Page 1

Precision Engineered Opto-Electronics™

INSTALLATION INSTRUCTIONS

EX36N

Day / Night Vision Camera

MAN-36N-04

Page 2

IMPORTANT SAFETY INSTRUCTIONS

1. Read these instructions.

2. Keep this instruction.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with dry cloth.

7. Do not block any ventilation openings. Install

in accordance with manufacturer instructions.

8. Do not install near any heat sources such as

radiators, heat registers, stoves or other

apparatus (including amplifiers) that produce

heat.

9. Do not defeat the safety purpose of the

polarized or grounding-type plug. A polarized

plug has two blades with one wider than the

other. A grounding type plug has two blades

and a third grounding prong. The wide blade

or the third prong is provided for your safety. If

the provided plug does not fit into your outlet,

Page 3

consult an electrician for replacement of the

obsolete outlet.

10. Protect the power cord from being walked on

or pinched particularly at plugs, convenience

receptacles, and the power where they exit

from the apparatus.

11. Only use attachments/accessories specified by

the manufacturer.

12. Use only with the cart, stand, tripod, bracket,

or table specified by the manufacturer, or sold

with the apparatus. When a cart is used, use

caution when moving the cart/apparatus

combination to avoid injury from tip-over.

13. Unplug this apparatus during lightning storms

or when unused for long periods of time.

14.

Refer all servicing to qualified service

personnel. Servicing is required when the

apparatus has been damaged in a way,

such as power-supply cord or plug is

damaged, liquid has been spilled or objects

have fallen into the apparatus, the apparatus

has been exposed to rain or moisture, does

not operate normally, or has been dropped.

Page 4

IMPORTANT

For best results, please read this Instruction Booklet prior

to installing the EX36N camera.

WARNING !

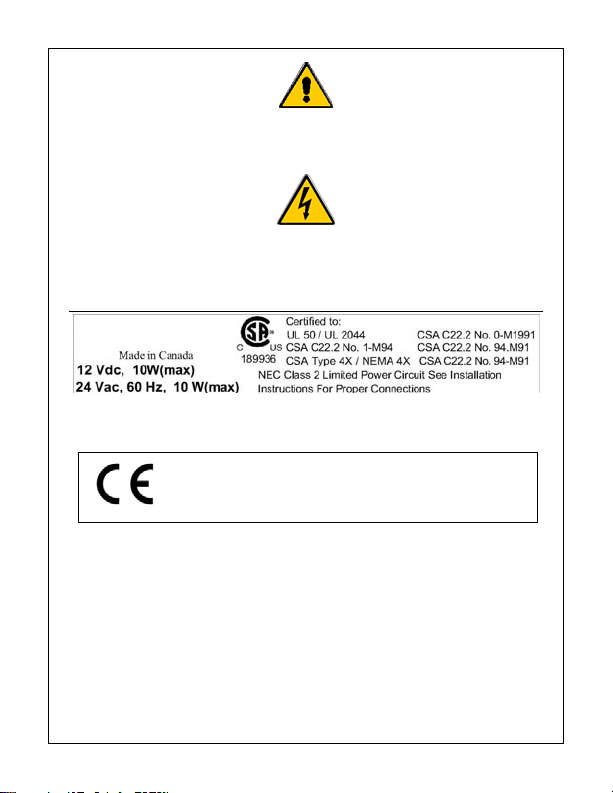

CSA Certified / UL Listed CLASS 2 power adaptors must

be used in order to comply with electrical safety standards.

This Product Has Been Certified By CSA International To

Include the Health Care Facility Requirements Of UL 2044.

EU Directives covered by this declaration:

72/9/EC Low Voltage Directives

Bosch Security Systems, Inc. will not be responsible for injuries

or damages resulting from the improper installation or use of any

product sold by Bosch Security Systems, Inc their agents,

distributors or dealers.

Page 5

NOTE: This equipment has been tested and found to

comply with the limits for a digital device, pursuant to

part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful

interference in a residential installation. As part of its’

normal operation this device can generate radio

frequency energy and if not installed and used in

accordance with the installation manual may cause

interference to radio communications. However, there

is no guarantee that interference will not occur on a

particular installation. If the device does cause

interference to radio or television reception the user is

encouraged to try to correct the interference by one or

more of the following measures:

1) Fit Ferrite beads on all cable to and from the power

supply box, within the box walls.

2) Route the composite cable between the camera and

the power supply in steel conduit piping over the entire

run of the cable up to and including connection to a

deep conduit base fitted under the camera and a

conduit fitting adaptor in the wall of the PSU box.

3) Contact BOSCH Service Center for further advice.

Page 6

INDEX – EX36

Page

Description.......................................................1

Unpacking........................................................2

Parts List..........................................................2

Items Required for Installation.........................2

Initial Preparations...........................................3

Guidelines........................................................3

Section 1. Faceplate Removal.......................4

Section 2. Input Power Connections .............7

Section 3. Mounting - Camera Housing ........9

Section 4. Camera –

Directional Adjustment...............12

Section 5. LEDs - Directional and

Power Adjustments.....................14

Section 6. Camera Re-Assembly ................16

Section 7. Troubleshooting – Camera.........18

Section 8. Troubleshooting – LEDs.............21

Section 9. General Specifications................23

Page 7

DESCRIPTION

The EX36N Night Vision Camera has been

designed with tilt on its faceplate to allow corner

mounting and provide better view angle in small

rooms. The housing and faceplate consist of

tough materials to withstand damage in hostile

environments such as prison cells and

psychiatric wards.

The smooth compact housing allows for tight

installations without exposed wiring or mounting

screws, while separate windows for the camera

lens and LEDs result in a perfect picture without

light rebound.

A photocell circuit is used to provide automatic

on/off infrared operation.

The voltage regulator circuit allows for 12V dc or

24V ac operation, and a range in between, also

providing protection from voltage surges,

transient spikes, and reverse voltage.

1

Page 8

UNPACKING

Care should be taken when unpacking the shipped

unit. Check the parts list and confirm all items have

been located. Inspect the equipment thoroughly to

ensure nothing was damaged in transit.

Contact BOSCH Service Center if a problem is

noted, see the rear page of this booklet for contact

numbers.

PARTS LIST (items supplied with unit)

- EX3x camera assembly

- Installation Instructions booklet

- Plastic bag containing one “security” Allen key

for removal of faceplate mounting screws

ITEMS REQUIRED FOR INSTALLATION

(not supplied with unit)

- Mounting hardware

- Mounting tools

2

Page 9

INITIAL PREPARATIONS

Determine the operating voltage at the

installation site.

Determine the optimum location for the

camera. Section 3, Mounting-Camera

Housing.

All cameras have been tested prior to

shipment. After the wiring has been

reconnected, it is advisable to check the

camera’s operation before installation.

GUIDELINES

The installation of the EX36N camera is

explained in Sections 1 to 6 listed below.

It is important that these steps are followed in

sequence:

1. Faceplate Removal

2. Input Power Connections

3. Mounting - Camera Housing

4. Camera Directional Adjustment

5. LED Directional and Power Adjustments

6. Camera Re-Assembly

3

Page 10

1. FACEPLATE REMOVAL

The faceplate must be removed prior to the

installation process. This is necessary because

the mounting holes need to be accessed. The

lens may need to have its directional angle

changed.

Refer to Figure 1-1 on page 5.

Step 1.1 - Place the camera housing on a flat

surface.

Step 1.2 - Use the supplied “security” Allen

wrench to remove the six screws

holding the faceplate into the

Step 1.3 - Remove the square foam cushion

attached to the camera lens.

Step 1.4 - Ensure the polycarbonate windows

housing.

in the faceplate are not scratched.

4

Page 11

FIGURE 1 – 1

Faceplate Removal

5

Page 12

This view shows the interior layout of the EX3xN

camera assembly after the faceplate has been

removed. Smaller details such as wiring and

terminal blocks are omitted for clarity. Refer to

the specific module sections for these details.

FIGURE 1 – 2

Layout of Modules

6

Page 13

2. INPUT POWER CONNECTIONS

The camera unit is pre-connected with an

electrically isolated power board for 24V ac or

12V dc operation with no wiring change or wiring

polarity. See Figure 2-1 and 2-2 for wiring

details.

Power

IN

Power

OUT

FIGURE 2 - 1

12VDC or 24VAC

Electrically Isolated Board, Camera VRB

7

Page 14

LED Power

Input

VRB Power

Input

FIGURE 2 -2

Board Connections, LED VRB

8

Page 15

3. MOUNTING - CAMERA HOUSING

Select a suitable location that is protected from

accidental damage, tampering, and

environmental conditions exceeding the camera’s

specifications.

Caution:

not place the camera in a situation where its

environmental specifications could be exceeded.

See page 24

Caution:

protected from falling objects, accidental contact

with moving objects, and unintentional

interference from personnel. Follow all applicable

building codes.

The selected mounting location should

Ensure the selected location is

The following installation guidelines must

be followed:

• Locate the camera such that it cannot be

easily interfered with, either intentionally or

accidentally.

• Select a mounting surface capable of

supporting the combined weight of the

camera and mounting hardware under all

9

Page 16

expected conditions of vibration and

temperature.

• Secure all cabling.

• Installations on drywall must use #8 screws

and #8 drywall nylon plugs or a superior

connection.

The camera’s mounting holes are located on the

left and right side of the housing.

Refer to Figure 3-1 on page 11.

Depending on the type of mounting surface

(brick, wood, etc.), it may be necessary to predrill these holes for the mounting screws. It is

recommended that these holes be marked using

the housing as a drill template and then drilled

separately. This way no burrs or debris will fall

into the housing.

Ensure the power and video cables are not

crimped or stressed after the camera has been

mounted.

10

Page 17

FIGURE 3 – 1

Mounting Holes – EX36 Camera Housing

11

Page 18

4. CAMERA - DIRECTIONAL

ADJUSTMENT

Both the camera and the LED array can be

adjusted for optimum picture quality.

The camera lens can be tilted on its axis via two

adjustment screws on the mounting bracket. It

can also be moved closer or farther away from

the viewing window.

Mount the Camera/LED Array Assembly into the

housing. Connect the video and power wires.

Check the picture for quality and directional

alignment.

Remove the Camera/LED Array Assembly if an

adjustment is required to the camera’s viewing

angle or picture quality.

Refer to Figure 4-1 on page 13.

12

Page 19

Loosen both adjustment screws for tilt or

horizontal directional alignment. This action may

require trial-and-error attempts to obtain perfect

picture alignment.

FIGURE 4 – 1

Camera Directional Alignment

13

Page 20

5. LED DIRECTIONAL AND POWER

ADJUSTMENTS

If the LEDs need to be adjusted for beam

spread, the Camera/LED Array Assembly does

not need to be removed from the housing. The

adjustment can be done by hand.

The EX3xN can be powered while making

adjustments, but make sure the power cable is

not pinched or chafed during this procedure.

Cover or adjust the photo-cell to turn the LEDs

“ON” (850nm LEDs will have a slight red glow

while 940nm LEDs are covert). Adjust the LED

power if they are too bright.

Refer to Figure 5-1 on page 15.

In some cases it may be necessary to bend the

LEDs slightly for better beam spread. Do not use

your fingers for this function. Use a flat wooden

object and gently push the outside row of LEDs

inwards or outwards. The camera should be

“ON” while this adjustment is in progress.

14

Page 21

LED ARRAY - POWER ADJUSTMENTS

If adjustment is needed, remove the rear cover for

access to the LRB. The EX36N needs to be

powered-up while making the LED power

adjustments. Cover the photocell to turn the LEDs

“ON” (850nm LEDs will have a slight red glow).

For photocell “On/Off” light-level adjustment, rotate

VR2. Clockwise is off and counter-clockwise is on.

LED Power

Adjustment

Photocell On/Off

Adjustment

LED Power and Photocell On/Off Adjustments

Adjust the LED power if they are too bright or too

dim. For IR power adjustment, rotate VR1.

Clockwise is high and counter-clockwise is low.

FIGURE 5 - 1

LED Array Power Adjustments

15

Page 22

6. CAMERA RE-ASSEMBLY

Make sure all wires are properly connected, all

holes are sealed against moisture penetration,

and all mounting screws are tight.

Step 6.1 - Slide the square foam pad over the

camera’s lens. Make sure the pad is

as close to the faceplate viewing

window as possible and the

photocell is not covered by the foam

pad. The foam pad is not

symmetrical. Make sure the LEDs

are not covered when installing the

pad.

Step 6.2 - Re-attach the faceplate with the six

tamper resistant screws. Tighten

carefully but do not over-tighten.

Step 6.3 - Power-up the camera and check its

operation.

Refer to Figure 6-1 on page 17.

16

Page 23

photocell

The foam pad is not symmetrical. Make sure the

LED is not covered when installing the foam

pad.

FIGURE 6 – 1

Camera Re - Assembly

17

Page 24

7. TROUBLESHOOTING - CAMERA

PROBLEM POSSIBLE

CAUSE

No Video 1. Power

Supply:

Connections….

-Voltage

Range...

2. Video

Connections

:

LIKELY

SOLUTION

Check input power

connections at the

terminal:

* AC input wires

to “ ac IN”.

* DC input wires

to “ dc IN”.

* Loose wires.

The supply range is:

12 – 28V ac OR

10.5 – 40V dc for the

camera section.

Measure the voltage

at the terminal block.

Determine if wiring

polarity at “Video

Connector” terminal

block is correct.

( V and GND )

18

Page 25

No Video

(cont’d.)

__________

Poor

Picture

Quality

Snowy

Image

2. Video

Connections:

(cont’d.)

Poor Video

Signal

Noisy Power

Supply

If still no video,

connect the camera

directly to the

monitor. Check the

video signal. If okay,

the problem is with

the interconnections.

If still no video,

contact BOSCH

Service Center. See

rear page of this

manual for contact

information.

_________________

Ensure video cable

is correctly matched

and terminated with

75 ohms at each

end. Make sure

video cables are

similar types.

Check connections.

Relocate or replace

power supply.

19

Page 26

Horizontal

Scan Lines,

Rolling Up

or Down.

Reversed

video or

faded image

Ground

Looping on

video cable

Low voltage

Check the coax

cable shield is not

touching ground, e.g.

at couplings.

Check voltage at

input power cable.

Must be >10.5V dc

or >12Vac for

camera section.

Check video leads

for reversed

connections.

20

Page 27

8. TROUBLESHOOTING - LEDs

Fuse Blows

Don’t know if LEDS are

“ON”

LEDs are not “ON”

PROBLEM

POSSIBLE SOLUTION

- Check fuse rating.

- Check for shorting between

the enclosure and the

input power.

850nm LEDs will have a

faint red glow when “ON”.

940nm LEDs are covert.

Aim the LEDs directly at an

IR sensitive camera to see

the lights or wait for the

LEDs to warm up (two

minutes).

- Cover the photo sensor to

activate power to the LEDs

( up to 30 seconds delay

for activation ).

- Adjust the photocell’s

variable resistor towards

the “ON” position.

- Adjust power to the LEDs.

- Measure input voltage

>12VDC

21

Page 28

PROBLEM

LEDs are not turning

“OFF” when sufficient

ambient light is present

POSSIBLE SOLUTION

- Make sure the photo

sensor is not covered or

hidden behind any object.

- Adjust the photocell’s

variable resistor towards

the “OFF” position.

The LEDS will stay “ON”

or “OFF” if the adjustments

are at full turn.

22

Page 29

9. GENERAL SPECIFICATIONS

CCD Sensor...................1/3’’ – IR Optimized

Video Signal Output............ 1 V p-p, 75 Ohm

LED Type............High Perf. 850nm / 940nm

Operational Range................-50°C to +50°C

(-58°F to 122°F)

Humidity Range.............Up to 85% (relative)

Power Supply.....................12V dc or 24V ac

(60Hz), 19W

Window............Polycarbonate (1/4” LEXAN)

Housing.............................Steel, welded and

powder coated paint

Dimensions..........................8.3” (211mm) W

6.0” (152mm) D

5.5” (140mm) H

Weight..................................2.64 lbs. (1.2kg)

Subject To Change Without Notice.

23

Page 30

Note:

Page 31

Note:

Page 32

Americas

Bosch Security Systems, Inc.

850 Greenfield Road

Lancaster, Pennsylvania 17601

USA

Telephone+1 888-289-0096

Fax +1 585-223-9180

Email: security.sales@us.bosch.com

www.boschsecurity.us

Europe, Middle East, Africa:

Bosch Security Systems B.V.

P.O. Box 80002

5600 JB Eindhoven,

The Netherlands

Phone: + 31 40 2577 284

Fax: +31 40 2577 330

emea.securitysystems@bosch.com

www.boschsecurity.com

© Bosch Security Systems, Inc. 2009; Data subject to change

without notice.

Asia-Pacific:

Bosch Security Systems Pte Ltd

38C Jalan Pemimpin

Singapore 577180

Phone: +65 6319 3450

Fax: +65 6319 3499

apr.securitysystems@bosch.com

www.boschsecurity.com

Loading...

Loading...