Bosch FAP-O 500, FAP-O 500-P, FAP−OC 500, FAP-OC 500-P Product Information

PRODUCT INFORMATION PI−34.70 en

A5.en / 02.02.2006

Page 0

ST−FIR/PRM1 / zab

BDL−F.01U.025.876

500 Series

LSN Fire Detectors (EU)

FAP−O 500 / FAP−O 500−P

FAP−OC 500 / FAP−OC 500−P

with FAA−500 Components

PI − 34.70 enProduct Information 500 Series LSN Fire Detectors (EU)

Page 3

BDL−F.01U.025.876

A5.en/ 02.02.2006

ST−FIR/PRM1 / zab

Table of Contents

1. Product Description 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1. System Description 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2. Configuration of the Detector 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3. Functional Description of the Sensor Technology 8. . . . . . . . . . . . . . . .

1.4. LED Operation 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5. Performance Features 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Planning Notes 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Programming 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Technical Specifications 14. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1. Detector and Trim Ring 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2. Detector Base 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3. Mounting Boxes 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Mounting Notes 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1. Ceiling Mount Back Box 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2. Detector Base / Detector Base with Relay 19. . . . . . . . . . . . . . . . . . . . . .

5.3. Detector and Trim Ring 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4. Built−in Housing for Concrete Ceilings 23. . . . . . . . . . . . . . . . . . . . . . . . .

5.5. Surface Mount Back Box 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6. External Detector Alarm Displays 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PI − 34.70 enProduct Information 500 Series LSN Fire Detectors (EU)

Page 4

BDL−F.01U.025.876

A5.en/ 02.02.2006

ST−FIR/PRM1 / zab

6. Order Overview 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1. Detectors and Trim Ring 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2. Detector Bases / Accessories 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3. Mounting Boxes 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4. Service Tools / Accessories 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. Maintenance and Service 32. . . . . . . . . . . . . . . . . . . . . . . . . .

7.1. Notes for the Service 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2. General Notes for Detector Testing 34. . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3. Inspection Procedure for FAP−OC 500 35. . . . . . . . . . . . . . . . . . . . . . . . .

7.4. Inspection Procedure for FAP−O 500 37. . . . . . . . . . . . . . . . . . . . . . . . . .

8. Repair 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. Disposal 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. Additional Documentation 38. . . . . . . . . . . . . . . . . . . . . . . . .

11. Abbreviations 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PI − 34.70 enProduct Information 500 Series LSN Fire Detectors (EU)

Page 5

BDL−F.01U.025.876

A5.en/ 02.02.2006

ST−FIR/PRM1 / zab

«

1. Product Description

With their low profile design, flush−mounted installation and possibilities for color toning, the fire detectors in the 500 series open up a new dimension with respect to aesthetic and functional demands.

The cooperation of engineers and designers has created the timeless, innovative design of this detector, which integrates pleasantly into the ceiling. The detectors with

associated trim ring are available in the versions «white» and «transparent with color

toning inserts». Through the use of the supplied color toning inserts, optimum adjustment to many different environments becomes possible.

The lack of an optical labyrinth and their easily−cleaned smooth surface means the

detectors are also suitable for applications in high−dust areas.

The low profile, flush−mounted design allows the use of the detectors even in areas

that must be free of protrusions.

Thanks to the geometric arrangement of two separate optical sensor systems, the detectors are not sensitive to interference, such as that caused by insects. The scattered

light volume that is evaluated by the sensors is located in the free space a few centimeters below the ceiling.

The contamination level is measured constantly. Contamination of the detector surface leads to an active adjustment of the threshold (drift compensation) and a fault indication at the panel in the case of heavier contamination.

The detector is available as a scattered light fire detector only or as a multisensor detector with an additional gas sensor.

The combination of scattered light detector and gas sensor allows the evaluation of

signals with the help of modern signal processing methods. The result is high immunity

against deceptive alarms and extended application possibilities in environments that

are not suitable for pure scattered light smoke detectors.

The FAP−500 detectors can be connected directly to the Local SecurityNetwork LSN.

Accessories

The detectors are generally mounted flush with the ceiling in false ceilings. The detector and base are installed in a robust ceiling mount back box. In addition, a housing

for mounting within concrete ceilings can be used.

For special applications where recessed ceiling mounting is not possible, a surface

mount back box is available. This is used as an alternative to the ceiling mount back box.

The surface mount back box with damp room seal also allows the detector to be used

in a humid environment.

For special applications, e.g. control of an emergency door in accordance with DIBt,

base variants are available with relay (only in combination with the Modular Fire Panel

FPA−5000).

PI − 34.70 enProduct Information 500 Series LSN Fire Detectors (EU)

Page 6

BDL−F.01U.025.876

A5.en/ 02.02.2006

ST−FIR/PRM1 / zab

In the GB−base versions, integrated jumper elements are provided that preserve the

loop function if the detector is removed.

All bases have an integrated strain relief for false ceiling cables.

The connection terminals are easily accessible. Cables up to 3.3 mm2 in cross section

can be used.

An innovative concept for locking the detector module utilizing the push−in/push−out prin-

ciple allows very quick and easy insertion and exchange of the click and lock detector.

For the detector test and detector exchange, a special user−friendly service accessory

is available.

Overview of the 500 series LSN detectors and accessories

LSN detectors

D FAP−O 500 Optical fire detector LSN, white

D FAP−O 500 P Optical fire detector LSN,

transparent with color toning inserts

D FAP−OC 500 Multisensor fire detector LSN, optical/chemical, white

D FAP−O 500−P Multisensor fire detector LSN, optical / chemical,

transparent with color toning inserts

D FAA−500−TR−W White trim ring for detectors series 500 and 520

D FAA−500−TR−P Transparent trim ring with color toning inserts for detectors

series 500 and 520

LSN detector bases

D FAA−500 LSN detector base

D FAA−500−R LSN detector base with relay*

D FAA−500−GB LSN detector base for Great Britain

D FAA−500−R−GB LSN detector base for Great Britain with relay*

D FAA−500−SPRING Spring for concrete and wooden ceiling

* for connection to the Modular Fire Panel FPA−5000 only

Mounting boxes

D FAA−500−BB Ceiling mount back box

D FAA−500−CB Built−in housing for concrete ceilings

D FAA−500−SB Surface mount back box

D FAA−500−SB−H Surface mount back box with damp room seal

Service Accessories

D FAA−500−RTL Detector exchanger for 500 and 520 series detectors

D FAA−500−TTL Test adapter with magnet for 500 and 520 series detectors

PI − 34.70 enProduct Information 500 Series LSN Fire Detectors (EU)

Page 7

BDL−F.01U.025.876

A5.en/ 02.02.2006

ST−FIR/PRM1 / zab

1.1. System Description

All detectors in the 500 series are equipped with two optical sensors and a pollution

sensor. The FAP−OC 500 multisensor detector contains a gas sensor as an additional

detection channel.

The response sensitivity of the detector can be programmed with the programming

software via the LSN network. All sensor signals are analyzed continually by the internal signal evaluation processor and are linked with each other.

By linking the optical sensors and the gas sensor, the OC detector can also be used

in places where the work carried out gives rise to small amounts of smoke, steam or

dust. The alarm will only be triggered automatically if the signal combination corresponds with the characteristic diagram of the installation location that was selected

during configuring.

1.2. Configuration of the Detector

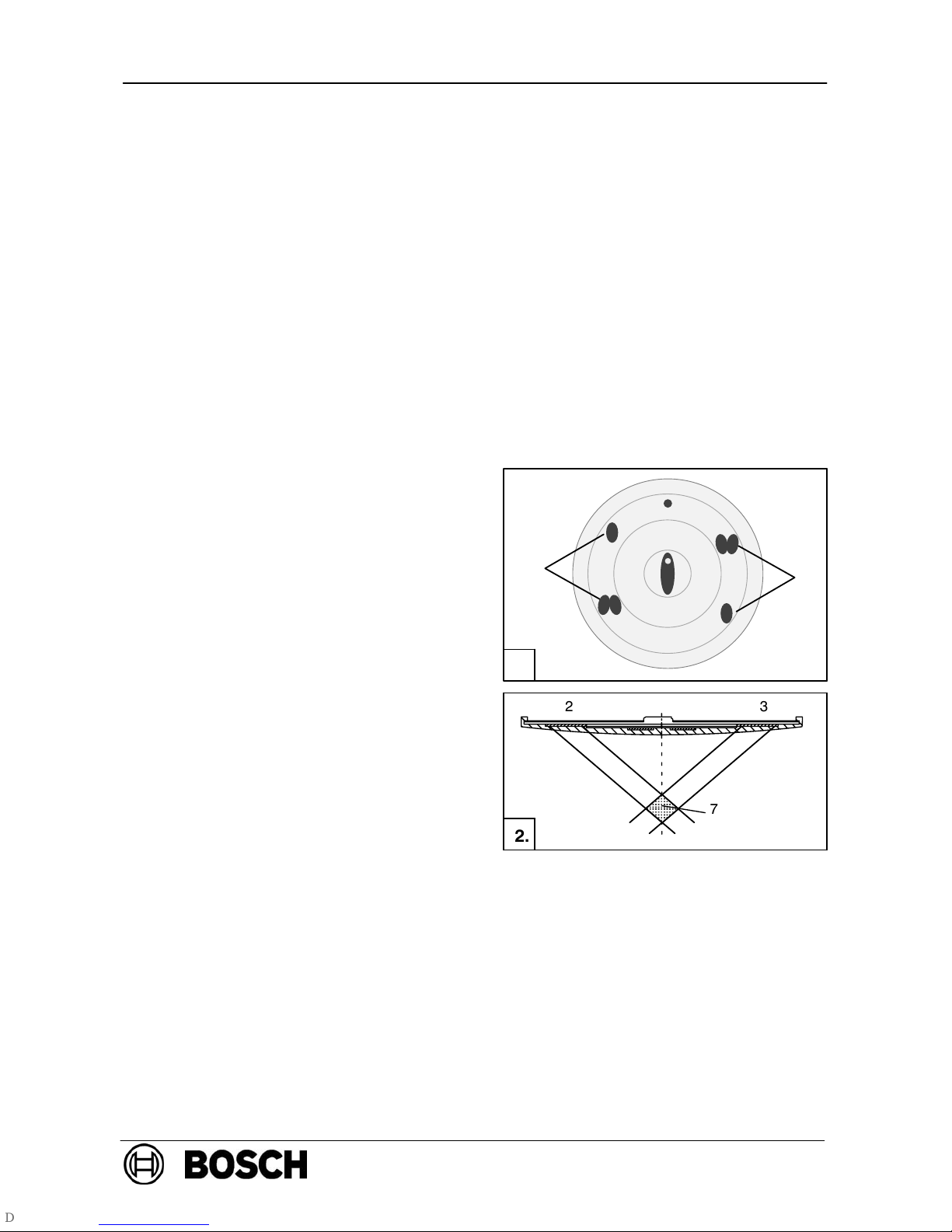

Fig. 1.: Detector front panel with sensors

Fig. 2.: Side view of detector cover

1 = Optical sensor

2 = Receiver (photo diodes)

3 = Transmitter (LEDs)

4 = CO sensor

5=Two−color LED:

red = alarm

green = test mode / trouble

6 = Pollution sensor

7 = Measuring area

1

1

2

3

3

2

4

5

6

1.

23

7

2.

PI − 34.70 enProduct Information 500 Series LSN Fire Detectors (EU)

Page 8

BDL−F.01U.025.876

A5.en/ 02.02.2006

ST−FIR/PRM1 / zab

1.3. Functional Description of the Sensor Technology

Optical sensor (smoke sensor)

The optical sensor (Fig. 1., Pos. 1) operates according to the scattered light principle.

The LEDs (Fig. 1., Pos. 3) transmit light at a defined angle into the measuring area

(Fig. 2., Pos. 7). In case of fire, the light is scattered by the smoke particles and strikes

the photo diodes (Fig. 1., Pos. 2), which transform the quantity of light into a proportional electrical signal.

The effects of daylight and commercial lighting sources are filtered out with an optical

daylight filter and by the use of electronic filtering and phase−locked rectification (ambient light stability: glare test DIN EN 54−7).

The various light−emitting and photo diodes of the detector are individually activated.

Consequently, signal combinations are produced that are independent of each other

and ideally suitable for the detection of smoke, which makes it possible to differentiate

between smoke and interference agents (insects, objects). In addition, the time characteristics and the correlation of the optical sensor signals for the fire or interference

detection are evaluated.

Moreover, plausibility checking of the various signals makes it possible to detect errors

in the evaluation electronics and the LEDs.

Chemical sensor (CO gas sensor)

The gas sensor (Fig. 1., Pos. 4) detects mainly the carbon monoxide (CO) that is produced by a fire, but it also detects hydrogen (H) and nitrogen monoxide (NO).

The basic measuring principle is CO oxidation on an electrode and the measurable current

that arises from this. The sensor signal value is proportional to the concentration of gas.

The gas sensor supplies additional information in order to reliably suppress the disturbance variables.

The CO sensor is monitored by supervision of the internal capacity. If the capacity lies

outside the permitted range, a malfunction signal is output on the fire panel. In this

case, the detector continues to operate purely as a scattered light smoke detector.

Pollution sensor

The contamination level of the detector surface is measured and evaluated continuously by the pollution sensor (Fig. 1., Pos. 6). A three−stage contamination display can

be read out at service (see Chapter 7.1.).

PI − 34.70 enProduct Information 500 Series LSN Fire Detectors (EU)

Page 9

BDL−F.01U.025.876

A5.en/ 02.02.2006

ST−FIR/PRM1 / zab

1.4. LED Operation

The two−color LED of the detector indicates the operation and alarm statuses.

During the whole life cycle, the sensors are self−monitored and the sensitivity is self−

adjusted according to the programmed threshold. In case the detector is heavily contaminated, a message is sent to the fire panel.

In case of an alarm, the LED flashes red. The detector is set back to standby if the

alarm is reset via the fire panel and if the cause of the alarm is gone.

LED Operation

Status LED

Standby off

Alarm red, flashes

Trouble green, double flash every 8 to12 second

Test mode green, flashes once every second

PI − 34.70 enProduct Information 500 Series LSN Fire Detectors (EU)

Page 10

BDL−F.01U.025.876

A5.en/ 02.02.2006

ST−FIR/PRM1 / zab

1.5. Performance Features

D Fulfills the highest aesthetic demands through the flush−mounting design and the

possibility of color toning

D Smooth, easily−cleaned detector surface

D Quick and easy insertion and exchange of the detector thanks to innovative

detector locking mechanism (click and lock principle).

D Easily−visible two−color LED for display of alarm, trouble and test mode

D Self−monitoring of the sensors, with display on the fire panel:

− Fault indication upon failure of the evaluation electronics or one of the LEDs of

the optical sensor

− Three−stage contamination display (analog value can be read out at service)

− Fault indication in the case of heavy contamination (instead of false alarm)

− Fault indication in the case of CO sensor failure (for the FAP−OC 500)

D Thanks to integrated isolators, the LSN loop will continue to function in case of wire

interruption or short−circuit of a detector

D Active adjustment of the threshold (drift compensation) if the optical sensor be-

comes contaminated

D Active adjustment of the threshold (drift compensation) of the chemical sensor

D Increased detection and false alarm immunity thanks to evaluation of the time

behavior of fire and disturbance variables

D Programmable sensitivity, i.e. can be adjusted to the area of operation

D Detector individual identification on the fire panel in the case of alarm

D A pre−alarm is signaled when 50% of alarm threshold is reached (indicator in the

event database of the fire panel).

D The serial number, contamination level, operating hours and current analog values

can be read out from each configured detector.

D Activation of an external detector alarm display is possible (not for relay bases)

D Activation of external devices with relay base is possible (only in combination with

the Modular Fire Panel FPA−5000)

D Easily−accessible connection terminals

D Service accessories for simple and comfortable detector test and exchange

D When using the FAA−500−TTL test adapter, an integrated reed switch automati-

cally switches the detector into the test mode.

D The EMC security fulfills the guidelines according to VdS 2110 (VdS Schaden-

verhütung GmbH) as well as UL 268.

D Can be connected to the LSN fire panels FPA−5000, BZ 500 LSN, UEZ 2000 LSN,

UGM 2020 and to other fire panels or their receiver modules with identical connection conditions.

D VdS Approval

D CE conform according to EN 54−7

PI − 34.70 enProduct Information 500 Series LSN Fire Detectors (EU)

Page 11

BDL−F.01U.025.876

A5.en/ 02.02.2006

ST−FIR/PRM1 / zab

2. Planning Notes

The 500 series detectors are approved for indoor use only!

The detectors must be installed exclusively in the FAA−500 bases

provided. In addition, the detector base must be installed in an

FAA−500−BB ceiling mount back box or in an FAA−500−SB surface

mount back box.

D Country−specific standards and guidelines must be observed during the planning

phase.

D The FAP−OC 500, like the FAP−O 500, is planned according to the guidelines for

optical detectors; see DIN VDE 0833 Part 2 and VdS 2095.

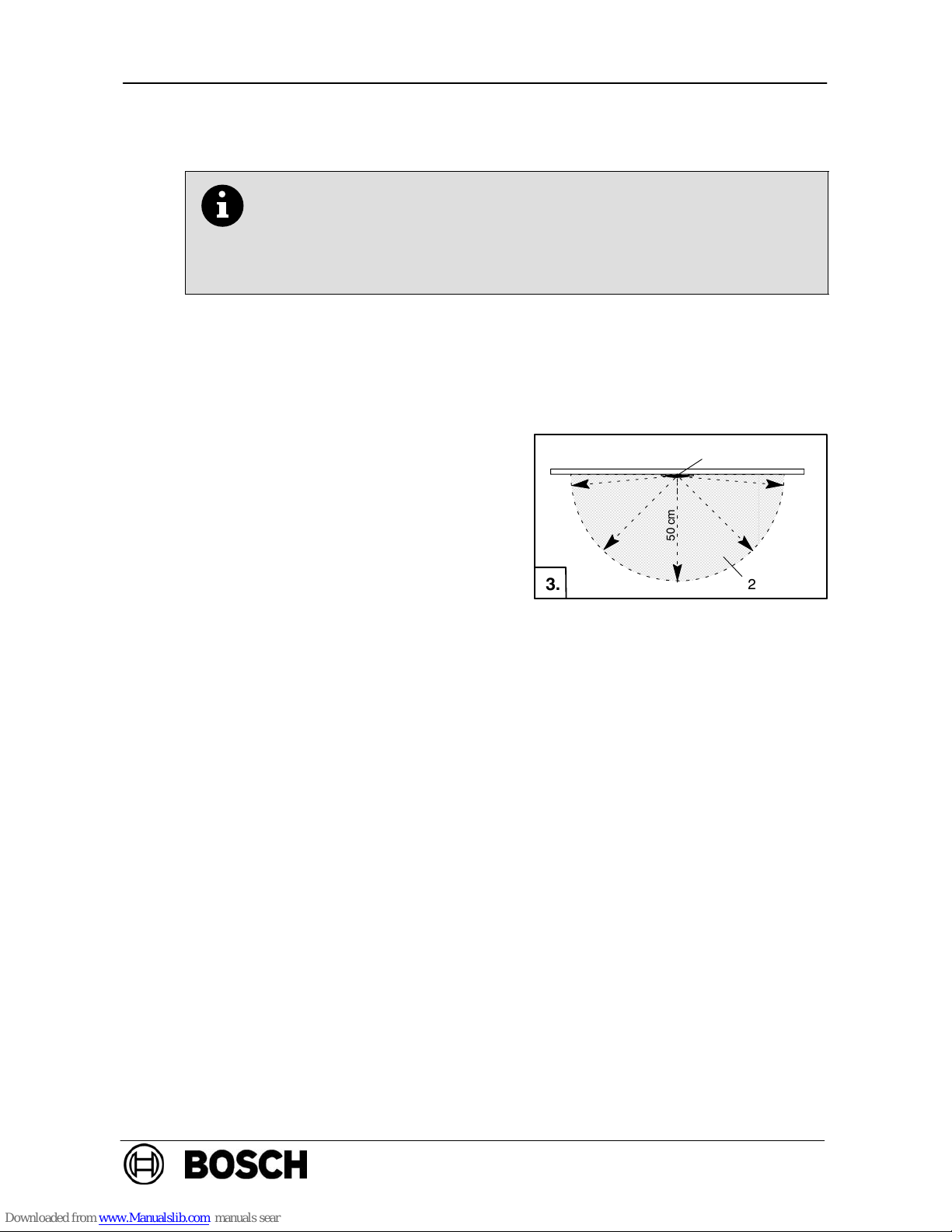

D A hemispherical space (see Fig. 3., Pos. 2)

with a radius of 50 cm must remain free

below the detector (Pos. 1).

Care must be taken to ensure that no people, larger animals, plants, opening doors

or any objects intrude into this area and

that no parts of the detector surface become covered.

D The detector may only be installed in a position which is out of arm’s reach.

Minimum installation height recommended by BOSCH: 2.70 m.

D The 500 series detectors may not be installed in rooms with data transmission by

means of high−intensity infra−red light (e.g. in rooms with IR systems for interpreters).

D The detectors must be mounted so that they are not exposed to any direct sunlight.

D A minimum distance of 50 cm from lamps must be maintained.

The detectors may not be mounted in a cone of light from lamps.

D The standard spring inside the bases allows detector mounting in false ceiling

panels. For concrete and wooden ceiling, replace with the FAA−500−SPRING with

red marking (ordering information see section 6.2.).

D Maximum permitted air speed: 20 m/s.

D Maximum number of FAP−500 detectors connectable to the Local SecurityNetwork

LSN:

− BOSCH LSN fire panels: up to 28 detectors per NVU as loop or stub line

− Modular Fire Panel FPA−5000: up to 85 detectors per LSN 0300−Modul.

1

50 cm

2

3.

PI − 34.70 enProduct Information 500 Series LSN Fire Detectors (EU)

Page 12

BDL−F.01U.025.876

A5.en/ 02.02.2006

ST−FIR/PRM1 / zab

3. Programming

LSN detectors are programmed according to the required operating mode.

Programming is carried out with the programming software using a PC or laptop con-

nected to the fire panel.

The suitable response sensitivity of the multisensor detector is programmed by speci-

fying the operating location (e.g. computer room, office, large kitchen). The selection of

the operation location determines the optimal characteristic diagram for the fire and disturbance variable evaluation.

If, according to the operating location, a low sensitivity is set for the optical sensor, the

alarm goes off only if the detector senses high levels of smoke and of CO at the same

time. This is the case with open or smouldering fire.

Programming the multisensor detector and linking all detectors by algorithms, considerably increases the fire detection reliability and lowers the false alarm rate.

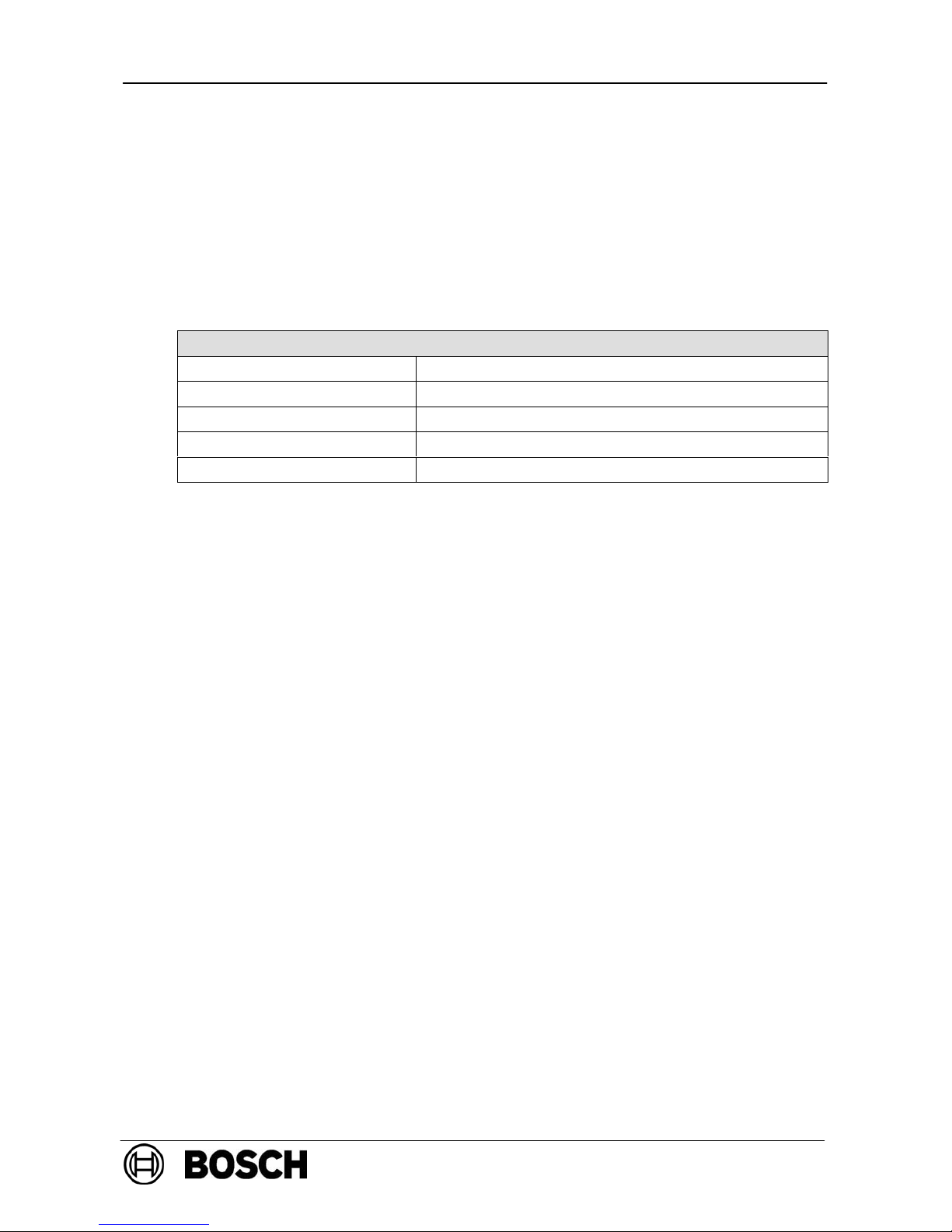

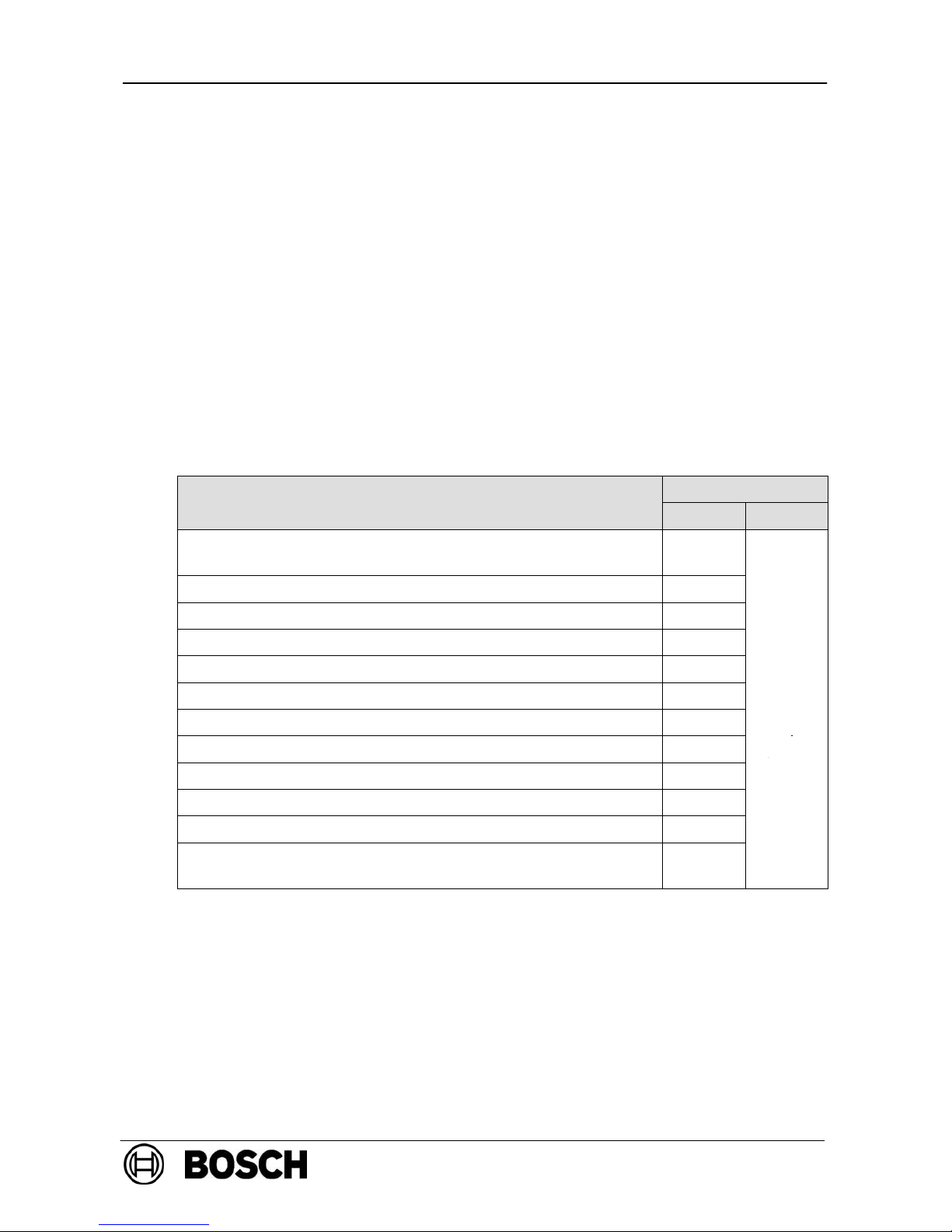

FAP−OC 500(−P)

Operating locations for multisensor detector

Sensitivity

Operating locations for multisensor detector

(FAP−OC 500) selectable via the programming software

O unit C unit

Office (smokers) / waiting room / restaurant / conference

room

low

g

Conference room / waiting room / exhibition hall low

s

atin

Warehouse with vehicle traffic low

wa

y

per

a

Production facilities low

s al

w

e o

Kitchen / casino / restaurant during operation low

nit i

s

f t

h

Garage low

C u

n

ss

o

Office (daily operation) medium

he

C

rdle

s

School / kindergarten medium

of t

h

ga

r

Theaters / concert halls medium

ity

o

, r

e

Office (no traffic) high

siti

v

hig

h

.

Computer room high

sen

lly

h

ion.

High−board warehouse without vehicle traffic with internal

combustion engines

high

The sequalocat

Loading...

Loading...