Bosch EX70C706‑N, EX70MX404-N, EX70MX404-P, EX70MX406-N, EX70MX406-P Specifications

...

Video | EX70 Compact Explosion‑protected Camera

The EX70 is a small, tough, compact, explosion-protected

camera with performance optics for safe, effective

surveillance in hazardous locations such as in oil and gas,

and chemical facilities.

The EX70 is certified for ATEX Zone 1 or NEC Class I,

Division 1 environments, the most stringent safety

standards for explosion-protected performance. By

definition, the Class I, Division 1 certifications signify that

the EX70 is safe for use even in environments where

explosive gases are present under normal operating

conditions.

The EX70 incorporates high-strength design, featuring a

construction of sand-cast, copper-free aluminum, strong

enough to withstand an internal explosion. Threaded

flame paths extinguish burning explosive gases and allow

them to exit the housing harmlessly, without risking

ignition in the external environment.

By meeting the rigorous requirements for Class I,

Division 1 environments, the EX70 assures safe, effective

performance at less hazardous Division 2 and Class II

locations.

Rated NEMA 4X for both indoor and outdoor use, the

EX70 carries a T6 temperature code, the lowest and safest

rating. The EX70 is available with either a 3.6 mm or

6.0 mm fixed lens and is easy to install into any 12 VDC or

24 VAC system. It is a safe and effective surveillance

solution for hazardous locations.

Functions

Performance Optics

•

Performance CCD with mechanical filter technology

•

Enables effective surveillance in low-light

environments

•

Sensor provides higher IR sensitivity, low smear, low

streaking and excellent anti-blooming characteristics

Compact Ruggedized Construction

•

Small, unobtrusive and discreet housing

•

NEMA 4X design for indoor and outdoor performance

•

High-strength reinforced aluminum construction

strong enough to withstand an internal explosion.

•

Threaded flame paths extinguish burning explosive

gases, allowing them to exit the housing harmlessly

without risking ignition in the external environment

Installer-Friendly Features

•

Fixed 3.6 mm or 6.0 mm lens

•

12 VDC / 24 VAC operation

•

Optional pan-tilt brackets

•

Optional wall and pole adapter plates

Applications

•

Petroleum processing facilities

•

Chemical factories

•

Agricultural processing plants

•

Refineries

•

Munitions storage

•

Oil and gas plants

•

Fuel storage sites

•

Industrial plants

•

Nuclear facilities

EX70 Compact Explosion‑protected

Camera

▶

UL/CSA or ATEX certified for explosion-protected

performance

▶

Class I, II, III, Div. 1, 2, Groups B, C, D, E, F, G, T6,

Ex II 2 G, Ex d IIC T6

▶

Performance optics with mechanical filter technology

▶

High-strength design can withstand an internal

explosion

▶

Small, compact housing, NEMA 4X rated

▶

Safe for use where explosive gases are normally

present

www.boschsecurity.com

2 | EX70 Compact Explosion‑protected Camera

•

Pharmaceutical plants

•

Aircraft hangers

Certifications and Approvals

Region Certification

Europe CE

ATEX

CSA/NRTL LR 113310

Class 2258 / 82 – Process Control Equipment – For Hazardous

Locations – Certified to US Standard

2258 / 02 – Process Control Equipment – For Hazardous

Locations

Safety UL / CSA / ATEX

UL 508, 16th Edition – Industrial Control Equipment

UL 698, 11th Edition – Industrial Control Equipment for

Use in Hazardous (Classified) Locations

UL 1203, 2nd Edition – Explosion-Proof and Dust-IgnitionProof Elec. Eqmt for Use in Hazardous (Classified) Locations

CSA C22.2 No.0-M1991 – General Requirements – Canadian Electrical Code Part II

CSA C22.2 No.0.4-M1982 – Bonding and Grounding of

Electrical Equipment (Protective Grounding)

CSA C22.2 No.25-M1966 – Enclosures for Use in Class II

Groups E, F and G Hazardous Locations

CSA C22.2 No.30-M1986 – Explosion-proof Enclosures

for Use in Class I Hazardous Locations

CSA C22.2 No.94-M1991 – Special Purpose Enclosures

CSA C22.2 No.142-M1987 – Process Control Equipment

Class I, Division 1 and 2, Groups B, C, and D

Class II, Division 1 and 2, Groups E, F, G

Class III

ATEX Ex II 2G certified – Equipment or Protective System

intended for use in Potentially Explosive Atmospheres; Directive 94/9/EC

ATEX Ex d IIC T6 certified – Equipment or Protective System intended for use in Potentially Explosive Atmospheres; Directive 94/9/EC

Operational Temperature Code T6 (At ambient operational temperature

of 40ºC, the maximum unit surface temperature will not exceed 85ºC.)

Environmental

CSA / NEMA TYPE 4X

Installation/Configuration Notes

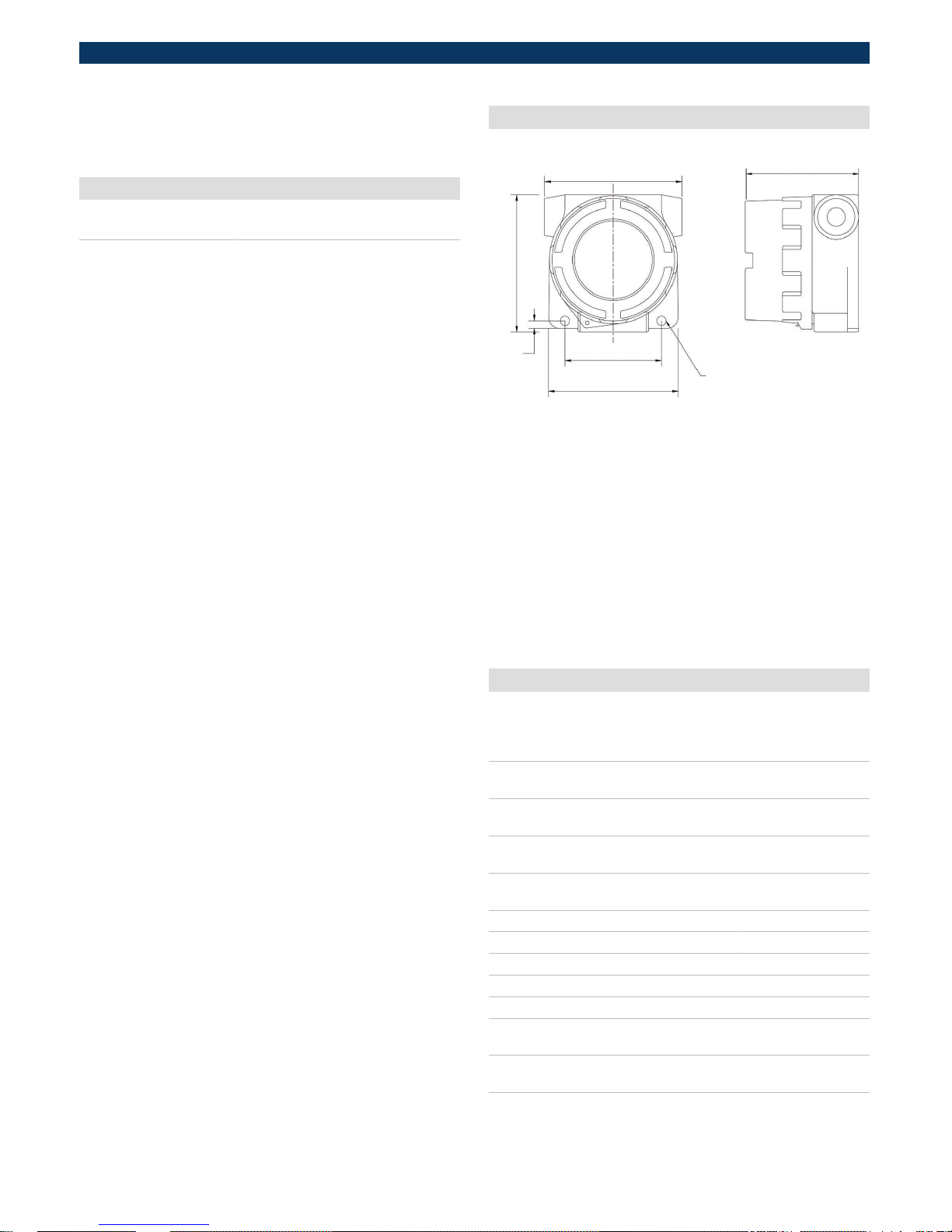

Dimensions

117 (4.63)

98 (3.85)

83 (3.25)

111 (4.38) mm (in)

Ø7.6 (0.30)

2x

6.3

(0.25)

117 (4.63)

Flexible Mounting Options

•

Wall mounting

-

use a combination of EXMB.070B (EX70 adapter

plate), EXMB.028B (pan/tilt bracket) and EXMB.

017B (wall mount adapter).

•

Pole mounting

-

use a combination of EXMB.070B (EX70 adapter

plate), EXMB.028B (pan/tilt bracket) and EXMB.

015B (pole mount adapter).

•

Ceiling mounting

-

use a combination of EXMB.070B (EX70 adapter

plate) and EXMB.002B (ceiling bracket).

All brackets are available as optional accessories.

Technical Specifications

Color Cameras

CCD MX4 CCD Mechanical

Filter

C7 High Resolution Color

Image Sensor 1/3 in CCD 1/3 in Interline Super-

HAD

Resolution 540 TVL color/ 540 TVL

mono

500 TVL

Effective Pixels

(NTSC)

768 (H) x 494 (V) 768 (H) x 494 (V)

Effective Pixels

(PAL)

752 (H) x 582 (V) 768 (H) x 582 (V)

Sensitivity 0.02 lx at F1.4 2.7 lx at F1.4

S/N Ratio Greater than 48 dB Greater than 48 dB

Output Signal 1 Vpp, 75 ohm

BLC On / Off selectable

Gain Control AGC automatic

Electronics Iris 1/60 to 1/100,000

(NTSC)

1/50 to 1/100,000

(PAL)

Voltage 12 - 24 VAC (50/60 Hz)

12 - 24 VDC

Power consumption 3.9 W max.

Loading...

Loading...