Bosch GWH 345 ESR User Manual

GWH 345/450 ESR

Temperature Modulated with Electronic Ignition

Suitable for heating and recirculating potable water

GWH-345/450-ESR-N - Natural Gas

GWH-345/450-ESR-L - Liquefied Petroleum (LP) Gas

Warning: If the information in this manual is not

followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

Do not store or use gasoline or other flammable

vapor and liquids in the vicinity of this or any other

appliance.

Improper installation, adjustment, alteration,

service or maintenance can cause injury or

property damage. Refer to this manual. For

assistance or additional information consult a

qualified installer, service agency or the gas

supplier.

In the Commonwealth of Massachusetts this

product must be installed by a licensed plumber or

gas fitter.

Upon completion of the installation, these

instructions should be handed to the user of the

appliance for future reference.

6 720 607 909 US (2007.04) JS

What to do if you smell gas

• Close gas valve. Open windows and doors, and

evacuate the building.

• Do not try to operate any appliance.

• Do not touch any electrical switch; do not use any

phone in your building

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

• Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

Index

Index

1Warning 2

2 Appliance details 4

2.1 Features 4

2.2 GWH-345/450-ESR Specifications (Technical data) 4

2.3 Unpacking the GWH-345/450-ESR heater 5

2.4 General rules to follow for safe operation 6

2.5 Dimensions and minimum installation clearances 7

2.6 Applications 8

2.7 Water quality 9

3 Installation instructions 10

3.1 Introduction 10

3.2 Proper location for installing your heater 10

3.3 Heater placement and clearances 10

3.4 Mounting installation 10

3.5 Combustion air requirements 11

3.6 Venting 13

3.6.1 Vent material and specifications 13

3.6.2 Vent connections and air inlet restrictors 14

3.6.3 Condensate drain requirements 17

3.6.4 Room sealed installation (Twin pipe) 17

3.6.5 Vertical terminations 18

3.6.6 Horizontal terminations 18

3.6.7 Exhaust vent configuration examples 21

3.7 Gas piping & connections 22

3.8 Measuring gas pressure 24

3.9

Checking restrictor plate size by measuring CO2 level value 24

3.10 Water connections 25

3.11 Electrical connections 25

1 Warning

For your safety

Do not store or use gasoline or other flammable,

combustible or corrosive vapors and liquids in the

vicinity of this or any other appliance.

Warning: Carefully plan where you

install the heater. Correct combustion

air supply and flue pipe installation are

very important. If a gas appliance is not

installed correctly, fatal accidents can

result from lack of air, carbon monoxide

poisoning or fire.

Warning: Exhaust gas must be vented

to outside using 3" single wall sealed

stainless steel vent pipe suitable for

category III vent systems and

temperatures up to 480°F. Vent and

combustion air connector piping must

be sealed gas-tight to prevent

possibility of flue gas spillage, carbon

monoxide emissions and risk of fire,

resulting in severe personal injury or

death.

4 Operating instructions 27

4.1 Initial filling instructions 27

4.2 For your safety read before operating your water heater 27

4.3 Startup instructions 27

4.4 Power 28

4.5 Recirculating water temperature 28

4.6 Temperature and hot water flow 28

4.7 Freeze protection 28

4.8 Electrical diagram 29

5 Maintenance and service 30

5.1 Service mode 30

6 Troubleshooting 32

7 GWH-345/450-ESR Functional scheme 34

8 Interior components diagram and parts list 35

8.1 Interior components 35

8.2 Components diagram 36

8.3 Parts list 37

9 Protecting the environment 38

Warning: Place the recirculating water

heater in a location where water leaks

will do NOT DAMAGE adjacent areas

or lower floors.

Warning: Field wiring connections and

electrical grounding must comply with

local codes, or in the absence of local

codes, with the latest edition of the

National Electric Code, ANSI/NFPA 70,

or in Canada, all electrical wiring must

comply with the local codes and the

Canadian Electrical Code, CSA C22.1

Part 1.

Warning: Shock hazard line voltage is

present. Before servicing the

recirculating water heater, turn off the

electrical power to the recirculating

water heater at the main disconnect or

circuit breaker. Failure to do so could

result in severe personal injury or death.

10 Ten Year Limited Warranty 39

2

6 720 607 909

Warning: The recirculating water

heater must be disconnected from the

gas supply piping system during any

pressure testing of that system at test

pressures equal to or more than 0.5

psig (14” W.C.).

FCC:

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2)

this device must accept any interference received,

including interference that may cause undesired

operation.

Caution: Any changes or

modifications not expressly approved

by the party responsible for compliance

could void the user’s authority to

operate the equipment.

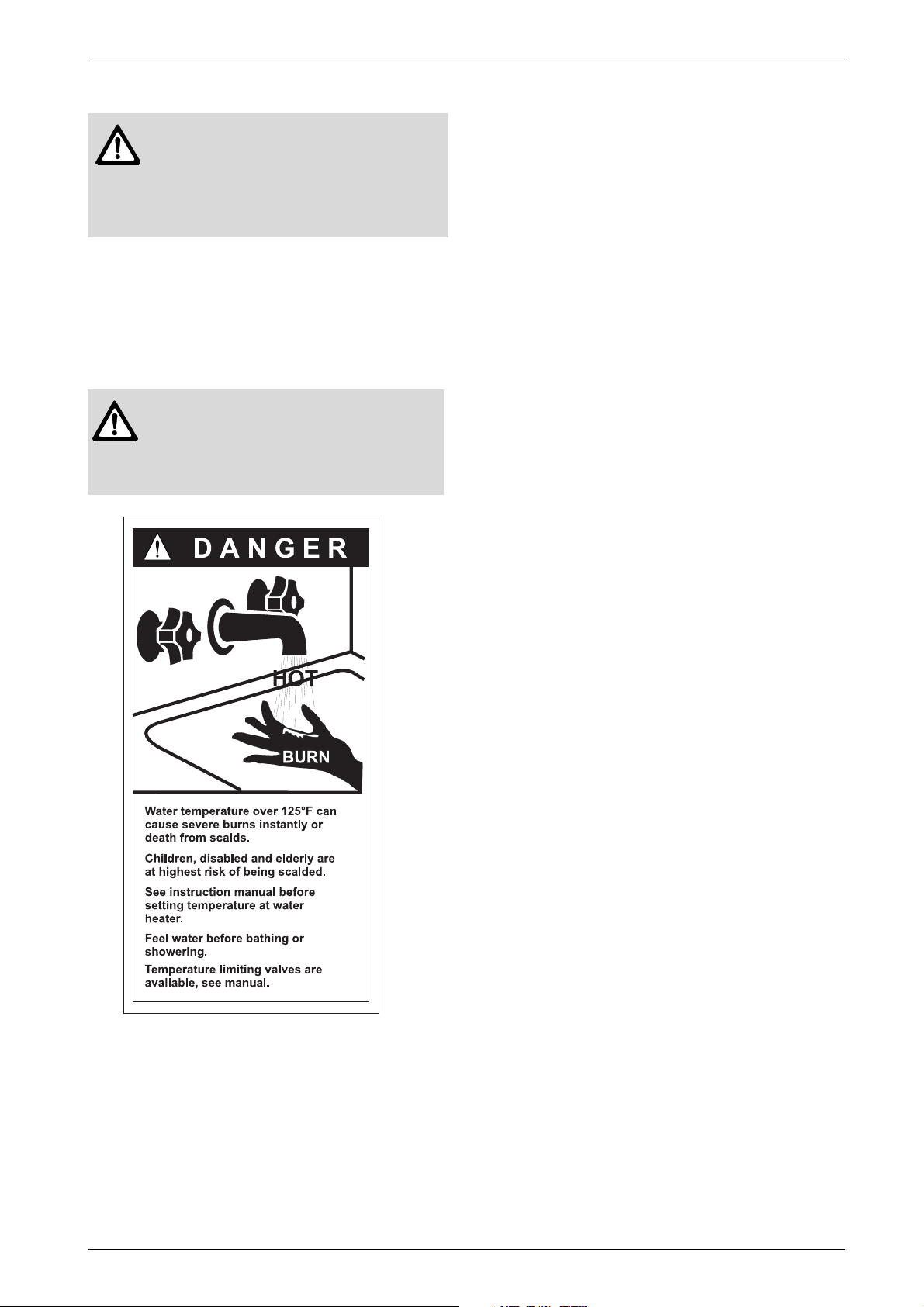

Warning

Fig. 1

6 720 607 909

3

Appliance details

2 Appliance details

2.1 Features

Parts

• Sealed combustion burner.

Safety

• Ionization flame sensor

• Over temperature protection.

High quality materials for long working life

• Copper heat exchanger

• Compact space saver: mounts on a wall with

supplied bracket.

Features

• LCD screen to display temperatures, burner

operation and error codes

• On/Off button and separate temperature controls for

domestic water heating and recirculating water

• Reset button

• Failure codes for diagnostics and repair

• Freeze prevention cycle.

BOSCH is constantly improving its

products, therefore specifications are

i

subject to change without prior notice.

Temperature Control

Selection range: 115°F (45°C) - 190°F (90°C)

Gas Requirement

Gas connection (inches) - ¾”

Inlet gas pressure under operation (with a high hot

water flow rate)*

• Propane: 11” - 14” water column

• Natural Gas: 5.5” - 8” water column.

* To measure gas pressure, see Measuring Gas

Pressure, chapter 3.8.

Venting

3" AL 29-4C single wall sealed stainless steel vent

pipe.

See chapter 3.6 for Venting.

Water

• Hot water connection - ¾” NPT

• Cold water connection - ¾” NPT.

Combustion

•NOx ≤ 100 ppm

•CO ≤ 250 ppm

•CO

level (see table 8 for correct restrictor

2

dimension).

2.2 GWH-345/450-ESR Specifications

(Technical data)

Approved in US/Canada

Capacity

GWH345 Maximum flow rate: 3.5 GPM (13 l/min) at a

45°F (25°C) rise.

GWH450 Maximum flow rate: 4.5 GPM (17 l/min) at a

45°F (25°C) rise.

Maximum output

GWH345 - 77,900 Btu/h (22.8 kW)

GWH450 - 98,400 Btu/h (28.8 kW)

Maximum input

GWH345 - 95,000 Btu/h (27.8 kW)

GWH450 - 120,000 Btu/h (35.1 kW)

Efficiency in %

GWH345 Combustion efficiency: 82%

GWH450 Combustion efficiency: 81%

Min. Output

GWH345 - 23,900 Btu/h (7 kW)

GWH450 - 35,500 Btu/h (10.4 kW)

Dimensions

• Depth (in): 11 ¾” (300 mm)

• Width (in): 15 ¾” (400 mm)

• Height (in): 27 ½” (700 mm)

• Weight: 47 pounds (21 kg).

Gas types

Natural Gas.

Liquid Propane.

The appliance is not field convertible.

Voltage

120 V AC (50/60 Hz)

Amperage

Idle - 40 mA

Operation - ≤ 1.5 A

Noise

≤ 50 db (A)

Safety devices

• Flame failure device (Ionization flame control)

• Overheat prevention (temperature limiter)

• Pressure switch (blocked vent protection).

4

6 720 607 909

Appliance details

Water resistant

IP X4 (protection against water drops)

2.3 Unpacking the GWH-345/450-ESR

heater

This heater is packed securely.

The box includes:

• Wall-mounted gas fired recirculating water heater

• Bracket and screws for wall hanging the heater

• Exhaust vent adaptor (with 4 screws and gasket

provided)

• Combustion air inlet adaptor (with 4 screws and

gasket provided)

• Installation manual

• Product registration card

• Energy Guide label

• Pressure relief valve

• Inlet air restrictors

– GWH 345 ESR N: Ø38/40/42

– GWH 345 ESR LP: Ø38/40/42

– GWH 450 ESR N: Ø44/47/50/55

– GWH 450 ESR LP: Ø47/50/55/60

Do not lose this manual. Please complete and return

the enclosed product registration card.

Before installing the unit, be certain you have the

correct heater for your type of Gas - Propane or

Natural Gas. Identification labels are found on the

shipping box, and on the rating plate which is located on

the right side panel of the cover.

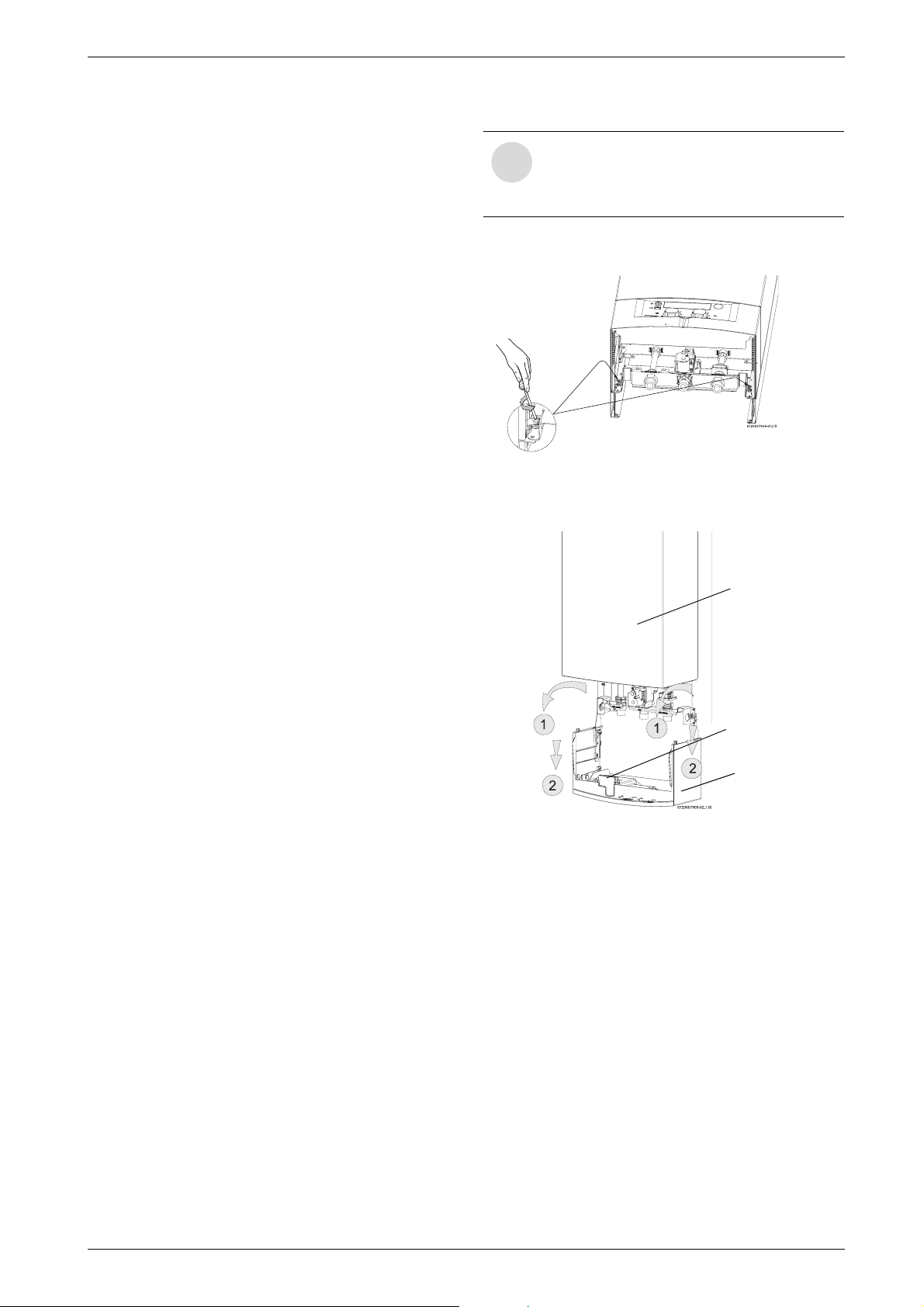

To remove front cover

The front cover is secured with two

screws to prevent unauthorized access.

i

Always secure the control panel and front

cover with these screws.

B Loosen the two Philips head screws located as

shown in fig. 2.

Fig. 2 Screws

B Pull control panel outwards and then pull it

downwards (Fig. 3).

Front cover

Low voltage

access cover

Control panel

6 720 607 909

Fig. 3 Service position to access water and electric

connections

B Lift front cover upward and remove.

The GWH-345/450-ESR is not approved or

designed for:

• Manufactured (mobile) homes, RV's or boats

•Outdoor installation

• Combination venting with other appliances

• Closed loop heating applications.

5

Appliance details

2.4 General rules to follow for safe

operation

1. You must follow these instructions when you install

your heater. In the United States: The installation

must conform with local codes or, in the absence of

local codes, the National Fuel Gas Code ANSI

Z223.1/NFPA 54.

In Canada: The Installation must conform with CGA

B149.(1,2) INSTALLATION CODES and /or local

installation codes.

2. Carefully plan where you install the heater. Correct

combustion air supply and vent pipe installation are

very important. If not installed correctly, fatal

accidents can be caused by lack of air, carbon

monoxide poisoning or fire.

3. When the unit is installed indoors with ROOM

SEALED (twin pipe) combustion air and venting, it is

permitted to be located in bathrooms, bedrooms and

occupied rooms that are normally kept closed. See

chapter 3.6. If the unit will be installed indoors and

use indoor combustion air, the place where you

install the heater must have enough ventilation. The

National Fire Codes do not allow UNSEALED gas

fired water heater installations in bathrooms,

bedrooms or any occupied rooms normally kept

closed. See chapter 3.2 and 3.5.

4. You must vent your heater. See chapter 3.6 Venting.

5. The appliance and its gas connection must be leak

tested before placing the appliance in operation. The

appliance must be isolated from the gas supply

piping system by closing its individual manual gas

shutoff valve (not supplied with heater) during any

pressure testing at pressures in excess of ½ Psig

(3.5 kPa).

6. Keep water heater area clear and free from

combustibles and flammable liquids. Do not locate

the heater over any material which might burn.

7. Correct gas pressure is critical for the optimum

operation of this heater. Gas piping must be sized to

provide the required pressure at the maximum output

of the heater, while all the other gas appliances are in

operation. Check with your local gas supplier, and

see the section on connecting the gas supply.

8. Should overheating occur or the gas supply fails to

shut off, turn off the gas supply at the manual gas

shut off valve, on the gas line. Note: manual gas

shutoff valve is not supplied with the heater.

9. Do not use this appliance if any part has been

underwater. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and any gas control

which has been underwater.

10.Failure to install heater correctly may lead to unsafe

operation and void the warranty.

11.The heater must not be installed in an unheated area

where temperatures will reach 36°F or lower. If the

heater is left in an area susceptible to such

temperatures, drain the unit and disconnect from

electrical supply. See Chapter 4.7 for additional

freeze prevention information.

12.In areas where water supply has a high mineral

content, a water softener is strongly recommended.

A water softener is required if the water hardness

exceeds 6 grains/gal (103 mg/l) calcium carbonate.

Damage to the water heater resulting from hard

water/scale deposits will not be covered under

warranty.

6

6 720 607 909

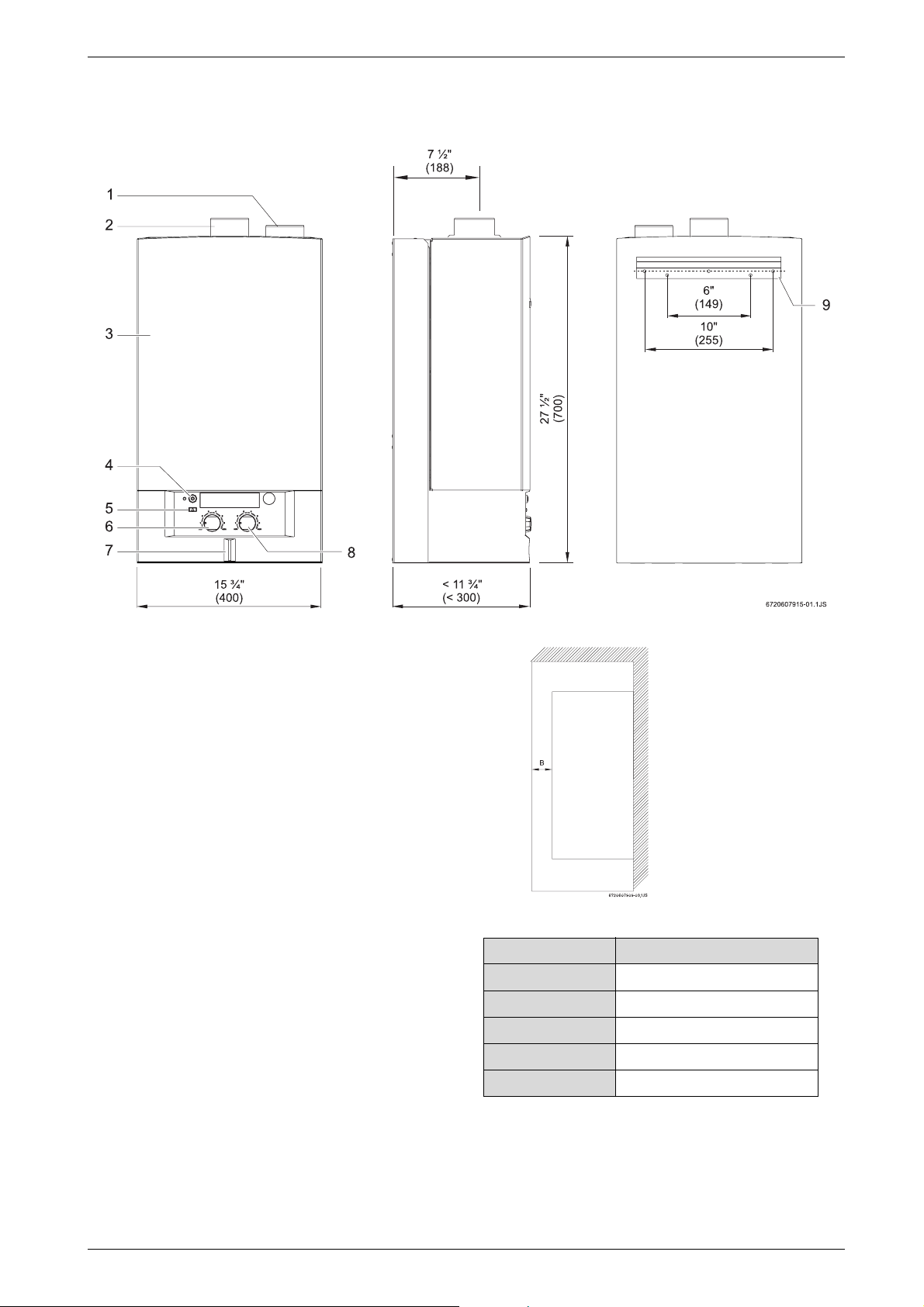

2.5 Dimensions and minimum installation clearances

Appliance details

Fig. 4 Dimensions

1 Combustion air inlet adapter (right side only)

2 Exhaust adapter with CO

3 Front cover

4 On/Off button

5 Reset button

6 Recirculating water temperature selector

7 LED - (ON) warning light (blinks when in error lock out)

8 Domestic hot water temperature selector

9 Mounting plate

measuring point

2

Fig. 5 Minimum clearances

Model GWH-345/450-ESR

TOP 12”

FRONT (B) 4”

BACK 0”

SIDES ½”

BOTTOM 12”

Table 1 Minimum clearances

6 720 607 909

7

Appliance details

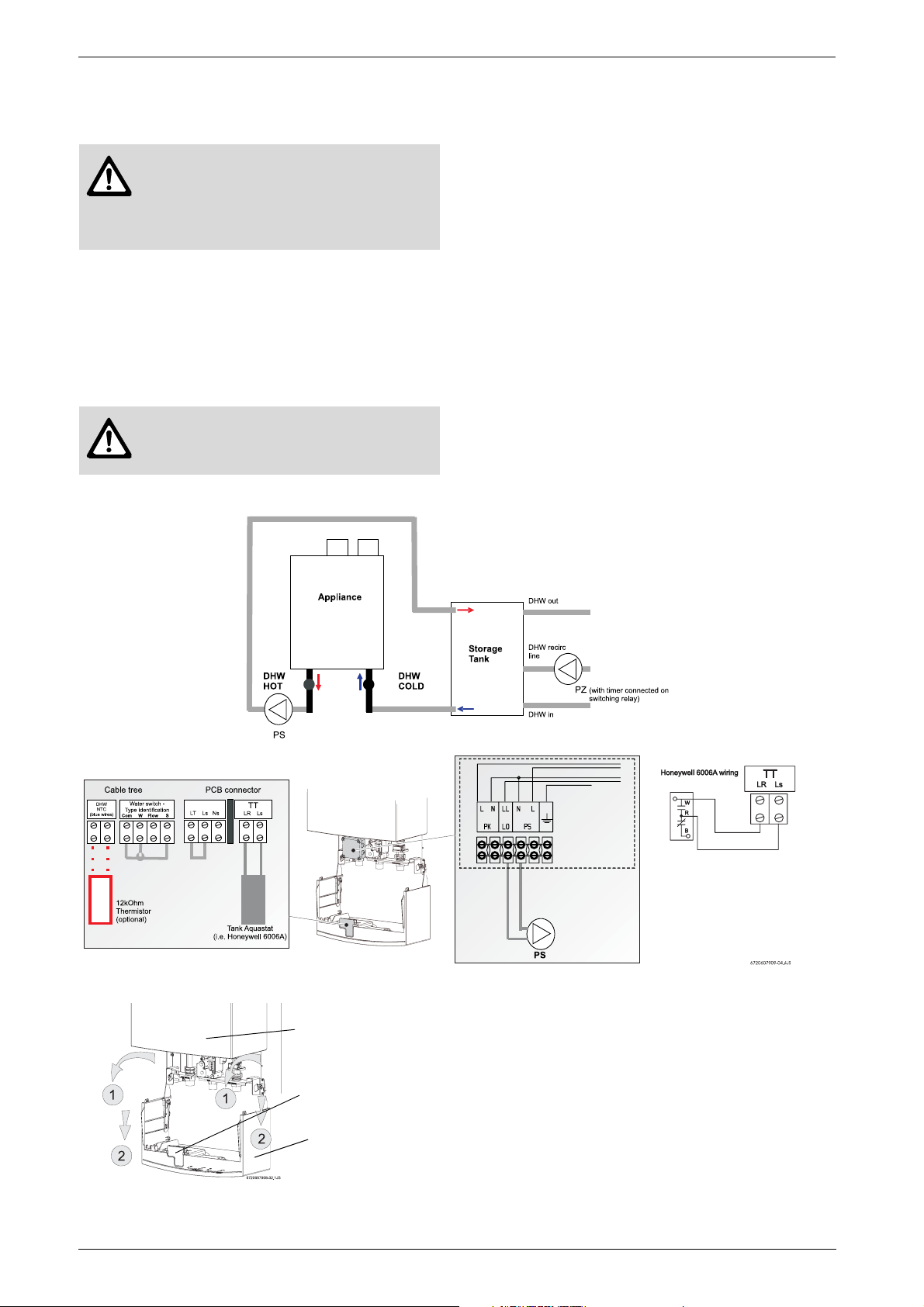

2.6 Applications

Caution: the water heater which will be

used to supply potable water shall not

be connected to any heating system or

component(s) previously used with a

nonpotable water heating appliance.

Introduction

The application designs provided in this manual are general guides to be used when installing this recirculating water

heater.

Pump Sizing

Required PS pumps are Taco 007 Bronze or Grundfos 15-42B. PZ pumps should be sized by a professional plumbing contractor based on the specific application.

Caution: Do not overpump the heater.

Maximum 5 gpm water flow permitted

through the heater.

Instantaneous water heater (direct tank load design)

Note: maximum amp draw:

1,5A. Do not connect

additional pump to the

appliance but use a relay panel

if powering multiple pumps.

Fig. 6

Front cover

Low voltage

access cover

Control panel

Fig. 7 Service position to access water and electric

connections

8

6 720 607 909

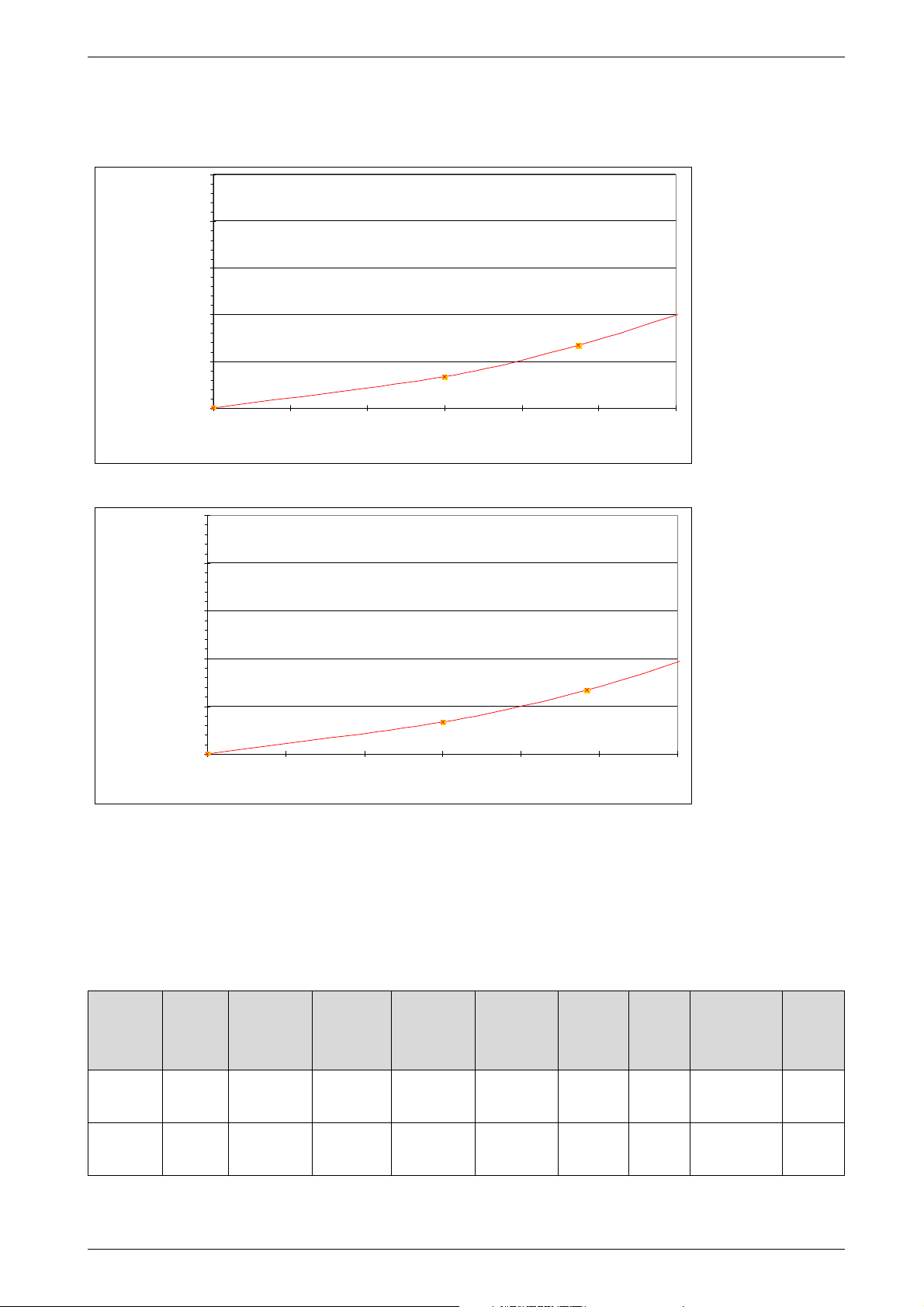

Pressure drop curves

Note: Flow above 6 GPM is not permitted.

50 feet of head

GWH 345 ESR

40 feet of head

30 feet of head

20 feet of head

Inlet pressure

10 feet of head

Appliance details

0 feet of head

0 GPM 1 GPM 2 GPM 3 GPM 4 GPM 5 GPM 6 GPM

Fig. 8 GWH 345 ESR

50 feet of head

40 feet of head

30 feet of head

20 feet of head

Inlet pressure

10 feet of head

0 feet of head

0 GPM 1 GPM 2 GPM 3 GPM 4 GPM 5 GPM 6 GPM

Fig. 9 GWH 450 ESR

water flow rate

GWH 450 ESR

wate r flow rate

2.7 Water quality

Water quality can have an impact on appliance performance and appliance longevity, and may not be covered by the

manufacturer's warranty.

For water analysis data call your local water department. If on a well system, have well water analyzed periodically. If

water quality is exceeding one or more of the values specified below, Bosch recommends installing a water conditioner or softener.

Description

Max.

Levels

Table 2 Venting Specifications

6 720 607 909

pH TDS

(Total

Total

hardness

Dissolved

Solids)

pH

range

mg/l or

ppm

mg/l or

ppm

6.5-8.5 500 100 (6

grains)

Aluminum Chlorides Copper Iron Manganese Zinc

mg/l or

ppm

mg/l or

ppm

mg/l or

ppm

mg/l or

ppm

mg/l or ppm mg/l or

ppm

0.2 250 1.0 0.3 0.05 5.0

9

Installation instructions

3 Installation instructions

3.1 Introduction

Please follow these instructions. Failure to follow

instructions may result in:

• Property damage or personal injury

•Improper operation

• Heater damage

• Loss of warranty.

Please contact Bosch Water Heating with any

questions.

3.2 Proper location for installing your

heater

Carefully select the location of the water heater. For

your safety and for proper heater operation, you must

provide combustion air to the heater and a proper

exhaust vent system.

Follow the guidelines below:

B 1. Locate the heater where venting, gas and

plumbing connections are feasible and convenient.

B 2. The hot water lines should be kept short to save

energy. Centrally locating the water heater is best. It

is always best to have hot water lines insulated.

Warning: The water in this

recirculating water heater is cold and

always remains cold except for the

times the burners are on. In the event of

power outage in conjunction with

freezing temperatures, it is

recommended that the heater be

drained to prevent heater from freezing.

See chapter 9 for draining instructions.

Warning: Flammable materials,

gasoline, pressurized containers, or any

other items or articles that are potential

fire hazards must NOT be placed on or

adjacent to the heater. The appliance

area must be kept free of all

combustible materials, gasoline and

other flammable vapors and liquids.

3.3 Heater placement and clearances

The GWH-345/450-ESR is design certified for

installation on a combustible wall (see 3.4 Mounting

installation) provided the floor covering below the

heater is noncombustible. For installations in an alcove

or closet, maintain the minimum clearances to

combustible and non-combustible materials listed

below. See also fig. 5.

A. Top 12 inches (305 mm)

B. Front 4 inches (100 mm)

C. Back 0 inches

D. Sides ½ inches (12 mm)

E. Bottom 12 inches (305 mm)

Clearances from any exhaust vent pipe are dependent

upon the clearance requirements of the stainless steel

vent pipe manufacturer. Single wall sealed stainless

steel (AL29-4C) vent pipe (rated for Category III

appliances) must be used when exhaust venting this

appliance. See 3.6 Venting.

3.4 Mounting installation

Warning: before starting installation:

B check that there are no loose parts

inside the appliance

B check that the gas type of the heater

matches the gas supply you will be

connecting to the heater.

B ensure that gas pipe, gas valve, fan and

burner have no damage and are properly fitted.

Front cover should be removed (see

instructions on page 5) in order to inspect

i

components visually.

B Secure the wall mounting bracket provided with the

heater to a wall surface.

Warning: Do not install this appliance

on a carpeted wall. The heater must be

mounted on a wall using appropriate

anchoring materials.

10

If wall is a stud wall sheathed with plasterboard, it is

recommended that support board(s), either 1x4’s or

1/2" (minimum) plywood first be attached across a pair

of studs. Then attach the heater’s bracket to the upper

support board. The heater should be kept level on the

wall surface. See Fig. 10.

6 720 607 909

Installation instructions

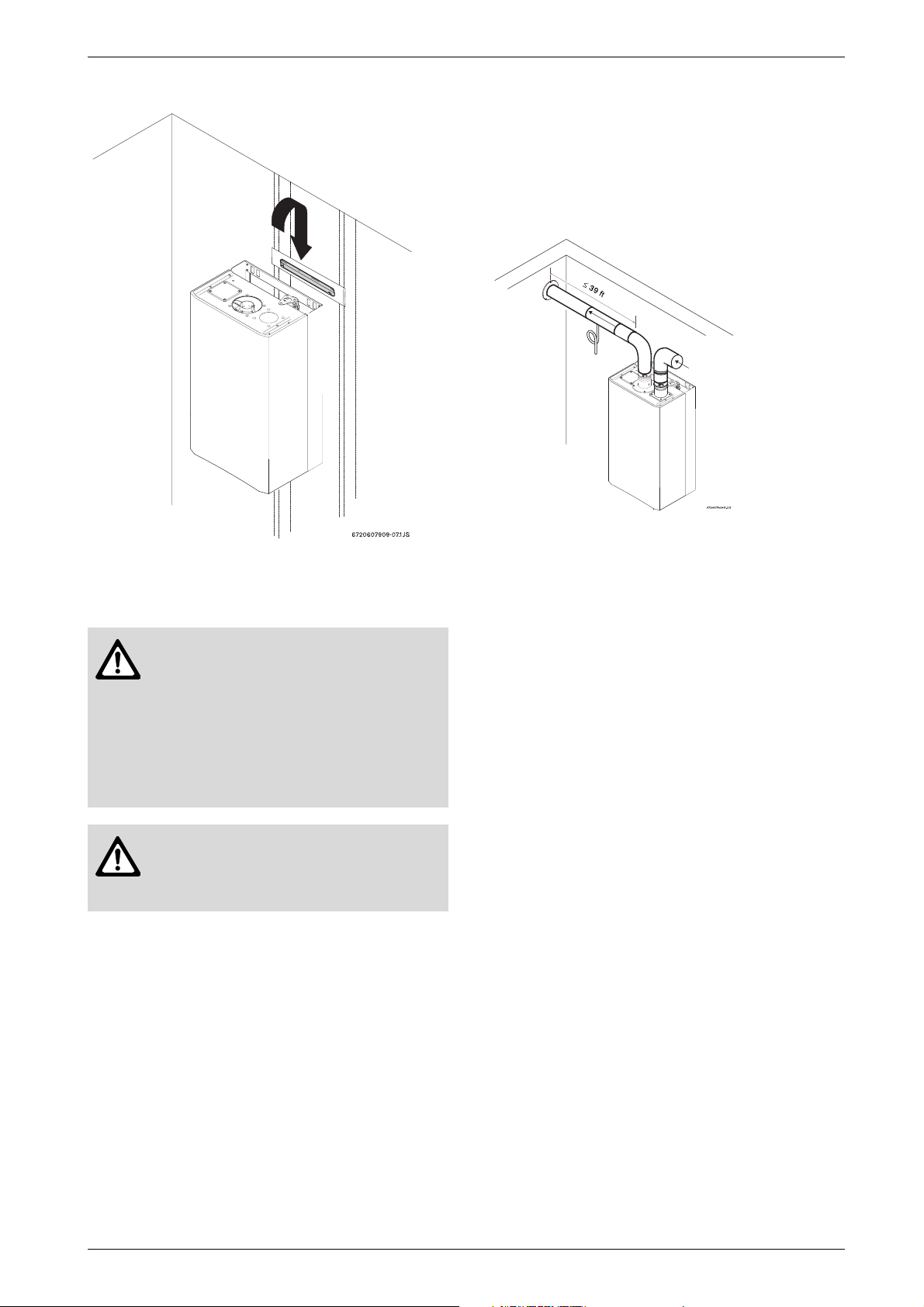

Single pipe

Although it is permissible to draw combustion air from

inside the structure, it is not the manufacturer’s recommended installation method. Always install a 3 inch

elbow on the combustion air inlet to prevent foreign

objects from falling into the unit (see Fig. 11).

Fig. 10 Mounting the heater

3.5 Combustion air requirements

Warning: In areas where freezing

temperatures are common the twin pipe

system is recommended. In a single

pipe installation, a negative air condition

may result in cold air being drawn

across the heat exchanger coil causing

it to freeze and burst. This failure is

not covered under the

manufacturer’s warranty.

Warning: When installed in an

environment where corrosive chemicals

or dirty air are present the twin pipe

system is required.

Twin pipe

The GWH-345/450-ESR is designed as a sealed

combustion appliance. It is recommended that the

combustion air be provided by a dedicated 3” pipe to

the outside. If terminating combustion air piping

horizontally, pitch vent down 1/4" per foot towards

termination to prevent rain from entering the appliance.

The combustion air pipe may be constructed of

aluminum flex, PVC or any other rigid or semi rigid

sealed pipe. The combustion air inlet must be located in

such a manner as to provide a minimum 3 foot

clearance from the exhaust vent terminator.

The maximum length of the combustion air inlet is 39

feet with one elbow. Subtract 6 feet for each additional

elbow. Maximum number of elbows permitted is 4.

Fig. 11

If a single pipe installation is performed. Use the following guidelines when providing adequate combustion air

for the recirculating water heater as well as any other

appliances that may consume air in the space. Always

follow local codes if more stringent.

• Appliances located in unconfined spaces:

– a) An unconfined space is one whose volume is

greater than 50 cubic feet (1.42 cubic meter) per

1000 Btu per hour (292.81 watts) of the

combined rating of all appliances installed in the

space. That would be 6200 cubic feet (175.6

cubic meter) of air required for the GWH-345/

450-ESR alone.

– b) In unconfined spaces in buildings of

conventional frame, masonry, or metal

construction, infiltration air is normally adequate to

provide air for combustion.

– c) Installations in structures that have been tightly

constructed (air infiltration rate of 0.40 ACH or

less) must provide combustion air per the National

Fuel Gas Code. Consult an HVAC specialist if

your air infiltration rate is questionable. For these

types of installations, the twin pipe system must be

used.

6 720 607 909

11

Installation instructions

• Appliances located in confined spaces:

The confined space must be provided with two permanent openings, one commencing within 12 inches

(304.8mm) of the top and one commencing within

12 inches (304.8mm) of the bottom of the enclosure.

Each opening must have a minimum free area of one

square inch per:

– 1000 Btu/hr (292.81 watts) if all air is taken from

inside the building

– 2000 Btu/hr (585.62 watts) if all air is taken from

the outside by horizontal ducts

– 4000 Btu/hr (1171.24 watts)if all air is taken from

the outside by direct openings.

Or the confined space must be provided with one

permanent opening or duct that is within 12 inches

(304.8mm) of the ceiling of the enclosure. This opening

must have a minimum free area of one square inch per:

– 3000 Btu/hr (878.43 watts) if all air is taken from

the outside by a direct opening.

Louvers, grills and screens have a blocking effect, when

used, increase the sizes of your openings by 400% for

wood louvers (as wood type will reduce the free air by

75%) and 135% for metal louvers (as metal will reduce

the free air by 30%). Refer to the National Fuel Gas

Code for complete information.

12

6 720 607 909

Loading...

Loading...