Bosch GSS Professional 280 AVE, GSS Professional 230 AVE Original Instructions Manual

Robert Bosch Power Tools GmbH

1 609 92A 4JA

70538 Stuttgart

GERMANY

www.bosch-pt.com

GSS Professional

1 609 92A 4JA (2018.07) T / 42

230 AVE | 280 AVE

en Original instructions

zh 正本使用说明书

zh 原始使用說明書

ko 사용 설명서 원본

th หนังสือคู่มือการใช้งานฉบับ

id Petunjuk-Petunjuk untuk Penggun

vi Bản gốc hướng dẫn sử dụng

ต้นแบบ

aan Orisinal

2 |

English . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 6

中文 . .. .. . .. .. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. 页 13

繁體中文. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. . 頁 17

한국어 .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. 페이지 20

ไทย. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. หน้า 25

Bahasa Indonesia. .. .. .. .. .. .. .. .. .. .. .. .. . .. .. .. .. .. . Halaman 30

Tiếng Việt . .. .. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. . Trang 35

1 609 92A 4JA | (18.07.2018) Bosch Power Tools

| 3

GSS 230 AVE

GSS 280 AVE

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(1)

(11)

(12)

(13)

(13)

(8)

(14)

(9)

(11)

(14)

(12)

A B

Bosch Power Tools 1 609 92A 4JA | (18.07.2018)

4 |

(15)

(10)

(14)

(16)(10)

(17)

(18)

(19)

(20)

(21)

(20)

(14)

(16)

C

D

E

F

G

H

1 609 92A 4JA | (18.07.2018) Bosch Power Tools

| 5

2

1

2

1

(7)

(7)

(6)

(6)

(22)

(23)

(22)

I

J

K L

M N

Bosch Power Tools 1 609 92A 4JA | (18.07.2018)

6 | English

English

Safety instructions

General Power Tool Safety Warnings

WARNING

tions provided with this power tool. Failure to follow all in-

structions listed below may result in electric shock, fire and/

or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless) power tool.

Work area safety

u Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

u Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust

or fumes.

u Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

Electrical safety

u Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

u Avoid body contact with earthed or grounded sur-

faces, such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your

body is earthed or grounded.

u Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric shock.

u Do not abuse the cord. Never use the cord for carry-

ing, pulling or unplugging the power tool. Keep cord

away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric

shock.

u When operating a power tool outdoors, use an exten-

sion cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

u If operating a power tool in a damp location is un-

avoidable, use a residual current device (RCD) protected supply. Use of an RCD reduces the risk of electric

shock.

Personal safety

u Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a

power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inatten-

Read all safety warnings, instructions, illustrations and specifica-

tion while operating power tools may result in serious personal injury.

u Use personal protective equipment. Always wear eye

protection. Protective equipment such as a dust mask,

non-skid safety shoes, hard hat or hearing protection

used for appropriate conditions will reduce personal injuries.

u Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

u Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal injury.

u Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

u Dress properly. Do not wear loose clothing or jew-

ellery. Keep your hair and clothing away from moving

parts. Loose clothes, jewellery or long hair can be caught

in moving parts.

u If devices are provided for the connection of dust ex-

traction and collection facilities, ensure these are connected and properly used. Use of dust collection can re-

duce dust-related hazards.

u Do not let familiarity gained from frequent use of tools

allow you to become complacent and ignore tool

safety principles. A careless action can cause severe in-

jury within a fraction of a second.

Power tool use and care

u Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was designed.

u Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

u Disconnect the plug from the power source and/or re-

move the battery pack, if detachable, from the power

tool before making any adjustments, changing accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the power tool

accidentally.

u Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

u Maintain power tools and accessories. Check for mis-

alignment or binding of moving parts, breakage of

parts and any other condition that may affect the

power tool’s operation. If damaged, have the power

tool repaired before use. Many accidents are caused by

poorly maintained power tools.

1 609 92A 4JA | (18.07.2018) Bosch Power Tools

English | 7

u Keep cutting tools sharp and clean. Properly main-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

u Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

u Keep handles and grasping surfaces dry, clean and

free from oil and grease. Slippery handles and grasping

surfaces do not allow for safe handling and control of the

tool in unexpected situations.

Service

u Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

Safety Warnings for Sander

u Hold the power tool firmly with both hands and make

sure you have a stable footing. The power tool can be

more securely guided with both hands.

u Only use the power tool for dry sanding. Water entering

a power tool will increase the risk of electric shock.

u Warning: Danger of fire! Avoid overheating the work-

piece and the sander. Always empty the dust collector

before taking a break from work. Sanding dust in the

dust bag, microfilter, paper bag (or in the filter bag or vacuum cleaner filter) can spontaneously combust under

certain conditions, for example if flying sparks are created when sanding metals. This risk is increased if the

sanding dust is mixed with paint or polyurethane residue

or with other chemical substances and if the workpiece is

hot as a result of prolonged work.

u Clean the air vents on your power tool regularly. The

motor’s fan will draw the dust inside the housing and excessive accumulation of powdered metal may cause electrical hazards.

u Secure the workpiece. A workpiece clamped with

clamping devices or in a vice is held more secure than by

hand.

u Always wait until the power tool has come to a com-

plete stop before placing it down.

Products sold in GB only:

Your product is fitted with an BS 1363/A approved electric

plug with internal fuse (ASTA approved to BS 1362).

If the plug is not suitable for your socket outlets, it should be

cut off and an appropriate plug fitted in its place by an authorised customer service agent. The replacement plug

should have the same fuse rating as the original plug.

The severed plug must be disposed of to avoid a possible

shock hazard and should never be inserted into a mains

socket elsewhere.

Product Description and Specifications

Read all the safety and general instructions.

Failure to observe the safety and general instructions may result in electric shock, fire

and/or serious injury.

Please observe the illustrations at the beginning of this operating manual.

Product features

The numbering of the product features refers to the diagram

of the power tool on the graphics page.

Auxiliary handle (insulated gripping surface)

(1)

Screw for auxiliary handle

(2)

Orbital stroke rate preselection thumbwheel

(3)

On/off switch

(4)

Lock-on button for on/off switch

(5)

Filter element (Microfilter system)

(6)

Complete dust box (Microfilter system)

(7)

Rear clamping bracket

(8)

Clamping lever

(9)

Sanding plate

(10)

Clamping lever

(11)

Front clamping bracket

(12)

Handle (insulated gripping surface)

(13)

Sanding sheet

(14)

Punch

(15)

Screws for sanding plate

(16)

Sanding plate, thin, elongated

(17)

Sanding sheet, elongated

(18)

Screws for elongated sanding plate

(19)

Sanding sheet, triangular

(20)

Sanding plate, triangular, elongated

(21)

Extraction outlet

(22)

Dust extraction hose

(23)

A)

Accessories shown or described are not included with the

product as standard. You can find the complete selection of

accessories in our accessories range.

A)

A)

A)

A)

A)

A)

A)

A)

A)

A)

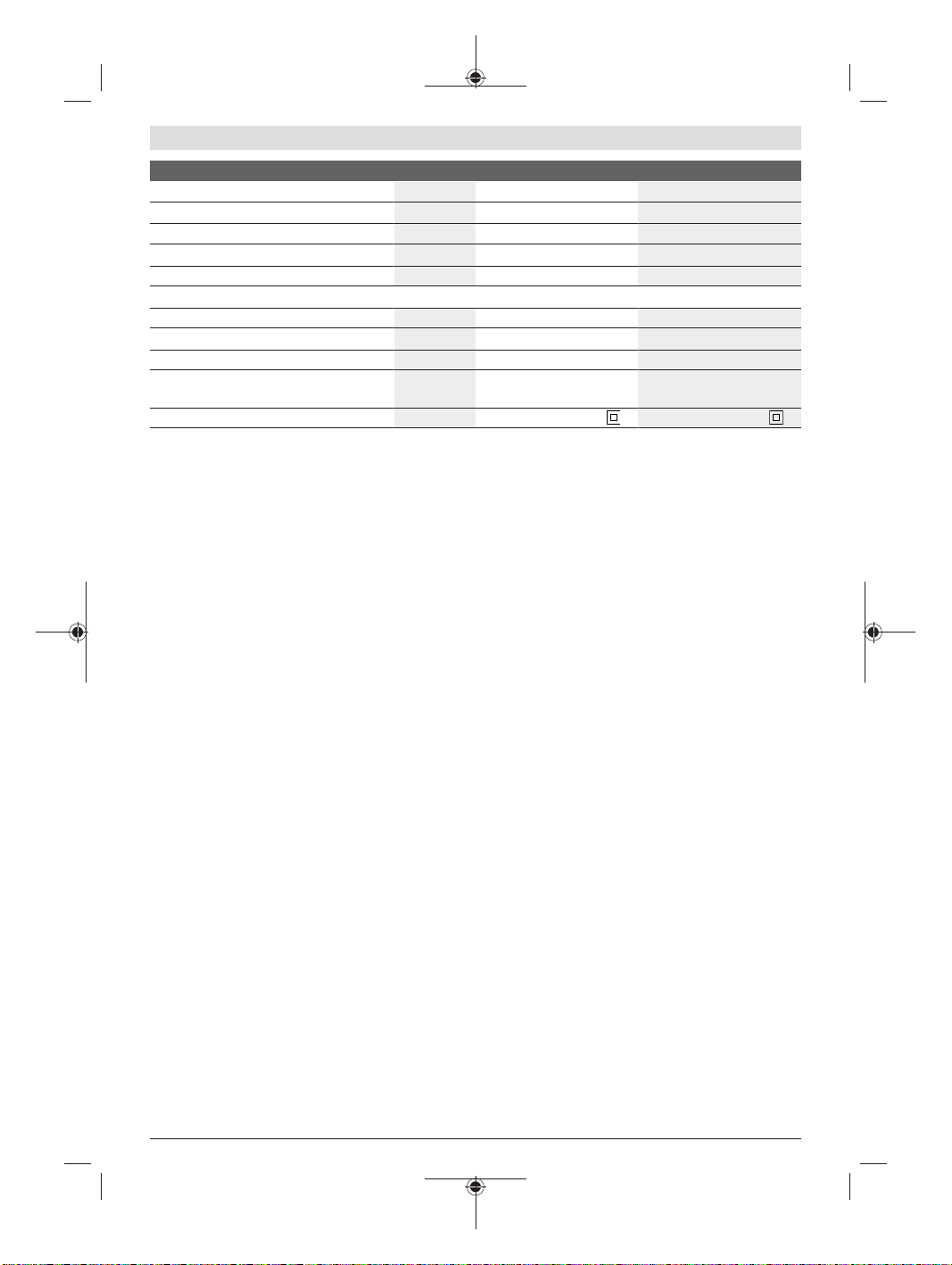

Technical data

Orbital sander GSS 230 AVE GSS 280 AVE

Article number

Dust box included with product ● ●

Bosch Power Tools 1 609 92A 4JA | (18.07.2018)

3 601 B92 8.. 3 601 B92 9..

8 | English

Orbital sander GSS 230 AVE GSS 280 AVE

Orbital stroke rate preselection ● ●

Rated power input W 300 350

No-load speed rpm 8000–11000 8000–11000

No-load orbital stroke rate rpm 16000–22000 16000–22000

Orbit diameter mm 2.4 2.4

Sanding sheet dimensions

– Hook-and-loop backing mm 93 x 185 115 x 230

– Clamping tension mm 93 x 230 115 x 280

Sanding plate dimensions mm 92 x 182 114 x 226

Weight according to EPTA-Procedure

01:2014

Protection class / II / II

The specifications apply to a rated voltage [U] of 230 V. These specifications may vary at different voltages and in country-specific models.

kg 2.5 2.8

Assembly

u Pull the plug out of the socket before carrying out any

work on the power tool.

Dust/chip extraction

The dust from materials such as lead paint, some types of

wood, minerals and metal can be harmful to human health.

Touching or breathing in this dust can trigger allergic reactions and/or cause respiratory illnesses in the user or in

people in the near vicinity.

Certain dusts, such as oak or beech dust, are classified as

carcinogenic, especially in conjunction with wood treatment

additives (chromate, wood preservative). Materials containing asbestos may only be machined by specialists.

– Use a dust extraction system that is suitable for the ma-

terial wherever possible.

– Provide good ventilation at the workplace.

– It is advisable to wear a P2 filter class breathing mask.

The regulations on the material being machined that apply in

the country of use must be observed.

u Avoid dust accumulation at the workplace. Dust can

easily ignite.

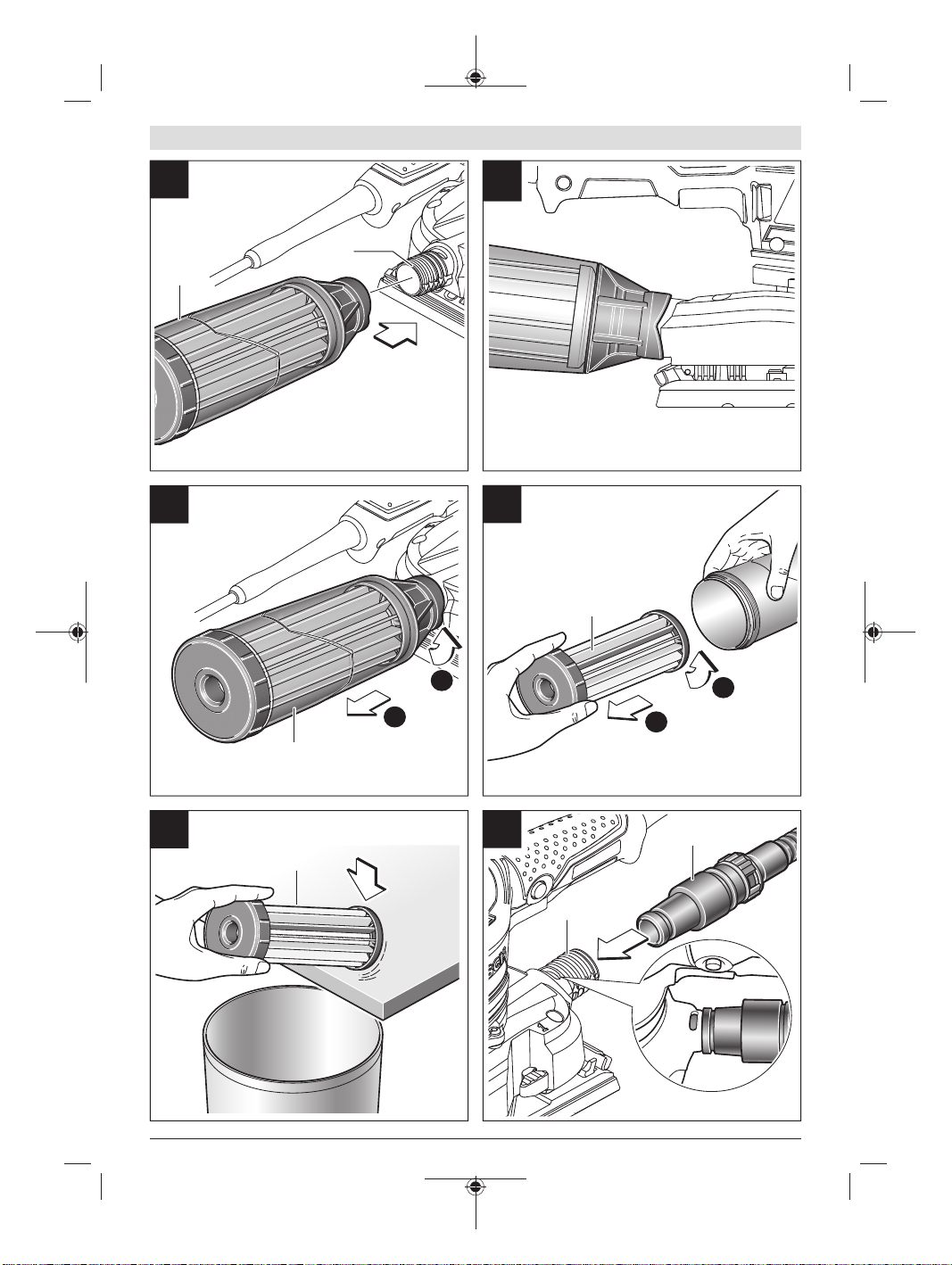

Self-generated dust extraction with dust box

(seefiguresI–M)

Slide the dust box (7) onto the extraction outlet (22). Turn

the dust box in such a manner that its recesses face against

the tips on the extraction outlet and the dust box can be felt

to engage.

You can easily check the filling level of the dust box (7)

through the transparent container.

To empty the dust box (7), rotate slightly and pull it back.

Unscrew the filter element (6) and pull it out of the dust box

(7). Empty the dust box.

Gently tap the filter element (6) against a solid surface to

loosen the dust. Use a soft brush to clean the flaps of the filter element (6).

Note: In order to ensure optimum dust extraction, empty the

dust box (7) in good time and clean the filter element (6)

regularly.

When working on vertical surfaces, hold the power tool with

the dust box (7) facing downwards.

External dust extraction (see figure N) Fit a dust extraction hose (23) onto the extraction outlet

(22). Mount the vacuum hose onto the extraction outlet (as

shown in the figure) in such a manner that the lateral openings on the extraction outlet remain free. This prevents the

power tool from adhering to the workpiece during sanding

and the surface quality of the workpiece from being impaired.

Connect the dust extraction hose (23) to an extractor. You

will find an overview of connecting to various dust extractors

at the end of these operating instructions.

The dust extractor must be suitable for the material being

worked.

When extracting dry dust that is especially detrimental to

health or carcinogenic, use a special dust extractor.

When working on vertical surfaces, hold the power tool with

the dust extraction hose facing downwards.

Changing the sanding sheet

Remove dirt and dust from the sanding plate (10), e.g. with

a brush, before attaching a new sanding sheet.

To ensure optimum dust extraction, make sure that the

punched holes in the sanding sheet are aligned with the

drilled holes in the sanding plate.

Sanding sheets with hook-and-loop backing

(seefigureE)

The sanding plate (10) is fitted with a hook-and-loop fastening, allowing sanding sheets with a similar backing to be secured quickly and easily.

Tap the hook-and-loop fastening of the sanding plate (10)

before fitting the sanding sheet (14) to facilitate maximum

adhesion.

1 609 92A 4JA | (18.07.2018) Bosch Power Tools

English | 9

Position the sanding sheet (14) so that it is flush with one

side of the sanding plate (10), then place the sanding sheet

on the sanding plate and press it on firmly.

To remove the sanding sheet (14), take hold of it by a corner

and pull it away from the sanding plate (10).

Sanding sheets without hook-and-loop backing

(seefiguresA–B)

Push the clamping lever (9) down.

Slide the sanding sheet (14) under the open front clamping

bracket (8) as far as possible and let go of the clamping lever

(9).

Open the clamping lever (11).

Position the sanding sheet (14) so that it fits tightly around

the sanding plate. Slide the other end of the sanding sheet

(14) under the open front clamping bracket (12) and clamp

the sanding sheet in place by closing the clamping lever

(11).

Unperforated sanding sheets, e.g. from rolls or bulk stock

sold by the metre, can be perforated using the punch (15)

for the purpose of dust extraction. To do this, fit the sanding

sheet on the power tool and push the tool down onto the

punch (see figureD).

To remove the sanding sheet (14), open the clamping lever

(11) and push the clamping lever (9) down. Pull the sanding

sheet out.

Choosing the sanding sheet

Different sanding sheets are available, depending on the material you are working with and the required surface removal

rate:

Grit

40–400

For processing all wood and wood-based materials

For pre-sanding, e.g. of rough and uneven beams and boards

For surface sanding and levelling of

slight irregularities

For finish-sanding and fine sanding of

hardwoods

For processing paint and lacquer layers or

primers such as fillers and bodyfillers

For sanding down paint Coarse 40, 60

For sanding undercoats Medium 80, 100,

For final sanding of primers prior to

painting

Note: To avoid the sanding sheet tearing, only use sanding

sheets with a grit of 80 or above.

Coarse 40, 60

Medium 80, 100,

120

Fine 180, 240,

320, 400

40–320

120

Fine 180, 240,

320

Changing the sanding plate (see figure F)

If necessary, the sanding plate (10) can be replaced.

Unscrew the six screws (16) completely and remove the

sanding plate (10). Fit the new sanding plate (10) and

retighten the screws.

Special Sanding Plates

You can replace the standard supplied sanding plate (10)

with one of the special sanding plates that are available as

accessories.

Special sanding plates are fitted in exactly the same way as

the standard supplied sanding plate.

Likewise, each sanding sheet is attached and removed in exactly the same way as the original sanding sheet.

Elongated sanding plate, triangular, thin (see figure G)

Using the triangular, thin, elongated sanding plate (17) enables you to sand difficult-to-reach places and tight spaces

such as window and door posts, grooves, or behind radiators and water pipes.

To fit the triangular, thin, elongated sanding plate (17), use

the screws designed for this purpose (19).

Elongated sanding plate, triangular (see figure H)

Using the triangular, elongated sanding plate (21) enables

you to sand edges and corners.

Fine sanding plate (without hook-and-loop backing)

(seefiguresA–B)

If you primarily use standard sanding sheets without hookand-loop backing, we recommend using the fine sanding

plate without hook-and-loop backing. The flat surface of the

fine sanding plate will help achieve optimal sanding results,

especially when carrying out fine sanding.

Auxiliary handle

The auxiliary handle (1) enables comfortable handling and

optimum power distribution, with a high sanding removal

rate in particular.

Use the screw (2) to secure the auxiliary handle (1) on the

housing.

Operation

Starting Operation

u Pay attention to the mains voltage. The voltage of the

power source must match the voltage specified on the

rating plate of the power tool. Power tools marked

with 230V can also be operated with 220V.

u Products that are only sold in AUS and NZ: Use a resid-

ual current device (RCD) with a nominal residual current

of 30 mA or less.

Switching on/off

u Make sure that you are able to press the On/Off switch

without releasing the handle.

To switch on the power tool, press and hold the on/off

switch (4).

To lock the on/off switch (4) press and hold it while also

pushing the lock-on button (5).

Bosch Power Tools 1 609 92A 4JA | (18.07.2018)

10 | English

To switch off the power tool, release the on/off switch (4).

If the on/off switch (4) is locked, press the switch first and

then release it.

Preselecting the orbital stroke rate

You can even preselect the orbital stroke rate during operation using the necessary orbital stroke rate preselection

thumbwheel (3).

The required orbital stroke rate is dependent on the material

and the work conditions and can be determined using practical tests.

Practical advice

u Pull the plug out of the socket before carrying out any

work on the power tool.

u Always wait until the power tool has come to a com-

plete stop before placing it down.

The material removal rate and sanding result are primarily

determined by the choice of sanding sheet, the preselected

orbital stroke rate level and the contact pressure.

Only immaculate sanding sheets achieve good sanding performance and make the power tool last longer.

Be sure to apply consistent contact pressure in order to increase the lifetime of the sanding sheets.

Excessively increasing the contact pressure will not lead to

increased sanding performance, rather it will cause more

severe wear of the power tool and of the sanding sheet.

Do not use a sanding sheet for other materials after it has

been used to work on metal.

Use only original Bosch sanding accessories.

Maintenance and Servicing

Maintenance and Cleaning

u Pull the plug out of the socket before carrying out any

work on the power tool.

u To ensure safe and efficient operation, always keep

the power tool and the ventilation slots clean.

In order to avoid safety hazards, if the power supply cord

needs to be replaced, this must be done by Bosch or by a

customer service centre that is authorised to repair Bosch

power tools.

After-sales Service and Advice on Using Products

Our after-sales service can answer questions concerning

product maintenance and repair, as well as spare parts. You

can find exploded drawings and information on spare parts

at: www.bosch-pt.com

The Bosch product use advice team will be happy to help you

with any questions about our products and their accessories.

www.powertool-portal.de, the internet portal for tradespeople and DIY enthusiasts.

In all correspondence and spare parts orders, please always

include the 10‑digit article number given on the type plate of

the product.

Cambodia

Robert Bosch (Cambodia) Co., Ltd

Unit 8BC, GT Tower, 08th Floor, Street 169,

Czechoslovakia Blvd, Sangkat Veal Vong

Khan 7 Makara, Phnom Penh

VAT TIN: 100 169 511

Tel.: +855 23 900 685

Tel.: +855 23 900 660

www.bosch.com.kh

People’s Republic of China

China Mainland

Bosch Power Tool (China) Co. Ltd.

Bosch Service Center

567, Bin Kang Road

Bin Kang District

Hangzhou, Zhejiang Province

China 310052

Tel.: (0571) 8887 5566 / 5588

Fax: (0571) 8887 6688 x 5566# / 5588#

E-mail: bsc.hz@cn.bosch.com

www.bosch-pt.com.cn

HK and Macau Special Administrative Regions

Robert Bosch Co. Ltd.

21st Floor, 625 King’s Road

North Point, Hong Kong

Customer Service Hotline: +852 2101 0235

Fax: +852 2590 9762

E-mail: info@hk.bosch.com

www.bosch-pt.com.hk

India

Bosch Service Center

69, Habibullah Road, (next to PSBB School), T. Nagar

Chennai–600077

Phone: (044) 64561816

Bosch Service Center Rishyamook

85A, Panchkuin Road

New Delhi–110001

Phone: (011) 43166190

Bosch Service Center 79,

Crystal Bldg., Dr. Annie Besant Road, Worli

Mumbai–400018

Phone: (022) 39569936 / (022 )39569959 /

(022) 39569967 / (022) 24952071

Indonesia

PT Robert Bosch

Palma Tower 10th Floor

Jalan RA Kartini II-S Kaveling 6

Pondok Pinang, Kebayoran Lama

Jakarta Selatan 12310

Tel.: (21) 3005-5800

www.bosch-pt.co.id

Malaysia

Robert Bosch Sdn. Bhd.(220975-V) PT/SMY

No. 8A, Jalan 13/6

1 609 92A 4JA | (18.07.2018) Bosch Power Tools

English | 11

46200 Petaling Jaya

Selangor

Tel.: (03) 79663194

Toll-Free: 1800 880188

Fax: (03) 79583838

E-mail: kiathoe.chong@my.bosch.com

www.bosch-pt.com.my

Pakistan

Robert Bosch Middle East FZE – Pakistan Liaison Office

2nd Floor Plaza # 10, CCA Block, DHA Phase 5

Lahore, 54810

Phone: +92(303)4444311

E-mail: Faisal.Khan@bosch.com

Philippines

Robert Bosch, Inc.

28th Floor Fort Legend Towers,

3rd Avenue corner 31st Street,

Fort Bonifacio, Global City,

1634 Taguig City

Tel.: (632) 8703871

Fax: (632) 8703870

www.bosch-pt.com.ph

Singapore

Powerwell Service Centre Ptd Ltd

Bosch Authorised Service Centre (Power Tools)

4012 Ang Mo Kio Ave 10, #01-02 TECHplace

Singapore 569628

Tel.: 6452 1770

Fax: 6452 1760

E-mail: ask@powerwellsc.com

www.powerwellsc.com

www.bosch-pt.com.sg

Thailand

Robert Bosch Ltd.

Liberty Square Building

No. 287, 11 Floor

Silom Road, Bangrak

Bangkok 10500

Tel.: 02 6393111

Fax: 02 2384783

Robert Bosch Ltd., P. O. Box 2054

Bangkok 10501

www.bosch.co.th

Bosch Service – Training Centre

La Salle Tower Ground Floor Unit No.2

10/11 La Salle Moo 16

Srinakharin Road

Bangkaew, Bang Plee

Samutprakarn 10540

Tel.: 02 7587555

Fax: 02 7587525

Vietnam

Branch of Bosch Vietnam Co., Ltd in HCMC

14th floor, Deutsches Haus, 33 Le Duan

Ben Nghe Ward, District 1, Ho Chi Minh City

Tel.: (028) 6258 3690

Fax: (028) 6258 3692 - 6258 3694

Hotline: (028) 6250 8555

E-mail: tuvankhachhang-pt@vn.bosch.com

www.bosch-pt.com.vn

Armenia, Azerbaijan, Georgia, Kyrgyzstan, Mongolia,

Tajikistan, Turkmenistan, Uzbekistan

TOO "Robert Bosch" Power Tools, After Sales Service

Rayimbek Ave., 169/1

050050, Almaty, Kazakhstan

Service e-mail: service.pt.ka@bosch.com

Official website: www.bosch.com, www.bosch-pt.com

Bahrain

Hatem Al Juffali Technical Equipment Establishment.

Kingdom of Bahrain, Setra Highway, Al Aker Area

Phone: +966126971777-311

Fax: +97317704257

E-mail: h.berjas@eajb.com.sa

Egypt

Unimar

20 Markaz kadmat

El tagmoa EL Aoul – New Cairo

Phone: +20 2224 76091-95

Phone: +20 2224 78072-73

Fax: +20222478075

E-mail: adelzaki@unimaregypt.com

Iran

Robert Bosch Iran

3rd Floor, No 3, Maadiran Building

Aftab St., Khodami St., Vanak Sq.

Tehran 1994834571

Phone: +9821 86092057

Iraq

Sahba Technology Group

Al Muthana airport road

Baghdad

Phone: +9647901906953

Phone Dubai: +97143973851

E-mail: bosch@sahbatechnology.com

Jordan

Roots Arabia – Jordan

Nasser Bin Jameel street, Building 37 Al Rabiah

11194 Amman

Phone: +962 6 5545778

E-mail: bosch@rootsjordan.com

Kuwait

Al Qurain Automotive Trading Company

Shuwaikh Industrial Area, Block 1, Plot 16, Street 3rd

P.O. Box 164 – Safat 13002

Phone: 24810844

Fax: 24810879

E-mail: josephkr@aaalmutawa.com

Lebanon

Tehini Hana & Co. S.A.R.L.

P.O. Box 90-449

Jdeideh

Dora-Beirut

Phone: +9611255211

E-mail: service-pt@tehini-hana.com

Bosch Power Tools 1 609 92A 4JA | (18.07.2018)

12 | English

Libya

El Naser for Workshop Tools

Swanee Road, Alfalah Area

Tripoli

Phone: +218 21 4811184

Oman

Malatan Trading & Contracting LLC

P.O. Box 131

Ruwi, 112 Sultanate of Oman

Phone: +968 99886794

E-mail: malatanpowertools@malatan.net

Qatar

International Construction Solutions W L L

P. O. Box 51,

Doha Phone: +974 40065458

Fax: +974 4453 8585

E-mail: csd@icsdoha.com

Saudi Arabia

Juffali Technical Equipment Co. (JTECO)

Kilo 14, Madinah Road, Al Bawadi District

Jeddah 21431

Phone: +966 2 6672222 Ext. 1528

Fax: +966 2 6676308

E-mail: roland@eajb.com.sa

Syria

Dallal Establishment for Power Tools

P.O. Box 1030

Aleppo

Phone: +963212116083

E-mail: rita.dallal@hotmail.com

United Arab Emirates

Central Motors & Equipment LLC, P.O. Box 1984

Al-Wahda Street – Old Sana Building

Sharjah

Phone: +971 6 593 2777

Fax: +971 6 533 2269

E-mail: powertools@centralmotors.ae

Yemen

Abualrejal Trading Corporation

Sana’a Zubiery St. Front to new Parliament Building

Phone: +967-1-202010

Fax: +967-1-279029

E-mail: tech-tools@abualrejal.com

Ethiopia

Forever plc

Kebele 2,754, BP 4806,

Addis Ababa

Phone: +251 111 560 600

E-mail: foreverplc@ethionet.et

Ghana

C.WOERMANN LTD.

Nsawam Road/Avenor Junction, P.O. Box 1779

Accra Phone: +233 302 225 141

Kenya

Robert Bosch East Africa Ltd

Mpaka Road P.O. Box 856

00606 Nairobi

Nigeria

Robert Bosch Nigeria Ltd.

52–54 Isaac John Street P.O. Box

GRA Ikeja – Lagos

Republic of South Africa

Customer service

Hotline: (011) 6519600

Gauteng – BSC Service Centre

35 Roper Street, New Centre

Johannesburg

Tel.: (011) 4939375

Fax: (011) 4930126

E-mail: bsctools@icon.co.za

KZN – BSC Service Centre

Unit E, Almar Centre

143 Crompton Street

Pinetown

Tel.: (031) 7012120

Fax: (031) 7012446

E-mail: bsc.dur@za.bosch.com

Western Cape – BSC Service Centre

Democracy Way, Prosperity Park

Milnerton

Tel.: (021) 5512577

Fax: (021) 5513223

E-mail: bsc@zsd.co.za

Bosch Headquarters

Midrand, Gauteng

Tel.: (011) 6519600

Fax: (011) 6519880

E-mail: rbsa-hq.pts@za.bosch.com

Tanzania

Diesel & Autoelectric Service Ltd.

117 Nyerere Rd., P.O. Box 70839

Vingunguti 12109, Dar Es Salaam

Phone: +255 222 861 793/794

Australia, New Zealand and Pacific Islands

Robert Bosch Australia Pty. Ltd.

Power Tools

Locked Bag 66

Clayton South VIC 3169

Customer Contact Center

Inside Australia:

Phone: (01300) 307044

Fax: (01300) 307045

Inside New Zealand:

Phone: (0800) 543353

Fax: (0800) 428570

Outside AU and NZ:

Phone: +61 3 95415555

www.bosch-pt.com.au

www.bosch-pt.co.nz

1 609 92A 4JA | (18.07.2018) Bosch Power Tools

Disposal

The power tool, accessories and packaging should be recycled in an environmentally friendly manner.

Do not dispose of power tools along with

household waste.

中文

安全规章

电动工具通用安全警告

警告!

会导致电击、着火和/或严重伤 害。

保存所有警告和说明书以备查阅。

在所有下列的警告中术语" 电动工具" 指市电驱动

(有线)电动工具或电池驱动(无线)电动工具。

工作场地的安全

保持工作场地清洁和明亮。

u

引 发事故。

不要在易爆环境,如有易燃液体、气体或粉尘的

u

环 境下操作电动工具。

点燃粉 尘或气体。

让儿童和旁观者离开后操作电动工具。

u

集 中会使操作者失去对工具的控制。

电气安全

电动工具插头必须与插座相配。绝不能以任何方

u

式 改装插头。需接地的电动工具不能使用任何转

换插 头。

电击危 险。

避免人体接触接地表面,如管道、散热片和冰

u

箱。

如果你身体接地会增加电击危险。

不得将电动工具暴露在雨中或潮湿环境中。

u

入 电动工具将增加电击危险。

不得滥用电线。绝不能用电线搬运、拉动电动工

u

具 或拔出其插头。使电线远离热源、油、锐边或

运动 部件。

险。

当在户外使用电动工具时,使用适合户外使用的

u

外 接软线。

险。

如果在潮湿环境下操作电动工具是不可避免的,

u

应 使用剩余电流动作保护器(RCD)。

可减 小电击危险。

人身安全

保持警觉,当操作电动工具时关注所从事的操作

u

并 保持清醒。当你感到疲倦,或在有药物、酒精

或治 疗反应时,不要操作电动工具。

工具时 瞬间的疏忽会导致严重人身伤害。

警告! 阅读所有警告和所有说

明!

不遵照以下警 告和说明

混乱和黑暗的场地会

电动工具产生的火花会

注意力不

未经改装的插头和相配的插座将减少

水进

受损或缠绕的软线会增加电击危

适合户外使用的软线将减少电击危

使用RCD

在操作电动

中文 | 13

使用个人防护装置。始终佩戴护目镜。

u

安全装

置, 诸如适当条件下使用防尘面具、防滑安全

鞋、安全 帽、听力防护等装置能减少人身伤害。

防止意外起动。确保开关在连接电源和/ 或电池

u

盒、拿起或搬运工具时处于关断位置。

手指放在

已 接通电源的开关上或开关处于接通时插入插头

可能 会导致危险。

在电动工具接通之前,拿掉所有调节钥匙或扳

u

手。

遗留在电动工具旋转零件上的扳手或钥匙会

导致人 身伤害。

手不要伸展得太长。时刻注意立足点和身体平

u

衡。

这样在意外情况下能很好地控制电动工具。

着装适当。不要穿宽松衣服或佩戴饰品。让衣

u

服、 手套和头发远离运动部件。

宽松衣服、佩

饰或长发 可能会卷入运动部件中。

如果提供了与排屑、集尘设备连接用的装置,要

u

确 保他们连接完好且使用得当。

使用这些装置

可减少 尘屑引起的危险。

即使由于经常使用电动工具而对此非常熟悉,也

u

不要就认为可以高枕无忧而忽略工具的安全规

定。

粗心大意的行为可能在瞬间就造成严重的伤

害。

电动工具使用和注意事项电动工具使用和注意事项

不要滥用电动工具,根据用途使用适当的电动工

u

具。

选用适当设计的电动工具会使你工作更有

效、 更安全。

如果开关不能接通或关断工具电源,则不能使用

u

该 电动工具。

如果开关不能接通或关断工具电

源,则不能使用该 电动工具。

在进行任何调节、更换附件或贮存电动工具之

u

前, 必须从电源上拔掉插头和/ 或使电池盒与工

具脱 开。

这种防护性措施将减少工具意外起动

的危险。

将闲置不用的电动工具贮存在儿童所及范围之

u

外, 并且不要让不熟悉电动工具或对这些说明不

了解的 人操作电动工具。

电动工具在未经培训

的用户手中 是危险的。

保养电动工具。检查运动件是否调整到位或卡

u

住, 检查零件破损情况和影响电动工具运行的其

他状 况。如有损坏,电动工具应在使用前修理

好。

许多 事故由维护不良的电动工具引发。

保持切削刀具锋利和清洁。

u

保养良好的有锋利切

削 刃的刀具不易卡住而且容易控制。

按照使用说明书,考虑作业条件和进行的作业来

u

使 用电动工具、附件和工具的刀头等。

将电动

工具用 于那些与其用途不符的操作可能会导致危

险。

保持手柄和握持表面干燥、清洁、无油污。

u

在突

发情况下,滑溜的手柄和握持表面无法确保安全

地握持和控制工具。

维修

将电动工具用 于那些与其用途不符的操作可能会

u

导致危险。

. 这样将确保所维修的电动工具的安

全 性。

Bosch Power Tools 1 609 92A 4JA | (18.07.2018)

Loading...

Loading...