Bosch CHP CE 400 NE, CHP CE 1200 NE, CHP CE 600 NE, CHP CE 800 NE, CHP CE 1287 NE Technical Manual

...Page 1

Technical guide

System solution

4-draught steam boiler and CHP

with MEC system

6 720 885 509 (2018/03) GB

Page 2

Contents

Systemlösung – 6 720 885 509 (2018/03)

2

Contents

1 System solution: 4-draught steam boiler with

combined heat and power (CHP) . . . . . . . . . . . . 3

1.1 Notice on technical guide . . . . . . . . . . . . . 3

1.2 System solution . . . . . . . . . . . . . . . . . . . . . 3

1.3 Features and benefits . . . . . . . . . . . . . . . . 4

2 System components . . . . . . . . . . . . . . . . . . . . . . 5

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Bosch CHP for external waste heat use . . 6

2.2.1 Description CHP CE ... NE . . . . . . . . . . . . . 6

2.2.2 Technical data . . . . . . . . . . . . . . . . . . . . . . 7

2.2.3 Operation conditions CHP . . . . . . . . . . . . 8

2.3 4-draught boiler system . . . . . . . . . . . . . . 9

2.3.1 Description of 4-draught boiler system . . . 9

2.3.2 Technical data . . . . . . . . . . . . . . . . . . . . . 10

2.3.3 Dimensions and connections . . . . . . . . . 11

2.4 MEC System – overview . . . . . . . . . . . . . 13

2.5 Further options for waste heat use/peak

load boiler . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5.1 Waste heat boiler HRSB . . . . . . . . . . . . . 14

2.5.2 3-draught waste heat boiler for use

of waste heat only . . . . . . . . . . . . . . . . . . 15

2.5.3 System extension with peak load boiler . 15

3 Engineering information and sizing . . . . . . . . . 16

3.1 Basic principles . . . . . . . . . . . . . . . . . . . . 16

3.1.1 Economic viability . . . . . . . . . . . . . . . . . . 16

3.1.2 Economic general conditions . . . . . . . . . 16

3.1.3 Technical system data . . . . . . . . . . . . . . . 17

3.2 Pre-dimensioning . . . . . . . . . . . . . . . . . . 18

3.2.1 Estimate design of key components . . . . 18

3.2.2 Investment costs . . . . . . . . . . . . . . . . . . . 18

3.2.3 Evaluation of economic viability . . . . . . . 19

3.2.4 Integration of 4-draught steam boiler . . . 20

3.3 Sizing of key components . . . . . . . . . . . . 23

3.3.1 Sizing of 4-draught steam boiler . . . . . . . 23

3.3.2 Sizing of CHP module . . . . . . . . . . . . . . . 24

3.3.3 Steam amount/waste heat output

and CHP/boiler combinations . . . . . . . . . 24

3.3.4 Demand for useful energy for

make-up water preheating, heating

energy and DHW . . . . . . . . . . . . . . . . . . . 28

3.3.5 Safety equipment . . . . . . . . . . . . . . . . . . 30

3.3.6 System control . . . . . . . . . . . . . . . . . . . . 30

3.3.7 Flue system . . . . . . . . . . . . . . . . . . . . . . . 32

3.4 System design . . . . . . . . . . . . . . . . . . . . . 34

3.4.1 Hydraulics with bypass . . . . . . . . . . . . . 34

3.4.2 Hydraulics without bypass . . . . . . . . . . . 36

3.4.3 Installation . . . . . . . . . . . . . . . . . . . . . . . 38

4 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.1 List of components . . . . . . . . . . . . . . . . . 40

4.2 Further technical documents . . . . . . . . . . 41

Keyword index . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Page 3

System solution: 4-draught steam boiler with combined heat and power (CHP)

3

Systemlösung – 6 720 885 509 (2018/03)

1 System solution: 4-draught steam boiler with combined heat and power (CHP)

On the background of increasingly scarce natural

resources, sharp increases in energy prices over the last

few years and a turnaround in energy policy, it has

become indispensable, not only from an ecological, but

also from an economic point of view, to review and

reduce one's own energy consumption.

The industrial sector, the most energy-demanding of the

economic sectors, provides a large savings potential.

Often industrial applications require a steam supply

system. Such a system can be optimised concerning

energy consumption and economic viability by using

combined heat and power (CHP) in combination with a

CHP module. In the context of a turnaround in energy

policy, CHP plays a very important role. Its part in the

power generation mix in Germany will increase until

2020 to 25 %.

1.1 Notice on technical guide

The existing technical guide “4-draught boiler and CHP

with MEC system” can be used as information to simplify

the planning and sizing of 4-draught steam boiler system

in combination with combined heat and power unit by

Bosch.

The technical guide shall help you to understand the

basics for using flue gas heat for creating steam in 4draught steam boilers and for designing the components

of a boiler system in conjunction with a combined heat

and power unit (CHP).

The existing technical guide will show possible ways of

execution and respond to open questions concerning

planning, calculation, economic viability and quotation.

1.2 System solution

For commercial and industrial applications, the use of a

CHP system in conjunction with a steam boiler with

integrated waste heat use can be an efficient alternative.

Here, the CHP unit (design as CHP module for external

flue gas use) creates electrical current. A downstream

boiler system uses the hot flue gases of the CHP for

efficient creation of process vapour. The motor heat of

the CHP module can be used for make-up water

preheating, for heating or for DHW heating.

The steam boiler with waste heat utilisation is a

conventionally fired 3-draught steam boiler with

integrated additional fourth draught (4-draught steam

boiler). The hot flue gas of the CHP module is led

through the boiler to support steam production. Thanks

to the integrated combustion in 4-draught steam boilers,

steam peak load boilers are not necessary here that are

usually required with pure waste heat boilers.

Investment costs, space requirements and equipment

effort can be reduced significantly.

The use of a CHP in combination with a 4-draught steam

boiler is gently on the environment in more than one

respect.

The most important aspect is the considerably lower

consumption of primary energy compared to

conventional, separated production of current, steam

and heat. With a CHP, natural resources are saved and

the environment is protected from pollutants from other

combustion processes.

For the combination of a 4-draught steam boiler series

UL-S by Bosch Industriekessel GmbH and a CHP system

by Bosch KWK Systeme GmbH, different system

hydraulics are proposed in this document and their

planning and execution is described (Æ chapter 3.4,

page 34). These are suggestions that allow a simple

realisation.

Page 4

System solution: 4-draught steam boiler with combined heat and power (CHP)

Systemlösung – 6 720 885 509 (2018/03)

4

1.3 Features and benefits

A CHP module provides several benefits, besides saving

resources and reducing the environmental impact,

significant revenues can be achieved using the current

produced by the CHP module.

The revenue is composed of credits for created current

and credits for created heat. Here is must be

differentiated whether the current is produced for own

use of whether it is completely fed in the upstream

mains.

Benefits for end-customers/investors/plant users

• Low consumption of primary energy compared to

conventional, separated production of current, steam

and heat

• Is gentle on the environment: Saves CO

2

and

resources

• Remuneration for self-produced current in

accordance with corresponding national regulations,

e. g. Germany EEG/KWKG

• Amortisation time/ROI of less than 3 years possible

• Sustainable due to decentral energy generation

• Space-saving, no installation of additional peak load

boilers

• Modular system with all benefits of CHP operation

concerning supply reliability, efficiency and current

cost reduction at simultaneously reduced complexity

Benefits for planners/engineers

• Safe planning

– Boiler and CHP module, all from one source

– Functional system hydraulics and standardised

schematic diagrams

– Complete list of components, defined limits of

delivery

– Integration of higher-level control

(Bosch MEC system)

• System safety

– Tuned and certified safety equipment

– All flue gas temperatures from the Bosch CHP

module are securely attained, also in partial load

operation

– Optimised flue gas sound insulation – smoothed

flue gas pulsation, solutions for use in industry,

mixed and residential areas

– Tuned control with bypass dampers with safety

function

– Matched flue system, optimised to admissible flue

gas back pressure of CHP module with regard to

wear of system, maintenance and contamination

– Matched material pairs in flue gas path

• Excellent price/performance ratio/fast ROI/low TCO

– Meaningful, sustainable calculation of economic

viability

– Overall efficiency of CHP module > 70 % by using

waste heat in steam boiler and limiting the flue gas

temperature downstream of the fourth draught/

economiser and use of MEC system

– By using the MEC system, the runtime of the CHP

module is optimised by tuned control strategy.

Page 5

System components

5

Systemlösung – 6 720 885 509 (2018/03)

2 System components

2.1 General

The CHP system with waste heat use for steam

generation consists of 2 key components plus required

accessories.

The key components are:

• A CHP module, designed for flue gas heat utilisation

(without flue gas heat exchanger), consisting of

combustion engine and generator

• A steam boiler with combustion and integrated fourth

draught for waste heat use

• The superordinate control of the combination CHP

and 4-draught steam boiler should be effected by the

Bosch control system MEC system.

The combustion motor is intended for activating the

generator. The hot flue gas, that is created during the

combustion process, with temperatures above 400 °C is

used in the 4-draught steam boiler for steam production.

In addition, during operation of the CHP module, engine

coolant with a temperature of up to 85 °C is created.

Depending on the loss of condensate in the steam

network, this can be used for make-up water preheating

in the steam boiler or for space heating or DHW heating.

The system control “MEC system” controls the

combination of CHP module and 4-draught steam boiler

and optimally integrates is in the compete energy

production system on site.

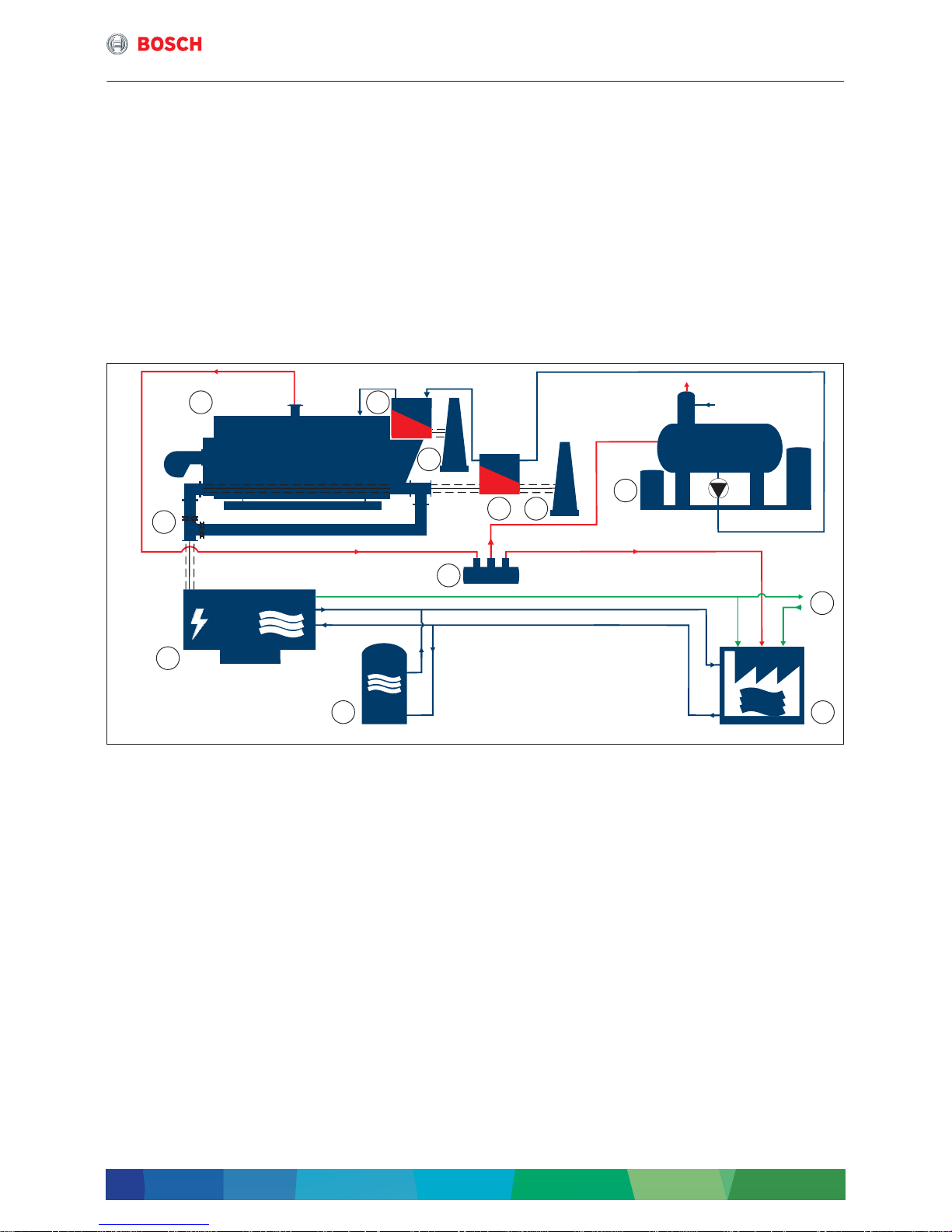

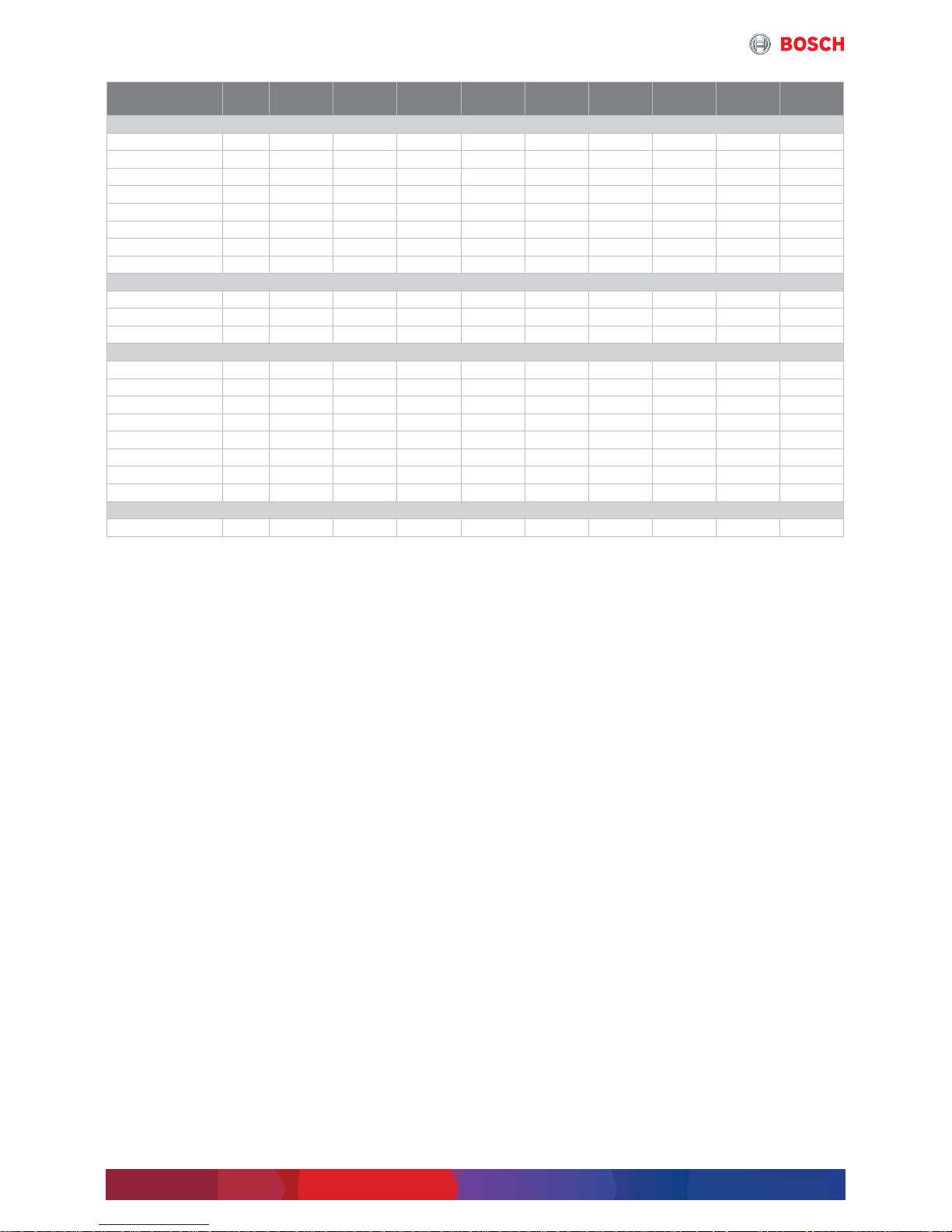

Fig. 1 Simplified function diagram 4-draught steam boiler and CHP module and CHP (simplified depiction)

[1] 4-draught steam boiler

[2] Economiser

[3] Chimney

[4] Flue gas heat exchanger

[5] Water service module

[6] Mains power supply

[7] Consumer

[8] Manifold

[9] Memory

[10] CHP

[11] Flue with bypass

Current

Water/condensate

Steam

Flue gas

If a replacement power supply is necessary, e.g. as in

hospitals or other safety-relevant facilities, a CHP

module can also be used as standby power generator.

6 720 819 535-01.1T

1 2

3

34

5

6

7

8

9

10

11

Page 6

System components

Systemlösung – 6 720 885 509 (2018/03)

6

2.2 Bosch CHP for external waste heat use

2.2.1 Description CHP CE ... NE

The modular construction system of CHP modules for

external waste heat use in the output range

240 kW

el

... 2000 kWel ensures an operation that

simplifies maintenance, commissioning and planning.

Bosch CHP modules care supplied for external waste

heat use in 2 different types and sizes:

• CHP CE ... NE with an output range to 400 kWel.

based on the approved Bosch CHP modules CHP CE

• CHP CE ... NE in the output range 600 ... 2000 kW

el

is a modular CHP module in the output range of

600 ... 2000 kW

el

.

The CHP module consists of a system module, that

can be extended in function via corresponding

accessory modules.

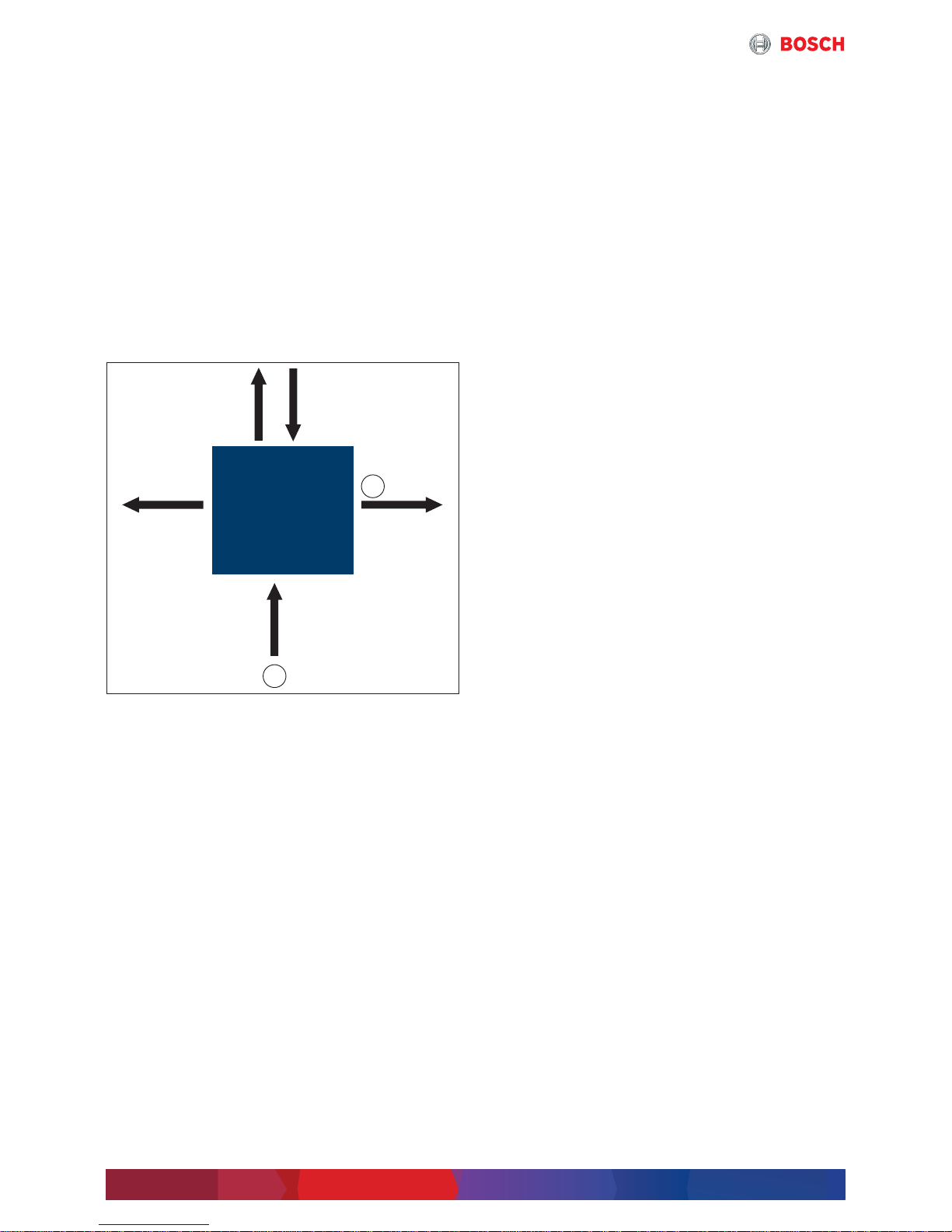

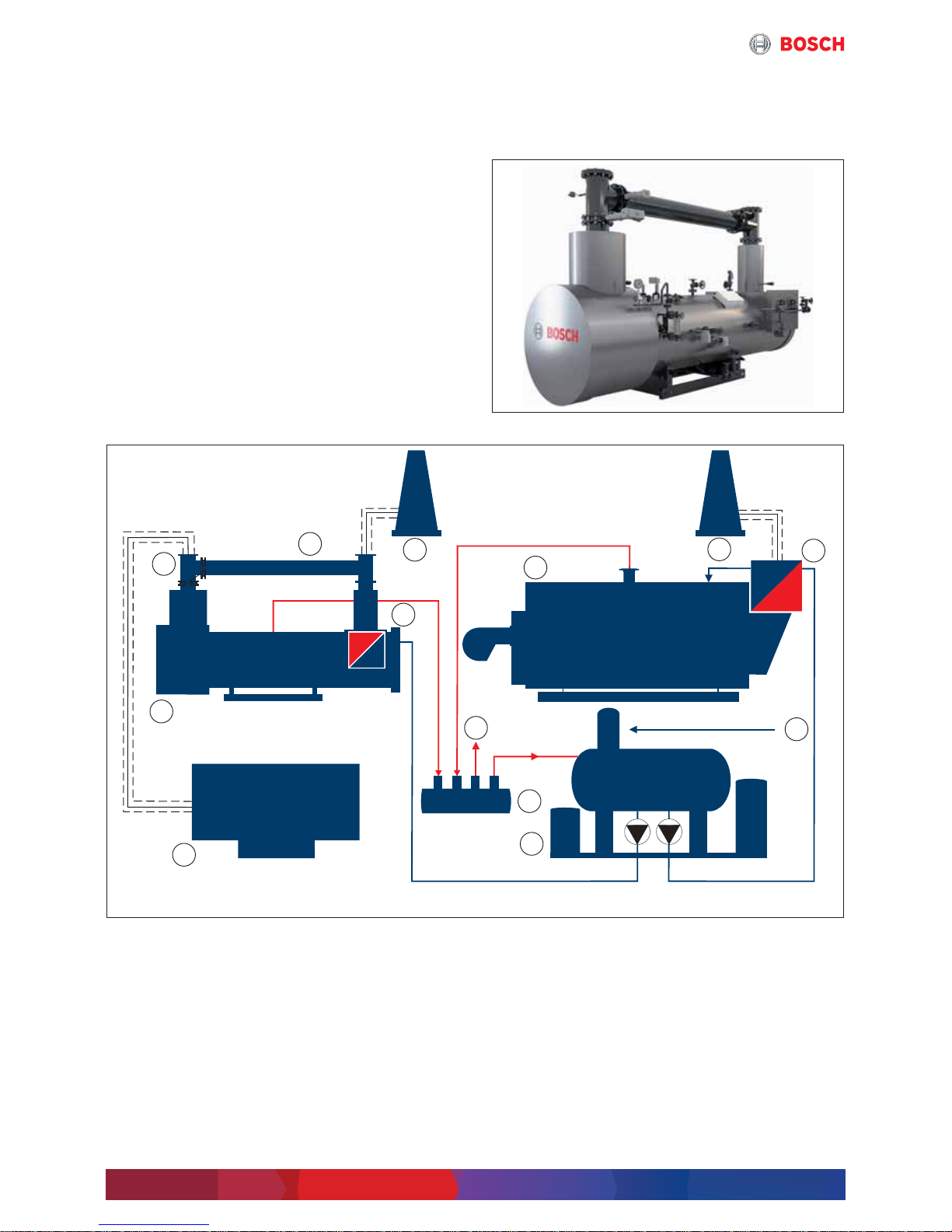

Fig. 2 Decoupling of heat of flue gas and cooling water

in a CHP module, example CHP module with

600 kW

el

performance

[1] Natural gas

[2] Waste heat performance (depending on

temperature change in steam boiler)

Electrical output 240 kW

el

and 400 kW

el

Both CHP modules with electrical output of 240 kWel

and 400 kW

el

are delivered as compact modules, ready

for connection. The components are integrated in the

soundproof cabinet. As ready-for-connection units, the

compact modules are equipped with an integrated

control cabinet. They further comprise a spark-ignited

gas engine (only for CHP CE 400 NE with flue gas

turbocharger) and a synchronous generator for

producing three-phase current (400 V, 50 Hz) and

heating energy. They are suitable for connection,

electrically and for control purposes, to the German lowvoltage network in accordance with VDE-AR-N 4105 or

the regulations of the Federal Association of the German

Energy and Water Industry (Bundesverband der

deutschen Energie- und Wasserwirtschaft, BDEW).

The variant described here spares the internal flue gas

heat exchanger, in consequence the flue gas heat is

available at a high temperature level for external use.

The catalytic converter is installed outside the closed

module frame for easy accessibility.

The flue gas silencers are designed for high

temperatures and a mounted downstream the catalytic

converter and upstream the external heat sink.

Electrical output 600 kW

el

... 2000 kW

el

Modular designed CHP modules are available in the

following output ranges:

• 600 kW

el

• 800 kW

el

• 854 kW

el

• 1200 kW

el

• 1287 kW

el

• 1560 kW

el

• 1718 kW

el

• 1999 kW

el

• 2000 kW

el

The core of the CHP consists of a perfectly tuned unit

with components such as a spark-ignited gas engine

with flue gas turbocharger and a synchronous generator

for producing three-phase current (400 V or 10.5 kV,

50 Hz).

The individual components, such as pumps, heat

exchangers or sensors are combined in modules, wired

and integrated electrotechnically in a terminal box. The

spatial arrangement of the modules can be adapted to

the existing spatial conditions. The options are

constructed in a way that they can be integrated in

existing modules without too much technical effort.

Independently of the ordered options, Bosch CHP

systems provide as standard a comprehensive safety

and fire prevention concept.

The 4-draught CHP modules fulfil, electrically and for

control purposes, the German grid connection

conditions in accordance with

VDE-AR-N 4105 low-voltage or the medium-voltage

regulation by the Federal Association of the German

Energy and Water Industry (Bundesverband der

deutschen Energie- und Wasserwirtschaft, BDEW).

In the variant described here, the CHP module is

designed for external heat utilisation and therefore

provides the flue gas heat for another system. The flue

system is designed for flue gas temperatures up to

550 °C.

Achievable performance of waste heat utilisation in

the steam boiler

The output of the utilised waste heat depends on the

cooling degree of the flue gases in the flue gas boiler. As

an estimate, this is at approx. 20 ... 25 % of natural gas

use in kW.

Bosch BHKW

CHP 600 NE

6 720 819 535-02.1T

1

2 453 °C

75 °C85 °C

333 kW

th

360 kW

th

600 kW

el

1438 kW

~

~

Page 7

System components

7

Systemlösung – 6 720 885 509 (2018/03)

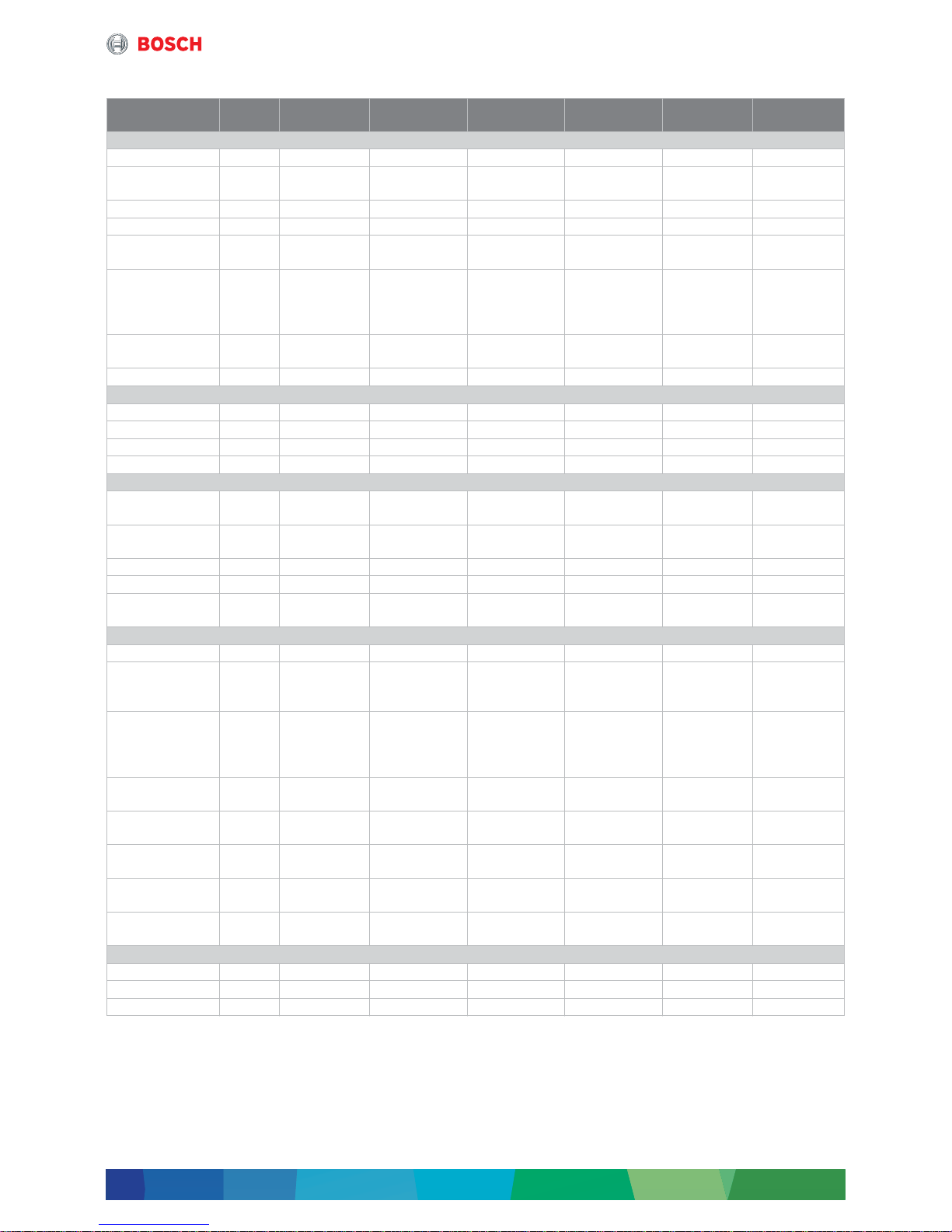

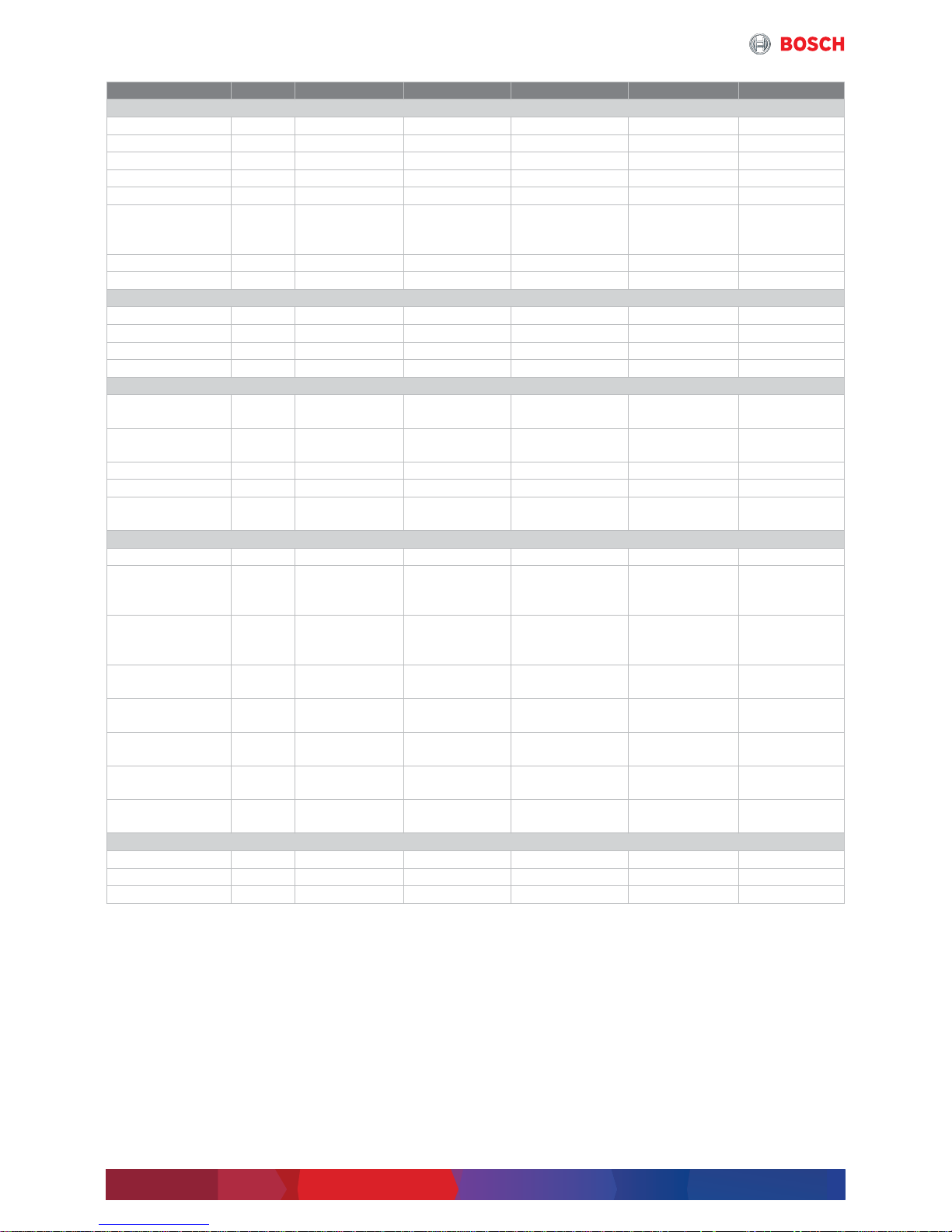

2.2.2 Technical data

Unit CHP CE 240 NECHP CE 400NECHP CE 600 NECHP CE 800

NE

CHP CE 854 NECHP CE 1200

NE

GenSet

Gas category – Natural gas Natural gas Natural gas Natural gas Natural gas Natural gas

Power

consumption

kW 668 1034 1438 1898 1993 2750

Electrical output kW 240 400 600 800 854 1200

Thermal output kW 236 288 333 431 443 625

Electrical

efficiency

% 35.9 38.7 41.7 42.1 42.8 43.6

Type – Design

external flue

gas heat

utilisation

Design

external flue gas

heat utilisation

Design

external flue gas

heat utilisation

Design

external flue gas

heat utilisation

Design

external flue

gas heat

utilisation

Design

external flue

gas heat

utilisation

Engine

manufacturer

– MAN MAN MWM MWM MTU MWM

Engine model – E2842 E 312 E2842 LE 322 TCG 2016 V12 C TCG 2016 V16 C 8V4000 L33 TCG 2020 V12

Dimensions

Length mm 4380 5300 3900 4057 4200 3900

Width mm 1510 1660 2400 1467 2000 2400

Height mm 1980 2472 2260 2190 2300 2260

Weight (empty) kg 4400 6950 6670 7550 10000 11730

Generation of electricity

Generator

manufacturer

– Leroy Somer Leroy Somer Marelli Marelli Stamford Marelli

Generator type – LSA 47.2

M7/4P

LSA 47.2 M7/4P

LSA 49.1 S4/4P

MJB 400 LC4 MJB 450 MB4 PE734C MJB 500 MB4

Voltage/Frequency V/Hz 400/50 400/50 400/50 400/50 400/50 400/50

Speed 1/min 1500 1500 1500 1500 1500 1500

Efficiency of

generator

% 96.1 96.2 96.8 97.1 95.9 97.3

Temperature levels

LT mixture circuit °C – 47.5/45 44/40 46/40 42/40 43/40

Heating water

without flue gas

heat exchanger

°C 83/70 82/72 85/75 85/75 85/75 85/75

Flue gas

temperature

without flue gas

heat exchanger

°C 570 440 453 452 443 414

Maximum flue gas

temperature

°C 650 650 550 550 550 550

Flue gas tube

dimension (KAT)

– DN 200/PN 10 DN 200/PN 10 DN 250/PN 10 DN 300/PN 10 DN 300/PN 10 DN 350/PN 10

Flue gas mass flow

rate (wet)

kg/h 877 2102 3343 4418 4524 6551

Available flue gas

back pressure

mbar 15 17 25 25 25 25

Flue gas back

pressure boiler

mbar 10 10 15 15 15 15

Flue gas limit values

CO mg/m

3

i.N.

d300 d300 d300 d300 d300 d300

NOx mg/m

3

i.N.

d250 d500 d250 d250 d250 d250

NMHC mg/m

3

i.N.

d150 d150 d150 d150 d150 d150

Table 1 Specifications CHP CE 240 NE ... CHP CE 1200 NE

Page 8

System components

Systemlösung – 6 720 885 509 (2018/03)

8

2.2.3 Operation conditions CHP

The following operating conditions are required to

maintain the warranty:

• Ensure dust and halogen-free cooling and

combustion air

• Ensure that the exhaust air and exhaust gas lines are

correctly dimensioned, and run them separately

• Maximum setup height without a drop in

performance: depending on model used 100 ... 500

meters above zero

• Ratio of starting/operating hours: 1 start to 6

operating hours averaged over the year

• Methane count: 80

• Natural gas Hi = 10 kWh/m

3

• Maximum exhaust gas counterpressure depending on

GenSet motor manufacturer 40 ... 60 mbar

• Module only suitable for setup within a building

• The condensate and flue gas line are pressurized and

must be appropriately designed, and the operating

pressure must be demonstrated in a pressure test.

Unit CHP CE 1287 NE CHP CE 1560 NE CHP CE 1718 NE CHP CE 1999 NE CHP CE 2000 NE

GenSet

Gas category – Natural gas Natural gas Natural gas Natural gas Natural gas

Power consumption kW 2974 3629 3991 4666 4588

Electrical output kW 1287 1560 1718 1999 2000

Thermal output kW 664 819 974 1076 1053

Electrical efficiency % 43.3 43 43 42.8 43.6

Type – Design

external flue gas

heat utilisation

Design

external flue gas

heat utilisation

Design

external flue gas

heat utilisation

Design

external flue gas

heat utilisation

Design

external flue gas

heat utilisation

Engine manufacturer – MTU MWM MTU MTU MWM

Engine model – 12V4000 L33 TCG 2020 V16 16V4000 L33 20V4000 L33 TCG 2020 V20

Dimensions

Length mm 4800 6300 5500 5900 7820

Width mm 2000 1800 2000 2000 1800

Height mm 2300 2500 2300 2400 2680

Weight (empty) kg 12000 13400 15000 19000 18100

Generation of electricity

Generator

manufacturer

– Stamford Marelli Leroy-Somer Stamford Marelli

Generator type – PE734F MJB 500 LA4 LSA 51.2

VL95 C6S/4P

LV804T MJB 560 LB4

Voltage/Frequency V/Hz 400/50 400/50 400/50 400/50 400/50

Speed 1/min 1500 1500 1500 1500 1500

Efficiency

generator

% 96.5 97.1 96.5 96.3 97.4

Temperature levels

LT mixture circuit °C 43/40 44/40 43/40 43/40 45/38

Heating water

without flue gas heat

exchanger

°C 85/75 85/75 85/75 85/75 85/75

Flue gas temperature

without flue gas heat

exchanger

°C 440 426 426 449 410

Maximum flue gas

temperature

°C 550 550 550 550 550

Flue gas tube

dimension (KAT)

– DN 350/PN 10 DN 400/PN 10 DN 400/PN 10 DN 450/PN 10 DN 450/PN 10

Flue gas mass flow

rate (wet)

kg/h 6700 8665 8940 10458 10983

Available flue gas

back pressure

mbar 25 25 25 25 25

Flue gas back

pressure boiler

mbar 15 15 15 15 15

Flue gas limit values

CO mg/m

3

i.N.

d300 d300 d300 d300 d300

NOx mg/m

3

i.N.

d250 d250 d250 d250 d250

NMHC mg/m

3

i.N.

d150 d150 d150 d150 d150

Table 2 Specifications CHP CE 1287 NE ... CHP CE 2000 NE

Page 9

System components

9

Systemlösung – 6 720 885 509 (2018/03)

2.3 4-draught boiler system

2.3.1 Description of 4-draught boiler system

The basis of a 4-draught steam boiler is a 3-draught

boiler from which a part of the smoke tubes is

separated. The hot flue gases of the CHP module

(in the design for external flue gas utilisation) are lead

through this separate smoke tube field, the so-called

fourth draught, and are used for steam generation.

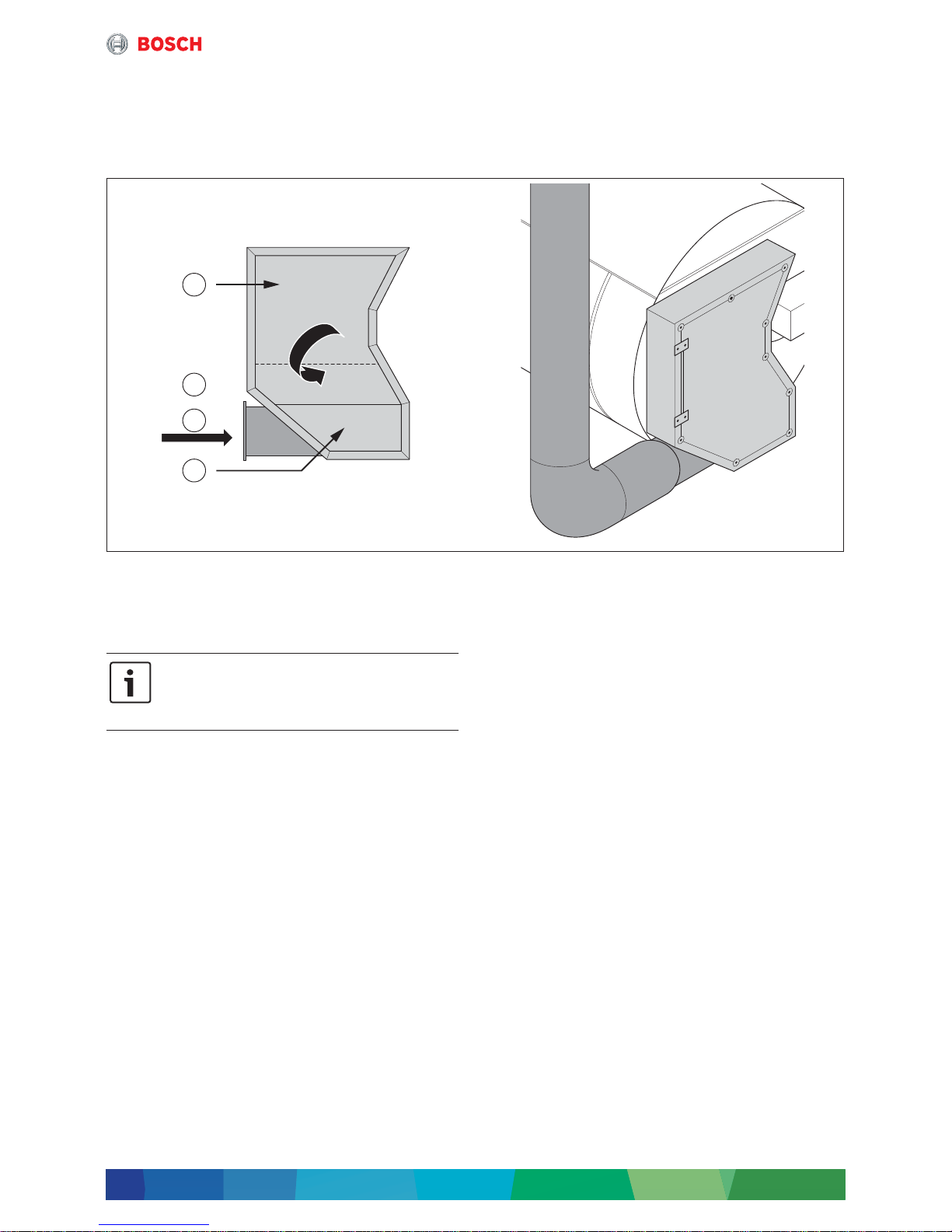

Fig. 3 Positioning of fourth draught in reversing chamber

[1] Second draught

[2] Third draught

[3] Flue gas

[4] Fourth draught

Due to different pressure ratios on burner and waste

heat side, and for avoiding back coupling, both flue gas

paths have to be clearly separated on the flue gas side.

This separation concerns, besides the boiler and

possibly existing economisers, also the flue gas routing

via 2 separate chimneys.

The auxiliary units required for a 4-draught steam boiler,

such as e.g. water treatment, feed water degassing

system, fuel supply, pumps etc. will not be treated

further in this document, because their requirements

concerning sizing and installation do not differ from a

conventional boiler system.

Especially, it has to be observed that the installation

location of the feed water control valve is between the

two economisers, in order to increase economic viability

and to save steam for heating up the feed water. In

addition, it is recommended to equip the feed water

container with an overflow device.

This ensures that an unwanted activation of the pressure

relief valve at the feed water container is prevented

during waste heat recovery of the CHP module in the flue

gas heat exchanger (ECO2) with at the same time very

low to no steam generation. Both points are shown in

the hydraulics (Æ chapter 3.4, page 34).

6 720 819 535-03.1T

1

2

3

4

By dividing the third draught, the amount of

steam generated by waste heat is limited for

the total output of the boiler

(Æ chapter 3.3.3, page 24).

Page 10

System components

Systemlösung – 6 720 885 509 (2018/03)

10

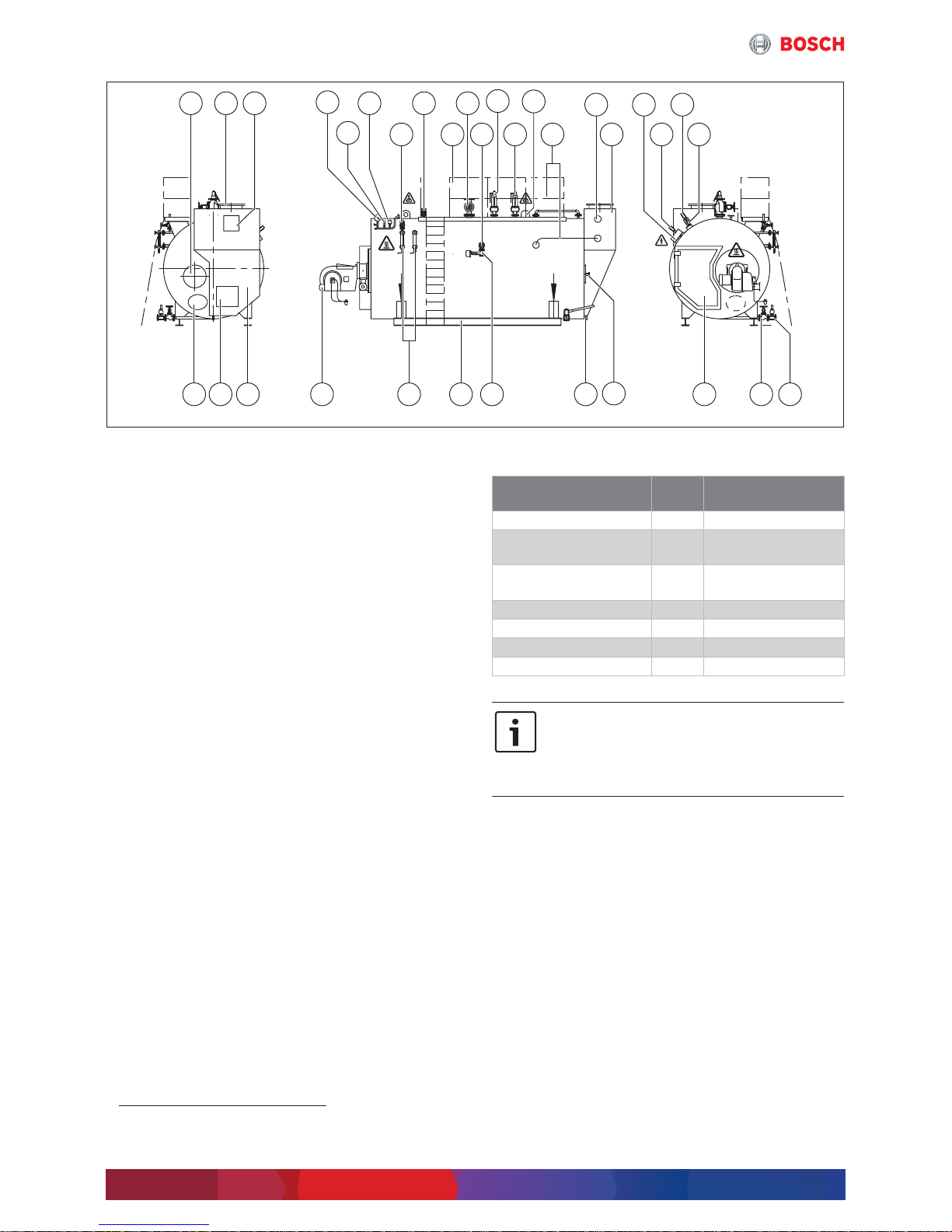

Fig. 4 Overview UNIVERSAL steam boiler

[1] Inspection aperture on the flue gas side

[2] Flue gas connecting branch

[3] Inspection aperture on the flue gas side

[4] Pressure indicator (with test function)

[5] Pressure transducer

[6] Pressure limiter

[7] Shut-off valve

[8] Vent shut-off valve (optional)

[9] Maintenance platform (optional)

[10] Steam shut-off valve

[11] Desalination shut-off valve

1)

[12] Positive pressure safety valve 2 (optional)

[13] Positive pressure safety valve 1

[14] Lifting lug

[15] Connection pipework

[16] Connection economiser

[17] Flue gas heat exchanger

[18] Conductivity transducer

[19] Terminal box

[20] Level measurement transformer

[21] Level limiter

[22] Mud quick action stop valve

[23] Outlet shut-off valve

[24] Reversing chamber door

[25] Flame inspection hole

[26] Connection for flue gas condensate

drainage system

[27] Desalination control valve

[28] Base frame

[29] Level indicator 1

Level indicator 2 (optional)

[30] Burner

[31] Flue gas chamber

[32] Inspection aperture on the flue gas side

[33] Inspection aperture water-side

2.3.2 Technical data

6 720 819 535-04.1T

1 2 3 8710

912111413 17

222324

25

26272830313233 29

19

16 182120

15

6

5

4

1) For boiler type UL-S 28000 there are 2 desalination

connections.

Unit UNIVERSAL

steam boiler

Type – UL-S

Heat transfer medium – High pressure

saturated steam

Type – 4-draught flue tube

technology

Performance kg/h 1250 ... 28000

Safety pressure bar d30

Maximum temperature °C 235

Fuel – Oil, gas

Table 3 Specifications UNIVERSAL steam boiler

The 4 ... 5-digit number in the boiler name

corresponds to the respective steam output

in kg/h.

1 kg/h corresponds to 0.65 kW burner

output.

Page 11

System components

11

Systemlösung – 6 720 885 509 (2018/03)

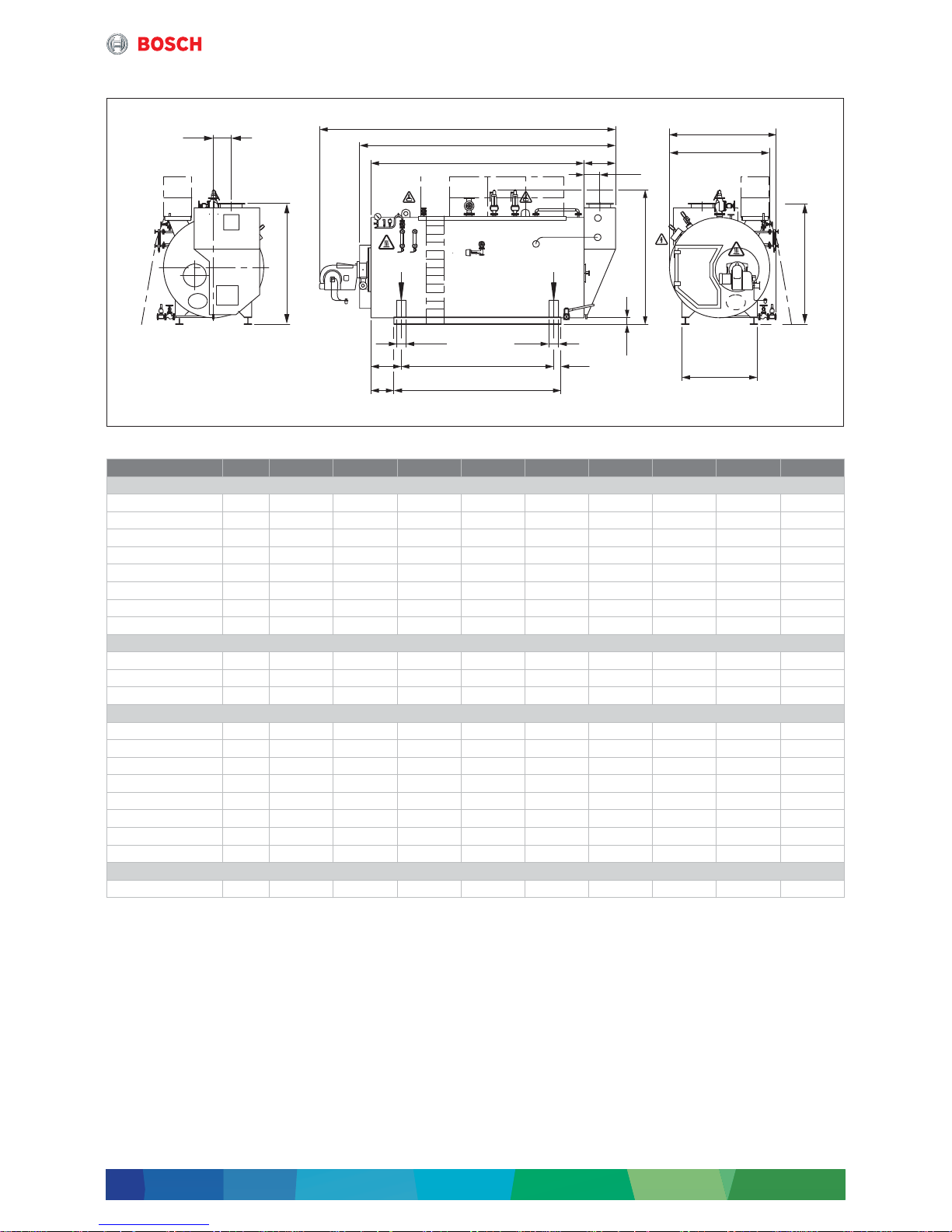

2.3.3 Dimensions and connections

Fig. 5 Dimensions and connections UNIVERSAL steam boiler UL-S

Unit UL-S 1250 UL-S 2000 UL-S 2600 UL-S 3200 UL-S 4000 UL-S 5000 UL-S 6000 UL-S 7000 UL-S 8000

Dimensions

L1

1)

1) The dimension L1 is a recommended dimension and is subject to the burner manufacturer, type and the actual steam output.

mm 4850 4653 4972 5927 6615 6615 7255 7255 7845

L2

2)3)

2) Minimum transport dimensions when valves, burner and terminal box have been removed

(without cable conduit; with cable conduit + 75 mm on the right).

3) Dimension increases depending on dimension of flue of CHP.

mm 3280 3820 4260 4760 5450 5450 6210 6210 6800

L3 mm 2620 2970 3270 3770 4600 4600 5100 5100 5550

L6 mm 500 640 780 780 640 640 780 780 920

B1 mm 1929 2102 2187 2182 2439 2634 2674 2774 2874

B2

2)

mm 1652 1825 1910 1905 2165 2360 2400 2500 2600

H1

4)

4) The dimension H1 varies depending on the valve manufacturer.

mm 2262 2512 2557 2642 2947 3177 3222 3312 3562

H2

2)5)6)

5) Dimension depending on selected flue gas temperature (influenced by number of tubes in height of economiser).

6) For boiler type UL-S 28000 there are 2 desalination connections.

mm 2150 2232 2210 2210 2575 2765 2975 2958 3178

Flue gas connection

L11 mm 233 303 373 373 303 303 373 373 443

B4 mm 170 270 290 290 318 273 119 153 85

H3

5)

mm 2150 2232 2210 2210 2575 2765 2975 2958 3178

Base frame

L4 mm 2270 2570 2120 2625 3750 3500 4000 4000 4450

L5 mm 1890 2150 1770 2175 3400 3150 3650 3650 3950

L7 mm 385 425 750 798 600 775 675 675 800

L8 mm 175 215 575 573 425 600 500 500 550

L9 mm 170 210 175 225 175 175 175 175 250

L10 mm 80 80 150 150 225 225 225 225 275

B3 mm 1060 1100 1360 1360 1655 1785 1820 1890 1950

H4 mm 200 190 135 135 190 165 160 150 170

Wide-flange beam

IPB/HEB – DIN1025 mm – – – – 180 180 180 180 200

Table 4 Dimensions and connections UNIVERSAL steam boiler UL-S 1250 ... UL-S 8000

6 720 819 535-05.1T

L1

L2

L3

L10 L10

L7 L5 L9

L8

L4

L6

L11

B4

H3

H2

H1

H4

B3

B1

B2

Page 12

System components

Systemlösung – 6 720 885 509 (2018/03)

12

• For information and instructions regarding the

requirements for the boiler installation room

Æ Technical information TI024

(Æ chapter 4.2, page 41)

• Equipment and complete dimensions according to

project-specific technical datasheet

• Measure the maximum weight at the front and back

feet of the foundation.

• Dimensions given with r1 % tolerance

• These dimensions are designed for standard

insulation

– 150 mm thick on floors

– 100 mm thick on casing

• The boiler types UL-S 1250/2000/2600/3200 have

inspection apertures on the right side, instead of the

bottom.

• For boiler types UL-S 1250 ... UL-S 3200, the outlet

shut-off valve and the mud quick action stop valve are

mounted in the boiler axis to the back to ensure

accessibility of the inspection aperture on the

water side.

• The boiler type UL-S 4000 has additional inspection

apertures on the side at the bottom.

• Sizing for the entrance

– Transport height: additional clearance of at least

100 mm from dimension H1 or dimension H2

(valves fitted/not fitted)

– Minimum door clearance: additional clearance of at

least 200 mm from dimension B1 or dimension B2

(valves fitted/not fitted)

• The height of the boiler room is determined by the

system equipment. The clearance above the

maintenance platform should be at least 2 m.

• For boiler types UL-S 1250 ... UL-S 3200 optionally a

shaft extension is available for the steam shut-off

valve.

• Level measurement transformer and level limiter

(image 4, [20] and [21], page 10) are positioned for

boiler type UL-S 1250 and UL-S 2000 on the top of the

boiler.

Unit UL-S

10000

UL-S

12000

UL-S

13000

UL-S

14000

UL-S

16000

UL-S

17000

UL-S

18000

UL-S

22000

UL-S

28000

Dimensions

L1

1)

1) The dimension L1 is a recommended dimension and is subject to the burner manufacturer, type and the actual steam output.

mm 8369 9007 9008 8674 9854 9920 9944 9610 9868

L2

2)3)

2) Minimum transport dimensions when valves, burner and terminal box have been removed

(without cable conduit; with cable conduit + 75 mm on the right).

3) Dimension increases depending on dimension of flue of CHP.

mm 6860 7265 7446 7456 8286 8286 8286 8705 8955

L3 mm 5550 5800 5800 5800 6630 6630 6630 7050 7050

L6 mm 980 1135 1136 1146 1146 1146 1146 1145 1395

B1 mm 3074 3224 3474 3474 3474 3669 3674 3874 4199

B2

2)

mm 2800 2950 3200 3200 3200 3400 3400 3600 4000

H1

4)

4) The dimension H1 varies depending on the valve manufacturer.

mm 3732 3867 4222 4222 4222 4467 4467 4747 5212

H2

2)5)6)

5) Dimension depending on selected flue gas temperature (influenced by number of tubes in height of economiser).

6) For boiler type UL-S 28000 there are 2 desalination connections.

mm 3065 3200 3465 3465 3465 3710 3685 3835 4302

Flue gas connection

L11 mm 503 588 588 598 598 598 598 598 778

B4 mm 240 240 380 380 380 380 380 635 600

H3

5)

mm 2923 2990 3270 3270 3270 3415 3415 3420 3585

Base frame

L4 mm 4450 4450 4700 4700 5500 5500 5500 5800 5800

L5 mm 3950 3950 4200 4200 5000 5000 5000 5200 5200

L7 mm 800 800 775 800 800 800 800 925 925

L8 mm 550 550 525 550 550 550 550 625 625

L9 mm 250 250 250 250 250 250 250 300 300

L10 mm 275 275 275 275 275 325 325 325 325

B3 mm 2080 2180 2340 2340 2340 2365 2365 2500 2700

H4 mm 140 125 140 140 140 185 185 160 225

Wide-flange beam

IPB/HEB – DIN1025 mm 200 200 240 240 240 260 260 260 300

Table 5 Dimensions and connections UNIVERSAL steam boiler UL-S 10000 ... UL-S 28000

Page 13

System components

13

Systemlösung – 6 720 885 509 (2018/03)

2.4 MEC System – overview

Transparent, efficient, smart

The MEC System (Master Energy Control) is a platform

for planning individual and customer-specific energy

supply systems. With the MEC system, you can combine

and control different plant types and field devices to

achieve an efficient energy system via user interface. The

MEC system is used in commercial, industrial and

communal sectors and is sold as system solution with

Bosch heat sources.

Activation

The MEC system controls different plant types

(e. g. boilers, CHPs) and the required system field

devices (e. g. pumps, valves). For this purpose, it

provides a large range of interfaces and, besides

integration of Bosch devices, it allows for integration

of existing and third-party products.

System control

The system control is the core know-how of the MEC

systems. As manufacturer of energy generation plants,

Bosch used its entire expert knowledge for developing

control and allows in consequence for optimum system

control with adherence to the system's operating

conditions.

Control for energy generation

The MEC system integrates for energy generation as

standard the following plant types:

• Warm water boiler

• Hot water boiler

• Steam boiler

• Biomass boiler

• CHP modules

• Solar

• Heat pumps

• Buffer storage tanks

• External heat

Further systems and plants are available on request.

Control for heat distribution

The range of functions for control of heat distribution

comprises:

• Local heat network

• Heating circuits

• Fans

• Heating circuits

• DHW heating

Further functions and control of systems and devices are

available on request.

System access

The MEC system gives humans and machines access to

the entire system:

• Via an integrated local web server, the user can

access the system using any terminal device

(such as PC, notebook or tablet) in the network with

a standard web browser.

• With the modern and intuitive user interface, the user

can access the complete system and each individual

plant.

• Having a large number of interfaces, the MEC system

allows for integration in super-ordinate systems, such

as building control systems, process control systems,

energy management and virtual power plant systems.

• Using MEC remote, the user has the opportunity to

access the local system from the Internet via a safe

connection.

Web and IP technologies

Web and IP technology have the following benefits:

• HMI scalable to different screen sizes

• Mouse and touch screen operation

• Unlimited number of terminal devices for visualisation

• Location-independent for terminal devices and

controller

• Simple network building with standard components

for large factory sites

• Easy integration in corporate networks

Comprehensive HMI functionality

The modern and intuitive HMI of the MEC system has

many benefits:

• Coloured, clear visualisation of states, temperatures

and performance

• Visualisation of device, system and operation

• User management

• Alarm management with alarm history

• Appliance configuration via HMI system

• Search

• Dashboard function

• Energy monitoring

• Diagram displays

• Export and print-out of graphs

• Transmission of alarms via e-mail, text message, fax

• Run time prognosis of CHP module

New HMI standards

The MEC system uses new standards for visualisation:

• The concept of operation is tuned to the end

customer's requirements

• Intuitive and new operation

• Structured and clear design

• Modern design

Page 14

System components

Systemlösung – 6 720 885 509 (2018/03)

14

2.5 Further options for waste heat use/peak load boiler

As an option, for waste heat use only of a CHP, further

Bosch industrial boilers can be used.

2.5.1 Waste heat boiler HRSB

As alternative to a 4-draught industrial steam boiler, a

pure waste heat boiler can be used. This variant should

be preferred in case of retrofitting (existing boiler

system). A bypass already exists in the waste heat boiler.

Fig. 6 Bosch waste heat boiler HRSB

Fig. 7 Simplified function diagram Bosch waste heat boiler HRSB and CHP (simplified depiction)

[1] Flue CHP module

[2] Flue bypass

[3] Chimney

[4] Economiser

[5] Peak load steam boiler

[6] Make-up water

[7] Water service module WSM-V

[8] Manifold

[9] Consumer

[10] CHP

[11] Waste heat boiler

Water/condensate

Steam

Flue gas

6 720 819 535-11.1T

6 720 819 535-12.1T

1

2

3

3

4

4

6

7

8

9

10

11

5

Page 15

System components

15

Systemlösung – 6 720 885 509 (2018/03)

2.5.2 3-draught waste heat boiler for use of waste heat only

If, due to very high waste heat mass flow or very high flue

gas temperatures, the limits of use of the waste heat

boiler HRSB should not be sufficient, a

3-draught waste heat boiler can be used for waste heat

utilisation only.

Fig. 8 Bosch 3-draught waste heat boiler

2.5.3 System extension with peak load boiler

If the motor waste heat provided by the CHP module is

not sufficient for the heating water supply or if it shall be

supply also redundantly to the CHP module, the system

can be extended by a boiler for covering these loads.

Fig. 9 Function diagram: System extension via peak load boiler (strongly simplified depiction)

[1] 4-draught steam boiler

[2] Economiser

[3] Chimney

[4] Flue gas heat exchanger

[5] Water service module

[6] Mains power supply

[7] Consumer

[8] Boiler

[9] Manifold

[10] Memory

[11] CHP

[12] Flue gas bypass

Current

Water/condensate

Steam

Flue gas

6 720 819 535-13.1T

6 720 819 535-14.1T

1

2

3

3

5

6

7

8

10

9

11

12

4

Page 16

Engineering information and sizing

Systemlösung – 6 720 885 509 (2018/03)

16

3 Engineering information and sizing

3.1 Basic principles

3.1.1 Economic viability

The economic viability of a system combined of CHP

with waste heat use in a 4-draught steam boiler is an

important criterion for making decisions on investment

and should therefore be made already during the basic

evaluation of the project.

In the following, important general conditions are shown

for the use of the described system combinations. These

general conditions are preconditions for an economic

use and allow for a first evaluation of economic

efficiency.

On this basis, the system can be dimensioned.

3.1.2 Economic general conditions

Creation of steam

Basic condition is a demand as continuous as possible of

water vapour for effecting thermal processes with a

required temperature level clearly above 100 °C. In

general, this is industrial process vapour.

When using the vapour, it has to be differentiated

between direct and indirect heating.

For indirect heating, the steam dispenses its

evaporation enthalpy (energy that is set free in the boiler

during water evaporation) via a heat exchanger to the

medium to be heated. The thus produces condensate is

led back to the steam boiler.

For direct heating, steam is directly lead to the medium

to be heated, the medium absorbs the steam in general

and no condensate forms, or the condensate cannot be

supplied to the process without additional measures.

A complete or partial direct heating requires an

increased additional amount of water. Energy required

for preheating can be supplied by motor waste heat of

the CHP module and can lead to an increased runtime of

the CHP module.

Internal power consumption

A CHP module creates high-temperature heat, lowtemperature heat and current.

The current of the CHP system can be used for internal

power consumption or can be supplied to the public

power network.

The infeed of current to the public network can be

promoted depending on CHP size in acc. with KWKG

(CHP Act, Germany).

For the economic viability of a CHP module, it is crucial

to clearly define the currently valid subsidy conditions.

If the created power is used internally, the economic

efficiency of the CHP module increases with the price

difference between electricity tariff and gas price.

LT heat (low-temperature heat)

In order to efficiently operate a CHP module, a high

amount of annual operating hours is required. Main task

is here the use of motor waste heat (temperature level

of approx. 85/70 °C).

The motor waste heat can be used for process heat,

for DHW heating, for heating or for make-up water

preheating for steam production. Here a heat transfer as

continuous as possible is important.

HT heat (high temperature heat)

For a CHP module with external waste heat use, the

motor flue is used for steam production at temperatures

above 110 °C in an external steam generator

(Æ chapter 2).

Summary

The used fuels and resulting energy flow should be

known.

Only if you know the energy consumption and energy

costs, you can optimally plan a system.

For designing and operation of an economically efficient

system, a use as continuous as possible of lowtemperature heat, steam and also internal current is

crucial.

The larger the margin between the energy price for gas

and the energy price for current, the higher the

efficiency of a CHP system.

At ... hours of

operation per year

a cost-efficient use of a CHP

module is ...

2000 very unlikely

3000 unlikely

4000 possible

5000 likely

6000 very likely

Table 6 Economic viability of a CHP module in relation to

the number of hours of operation in a year

For system reasons, current, LT heat and HT

heat are always created simultaneously. To

ensure a high annual efficiency, during CHP

operation a performance assessments by

the corresponding generators in the steam

boiler should be effected.

Page 17

Engineering information and sizing

17

Systemlösung – 6 720 885 509 (2018/03)

3.1.3 Technical system data

In the following, the maximum and minimum system

parameters are summarised in an clearly arranged table.

Using the table, you will get a quick overview whether

from a technical point of view a 4-draught steam boiler

or a CHP module should be used.

Medium System parameters Unit Within system limits

Yes No

Steam Performance Min. 1250 kg/h

Max. 28000 kg/h

4-draught

steam boiler

Part of fourth

draught

(waste heat)

Max. 20 %

Positive pressure Max. 30 bar

Steam

temperature

Max. 235 °C

Current Performance Min. 240 kW

el.

Max. 2000 kW

el.

Voltage Min. 230 V

Max. 400 V

Heating

water

Performance Min. 230 kW

th.

CHP Max. 1100 kW

th.

Pressure rating Max. 6 bar

Temperature Flow 83 ... 85 °C

Return d70 °C

Waste heat Performance Min. 120 kW

th.

Max. 1300 kW

th.

Waste heat

temperature

Ø 450 °C

Max. 650 °C

Table 7 Technical system data

Page 18

Engineering information and sizing

Systemlösung – 6 720 885 509 (2018/03)

18

3.2 Pre-dimensioning

During a first planning phase, an estimate design of the

important system parts, a cost estimate and a

preliminary consideration of economic efficiency are

crucial.Important functional principles have to be

explained with schematic diagrams.

3.2.1 Estimate design of key components

Estimate sizing of 4-draught steam boiler

The size of the steam boiler can approximately be

calculated from the total of the individual steam

consumers plus an addition of approx. 10 % as own

steam consumption. If consumption times of individual

consumers are already defined, coincidence factors can

possibly be taken into consideration.

Estimate sizing of CHP module

The waste heat performance in the steam boiler from the

CHP module must not exceed maximum 20 %.

Estimate of elapsed time

To achieve an informative profitability assessment, the

theoretic runtimes of steam boiler and CHP module have

to be determined, by means of the existing load profiles

or operating specifications for sufficiently precisely

defined load profiles.

3.2.2 Investment costs

As a sound basis for an investment decision and for

evaluation of the investment costs and preliminary

consideration of economic efficiency, the system with

4-draught steam boiler and CHP module with MEC has to

be compared with the construction of a 3-draught boiler

system.

The shown cost estimate is based on the following

framework conditions:

• Output steam boiler, 2000 kg/h each

• Output BHKW 400 kW

el.

• Peak load boiler for heating and DHW production

700 kW

th.

• The costs have been determined incl. installation and

incidental expenses. The height of this share of costs

strongly depends on the particular local conditions of

the project. The following cost estimate is therefore

exemplary.

Position Size Unit Investment costs 4-

draught steam boiler and

CHP with MEC system

Investment costs steam

boiler

[€] [€]

Steam boiler 2000 kg/h – 110 000

Steam boiler, 4-draught steam design 2000 kg/h 130 000 –

CHP module 400 kW

el.

350 000 –

Waste heat line incl. silencer – – 15 000 –

Flue gas line/chimney – – 30 000 20 000

MSR technology – – 35 000 25 000

Floor standing condensing boiler, peak

load for heating

700 kW

th.

20 000 20 000

Installation costs – – 120 000 100 000

Required building measures – – 50 000 40 000

Other services – – 50 000 50 000

Planning costs 10 % 100 000 45 000

Safety margin/contingencies 5 % 50 000 25 000

Total –– 950 000 435 000

Table 8 Investment costs

Page 19

Engineering information and sizing

19

Systemlösung – 6 720 885 509 (2018/03)

3.2.3 Evaluation of economic viability

In the following assessment of economic viability, the

calculation is based on a runtime of approx. 5,300 h/a

for steam boiler and CHP module. The calculation is

carried out conservatively, e. g. statically, with regard to

the basic year and without consideration of energy price

increase. The costs are individually calculated for fuel,

current, cost allocation and refunds as well as for

occurring service costs. The additional investment costs

and the savings during operation result in an

amortisation time (ROI) for investment.

Energy costs

Running costs

Summary

The increased investment costs in this example pay off within 3 years.

Position Rate Unit Annual

consumpti

on

Unit Annual consumption

costs 4-draught steam

boiler and CHP with

MEC system

Annual

consumption costs

steam boiler

[€] [€]

Fuel demand steam boiler 35 €/MWh 5800 MWh – 203 000

Fuel demand steam boiler, 4-

draught steam design

35 €/MWh 5000 MWh 175 000 –

Fuel demand CHP module 35 €/MWh 5300 MWh 186 900

Fuel demand floor standing

condensing boiler

35 €/MWh 2700 MWh – 94 500

700 MWh 25 700 –

Power drawn 150 €/MWh 1600 MWh 246 900 –

3500 MWh – 525 000

Cost allocation, internal power

consumption

– – – – 45 300 –

Reduction peak load 90 €/kW 400 kW – 36 000 –

Reimbursement of petroleum tax – – – – – 29 400 –

Total of consumption costs 614 000 822 500

Table 9 Energy costs

Position Annual service costs 4-draught steam

boiler and CHP with MEC system

Annual service costs

steam boiler

[€] [€]

Service costs floor standing

condensing boiler

500 500

Annual service costs steam boiler 4500 4500

Service costs CHP module 35 000 –

Total of running costs 40 000 5 000

Table 10 Running costs

Costs €/a Annual running costs 4-draught steam

boiler and CHP with MEC system

Unit Annual running costs

steam boiler

Unit

Investment 950 000 € 435 000 €

Additional investment costs 515 000 € – –

Consumption 614 000 € 822 500 €

Appliance operation 40 000 € 5000 €

Total of consumption costs 654 400 €/a 827 500 €/a

Additional consumption

costs

– 173 100 €/a

ROI 3.0

Table 11 Summary

Page 20

Engineering information and sizing

Systemlösung – 6 720 885 509 (2018/03)

20

3.2.4 Integration of 4-draught steam boiler

The integration of a 4-draught steam boiler is effected

via the flue of the CHP module. Here, 2 versions have to

be distinguished.

4-draught steam boiler with bypass

By installing a bypass, an operation independently of the

CHP module is possible. Instead of shutting down the

CHP module in case of a boiler fault or after achieving

the boiler target pressure, the bypass mode is activated,

thus current and LT heat continue to be produced.

Also during maintenance on the steam boiler, the CHP

module can be operated in bypass mode, but is has to

be observed that all inspection apertures on the flue gas

side are closed during operation of the CHP module to

prevent reverse flow of fuel.

Fig. 10 4-draught steam boiler with bypass

Changing from normal to bypass operation is effected

via pneumatically controlled flaps in the flue gas line of

the CHP module. Here one of the bypass flaps is opened

and subsequently the flue gas line leading to the fourth

draught of the boiler is closed. The flue flows unused

directly to the chimney, and passes the boiler and

possibly existing economisers. It has to be observed that

always one flue gas path is open and that both flue gas

paths are never closed at the same time. The flap control

is monitored with regard to safety, so that at eventual

faults, the system is securely shut down.

The bypass operation should only be used

for a limited time.

Otherwise all heat contained in the flue is

lost, because no flue gas heat exchanger is

connected to the bypass. In consequence,

the efficiency of the total plant is

considerably reduced.

6 720 819 535-06.1T

Page 21

Engineering information and sizing

21

Systemlösung – 6 720 885 509 (2018/03)

4-draught steam boiler without bypass

If a system is installed without bypass, the entire flue gas

mass flow rate of the CHP module is led via the fourth

draught of the steam boiler. In consequence, when the

boiler target pressure is achieved, not only the boiler but

also the CHP module have to be shut down, to prevent

further increase of the boiler pressure. Due to this fact,

at times of low steam consumption, pulsing of the CHP

module can occur.

Fig. 11 4-draught steam boiler without bypass

6 720 819 535-07.1T

Page 22

Engineering information and sizing

Systemlösung – 6 720 885 509 (2018/03)

22

Additional Economiser (ECO)

Due to the precise separation on the steam gas side

between burner side and waste heat side, a further

increase in efficiency can be obtained with the 4-draught

steam boiler by implementing a second economiser. On

the burner side, usually an integrated economiser is

used. The Economiser for the CHP module however is

installed as “Stand-Alone” version behind the fourth

draught of the boiler.

The connection of the economisers is effected in parallel

on the flue gas side and in rows on the water side,

whereby ECO of the fourth draught in flow direction is

always passed through first. Due to the feed water

control valve with pump freewheel function between

both economisers, part of the feed water can be led

back to the feed water container and the container can

be used as heat reservoir. In consequence, runtimes of

the CHP module as well as the efficiency of the system

can be increased. For this, the feed water container

must be equipped with an overflow device.

At factory, the economisers are designed to the currently

valid temperature limits and are protected from

evaporation of feed water.

Fig. 12 Boiler with fourth draught, integrated economiser for boiler side and “Stand-Alone” economiser for fourth draught

side

6 720 819 535-08.1T

Page 23

Engineering information and sizing

23

Systemlösung – 6 720 885 509 (2018/03)

3.3 Sizing of key components

With the customer-specific requirements concerning

steam, LT heat and current demand, the optimum

system combination is selected. The occurring

temperatures, pressures and mass flow rates of the

individual components must be optimally matched.

3.3.1 Sizing of 4-draught steam boiler

For sizing the steam boiler, it is important in a first step,

to determine together with the user the most important

design criteria:

• Fuel

• Vapour pressure

• Vapour demand

The amount of steam required by the customer, results

from the total of the steam amounts that are used for the

respective processes. To which extent different

concurrences have to be considered here, has to be

determined together with the user.

To determine the amount of steam that the boiler has to

provide, simply the customer steam amount and the

internal consumption (for feed water heating, heat

losses etc.) have to be added.

As an estimate, this internal steam amount can be

assumed as a value between 5 % ... 15 % of the

customer steam amount, depending on portion and

temperature of the reusable condensate. For optimum

waste heat use of the CHP flue gases by the steam

boiler, a base load requirement as continuous as

possible is decisive.

IMPORTANT: If the maximum steam amount must be

available at any time, e.g. also if the CHP module is idle

due to missing LT heat utilisation or maintenance, the

output of the fourth draught must not be considered for

sizing.

Fig. 13 Ratio boiler output/required steam amount for

system

[1] Required steam amount for system

[2] Required boiler output with consideration of waste

heat part

[3] Required boiler output without consideration of

waste heat part

Performance of fourth draught

(waste heat, CHP module)

Performance first ... third draught

The higher the waste hear performance, i.e. the flue gas

mass flow rate of the CHP module, the more flue pipes

are required in the steam boiler for the fourth draught.

Because these flue pipes “miss” in the third draught, the

maximum steam output in the boiler is reduced. Possibly

a larger boiler, with correspondingly higher costs, is

required.

Therefor it makes sense to set the output of the fourth

draught in relation to the total output with d20 % of the

total output.

Higher performance of the fourth draught is

possible, but must be checked precisely by

Bosch Industriekessel GmbH.

In this case please contact the responsible

sales person.

6 720 819 535-15.1T

[%]

120

100

80

60

40

20

0

3

1

2

Page 24

Engineering information and sizing

Systemlösung – 6 720 885 509 (2018/03)

24

3.3.2 Sizing of CHP module

A Bosch CHP module for waste heat use generally

consists of a gas engine, a three-phase generator and a

heat exchanger system.

The engine drives the generator for power generation.

Depending on the operating conditions, synchronous

generators are used for power generation. They

generate three-phase current with a frequency of 50 Hz

and a voltage of 400 V.

The three-phase current generated by the generator is

fed into the main low-voltage distribution board on-site

(LVDB = 0.4 kV level). The power is used according to

the current demand in the connected building, excess

power can be fed into the network of the electricity

operator.

Waste heat is generated during this energy conversion,

as it is in all combustion engines.

The heat from the lubricating oil and the engine coolant

is transferred via a heat exchanger system to a closed

DHW/heating system.

The heated water can be used for:

• Building heating

• DHW heating

• LT process heat

• Make-up water treatment in steam process

The reduction of the low temperature must be ensured

for operation of the CHP module and is thus a restriction

for sizing the combination.

The hot motor flue gases are used in the fourth draught

of the downstream 4-draught steam boiler for creating

steam. The energy utilisation of the CHP module is,

including waste heat utilisation in the steam boiler, up to

approx. 94 %.

The energy is provided as high-quality electrical energy,

LT and HT energy for steam generation.

For a planned waste heat utilisation, the sizing of the

CHP module should be oriented towards the maximum

output of the fourth draught of the steam boiler.

3.3.3 Steam amount/waste heat output and CHP/boiler combinations

As already described in chapter 3.3.1, page 23, this

results in general in a technically sensible factor of the

waste heat utilisation in the steam boiler of < 20 %.

A possible allocation of CHP/steam boiler is given in

table 14, üage 27 and table 15, page 28.

The steam amount that can be created from HT waste

heat in a 4-draught steam boiler with the selected

combination CHP/steam boiler is given in % and kg/h.

Reference value is the given total steam output of the

boiler.

The hot flue gases produced by the CHP are directly

used for steam generation in the fourth draught of the

steam boiler. A decoupling in time by temporary storage

of the flue gases is not possible for technical reasons.

The runtime of a CHP therefore mainly depends on the

useful life of the boiler system. For correct

determination of the runtime of the CHP module during

planning, is makes sense to create a sorted annual load

duration curve for steam demand, in analogy to the LT

heat energy demand.

If the CHP shall be operated for a longer time or not in

parallel with the boiler, a bypass must be available in the

flue gas line for bypassing the boiler system

(Æ page 20).

For covering the LT heat required in the

system, an additional peak load boiler can

be necessary.

Page 25

Engineering information and sizing

25

Systemlösung – 6 720 885 509 (2018/03)

Overview Steam amount/waste heat performance – boiler type/CHP

1250 kg/h ... 12000 kg/h

Amount of steam incl. own use of boiler (burner + waste heat performance) in [kg/h]

CHP Unit 1250 2000 2600 3200 4000 5000 6000 7000 8000 10000 12000

CHP CE

240 NE

Waste heat

performance

kg/h

126 109 123 129 129 129 137 139 129 140 134

Waste heat,

proportional

% 10.1 5.5 4.7 4.0 3.2 2.6 2.3 2.0 1.6 1.4 1.1

CHP CE

400 NE

Waste heat

performance

kg/h

168 168 176 188 188 187 198 191 174 205 183

Waste heat,

proportional

% 13.4 8.4 6.8 5.9 4.7 3.7 3.3 2.7 2.2 2.1 1.5

CHP CE

600 NE

Waste heat

performance

kg/h

273 273 296 296 296 293 312 319 296 325 286

Waste heat,

proportional

% 21.8 13.7 11.4 9.3 7.4 5.9 5.2 4.6 3.7 3.3 2.4

CHP CE

800 NE

Waste heat

performance

kg/h

358 395 395 395 393 393 408 408 376 437 394

Waste heat,

proportional

% 28.6 19.8 15.2 12.3 9.8 7.9 6.8 5.8 4.7 4.4 3.3

CHP CE

854 NE

Waste heat

performance

kg/h

347 383 383 383 381 381 396 396 365 424 382

Waste heat,

proportional

% 27.8 19.2 14.7 12.0 9.5 7.6 6.6 5.7 4.6 4.2 3.2

CHP CE

1200 NE

Waste heat

performance

kg/h

478 478 478 478 508 501 501 462 462 533 459

Waste heat,

proportional

% 38.2 23.9 18.4 14.9 12.7 10.0 8.4 6.6 5.8 5.3 3.8

CHP CE

1287 NE

Waste heat

performance

kg/h

551 551 551 551 586 598 532 532 532 614 529

Waste heat,

proportional

% 44.1 27.6 21.2 17.2 14.7 12.0 8.9 7.6 6.7 6.1 4.4

CHP CE

1560 NE

Waste heat

performance

kg/h

670 670 670 707 707 707 626 626 626 655 655

Waste heat,

proportional

% 53.6 33.5 25.8 22.1 17.7 14.1 10.4 8.9 7.8 6.6 5.5

CHP CE

1718 NE

Waste heat

performance

kg/h

688 688 688 727 727 727 674 771 771 673 673

Waste heat,

proportional

% 55.0 34.4 26.5 22.7 18.2 14.5 11.2 11.0 9.6 6.7 5.6

CHP CE

1999 NE

Waste heat

performance

kg/h

994 994 994 994 893 893 893 1053 932 932 932

Waste heat,

proportional

% 79.5 49.7 38.2 31.1 22.3 17.9 14.9 15.0 11.7 9.3 7.8

CHP CE

2000 NE

Waste heat

performance

kg/h

837 837 837 837 752 752 752 887 785 785 785

Waste heat,

proportional

% 67.0 41.9 32.2 26.2 18.8 15.0 12.5 12.7 9.8 7.9 6.5

Table 12 Steam amount/waste heat performance – boiler type/CHP (1250 kg/h ... 12000 kg/h)

The boiler type corresponds to the

colour of the respective cell

UL-S

1250

UL-S

2000

UL-S

2600

UL-S

3200

UL-S

4000

UL-S

5000

UL-S

6000

UL-S

7000

UL-S

8000

UL-S

10000

UL-S

12000

Page 26

Engineering information and sizing

Systemlösung – 6 720 885 509 (2018/03)

26

13000 kg/h ... 28000 kg/h

Amount of steam incl. own use of boiler (burner + waste heat performance) in [kg/

h]

CHP Unit 13000 14000 16000 17000 18000 22000 28000

CHP CE 240 NE Waste heat

performance

kg/h

131 133 140 142 143 144 –

Waste heat,

proportional

% 1.0 1.0 0.9 0.8 0.8 0.7 0.0

CHP CE 400 NE Waste heat

performance

kg/h

178 181 193 197 199 201 –

Waste heat,

proportional

% 1.4 1.3 1.2 1.2 1.1 0.9 0.0

CHP CE 600 NE Waste heat

performance

kg/h

302 283 304 310 313 317 –

Waste heat,

proportional

% 2.3 2.0 1.9 1.8 1.7 1.4 0.0

CHP CE 800 NE Waste heat

performance

kg/h

385 391 418 423 400 435 –

Waste heat,

proportional

% 3.0 2.8 2.6 2.5 2.2 2.0 0.0

CHP CE 854 NE Waste heat

performance

kg/h

374 379 406 410 388 422 –

Waste heat,

proportional

% 2.9 2.7 2.5 2.4 2.2 1.9 0.0

CHP CE 1200 NE Waste heat

performance

kg/h

476 456 491 497 499 512 –

Waste heat,

proportional

% 3.7 3.3 3.1 2.9 2.8 2.3 0.0

CHP CE 1287 NE Waste heat

performance

kg/h

548 525 565 572 575 590 –

Waste heat,

proportional

% 4.2 3.8 3.5 3.4 3.2 2.7 0.0

CHP CE 1560 NE Waste heat

performance

kg/h

646 655 704 709 714 736 –

Waste heat,

proportional

% 5.0 4.7 4.4 4.2 4.0 3.3 0.0

CHP CE 1718 NE Waste heat

performance

kg/h

663 673 723 728 734 756 –

Waste heat,

proportional

% 5.1 4.8 4.5 4.3 4.1 3.4 0.0

CHP CE 1999 NE Waste heat

performance

kg/h

919 932 976 976 976 1007 –

Waste heat,

proportional

% 7.1 6.7 6.1 5.7 5.4 4.6 0.0

CHP CE 2000 NE Waste heat

performance

kg/h

774 785 822 822 822 848 –

Waste heat,

proportional

% 6.0 5.6 5.1 4.8 4.6 3.9 0.0

Table 13 Steam amount/waste heat performance – boiler type/CHP (13000 kg/h ... 28000 kg/h)

The boiler type corresponds to the

colour of the respective cell

UL-S 13000 UL-S 14000 UL-S 16000 UL-S 17000 UL-S 18000 UL-S 22000 UL-S 28000

Page 27

Engineering information and sizing

27

Systemlösung – 6 720 885 509 (2018/03)

Overview CHP/boiler combinations

1250 kg/h ... 12000 kg/h

Amount of steam incl. own use of boiler (burner + waste heat performance) in [kg/h]

1250 2000 2600 3200 4000 5000 6000 7000 8000 10000 12000

CHP CHP CE ...

240 NE 240 NE 240 NE 240 NE 240 NE 240 NE 240 NE 240 NE 240 NE 240 NE 240 NE

steam boiler UL-S ...

1250 2000 2600 4000 4000 5000 6000 7000 8000 10000 12000

CHP CHP CE ... 400 NE 400 NE 400 NE 400 NE 400 NE 400 NE 400 NE 400 NE 400 NE 400 NE 400 NE

steam boiler UL-S ... 2000 2000 2600 4000 4000 5000 6000 7000 8000 10000 12000

CHP CHP CE ...

600 NE 600 NE 600 NE 600 NE 600 NE 600 NE 600 NE 600 NE 600 NE 600 NE 600 NE

steam boiler UL-S ...

2000 2000 4000 4000 4000 5000 6000 7000 8000 10000 12000

CHP CHP CE ... 800 NE 800 NE 800 NE 800 NE 800 NE 800 NE 800 NE 800 NE 800 NE 800 NE 800 NE

steam boiler UL-S ... 2000 4000 4000 4000 5000 5000 7000 7000 8000 10000 12000

CHP CHP CE ...

854 NE 854 NE 854 NE 854 NE 854 NE 854 NE 854 NE 854 NE 854 NE 854 NE 854 NE

steam boiler UL-S ...

2000 4000 5000 4000 5000 5000 7000 7000 8000 10000 12000

CHP CHP CE ... 1200 NE 1200 NE 1200 NE 1200 NE 1200 NE 1200 NE 1200 NE 1200 NE 1200 NE 1200 NE 1200 NE

steam boiler UL-S ... 4000 4000 5000 5000 6000 7000 7000 8000 8000 10000 12000

CHP CHP CE ...

1287 NE 1287 NE 1287 NE 1287 NE 1287 NE 1287 NE 1287 NE 1287 NE 1287 NE 1287 NE 1287 NE

steam boiler UL-S ...

4000 4000 5000 5000 6000 7000 8000 8000 8000 10000 12000

CHP CHP CE ... 1560 NE 1560 NE 1560 NE 1560 NE 1560 NE 1560 NE 1560 NE 1560 NE 1560 NE 1560 NE 1560 NE

steam boiler UL-S ... 5000 5000 5000 7000 7000 7000 8000 8000 8000 12000 12000

CHP CHP CE ...

1718 NE 1718 NE 1718 NE 1718 NE 1718 NE 1718 NE 1718 NE 1718 NE 1718 NE 1718 NE 1718 NE

steam boiler UL-S ...

5000 5000 5000 7000 7000 7000 8000 10000 10000 12000 12000

CHP CHP CE ... 1999 NE 1999 NE 1999 NE 1999 NE 1999 NE 1999 NE 1999 NE 1999 NE 1999 NE 1999 NE 1999 NE

steam boiler UL-S ... 7000 7000 7000 7000 8000 8000 8000 10000 12000 12000 12000

CHP CHP CE ...

2000 NE 2000 NE 2000 NE 2000 NE 2000 NE 2000 NE 2000 NE 2000 NE 2000 NE 2000 NE 2000 NE

steam boiler UL-S ...

7000 7000 7000 7000 8000 8000 8000 10000 12000 12000 12000

Table 14 CHP/boiler combinations (1250 kg/h ... 12000 kg/h)

+ 0 boiler sizes Recommended

+1 boiler size Recommended

+ 2 boiler sizes Check economic viability

More than +2 boiler sizes Not recommended

Page 28

Engineering information and sizing

Systemlösung – 6 720 885 509 (2018/03)

28

13000 kg/h ... 28000 kg/h

3.3.4 Demand for useful energy for make-up water

preheating, heating energy and DHW

The motor waste heat that occurs in the CHP should

primarily be used for heating the make-up water

required for the steam boiler.

Besides the boiler size, the amount of make-up water is

dependent on the form of heating (directly or indirectly),

on the existing or planned condensate management in

the object and on water quality.

The required make-up ware amount has to be

determined depending on the corresponding standards.

The make-up water is heated up here as much as

possible. Then the make-up water is heated up further in

the feed water container with steam to approx. 103 °C

and is led to the boiler via the two economisers.

In doing so, internal steam for make-up water treatment

is saved and the make-up water heating is used as heat

sink for the motor waste heat of the CHP to increase its

runtime.

Graph 14 shows the possible content of make-up water

preheating (heating from 10 °C to 75 °C) with regard to

boiler output in kg/h and the required additional water

amount in %.

If the occurring motor heat output is larger than the

required heat for make-up water preheating, the excess

heat can be used for covering the heat load or for DHW

heating.

Amount of steam incl. own use of boiler (burner + waste heat performance) in [kg/h]

13000 14000 16000 17000 18000 22000 28000

CHP CHP CE ...

240 NE 240 NE 240 NE 240 NE 240 NE 240 NE 240 NE

steam boiler UL-S ...

13000 14000 16000 17000 18000 22000 28000

CHP CHP CE ... 400 NE 400 NE 400 NE 400 NE 400 NE 400 NE 400 NE

steam boiler UL-S ... 13000 14000 16000 17000 18000 22000 28000

CHP CHP CE ...

600 NE 600 NE 600 NE 600 NE 600 NE 600 NE 600 NE

steam boiler UL-S ...

13000 14000 16000 17000 18000 22000 28000

CHP CHP CE ... 800 NE 800 NE 800 NE 800 NE 800 NE 800 NE 800 NE

steam boiler UL-S ... 13000 14000 16000 17000 18000 22000 28000

CHP CHP CE ...

854 NE 854 NE 854 NE 854 NE 854 NE 854 NE 854 NE

steam boiler UL-S ...

13000 14000 16000 17000 18000 22000 28000

CHP CHP CE ... 1200 NE 1200 NE 1200 NE 1200 NE 1200 NE 1200 NE 1200 NE

steam boiler UL-S ... 13000 14000 16000 17000 18000 22000 28000

CHP CHP CE ...

1287 NE 1287 NE 1287 NE 1287 NE 1287 NE 1287 NE 1287 NE

steam boiler UL-S ...

13000 14000 16000 17000 18000 22000 28000

CHP CHP CE ... 1560 NE 1560 NE 1560 NE 1560 NE 1560 NE 1560 NE 1560 NE

steam boiler UL-S ... 13000 14000 16000 17000 18000 22000 28000

CHP CHP CE ...

1718 NE 1718 NE 1718 NE 1718 NE 1718 NE 1718 NE 1718 NE

steam boiler UL-S ...

13000 14000 16000 17000 18000 22000 28000

CHP CHP CE ... 1999 NE 1999 NE 1999 NE 1999 NE 1999 NE 1999 NE 1999 NE

steam boiler UL-S ... 13000 14000 18000 18000 18000 22000 28000

CHP CHP CE ...

2000 NE 2000 NE 2000 NE 2000 NE 2000 NE 2000 NE 2000 NE

steam boiler UL-S ... 13000 14000 18000 18000 18000 22000 28000

Table 15 CHP/boiler combinations (13000 kg/h ... 28000 kg/h)

+ 0 boiler sizes Recommended

+1 boiler size Recommended

+ 2 boiler sizes Check economic viability

Page 29

Engineering information and sizing

29

Systemlösung – 6 720 885 509 (2018/03)

Fig. 14 Make-up water preheating

A Make-up water preheating

B Ratio make-up water/steam amount

C Performance steam boiler

[1] CHP 240 NE

[2] CHP 400 NE

[3] CHP 600 NE

[4] CHP 800 NE

[5] CHP 854 NE

[6] CHP 1200 NE

[7] CHP 1287 NE

[8] CHP 1560 NE

[9] CHP 1718 NE

[10] CHP 1999 NE/CHP 2000 NE

6 720 819 535-17.1T

0

10

20

30

40

50

60

70

80

90

100

0

5 000

5 000

10 000

10 000

15 000

15 000

20 000

20 000

C [kg/h]

A [l/h] B [%]

10

9

8

7

6

5

4

3

2

1

Page 30

Engineering information and sizing

Systemlösung – 6 720 885 509 (2018/03)

30

3.3.5 Safety equipment

In correspondence with the statutory and normative

rules, the key components CHP and 4-draught boiler are

equipped with the required safety equipment.

For connecting the bypass function (Æ chapter 3.4.1,

page 34) a functionality has been defined by the German

Technical Control Board TÜV that is described in the

Technical Paper TI 041: “Requirements to the waste heat

generating power unit in conjunction with a downstream

waste heat steam generator for waste heat utilisation”

(Æ Chapter 4.2, Page 41).

All documents and licences required for receiving a TÜV

certification exist and are provided by Bosch. Bosch

provides during quotation phase a P&ID (piping and

instrumentation diagram) that is released for external

use, exemplary installation drawings in PDF and DXF as

well as comprehensive quotation texts.

3.3.6 System control

The superordinate control of the combination CHP and

4-draught steam boiler should be mainly effected by the

Bosch control system MEC system.

A control with MEC system is possible, but the system

benefits generated by MEC, that are presented in the

following chapters, cannot be achieved.

MEC System

The system control MEC System is a possibility for

intelligently controlling the combinaton CHP with

4-draught steam boiler. MEC System controls the

subsystem CHP and 4-draught steam boiler and

optimally integrates it in the overall energy generation

system on site.

Benefits of the control are among others:

• Optimum activation of devices while maintaining the

operating conditions

• Integration of device controller via Modbus interface.

The amount of transferred data points allows for

optimum control and visualisation.

Fig. 15 Visualisation

6 720 819 535-09 .1T

Page 31

Engineering information and sizing

31

Systemlösung – 6 720 885 509 (2018/03)

• Modulating or step CHP control depends on steam

demand of a 4-draught steam boiler and heat

requirement of the DHW system

Fig. 16 Control behaviour CHP – 4-draught steam boiler

• Calculation of used CHP flue gas performance in the

steam boiler is possible without expensive additional

measuring devices. The obtained value is used in the

control and visualised in the HMI

1)

.

• Visualisation of CHP runtime for monitoring and

adherence to CHP subsidy with runtime prognosis

function

• Bar chart for created vapour, DHW and current for the

corresponding CHP section

• CHP control with adherence to CHP subsidy: With

bypass operation, as described in

on page

20

, it is

possible to achieve certain benefits, such as a longer

CHP runtime and the reduction or prevention of CHP

pulsing. In this operating condition, the CHP annual

efficiency is reduced due to not used flue gas energy

which leads to problems for obtaining public subsidy

programmes. For this reason, the customer has the

possibility to enter the limit corresponding to the