Page 1

Page 2

2

en

page 13–16

fr

page 17– 30

es

página 31 – 44

Page 3

3

몇 WARNING

To reduced the risk of fire, electric shock,

or injury to persons, observe the following:

A. Installation work and electrical wiring

must be done by authorized person(s)

in accordance with all applicable

codes and standards, including firerelated construction.

B. Sufficient air is needed for proper

combustion and exhausting of gases

through the flue (chimney) of fuel burning equipment to prevent backdrafting. Follow the heating equipment

manufacturer’s guideline and safety

standards such as those published by

the National Fired Protection Association (NFPA), and the American Society

for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE),

and the local code authorities.

C. When cutting or drilling into wall or

ceiling, do not damage electrical

wiring and other hidden utilities.

D. Ducted fans must always be vented

to the outdoors.

E. Always unplug or disconnect the

appliance from the power supply

before servicing.

F. This unit is designed for indoor use

only. Use this unit only in the manner

intended by the manufacturer.

G. Make certain the cooktop is appro-

priate for use with a downdraft vent.

H. Not intended for use with professio-

nal-style cooktops.

몇 WARNING

For general ventilating use only. Do not

use to exhaust hazardous or explosive

materials and vapors.

To reduce risk of fire and to properly

exhaust air, be sure to duct air outside.

Do not vent exhaust air into spaces within walls, ceilings, attics, crawl spaces or

garages.

To reduced the risk of fire, use only metal

duct work.

To reduce the risk of fire, electric shock

and injury to persons, Downdraft must

be used with Internal, Remote or Inline

Blower.

To reduce the risk of fire or electric

shock, do not use the fan with any solidstate speed control device.

This appliance has been found to be in

compliance with UL 507 Standard for

Electric Fans and CAN/CSA-22.2 No.

113 Canadian Standard for Fans and

Ventilators. It is the responsibility of the

owner and the installer to determine if

additional requirements or standard apply in specific installation.

몇

SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE.

READ AND SAVE THESE INSTRUCTIONS

Page 4

4

Parts Needed (standard)

G Tape Measure

G Phillips Head Screwdriver

G Aluminum Duct Tape

G Ductwork (configuration varies depen-

ding on location; See pages 7-12 for further information)

G Additional Sheetmetal screws (as neces-

sary for ductwork installation)

G Saw (or equivalent for cutting counter-

top)

G #8 x 1 1/4” Wood Screws (4)

G Plumb Bob

G Wire to reach Remote or Inline Blower

Parts Needed (special)

G Special Blower

G Transition Box (for use only with Inline

and Remote Blowers)

G Recirculation Module (used only for recir-

culation applications)

Note: Downdrafts work with these blowers: 600 CFM Integrated, Remote or Inline

Blowers 1000 CFM Remote or Inline Blowers

Parts Supplied

G Downdraft assembly (1)

G #8 Sheetmetal Screws (8)

G Blower Cord Strain Relief (1)

G Hardware for brackets on vent (2)

G Remote Blower Pigtail

Page 5

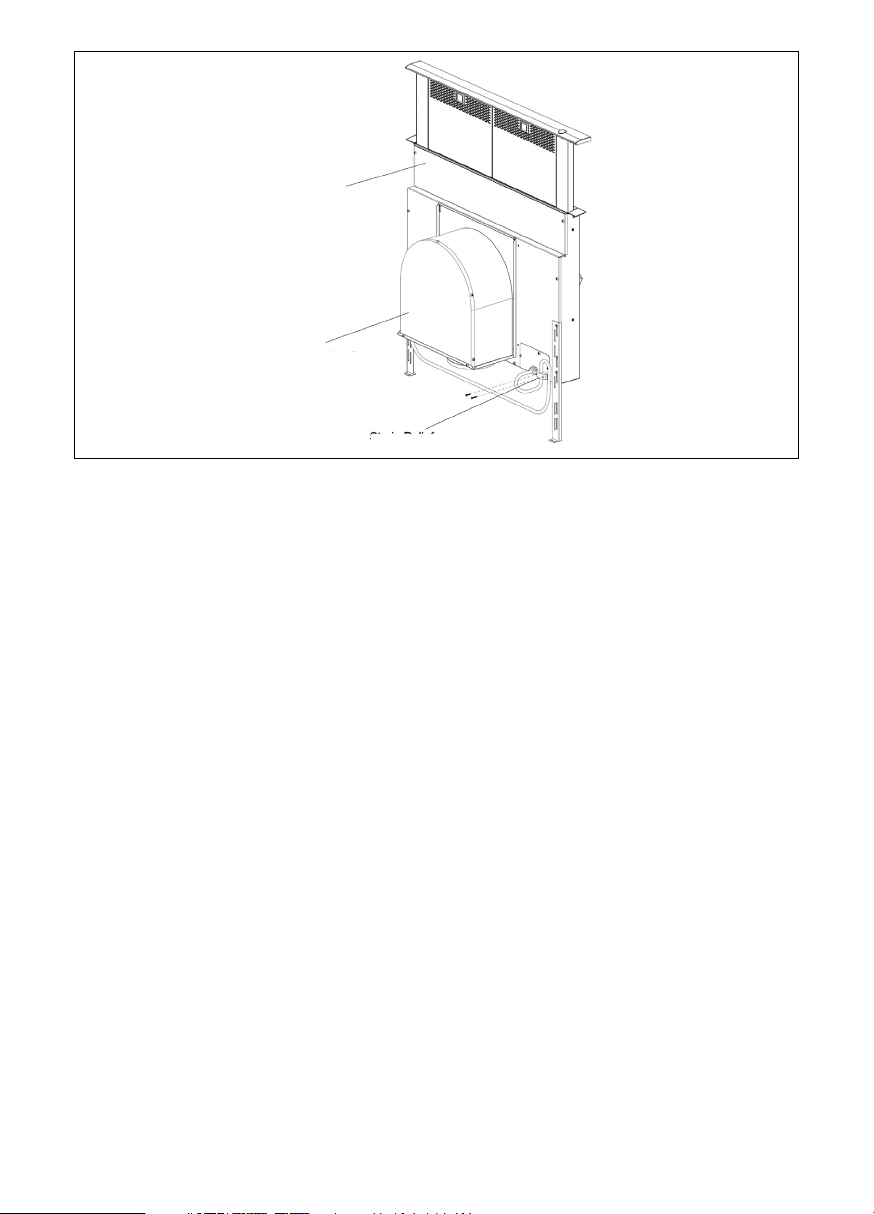

INTRODUCTION

GENERAL DESCRIPTION

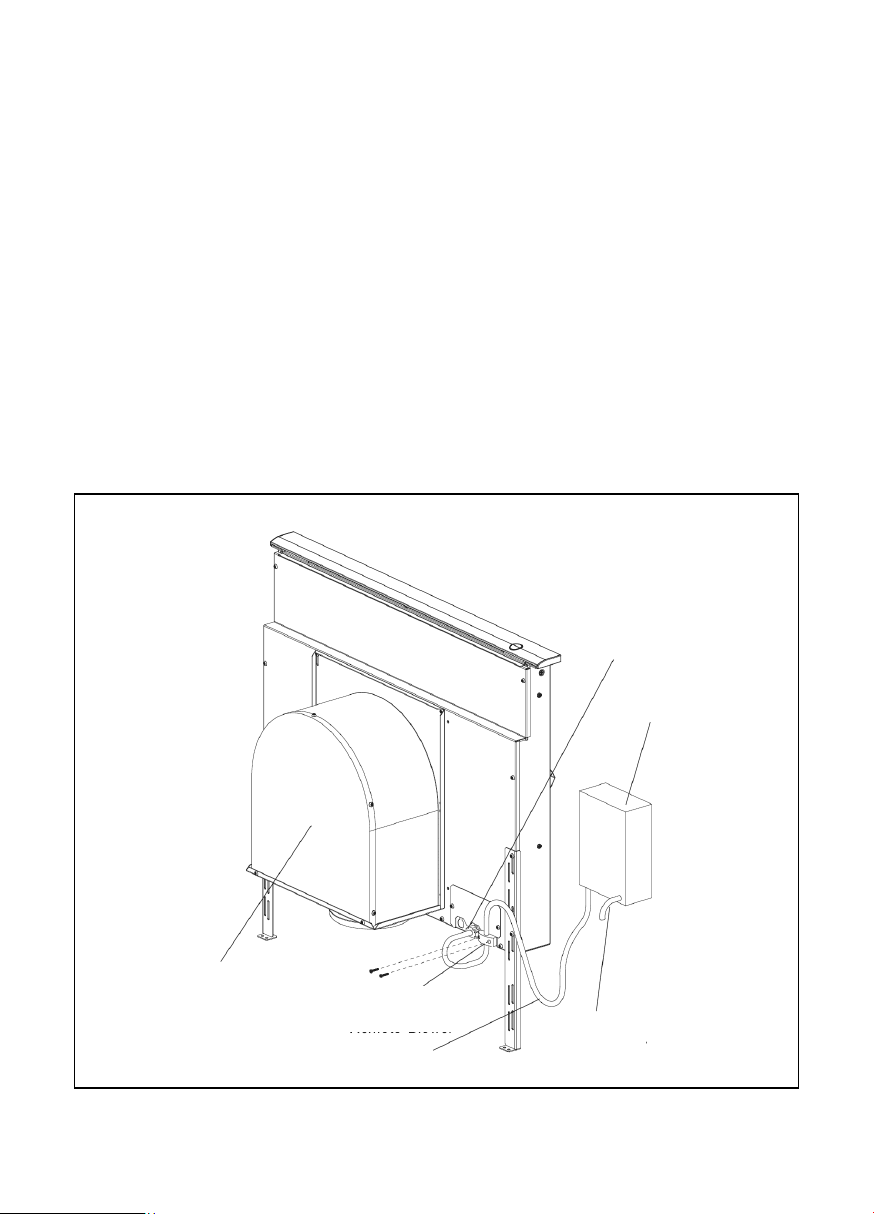

The complete downdraft system consists of

the downdraft, a blower and a transition

box if using an Inline or Remote Blower. A

recirculation module is also available when

ducting to the outside is not preferred or

not possible. (See Fig. 1).

The blower can be either integral (mounted

on the vent intake in the cabinet under the

cooktop), an inline (mounted between the

kitchen and exterior wall anywhere within

the duct line), or a remote (mounted on the

roof or outside wall). When a remote or inline blower is used, a duct transition is

mounted on the ventilator intake in place of

the integral blower to connect the intake to

the duct work. The duct transition must be

purchased separately.

The integral blower or duct transition can

be mounted in different positions on the

intake to route ductwork to avoid cabinet,

building framing, utilities, etc.

The downdraft system is available in 30inch or 36- inch. Intended for non-professional style cooktops only.

A Recirculation Kit can be purchased separately and used in conjunction with the Integral Blower if ducting to the outside is not a

viable option.

Step 1: Plan the installation

Carefully follow the planning procedures

listed below (See Figure 2). Sketches are

NOT intended to be a replacement for

careful planning.

A. Determine whether a remote, inline, or

integral blower will be used. Remote

and inline blower installation requires

4 wires plus a ground wire to run from

the downdraft to the blower.

B. Make sure that adequate cabinet and

counter space has been provided and

that the intake and blower will be accessible if service is required.

C. Consider that cross drafts created by

adjacent open windows, doors, air conditioning, old heating vents, recessed

ceiling lights, and traffic patterns may

affect performance.

D. For gas cooktop installations make sure

that a minimum 10 square inch opening

is provided in the toe-kick or other cabinet area. Inadequate ventilation of the

cabinet below the cooktop may result in

flame outage when operating the vent

system.

E. Provide for air supply or ”make-up

air” to the room where unit will be

installed. If ”make-up air” is not provided, then problems, such as fireplace

chimney downdrafts, could result.

Fig. 1

5

Downdraft - Unit

Strain Relief

Blower /

Duct Transition Box

(Not Included)

Page 6

Fig. 2

F. Investigate potential ductwork routes

and choose the shortest possible route

from the unit to an outside wall or to the

roof via an inside wall and attic. For guidance, typical ducting installations are

shown in figures 3 through 6. Installation

in island locations will require under floor

ducting. Peninsula locations usually

require ducting laterally through cabinets

or under cabinet toe spaces. Consider

potential interferences to ductwork from

building framing (floor joists, wall studs,

etc.) and utilities (electrical wiring, water,

gas, or sewer lines, etc).

G. Purchase the necessary ductwork as

needed to duct to the outside or purchase separately the downdraft Recirculation Module if ducting to the outside is not

a viable option.

• Be certain to avoid interference with gas and electric supply to cooktop.

• Shelving and drawer depths

are dependent upon cooktop depth and setback.

6

Dimension depends on Countertop

min.

Vent

Blower /

Duct Transition Box

Dimension depends on Cabinet

Page 7

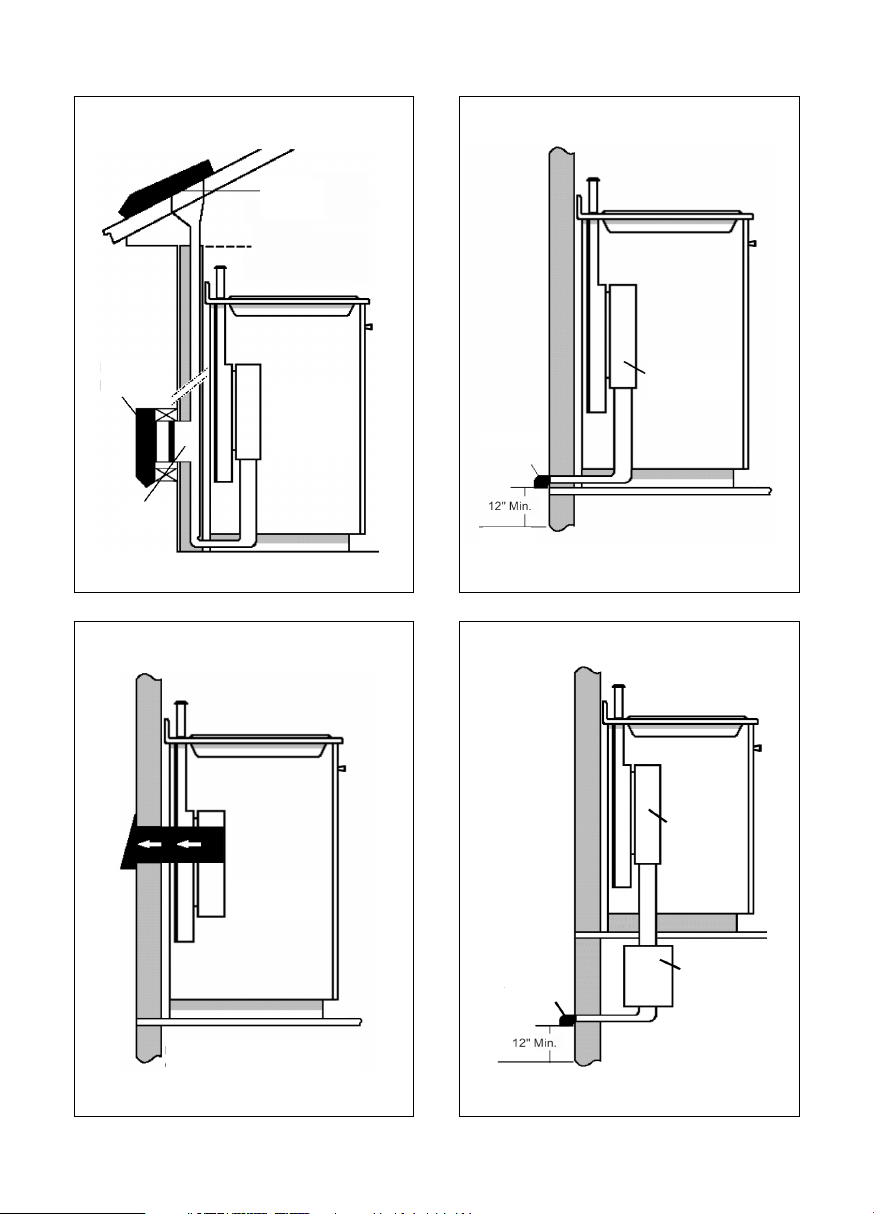

Figures 3 through 6 are examples of possible ducting

Fig. 3

Remote Blower

Roof Mount Installation

Through wall installation

Fig. 4

Integral Blower

Through Wall Installation

Fig. 5

Integral Blower

Through Wall Installation

Fig. 6

Inline Blower

Through Wall Installations

7

Remote

Blower

Remote

Blower

Duct

Transition

Box

Collar

Ground

Wall Cap

Duct

Transition

Box

Wall Cap

Ground

Inline

Blower

Integral Blower

BLOWER ROTATED 90° FOR SIDE

CONNECTION

Integral Blower

Page 8

DUCTWORK INSTALLATION GUIDELINES

G Ducting should vent directly outdoors

(not into an attic, underneath the house,

into the garage or into any enclosed

space). A Recirculation Module is available when ducting to the outside is not

possible.

G Keep duct runs as short and straight as

possible.

G Duct fittings (elbows and transitions)

reduce air flow efficiency.

G Back to back elbows and ”S” turns give

very poor delivery and are not recommended.

G A short straight length of duct at the inlet

of the remote blower gives the best delivery.

G Transition to duct from the integral blo-

wer or remote duct transition as close to

the downdraft as is possible. In order of

preference, use

1st. 10” round duct

2nd. 8” round duct

3rd. 3-1/4” x 14” duct

4th. 7” round duct

5th. 3 -1/4” x 10” duct

6th. 6” round duct

G The use of flexible metal round duct

should only be used when no other duct

fitting exists. Limit use to short lengths

and do not crush when making corners.

G Back to back elbows should be avoided.

DUCTWORK INSTALLATION

GUIDELINES

G Where local codes permit, plastic pipe

(PVC-schedule 40 pipe or ABS pipe 7”

or 8” diameter) can be used in areas of

high ground moisture and in slab floors

to eliminate future rusting.

G Use only duct work constructed of mate-

rials that are acceptable by the applicable codes. All duct should be 26 gauge

or heavier to minimize flex due to air

flow.

G The remote blowers require a 10” or 6”

diameter round duct (depending on

model) to match the inlet ring. A transition is necessary from other duct sizes.

G Use sheet metal screws as required to

support the duct weight, and seal all

joints with duct tape.

G Be certain that the duct work does not

interfere with floor joists or wall studs.

G Do not exhaust more than one vent into

a single duct run.

G Cold weather installations should have

an additional backdraft damper installed

to minimize backward cold air flow and a

nonmetallic thermal break to minimize

conduction of outside temperatures as

part of the ductwork. The damper

should be on the cold air side of the

thermal break. The break should be as

close as possible to where the ducting

enters the heated portion of the house.

G Always use an appropriate roof or wall-

cap with damper. Laundry type wall caps

should never be used.

8

Page 9

Step 2: Prepare Countertop Cutout

Refer to the cooktop installation instructions

for dimensions of cooktop, countertop cutout, and cabinet requirements prior to

making any cutouts. Cooktop depth and

countertop back-splash depth can vary

greatly from one to another. These variations may cause the fit of the downdraft and

cooktop to be tight. A countertop (front

edge) with a raised lip and/or a wide backsplash (back edge) may not allow enough flat

countertop for a proper installation.

Y Check that the cooktop is far enough

forward that the downdraft will fit behind

it. Verify all dimensions prior to cutting

the countertops.

Use the physical products to confirm

cutouts whenever possible.

For all installations verify that all cutouts will

clear the inside of the front countertop support rail, and that the cooktop and vent will

be centered left to right within the cutout.

Also, make certain that the front

and rear cutouts are straight and parallel to

the front edge of countertop and the rear

backsplash and/or wall. Assure that the

side cutouts are square to the front and rear

cutouts.

All illustrations and dimensions are based

on standard 24” deep by 36” high American

style base cabinets with 25” countertops.

When installing laminated or solid surface

countertops such as Surell™ and Corian

®

,

be sure to follow the countertop manufacturer’s instructions regarding minimum

comer radii, reinforcement of corners, etc.

Note: Check boxes as tasks are completed.

For overhead cabinet and cooktop side

clearances consult cooktop Installation

Instructions.

9

Page 10

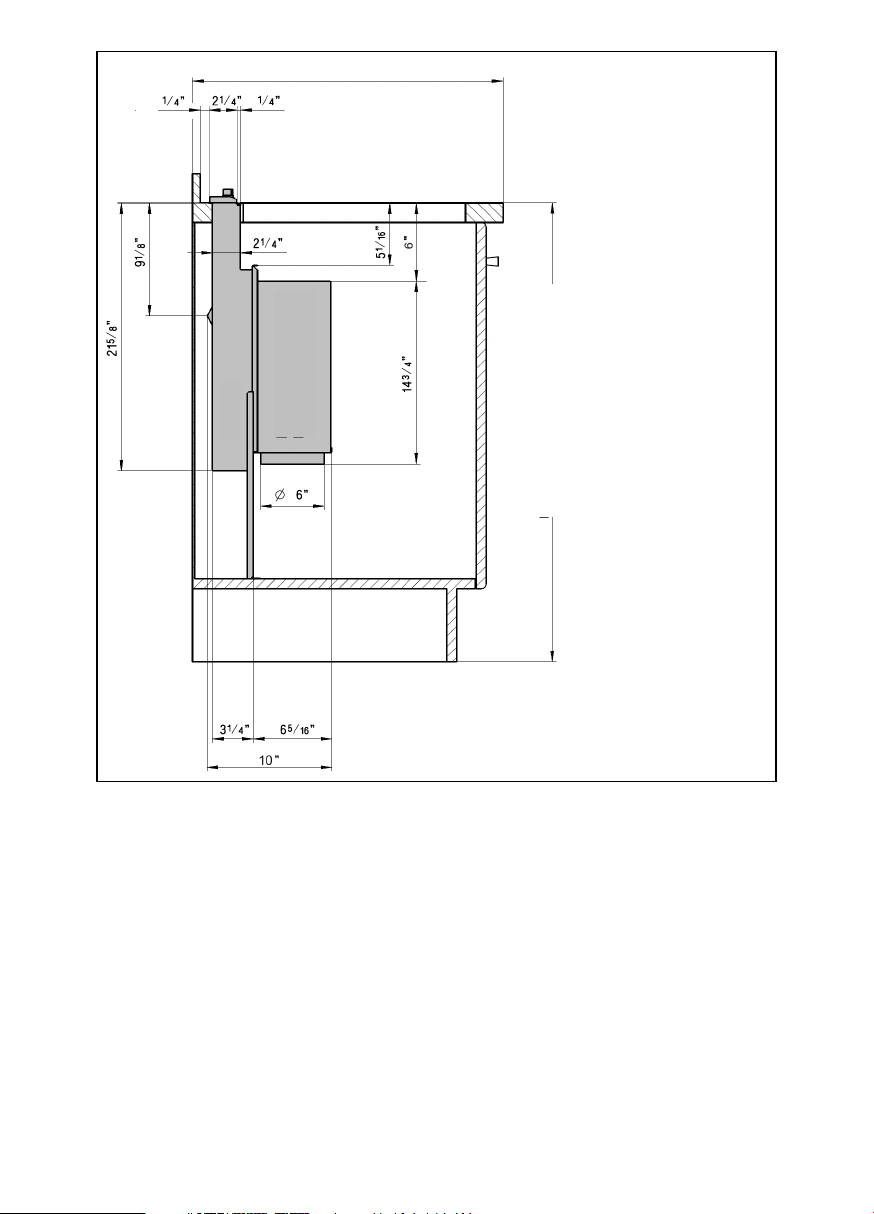

10

Notes

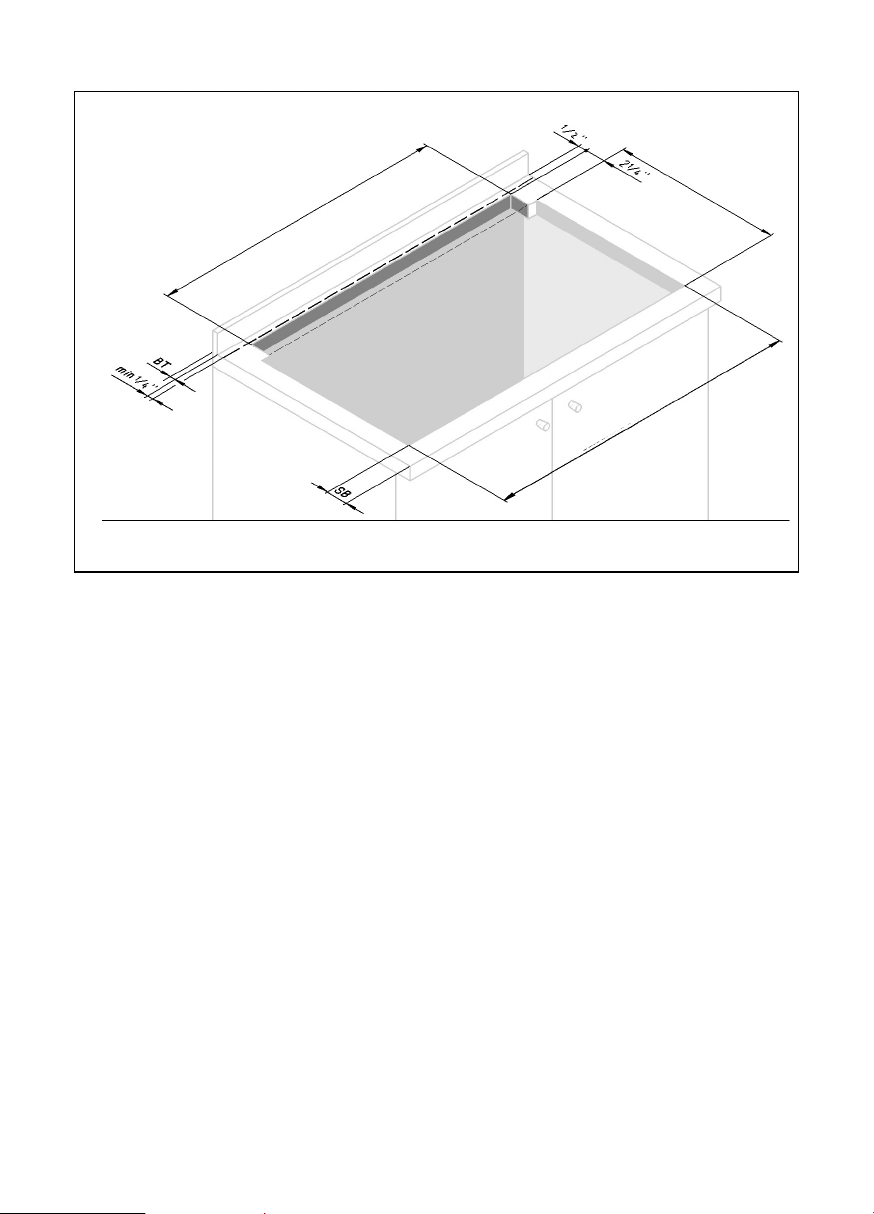

Dimension ”SB” is the minimum distance from the leading edge of the counter to the leading

edge of the cutout.

Dimension ”BT” is the thickness of backsplash that provides 1/4” clearance between vent

and backsplash. Any backsplash with a curved radius where it meets the counter will require

additional clearance. Thicker backsplashes may be used by increasing the counter and cabinet depths.

Set the cooktop into the countertop opening so that the back edge of the cooktop overlaps

the leading edge of the downdraft.

Fig. 7

INSTALLATION WITH COOKTOPS

Wide 31”: 28

3

/

8

”

Wide 37”: 34

3

/

8

”

Cutout and Overall Dimensions

Cutout and Overall Dimensions

Page 11

11

Fig. 8

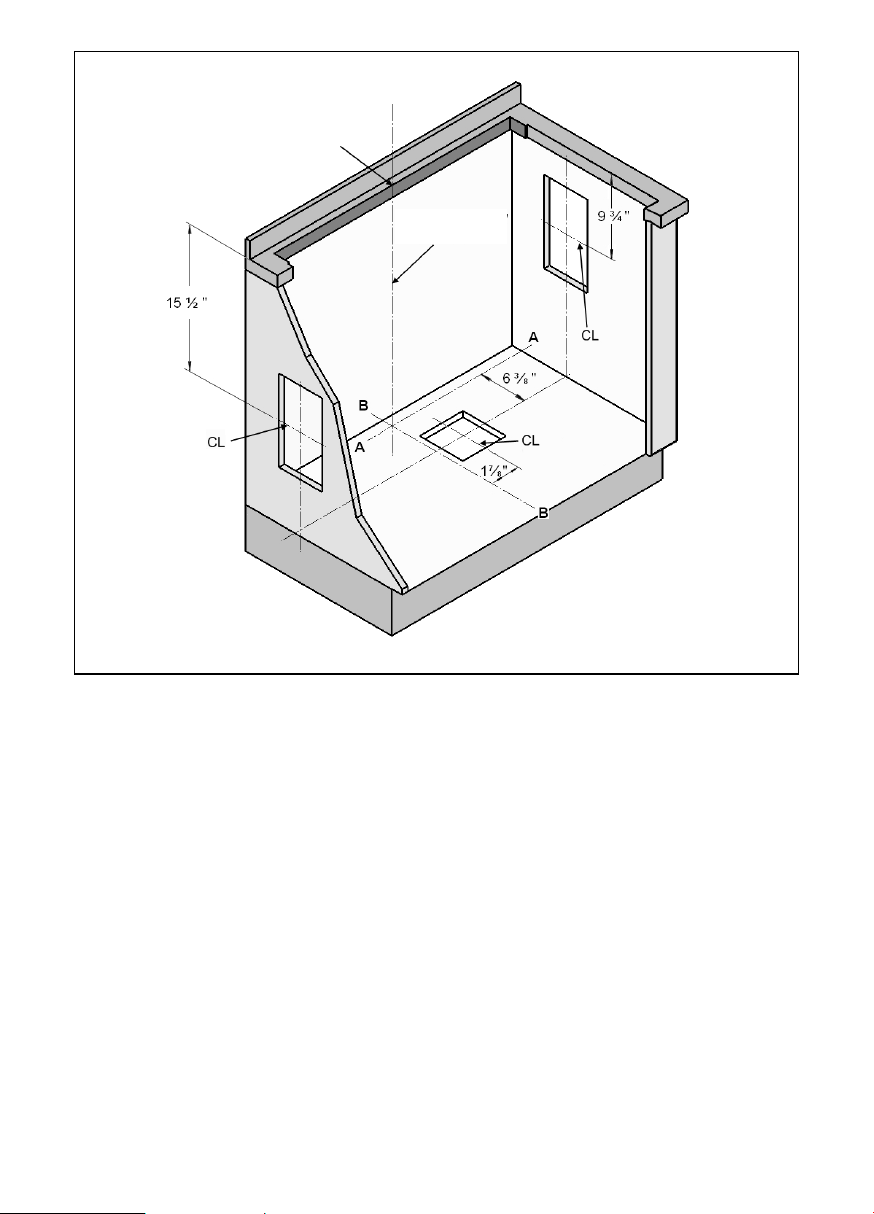

Step 3: Prepare Duct Cutouts in

Cabinet

Y A. Refer to Figure 8. Drop a plumb-line

from Point ”P” at the rear center of the

countertop cutout. Mark this point on the

bottom of the cabinet below. Construct

two reference lines through this point:

one should be parallel to the cabinet

front and directly below the rear countertop cutout (Line A-A), and the other (Line

B-B) should be at right angles to A-A.

Y B. Using these reference lines as a base

for the measurements, layout the necessary cabinet cutouts needed to implement the planned ductwork route. Where

a range of measurements is noted,

choose a measurement that allows best

clearance from wall studs, floor joists,

utilities, or other obstructions.

Step 3: Prepare Duct Cutouts in

Step 3: Cabinet

Y C. Before cutting for ducting, temporarily

set intake and cooktop in place and

attach integral blower (or duct transition

fitting if a remote or inline blower is installed). Refer to steps 6 and 7. Verify that

the duct cutouts as marked will match

the hardware installation. Adjust the duct

cutout as necessary to match hardware

installation.

Y D. Remove temporarily placed hardware

and make cutouts in cabinet to accommodate ductwork installation.

Y E. Make all other cabinet modifications

needed to provide proper clearances for

drawers or removable shelving.

Note: Check boxes as tasks are completed.

Center Line (CL)/

Plumline

Point "P"

Page 12

Step 4: Install Ductwork (Remote or

Inline Blower, If Used)

Y A. Install the ductwork and remote blo-

wer (if used) in accordance with the ductwork routing plan developed in Step 1.

Y B. Make sure that the installation com-

plies with all installations guidelines. Type

and length of ducting and lack of makeup air may reduce CFM. Also check that

the opening where duct passes through

outside wall or roof has been properly

flashed and sealed to prevent leakage.

Y C. If using Integral Blower, proceed to

Step 5.

Y D. If using Remote or Inline Blower, refer

to Installation Instructions with that

model.

Step 5: Install Electrical Service

Y Check your local building codes for pro-

per method of installation. In the U.S., if

there are no applicable local codes, this

unit should be installed in accordance

with the National Electric Code

ANSI/NFPA No. 70, Current Issue. (In

Canada, installation must be in accordance with the CAN 1-B149.1 and .2Installation Codes for Gas Burning Appliances and/or local codes).

Y The appliance must be grounded. In the

event of an electrical short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric

current. This appliance is equipped with

a cord having a grounding wire with a

grounding plug. The plug must be plugged into an outlet that is properly installed and grounded.

몇 WARNING – Improper grounding can

result in a risk of electric shock.

Only a qualified electrician, or similarly quali-

fied persons, should make the electrical

connections.

Do not use an extension cord. If the power

supply cord is too short, have a qualified

electrician install an outlet near the appliance.

The receptacle should be located under

the countertop so that the 30 inch long

power cord from the vent will reach it.

See Figure 8.

Y The cord should be routed beneath the

appliance and away from heat generated

by the cooktop. Access should not be

obstructed by blower, cabinet work,

ductwork or electrical/gas utilities for the

cooktop. All power for the vent system

(including the remote blower, if used) is

supplied via the cord to the intake unit.

The outlet can usually be extended from

another kitchen outlet or have its own

circuit from the main service panel.

Do not plug vent cord into receptacle

until Step 8.

Step 6: Mount Vent and Cooktop

Y A. Remove grease filters and any

packing materials from inside the intake.

Y B. Set the vent intake into rear of coun-

tertop opening. Carefully lower it into

position so that the flanges on the rear

sides and edges fully support the unit

hanging from the countertop.

Y C. Hold the unit against the rear of the

countertop opening, and slide the leg

brackets down to meet the bottom of

cabinet. Check and adjust for plumb,

then fasten leg brackets to cabinet with

hardware provided.

Note: Check boxes as tasks are completed.

12

Page 13

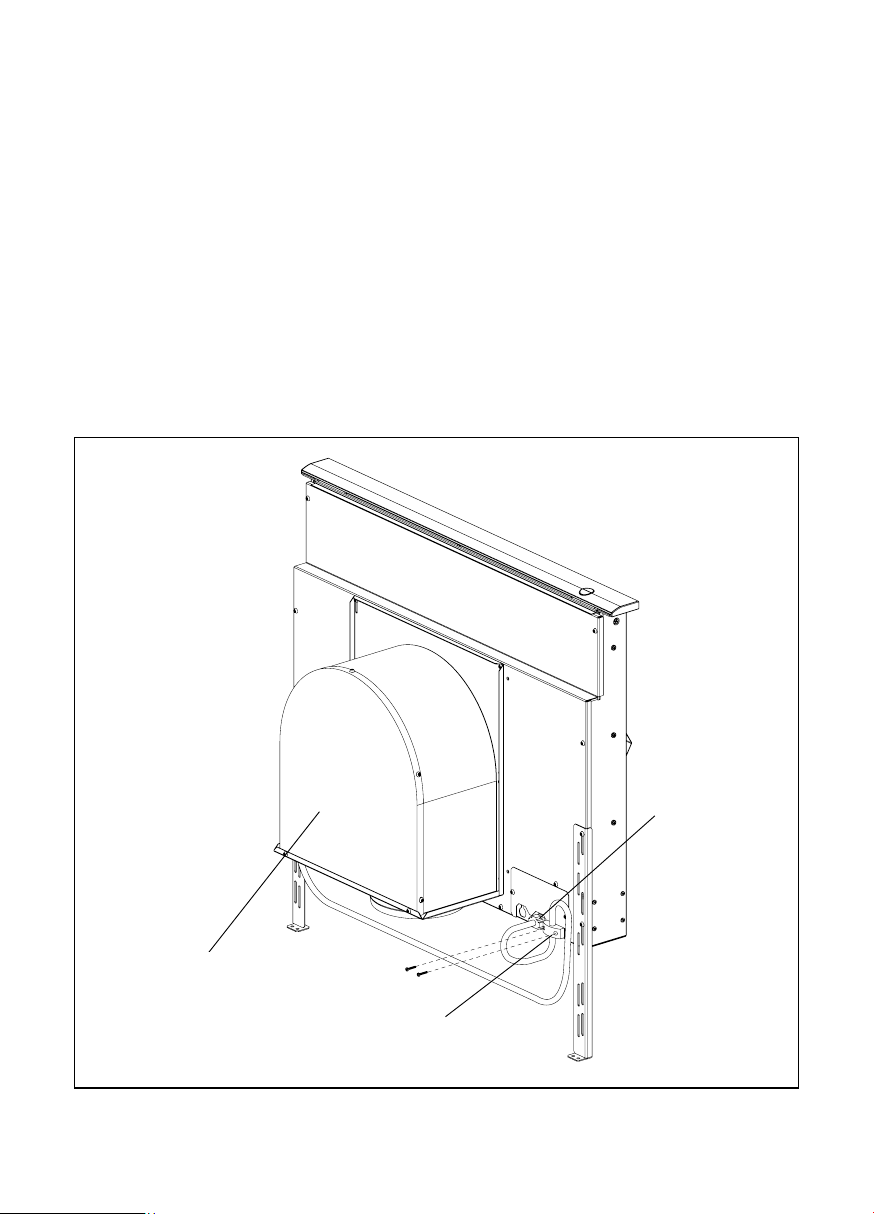

Step 7: Mount Integral Blower or

Outlet Duct Transition for Remote or

Inline Blower

Integral Blower (see Figures 9 and 11 for

further detail):

Y A. Attach blower in front of round

exhaust outlet with 4-6 (depending on

configuration) #8 sheetmetal screws.

Y B. Feed cord from blower through strain

relief.

Y C. Secure strain relief with screws.

Y D. Attach strain relief to downdraft near

junction box.

Y E. Connect cord to downdraft at 6 pin

connector.

Y F. Connect blower to ductwork.

Fig. 9 – Internal Blower

13

Step 7: Mount Integral Blower or

Outlet Duct Transition for Remote

Blower

Integral Blower VTN600CV2C (see Figures

10 and 12 for further detail):

Y G. Place the cooktop in countertop ope-

ning with the rear edge of cooktop overlapping the front edge of the vent. Make

sure rear edge of cooktop does not bind

against front of snorkel. Follow the

manufacturer’s installation Instructions

for installing gasket strips, protective

heat tape (if required), securing the cooktop to the countertop and making the

cooktop electrical and/or gas connections.

Note: Check boxes as tasks are completed.

Internal Blower

Strain Relief

6 Pin

Connector

<*^"P) 6^"

G*"P)F^^

')D

^W*"

Page 14

Remote or Inline Blower (see Figures 10

and 11 for further detail):

Y A. Remove junction box cover and

connect conduit with 5 wires from remote

blower. Hook up wires per Wiring.Fig. 10.

Replace junction box cover.

Y B. Attach Duct Transition Box at moun-

ting holes with sheetmetal screws.

Y C. Feed remote blower pigtail through

strain relief.

Y D. Attach strain relief to downdraft near

junction box.

Y E. Connect pigtail to downdraft at 6 pin

connector.

Y F. Run pigtail wires to junction box.

Y G. Inside junction box, connect conduit

with five wires from remote or inline blower. Use a conduit connector to secure.

Fig. 10 – Remote Blower

14

Integral Blower VTN600CV2C (see Figures

10 and 12 for further detail):

Note: Blower and duct transition box may

be installed with duct outlet left, down or

right. Install blower or duct transition in

such a way that access panels can be

removed for service.

Y H. Place the cooktop in countertop ope-

ning with the rear edge of cooktop overlapping the front edge of the vent. Make

sure rear edge of cooktop does not bind

against front of snorkel.

Follow the manufacturer’s installation

Instructions for installing gasket strips,

protective heat tape (if required), securing the cooktop to the countertop and

making the cooktop electrical and/or gas

connections.

Note: Check boxes as tasks are completed.

Strain Relief

Remote Blower

Pigtail

6 Pin Connector

Junction Box

Duct Transition Box

Conduit To

Remote Blower

Page 15

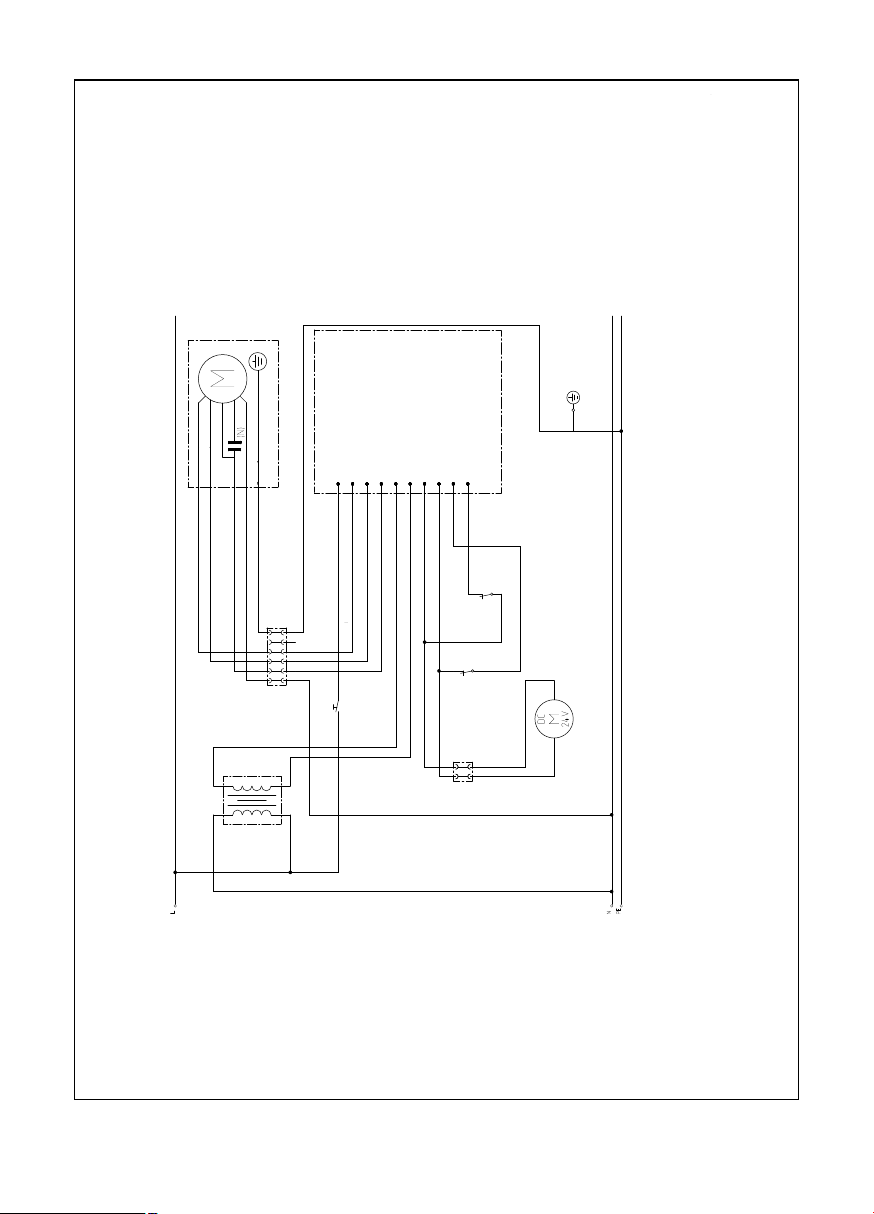

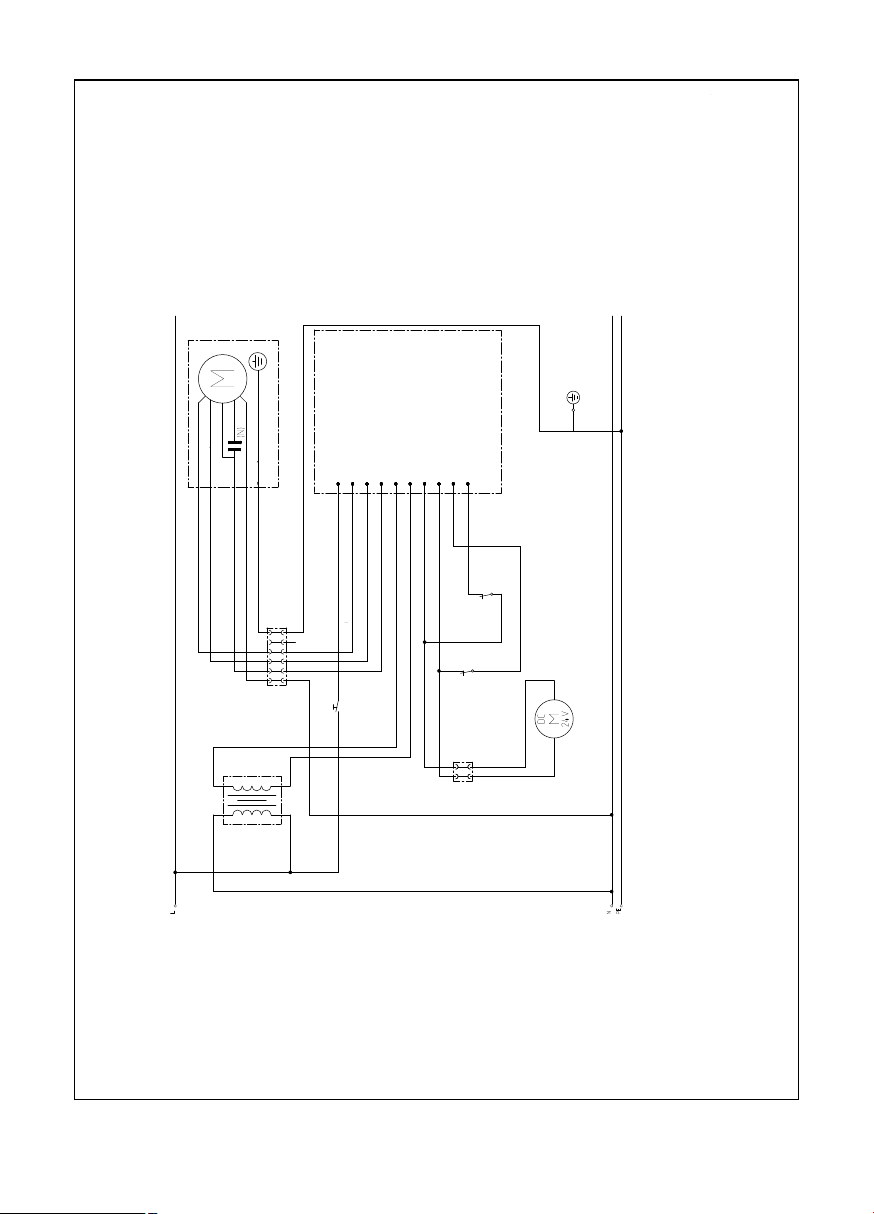

Wiring Diagram

Fig. 11

15

WARNING: POWER MUST BE DISCONNECTED BEFORE SERVICING THIS APPLICANE

SW POSITION

SHOWN WITH

DOWNDRADT IN

LOWERED POSITION

ABBREVIATIONS:

C = COMMON

NO = NORMALLY OPEN

NC = NORMALLY CLOSED

POWER

3 WIRE SINGLE PHASE 60 Hz

L1: 120 V

N: GROUNDED WHITE WIRE

SPEED 1 RED WIRE

SPEED 2 BLUE WIRE

SPEED 3 BROWN WIRE

GND: GROUNDED GREEN WIRE

RATING: 120V-10A

control pc board

brown Speed 3

blue Speed 2

Speed 1

red

white

green/yellow

green/yellow

white

brown

blue

red

+)M<F G<A? D;G)':);9

DBMF

GD)+)FBMA M<F

?Y),:)L

AY FBIA M;<H M<F

FH<AY),: L:

GD),)?I M<F

AY FBIA FAM<F

GD))F M<F

-"^),))M")P"P \Y\/^]/[/ Y]\\ ]/YY\/ XY/^^ZY\

GM DBG<H<BA

G;BMA M<H;

BMAFH<A

?BMF DBG<H<BA

FL<H<BAGY

)B@@BA

AB))ABF@??O BDA

))ABF@??O ?BG

A

Page 16

Step 8: Verify Installation, Operation

and Cooktop Alignment

Y Before performing this procedure, verify

that all packing materials were removed

from inside the snorkel and that the grease filters and front panel have been properly installed. Refer to the Care and Use

Manual for instructions regarding filter

and front panel installation.

Y Plug the vent power cord into a proper

electrical receptacle and ensure that the

circuit is energized.

Y A. Raise the snorkel to its fully extended

position by pressing the UP/DOWN

push-button once. Do not hold the pushbutton. The elevating motor will stop

when the snorkel reaches its full height.

(Note: the blower will not operate unless

the snorkel is fully raised).

Y B. Remove protective tape from top cap.

Y C. Turn the blower ON by selecting in

turn each of the 3 speeds. Let the blower run several minutes at each speed to

evaluate its operation.

Y D. With the blower running, lower the

snorkel to its fully retracted position by

pressing the UP/DOWN push-button

once. The blower will immediately turn

off.

Step 8: Verify Installation, Operation

and Cooktop Alignment

Y E. With the blower on HIGH, close the

windows and doors to the area to ensure

that fan does not cause back drafting in

any outlet vent for another appliance.

Y F. Raise and lower the vent again, and

check to make sure that the top cap on

the snorkel does not catch on the back

edge of the cooktop when it is lowered. If

interference occurs, adjust the position

of the cooktop by moving it against the

front edge of the countertop. Failure to

eliminate interference may result in permanent damage to the vent. Also, ensure that the vent support legs have been

properly secured to the cabinet base

using the screws provided.

몇 If the vent system does not operate

satisfactorily during any of the above procedures, review all steps in these Installation

Instructions to ensure that nothing has been

omitted or overlooked. Also, refer to the

Care & Use Manual for additional information or call Thermador Customer Support 1800-735-4328.

Note: Check boxes as tasks are completed.

16

Page 17

17

몇 AVERTISSEMENT

Pour réduire le risque d'incendie, de

choc électrique ou de lésions corporelles, observer ce qui suit :

A. L'installation et le câblage électrique

doivent être effectués par des personnes qualifiées conformément à

toutes les normes et codes applicables, incluant la construction relative au feu.

B. Suffisamment d'air est nécessaire

pour une combustion appropriée et

l'échappement des gaz par tirage

(cheminée) d’équipement à combustion pour éviter le tirage arrière. Suivre

les directives du fabricant d’équipement de chauffage et les normes de

sécurité telles celles fournies par l’Association nationale de protection

contre les incendies (NFPA) et la

Société américaine d'ingénierie de

chauffage, réfrigération et climatisation

(ASHRAE) ainsi que les codes locaux.

C. Au moment de couper ou percer un

mur ou plafond, ne pas endommager

le câblage électrique et autres services publics non apparents.

D. Les ventilateurs à conduit doivent

toujours être ventilés vers l’extérieur.

E. Avant toute intervention, pensez à

toujours débrancher l'appareil du

réseau d'alimentation électrique.

F. Cet appareil est conçu pour une utili-

sation intérieure seulement. Utiliser

cet appareil uniquement de la façon

préconisée par le fabricant.

G. S'assurer que la table de cuisson est

appropriée pour l'utilisation avec un

évent de contre-tirage.

H. L'appareil n 'est pas destiné à être

utilisé avec des tables de cuisson

professionnelles.

몇 AVERTISSEMENT

Pour ventilation générale seulement. Ne

pas ventiler des vapeurs ou matériaux

explosifs ou hasardeux.

Pour réduire le risque d'incendie et pour

un échappement d'air approprié, s'assurer d'acheminer l'air vers l'extérieur. Ne

pas ventiler l’air d'échappement dans les

murs, plafonds, greniers, espaces fermés ou garages.

Pour réduire le risque d'incendie, utiliser

des conduits en métal.

Pour réduire le risque d'incendie, de

choc électrique et de lésions corporelles,

le système de contre-tirage doit être utilisé avec une soufflerie intégrée, à distance ou en conduite.

Pour réduire le risque d'incendie ou de

choc électrique, ne pas utiliser le ventilateur avec un dispositif de contrôle de

vitesse à semi-conducteur.

Cet appareil est conforme avec la norme

UL 507 pour ventilateurs électriques et la

norme canadienne CAN/CSA-22.2 n°

113 pour ventilateurs. Le propriétaire et

l'installateur sont tenus de déterminer si

des normes ou exigences additionnelles

s'appliquent pour une installation spécifique.

몇

CONSIGNES DE SÉCURITÉ

LIRE TOUTES LES INSTRUCTIONS AVANT D'UTILISER L'APPAREIL.

LIRE ET CONSERVER CES INSTRUCTIONS

Page 18

18

Pièces nécessaires (standard)

G Ruban à mesurer

G Tournevis à tête Phillips

G Ruban d'aluminium pour conduits

G Conduit (configuration variant selon l'em-

placement ; voir pages 7 à 12 pour plus

de détails)

G Vis à tôle additionnelles (au besoin pour

l'installation de conduits)

G Scie (ou équivalent pour couper le plan

de travail)

G Vis à bois n° 8 x 1 1/4 po (4)

G Plomb

G Fil pour atteindre la soufflerie à distance

ou en conduite

Pièces nécessaires (spéciales)

G Soufflerie spéciale

G Boîte de transition (pour utilisation avec

souffleries en conduite et à distance uniquement)

G Module de recirculation (utilisé unique-

ment pour les applications à recirculation)

Remarque : les systèmes de contre-tirage

fonctionnent avec les souffleries suivantes :

souffleries intégrées, à distance ou en

conduite 600 pi3/mn souffleries à distance

ou en conduite 1000 pi3/mn

Pièces fournies

G Ensemble de contre-tirage (1)

G Vis à tôle n° 8 (8)

G Réducteur de tension du cordon de

soufflerie (1)

G Quincaillerie pour fixations sur évent (2)

G Queue de cochon de soufflerie à distan-

ce

Page 19

INTRODUCTION

DESCRIPTION GÉNÉRALE

Le système de contre-tirage complet comprend le contre-tirage, une soufflerie et une

boîte de transition si l'on utilise une soufflerie en conduite ou à distance. Un module

de recirculation est également disponible

lorsque la mise en place de conduits vers

l'extérieur n'est pas privilégiée ou est

impossible. (Voir fig. 1).

La soufflerie peut être soit intégrée (montée

sur l'entrée d'évent dans l'armoire sous la

table de cuisson), en conduite montée entre

la cuisine et le mur extérieur à l'intérieur du

conduit), ou à distance (montée sur le toit ou

le mur extérieur). Lorsqu'une soufflerie à distance ou en conduite est utilisée, une transition de conduit est fixée sur l'entrée de ventilateur au lieu d'une soufflerie intégrée pour

brancher l'entrée sur le conduit. La transition

de conduit doit être achetée séparément.

La soufflerie intégrée ou la transition de

conduit peut être monté dans différentes

positions sur l'entrée pour acheminer le

conduit afin d'éviter l'armoire, la structure

de l'édifice, les services publics, etc.

Le système de contre-tirage est disponible

en 30 ou 36 po. Il est prévu pour être utilisé

uniquement avec des tables de cuisson

non professionnelles.

Un kit de recirculation peut être acheté

séparément et utilisé parallèlement à la soufflerie intégrée si le conduit posé vers l'extérieur ne constitue pas une option viable.

Étape 1 : plan d'installation

Suivre attentivement le processus de planification indiqué ci-dessous (voir figure 2). Les

schémas n'ont PAS pour fonction de tenir

lieu de planification soigneuse.

A. Déterminer si une soufflerie à distance,

en conduite ou intégrée est utilisée.

L'installation d'une soufflerie à distance et en conduite requiert 4 fils plus

un fil de mise à la terre allant du système de contre-tirage à la soufflerie.

B. S'assurer que l'espace d’armoire et de

plan de travail est adéquat et que l'entrée et la soufflerie sont accessibles si

une réparation est requise

C. Il faut considérer les courants d'air créés

par les fenêtres ouvertes, portes, climatiseur, évents de chauffage anciens, éclairages encastrés et le trafic pouvant

réduire le rendement.

D. Pour les installations de tables de cuisson

à gaz, s'assurer qu'une ouverture minimale

de 10 po2 est prévue au coup-de-pied ou

autre armoire. Une ventilation inadéquate

de l'armoire sous la table de cuisson peut

causer l'extinction de la flamme au

moment d'actionner le système d’évent.

E. Assurer une alimentation en air dans

la pièce où l'appareil est installé. Si

l’air d'appoint n’est pas assuré, alors

il peut en résulter des problèmes

comme un contre-tirage de la cheminée du foyer.

Fig. 1

19

Appareil de

contre-tirage

Réducteur de tension

Soufflerie /

Boîte de transition

de conduit

(non fournie)

Page 20

Fig. 2

F. Vérifier les chemins de conduit potentiels

et choisir le plus court possible depuis

l'appareil au mur extérieur ou au toit par

un mur intérieur et le grenier. À des fins

d'aide, des installations de conduit

typiques sont montrées aux figures 3 à

6. L'installation pour un îlot requiert un

conduit sous le plancher. Les emplacements péninsules requièrent habituellement des conduits latéraux par les

armoires ou sous la base des armoires. Il

faut prendre en considération les interférences potentielles des conduits par la

structure de l'édifice (montants de plan-

cher ou de mur) et les services publics

(câblage électrique, eau, gaz, ou

conduites d'égout, etc.).

G. Acheter les conduits nécessaires pour

raccorder les conduits vers l'extérieur ou

acheter le module de recirculation de

contre-tirage séparément si le raccordement des conduits vers l'extérieur n'est

pas une option viable.

• S’assurer d'éviter une interférence avec le gaz et l'alimentation électrique à la

table de cuisson.

• La profondeur de la tablette

et du tiroir est dépendante

de la profondeur et du retrait

de la table de cuisson.

20

La dimension dépend du plan de travail

min.

Évent

Soufflerie/Boîte de

transition de conduit

La dimension dépend de l'armoire

Page 21

Les figures 3 à 6 sont des exemples de conduits possibles

Fig. 3

Soufflerie à distance

Installation sur le toit

Installation par le mur

Fig. 4

Soufflerie intégrée

Installation par le mur

Fig. 5

Soufflerie intégrée

Installation par le mur

Fig. 6

Soufflerie en conduite

Installations par le mur

21

Soufflerie

à distance

Soufflerie

à distance

Boîte de

transition

de conduit

Collier

Sol

Bouche

de décharge murale

Boîte de

transition

de conduit

Bouche de

décharge murale

Sol

Soufflerie

en conduite

Soufflerie intégrée

SOUFFLERIE TOURNÉE À 90°

POUR CONNEXION LATÉRALE

Soufflerie

intégrée

Page 22

DIRECTIVES D'INSTALLATION DE

CONDUITS

G Le conduit doit ventiler directement vers

l'extérieur (non dans un grenier, sous la

résidence, dans le garage ou espace

confiné). Un module de recirculation est

disponible lorsque la pose de conduits

vers l'extérieur est impossible.

G Garder les tracés de gaines les plus

courts et droits possible.

G Les raccords (coudes et transitions)

réduisent l'efficacité du débit d’air.

G Des coudes et des S, les uns à la suite

des autres, offrent un débit faible et ne

sont pas recommandés.

G Une courte longueur droite à l'entrée de

la soufflerie à distance offre un meilleur

débit.

G La transition à un conduit depuis la souf-

flerie intégrée ou de la transition de soufflerie à distance doit être aussi près que

possible du contre-tirage. En ordre de

préférence, utiliser :

1er conduit rond 10 po

2e conduit rond 8 po

3e conduit 3-1/4 po x 14 po

4e conduit rond 7 po

5e conduit 3-1/4 po x 10 po

6e conduit rond 6 po

G L'utilisation de conduit rond en métal

flexible peut se faire seulement si aucun

autre raccord de conduit n'existe. Limiter

l'utilisation à de courtes longueurs et ne

pas écraser les coins.

G Les coudes posés les uns à la suite des

autres doivent être évités.

DIRECTIVES D'INSTALLATION DE

CONDUITS

G Là où les codes locaux le permettent, un

tuyau en plastique (40 PCV ou ABS de 7

ou 8 po de diamètre) peut être utilisé

dans les endroits où il y a beaucoup

d'humidité et des planchers en béton

pour empêcher la rouille potentielle.

G Utiliser seulement des conduits fabriqués

en matériaux acceptables conformément

aux codes applicables. Tous les conduits

doivent être de calibre 26 ou plus pour

minimiser la flexibilité causée par le débit

d'air.

G Les souffleries à distance requièrent un

conduit rond de 10 ou 6 po de diamètre

(selon le modèle) pour correspondre à

l'anneau d’entrée. Une transition est

nécessaire depuis d'autres dimensions

de conduits.

G Utiliser des vis à tôle pour supporter le

poids du conduit et sceller tous les joints

avec du ruban à conduit.

G S'assurer que les conduits n'interfèrent

pas avec les montants du plancher et du

mur.

G Ne pas ventiler plus d'un évent dans un

conduit simple.

G Pour les installations dans des endroits

où il fait froid, il doit y avoir un registre

anti-refoulement additionnel afin de minimiser le refoulement d'air froid et une

barrière thermique non métallique pour

minimiser la transmission des températures extérieures à l'intérieur des

conduits. Le registre doit être placé du

côté de l'air froid de la barrière thermique. La barrière thermique doit être

aussi près que possible de l'endroit où le

conduit entre dans la portion chauffée de

la résidence.

G Toujours utiliser une bouche de déchar-

ge par le toit ou murale appropriée avec

un registre. Les bouches de décharge

murales de type sécheuse ne doivent

jamais être utilisées.

22

Page 23

Étape 2 : préparation de la découpe

du plan de travail

Consulter la notice d'installation de la table

de cuisson pour obtenir les dimensions de

la table de cuisson, de la découpe du plan

de travail et les exigences de l'armoire

avant d'effectuer une découpe. La profondeur de la table de cuisson et la profondeur

du dosseret du plan de travail peuvent

varier considérablement l'une de l'autre.

Ces variations peuvent occasionner un

ajustement serré du contre-tirage et de la

table de cuisson. Un plan de travail (bord

antérieur) doté d'un rebord et/ou d'un dosseret anti-éclaboussure de taille importante

(bord arrière) peut ne pas avoir suffisamment d'espace plat pour une installation

adéquate.

Y Vérifier que la table de cuisson est mon-

tée suffisamment vers l'avant afin que le

contre-tirage puisse être installé derrière.

Vérifier toutes les dimensions avant de

découper le plan de travail.

Utiliser les produits physiques pour

confirmer les découpes chaque fois que

possible.

Pour toutes les installations, s'assurer que

toutes les découpes dégagent l'intérieur du

devant du rail support du plan de travail et

que la table de cuisson et l'évent sont centrés de gauche à droite dans la découpe.

De plus, s’assurer que les découpes avant

et arrière sont droites et parallèles au bord

avant du plan de travail et au mur et/ou

dosseret arrière. S'assurer que les

découpes latérales sont d'équerre avec les

découpes avant et arrière.

Toutes les illustrations et les dimensions

sont en fonction des armoires de type américain de 24 po de profondeur x 36 po de

haut standard avec plan de travail de 25

po.

Si l'on installe un plan de travail uni ou laminé comme Surrell™ et Corian

®

, s'assurer

de suivre les instructions du fabricant du

plan de travail concernant les rayons

d'angle minimum, les renforts de coin, etc.

Remarque : cocher les cases au fur et à

mesure de l'exécution des tâches.

Pour les dégagements latéraux pour

armoires suspendues et tables de cuisson, consulter la notice d'installation de

la table de cuisson.

23

Page 24

24

Remarques

La dimension « SB » est la distance minimale du bord du comptoir au bord de la découpe.

La dimension « BT » est l'épaisseur du dosseret donnant un dégagement de 1/4 de po entre

l'évent et le dosseret. Tout dosseret avec un rayon courbé à la rencontre du comptoir requiert

un dégagement additionnel. L'épaisseur du dosseret peut être utilisée pour augmenter la profondeur de l'armoire et du plan de travail.

Positionner la table de cuisson dans l'ouverture du plan de travail de manière à ce que le bord

arrière de la table soit superposé sur le bord arrière du système de contre-tirage.

Fig. 7

INSTALLATION AVEC TABLE DE CUISSON

Largeur 31 po : 28

3

/

8

po

Largeur 37 po : 34

3

/

8

po

Dimensions de la découpe

et encombrement

Dimensions de la découpe

et encombrement

Page 25

Fig. 8

Étape 3 : préparation des découpes

de conduits dans l'armoire

Y A. Voir figure 8. Tirer une ligne du point «

P » au centre arrière de la découpe du

plan de travail. Marquer ce point au bas

de l'armoire en dessous. Établir deux

lignes de références par ce point : une

doit être parallèle au devant de l'armoire

et directement sous la découpe du plan

de travail arrière (ligne A-A) et l'autre

(ligne B-B) doit être à angle droit par rapport à la ligne A-A.

Y B. Utiliser ces lignes de références com-

me base aux mesures pour établir les

découpes d'armoire nécessaires pour

mettre en place le chemin de conduit

planifié. Là où une gamme de mesures

est notée, choisir une mesure que offre le

meilleur dégagement des montants de

murs, plafonds, services publics et

autres obstructions.

Étape 3 : préparation des découpes

de conduits dans l'armoire

Y C. Avant d'effectuer les découpes de

conduits, mettre temporairement l'entrée

et la table de cuisson en place et fixer la

soufflerie intégrée (ou raccord de transition

de conduit si soufflerie à distance ou soufflerie en conduite installée). Voir étapes 6

et 7. S'assurer que les découpes de

conduit marquées correspondent à l'installation des ferrures. Ajuster la découpe

de conduit comme nécessaire pour correspondre à l'installation de ferrure.

Y D. Enlever les ferrures placées temporaire-

ment et faire les découpes dans l'armoire

pour accommoder l'installation de conduit.

Y E. Faire toutes les modifications d'armoi-

re nécessaires pour assurer les dégagements appropriés pour les tiroirs ou

tablettes amovibles.

Remarque : cocher les cases au fur et à

mesure de l'exécution des tâches.

Ligne médiane

(CL) /Fil à plomb

Point « P »

25

Page 26

Étape 4 : installation des conduits

(soufflerie à distance ou en conduite,

si utilisée)

Y A. Installer les conduits et la soufflerie à

distance (si utilisée) conformément au

plan d'acheminement des conduits établi

à l'étape 1.

Y B. S'assurer que l'installation est confor-

me à toutes les directives d'installation.

Le type et la longueur des conduits et le

manque d'air d'appoint peuvent réduire

le débit en pi3/mn. Vérifier aussi si l’ouverture où passe le conduit par le mur

extérieur ou toit a été bien ajustée et

scellée pour empêcher les fuites.

Y C. Si l'on utilise une soufflerie intégrée,

passer à l'étape 5.

Y D. Si l'on utilise une soufflerie à distance

ou en conduite, voir la notice d'installation fournie avec ce modèle.

Étape 5 : installation de l'électricité

Y Vérifier les codes de construction locaux

pour la méthode appropriée d'installation. Aux É.-U., s'il n'y a pas de codes

locaux applicables, cet appareil doit être

installé conformément au Code national

de l'électricité ANSI/NFPA n° 70, édition

courante. (Au Canada, l'installation doit

être conforme aux codes d'installation

CAN 1-B149.1 et .2 pour appareils à gaz

et/ou aux codes locaux.

Y L'appareil doit être mis à la terre. En cas

de court-circuit, la mise à la terre réduit le

risque de choc électrique en permettant

au courant électrique de s'échapper par

la terre. Cet appareil est doté d'un cordon ayant un fil de mise à la terre avec

une fiche mise à la terre. La fiche doit

être branchée sur une prise adéquatement installée et mise à la terre.

몇 AVERTISSEMENT – une mise à la terre

inadéquate peut causer un risque de choc

électrique.

Seul un électricien qualifié, ou une personne

de qualification similaire, doit effectuer les

branchements électriques.

Ne pas utiliser de rallonge. Si le cordon

d'alimentation est trop court, demander à

un électricien qualifié d'installer une prise à

proximité de l'appareil.

La prise doit être située sous le plan de

travail afin que le cordon d'alimentation

de 30 po venant de l'évent puisse l'atteindre. Voir figure 8.

Y Le cordon doit être acheminé sous l'ap-

pareil et loin de la chaleur générée par la

table de cuisson. L'accès ne doit pas

être obstrué par la soufflerie, l'armoire, le

conduit ou les services électricité/gaz

pour la table de cuisson. Toute l'alimentation pour le système d'évent, incluant

la soufflerie à distance, si utilisée, est

fournie par le cordon à l'appareil d'entrée. La prise de courant peut être habituellement alimentée par une autre prise

de courant de la cuisine ou avoir son

propre circuit depuis le panneau de service principal.

Ne pas brancher le cordon de l'évent sur

la prise avant l'étape 8.

Étape 6 : installation de l'évent et de

la table de cuisson

Y A. Enlever les filtres à graisse et tout

matériel d'emballage à l'intérieur de l'entrée.

Y B. Régler l'entrée d'évent à l'arrière de

l'ouverture du plan de travail. Mettre délicatement en position afin que les

rebords sur les côtés arrières et que les

bords supportent entièrement l'appareil

suspendu au plan de travail.

Y C. Maintenir l'appareil contre l'arrière de

l'ouverture du plan de travail, faire glisser

la fixation de pied vers le bas pour rencontrer le bas de l'armoire. Vérifier et

régler le niveau, puis fixer les fixations de

pieds à l'armoire avec les ferrures comprises.

Remarque : cocher les cases au fur et à

mesure de l'exécution des tâches.

26

Page 27

Étape 7 : installation de la soufflerie

intégrée ou de la transition de

conduit de sortie pour la soufflerie à

distance ou en conduite

Soufflerie intégrée (voir figures 9 et 11

pour plus de détails) :

Y A. Fixer la soufflerie à l'avant de la sortie

d'échappement ronde avec 4 à 6 vis à

tôle n°8 (selon la configuration).

Y B. Faire passer le cordon de la souffle-

rie à travers le réducteur de tension.

Y

C. Fixer le réducteur de tension avec les vis.

Y D. Fixer le réducteur de tension au

contre-tirage près de la boîte de jonction.

Y E. Brancher le cordon sur le contre-tira-

ge au connecteur à 6 broches.

Y F. Brancher la soufflerie sur le conduit.

Fig. 9 – Soufflerie intégrée

27

Étape 7 : installation de la soufflerie

intégrée ou de la transition de

conduit de sortie pour la soufflerie à

distance

Y

G. Positionner la table de cuisson dans l'ouverture du plan de travail de manière à ce

que le bord arrière de la table soit superposé sur le bord avant de l'évent. S'assurer

que le bord arrière de la table de cuisson ne

bute pas contre l'avant de l'élévateur. Suivre

la notice d'installation du fabricant pour installer les bandes d'étanchéité, le ruban isolant protecteur (si nécessaire), fixer solidement la table de cuisson au plan de travail

et effectuer les raccordements électriques

et/ou de gaz de la table de cuisson.

Remarque : cocher les cases au fur et à

mesure de l'exécution des tâches.

Soufflerie intégrée

Réducteur de tension

Connec-

teur à

6 broches

<*^"P) 6^"

G*"P)F^^

')D

^W*"

Page 28

Fig. 10 – Soufflerie à distance

28

Remarque : la soufflerie et la boîte de transition de conduit peuvent être installées avec

la sortie de conduit à gauche, vers le bas ou

à droite. Installer la soufflerie ou la transition

de conduit de façon à ce que le panneau

d'accès puisse être enlevé pour réparation.

Y H. Positionner la table de cuisson dans

l'ouverture du plan de travail de manière

à ce que le bord arrière de la table soit

superposé sur le bord avant de l'évent.

S'assurer que le bord arrière de la table

de cuisson ne bute pas contre l'avant de

l'élévateur. Suivre la notice d'installation

du fabricant pour installer les bandes

d'étanchéité, le ruban isolant protecteur

(si nécessaire), fixer solidement la table

de cuisson au plan de travail et effectuer

les raccordements électriques et/ou de

gaz de la table de cuisson.

Remarque : cocher les cases au fur et à

mesure de l'exécution des tâches.

Réducteur de tension

Queue de cochon de

soufflerie à distance

Connecteur

à 6 broches

Boîte de jonction

Boîte de transition

de conduit

Conduit vers la

soufflerie à distance

Soufflerie à distance ou en conduite (voir

figures 10 et 11 pour plus de détails) :

Y

A. Retirer le couvercle de la boîte de jonction

et brancher le conduit avec 5 fils depuis la

soufflerie à distance. Brancher les fils selon le

diagramme de câblage, figure 10 Remettre le

couvercle de la boîte de jonction.

Y B. Fixer la boîte de transition de conduit

sur les trous de fixation avec les vis à tôle.

Y C. Faire passer la queue de cochon de la

soufflerie à distance à travers le réducteur

de tension.

Y D. Fixer le réducteur de tension au

contre-tirage près de la boîte de jonction.

Y E. Brancher la queue de cochon sur le

contre-tirage au connecteur à 6 broches.

Y F. Acheminer les fils en tire-bouchon à la

boîte de jonction.

Y G. Dans la boîte de jonction, brancher le

conduit avec 5 fils de la soufflerie à distance ou intégrée. Utiliser un connecteur

de conduit pour fixer solidement le tout.

Page 29

Schéma de câblage

Fig. 11

29

AVERTISSEMENT : DÉBRANCHER L'ALIMENTATION AVANT DE RÉPARER CET APPAREIL

EXIGENCE ÉLECTRIQUE

3 FILS, PHASE SIMPLE, 60 Hz

L1 : 120 V

N : FIL BLANC DE MISE À LA TERRE

VITESSE 1 FIL ROUGE

VITESSE 2 FIL BLEU

VITESSE 3 FIL BRUN

GND : FIL VERT DE MISE À LA TERRE

COTE : 120V-10A

carte à circuit imprimé

brun Vitesse 3

bleu Vitesse 2

Vitesse 1

rouge

blanc

vert/jaune

vert/jaune

blanc

brun

bleu

rouge

POSITION INTERRUPTEUR

MONTRÉE AVEC

CONTRE-TIRAGE EN

POSITION ABAISSÉE

ABRÉVIATIONS :

C = COMMUN

NO = NORMALEMENT OUVERT

NC = NORMALEMENT FERMÉ

+)M<F G<A? D;G)':);9

DBMF

GD)+)FBMA M<F

?Y),:)L

AY FBIA M;<H M<F

FH<AY),: L:

GD),)?I M<F

AY FBIA FAM<F

GD))F M<F

-"^),))M")P"P \Y\/^]/[/ Y]\\ ]/YY\/ XY/^^ZY\

GM DBG<H<BA

G;BMA M<H;

BMAFH<A

?BMF DBG<H<BA

))ABF@??O ?BG

FL<H<BAGY

)B@@BA

AB))ABF@??O BDA

A

Page 30

Étape 8 : Vérifier l'installation, le

fonctionnement et l'alignement de la

table de cuisson

Y Avant d'effectuer cette marche à suivre,

s'assurer que tout matériel d'emballage

a été enlevé à l'intérieur de l'élévateur et

que les filtres à graisse et le panneau

avant sont bien installés. Consulter le

guide d'entretien et d'utilisation pour des

instructions relatives à l'installation des

filtres et du panneau avant.

Y Brancher le cordon d'alimentation de

l'évent sur une prise électrique appropriée et s'assurer que le circuit est sous

tension.

Y A. Élever l'élévateur en position maxima-

le en pressant la touche UP/DOWN une

fois. Ne pas maintenir la touche enfoncée. Le moteur s'arrête lorsque l'élévateur atteint sa pleine hauteur.

(Remarque : la soufflerie ne fonctionne

pas à moins que l'élévateur ne soit complètement élevé).

Y B. Retirer la pellicule protectrice du des-

sus de l'embout.

Y C. Mettre la soufflerie en circuit en choi-

sissant, tour à tour, chacune des 3

vitesses. La laisser fonctionner quelques

minutes à chaque vitesse pour évaluer le

rendement.

Y D. La soufflerie en fonctionnement,

abaisser l'élévateur à sa position rétractée en pressant la touche UP/DOWN. La

soufflerie se met immédiatement hors

circuit.

Étape 8 : Vérifier l'installation, le

fonctionnement et l'alignement de la

table de cuisson

Y E. La soufflerie en position élevée, fermer

les fenêtres et portes de la pièce pour

s'assurer que le ventilateur ne cause pas

un contre-tirage dans tout évent de sortie d'autres appareils.

Y F. Élever et abaisser de nouveau l'évent

et s'assurer que l'embout sur l'élévateur

n'accroche pas le bord arrière de la table

de cuisson lorsqu'il est abaissé. S'il y a

une interférence, régler la position de la

table de cuisson en la déplaçant contre

le bord avant du plan de travail. Si l'interférence n'est pas éliminée, cela peut

causer des dommages permanents à

l’évent. De plus, s'assurer que les pieds

supports de l'évent sont fixés adéquatement à la base de l'armoire avec les vis

fournies.

몇 Si le système d'évent ne fonctionne

pas adéquatement pendant une des

marches à suivre susmentionnées, revoir

toutes les étapes de cette notice d'installation pour s’assurer que rien n’a été oublié.

Pour de plus amples informations, consulter

également le guide d'entretien et d'utilisation ou téléphoner au service à la clientèle

de Thermador au 1-800-735-4328.

Remarque : cocher les cases au fur et à

mesure de l'exécution des tâches.

30

Page 31

31

몇 ADVERTENCIA

Para reducir el riesgo de fuego, descargas eléctricas o sufrir lesiones, observe

lo siguiente:

A. El trabajo de instalación y la instala-

ción eléctrica deben ser realizados

por (una) persona(s) autorizada(s) de

acuerdo con todos los códigos y normas aplicables, incluidos los códigos

de construcción con respecto a

incendios.

B. Se necesita suficiente aire para lograr

una combustión apropiada y para

sacar los gases a través del tubo de

humo (chimenea) del quemador de

combustible para evitar el contratiro.

Siga las pautas del fabricante del

equipo de calefacción y las normas de

seguridad, tales como las que fueron

publicadas por la Asociación Nacional

de Protección contra Fuegos (NFPA) y

la Sociedad Americana para Ingeniería

de Calefacción, Refrigeración y Aire

Acondicionado (ASHRAE), y de las

autoridades locales.

C. No dañe el cableado eléctrico ni otras

instalaciones de servicios ocultas cuando corte o perfore la pared o el techo.

D. Los ventiladores entubados siempre

deben ser ventilados hacia el exterior.

E. Siempre desenchufe o desconecte el

aparato de la fuente de alimentación

eléctrica antes de realizar el servicio

técnico.

F. Esta unidad fue diseñada para uso

exclusivo en interiores. Use esta

unidad solamente para el uso previsto

por el fabricante.

G. Asegúrese de que la parrilla sea ade-

cuada para uso con una ventilación

de tiro descendente.

H. No diseñado para uso con parrillas

profesionales.

몇 ADVERTENCIA

Solamente para uso de ventilación general. No se debe usar para extraer materiales ni vapores peligrosos o explosivos.

Para reducir el riesgo de fuego y para

extraer el aire correctamente, asegúrese

de conducir el aire hacia el exterior. No

extraiga el aire de escape a espacios

dentro de paredes, techos, áticos, huecos sanitarios o garajes.

Para reducir el riesgo de fuego, utilice

solamente ductos de metal.

Para reducir el riesgo de fuego, descargas eléctricas y lesiones a personas, el

tiro descendente debe utilizarse con un

ventilador interno, remoto o en línea.

Para reducir el riesgo de fuego o descargas eléctricas, no use el ventilador con

ningún regulador de velocidad de estado

sólido.

Este aparato cumple con la norma UL

507 para ventiladores eléctricos y la norma canadiense CAN/CSA-22.2 No. 113

para ventiladores. Es la responsabilidad

del propietario y del instalador determinar si se aplican requisitos o normas adicionales en instalaciones específicas.

몇

INSTRUCCIONES DE SEGURIDAD

LEA TODAS LAS INSTRUCCIONES ANTES DE USAR EL APARATO.

LEA Y GUARDE ESTAS INSTRUCCIONES

Page 32

32

Partes necesarias (estándares)

G Cinta de medir

G Destornillador de cabeza Phillips

G Cinta para ductos de aluminio

G Ductos (la configuración varía según el

lugar; Ver las páginas 7-12 para más

información)

G Tornillos autorroscantes adicionales

(según sea necesario para instalar los

ductos)

G Sierra (o elemento equivalente para cort-

ar la cubierta)

G Tornillos para madera (4) #8 x 1 1/4"

G Plomada

G Cable para el ventilador remoto o en

línea

Partes necesarias (especiales)

G Ventilador especial

G Caja de transición (para uso solamente

con ventiladores en línea y remotos)

G Módulo de recirculación (utilizado sola-

mente para aplicaciones de recirculación)

Nota: Los tiros descendentes son aptos

para los siguientes ventiladores: Ventiladores integrados, remotos o en línea 600 CFM

Ventiladores remotos o en línea 1000 CFM

Partes que se incluyen

G Conjunto del tiro descendente (1)

G Tornillos autorroscantes #8 (8)

G Prensacables para el cable del ventilador

(1)

G Equipo para soportes en la ventilación

(2)

G Cable flexible del ventilador remoto

Page 33

INTRODUCCIÓN

DESCRIPCIÓN GENERAL

El sistema de tiro descendente completo

consta de un tiro descendente, un ventilador y una caja de transición en caso de utilizar un ventilador en línea o remoto. También se dispone de un módulo de recirculación cuando no se prefiere o no es posible

tener una salida de aire hacia el exterior.

(Ver la Fig. 1).

El ventilador puede ser integral (montado

sobre la toma de aire del ventilador en el

gabinete abajo de la parrilla), en línea (montado entre la cocina y la pared exterior a lo

largo de la línea del ducto) o remoto (montado en el techo o la pared exterior). Cuando se utiliza un ventilador remoto o en línea,

se debe montar una transición del ducto en

la toma de aire del ventilador en lugar del

ventilador integral para conectar la toma de

aire al ducto. Se debe comprar la transición

del ducto por separado.

Se puede montar el ventilador integral o la

transición del ducto en posiciones diferentes sobre la toma de aire para enrutar los

ductos y evitar gabinetes, marcos de construcción, instalaciones de servicios, etc.

El sistema de tiro descendente está disponible en 30 pulgadas o 36 pulgadas.

Diseñado únicamente para uso con parrillas

no profesionales.

Se puede comprar un kit de recirculación

por separado y utilizarlo junto con el ventilador integral si tener una salida de aire hacia

el exterior no es una opción viable.

Paso 1: Planear la instalación

Seguir los procedimientos de planeación

a continuación cuidadosamente (Ver la

Figura 2). Los dibujos NO reemplazan una

planeación cuidadosa.

A. Determinar si se va a utilizar un ventila-

dor remoto, en línea o integral. La

instalación de un ventilador remoto

y en línea requiere 4 cables más un

cable de tierra desde el tiro descendente hasta el ventilador.

B. Asegurarse de proporcionar el espacio

apropiado de gabinete y cubierta, y que

la toma de aire y el ventilador estén

accesibles por si se requiere realizar el

servicio técnico.

C. Considerar que las corrientes cruzadas

creadas por ventanas y puertas abiertas

adyacentes, aire acondicionado, ventilaciones de calefacción usadas, luces

empotradas del techo y patrones de

tránsito pueden afectar el rendimiento.

D.

Para instalaciones de parrillas de gas, asegurar una abertura mínima de 10 pulgadas

cuadradas en el área del panel de pie u otra

área del gabinete. Una ventilación incorrecta del gabinete abajo de la parrilla puede

provocar que se apaguen las llamas al operar el sistema de ventilación.

E. Proporcionar suministro de aire o

“aire necesario” al cuarto donde se

va a instalar la unidad. Cuando no se

proporciona el “aire necesario”,

entonces se pueden presentar problemas, tales como corrientes descendentes del tiro de una chimenea.

Fig. 1

33

Unidad de tiro descendente

Prensacables

Ventilador/caja de

transición del ducto

(no incluidos)

Page 34

Fig. 2

F. Investigar posibles rutas de los ductos y

escoger la ruta más corta posible desde

la unidad a una pared exterior o al techo

a través de una pared interior y ático.

Para fines de orientación, las figuras 3 a

6 muestran instalaciones típicas de ductos como ejemplos. La instalación en

una isla requiere colocar los ductos

debajo del piso. Las instalaciones en

península generalmente requieren colocar los ductos en forma lateral, a través

de los gabinetes, o debajo de los espacios para los pies en los gabinetes. Con-

siderar posibles interferencias con los

ductos debido a bastidores y marcos de

construcción (viguetas de piso, pernos

de pared, etc.) e instalaciones de servicios (cableado eléctrico, líneas de gas,

agua o de desagüe, etc.).

G. Comprar los ductos necesarios para que

el aire salga hacia el exterior o comprar

el módulo de recirculación de tiro descendente por separado si tener una salida de aire hacia el exterior no es una

opción viable.

• Asegúrese de evitar la interferencia con el suministro

eléctrico y de gas a la parrilla.

• Las profundidades de

estantes y cajones dependen de la profundidad y el

retallo de la parrilla.

34

Las dimensiones dependen de la cubierta

mín.

Ventilación

Ventilador/caja de

transición del ducto

Las dimensiones dependen del gabinete

Page 35

Las Figuras 3 a 6 son ejemplos de posibles ductos

Fig. 3

Ventilador remoto Instalación con

montaje en el techo Instalación a

través de la pared

Fig. 4

Ventilador integral Instalación

a través de la pared

Fig. 5

Ventilador integral Instalación

a través de la pared

Fig. 6

Ventilador en línea Instalaciones a través de la pared

35

Ventilador

remoto

Ventilador

remoto

Caja de

transición

del ducto

Collar

Suelo

Tapa de pared

Caja de

transición

del ducto

Tapa de pared

Suelo

Ventilador

en línea

Ventilador integral

VENTILADOR ROTADO A 90°

PARA CONEXIÓN LATERAL

Ventilador

integral

Page 36

LINEAMIENTOS PARA LA INSTALACIÓN DE DUCTOS

G Los ductos deben extraer el aire directa-

mente hacia el exterior (no hacia un

ático, debajo de la casa, al garaje o a

cualquier espacio confinado). Se dispone de un módulo de recirculación cuando no es posible tener una salida de aire

hacia el exterior.

G Los tramos de los ductos deben quedar

lo más cortos y rectos posible.

G Las conexiones de ductos (codos y tran-

siciones) reducen la eficiencia del flujo de

aire.

G Los codos conectados uno al otro y los

giros en forma de “S” reducen el flujo y

no se recomiendan.

G Un ducto corto y recto a la entrada del

ventilador remoto produce el mejor rendimiento.

G La transición al ducto del ventilador inte-

gral o la transición del ducto remoto

debe estar lo más cerca posible del tiro

descendente. En orden de preferencia,

utilizar

1er ducto redondo de 10"

2do ducto redondo de 8"

3er ducto de 3-1/4" x 14"

4to. ducto redondo de 7"

5to. ducto de 3-1/4" x 10"

6to. ducto redondo de 6"

G Solamente se deben usar ductos redon-

dos flexibles de metal cuando no existe

ninguna otra conexión de ductos. Limitar

el uso a longitudes cortas y no aplastarlos al hacer esquinas.

G Se deben evitar los codos conectados

uno al otro.

LINEAMIENTOS PARA LA INSTALACIÓN DE DUCTOS

G Donde los códigos locales lo permiten,

se puede utilizar tubo de plástico (tubo

de PVC calibre 40 o tubo ABS con diámetro de 7" u 8") en áreas con elevada

humedad del suelo y en pisos de losa

para eliminar la futura oxidación.

G Utilizar solamente ductos construidos de

materiales aceptables por los códigos

aplicables. Todos los ductos deben ser

de calibre 26 o más grueso para minimizar la flexión debido al flujo de aire.

G Los ventiladores remotos requieren un

ducto redondo con diámetro de 10" o 6"

(según el modelo) para hacer juego con

el anillo de entrada. Se necesita una

transición para otros tamaños de ductos.

G Usar tornillos autorroscantes como se

requieren para soportar el peso del

ducto y sellar todas las uniones con

cinta para ductos.

G Asegurarse de que el ducto no interfiera

con las viguetas de piso o pernos de

pared.

G No extraer el aire de más de una ventila-

ción a un solo tramo del ducto.

G Las instalaciones en clima frío deben

contar con un regulador de contratiro

adicional instalado para minimizar el

reflujo de aire frío y una barrera térmica

no metálica para minimizar la conducción de las temperaturas externas como

parte del ducto. El regulador de tiro

debe estar en el lado del aire frío de la

barrera térmica. La barrera debe estar

tan cerca como sea posible del lugar

donde el ducto ingresa a la parte calefaccionada de la casa.

G Siempre utilizar una tapa apropiada de

techo o pared con un regulador de tiro.

Nunca se deben usar tapas de pared

tipo lavandería.

36

Page 37

Paso 2: Preparar el recorte en la

cubierta

Consultar las instrucciones de instalación

de la parrilla para conocer las dimensiones

de la parrilla, del recorte en la cubierta y los

requisitos de los gabinetes antes de realizar

cualquier recorte. La profundidad de la parrilla y la profundidad de la salpicadura trasera de la cubierta pueden variar en gran

medida de una a otra. Estas variaciones

pueden hacer que quede muy poco espacio entre el tiro descendente y la parrilla. Es

posible que una cubierta (borde delantero)

con un reborde elevado y/o una salpicadura trasera (borde trasero) ancha no deje

suficiente cubierta plana para realizar una

instalación adecuada.

Y Verificar que la parrilla se encuentre lo

suficientemente hacia adelante para que

el tiro descendente entre detrás. Verificar

todas las dimensiones antes de cortar

las cubiertas.

Usar los productos físicos para confirmar

los recortes, siempre que sea posible.

Verificar para todas las instalaciones que

todos los recortes liberen el interior del riel

de soporte delantero de la cubierta, y que

la parrilla y la ventilación queden centradas

de izquierda a derecha dentro del recorte.

Además, asegurar que los recortes en la

parte delantera

y trasera estén rectos y paralelos al borde

delantero de la cubierta y la salpicadura trasera y/o la pared. Asegurar que los recortes

laterales estén en escuadra respecto de los

recortes de la parte delantera y trasera.

Todas las ilustraciones y dimensiones se

basan en gabinetes estándares estilo americano de 24" de profundidad por 36" de

altura con cubiertas de 25".

Al instalar cubiertas laminadas o con superficies sólidas como Surell™ y Corian

®

, asegurarse de seguir las instrucciones del

fabricante de la cubierta con respecto a los

radios mínimos de esquinas, el refuerzo de

las esquinas, etc.

Nota: Marcar las casillas a medida que se

completen las tareas.

Consultar las instrucciones de instalación de la parrilla para los espacios libres de gabinetes elevados y los costados de la parrilla.

37

Page 38

38

Notas

La dimensión “SB” es la mínima distancia del borde delantero de la cubierta al borde delantero del recorte.

La dimensión “BT” es el espesor de la salpicadura trasera que proporciona 1/4" de

espacio libre entre la ventilación y la salpicadura trasera. Una salpicadura con radio curvado

donde hace contacto con la cubierta va a necesitar un espacio libre adicional. Se pueden

usar salpicaduras traseras más gruesas aumentando las profundidades de la cubierta y del

gabinete.

Colocar la parrilla en la abertura de la cubierta de modo que el borde trasero de la parrilla se

superponga con el borde delantero del tiro descendente.

Fig. 7

INSTALACIÓN CON PARRILLAS

31" de ancho: 28

3

/

8

"

37" de ancho: 34

3

/

8

"

Dimensiones de recortes

y generales

Dimensiones de recortes y generales

Page 39

Fig. 8

Paso 3: Preparar los recortes para

los ductos en el gabinete

Y A. Consultar la Figura 8. Establecer una

línea vertical desde el punto “P” en el

centro trasero del recorte en la cubierta.

Marcar este punto en el fondo del gabinete que se encuentra debajo. Construir

dos líneas de referencia a través de este

punto: una debe quedar paralela al frente del gabinete y directamente debajo

del recorte trasero de la cubierta (Línea

A-A), y la otra (Línea B-B) debe quedar

en ángulos rectos a A-A.

Y

B. Utilizando estas líneas de referencia

como base para las mediciones, diseñar

los recortes necesarios del gabinete para

implementar la ruta planeada del ducto.

Donde se nota un rango de mediciones,

escoger una medición que permita el espacio libre más adecuado desde los pernos

de pared, viguetas de pisos, instalaciones

de servicios u otras obstrucciones.

Y C. Antes de hacer los recortes del ducto,

colocar la toma de aire y la parrilla temporalmente en su lugar y fijar el ventilador integral (o la conexión para la transición del ducto si se instala un ventilador

remoto o en línea). Consultar los pasos 6

y 7. Verificar que los recortes del ducto,

tal como están marcados, coincidan con

la instalación del equipo. Ajustar el recorte del ducto según sea necesario para

coincidir con la instalación del equipo.

Y D. Quitar el equipo colocado temporal-

mente y hacer los recortes en el gabinete

para acomodar la instalación del ducto.

Y E. Realizar todas las otras modificacio-

nes necesarias en el gabinete para proporcionar espacios libres suficientes para

los cajones o estantes removibles.

Nota: Marcar las casillas a medida que se

completen las tareas.

Línea central

(CL)/Línea vertical

Punto "P"

39

Page 40

Paso 4: Instalar el ducto (ventilador

remoto o en línea, si se usa)

Y A. Instalar el ducto y el ventilador remoto

(si se usa) de acuerdo con el plan de

enrutamiento del ducto desarrollado en

el paso 1.

Y B. Asegurar que la instalación cumpla

con todos los lineamientos de instalación. El tipo y la longitud del ducto, y la

falta de aire de reposición pueden reducir los CFM. Verificar también que la

abertura donde el ducto atraviesa la

pared exterior o el techo haya sido sellada correctamente para evitar fugas.

Y C. Si se utiliza el ventilador integral,

seguir con el paso 5.

Y D. Si se utiliza el ventilador remoto o en

línea, consultar las instrucciones de

instalación para ese modelo.

Paso 5: Instalar el servicio eléctrico

Y Primero se deben revisar los códigos loca-

les de construcción para conocer el método correcto de instalación. En los E.U.A.,

cuando no hay códigos locales aplicables,

se debe instalar esta unidad de acuerdo

con el Código Eléctrico Nacional ANSI/

NFPA No. 70, edición actual. (En Canadá,

la instalación debe cumplir con los códigos de instalación CAN 1-B149.1 y .2

para aparatos con quemadores de gas

y/o los códigos locales).

Y El aparato debe estar conectado a tierra.

En caso de un cortocircuito eléctrico, la

conexión a tierra reduce el riesgo de una

descarga eléctrica proporcionando un

cable de escape para la corriente eléctrica. Esta aparato viene equipado con un

cable con un hilo de conexión a tierra y

un enchufe para conexión a tierra. Se

debe enchufar en un tomacorriente correctamente instalado y puesto a tierra.

몇 ADVERTENCIA – Una conexión incor-

recta a tierra puede crear el riesgo de sufrir

una descarga eléctrica.

Únicamente un electricista calificado o una

persona que esté igualmente calificada

deben realizar las conexiones eléctricas.

No usar un cable de extensión. Si el cable

de alimentación eléctrica es muy corto, contratar a un electricista calificado para que

instale un tomacorriente cerca del aparato.

El receptáculo debe quedar debajo de la

cubierta, de modo que el cable de alimentación de 30 pulgadas de largo de la

ventilación pueda alcanzarlo. Ver la Figura 8.

Y Se debe enrutar el cable por debajo del

aparato y lejos del calor generado por la

parrilla. El acceso no debe estar obstruido por el ventilador, el gabinete, el ducto

ni las instalaciones eléctricas/de gas

para la parrilla. Toda la corriente para el

sistema de ventilación (incluido el ventilador remoto, si se usa) es suministrada a

través del cable a la unidad de toma de

aire. Generalmente se puede extender el

tomacorriente desde otro tomacorriente

en la cocina o puede tener su propio circuito del panel principal de servicio.

No se debe enchufar el cable del ventilador al receptáculo hasta el paso 8.

Paso 6: Montar el ventilador y la parrilla

Y A. Sacar los filtros de grasa y cualquier

material de empaque desde el interior de

la toma de aire.

Y B. Poner la toma de aire en la parte tra-

sera de la abertura de la cubierta. Bajarla

cuidadosamente a su posición de modo

que las bridas de los lados traseros y los

bordes soporten completamente la

unidad que cuelga de la cubierta.

Y C. Sostener la unidad contra la parte tra-

sera de la abertura de la cubierta y deslizar las abrazaderas de las patas hacia

abajo hasta tener contacto con el fondo

del gabinete. Revisar si está nivelada y

hacer ajustes si es necesario, luego fijar

las abrazaderas de las patas al

gabinete con los tornillos que se incluyen.

Nota: Marcar las casillas a medida que se

completen las tareas.

40

Page 41

Paso 7: Montar el ventilador integral

o la transición del ducto de salida

para el ventilador remoto o en línea

Ventilador integral (ver Figuras 9 y 11 para

más detalles):

Y A. Fijar el ventilador en el frente de la salida

redonda de escape con 4-6 tornillos autorroscantes #8 (según la configuración).

Y B. Pasar el cable del ventilador a través

del prensacables.

Y C. Fijar el prensacables con tornillos.

Y D. Fijar el prensacables al tiro descen-

dente cerca de la caja de conexiones.

Y E. Conectar el cable al tiro descendente

en el conector de 6 clavijas.

Y F. Conectar el ventilador al ducto.

Fig. 9 – Ventilador interno

41

Paso 7: Montar el ventilador integral

o la transición del ducto de salida

para el ventilador remoto

Y G. Colocar la parrilla en la abertura de la

cubierta con el borde trasero de la parrilla superpuesto al borde delantero de la

ventilación. Asegurarse de que el borde

trasero de la parrilla no toque el frente

del tubo de respiración. Seguir las

instrucciones de instalación del fabricante para instalar tiras de empaque, cinta

de protección térmica (si es necesario),

asegurar la parrilla a la cubierta y hacer

las conexiones eléctricas y/o de gas de

la parrilla.

Nota: Marcar las casillas a medida que se

completen las tareas.

Ventilador

interno

Prensacables

Conector de

6 clavijas

<*^"P) 6^"

G*"P)F^^

')D

^W*"

Page 42

Ventilador remoto o en línea (ver Figuras

10 y 11 para más detalles):