Bosch CLIMO A D00 A40 103, CLIMO A D00 A40 100, CLIMO A D00 A40 102, CLIMO A D00 A40 101 User Manual

Page 1

Micro Climate Monitoring System

BOSCH CLIMO

Page 2

A D00 A49 029

|

2017-06-09 Robert Bosch Engineering and Business Solutions Private Limited

Table of Contents

1.

Symbols and safety precautions

3

1.1 Explanation of symbols 3

1.1.1 Warning notices Structure and meaning 3

1.2 Symbols in this documentation 3

1.3 On the product 3

5.

User Interface 15

5.1 Air Quality Index 15

5.2 User Interface 15

5.3

Interpreting the outputs 15

5.3.1 To access the device through Web app 15

1.4 Important safety instructions 3

1.5

Important Notices 4

6. Troubleshooting 15

1.5.1 Don'ts 4

1.5.2

Environmental statement 4 7. Maintenance 16

1.5.3

Moving 4

1.5.4

Unpacking 4

1.5.5

3/CP300H (3.6V NI-MH BATTERY) &

8. Recommendations 16

8.1 Disposal 16

CR2032H BATTERY: 4

1.6

Enclosure safe handling instructions 5 9. Warranty 16

1.7 Short information 5

10.

FCC Warning statement 15.19

17

2.

BOSCH CLIMO overview

6

2.1

Version of product 6 11. FCC Warning statement 15.105 17

2.2 Applications 6

2.3

Site & Parameter selection as per CPCB

guidelines on measurement of Ambient Air

12.

Statement

17

Pollutants (Air Quality) 6

2.4

Device specifications 7 13. Mobile Device 17

2.5 Technical data 8

14.

RED Requirement

17

3.

Pre Installation

9

3.1 Installation Kit

9

3.2 Tools

9

3.3 Torque table

9

3.4 SIM insertion (for Micro Climate Monitoring

System 3G variant AD00 A40 00)

9

3.5 configuration (Micro Climate Monitoring

System

variant AD00 A40 002

9

3.6 Ethernet and USB connectors

9

3.6.1

Panel mount

connectors

9

3.6.2

Mating

connectors

9

3.7 Calibration

10

3.8 Health indicators

10

3.9 Pre installation Acc

eptance checklist

10

3.10 Post installation Acceptance checklist

11

4. Installation

12

4.1 Unpacking

12

4.2 Installing SIM

12

4.3 Mounting bracket assembly

12

4.4 Pole mounting

13

4.5 Wall mounting

13

4.6 Sun shade and UV sensor assembly

13

4.7

Splash guard and CO

sensor assembly

14

4.8 AC DC connection

14

en 2 |

Page 3

A D00 A49 029 | 2017-06-09Robert Bosch Engineering and Business Solutions Private Limited

|

1.

Symbols and safety

precautions

1.1

Explanation of symbols

1.1.1 Warning notices Structure and meaning

Warning notices warn of dangers to the user or people

in the vicinity. Warning notices also indicate the

consequences of the hazard as well as preventive action.

Warning notices have the following structure:

Abbreviations used in this manual:

Warning

symbol

KEY WORD – Nature and source of hazard!

Consequences of hazard in the event of failure

to observe action and information given.

➢

Hazard prevention action and information.

The key word indicates the likelihood of occurrence and

the severity of the hazard in the event of non-observance

Key word Probability of

occurrence

Severity of danger if

instructions not observed

DANGER

Immediate

impending

danger

Death

or

severe

injury

WARNING

Possible

impending

danger

Death

or

severe

injury

CAUTION

Possible

dangerous

situation

Minor

injury

1.4

Important safety instructions

Read, follow, and retain for future reference all of the

following safety instructions before operating the unit.

•

Do not install or store the unit near any heat sources

such as radiators, heaters, stoves, or other equipment

(including amplifiers) that produce heat.

•

Do not block or cover any of the openings provided in

the unit. They are provided for ventilation, to prevent

from overheating and to ensure reliable operation.

Keep open distance of approximate 200mm all round

the unit.

•

Do not place objects filled with liquids, such as vases

or cups on the unit. Never spill liquid of any kind on

the unit.

•

Do not open the mating connector and dust cap in rainy

1.2

Symbols in this documentation

Symbol Designation Explanation

!

Attention Warns about possible property damage.

i

Information

Practical hints and other useful

information.

1.

2.Multi-step

operation

Instruction consisting of several steps.

1.3

On the product

!

Observe all warning notices on products and ensure

they remain legible.

season, as the water might enter the unit and lead to

fire or electrical shock.

•

Disconnect the electrical connection before cleaning.

Use only a dry cloth. Do not use liquid cleaners or

aerosol cleaners.

•

Do not attempt to service a damaged device yourself,

unless qualified. Contact your associated channel

partner for all types of servicing, such as

–

The power supply cord or plug is damaged;

–

Sensor damaged due to exposure of moisture,

water, and/or inclement weather (rain, snow,

etc.);

–

Liquid has been spilled in or on the equipment;

–

Unit has been dropped or the unit cabinet is

damaged;

–

Unit exhibits a distinct change in performance;

–

Unit does not operate normally when the user

correctly follows the operating instructions.

•

Install in accordance with the manufacturer's

instructions in accordance with applicable local

codes.

•

Use only attachments or accessories specified by

the manufacturer. Equipment change or modification

could void the user's guarantee or authorization

agreement.

Symbols and safety precautions | 3 en

AQI

Air Quality Index

IoT

Internet of Things

IP

Ingress Protection

PCB

Printed Circuit Board

PSK

Pre-Shared Key

SIM

Subscriber Identity Module

Page 4

A D00 A49 029

|

2017-06-09

Robert Bosch Engineering and Business Solutions Private Limited

•

Be sure that the service technician uses replacement

parts specified by the manufacturer, or that which

have the same characteristics as the original parts.

Unauthorized substitutions may cause injuries or

other hazards.

i

The IMPORTANT SAFEGUARDS and WARNINGS

presented in this manual do not cover all possible

conditions that may occur. Common sense, caution

and care must be exercised when installing,

maintaining or operating the unit.

1.5

Important Notices

Accessories - Do not place this unit on an

unstable stand, tripod, bracket, or mount.

The unit may fall, causing serious injury

and/or serious damage to the unit. Use

only with mounting solutions specified

by the manufacturer. When a cart is used,

use caution and care when moving the

cart/unit combination to avoid injury from

tip-over. Quick stops, excessive force, or

uneven surfaces may cause the cart/unit

combination to overturn. Mount the unit as

per the installation instructions. .

1.5.1 Don'ts

•

Do not connect the unit to the electrical power supply

using cables that have been damaged.

•

Do not remove any of the connectors.

•

Do not keep the unit below water body and water

pipes.

•

Do not keep the unit in temperature range other than

indicated in recommendation section.

•

Do not power the unit with other power sources than

the original provided by RBEI. Voltage and current

maximum ratings can be exceeded, stopping unit from

working and voiding warranty.

•

Do not try to extract, screw, break or move connectors

far from necessary usage, waterproof sealing can be

damaged and warranty will be voided.

•

Do not connect any sensor not provided by RBEI.

•

Do not place nodes on places or equipment where

it could be exposed to shocks and/or big vibrations.

•

Do not keep mating connectors or dust caps in unlock

condition.

•

Do not use dropped unit.

•

Do not replace the sensor or any parts in the mounting

condition.

•

Do not carry the unit in assembled condition (with sun

shade, splash guard, hose clamp and screw hardware).

•

Do not mishandle CO2 and UV sensor as it may cause

reading disturbance due to vibration or shock.

1.5.2 Environmental statement

Bosch has a strong commitmenttowards the environment.

This unit has been designed to respect the environment

as much as possible.

1.5.3 Moving

Disconnect the power before moving the unit. Move the

unit with care. Excessive force or shock may damage the

unit.

1.5.4 Unpacking

•

This equipment should be unpacked and handled

with care. If an item appears to have been damaged in

shipment, repack it in the original packaging and notify

the shipping agent or supplier immediately.

•

Verify that all the parts listed in the parts list below

are included. If any items are missing, notify your RBEI

representative.

•

The original packing carton is the safest container to

transport the unit and must be used if returning the

unit for service. Save it if possible, for future use.

1.5.5 3/CP300H (3.6V NI-MH BATTERY) & CR2032H

BATTERY:

Caution:

Risk of explosion if battery is replaced by an

incorrect type.

Dispose of used batteries (3/CP300H & CR2032H

battery) according to the instructions.

Refer section 8.1

en 4 | Symbols and safety precautions

Page 5

A D00 A49 029 | 2017-06-09

Robert Bosch Engineering and Business Solutions Private Limited

|

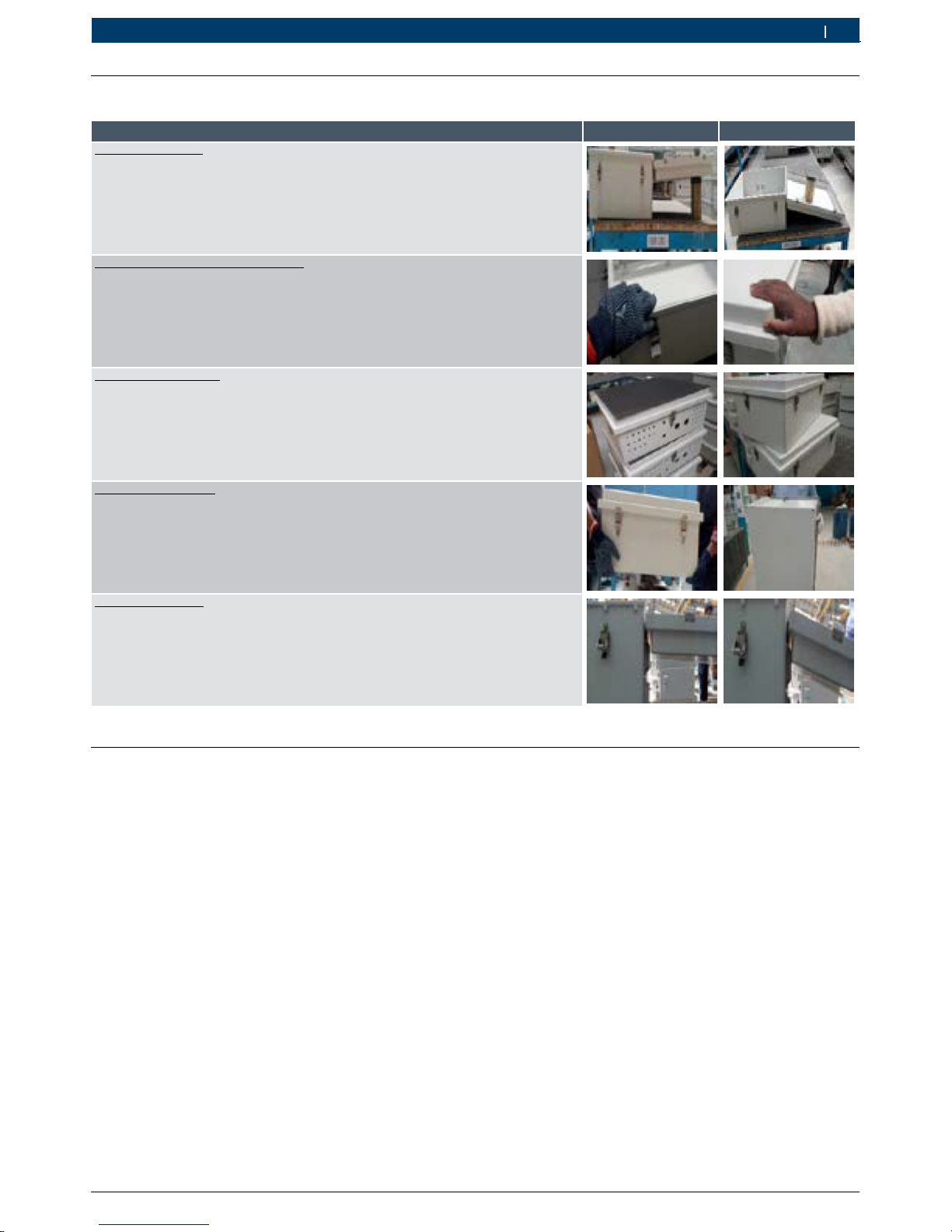

1.6

Enclosure safe handling instructions

Alert type

Do'

s

Don'ts

No load on hinges

Do’s:

Always provide support at the bottom side for enclosure cover, in cover open

condition to avoid load on hinges.

Don’ts:

Do not keep enclosure cover without proper support. Do not keep any load

on enclosure cover from inside.

Cotton gloves for product handling

Do’s:

Always use clean hand gloves to handle the enclosure.

Don’ts:

Do not touch the enclosure with bare hands and dirty gloves.

Stacking of enclosure

s

Do’s:

Use spacer material (preferably foam) to stack empty enclosure.

Don’ts:

Do not stack empty enclosure without any spacer material in-between.

Stacking of assembled enclosures are not recommended.

Enclosure movement

Do’s:

Hold horizontally and ensure support from all the sides during hand carry of

enclosures. 4 hands support for larger size (control series) is a must.

Don’ts:

Do not hold enclosure in vertical position and hand carry.

Load on vent kits

Do’s:

Enclosure covers are to be placed at 180° with bottom support.

Don’ts:

Do not rest enclosure cover on vent kits. Do not rest enclosure itself on vent kit.

1.7

Short information

All efforts have been made to ensure the accuracy of material provided in this document at the time of release. However,

the items described in this document are subject to continuous development and improvement. All specifications

are subjected to change without notice and do not represent a commitment on the part of Robert Bosch Engineering

and Business Solutions Private Limited (RBEI). RBEI will not be responsible for any loss or damages incurred related

to the use of information contained in this document.

!

Before starting up, connecting and operating this product, it is absolutely essential that the installation instructions

and, in particular, the safety instructions are studied carefully. By doing so, any uncertainties in handling this

product can be eradicated and will ultimately help to avoid damage to the unit.

Copyright

This manual is the intellectual property of RBEI and is protected by copyright.

All rights reserved.

Trademarks

All hardware and software product names used in this document are likely to be registered trademarks and must

be treated accordingly.

Symbols and safety precautions | 5 en

Page 6

A D00 A49 029

|

2017-06-09 Robert Bosch Engineering and Business Solutions Private Limited

2.

BOSCH CLIMO overview

BOSCH CLIMO is designed to measure certain

atmospheric gases and factors of the ambient

environment.

BOSCH CLIMO features are:

2.1 Version of product

There are four versions of product that is available for

customer based on connectivity;

•

Micro Climate Monitoring System (SC_3G)

A D00 A40 103

•

Micro Climate Monitoring System (3G)

A D00 A40 100

•

Micro Climate Monitoring System

A D00 A40 101

•

Micro Climate Monitoring System (Standard- RJ45)

A D00 A40 102

•

It is easy to deploy, technologically advanced and

incurs zero added infrastructure investment.

•

It connects compact wireless sensors over

3G networks enabling micro-climatic data collection.

•

BOSCH CLIMO is powered with the state-of-the-art

IoT-friendly Intel Quark processor enabled with a

“pattern matching” technology; facilitating energyefficiency, scalability and sustainability for real-world

applications.

i

Whilst robust in design, the unit is a sensitive piece

of scientific equipment and should be treated as

such.

!

The device must be protected from strong direct

sunlight as this will quickly raise the temperature of the

device beyond its operating range. BOSCH CLIMO unit

has been provided with a sun shade guard to protect

from the effects of sunlight.

i

Mount the unit facing North or South direction

!

There will be variation in sensor behavior due to

limitation of NO, NO2, and O3 sensors on higher

temperature range beyond 40°C and PM sensor for

below -10°C.

2.2 Applications

•

Real Estate and Community:

BOSCH CLIMO will

be the indicator for quality of life index and the

breathability of the ambient air. The recommendations

and early warning system based on air profiling will

help the society to make smarter choices.

•

Smart Cities:

It will form a mandatory component for

any smart city as it aides in awareness and better city

management.

•

Industries Construction:

It assists in perimeter

monitoring of the site, measure the factory health

and determines the condition in which the workers

are working.

•

Mining and Oil and Gas: This is a heavily polluting

sector by the nature of the industry itself. BOSCH

CLIMO will help in compliance adherence by constant

monitoring and thus making it a greener sector.

2.3 Site & Parameter selection as per

CPCB guidelines on measurement of

Ambient Air Pollutants (Air Quality)

Site Selection

•

Away from source & other interferences (inlet 15m

away from source/traffic artery).

•

Height of inlet >3m (preferably 3-10m) Double the

height of nearby wall/obstructed.

•

Free flowing, well mixed.

•

Elevated angle <30 (from inlet to top of building).

•

Collocated samplers should be 2m apart.

Parameter Selection

•

Sensitive location (SO2 & NO2).

•

Health Impact stations (All pollutants).

•

Population & exposure (All criteria pollutants).

•

Kerb side (Traffic intersection) (criteria pollutants +

CO).

•

Downtown (Accumulative, 50 m away traffic

intersection) (criteria pollutants + O3).

en 6 | BOSCH CLIMO overview

Page 7

A D00 A49 029 | 2017-06-09

Robert Bosch Engineering and Business Solutions Private Limited

|

2.4

Device specifications

This section shows the overall dimensions of the BOSCH CLIMO design. Detailed installation steps are explained in

further sections.

Fig. 1: Mounting envelope

BOSCH CLIMO overview | 7

en

Page 8

A D00 A49 029

|

2017-06-09 Robert Bosch Engineering and Business Solutions Private Limited

2.5

Technical data

The unit has the following features:

Category

Features

Range

Resolution / Remarks

Gas Sensors

Particulate Matter PM 2.5

0 – 500 µg/m³

± 5 µg/m³

Particulate Matter PM 10

0 – 1000 µg/m³

± 5 µg/m³

Carbon Monoxide (CO)*

0 – 31000 ppb

100 ppb

Nitrogen Dioxide (NO₂ )*

0 – 300 ppb

10 ppb

Ozone (O₃ )*

0 – 400 ppb

10 ppb

Sulphur Dioxide (SO₂ )*

0 – 700 ppb

10 ppb

Nitric Oxide (NO)* (Optional) 0 – 300 ppb

10 ppb

External Mount

Sensors (Optional)

CO

2

0 – 5% (5000PPM)

UV

up to 15 UVI

Environmental

Sensors

Humidity

10% – 95% RH

Temperature

-40°C – +70°C

Sound

45dBA – 100 dBA

Light

up to 188000 Lux

Pressure

500 to 1500 mB (hPa)

Connectivity

WCDMA/3G

WCDMA/3G

Ethernet

10/100 baseT

USB 2.0

Physical Attributes

Ruggedness

IP 53 High durability,

ingress

and shock

protection

Power supply

100VAC

– 240VAC, 50

-

60 Hz or

9 – 12 V DC

Maximum power rating

20W

Ambient Operating Temperature -20°C – +50°C

Humidity

15% – 85% RH

Enclosure

UV stabilized industrial housing molded

fiberglass reinforced polyester

Color

RAL 7035 light gray

System weight

< 6 kgs

Dimension (L x W x H)

L 30cm x W 25cm x H 15cm

Compact housing

Certifications

3G & Ethernet version CE and FCC certified.

PTCRB (is pending)

UL Certificate Number 20170731-E492562

Warranty

1 year

Software

Cloud Connectivity or Infra

Optional

API Interface

OTA update

Data uplink rate to cloud

Configurable (1 Min to 1 Hour)

Device Management

Clients and Universality

Data backup

Configurable up to 5 days

Remote monitoring, fault

detection and self-diagnosis

External Interfaces /

add-on accessories

Mounting

Pole or Wall mount

Splash guard and Sun shade

Battery power pack

DC power provisions

Optional external battery

(12V/40Ah/36W)

Solar power pack

12V DC power from Solar panel

Optional

en 8 | BOSCH CLIMO overview

Page 9

A D00 A49 029 | 2017-06-09Robert Bosch Engineering and Business Solutions Private Limited

|

3.

Pre Installation

3.1

Installation Kit

The installation kit contains:

3.4 SIM insertion (for Micro Climate

Monitoring System 3G variant AD00

A40 00)

SIM card is not part of the product, it has to be purchased

and assembled by the customer or the end user.

•

SIM card must be micro-SIM (3ff) industrialization

grade robust or super-robust plastic type with

operating temperature of -40°C to 105°C.

•

Before installing the unit on pole or wall, assemble the

SIM and check for the connectivity.

3.2

Tools

The following tools are helpful:

Tool Description

Purpose

Philip head screw driver For all kinds of screws

Gloves (ESD protected

and safety gloves)

Safety for hands

Goggles

To protect from dust during drilling

wall

Flat screw driver

To fix pole mounting ring to pole

Use power operated tools to avoid fatigue to

the installer.

3.3

Torque table

3.5 configuration (Micro Climate

Monitoring System variant AD00 A40

002

Configuration has to be done.

3.6 Ethernet and USB connectors

3.6.1 Panel mount connectors

The table below gives the detailed information of the

panel mount connectors which are used in BOSCH

CLIMO unit:

Panel mount

connector

Part Number Description

Ethernet

17-10000

CONN MOD Coupler 8P8C TO

8P8C

USB

17-200161

CONN USB ADPT F

-

F W/Cover

IP67

3.6.2 Mating connectors

i

Refer to the Connector website for installation of

Ethernet cable with Ethernet mounting connector.

i

Mating connector is not part of BOSCH CLIMO unit.

It is recommended to use IP65 compliant mating

connectors mentioned in the table below

Mating

connector

Mfr.

Part

Number

Description

Ethernet Conec 17-10001

Plug modular connector

8p8c (RJ45, Ethernet)

position shielded Cat5e IDC

USB

Conec 17-200121

USB -

A USB 2.0 plug

connector 4 position free

hanging (In-Line)

i

There is a waterproof dust cap, which protects

the connector when it is not mated with the above

connectors.

If the

above mating connectors are not used t

hen

the req

uired IP is not guar

anteed.

Pre Installation | 9

en

Qty Component

2

ASSY, Mounting bkt

4

Screw, Pan head Philips with washer

1

Splash guard_smartcity

8

Machine screw, Pan head Phillips m3 x 12lg

2

Vibration

-

resistant worm

-

drive clamps for "od 4 inch to

7 inch"

4

Screw, 8 x 80lg self

-

tapping along with dry wall

anchors

1

Sun shade guard_smartcity

1

Template for wall mounting

1

Assembly for external AC power supply cable

1

Assembly for external DC power supply cable

1

CO2 sensor

1

Plastic mounting flange (dia 18.5mm)

1

UV sensor

Part No.

Description

Tightening

Torque (N-m)

AD00A43029

CO2 Sensor self

-

tapping screw

on Mounting Flange

0.3-0.5

AD00A41073

M5 X 12 CO2 Sensor Mounting

Flange

0.5-0.8

AD00A43030 UV Sensor Mounting

0.3-0.6

AD00A41027

M3 x 12 LG Screw of Property

class 5.8

0.5 to 0.7

AD00A41030

M3 x 6 LG Screw of Property

class 5.8 (Countersunk)

0.5 to 0.7

AD00A41045

M3 x 6 LG Screw of Property

class 5.8

0.5 to 0.7

Page 10

A D00 A49 029

|

2017-06-09

Robert Bosch Engineering and Business Solutions Private Limited

3.7

Calibration

The gas sensors that are available as part of the BOSCH CLIMO are pre-calibrated by the sensor manufacturer

and should have expected response to change in ambient air conditions within the first 7 days, post installation.

However, these gas sensors are known to drift over time. Hence they require frequent recalibration. BOSCH CLIMO

uses the following 2 methods for recalibration:

•

Regular recalibration cycles or field recalibration:

This is done by using data from an EPA graded instrument,

co-located along with or available in the near vicinity of the BOSCH CLIMO. This recalibration is handled

remotely using the remote device management platform.

•

In-house recalibration:

This is carried out by unmounting the device and recalibrating it in a laboratory environment

with NIST certified calibration gases or completely replacing the sensor to have a new one in place of the existing

one.

i

For use cases which require greater accuracy of data, frequent recalibration would be required. The best suited

recalibration cycle can be defined by observing the trend of sensor data from the BOSCH CLIMO in its current

deployment location for the first few days.

i

Environment and particulate matter sensors do not exhibit any behavioral drift over time and hence may not

need regular recalibration cycles.

3.8

Health indicators

You can know the device is functional by checking the red LED indicator. Blinking of this LED, indicates that there

is a proper connection of the BOSCH CLIMO device with cloud and the data is being transmitted successfully.

3.9

Pre installation Acceptance checklist

i

Take the print out of the checklists, sign and store it for every unit.

Sl. No. Description

Test Passed

(Yes/No/NA)

Comments

1

Availability

of

product

handling

or

installation

safety

precaution

(ex. hand

gloves, ladder, helmet, safety belt)

2

Availability of ESD protection for SIM installation

3

Device Serial number

4

Device Mac ID

5

Location

6

Latt and Long

7

SIM card number

8

SIM ID Number

9

SIM must be industrial

grade

and WCDMA/3G

MICRO

SIM (3ff) (Micro

-

SIM

(3ff) industrialization grade robust or super-robust plastic type with

operating

temperature -40 ˇ c to 105 ˇ c)

10

Availability of Ethernet mating connector along with cable

11

Availability of Ethernet connection at location

12

Confirmation

of

signal

strength

from Service

provider

at

the installation

location

13

Availability and verification of dispatch checklist

14

Physical verification of the complete product and accessory kit

15

Test report available

16

Torque controlled Tools availability for installation

17

Installation manual (soft copy)

18

Availability of DC/AC power socket

19

Ensure the proper voltage (12v DC/230v ac)

20

Ensure no obstruction in north and south direction at the installation pole

21

Installation height must be within 8 to 12 feet

22

Date and time of installation

en 10 | Pre Installation

Page 11

A D00 A49 029 | 2017-06-09Robert Bosch Engineering and Business Solutions Private Limited

|

3.10 Post installation Acceptance checklist

Sl. No. Description

Test Passed

(Yes/No/NA)

Comments

1

Torque measurement and record of the mounting

- Mounting bracket

- Splash guard

- CO2 Sensor assembly

- UV sensor assembly

- Solar Shade

2

Ensure mating connectors and dust caps should be in locked condition

3

Connection details (Ethernet/3G)

4

Switch on the unit and observe blinking of the red LED

5

Ensure the device updating the data on the cloud verified by customer

using their system

6

Picture of installation in four direction

7

Details of the four direction at the location

North

East

West

South

Pre Installation | 11

en

Page 12

A D00 A49 029

|

2017-06-09

Robert Bosch Engineering and Business Solutions Private Limited

4.

Installation

The right behaviour of BOSCH CLIMO unit depends

on a reliable installation. RBEI provides the necessary

accessories to make it easier, like mounting bracket,

screws, connectors, and other accessories.

Wherever BOSCH CLIMO unit is placed, make sure that

you tight it firmly and the enclosure is not affected by

wind, vibrations and other environmental conditions.

RBEI does not take responsibility of damages caused due

to tampering or bad installation.

!

During the process of unpacking, installing, assembly

and servicing, all relevant ESD precautions must be

undertaken and handled with care in order to avoid

damage and accident.

!

Ensure to place the unit on the table that is sturdy

and use soft cover that will not damage the unit.

4.1

Unpacking

1. Detach the upper box from the outer carton

package.

2. Remove the unit from the box carefully and verify

whether there is any damage or not on the unit, during

transporting.

3. Open the carton box of the installation kit.

4. Check the delivery carefully to make sure that all parts

have been delivered. If there is any mistake, please

contact your authorized dealer at once.

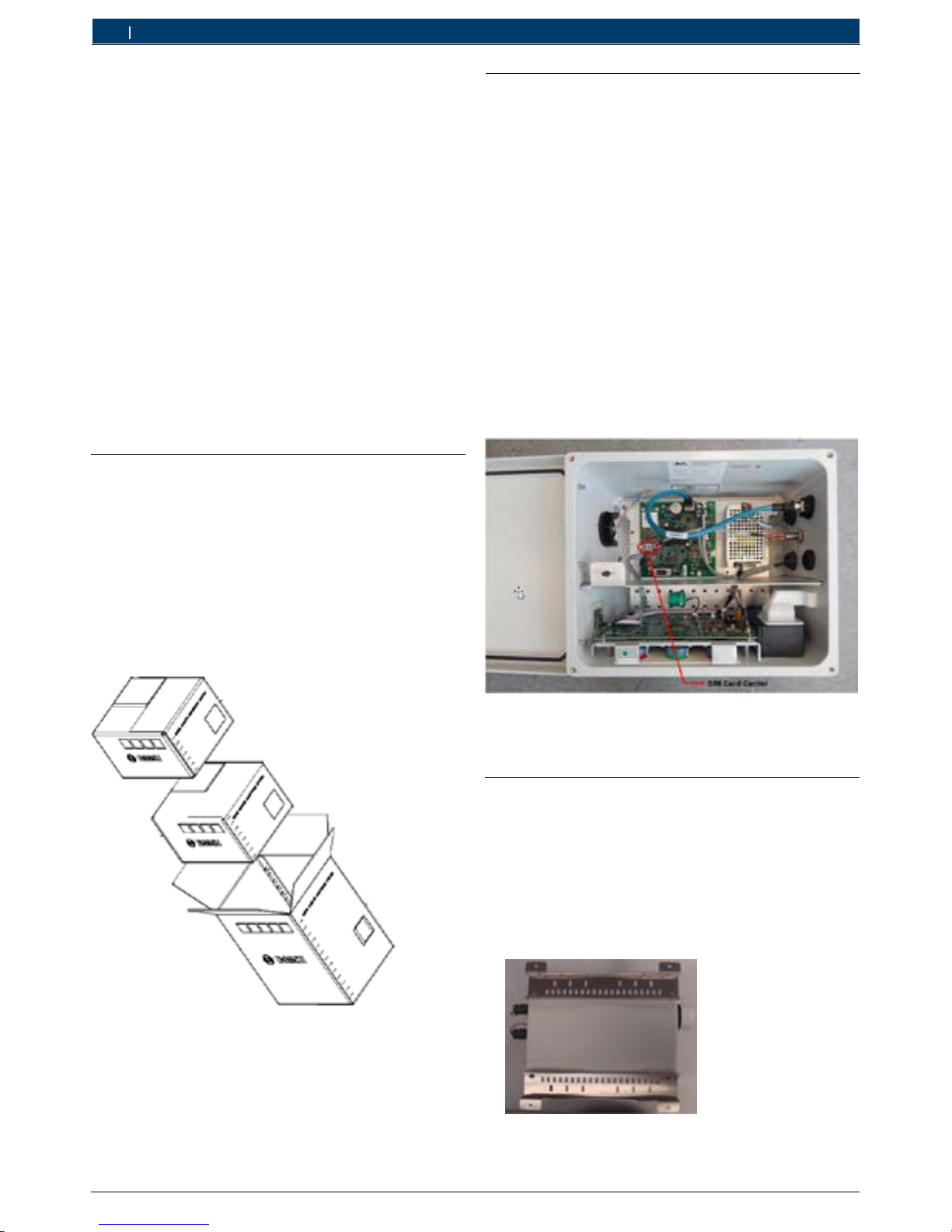

Fig. 2: Packaging

i

In the installation kit, parts for both wall mounting and

pole mounting are available.

i

Keep the original package for the future transporting.

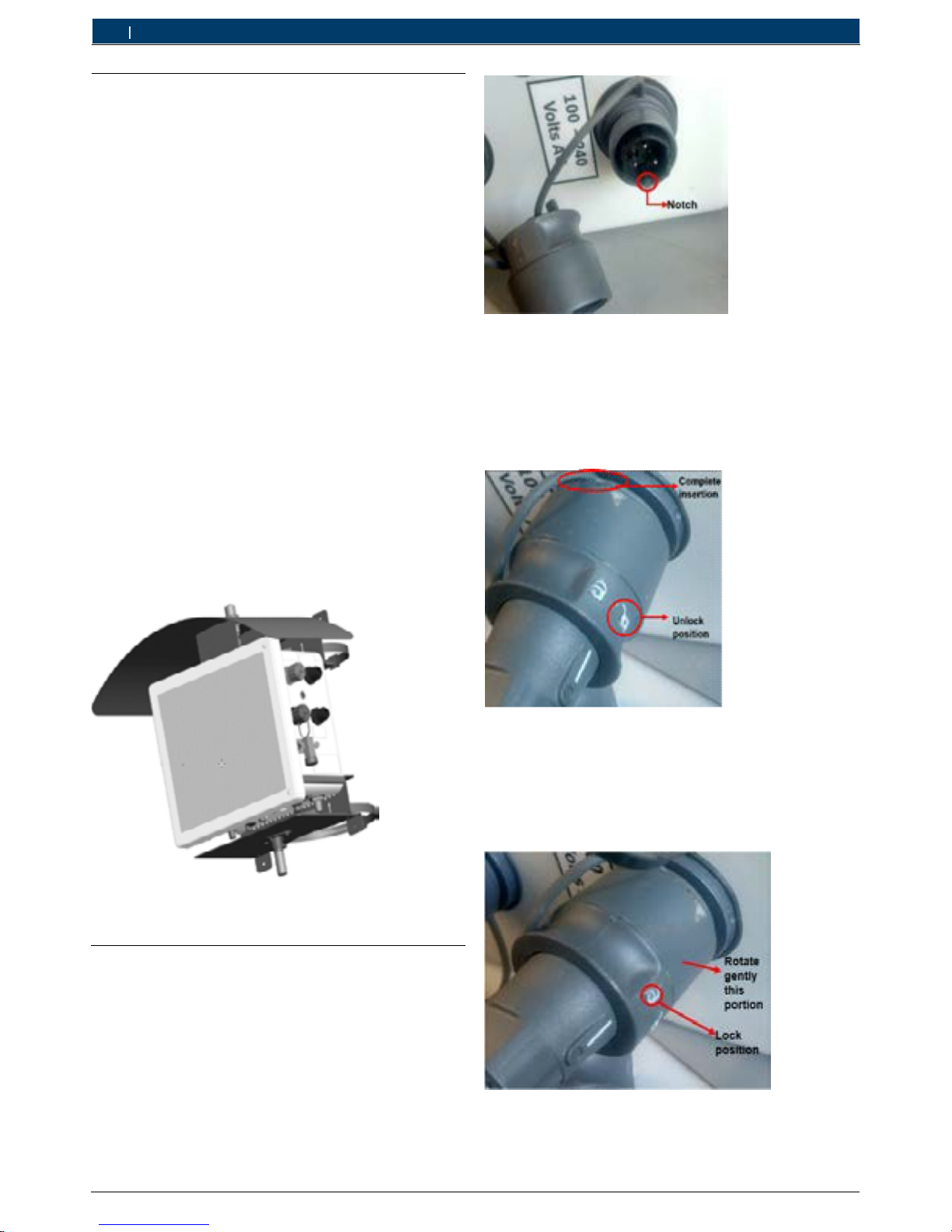

4.2 Installing SIM

To install SIM in the unit:

!

Ensure to take necessary ESD precautions during

inserting and removing the SIM card.

i

Do not insert or remove the SIM card while the unit

is plugged to power supply.

1. Unscrew the two screws.

i

Do not remove the screws from the cover panel.

2. Locate the SIM card carrier in the Processor Board.

3. Slide the metal cover of the SIM card holder towards

the back of the box to unlock.

4. Insert the SIM card into the slot and slide the metal

cover to its original position.

Fig. 3: SIM card in the unit

5.

Tighten back the screws of the cover panel.

4.3 Mounting bracket assembly

To mount bracket to the unit:

1. Place the unit on the table.

2. Fix the mounting bracket to the rear side of the

unit with the screws provided (M5 x 12LG 4Nos “

AD00A41031”).

i

The surface on which the unit is placed should be

smooth and soft, such that the unit is not damaged,

Fig. 4: Mounting bracket fixed to unit

en 12 | Installation

Page 13

A D00 A49 029 | 2017-06-09

Robert Bosch Engineering and Business Solutions Private Limited

|

4.4

Pole mounting

To pole mount the unit:

1. Insert the provided vibration-resistant worm-drive

clamps, to the mounting bracket slots.

2.

Wrap the clamps around the pole.

i

The pole mounting clamp provided in the installation

kit suits for “5 inch to 6 inch” diameter. If the pole

diameter is outside this limit, the installer or user

should take care of the mounting clamp.

Fig. 5: Pole mounting

3. Tighten the hexagonal bolt with respect to the pole.

i

Assemble worm-drive clamps to the mounting bracket

before assembling Sun shade and Splash guard.

i

Fix the unit on a flat wall, otherwise mounting of

splash guard could be difficult and RBEI will not be

responsible for the damage caused.

Fig. 6: Wall mounting

4.6

Sun shade and UV sensor assembly

To assemble sun shade and UV sensor on the unit:

i

Sun shade has to be assembled when the unit is

mounted on pole or wall. This is needed as space

is required to fix the screw through the mounting

bracket.

1. Fix the UV sensor on the sun shade from bottom first,

4.5

Wall mounting

To wall mount the unit:

1.

Use the wall mounting template to mark out the four

mounting holes on the wall.

2. Drill holes on the marked points of the wall.

i

The mounting holes should be such that it can

accommodate the proposed wall plugs and screws.

3.

Insert the supplied mounting plugs into the mounting

holes.

4.

Fix the unit to the wall with self-tapping screw that is

provided, to securely mount the unit to the surface.

5.

Fasten the screws.

i

Use the screws provided, for the unit to be safe on

wall.

i

Any screws and wall plug can be used that is suitable

for the hole provided in the mounting bracket.

i

Fix the splash guard, after the unit is fixed on the wall.

and lock nut on top.

2. Fix the sun shade on to the top mounting bracket with

the provided screws.

3. Connect the USB mating connector.

!

Take care not to apply excess load while installing the

sun shade, as the unit is not a load carrying component

and can cause damage.

!

Do not rest the unit on sun shade.

i

While assembling handle UV sensor with care.

Fig. 7: Sun shade with UV sensor

Installation | 13

en

Page 14

A D00 A49 029

|

2017-06-09

Robert Bosch Engineering and Business Solutions Private Limited

4.7

Splash guard and CO2 sensor

assembly

To assemble splash guard and CO2 sensor on the unit:

i

Splash guard has to be assembled when the unit is

mounted on wall. This is needed as space is required

to fix the screw through the mounting bracket.

i

Avoid installing any other equipment around sensors

(CO2 & UV sensors).

1. Assemble the CO2 sensor, and plastic mounting flange

with self tapping screw.

2. Fix it to the Splash guard with the provided M5 screws.

3.

Fix the Splash guard to the bottom mounting bracket

with help of provided screws.

!

Take care not to apply excess load while installing

the splash guard, as the unit is not a load carrying

component and can cause damage.

!

Do not rest the unit on splash guard.

i

While assembling handle, CO2 sensor with care and

avoid installing any other equipment around the

sensor.

Fig. 8: Splash guard with CO2 sensor

4.8

AC DC connection

To connect AC or DC cable to the unit:

1.

When the unit is assembled either on pole or wall,

check that the unit is in perfect condition and

without any damage.

2. Fix the AC or DC cable harness as per the label

indicated on the unit.

Fig. 9: Notch for mating connector

3.

Insert the mating connector keeping notch as

reference.

i

Mating connector should be in unlock position and

inserted completely as shown in the figure below.

Fig. 10: Mating connector insertion

4.

Lock the mating connector.

i

Carefully insert the connector into the notch with

a gentle push and it should not give crunch sound.

Smooth lock should happen.

Fig. 11: Mating connector locked

en 14 | Installation

Page 15

A D00 A49 029 | 2017-06-09Robert Bosch Engineering and Business Solutions Private Limited

|

i

In the accessory kit, a separate compatible AC and

DC connectors are available with a cable length of

around 3m. Before assembling the unit, the other

end of the cable has to be assembled to a power

socket which is not part of the accessory kit.

1. Based on the power socket on the other end of the

cable, fix the necessary plug and connect to power

socket. Switch ON the unit and check if the unit is

working.

i

A red glow of the LED indicates that the unit is ON

and working.

5.

User Interface

application or as part of a customer specific enterprise

platform.

These content rich visual displays helps to understand not

only the device location and status (online or offline or

error prone, etc.) but also, view the instantaneous value

of sensor data. The Air Quality Index (AQI) parameter,

usually displayed prominently in all these applications,

is an important element to understand the overall

ambient air conditions within specific geographical

boundaries. The AQI is calculated by the analytics

platform on the cloud and is based on the incumbent of

air quality regulations in the region of deployment. The

APIs also allow construction of intuitive dashboards to

represent the trend of data over time thereby providing

an understanding of changing atmospheric conditions in

relation to seasonal or specific events. These applications

also generate, customized reports for offline analysis

5.1

Air Quality Index

which can aid planning of corrective actions to make the

ambient air safer.

AQI (Air Quality Index) formulated by the Central Pollution

Control Board along with State Pollution Control Boards

is an effective tool for dissemination of air quality

information to people. There are six AQI categories,

namely: Good, Satisfactory, Moderately polluted, Poor,

Very Poor, and Severe. The range and associated health

risks for each category are as follows:

AQI category Range Associated health impacts

Good

0-50

Minimal impact

Satisfactory 51-100

May cause minor breathing

discomfort to sensitive people.

Moderately

polluted

101–

200

May cause breathing discomfort to

people with lung disease such as

asthma, and discomfort to people

with heart disease, children and

older adults.

Poor

201-300

May cause breathing discomfort to

people on prolonged exposure,

and

discomfort to people with h

eart

disease.

Very poor

301-400

May

cause respiratory illness

to

the people on prolonged exposure.

Effect may be more pronounced in

people with lung and heart diseases.

Severe

401-500

May cause respiratory impact even

on healthy people, and serious

health

impacts on people with lung/heart

disease. The health impacts may

be experienced even during light

physical activity.

5.2

User Interface

The user interface is a medium through which personas

associated with the business entity owning the product

(or general public, if allowed) can view device information

and sensor data. The APIs available in the platform enable

the presentation of data as a web application, mobile

5.3 Interpreting the outputs

5.3.1

To access the device through Web app

1. Contact your installation agent for getting website

link and user credentials i.e. username and password.

i

Once it is activated you will be able to access the UI.

2.

Enter your user name and password.

3.

Click Login to proceed.

6.

Troubleshooting

Malfunction

Possible

causes

Solution

Unit does not

operate.

Power failure

Check AC or DC power

supply

Faulty cable

connections

Check all cables, plugs,

contacts and connections.

No connection

established,

no data

transmission

Network

unavailability

Check the required

telephone network is

available in the area

Faulty

installation

Check the SIM card for

proper installation

NO cloud

connection

Check for blinking of panel

LED .

i

If you find any other malfunctions apart from

the above mentioned ones, please contact your

associated channel partner.

User Interface | 15

en

Page 16

A D00 A49 029

|

2017-06-09 Robert Bosch Engineering and Business Solutions Private Limited

7.

Maintenance

Although BOSCH CLIMO unit is highly resistant to external

environment and load, periodic maintenance and care of

i

Periodic maintenance is required for all the sensor

probes like particle matter sensor, temperature

and humidity, UV sensor and CO2 sensor to ensure

accurate readings.

the unit is required for a longer useful life.

8.1 Disposal

•

Handle BOSCH CLIMO unit with care during

installation, transportation and maintenance.

•

While transporting the unit, proper packaging needs

to be taken care.

•

Avoid placing the unit in place where there is chance

of reaching high temperatures, this could damage the

electronic components.

•

The locknut of connectors are gentle, do not apply

excessive force upon installing or it may get damaged.

•

CO2 and UV sensors are highly sensitive and extra care

is required for assembly handling and storage.

•

Do not use any type of paint on the device, it could

deteriorate the properties.

•

Do not use aggressive chemical products for cleaning, .

i

Gas sensors may require replacement for optimal

accuracy. The periodic replacement depends on the

location at which the unit is installed.

i

Automatic system notification is sent to the

administrator, whenever the maintenance is required.

8.

Recommendations

RBEI gives some recommendations to improve

performance and efficiency of BOSCH CLIMO unit,

enlarging useful life of all of its elements.

•

Keep the unit and its sensors out of direct sunlight

and glare. It is known that, sun rays accelerates plastic

elements deterioration.

•

BOSCH CLIMO unit is waterproof (rated at IP53).

Extra precautions are taken to protect the unit against

most weather conditions, however make sure that the

water does not enter the unit directly. If your model

includes external solar panel, it is recommended to

place the unit under the solar panel, to keep the node

out of the rain. Ensure that the solar panel is faced

to south (north if you are on the south hemisphere)

and tilted 45º.

•

Always place the unit such that the connectors and

antenna face towards either to west or east.

•

Keep the unit out of range of people who can damage

installation, wet sensors, etc.

•

As per sensor manufacturer’s specification, sensors

are capable of producing accurate data under stable

temperature & humidity. The standard test conditions

are 20°C and 80% RH and in the absence of interfering

gases.

•

RBEI takes no responsibility of any damage to third

parties caused by a bad installation.

Disposal - Your Bosch product was

developed and manufactured with

high-quality material and components

that can be recycled and reused. This

symbol means that electronic and electrical

appliances, which have reached the end of

their working life, must be collected and

disposed of separately from household

waste material. Separate collecting

systems are usually in place for disused

electronic and electrical products. Please

dispose of these units at an environmentally

compatible recycling facility, as per the law

of the land.

!

Hand over the old/discarded electronic equipment

only to authorized collection centers for disposal.

See also:

Contact No: 180042535287 (toll-free)

E-mail: recycle@ewasteindia.com

Online website: www.ewasteindia.com

9.

Warranty

•

This unit is guaranteed, to the original end user

purchaser, against defect in materials and

workmanship for a period of 12 months from the

date of the shipment to the user. During this period

Bosch will repair or replace defective parts on an

exchange basis. The decision to repair or replace will

be determined by Bosch.

•

To maintain this warranty, the purchaser must perform

the installation and maintenance as prescribed in

the manual. Only the parts supplied by Bosch should

be fitted. Normal wear and tear, and parts damaged

by abuse, misuse, negligence, or accidents are

specifically excluded from the warranty.

•

Exposure to temperature outside the range of -20°C

to +50°C (with clause for PM sensor, NO, NO2 and O

3

sensor) or to relative humidity outside the range of

15% to 85% will void the warranty.

en 16 | Maintenance

Page 17

A D00 A49 029 | 2017-06-09Robert Bosch Engineering and Business Solutions Private Limited

|

10.

FCC Warning statement

15.19

•

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received,

including interference that may cause undesired

operation.

•

Any changes or modifications not expressly approved

by the party responsible for compliance could void the

authority to operate equipment.

•

This device and its antenna must not be colocated or

operating in conjunction with any other antenna or

transmitter.

•

End-users and installers must be provided with

antenna installation instructions and transmitter

operating conditions for satisfying RF exposure

compliance.

•

For product available in the USA/Canada market, only

channel 1~11 can be operated. Selection of other

channels is not possible.

11.

FCC Warning statement

15.105

This equipment has been tested and found to comply with

the limits for a Class B digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in

a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions,

may cause harmful interference to radio communications.

However, there is no guarantee that interference will

not occur in a particular installation. If this equipment

does cause harmful interference to radio or television

reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following

measures:

•

Reorient or relocate the receiving antenna.

•

Increase the separation between the equipment and

receiver.

•

Connect the equipment into an outlet on a

circuit different from that to which the receiver is

connected.

•

Consult the dealer or an experienced radio/TV

technician for help.

12.

Statement

i

Any changes or modifications not expressly

approved by the party responsible for compliance

could void the authority to operate equipment.

i

This device and its antenna must not be co-

located

or operating in conjunction with any other antenna

or transmitter.

i

End-users and installers must be provided with

antenna installation instructions and transmitter

operating conditions for satisfying RF exposure

compliance.

13.

Mobile Device

This equipment complies with FCC radiation exposure

limits set forth for an uncontrolled environment. This

equipment should be installed and operated with

minimum distance 20cm between the radiator & your

body.

14.

RED Requirement

•

Ensure that the equipment can operate in at least

one Member State. “The radio equipment can be

used in one member state at least”

•

CE mark

•

A copy DoC / simplified DoC which shall accompany

the product

–

Copy of DoC is made available to user.

http://35.157.28.63/app/index.html#/login

FCC Warning statement 15.19 | 17 en

Page 18

Robert Bosch Engineering and Business Solutions Private Limited

123, Industrial Layout,

Hosur Road, Koramangala,

Bangalore 560 095

INDIA

Loading...

Loading...