Page 1

Robert Bosch Power Tools GmbH

1 609 92A 4JV

70538 Stuttgart

GERMANY

www.bosch-pt.com

1 609 92A 4JV (2018.09) O / 31

GKS 20-65 Professional

en Original instructions

pt Manual de instruções original

es Manual original

Page 2

2 |

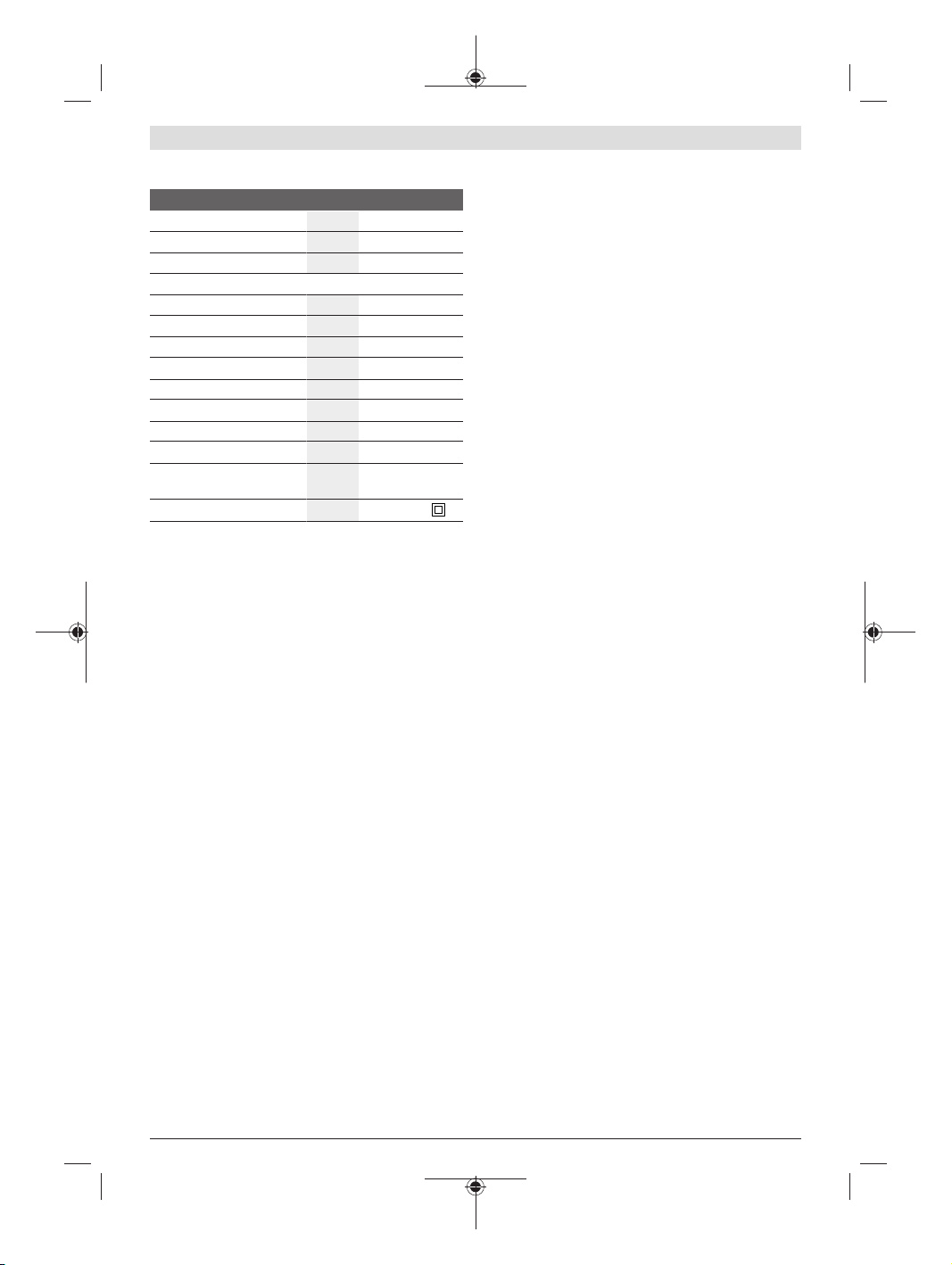

English . . .. .. .. .. .. . .. .. .. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. page 6

Português do Brasil. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. Página 14

Español . .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . Página 20

1 609 92A 4JV | (20.09.2018) Bosch Power Tools

Page 3

| 3

(1) (2)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(3)

(17)

(3)

Bosch Power Tools 1 609 92A 4JV | (20.09.2018)

Page 4

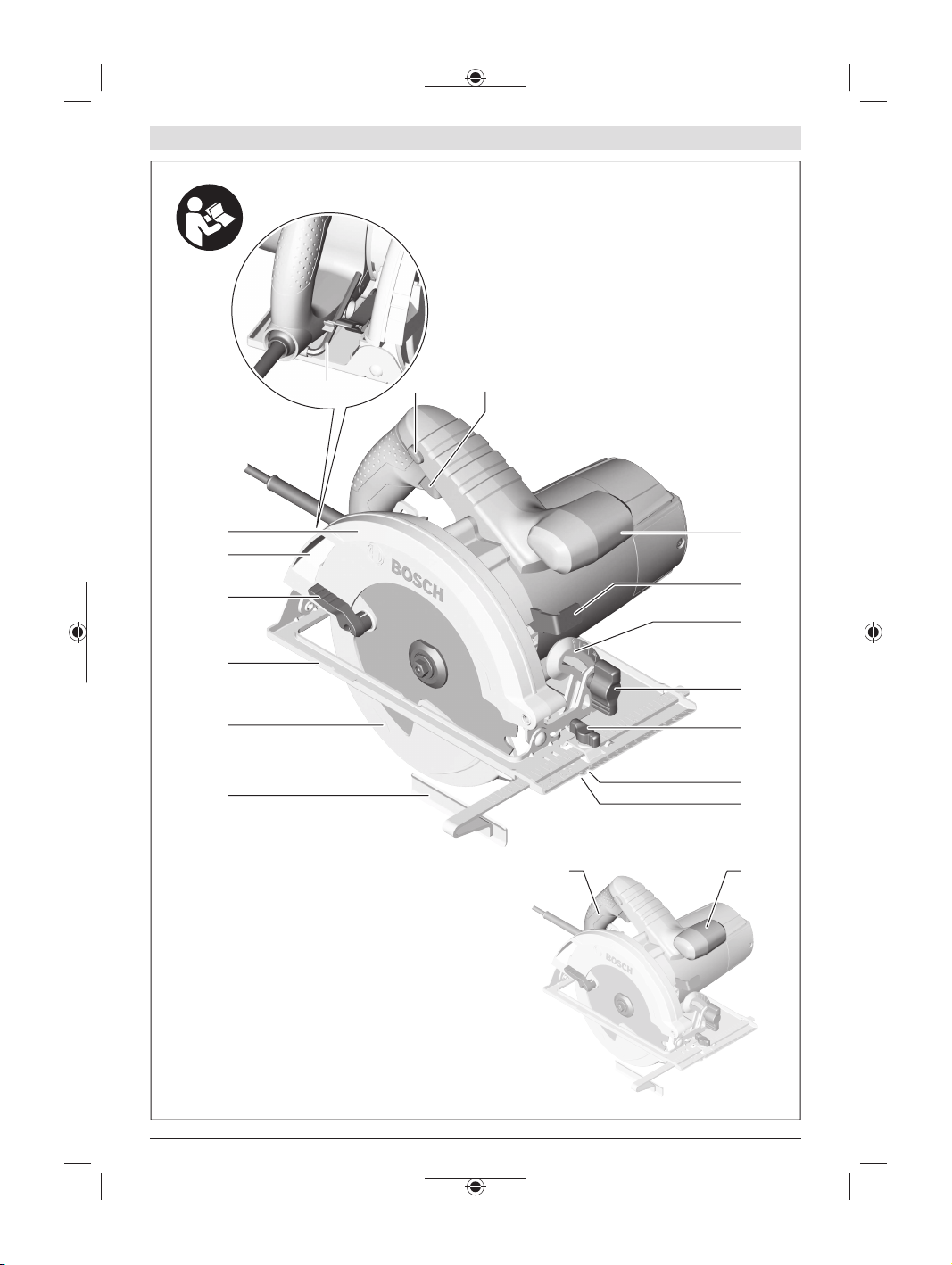

A

(4)

(22)(21)

(20)

(19)(18)(17)

4 |

1 609 92A 4JV | (20.09.2018) Bosch Power Tools

Page 5

| 5

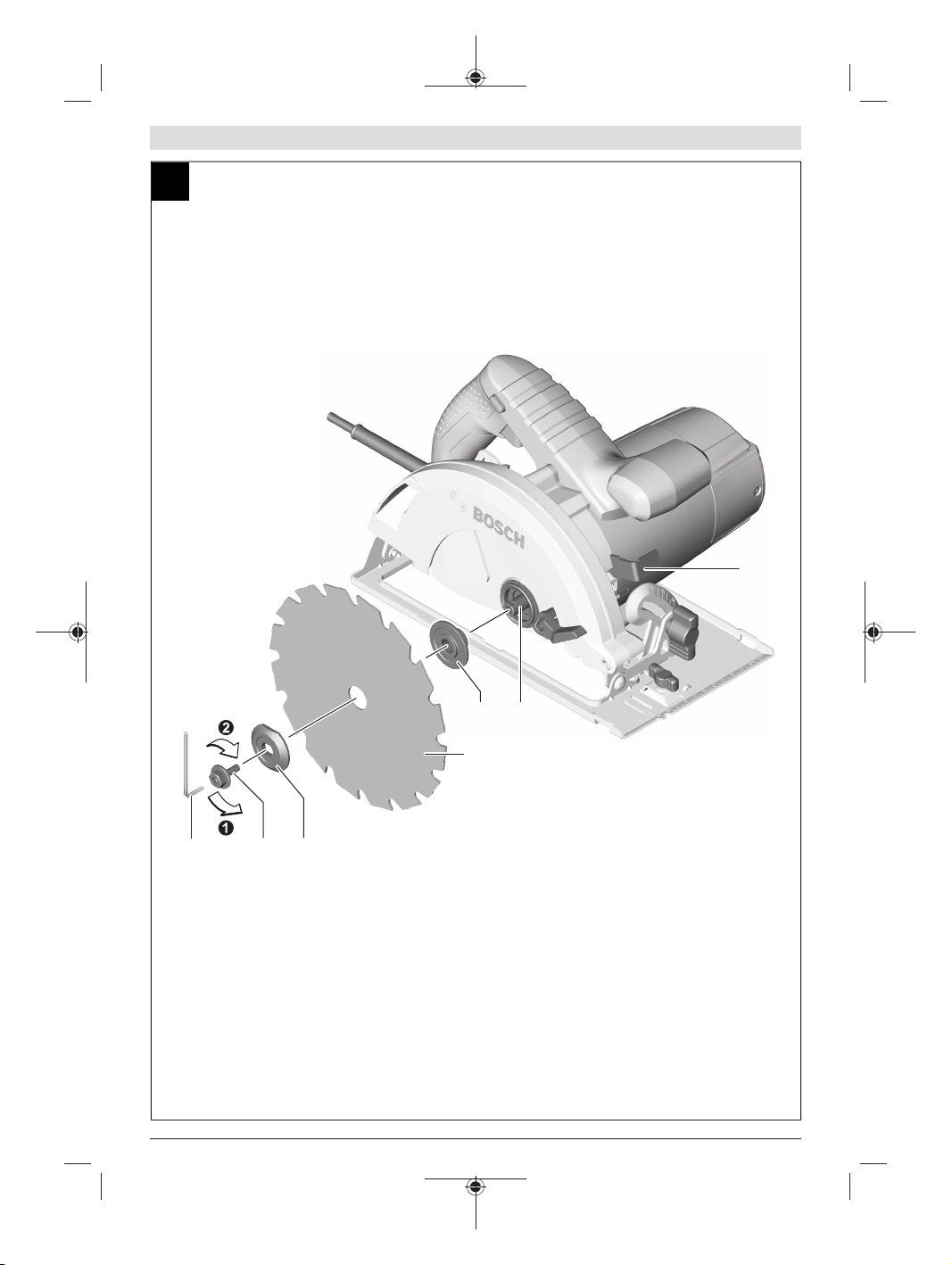

AA

(24)

(25)

(17)

(10)

(23)

B

C

D

Bosch Power Tools 1 609 92A 4JV | (20.09.2018)

Page 6

6 | English

English

Safety instructions

General Power Tool Safety Warnings

WARNING

tions provided with this power tool. Failure to follow all in-

structions listed below may result in electric shock, fire and/

or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless) power tool.

Work area safety

u Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

u Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust

or fumes.

u Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

Electrical safety

u Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

u Avoid body contact with earthed or grounded sur-

faces, such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your

body is earthed or grounded.

u Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric shock.

u Do not abuse the cord. Never use the cord for carry-

ing, pulling or unplugging the power tool. Keep cord

away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric

shock.

u When operating a power tool outdoors, use an exten-

sion cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

u If operating a power tool in a damp location is un-

avoidable, use a residual current device (RCD) protected supply. Use of an RCD reduces the risk of electric

shock.

Personal safety

u Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a

power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inatten-

Read all safety warnings, instructions, illustrations and specifica-

tion while operating power tools may result in serious personal injury.

u Use personal protective equipment. Always wear eye

protection. Protective equipment such as a dust mask,

non-skid safety shoes, hard hat or hearing protection

used for appropriate conditions will reduce personal injuries.

u Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

u Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal injury.

u Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

u Dress properly. Do not wear loose clothing or jew-

ellery. Keep your hair and clothing away from moving

parts. Loose clothes, jewellery or long hair can be caught

in moving parts.

u If devices are provided for the connection of dust ex-

traction and collection facilities, ensure these are connected and properly used. Use of dust collection can re-

duce dust-related hazards.

u Do not let familiarity gained from frequent use of tools

allow you to become complacent and ignore tool

safety principles. A careless action can cause severe in-

jury within a fraction of a second.

Power tool use and care

u Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was designed.

u Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

u Disconnect the plug from the power source and/or re-

move the battery pack, if detachable, from the power

tool before making any adjustments, changing accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the power tool

accidentally.

u Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

u Maintain power tools and accessories. Check for mis-

alignment or binding of moving parts, breakage of

parts and any other condition that may affect the

power tool’s operation. If damaged, have the power

tool repaired before use. Many accidents are caused by

poorly maintained power tools.

1 609 92A 4JV | (20.09.2018) Bosch Power Tools

Page 7

English | 7

u Keep cutting tools sharp and clean. Properly main-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

u Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

u Keep handles and grasping surfaces dry, clean and

free from oil and grease. Slippery handles and grasping

surfaces do not allow for safe handling and control of the

tool in unexpected situations.

Service

u Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

Safety instructions for circular saws

Cutting procedures

u DANGER: Keep hands away from cutting area and

the blade. Keep your second hand on auxiliary handle,

or motor housing. If both hands are holding the saw,

they cannot be cut by the blade.

u Do not reach underneath the workpiece. The guard

cannot protect you from the blade below the workpiece.

u Adjust the cutting depth to the thickness of the work-

piece. Less than a full tooth of the blade teeth should be

visible below the workpiece.

u Never hold the workpiece in your hands or across your

leg while cutting. Secure the workpiece to a stable

platform. It is important to support the work properly to

minimise body exposure, blade binding, or loss of control.

u Hold the power tool by insulated gripping surfaces,

when performing an operation where the cutting tool

may contact hidden wiring or its own cord. Contact

with a "live" wire will also make exposed metal parts of the

power tool "live" and could give the operator an electric

shock.

u When ripping always use a rip fence or straight edge

guide. This improves the accuracy of cut and reduces the

chance of blade binding.

u Always use blades with correct size and shape (dia-

mond versus round) of arbour holes. Blades that do not

match the mounting hardware of the saw will run offcentre, causing loss of control.

u Never use damaged or incorrect blade washers or

bolt. The blade washers and bolt were specially designed

for your saw, for optimum performance and safety of operation.

Kickback causes and related warnings

- kickback is a sudden reaction to a pinched, jammed or misaligned saw blade, causing an uncontrolled saw to lift up and

out of the workpiece toward the operator;

- when the blade is pinched or jammed tightly by the kerf

closing down, the blade stalls and the motor reaction drives

the unit rapidly back toward the operator;

- if the blade becomes twisted or misaligned in the cut, the

teeth at the back edge of the blade can dig into the top surface of the wood causing the blade to climb out of the kerf

and jump back toward the operator.

Kickback is the result of saw misuse and/or incorrect operating procedures or conditions and can be avoided by taking

proper precautions as given below.

u Maintain a firm grip with both hands on the saw and

position your arms to resist kickback forces. Position

your body to either side of the blade, but not in line

with the blade. Kickback could cause the saw to jump

backwards, but kickback forces can be controlled by the

operator, if proper precautions are taken.

u When blade is binding, or when interrupting a cut for

any reason, release the trigger and hold the saw motionless in the material until the blade comes to a complete stop. Never attempt to remove the saw from the

work or pull the saw backward while the blade is in

motion or kickback may occur. Investigate and take cor-

rective actions to eliminate the cause of blade binding.

u When restarting a saw in the workpiece, centre the

saw blade in the kerf so that the saw teeth are not engaged into the material. If a saw blade binds, it may walk

up or kickback from the workpiece as the saw is restarted.

u Support large panels to minimise the risk of blade

pinching and kickback. Large panels tend to sag under

their own weight. Supports must be placed under the

panel on both sides, near the line of cut and near the edge

of the panel.

u Do not use dull or damaged blades. Unsharpened or im-

properly set blades produce narrow kerf causing excessive friction, blade binding and kickback.

u Blade depth and bevel adjusting locking levers must

be tight and secure before making the cut. If blade adjustment shifts while cutting, it may cause binding and

kickback.

u Use extra caution when sawing into existing walls or

other blind areas. The protruding blade may cut objects

that can cause kickback.

Lower guard function

u Check the lower guard for proper closing before each

use. Do not operate the saw if the lower guard does

not move freely and close instantly. Never clamp or tie

the lower guard into the open position.If the saw is ac-

cidentally dropped, the lower guard may be bent. Raise

the lower guard with the retracting handle and make sure

it moves freely and does not touch the blade or any other

part, in all angles and depths of cut.

u Check the operation of the lower guard spring. If the

guard and the spring are not operating properly, they

must be serviced before use. Lower guard may operate

Bosch Power Tools 1 609 92A 4JV | (20.09.2018)

Page 8

8 | English

sluggishly due to damaged parts, gummy deposits, or a

build-up of debris.

u The lower guard may be retracted manually only for

special cuts such as "plunge cuts" and "compound

cuts”. Raise the lower guard by the retracting handle

and as soon as the blade enters the material, the lower

guard must be released.For all other sawing, the lower

guard should operate automatically.

u Always observe that the lower guard is covering the

blade before placing the saw down on bench or

floor.An unprotected, coasting blade will cause the saw

to walk backwards, cutting whatever is in its path. Be

aware of the time it takes for the blade to stop after

switch is released.

Additional safety warnings

u Do not allow the chip ejector to come into contact with

your hands. You may be injured by rotating parts.

u Do not use the saw above the level of your head. Doing

so will mean you have inadequate control of the power

tool.

u Use suitable detectors to determine if utility lines are

hidden in the work area or call the local utility company for assistance. Contact with electric lines can lead

to fire and electric shock. Damaging a gas line can lead to

explosion. Penetrating a water line causes property damage or may cause an electric shock.

u Do not operate the power tool when stationary . It is

not suitable for operation with a saw table.

u When performing plunge cuts which are not right-

angled, secure the guide plate of the saw so that it will

not shift sideways.In the event of a sideways shift, the

saw blade may become jammed, which could lead to kickback.

u Do not use HSS saw blades. Such saw blades can easily

break.

u Do not saw any ferrous metals. Hot chips may ignite the

dust extractor.

Products sold in GB only:

Your product is fitted with an BS 1363/A approved electric

plug with internal fuse (ASTA approved to BS 1362).

If the plug is not suitable for your socket outlets, it should be

cut off and an appropriate plug fitted in its place by an authorised customer service agent. The replacement plug

should have the same fuse rating as the original plug.

The severed plug must be disposed of to avoid a possible

shock hazard and should never be inserted into a mains

socket elsewhere.

u Always wait until the power tool has come to a com-

plete stop before placing it down. The application tool

can jam and cause you to lose control of the power tool.

u Hold the power tool firmly with both hands and make

sure you have a stable footing. The power tool can be

more securely guided with both hands.

Product Description and Specifications

Read all the safety and general instructions.

Failure to observe the safety and general instructions may result in electric shock, fire

and/or serious injury.

Please observe the illustrations at the beginning of this operating manual.

Intended use

The power tool is intended for making straight cuts in wood

with and against the grain and mitre cuts in wood while resting firmly against the workpiece.

Product Features

The numbering of the product features refers to the diagram

of the power tool on the graphics page.

On/off switch

(1)

Lock-off switch for on/off switch

(2)

Auxiliary handle (insulated gripping surface)

(3)

Spindle lock button

(4)

Scale for mitre/bevel angles

(5)

Wing bolt for mitre/bevel angle preselection

(6)

Wing bolt for parallel guide

(7)

Cut mark 45°

(8)

Cut mark 0°

(9)

Parallel guide

(10)

Retracting blade guard

(11)

Base plate

(12)

Adjusting lever for retracting blade guard

(13)

Chip ejector

(14)

Protective guard

(15)

Handle (insulated gripping surface)

(16)

Hex key

(17)

Clamping bolt with washer

(18)

Clamping flange

(19)

Circular saw blade

(20)

Mounting flange

(21)

Saw spindle with mounting flange

(22)

Clamping lever for cutting depth preselection

(23)

Cutting depth scale

(24)

Pair of screw clamps

(25)

A)

Accessories shown or described are not included with the

product as standard. You can find the complete selection of

accessories in our accessories range.

B)

Commercially available (not included in the scope of delivery)

A)

B)

A)

1 609 92A 4JV | (20.09.2018) Bosch Power Tools

Page 9

English | 9

Technical Data

Hand-held circular saw GKS 20-65

Article number

3 601 FB2 0..

Rated power input W 2000

No-load speed rpm 5300

Max. cutting depth with 184mm saw blade diameter

– at a 0° mitre/bevel angle mm 62

– at a 45° mitre/bevel angle mm 46

Spindle lock ●

Base plate dimensions mm 302 x 160

Max. saw blade diameter mm 184

Min. saw blade diameter mm 184

Max. base blade thickness mm 2.0

Locating bore mm 15.9

Weight according to

kg 5.7

EPTA-Procedure 01:2014

Protection class / II

The specifications apply to a rated voltage [U] of 220V. These specifications may vary at different voltages and in country-specific models.

Noise/Vibration Information

Noise emission values determined according

toEN62841-2-5.

Typically, the A-weighted noise level of the power tool is:

Sound pressure level 92dB(A); sound power level

103dB(A). Uncertainty K=3dB.

Wear hearing protection

Total vibration values ah (triax vector sum) and uncertainty K

determined according toEN62841-2-5:

Sawing wood: ah<1.4m/s2, K=1.5m/s

The vibration level and noise emission value given in these

instructions have been measured in accordance with a

standardised measuring procedure detailed in EN 62841

and may be used to compare power tools. They may also be

used for a preliminary estimation of vibration and noise

emissions.

The given vibration level and noise emission value represent

the main applications of the power tool. However, if the

power tool is used for other applications, with different application tools or is poorly maintained, the vibration level

and noise emission value may differ. This may significantly

increase the vibration and noise emissions over the total

working period.

To estimate vibration and noise emissions accurately, the

times when the tool is switched off or when it is running but

not actually being used should also be taken into account.

This may significantly reduce vibration and noise emissions

over the total working period.

Implement additional safety measures to protect the operator from the effects of vibration, such as servicing the

power tool and application tools, keeping the hands warm,

and organising workflows correctly.

2

Fitting

u Only use saw blades the maximum permitted speed of

which is higher than the no-load speed of the power

tool.

Inserting/changing the circular saw blade

u Pull the plug out of the socket before carrying out any

work on the power tool.

u Wear protective gloves when fitting the saw blade.

Danger of injury when touching the saw blade.

u Only use saw blades that match the specifications

given in this operating manual and on the power tool.

u The permitted speed of the application tool must be at

least equal to the maximum speed marked on the

power tool. If accessories run faster than their rated

speed, they may break and fly off.

u Do not use abrasive wheels as the application tool un-

der any circumstances.

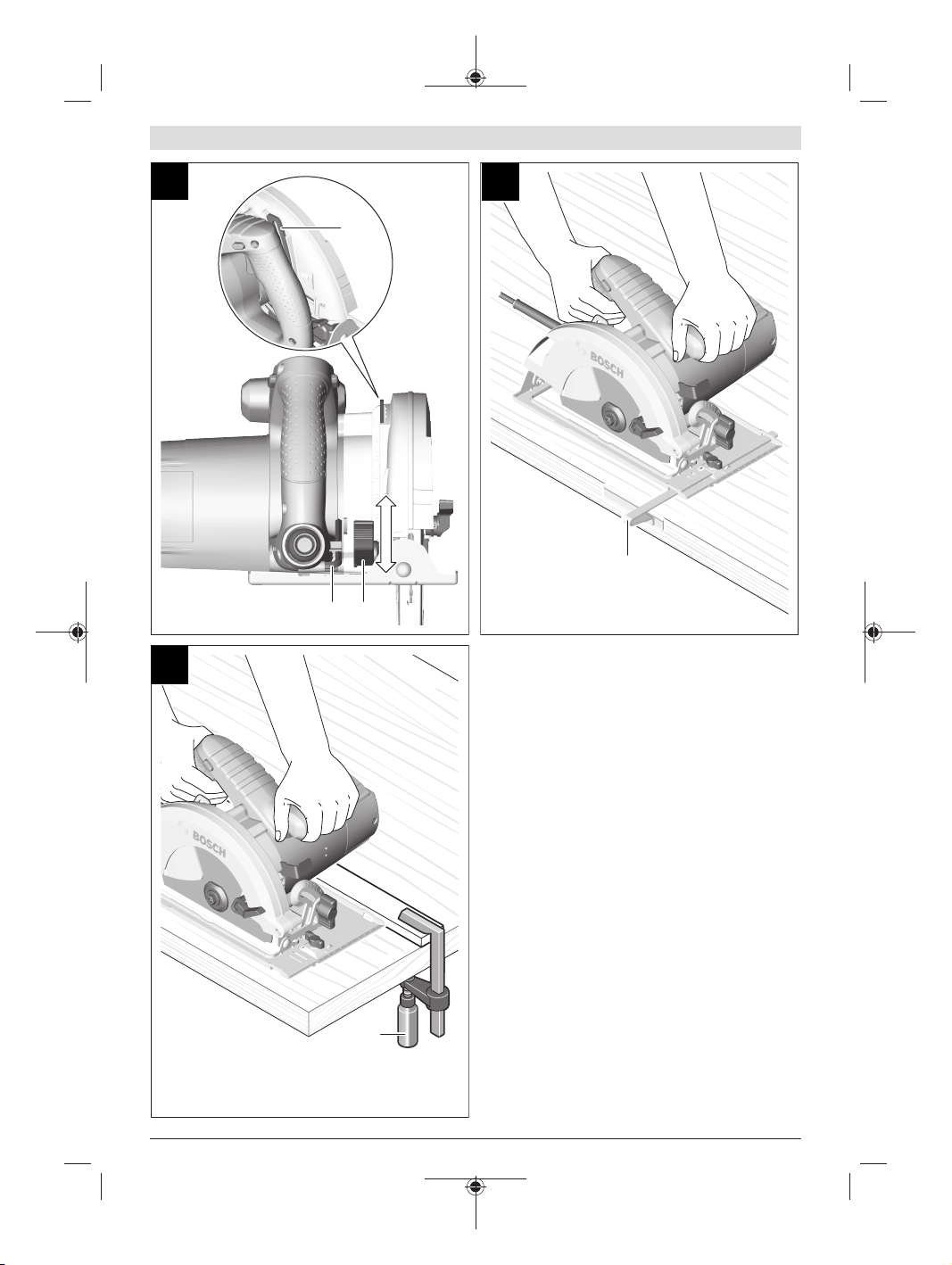

Removing the saw blade (see figure A)

To change tools, we recommend that you place the power

tool down on the front side of the motor housing.

– Press and hold the spindle lock button (4).

u Do not press the spindle lock button (4) while the saw

spindle is moving. The power tool may become damaged

if this happens.

– Use the hex key (17) to undo the clamping bolt (18) in ro-

tational direction ➊.

– Swing the retracting blade guard (11) back and hold on

to it firmly.

– Remove the clamping flange (19) and the saw blade (20)

from the saw spindle (22).

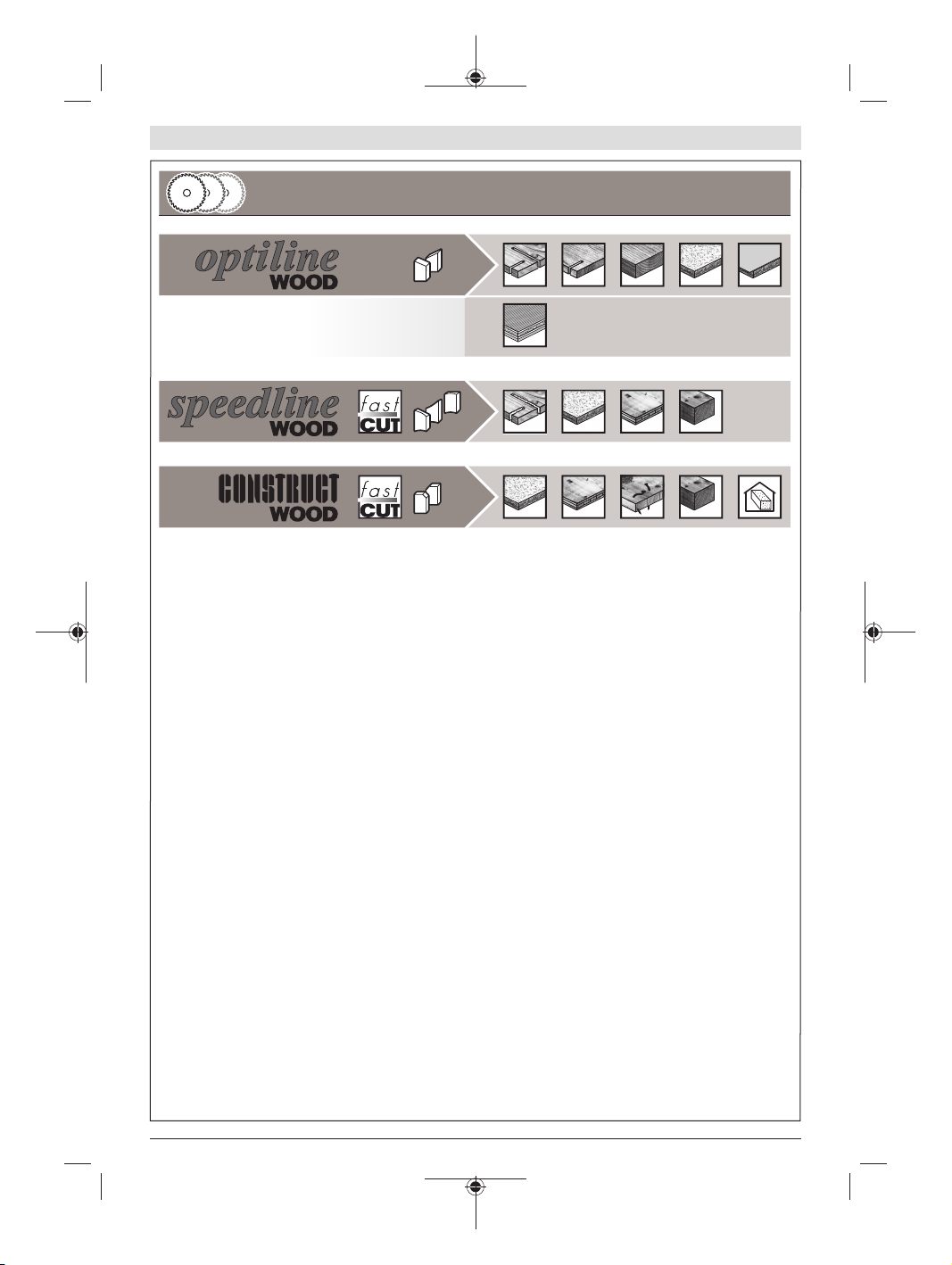

Selecting the saw blade

You will find an overview of recommended saw blades at the

end of these operating instructions.

Fitting the saw blade (see figure A)

To change tools, we recommend that you place the power

tool down on the front side of the motor housing.

– Clean the saw blade (20) and all the clamping elements

to be fitted.

– Swing the retracting blade guard (11) back and hold on

to it firmly.

– Place the saw blade (20) on the mounting flange (21).

The cutting direction of the teeth (direction of the arrow

on the saw blade) must match the rotational direction of

the arrow on the protective guard (11).

– Attach the clamping flange (19) and screw in the clamp-

ing bolt in rotational direction ➋. Ensure that the mounting flange (21) and clamping flange (19) are installed in

the correct position.

– Press and hold the spindle lock button (4).

Bosch Power Tools 1 609 92A 4JV | (20.09.2018)

Page 10

10 | English

0

45

0

45

– Use the hex key (17) to tighten the clamping bolt in rota-

tional direction ➋. The tightening torque should be 6–

9Nm, which corresponds to hand-tight plus ¼ turn.

Dust/chip extraction

The dust from materials such as lead paint, some types of

wood, minerals and metal can be harmful to human health.

Touching or breathing in this dust can trigger allergic reactions and/or cause respiratory illnesses in the user or in

people in the near vicinity.

Certain dusts, such as oak or beech dust, are classified as

carcinogenic, especially in conjunction with wood treatment

additives (chromate, wood preservative). Materials containing asbestos may only be machined by specialists.

– Use a dust extraction system that is suitable for the ma-

terial wherever possible.

– Provide good ventilation at the workplace.

– It is advisable to wear a P2 filter class breathing mask.

The regulations on the material being machined that apply in

the country of use must be observed.

u Avoid dust accumulation at the workplace. Dust can

easily ignite.

Operation

Operating modes

u Pull the plug out of the socket before carrying out any

work on the power tool.

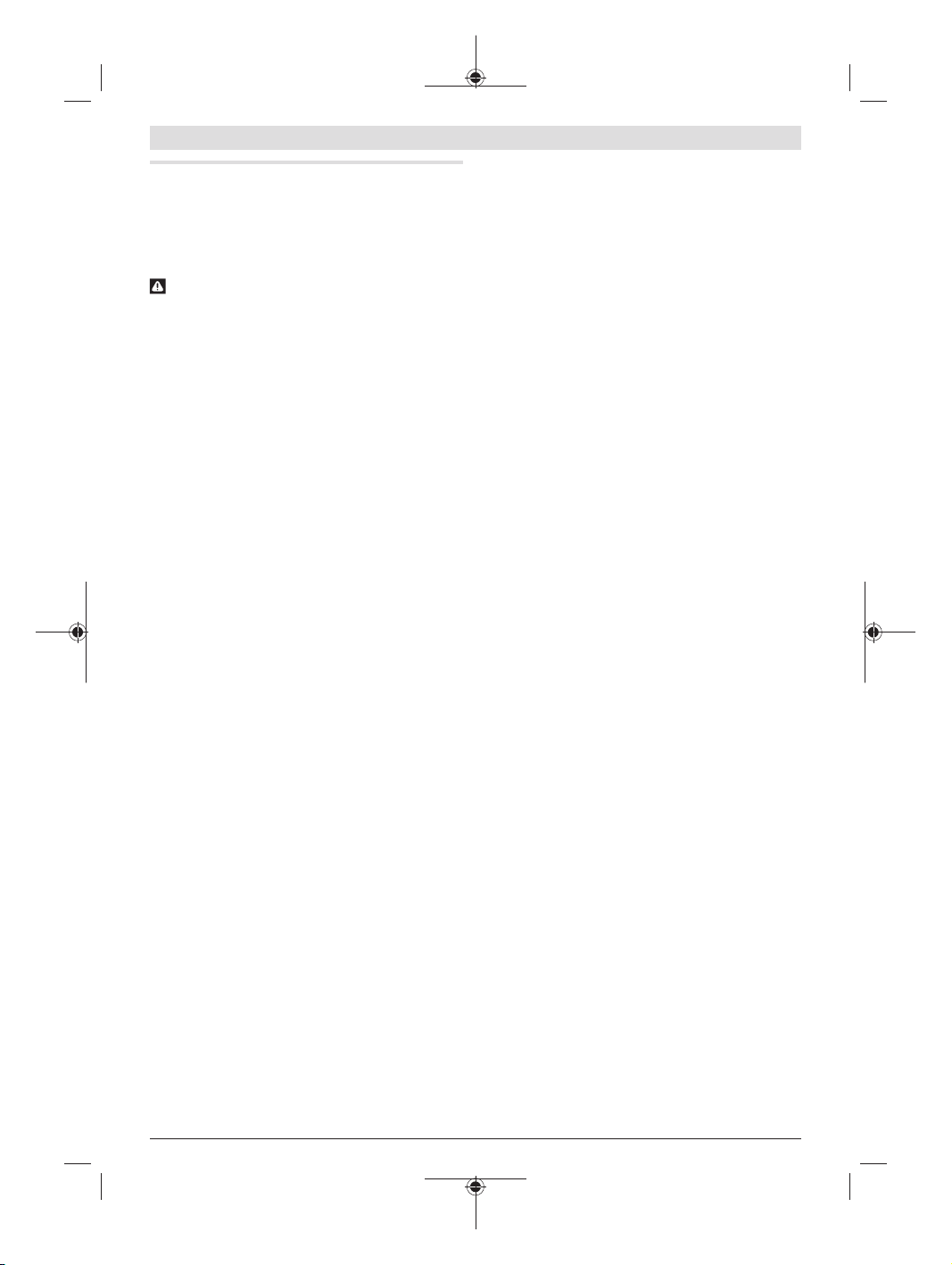

Setting the Cutting Depth (see figure B)

u Adapt the cutting depth to the thickness of the work-

piece. A space of less than the height of one full tooth

should be visible under the workpiece.

Loosen the clamping lever (23). For a smaller cutting depth,

pull the saw away from the base plate (12); for a larger cutting depth, push the saw towards the base plate (12). Adjust

the desired cutting depth at the cutting-depth scale.

Retighten the clamping lever (23).

If you are unable to fully adjust the cutting depth after

loosening the clamping lever (23), pull the clamping lever

(23) away from the saw and swivel it downwards. Loosen

the clamping lever (23) again. Repeat this process until the

required cutting depth can be set.

The clamping force of the clamping lever (23) can be readjusted. To do so, unscrew the clamping lever (23) and

retighten it in a position offset by at least 30° in an anticlockwise direction.

If you are unable to adequately fix the cutting depth after

tightening the clamping lever (23), pull the clamping lever

(23) away from the saw and swivel it upwards. Loosen the

clamping lever (23) again. Repeat this process until the cutting depth is fixed.

Adjusting the Mitre/Bevel Angle

We recommend that you place the power tool down on the

front side of the protective guard (15).

Loosen the wing bolt (6). Swivel the saw to the side. Set the

required mitre angle on the scale (5). Retighten the wing

bolt (6).

Note: When making mitre cuts, the cutting depth is less than

the value shown on the cutting depth scale (24).

Cut marks

The 0° cut mark (9) indicates the position of the saw blade

when making a right-angled cut. The 45° cut mark (8) indicates the position of the saw blade when making a 45° cut.

For a precise cut, place the circular saw against the workpiece as shown in the figure. We recommend making a test

cut.

Setting the Cutting Depth (see figure B)

u Adapt the cutting depth to the thickness of the work-

piece. A space of less than the height of one full tooth

should be visible under the workpiece.

Loosen the clamping lever (23). For a smaller cutting depth,

pull the saw away from the base plate (12); for a larger cutting depth, push the saw towards the base plate (12). Adjust

the desired cutting depth at the cutting-depth scale.

Retighten the clamping lever (23).

If you are unable to fully adjust the cutting depth after

loosening the clamping lever (23), pull the clamping lever

(23) away from the saw and swivel it downwards. Loosen

the clamping lever (23) again. Repeat this process until the

required cutting depth can be set.

The clamping force of the clamping lever (23) can be readjusted. To do so, unscrew the clamping lever (23) and

retighten it in a position offset by at least 30° in an anticlockwise direction.

If you are unable to adequately fix the cutting depth after

tightening the clamping lever (23), pull the clamping lever

(23) away from the saw and swivel it upwards. Loosen the

clamping lever (23) again. Repeat this process until the cutting depth is fixed.

Start-up

u Pay attention to the mains voltage. The voltage of the

power source must match the voltage specified on the

rating plate of the power tool. Power tools marked

with 230V can also be operated with 220V.

u Products that are only sold in AUS and NZ: Use a resid-

ual current device (RCD) with a nominal residual current

of 30 mA or less.

1 609 92A 4JV | (20.09.2018) Bosch Power Tools

Page 11

English | 11

Switching on/off

u Make sure that you are able to press the On/Off switch

without releasing the handle.

To start the power tool, first press the lock-off switch (2),

then press and hold the on/off switch (1).

To switch off the power tool, release the on/off switch (1).

Note: For safety reasons, the on/off switch (1) cannot be

locked; it must remain pressed during the entire operation.

Practical advice

u Pull the plug out of the socket before carrying out any

work on the power tool.

Protect saw blades against shock and impact.

Guide the power tool evenly, pushing it gently in the cutting

direction. Applying too much pressure to the power tool

when moving it in the cutting direction significantly reduces

the service life of the application tools and can damage the

power tool.

The sawing performance and the quality of the cut essentially depend on the condition and the tooth shape of the

saw blade. This is why you should only use sharp saw blades

that are suitable for the material being machined.

Sawing wood

Choosing the right saw blade depends on the wood type,

wood quality and whether cuts with or against the grain are

required.

Making cuts in spruce with the grain produces long, spiralshaped chips.

Beech and oak dust is especially detrimental to health.

Therefore, work only with dust extraction.

Sawing with a parallel guide (see figure C)

The parallel guide (10) allows you to make precise cuts

along the edge of a workpiece and cut strips with the same

dimensions.

Loosen the wing bolt (7) and slide the scale of the parallel

guide (10) through the guide in the base plate (12). Adjust

the desired cutting width as a scale value at the corresponding (9) or (8) cut mark, see the section "Cut marks".

Retighten the wing bolt (7).

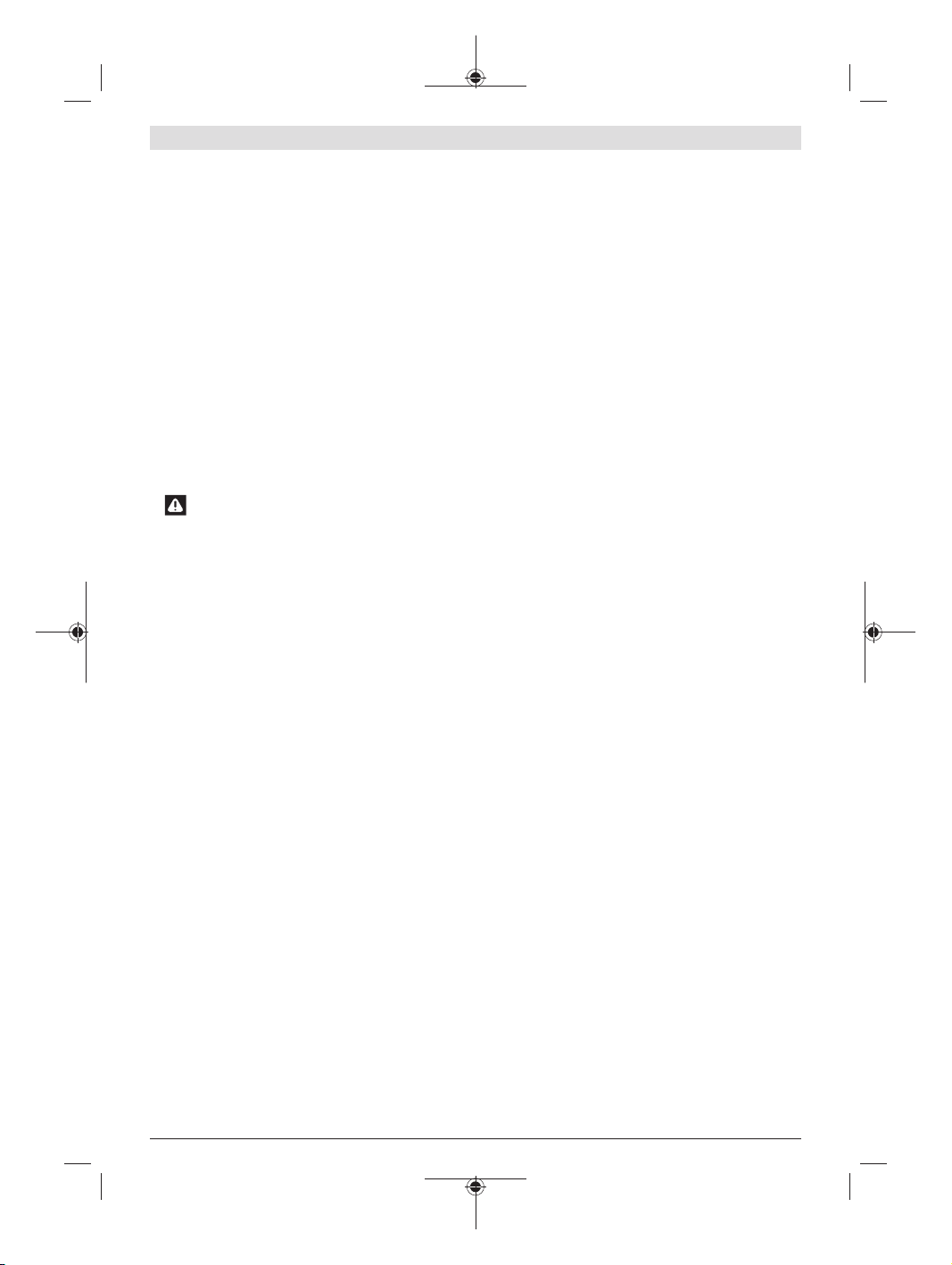

Sawing with an auxiliary guide (see figure D)

For working on large workpieces or for cutting straight

edges, you can securely fasten a board or rail to the workpiece as an auxiliary guide. The circular saw can be guided

along the path of this auxiliary guide with the base plate.

Maintenance and Servicing

Maintenance and cleaning

u Pull the plug out of the socket before carrying out any

work on the power tool.

u To ensure safe and efficient operation, always keep

the power tool and the ventilation slots clean.

The retracting blade guard must always be able to move

freely and retract automatically. It is therefore important to

keep the area around the retracting blade guard clean at all

times. Remove dust and chips with a paintbrush.

Non-coated saw blades can be protected against corrosion

using a thin layer of acid-free oil. Remove the oil again before

sawing as failure to do so will stain the wood.

Resin or glue residue on the saw blade has a detrimental effect on the quality of the cut. You should therefore clean saw

blades straight after use.

In order to avoid safety hazards, if the power supply cord

needs to be replaced, this must be done by Bosch or by a

customer service centre that is authorised to repair Bosch

power tools.

After-sales Service and Advice on Using Products

Our after-sales service can answer questions concerning

product maintenance and repair, as well as spare parts. You

can find exploded drawings and information on spare parts

at: www.bosch-pt.com

The Bosch product use advice team will be happy to help you

with any questions about our products and their accessories.

www.powertool-portal.de, the internet portal for tradespeople and DIY enthusiasts.

In all correspondence and spare parts orders, please always

include the 10‑digit article number given on the type plate of

the product.

Cambodia

Robert Bosch (Cambodia) Co., Ltd

Unit 8BC, GT Tower, 08th Floor, Street 169,

Czechoslovakia Blvd, Sangkat Veal Vong

Khan 7 Makara, Phnom Penh

VAT TIN: 100 169 511

Tel.: +855 23 900 685

Tel.: +855 23 900 660

www.bosch.com.kh

People’s Republic of China

China Mainland

Bosch Power Tool (China) Co. Ltd.

Bosch Service Center

567, Bin Kang Road

Bin Kang District

Hangzhou, Zhejiang Province

China 310052

Tel.: (0571) 8887 5566 / 5588

Fax: (0571) 8887 6688 x 5566# / 5588#

E-mail: bsc.hz@cn.bosch.com

www.bosch-pt.com.cn

HK and Macau Special Administrative Regions

Robert Bosch Co. Ltd.

21st Floor, 625 King’s Road

North Point, Hong Kong

Customer Service Hotline: +852 2101 0235

Fax: +852 2590 9762

E-mail: info@hk.bosch.com

www.bosch-pt.com.hk

India

Bosch Power Tools 1 609 92A 4JV | (20.09.2018)

Page 12

12 | English

Bosch Service Center

69, Habibullah Road, (next to PSBB School), T. Nagar

Chennai–600077

Phone: (044) 64561816

Bosch Service Center Rishyamook

85A, Panchkuin Road

New Delhi–110001

Phone: (011) 43166190

Bosch Service Center 79,

Crystal Bldg., Dr. Annie Besant Road, Worli

Mumbai–400018

Phone: (022) 39569936 / (022 )39569959 /

(022) 39569967 / (022) 24952071

Indonesia

PT Robert Bosch

Palma Tower 10th Floor

Jalan RA Kartini II-S Kaveling 6

Pondok Pinang, Kebayoran Lama

Jakarta Selatan 12310

Tel.: (21) 3005-5800

www.bosch-pt.co.id

Malaysia

Robert Bosch Sdn. Bhd.(220975-V) PT/SMY

No. 8A, Jalan 13/6

46200 Petaling Jaya

Selangor

Tel.: (03) 79663194

Toll-Free: 1800 880188

Fax: (03) 79583838

E-mail: kiathoe.chong@my.bosch.com

www.bosch-pt.com.my

Pakistan

Robert Bosch Middle East FZE – Pakistan Liaison Office

2nd Floor Plaza # 10, CCA Block, DHA Phase 5

Lahore, 54810

Phone: +92(303)4444311

E-mail: Faisal.Khan@bosch.com

Philippines

Robert Bosch, Inc.

28th Floor Fort Legend Towers,

3rd Avenue corner 31st Street,

Fort Bonifacio, Global City,

1634 Taguig City

Tel.: (632) 8703871

Fax: (632) 8703870

www.bosch-pt.com.ph

Singapore

Powerwell Service Centre Ptd Ltd

Bosch Authorised Service Centre (Power Tools)

4012 Ang Mo Kio Ave 10, #01-02 TECHplace

Singapore 569628

Tel.: 6452 1770

Fax: 6452 1760

E-mail: ask@powerwellsc.com

www.powerwellsc.com

www.bosch-pt.com.sg

Thailand

Robert Bosch Ltd.

Liberty Square Building

No. 287, 11 Floor

Silom Road, Bangrak

Bangkok 10500

Tel.: 02 6393111

Fax: 02 2384783

Robert Bosch Ltd., P. O. Box 2054

Bangkok 10501

www.bosch.co.th

Bosch Service – Training Centre

La Salle Tower Ground Floor Unit No.2

10/11 La Salle Moo 16

Srinakharin Road

Bangkaew, Bang Plee

Samutprakarn 10540

Tel.: 02 7587555

Fax: 02 7587525

Vietnam

Branch of Bosch Vietnam Co., Ltd in HCMC

14th floor, Deutsches Haus, 33 Le Duan

Ben Nghe Ward, District 1, Ho Chi Minh City

Tel.: (028) 6258 3690

Fax: (028) 6258 3692 - 6258 3694

Hotline: (028) 6250 8555

E-mail: tuvankhachhang-pt@vn.bosch.com

www.bosch-pt.com.vn

Armenia, Azerbaijan, Georgia, Kyrgyzstan, Mongolia,

Tajikistan, Turkmenistan, Uzbekistan

TOO "Robert Bosch" Power Tools, After Sales Service

Rayimbek Ave., 169/1

050050, Almaty, Kazakhstan

Service e-mail: service.pt.ka@bosch.com

Official website: www.bosch.com, www.bosch-pt.com

Bahrain

Hatem Al Juffali Technical Equipment Establishment.

Kingdom of Bahrain, Setra Highway, Al Aker Area

Phone: +966126971777-311

Fax: +97317704257

E-mail: h.berjas@eajb.com.sa

Egypt

Unimar

20 Markaz kadmat

El tagmoa EL Aoul – New Cairo

Phone: +20 2224 76091-95

Phone: +20 2224 78072-73

Fax: +20222478075

E-mail: adelzaki@unimaregypt.com

Iran

Robert Bosch Iran

3rd Floor, No 3, Maadiran Building

Aftab St., Khodami St., Vanak Sq.

Tehran 1994834571

Phone: +9821 86092057

Iraq

Sahba Technology Group

Al Muthana airport road

1 609 92A 4JV | (20.09.2018) Bosch Power Tools

Page 13

English | 13

Baghdad

Phone: +9647901906953

Phone Dubai: +97143973851

E-mail: bosch@sahbatechnology.com

Jordan

Roots Arabia – Jordan

Nasser Bin Jameel street, Building 37 Al Rabiah

11194 Amman

Phone: +962 6 5545778

E-mail: bosch@rootsjordan.com

Kuwait

Al Qurain Automotive Trading Company

Shuwaikh Industrial Area, Block 1, Plot 16, Street 3rd

P.O. Box 164 – Safat 13002

Phone: 24810844

Fax: 24810879

E-mail: josephkr@aaalmutawa.com

Lebanon

Tehini Hana & Co. S.A.R.L.

P.O. Box 90-449

Jdeideh

Dora-Beirut

Phone: +9611255211

E-mail: service-pt@tehini-hana.com

Libya

El Naser for Workshop Tools

Swanee Road, Alfalah Area

Tripoli

Phone: +218 21 4811184

Oman

Malatan Trading & Contracting LLC

P.O. Box 131

Ruwi, 112 Sultanate of Oman

Phone: +968 99886794

E-mail: malatanpowertools@malatan.net

Qatar

International Construction Solutions W L L

P. O. Box 51,

Doha Phone: +974 40065458

Fax: +974 4453 8585

E-mail: csd@icsdoha.com

Saudi Arabia

Juffali Technical Equipment Co. (JTECO)

Kilo 14, Madinah Road, Al Bawadi District

Jeddah 21431

Phone: +966 2 6672222 Ext. 1528

Fax: +966 2 6676308

E-mail: roland@eajb.com.sa

Syria

Dallal Establishment for Power Tools

P.O. Box 1030

Aleppo

Phone: +963212116083

E-mail: rita.dallal@hotmail.com

United Arab Emirates

Central Motors & Equipment LLC, P.O. Box 1984

Al-Wahda Street – Old Sana Building

Sharjah

Phone: +971 6 593 2777

Fax: +971 6 533 2269

E-mail: powertools@centralmotors.ae

Yemen

Abualrejal Trading Corporation

Sana’a Zubiery St. Front to new Parliament Building

Phone: +967-1-202010

Fax: +967-1-279029

E-mail: tech-tools@abualrejal.com

Ethiopia

Forever plc

Kebele 2,754, BP 4806,

Addis Ababa

Phone: +251 111 560 600

E-mail: foreverplc@ethionet.et

Ghana

C.WOERMANN LTD.

Nsawam Road/Avenor Junction, P.O. Box 1779

Accra Phone: +233 302 225 141

Kenya

Robert Bosch East Africa Ltd

Mpaka Road P.O. Box 856

00606 Nairobi

Nigeria

Robert Bosch Nigeria Ltd.

52–54 Isaac John Street P.O. Box

GRA Ikeja – Lagos

Republic of South Africa

Customer service

Hotline: (011) 6519600

Gauteng – BSC Service Centre

35 Roper Street, New Centre

Johannesburg

Tel.: (011) 4939375

Fax: (011) 4930126

E-mail: bsctools@icon.co.za

KZN – BSC Service Centre

Unit E, Almar Centre

143 Crompton Street

Pinetown

Tel.: (031) 7012120

Fax: (031) 7012446

E-mail: bsc.dur@za.bosch.com

Western Cape – BSC Service Centre

Democracy Way, Prosperity Park

Milnerton

Tel.: (021) 5512577

Fax: (021) 5513223

E-mail: bsc@zsd.co.za

Bosch Headquarters

Midrand, Gauteng

Tel.: (011) 6519600

Fax: (011) 6519880

E-mail: rbsa-hq.pts@za.bosch.com

Bosch Power Tools 1 609 92A 4JV | (20.09.2018)

Page 14

14 | Português do Brasil

Tanzania

Diesel & Autoelectric Service Ltd.

117 Nyerere Rd., P.O. Box 70839

Vingunguti 12109, Dar Es Salaam

Phone: +255 222 861 793/794

Australia, New Zealand and Pacific Islands

Robert Bosch Australia Pty. Ltd.

Power Tools

Locked Bag 66

Clayton South VIC 3169

Customer Contact Center

Inside Australia:

Phone: (01300) 307044

Fax: (01300) 307045

Inside New Zealand:

Phone: (0800) 543353

Fax: (0800) 428570

Outside AU and NZ:

Phone: +61 3 95415555

www.bosch-pt.com.au

www.bosch-pt.co.nz

Disposal

The power tool, accessories and packaging should be recycled in an environmentally friendly manner.

Do not dispose of power tools along with

household waste.

Português do Brasil

Indicações de segurança

Instruções gerais de segurança para ferramentas elétricas

AVISO

e especificações fornecidas com esta ferramenta

elétrica. O desrespeito das instruções apresentadas abaixo

poderá resultar em choque elétrico, incêndio e/ou

ferimentos graves.

Guarde todas as advertências e instruções para futura

referência.

O termo "ferramenta elétrica" usado nas advertências

refere‑se a ferramentas elétricas operadas com corrente de

rede (com fio) ou ferramentas elétricas operadas com

acumulador (sem fio).

Leia todas as indicações de

segurança, instruções, ilustrações

Segurança da área de trabalho

u Mantenha a área de trabalho limpa e bem iluminada.

As áreas de trabalho desarrumadas ou escuras podem

levar a acidentes.

u Não opere as ferramentas elétricas em atmosferas

explosivas, ou seja, na presença de líquidos, gases ou

pós inflamáveis. As ferramentas elétricas produzem

chispas, que podem inflamar os pós ou vapores.

u Mantenha as crianças e outras pessoas afastadas da

ferramenta elétrica durante o uso. As distrações

podem resultar na perda do controle.

Segurança elétrica

u A ficha de conexão da ferramenta elétrica deve

combinar com a tomada. Jamais modifique o plugue

de alguma forma. Não use plugues de adaptador junto

com ferramentas elétricas aterradas. Plugues não

modificados e tomadas apropriadas reduzem o risco de

choque elétrico.

u Evite o contato do corpo com superfícies aterradas,

como tubos, aquecedores, fogões e geladeiras. Há um

risco elevado de choque elétrico se seu corpo estiver

aterrado.

u Mantenha as ferramentas elétricas afastadas da

chuva ou umidade. A entrada de água em uma

ferramenta elétrica aumenta o risco de choque elétrico.

u Não use o cabo para outras finalidades. Jamais use o

cabo para transportar, puxar ou desconectar a

ferramenta elétrica. Mantenha o cabo afastado do

calor, do óleo, de arestas afiadas ou de partes móveis.

Os cabos danificados ou emaranhados aumentam o risco

de um choque elétrico.

u Ao operar uma ferramenta elétrica ao ar livre, use um

cabo de extensão adequado para áreas exteriores. O

uso de um cabo de extensão apropriado para áreas

exteriores reduz o risco de choque elétrico.

u Se não for possível evitar o funcionamento da

ferramenta elétrica em áreas úmidas, deverá usar um

disjuntor de corrente de avaria. O uso de um disjuntor

de corrente de avaria reduz o risco de um choque

elétrico.

Segurança pessoal

u Esteja atento, observe o que está fazendo e use o bom

senso ao operar uma ferramenta elétrica. Não use

uma ferramenta elétrica quando estiver fatigado ou

sob a influência de drogas, álcool ou medicamentos.

Um momento de descuido ao operar ferramentas

elétricas pode resultar em lesões graves.

u Use equipamento de proteção individual. Use sempre

óculos de proteção. O uso de equipamento de proteção

individual, como máscara de proteção contra poeira,

sapatos de segurança antiderrapantes, capacete de

segurança ou proteção auricular, usado nas condições

adequadas irá reduzir o risco de ferimentos pessoais.

u Evite a colocação em funcionamento involuntária.

Assegure‑se de que o interruptor está na posição de

1 609 92A 4JV | (20.09.2018) Bosch Power Tools

Page 15

Português do Brasil | 15

desligado antes de conectar à alimentação de rede e/

ou ao acumulador, antes de pegar ou transportar a

ferramenta. Se transportar ferramentas elétricas com o

seu dedo no interruptor ou se energizar ferramentas

elétricas com o interruptor ligado, poderão ocorrer

acidentes.

u Remova qualquer ferramenta ou chave de ajuste antes

de ligar a ferramenta elétrica. Uma ferramenta ou

chave ainda ligada a uma parte rotativa da ferramenta

elétrica pode resultar em ferimentos pessoais.

u Evite uma posição anormal. Mantenha uma posição

firme e mantenha sempre o equilíbrio. Desta forma é

mais fácil controlar a ferramenta elétrica em situações

inesperadas.

u Use vestuário apropriado. Não use roupa larga nem

joias. Mantenha seus cabelos e roupas afastados de

partes móveis. As roupas largas, joias ou cabelos longos

podem ser agarrados por partes móveis.

u Se for possível montar dispositivos de aspiração ou de

coleta, assegure‑se de que são conectados e usados

corretamente. O uso de um dispositivo de coleta de

poeira pode reduzir os riscos associados a poeiras.

u Não deixe que a familiaridade resultante do uso

frequente de ferramentas permita que você se torne

complacente e ignore os princípios de segurança da

ferramenta. Uma ação descuidada pode causar

ferimentos graves numa fração de segundo.

Uso e manuseio cuidadoso da ferramenta elétrica

u Não sobrecarregue a ferramenta elétrica. Use a

ferramenta elétrica correta para a sua aplicação. É

melhor e mais seguro trabalhar com a ferramenta elétrica

apropriada na área de potência para a qual foi projetada.

u Não use a ferramenta elétrica se o interruptor estiver

defeituoso. Qualquer ferramenta elétrica que não pode

mais ser controlada com o interruptor é perigosa e deve

ser reparada.

u Desconecte o plugue da alimentação e/ou remova o

acumulador, se amovível, da ferramenta elétrica

antes de efetuar ajustes, trocar acessórios ou guardas

as ferramentas elétricas. Essas medidas de segurança

preventivas reduzem o risco de partida involuntária da

ferramenta elétrica.

u Guarde as ferramentas elétricas não utilizadas fora do

alcance das crianças e não permita que as pessoas que

não estejam familiarizadas com a ferramenta elétrica

ou com essas instruções usem a ferramenta elétrica.

As ferramentas elétricas são perigosas nas mãos de

usuários não treinados.

u Trate as ferramentas elétricas e acessórios com

cuidado. Verifique se existe desalinhamento ou

emperramento das partes móveis, se há peças

quebradas ou outra condição que possa afetar o

funcionamento da ferramenta elétrica. Se houver

danos, repare a ferramenta elétrica antes do uso.

Muitos acidentes são causados ferramentas elétricas com

manutenção insuficiente.

u Mantenha as ferramentas de corte afiadas e limpas.

As ferramentas de corte cuidadosamente mantidas e com

arestas de corte afiadas emperram com menos

frequência e são mais fáceis de controlar.

u Use a ferramenta elétrica, acessórios, bits etc. de

acordo com essas instruções, considerando as

condições de trabalho e o trabalho a executar. O uso

da ferramenta elétrica em tarefas diferentes das previstas

poderá resultar em uma situação perigosa.

u Mantenha as empunhadeiras e as superfícies de

agarrar secas, limpas e livres de óleo e graxa. As

empunhadeiras e superfícies de agarrar escorregadias

não permitem o manuseio e controle seguros da

ferramenta em situações inesperadas.

Serviço

u Somente permita que a sua ferramenta elétrica seja

reparada por pessoal qualificado e usando peças de

reposição originais. Só dessa forma é assegurada a

segurança da ferramenta elétrica.

Instruções de segurança para serras circulares

Procedimentos de corte

u PERIGO: Manter as mãos afastadas da área de

corte e do disco. Mantenha a segunda mão no punho

auxiliar ou na carcaça do motor. Se ambas as mãos

estiverem segurando a serra, elas não podem ser

cortadas pelo disco.

u Não coloque as mãos por baixo da peça de trabalho. A

proteção não o pode proteger do disco por baixo da peça

de trabalho.

u Ajuste a profundidade de corte à espessura da peça de

trabalho. Deve ficar visível por baixo da peça de trabalho

menos de um dente completo dos dentes do disco.

u Nunca segure a peça que está sendo cortada nas mãos

ou sobre as pernas. Fixe a peça de trabalho a uma

plataforma estável. É importante apoiar o trabalho

corretamente para minimizar a exposição do corpo, o

bloqueio do disco ou a perda de controle.

u Segure a ferramenta elétrica pelas superfícies

isoladas de manuseio, ao realizar uma operação onde

o acessório de corte pode entrar em contato com a

fiação não aparente ou seu próprio cabo. O contato

com um fio energizado também tornará "vivas" as partes

metálicas expostas da ferramenta elétrica e pode causar

choque elétrico ao operador.

u Ao cortar use sempre a guia de corte ou a guia de

aresta reta. Isso melhora a precisão do corte e reduz a

possibilidade de bloqueio do disco.

u Use sempre discos com furos interiores com tamanho

e forma corretos (diamante versus redondo). Os

discos que não correspondem com a montagem na serra

ficam fora de centro, causando a perda de controle.

u Jamais use anilhas ou parafusos de disco de serra

danificados ou incorretos. As anilhas e os parafusos de

disco de serra foram especialmente projetados para sua

Bosch Power Tools 1 609 92A 4JV | (20.09.2018)

Page 16

16 | Português do Brasil

serra, para um excelente desempenho e uma operação

segura.

Causas do contragolpe e indicações relacionadas

- O contragolpe é uma reação súbita a um disco de serra

encravado, bloqueado ou desalinhado, causando um

levantamento descontrolado da serra se afastando da peça

na direção do operador;

- Quando o disco é encravado ou fortemente bloqueado à

medida que o corte aperta, o disco estagna e a reação do

motor conduz a unidade rapidamente de volta na direção do

operador;

- Se o disco ficar torcido ou desalinhado no corte, os dentes

na extremidade posterior do disco podem mergulhar na

superfície da madeira fazendo com que o disco suba saindo

do corte e salte de volta na direção do operador.

O contragolpe é o resultado do uso errado e/ou condições

ou procedimentos incorretos de utilização da serra e pode

ser evitado tomando as precauções indicadas abaixo.

u Mantenha a serra bem segura com as duas mãos e

posicione os braços para resistir às forças de

contragolpe. Posicione o corpo de um dos lados do

disco, mas não alinhado com o disco. O contragolpe

poderia fazer com que a serra saltasse para trás, mas as

forças de contragolpe podem ser controladas pelo

operador, se forem tomadas as devidas precauções.

u Quando o disco está bloqueando ou ao interromper

um corte por qualquer motivo, liberte o disparador e

segure a serra sem a mover no material até o disco

parar completamente. Nunca tente remover a serra

da peça de trabalho, puxando a serra para trás

enquanto o disco está em movimento ou pode ocorrer

um contragolpe. Investigue e tome medidas corretivas

para eliminar a causa do bloqueio do disco.

u Ao voltar a colocar a serra na peça de trabalho, centre

o disco de serra no corte para que os dentes da serra

não fiquem encaixados no material. Se o disco de serra

estiver bloqueando, pode subir ou fazer contragolpe da

peça de trabalho quando a serra é reiniciada.

u Suporte os painéis grandes para minimizar o risco de

compressão do disco e de contragolpe. Os painéis

grandes tendem a abater sob seu próprio peso. Os

suportes têm de ser colocados por baixo do painel de

ambos os lados, próximo da linha de corte e próximo da

extremidade do painel.

u Não use discos rombos ou danificados. Discos não

afiados ou incorretamente colocados produzem um corte

estreito, causando uma fricção excessiva, o bloqueio do

disco e contragolpe.

u A profundidade do disco e as alavancas de bloqueio de

ajuste do chanfro têm de estar apertadas e seguras

antes de fazer o corte. Se o ajuste do disco se deslocar

durante o corte, pode causar bloqueio ou contragolpe.

u Tome precauções redobradas ao serrar paredes ou

áreas sem visibilidade. O disco saliente pode cortar

objetos, o que pode causar contragolpe.

Funcionamento da proteção inferior

u Verifique se a proteção inferior fecha devidamente

antes de cada utilização. Não utilize a serra se a

proteção inferior não se mover livremente ou não

fechar instantaneamente. Nunca fixe ou ate a

proteção inferior na posição aberta.Se a serra cair

acidentalmente, a proteção inferior pode ficar dobrada.

Levante a proteção inferior com a empunhadeira retrátil e

se certifique de que se move livremente e não toca no

disco ou em outra peça, em todos os ângulos e

profundidades de corte.

u Verifique a operação da mola da proteção inferior. Se

a proteção e a mola não estiverem funcionando

devidamente, têm de ser alvo de uma reparação antes

da utilização. A proteção inferior pode operar

lentamente devido a peças danificadas, a depósitos de

goma ou à acumulação de resíduos.

u A proteção inferior pode ser retraída manualmente

apenas para cortes especiais como "cortes de

imersão" e "cortes compostos". Levante a proteção

inferior, retraindo a empunhadeira, e assim que o

disco entrar no material a proteção inferior tem de ser

libertada.Para todos os outros trabalhos de serragem, a

proteção inferior deve ser operada automaticamente.

u Observe sempre se a proteção inferior está cobrindo o

disco antes de pousar a serra na bancada ou no

chão.Um disco não protegido em marcha livre irá fazer

com que a serra ande para trás, cortando tudo o que se

atravessar em seu caminho. Tenha atenção ao tempo que

demora para o disco parar depois que o interruptor é

libertado.

Instruções de segurança adicionais

u Não insira as mãos na remoção de aparas. Você pode

sofrer ferimentos nas peças em rotação.

u Não trabalhe com a serra acima do nível da cabeça. Se

o fizer, não terá controle suficiente sobre a ferramenta

elétrica.

u Utilizar detectores apropriados, para encontrar cabos

escondidos, ou consultar a companhia elétrica local. O

contato com cabos elétricos pode provocar fogo e

choques elétricos. Danos em tubos de gás podem levar a

explosões. A penetração em um cano de água causa

danos materiais ou pode provocar um choque elétrico.

u Não opere a ferramenta elétrica de forma

estacionária. Ela não é adequada para o funcionamento

com mesa de serrar.

u Ao fazer um "corte de imersão" que não é executado

em ângulo reto, proteja a placa de guia contra

deslocamento lateral. Um deslocamento lateral pode

fazer com que o disco de serra emperre, provocando um

contragolpe.

u Não use discos de serra de aço HSS. Eles podem

quebrar facilmente.

u Não serre metais ferrosos. As aparas quentes podem

incendiar o sistema de aspiração de pó.

1 609 92A 4JV | (20.09.2018) Bosch Power Tools

Page 17

Português do Brasil | 17

u Espere a ferramenta elétrica parar completamente,

antes de depositá‑la. O acessório acoplável pode

emperrar e levar à perda de controle sobre a ferramenta

elétrica.

u Durante o trabalho, segure a ferramenta elétrica com

as duas mãos e providencie uma estabilidade segura.

A ferramenta elétrica se deixa conduzir de forma segura

com as duas mãos.

Descrição do produto e especificações

Ler todas as indicações de segurança e

instruções. Odesrespeito das advertências e

das instruções de segurança apresentadas

abaixo pode causar choque elétrico, incêndio

e/ou graves lesões.

Respeite as ilustrações na parte da frente do manual de

instruções.

Utilização adequada

A ferramenta elétrica destina-se a fazer cortes longitudinais

e transversais em bases fixas com traçado de corte reto e em

meia-esquadria em madeira.

Componentes ilustrados

A numeração dos componentes ilustrados refere‑se à

apresentação da ferramenta elétrica na página de

esquemas.

Interruptor de ligar/desligar

(1)

Bloqueio de ligação para o interruptor de ligar-

(2)

desligar

Punho adicional (superfícies do punho isoladas)

(3)

Tecla de bloqueio do eixo

(4)

Escala do ângulo de meia-esquadria

(5)

Parafuso borboleta para pré-seleção de ângulos de

(6)

meia-esquadria

Parafuso borboleta para o limitador paralelo

(7)

Marcação de corte 45°

(8)

Marcação de corte 0°

(9)

Limitador paralelo

(10)

Capa de proteção pendular inferior

(11)

Placa de base

(12)

Alavanca de ajuste para a capa de proteção pendular

(13)

inferior

Expulsão de aparas

(14)

Cobertura de proteção

(15)

Punho (superfície isolada)

(16)

Chave de sextavado interno

(17)

Parafuso de aperto com arruela

(18)

Flange de aperto

(19)

Disco de serra circular

(20)

A)

A)

Flange de admissão

(21)

Fuso da serra com flange de admissão

(22)

Alavanca de aperto para pré-seleção da profundidade

(23)

do corte

Escala de profundidade de corte

(24)

Par de grampos

(25)

A)

Acessórios apresentados ou descritos não pertencem ao

volume de fornecimento. Todos os acessórios encontram-se

no nosso catálogo de acessórios.

B)

disponível no mercado convencional (não incluído no

volume de fornecimento)

B)

Dados técnicos

Serra circular manual GKS 20-65

N° do produto

3 601 FB2 0..

Potência nominal consumida W 2000

N° de rotações por min (sem

rpm 5300

carga)

Profundidade máx. de corte com diâmetro de disco de

serra de 184mm

– com ângulo de meia-

mm 62

esquadria de 0°

– com ângulo de meia-

mm 46

esquadria de 45°

Trava do eixo ●

Dimensões placa base mm 302 x 160

Diâmetro máx. do disco de

mm 184

serra

Diâmetro mín. do disco de

mm 184

serra

máx. espessura do corpo da

mm 2,0

serra

Furo de centragem mm 15,9

Peso conforme

kg 5,7

EPTA-Procedure 01:2014

Classe de proteção /II

Os dados são válidos para uma tensão nominal [U] de 220V. No caso

de tensões divergentes e em versões específicas do país, estes dados

podem variar.

Informação sobre ruídos/vibrações

Os valores de emissão de ruído foram determinados de

acordo com EN62841-2-5.

O nível sonoro avaliado A da ferramenta elétrica é

normalmente: nível de pressão sonora 92dB(A); nível de

potência sonora 103dB(A). Incerteza K=3dB.

Usar protetor auricular!

Valores totais de vibração ah (soma vetorial nas três

direções ) e incerteza K determinada em função da

EN62841-2-5:

Serrar madeira: ah<1,4m/s2, K=1,5m/s

O nível de vibrações indicado nestas instruções e o valor de

emissão de ruído foram medidos de acordo com um método

2

Bosch Power Tools 1 609 92A 4JV | (20.09.2018)

Page 18

18 | Português do Brasil

de medição padronizado pela norma EN 62841 e podem ser

usados para comparar ferramentas elétricas entre si.

Também são adequados para uma avaliação preliminar das

emissões de vibrações e ruído.

O nível de vibrações indicado e o valor de emissão de ruído

representam as principais aplicações da ferramenta elétrica.

No entanto, se a ferramenta elétrica for usada para outras

aplicações, com diferentes acessórios acopláveis ou com

manutenção insuficiente, o nível de vibrações e o valor de

emissão de ruído podem ser diferentes. Isso pode aumentar

significativamente as emissões de vibrações e ruído durante

todo o período de trabalho.

Para uma estimativa precisa das emissões de vibrações e

ruído, também devem ser considerados os momentos em

que a ferramenta está desligada ou em funcionamento, mas

não está realmente em uso. Isso pode reduzir

significativamente as emissões de vibrações e ruído durante

todo o período de trabalho.

Além disso também deverão ser estipuladas medidas de

segurança para proteger o operador contra o efeito de

vibrações, como por exemplo: a manutenção das

ferramentas elétricas e dos acessórios acopláveis, mãos

quentes durante o trabalho e a organização dos processos

de trabalho.

Montagem

u Use apenas discos de serra, cuja velocidade máxima

permitida é superior à rotação em vazio de sua

ferramenta elétrica.

Introduzir/substituir o disco de serra circular

u Antes de todos trabalhos na ferramenta elétrica,

retirar o plugue da tomada.

u Para a montagem do disco de serra é necessário usar

luvas de proteção. Há perigo de lesões no caso de

contato com o disco de serra.

u Só utilizar discos de serra que correspondam aos

dados caraterísticos indicados nesta instrução de

serviço e na ferramenta elétrica.

u O número de rotações permitido do acessório

acoplável tem de ser pelo menos tão elevado como o

número de rotações máximo indicado na ferramenta

elétrica. Acessórios que girem mais rápido do que

permitido, podem quebrar e serem atirados para longe.

u Jamais usar discos abrasivos como ferramentas de

trabalho.

Desmontar o disco de serra (ver figura A)

Para trocar o disco de serra, é recomendável apoiar a

ferramenta elétrica sobre o lado do motor.

– Pressionar a tecla de bloqueio do veio (4) e manter

premida.

u Acionar a tecla de bloqueio do veio (4) apenas com o

veio de serra parado. Caso contrário, a ferramenta

elétrica pode ficar danificada.

– Desapertar com a chave sextavada interior (17) o

parafuso de fixação (18) no sentido ➊.

– Oscilar a capa de proteção pendular (11) para trás e

segurar a mesma.

– Retire o flange de aperto (19) e o disco de serra (20) do

veio da serra (22).

Selecionar o disco de serra

No final desta instrução de serviço encontra‑se uma vista

geral dos discos de serra recomendadas.

Montar o disco de serra (ver figura A)

Para trocar o disco de serra, é recomendável apoiar a

ferramenta elétrica sobre o lado do motor.

– Limpar o disco de serra (20) e todas as peças de fixação.

– Oscilar a capa de proteção pendular (11) para trás e

segurar a mesma.

– Colocar o disco de serra (20) no flange de admissão

(21). O sentido de corte dos dentes (direção da seta no

disco da serra) e a direção da seta de rotação na tampa

de proteção (11) têm de coincidir.

– Colocar o flange de aperto (19) e apertar o parafuso de

fixação no sentido ➋. Prestar atenção à posição de

montagem do flange de admissão (21) e do flange de

aperto (19).

– Pressionar a tecla de bloqueio do veio (4) e manter

premida.

– Apertar com a chave sextavada interior (17) o parafuso

de fixação no sentido ➋. O torque de aperto deve ser de

6–9Nm, o que significa à mão e mais um ¼ de volta.

Aspiração de pó/de aparas

Pós de materiais, como por exemplo, tintas que contêm

chumbo, alguns tipos de madeira, minerais e metais, podem

ser nocivos à saúde. O contato com o pó ou sua inalação

pode provocar reações alérgicas e/ou doenças nas vias

respiratórias do utilizador ou das pessoas que se encontrem

por perto.

Certos pós, como por exemplo pó de carvalho e faia são

considerados cancerígenos, especialmente quando juntos

com substâncias para o tratamento de madeiras (cromato,

preservadores de madeira). Material que contem amianto só

deve ser processado por pessoal especializado.

– Se possível, deverá utilizar uma aspiração de pó.

– Assegurar uma boa ventilação do local de trabalho.

– É recomendável usar uma máscara de proteção

respiratória com filtro da classeP2.

Observe as diretrizes, vigentes no seu país, relativas aos

materiais a serem trabalhados.

u Evitar acúmulos de pó no local de trabalho. Pós podem

se inflamar levemente.

1 609 92A 4JV | (20.09.2018) Bosch Power Tools

Page 19

0

45

0

45

Português do Brasil | 19

Funcionamento

Tipos de funcionamento

u Antes de todos trabalhos na ferramenta elétrica,

retirar o plugue da tomada.

Ajustar profundidade de corte (ver figura B)

u Adaptar a profundidade de corte à espessura da peça.

Menos do que uma completa altura de dente deve estar

visível sob a peça a ser trabalhada.

Liberar a alavanca de aperto (23). Para uma profundidade

de corte mais pequena, afastar a serra da placa base (12),

para uma profundidade de corte maior pressionar a serra em

direção à placa base (12). Ajustar a medida desejada na

escala de profundidade de corte. Apertar novamente a

alavanca de aperto (23).

Se não conseguir ajustar completamente a profundidade de

corte depois de liberar a alavanca de aperto(23), puxe a

alavanca de aperto (23) para longe da serra e vire-a para

baixo. Voltar a soltar a alavanca de aperto (23). Repetir este

processo até ser possível ajustar a profundidade de corte

desejada.

A força de aperto do alavanca de aperto (23) pode ser

reajustada. Para isso, desapertar a alavanca de aperto (23)

e voltar a apertar a alavanca deslocada em pelo menos 30°

para a esquerda.

Se não conseguir fixar o suficiente a profundidade de corte

depois de apertar a alavanca de aperto (23), puxe a

alavanca de aperto (23) para longe da serra e vire-a para

cima. Voltar a soltar a alavanca de aperto (23). Repetir este

processo até a profundidade de corte estar fixada

Escala do ângulo de meia-esquadria

Colocar preferencialmente a ferramenta elétrica no lado

frontal da tampa de proteção (15).

Liberar o parafuso de orelhas (6). Deslocar lateralmente o

disco de serra. Ajustar a medida desejada na escala (5).

Voltar a apertar o parafuso de orelhas (6).

Nota: Nos cortes de meia-esquadria, a profundidade de

corte é inferior ao valor indicado na escala de profundidade

de corte (24).

Marcações de corte

Para um corte exato, deverá colocar o disco de serra sobre a

peça, como indicado na figura. Executar, de preferência, um

corte de ensaio.

Ajustar profundidade de corte (ver figura B)

u Adaptar a profundidade de corte à espessura da peça.

Menos do que uma completa altura de dente deve estar

visível sob a peça a ser trabalhada.

Liberar a alavanca de aperto (23). Para uma profundidade

de corte mais pequena, afastar a serra da placa base (12),

para uma profundidade de corte maior pressionar a serra em

direção à placa base (12). Ajustar a medida desejada na

escala de profundidade de corte. Apertar novamente a

alavanca de aperto (23).

Se não conseguir ajustar completamente a profundidade de

corte depois de liberar a alavanca de aperto(23), puxe a

alavanca de aperto (23) para longe da serra e vire-a para

baixo. Voltar a soltar a alavanca de aperto (23). Repetir este

processo até ser possível ajustar a profundidade de corte

desejada.

A força de aperto do alavanca de aperto (23) pode ser

reajustada. Para isso, desapertar a alavanca de aperto (23)

e voltar a apertar a alavanca deslocada em pelo menos 30°

para a esquerda.

Se não conseguir fixar o suficiente a profundidade de corte

depois de apertar a alavanca de aperto (23), puxe a

alavanca de aperto (23) para longe da serra e vire-a para

cima. Voltar a soltar a alavanca de aperto (23). Repetir este

processo até a profundidade de corte estar fixada

Colocação em funcionamento

u Observar a tensão de rede! A tensão da fonte de

corrente elétrica deve coincidir com a indicada na

chapa de identificação da ferramenta elétrica. As

ferramentas elétricas assinaladas com 230V também

podem ser operadas com 220V.

Ligar e desligar

u Certifique-se de que consegue acionar o interruptor

de ligar/desligar sem ter de soltar o punho.

Para a colocação em funcionamento da ferramenta

elétrica, empurrar primeiro o bloqueio de ligação (2) e

pressionar de seguida o interruptor de ligar/desligar (1) e

manter premido.

Para desligar a ferramenta elétrica, soltar o interruptor de

ligar/desligar (1).

Nota: Por motivos de segurança o interruptor de ligar/

desligar (1) não pode ser travado, tem de permanecer

continuamente pressionado durante o funcionamento.

Indicações de trabalho

A marcação de corte 0° (9) indica a posição do disco de

serra no corte em ângulo reto. A marcação de corte 45°

(8)indica a posição do disco de serra no corte em 45°.

Bosch Power Tools 1 609 92A 4JV | (20.09.2018)

u Antes de todos trabalhos na ferramenta elétrica,

retirar o plugue da tomada.

Proteger os discos de serra contra golpes e pancadas.

Conduzir a ferramenta elétrica uniformemente e com avanço

moderado no sentido de corte. Um avanço muito forte reduz

Page 20

20 | Español

substancialmente a vida útil do disco de serra e pode

danificar a ferramenta elétrica.

A potência de serragem e a qualidade de corte dependem do

estado e da forma dos dentes do disco de serra. Portanto só

deverá utilizar discos de serra afiados e apropriados para o

material a ser trabalhado.

Serrar madeira

A seleção correta do disco de serra depende do tipo e da

qualidade da madeira e se devem ser executados cortes

longitudinais ou transversais.

Cortes longitudinais em aberto são produzidas aparas em

formato espiral.

O pó de faia e carvalho são especialmente prejudiciais à

saúde, por isso trabalhe com sistema de aspiração de pó.

Serrar com limitador paralelo (ver figura C)

O limitador paralelo (10) permite cortes exatos ao longo da

aresta da peça ou cortar tirar iguais.

Soltar o parafuso de orelhas (7) e introduzir a escala do

limitador paralelo (10) pelo guia da placa base (12). Ajustar

a largura de corte desejada como valor de escala na

respectiva marcação de corte (9) ou (8), ver seção

"Marcações de corte". Voltar a apertar o parafuso de orelhas

(7).

Serrar com limitador auxiliar (ver figura D)

Para trabalhar peças maiores ou para cortar lados retos, é

possível fixar uma tábua ou ripa, como limitador auxiliar, à

peça a ser trabalhada e conduzir a serra circular com a placa

de base ao longo do limitador auxiliar.

Manutenção e serviço

Manutenção e limpeza

u Antes de todos trabalhos na ferramenta elétrica,

retirar o plugue da tomada.

u Manter a ferramenta elétrica e as aberturas de

ventilação sempre limpas, para trabalhar bem e de

forma segura.

A capa de proteção pendular deve sempre movimentar‑se

livremente e fechar‑se automaticamente. Portanto deverá

sempre manter a área em volta da capa de proteção

pendular limpa. Remova pó e aparas com um pincel.

Discos de serra não revestidos podem ser protegidos contra

surgimento de corrosão por uma fina camada de óleo livre

de ácido. Remover o óleo antes de serrar, caso contrário

poderão surgir nódoas na madeira.

Resíduos de resina ou de aglutinante no disco de serra

reduzem a qualidade de corte. Portanto deverá sempre

limpar o disco de serra imediatamente após a utilização.

Se for necessário substituir o cabo de conexão, isto deverá

ser realizado pela Bosch ou por uma oficina de serviço pósvenda autorizada para todas as ferramentas elétricas Bosch

para evitar riscos de segurança.

Serviço pós-venda e assistência ao cliente

O serviço pós-venda responde às suas perguntas a respeito

de serviços de reparação e de manutenção do seu produto,

assim como das peças sobressalentes. Desenhos explodidos

e informações sobre peças sobressalentes também em:

www.bosch-pt.com

A equipe de consultores Bosch esclarece com prazer todas

as suas dúvidas a respeito dos nossos produtos e

acessórios.

www.powertool-portal.de, o portal de Internet para

profissionais e aficionados.

Indique em todas as questões ou encomendas de peças

sobressalentes impreterivelmente a referência de 10 dígitos

de acordo com a placa de características do produto.

Brasil

Robert Bosch Ltda. – Divisão de Ferramentas Elétricas

Caixa postal 1195 – CEP: 13065-900

Campinas – SP

Tel.: 0800 7045 446

www.bosch.com.br/contato

Angola

InvestGlobal

Parque Logístico

Estrada de Viana Km 12

Luanda

Tel. : +212 948 513 580

E-Mail: helderribeiro@investglobal-ang.com

Descarte

Ferramentas elétricas, acessórios e embalagens devem ser

enviados a uma reciclagem ecológica de matérias primas.

Não jogar as ferramentas elétricas no lixo

doméstico!

Español

Indicaciones de seguridad

Indicaciones generales de seguridad para herramientas eléctricas

ADVERTEN-

CIA

nes entregadas con esta herramienta eléctrica. En caso

de no atenerse a las instrucciones siguientes, ello puede

ocasionar una descarga eléctrica, un incendio y/o una lesión

grave.

Guardar todas las advertencias de peligro e instrucciones para futuras consultas.

El término "herramienta eléctrica" empleado en las siguientes advertencias de peligro se refiere a herramientas eléctri-

Lea íntegramente las advertencias

de peligro, las instrucciones, las

ilustraciones y las especificacio-

1 609 92A 4JV | (20.09.2018) Bosch Power Tools

Page 21

Español | 21

cas de conexión a la red (con cable de red) y a herramientas

eléctricas accionadas por acumulador (sin cable de red).

Seguridad del puesto de trabajo

u Mantenga el área de trabajo limpia y bien iluminada.

Las áreas desordenadas u oscuras pueden provocar accidentes.

u No utilice herramientas eléctricas en un entorno con

peligro de explosión, en el que se encuentren combustibles líquidos, gases o material en polvo. Las herra-

mientas eléctricas producen chispas que pueden llegar a

inflamar los materiales en polvo o vapores.

u Mantenga alejados a los niños y otras personas de su

puesto de trabajo al emplear la herramienta eléctrica.

Una distracción le puede hacer perder el control sobre la

herramienta eléctrica.

Seguridad eléctrica

u El enchufe de la herramienta eléctrica debe corres-

ponder a la toma de corriente utilizada. No es admisible modificar el enchufe en forma alguna. No emplear

adaptadores en herramientas eléctricas dotadas con

una toma de tierra. Los enchufes sin modificar adecua-

dos a las respectivas tomas de corriente reducen el riesgo

de una descarga eléctrica.

u Evite que su cuerpo toque partes conectadas a tierra

como tuberías, radiadores, cocinas y refrigeradores.

El riesgo a quedar expuesto a una sacudida eléctrica es

mayor si su cuerpo tiene contacto con tierra.

u No exponga la herramienta eléctrica a la lluvia o a con-

diciones húmedas. Existe el peligro de recibir una descarga eléctrica si penetran ciertos líquidos en la herramienta eléctrica.

u No abuse del cable de red. No utilice el cable de red

para transportar o colgar la herramienta eléctrica, ni

tire de él para sacar el enchufe de la toma de corriente. Mantenga el cable de red alejado del calor, aceite,

esquinas cortantes o piezas móviles. Los cables de red

dañados o enredados pueden provocar una descarga

eléctrica.

u Al trabajar con la herramienta eléctrica a la intempe-

rie utilice solamente cables de prolongación apropiados para su uso al aire libre. La utilización de un cable

de prolongación adecuado para su uso en exteriores reduce el riesgo de una descarga eléctrica.

u Si fuese imprescindible utilizar la herramienta eléctri-

ca en un entorno húmedo, es necesario conectarla a

través de un dispositivo de corriente residual (RCD)

de seguridad (fusible diferencial). La aplicación de un

fusible diferencial reduce el riesgo a exponerse a una descarga eléctrica.

Seguridad de personas

u Esté atento a lo que hace y emplee sentido común

cuando utilice una herramienta eléctrica. No utilice la

herramienta eléctrica si estuviese cansado, ni tampoco después de haber consumido drogas, alcohol o me-

dicamentos. El no estar atento durante el uso de la herra-

mienta eléctrica puede provocarle serias lesiones.

u Utilice un equipo de protección personal. Utilice siem-

pre una protección para los ojos. El riesgo a lesionarse

se reduce considerablemente si se utiliza un equipo de

protección adecuado como una mascarilla antipolvo, zapatos de seguridad con suela antideslizante, casco, o protectores auditivos.

u Evite una puesta en marcha involuntaria. Asegurarse

de que la herramienta eléctrica esté desconectada antes de conectarla a la toma de corriente y/o al montar

el acumulador, al recogerla y al transportarla. Si trans-

porta la herramienta eléctrica sujetándola por el interruptor de conexión/desconexión, o si alimenta la herramienta eléctrica estando ésta conectada, ello puede dar lugar

a un accidente.

u Retire las herramientas de ajuste o llaves fijas antes

de conectar la herramienta eléctrica. Una herramienta

de ajuste o llave fija colocada en una pieza rotante puede

producir lesiones al poner a funcionar la herramienta