Bosch DUH30152U, DUH36152U, DUH36252U Installation Manual

Bosch

ventilation installation

DUH Models

manual

APPROVED FOR RESIDENTIAL APPLIANCES

FOR RESIDENTIAL USE ONLY

READ AND SAVE THESE INSTRUCTIONS

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING.

INSTALLATION MUST COMPLY WITH ALL LOCAL CODES.

IMPORTANT: Save these Instructions for the Local Electrical Inspector’s use.

INSTALLER: Please leave these Instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

Safety Warning: Turn off power circuit at service panel and lock out panel, before wiring this appliance.

Requirement: 120 V AC, 60 Hz. 15 or 20 A Branch Circuit

2

IMPORTANT SAFETY INSTRUCTIONS

Read All Instructions Before Using the Appliance.

READ AND SAVE THESE INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE

THE FOLLOWING:

A. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact

the manufacturer.

B. Before servicing or cleaning the unit, switch

power off at service panel and lock service

panel disconnecting means to prevent power

from being switched on accidentally. When the

service disconnecting means cannot be locked,

securely fasten a prominent warning device,

such as a tag, to the service panel.

C. Installation Work and Electrical Wiring Must Be

Done By Qualified Person(s) In Accordance

With All Applicable Codes & Standards,

Including Fire-rated Construction.

D. Sufficient air is needed for proper combustion

and exhausting of gases through the flue

(chimney) of fuel burning equipment to prevent

back- drafting. Follow the heating equipment

manufacturers guideline and safety standards

such as those published by the National Fire

Protection Association (NFPA), the American

Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the

local code authorities.

E. When cutting or drilling into wall or ceiling, do

not damage electrical wiring and other hidden

utilities.

F. Ducted systems must always be vented to the

outdoors.

WARNING

CAUTION

FOR GENERAL VENTILATING USE ONLY.

NOT USE TO EXHAUST HAZARDOUS OR

EXPLOSIVE MATERIALS OR VAPORS.

CAUTION

To reduce risk of fire and to properly exhaust

air, be sure to duct air outside - do not vent

exhaust air into spaces within walls, ceilings,

attics, crawl spaces, or garages.

WARNING

TO REDUCE THE RISK OF FIRE, USE ONLY

METAL DUCT WORK.

Install this hood in accordance with all

requirements specified.

WARNING

To Reduce The Risk Of Fire Or Electric Shock,

Do Not Use This Hood With Any External Solid

State Speed Control Device.

OPERATION

a. Always leave safety grills and filters in place.

Without these components, operating blowers

could catch onto hair, fingers and loose clothing.

The manufacturer declines all responsibility in the

event of failure to observe the instructions given

here for installation, maintenance and suitable use

of the product. The manufacturer further declines

all responsibility for injury due to negligence and

the warranty of the unit automatically expires due to

improper maintenance.

DO

This unit is manufactured for indoor use only. Do not use this unit outdoors.

3

IMPORTANT SAFETY INSTRUCTIONS

Read All Instructions Before Using the Appliance.

READ AND SAVE THESE INSTRUCTIONS

Electrical requirements

IMPORTANT

Observe all governing codes and ordinances.

It is the customer’s responsibility:

To contact a qualified electrical installer.

To assure that the electrical installation is adequate

and in conformance with National Electrical Code,

ANSI/NFPA 70 — latest edition*, or CSA Standards

C22.1-94, Canadian Electrical Code, Part 1 and

C22.2 No.0-M91 - latest edition** and all local

codes and ordinances.

If codes permit and a separate ground wire is used,

it is recommended that a qualified electrician

determine that the ground path is adequate.

Do not ground to a gas pipe.

Check with a qualified electrician if you are not sure

range hood is properly grounded.

Do not have a fuse in the neutral or ground circuit.

IMPORTANT

Save Installation Instructions for electrical

inspector’s use.

The range hood must be connected with copper

wire only.

The range hood should be connected directly to the

fused disconnect (or circuit breaker) box through

metal electrical conduit.

Wire sizes must conform to the requirements of the

National Electrical Code ANSI/NFPA 70 — latest

edition*, or CSA Standards C22.1-94, Canadian

Electrical Code Part 1 and C22.2 No. 0-M91 - latest

edition** and all local codes and ordinances.

A U.L.- or C.S.A.-listed conduit connector must be

provided at each end of the power supply conduit

(at the range hood and at the junction box).

Copies of the standards listed may be obtained from:

* National Fire Protection Association Batterymarch Park

Quincy, Massachusetts 02269

** CSA International 8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

4

Parts Included with your Hood

• Hood Canopy Assembly with Round Metal

Transition installed.

• Rectangular Metal Transition with Back draft

dampers.

• Care & Use /Installation Instructions

• 2 Filters

• Fitting Screws.

Parts Not Included with your

Hood

• Duct Tape

• 1/2" Conduit

• Wire Nuts

• Round or Rectangular Duct.

• Charcoal filters

• Round back draft damper

• Wiring clamp

• Models DUH30252UC and DUH36252UCOnly:

CAUTION! Lamps are not supplied, use

ONLY 120 Volt, 50 Watt (maximum) 50°

halogen light made or a GU10 base.

Tools required

Flat blade and Phillips screwdrivers

Pencil

Metal snips (in some applications)

Electric drill

Saw (saber or keyhole)

Duct tape

Pliers

Level

Caulking

Tape measure

1/4.pivoting hex socket

Flashlight

Wire stripper

1/4. Nutdriver

Small hammer

INSTALLING THE HOOD

• For the most efficient air flow exhaust, use a

straight run or as few elbows as possible.

CAUTION: Vent unit to outside of

building, only.

• One person is necessary for installation.

On avarage 2 hours are necessary to complete

installation (without considering cut to be done

on wall and or on cabinet, installation of ducts ,

conduit and electrical connections to the mains).

16 installation steps are required.

• The hood is fitted with Screws and Drywall

Anchors suitable for most surfaces, consult a

Qualified Installer, check if they perfectly fit with

your cabinet/wall.

• Do not use flex ducting.

• COLD WEATHER installations should have an

additional backdraft damper installed to

minimize backward cold air flow and a

nonmetallic thermal break to minimize

conduction of outside temperatures as part of

the ductwork. The damper should be on the

cold air side of the thermal break.

The break should be as close as possible to

where the ducting enters the heated portion of

the house.

• Remote blowers require a five wire installation.

• Make up air: Local building codes may require

the use of Make-Up Air Systems when using

Ducted Ventilation Systems greater than

specified CFM of air movement.

The specified CFM varies from locale to locale.

Consult your HVAC professional for specific

requirements in your area.

• Typical installation

Min installation height from the countertop to the

bottom of the hood is 24” to 30“.These hoods

are not recommended to be used over indoor

grills.

5

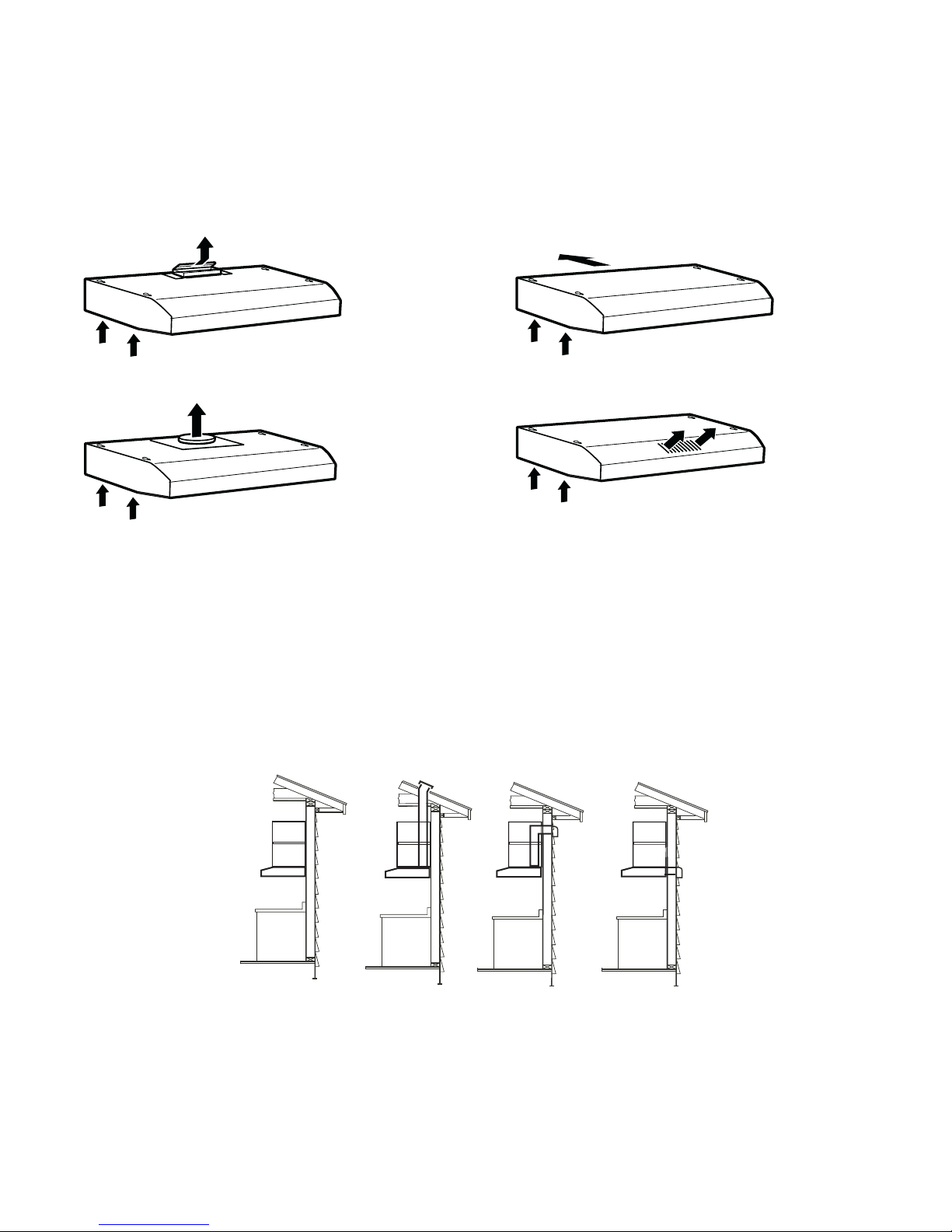

1. Choose vent options

Vent Exhaust Option

The hood is designed for vertical or horizontal

discharge or can be installed in a recirculating

ductless version:

Vertical discharge:

Use a rectangular duct 3 1/4” x 10”.....

Horizontal discharge:

Use a rectangular duct 3 1/4” x 10”

....or use a round 7” duct

Examples of possible ducting

Recirculating (non vented ductless)

Horizontal dischargeVertical dischargeRecirculating

6

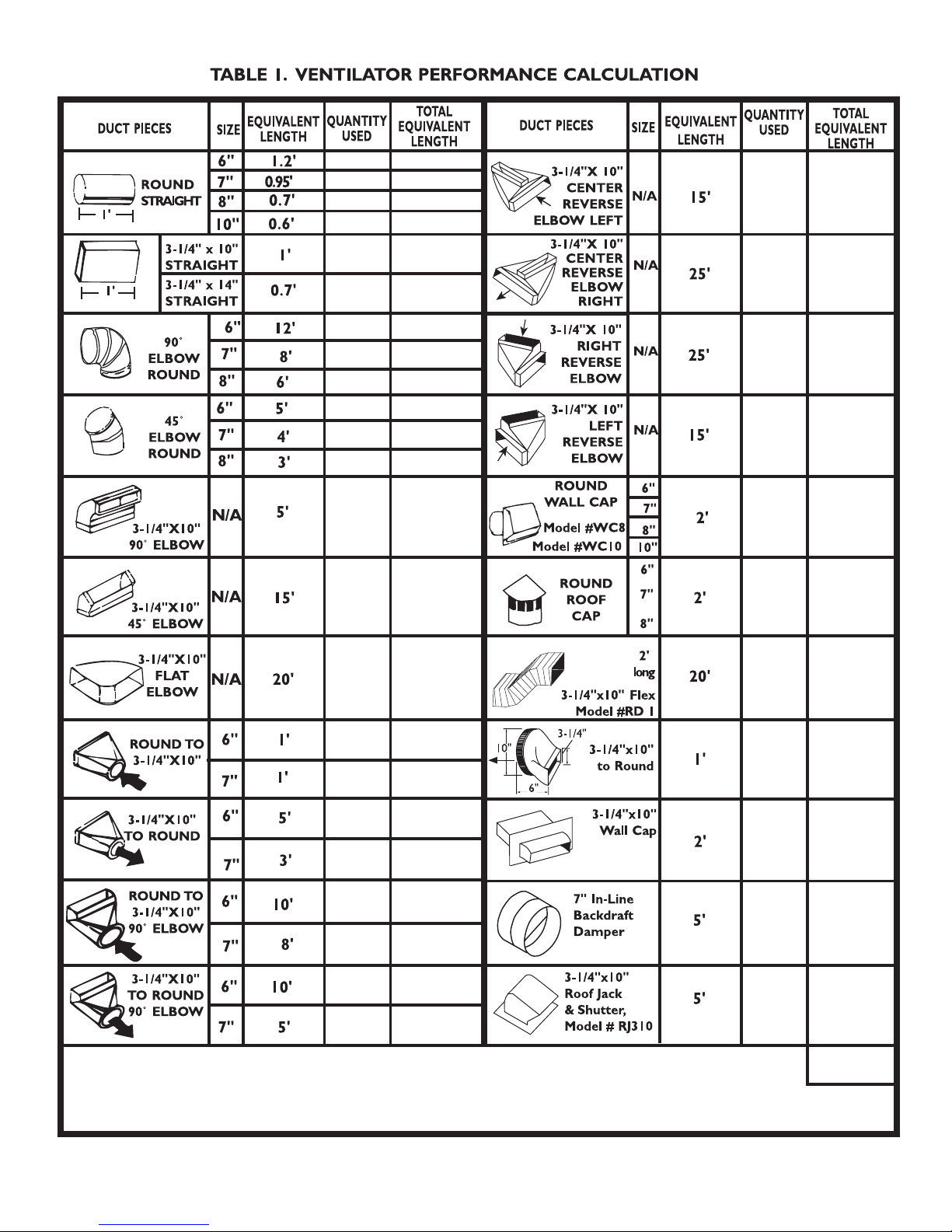

TOTAL (of both columns)=

7

TABLE 2. DUCTWORK

INSTALLATION GUIDELINES

For safety reasons, ducting should vent directly

outdoors (not into an attic, underneath the

house, into the garage or into any enclosed

space).

Keep duct runs as short and straight as

possible.

Duct fittings (elbows and transitions) reduce air

flow efficiency.

Back to back elbows and „S“ turns give very

poor delivery and are not recommended.

A short straight length of duct at the inlet of the

remote blower gives the best delivery.

Transition to duct from the integral blower or

remote duct transition as close to the downdraft

as is pos-sible.

In order of preference, use

1st. 10" round duct

2nd. 8" round duct

3rd. 3-1/4" x 14" duct

4th. 7" round duct

5th. 3-1/4" x l0" duct

6th. 6" round duct

The use of flexible metal round duct should

only be used when no other duct fitting exists.

Limit use to short lengths and do not crush

when making corners.

After having choosen the vent option, proceed

as follows:

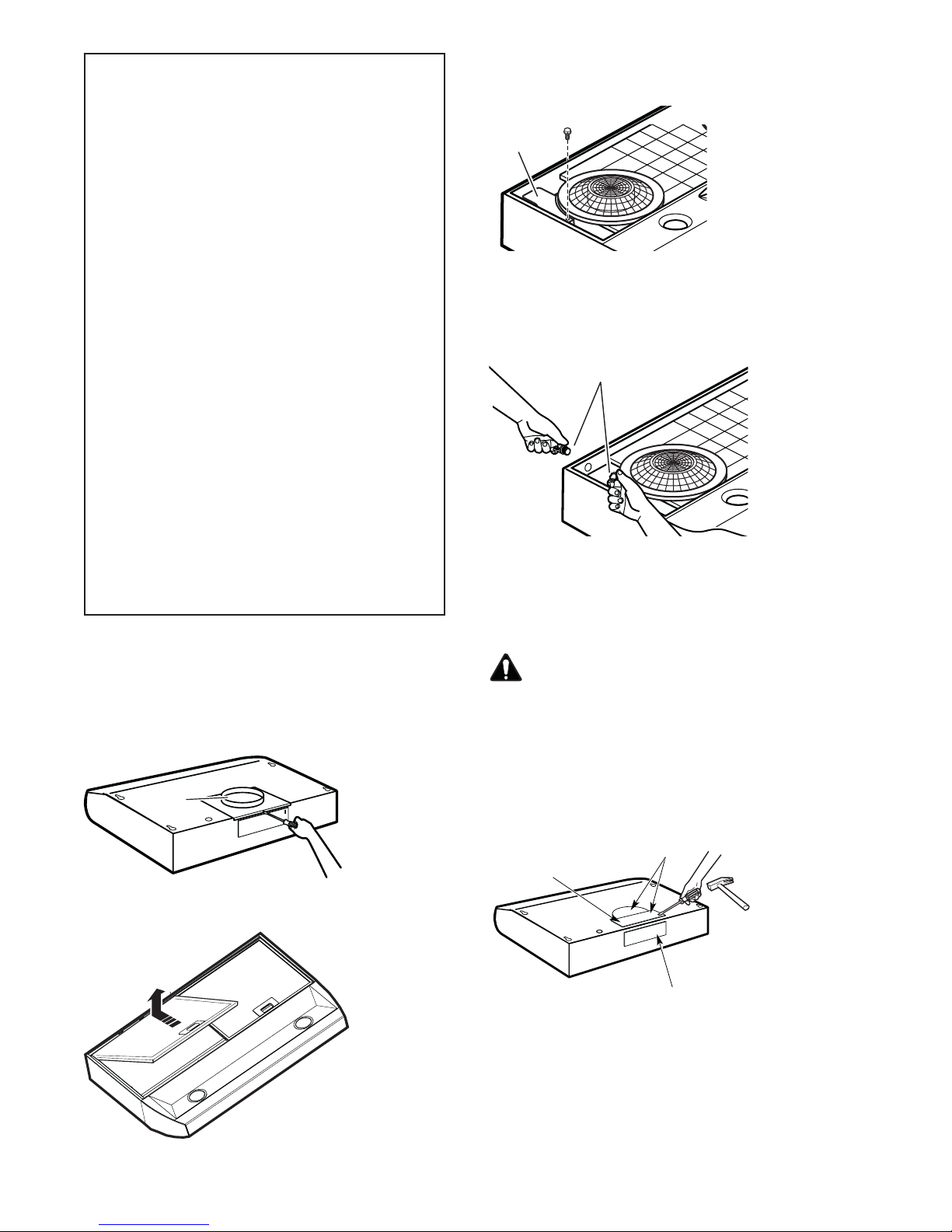

2. Remove the round transition from its seat by

unscrewing the its fixing screws (save the

screws).

7" Round

Transition

4. Remove the junction box cover.

J-Box

Cover

Remove either the top or the back wiring knockout

according the preference and install an approved

wiring clamp

wiring

clamp

5. Remove the duct knockouts using a flat blade

screwdriver

and a small hammer.

Use the screwdriver by knocking out the pannel in

similar fashion to a scalpel.

Take care of sharp edges.

Attention!

If is intended to use the hood in recirculating version do

not remove any duct knockouts and order the necessary

charcoal filter from your supplier.

Round

vertical

R2

discharge

R1

Rectangular

vertical

discharge

3. Remove the grease filters.

Rectangular

horizontal

R1

discharge

R1= Remove rectangular duct knockout only.

R2 = Remove semicircular and rectangular duct

knockouts.

8

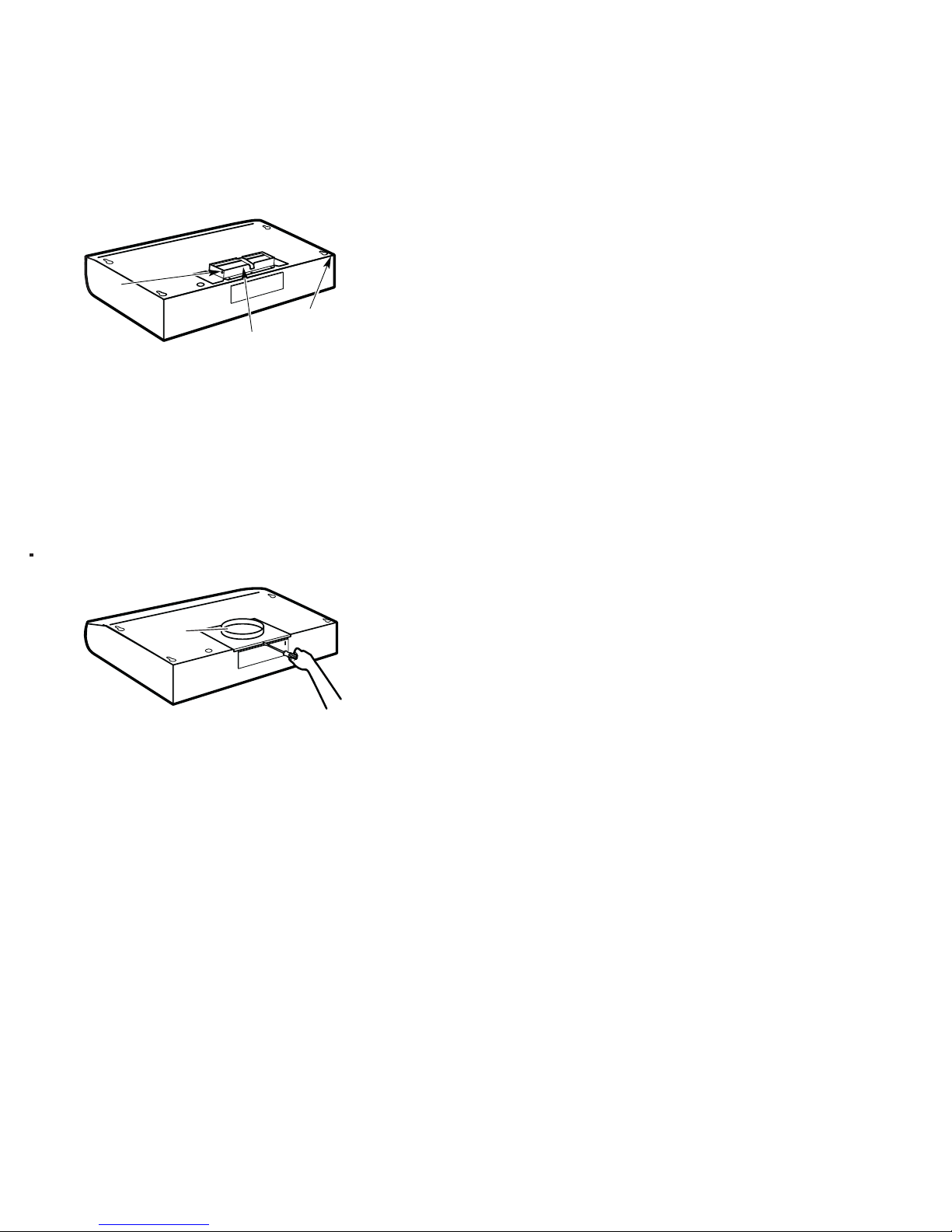

6. For rectangular ducted discharge installations

only (otherwise skip to next step)

Attach exhaust adaptor/damper over knockout

opening with two exhaust adaptor screws. Make sure

damper pivot is nearest to top/back edge of hood.

Remove tape from damper flap.

Pivot

Top/back

edge

Exhaust

transition/damper

NOTE: The exhaust adaptor/damper can be

installed up to 1 inch on either side of the hood

center to accommodate off-center ductwork. In

extreme off-center installations, one end of the duct

connector may need to be trimmed to clear the

electrical cable clamp.

7. For round ducted discharge installations only

Re-install the round transition with its screws.

7" Round

Transition

NOTE: The round transition can be installed up to 1

inch on either side of the hood center to

accommodate off-center ductwork. In extreme offcenter installations, one end of the duct connector

may need to be trimmed to clear the electrical cable

clamp.

9

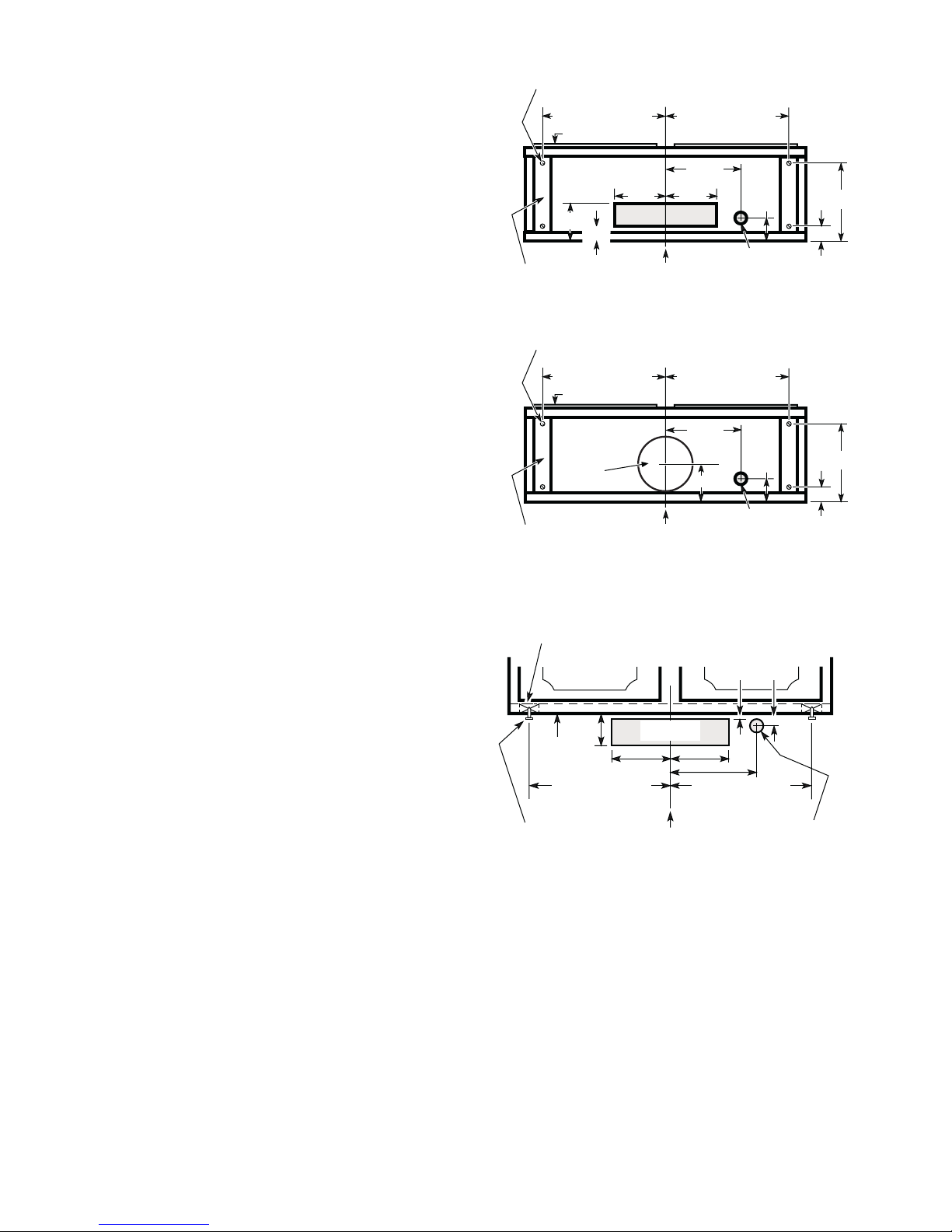

8. Mark holes

Select the vent option that your installation will

require and proceed to that section:

Outside top exhaust

(Vertical duct– 3 1/4”x 10” Rectangular)

Use the diagram or the hood as a template and

mark the locations on the cabinet for ductwork,

electrical wiring and keyhole screw slots.

Outside top exhaust

(Vertical duct–7” Round)

Use the diagram or the hood as a template and

mark the locations on the cabinet for ductwork,

electrical wiring and keyhole screw slots.

Hood mounting screws (4)

13 15/16" (30" Hood)

16 15/16" (36" Hood)

Cabinet front

Cabinet Bottom

"

5"

"

1 1/4"

Wood shims (recessed

bottom cabinets only)

Hood mounting screws (4)

13 15/16" (30" Hood)

16 15/16" (36" Hood)

Cabinet front

Cabinet Bottom

Access

hole for 7"

round duct

Wood shims (recessed

bottom cabinets only)

5 1/4"

Vertical duct

access hole

8" DIA.

HOLE

13 15/16" (30" Hood)

16 15/16" (36" Hood)

12 9/16"

5 1/4"

Electrical access hole

Center

line

Center

line

Electrical access hole

(in cabinet bottom)

(in cabinet bottom)

13 15/16" (30" Hood)

16 15/16" (36" Hood)

12 1/2"

5"

Electrical access hole

Electrical access hole

(in cabinet bottom)

(in cabinet bottom)

"

2"

"

2 1/4"

10 1/2"

1 1/4"

10 1/2"

1 1/2"

Outside rear exhaust

(Horizontal duct– 3 1/4”x 10” Rectangular)

• Use the diagram or the hood as a template and

mark the locations on the cabinet for ductwork,

electrical wiring and keyhole screw slots.

Recirculating

Use the hood as a template and mark the locations

on the cabinet for the electrical wiring and keyhole

screw slots.

Since the hood is to be recirculated (not to be

vented outside), do not cut out any vent openings in

the wall or cabinet bottom.

Wood shims (recessed

bottom cabinets only)

3 3/4"

Cabinet

bottom

13 15/16" (30" Hood)

16 15/16" (36" Hood)

Hood mounting screws (4)

Cabinet front

Horizontal duct

access hole

5 1/4" 5 1/4"

Center line

12 7/16"

13 15/16" (30" Hood)

16 15/16" (36" Hood)

1/8"

7/16"

Electrical access hole

(in wall)

10

Loading...

Loading...