Page 1

CHINA•BA 2 609 931 754•GSS 14/14 A/16 A•OSW 06/99•Titel

METAL

2 609 931 754 (99.06) O

Chlor

GSS 14

GSS 14 A

GSS 16 A

GB

6.....9

10...13

14...16

ø 25/35 mm

(3x) 2 605 411 067

(10x) 2 605 411 068

(1x) 2 605 411 096

(1x) 2 605 702 014

(1x) 1 600 499 005

GSS 14/A

GSS 16 A

GSS 16 A

GSS 16 A

(1x) 2 608 190 018

(1x) 2 608 190 011

(1x) 2 608 000 128

(1x) 2 608 000 071

180

…

320

GSS 14

GSS 14 A GSS 16 A GSS 16 A Nº

115 x 140 mm 80 x 133 mm 80 x 166 mm

10 P60 2 607 018 062

10 P80 2 607 018 063

10 P120 2 607 018 064

10 P180 2 607 018 065

10 P240 2 607 018 066

10 P60 2 607 018 087

10 P80 2 608 604 156

10 P120 2 607 018 088

10 P180 2 607 018 089

10 P240 2 608 604 157

10 P320 2 608 604 158

25 P40 2 607 018 091

25 P60 2 607 018 092

25 P80 2 607 018 093

25 P120 2 607 018 094

25 P180 2 607 018 095

25 P240 2 607 018 096

25 P40 2 607 018 079

25 P60 2 607 018 080

25 P80 2 607 018 081

25 P100 2 607 018 082

25 P120 2 607 018 083

25 P150 2 607 018 084

25 P180 2 607 018 085

25 P240 2 607 018 086

10 3xP120 2 607 018 090

40

…

120

240

4xP60

3xP180

60

…

180

…

320

80

…

240

40

…

120

120

…

240

Page 2

1

2

GSS 14 A

5

GSS 14

34

1

6

8

7

6

2

GSS 16 A

34

5

GSS 14 A

GSS 16 A

Page 3

4

4

3

GSS 14

GSS 14 A

9

3

GSS 16 A

10

Page 4

1

2

3

4

5

6

7

8

9

■

/ II /

■

■

■

■

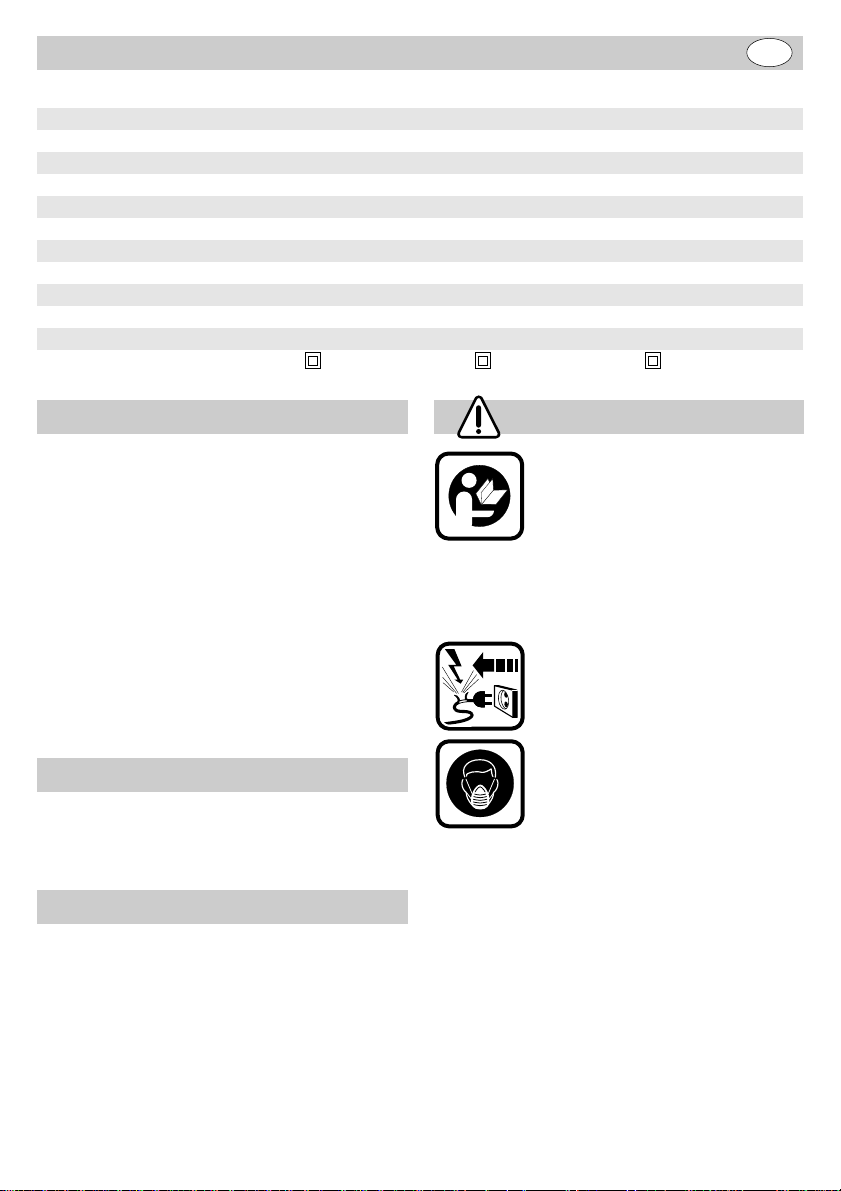

Tool Specifications

Orbital Sander GSS 14 GSS 14 A GSS 16 A

Part number

Input power 150 W 150 W 150 W

Output power 70 W 70 W 70 W

No-load speed 12 000 min

Oscillations

Oscillation range - ø 2,4 mm 2,4 mm 2,4 mm

Sanding Plate 113 x 105 mm 113 x 105 mm 80 x 130 mm

Sanding sheet (SDS) — — 80 x 133 mm

Sanding sheet (Standard) 115 x 140 mm 115 x 140 mm 80 x 166 mm

Integral dust extraction adapter attachable • •

Weight approx. 1,3 kg approx. 1,3 kg approx. 1,3 kg

Protection class / II

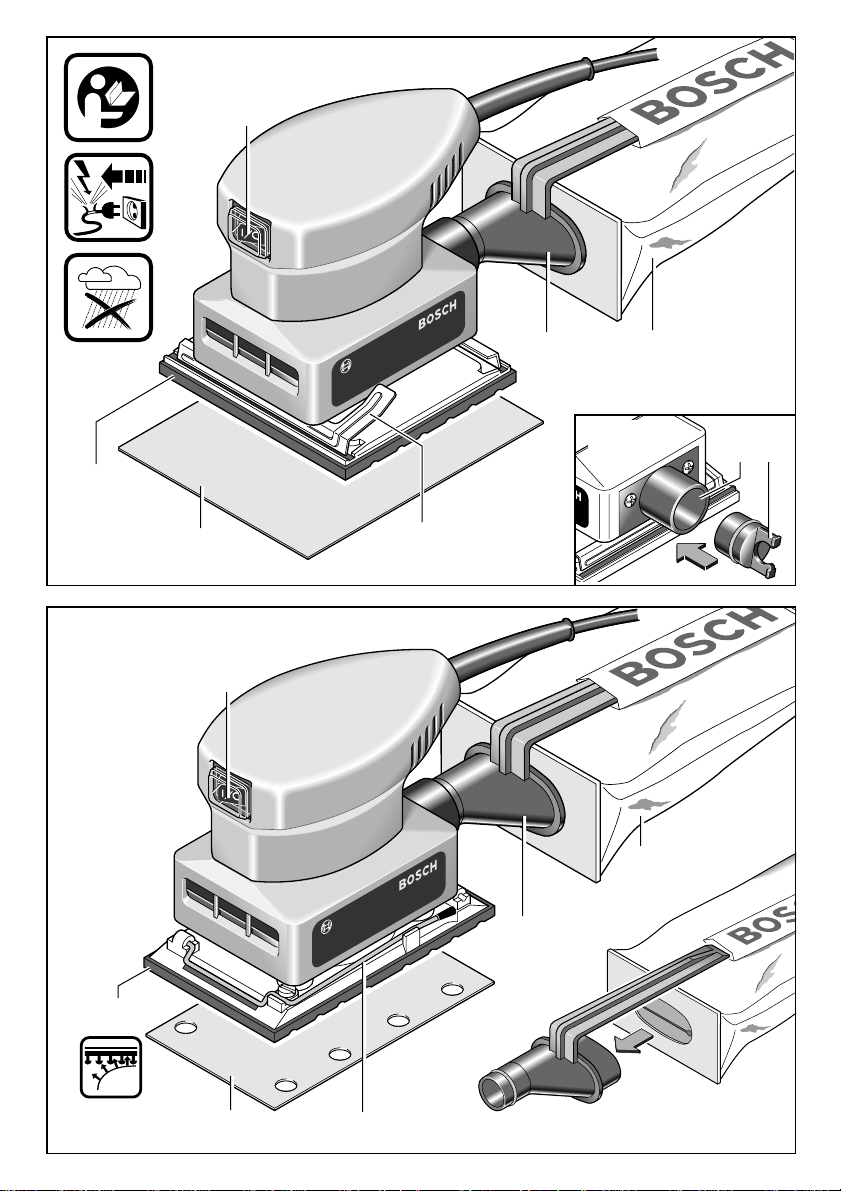

Operating Controls

ON/OFF switch

Sanding plate

Sanding sheet*

Clamping lever

Adapter

Paper dust bag

Vacuum socket

Plug

Punching tool

10 Tissue dust bag

*Accessory

*Not all of the accessories illustrated or described are

included as standard delivery.

Use as Intended

The machine is intended for the dry sanding of

wood, plastic, metal and filler material as well as

painted surfaces.

Noise/Vibration Information

Measured values determined according to

EN 50 144.

Typically the A-weighted sound pressure level of the

tool is 75 dB (A). The noise level when working can

exceed 85 dB (A).

Wear ear protection!

The typical weighted acceleration is 3,5 m/s

0 601 289 1.. 0 601 289 1.. 0 601 289 0..

24 000 min

-1

-1

12 000 min

24 000 min

-1

-1

12 000 min

24 000 min

II

For Your Safety

Working safely with this machine is

possible only when the operating

and safety information are read

completely and the instructions

contained therein are strictly followed. In addition, the general

safety instructions in the enclosed

booklet must be followed.

Before using for the first time, ask

for a practical demonstration.

If the cable is damaged or cut through

while working, do not touch the cable

but immediately pull the mains plug.

Never use the machine with a damaged cable.

The dust that is produced while working is detrimental to health. Use dust

extraction and wear a dust mask.

Do not work with materials containing

asbestos.

Connect machines that are used in the open via a

residual current circuit breaker with a triggering

current of 30 mA maximum. Use only extension

cables that are intended for outdoor use and are

protected against splash water.

The machine can be used only for dry sanding.

When working with the machine, always hold it

firmly with both hands and provide for a secure

stance.

Always direct the cable to the rear away from the

2

.

machine.

Bosch can assure flawless functioning of the

machine only when original accessories are

used.

GB

-1

-1

6

Page 5

■

■

■

■

Initial Operation

Always use the correct supply voltage: The voltage

of the power source must agree with the value given

on the nameplate of the machine.

Switching on and off

Switching on: Set ON/OFF switch 1 to “I“.

Switching off: Set ON/OFF switch 1 to “0“.

Dust Extraction

Dust extraction prevents large accumulations of dust, high concentrations

of dust in the ambient air and facilitates disposal.

For long periods of working with wood

or for commercial use on materials

that produce dust that is detrimental

to health, the machine is to be connected to a suitable external dust ex-

traction device.

Note: When working without a dust vacuum, plug 8

must be inserted in vacuum socket 7 .

Paper dust bag

Push dust bag 6 on adapter 5 . Ensure that adapter

engages in provided holder on dust bag. Insert dust

bag with adapter in vacuum socket 7 .

Empty or replace dust bag 6 regularly to ensure optimum dust extraction.

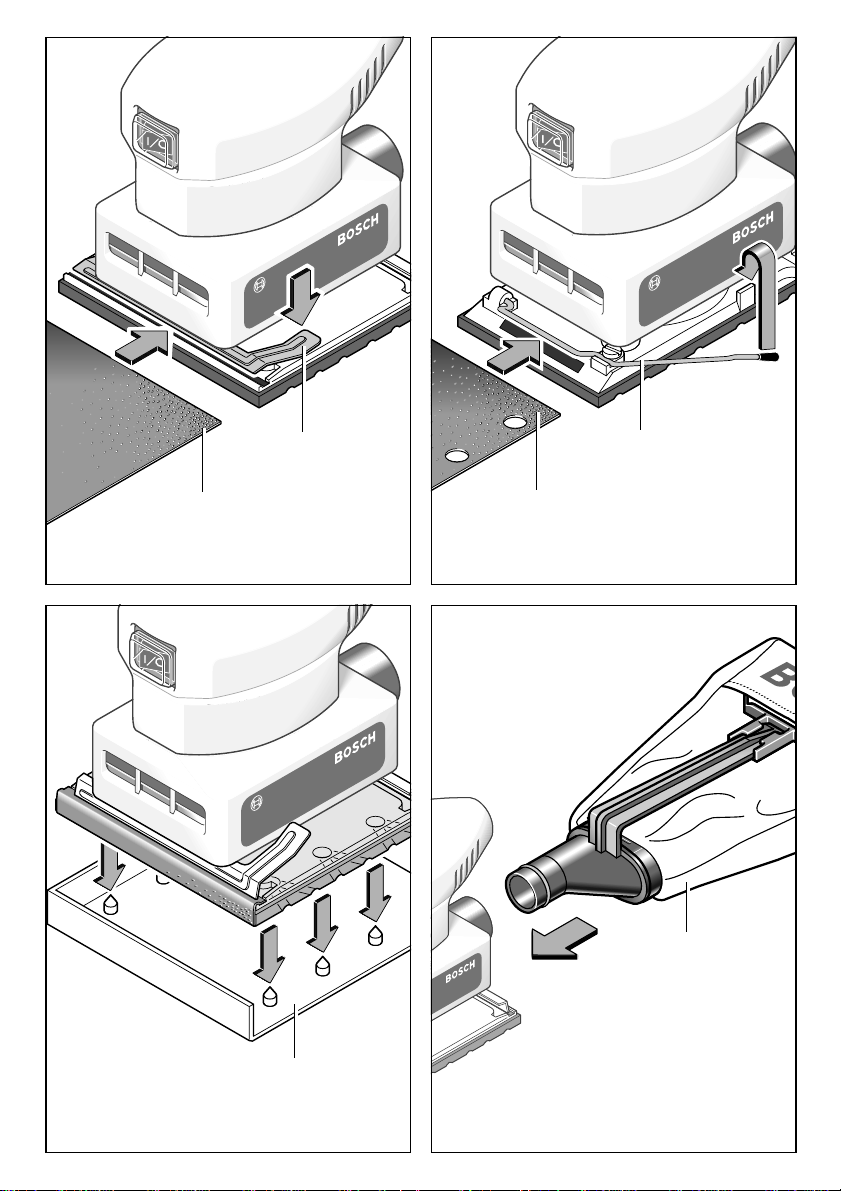

Changing Sanding Sheet

Before fitting new sanding sheets remove any dust

and dirt from sanding plate 2 .

Standard sanding sheets

Press or release securing clip 4 .

Push and lock sanding sheet under the open secur-

ing clip 4 .

Lock other end in the same manner. Ensure that

sanding sheet fits firmly against sanding plate 2 .

The perforation pattern in sanding plate 2 must be

aligned with that of sanding sheet 3 in order to ensure proper dust extraction through the sanding

plate.

Use punching tool 9 to punch holes for dust extraction into unperforated sanding sheets.

Sanding sheets with connecting link

system

(GSS 16 A)

The machine is fitted with a quickchange (connecting link) system, enabling sanding sheets to be changed

easily.

The pressure-sensitive sanding sheets are simply

pressed onto the Velcro-type sanding plate. Finished!

Only use original Bosch sanding sheets with

the pressure-sensitive connecting link.

Tissue dust bag (Accessory)

Push dust bag 10 on adapter 5 . Ensure that adapter

engages in provided holder on dust bag. Insert dust

bag with adapter in vacuum socket 7 .

External dust extraction with vacuum

cleaner

A vacuum adapter must be utilized when a vacuum

cleaner is used for external dust extraction (Accessory).

The appliance can be plugged directly into the

socket of a Bosch all-purpose vacuum cleaner which

incorporates a remote-control start device. The vacuum cleaner automatically starts when the appliance

is switched on.

Operating Instructions

Sanding

The removal rate is determined mainly by the sanding sheet selected and the controlled contact pressure of the sanding plate.

Move the orbital sander parallel and in circular spots

or alternately in lengthways and crossways directions. Do not apply excessive pressure to the orbital

sander!

An excessive increase in the application pressure

produces no increase in the sanding performance

and causes heavy wear to the machine and the

sanding tool.

Take care to apply uniform application pressure.

This increases the service life of the sanding

sheet.

Only flawless sanding sheet produce good sand-

ing results and protect the machine. Clogged

sanding sheet produce poor sanding results.

7

Page 6

■

■

Do not sand wood and metal with the same sand-

ing sheet.

Use only original Bosch sanding sheets and ac-

cessories.

Sample applications:

Material Grit

Paints: Roughening

Repairing scratches

Removing rust

Wood: Soft wood

Hard wood

Veneers

Metal: Aluminium

Steel

These are recommendations. The optimal sanding

grit and the best rotational speed are best determined in actual practice.

180

120

40

60-80

60

240

80

60

Maintenance and Cleaning

Before any work on the machine itself, pull the

mains plug.

Always keep the machine and the ventilation slots

clean.

If the machine should happen to fail despite the care

taken in manufacture and testing, repair should be

carried out by an authorised customer services

agent for Bosch power tools.

For all correspondence and spare parts orders, always include the 10 digit order number from the

nameplate of the machine!

Guarantee

We guarantee Bosch equipment in accordance with

statutory/country-specific regulations (proof of purchase by invoice or delivery note).

Damage attributable to normal wear and tear, overload or improper handling is excluded from the guarantee.

Claims can be recognised only when the machine is

sent, undismantled, to the dealer or a Bosch customer service centre for electric tools.

Environmental Protection

Recycle raw materials instead of

disposing as waste.

Machine, accessories and packaging

should be sorted for environmentfriendly recycling.

These instructions are printed on recycled paper

manufactured without chlorine. The plastic components are labelled for categorized recycling.

8

Page 7

Service

In case of a claim, repair or purchase of replacement parts or in case of queries or other problems please

contact your local dealer or Bosch-Representative.

People’s Republic of China

Shanghai

C. Melchers Ltd.

13/Fl, East Ocean Centre

588 Yan ‘an Road (East)

Shanghai 200001

Tel.

.................................................................

Fax

.................................................................

Guangzhou

C. Melchers Ltd.

Room 1108, T.P. Plaza

9/109 Liu Hua Road

Guangzhou 510010

Tel.

.................................................................

Fax

.................................................................

Beijing

C. Melchers Ltd.

Beijing Representatives

Room 503-504 Beijing Tower

No.10 Chang ‘an Avenue (East)

Beijing 100006

Tel.

...................................................................

Fax

..................................................................

Hongkong

C. Melchers Ltd.

1210 Shun Tak Centre, West-Tower

168-200 Connaught Road, Central

Hongkong

.......................................................................

Tel.

......................................................................

Fax

Indonesia

P. T. Multi Tehaka

Karang Anyar Permai Block B-24

Jl. Karang Anyar No. 55

Jakarta Pusat 10740

Indonesia

Tel.

...............................................

Fax

...............................................

(021) 659 5222 (5 lines)

(021) 659 5252 - 3

Phillippines

Robert Bosch Inc

Zuellig Building

Sen. Gil Puyat Avenue

Makati City 1200, Metro Manila

Philippines

......................................................................

Tel.

......................................................................

Tel.

......................................................................

Fax

(021) 635 28848

(021) 635 13138

(020) 866 68700

(020) 866 77845

(010) 512 3355

(010) 512 3505

(025) 469069

(025) 487914

(02) 844 8835

(02) 816 1303

(02) 843 8144

Thailand

Robert Bosch Ltd.

Liberty Square Building

No. 287, 11 Floor

Silom Road, Bangrak

Bangkok 10500

Tel.

............................... (02) 631 1879 - 1888 (10 lines)

............................... (02) 238 4783

Fax

Robert Bosch Ltd.

P. O. Box 2054

Bangkok 10501

Thailand

Bosch Service - Training Centre

2869-2869/1 Soi Ban Kluay

Rama IV Road (near old Paknam Railway)

Prakanong District

10110 Bangkok

Thailand

Tel. .............................................................. (02) 671 7800-4

Fax .............................................................. (02) 249 4296

Fax .............................................................. (02) 249 5299

Malaysia

Robert Bosch (SEA.) Pte. Ltd.

No 8a, Jalan 13/6

Selangor Darul Ehsan

Petaling Jaya 46200

Malaysia

Tel. ...................................................................... (03) 758 3000

Fax (EW Dept.) ............................................. (03) 758 3838

Singapore

Robert Bosch (SEA.) Pte. Ltd.

Thompson Road P.O. Box 4

Singapore 915701

Republic of Singapore

Tel. .................................................................................. 58 5511

Fax .................................................................................. 58 4671

Visitors:

38 C Jalan Pemimpin

Singapore 577180

Vietnam

Ho Chi Minh City

Robert Bosch (S.E.A.) Pte. Ltd.

Representative Office HCMC

243 Hoang van Thu - Tan Binh

Ho Chi Minh City

.................................................................. (848) 847 87 65

Tel.

Fax .................................................................. (848) 847 83 28

Subject to change without notice

9

Page 8

10

SDS

1

2

3

4

5

6

7

8

9

GSS 14 GSS 14 A GSS 16 A

0 601 289 1..

150

70

12 000

24 000

2.4

113 x 105

0 601 289 1.. 0 601 289 0..

150

70

12 000

24 000

2.4

113 x 105

150

70

12 000

24 000

2.4

80 x 130

– – 80 x 133

115 x 140

1.3

/ II

115 x 140

••

1.3

/ II

80 x 166

1.3

/ II

E E E

10

85 dB (A)

3.5 m/s

EN 50 144

75 dB (A)

2

■

30mA

■

■

■

■

Bosch

Page 9

2

4

”1“

”0“

2

(GSS 16 A)

2

3

9

4

8

7

■

BOSCH

6

10

5

7

6

5

7

Bosch

■

■

■

■

■

Bosch

11

Page 10

180

120

Bosch

10

40

60-80

60

240

80

60

Bosch

Bosch

12

Page 11

10

503-504

(0086) 10 512 3355, 512 3356

(0086) 10 512 3505

100006

200

713

(00852) 25 469069

(00852) 25 487914

1210

588

13

(0086) 21 635 28848

(0086) 21 635 13138

200001

109

1108

(0086) 20 86668700

(0086) 20 86677845

510010

13 6 8

(0060) 3 758 3000

(0060) 3 758 3838

9

4

9157

(0065) 258 5511

46200

13

Page 12

RC

10

SDS

1

2

3

4

5

6

7

8

9

GSS 14 GSS 14 A GSS 16 A

0 601 289 1..

150

70

12 000

24 000

2.4

113 x 105

– – 80 x 133

115 x 140

1.3

/ II

E E E

0 601 289 1.. 0 601 289 0..

150

70

12 000

24 000

2.4

113 x 105

115 x 140

••

1.3

/ II

150

70

12 000

24 000

2.4

80 x 130

80 x 166

1.3

/ II

14

85 dB (A)

3.5 m/s

2

EN 50 144

75 dB (A)

Bosch

30

mA

■

■

■

■

■

Page 13

2

4

”I“

”0“

2

(GSS 16 A)

2

3

9

4

8

7

■

BOSCH

6

10

5

7

6

5

7

Bosch

■

■

■

■

■

Bosch

15

Page 14

180

120

■

Bosch

10

40

60-80

60

240

80

60

Bosch

10454

(00886) 2 551 3264-9

(00886) 2 551 3260

Bosch

380

9

16

Loading...

Loading...