Bosch GSS20-40 Owner’s Manual

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de sécurité/d’utilisation

Instrucciones de funcionamiento y seguridad

GSS20-40

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informa-

tions et les adresses de nos

centres de

service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

For English Version Version française Versión en español

See page 2 Voir page 13 Ver la página 24

1600A00HX5 11-15 GSS20-40.indd 1 11/9/15 7:22 AM

Safety Symbols

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

This is the safety alert symbol. It is used to

alert you to potential personal injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation

which, if not avoided, will result in death or

serious injury.

WARNING indicates a hazardous situation

which, if not avoided, will result in death or

serious injury.

CAUTION, used with the safety alert symbol,

indicates a hazardous situation which, if not

avoided, will result in minor or moderate injury.

General Power Tool Safety Warnings

Read all safety warnings and all instructions. Failure to follow the warn-

ings and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power

tool or battery-operated (cordless) power tool.

Work area safety

Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric shock.

Avoid body contact with earthed or

grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an

increased risk of electric shock if your body is

earthed or grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric

shock.

When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

If operating a power tool in a damp location

is unavoidable, use a Ground Fault Circuit

Interrupter (GFCI) protected supply. Use of

an GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and

use common sense when operating a power tool. Do not use a power tool while you

2

1600A00HX5 11-15 GSS20-40.indd 2 11/9/15 7:22 AM

are tired or under the influence of drugs,

alcohol or medication. A moment of inatten-

tion while operating power tools may result in

serious personal injury.

Use personal protective equipment. Always wear eye protection. Protective equip-

ment such as dust mask, non-skid safety

shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal

injuries.

Prevent unintentional starting. Ensure the

switch is in the off-position before connecting to power source and / or battery

pack, picking up or carrying the tool. Carry-

ing power tools with your finger on the switch

or energizing power tools that have the switch

on invites accidents.

Remove any adjusting key or wrench before turning the power tool on. A wrench

or a key left attached to a rotating part of the

power tool may result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. This enables better con-

trol of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing

and gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in

moving parts.

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

Power tool use and care

Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and

safer at the rate for which it was designed.

Do not use the power tool if the switch

does not turn it on and off. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of

children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools

are dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may

affect the power tool’s operation. If damaged, have the power tool repaired before

use. Many accidents are caused by poorly

maintained power tools.

Keep cutting tools sharp and clean. Prop-

erly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

Use the power tool, accessories and tool

bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use

of the power tool for operations different from

those intended could result in a hazardous

situation.

Service

Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the

safety of the power tool is maintained.

3

1600A00HX5 11-15 GSS20-40.indd 3 11/9/15 7:22 AM

Safety Rules for Orbital Sanders

Unplug the sander before changing accessories. Accidental start-ups may occur if

sander is plugged in while changing an accessory.

Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding the work by hand or

against your body is unstable and may lead to

loss of control.

Your tool is equipped with a dust canister, empty it frequently, after completion of

sanding and before storing the sander. Be

extremely careful of dust disposal, materials

in fine particle form may be explosive. Do not

throw sanding dust on an open fire. Combustion from mixture of varnishes, lacquers, polyurethane, oil or water with dust particles can

occur if there is a static discharge, spark introduced in the box, or excessive heat.

Always wear eye and respiratory protection for dusty applications and when sanding overhead. Sanding particles can be ab-

Additional Safety Warnings

sorbed by your eyes and inhaled easily and

may cause health complications.

Use special precautions when sanding

chemically pressure treated lumber, paint

that may be lead based, or any other materials that may contain carcinogens. A

suitable breathing respirator and protective

clothing must be worn by all persons entering the work area. Work area should be sealed

by plastic sheeting and persons not protected

should be kept out until work area is thoroughly cleaned.

Do not wet sand with this sander. Liquid entering the motor housing is an electrical shock

hazard.

Do not use sandpaper intended for larger

sanding pads. Larger sandpaper will extend

beyond the sanding pad causing snagging,

tearing of the paper or kick-back. Extra paper

extending beyond the sanding pad can also

cause serious lacerations.

GFCI and personal protection devices like

electrician’s rubber gloves and footwear will

further enhance your personal safety.

Do not use AC only rated tools with a DC

power supply. While the tool may appear to

work, the electrical components of the AC

rated tool are likely to fail and create a hazard

to the operator.

Keep handles dry, clean and free from oil

and grease. Slippery hands cannot safely

control the power tool.

Develop a periodic maintenance schedule

for your tool. When cleaning a tool be careful not to disassemble any portion of the

tool since internal wires may be misplaced

or pinched or safety guard return springs

may be improperly mounted. Certain clean-

ing agents such as gasoline, carbon tetrachloride, ammonia, etc. may damage plastic parts.

Ensure the switch is in the off position

before inserting battery pack. Inserting the

battery pack into power tools that have the

switch on invites accidents.

grinding, drilling, and other construction

activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies, de-

pending on how often you do this type of work.

To reduce your exposure to these chemicals:

work in a well ventilated area, and work with

approved safety equipment, such as those

dust masks that are specially designed to filter

out microscopic particles.

Some dust created by

power sanding, sawing,

4

1600A00HX5 11-15 GSS20-40.indd 4 11/9/15 7:22 AM

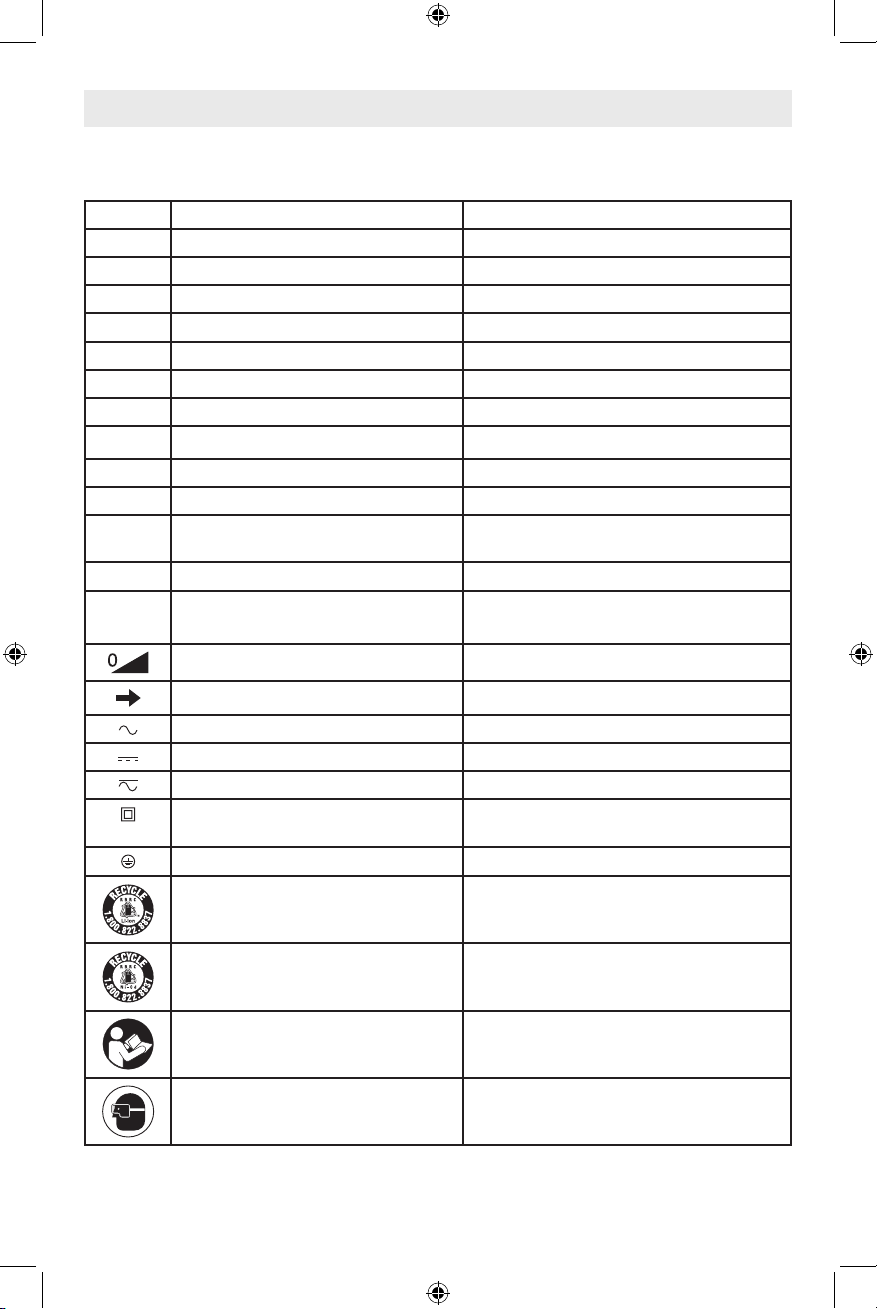

Symbols

IMPORTANT: Some of the following symbols may be used on your tool. Please study them and

learn their meaning. Proper interpretation of these symbols will allow you to operate the tool

better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Powe r

kg Kilograms Weight

min Minutes Time

s Seconds Time

⌀

.../min Revolutions or reciprocation per min-

1, 2, 3, ...

I, II, III,

Diameter Size of drill bits, grinding wheels, etc.

No load speed Rotational speed, at no load

n

0

n Rated speed Maximum attainable speed

ute

0 Off position Zero speed, zero torque...

Selector settings Speed, torque or position settings. Higher

Infinitely variable selector with off Speed is increasing from 0 setting

Revolutions, strokes, surface speed, orbits etc. per minute

number means greater speed

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated Construc-

tion tools.

Earthing terminal Grounding terminal

Li-ion RBRC seal Designates Li-ion battery recycling pro-

gram

Ni-Cad RBRC seal Designates Ni-Cad battery recycling pro-

gram

Read manual symbol Alerts user to read manual

Wear eye protection symbol Alerts user to wear eye protection

5

1600A00HX5 11-15 GSS20-40.indd 5 11/9/15 7:22 AM

Symbols (continued)

IMPORTANT: Some of the following symbols may be used on your tool. Please study them and

learn their meaning. Proper interpretation of these symbols will allow you to operate the tool

better and safer.

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this component is recognized by Underwriters Laboratories.

This symbol designates that this tool is listed by Underwriters Laboratories, to United States and Canadian

Standards.

This symbol designates that this tool is listed by the Canadian Standards Association.

This symbol designates that this tool is listed by the Canadian Standards Association, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Intertek Testing Services, to United States and Canadian

Standards.

This symbol designates that this tool complies to NOM

Mexican Standards.

6

1600A00HX5 11-15 GSS20-40.indd 6 11/9/15 7:22 AM

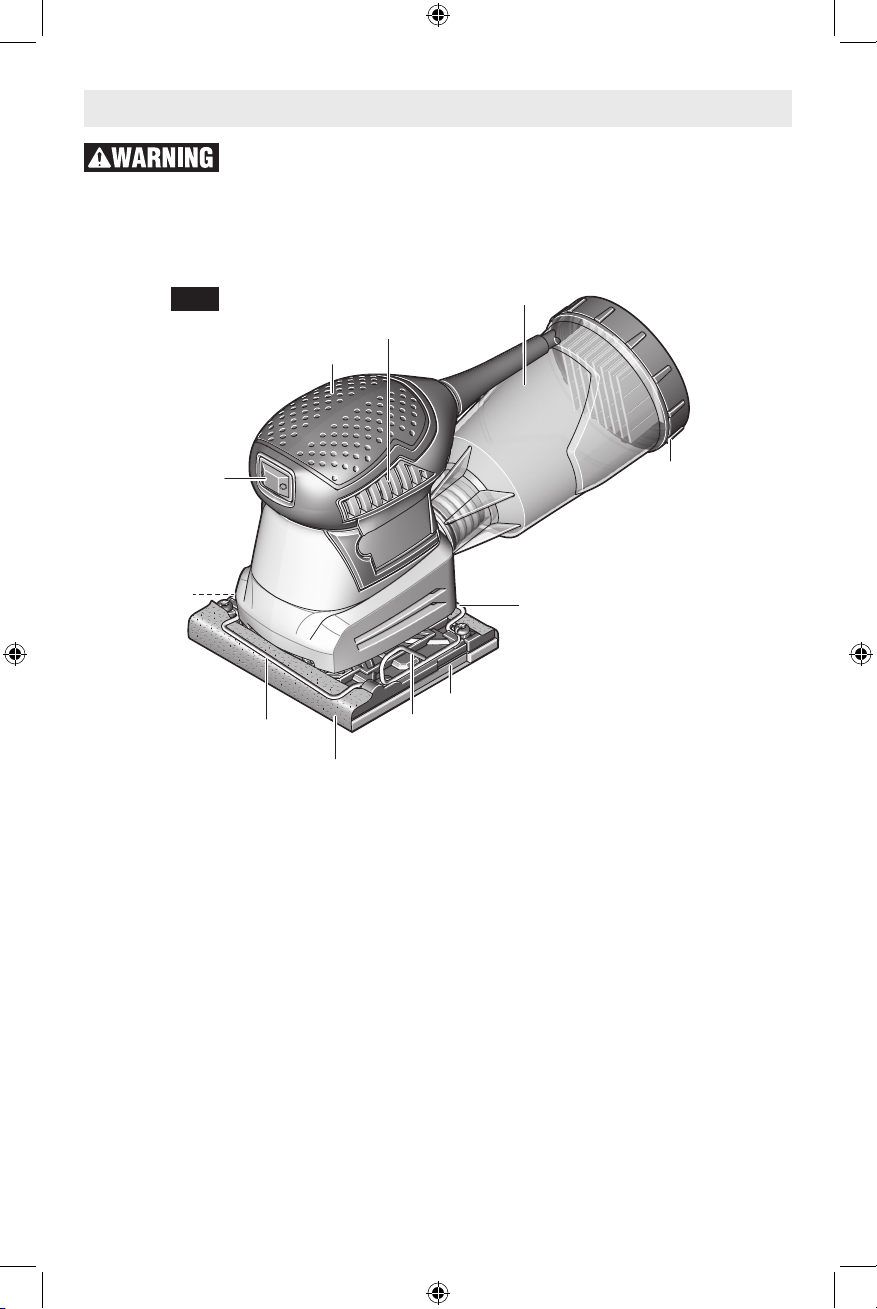

Functional Description and Specifications

2

Disconnect the plug from the power source before making any assem-

sures reduce the risk of starting the tool accidentally.

bly, adjustments or changing accessories. Such preventive safety mea-

Orbital Sander

Fig. 1

9

8

1

6A

6B

7

1 Dust-sealed switch

2 Dust canister

3 Microfilter

4 Sanding pad

5A Rear clamp lever

5B Rear clamping bracket

Model number GSS20-40

Pad Size:

Regular Sanding Sheet:

PSA (Stick-On) Sanding Sheet:

3

5B

4

5A

6A Front clamp lever

6B Front clamping bracket

7 Sanding sheet

8 Soft-grip area

9 Ventilation openings

4 1/2” x 4 1/8” (1/4 sheet)

4 1/2” x 5 1/2”

4 1/2” x 4 1/2”

NOTE: For tool specifications refer to the nameplate on your tool.

7

1600A00HX5 11-15 GSS20-40.indd 7 11/9/15 7:22 AM

Assembly

Always disconnect the

source before attaching or removing sanding sheets.

plug from the power

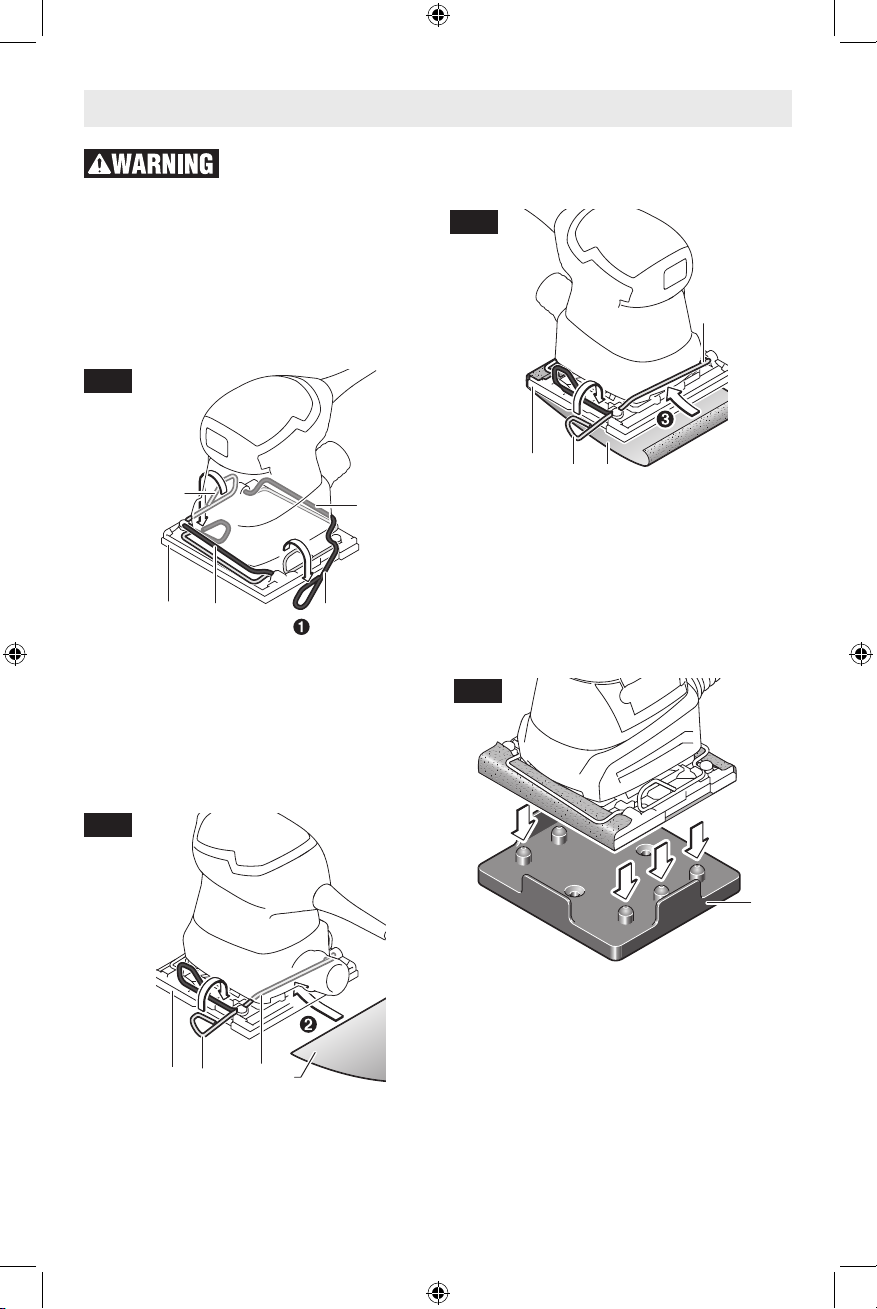

ATTACHING SANDING SHEETS

When attaching a new sanding sheet, remove

any dust or debris from the sanding pad 4

(e.g. with a brush).

1. Unlock both sanding-sheet clamp levers 5A

and 6A and swivel them downwards (Fig. 2).

Fig. 2

6A

4

6B

2. Insert the sanding sheet 7 under the rear

clamping bracket 5B. Ensure that the sanding sheet 7 is not too short to be correctly

clamped under clamping brackets 5A and

5B. Swivel the sanding sheet clamp lever

5A back into the starting position and lock it

there (Fig. 3).

Fig. 3

5B

5A

clamped. Swivel the sanding-sheet clamping lever 6A back into the starting position

and lock it there (Fig. 4).

Fig. 4

6B

4

6A

7

PUNCH PLATE

After the sanding sheet has been installed,

it will be necessary to punch holes into the

sheet using the punch plate provided with

your sander. Align sander base with punch

plate and push down on sander until punch

plate pierces the sheet. Then remove punch

plate from sander (Fig. 5)

Fig. 5

13

To ensure optimum dust extraction, pay attention that the punched holes in the sanding sheet match with the holes in the sanding

plate.

4

3. Place the sanding sheet taut around the

sanding pad 4. Clamp the front part of the

sanding sheet under the front clamping

bracket 6B. Ensure that the sanding sheet

7 is not too short and that it is correctly

75A 5B

REMOVING SANDING SHEETS

To remove the sanding sheet 7, unlock both

sanding-sheet clamp levers 5A and 6A and

pull the sanding sheet out of its holder.

8

1600A00HX5 11-15 GSS20-40.indd 8 11/9/15 7:22 AM

ATTACHING PSA “STICK-ON”

SANDING SHEETS

Your sander can also be used with PSAbacked “stick-on” sanding sheets (sandpaper), which have pressure sensitive adhesive.

1. Peel protective sheet from the back of PSA

sheet.

2. Align PSA sheet with backing pad and

press firmly in place.

Notes:

• Make sure that clamp levers are latched,

even when PSA sanding sheets are used.

Dust Collection

• Remove PSA sheets soon after completing

each sanding operation in order to prevent

the adhesive from creating a hardened

bond with the backing pad.

REMOVING PSA SANDING SHEETS

To remove, lift an edge of sheet with your fingernail and peel it off the backing pad.

Note: If PSA sheet is accidentally left on the

pad and has cooled down, the best way to remove it is to sand for three to five minutes to

soften the adhesive backing.

MICROFILTER DUST CANISTER — The integral dust extraction system collects sanding

dust in canister supplied with your sander. For

maximum efficiency, the dust canister should

be emptied frequently during operation.

Your tool is equipped

with a dust canister,

empty it frequently, after completion of

sanding and before storing the sander. Be

extremely careful of dust disposal, materials in

fine particle form may be explosive. Do not

throw sanding dust on an open fire. Combustion from mixture of varnishes, lacquers, polyurethane, oil or water with dust particles can

occur if there is a static discharge, spark introduced in the box, or excessive heat. Do not

mix collected dust with paint or varnish, or use

it to absorb or dry liquid chemicals.

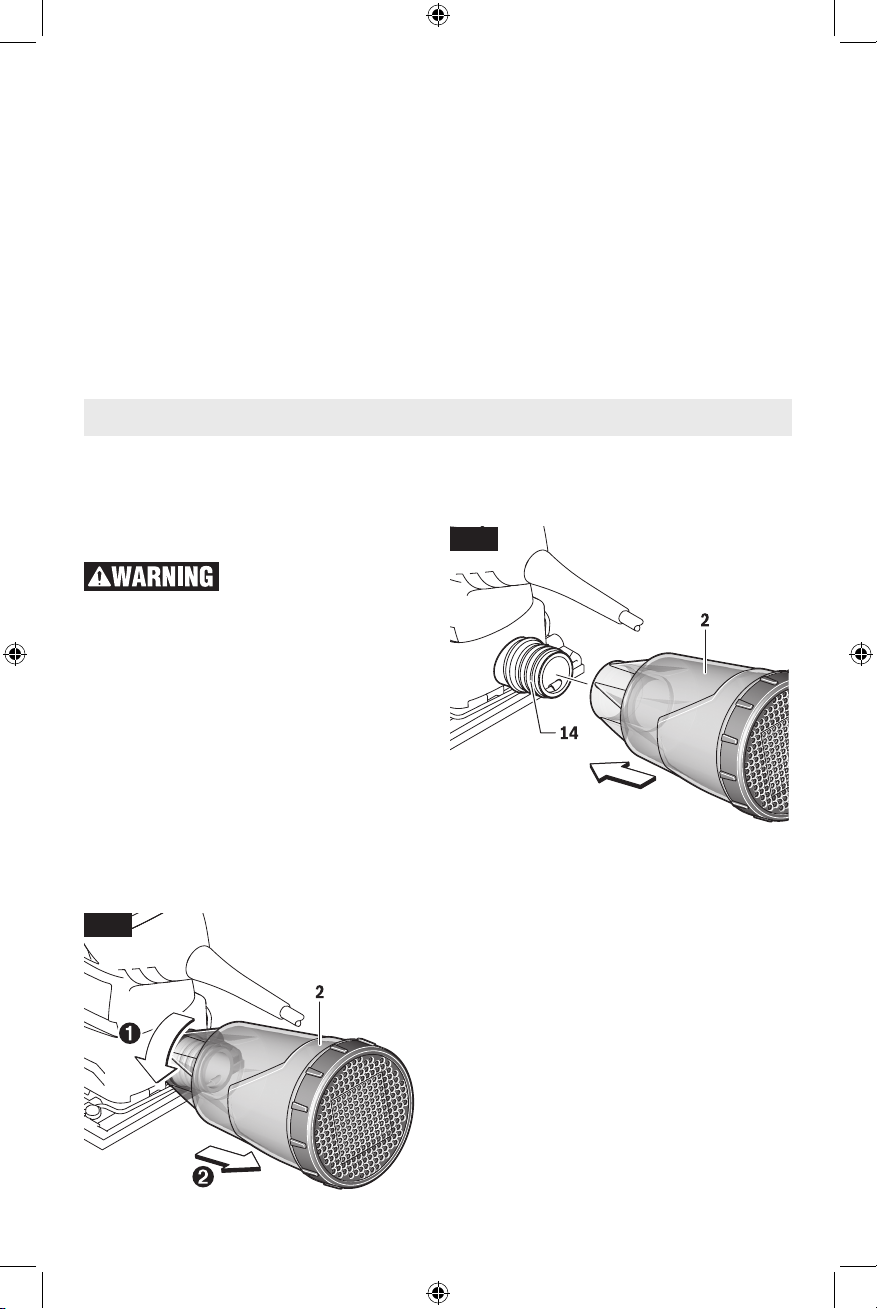

REMOVING AND INSTALLING

DUST CANISTER

To remove dust canister: rotate dust canister 2

while pulling it away from the tool (Fig. 6).

Fig. 6

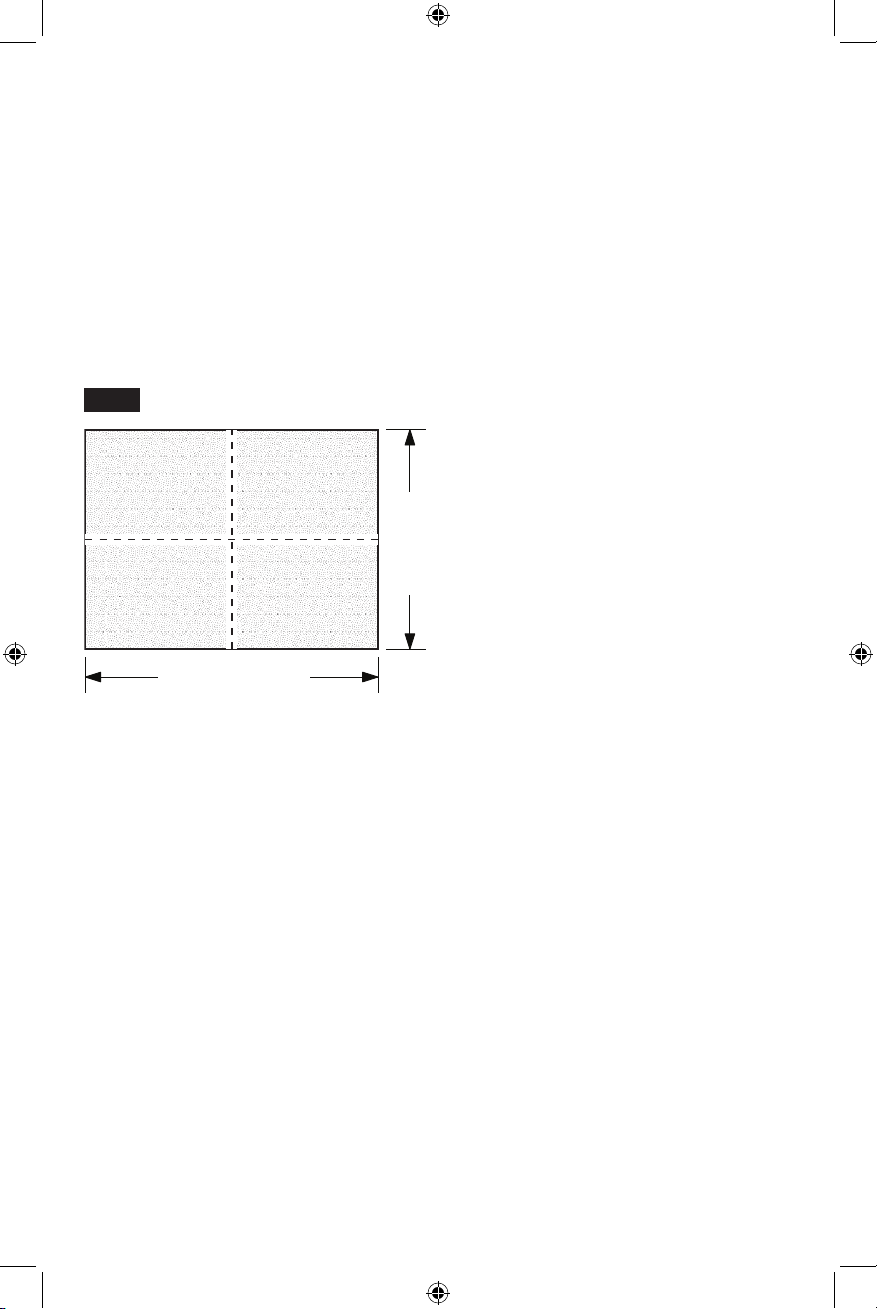

To install dust canister: align dust port 14 with

hole in canister 2 and push canister onto tool

until it locks into place (Fig. 7).

Fig. 7

CLEANING AND EMPTYING

THE DUST CANISTER

The dust canister is transparent which will

allow you to easily see when empting and

cleaning is required.

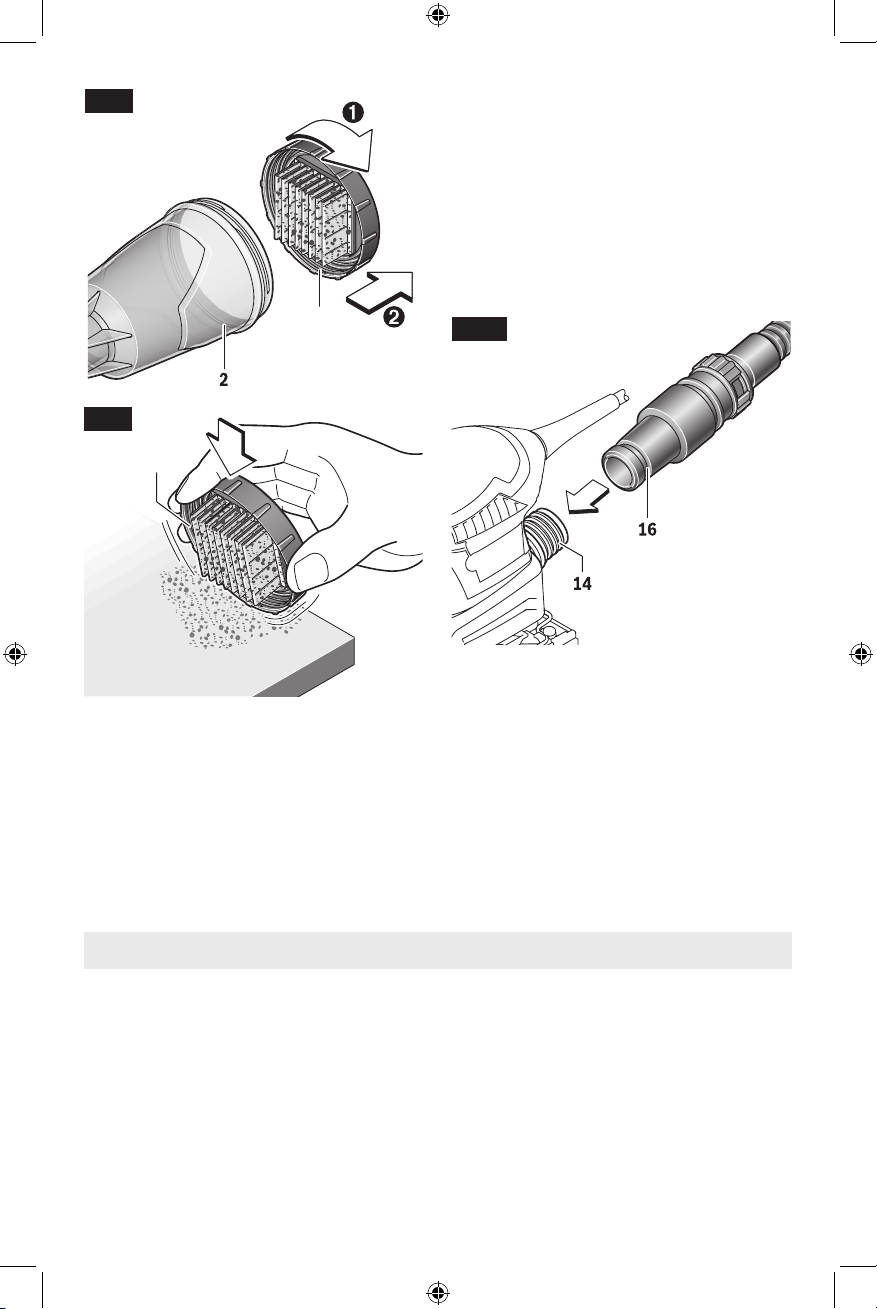

To empty the dust canister: screw off and

remove microfilter 3 from the dust canister 2

(Fig. 8).

Empty dust canister 2. It is recommended to

loosen dust from the microfilter 3 by gently

striking it against a solid surface (Fig. 9).

Knock excess dust out of the microfilter, or remove dust with your fingers or a soft brush.

You may notice that all the dust may not come

out of the canister. This will not affect sanding

performance but will reduce dust collection efficiency.

9

1600A00HX5 11-15 GSS20-40.indd 9 11/9/15 7:22 AM

Fig. 8

3

Fig. 9

3

Note: Do not wash the microfilter with soap

and water. Dust may become more firmly

lodged in the pores, which will reduce dust

collection, and damage the micro filter.

To ensure optimum dust extraction, empty and

clean the canister and microfilter frequently.

ATTACHING VACUUM HOSE

Dust collection can also be achieved by attaching the tool to a vacuum cleaner.

The tool’s dust port is sized to accept Bosch

vacuum cleaner hoses (sold separately) that

have rubber nozzles.

1. Attach the vacuum cleaner hose’s nozzle 16

to dust port 14 (Fig. 10).

2. Attach the opposite end of the hose to the

vacuum cleaner.

Fig. 10

To attach a 1-1/4” or 1-1/2” hose to the tool, the

Bosch VAC024 vacuum hose adapter (sold

separately) is required.

When vacuuming dry dust that is especially

detrimental to health or may be carcinogenic,

use a vacuum cleaner that is specifically designed for that purpose.

When sanding on vertical surfaces, hold the

power tool in such a manner that the vacuum

hose faces downward.

Operating Instructions

ROCKER “ON/OFF” SWITCH

To turn the tool ON or OFF: Push IN the

switch rocker to the left or right side of the

tool. Always hold the sander off the work when

turning the switch ON or OFF.

SANDING SHEETS (SANDPAPER)

Aluminum oxide, silicon carbide, or other synthetic abrasives are recommended for power

sanding use. Natural abrasives, such as flint

10

1600A00HX5 11-15 GSS20-40.indd 10 11/9/15 7:22 AM

or garnet sheet are too soft for economical

use in power sanding. For best results, use

Bosch sanding sheets: The uniform spacing

between grains minimizes filling or loading.

The high quality aluminum oxide sheet with

heavy backing cuts faster and lasts longer.

The following are recommended sanding

sheets and applications:

• Coarse Grit: For rough wood sanding.

• Medium Grit: For general wood sanding.

• Fine Grit: For smoothing wood or plaster

patches.

• Extra Fine Grit: For final sanding bare wood

and smoothing old paint.

There are also different types of sanding

sheets made for wood, paint and other surfaces.

Sanding sheets can be purchased pre-sized

or can be conveniently cut from large-size

commercially available sheets (standard

size: 9” x 11-1/16” or 228 x 280 mm). Cut into

four pieces of equal size as shown (Fig. 11).

Choose the proper grit for the job.

Fig. 11

CUT HERE

9" (228mm)

CUT HERE

11-1/16" (280mm)

SANDING TIPS

Bosch orbital sanders are designed to produce exceptional finishes on wood surfaces,

speed stock removal, or to remove lacquer,

varnish, and other coated finishes.

Orbital sanding provides fast, smooth final

finishes. And this model can sand flush on all

three sides of the tool to get in tight places

typical of cabinets, desks and shelving.

• Starting and stopping of sanding - Contact the work with the tool after sander has

reached its full speed and remove it from

the work before turning the switch “OFF”.

Operating in this manner will prolong switch

and motor life and will greatly increase the

quality of your work.

• This sander’s even weight distribution and

the prevention of sanding sheet slippage by

the clamping system virtually eliminate any

benefit from pressing on the sander. Excessive pressure to the sander may result in

an uneven sanding job and premature grit

wear. Constant and excessive pressure can

cause overheating and possible damage to

the motor, as well as premature wear out of

the pad.

• It’s usually best to work in strokes that parallel the grain, using some lateral motion so

the main strokes are overlapped as much

as 75%.

• If the surface is rough, start sanding with a

coarse grit, then medium, and then finish

with a fine or extra-fine grit. This procedure

will vary with different types of materials and

work.

• Continue to sand with each grit until the surface looks uniform.

• When going from one grit size to a finer

size, do not skip more than two grit sizes.

• To remove the greatest amount of stock, use

a coarse grit and move the sander steadily

over the entire surface against the grain as

well as with the grain. DO NOT REMAIN IN

ONE SPOT TOO LONG. It may remove too

much material and uneven sanding will result.

• Sanding with the grain of the wood gives the

smoothest final finish.

STORING THE SANDER

Do not store tool with PSA sanding sheets

on pad, as sanding creates heat, which will

cause an adhesive bond between the sheet

and the pad to harden when sheet and pad

cool down. (See REMOVING PSA SANDING

SHEETS on page 9.)

11

1600A00HX5 11-15 GSS20-40.indd 11 11/9/15 7:22 AM

Loading...

Loading...