Page 1

2 609 140 081 - Buch Seite 1 Dienstag, 20. Januar 2004 8:52 08

GWS 6-100 (E)

GWS 6-115 (E)

GWS 8-100 C (CE)

GWS 8-115 C (CE)

GWS 8-125 C (CE)

PROFESSIONAL

Bedienungsanleitung

Operating instructions

Instructions d’emploi

Instrucciones de servicio

Manual de instruções

Istruzioni d’uso

Gebruiksaanwijzing

Betjeningsvejledning

Bruksanvisning

Brukerveiledningen

Käyttöohje

Οδηγία χειρισµού

Kullan∂m k∂lavuzu

* Des idées en action.

Page 2

2 609 140 081 - Buch Seite 2 Dienstag, 20. Januar 2004 8:52 08

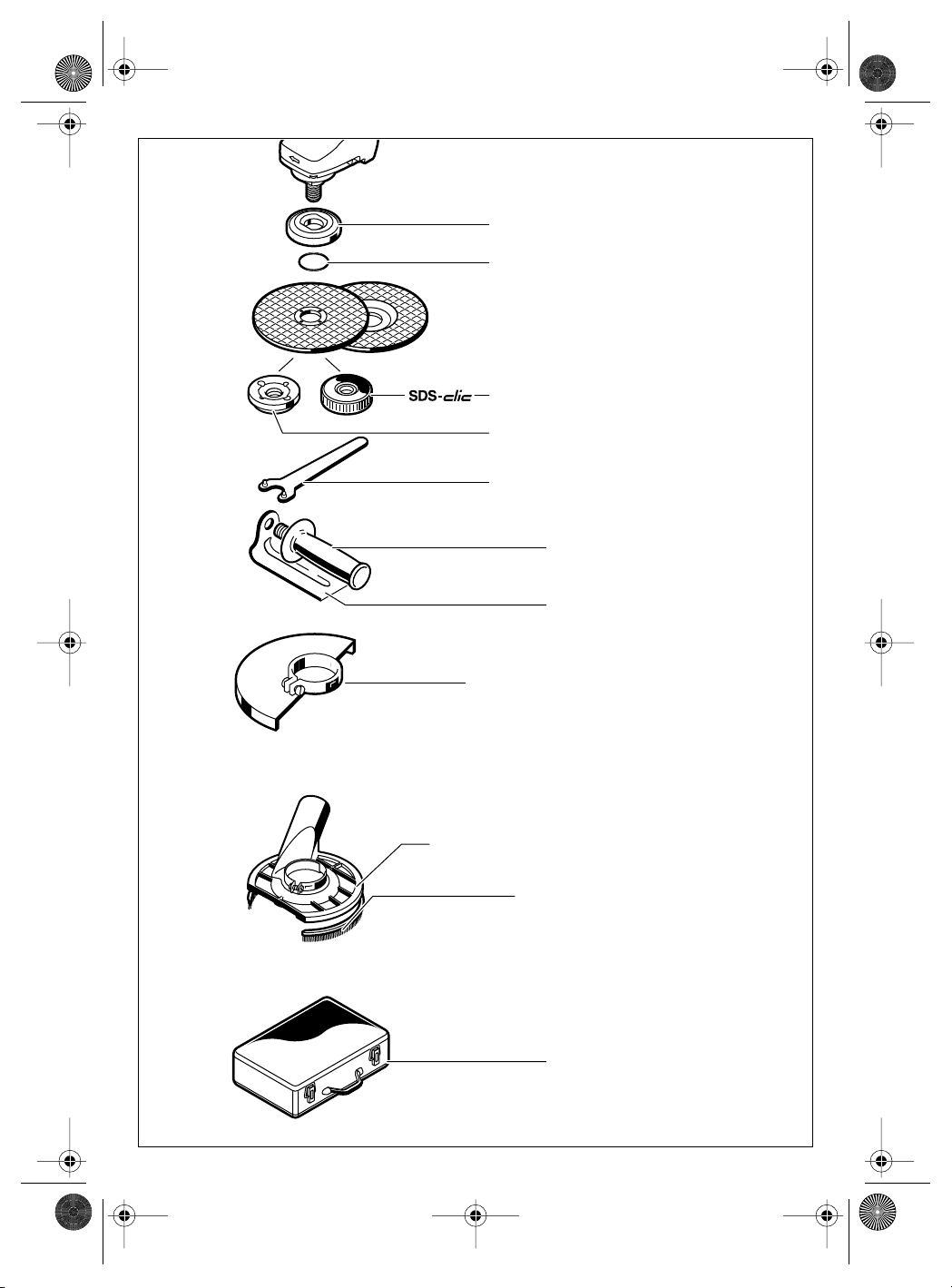

(M 10)

(M 14)

(M 14)

(M 14)

(M 10)

(M 14)

(M 10)

(M 14)

Ø 100 mm

Ø 115 mm

Ø 125 mm

2 605 703 030

1 605 703 099

1 600 210 039

1 603 340 031

2 603 340 018

1 603 340 040

1 607 950 040

2 607 950 043

1 602 025 024

1 601 329 013

2 605 510 155

2 605 510 156

2 605 510 172

2 • 2 609 140 081 • 04.01

Ø 100 –125 mm

2 x

1 610 510 197

2 605 730 036

2 605 438 343

Page 3

2 609 140 081 - Buch Seite 3 Dienstag, 20. Januar 2004 8:52 08

3 • 2 609 140 081 • 04.01

Page 4

6

2 609 140 081 - U4+5 Seite 4 Dienstag, 20. Januar 2004 8:05 08

4

1

2

3

6

7

8

9

10

11

4 +5 • 2 609 140 081 • 04.01

5

12

13

14

15

12

16

GWS 6-100 E

GWS 6-115 E

GWS 8-100 CE

GWS 8-115 CE

GWS 8-125 CE

PROFESSIONAL

Page 5

2 609 140 081 - Buch Seite 1 Dienstag, 20. Januar 2004 8:52 08

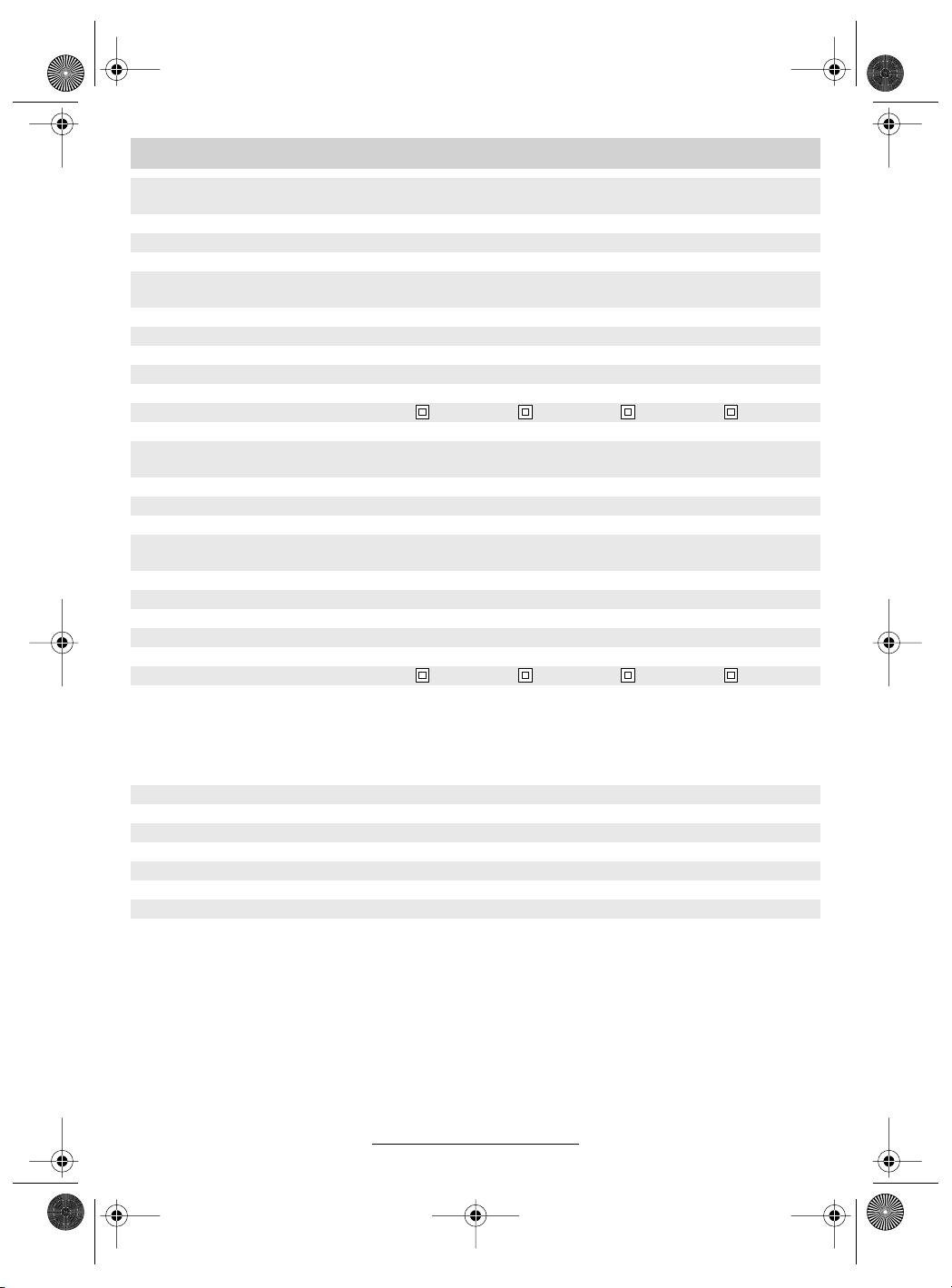

Tool Specifications

Angle Grinder GWS …

6-100 6-100 E 6-115 6-115 E

PROFESSIONAL

Order number 0 601 375 0.. 0 601 375 7.. 0 601 375 0.. 0 601 375 7..

Rated input power* [W] 670 670 670 670

Output power* [W] 400 400 400 400

No-load speed [rpm] 11 000 2 800 –

11 000

11 000 2 800 –

11 000

Grinding disc dia., max. [mm] 100 100 115 115

Grinder spindle thread M 10 M 10 M 14 M 14

Constant Electronic Control – – – –

Speed Preselection – ● – ●

Weight without cable, approx. [kg] 1.4 1.4 1.4 1.4

Protection class / II / II / II / II

Angle Grinder GWS …

PROFESSIONAL

8-100 C 8-100 CE 8-115 C/

8-125 C

8-115 CE/

8-125 CE

Order number 0 601 377 ... 0 601 378 ... 0 601 377 ... 0 601 378 ...

Rated input power* [W] 850 850 850 850

Output power* [W] 490 490 490 490

No-load speed [rpm] 11 000 2 800 –

11 000

11 000 2 800 –

11 000

Grinding disc dia., max. [mm] 100 100 115/125 115/125

Grinder spindle thread M 10 M 10 M 14 M 14

Constant Electronic Control ● ● ● ●

Speed Preselection – ● – ●

Weight without cable, approx. [kg] 1.5 1.5 1.5 1.5

Protection class / II / II / II / II

Please observe the order number of your machine. The trade names of the individual machines may vary.

* The values given are valid for nominal voltages [U] of 230/240 V. For lower voltages and models for specific countries,

these values can vary.

Speed Preselection

(GWS 6-100 E, GWS 6-115 E, GWS 8-100 CE, GWS 8-115 CE, GWS 8-125 CE)

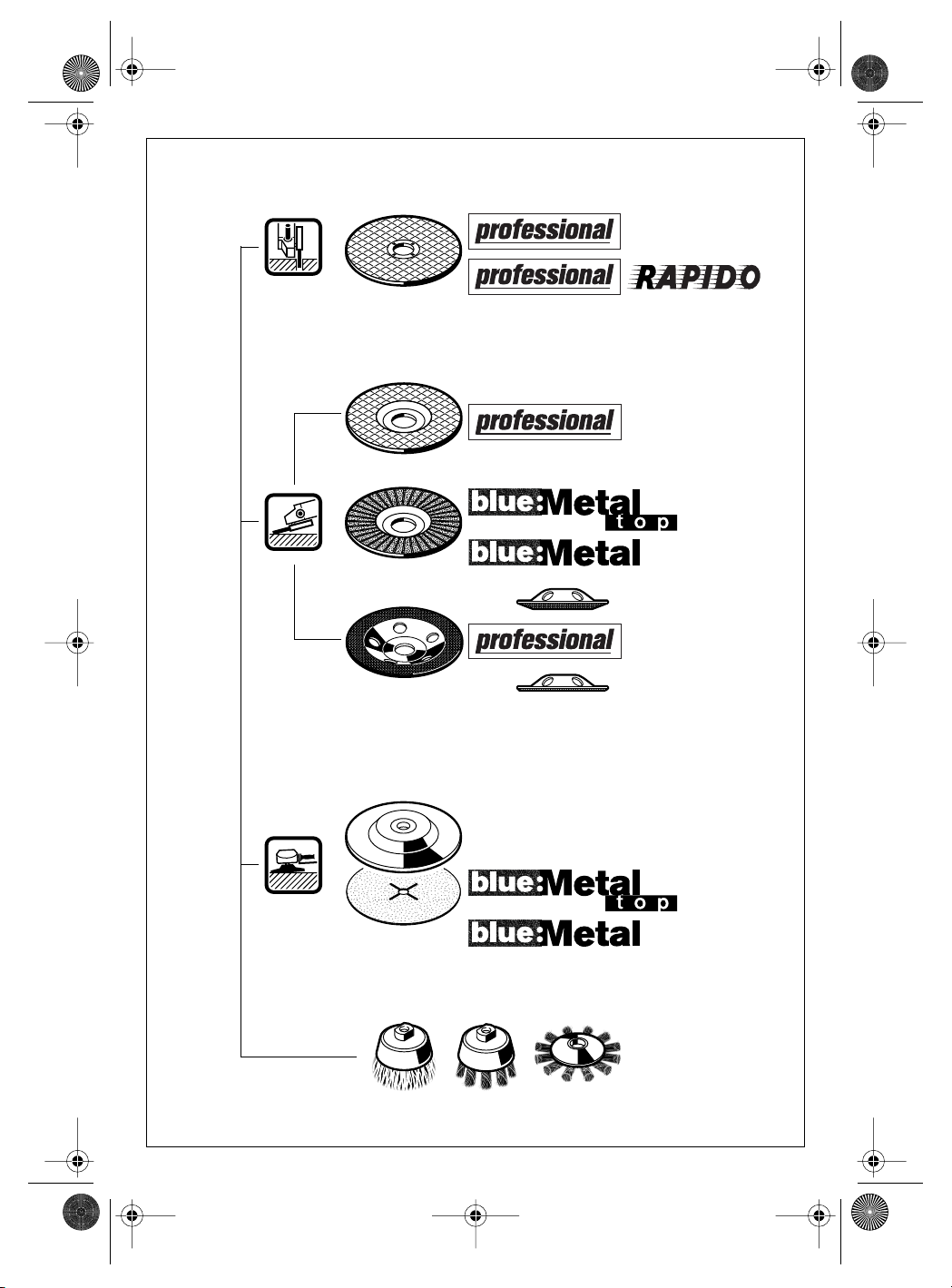

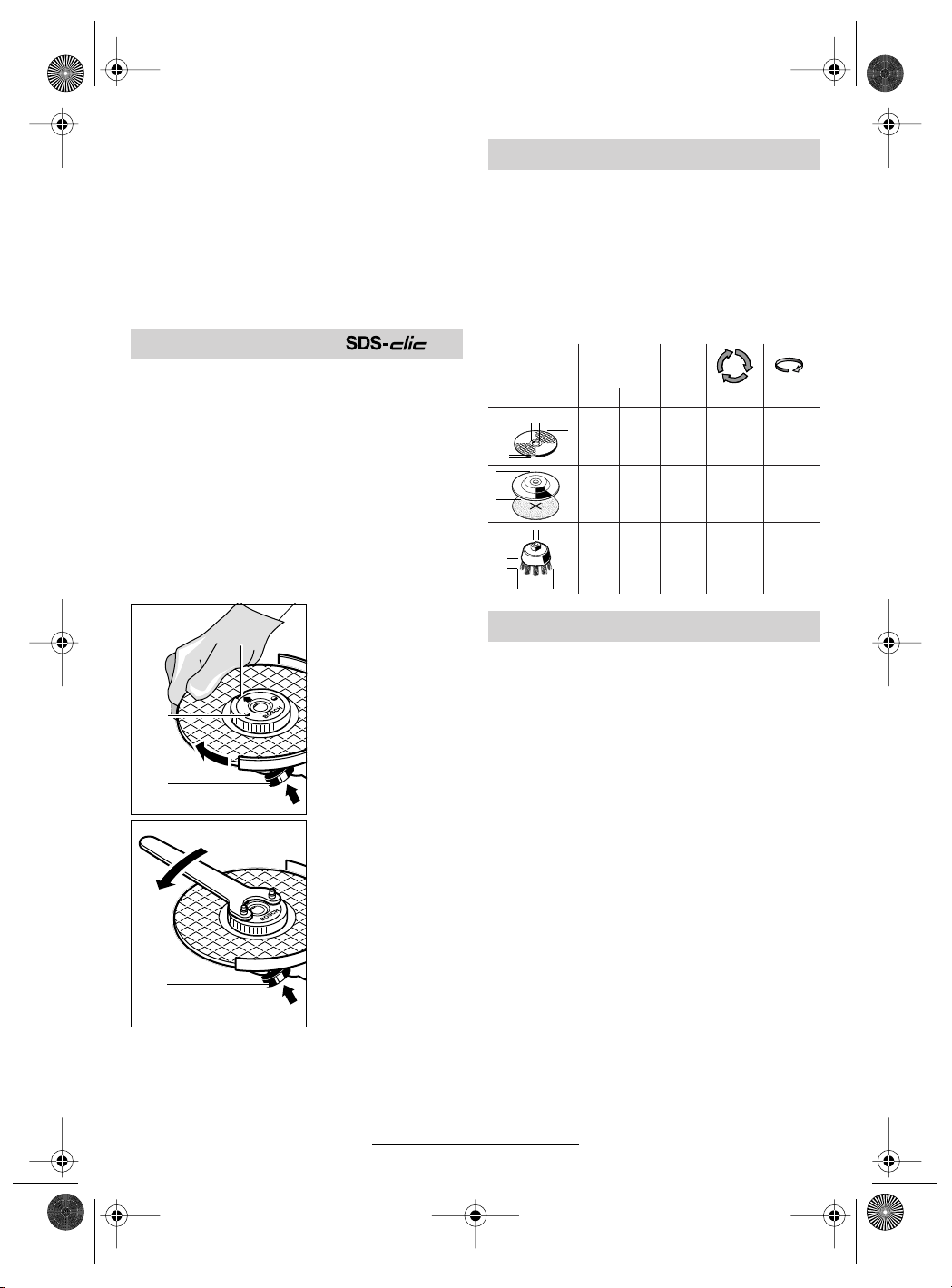

Material Application Tool Thumbwheel

Plastic Polishing Lamb’s wool hood 1

Finish polishing Felt polishing disk 1

Metal Finish grinding Buffing disk 1

Removing paint Sanding sheet 2 – 3

Wood, Metal Brushing, Removing rust Cup brush, sanding sheet 3

Metal, Stone Grinding Grinding disk 4 – 6

Metal Roughing Grinding disc 6

13 • 2 609 140 081 • TMS • 15.01.04

English - 1

Page 6

2 609 140 081 - Buch Seite 2 Dienstag, 20. Januar 2004 8:52 08

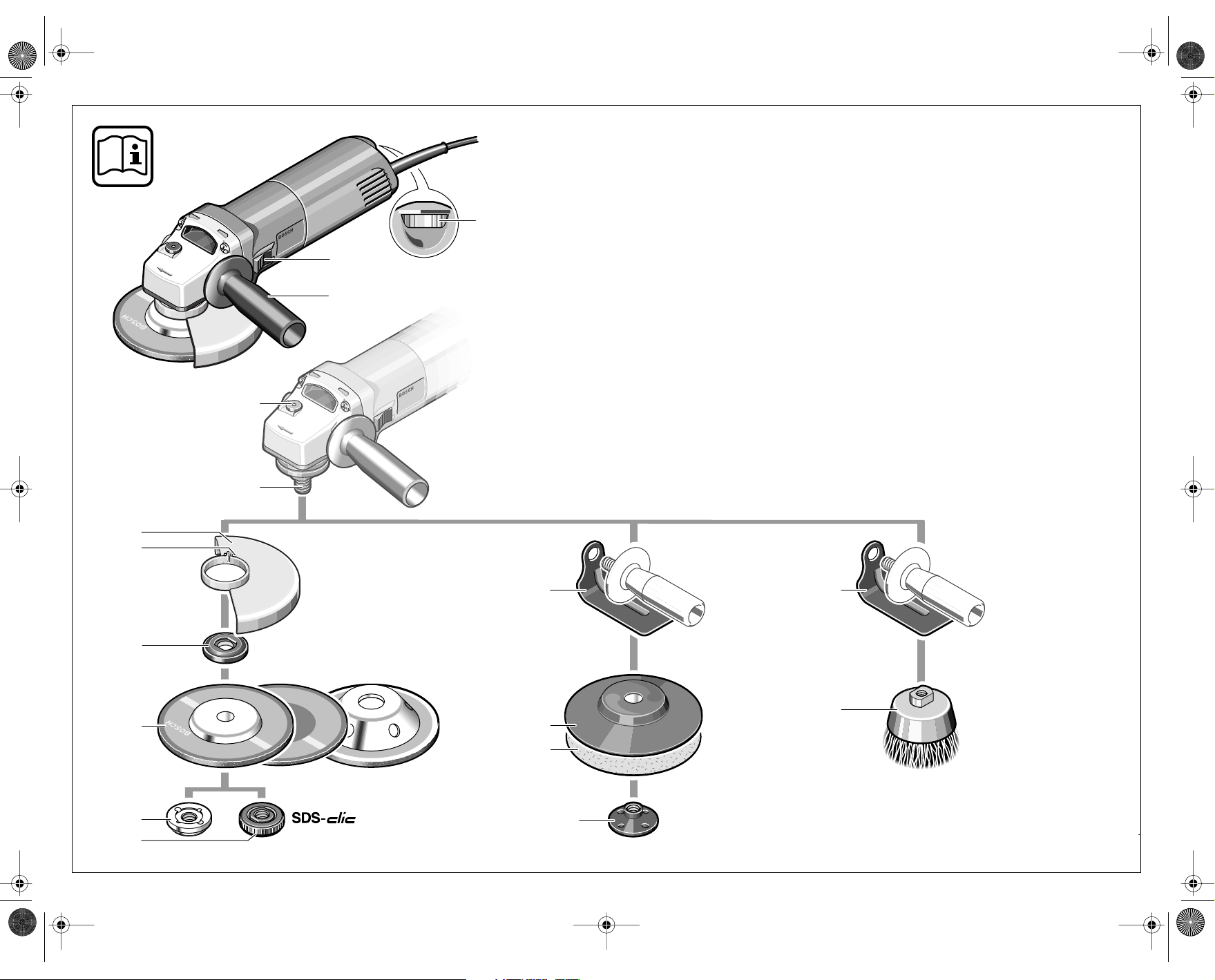

Machine Elements

The numbering of the device elements refers to

the illustration of the machine on the graphics

page.

While reading the operating instructions, unfold

the graphics page for the device and leave it

open.

1 Thumbwheel for speed preselection

(GWS 6-100 E, GWS 6-115 E,

GWS 8-100 CE, GWS 8-115 CE,

GWS 8-125 CE)

2 On/Off switch

3 Auxiliary handle

4 Spindle lock button

5 Grinder spindle

6 Protection guard

7 Screw

8 Mounting flange

(for the M 14 grinding spindle with O-ring)

9 Grinding-/cutting disc*

10 Clamping nut

11 quick-clamping nut*

(for M 14 grinder spindle)

12 Hand guard*

13 Rubber sanding plate*

14 Sanding sheet*

15 Round nut*

16 Cup brush*

17 Mounting flange M 10

* Not all of the accessories illustrated or described are

included as standard delivery.

Noise/Vibration Information

Measured values determined according to

EN 50 144.

Typically the A-weighted noise levels of the machine are: Sound pressure level: 89 dB (A);

sound power level: 102 dB (A).

Wear hearing protection!

The typically weighted acceleration is 5.0 m/s

2

.

Intended Use

The machine is intended for cutting, roughing and

brushing metal and stone materials without using

water. For cutting stone, a cutting guide is required.

For machines with electronic control: With approved sanding tools, the machine can be used

for sanding and polishing.

Information on Structures

Slots in structural walls are subject to the Standard DIN 1053, Part 1 or country-specific regulations.

These regulations are to be observed under all

circumstances. Before beginning work, consult

the responsible structural engineer, architects or

the construction supervisor.

For Your Safety

Working safely with this machine is possible only when the

operating and safety information

are read completely and the instructions contained therein are

strictly followed. In addition, the

general safety notes in the enclosed booklet

must be observed. Before using for the first

time, ask for a practical demonstration.

■ Wear protective glasses and hearing protec-

tion.

■ Wear additional protection equipment for your

safety, such as protective gloves, sturdy

shoes, hard hat and apron.

■ The dust that is produced while working can be

detrimental to health, inflammable or explosive. Suitable safety measures are required.

Examples: Some dusts are regarded as carcinogenic. Use suitable dust/chip extraction and

wear a dust respirator.

■ Dust from light alloys can burn or explode. Al-

ways keep the workplace clean, as blends of

materials are particularly dangerous.

■ If the mains cable is damaged or cut through

while working, do not touch the cable but immediately pull the mains plug. Never use the

machine with a damaged cable.

14 • 2 609 140 081 • TMS • 15.01.04

English - 2

Page 7

2 609 140 081 - Buch Seite 3 Dienstag, 20. Januar 2004 8:52 08

■ Connect machines that are used in the open

via a residual current device (RCD) with an actuating current of 30 mA maximum. Do not operate the machine in rain or moisture.

■ When working with the machine, always hold it

firmly with both hands and provide for a secure

stance.

■ Secure the workpiece. A workpiece clamped

with clamping devices or in a vice is held more

secure than by hand.

■ Always direct the cable to the rear away from

the machine.

■ Always switch the machine off and wait until it

has come to a standstill before placing it down.

■ For power outage or when the mains plug is

pulled, unlock the On/Off switch immediately

and turn it to the off position. This prevents uncontrolled restarting.

■ The machine must be used only for dry cutting /

grinding.

■ For all work with the machine, the auxiliary

handle must be mounted.

■ Hold the power tool only by the insulated

gripping surfaces, when performing an operation where the cutting tool may run into

hidden wiring or its own cord.

Contact with a “live” wire will make exposed

metal parts of the tool “live” and shock the operator.

■ Use appropriate detectors to determine if

utility lines are hidden in the work area or

call the local utility company for assistance.

Contact with electric lines can lead to fire and

electric shock. Damaging a gas line can lead

to explosion. Penetrating a water line causes

property damage or may cause an electric

shock.

■ For work with grinding or cutting discs, the protection guard 6 must be mounted. For work

with the rubber sanding plate 13 or with the

cup brush 16/disc brush/flap disc, the hand

guard 12 (accessory) is to be mounted.

■ Use dust extraction when working with stone.

The vacuum cleaner must be approved for masonry dust. When cutting stone, use the cutting

guide.

■ Do not work with materials containing asbestos.

■ Use only grinding tools with a permissible

speed at least as high as the no-load speed of

the machine.

■ Check grinding tools before use. The grinding

tool must be properly mounted and turn freely.

Perform a test run for at least 30 seconds without load. Do not use damaged, out-of-round or

vibrating grinding tools.

■ Protect the grinding tool from impact, shock

and grease.

■ Apply the machine to the workpiece only when

switched on.

■ Keep hands away from rotating grinding tools.

■ Pay attention to the direction of rotation. Al-

ways hold the machine so that sparks and

grinding dust fly away from the body.

■ When grinding metal, flying sparks are produced. Take care that no persons are endangered. Due to danger of fire, no combustible

materials should be located in the vicinity

(spark flight zone).

■ Be careful when cutting grooves, e. g. in structural walls: See Information on Structures.

■ Blocking the cutting disc leads to jerking reaction forces on the machine. In this case switch

off the machine immediately.

■ Observe the dimensions of the grinding discs.

The hole diameter must fit mounting

flange 8 (M 14), 17 (M 10). Do not use any reducers or adapters.

■ Never use cutting discs for rough grinding. Do

not exert any lateral pressure on the cutting

discs.

■ Observe the manufacturer’s instructions for

mounting and using grinding tools.

■ Caution! The grinding tool runs on after the

machine is switched off.

■ Do not clamp the machine in a vice.

■ Never allow children to use the machine.

■ Bosch is only able to ensure perfect operation

of the machine if the original accessories intended for it are used.

15 • 2 609 140 081 • TMS • 15.01.04

English - 3

Page 8

2 609 140 081 - GB Seite 4 Dienstag, 20. Januar 2004 11:34 11

Mounting the

Protective Devices

■ Before any work on the machine itself, pull

the mains plug.

Protection Guard

■ For work with grinding or cutting discs, the protection guard 6 must be mounted.

Place the protection guard 6 on the spindle collar.

Adjust the position of the protection guard 6 to

the requirements of the work process. Clamp with

the screw 7.

The closed side of the protection guard 6

must always point to the operator.

Auxiliary Handle

■ For all work with the machine, the auxiliary

handle must be mounted.

Screw the auxiliary handle 3 on the right or left of

the machine head depending on the working

method.

Hand Guard

For work with the rubber sanding plate 13 or with

the cup brush 16/disc brush/flap disc, the hand

guard 12 (accessory) is to be mounted. The hand

guard 12 is fastened with the auxiliary handle 3.

Mounting the Grinding Tools

■ Before any work on the machine itself, pull

the mains plug.

Use only grinding tools with a permissible speed at least as high as the no-load

speed of the machine.

Grinding and cutting discs become very

hot while working; do not touch until

they have cooled.

■ Clean the grinder spindle and all parts to be

mounted. For clamping and loosening the

grinding tools, lock the grinder spindle 5 with

the spindle lock button 4.

Actuate the spindle lock button 4 only when

the grinder spindle is at a standstill!

Grinding-/Cutting Disc

■ Observe the dimensions of the grinding discs.

The hole diameter must fit mounting

flange 8 (M 14), 17 (M 10). Do not use any reducers or adapters.

For mounting, see the illustration page.

Screw on the clamping nut 10 and tighten with

the two-pin spanner (see Section “Quick Clamping Nut”).

Mounting flange for

grinding spindle

M 14

8

If the O-ring is missing or is damaged, it must

in all cases be replaced (Order No.

1 600 210 039) before the mounting flange 8 is

mounted.

17

After mounting the grinding tool and be-

☞

fore switching on, check that the grinding tool is correctly mounted and that it

can turn freely.

An O-ring (plastic

part) is inserted in

the mounting

flange 8 around the

spigot.

Mounting flange for

grinding spindle

M 10

The supporting

flange 17 can be

used on both sides.

Do not use any reducers or adapters.

Flap Disc

(for M 14 grinder spindle)

Depending on the application, remove the protection guard 6 and mount the hand guard 12. Place

the special mounting flange 8 (accessory, Order

No. 2 605 703 028) and the flap disc on the

grinder spindle 5. Screw on the clamping nut 10

and tighten with the two-pin spanner.

Rubber Sanding Plate 13

Depending on the application, remove the protection guard 6 and mount the hand guard 12.

For mounting, see the illustration page.

Screw on the round nut 15 and tighten with the

two-pin spanner.

16 • 2 609 140 081 • TMS • 15.01.04

English - 4

Page 9

2 609 140 081 - Buch Seite 5 Dienstag, 20. Januar 2004 8:52 08

Cup Brush 16/Disc Brush

(for M 14 grinder spindle)

Depending on the application, remove the protection guard 6 and mount the hand guard 12.

The grinding tool must be able to be screwed

onto the grinding spindle 5 until it rests firmly

against the grinder spindle flange at the end of

the grinder spindle threads. Tighten with an

open-end spanner.

Quick Clamping Nut

(for M 14 grinder spindle)

Instead of the clamping nut 10, the quick-clamping nut 11 (accessory) can be used. Grinding

tools can then be mounted without using tools.

The quick-clamping nut 11 may be used only

for grinding and cutting discs.

Use only a flawless, undamaged quick-clamping nut 11.

When screwing on, take care that the side

with printing does not point to the grinding

disc. The arrow must point to the index

mark 18.

Lock the grinder

18

11

spindle with the spindle lock button 4.

Tighten the quickclamping nut by

forcefully turning the

grinding disc in the

clockwise direction.

4

A properly tightened

undamaged, quickclamping nut can be

loosened by hand

turning the knurled

ring in anticlockwise

direction.

Never loosen a tight

quick-clamping nut

4

with pliers but use a

two-pin spanner. In-

sert the two-pin

spanner as shown in

the illustration.

Approved Grinding Tools

All grinding tools mentioned in this operating

manual instruction can be used.

The permissible speed [rpm] or the circumferential speed [m/s] of the grinding tools used must at

least match the values given in the table.

Therefore, always observe the permissible

rotational/circumferential speed on the label

of the grinding tool.

max.

[mm] [mm]

Db d[rpm] [m/s]

d

100

6

16.0

115

b

D

b

D

d

D

6

125

6

100

–

115

–

125

–

70753030M 10

22.2

22.2

–

–

–

M 14

11 000

11 000

11 000

11 000

11 000

11 000

11 000

11 0004545

80

80

80

80

80

80

Starting Operation

Observe correct mains voltage: The voltage of

the power source must agree with the voltage

specified on the nameplate of the machine.

Equipment marked with 230 V can also be connected to 220 V.

To start the machine, press the On/Off switch 2

forward.

To lock-on, press the On/Off switch 2 down at

the front until it engages.

To switch off the machine, release the On/Off

switch 2 or press the rear tip of it down.

Test run!

☞

Check the grinding tool before use. The

grinding tool must be properly mounted

and rotate freely. Perform a test run of at

least 30 seconds without load. Do not use

damaged, out-of-round or vibrating grinding tools.

17 • 2 609 140 081 • TMS • 15.01.04

English - 5

Page 10

2 609 140 081 - Buch Seite 6 Dienstag, 20. Januar 2004 8:52 08

Constant Electronic Control

(GWS 8-100 C, GWS 8-100 CE,

GWS 8-115 C, GWS 8-125 C,

GWS 8-125 CE)

Constant electronic control holds the speed constant at no-load and under load, and ensures uniform working performance.

Speed Preselection (GWS 6-100 E,

GWS 6-115 E, GWS 8-100 CE,

GWS 8-115 CE, GWS 8-125 CE)

Preselect the required speed using the thumb

wheel 1 according to the table following the section “Tool Specifications” (reference values).

Operating Instructions

■ Clamp the workpiece if it does not remain

stationary due to its own weight.

■ Do not strain the machine so heavily that it

comes to a standstill.

■ Grinding and cutting discs become very

hot while working; do not touch until they

have cooled.

Rough Grinding

The best roughing results are

achieved when setting the machine

at an angle of 30° to 40°. Move the

machine back and forth with moderate pressure. In this manner, the

workpiece will not become too hot,

does not discolour and no grooves

are formed.

Never use a cutting disc for roughing.

Flap Disc

With the flap disc (accessory), curved surfaces

and profiles (contour sanding) can be worked.

Flap discs have a considerably higher service life

than sanding sheets, lower noise level and lower

sanding temperatures.

Cutting

When cutting, do not press, jam or

oscillate the machine. Work with

moderate feed, adapted to the material being machined.

Do not reduce the speed of running

down cutting discs by applying

sideward pressure.

18 • 2 609 140 081 • TMS • 15.01.04

English - 6

The direction in

which the cutting is

performed is important.

The machine must

always work in an

up-grinding motion.

Therefore, never

move the machine in

the other direction!

Otherwise, the danger exists of it being

pushed uncon-

trolled out of the cut.

When cutting profiles and square pipes, it is best

to start with the smallest cross section.

Rotating the Machine Head

■ Before any work on the machine itself, pull

the mains plug.

The machine head

can be rotated with

respect to the machine housing in 90°

steps. In this manner,

the On/Off switch

can be brought to an

advantageous handling position for special working situations, e. g., for cutting

guide/cutting grinder stand (accessory) or for

left-handed persons.

Unscrew completely the four screws.

Rotate the machine head carefully and without

removing from the housing to the new position.

Screw in the screws again and tighten.

work with the cutting

Maintenance and Cleaning

■ Before any work on the machine itself, pull

the mains plug.

For safe and proper working, always keep

☞

the machine and the ventilation slots clean.

In extreme working conditions, conductive

dust can accumulate in the interior of the

machine when working with metal. The

protective insulation of the machine can be

degraded. The use of a stationary extraction system is recommended in such cases

as well as frequently blowing out the ventilation slots and installing a residual current

device (RCD).

Page 11

2 609 140 081 - Buch Seite 7 Dienstag, 20. Januar 2004 8:52 08

If the machine should fail despite the care taken

in manufacturing and testing procedures, repair

should be carried out by an after-sales service

centre for Bosch power tools.

In all correspondence and spare parts orders,

please always include the 10-digit order number

given on the nameplate of the machine.

WARNING! Important instructions for connecting a new 3-pin plug to the 2-wire cable.

The wires in the cable are coloured according to

the following code:

strain relief

To be fitted

live = brown

neutral = blue

connect the blue or brown wire to the

Do not

by qualified

professional only

earth terminal of the plug.

Important: If for any reason the moulded plug is

removed from the cable of this machine, it must

be disposed of safely.

Environmental Protection

Recycle raw materials instead of

disposing as waste

The machine, accessories and

packaging should be sorted for environmental-friendly recycling.

These instructions are printed on recycled paper

manufactured without chlorine.

The plastic components are labelled for categorized recycling.

Ireland

Beaver Distribution Ltd.

Greenhills Road

Tallaght-Dublin 24

✆ Service................................... +353 (0)1 / 414 9400

.................................................... +353 (0)1 / 459 8030

Fax

Australia

Robert Bosch Australia Ltd.

RBAU/SPT2

1555 Centre Road

P.O. Box 66 Clayton

3168 Clayton/Victoria

✆ ............................................... +61 (0)1 / 800 804 777

............................................... +61 (0)1 / 800 819 520

Fax

www.bosch.com.au

E-Mail: CustomerSupportSPT@au.bosch.com

New Zealand

Robert Bosch Limited

14-16 Constellation Drive

Mairangi Bay

Auckland

New Zealand

✆ ..................................................... +64 (0)9 / 47 86 158

..................................................... +64 (0)9 / 47 82 914

Fax

Service and Customer

Assistance

Exploded views and information on spare

parts can be found under:

www.bosch-pt.com

Great Britain

Robert Bosch Ltd. (B.S.C.)

P.O. Box 98

Broadwater Park

North Orbital Road

Denham-Uxbridge

Middlesex UB 9 5HJ

✆ Service............................ +44 (0) 18 95 / 83 87 82

✆ Advice line .................... +44 (0) 18 95 / 83 87 91

............................................. +44 (0) 18 95 / 83 87 89

Fax

19 • 2 609 140 081 • TMS • 15.01.04

English - 7

Declaration of Conformity

We declare under our sole responsibility that this

product is in conformity with the following standards or standardization documents: EN 50 144

according to the provisions of the directives

89/336/EEC, 98/37/EC.

Dr. Egbert Schneider Dr. Eckerhard Strötgen

Senior Vice President Head of Product

Engineering Certification

Robert Bosch GmbH, Geschäftsbereich Elektrowerkzeuge

Subject to change without notice

Page 12

2 609 140 081 - Buch Seite 1 Dienstag, 20. Januar 2004 8:52 08

Características técnicas

Amoladora GWS …

6-100 6-100 E 6-115 6-115 E

PROFESSIONAL

Número de pedido 0 601 375 0.. 0 601 375 7.. 0 601 375 0.. 0 601 375 7..

Potencia absorbida nominal* [W] 670 670 670 670

Potencia útil* [W] 400 400 400 400

Revoluciones en vacío [min-1] 11 000 2 800 –

11 000

11 000 2 800 –

11 000

Ø de discos de amolar, máx. [mm] 100 100 115 115

Rosca del husillo M 10 M 10 M 14 M 14

Electrónica Constante – – – –

Preselección de revoluciones – ● – ●

Peso sin cable de red, aprox. [kg] 1,4 1,4 1,4 1,4

Clase de protección / II / II / II / II

Amoladora GWS …

PROFESSIONAL

8-100 C 8-100 CE 8-115 C/

8-125 C

8-115 CE/

8-125 CE

Número de pedido 0 601 377 ... 0 601 378 ... 0 601 377 ... 0 601 378 ...

Potencia absorbida nominal* [W] 850 850 850 850

Potencia útil* [W] 490 490 490 490

Revoluciones en vacío [min-1] 11 000 2 800 –

11 000

11 000 2 800 –

11 000

Ø de discos de amolar, máx. [mm] 100 100 115/125 115/125

Rosca del husillo M 10 M 10 M 14 M 14

Electrónica Constante ● ● ● ●

Preselección de revoluciones – ● – ●

Peso sin cable de red, aprox. [kg] 1,5 1,5 1,5 1,5

Clase de protección / II / II / II / II

Preste atención al nº de pedido de su máquina. Las denominaciones comerciales en ciertas máquinas pueden variar.

* Indicaciones válidas para tensiones nominales [U] de 230/240 V. Estas indicaciones pueden variar para tensiones

menores y en algunas ejecuciones para ciertos países.

Preselección de revoluciones

(GWS 6-100 E, GWS 6-115 E, GWS 8-100 CE, GWS 8-115 CE, GWS 8-125 CE)

Material Aplicación Útil Rueda de ajuste

Material sintético Pulido Caperuza de lana de oveja 1

Lijado fino Disco pulidor de fieltro 1

Metal Lijado fino Disco de paño para pulir 1

Decapado Hoja lijadora 2 – 3

Madera, metal Cepillado, desoxidación Cepillo de vaso, hoja lijadora 3

Metal, piedra Amolado Disco de amolar 4 – 6

Metal Desbastado Disco amolador 6

28 • 2 609 140 081 • TMS • 15.01.04

Español - 1

Page 13

2 609 140 081 - Buch Seite 2 Dienstag, 20. Januar 2004 8:52 08

Elementos del aparato

La numeración de los elementos del aparato está

referida a su imagen en la página ilustrada.

Despliegue y mantenga abierta la solapa con la

imagen del aparato mientras lee las instrucciones de manejo.

1 Rueda preselectora de revoluciones

(GWS 6-100 E, GWS 6-115 E,

GWS 8-100 CE, GWS 8-115 CE,

GWS 8-125 CE)

2 Interruptor de conexión/desconexión

3 Empuñadura adicional

4 Botón de bloqueo de husillo

5 Husillo

6 Caperuza protectora

7 Tornillo

8 Brida de apoyo (con junta anular en husillos

portamuelas de rosca M 14)

9 Disco amolador/tronzador*

10 Tuerca de fijación

11 Tuerca de fijación rápida *

(para husillo con rosca M 14)

12 Protección para las manos*

13 Plato lijador de goma*

14 Hoja lijadora*

15 Tuerca tensora*

16 Cepillo de vaso*

17 Brida de apoyo M 10

* Los accesorios descritos e ilustrados no correspon-

den en parte al material que se adjunta de serie.

Información sobre ruidos y

vibraciones

Determinación de los valores de medición según

norma EN 50 144.

El nivel de ruido típico del aparato corresponde a:

nivel de presión de sonido 89 dB (A); nivel de potencia de sonido 102 dB (A).

¡Usar protectores auditivos!

El nivel de vibraciones típico es de 5,0 m/s

2

.

Utilización reglamentaria

El aparato ha sido proyectado para tronzar, desbastar y cepillar metales y materiales de piedra

sin la aportación de agua. Al tronzar piedra es

obligatorio utilizar el soporte guía.

En aparatos dotados de un control electrónico:

siempre que se utilicen con los útiles autorizados

para ello pueden usarse también para amolar y

pulir.

Indicaciones concernientes a la

estática

Las ranuras en paredes portantes deben practicarse conforme a la norma DIN 1053 parte 1, o

bien, de acuerdo a las disposiciones específicas

de cada país.

Es imperativo atenerse a estas disposiciones.

Antes de iniciar el trabajo debe consultarse al

aparejador, arquitecto o los responsables de la

dirección de obras.

Para su seguridad

Solamente puede trabajar sin peligro con el aparato si lee ínte-

gramente las instrucciones de

manejo y las indicaciones de seguridad, ateniéndose estricta-

mente a las recomendaciones

allí comprendidas. Adicionalmente deberán

respetarse las instrucciones de seguridad generales comprendidas en el folleto adjunto.

Déjese instruir prácticamente en el manejo

antes de la primera aplicación.

■ Llevar gafas de protección y protectores audi-

tivos.

■ Para su seguridad, emplee además otros ele-

mentos de protección como guantes de protección, calzado fuerte, casco y mandil.

■ El polvo producido al trabajar puede ser no-

civo para la salud, combustible o explosivo.

Ello requiere tomar unas medidas de protección adecuadas.

Por ejemplo: Ciertos tipos de polvo son cancerígenos. Emplear un equipo de aspiración

para polvo y virutas adecuado, y colocarse

una mascarilla antipolvo.

■ El polvo de aleaciones ligeras puede infla-

marse o explotar. Mantener siempre limpio el

puesto de trabajo, puesto que al mezclarse el

polvo de diferentes materiales, éstos pueden

resultar especialmente peligrosos.

29 • 2 609 140 081 • TMS • 15.01.04

Español - 2

Page 14

2 609 140 081 - Buch Seite 3 Dienstag, 20. Januar 2004 8:52 08

■ Si llega a dañarse o cortarse el cable de red du-

rante el trabajo, no tocar el cable, sino extraer

inmediatamente el enchufe de la red. No usar

jamás el aparato con un cable deteriorado.

■ Conectar los aparatos utilizados en la intemperie a través de un fusible diferencial con una

corriente de disparo máxima de 30 mA. No exponer el aparato a la lluvia o humedad.

■ Trabajar siempre con el aparato sujetándolo

firmemente con ambas manos y manteniendo

una posición estable.

■ Asegure la pieza de trabajo. Una pieza de

trabajo fijada con unos dispositivos de sujeción, o en un tornillo de banco, se mantiene

sujeta de forma mucho más segura que con la

mano.

■ Mantener el cable siempre detrás del aparato.

■ Siempre desconectar y esperar a que se de-

tenga el aparato, antes de depositarlo.

■ En caso de un corte del fluido eléctrico, o al ex-

traer directamente el enchufe de red, desenclavar inmediatamente el interruptor de

conexión/desconexión y llevarlo a la posición

de desconexión. De esta manera se evita un

arranque accidental.

■ El aparato debe utilizarse solamente para el

tronzado y amolado en seco.

■ Trabajar siempre con la empuñadura adicional

montada en el aparato.

■ Únicamente sujetar la herramienta eléc-

trica por las empuñaduras aisladas en

caso de que el útil pudiera llegar a dañar un

conductor oculto o el propio cable de red

del aparato.

El contacto con un conductor portador de tensión pone bajo tensión las partes metálicas del

aparato pudiendo causar una descarga al

usuario.

■ Utilice unos instrumentos de exploración

adecuados para detectar tuberías y cables

ocultos, o consulte a su compañía abastecedora local.

El contacto con cables eléctricos puede provocar un incendio o sacudida eléctrica. El deterioro de tuberías de gas puede producir una

explosión. La perforación de una tubería de

agua puede causar daños materiales o una

sacudida eléctrica.

■ Al trabajar con discos amoladores o tronzadores deberá montarse la caperuza protectora 6.

Al trabajar con el plato lijador de goma 13, con

el cepillo de vaso 16, un cepillo de disco, o un

disco lijador segmentado, deberá montarse la

protección para las manos 12 (accesorio especial).

■ Al trabajar piedra emplear un sistema para aspiración de polvo. El aspirador debe estar homologado para aspirar polvo de piedra. Al

tronzar piedra debe utilizarse un soporte guía.

■ No deben trabajarse materiales que contengan amianto.

■ Emplear solamente útiles cuyas revoluciones

admisibles sean como mínimo iguales a las revoluciones en vacío del aparato.

■ Comprobar los útiles antes de su uso. El útil de

amolar debe estar perfectamente montado y

debe girar sin rozar en ningún lado. Efectuar

un funcionamiento de prueba dejándolo girar

en vacío durante 30 segundos como mínimo.

No utilizar los útiles de amolar si están daña-

dos, si giran de forma descentrada o vibran.

■ Proteger el útil de amolar de los golpes, cho-

ques y de la grasa.

■ Aproximar el aparato a la pieza solamente estando conectado.

■ Mantenga alejadas sus manos de los útiles de

amolar en funcionamiento.

■ Observar el sentido de giro. Sujetar siempre el

aparato de manera que las chispas y las partí-

culas producidas al trabajar sean lanzadas en

dirección contraria al cuerpo.

■ Al lijar metales se proyectan chispas. Prestar

atención a que no sean lanzadas contra personas. Por el peligro de incendio existente no

deben encontrarse materiales inflamables en

las proximidades (área de alcance de las chispas).

■ Tenga precaución al practicar ranuras, p. ej.

en paredes portantes: véase “Indicaciones

concernientes a la estática”.

■ Si el disco tronzador llegase a bloquearse repentinamente se obtiene un par de reacción

brusco en el aparato. En estos casos debe

desconectarse inmediatamente el aparato.

■ Considerar las dimensiones de los discos de

amolar. El diámetro del orificio debe ser el

adecuado a la brida de apoyo 8 (M 14),

17 (M 10). No emplear piezas de reducción o

adaptadores.

■ Jamás desben emplearse los discos tronzado-

res para desbastar. No ejercer una fuerza lateral sobre los discos tronzadores.

■ Atenerse a las instrucciones del fabricante al

montar y aplicar el útil.

30 • 2 609 140 081 • TMS • 15.01.04

Español - 3

Page 15

2 609 140 081 - Buch Seite 4 Dienstag, 20. Januar 2004 8:52 08

■ ¡Atención! El útil continúa funcionando por

inercia después de desconectar el aparato.

■ No sujetar el aparato en un tornillo de banco.

■ Jamás permita que los niños utilicen el apa-

rato.

■ Bosch solamente puede garantizar el funcionamiento correcto del aparato si se utilizan los

accesorios originales previstos.

Montaje de los

dispositivos protectores

■ Antes de cualquier manipulación en el apa-

rato extraer el enchufe de la red.

Caperuza protectora

■ Al trabajar con discos amoladores o tronzadores deberá montarse la caperuza protectora 6.

Introducir la caperuza protectora 6 sobre el cuello del husillo. La posición de la caperuza protectora 6 debe adaptarse a los requerimientos del

trabajo. Sujetarla con el tornillo 7.

El lado cerrado de la caperuza protectora 6

debe mostrar siempre hacia el usuario.

Empuñadura adicional

■ Trabajar siempre con la empuñadura adi-

cional montada en el aparato.

Enroscar la empuñadura adicional 3 a la derecha

o izquierda del cabezal del aparato dependiendo

del trabajo que vaya a realizarse.

Protección para las manos

Al trabajar con el plato lijador de goma 13, con el

cepillo de vaso 16, un cepillo de disco, o un disco

lijador segmentado, deberá montarse la protección para las manos 12 (accesorio especial). La

protección para las manos 12 se sujeta junto con

la empuñadura adicional 3.

Montaje de los útiles

■ Antes de cualquier manipulación en el apa-

rato extraer el enchufe de la red.

Emplear solamente útiles cuyas revoluciones admisibles sean como mínimo

iguales a las revoluciones en vacío del

aparato.

Los discos amoladores o tronzadores

se calientan mucho al trabajar con

ellos; esperar a que se hayan enfriado

antes de tocarlos.

■ Limpiar el husillo y todas las partes a montar.

Para apretar y aflojar los útiles retener el husillo 5 presionando el botón de bloqueo del husillo 4.

¡Accionar el botón de bloqueo del husillo 4

solamente con el husillo detenido!

Disco amolador/tronzador

■ Considerar las dimensiones de los discos de

amolar. El diámetro del orificio debe ser el

adecuado a la brida de apoyo 8 (M 14),

17 (M 10). No emplear piezas de reducción o

adaptadores.

Realizar el montaje según la hoja ilustrada.

Enroscar la tuerca de fijación 10 y apretarla con

la llave de dos pivotes (ver apartado “Tuerca de

fijación rápida”).

Brida de apoyo

para husillo portamuelas M 14

8

Si la junta anular faltase o estuviese dañada,

es imprescindible montar una junta nueva (nº de

pedido 1 600 210 039) antes de emplear la brida

de apoyo 8.

17

Después de montar el útil de amolar,

☞

debe verificarse si éste está correctamente montado y si gira sin rozar, antes

de conectar el aparato.

El cuello de centrado

de la brida de

apoyo 8 lleva una

junta anular (pieza

de plástico).

Brida de apoyo

para husillo portamuelas M 10

La brida de apoyo 17

puede usarse por

ambas caras.

No emplear piezas

de reducción o adaptadores.

31 • 2 609 140 081 • TMS • 15.01.04

Español - 4

Page 16

2 609 140 081 - Buch Seite 5 Dienstag, 20. Januar 2004 8:52 08

Disco lijador segmentado

(plato pulidor de fibra)

(para husillo con rosca M 14)

Para ciertas aplicaciones deberá desmontarse la

caperuza protectora 6 y montar la protección

para las manos 12. Montar la brida de apoyo especial 8 (accesorio especial, nº de pedido

2 605 703 028) y el disco lijador segmentado sobre el husillo portamuelas 5. Enroscar la tuerca

de fijación 10 y apretarla con la llave de dos pivotes.

Plato lijador de goma 13

Para ciertas aplicaciones deberá desmontarse la

caperuza protectora 6 y montar la protección

para las manos 12.

Realizar el montaje según la hoja ilustrada.

Enroscar la tuerca tensora 15 y apretarla con la

llave de dos pivotes.

Cepillo de vaso 16/cepillo de disco

(para husillo con rosca M 14)

Para ciertas aplicaciones deberá desmontarse la

caperuza protectora 6 y montar la protección

para las manos 12.

El útil tiene que poder enroscarse a una profundidad suficiente en el husillo 5 para que asiente

firmemente contra la brida del husillo que se encuentra al final de la rosca del husillo. Apretar el

útil con la llave fija.

Tuerca de fijación rápida

(para husillo con rosca M 14)

En lugar de la tuerca de fijación 10 puede emplearse la tuerca de fijación rápida 11 (accesorio

especial). Los útiles de amolar pueden montarse

entonces sin precisar un útil adicional.

Solamente deberá emplearse la tuerca de fijación rápida 11 para sujetar discos amoladores y tronzadores.

Utilizar únicamente una tuerca de fijación rápida 11 en perfecto estado.

Al montar la tuerca, prestar atención a que la

cara que lleva la inscripción no asiente sobre

el disco de amolar; la flecha debe encontrarse además sobre la marca índice 18.

Retener el husillo

18

11

portamuelas presionando el botón de

bloqueo del husillo 4.

Apretar la tuerca de

fijación rápida girando con fuerza el

disco de amolar en el

sentido de las agujas

del reloj.

4

Una tuerca de fijación rápida sin dañar,

correctamente montada, se deja aflojar a

mano girando el anillo moleteado en sentido contrario a las

agujas del reloj.

No intentar aflojar

4

nunca con una tenaza una tuerca de

fijación rápida bloqueada, sino con la

llave de dos pivotes. Aplicar la llave

de dos pivotes según

se muestra en la figura.

32 • 2 609 140 081 • TMS • 15.01.04

Español - 5

Page 17

2 609 140 081 - Buch Seite 6 Dienstag, 20. Januar 2004 8:52 08

Útiles admisibles

Pueden emplearse todos los útiles mencionados

en estas instrucciones de manejo.

Las revoluciones [min

rica [m/s] admisibles en los útiles deben corresponder, como mínimo, a los valores indicados en

la tabla.

Deben considerarse por lo tanto siempre las re-

voluciones/velocidad periférica admisibles

marcadas sobre la etiqueta de los útiles.

d

100

115

D

b

D

b

D

125

100

115

125

d

70753030M 10

-1

] o velocidad perifé-

máx.

[mm] [mm]

Db d[min

6

16,0

22,2

22,2

–

–

–

M 14

11 000

11 000

11 000

11 000

11 000

11 000

11 000

11 0004545

6

6

–

–

–

-1

] [m/s]

80

80

80

80

80

80

Puesta en servicio

Cerciorarse de que la tensión de la red sea

correcta: La tensión de la fuente de energía

debe coincidir con las indicaciones en la placa de

características del aparato. Los aparatos marcados con 230 V pueden funcionar también a

220 V.

Para la puesta en marcha del aparato desplazar

hacia adelante el interruptor de conexión/desco-

nexión 2.

Para enclavar el interruptor de conexión/desconexión 2 presionarlo adelante hasta enclavarlo.

Para desconectar el aparato soltar, o presionar

atrás si se encuentra enclavado, el interruptor de

conexión/desconexión 2.

¡Funcionamiento de prueba!

☞

Comprobar los útiles antes de su uso. El

útil debe estar perfectamente montado y

debe girar sin rozar en ningún lado. Efectuar un funcionamiento de prueba deján-

dolo girar en vacío durante 30 segundos

como mínimo. No utilizar los útiles si están

dañados, si giran de forma descentrada o

vibran.

Electrónica Constante (GWS 8-100 C,

GWS 8-100 CE, GWS 8-115 C,

GWS 8-125 C, GWS 8-125 CE)

La electrónica Constante mantiene práctica-

mente iguales las revoluciones en vacío y bajo

carga, garantizando así un rendimiento de trabajo constante.

Preselección de revoluciones

(GWS 6-100 E, GWS 6-115 E,

GWS 8-100 CE, GWS 8-115 CE,

GWS 8-125 CE)

Preseleccionar las revoluciones requeridas con

la rueda de ajuste 1 según indicaciones en la tabla que figura bajo “Características técnicas” (valores orientativos).

Instrucciones de trabajo

■ Sujetar la pieza de trabajo, a no ser que

quede bien firme por su propio peso.

■ No solicitar el aparato de manera que llegue a detenerse.

■ Los discos amoladores o tronzadores se

calientan mucho al trabajar con ellos; esperar a que se hayan enfriado antes de tocarlos.

Desbastado

Con ángulos de ataque de 30° a

40° se obtiene el mejor resultado al

desbastar. Guiar el aparato con

movimiento de vaivén ejerciendo

una presión moderada. Así, no se

produce un calentamiento excesivo

y se evita que la pieza de trabajo

cambie de color y que se marque

con estrías.

Jamás deben usarse discos tronzadores para desbastar.

Disco lijador segmentado

(plato pulidor de fibra)

Con el disco lijador segmentado (accesorio especial) pueden trabajarse también superficies

abombadas y perfiles (amolado de contornos).

Los discos lijadores segmentados tienen una duración notablemente mayor que las hojas lijadoras, generan un nivel de ruido menor, y calientan

menos la pieza al trabajar.

33 • 2 609 140 081 • TMS • 15.01.04

Español - 6

Page 18

2 609 140 081 - Buch Seite 7 Dienstag, 20. Januar 2004 8:52 08

Tronzado

Al tronzar, el disco no debe presionarse excesivamente ni ladearse,

ni guiarse con un movimiento oscilante. Trabajar con un avance moderado y adecuado al tipo de material a trabajar.

No frene los discos tronzadores en

marcha por inercia presionándolos

lateralmente contra el material.

Al tronzar es importante que el sentido

de avance de la má-

quina sea el correcto.

El aparato debe

guiarse siempre a

contramarcha,

¡nunca en sentido

opuesto! De lo contrario existe el riesgo

de que el aparato sea

rechazado bruscamente.

Al tronzar perfiles y tubos rectangulares se recomienda iniciar el corte por el lado más estrecho.

Giro del cabezal del aparato

■ Antes de cualquier manipulación en el apa-

rato extraer el enchufe de la red.

El cabezal del aparato puede montarse

girado en pasos de

90° respecto a la carcasa del aparato.

Ello permite situar al

interruptor de conexión/desconexión

en una posición más

cómoda al efectuar

trabajos especiales

como, p. ej., en operaciones de tronzado con un soporte guía/mesa

de tronzar (accesorios), o en caso de que el

usuario sea zurdo.

Desenroscar completamente los cuatro tornillos.

Girar el cabezal del aparato con cuidado, y sin

separarlo de la carcasa, hasta la nueva posición.

Enroscar nuevamente los tornillos, y apretarlos.

Mantenimiento y limpieza

■ Antes de cualquier manipulación en el apa-

rato extraer el enchufe de la red.

Mantener siempre limpios el aparato y las

☞

rejillas de refrigeración para poder trabajar

con seguridad.

En casos especiales puede ocurrir que se

acumule polvo metálico susceptible de

conducir electricidad en el interior del aparato. Ello puede llegar a mermar la protección de aislamiento del aparato. En estos

casos se recomienda la aplicación de un

equipo de aspiración estacionario, soplar

frecuentemente las rejillas de refrigeración, e intercalar un fusible diferencial.

Si a pesar de los esmerados procesos de fabricación y control, el aparato llegase a averiarse, la

reparación deberá encargarse a un taller de servicio autorizado para herramientas eléctricas

Bosch.

Al realizar consultas o solicitar piezas de repuesto, es imprescindible indicar siempre el nú-

mero de pedido de 10 dígitos que figura en la

placa de características del aparato.

34 • 2 609 140 081 • TMS • 15.01.04

Español - 7

Page 19

2 609 140 081 - Buch Seite 8 Dienstag, 20. Januar 2004 8:52 08

Protección del medio ambiente

Recuperación de materias primas en lugar de

producir desperdicios

El aparato, los accesorios y el embalaje debieran

someterse a un proceso de recuperación que

respete el medio ambiente.

Estas instrucciones se han impreso sobre papel

reciclado sin la utilización de cloro.

Para efectuar un reciclaje selectivo se han identificado las piezas de plástico.

Servicio técnico y asistencia al

cliente

Los dibujos de despiece e informaciones sobre las piezas de repuesto las encontrará en

internet bajo:

www.bosch-pt.com

España

Robert Bosch España, S.A.

Departamento de ventas

Herramientas Eléctricas

C/Hermanos García Noblejas, 19

28037 Madrid

✆ Asesoramiento al cliente.... +34 901 11 66 97

........................................................... +34 91 327 98 63

Fax

Venezuela

Robert Bosch S.A.

Final Calle Vargas. Edf. Centro Berimer P.B.

Boleita Norte

Caracas 107

✆ ..................................................... +58 (0)2 / 207 45 11

México

Robert Bosch S.A. de C.V.

✆ Interior:........................... +52 (0)1 / 800 627 1286

✆ D.F.:...................................... +52 (0)1 / 52 84 30 62

E-Mail: arturo.fernandez@mx.bosch.com

Argentina

Robert Bosch Argentina S.A.

Córdoba 5160

1414 Buenos Aires (Capital Federal)

Atención al Cliente

✆ ................................................. +54 (0)810 / 555 2020

E-Mail: herramientas.bosch@ar.bosch.com

Perú

Autorex Peruana S.A.

República de Panamá 4045,

Lima 34

✆ ...................................................... +51 (0)1 / 475-5453

E-Mail: vhe@autorex.com.pe

Chile

EMASA S.A.

Irarrázaval 259 – Ñuñoa

Santiago

✆ ....................................................... +56 (0)2 / 520 3100

E-Mail: emasa@emasa.cl

Declaración de conformidad

Declaramos bajo nuestra sola responsabilidad

que este producto está en conformidad con las

normas o documentos normalizados siguientes:

EN 50 144 de acuerdo con las regulaciones

89/336/CEE, 98/37/CE.

Dr. Egbert Schneider Dr. Eckerhard Strötgen

Senior Vice President Head of Product

Engineering Certification

Robert Bosch GmbH, Geschäftsbereich Elektrowerkzeuge

35 • 2 609 140 081 • TMS • 15.01.04

Reservado el derecho de modificaciones

Español - 8

Page 20

2 609 140 081 - Buch Seite 1 Dienstag, 20. Januar 2004 8:52 08

Dados técnicos do aparelho

Rebarbadora GWS …

6-100 6-100 E 6-115 6-115 E

PROFESSIONAL

Nº de encomenda 0 601 375 0.. 0 601 375 7.. 0 601 375 0.. 0 601 375 7..

Potência nominal consumida* [W] 670 670 670 670

Potência útil* [W] 400 400 400 400

Rotações em vazio [min-1] 11 000 2 800 –

11 000

11 000 2 800 –

11 000

Discos abrasivos-Ø, máx. [mm] 100 100 115 115

Rosca de veio de rectificação M 10 M 10 M 14 M 14

Constant-Electronic – – – –

Pré-selecção de número de

rotação

– ● – ●

Peso sem cabo de rede, aprox. [kg] 1,4 1,4 1,4 1,4

Classe de protecção / II / II / II / II

Rebarbadora GWS …

PROFESSIONAL

8-100 C 8-100 CE 8-115 C/

8-125 C

8-115 CE/

8-125 CE

Nº de encomenda 0 601 377 ... 0 601 378 ... 0 601 377 ... 0 601 378 ...

Potência nominal consumida* [W] 850 850 850 850

Potência útil* [W] 490 490 490 490

Rotações em vazio [min-1] 11 000 2 800 –

11 000

11 000 2 800 –

11 000

Discos abrasivos-Ø, máx. [mm] 100 100 115/125 115/125

Rosca de veio de rectificação M 10 M 10 M 14 M 14

Constant-Electronic ● ● ● ●

Pré-selecção de número de

rotação

– ● – ●

Peso sem cabo de rede, aprox. [kg] 1,5 1,5 1,5 1,5

Classe de protecção / II / II / II / II

Por favor observar o número de encomenda da sua máquina. A designação comercial de diversas máquinas pode variar.

* As indicações valem para tensões nominais de [U] 230/240 V. Estas indicações podem variar no caso de tensões mais

baixas e modelos específicos de países.

Pré-selecção de número de rotação

(GWS 6-100 E, GWS 6-115 E, GWS 8-100 CE, GWS 8-115 CE, GWS 8-125 CE)

Material Aplicação Ferramenta Roda de ajuste

Plástico Polir Boina de lã de codeiro 1

Lixamento fino Disco de feltro para polir 1

Metal Lixamento fino Disco de pano para polir 1

Retirar tinta Lixa 2 – 3

Madeira, metal Escovas, desenferrujar Escova tipo tacho, lixa 3

Metal, pedra Lixar Disco abrasivo 4– 6

Metal Desbastar Disco de lixar 6

36 • 2 609 140 081 • TMS • 15.01.04

Português - 1

Page 21

2 609 140 081 - Buch Seite 2 Dienstag, 20. Januar 2004 8:52 08

Elementos do aparelho

A numeração dos elementos do aparelho referese à apresentação do aparelho na página de gráficos.

Por favor abra a aba com a apresentação do

aparelho, e deixe a página aberta enquanto ler a

instrução de serviço.

1 Rodela de ajuste do número de rotações

(GWS 6-100 E, GWS 6-115 E,

GWS 8-100 CE, GWS 8-115 CE,

GWS 8-125 CE)

2 Interruptor de ligar/desligar

3 Punho adicional

4 Tecla de travamento de veio

5 Veio de rectificação

6 Capa de protecção

7 Parafuso

8 Flange de admissão (no caso do veio de

rectificação M 14 com O-Ring)

9 Disco de lixar/de corte*

10 Porca de aperto

11 Porca de aperto rápido *

(para veio de rectificação M 14)

12 Protecção para as mãos*

13 Prato de lixar de borracha*

14 Lixa*

15 Porca redonda*

16 Escova tipo tacho*

17 Flange de admissão M 10

* Os acessórios ilustrados e descritos nas instruções

de serviço nem sempre são abrangidos pelo conjunto

de fornecimento!

Informações sobre ruído e

vibrações

Valores de medida de acordo com EN 50 144.

O nível de ruído avaliado A do aparelho é tipica-

mente: Nível de pressão acústica 89 dB (A). Ní-

vel de potência acústica 102 dB (A).

Utilize protectores auriculares!

A aceleração avaliada é tipicamente de 5,0 m/s

Utilização de acordo com as

disposições

O aparelho é determinado para cortar, desbastar

e escovar materiais de metal e de pedra, sem utilizar água. Para cortar pedras é necessário utilizar um carril de guia.

No caso de aparelhos com comando electrónico:

Com ferramentas abrasivas admissíveis, também é possível utilizar o aparelho para lixar e polir.

Indicações sobre a estática

Aberturas em paredes portantes devem ser realizadas de acordo com a norma DIN 1053 parte 1

ou com as disposições do respectivo país.

É imprescindível seguir estas directivas. Antes

de iniciar o trabalho, deverá consultar o especialista em estática, o arquitecto ou os responsáveis

pela obra.

Para sua segurança

Um trabalho seguro com o aparelho só é possível após ter lido

completamente as instruções de

serviço e as indicações de segurança e após observar rigorosa-

das. Adicionalmente deverá seguir as indicações gerais de segurança que se encontram

no caderno em anexo. Uma instrução prática

é vantajosa.

■ Usar óculos de protecção e protecção para os

ouvidos.

■ Para a sua segurança, use também outros

utensílios de segurança pessoal, como por

exemplo luvas de protecção, sapatos firmes e

robustos, capacete e avental.

■ Durante o trabalho são produzidos pós que

podem ser nocivos à saúde, inflamáveis ou

explosivos. São necessárias medidas de protecção adequadas.

Por exemplo: Alguns pós são considerados

cancerígenos. Utilize uma apropriada aspiração de pó/aparas e use uma máscara de pro-

2

tecção contra pó.

.

■ Pó de metal leve pode queimar ou explodir.

Sempre manter o local de trabalho limpo, pois

misturas de material são extremamente perigosas.

■ Caso o cabo de rede for danificado ou cortado

durante o trabalho, não toque no cabo. Tire

imediatamente a ficha da tomada. Jamais utilizar o aparelho com um cabo danificado.

mente as indicações nelas conti-

37 • 2 609 140 081 • TMS • 15.01.04

Português - 2

Page 22

2 609 140 081 - Buch Seite 3 Dienstag, 20. Januar 2004 8:52 08

■ Aparelhos utilizados ao ar livre devem ser conectados através de um interruptor de protecção contra corrente residual com uma corrente

de activação de no máximo 30 mA. Não utilizar o aparelho na chuve ou em ambientes hú-

midos.

■ Ao trabalhar com o aparelho, segure-o sempre

com ambas as mãos e mantenha uma posição

firme.

■ Fixar a peça a ser trabalhada. Uma peça a

ser trabalhada fixa através de dispositivos de

fixação ou torno de bancada está mais fixo do

que quando segurado com a mão.

■ Conduzir o cabo sempre por detrás da má-

quina.

■ Sempre desligar o aparelho antes de depositá-la e aguardar até que o aparelho páre

completamente.

■ No caso de falha de corrente ou se fôr puxada

a tomada de corrente, deverá destravar imediatamente o interruptor de ligar/desligar e colocar na posição desligada. Isto evita um novo

arranque involuntário.

■ O aparelho só deve ser utilizado para cortes a

seco/polimento a seco.

■ O punho adicional deve ser montado durante

todos os trabalhos com o aparelho.

■ Apenas segurar a ferramenta eléctrica pe-

las superfícies de manuseio isoladas, caso

a ferramenta de utilização possa entrar em

contacto com uma tubulação escondida no

muramento ou o próprio cabo eléctrico.

O contacto com um cabo que conduz tensão

eléctrica, colocará sob tensão as partes de

metal expostas da ferramenta e pode levar a

um choque eléctrico.

■ Utilize aparelhos detectores apropriados

para detectar cabos de alimentação ou

peça apoio da sua firma de abastecimento.

O contacto com cabos eléctricos pode provocar incêndio e choque eléctrico. O dano de

uma linha de gás pode levar a uma explosão.

Uma perfuração de um tubo de água provoca

um dano material ou pode provocar um choque eléctrico.

■ Para trabalhos com discos de lixar ou de corte

é necessário que a capa de protecção 6 esteja

montada. Para trabalhos com o prato de lixar

de borracha 13 ou com a escova em forma de

tacho 16/escova em forma de disco/disco

abrasivo em forma de leque, é necessário

montar a protecção para as mãos 12 (acessó-

rio).

■ Use uma aspiração a vácuo para pó de pedras

ao trabalhar com as tais. O aspirador de pó

deve ser aprovado para aspirar pó de pedras.

Usar um carril de guia para cortar pedras.

■ Materiais que contém amianto não devem ser

trabalhados.

■ Apenas utilize ferramentas abrasivas, com um

número de rotações admissível que seja no

mínimo tão alto como o número de rotações

em vazio do aparelho.

■ Controlar as ferramentas abrasivas antes da

utilização. A ferramenta abrasiva deve estar

perfeitamente montada e deve poder girar livremente. Realizar um funcionamento de ensaio sem carga, durante no mínimo 30 segundos. Ferramentas abrasivas danificadas, descentradas ou vibrantes não devem ser

utilizadas.

■ Proteger as ferramentas abrasivas contra golpes, trepidações e gordura.

■ Só contactar a peça a ser trabalhada quando

o aparelho já estiver ligado.

■ Não toque nas ferramentas abrasivas em rota-

ção.

■ Observar o sentido de rotação. Sempre segu-

rar o aparelho de forma que faíscas ou pó de

lixar voem para longe do corpo.

■ Ao lixar metais voam faíscas. Observe que ne-

nhuma pessoa corra perigo. Devido ao perigo

de incêndio, não devem encontra-se materiais

inflamáveis nas proximidades (área de vôo de

faíscas).

■ Cuidado ao abrir cavidades p. ex. em paredes

portantes: Veja as indicações sobre a estática.

■ O aparelho reage com movimentos bruscos,

quando o disco de corte é bloqueado. Neste

caso o aparelho deve ser desligado imediatamente.

■ Observar as dimensões dos discos abrasivos.

O diâmetro do orifício deve ajustar-se à flange

de admissão 8 (M 14), 17 (M 10). Não utilizar

peças de redução ou adaptadores.

■ Jamais utilize discos de corte para desbastar.

Não pressionar lateralmente os discos de

corte.

■ Observe as indicações do fabricante sobre a

montagem e a aplicação da ferramenta abrasiva.

■ Cuidado! A lixa funciona por inércia após des-

ligar o aparelho.

■ Não fixar o aparelho com um torno de ban-

cada.

■ Jamais deverá permitir que crianças utilizem

este aparelho.

■ A Bosch só pode assegurar um funciona-

mento perfeito do aparelho, se para este aparelho foram utilizados acessórios originais previstos para tal.

38 • 2 609 140 081 • TMS • 15.01.04

Português - 3

Page 23

2 609 140 081 - Buch Seite 4 Dienstag, 20. Januar 2004 8:52 08

Montar os dispositivos

de protecção

■ Tirar a ficha da tomada antes do todos os

trabalhos no aparelho.

Capa de protecção

■ Para trabalhos com discos de lixar ou de corte

é necessário que a capa de protecção 6 esteja

montada.

Colocar a capa de protecção 6 sobre o colar do

fuso. A posição da placa de protecção 6 deve ser

ajustada às necessidades de trabalho. Fixá-la

com o parafuso 7.

O lado fechado da capa de protecção 6 deve

mostrar sempre para o operador.

Punho adicional

■ O punho adicional deve ser montado durante todos os trabalhos com o aparelho.

Aparafusar o punho adicional 3 de acordo com

as indicações de trabalho, no lado direito ou esquerdo da cabeça do aparelho.

Protecção para as mãos

Para trabalhos com o prato de lixar de borracha 13 ou com a escova em forma de tacho 16/

escova em forma de disco/disco abrasivo em

forma de leque, é necessário montar a protecção

para as mãos 12 (acessório). A protecção para

mãos 12 é fixada com o punho adicional 3.

Montar as ferramentas

abrasivas

■ Tirar a ficha da tomada antes do todos os

trabalhos no aparelho.

Apenas utilize ferramentas abrasivas,

com um número de rotações admissível

que seja no mínimo tão alto como o nú-

mero de rotações em vazio do aparelho.

Os discos de lixar e de corte tornam-se

muito quentes, não toque neles antes

de arrefecerem.

■ Limpar o veio de rectificação e todas as peças

a serem montadas. Para apertar e soltar as

ferramentas abrasivas, deverá fixar o veio de

rectificação 5 com a tecla de travamento de

veio 4.

Apenas accionar a tecla de travamento de

veio 4 com o veio de rectificação parado!

Disco de lixar/de corte

■ Observar as dimensões dos discos abrasivos.

O diâmetro do orifício deve ajustar-se à flange

de admissão 8 (M 14), 17 (M 10). Não utilizar

peças de redução ou adaptadores.

Informações sobre a montagem encontramse na página com figura.

Desaparafusar a porca de aperto 10 e apertar

com uma chave de dois furos (veja trecho “Porca

de aperto rápido”).

Flange de admissão para veio de

rectificação M 14

8

Caso o O-Ring estiver faltando ou estiver danificado, será imprescindível substituí-lo (N° de

encomenda 1 600 210 039), antes de montar a

flange de admissão 8.

17

Após montar a ferramenta abrasiva, de-

☞

verá controlar antes de ligar, se a ferramenta abrasiva está correctamente

montada e se pode girar livremente.

Na flange de admissão 8 encontra-se

um O-Ring (peça de

plástico) em torno da

gola de centragem.

Flange de admissão para veio de

rectificação M 10

A flange de admissão 17 pode ser utilizada de ambos os lados.

Não utilizar peças de

redução ou adaptadores.

Disco abrasivo em leque

(prato de tecido abrasivo)

(para veio de rectificação M 14)

De acordo com a aplicação, deverá retirar a capa

de protecção 6 e montar a protecção para as

mãos 12. Colocar a flange especial de

admissão 8 (acessório, n° de encomenda

2 605 703 028) e o disco abrasivo em leque

sobre o veio de rectificação 5. Aparafusar a

porca de aperto 10 apertar com a chave de dois

furos.

39 • 2 609 140 081 • TMS • 15.01.04

Português - 4

Page 24

2 609 140 081 - Buch Seite 5 Dienstag, 20. Januar 2004 8:52 08

Prato abrasivo de borracha 13

De acordo com a aplicação, deverá retirar a capa

de protecção 6 e montar a protecção para as

mãos 12.

Informações sobre a montagem encontramse na página com figura.

Aparafusar a porca redonda 15 e apertar a chave

de dois furos.

Escova tipo tacho 16/escova em disco

(para veio de rectificação M 14)

De acordo com a aplicação, deverá retirar a capa

de protecção 6 e montar a protecção para as

mãos 12.

Deve ser possível aparafusar a ferramenta abrasiva no veio de rectificação 5, de modo que esteja firme na flange do veio de rectificação na extremidade da rosca do veio de rectificação. Apertar com a chave de forqueta.

Porca de aperto rápido

(para veio de rectificação M 14)

Em vez da porca de aperto 10, também pode ser

utilizada uma porca de aperto rápido 11 (acessó-

rio). Desta forma também será possível montar

ferramentas abrasivas sem a necessidade de utilizar ferramentas.

A porca de aperto rápido 11 só deve ser utilizada para discos de lixar e de corte.

Apenas utilizar porcas de aperto rápido 11

em perfeito estado em que não apresentam

avarias.

Ao aparafusar, deverá observar que o lado

com a descrição não mostre no sentido do

disco abrasivo; a seta deve indicar no sentido

da marca de índice 18.

Fixar o veio de rectifi-

18

cação com a tecla de

travamento de

veio 4. Apertar a

porca de aperto rá-

pido girando firme-

11

mente o disco abrasivo no sentido dos

ponteiros do relógio.

4

Uma porca de aperto

rápido que não apresenta danos e que

está fixa de forma

correcta, pode ser

solta girando manualmente o anel serrilhado no sentido dos

ponteiros do relógio.

4

Jamais soltar com

um alicate, uma

porca de aperto rá-

pido que estiver

emperrada, mas

sim utilizar uma

chave de dois furos. Aplicar a chave

de dois furos, como

indicado na figura.

Ferramentas abrasivas

admissíveis

Podem ser utilizadas todas as ferramentas abrasivas mencionadas nesta instrução de serviço.

O número de rotações admissível [min

velocidade circunferencial [m/s] das ferramentas

abrasivas utilizadas deve corresponder no mí-

nimo às indicações na tabela.

Por este motivo deverá sempre observar o nú-

mero de rotações/velocidade circunferencial

indicados na etiqueta da respectiva ferramenta

abrasiva.

máx.

[mm] [mm]

Db d[min

d

100

6

115

D

b

D

125

100

115

125

d

b

D

70753030M 10

16,0

6

22,2

6

22,2

–

–

–

–

–

–

M 14

-1

] ou a

-1

] [m/s]

11 000

11 000

11 000

11 000

11 000

11 000

80

80

80

80

80

80

11 000

11 0004545

40 • 2 609 140 081 • TMS • 15.01.04

Português - 5

Page 25

2 609 140 081 - Buch Seite 6 Dienstag, 20. Januar 2004 8:52 08

Colocação em funcionamento

Tenha em atenção a tensão de rede: A tensão

da fonte de corrente deve coincidir com as indicações no logotipo do aparelho. Aparelhos com

a indicação de 230 V também podem ser operados com 220 V.

Para colocar em funcionamento o aparelho,

deverá empurrar o interruptor de ligar/desligar 2

para frente.

Para imobilizar o interruptor de ligar/desligar 2,

deverá pressioná-lo no lado da frente até que engate.

Para desligar o aparelho, deverá soltar o interruptor de ligar/desligar 2 ou premir no lado de

trás.

Marcha de ensaio!

☞

Controlar as ferramentas abrasivas antes

da utilização. A ferramenta abrasiva deve

estar perfeitamente montada e deve ser girada livremente. Realizar um funcionamento de ensaio sem carga, durante no

mínimo 30 segundos. Ferramentas abrasivas danificadas, descentradas ou vibrantes não devem ser utilizadas.

Constant-Electronic (GWS 8-100 C,

GWS 8-100 CE, GWS 8-115 C,

GWS 8-125 C, GWS 8-125 CE)

A Constant-Electronic mantém o número de rota-

ções quase que constantes durante a marcha em

vazio e sob carga e assegura uma potência de

trabalho uniforme.

Pré-selecção de número de rotação

(GWS 6-100 E, GWS 6-115 E,

GWS 8-100 CE, GWS 8-115 CE,

GWS 8-125 CE)

Pré-seleccionar o número de rotações necessário com a roda de ajuste 1, de acordo com a tabela no trecho “Dados técnicos do aparelho” (Valores de referência).

Instruções para o trabalho

■ Fixar a peça a ser trabalhada, caso esta

não estiver firme devido ao seu peso próprio.

■ O aparelho não deve ser demasiadamente

carregado, de modo que possa parar.

■ Os discos de lixar e de corte tornam-se

muito quentes, não toque neles antes de

arrefecerem.

Desbastar

Com os ângulos de ataque de 30°

a 40°, alcança-se os melhores resultados ao desbastar. Movimentar

o aparelho para lá e para cá com

pressão moderada. Desta forma o

aparelho não se torna demasiadamente quente, não muda de cor e

não há sulcos na superfície do material.

Jamais utilize disco de cortar para desbastar.

Disco abrasivo em leque

(prato de tecido abrasivo)

Com o disco abrasivo em leque (acessório), também é possível trabalhar superfícies onduladas e

perfís (lixar contornos).

Discos abrasivos em leque possuem uma durabilidade bem maior do que lixas, um nível de ruído e temperaturas de lixamento mais baixas.

Cortar

Ao cortar, não deverá premir, emperrar nem oscilar. Trabalhar com

um avanço moderado e adaptado

ao material a ser trabalhado.

Não travar discos abrasivos de

corte, premindo-os lateralmente.

Importante, é o sentido no qual é cortado.

O aparelho deve

sempre trabalhar na

rotação antagonista;

portanto não movimente o aparelho na

outra direcção! Caso

contrário há perigo,

de que o aparelho

seja premido incon-

troladamente para

fora do corte.

Ao cortar perfis e tubos rectangulares, deverá começar o trabalho de preferência pelo lado menor.

41 • 2 609 140 081 • TMS • 15.01.04

Português - 6

Page 26

2 609 140 081 - Buch Seite 7 Dienstag, 20. Januar 2004 8:52 08

Girar a cabeça do aparelho

■ Tirar a ficha da tomada antes do todos os

trabalhos no aparelho.

A cabeça do aparelho pode ser girada

na carcaça do aparelho em passos de

90°. Desta forma é

possível colocar o interruptor de ligar/

desligar numa posição mais propícia

para cetas situações

especiais de traba-

lhos de corte com carril de guia/suporte de corte

(acessório) ou para canhotos.

Desaparafusar completamente os parafusos.

Girar a cabeça do aparelho cuidadosamente

para a nova posição e sem retirar da carcaça.

Os parafusos devem ser introduzidos e aperta-

dos novamente.

lho, p. ex. para traba-

Manutenção e conservação

■ Tirar a ficha da tomada antes do todos os

trabalhos no aparelho.

Sempre manter o aparelho e as aberturas

☞

de ventilação limpas, para trabalhar bem e

de forma segura.

No caso de extremas condições de aplicação, pode depositar-se pó conductivo no

interior do aparelho. O isolamento de protecção do aparelho pode ser prejudicado.

Nestes casos é recomendável a utilização

de um equipamento estacionário de aspiração, soprar repetidamente as aberturas

de ventilação e intercalar um interruptor de

protecção contra corrente de falha (FI).

Caso o aparelho venha a apresentar falhas, apesar de cuidadosos processos de fabricação e de

controlo de qualidade, deve ser reparado em um

serviço técnico autorizado para aparelhos eléctricos Bosch.

No caso de informações e encomendas de acessórios, indique por favor sem falta o número de

encomenda de 10 algarismos do aparelho!

Protecção do meio-ambiente

Reciclagem de matérias primas em vez de eliminação de lixo

Recomenda-se sujeitar o aparelho, os acessó-

rios e a embalagem à uma reutilização ecológica.

Estas instruções foram manufacturadas com papel reciclável isento de cloro.

Para efeitos de uma reciclagem específica, as

peças de plástico dispõem de uma respectiva

marcação.

Serviço

Desenhos e informações a respeito das pe-

ças sobressalentes encontram-se em:

www.bosch-pt.com

Portugal

Robert Bosch LDA

Avenida Infante D. Henrique

Lotes 2E-3E

1800 Lisboa

✆ .................................................... +351 21 / 8 50 00 00

.................................................... +351 21 / 8 51 10 96

Fax

Brasil

Robert Bosch Ltda.

Caixa postal 1195

13065-900 Campinas

✆ .............................................................. 0800 / 70 45446

E-Mail: sac@bosch-sac.com.br

Declaração de conformidade

Declaramos sob nossa exclusiva responsabilidade que este produto cumpre as seguintes normas ou documentos normativos: EN 50 144 conforme as disposições das directivas 89/336/CEE,

98/37/CE.

Dr. Egbert Schneider Dr. Eckerhard Strötgen

Senior Vice President Head of Product

Engineering Certification

42 • 2 609 140 081 • TMS • 15.01.04

Robert Bosch GmbH, Geschäftsbereich Elektrowerkzeuge

Reservado o direito a modificações

Português - 7

Page 27

2 609 140 081 - Buch Seite 1 Dienstag, 20. Januar 2004 8:52 08

* Des idées en action.

Chlor

Robert Bosch GmbH

Geschäftsbereich Elektrowerkzeuge

70745 Leinfelden-Echterdingen

www.bosch-pt.com

2 609 140 081

Printed in PRC - Imprimé en PRC

(04.01) O / 104

Loading...

Loading...