Bosch GSR12V-140FC User Manual

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Saf

Consignes de sécurité/d’utilisation

Instrucciones de funcionamiento y seguridad

GSR12V-140FC

ety Instructions

Call Toll Free for

Consumer Information

and Service Locations

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

For English Version Version française Versión en español

See page 2 Voir page 15 Ver la página 29

2610045267 A5.indd 1 11/23/16 9:49 AM

Pour obtenir des informa-

tions et les adresses de nos

centres de

service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

Safety Symbols

The definitions below describe the level of severity for each signal word. Please read the manual

!

and pay attention to these symbols.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not avoided, will result in minor or moderate injury.

General Power Tool Safety Warnings

Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

Work area safety

Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create

sparks which may ignite the dust or fumes.

Keep children and bystanders away while operating a power tool. Distractions can cause you

to lose control.

Electrical safety

Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of elec-

tric shock if your body is earthed or grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

2

cords increase the risk of electric shock.

When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

If operating a power tool in a damp location is

unavoidable, use a Ground Fault Circuit Interrupter (GFCI) protected supply. Use of an GFCI

reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication. A moment of inattention while operating

power tools may result in serious personal injury.

Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat,

or hearing protection used for appropriate conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and / or battery pack, picking

up or carrying the tool. Carrying power tools

with your finger on the switch or energizing power

tools that have the switch on invites accidents.

2610045267 A5.indd 2 11/23/16 9:49 AM

Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or

jewelry. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewelry

or long hair can be caught in moving parts.

If devices are provided for the connection of

dust extraction and collection facilities, ensure these are connected and properly used.

Use of dust collection can reduce dust-related

hazards.

Power tool use and care

Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such pre-

ventive safety measures reduce the risk of starting the power tool accidentally.

Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate the power tool. Power tools are dangerous in

the hands of untrained users.

Maintain power tools. Check for misalignment or binding of moving parts, breakage of

parts and any other condition that may affect

the power tool’s operation. If damaged, have

the power tool repaired before use. Many ac-

cidents are caused by poorly maintained power

tools.

Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the pow-

er tool for operations different from those intended could result in a hazardous situation.

Battery tool use and care

Recharge only with the charger specified by

the manufacturer. A charger that is suitable for

one type of battery pack may create a risk of fire

when used with another battery pack.

Use power tools only with specifically designated battery packs. Use of any other battery

packs may create a risk of injury and fire.

When battery pack is not in use, keep it away

from other metal objects like paper clips,

coins, keys, nails, screws, or other small metal objects that can make a connection from

one terminal to another. Shorting the battery

terminals together may cause burns or a fire.

Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact

accidentally occurs, flush with water. If liquid

contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation or burns.

Service

Have your power tool serviced by a qualified

repair person using only identical replacement parts. This will ensure that the safety of the

power tool is maintained.

Safety Rules for Cordless Drill/Drivers

Use auxiliary handle(s) if supplied with the

tool. Loss of control can cause personal injury.

Hold power tool by insulated gripping surfaces, when performing an operation where the

cutting accessory may contact hidden wiring.

Cutting accessory contacting a “live” wire may

make exposed metal parts of the power tool “live”

and could give the operator an electric shock.

Use clamps or another practical way to se-

2610045267 A5.indd 3 11/23/16 9:49 AM

cure and support the workpiece to a stable

platform. Holding the work by hand or against

your body leaves it unstable and may lead to loss

of control.

Do not drill, fasten or break into existing walls

or other blind areas where electrical wiring

may exist. If this situation is unavoidable, dis-

connect all fuses or circuit breakers feeding this

worksite.

3

Always hold the tool with both hands. If the

bit jams two hands will give you maximum control

over torque reaction or kickback.

Always wear safety goggles or eye protection

when using this tool. Use a dust mask or respirator for applications which generate dust.

Secure the material being drilled. Never hold

it in your hand or across legs. Unstable sup-

port can cause the drill bit to bind causing loss of

control and injury.

Disconnect battery pack from tool or place

the switch in the locked or off position before making any assembly, adjustments or

changing accessories. Such preventive safety

measures reduce the risk of starting the tool accidentally.

Position yourself to avoid being caught between the tool or side handle and walls or

posts. Should the bit become bound or jammed

in the work, the reaction torque of the tool could

crush your hand or leg.

If the bit becomes bound in the workpiece,

release the trigger immediately, reverse the

direction of rotation and slowly squeeze the

trigger to back out the bit. Be ready for a strong

Additional Safety Warnings

reaction torque. The drill body will tend to twist in

the opposite direction as the drill bit is rotating.

Do not grasp the tool or place your hands too

close to the spinning chuck or drill bit. Your

hand may be lacerated.

When installing a bit, insert the shank of the

bit well within the chuck. If the bit is not insert-

ed deep enough, the grip of the chuck over the

bit is reduced and the loss of control is increased.

After bit insertion, pull on bit to ensure it is locked.

Do not use dull or damaged bits and accessories. Dull or damaged bits have a greater ten-

dency to bind in the workpiece.

When removing the bit from the tool avoid

contact with skin and use proper protective

gloves when grasping the bit or accessory.

Accessories may be hot after prolonged use.

Check to see that keys and adjusting wrenches are removed from the drill before switching

the tool “ON”. Keys or wrenches can fly away at

high velocity striking you or a bystander.

Do not run the drill while carrying it at your

side. A spinning drill bit could become entangled

with clothing and injury may result.

GFCI and personal protection devices like electrician’s rubber gloves and footwear will further

enhance your personal safety.

Do not use AC only rated tools with a DC power supply. While the tool may appear to work, the

electrical components of the AC rated tool are

likely to fail and create a hazard to the operator.

Keep handles dry, clean and free from oil and

grease. Slippery hands cannot safely control the

power tool.

Develop a periodic maintenance schedule for

your tool. When cleaning a tool be careful not

to disassemble any portion of the tool since

internal wires may be misplaced or pinched

or safety guard return springs may be improperly mounted. Certain cleaning agents such as

gasoline, carbon tetrachloride, ammonia, etc.

may damage plastic parts.

Ensure the switch is in the off position before

inserting battery pack. Inserting the battery

pack into power tools that have the switch on invites accidents.

ing, drilling, and other construction activities

contains chemicals known to cause cancer,

birth defects or other reproductive harm.

Some examples of these chemicals are:

• Leadfromlead-basedpaints,

• Crystallinesilica frombricksandcementand

other masonry products, and

• Arsenicandchromium from chemically-treated lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are

specially designed to filter out microscopic particles.

Some dust created by power sanding, sawing, grind-

4

2610045267 A5.indd 4 11/23/16 9:49 AM

Symbols

IMPORTANT: Some of the following symbols may be used on your tool. Please study them and learn

their meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Powe r

kg Kilograms Weight

min Minutes Time

s Seconds Time

⌀

.../min Revolutions or reciprocation per min-

1, 2, 3, ...

I, II, III,

Diameter Size of drill bits, grinding wheels, etc.

No load speed Rotational speed, at no load

n

0

n Rated speed Maximum attainable speed

ute

0 Off position Zero speed, zero torque...

Selector settings Speed, torque or position settings. Higher num-

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated Construction tools.

Earthing terminal Grounding terminal

Li-ion RBRC seal Designates Li-ion battery recycling program

Revolutions, strokes, surface speed, orbits etc.

per minute

ber means greater speed

Ni-Cad RBRC seal Designates Ni-Cad battery recycling program

Read manual symbol Alerts user to read manual

Wear eye protection symbol Alerts user to wear eye protection

5

2610045267 A5.indd 5 11/23/16 9:49 AM

Symbols (continued)

IMPORTANT: Some of the following symbols may be used on your tool. Please study them and learn

their meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this component is recognized by Underwriters Laboratories.

This symbol designates that this tool is listed by Underwriters Laboratories, to United States and Canadian

Standards.

This symbol designates that this tool is listed by the Canadian Standards Association.

This symbol designates that this tool is listed by the Canadian Standards Association, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Intertek Testing Services, to United States and Canadian

Standards.

This symbol designates that this tool complies to NOM

Mexican Standards.

6

2610045267 A5.indd 6 11/23/16 9:49 AM

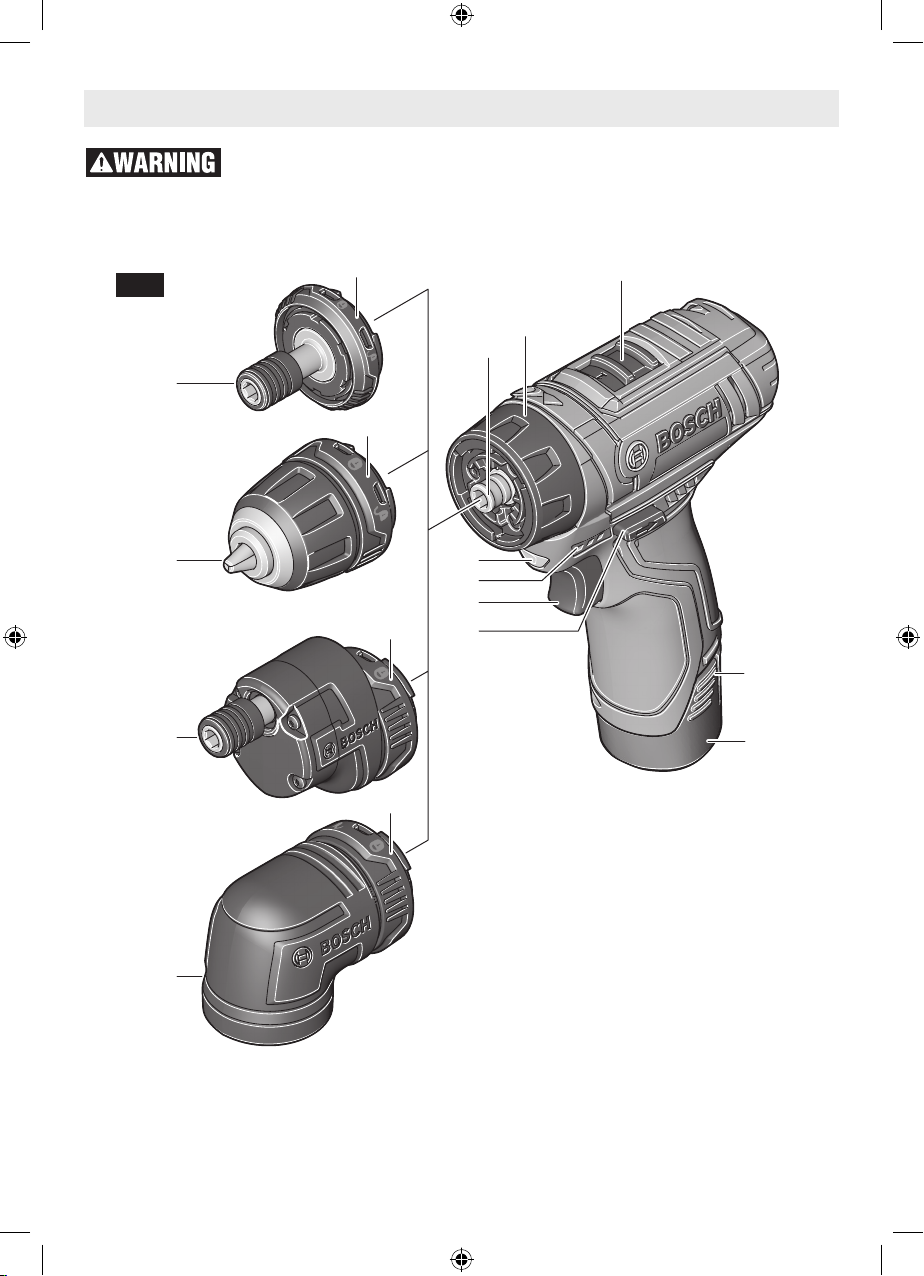

Disconnect battery pack from tool before making any assembly, adjustments

14

or changing accessories. Such preventive safety measures reduce the risk of

starting the tool accidentally.

Functional Description

Cordless Drill/Driver

Fig. 1

10

11

12

13

14

14

14

3

2

1

9

8

7

6

4

5

1 Hex Drive

2 Adjustable clutch

3 Gear shifter

4 Battery release tabs

5 Battery pack

6 Forward/reversing lever and trigger lock

7 Variable speed trigger switch

8 Battery charge status indicator lights

9 Built in work light

10 Bit holder adapter

11 Drill chuck adapter

12 Offset adapter

13 Right angle adapter

14 Lock ring

7

2610045267 A5.indd 7 11/23/16 9:49 AM

Specifications

Model number GSR12V-140FC

Voltage rating 10.8V/12V

No load speed 1 n

No load speed 2 n

Bit holder 1/4" (6.35mm) Hex-shank with power groove

Drill chuck Ø 3/8" (10mm)

Driving screw sizes 9/32" (7mm)

Drilling wood 3/4" (19mm)

Please refer to the Charger Manual included with your tool.

NOTE: For tool specifications refer to the nameplate on your tool.

0-400/min

0

0-1,300/min

0

Maximum Capacities:

Battery Packs/Chargers

MAX

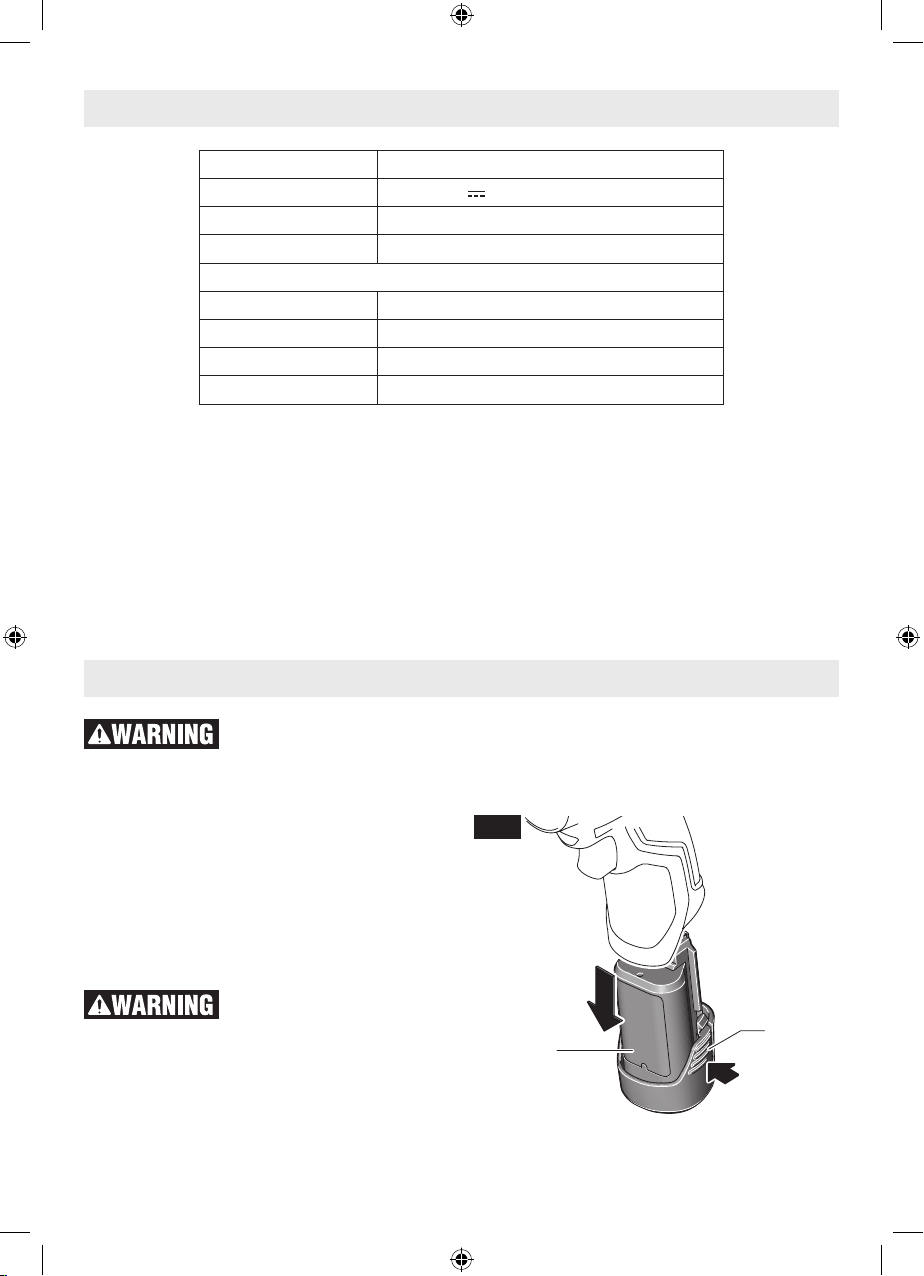

Assembly

Disconnect battery pack from tool before making any assembly, adjustments

starting the tool accidentally.

Inserting and releasing

or changing accessories. Such preventive safety measures reduce the risk of

Fig. 2

battery pack

Release battery pack 5 from tool by pressing on

both sides of the battery release tabs 4 and pulling battery downward (Fig. 2).

To insert battery, align battery and slide battery

pack 5 into tool until it locks into position. Do not

force.

If battery release tabs are

aged, do not insert into tool. Battery can fall out

during operation.

cracked or otherwise dam-

5

8

2610045267 A5.indd 8 11/23/16 9:49 AM

4

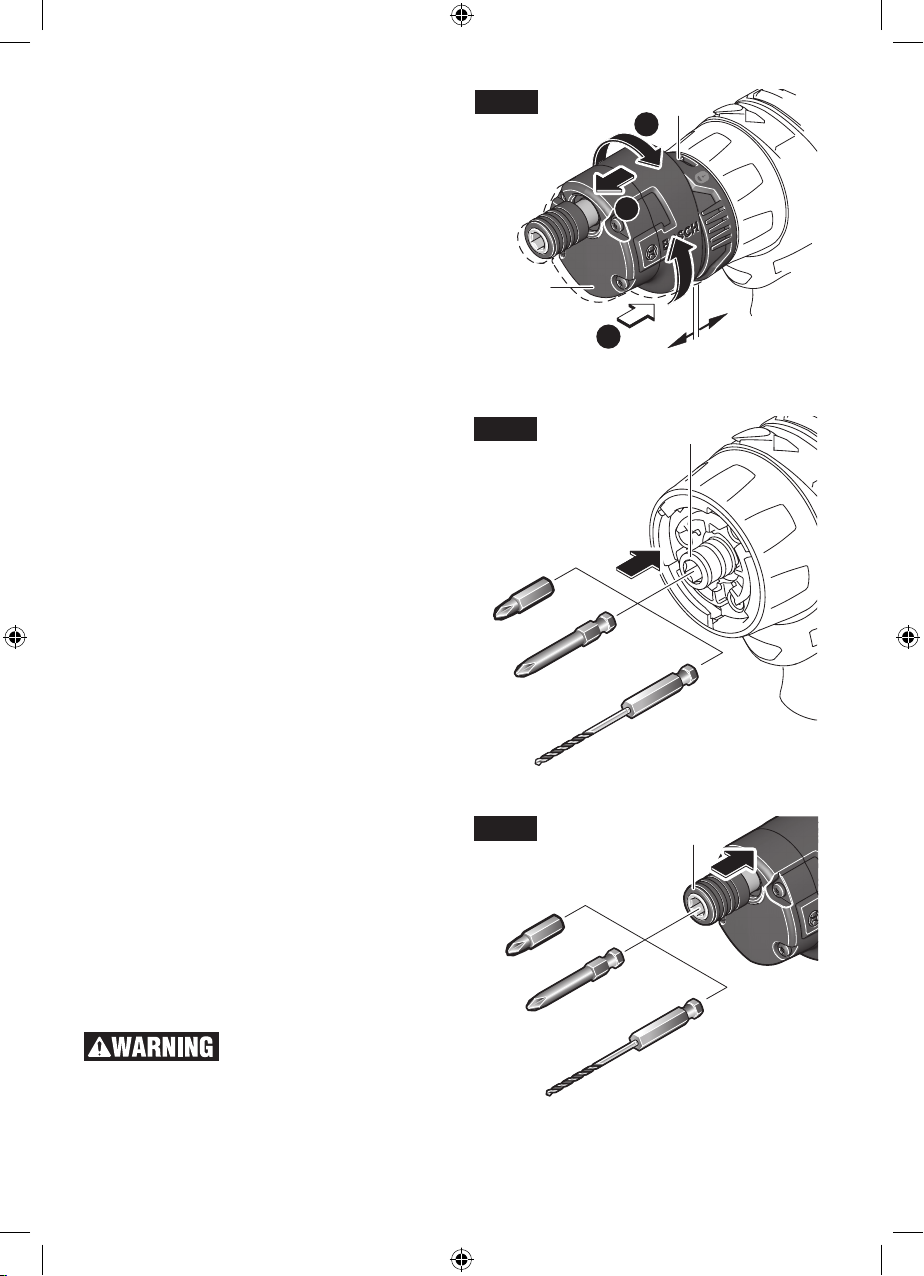

Mounting and Removing Adapters

)

A. Make sure the hex drive 1 is free. Pull out any

bit you might have used.

B. Insert the hex shaft of an adapter into the drive

1 and push the adapter until it snaps in place.

You may need to rotate the adapter a little.

C. Lock the adapter in place by turning the lock

ring 14 in the direction shown until it clicks

(Fig. 3).

To remove any adapter, turn the lock ring 14 in

the direction shown until it clicks. Pull the adapter

away from the tool (Fig. 4).

Fig. 3

1

B

A

C

14

Using Right Angle Adapter

You can rotate the right angle adapter 13 to any

position around the axis of the tool in 9° increments. See Fig. 5.

A. Make sure the adapter is locked on the tool.

Pull the adapter 13 away from the lock ring 14

approximately 3/16” (5mm).

B. Rotate the adapter 13 to a desired position.

C. Release the pull and let the adapter return to

the locked position.

The right angle adapter’s interface 13a is identical to the interface of the power tool. You can

attach the other 3 adapters to it the same way

as the adapters are mounted to the tool (See

“Mounting and Removing Adapters”).

Fig. 4

Fig. 5

13a

14

max. 3/16” (5mm

B

A

14

13

C

9

2610045267 A5.indd 9 11/23/16 9:49 AM

Using Offset Adapter

You can rotate the offset adapter 12 to any position around the axis of the tool in 9° increments.

See Fig. 6.

A. Make sure the adapter is locked on the tool.

Pull the adapter 12 away from the lock ring 14

by approximately 3/16” (5mm).

B. Rotate the adapter 12 to desired position.

C. Let the adapter snap back towards the lock

ring 14.

Fig. 6

14

B

A

12

C

max. 3/16” (5mm)

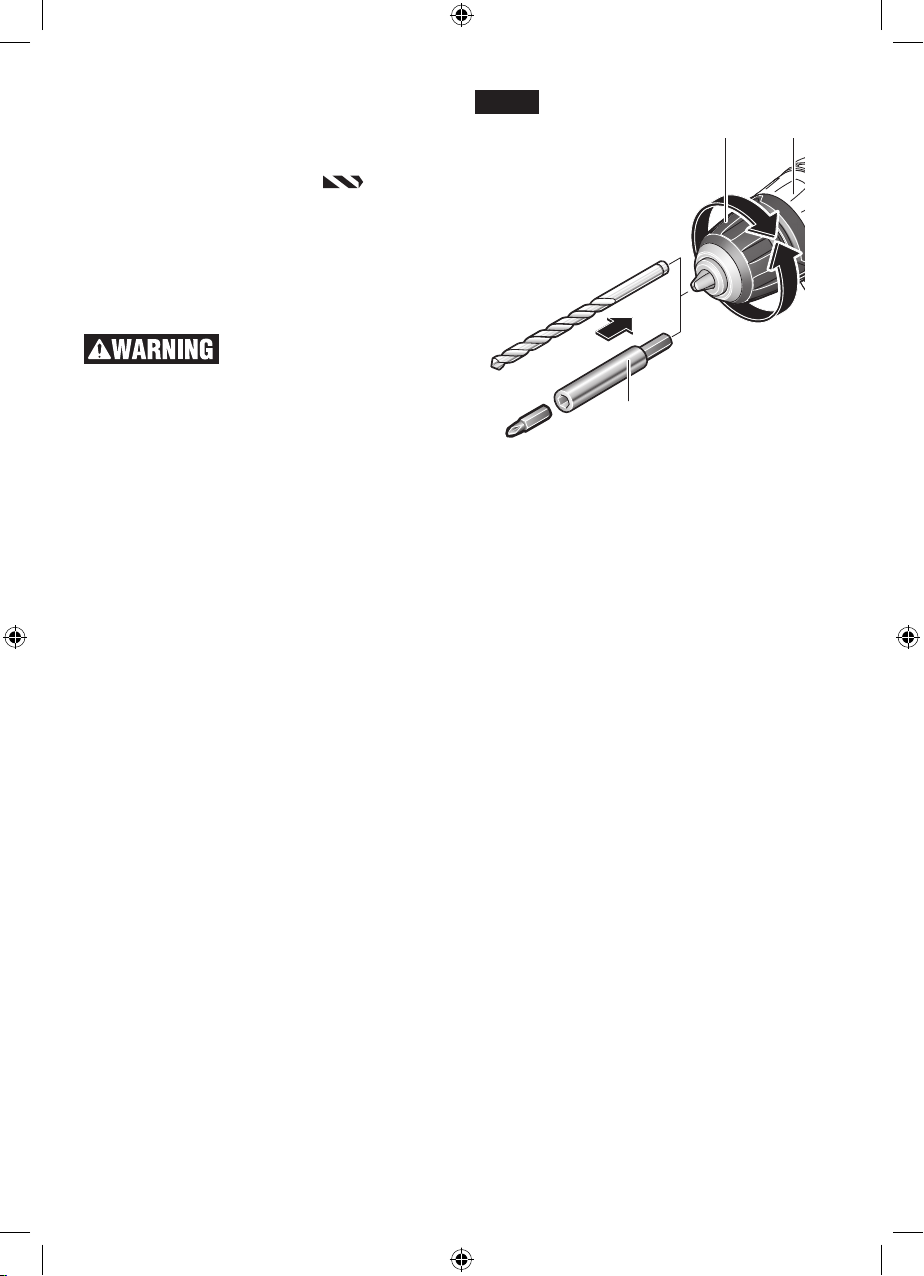

Inserting and Removing Bits

(Main Hex Drive)

You can insert any 1/4” hex bits directly into the

main hex drive 1 without using any of the adapters (Fig. 7). The hex drive is magnetized and will

prevent the bits from falling out during light drilling

or driving.

To remove a bit, simply pull it out.

Inserting and Removing Bits (Hex

Chuck)

Bit holder adapter 10 and offset adapter 12 have

a chuck that accepts any 1/4” hex bit.

To insert an accessory, simply pull locking sleeve

12a backward, insert desired accessory into

chuck and release the locking sleeve to lock the

bit (Fig. 8).

To remove an accessory, pull locking sleeve

backward and remove it from the chuck.

To avoid loss of control, ensure bit is locked in chuck

by pulling on bit after it has been inserted.

Fig. 7

Fig. 8

1

12a

10

2610045267 A5.indd 10 11/23/16 9:49 AM

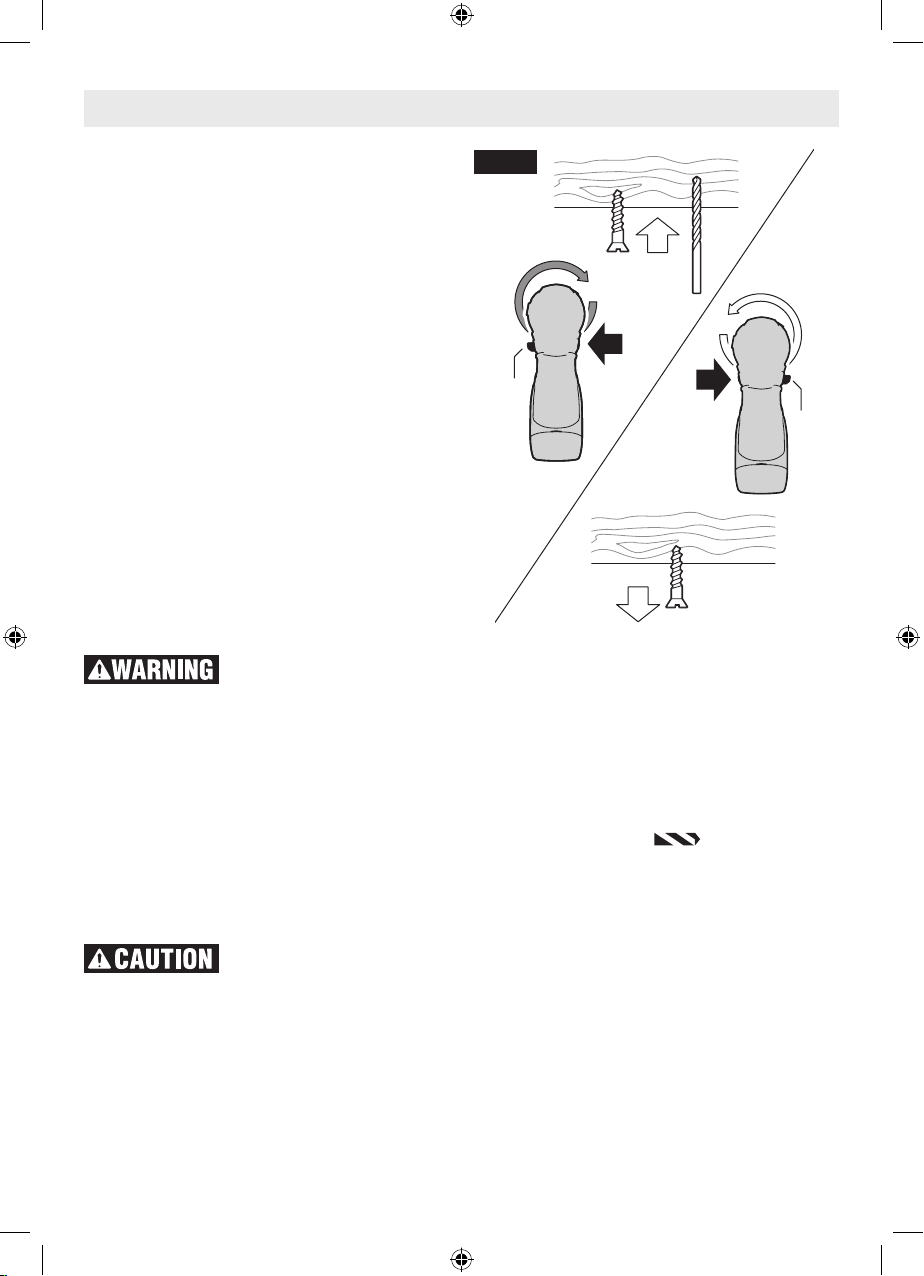

Inserting and Removing Bits

(Drill Chuck)

Move forward/reversing lever 6 to the center “OFF”

position. Remove battery pack 5 and rotate the

clutch ring 2 to the drill bit symbol

chuck sleeve 11a counter-clockwise viewing from

chuck end, and open chuck to approximate drill

bit diameter. Insert a clean bit up to the drill bit

flutes for small bits, or as far as it will go for large

bits. Close chuck by rotating the chuck sleeve

11a clockwise and securely tighten by hand (Fig.

9).

Do not use the power of the

drill while grasping chuck

to loosen or tighten bit. Friction burn or hand

injury is possible if attempting to grasp the spinning chuck.

. Rotate the

Fig. 9

11a 2

16

11

2610045267 A5.indd 11 11/23/16 9:49 AM

Operating Instructions

Protection Against

Deep Discharging

The lithium ion battery is protected against deep

discharging by the “Electronic Cell Protection

(ECP)”. When the battery is discharged, the tool

is switched off by means of a protective circuit.

Variable Speed Controlled Trigger

Switch

Your tool is equipped with a variable speed trigger switch. The tool can be turned “ON” or “OFF”

by squeezing or releasing the trigger. The speed

can be adjusted from the minimum to maximum

nameplate RPM by the pressure you apply to

the trigger. Apply more pressure to increase the

speed and release pressure to decrease speed

(Fig. 1).

Brake

When the trigger switch is released it activates

the brake to stop the chuck quickly. This is especially useful in the repetitive driving and removal

of screws.

Forward/Reversing Lever

and Trigger Lock

After tool use, lock trigger

in “OFF” position to help

prevent accidental starts and accidental discharge.

Your tool is equipped with a forward/reversing lever and trigger lock 6 located above the trigger

(Fig. 10). This lever was designed for changing

rotation of the bit, and for locking the trigger in an

“OFF” position.

For forward rotation, (with chuck pointed away

from you) move the lever to the far left.

For reverse rotation move the lever to the far right.

To activate trigger lock move lever to the center

off position.

Do not change direction of

rotation until the tool comes

to a complete stop. Shifting during rotation of

the chuck can cause damage to the tool.

Gear Shifting

Your tool is equipped with two separate gear

ranges, low gear and high gear. Low gear provides high-torque and slower drilling speeds for

heavy duty work or for driving screws. High gear

provides faster speeds for drilling lighter work. To

Fig. 10

6

6

change speeds slide switch, to the high or low

position (Fig. 1).

ATTENTION: If your tool appears to be running,

but the chuck will not turn, check to make sure

the gear shifting switch is pushed fully into desired setting.

Adjustable Clutch

Your tool features 21 clutch settings. Output

torque will increase as the clutch ring, is rotated

from 1 to 20. The drill “

up the clutch to permit drilling and driving heavy

duty work (Fig. 1).

” position will lock

Autolock™

Your tool is equipped with an automatic locking

system. This feature will lock the bit holder in one

position when the trigger switch is released. This

will allow you to tighten or loosen a nut or screw

by rotating the tool by hand with the switch off.

This is convenient when higher turning torque is

needed.

Built-in Work Light

Your tool is also equipped with a light that turns

on automatically when the switch is activated, for

better visibility when drilling/driving (Fig. 1).

12

2610045267 A5.indd 12 11/23/16 9:49 AM

Battery Charge Condition

Indicator Lights

Your tool is equipped with charge condition indicator lights (Fig. 1). The indicator lights shows the

charge condition of the battery for a few second

when the On/Off trigger is pressed halfway or

fully.

Operating Tips

LED Capacity

Continuous lighting 3 x green > 2/3

Continuous lighting 2 x green > 1/3

Continuous lighting 1 x green < 1/3

Flashing light 1 x green reserve

Driving Nuts And Bolts

Variable speed control must be used with caution

for driving nuts and bolts with socket set attachments. The technique is to start slowly, increasing

speed as the nut or bolt runs down. Set the nut

or bolt snugly by slowing the drill to a stop. If this

procedure is not followed, the tool will have a tendency to torque or twist in your hands when the

nut or bolt seats.

Drilling

You will extend the life of your bits and do neater

work if you always put the bit in contact with the

work before pulling the trigger. During the opera tion, hold the tool firmly and exert light, steady

pressure. Too much pressure at low speed will

stall the tool. Too little pressure will keep the bit

from cutting and cause excess friction by sliding

over the surface. This can be damaging to both

tool and bit.

Drilling With Variable Speed

The variable speed trigger allows you to slowly

increase RPM. By using a slow starting speed,

you are able to keep the bit from “wander ing”. You

can increase the speed as the bit “bites” into the

work by squeezing the trigger.

Driving With Variable Speed

Variable speed drills will double as a power

screwdriver by using a screwdriver bit. Prior to

driving screws, pilot and clearance holes should

be drilled. Place the threaded end of the screw in

the pilot or clearance hole and start driving the

screw slowly, increasing the speed as the screw

runs down. Set the screw snugly by slowing to a

stop.

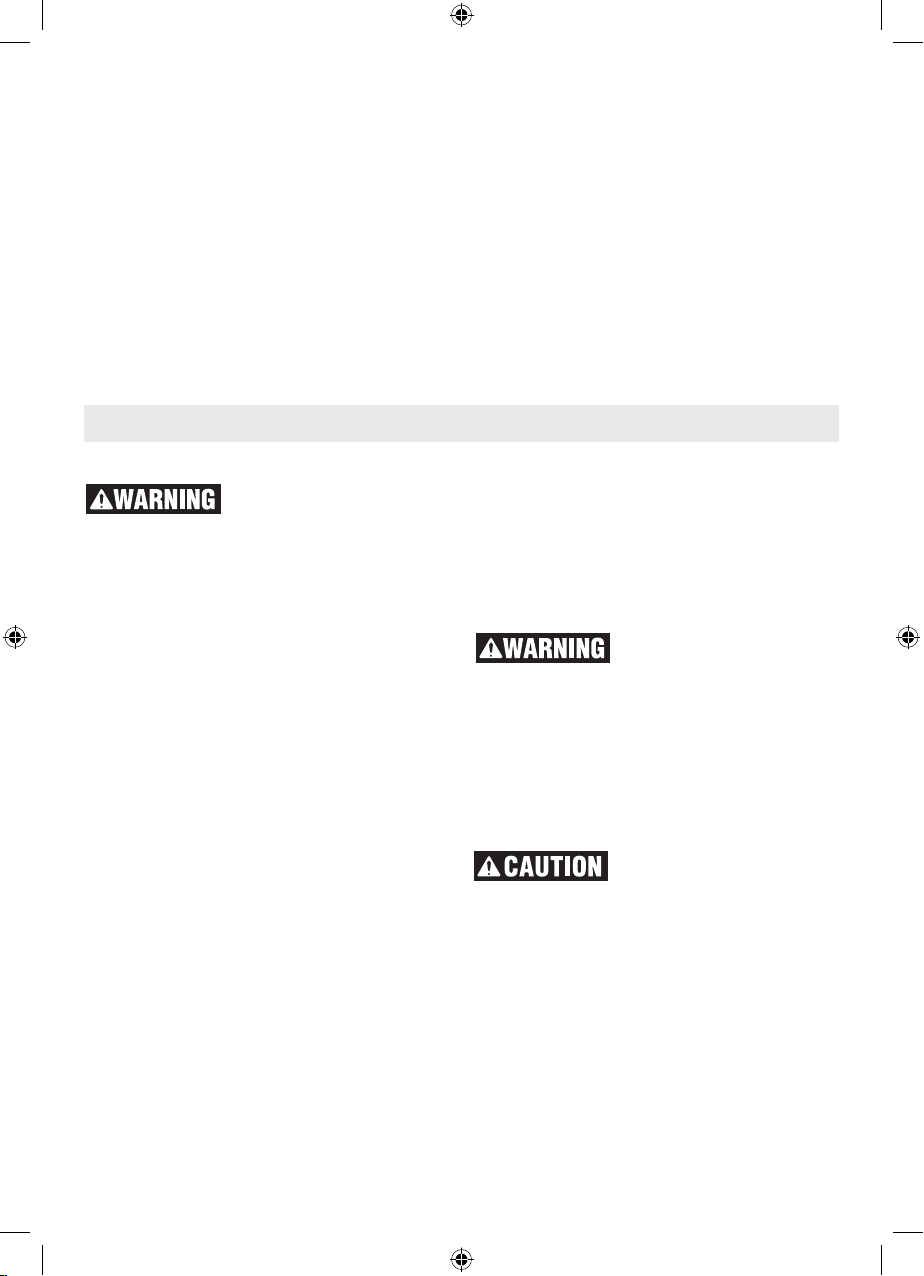

Fastening With Screws

The procedure shown in Fig. 11 will enable you to

fasten materials together using your drill without

stripping, splitting or separating the material.

First, clamp the pieces together and drill the hole

2/3 the diameter of the screw. If the material is

FASTENING WITH

SCREWS

1. Drill 2/3 diameter

and 2/3 of screw

length for soft materials, full length for

hard materials.

Apply a slight even

pressure when driving

screws.

2. Drill same di-

ameter as screw

shank.

3. Countersink

same diameter

as screw head.

Screw

Top

Bottom

Fig. 11

soft, drill only 2/3 the proper length. If it is hard,

drill the entire length.

Second, unclamp the pieces and drill the hole in

the top piece of wood again to the same diameter

as the shank of the screw.

Third, if flat head screw is used, countersink the

hole to make the screw flush with the surface.

Realign the holes on the two pieces and apply

even pressure when driving the screw. The screw

shank clearance hole in the first piece allows the

screw head to pull the pieces tightly together.

The adjustable screw drill accessory will do all of

these operations quickly and easily. Screw drills

are available for screw sizes No. 6, 8, 10 and 12.

Drill Bits

Always inspect drill bits for excessive wear. Use

only bits that are sharp and in good condition.

TWIST BITS: Available with straight and reduced

shanks for wood and light duty metal drilling. High

speed bits cut faster and last longer on hard materials.

CARBIDE TIPPED BITS: Used for drilling stone,

con crete, plaster, cement and other unusually hard nonmetals. Use continuous heavy feed

pres sure when employing carbide tip bits.

13

2610045267 A5.indd 13 11/23/16 9:49 AM

Drilling Wood

Be certain workpiece is clamped or anchored

firm ly. Always apply pressure in a straight line with

the drill bit. Maintain enough pressure to keep the

drill “biting”.

When drilling holes in wood, twist bits can be

used. Twist bits may overheat unless pulled out

frequently to clear chips from flutes.

Use a “back-up” block of wood for work that is

likely to splinter, such as thin materials.

You will drill a cleaner hole if you ease up on the

pressure just before the bit breaks through the

wood. Then complete the hole from the back side.

Maintenance

Drilling Metal

There are two rules for drilling hard materials.

First, the harder the material, the greater the

pres sure you need to apply to the tool. Second,

the harder the material, the slower the speed.

Here are a couple of tips for drilling in metal.

Lubri cate the tip of the bit occasionally with cutting oil except when drilling soft metals such as

alu minum, cop per or cast iron. If the hole to be

drilled is fairly large, drill a smaller hole first, then

enlarge to the required size, it’s often faster in the

long run. Main tain enough pressure to assure

that the bit does not just spin in the hole. This will

dull the bit and greatly shorten its life.

Service

NO USER SERVICEABLE

PARTS INSIDE. Preventive

maintenance performed by un au thorized personnel may result in misplacing of internal

wires and components which could cause serious hazard. We recom mend that all tool ser-

vice be performed by a Bosch Factory Service

Center or Authorized Bosch Service Station.

SERVICE MEN: Disconnect tool and/or charger

from power source before servicing.

Batteries

Be alert for battery packs that are nearing

their end of life. If you notice decreased tool

performance or significantly shorter running time

between charges then it is time to replace the

battery pack. Failure to do so can cause the tool

to operate improperly or damage the charger.

Tool Lubrication

Your Bosch tool has been properly lubricated and

is ready for use.

Motors

The motor in your tool has been engineered for

many hours of dependable service. To maintain

peak efficiency of the motor, we recommend it

be examined every six months. Only a genuine

Bosch replacement motor specially designed for

your tool should be used.

Cleaning

To avoid accidents, always

disconnect the tool and/or

charger from the power supply before cleaning. The tool may be cleaned most effectively

with com pressed dry air. Always wear safety

goggles when cleaning tools with compressed air.

Ventilation openings and switch levers must be

kept clean and free of foreign matter. Do not

attempt to clean by inserting pointed objects

through opening.

Certain cleaning agents and

solvents damage plastic

parts. Some of these are: gasoline, car bon tetra-

chloride, chlorinated cleaning solvents, ammonia

and household detergents that contain ammonia.

14

2610045267 A5.indd 14 11/23/16 9:49 AM

Loading...

Loading...