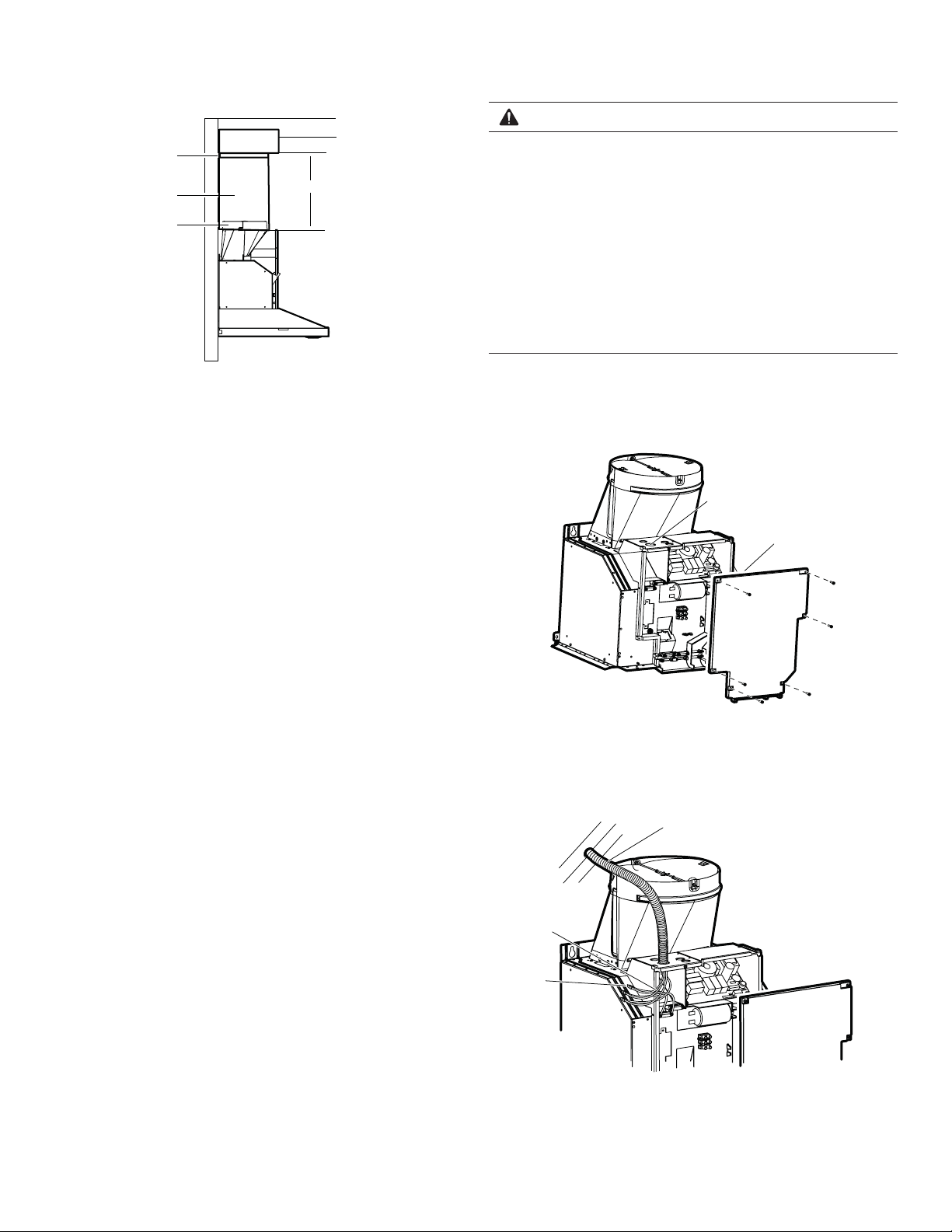

Page 11

2. Measure the distance (x) between the bottom edge of

A

A

the housing for the recirculation module and the

bottom edge of the back-pressure ap.

Connect Electrical Supply

WARNING

B

C

D

A Recirculation module

B Clamps

C Flue duct

D Exhaust air duct

x

3. Shorten the exhaust air pipe to the length measured.

4. Remove the recirculation module.

5. Push the exhaust air pipe onto the bottom side of the

recirculation module.

6. Position the recirculation module with exhaust air pipe

over the air extraction duct of the extractor hood.

RISK OF ELECTRIC SHOCK

Before wiring the appliance, interrupt the main electrical

circuit at the electrical control cabinet. A circuit with 120

VAC, 15 or 20 Ampere is required.

Grounding notes: this appliance is equipped with a

distributor box with 3 cables. Use the green-yellow cable

for grounding the appliance. Connect the green-yellow

cable to the grounding cable on the house connection to

prevent electric shock. Do not under any circumstances

damage or remove the green-yellow cable. Non-adherence can cause deadly injuries or electric shock.

1. Remove the left cable passage and the cover of the

motor controller. Fasten the connecting piece for the

installation pipe (listed in cULus) to the cable

passage.

A

B

7. Use 4 screws to fasten the recirculation module to the

angle bracket.

8. Secure connections with clamps.

A Cable passage

B Cover of the motor controller

2. Connect 1/2” (12.7 mm) installation pipe to motor

controller.

B

C

A Installation pipe

B Power connection

C Cable connector listed in UL

Page 11

Page 12

Attaching flue duct

AB

Hidden surfaces may have sharp edges. Use caution

when reaching behind or under appliance.

1. Remove the protective foil from both ue ducts.

2. Push one ue duct into the other.

Notes

• To prevent scratches, lay paper over the edges of

the lower ue duct to protect the surface.

• For ducted operation, turn the upper ue duct so

that the ventilation slots point downward.

7. Fasten the lower part of the ue duct using two

screws.

8. Remove the protective paper from the lower ue duct.

9. Install metal-mesh grease lter.

Removing the appliance

1. Remove the metal-mesh grease lter.

2. Loosen the ue duct.

3. Remove the protective foil from the extractor hood.

4. Place ue ducts on the appliance.

5. Push the inner ue duct upwards and attach it to the

angle brackets on the left and right.

6. Screw the ue duct to the sides of the angle bracket

using two screws.

3. Disconnect the appliance from the power supply.

4. Loosen the exhaust air lines.

5. Loosen screws for fastening the appliance.

6. Remove the appliance.

A Installation pipe

B Power connection

C Cable connector listed in UL

Page 12

Page 13

Table des

Dénitions de

MATIÈRES

Sécurité .............................................................................. 13

Consignes de Sécurité Importantes ........................... 14

Généralités .................................................................. 14

Branchement électrique.............................................. 16

Avant de commencer ......................................................... 18

Distances de sécurité ................................................. 19

Calcul de perfomance de ventilation ......................... 20

Procédure d’installation ..................................................... 21

Préparer l’installation .................................................. 21

Monter la hotte aspirante au mur .............................. 22

Brancher l’alimentation électrique ............................ 23

Monter le capot de cheminée .................................... 24

SÉCURITÉ

AVERTISSEMENT

Ceci indique que le non respect de cet avertissement

peut entraîner des blessures graves, voire la mort.

ATTENTION

Ceci indique que le non respect de cet avertissement

peut entraîner des blessures légères ou modérées.

AVIS: Ceci indique que la non-conformité à cet avis de

sécurité peut entraîner des dégâts à l’appareil ou à la propriété.

Remarque: Ceci vous avertit que d’importantes informations et/ou conseils sont fournis.

Cet appareil électroménager de Bosch

est fait par BSH Home Appliances LtD

6696 Financial Drive, Unit 3

Mississauga, ON L5N 7J6

Des questions?

1-800-735-4328

www.bosch-home.com/us

Nous attendons de vos nouvelles!

Page 13

Page 14

CONSIGNES DE SÉCURITÉ IMPORTANTES

LISEZ ET CONSERVEZ CES INSTRUCTIONS

Généralités

AVERTISSEMENT

N’utilisez cet appareil que de la manière prévue par le fabricant. Si vous avez des questions, contactez le fabricant.

AVERTISSEMENT

• Veillez à ne pas endommager le câblage électrique ou

d’autres équipements non apparents lors de la

découpe ou du perçage du mur ou du plafond.

• Les ventilateurs canalisés doivent toujours rejeter l’air

à l’extérieur.

INSTALLATEUR : LAISSEZ CES INSTRUCTIONS AVEC

L’APPAREIL UNE FOIS L’INSTALLATION TERMINÉE.

IMPORTANT : À CONSERVER POUR L’USAGE DE

L’INSPECTEUR LOCAL.

AVERTISSEMENT

Lorsqu’il est bien entretenu, votre nouvel appareil est

conçu pour être sécuritaire et able. Lisez attentivement

ces instructions avant d’utiliser l’appareil. Ces précautions

réduiront les risques de brûlures, de chocs électriques,

d’incendie et de blessures. Lorsque vous utilisez des

appareils électroménagers, il est indispensable de suivre

des précautions de sécurité de base, notamment celles

indiquées dans les pages suivantes.

ATTENTION

La graisse restant sur les ltres peut se fondre à nouveau

et se déplacer à l’intérieur de l’évent.

AVERTISSEMENT

Les surfaces cachées peuvent avoir des bords tranchants.

Soyez prudent lors des manoeuvres derrière ou sous la

hotte. Veuillez porter des gants en tout temps lors de

l’installation de cette hotte.

Sécurité-incendie

AVERTISSEMENT

Utilisez cet appareil seulement de manière conforme à

l’usage prévu par le fabricant.

Toujours avoir un détecteur de fumée en état de marche

près de la cuisine. Si des vêtements s’enamment, rouler

par terre immédiatement pour éteindre les ammes.

Avoir un extincteur approprié disponible, à proximité, très

visible et facilement accessible à proximité de l’appareil.

Étouffez les ammes d’un feu d’aliments autre qu’un feu

de graisse à l’aide de bicarbonate de soude. Ne jamais

utiliser d’eau sur les feux de cuisson.

Installation et entretien corrects

AVERTISSEMENT

Enlever le ruban adhésif et l’emballage avant d’utiliser

l’appareil. Détruire l’emballage après avoir déballé

l’appareil. Ne jamais laisser les enfants jouer avec les

matériaux de conditionnement.

Cet appareil est destiné uniquement à une utilisation

domestique normale. Il n’est pas homologué pour un

usage en extérieur. Voyez la garantie. Si vous avez des

questions, communiquez avec le fabricant.

Ne pas entreposer ni utiliser de produits chimiques

corrosifs, vapeurs, substances inammables ou produits

non alimentaires à l’intérieur ou à proximité de l’appareil.

Il a été spécialement conçu pour être utilisé pendant le

chauffage et la cuisson des aliments. L’emploi de produits

chimiques corrosifs pour chauffer ou nettoyer l’appareil

endommagera ce dernier et peut provoquer des blessures.

Ne pas se servir de cet appareil s’il ne fonctionne pas

correctement ou s’il est endommagé. Communiquer avec

un réparateur autorisé. Ne pas réparer ni remplacer toute

pièce de l’appareil à moins que cela ne soit spéciquement recommandé par ce manuel. Toute réparation doit

être effectuée par un centre de réparation autorisé par l’usine.

Page 14

Page 15

CONSIGNES DE SÉCURITÉ IMPORTANTES

LISEZ ET CONSERVEZ CES INSTRUCTIONS

AVERTISSEMENT

POUR RÉDUIRE LE RISQUE DE LÉSIONS CORPORE-

LLES EN CAS D’UN FEU DE FRITURE SUR UNE CUISINIÈRE, OBSERVER CE QUI SUIT:

• ÉTOUFFER LES FLAMMES à l’aide d’un couvercle

bien hermétique, d‘une tôle à biscuits ou d’un plateau en

métal, puis éteindre le brûleur. FAIRE ATTENTION À

NE PAS SE BRÛLER. S i les ammes ne s ‘éteignent

pas immédiatement, ÉVACUER LES LIEUX ET FAIRE

APPEL AU SERVICE D’INCENDIE.

• NE JAMAIS SOULEVER UNE POÊLE EN FLAMMES –

Vous pourriez vous brûler.

• NEPAS UTILISER D ‘EAU, y compris l es chiffons ou

serviettes mouillées - une violente explosion de

vapeur pourrait se produire.

• Utiliser UNIQUEMENT un extincteur si:

a) Vous savez que vous avez un extincteur de classe

ABC et comment l’utiliser.

b) Le feu est petit et circonscrit à la zone où il a

débuté.

c) Le service d’incendie est appelé.

d) Si l’on peut combattre le feu en ayant le dos vers

une sortie.

a

Recommandations tirées des conseils de sécurité en cas

d’incendie de cuisine publiés par la NFPA.

Dans la mesure du possible, ne pas faire fonctionner le

système de ventilation lorsqu’un feu se déclenche sur une

table de cuisson. Toutefois, ne pas passer la main à travers

le feu pour mettre le système de ventilation hors tension.

AVERTISSEMENT

RISQUE D’INCENDIE

L’huile et la graisse très chaudes s’enamment rapidement.

Ne jamais laisser de l’huile et de la graisse chaudes sans

surveillance. Ne jamais éteindre un incendie avec de l’eau.

Éteindre le foyer. Étouffer les ammes avec précaution au

moyen d’un couvercle, d’une couverture antifeu ou

équivalent.

AVERTISSEMENT

RISQUE D’INCENDIE

Les dépôts se trouvant dans le ltre à graisse peuvent

s’enammer.

Nettoyer le ltre à graisser au moins tous les 2 mois.

Ne jamais faire fonctionner l’appareil sans son ltre à

graisse.

a

AVERTISSEMENT

RISQUE D’INCENDIE

Les dépôts se trouvant dans le ltre à graisse peuvent

s’enammer. Ne jamais cuisiner à proximité de l’appareil

avec une amme ouverte (par exemple pour faire am-

ber). Installer l’appareil près d’un foyer pour combustibles

solides (bois ou charbon par exemple) seulement s’il y a

un couvercle fermé et non amovible. Il ne faut pas qu’il se

produise de projection d’étincelles

AVERTISSEMENT

RISQUE D’INCENDIE

utiliser uniquement des gaines en métal.

AVERTISSEMENT

RISQUE DE BRÛLURE

Les parties accessibles chauffent lorsque la table est

allumée. Ne touchez jamais aux parties très chaudes.

Tenez les enfants à distance.

ATTENTION

Il est recommandé de porter des gants et des manches

longues pour protéger les mains et les avant-bras des éra-

ures et d’éventuelles égratignures lors de l’installation.

Sécurité des enfants

Lorsque les enfants sont assez âgés pour utiliser

l’appareil, il incombe auxparents ou tuteurs légaux de

veiller à ce qu’ils soient formés aux pratiques sécuritaires

par des personnes qualiées.

Ne permettre à personne de grimper, rester debout,

s’appuyer, s’asseoir ou se pencher sur toute partie d’un

appareil, notamment une porte, un tiroir-réchaud ou un

tiroir de rangement. Ceci peut endommager l’appareil qui

risque de basculer et causer des blessures sérieuses.

AVERTISSEMENT

S’assurer que l’appareil a complètement refroidi (y compris les ltres à graisse et les ampoules, le cas échéant) et

que la graisse s’est solidiée avant de tenter de nettoyer

une quelconque partie de l’appareil.

Ne pas utiliser de nettoyeur à vapeur pour nettoyer

l’appareil.

Page 15

Page 16

Avertissement issu de la proposition 65

Ce produit pourrait contenir un produit chimique reconnu

par l’État de la Californie comme cancérigène ou ayant des

effets nocifs sur la reproduction. Par conséquent,

l’emballage de votre produit pourrait porter l’étiquette

suivante, comme requis par la Californie:

AVERTISSEMENT ISSUE DE LA PROPOSITION 65 DE

L’ÉTAT DE LA CALIFORNIE:

AVERTISSEMENT

Cancer et dommages à la reproduction –

www.P65Warnings.ca.gov.

Protection de l’environnement

Déballez l’appareil et mettez l’emballage au rebut conformément aux exigences environnementales.

REMARQUE

Risque de dommages dus à la corrosion. Mettez toujours

l’appareil en marche lorsque vous cuisinez pour éviter

l’accumulation de condensation. La condensation peut

entraîner des dommages liés à la corrosion.

Risque de dommages dû à l’humidité pénétrant dans les

circuits électroniques. Ne nettoyez jamais le panneau de

commande avec un chiffon humide.

Dommages à la surface en cas de nettoyage non adapté.

Nettoyez les surfaces en acier inoxydable dans le sens du

grain uniquement. N’utilisez pas de nettoyants pour l’acier

inoxydable sur le panneau de commande. N’utilisez jamais

de nettoyants forts ou abrasifs, au risque d’endommager la

surface.

Risque de dommages causés par un refoulement de la

condensation. Installez le conduit de sortie de manière à ce

qu’il soit légèrement incliné par rapport à l’appareil (inclinaison de 1°).

Instructions Générales

Mode évacuation

Remarque: Il ne faut pas rejeter l’air usé dans une

cheminée d’évacuation en service, ni dans un conduit

servant à la ventilation de pièces où sont installés des

foyers.

• Pour rejeter l’air dans un conduit de fumées qui n’est

pas en service, il faut demander l’accord du maître

ramoneur compétent.

• Si l’air est évacué à travers le mur extérieur de

l’habitation, il faut utiliser un caisson mural

télescopique.

Conduit d’évacuation

Remarque : Le fabricant de l’appareil n’assume aucune

garantie pour les problèmes dus à la tuyauterie.

• L’appareil atteint sa puissance maximale si le tuyau

d’évacuation est court et droit et a un diamètre le plus

grand possible.

• L’emploi de tuyaux d’évacuation longs et à surface

rugueuse, comportant de nombreux coudes ou ayant

un diamètre inférieur à 150 mm (5 15/16”), empêche

l’appareil d’atteindre sa puissance d’aspiration

maximale et le bruit de fonctionnement est plus fort.

• Les tuyaux rigides et souples utilisés pour le conduit

d’évacuation doivent être fabriqués dans un matériau

non inammable.

Tuyaux ronds

Un diamètre intérieur de 8” (200 mm) est préconisé.

Page 16

Page 17

Branchement électrique

AVERTISSEMENT

RISQUE DE CHOC ÉLECTRIQUE

Les pièces se trouvant dans l’appareil peuvent

présenter des arêtes vives. Le cordon de branchement

peut être endommagé. Ne pas couder ni coincer le cordon de branchement pendant la pose.

Avant de raccorder l’appareil, vérier l’installation

domestique. Veiller à ce que la protection de l’installation

domestique soit appropriée. La tension et la fréquence de

l’appareil doivent correspondre à l’installation électrique

(voir la plaque signalétique).

L’appareil répond à la classe de protection I et doit

uniquement être utilisé avec une prise de terre.

Un sectionneur omnipolaire avec un interstice d’ouverture

de contact d’au moins 3 mm doit être présent dans

l’installation. Celui-ci doit encore être accessible après

l’encastrement.

Seul un électricien agréé est habilité à installer ou à

remplacer le câble de raccordement, en respectant les

prescriptions en vigueur.

Respecter toutes les normes et lois en vigueur.

Veiller à ce que le raccordement électrique réponde aux

exigences de toutes les normes et lois applicables dans

le pays correspondant et aux spécications des éditions

les plus récentes des normes suivantes : National

Electrical Code, ANSI/NFPA 70*, ou normes

CSA C22.1-94, Code canadien de l’électricité, partie 1 et

C22.2 No.0-M91**.

Faire contrôler par un électricien le raccordement à la terre

de l’appareil.

Ne pas mettre à la terre avec une canalisation de gaz.

S’assurer de ne pas avoir de fusible dans le circuit

électrique neutre ou de mise à la terre.

Conserver la notice de montage. Raccorder l’appareil

uniquement avec un câblage de cuivre. Raccorder

l’appareil si possible avec un guide de câble métallique

directement au boîtier à fusibles.

Le diamètre du l doit répondre aux exigences de toutes

les normes et lois applicables dans le pays

correspondant et aux spécications des éditions les plus

récentes des normes suivantes : National Electrical Code

ANSI/NFPA 70*, ou normes CSA C22.1-94, Code

canadien de l’électricité, partie 1 et C22.2 No. 0-M91**.

Fixer une gaine de protection gurant dans la liste U.L.

ou C.S.A. aux deux extrémités du câble de raccordement,

à savoir au niveau de l’appareil et au boîtier à fusibles.

Vous pouvez obtenir des copies des normes mentionnées

auprès de :

* National Fire Protection Association Batterymarch Park

Quincy, Massachusetts 02269

** CSA International 8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575.

Page 17

Page 18

Avant de commencer

Outils et pièces nécessaires

Cotes de l’apparei

• Décamètre à ruban

• Crayon

• Tournevis Phillips (Posidrive) #2

• Perceuse avec les forets suivants : 5/16” (7,9 mm) et

3/8” (9,5 mm)

• Niveau à bulle

• Ruban en aluminium (NE PAS utiliser un ruban isolant)

• Canal d’évacuation d’air (la conguration dépend de la

situation de montage).

• Vis à tôle supplémentaires (si nécessaires pour

l’installation du conduit d’évacuation)

• Scie

Pièces comprises

• Hotte aspirante avec ventilateur, volet anti-refoulement

• Lampe, déjà montée

• Filtre à graisse en métal

• Capot de cheminée

• Gabarit de perçage

• 1 cornière de retenue pour le capot de cheminée

• Notice d’utilisation et d’installation

• 6 vis, 5 x 45 mm

• 8 vis, 4,2 x 8 mm

• 2x rondelles

• 2x chevilles pour corps creux, 8x40 mm

• 4x chevilles pour corps creux,10x50 mm

• Adaptateur Torx, 10 & 20

3

10

(273 mm)

13

(335 mm)

24 po (610 mm) ou

30 po (762 mm) ou

36 po (914 mm)

/4 po

3

/16 po

7

7

/8 po

(200 mm)

45/8 po

(118 mm)

5 po

(126 mm)

11

/

po

19

16

(500 mm)

A

A Uniquement en cas de mode recirculation de l’air :

*Max. 42 9/16” (1081 mm)

*Min. 28 1/4” (718 mm)

Uniquement en cas de mode évacuation de l’air :

*Max. 38 7/8” (988 mm)

*Min. 24 9/16” (625 mm)

Page 18

Page 19

Distances de sécurité

AVERTISSEMENT

RISQUE D’INCENDIE

Les dépôts de graisse dans le ltre à graisse peuvent

s’enammer. La distance de sécurité recommandée doit

être respectée an d’éviter une accumulation de chaleur.

Veuillez respecter les spécications de votre appareil

de cuisson. Si des cuisinières électriques et à gaz sont

utilisées ensemble, la plus grande distance indiquée

s’applique.

L’appareil peut seulement être installé directement contre

un mur ou une armoire sur un côté.

L’espacement du mur ou de l’armoire doit être d’au

moins 1/16” (2 mm).

La distance entre la surface de rangement sur la table de

cuisson et le dessous de la hotte ne doit pas être

inférieure à 24” (610 mm) pour les tables de cuisson

électriques et 27” (686 mm) pour les cuisinières à gaz ou

combinées.

Si les instructions pour l’installation de l’appareil de

cuisson au gaz spécient une plus grande distance, celleci

doit être prise en compte.

Table de cuisson électrique

min. 24" (610 mm)

Mode évacuation

Remarque: Il ne faut pas rejeter l’air usé dans une

cheminée d’évacuation en service, ni dans un conduit

servant à la ventilation de pièces où sont installés des

foyers.

• Pour rejeter l’air dans un conduit de fumées qui n’est

pas en service, il faut demander l’accord du maître

ramoneur compétent.

• Si l’air est évacué à travers le mur extérieur de

l’habitation, il faut utiliser un caisson mural télescopique.

Conduit d’évacuation

Remarque: Le fabricant de l’appareil décline toute garantie

en cas de réclamation imputable à des problèmes liés au

parcours des conduits.

• L’ouverture d’évacuation d’air et les conduits

d’évacuation doivent être exécutés en fonction des

conditions locales.

• L’appareil atteindra un rendement supérieur si le

conduit d’évacuation est court et droit et que son

diamètre est grand.

• Des conduits d’évacuation d’air longs, aux parois

rugueuses, comportant plusieurs coudes ou des

diamètres trop petits, empêchent d’atteindre une

puissance d’aspiration optimale et le ventilateur

devient plus bruyant.

• Les tuyaux rigides ou souples constituant le conduit

d’évacuation doivent être en matériau ininammable.

• Lisser la zone de raccordement des tuyaux avant le

montage.

• Étancher les zones de jonction.

Tuyaux ronds

Nous recommandons un diamètre intérieur de Ø 8” (200

mm).

Table de cuisson au gaz

min. 27" (686 mm)

Vérifier le mur

• Le mur doit être plat, vertical et offrir une portance

sufsante.

• La profondeur des trous percés doit être adaptée à la

longueur des vis. Les chevilles doivent offrir une

retenue sûre.

• Les vis et chevilles fournies conviennent pour la

maçonnerie massive. En présence d’autres matériaux

de construction, il faut utiliser des moyens de xation

correspondants.

Page 19

Page 20

Calcul de perfomance de ventilation

61

62

82

62

82

61

Pièce du système Pièce du système

Lisse, droite

3¼ x 10 po, droit S.O. 1

Taille

(po)

61.2

80.7

10 0.6

Longueur

équivalente

(pi)

Orifice rond jusqu’à

3¼ x 10 po,

avec coude 90 degrés

3¼ x 10 po avec

coude de 90 degrés,

rond

Taille

(po)

Longueur

équivalente

(pi)

0

0

3¼ x 14 po, droit S.O. 0.7

612

Coude 90 degrés,

rond

Coude 45 degrés,

rond

3¼ x 10 po

coude 90 degrés, rond

3¼ x 10 po,

coude 45 degrés, rond

3¼ x 10 po,

coude plat

Orifice rond jusqu’à

3¼ x 10 po

3¼ x 10 po

jusqu’à l’orifice rond

86

10

65

83

10

S.O. 5

S.O. 15

S.O. 20

61

810

65

82

3¼ x 10 po coude

centré, inversé,

gauche

3¼ x 10 po coude

centré, inversé,

droit

5

2

REMARQUE: Ces pièces courantes pour installation sont offertes dans

les quincailleries locales. Bosch ne fabrique pas toutes ces pièces.

3¼ x 10 po coude à

gauche, inversé

3¼ x 10 po coude

droit, inversé

Lisse, ronde

Lisse de toit, ronde

Gaine souple, 2 pi long,

3¼ x 10 po

Trémie de cheminée et

volet d’obturation,

3¼ x 10 po

S.O. 25

S.O. 15

S.O. 25

10 2

10

S.O. 20

S.O.

15S.O.

2

2

Page 20

Page 21

Procédure d’installation

Ventilation

Ventilation

Aucune

A. Capuchon de toit

B. Conduit rond de

C. Sceller les joints

Les conduits menant de la hotte à l’extérieur du bâtiment

ont un impact important sur la circulation d’air, le bruit et la

consommation énergétique de la hotte. Utilisez la

conguration de conduits la plus courte et la plus droite

possible pour un rendement optimal, et évitez d’installer la

hotte avec des conduits d’une taille plus petite que celle

recommandée. L’isolation autour des conduits peut réduire

la perte énergétique et prévenir la formation de moisissure.

Des hottes installées avec des conduits déjà en place

peuvent ne pas atteindre leur débit d’air nominal.

ATTENTION

Veillez à ce qu’il n’y ait pas de conduites électriques,

ou tuyaux de gaz et d’eau au niveau des perçages.

par le toit

A

B

C

murale

B

C A

ventilation*

(Recirculation)

A

B

C

Préparer l’installation

5. Du plafond au bord inférieur de la hotte aspirante,

tracer une ligne médiane verticale sur le mur.

6. Aligner le gabarit de perçage à la ligne médiane et au

bord inférieur de la hotte et le coller.

7. Marquer les emplacements des vis et le contour de la

zone d’accrochage.

8. Marquer les perçages pour les cornières de retenue de

la cheminée. Le milieu des cornières de retenue est

repéré par un perçage. Appliquer les cornières de

retenue de façon centrée à la ligne médiane, les aligner

horizontalement et marquer l’emplacement des

perçages.

Montage de la fixation murale

1. Percer les trous avec le foret de Ø 5/16” (7,9 mm)

pour la cornière de retenue.

2. Enfoncer les chevilles à eur du mur.

3. Visser les vis (5x45 mm) à la main dans les chevilles,

an d’écarter la cheville.

A. Capuchon mural

B. Conduit rond de

8 po (20,3 cm)

des conduits avec

du ruban adhésif/

produit calfeutrant

*La version de recirculation n’est pas certiée Energy Star ou HVI.

8 po (20,3 cm)

C. Sceller les joints

des conduits avec

du ruban adhésif/

produit calfeutran

A. Dériveur

B. Conduit rond de

8 po (20,3 cm)

C. Sceller les joints

des conduits avec

du ruban adhésif/

produit calfeutran

Assurez-vous que les joints des conduits et les orices

extérieurs sont scellés avec un produit calfeutrant ou un

autre matériau similaire pour créer un passage hermétique,

minimiser les variations thermiques du bâtiment et réduire

le risque de condensation.

Placez/enroulez l’isolation autour des conduits et/ou de la

hotte pour réduire le risque d’accumulation de condensation dans les conduits et pour minimiser les variations

thermiques du bâtiment.

4. Dévisser les vis.

5. Visser la cornière pour la cheminée.

Percement du plafond

1. Prolonger la ligne médiane du gabarit de perçage

vers le plafond à l’aide d’un niveau à bulle.

2. Marquer le perçage du plafond (Ø 8 1/2” (216 mm)) à

une distance d’au moins 4 5/8” (117 mm) du mur.

Percement du mur

1. Prolonger la ligne médiane du gabarit de perçage vers

le plafond à l’aide d’un niveau à bulle.

2. En fonction du coude, marquer le perçage du mur

(Ø 8 1/2” (216 mm)) à une distance d’au moins

26 1/2” (660 mm) au-dessus du bord supérieur de la

hotte.

Page 21

Page 22

Monter la hotte aspirante au mur

C

AVERTISSEMENT

RISQUE DE BLESSURE

L’appareil est lourd. 2 personnes sont nécessaires pour

déplacer l’appareil. Utiliser exclusivement des moyens

appropriés.

1. Retirer d’abord le lm protecteur du dos de l’appareil,

puis intégralement une fois le montage achevé.

2. Marquer les perçages supérieurs sur le mur.

Remarque : S’assurer que les perçages sont alignés

horizontalement et de manière centrée à la ligne

médiane.

3. Percer les trous supérieurs. Respecter une distance de

1/4” (6 mm) entre le mur et la tête de la vis.

4. Enlever le ltre à graisse.

5. Accrocher la hotte au mur aux vis supérieures.

6. Marquer les perçages inférieurs.

7. Enlever la hotte du mur.

8. Percer les trous inférieurs.

9. Accrocher la hotte au mur aux vis supérieures.

10. Serrer les vis supérieures et inférieures à la main.

Montage du volet anti-refoulement

Visser le volet anti-refoulement sur la hotte à l’aide de

4 vis (4x8 mm).

Effectuer le raccordement de l’évacuation de l’air (uniquement en cas de mode évacuation de l’air)

Remarque : En cas d’utilisation d’un tuyau en aluminium,

lisser au préalable la zone de raccordement.

1. Fixer le tuyau d’évacuation et l’étancher.

2. Vérier si le volet anti-refoulement fonctionne.

Montage du module de recirculation (uniquement en cas

de mode recirculation)

1. Visser le boîtier pour le module de recirculation sur la

cornière de retenue à l’aide de 4 vis (4x8 mm).

A

B

A Vis

B Module de recirculation

C Cornière de retenue

Page 22

Page 23

2. Mesurer la distance (x) entre le bord inférieur du boîtier

A

A

pour le module de recirculation et le bord inférieur du

volet anti-refoulement.

B

C

D

A Module de recirculation

B Colliers

C Capot de cheminée

D Canal d’évacuation d’air

x

3. Raccourcir le tuyau d’évacuation à la longueur mesurée.

4. Enlever le module de recirculation.

5. Pousser le tuyau d’évacuation sur la face inférieure du

module de recirculation.

6. Positionner le module de recirculation avec le tuyau

d’évacuation sur le canal d’évacuation.

Brancher l’alimentation électrique

AVERTISSEMENT

RISQUE D’ÉLECTROCUTION

Avant de procéder au câblage de l’appareil, couper le

circuit électrique principal au boîtier électrique. Un

circuit électrique de 120 VAC, 15 ou 20 ampères est

nécessaire.

Indications pour la mise à la terre : Cet appareil est

équipé d’un boîtier de distribution avec 3 câbles.

Utiliser le câble vert-jaune pour la mise à la terre de

l’appareil. Relier le câble vert-jaune au câble de mise

à la terre du raccordement domestique, an d’éviter

une décharge électrique. N’endommager ou n’enlever

en aucun cas le câble vert-jaune. Le non- respect peut

conduire à des blessures mortelles ou des décharges

électriques

1. Enlever le passage de câbles côté gauche et le

couvercle de la commande du moteur. Fixer la pièce

de raccordement pour la gaine d’installation (dans la

liste cULUS) au passage de câbles.

A

B

7. Fixer le module de recirculation sur la cornière de

retenue à l’aide de 4 vis.

8. Assurer les jonctions avec les colliers.

A Passage de câble

B Couvercle de la commande du moteur

2. Raccorder la gaine d’installation de 1/2” (12,7 mm) à

la commande du moteur.

B

C

A Gaine d’installation

B Raccordement électrique

C Connecteurs de câböes indiqués dans la liste UL

Page 23

Page 24

Monter le capot de cheminée

AB

Certaines surfaces peuvent avoir des bords tranchants.

Faire attention en étendant le bras derrière l’appareil ou en

dessous.

1. Retirer les pellicules protectrices recouvrant les deux

capots de cheminée.

2. Faire coulisser les capots de cheminée l’un dans l’autre.

• Pour éviter les rayures, poser du papier, à titre de

protection, sur les bords du capot extérieur.

• En mode évacuation de l’air, tourner le capot de

cheminée supérieur de façon à ce que les fentes

d’aération se trouvent en bas.

7. Fixer la partie inférieure du capot de cheminée à l’aide

de deux vis.

8. Retirez le papier protecteur du capot de cheminée.

9. Mettre en place le ltre à graisse en métal.

Dépose de l’appareil

1. Retirer le ltre à graisse en métal.

2. Détacher le capot de cheminée.

3. Retirer les pellicules protectrices recouvrant la hotte.

4. Poser les capots de cheminée sur l’appareil.

5. Pousser le capot de cheminée intérieur vers le haut et

l’accrocher sur les côtés gauche et droit à la cornière

de retenue.

6. À l’aide de deux vis, visser le capot de cheminée

latéralement sur la cornière de retenue.

3. Mettre l’appareil hors tension.

4. Détacher les conduits d’évacuation.

5. Desserrer les vis pour la xation de l’appareil.

6. Enlever l’appareil.

Page 24

Page 25

Índice de

Deniciones de

CONTENIDOS

Seguridad .......................................................................... 25

Instrucciones Importantes de Seguridad ................... 26

Notas Generales ......................................................... 26

Conexión Eléctrica...................................................... 29

Antes de empezar ............................................................. 30

Distancias de Seguridad ............................................ 31

Calculando la longitud de ventilación ....................... 32

Procedimiento de Instalación ........................................... 33

Preparativos de la Instalación ..................................... 33

Montaje de la campara en la pared ........................... 34

Conexión de la alimentación eléctrica....................... 35

Attaching Flue Duct..................................................... 36

SEGURIDAD

ADVERTENCIA

Esto indica que se pueden producir lesiones graves o la

muerte si no se cumple con esta advertencia.

PRECAUCIÓN

Esto indica que pueden producirse lesiones leves o moderadas si no se cumple con esta advertencia.

AVISO: Esto indica que podrían producirse daños al electrodoméstico o a la propiedad como resultado de no hacer

caso de este aviso.

Nota: Esto le alerta ante información o consejos importantes.

Este electrodoméstico de Bosch está hecho

por BSH Home Appliances Corporation

1901 Main Street, Suite 600

Irvine, CA 92614

¿Preguntas?

1-800-735-4328

www.bosch-home.com/us

¡Esperamos oír de usted!

Page 25

Page 26

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

LEA Y GUARDE ESTAS INSTRUCCIONES

Notas Generales

ADVERTENCIA

Use la unidad solo de la manera indicada por el fabricante. Si tiene preguntas, comuníquese con el fabricante.

ADVERTENCIA

• Al cortar o perforar a través de la pared o del cielo

raso, tenga cuidado de no dañar el cableado eléctrico

ni otros servicios ocultos.

• Los ventiladores con conductos siempre deben

ventearse hacia el exterior.

IINSTALADOR: DEJE ESTAS INSTRUCCIONES CON EL

ELECTRODOMÉSTICO DESPUÉS DE TERMINAR CON

LA INSTALACIÓN.

IMPORTANTE: GUARDE PARA EL USO DEL INSPECTOR

LOCAL.

ADVERTENCIA

Su nuevo electrodoméstico ha sido diseñado para ser

seguro y conable cuando es bien cuidado. Lea detenidamente todas las instrucciones antes de usarlo. Estas precauciones reducirán el riesgo de quemaduras, descarga

eléctrica, incendio y lesiones a personas. Al usar electrodomésticos de cocina, deben seguirse las precauciones.

Instalación y mantenimiento adecuados

Este electrodoméstico ha sido diseñado solo para uso

doméstico familiar normal. No está aprobado para usarse

en exteriores. Consultar la declaración de garantía limitada en el Manual de uso y cuidado. Si tiene preguntas,

comuníquese con el fabricante.

No guarde ni use productos químicos corrosivos, vapores,

o productos inamables o que no sean alimentos en o

cerca de este electrodoméstico. Está diseñado especíca-

mente para usarlo al calentar o cocinar alimentos. El

uso de productos químicos corrosivos al calentar o limpiar

dañará el electrodoméstico y podría ocasionar lesiones.

No opere este electrodoméstico si no funciona adecuadamente o si se ha dañado. Comuníquese con un proveedor

de servicio autorizado.

No repare ni reemplace ninguna pieza del electrodomés-

tico a menos que así se recomiende especícamente

en este manual. Reera todo el servicio a un centro de

servicio autorizado de fábrica.

PRECAUCIÓN

La grasa que queda sobre los ltros se puede derretir y

moverse hacia el ventilador.

ADVERTENCIA

Las supercies ocultas pueden tener bordes alados.

Tenga cuidado al meter la mano detrás o debajo del

electrodoméstico.

ADVERTENCIA

Retire toda la cinta y el empaque antes de usar el electrodoméstico.

Destruya el empaque después de desempacar el electrodoméstico. Nunca permita que los niños jueguen con el

material de empaque.

Seguridad ante incendios

ADVERTENCIA

Use este electrodoméstico únicamente para lo que está

diseñado, tal como se describe en este manual.

Siempre tenga cerca de la cocina un detector de humos

en funcionamiento. En caso de que la ropa o el cabello se

incendie, déjese caer de inmediato y ruede, para apagar

las llamas.

Tenga cerca del electrodoméstico un extintor de incendios adecuado disponible, muy visible y fácilmente

accesible.

Apague con bicarbonato de sodio las llamas de incendios

de madera que no sean producidos por grasa. Nunca use

agua sobre incendios que surjan al cocinar.

Page 26

Page 27

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

LEA Y GUARDE ESTAS INSTRUCCIONES

ADVERTENCIA

PARA REDUCIR EL RIESGO DE LESIONES A LAS PER-

SONAS EN CASO DE UN INCENDIO PRODUCIDO POR

GRASA EN UNA ESTUFA, OBSERVE LO SIGUIENTE:

• APAGUE LAS LLAMAS con una tapa de ajuste exacto,

una charola para galletas o una bandeja de metal,

y después apague el quemador. PROCEDA CON

CUIDADO PARA EVITAR QUEMADURAS.

Si las llamas no se apagan inmediatamente, EVACUE

EL ÁREA Y LLAME A LOS BOMBEROS.

• NUNCA LEVANTE UNA CACEROLA INCENDIADA,

se puede quemar.

• NO USE AGUA, ni trapos o toallas de cocina

mojados; puede producirse una explosión violenta

de vapor.

• Use un extintor SÓLO si:

a) Sabe que el extintor es de Clase ABC y sabe

cómo hacerlo funcionar.

b) El incendio es pequeño y está connado al área

en la que se inició.

c) Se está llamando al Departamento de Bomberos.

d) Puede combatir el incendio teniendo la espalda

orientada hacia una salida.

a

Basado en “Kitchen Fire Safety Tips” (Sugerencias para

la seguridad contra incendios en la cocina) publicado por

NFPA.

Siempre que sea posible, no accione el sistema de ventilación en caso de incendio en una estufa. Sin embargo, no

atraviese el fuego para apagarlo.

ADVERTENCIA

RIESGO DE INCENDIO

El aceite y la grasa calientes se incendian rápido. Nunca

deje aceite y grasa calientes sin supervisión. Nunca extinga un incendio con agua. Apague el quemador correspondiente.

Sofoque las llamas con cuidado con una tapa, una manta

para incendios o algo similar

ADVERTENCIA

RIESGO DE INCENDIO

Los depósitos de grasa en el ltro de grasa se pueden

incendiar. Limpie el ltro de grasa por lo menos cada dos

meses o con la frecuencia que sea necesaria.

Nunca opere el electrodoméstico sin el ltro de grasa.

a

ADVERTENCIA

RIESGO DE INCENDIO

Los depósitos de grasa en el ltro de grasa se pueden

incendiar. Nunca trabaje con una llama abierta cerca

del electrodoméstico (por ejemplo, al amear). Instale

la unidad cerca de un electrodoméstico que produzca

calor para combustibles sólidos (por ejemplo, madera o

carbón) únicamente si hubiera una cubierta cerrada que

no se quita. No debe haber chispas volando.

ADVERTENCIA

RIESGO DE INCENDIO

Utilice solo conductos metálicos.

ADVERTENCIA

RIESGO DE QUEMADURAS

Las piezas accesibles pueden calentarse durante la operación. Nunca toque las piezas calientes. Mantenga lejos a

los niños.

PRECAUCIÓN

Se recomienda usar guantes y manga larga para proteger

manos y antebrazos de abrasión y posibles rasguños

durante el proceso de instalación.

Seguridad con los niños

Cuando los niños crecen lo suciente como para usar

el electrodoméstico, es responsabilidad de los padres o

tutores legales asegurarse de que personas calicadas los

instruyan en prácticas seguras.

No permita que nadie trepe, se pare, se incline, se siente o

se cuelgue de ninguna parte de un electrodoméstico. Esto

puede dañar el electrodoméstico o causar lesiones.

ADVERTENCIA

Asegúrese de que todo el electrodoméstico (incluidos

los ltros de grasa y bombillas de luz, si corresponde),

se haya enfriado y la grasa se haya solidicado antes de

intentar limpiar cualquier parte del electrodoméstico.

No use limpiadores de vapor para limpiar el electrodo-

méstico.

Page 27

Page 28

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

LEA Y GUARDE ESTAS INSTRUCCIONES

Advertencia en virtud de la Proposición 65

Este producto puede contener un químico que el Estado

de California reconoce como potencialmente cancerígeno

o causante de daños reproductivos. Por tanto, su producto

debe llevar en su embalaje la siguiente etiqueta de conformidad con la legislación de California:

ADVERTENCIA EN VIRTUD DE LA PROPOSICIÓN 65

DEL ESTADO DE CALIFORNIA:

ADVERTENCIA

Cáncer y daño reproductivo - www.P65Warnings.ca.gov.

Protección del medio ambiente

Desempaque el electrodoméstico y deseche el empaque,

de acuerdo con los requisitos ambientales.

AVISO

Riesgo de daños debidos a la corrosión. Siempre encienda el electrodoméstico cuando cocine, para evitar la

acumulación de condensación. La condensación puede

conducir a daños por corrosión.

Riesgo de daños debido a la entrada de humedad en los

circuitos electrónicos. Nunca limpie los controles del operador con un paño húmedo.

Puede dañarse la supercie por una limpieza incorrecta.

Limpie las supercies de acero inoxidable solo en la direc-

ción del grano. No use limpiadores de acero inoxidable en

los controles del operador. Nunca use agentes de limpieza

fuertes o abrasivos, pues pueden dañar la supercie.

Riesgo de daños por el contraujo de la condensación. Ins-

tale un ventilador de escape en una pendiente ligeramentedescendente, lejos del electrodoméstico (pendiente de 1°).

Page 28

Page 29

Información general

Funcionamiento con extracción de aire

Note: La emisión de los gases no se debe canalizar hacia

una chimenea de humo o de gases de escape que esté

en funcionamiento, ni hacia un tiro que sirva para sacar el

aire de las habitaciones donde haya equipos con fuegoIf

the ventilation is intended to pass through a smoke or

exhaust that is not in operation, the responsible area

heating inspector must give approval.

• Si los gases de escape se van a canalizar hacia una

chimenea de humo o de gases de escape que no esté

en funcionamiento, se tiene que conseguir la aproba ción del especialista en chimeneas correspondiente.

• Si las emisiones de gases se canalizan a través del

muro externo, se tiene que utilizar una caja telescópica

para muros.

Conducto de escape

Nota: El fabricante no asume ninguna garantía por las

reclamaciones debidas a la tubería.

• El equipo consigue su mejor funcionamiento con un

tubo de escape corto, recto y con el diámetro del tubo

lo más grande posible.

• Con tubos de escape largos, ásperos, con muchos

dobleces, o tubería de diámetro menor a 5 15/16”

(150 mm) no se alcanza la potencia de succión óptima

y el ruido del ventilador es más alto.

• Las tuberías o los tubos para el tendido de la línea de

escape deben hacerse de material no combustible.

Tubos redondos

Es necesario un diámetro de 8” (200 mm).

Conexión Eléctrica

ADVERTENCIA

PELIGRO DE DESCARGA ELÉCTRICA

Los componentes dentro del equipo pueden tener

bordes losos. Puede dañarse el cable de conexión.

No retorcer ni constreñir el cable durante la

instalación.

Comprobar la instalación doméstica antes de conectar el

aparato. Comprobar que la instalación doméstica dispone

de los fusibles apropiados. El voltaje y la frecuencia del

aparato deben coincidir con la instalación eléctrica del

aparato (ver placa de características).

El aparato pertenece a la clase de protección I y solo

puede utilizarse conectado a una conexión con conductor

de toma a tierra.

Para la instalación se necesita un dispositivo de

separación omnipolar con una abertura de contacto de

3 mm como mínimo. Este dispositivo debe estar accesible

incluso después del montaje.

La colocación o la sustitución del cable de conexión solo

puede llevarla a cabo un técnico electricista observando

las instrucciones pertinentes.

Seguir todas las normas y disposiciones legales válidas.

Asegurarse de que la conexión eléctrica satisface las

exigencias de todas las normas y disposiciones legales

aplicables en cada país relativas a las últimas versiones

de las siguientes normas: Código Eléctrico Nacional

(NEC), ANSI/NFPA 70* o estándares CSA C22.1-94,

Código Eléctrico Canadiense (CEC), parte 1 y C22.2 n.º

0-M91**.

Solicitar a un instalador eléctrico que compruebe la toma

a tierra del aparato.

No conectar a tierra con conducto de gas.

No debe colocarse ningún fusible en el circuito eléctrico

neutro o en el de toma a tierra.

Conservar las instrucciones de montaje. Conectar el

aparato solo con cable de cobre. De ser posible, conectar

el aparato con una guía de cable metálica directamente a

la caja de fusibles.

El diámetro del alambre debe cumplir las exigencias de

todas las normas y disposiciones legales aplicables en

cada país relativas a las últimas versiones de las

siguientes normas: Código Eléctrico Nacional (NEC),

ANSI/NFPA 70* o estándares CSA C22.1-94, Código

Eléctrico Canadiense (CEC), parte 1 y C22.2 n.º 0-M91**.

Colocar un tubo aislante, incluido en la lista U.L. o C.S.A.,

en los dos extremos del cable de conexión, es decir, en el

aparato y en la caja de fusibles.

Hay disponible una copia de las normas en cuestión en:

* National Fire Protection Association Batterymarch Park

Quincy, Massachusetts 02269

** CSA International 8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

Page 29

Page 30

Antes de empezar

Herramientas y piezas necesarias

• Cinta métrica

• Lápiz

• Desarmador Phillips (Posidrive) #2

• Taladro con las siguientes brocas: 5/16” (7,9 mm) y

3/8” (9,5 mm)

• Nivel de burbuja

• Cinta de aluminio (NO usar cinta aislante)

• Conducto de salida de aire (la conguración depende

de la situación de montaje).

• Además, tornillos para chapa (en caso de que sea

necesario para la instalación del conducto de salida

del aire)

• Sierra

Piezas incluidas

Dimensiones del equipo

3

/4"

10

(273 mm)

3

/16"

13

(335 mm)

7

7

/8"

(200 mm)

5

4

/8"

(118 mm)

5"

(126 mm)

A

• Campana extractora con ventilador, válvula de

retención

• Lámpara, ya montada

• Filtro metálico antigrasa

• Revestimiento de chimenea

• Plantilla de perforación

• 1 escuadra de sujeción para el revestimiento de la

chimenea

• Instrucciones de uso y de instalación

• 6 tornillos de 5 x 45 mm

• 8 tornillos de 4.2 x 8 mm

• 2 rondanas

• 2 taquetes de 8 x 40 mm

• 4 taquetes de 10 x 50 mm

Adaptador Torx, 10 y 20

24" (610 mm) ó

30" (762 mm) ó

36" (914 mm)

11

19

/16"

(500 mm)

A Solo con funcionamiento en recirculación:

*Max. 42 9/16” (1081 mm)

*Min. 28 1/4” (718 mm)

Solo con funcionamiento en salida de aire al

exterior:

*Max. 38 7/8” (988 mm)

*Min. 24 9/16” (625 mm)

Page 30

Page 31

Distancias de seguridad

ADVERTENCIA

RIESGO DE INCENDIO

Los depósitos de grasa en el ltro antigrasa pueden

incendiarse. Se debe observar el espacio libre de seguridad dado para evitar la acumulación de calor.

Tener en cuenta las especicaciones de su aparato de

cocción. Si se usan conjuntamente placas de cocción

eléctricas y de gas, entonces aplicará el mayor espacio

libre indicado.

El aparato solo se podrá instalar directamente junto a un

gabinete o pared a un lado. El espacio libre de la pared o

del gabinete debe ser por lo menos de 1/16” (2 mm).

La distancia entre las supercies de apoyo sobre la placa

de cocción y la parte inferior de la campana extractora no

debe superar 24” (610 mm), en caso de placas de

cocción eléctricas, y 27” (686 mm), en caso de estufas de

gas o combinadas.

Cuando las instrucciones de instalación de la estufa de

gas establecen una distancia mayor, esta deberá tenerse

en cuenta.

Placa de cocción eléctrica

min. 24" (610 mm)

Placa de cocción de gas

Funcionamiento con extracción de aire

Nota: La emisión de los gases no se debe canalizar hacia

una chimenea de humo o de gases de escape que esté

en funcionamiento, ni hacia un tiro que sirva para sacar el

aire de las habitaciones donde haya equipos con fuego.

• Si los gases de escape se van a canalizar hacia una

chimenea de humo o de gases de escape que no esté

en funcionamiento, se tiene que conseguir la

aprobación del especialista en chimeneas

correspondiente.

• Si las emisiones de gases se canalizan a través del

muro externo, se tiene que utilizar una caja telescópica

para muros.

Conducto de escape

Nota: La garantía del fabricante del aparato no cubre las

reclamaciones que se atribuyan al segmento de conductos.

• La abertura de salida de aire y los conductos del aire

de salida deben estar montados conforme a la situación

real del lugar.

• El aparato alcanza su potencia óptima con un conducto

de salida de aire rectilíneo y corto y con un diámetro

grande de conducto en la medida de lo posible.

• Con conductos de salida de aire largos y rugosos,

muchos codos de tubo o diámetros de tubo de un

tamaño demasiado pequeño, no se consigue la

capacidad de aspiración óptima y los ruidos del

ventilador serán mayores.

• Los conductos o mangueras para el tendido del

conducto de salida del aire deben estar fabricados con

material ignífugo.

• Antes del montaje, pulir previamente la zona de

empalme de los conductos.

• Obturar los puntos de unión de los tubos.

Conductos cilíndricos

Se recomienda una circunferencia interior de Ø 8” (200

mm).

min. 27" (686 mm)

Revisar la pared

• La pared debe ser plana, vertical y tener suciente

capacidad de carga.

• La profundidad de los agujeros debe ser equivalente a

la longitud de los tornillos. Los taquetes deben quedar

bien sujetos.

• Los tornillos y taquetes suministrados son apropiados

para mampostería sólida. Para otro tipo de

construcciones se deberán utilizar medios de jación

apropiados.

Page 31

Page 32

Calculando la longitud de ventilación

61

D2

D1

D2

62

82

62

82

D2

61

Pieza de ducto Pieza de ducto

Circular, recto

3¼” x 10”, recto N/D 1

Tamaño

(pulgadas)

61.2

80.7

10 0.6

Longitud

equivalente

(pies)

Circular a codo de

3¼" x 10" a 90°

3¼" x 10" a codo

circular a 90°

Tamaño

(pulgadas)

Longitud

equivalente

(pies)

0

0

3¼” x 14”, recto N/D 0.7

612

Codo a 90°, circular

Codo a 45°, circular

3¼” x 10”

codo a 90°, circular

3¼” x 10”,

codo a 45°, circular

3¼” x 10”,

codo plano

Circular a 3¼" x 10”

3¼" x 10" a circular

86

10

65

83

10

N/D 5

N/D 15

N/D 20

61

810

65

82

3¼" x 10", codo

invertido central,

izquierda

3¼" x 10", codo

invertido central,

derecha

5

2

NOTA:

Estas partes de instalación de uso frecuente se pueden adquirir

en ferreterías locales. Bosch no fabrica todas estas piezas.

3¼" x 10", codo

invertido izquierda

3¼" x 10", codo

invertido izquierda

Tapa circular de pared

Tapa circular de techo

2" longitud, 3¼" x 10"

flexible

3¼" x 10", soporte de

fijación y toma de techo

N/

N/

N/

10 2

10

N/

N/D

15N/D

5

5

5

2

0

2

Page 32

Page 33

Procedimiento de instalación

Ventilación

Ventilación

Sin ventilación*

A. Tapa de tech

B. 8" (20.3 cm

C. Sellar las juntas

a

El ducto de este ventilador hacia el exterior del edicio

tiene un fuerte efecto sobre el ujo de aire, el ruido y el

uso de energía del ventilador. Utilizar la ruta más corta y

más recta posible del ducto para un mejor desempeño y

evitar instalar el ventilador con ductos más pequeños de

lo recomendado. El aislamiento alrededor de los ductos

puede reducir la pérdida de energía e inhibir el

crecimiento de moho. Los ventiladores instalados con

ductos existentes pueden no alcanzar su ujo de aire

nominal.

PRECAUCIÓN

Asegurarse de que no haya cables eléctricos o tuberías

de gas o agua en el área donde se va a taladrar.

de techo

A

B

C