Page 1

Robert Bosch Power Tools GmbH

1 609 92A 5P8

70538 Stuttgart

GERMANY

www.bosch-pt.com

1 609 92A 5P8 (2020.09) T / 37

GSA 1300 PCE Professional

en Original instructions

zh 正本使用说明书

zh 原始使用說明書

ko 사용 설명서 원본

th หนังสือคู่มือการใช้งานฉบับ

id Petunjuk-Petunjuk untuk

vi Bản gốc hướng dẫn sử dụng

ต้นแบบ

Penggunaan Orisinal

Page 2

2 |

English . . .. .. .. .. .. . .. .. .. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. Page 5

中文 . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. 页 9

繁體中文. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. . 頁 13

한국어 .. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. 페이지 16

ไทย. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. . หน้า 21

Bahasa Indonesia. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. Halaman 26

Tiếng Việt . .. .. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. .. Trang 31

1 609 92A 5P8 | (14.09.2020) Bosch Power Tools

Page 3

A B

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(1)

(3)

(4)

(1)

(4)

| 3

Bosch Power Tools 1 609 92A 5P8 | (14.09.2020)

Page 4

4 |

C D

E F

G

(2)

(8)

(5)

(2)

1 609 92A 5P8 | (14.09.2020) Bosch Power Tools

Page 5

English

Safety instructions

General Power Tool Safety Warnings

WARNING

tions provided with this power tool. Failure to follow all in-

structions listed below may result in electric shock, fire and/

or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless) power tool.

Work area safety

u Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

u Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust

or fumes.

u Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

Electrical safety

u Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

u Avoid body contact with earthed or grounded sur-

faces, such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your

body is earthed or grounded.

u Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric shock.

u Do not abuse the cord. Never use the cord for carry-

ing, pulling or unplugging the power tool. Keep cord

away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric

shock.

u When operating a power tool outdoors, use an exten-

sion cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

u If operating a power tool in a damp location is un-

avoidable, use a residual current device (RCD) protected supply. Use of an RCD reduces the risk of electric

shock.

Personal safety

u Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a

power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inatten-

Read all safety warnings, instructions, illustrations and specifica-

English | 5

tion while operating power tools may result in serious personal injury.

u Use personal protective equipment. Always wear eye

protection. Protective equipment such as a dust mask,

non-skid safety shoes, hard hat or hearing protection

used for appropriate conditions will reduce personal injuries.

u Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

u Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal injury.

u Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

u Dress properly. Do not wear loose clothing or jew-

ellery. Keep your hair and clothing away from moving

parts. Loose clothes, jewellery or long hair can be caught

in moving parts.

u If devices are provided for the connection of dust ex-

traction and collection facilities, ensure these are connected and properly used. Use of dust collection can re-

duce dust-related hazards.

u Do not let familiarity gained from frequent use of tools

allow you to become complacent and ignore tool

safety principles. A careless action can cause severe in-

jury within a fraction of a second.

Power tool use and care

u Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was designed.

u Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

u Disconnect the plug from the power source and/or re-

move the battery pack, if detachable, from the power

tool before making any adjustments, changing accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the power tool

accidentally.

u Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

u Maintain power tools and accessories. Check for mis-

alignment or binding of moving parts, breakage of

parts and any other condition that may affect the

power tool’s operation. If damaged, have the power

tool repaired before use. Many accidents are caused by

poorly maintained power tools.

Bosch Power Tools 1 609 92A 5P8 | (14.09.2020)

Page 6

6 | English

u Keep cutting tools sharp and clean. Properly main-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

u Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

u Keep handles and grasping surfaces dry, clean and

free from oil and grease. Slippery handles and grasping

surfaces do not allow for safe handling and control of the

tool in unexpected situations.

Service

u Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

Safety instructions for reciprocating saws

u Hold the power tool by insulated gripping surfaces,

when performing an operation where the cutting accessory may contact hidden wiring or its own cord.

Cutting accessory contacting a "live" wire may make exposed metal parts of the power tool "live" and could give

the operator an electric shock.

u Use clamps or another practical way to secure and

support the workpiece to a stable platform. Holding

the workpiece by hand or against your body leaves it unstable and may lead to loss of control.

u Keep hands away from the sawing area. Do not reach

under the workpiece. Contact with the saw blade can

lead to injuries.

u Hold the power tool firmly with both hands and make

sure you have a stable footing. The power tool can be

more securely guided with both hands.

u Only bring the power tool into contact with the work-

piece when switched on. Otherwise there is danger of

kickback if the cutting tool jams in the workpiece.

u Ensure that the footplate is always resting on the

workpiece while sawing. The saw blade can jam and

lead to loss of control over the power tool.

u When the cut is completed, switch off the power tool

and then pull the saw blade out of the cut only after it

has come to a standstill. In this manner you can avoid

kickback and can place down the power tool securely.

u Always wait until the power tool has come to a com-

plete stop before placing it down. The application tool

can jam and cause you to lose control of the power tool.

u Use only undamaged saw blades that are in perfect

condition. Bent or dull saw blades can break, negatively

influence the cut, or lead to kickback.

u Do not brake the saw blade to a stop by applying side

pressure after switching off. The saw blade can be damaged, break or cause kickback.

u Ensure that the material is securely clamped. Do not

support the workpiece using your hands or feet. Do

not touch any objects or the floor with the saw while it

is running. There is a risk of kickback.

u Use suitable detectors to determine if utility lines are

hidden in the work area or call the local utility company for assistance. Contact with electric lines can lead

to fire and electric shock. Damaging a gas line can lead to

explosion. Penetrating a water line causes property damage or may cause an electric shock.

Products sold in GB only:

Your product is fitted with an BS 1363/A approved electric

plug with internal fuse (ASTA approved to BS 1362).

If the plug is not suitable for your socket outlets, it should be

cut off and an appropriate plug fitted in its place by an authorised customer service agent. The replacement plug

should have the same fuse rating as the original plug.

The severed plug must be disposed of to avoid a possible

shock hazard and should never be inserted into a mains

socket elsewhere.

Product Description and Specifications

Read all the safety and general instructions.

Failure to observe the safety and general instructions may result in electric shock, fire

and/or serious injury.

Please observe the illustrations at the beginning of this operating manual.

Intended Use

The power tool is suitable for sawing wood, plastic, metal

and building materials on a firm surface. It is suitable for

straight and curved cuts. When using designated suitable bimetal saw blades, flush cutting is also possible. The saw

blade recommendations are to be observed.

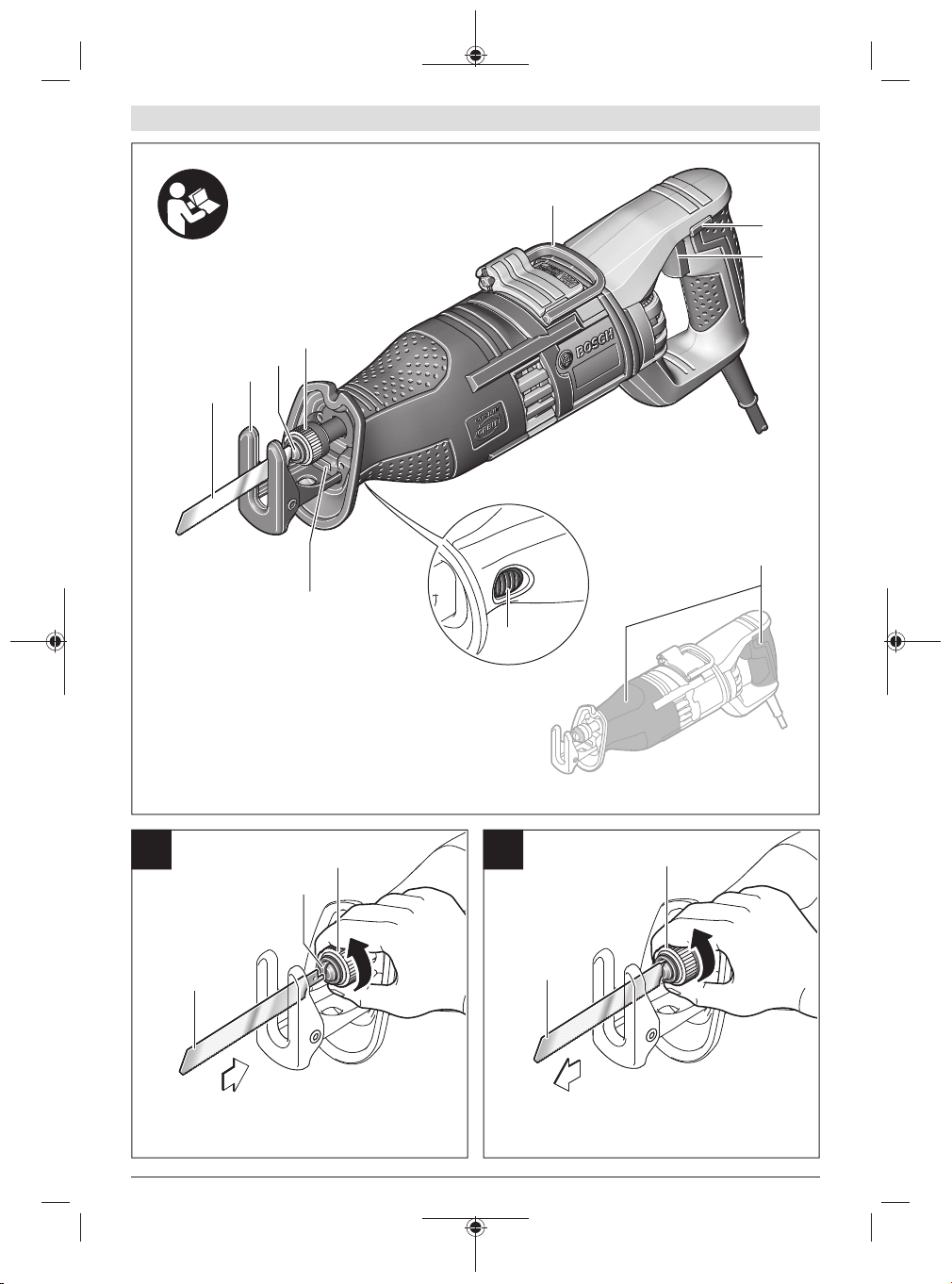

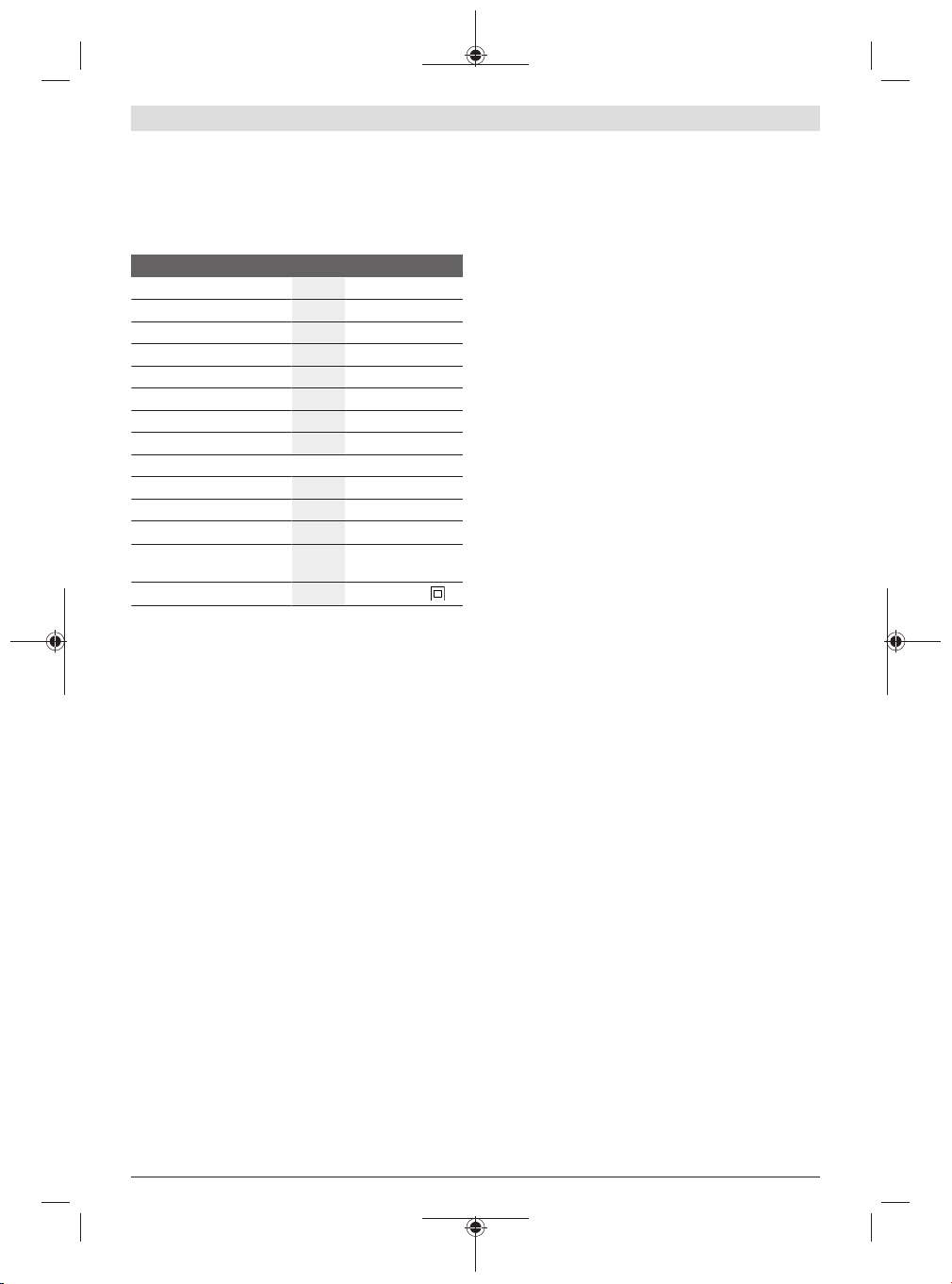

Product features

The numbering of the product features refers to the diagram

of the power tool on the graphics page.

A)

Saw blade

(1)

Adjustable base plate

(2)

Saw blade receptacle

(3)

Locking sleeve for saw blade

(4)

Utility hook

(5)

Lock-off switch for on/off switch (3601F4E240)

(6)

Locking mechanism for on/off switch

(6)

(3601F4E280, 3601F4E2B0, 3601F4E2C0,

3601F4E2K0, 3601F4E2L0)

On/off switch

(7)

Base plate release button

(8)

Worklight

(9)

1 609 92A 5P8 | (14.09.2020) Bosch Power Tools

Page 7

English | 7

Handle (insulated gripping surface)

(10)

A)

Accessories shown or described are not included with the

product as standard. You can find the complete selection of

accessories in our accessories range.

Technical data

Reciprocating saw GSA 1300 PCE

Article number

3601F4E2..

Pendulum action ●

Constant electronic control ●

Stroke rate control ●

Rated power input W 1300

No-load stroke rate n

0

min

-1

0−2900

Tool holder SDS

Stroke mm 28

Max. cutting depth

– in wood mm 220

– in steel (unalloyed) mm 20

– Pipe diameter mm 175

Weight according to

kg 4.1

EPTA-Procedure 01:2014

Protection class

The specifications apply to a rated voltage [U] of 230 V. These specifications may vary at different voltages and in country-specific models.

/Ⅱ

Assembly

u Pull the plug out of the socket before carrying out any

work on the power tool.

Inserting/changing the saw blade

u When fitting or changing the saw blade, wear protect-

ive gloves. Blades are sharp and can become hot when

used for prolonged periods of time.

u While replacing the saw blade, ensure that the saw

blade receptacle is free of material residue, e.g. wood

or metal chips.

Selecting the saw blade

You will find an overview of recommended saw blades at the

end of these operating instructions. Only use saw blades

with a 1/2" universal shank. The saw blade should not be

longer than required for the intended cut.

Inserting the saw blade (seefigureA)

Turn the locking sleeve(4) approx. 90° in the direction of

the arrow and hold it firmly. Push the saw blade(1) into the

saw blade receptacle(3). Release the locking sleeve again.

u Check that it is seated securely by pulling the saw

blade. A loose saw blade can fall out and lead to injuries.

For particular jobs, the saw blade(1) can also be flipped

180° (teeth point upwards) and refitted.

Removing the Saw Blade (seefigureB)

u Let the saw blade cool down before removing it. There

is a risk of injury when touching the hot saw blade.

Turn the locking sleeve(4) approx. 90° in the direction of

the arrow and hold it firmly. Remove the saw blade(1).

Dust/Chip Extraction

Dust from materials such as lead-containing coatings, some

wood types, minerals and metal can be harmful to one’s

health. Touching or breathing-in the dust can cause allergic

reactions and/or lead to respiratory infections of the user or

bystanders.

Certain dust, such as oak or beech dust, is considered carcinogenic, especially in connection with wood-treatment additives (chromate, wood preservative). Materials containing

asbestos may only be worked by specialists.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the ma-

terials to be worked.

u Avoid dust accumulation at the workplace. Dust can

easily ignite.

Operation

u Products that are only sold in AUS and NZ: Use a resid-

ual current device (RCD) with a nominal residual current

of 30 mA or less.

Starting Operation

u Pay attention to the mains voltage. The voltage of the

power source must match the voltage specified on the

rating plate of the power tool. Power tools marked

with 230V can also be operated with 220V.

Worklight

The worklight(9) lights up when connected to the mains

power and improves visibility in the immediate work area.

u Do not look directly into the worklight; it can blind

you.

Switching On and Off (3601F4E240)

To switch on the power tool, press the lock-off switch (6)

first. Then press the on/off switch (7) and keep it pressed.

To switch off the power tool, release the on/off switch (7).

Note: For safety reasons, the on/off switch (7) cannot be

locked; it must remain pressed during the entire operation.

Switching On and Off (3601F4E280, 3601F4E2B0,

3601F4E2C0, 3601F4E2K0, 3601F4E2L0)

u Make sure that you are able to press the On/Off switch

without releasing the handle.

To switch on the power tool, press the on/off switch (7).

To lock the on/off switch (7), press and hold it while also

pressing the locking mechanism (6).

Bosch Power Tools 1 609 92A 5P8 | (14.09.2020)

Page 8

8 | English

To switch off the power tool, release the on/off switch (7).

If the on/off switch (7) is locked, press the switch first and

then release it.

Constant Electronic control

The Constant Electronic control keeps the stroke rate at no

load and under load virtually consistent, guaranteeing uniform performance.

Controlling the stroke rate

You can variably adjust the stroke rate of the power tool

when it is on by pressing in the on/off switch (7) to varying

extents.

Applying light pressure to the on/off switch (7) results in a

low stroke rate. Applying increasing pressure to the switch

increases the stroke rate.

The required stroke rate is dependent on the material and

the work conditions and can be determined using practical

tests.

It is recommended that you reduce the stroke rate when

placing the saw blade on the workpiece and when sawing

plastic and aluminium.

During prolonged periods of use at a low stroke rate, the

power tool may heat up significantly. Remove the saw blade

and let the power tool run at the maximum stroke rate for

around three minutes to cool down.

Pendulum action

The pendulum action is permanently in operation in order to

achieve a high cutting speed.

Working Advice

u Pull the plug out of the socket before carrying out any

work on the power tool.

u Switch the power tool off immediately if the saw blade

becomes blocked.

Tips

u When sawing lightweight materials, take into account

the statutory provisions and recommendations of the

material manufacturers.

Before sawing into wood, chipboard, building materials,

etc., check for any foreign objects such as nails, screws, etc.

and use a suitable saw blade.

Switch on the power tool and guide it towards the workpiece

you wish to work on. Place the base plate(2) on the surface

of the workpiece and saw through the material applying even

pressure and feed. Switch the power tool off once you have

finished your work.

Switch the power tool off immediately if the saw blade jams.

Widen the sawing gap slightly with a suitable tool and pull

the power tool out.

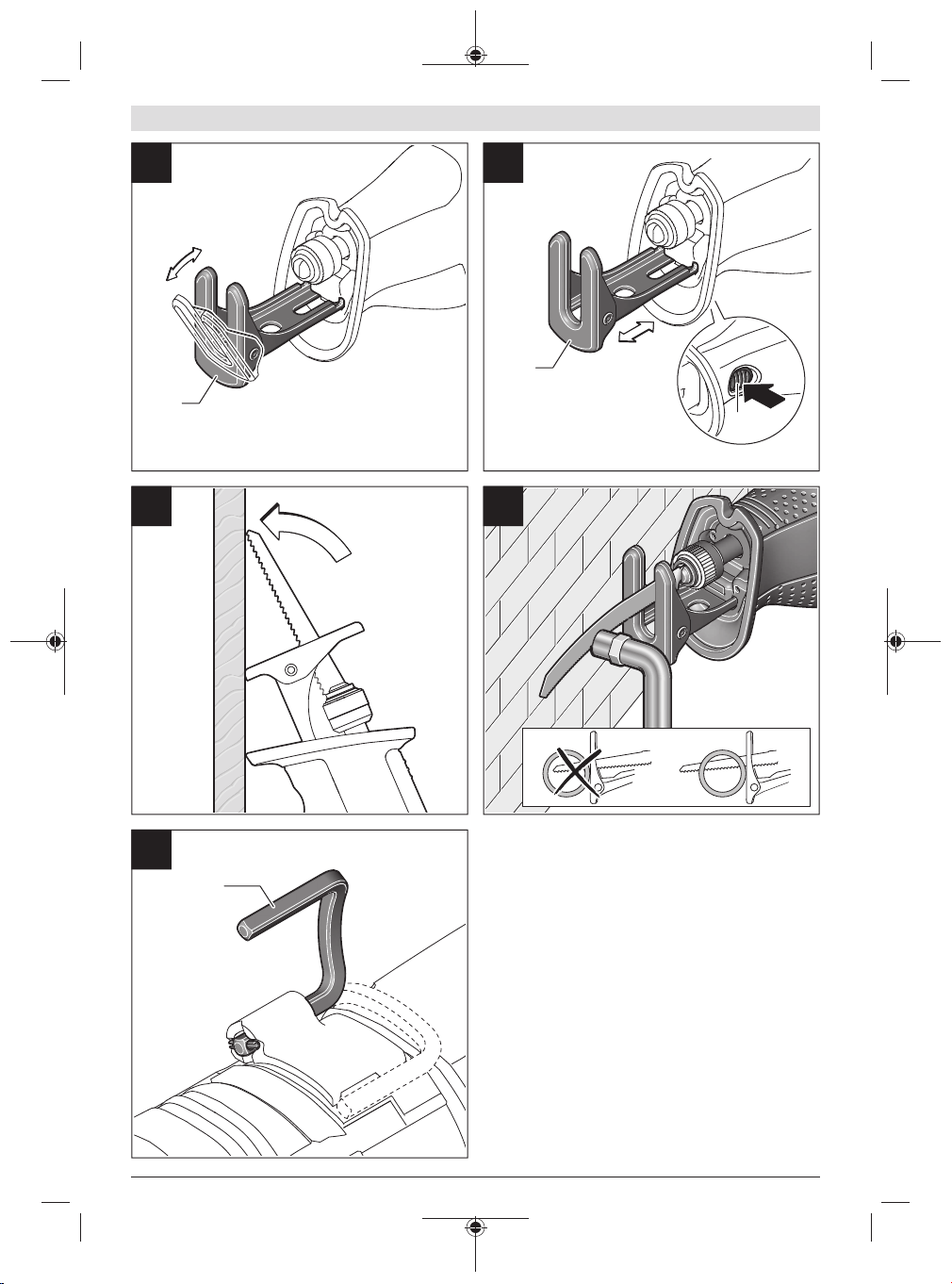

Swivelling, pull-out base plate

(see figuresC−D)

Thanks to its mobility, the base plate(2) adopts the required

angle position of the surface.

Depending on the application and the saw blade used, the

base plate(2) can be moved to threedifferent settings

lengthwise.

Press the release button(8) and slide the base plate(2) into

the required position. Release the release button and check

whether the base plate has securely clicked into place. If required, slide the base plate until it securely clicks into place.

Plunge cutting (see figureE)

u Plunge cuts may only be applied to soft materials,

such as wood, gypsum board, etc. Do not plunge cut

metal materials.

For plunge cutting, use only short saw blades.

Place the power tool so that the edge of the base plate(2)

rests on the workpiece, without the saw blade(1) touching

the workpiece, and switch it on. When using power tools

with stroke rate control, select the maximum stroke rate.

Press the power tool firmly against the workpiece and allow

the saw blade to plunge slowly into the workpiece.

As soon as the base plate(2) rests fully on the workpiece,

continue sawing along the required cutting line.

For particular jobs, the saw blade(1) can also be fitted after

being turned 180° in order to operate the power tool the

other way around.

Flush sawing (see figure F)

Protruding components such as water pipes, for example,

can be cut directly at the wall using elastic bi-metal saw

blades.

u Ensure that the saw blade is always longer than the

diameter of the workpiece. There is a risk of kickback.

Place the saw blade directly against the wall and bend it

slightly by applying lateral pressure to the power tool until

the base plate is flush with the wall. Switch on the power tool

and saw through the workpiece applying consistent lateral

pressure.

Utility hook (see figure G)

Your power tool is equipped with a utility hook (5) for

hanging it, e. g., from a ladder. Simply fold out the utility

hook to the required position.

u When the power tool is hung up, take care that the

saw blade is protected from accidental contact. This

poses a risk of injury.

Fold the utility hook (5) in again when you want to begin

work with the power tool.

Coolant/lubricant

As the material heats up along the cutting line when cutting

metal, you should apply coolant or lubricant.

Maintenance and Service

Maintenance and Cleaning

u Pull the plug out of the socket before carrying out any

work on the power tool.

u To ensure safe and efficient operation, always keep

the power tool and the ventilation slots clean.

1 609 92A 5P8 | (14.09.2020) Bosch Power Tools

Page 9

In order to avoid safety hazards, if the power supply cord

needs to be replaced, this must be done by Bosch or by an

after-sales service centre that is authorised to repair Bosch

power tools.

Carefully clean the saw blade receptacle with a soft cloth. To

do so, remove the saw blade from the power tool. Keep the

saw blade receptacle operational using suitable lubricants.

If the power tool becomes very dirty, this can lead to serious

faults. For this reason, do not cut materials which generate

large quantities of dust from below or overhead.

After-Sales Service and Application Service

Our after-sales service responds to your questions concerning maintenance and repair of your product as well as spare

parts. You can find explosion drawings and information on

spare parts at: www.bosch-pt.com

The Bosch product use advice team will be happy to help you

with any questions about our products and their accessories.

In all correspondence and spare parts orders, please always

include the 10‑digit article number given on the nameplate

of the product.

Malaysia

Robert Bosch Sdn. Bhd.(220975-V) PT/SMY

No. 8A, Jalan 13/6

46200 Petaling Jaya

Selangor

Tel.: (03) 79663194

Toll-Free: 1800 880188

Fax: (03) 79583838

E-Mail: kiathoe.chong@my.bosch.com

www.bosch-pt.com.my

You can find further service addresses at:

www.bosch-pt.com/serviceaddresses

Disposal

The power tool, accessories and packaging should be recycled in an environmentally friendly manner.

Do not dispose of power tools along with

household waste.

中文

安全规章

电动工具通用安全警告

警告!

击、着火和/或严重伤害。

保存所有警告和说明书以备查阅。

阅读所有警告和所有说明! 不遵

照以下警告和说明会导致电

中文 | 9

在所有下列的警告中术语"电动工具"指市电驱动(有

线)电动工具或电池驱动(无线)电动工具。

工作场地的安全

u 保持工作场地清洁和明亮。混乱和黑暗的场地会

引发事故。

u 不要在易爆环境,如有易燃液体、气体或粉尘的

环境下操作电动工具。电动工具产生的火花会点

燃粉尘或气体。

u 让儿童和旁观者离开后操作电动工具。注意力不

集中会使操作者失去对工具的控制。

电气安全

u 电动工具插头必须与插座相配。绝不能以任何方

式改装插头。需接地的电动工具不能使用任何转

换插头。未经改装的插头和相配的插座将减少电

击危险。

u 避免人体接触接地表面,如管道、散热片和冰

箱。如果你身体接地会增加电击危险。

u 不得将电动工具暴露在雨中或潮湿环境中。水进

入电动工具将增加电击危险。

u 不得滥用电线。绝不能用电线搬运、拉动电动工

具或拔出其插头。使电线远离热源、油、锐边或

运动部件。受损或缠绕的软线会增加电击危险。

u 当在户外使用电动工具时,使用适合户外使用的

外接软线。适合户外使用的软线将减少电击危

险。

u 如果在潮湿环境下操作电动工具是不可避免的,

应使用剩余电流动作保护器(RCD)。使用RCD

可减小电击危险。

人身安全

u 保持警觉,当操作电动工具时关注所从事的操作

并保持清醒。当你感到疲倦,或在有药物、酒精

或治疗反应时,不要操作电动工具。在操作电动

工具时瞬间的疏忽会导致严重人身伤害。

u 使用个人防护装置。始终佩戴护目镜。安全装

置,诸如适当条件下使用防尘面具、防滑安全

鞋、安全帽、听力防护等装置能减少人身伤害。

u 防止意外起动。确保开关在连接电源和/或电池

盒、拿起或搬运工具时处于关断位置。手指放在

已接通电源的开关上或开关处于接通时插入插头

可能会导致危险。

u 在电动工具接通之前,拿掉所有调节钥匙或扳

手。遗留在电动工具旋转零件上的扳手或钥匙会

导致人身伤害。

u 手不要伸展得太长。时刻注意立足点和身体平

衡。这样在意外情况下能很好地控制电动工具。

u 着装适当。不要穿宽松衣服或佩戴饰品。让衣

服、手套和头发远离运动部件。宽松衣服、佩饰

或长发可能会卷入运动部件中。

u 如果提供了与排屑、集尘设备连接用的装置,要

确保他们连接完好且使用得当。使用这些装置可

减少尘屑引起的危险。

u 即使由于经常使用电动工具而对此非常熟悉,也

不要就认为可以高枕无忧而忽略工具的安全规

定。粗心大意的行为可能在瞬间就造成严重的伤

害。

Bosch Power Tools 1 609 92A 5P8 | (14.09.2020)

Page 10

10 | 中文

电动工具使用和注意事项电动工具使用和注意事项

u 不要滥用电动工具,根据用途使用适当的电动工

具。选用适当设计的电动工具会使你工作更有

效、更安全。

u 如果开关不能接通或关断工具电源,则不能使用

该电动工具。如果开关不能接通或关断工具电

源,则不能使用该电动工具。

u 在进行任何调节、更换附件或贮存电动工具之

前,必须从电源上拔掉插头和/或使电池盒与工具

脱开。这种防护性措施将减少工具意外起动的危

险。

u 将闲置不用的电动工具贮存在儿童所及范围之

外,并且不要让不熟悉电动工具或对这些说明不

了解的人操作电动工具。电动工具在未经培训的

用户手中是危险的。

u 保养电动工具。检查运动件是否调整到位或卡

住,检查零件破损情况和影响电动工具运行的其

他状况。如有损坏,电动工具应在使用前修理

好。许多事故由维护不良的电动工具引发。

u 保持切削刀具锋利和清洁。保养良好的有锋利切

削刃的刀具不易卡住而且容易控制。

u 按照使用说明书,考虑作业条件和进行的作业来

使用电动工具、附件和工具的刀头等。将电动工

具用于那些与其用途不符的操作可能会导致危

险。

u 保持手柄和握持表面干燥、清洁、无油污。在突

发情况下,滑溜的手柄和握持表面无法确保安全

地握持和控制工具。

维修

u 将你的电动工具送交专业维修人员,使用同样的

备件进行修理。 这样将确保所维修的电动工具的

安全性。

针对马刀锯的安全规章

u 在切削附件可能触及暗线或其自身软线之处进行

操作时,要通过绝缘握持面来握持工具。切削附

件碰到带电导线会使工具外露的金属零件带电从

而使操作者受到电击。

u 使用夹箍或其他实用方式将加工件固定和支承到

一个稳定的平台上。 用手握住或用身体顶住加工

件会导致不稳定,从而引起失控。

u 双手必须远离锯割范围,手不可以握在工件下

端。如果不小心碰触了锯片可能被割伤。

u 工作时要使用双手握紧电动工具并确保站稳。使

用双手才能够稳定地操作电动工具。

u 先开动电动工具后再把工具放置在工件上切割。

如果电动工具被夹在工件中,会有反弹的危险。

u 注意锯割时必须把底盘正确安稳地放置在工件

上。锯片可能在工作中被夹住,而令您无法控制

电动工具。

u 工作告一段落时,必须先关闭电动工具并等待机

器完全静止后,才可以从锯缝中拔出锯刀。如此

不但可以防止反弹,而且可以防止放置机器时发

生危险。

u 等待电动工具完全静止后才能够放下机器。 机器

上的工具可能在工作中被夹住,而令您无法控制

电动工具。

u 只能使用未受损的功能正常的锯片。弯曲或变钝

的锯片可能断裂,对锯痕造成负面影响或导致反

弹。

u 关机后不可以侧压刀片来制止仍然继续转动的刀

片。锯刀可能因此受损、断裂或者造成反击。

u 材料要牢固夹紧。不得用手或脚支撑工件。不得

用正在运转的锯片触碰物体或地面。有反弹危

险。

u 使用合适的侦测装置侦察隐藏的电线,或者向当

地的相关单位寻求支援。 接触电线可能引起火灾

並让操作者触电。损坏了瓦斯管会引起爆炸。凿

穿水管不仅会造成严重的财物损失,也可能导致

触电。

产品和性能说明

请阅读所有安全规章和指示。不遵照以

下警告和说明可能导致电击、着火和/或

严重伤害。

请注意本使用说明书开头部分的图示。

按照规定使用

本电动工具可以锯割木材、塑料、金属和一般建

材。锯割时必须用力地将机器顶向工件。适用于直

线和曲线切割。安装了专用的双金属锯刀后,能够

锯割出非常平整的锯口。选用锯刀时请参考本公司

提出的建议。

插图上的机件

机件的编号和电动工具详解图上的编号一致。

A)

锯片

(1)

可调底板

(2)

锯片架

(3)

锯片锁紧套筒

(4)

挂钩

(5)

电源开关的开机锁(3601F4E240)

(6)

电源开关的止动件(3601F4E280、

(6)

3601F4E2B0、3601F4E2C0、

3601F4E2K0、3601F4E2L0)

电源开关

(7)

底板解锁按钮

(8)

工作灯

(9)

手柄(绝缘握柄)

(10)

A) 图表或说明上提到的附件,并不包含在基本的供货范围

中。本公司的附件清单中有完整的附件供应项目。

技术参数

马刀锯

物品代码

振荡功能

GSA 1300 PCE

3601F4E2..

●

1 609 92A 5P8 | (14.09.2020) Bosch Power Tools

Page 11

马刀锯

GSA 1300 PCE

恒定电子装置

冲击次数控制装置

额定输入功率

空载转速n

0

工具夹头

冲程

瓦 1300

转/分钟 0−2900

SDS

毫米 28

最大切割深度

– 木材

– 钢材(非合金)

– 管直径

重量符合

毫米 220

毫米 20

毫米 175

千克 4.1

EPTA-Procedure

01:2014

保护等级

所有参数适用于230伏的额定电压[U],对于其他不同的电压

和国际规格,数据有可能不同。

/Ⅱ

安装

u 在电动工具上进行所有操作之前都必须从插座上

拔出电源插头。

安装/更换锯片

u 安装或更换工具刀头时务必佩戴保护手套。工具

刀头非常锋利,长时间使用后会变热。

u 更换锯刀时请注意,锯片架上不可以有任何杂

物,例如木屑或金属屑等。

选择锯片

在本说明书的最后有锯片的一览表。只能安装带1/2

英寸通用刀柄的锯片。锯片长度不得超过预定锯切

线所需的数值。

安装锯片(见图片A)

沿箭头方向转动锁紧套筒(4)约90°并固定住。将锯

片(1)按入锯片架(3)。再次松开锁紧套筒。

u 通过拉动锯片来检查安装是否牢固。松脱的锯片

会从接头掉落并伤害您。

对于某些操作,也可以将锯片(1)翻转180°(锯齿朝

上)后再使用。

取下锯片(参见插图B)

u 锯片冷却后才能取出。接触炙热的锯片有受伤的

危险。

沿箭头方向转动锁紧套筒(4)约90°并固定住。取下

锯片(1)。

吸锯尘/吸锯屑

含铅的颜料以及某些木材、矿物和金属的加工废尘

有害健康。机器操作者或者工地附近的人如果接

触、吸入这些废尘,可能会有过敏反应或者感染呼

吸道疾病。

某些尘埃(例如加工橡木或山毛榉的废尘)可能致

癌,特别是和处理木材的添加剂(例如木材的防腐

剂等)结合之后。只有经过专业训练的人才能够加

工含石棉的物料。

●

– 工作场所要保持空气流通。

●

– 最好佩戴P2滤网等级的口罩。

请留心并遵守贵国和加工物料有关的法规。

u 避免让工作场所堆积过多的尘垢。尘埃容易被点

燃。

运行

投入使用

u 注意电源电压!电源的电压必须和电动工具铭牌

上标示的电压一致。标记为230伏电动工具用220

伏的电压可以驱动。

工作灯

在插入电源插头时工作灯(9)会亮起,改善紧邻工作

区域内的能见度。

u 勿直视工作灯,强光会刺眼。

接通/关闭(3601F4E240)

如要接通电动工具,请首先按压开机锁(6)。接着按

压电源开关(7)并按住。

如要关闭电动工具,请松开电源开关(7)。

提示:基于安全的顾虑,电源开关(7)无法被锁定。

所以操作机器时必须持续地按住开关。

接通/关闭(3601F4E280、3601F4E2B0、

3601F4E2C0、3601F4E2K0、

3601F4E2L0)

u 请确保握住手柄时可以开启/关闭开关。

要 接通 电动工具,按压起停开关 (7)。

要锁定起停开关 (7),按住起停开关并另外按压止动

件 (6)。

要关闭电动工具,松开起停开关 (7)。起停开关 (7)

锁住时,请先按压,然后再松开。

恒定电子装置

有了恒定电子装置,机器的冲击次数能够在空转和

负载时都保持恒定。如此能够确保均匀的运作功

率。

控制冲击次数

可以无级调节已接通电动工具的冲击次数,视按压

起停开关 (7) 的力道程度决定。

以较小的力按压起停开关 (7)时,冲击次数较低。逐

渐在开关上加压,冲击次数也会跟着提高。

正确的冲击次数必须视工件物料和工作状况而定。

唯有实际操作才能找出最合适的冲击次数。

起锯时,或者锯割塑料、铝片时最好降低冲击次

数。

以小的冲击次数长期工作之后,电动工具会变得很

热。拆下锯片,让电动工具以最高冲击次数运作3分

钟以加速冷却。

振荡功能

持续运行振荡功能可实现更高的锯割速度。

中文 | 11

Bosch Power Tools 1 609 92A 5P8 | (14.09.2020)

Page 12

12 | 中文

工作提示

u 在电动工具上进行所有操作之前都必须从插座上

拔出电源插头。

u 当锯片被夹住时,请立即关闭电动工具。

建议

u 锯割轻建材时,必须注意有关的法令规定以及材

料供应商提供的建议事宜。

锯切木材、刨花板、建筑材料等材料前应检查是否

有异物,比如钉子、螺栓等类似物质,请使用合适

的锯片。

先开动电动工具再把工具靠在工件上。将底板(2)放

到工件表面上,用均匀的压力或进给量锯断材料。

工作完备后随手关闭电动工具。

如果锯刀被夹住了,必须马上关闭电动工具。使用

合适的工具撑开锯缝并拔出电动工具。

可翻转并抽出的底板 (见图片C−D)

底板(2)通过表面所需角度位置的移动来自动调整。

视所用锯片和应用情况而定,底板(2)可以沿纵向以

3个档位抽出。

按下解锁按钮(8),并将底板(2)推至所需位置。松

开解锁按钮,检查底板是否已牢牢卡住。必要时尽

可能推动底板,直至其牢牢卡住。

切入式锯切(见图片 E)

u 在切入式锯切工艺中,仅允许加工软材料,比如

木材、石膏板等类似材料!不要使用切入式锯切

工艺加工金属。

切入式锯切时只能使用短锯片。

将电动工具底板(2)的一边放到工件上,锯片(1)不

要触碰到工件,然后开机。如果电动工具有冲击次

数控制装置,必须选择最高冲击次数。将电动工具

用力压向工件,并让锯片慢慢地切入工件中。

一旦底板(2)齐平地贴着工件,就可沿着所需的锯切

线继续切割。

对于某些操作,可将锯片(1)旋转180°后安装并相应

地翻转电动工具。

齐平锯切(参见插图F)

使用双金属弹性锯片,可以直接在墙壁上锯切突出

的结构件,比如水管。

u 注意锯片应始终长于待加工工件的直径。有反弹

危险。

把锯刀直接靠在墙上,侧向按压电动工具,让锯片

稍稍弯曲,直到底板贴在墙面上。将电动工具开

机,使用恒定的侧向压力锯断工件。

挂钩(参见插图G)

使用挂钩(5)可以把电动工具挂到比如梯子上。为此

将挂钩翻到需要的位置。

u 悬挂电动工具时注意保护锯片,以免无意间碰

到。有受伤的危险。

如果要使用电动工具,则重新合起挂钩(5)。

冷却剂/润滑剂

锯割金属时由于物料会变热,必须沿着锯割线涂抹

冷却剂或润滑剂。

维修和服务

保养和清洁

u 在电动工具上进行所有操作之前都必须从插座上

拔出电源插头。

u 电动工具和通气孔必须随时保持清洁,以确保工

作效率和工作安全。

如果必须更换连接线,务必把这项工作交给Bosch

或者经授权的Bosch电动工具顾客服务执行,以避

免危害机器的安全性能。

最好用软刷清洁锯片架。此时必须先拆卸电动工具

上的锯片。请使用合适的润滑剂来确保锯片架的正

常功能。

电动工具如果沾满污垢,可能会影响机器的功能。

因此,请勿从下方或在头顶上切割会产生大量粉尘

的材料。

客户服务和应用咨询

本公司顾客服务处负责回答有关本公司产品的修

理、维护和备件的问题。备件的展开图纸和信息也

可查看:www.bosch-pt.com

博世应用咨询团队乐于就我们的产品及其附件问题

提供帮助。

询问和订购备件时,务必提供机器铭牌上标示的10

位数物品代码。

中国大陆

博世电动工具(中国)有限公司

中国 浙江省 杭州市

滨江区 滨康路567号

102/1F 服务中心

邮政编码:310052

电话:(0571)8887 5566 / 5588

传真:(0571)8887 6688 x 5566# / 5588#

电邮:bsc.hz@cn.bosch.com

www.bosch-pt.com.cn

制造商地址:

Robert Bosch Power Tools GmbH

罗伯特· 博世电动工具有限公司

70538 Stuttgart / GERMANY

70538 斯图加特 / 德国

其他服务地址请见:

www.bosch-pt.com/serviceaddresses

处理废弃物

必须以符合环保要求的方式回收再利用电动工具、

附件和包装材料。

请勿将电动工具扔到生活垃圾中!

1 609 92A 5P8 | (14.09.2020) Bosch Power Tools

Page 13

繁體中文

安全注意事項

電動工具一般安全注意事項

警告

遵照以下列出的指示,將可能導致電擊、著火和/

或人員重傷。

保存所有警告和說明書以備查閱。

在所有警告中,「電動工具」此一名詞泛指:以市

電驅動的(有線)電動工具或是以電池驅動的(無

線)電動工具。

工作場地的安全

u 保持工作場地清潔和明亮。混亂和黑暗的場地會

引發事故。

u 不要在易爆環境,如有易燃液體、氣體或粉塵的

環境下操作電動工具。電動工具產生的火花會點

燃粉塵或氣體。

u 讓兒童和旁觀者離開後操作電動工具。注意力不

集中會使您失去對工具的控制。

電氣安全

u 電動工具插頭必須與插座相配。 絕不能以任何方

式改裝插頭。 需接地的電動工具不能使用任何轉

換插頭。未經改裝的插頭和相配的插座將減少電

擊危險。

u 避免人體接觸接地表面,如管道、散熱片和冰

箱。如果您身體接地會增加電擊危險。

u 不得將電動工具暴露在雨中或潮濕環境中。水進

入電動工具將增加電擊危險。

u 不得濫用電線。 絕不能用電線搬運、拉動電動工

具或拔出其插頭。 使電線遠離熱源、油、銳利邊

緣或移動零件。受損或纏繞的軟線會增加電擊危

險。

u 當在戶外使用電動工具時,使用適合戶外使用的

延長線。適合戶外使用的軟線,將減少電擊危

險。

u 如果在潮濕環境下操作電動工具是不可避免的,

應使用剩餘電流動作保護器(RCD)。使用RCD

可降低電擊危險。

人身安全

u 保持警覺,當操作電動工具時關注所從事的操作

並保持清醒。 當您感到疲倦,或在有藥物、酒精

或治療反應時,不要操作電動工具。在操作電動

工具時瞬間的疏忽會導致嚴重人身傷害。

u 使用個人防護裝置。 始終佩戴護目鏡。安全裝

置,諸如適當條件下使用防塵面具、防滑安全

鞋、安全帽、聽力防護等裝置能減少人身傷害。

u 防止意外起動。 確保開關在連接電源和/或電池

盒、拿起或搬運工具時處於關閉位置。手指放在

已接通電源的開關上或開關處於接通時插入插頭

可能會導致危險。

請詳讀工作臺及電動工具的所

有安全警告與使用說明。若不

繁體中文 | 13

u 在電動工具接通之前,拿掉所有調節鑰匙或扳

手。遺留在電動工具旋轉零件上的扳手或鑰匙會

導致人身傷害。

u 手不要伸展得太長。 時刻注意立足點和身體平

衡。這樣在意外情況下能很好地控制電動工具。

u 著裝適當。 不要穿寬鬆衣服或佩戴飾品。 讓您的

衣物及頭髮遠離運動部件。寬鬆衣服、佩飾或長

髮可能會捲入運動部件中。

u 如果提供了與排屑、集塵設備連接用的裝置,要

確保他們連接完好且使用得當。使用這些裝置可

減少塵屑引起的危險。

u 切勿因經常使用工具所累積的熟練感而過度自

信,輕忽工具的安全守則。任何一個魯莽的舉動

都可能瞬間造成人員重傷。

電動工具使用和注意事項

u 不要濫用電動工具, 根據用途使用適當的電動工

具。選用適當設計的電動工具會使您工作更有

效、更安全。

u 如果開關不能開啟或關閉工具電源,則不能使用

該電動工具。不能用開關來控制的電動工具是危

險的且必須進行修理。

u 在進行任何調整、更換配件或貯存電動工具之

前,必須從電源上拔掉插頭並/或取出電池盒。

這種防護性措施將減少工具意外起動的危險。

u 將閒置不用的電動工具貯存在兒童所及範圍之

外,並且不要讓不熟悉電動工具或對這些說明不

瞭解的人操作電動工具。電動工具在未經培訓的

用戶手中是危險的。

u 保養電動工具與配備。 檢查運動件是否調整到位

或卡住,檢查零件破損情況和影響電動工具運行

的其他狀況。 如有損壞,電動工具應在使用前修

理好。許多事故由維護不良的電動工具引發。

u 保持切削刀具鋒利和清潔。保養良好的有鋒利切

削刃的刀具不易卡住而且容易控制。

u 按照使用說明書,考慮作業條件和進行的作業來

使用電動工具、配件和工具的刀頭等。將電動工

具用於那些與其用途不符的操作可能會導致危

險。

u 把手及握持區應保持乾燥、潔淨,且不得沾染任

何油液或油脂。易滑脫的把手及握持區將無法讓

您在發生意外狀況時安全地抓緊並控制工具。

檢修

u 將您的電動工具送交專業維修人員,必須使用同

樣的備件進行更換。這樣將確保所維修的電動工

具的安全性。

軍刀鋸安全注意事項

u 進行作業時,負責進行切割的配件可能會碰觸到

隱藏的配線或電動工具的電線,請從絕緣握把處

拿持電動工具。負責進行切割的配件若是觸及

「導電」電線,可能導致電動工具外露的金屬部

件「導電」,進而使操作人員遭受電擊。

u 請用夾具或其他可行方式將工件穩固地架在可靠

平台上。用手握持工件或將它貼靠在您身上會因

無法確實固定而導致失控。

Bosch Power Tools 1 609 92A 5P8 | (14.09.2020)

Page 14

14 | 繁體中文

u 雙手必須遠離鋸割範圍,手不可以握在工件下

端。如果不小心碰觸了鋸片可能被割傷。

u 作業期間請用雙手牢牢握緊電動工具並保持穩

固。使用雙手才能夠更穩定地操作電動工具。

u 先啟動電動工具後再把工具放置在工件上切割。

如果電動工具被夾在工件中,會有反彈的危險。

u 請注意:進行鋸切時,請將底座保持貼靠在工件

上。鋸片可能在工作中被夾住,而令您無法控制

電動工具。

u 工作告一段落時,必須先關閉電動工具並等待機

器完全靜止後,才可以從鋸縫中抽出鋸刀。如此

不但可以防止反彈,而且可以防止放置機器時發

生危險。

u 必須等待電動工具完全靜止後才能將它放下。嵌

件工具可能卡住而使電動工具失控。

u 只能使用未受損、功能正常的鋸片。彎曲或變鈍

的鋸片可能斷裂,對鋸痕造成負面影響或導致反

彈。

u 關機後不可以側壓刀片來制止仍然繼續轉動的刀

片。鋸刀可能因此受損、斷裂或者造成反彈。

u 請確實夾緊加工材料。請勿用手或用腳撐住工

件。請勿讓運轉中的電鋸碰觸任何物品或地面。

可能會發生反彈。

u 使用合適的偵測裝置偵察隱藏的電線,或者向當

地的相關單位尋求支援。接觸電線可能引起火災

並讓操作者觸電。若損壞瓦斯管會引起爆炸。鑿

穿水管不僅會造成嚴重的財物損失,也可能導致

觸電。

產品和功率描述

請詳讀所有安全注意事項和指示。如未

遵守安全注意事項與指示,可能導致火

災、人員遭受電擊及/或重傷。

請留意操作說明書中最前面的圖示。

依規定使用機器

本電動工具設計用來鋸切有固定擋塊的木材、塑

膠、金屬和建材。本機器不僅能夠鋸切直線,也可

以鋸切曲線。安裝了專用的雙金屬鋸片後,即能鋸

切出非常平整的鋸口。選用鋸片時請參考本公司建

議。

插圖上的機件

機件的編號和電動工具詳解圖上的編號一致。

A)

鋸片

(1)

可調式底座

(2)

鋸片座

(3)

鋸片鎖緊套

(4)

掛鈎

(5)

起停開關的作動安全鎖(3601F4E240)

(6)

起停開關鎖扣(3601F4E280、

(6)

3601F4E2B0、3601F4E2C0、

3601F4E2K0、3601F4E2L0)

起停開關

(7)

底座的解鎖按鈕

(8)

工作燈

(9)

把手(絕緣握柄)

(10)

A) 圖表或說明上提到的配件,並不包含在基本的供貨範圍

中。本公司的配件清單中有完整的配件供應項目。

技術性數據

軍刀鋸

產品機號

振蕩功能

電子穩定控制系統

衝擊次數調控

額定輸入功率

無負載轉速 n

0

min

工具夾座

衝程

最大鋸切深度

– 在木材上

– 在鋼材上(非合金)

– 管徑

重量符合

EPTA-Procedure

01:2014

絕緣等級

本說明書提供的參數是以 230 伏特為依據,於低電壓地區,

此數據有可能不同。

GSA 1300 PCE

3601F4E2..

W 1300

−1

0−2900

SDS

mm 28

mm 220

mm 20

mm 175

kg 4.1

/Ⅱ

安裝

u 維修電動工具或換裝零、配件之前,務必從插座

上拔出插頭。

安裝/更換鋸片

u 安裝或更換嵌件工具時務必穿戴防護手套。嵌件

工具極為銳利,而且長時間使用後可能發燙。

u 更換鋸片時請注意,鋸片座上不可以有任何殘留

的材料,例如木屑或金屬屑等。

選擇鋸片

本手冊最後面另外刊錄了鋸片一覽表。所使用的鋸

片必須具有 1/2" 通用柄。鋸片長度不得超過預定鋸

線。

安裝鋸片(請參考圖A)

沿箭頭方向將鎖緊套(4) 轉動約 90°,然後予以固

定。將鋸片(1) 推入鋸片座(3) 裡。重新放開鎖緊

套。

u 透過拉動,確認鋸片是否已裝牢。鬆動的鋸片可

能脫落並造成您受傷。

針對某些特定加工作業,亦可將鋸片 (1) 翻面後

(即鋸齒朝上)再重新裝上。

●

●

●

1 609 92A 5P8 | (14.09.2020) Bosch Power Tools

Page 15

卸下鋸片(請參考圖B)

u 取下鋸片之前,請先讓它冷卻。接觸炙熱的鋸片

有受傷之虞。

沿箭頭方向將鎖緊套(4) 轉動約 90°,然後加以固

定。取出鋸片(1)。

吸鋸塵/吸鋸屑

含鉛的顏料及部分木材、礦物和金屬的加工廢塵有

害健康。機器操作者或者工地附近的人如果接觸、

吸入這些廢塵,可能會有過敏反應或者感染呼吸道

疾病。

特定粉塵(例如加工橡木或山毛櫸的廢塵)可能致

癌,特別是與處理木材的添加劑(例如木材的防腐

劑等)混合之後。只有經過專業訓練的人才允許加

工含石棉的物料。

– 工作場所要保持空氣流通。

– 建議佩戴 P2 濾網等級的口罩。

請留意並遵守貴國與加工物料有關的法規。

u 避免讓工作場所堆積過多的塵垢。塵埃容易被點

燃。

操作

操作機器

u 請注意電源電壓!電源的電壓必須和電動工具銘

牌上標示的電壓一致。標示為 230V 的電動工具

亦可接上 220V 電源。

工作燈

電源插頭插上時,工作燈(9) 將亮起,可改善緊鄰

之工作範圍的照明。

u 勿直視工作燈,強光會刺眼。

啟動/關閉(3601F4E240)

若要啟動電動工具,請先按壓作動安全鎖 (6)。接

著,按壓起停開關 (7) 不要放開。

若要關閉電動工具,放開起停開關 (7) 即可。

提示:基於安全考量,無法鎖定起停開關 (7) 的位

置,所以操作機器時必須持續按住此開關。

啟動/關閉(3601F4E280、3601F4E2B0、

3601F4E2C0、3601F4E2K0、

3601F4E2L0)

u 請確定您不用放開把手,就能操作起停開關。

若要啟動電動工具:按下起停開關 (7)。

若要固定起停開關 (7) 的位置,請將它按住不放並

同時按壓鎖扣 (6)。

若要關閉電動工具,放開起停開關 (7) 即可。起停

開關 (7) 的位置若是已被鎖定,請按一下該開關然

後放開。

電子穩定控制系統

有了電子穩定控制系統,機器的衝擊次數能夠在空

轉和負載時都保持恆定,以確保運作功率保持一

致。

繁體中文 | 15

調整衝擊次數

您可為已啟動的電動工具無段調控轉速,衝擊次數

是由按壓起停開關 (7) 的深度而定。

輕按起停開關 (7) 時,衝擊次數較少。按得越緊衝

擊次數越多。

正確的衝擊次數必須視工件物料和工作狀況而定。

唯有實際操作才能找出最合適的衝擊次數。

將鋸片放到工件上時c以及鋸切塑膠、鋁片時,建議

您降低衝擊次數。

以較少的衝擊次數長時間加工後,電動工具會變得

很熱。拆下鋸片,讓電動工具以最高衝擊次數運作

3 分鐘以加速冷卻。

振蕩功能

為達成高度鋸切速度,振蕩功能會持續運作。

作業注意事項

u 維修電動工具或換裝零、配件之前,務必從插座

上拔出插頭。

u 如果鋸片被夾住了,請立刻關閉電動工具的電

源。

建議

u 鋸切輕建材時,必須注意有關的法令規定以及材

料供應商提供的建議事宜。

在鋸進木材、塑合板、建材等物的內部前,請先確

認有無異物(例如鐵釘、螺栓等),並且應使用適

合的鋸片。

先啟動電動工具再把工具靠在工件上。請將底座 (2)

靠在工件表面上,然後施力均勻地鋸開或推進。工

作完成後隨手關閉電動工具。

如果鋸片被夾住了,必須馬上關閉電動工具。使用

合適的工具撐開鋸縫,然後將電動工具拔出。

活動抽拉式底座

(請參考圖C−D)

底座 (2) 活動自如,可隨時配合加工表面所需的角

度位置調整。

底座(2) 可根據您所使用的鋸片和使用情況不同分

3 段移動。

按下解鎖按鈕(8) 並將底座(2) 推至所需位置。放

開解鎖按鈕,檢查底座是否確實卡緊。必要時推動

底座,直到確實卡緊。

潛鋸(請參考圖 E)

u 僅在加工木材、石膏板等這類軟性材料時可進行

潛鋸!不可以在金屬上進行潛鋸!

潛鋸時只能使用短型鋸片。

將電動工具的底座 (2) 邊緣放到工件上,但不要讓

鋸片 (1) 接觸到工件,然後啟動機器。如果電動工

具具備衝擊次數調控功能的話,必須選擇最高衝擊

次數。用力地把電動工具壓向工件,並讓鋸片慢慢

地潛入工件中。

待底座 (2) 完全貼靠在工件上時,便立刻沿著預計

完工的鋸切線繼續鋸切。

針對某些特定加工作業,亦可將鋸片 (1) 旋轉

180°,並配合其方向推進電動工具。

Bosch Power Tools 1 609 92A 5P8 | (14.09.2020)

Page 16

16 | 한국어

平鋸(請參考圖 F)

彈性雙金屬鋸片可讓您平貼在牆壁上鋸開凸出的建

築構件,例如水管。

u 請注意:鋸片的長度必須全程超出加工工件的直

徑。可能會發生反彈。

把鋸片直接靠在牆上,側壓電動工具讓底盤貼在牆

面上。啟動電動工具並透過均力地側壓鋸斷工件。

掛鈎(請參考圖G)

使用掛鈎(5) 即可把電動工具掛在例如梯子上。若

要這樣做,請將掛鈎翻折至所需位置。

u 電動工具懸掛時請注意:為避免不慎碰觸,鋸片

應做好防護措施。人員有受傷之虞。

使用電動工具時,請您將掛鈎(5) 收折起來。

冷卻劑/潤滑劑

鋸切金屬時由於物料會變熱,必須在鋸割線上塗抹

冷卻劑或潤滑劑。

維修和服務

保養與清潔

u 維修電動工具或換裝零、配件之前,務必從插座

上拔出插頭。

u 電動工具和通風口都必須保持清潔,這樣才能夠

提高工作品質和安全性。

如果必須更換連接線,請務必交由 Bosch 或者經授

權的 Bosch 電動工具顧客服務執行,以避免危害機

器的安全性能。

軟刷是清潔鋸片座的最佳工具。此時必須先拆除電

動工具上的鋸片。使用合適的潤滑劑保養鋸片座,

即可常保運作正常。

電動工具如果沾滿污垢,可能會影響機器性能。請

勿從下方或從高於頭部的位置鋸切會生成大量粉塵

的材料。

顧客服務處和顧客咨詢中心

本公司顧客服務處負責回答有關本公司產品的維

修、維護和備用零件的問題。以下的網頁中有分解

圖和備用零件相關資料:www.bosch-pt.com

如果對本公司產品及其配件有任何疑問,博世應用

諮詢小組很樂意為您提供協助。

當您需要諮詢或訂購備用零件時,請務必提供本產

品型號銘牌上 10 位數的產品機號。

台灣

台灣羅伯特博世股份有限公司

建國北路一段90 號6 樓

台北市10491

電話: (02)77342588

傳真: (02)25161176

www.bosch-pt.com.tw

制造商地址:

Robert Bosch Power Tools GmbH

羅伯特· 博世電動工具有限公司

70538 Stuttgart / GERMANY

70538 斯圖加特/ 德國

以下更多客戶服務處地址:

www.bosch-pt.com/serviceaddresses

廢棄物處理

必須以符合環保的方式,回收再利用損壞的機器、

配件和廢棄的包裝材料。

不可以把電動工具丟入一般的家庭垃圾

中。

한국어

안전 수칙

전동공구 일반 안전 수칙

경고

사양을 숙지하십시오. 다음의 지시 사항을 준수하

지 않으면 감전, 화재, 또는 심각한 부상을 초래할

수 있습니다.

앞으로 참고할 수 있도록 이 안전수칙과 사용 설명

서를 잘 보관하십시오.

다음에서 사용되는 "전동공구"라는 개념은 전원에

연결하여 사용하는 (전선이 있는) 전동 기기나 배터

리를 사용하는 (전선이 없는) 전동 기기를 의미합니

다.

작업장 안전

u 작업장을 항상 깨끗이 하고 조명을 밝게 하십시

오. 작업장 환경이 어수선하거나 어두우면 사고

를 초래할 수 있습니다.

u 가연성 유체, 가스 또는 분진이 있어 폭발 위험이

있는 환경에서 전동공구를 사용하지 마십시오.

전동공구는 분진이나 증기에 점화하는 스파크를

일으킬 수 있습니다.

u 전동공구를 사용할 때 구경꾼이나 어린이 혹은

다른 사람이 작업장에 접근하지 못하게 하십시

오. 다른 사람이 주의를 산만하게 하면 기기에 대

한 통제력을 잃기 쉽습니다.

전기에 관한 안전

u 전동공구의 전원 플러그가 전원 콘센트에 잘 맞

아야 합니다. 플러그를 절대 변경시켜서는 안 됩

니다. (접지된) 전동공구를 사용할 때 어댑터 플

러그를 사용하지 마십시오. 변형되지 않은 플러

그와 잘 맞는 콘센트를 사용하면 감전의 위험을

줄일 수 있습니다.

u 파이프 관, 라디에이터, 레인지, 냉장고와 같은 접

지 표면에 몸이 닿지 않도록 하십시오. 몸에 닿을

경우 감전될 위험이 높습니다.

u 전동공구를 비에 맞지 않게 하고 습기 있는 곳에

두지 마십시오. 전동공구에 물이 들어가면 감전

될 위험이 높습니다.

본 전동공구와 함께 제공된 모

든 안전경고, 지시사항, 그림 및

1 609 92A 5P8 | (14.09.2020) Bosch Power Tools

Page 17

u 전원 코드를 잘못 사용하는 일이 없도록 하십시

오. 전원 코드를 잡고 전동공구를 운반해서는 안

되며, 콘센트에서 전원 플러그를 뽑을 때 전원 코

드를 잡아 당겨서는 절대로 안 됩니다. 전원 코드

가 열과 오일에 접촉하는 것을 피하고, 날카로운

모서리나 기기의 가동 부위에 닿지 않도록 주의

하십시오. 손상되거나 엉킨 전원 코드는 감전을

유발할 수 있습니다.

u 실외에서 전동공구로 작업할 때는 실외용으로 적

당한 연장 전원 코드만을 사용하십시오. 실외용

연장 전원 코드를 사용하면 감전의 위험을 줄일

수 있습니다.

u 전동공구를 습기 찬 곳에서 사용해야 할 경우에

는 누전 차단기를 사용하십시오. 누전 차단기를

사용하면 감전 위험을 줄일 수 있습니다.

사용자 안전

u 신중하게 작업하며, 전동공구를 사용할 때 경솔

하게 행동하지 마십시오. 피로한 상태이거나 약

물 복용 및 음주한 후에는 전동공구를 사용하지

마십시오 . 전동공구를 사용할 때 잠시라도 주의

가 산만해지면 중상을 입을 수 있습니다.

u 작업자 안전을 위한 장치를 사용하십시오. 항상

보안경을 착용하십시오. 전동공구의 종류와 사

용에 따라 먼지 보호 마스크, 미끄러지지 않는 안

전화, 안전모 또는 귀마개 등의 안전한 복장을 하

면 상해의 위험을 줄일 수 있습니다.

u 실수로 기기가 작동되지 않도록 주의하십시오.

전동공구를 전원에 연결하거나 배터리를 끼우기

전에, 혹은 기기를 들거나 운반하기 전에, 전원 스

위치가 꺼져 있는지 다시 확인하십시오. 전동공

구를 운반할 때 전원 스위치에 손가락을 대거나

전원 스위치가 켜진 상태에서 전원을 연결하면

사고 위험이 높습니다.

u 전동공구를 사용하기 전에 조절하는 툴이나 키

등을 빼 놓으십시오. 회전하는 부위에 있는 툴이

나 키로 인해 상처를 입을 수 있습니다.

u 자신을 과신하지 마십시오. 불안정한 자세를 피

하고 항상 평형을 이룬 상태로 작업하십시오 . 안

정된 자세와 평형한 상태로 작업해야만이 의외의

상황에서도 전동공구를 안전하게 사용할 수 있습

니다.

u 알맞은 작업복을 입으십시오. 헐렁한 복장을 하

거나 장신구를 착용하지 마십시오. 머리나 옷이

가동하는 기기 부위에 가까이 닿지 않도록 주의

하십시오. 헐렁한 복장, 장신구 혹은 긴 머리는 가

동 부위에 말려 사고를 초래할 수 있습니다.

u 분진 추출장치나 수거장치의 조립이 가능한 경

우, 이 장치가 연결되어 있는지, 제대로 작동이 되

는지 확인하십시오. 이러한 분진 추출장치를 사

용하면 분진으로 인한 사고 위험을 줄일 수 있습

니다.

u 툴을 자주 사용한다고 해서 안주하는 일이 없게

하고 공구의 안전 수칙을 무시하지 않도록 하십

시오. 부주의하게 취급하여 순간적으로 심각한

부상을 입을 수 있습니다.

한국어 | 17

전동공구의 올바른 사용과 취급

u 기기를 과부하 상태에서 사용하지 마십시오. 작

업할 때 이에 적당한 전동공구를 사용하십시오.

알맞은 전동공구를 사용하면 지정된 성능 한도

내에서 더 효율적으로 안전하게 작업할 수 있습

니다.

u 전원 스위치가 고장 난 전동공구를 사용하지 마

십시오. 전원 스위치가 작동되지 않는 전동공구

는 위험하므로, 반드시 수리를 해야 합니다.

u 전동공구를 조정하거나 액세서리 부품 교환 혹은

공구를 보관할 때, 항상 전원 콘센트에서 플러그

를 미리 빼어 놓거나 배터리를 분리하십시오. 이

러한 조치는 실수로 전동공구가 작동하게 되는

것을 예방합니다.

u 사용하지 않는 전동공구는 어린이 손이 닿지 않

는 곳에 보관하고, 전동공구 사용에 익숙지 않거

나 이 사용 설명서를 읽지 않은 사람은 기기를 사

용해서는 안됩니다. 경험이 없는 사람이 전동공

구를 사용하면 위험합니다.

u 전동공구 및 액세서리를 조심스럽게 관리하십시

오. 가동 부위가 하자 없이 정상적인 기능을 하는

지, 걸리는 부위가 있는지, 혹은 전동공구의 기능

에 중요한 부품이 손상되지 않았는지 확인하십시

오. 손상된 기기의 부품은 전동공구를 다시 사용

하기 전에 반드시 수리를 맡기십시오. 제대로 관

리하지 않은 전동공구의 경우 많은 사고를 유발

합니다.

u 절단 공구를 날카롭고 깨끗하게 관리하십시오.

날카로운 절단면이 있고 잘 관리된 절단공구는

걸리는 경우가 드물고 조절하기도 쉽습니다.

u 전동공구, 액세서리, 장착하는 공구 등을 사용할

때, 이 지시 사항과 특별히 기종 별로 나와있는 사

용 방법을 준수하십시오. 이때 작업 조건과 실시

하려는 작업 내용을 고려하십시오. 원래 사용 분

야가 아닌 다른 작업에 전동공구를 사용할 경우

위험한 상황을 초래할 수 있습니다.

u 손잡이 및 잡는 면을 건조하게 유지하고, 오일 및

그리스가 묻어 있지 않도록 깨끗하게 하십시오.

손잡이 또는 잡는 면이 미끄러우면 예상치 못한

상황에서 안전한 취급 및 제어가 어려워집니다.

서비스

u 전동공구 수리는 반드시 전문 인력에게 맡기고 ,

수리 정비 시 보쉬 순정 부품만을 사용하십시오.

그렇게 함으로써 기기의 안전성을 오래 유지할

수 있습니다.

컷쏘 관련 안전 수칙

u 절단용 액세서리가 숨겨진 배선 또는 코드를 접

촉할 가능성이 있는 작업을 수행할 경우, 전동공

구의 절연된 손잡이 면만 잡으십시오. 절단용 액

세서리가 "전류가 흐르는" 전선에 접촉되면, 전동

공구의 노출된 금속 부품에 "전류가 흐르는" 상태

로 만들어 작업자가 감전될 수 있습니다.

u 클램프 등을 사용하여 가공물을 작업대에 안전하

게 고정하고 받쳐주십시오. 가공물을 손으로 잡

거나 몸쪽을 향하도록 잡으면 불안정한 상태가

되어 통제력을 잃을 수도 있습니다.

Bosch Power Tools 1 609 92A 5P8 | (14.09.2020)

Page 18

18 | 한국어

u 톱 쪽으로 손을 가까이 대지 마십시오. 작업물의

아래쪽을 잡지 마십시오. 톱날과 접하게 되면 부

상을 입을 수 있습니다.

u 전동 공구를 양손으로 꽉 잡고 안전한 자세로 작

업하십시오. 전동공구를 양손으로 잡고 움직이면

더 안전합니다.

u 전동공구를 켠 상태에서만 작업물에 서서히 접근

하십시오. 그렇지 않으면 톱날이 작업물에 걸리

면서 반동이 생길 위험이 있습니다.

u 톱질 작업 시 밑판이 항상 작업물에 밀착되도록

하십시오. 톱날이 걸리거나 전동공구에 대한 통

제가 어려워질 수 있습니다.

u 작업을 마치고 나서 전동공구의 전원을 끄고 기

기가 완전히 정지된 후에 절단면에서 톱날을 빼

내십시오. 이렇게 하면 반동이 생기는 것을 방지

할 수 있으며 전동공구를 안전하게 내려 놓을 수

있습니다.

u 전동공구를 내려놓기 전에 기기가 완전히 멈추었

는지 확인하십시오. 삽입공구가 걸리거나 전동공

구에 대한 통제가 어려워질 수 있습니다.

u 반드시 손상되지 않고 결함이 없는 톱날만 사용

하십시오. 휘거나 날카롭지 않은 톱날이 부러져

절단 작업을 방해하거나 반동을 유발할 수 있습

니다.

u 전원을 끈 후 옆에서 톱날을 눌러 정지해서는 안

됩니다. 이로 인해 톱날이 손상되거나 부러질 수

있으며 혹은 반동을 유발할 수 있습니다.

u 자재를 단단히 잘 조이십시오. 손이나 발로 작업

물을 받치지 마십시오. 톱이 작동할 때 물건 또는

바닥에 닿지 않도록 하십시오. 반동이 발생할 수

있습니다.

u 보이지 않는 부위에 에너지 배선 및 배관 여부를

확인하려면 적당한 탐지기를 사용하거나 담당 전

력 공급회사에 문의하십시오. 전선에 접하게 되

면 화재나 전기 충격을 야기할 수 있습니다. 가스

관을 손상시키면 폭발 위험이 있습니다. 수도관

을 파손하게 되면 재산 피해를 유발하거나 전기

충격을 야기할 수 있습니다.

제품 및 성능 설명

모든 안전 수칙과 지침을 숙지하십시오.

다음의 안전 수칙과 지침을 준수하지 않

으면 화재 위험이 있으며 감전 혹은 중

상을 입을 수 있습니다.

사용 설명서 앞 부분에 제시된 그림을 확인하십시

오.

규정에 따른 사용

본 전동공구는 목재, 플라스틱, 금속 및 건축 자재의

톱 작업에 사용해야 합니다. 직선 및 곡선 절단 작업

에 적합합니다. 적합한 바이메탈 톱날을 사용하면

작업물 표면에 플러시 절단 작업도 가능합니다. 권

장하는 톱날을 사용해야 합니다.

제품의 주요 명칭

제품의 주요 명칭에 표기되어 있는 번호는 기기 그

림이 나와있는 면을 참고하십시오.

A)

톱날

(1)

조절식 밑판

(2)

톱날 홀더

(3)

톱날 고정 슬리브

(4)

걸이 고리

(5)

시동 안전 잠금장치(3601F4E240)

(6)

전원 스위치 잠금 버튼(3601F4E280,

(6)

3601F4E2B0, 3601F4E2C0,

3601F4E2K0, 3601F4E2L0)

전원 스위치

(7)

밑판 잠금 해제 버튼

(8)

작업 램프

(9)

손잡이(절연된 손잡이 부위)

(10)

A) 도면이나 설명서에 나와있는 액세서리는 표준 공급부

품에 속하지 않습니다. 전체 액세서리는 저희 액세서리

프로그램을 참고하십시오.

제품 사양

컷쏘

제품 번호

오비탈 작동

일정 속도 전자 제어 장

치

스트로크 수 제어

소비 전력

공회전 스트로크 수 n

min

0

툴 홀더

스트로크

최대 절단 깊이

– 목재

– 강(비합금)

– 파이프 직경

EPTA-Procedure

01:2014에 따른

중량

보호 등급

자료는 정격 전압 [U] 230V를 기준으로 한 것입니다. 전압이

다른 경우 및 국가별 사양에 따라 변동이 있을 수 있습니다.

GSA 1300 PCE

3601F4E2..

W 1300

−1

0−2900

SDS

mm 28

mm 220

mm 20

mm 175

kg 4.1

조립

u 전동공구를 보수 정비하기 전에 반드시 콘센트에

서 전원 플러그를 빼십시오.

톱날 끼우기/교환하기

u 톱날을 조립 또는 교체할 경우 보호 장갑을 착용

하십시오. 톱날은 날카로우며, 장시간 사용하면

뜨거워질 수 있습니다.

●

●

●

/Ⅱ

1 609 92A 5P8 | (14.09.2020) Bosch Power Tools

Page 19

u 톱날을 교환할 때 톱날 홀더에 절단 시 생기는 목

재의 톱밥이나 금속 찌꺼기가 남아 있지 않은지

확인하십시오.

톱날 선택하기

추천하는 톱날 목록은 본 설명서의 마지막 부분에

나와 있습니다. 1/2" 유니버셜 섕크 방식의 톱날만

사용하십시오. 톱날이 절단하려는 깊이보다 길면 안

됩니다.

톱날 끼우기(그림A 참조)

고정 슬리브(4) 를 약 90° 정도 화살표 방향으로 돌

린 후 꽉 잡으십시오. 톱날(1) 을 톱날 홀더(3) 쪽

으로 미십시오. 고정 슬리브에서 다시 손을 떼십시

오.

u 당겨보면서 톱날이 제대로 끼워졌는지 확인해 보

십시오. 느슨하게 풀린 톱날은 빠질 수 있으며, 이

로 인해 작업자가 상해를 입을 수 있습니다.

특정한 작업 진행을 위해 톱날(1) 을 (톱니가 위쪽

을 향하도록) 180° 돌린 후 다시 사용할 수도 있습

니다.

톱날 분리하기(그림B 참조)

u 분리하기 전에 톱날의 열을 식히십시오. 뜨거운

톱날에 닿게 되면 상해 위험이 있습니다.

고정 슬리브(4) 를 약 90° 정도 화살표 방향으로 돌

린 후 꽉 잡으십시오. 톱날(1) 을 분리하십시오.

분진 및 톱밥 추출장치

납 성분을 포함한 페인트나 몇몇 나무 종류, 또는 광

물 성분 그리고 철과 같은 재료의 분진은 건강을 해

칠 수 있습니다. 이 분진을 만지거나 호흡할 경우,

사용자나 주변 사람들은 알레르기 반응이나 호흡기

장애를 일으킬 수 있습니다.

떡갈나무나 너도밤나무와 같은 특정한 분진은 암을

유발시키며, 특히 목재 처리용으로 사용되는 부가

원료(크로마트, 목재 보호제)와 혼합되면 암을 유발

시키게 됩니다. 석면 성분을 포함한 재료는 오직 전

문가가 작업을 해야 합니다.

– 작업장의 통풍이 잘 되도록 하십시오.

– 필터등급 P2에 해당되는 호흡 마스크를 사용하

십시오.

작업용 재료에 관해 국가가 지정한 규정을 고려하십

시오.

u 작업장에 분진이 쌓이지 않도록 하십시오. 분진

이 쉽게 발화할 수 있습니다.

작동

기계 시동

u 전원의 전압에 유의하십시오! 공급되는 전원의

전압은 전동공구의 명판에 표기된 전압과 동일해

야 합니다. 230 V 로 표시된 전동공구는 220 V

에서도 작동이 가능합니다.

작업 램프

전원 플러그를 끼우면 작업 램프(9) 가 점등되고,

인접한 작업 영역의 가시 상황을 개선시켜줍니다.

한국어 | 19

u 작업 램프 안을 들여다보지 마십시오, 시력이 저

하될 수 있습니다.

전원 켜기/끄기(3601F4E240)

전동공구의 전원을 켜려면 먼저 시동 안전 잠금장

치(6) 를 누르십시오. 이어서 전원 스위치 (7) 를

누르고 누른 상태를 유지하십시오.

전동공구를 끄려면 전원 스위치 (7) 에서 손을 떼십

시오.

지침: 작업 안전상의 이유로 전원 스위치 (7) 를 고

정할 수 없으므로, 작동 중에 이를 계속 누르고 있어

야 합니다.

전원 켜기/끄기(3601F4E280, 3601F4E2B0,

3601F4E2C0, 3601F4E2K0, 3601F4E2L0)

u 손잡이에서 손을 떼지 않고 전원 스위치를 작동

할 수 있는지 확인하십시오.

전동공구의 전원을 켜려면 전원 스위치 (7) 를 누르

십시오.

전원 스위치 (7) 를 고정시키려면 전원 스위치를 누

른 상태로 잠금 버튼 (6) 을 더 누릅니다.

전동공구의 전원을 끄려면 전원 스위치 (7) 에서 손

을 떼십시오. 전원 스위치 (7) 가 고정된 상태에서

먼저 전원 스위치를 눌렀다가 전원 스위치에서 손을

떼십시오.

일정 속도 전자 제어 장치

일정 속도 전자제어장치는 무부하 시나 부하 시의

회전 속도를 거의 일정하게 유지하여 동일한 작업

결과를 보장합니다.

스트로크 수 조절하기

전원 스위치 (7) 를 밀어 이동시키는 만큼 전원이

켜진 전동공구의 스트로크 수를 조절할 수 있습니

다.

전원 스위치 (7) 를 약간만 밀면 스트로크 수가 낮

아집니다. 세게 누르면 스트로크 수가 높아집니다.

작업 소재와 작업 조건에 따라 필요로 하는 스트로

크 수가 달라지므로 실제 시험을 통해 결정할 수 있

습니다.

톱날을 작업물에 대거나 플라스틱과 알루미늄에 톱

작업을 할 때 스트로크 수를 줄이는 것이 좋습니다.

낮은 속도로 장시간 작업할 경우 전동공구가 과열될

수 있습니다. 이 경우 톱날을 빼고 전동공구를 식히

기 위해 최대 속도로 약 3분간 작동시켜 주십시오.

오비탈 작동

오비탈 작동은 높은 절단 속도를 내기 위해 지속적

으로 작동됩니다.

사용 방법

u 전동공구를 보수 정비하기 전에 반드시 콘센트에

서 전원 플러그를 빼십시오.

u 톱날이 물리면 즉시 전동공구 스위치를 끄십시

오.

참고

u 연질의 건축 자재에 톱질작업을 할 경우 법정 규

정에 따르고 소재 제조사의 추천 내용을 준수하

십시오.

Bosch Power Tools 1 609 92A 5P8 | (14.09.2020)

Page 20

20 | 한국어

목재, 칩보드, 건축 자재 등에서 작업하기 전에 못,

나사와 같은 이물질이 없는지 확인한 후 적합한 톱

날을 사용하십시오.

전동공구의 스위치를 켜고 작업하려는 작업물에 접

근하십시오. 밑판(2) 을 작업물 표면에 가져온 후

균일한 압력 또는 이송 속도로 자재를 절단하십시

오. 작업을 마치고 나서 전동공구의 스위치를 끕니

다.

톱날이 물려 움직이지 않을 경우 곧바로 전동공구의

스위치를 끄십시오. 적합한 공구를 사용하여 톱날이

끼인 틈새를 약간 벌린 후 전동공구를 빼냅니다.

회전 및 탈착 가능한 밑판

(그림C−D참조)

밑판(2) 은 각각 요구되는 표면의 각도 위치 움직

임에 따라 조절할 수 있습니다.

밑판(2) 은 사용하는 톱날 및 작업에 따라 3단계로

길이 방향으로 이동할 수 있습니다.

잠금해제 버튼(8) 을 누른 후 밑판(2) 을 원하는

위치로 미십시오. 잠금해제 버튼에서 손을 뗀 후 밑

판이 잘 고정되었는지 점검하십시오. 밑판이 단단히

고정될 때까지 필요에 따라 미십시오.

플런지 쏘(그림E 참조)

u 목재, 석고보드와 같은 연질 소재의 경우에만 플

런지 절단 방식으로 가공할 수 있습니다! 금속 소

재에는 플런지 절단 방식으로 작업해서는 안 됩

니다!

플런지 절단 작업 시에는 짧은 톱날만 사용하십시

오.

전동공구를 밑판 (2) 의 가장자리와 함께 작업물에

설치하십시오. 이때 톱날 (1) 이 작업물을 건드리지

않게 유의하고, 전동공구의 전원을 켜십시오. 스트

로크 수 제어장치가 있는 전동공구의 경우 최대 값

으로 선택하십시오. 전동공구를 작업물에 대고 누르

고 톱날을 천천히 작업물 안으로 들어가게 합니다.

밑판 (2) 이 작업물의 전체 표면에 닿으면, 원하는

절단선을 따라 절단 작업을 진행합니다.

특정한 작업을 진행하기 위해 톱날(1) 을 180° 돌

린 후 전동공구를 이에 맞춰 돌려 끼울 수도 있습니

다.

플러시 절단 작업(그림F 참조)

신축성이 있는 바이메탈 톱날을 이용하여 벽 바로

옆에 있는 수배관 등의 돌출된 건축 자재를 잘라낼

수 있습니다.

u 톱날은 항상 작업물 직경보다 길어야 합니다. 반

동이 발생할 수 있습니다.

톱날을 벽 바로 옆에 대고 밑판이 벽에 닿을 때까지

전동공구에 가로 압력을 가하여 약간 휘게 합니다.

전동공구의 스위치를 켜고 일정한 가로 압력을 가하

며 작업물을 절단하십시오.

톱 걸이 고리(그림G참조)

톱 걸이 고리(5) 를 이용하면 사다리 등에 전동공

구를 걸어둘 수 있습니다. 이를 위해 톱 걸이 고리를

원하는 위치로 젖히십시오.

u 전동공구가 걸려 있을 때는 의도하지 않게 톱날

과 접촉되는 경우를 방지할 수 있도록 유의하십

시오. 부상을 입을 수 있습니다.

전동공구로 작업하고자 할 때는 다시 톱 걸이 고

리(5) 를 접어 두십시오.

냉각제/윤활제

금속에 톱질 작업을 할 때 작업물이 과열되기 때문

에 절단선을 따라 냉각제나 윤활제를 발라 주어야

합니다.

보수 정비 및 서비스

보수 정비 및 유지

u 전동공구를 보수 정비하기 전에 반드시 콘센트에

서 전원 플러그를 빼십시오.

u 안전하고 올바른 작동을 위하여 전동공구와 전동

공구의 통풍구를 항상 깨끗이 하십시오.

연결 코드를 교환해야 할 경우 안전을 기하기 위해

Bosch 또는 Bosch 지정 전동공구 서비스 센터에

맡겨야 합니다.

특히 부드러운 붓을 이용해 톱날 홀더를 닦아주십시

오. 이때 톱날을 전동공구에서 빼내십시오. 톱날 홀

더는 적절한 윤활제를 사용하여 그 기능을 유지해

주십시오.

전동공구가 지나치게 오염되어 있으면 기능 장애가

생길 수 있습니다. 따라서 분진이 많이 배출되는 소

재는 아래쪽 또는 머리 위쪽에서 작업하지 마십시

오.

AS 센터 및 사용 문의

AS 센터에서는 귀하 제품의 수리 및 보수정비, 그리

고 부품에 관한 문의를 받고 있습니다. 대체 부품에

관한 분해 조립도 및 정보는 인터넷에서도 찾아 볼

수 있습니다 - www.bosch-pt.com

보쉬 사용 문의 팀에서는 보쉬의 제품 및 해당 액세

서리에 관한 질문에 기꺼이 답변 드릴 것입니다.

문의나 대체 부품 주문 시에는 반드시 제품 네임 플

레이트에 있는 10자리의 부품번호를 알려 주십시

오.

콜센터

080-955-0909

다른 AS 센터 주소는 아래 사이트에서 확인할 수 있 습니다:

www.bosch-pt.com/serviceaddresses

처리

기기와 액세서리 및 포장 등은 환경 친화적인 방법

으로 재생할 수 있도록 분류하십시오.

전동공구를 가정용 쓰레기로 처리하지

마십시오!

1 609 92A 5P8 | (14.09.2020) Bosch Power Tools

Page 21

ไทย

คำเตือนเพื่อความปลอดภัย

คำเตือนเพื่อความปลอดภัยทั่วไปสำหรับเครื่องมือ ไฟฟ้า

คำเตือน

จำเพาะทั้งหมดที่จัดส่งมาพร้อมกับเครื่องมือไฟฟ้า

การไม่ปฏิบัติตามคําแนะนําทั้งหมดที่ระบุไว้ด้าน

ล่างนี้อาจทำให้ถูกไฟฟ้าดูด เกิดไฟไหม้ และ/หรือได้รับบาด

เจ็บอย่างร้ายแรง

เก็บรักษาคำเตือนและคำสั่งทั้งหมดสำหรับเปิดอ่านในภาย

หลัง

คำว่า "เครื่องมือไฟฟ้า" ในคำเตือนหมายถึง เครื่องมือไฟฟ้า

ของท่านที่ทำงานด้วยพลังงานไฟฟ้าจากแหล่งจ่ายไฟหลัก (มี

สายไฟฟ้า) และเครื่องมือไฟฟ้าที่ทำงานด้วยพลังงานไฟฟ้า

จากแบตเตอรี่ (ไร้สาย)

ความปลอดภัยในสถานที่ทำงาน

u รักษาสถานที่ทำงานให้สะอาดและมีไฟส่องสว่างดี

สถานที่ที่มืดหรือรกรุงรังนำมาซึ่งอุบัติเหตุ

u อย่าใช้เครื่องมือไฟฟ้าทำงานในสภาพบรรยากาศที่จุด

ติดไฟได้ เช่น ในที่ที่มีของเหลวไวไฟ ก๊าซ หรือฝุ่น

เมื่อใช้เครื่อง

มือไฟฟ้าจะเกิดประกายไฟซึ่งอาจจุดฝุ่นหรือไอให้ลุกเป็นไ

ฟได้

u ขณะใช้เครื่องมือไฟฟ้าทำงาน ต้องกันเด็กและผู้ยืนดูให้

ออกห่าง

การหันเหความสนใจอาจทำให้ท่านขาดการควบคุมเครื่องไ

ด้

ความปลอดภัยเกี่ยวกับไฟฟ้า

u ปลั๊กของเครื่องมือไฟฟ้าต้องเหมาะพอดีกับเต้าเสียบ

อย่าดัดแปลงปลั๊กไม่ว่าในลักษณะใดๆ อย่างเด็ดขาด

อย่าใช้ปลั๊กพ่วงต่อใดๆ กับเครื่องมือไฟฟ้าที่มีสายดิน

ปลั๊กที่ไม่ดัดแปลงและเต้าเสียบที่เข้ากันช่วยลดความ

เสี่ยงจากการถูกไฟฟ้าดูด

u หลีกเลี่ยงอย่าให้ร่างกายสัมผัสกับพื้นผิวที่ต่อสายดินหรือ

ลงกราวด์ไว้ เช่น ท่อ เครื่องทำความร้อน เตา และตู้

เย็น จะเสี่ยงอันตรายจากการถูกไฟฟ้าดูดมาก

ขึ้นหากกระแสไฟฟ้าวิ่งผ่านร่างกายของท่านลงดิน

อ่านคำเตือนเพื่อความปลอดภัย คำ

แนะนำ ภาพประกอบ และข้อมูล

ไทย | 21

u อย่าให้เครื่องมือไฟฟ้าถูกฝนหรืออยู่ในสภาพเปียกชื้น

หากน้ำเข้าในเครื่องมือไฟฟ้า จะเพิ่มความเสี่ยงจากการ

ถูกไฟฟ้าดูด

u อย่าใช้สายไฟฟ้าในทางที่ผิด อย่าใช้สายไฟฟ้าเพื่อยก

ดึง หรือถอดปลั๊กเครื่องมือไฟฟ้า กันสายไฟฟ้าออกห่าง

จากความร้อน น้ำมัน ขอบแหลมคม หรือชิ้นส่วนที่

เคลื่อนที่ สายไฟฟ้าที่ชำรุดหรือพันกันยุ่งเพิ่มความ

เสี่ยงจากการถูกไฟฟ้าดูด

u เมื่อใช้เครื่องมือไฟฟ้าทำงานกลางแจ้ง ให้ใช้สายไฟ

ต่อที่เหมาะสำหรับการใช้งานกลางแจ้ง การใช้สาย

ไฟต่อที่เหมาะสมสำหรับงานกลาง

แจ้งช่วยลดอันตรายจากการถูกไฟฟ้าดูด

u หากไม่สามารถหลีกเลี่ยงการใช้เครื่องมือไฟฟ้าทำงาน

ในสถานที่เปียกชื้นได้ ให้ใช้สวิ

ทช์ตัดวงจรเมื่อเกิดการรั่วไหลของไฟฟ้าจากสายดิน

(RCD) การใช้สวิทช์ตัดวงจรเมื่อเกิดการรั่ว

ไหลของไฟฟ้าจากสายดินช่วยลดความเสี่ยงต่อการถูกไฟฟ้

าดูด

ความปลอดภัยของบุคคล

u ท่านต้องอยู่ในสภาพเตรียมพร้อม ระมัดระวังในสิ่งที่

ท่านกำลังทำอยู่ และมีสติขณะใช้เครื่องมือไฟฟ้าทำงาน

อย่าใช้เครื่องมือไฟฟ้าขณะที่ท่านกำลังเหนื่อย หรืออยู่

ภายใต้การครอบงำของฤทธิ์ของยาเสพติด

แอลกอฮอล์ และยา เมื่อใช้เครื่องมือไฟฟ้าทำงาน

ในชั่วนาทีที่ท่านขาดความเอาใจใส่อาจทำให้บุคคลบาด

เจ็บอย่างรุนแรงได้

u ใช้อุปกรณ์ปกป้องร่างกาย สวมแว่นตาป้องกันเสมอ

อุปกรณ์ปกป้อง เช่น หน้ากากกันฝุ่น รองเท้ากันลื่น หมวก

แข็ง หรือประกบหูกันเสียงดังที่ใช้ตามความเหมาะสมกับ

สภาพการทำงาน จะลดการบาดเจ็บทางร่างกาย

u ป้องกันการติดเครื่องโดยไม่ตั้งใจ ตรวจสอบให้แน่ใจ

ว่าสวิทช์อยู่ในตำแหน่งปิดก่อนเชื่อมต่อเข้ากับแหล่ง

จ่ายไฟ และ/หรือแบตเตอรี่แพ็ค ยกหรือถือเครื่องมือ

การถือเครื่องโดยใช้นิ้วหิ้วที่สวิทช์ หรือเสียบพลัง

ไฟฟ้าขณะสวิทช์เปิดอยู่ อาจนำไปสู่อุบัติเหตุที่ร้ายแรงได้

u นำเครื่องมือปรับแต่งหรือประแจปากตายออกก่อนเปิด

สวิทช์เครื่องมือไฟฟ้า เครื่องมือหรือประแจปาก

ตายที่วางอยู่กับส่วนของเครื่องที่กำลังหมุนจะทำให้บุคคลบ

าดเจ็บได้

u อย่าเอื้อมไกลเกินไป ตั้งท่ายืนที่มั่นคงและวางน้ำหนักให้

สมดุลตลอดเวลา ในลักษณะนี้ท่านสามารถควบคุมเครื่อง

มือไฟฟ้าในสถานการณ์ที่ไม่คาดคิดได้ดีกว่า

u แต่งกายอย่างเหมาะสม อย่าใส่เสื้อผ้าหลวมหรือสวม

เครื่องประดับ เอาผมและเสื้อผ้าออกห่างจากชิ้นส่วนที่

Bosch Power Tools 1 609 92A 5P8 | (14.09.2020)

Page 22

22 | ไทย

เคลื่อนที่ เสื้อผ้าหลวม เครื่องประดับ และผม

ยาวอาจเข้าไปติดในชิ้นส่วนที่เคลื่อนที่

u หากเครื่องมือไฟฟ้ามีข้อเชื่อมต่อกับเครื่องดูดฝุ่นหรือ

เครื่องเก็บผง ให้ตรวจสอบให้แน่ใจว่าได้เชื่อมต่อและ

ใช้งานอย่างถูกต้อง การใช้อุปกรณ์ดูด

ฝุ่นช่วยลดอันตรายที่เกิดจากฝุ่นได้

u เมื่อใช้งานเครื่องบ่อยครั้งจะเกิดความคุ้นเคย อย่าให้

ความคุ้นเคยทำให้ท่านเกิดความชะล่าใจและละเลยกฎ

เกณฑ์ด้านความปลอดภัยในการใช้งานเครื่อง การ

ทำงานอย่างไม่ระมัดระวังอาจทำให้เกิดการบาด

เจ็บอย่างร้ายแรงภายในเสี้ยววินาที

การใช้และการดูแลรักษาเครื่องมือไฟฟ้า

u อย่างฝืนกำลังเครื่องมือไฟฟ้า ใช้เครื่องมือไฟฟ้าที่ถูก

ต้องตรงตามลักษณะงานของท่าน เครื่องมือไฟฟ้าที่ถูก

ต้องจะทำงานได้ดี

กว่าและปลอดภัยกว่าในระดับสมรรถภาพที่ออกแบบไว้

u อย่าใช้เครื่องมือไฟฟ้าถ้าสวิทช์ไม่สามารถเปิดปิดได้

เครื่องมือไฟฟ้าที่ไม่สามารถควบคุมการเปิดปิดด้วยสวิ

ทช์ได้ เป็นเครื่อง

มือไฟฟ้าที่ไม่ปลอดภัยและต้องส่งซ่อมแซม

u ก่อนปรับแต่งเครื่อง เปลี่ยนอุปกรณ์ประกอบ หรือเก็บ

เครื่องเข้าที่ ต้องถอดปลั๊กออกจากแหล่งจ่ายไฟ และ/

หรือถอดแบตเตอรี่แพ็คออกจากเครื่องมือไฟฟ้าหาก

ถอดออกได้

มาตรการป้องกันเพื่อความปลอดภัยนี้ช่วยลดความ

เสี่ยงจากการติดเครื่องโดยไม่ได้ตั้งใจ

u เมื่อเลิกใช้งานเครื่องมือไฟฟ้า ให้เก็บเครื่องไว้ในที่ที่

เด็กหยิบไม่ถึง และไม่อนุญาตให้บุคคลที่ไม่คุ้นเคยกับ

เครื่องหรือบุคคลที่ไม่ได้อ่านคำแนะนำเหล่านี้ใช้เครื่อง

เครื่องมือไฟฟ้าเป็นของอันตรายหากตกอยู่ในมือของผู้

ใช้ที่ไม่ได้รับการฝึกฝน

u บำรุงรักษาเครื่องมือไฟฟ้าและอุปกรณ์ประกอบ ตรวจ

สอบชิ้นส่วนที่เคลื่อนที่ว่าวางไม่ตรงแนวหรือติดขัดหรือ

ไม่ ตรวจหาการแตกหักของชิ้นส่วนและสภาพอื่นใดที่

อาจมีผลต่อการทำงานของเครื่องมือไฟฟ้า หากชำรุด

ต้องส่งเครื่องมือไฟฟ้าไปซ่อมแซมก่อนใช้งาน

อุบัติเหตุหลายอย่างเกิดขึ้นเนื่องจากดูแลรักษาเครื่องไม่

ดีพอ

u รักษาเครื่องมือตัดให้คมและสะอาด

หากบำรุงรักษาเครื่องมือที่มีขอบตัดแหลมคมอย่างถูกต้อง

จะสามารถตัดได้ลื่นไม่ติดขัดและควบคุมได้ง่ายกว่า

u ใช้เครื่องมือไฟฟ้า อุปกรณ์ประกอบ เครื่องมือ และอุปก

รณ์อื่นๆ ตรงตามคำแนะนำเหล่านี้ โดยคำนึงถึง

เงื่อนไขการทำงานและงานที่จะทำ การใช้เครื่อง

มือไฟฟ้าทำงานที่ต่างไปจากวัตถุประสงค์การ

ใช้งานของเครื่อง อาจนำไปสู่สถานการณ์ที่เป็นอันตรายได้

u ดูแลด้ามจับและพื้นผิวจับให้แห้ง สะอาด และปราศจาก

คราบน้ำมันและจาระบี ด้ามจับและพื้นผิว

จับที่ลื่นทำให้หยิบจับได้ไม่ปลอดภัย

และไม่สามารถควบคุมเครื่องมือในสถานการณ์ที่ไม่คาดคิด

การบริการ

u ส่งเครื่องมือไฟฟ้าของท่านเข้ารับบริการจากช่าง

ซ่อมที่มีคุณสมบัติเหมาะสม โดยใช้อะไหล่ที่เหมือน

กันเท่านั้น ในลักษณะนี้ท่านจะแน่ใจได้ว่าเครื่อง

มือไฟฟ้าอยู่ในสภาพที่ปลอดภัย

คำเตือนเพื่อความ

ปลอดภัยสำหรับเลื่อยอเนกประสงค์

u เมื่อทำงานในบริเวณที่อุปกรณ์ตัดอาจสัมผัสสายไฟฟ้าที่

ซ่อนอยู่หรือสายไฟฟ้าของตัวเครื่องเอง ต้องจับเครื่อง

มือไฟฟ้าตรงพื้นผิวจับที่หุ้มฉนวน หากอุปกรณ์ตัดสัมผัส

สายที่ “มีกระแสไฟฟ้า” ไหลผ่าน จะทำให้ชิ้นส่วนโลหะที่

ไม่ได้หุ้มฉนวนของเครื่องมือไฟฟ้าเกิด “มีกระแสไฟฟ้า”

ด้วย และส่งผลให้ผู้ใช้งานเครื่องถูกไฟฟ้าดูดได้

u ใช้เครื่องหนีบหรือวิธีอื่นที่ได้ผลเพื่อยึดและหนุนชิ้นงาน

กับแท่นที่มั่นคง การจับชิ้นงานด้วยมือหรือยันไว้กับ

ร่างกายจะไม่มั่นคง และอาจทำให้สูญเสียการควบคุมได้

u เอามือออกห่างจากบริเวณแนวเลื่อย อย่าเอื้อมมือเข้า

ใต้ชิ้นงาน การสัมผัสกับใบเลื่อยจะทำให้บาดเจ็บได้

u จับเครื่องมือไฟฟ้าให้แน่นด้วยมือทั้งสองข้างและตั้งท่า

ยืนให้มั่นคงขณะทำงาน ท่านจะสามารถนำทางเครื่องมือ

ไฟฟ้าได้ปลอดภัยกว่าเมื่อจับเครื่องด้วยมือทั้งสองข้าง

u จับเครื่องมือไฟฟ้าเข้าหาชิ้นงานเมื่อเครื่องเปิดสวิ

ทช์อยู่เท่านั้น มิฉะนั้นอาจได้รับอันตรายจากการตี

กลับหากเครื่องมือตัดติดขัดอยู่ในชิ้นงาน

u ตรวจสอบให้แน่ใจว่าขณะเลื่อยได้วางแผ่นฐานไว้ชิดกับ

ชิ้นงานเสมอ ใบเลื่อยอาจติดขัดและทำให้สูญเสียการ

ควบคุมเครื่องมือไฟฟ้า

u เมื่อเสร็จสิ้นการทำงาน ให้ปิดสวิทช์เครื่องมือไฟฟ้า

และดึงใบเลื่อยออกจากร่องตัดเมื่อใบเลื่อยหยุด

นิ่งอยู่กับที่แล้วเท่านั้น ในลักษณะนี้ท่านสามารถหลีก

เลี่ยงการตีกลับ และวางเครื่องลงได้อย่างปลอดภัย

u รอให้เครื่องมือไฟฟ้าหยุดสนิทก่อนวางเครื่องลงบนพื้น

เครื่องมือที่ใส่อยู่อาจติดขัดและทำให้สูญเสียการ

ควบคุมเครื่องมือไฟฟ้า

u ใช้เฉพาะใบเลื่อยที่ไม่ชำรุดและมีสภาพที่สมบูรณ์เท่านั้น

ใบเลื่อยที่ทื่อหรือบิดงอสามารถแตกหัก ส่งผลเชิง

ลบต่อการตัด หรือทำให้เกิดการตีกลับได้

1 609 92A 5P8 | (14.09.2020) Bosch Power Tools

Page 23

ไทย | 23

u หลังปิดสวิทช์ อย่าเบรกใบเลื่อยให้หยุดวิ่งโดยการกด

ลงด้านข้าง ใบเลื่อยอาจชำรุด แตกหัก หรือทำให้เกิด

การตีกลับได้

u ยึดหนีบวัสดุให้แน่น อย่าใช้มือหรือเท้าของท่านพยุงชิ้น

งานไว้ อย่าให้เครื่องเลื่อยที่กำลังทำงานสัมผัสวัตถุหรือ

พื้น อันตรายจากการตีกลับ

u ใช้เครื่องตรวจจับที่เหมาะสมเพื่อตรวจหาสายไฟฟ้า

หรือท่อสาธารณูปโภคที่อาจซ่อนอยู่ในบริเวณทำงาน

หรือติดต่อบริษัทสาธารณูปโภคในพื้นที่เพื่อขอความ

ช่วยเหลือ การสัมผัสกับสายไฟฟ้าอาจทำให้เกิดไฟ

ไหม้หรือถูกไฟฟ้าดูด การทำให้ท่อแก๊ซเสียหายอาจ

ทำให้เกิดระเบิด การเจาะเข้าในท่อน้ำทำให้ทรัพย์สินเสีย

หาย หรืออาจเป็นเหตุให้ถูกไฟฟ้าดูดได้

รายละเอียดผลิตภัณฑ์และข้อมูล จำเพาะ

อ่านคำเตือนเพื่อความปลอดภัยและคำ

แนะนำทั้งหมด การไม่ปฏิบัติตามคำเตือนและ

คำสั่งอาจเป็นสาเหตุให้ถูกไฟฟ้าดูด เกิดไฟไหม้

และ/หรือได้รับบาดเจ็บอย่างร้ายแรง

กรุณาดูภาพประกอบในส่วนหน้าของคู่มือการใช้งาน

ประโยชน์การใช้งานของเครื่อง

เครื่องนี้ใช้สำหรับเลื่อยไม้ พลาสติก โลหะ และวัสดุก่อสร้าง

ในขณะที่วางอยู่บนชิ้นงานอย่างแน่นหนา เครื่อง

นี้เหมาะสำหรับตัดแนวตรงและตัดโค้ง เมื่อใช้ใบเลื่อยที่ทำ

จากแผ่นโลหะคู่ (bimetal) ที่เหมาะสม จะสามารถตัดออก

ได้เรียบเสมอพื้นผิวชิ้นงาน อ่านและปฏิบัติตามข้อแนะนำเกี่ยว

กับใบเลื่อย

ส่วนประกอบที่แสดงภาพ

ลำดับเลขของส่วนประกอบผลิตภัณฑ์อ้างถึงส่วน

ประกอบของเครื่องที่แสดงในหน้าภาพประกอบ

A)

ใบเลื่อย

(1)

แผ่นฐานแบบปรับได้

(2)

ตัวจับใบเลื่อย

(3)

ปลอกล็อคสำหรับใบเลื่อย

(4)

ตะขอแขวน

(5)

ปุ่มล็อคไม่ให้สวิทช์เปิด-ปิดทำงาน

(6)

(3601F4E240)

การล็อคสวิทช์เปิด-ปิดทำงาน (3601F4E280,

(6)

3601F4E2B0, 3601F4E2C0,

3601F4E2K0, 3601F4E2L0)

สวิทช์เปิด-ปิด

(7)

ปุ่มปลดล็อคแผ่นฐาน

(8)

ไฟส่องบริเวณทำงาน

(9)

ด้ามจับ (พื้นผิวจับหุ้มฉนวน)

(10)

A) อุปกรณ์ประกอบที่แสดงภาพหรืออธิบายไม่รวมอยู่ในการ

จัดส่งมาตรฐาน

กรุณาดูอุปกรณ์ประกอบทั้งหมดในรายการแสดงอุปกรณ์ประ

กอบของเรา

ข้อมูลทางเทคนิค

เลื่อยอเนกประสงค์

หมายเลขสินค้า

การเตะ

ระบบอิเล็กทรอนิกส์คงที่

การควบคุมอัตราขยับชัก

กำลังไฟฟ้าพิกัดด้านเข้า

อัตราขยับชักเดินตัวเปล่า n

วัตต์ 1300

min

0

ด้ามจับเครื่องมือ

ระยะช่วงชัก

ความลึกการตัด สูงสุด

– ในไม้

– ในเหล็กกล้า (ไม่เจือ)

– เส้นผ่าศูนย์กลางท่อ

น้ำหนักตามระเบียบการ

EPTA-Procedure

01:2014

ระดับความปลอดภัย

ค่าที่ให้นี้ใช้ได้กับแรงดันไฟฟ้านอมินอล [U] 230 โวลท์ค่าเหล่า

นี้อาจเปลี่ยนแปลงไปสำหรับแรงดันไฟฟ้าที่แตกต่างกัน

และโมเดลที่ผลิตสำหรับเฉพาะประเทศ

GSA 1300 PCE

3601F4E2..

−1

0−2900

มม. 28

มม. 220

มม. 20

มม. 175

กก. 4.1

การติดตั้ง

u ดึงปลั๊กไฟออกจากเต้าเสียบก่อนปรับแต่งเครื่อง

●

●

●

SDS

/Ⅱ

Bosch Power Tools 1 609 92A 5P8 | (14.09.2020)

Page 24

24 | ไทย

การใส่/การเปลี่ยนใบเลื่อย

u เมื่อติดตั้งหรือเปลี่ยนเครื่องมือ ต้องสวมถุงมือป้องกัน

เครื่องมือมีความคมและอาจร้อนขึ้นเมื่อใช้งานเป็นเวลา

นาน

u เมื่อเปลี่ยนใบเลื่อย ต้องระมัดระวังอย่าให้

มีเศษวัสดุตกค้างอยู่ที่ที่จับใบเลื่อย ต. ย. เช่น ขี้

เลื่อยไม้หรือโลหะ

การเลือกใบเลื่อย

กรุณาดูภาพรวมของใบเลื่อยที่แนะนำในตอนท้ายของคู่มือ

การใช้งาน ใช้เฉพาะใบเลื่อยที่มีก้านสากลขนาด ½" เท่านั้น

ใบเลื่อยไม่ควรยาวเกินกว่าที่จำเป็นสำหรับการตัดชิ้นงานที่

ต้องการ

การใส่ใบเลื่อย (ดูภาพประกอบA)

หมุนปลอกล็อค(4) ประมาณ 90° ไปทางทิศทางลูกศรและ

ยึดให้แน่น ดันใบเลื่อย(1) เข้าในตัวจับใบเลื่อย(3) ปล่อย

นิ้วจากปลอกล็อค

u ดึงใบเลื่อยเพื่อตรวจสอบว่าใบเลื่อยเข้าตำแหน่งอย่าง

แน่นหนาแล้วหรือไม่ ใบเลื่อยที่ใส่ไว้หลวมๆ อาจหล่นออก

มาและทำให้บาดเจ็บได้

สำหรับงานบางประเภท ท่านยังสามารถหมุนใบเลื่อย(1) ไป

180° (ฟันหันขึ้นด้านบน) และใส่ใบเลื่อยกลับเข้าไปอีกครั้ง

การถอดใบเลื่อย (ดูภาพประกอบB)

u ปล่อยใบเลื่อยให้เย็นลงก่อนถอดออก

อันตรายจากการบาดเจ็บเมื่อสัมผัสใบเลื่อยที่ร้อน

หมุนปลอกล็อค(4) ประมาณ 90° ไปทางทิศทางลูกศร ถอด

ใบเลื่อย(1) ออก

การดูดฝุ่น/ขี้เลื่อย

ฝุ่นที่ได้จากวัสดุ เช่น เคลือบผิวที่มีสารตะกั่ว ไม้บางประเภท

แร่ธาตุ และโลหะ อาจเป็นอันตรายต่อสุขภาพ การ

สัมผัสหรือการหายใจเอาฝุ่นเข้าไปอาจทำให้เกิดปฏิกิริยาแพ้

ฝุ่น และ/หรือนำมาซึ่งโรคติดเชื้อระบบหายใจแก่ผู้

ใช้เครื่องหรือผู้ที่ยืนอยู่ใกล้เคียง

ฝุ่นบางประเภท เช่น ฝุ่นไม้โอ๊ก หรือไม้บีช นับ

เป็นสารที่ทำให้เกิดมะเร็ง โดยเฉพาะอย่างยิ่งเมื่อผสม

กับสารเติมแต่งเพื่อบำบัดไม้ (โครเมต ผลิตภัณฑ์รักษาเนื้อไม้)

สำหรับวัสดุที่มีแอสเบสทอสต้องให้ผู้เชี่ยวชาญทำงานเท่านั้น

– จัดสถานที่ทำงานให้มีการระบายอากาศที่ดี

– ขอแนะนำให้สวมหน้ากากป้องกันการติดเชื้อที่มีระดับ-ไส้

กรอง P2

ปฏิบัติตามกฎข้อบังคับสำคัญอื่นๆ ที่เกี่ยวกับวัสดุชิ้นงาน

ที่บังคับใช้ในประเทศของท่าน

u ป้องกันการสะสมของฝุ่นในสถานที่ทำงาน

ฝุ่นสามารถลุกไหม้อย่างง่ายดาย

การปฏิบัติงาน

การเริ่มต้นปฏิบัติงาน

u ให้สังเกตแรงดันไฟฟ้า! แรง

ดันไฟฟ้าจากแหล่งจ่ายไฟฟ้าต้องมีค่าตรงกับค่าแรง

ดันไฟฟ้าที่ระบุไว้บนแผ่นป้ายพิกัดเครื่อง เครื่องมือ

ไฟฟ้าที่มีเครื่องหมาย 230 โวลท์ สามารถใช้งานกับ

220 โวลท์ ได้ด้วย

ไฟส่องบริเวณทำงาน

ไฟส่องบริเวณ(9) สว่างขึ้นเมื่อเสียบปลั๊กไฟและช่วยให้มอง

เห็นในพื้นที่ทำงานได้ดียิ่งขึ้น

u อย่ามองตรงเข้าไปในไฟส่องบริเวณทำงาน ไฟอาจ

ทำให้ท่านตาพร่าได้

สวิทช์เปิด-ปิด (3601F4E240)

เมื่อต้องการให้เครื่องมือไฟฟ้าเปิดสวิตช์ ให้กดปุ่มล็อค (6)

จากนั้นให้กดสวิทช์เปิด-ปิด (7) และกดค้างไว้

ปิดสวิทช์ เครื่องมือไฟฟ้าโดยปล่อยนิ้วจากสวิทช์เปิด-ปิด (7)

หมายเหตุ: ด้วยเหตุผลด้านความปลอดภัยจึงไม่สามารถล็อค

สวิทช์เปิด-ปิด (7) ได้ จะต้องกดสวิทช์เปิด-ปิดตลอดเวลา

ทำงาน

สวิทช์เปิด-ปิด (3601F4E280, 3601F4E2B0,

3601F4E2C0, 3601F4E2K0, 3601F4E2L0)

u ตรวจสอบให้แน่ใจว่าท่านสามารถใช้งานสวิทช์เปิด-ปิด

ได้โดยไม่ต้องปล่อยด้ามจับ

เปิดสวิทช์เครื่องมือไฟฟ้าโดยกดสวิทช์เปิด-ปิด (7)

ล็อคสวิทช์เปิด-ปิด (7) โดยกดสวิทช์ค้างไว้และกดปุ่มล็อค

(6) เพิ่ม

ปิดสวิทช์เครื่องมือไฟฟ้าโดยปล่อยนิ้วจากสวิทช์เปิด-ปิด (7)

หากสวิทช์เปิด-ปิด (7) ถูกล็อคไว้ ให้กดสวิทช์ก่อน แล้วจึง

ปล่อยนิ้ว

ระบบอิเล็กทรอนิกส์คงที่

ระบบควบคุมอิเล็กทรอนิกส์คงที่จะรักษาอัตราขยับชักขณะ

เดินเครื่องตัวเปล่าและขณะใช้งานให้มีค่าเกือบคงที่ และทำให้

ได้ประสิทธิภาพการทำงานที่สม่ำเสมอ

การควบคุมอัตราขยับชัก

ท่านสามารถควบคุมความเร็วขยับชักของเครื่องมือไฟฟ้าที่เปิด

สวิทช์ไว้ได้อย่างต่อเนื่อง โดยเพิ่มหรือลดแรงกดบนสวิทช์เปิดปิด (7)

1 609 92A 5P8 | (14.09.2020) Bosch Power Tools

Page 25

ไทย | 25

เมื่อกดบนสวิทช์เปิด-ปิด (7) เบาๆ จะได้ความเร็วขยับชักต่ำ

ถ้ากดแรงขึ้น ความเร็วขยับชักก็จะเพิ่มขึ้นด้วย

เกณฑ์จังหวะขยับชักที่ต้องใช้ขึ้นอยู่กับประเภทวัสดุชิ้น

งานและเงื่อนไขการทำงาน การทดลองภาคปฏิบัติจะช่วยให้

ได้เกณฑ์จังหวะที่ดีที่สุด

ขอแนะนำให้ลดอัตราขยับชักลงขณะใบเลื่อยขบเข้าในวัสดุชิ้น

งาน และเมื่อเลื่อยพลาสติกและอะลูมิเนียม

เมื่อทำงานที่อัตราขยับชักต่ำเป็นเวลานาน เครื่องอาจร้อน

ขึ้นมาก ให้ถอดใบเลื่อยออก และทำให้เครื่องมือไฟฟ้าเย็นลง

โดยปล่อยให้เครื่องเดินด้วยความเร็วขยับชักสูงสุดนาน

ประมาณ 3 นาที

การเตะ

การเตะทำงานอย่างถาวรเพื่อให้ได้ความเร็วในการตัดสูง

ข้อแนะนำในการทำงาน

u ดึงปลั๊กไฟออกจากเต้าเสียบก่อนปรับแต่งเครื่อง

u หากใบเลื่อยติดขัด ให้ปิดสวิทช์เครื่องทันที

คำแนะนำ

u เมื่อเลื่อยวัสดุก่อสร้างน้ำหนักเบา

ต้องปฏิบัติตามข้อกำหนดทางกฎหมายและข้อแนะนำข

องบริษัทผลิตวัสดุก่อสร้าง

ก่อนเลื่อย ให้ตรวจสอบไม้ พาร์ติเคิลบอร์ด วัสดุก่อสร้าง และ

อื่นๆ เพื่อหาวัตถุแปลกปลอม เช่น ตะปู สกรู หรือวัตถุคล้าย

คลึงอื่นๆ และใช้ใบเลื่อยที่ถูกต้อง

เปิดสวิทช์เครื่องและเคลื่อนเครื่องเข้าหาชิ้นงาน วางแผ่นฐาน

(2) ทาบลงบนผิวหน้าชิ้นงาน และเลื่อยวัสดุออกโดยใช้แรง

กดสัมผัสและการป้อนที่สม่ำเสมอ เมื่อกระบวนการทำงานสิ้น

สุด ให้ปิดสวิทช์เครื่อง

หากใบเลื่อยติดขัด ให้ปิดสวิทช์เครื่องทันที ถ่างร่องตัดเล็ก

น้อยด้วยเครื่องมือที่เหมาะสม และดึงเครื่องออก

แผ่นฐานแบบหมุนและดึงออกได้

(ดูภาพประกอบC−D)

เนื่องจากแผ่นฐาน (2) เคลื่อนไหวไปมาได้ จึงสามารถปรับ

ให้เข้ากับตำแหน่งมุมที่ต้องการของพื้นผิวได้

การใช้งานแผ่นฐาน(2) สามารถเคลื่อนย้ายได้ 3 ขั้นตอนใน

ทิศทางตามยาว ทั้งนี้ขึ้นอยู่กับใบเลื่อยที่ใช้

กดปุ่มปลดล็อค(8) และเลื่อนแผ่นฐาน(2) ไปยังตำแหน่งที่

ต้องการ ปล่อยปุ่มปลดล็อคและตรวจสอบว่าแผ่นรองพื้นล็อค

เข้าที่อย่างแน่นหนาแล้วหรือไม่ หากจำเป็น ให้ดันแผ่นรองพื้น

จนล็อคเข้าที่อย่างแน่นหนา

การจ้วงตัด (ดูภาพประกอบ E)

u การจ้วงตัดจะทำได้เฉพาะเมื่อตัดวัสดุนิ่ม เช่น ไม้ แผ่น

ยิปซัม หรือวัสดุคลายคลึงเท่านั้น! อย่าเลื่อยวัสดุที่

เป็นโลหะด้วยกระบวนการจ้วงตัด!

สำหรับการจ้วงตัด ให้ใช้เฉพาะใบเลื่อยสั้นเท่านั้น

วางเครื่องโดยให้ขอบแผ่นฐาน (2) อยู่บนชิ้นงาน แต่อย่าให้

ใบเลื่อย (1) สัมผัสกับชิ้นงาน และเปิดสวิทช์เครื่อง

สำหรับเครื่องมือไฟฟ้าที่มีการควบคุมความเร็วขยับชัก

ให้ตั้งความเร็วขยับชักสูงสุด จับเครื่องมือไฟฟ้าเข้าหาชิ้น

งานอย่างมั่นคง และจ้วงใบเลื่อยเข้าในชิ้นงานอย่างช้าๆ

ทันทีที่แผ่นฐาน (2) วางลงบนพื้นผิวของชิ้นงานทั้งหมด ให้

เลื่อยต่อไปตามรอยตัดที่ต้องการ

สำหรับงานบางประเภท ท่านยังสามารถใส่ใบเลื่อย(1) โดย

หมุนกลับด้านไป 180° และเคลื่อนนำเลื่อยอเนกประสงค์ใน

ลักษณะกลับทางตามไปด้วย

การตัดเรียบเสมอกัน (ดูภาพประกอบ F)

เมื่อใช้ใบเลื่อยที่ทำจากแผ่นโลหะคู่ (bimetal) ที่ยืดหยุ่น

ท่านสามารถเลื่อยชิ้นส่วนก่อสร้างที่ยื่นออกมา เช่น ท่อน้ำ ได้

เรียบเสมอกับฝาผนัง

u ตรวจสอบให้แน่ใจว่าใบเลื่อยมีขนาดยาวกว่าเส้นผ่า

ศูนย์กลางของชิ้นงานที่จะเลื่อยเสมออันตรายจากการตี

กลับ

วางใบเลื่อยทาบกับฝาผนังโดยตรง และดัดใบเลื่อยให้โค้งเล็ก

น้อยโดยกดลงด้านข้างบนเครื่องมือไฟฟ้าจนแผ่นฐานชิดกับ

ฝาผนัง เปิดสวิทช์เครื่องมือไฟฟ้า และเลื่อยผ่านชิ้นงานโดยกด

ลงด้านข้างอย่างคงที่

ตะขอแขวน (ดูภาพประกอบG)

คุณสามารถใช้ตะขอแขวน (5) เครื่องมือไฟฟ้าได้ เช่น เข้า

กับตัวนำได้ พับตะขอแขวนเข้าในตำแหน่งที่ต้องการ

u เมื่อแขวนเครื่องมือไฟฟ้าตรวจสอบให้แน่ใจว่าได้

ป้องกันใบเลื่อยจากการสัมผัสโดยไม่ได้ตั้งใจ มีความ

เสี่ยงต่อการบาดเจ็บ

พับตะขอแขวน(5) กลับเข้าที่เมื่อคุณต้องการใช้งานกับ

เครื่องมือไฟฟ้า

สารหล่อเย็น/น้ำมันหล่อลื่น

เมื่อเลื่อยโลหะ ให้ชโลมสารหล่อเย็น/น้ำมันหล่อลื่นตามรอย

ตัดเนื่องจากวัสดุร้อนขึ้น

การบำรุงรักษาและการบริการ

การบำรุงรักษาและการทำความสะอาด

u ดึงปลั๊กไฟออกจากเต้าเสียบก่อนปรับแต่งเครื่อง

Bosch Power Tools 1 609 92A 5P8 | (14.09.2020)

Page 26

26 | Bahasa Indonesia

u เพื่อให้ทำงานได้อย่างถูกต้องและปลอดภัย

ต้องรักษาเครื่องและช่องระบายอากาศ

ให้สะอาดอยู่เสมอ

หากจำเป็นต้องเปลี่ยนสายไฟฟ้า ต้องส่งเครื่องให้ Bosch

หรือศูนย์บริการหลังการขายที่ได้รับมอบหมายสำหรับเครื่อง

มือไฟฟ้า Bosch เปลี่ยนให้ ทั้งนี้เพื่อหลีกเลี่ยงอันตราย

ควรทำความสะอาดที่จับใบเลื่อยโดยใช้แปรงนุ่มปัด

สำหรับการทำความสะอาด ให้ถอดใบเลื่อยออกจากเครื่องมือ

ไฟฟ้า บำรุงรักษาที่จับใบเลื่อยให้ทำงานได้ดีโดยใช้สารหล่อ

ลื่นที่เหมาะสม

หากเครื่องมือไฟฟ้าสกปรกมาก เครื่องอาจทำงานผิดปกติได้

ดังนั้นอย่าเลื่อยวัสดุที่ให้ฝุ่นมากจากทางด้านล่างหรือเหนือ

ศีรษะ

การบริการหลังการขายและการให้คำปรึกษาการ ใช้งาน

ศูนย์บริการหลังการขายของเรายินดีตอบคำถามของ

ท่านที่เกี่ยวกับการบำรุงรักษาและการซ่อมแซมผลิตภัณฑ์รวม

ทั้งเรื่องอะไหล่ ภาพเขียนแบบการประกอบและข้อมูลเกี่ยวกับ

อะไหล่ กรุณาดูใน: www.bosch-pt.com

ทีมงานที่ปรึกษาของ บ๊อช ยินดีให้ข้อมูลเกี่ยวกับผลิตภัณฑ์

ของเราและอุปกรณ์ประกอบต่างๆ

เมื่อต้องการสอบถามและสั่งซื้ออะไหล่ กรุณาแจ้งหมายเลข

สินค้า 10 หลักบนแผ่นป้ายรุ่นของผลิตภัณฑ์ทุกครั้ง

ไทย

ไทย บริษัท โรเบิร์ต บ๊อช จำกัด

เอฟวายไอ เซ็นเตอร์ อาคาร 1 ชั้น 5

เลขที่ 2525 ถนนพระราม 4

แขวงคลองเตย เขตคลองเตย กรุงเทพฯ 10110

โทร: +66 2012 8888

แฟกซ์: +66 2064 5800

www.bosch.co.th

ศูนย์บริการซ่อมและฝึกอบรม บ๊อช

อาคาร ลาซาลทาวเวอร์ ชั้น G ห้องเลขที่ 2

บ้านเลขที่ 10/11 หมู่ 16

ถนนศรีนครินทร์ ตำบลบางแก้ว อำเภอบางพลี

จังหวัดสมุทรปราการ 10540

ประเทศไทย

โทรศัพท์ 02 7587555

โทรสาร 02 7587525

สามารถดูที่อยู่ศูนย์บริการอื่นๆ ได้ที่:

www.bosch-pt.com/serviceaddresses

การกำจัดขยะ

เครื่องมือไฟฟ้า อุปกรณ์ประกอบ และหีบห่อ ต้องนำ

ไปแยกประเภทวัสดุเพื่อการรีไซเคิลที่เป็นมิตรต่อสิ่งแวดล้อม

อย่าทิ้งเครื่องมือไฟฟ้าลงในขยะครัวเรือน!

Bahasa Indonesia

Petunjuk Keselamatan

Petunjuk keselamatan umum untuk perkakas listrik

PERINGATAN

keselamatan yang diberikan bersama perkakas listrik

ini. Kesalahan dalam menjalankan petunjuk di bawah ini

dapat mengakibatkan sengatan listrik, kebakaran, dan/atau

cedera serius.

Simpanlah semua peringatan dan petunjuk untuk

penggunaan di masa mendatang.

Istilah "perkakas listrik" dalam peringatan mengacu pada

perkakas listrik yang dioperasikan dengan listrik

(menggunakan kabel) atau perkakas listrik yang

dioperasikan dengan baterai (tanpa kabel).

Keamanan tempat kerja

u Jaga kebersihan dan pencahayaan area kerja. Area

yang berantakan atau gelap dapat memicu kecelakaan.

u Jangan mengoperasikan perkakas listrik di

lingkungan yang dapat memicu ledakan, seperti

adanya cairan, gas, atau debu yang mudah terbakar.

Perkakas listrik dapat memancarkan bunga api yang

kemudian mengakibatkan debu atau uap terbakar.

u Jauhkan dari jangkauan anak-anak dan pengamat saat

mengoperasikan perkakas listrik. Gangguan dapat

menyebabkan hilangnya kendali.

Keamanan listrik

u Steker perkakas listrik harus sesuai dengan

stopkontak. Jangan pernah memodifikasi steker.

Jangan menggunakan steker adaptor bersama dengan

perkakas listrik yang terhubung dengan sistem

grounding. Steker yang tidak dimodifikasi dan

stopkontak yang cocok akan mengurangi risiko sengatan

listrik.

u Hindari kontak badan dengan permukaan yang

terhubung dengan sistem grounding, seperti pipa,

radiator, kompor, dan lemari es. Terdapat peningkatan

risiko terjadinya sengatan listrik jika badan Anda

terhubung dengan sistem grounding.

Baca semua peringatan, petunjuk,

ilustrasi, dan spesifikasi

1 609 92A 5P8 | (14.09.2020) Bosch Power Tools

Page 27

Bahasa Indonesia | 27

u Perkakas listrik tidak boleh terpapar hujan atau

basah. Air yang masuk ke dalam perkakas listrik

menambah risiko terjadinya sengatan listrik.

u Jangan menyalahgunakan kabel. Jangan gunakan

kabel untuk membawa, menarik, atau melepas steker

perkakas listrik. Jauhkan kabel dari panas, minyak,

tepi yang tajam, atau komponen yang bergerak. Kabel

listrik yang rusak atau tersangkut menambah risiko

terjadinya sengatan listrik.

u Saat mengoperasikan perkakas listrik di luar ruangan,

gunakan kabel ekstensi yang sesuai untuk

penggunaan di luar ruangan. Penggunaan kabel yang

cocok untuk pemakaian di luar ruangan mengurangi risiko

terjadinya sengatan listrik.

u Jika perkakas listrik memang harus dioperasikan di

tempat yang lembap, gunakan pemutus arus listrik

residu (RCD). Penggunaan RCD akan mengurangi risiko

terjadinya sengatan listrik.

Keselamatan personel

u Tetap waspada, perhatikan aktivitas yang sedang

dikerjakan dan gunakan akal sehat saat

mengoperasikan perkakas listrik. Jangan gunakan

perkakas listrik saat mengalami kelelahan atau di