Page 1

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

CET3-10

CET4-20

CET4-20W

Call Toll Free for Pour obtenir des informations Llame gratis para

Consumer Information et les adresses de nos centres obtener información

& Service Locations: de service après-vente, para el consumidor y

appelez ce numéro gratuit ubicaciones de servicio

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

For English Version Version française Versión en español

See page 2 Voir page 17 Ver la página 32

1

-E/F/S-190609

Page 2

GenerAl sAfety rules

DANGER

result in electric shock, re, serious personal injury or death.

All users and employers/owners must read and understand all instructions in this manual before

operating or maintaining this compressor.

Failure to follow all instructions listed below may

sAVe tHese InstruCtIons

Work AreA

Keep your work area clean and well lit.

benches and dark areas increase the risks of

accidents, electric shock, re, and injury to persons.

Do not operate compressor in explosive atmospheres,

such as in the presence of ammable liquids, gases,

or dust. Keep work area well ventilated. Always locate

the compressor at least 20 ft. (6.1 m) away from work

area if spraying ammable materials. DO NOT SMOKE

if spraying ammable materials.

able to create sparks which may ignite the dust or

fumes. Never use the compressor in sites containing

lacquer, paint, benzene, thinner, gasoline, gases,

adhesive agents, and other materials which are

combustible or explosive. A longer hose may be

required.

Always operate the compressor in a well ventilated

area. Follow all safety instructions and use a respirator

as directed in the safety instructions provided with

the material to be sprayed.

such as paint, paint solvents, paint remover,

insecticides, weed killers, etc contain harmful vapors

and poisons.

Keep bystanders, children, and visitors away while

operating a compressor. Do not allow children to

operate compressor.

of control of the tools which may cause injury to

bystanders.

Never engage in horseplay with the compressor.

Respect the compressor as a working implement.

Always operate the compressor from a stable secure

position. Never operate the compressor from a roof or

table.

Use additional air hose to allow tools to reach

high locations.

Equip the work area with a suitable re extinguisher.

Do not remove, tamper with, or otherwise cause

the tool operating controls to become disabled or

inoperable.

and may result in the risk of injury.

Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing,

and gloves away from moving parts.

jewelry, or long hair can be caught in moving parts

This will cause the tool to work irregularly

Distractions may cause loss

PersonAl sAfety

The compressor is

Some sprayed materials

Cluttered

Loose clothes,

and increases the risk of injury.

Always wear eye and ear protection when using this

tool. Use additional personal protective equipment

as appropriate when operating this tool.

and others in work area must wear safety glasses.

Prolonged exposure to high intensity noise is able

to cause hearing loss. Dust mask, non-skid safety

shoes, hard hat and other personal protective

equipment, must be used for appropriate conditions.

Do not operate the compressor unless you are familiar

with controls.

operate compressor in an unsafe manner, injuring

themselves or others.

Keep handles and controls dry, clean and free from oil

and grease.

tool.

Stay alert. Watch what you are doing, and use

common sense when operating a compressor. Do not

use compressor while tired or under the inuence of

drugs, alcohol, or medication.

while operating the compressor may result in serious

personal injury.

Do not direct air stream at people or animals.

pressure air can propel dust and debris at high

speed. Compressed air from a compressor

can contain water, oil, metal particles or other

contaminants which can cause serious injury.

Do not use compressed air for breathing or

respiration. Never inhale air directly from compressor

or from breathing apparatus connected to compressor.

Compressed air stream may contain carbon

monoxide, toxic vapors or solid particles from air tank

which if inhaled could cause serious injury or death.

Use care when touching exposed metal surfaces of

compressor.

head, engine/motor, and tubing will remain hot even

after the air compressor has been shut down. Allow

compressor to cool before moving or attempting

maintenance.

Do not stand on compressor. Keep proper footing

and balance at all times.

balance enable better control of tools in unexpected

situations.

Make sure air hose is free of snags and obstructions.

Do not attach an air hose or tool to your body.

Users unfamiliar with controls may

Slippery hands cannot safely control the

A moment of inattention

Many components such as compressor

Proper footing and

Operators

High

2

Page 3

Entangled or snarled hoses can cause a loss of

balance or footing in addition to unintentional tool

operation. Attach the hose to the structure to reduce

the risk of loss of balance if the hose shifts.

Do not abuse the air hose. Protect all hoses from

kinks, restrictions, solvents or sharp objects. Keep air

hose away from heat, oil, sharp edges or moving parts.

Replace damaged hoses immediately. Damaged

hoses can burst or whip around work area.

Only use hoses with a minimum rating of 200 PSI.

of hoses with a high pressure rating reduce the risk

of injury from a hose bursting.

Firmly grasp hose in hand when installing hoses.

hose is not held rmly or correctly installed, hose may

whip and injure personnel in the operating area.

Use care when lifting and carrying the compressor.

Some compressors are too heavy to be lifted by one

person. Get assistance before attempting to lift a

compressor to reduce the risk of injury.

When moving or loading a wheeled compressor ensure

that the compressor is always on a level surface.

compressor is placed on a sloped surface, it may

move unexpectedly and result in personal injury.

This product contains chemicals, including lead,

known to the State of California to cause birth defects

and other reproductive harm.

using.

tool use And CAre

Use this compressor and all accessories in accordance

with the instructions.

must be used for the purpose for which they are

designed. Use of the compressor for operations

other than what is described in this manual can result

in a hazardous situation.

Use only accessories that are recommended by

BOSCH for your particular model.

may be recommended for a particular model tool

may not be suitable on other model tools and may

result in personal injury.

Before each use, inspect all ttings, hoses, pipes,

connections of the compressor. Do not operate if any

portion of the compressor is loose, missing, damaged,

malfunctioning, disconnected or altered. Never use

a compressor that appears damaged or is operating

abnormally.

operating unusually and/or making strange noises,

stop using it immediately and contact your local

BOSCH service center. There is a risk of bursting if

the compressor is damaged.

Before each use inspect compressor for signs of leaks

or damage. If leaks are found in the compressor pump,

air tanks or tubing, replace compressor immediately.

If the compressor appears to be

Compressor and accessories

Wash hands after

Accessories that

Use

If

If the

Never attempt repair leaks, weld or make

modications to the air tank or other uid conning

parts as there is a risk of bursting.

Do not attempt to operate this air compressor without

rst verifying the oil level in the crankcase. This

compressor is shipped with oil in the crankcase.

Serious damage of the compressor can result from

even momentary operation without proper lubrication.

Never operate the compressor without the safety

valve. Verify operation of the safety valve on a daily

basis. Do not use the safety valve for complete tank

drainage.

pressure to reduce the risk of bursting.

Never operate compressor without all guards and

other safety features in place and performing intended

function.

of guard or safety feature, be sure to replace the

guard or safety feature before resuming operation of

the compressor. Replace damaged guards or safety

features immediately.

Never touch moving parts.

your body near compressor moving parts. Do not

reach around guards to reduce the risk of injury.

Do not operate compressor without the air lter.

Filters prevent large particles from entering the

air stream and damaging compressor internal

components.

Do not allow particulates such as sawdust to fall into

crankcase when crankcase is open for inspection.

Particulates in oil may reduce compressor life.

Do not use a detergent oil in crankcase.

oils will leave deposits on internal compressor

components reducing compressor life and

components.

Do not use compressor for unattended operation.

Always remain in area when compressor is operating

and turn off compressor when not in use to reduce

the risk of re.

Never place objects on top or next to compressor.

Locate compressor at least 12 in. (30 cm) away from

all obstructions.

ventilation openings can cause overheating and

could cause a re.

Do not operate the compressor with any power source

other than that specied in the tool operating/safety

instructions.

result in malfunctions of the compressor and the

power source which may lead to serious injury of you

or others in your surroundings.

Follow all recommendations for sizes of hoses, ttings

The safety valve is designed to relieve tank

If maintenance or servicing requires removal

Do not place any part of

Detergent

Restricting any of the compressor’s

Use of alternative power sources may

3

Page 4

and other compressed air accessories.

sized tting or components may result in the risk of

injury or property damage

Never move the compressor by pulling on a hose.

compressor, air ttings and the air hose may become

damaged and burst.

Check air supply lines for restrictions before adjusting

tool.

Air volume is as important as air pressure.

Restricted air ow will prevent the tools from

operating as designed.

Never exceed the maximum allowable pressure

rating marked on tools and attachments. Do not use

compressor to inate low pressure objects such

as toys.

pressure of tools and attachments can cause them

to burst. The correct pressure is the lowest pressure

that will do the job.

Drain condensate from air tanks daily with drain valve.

Draining water from the air compressor reduces the

risk of air tank corrosion. Corroded air tanks increase

the risk of bursting.

Stop the compressor, drain air tanks and allow it

to cool before making adjustments, moving the

compressor, leaving the work area, performing

maintenance or storing the compressor.

precautionary safety measures reduce a risk of

injury.

Do not modify this compressor or operate compressor

at pressures or speeds greater than designed

alteration or modication is a misuse and may result

in a dangerous condition such as re or bursting.

When transporting compressor, keep level and place

on a protective mat. Do not place compressor on

its side.

danger to personnel from oil fumes.

Exceeding the maximum recommended

Such precautions reduce the risk of re or

Improperly

The

Such

. Any

serVICe

Maintenance performed by unauthorized personnel

may result in misplacing of the internal components

which could cause serious hazard.

that all compressor service be performed by a

BOSCH factory service center or authorized BOSCH

service station.

Develop a periodic maintenance schedule for your

tool. When cleaning a compressor be careful not to

disassemble any portion of the tool since internal

components may be misplaced or safety components

may be improperly mounted.

such as gasoline, carbon tetrachloride, ammonia, etc.

may damage plastic parts and o-rings.

When servicing the compressor, use only

recommended BOSCH replacement parts. Follow

instructions in the Maintenance section of this

manual.

Maintenance Instructions can cause a risk of injury.

Replace missing or damaged warning labels.

schematic for correct placement and part number.

Maintain compressor with care. Keep the compressor

clean and lubricated.

less likely to break and cause injury. Any alteration

or modication is a misuse and may result in a

dangerous condition. Clean the tool at least daily and

lubricate as required.

When not in use, store the compressor out of reach

of children and other personnel unfamiliar with

compressor operation.

should be disconnected and stored in a dry place.

Vent the air tank. Keep out of reach of children. Lock

the storage area. Compressor can be dangerous in

the hands of users unfamiliar with its operation.

Use of unauthorized parts or failure to follow

Properly maintained tools are

When not in use, the tool

We recommend

Certain cleaning agents

Refer to

4

Page 5

sAfety rules for eleCtrIC ComPressors

Power cord plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodied plugs and matching outlets will

reduce risk of electric shock.

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Replace damaged cord immediately.

Damaged or entangled cords increase the risk of

electric shock.

Do not expose this compressor to rain. Do not

use in damp or wet locations. Moisture increases

the risk of electric shock with this equipment.

Do not touch plug with wet hands. Moisture

increases the risk of electric shock with this

equipment.

Keep all electrical connections dry and off the

ground. Do not allow electrical connections

to lay in water or in such a position where

water could come into contact with cord and

connection. Moisture increases the risk of electric

shock with this equipment.

When operating a power tool outdoors, use an

extension cord suitable for outdoor use and with

correct amperage capacity. Use of a cord rated for

outdoor use reduces the risk of electric shock.

Always disconnect compressor from power

supply, vent air tanks, and allow compressor to

cool before servicing. Compressors with automatic

pressure controls can restart at any time.

Always turn off the motor when not in use and

before moving compressor. Stopping the motor

prevents unintentional starting of the compressor.

Some dust created by power sanding, sawing,

grinding, drilling, and other construction

activities contains chemicals known to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other

masonry products, and

• Arsenic and chromium from chemically treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to

lter out microscopic particles.

sAVe tHese InstruCtIons

5

Page 6

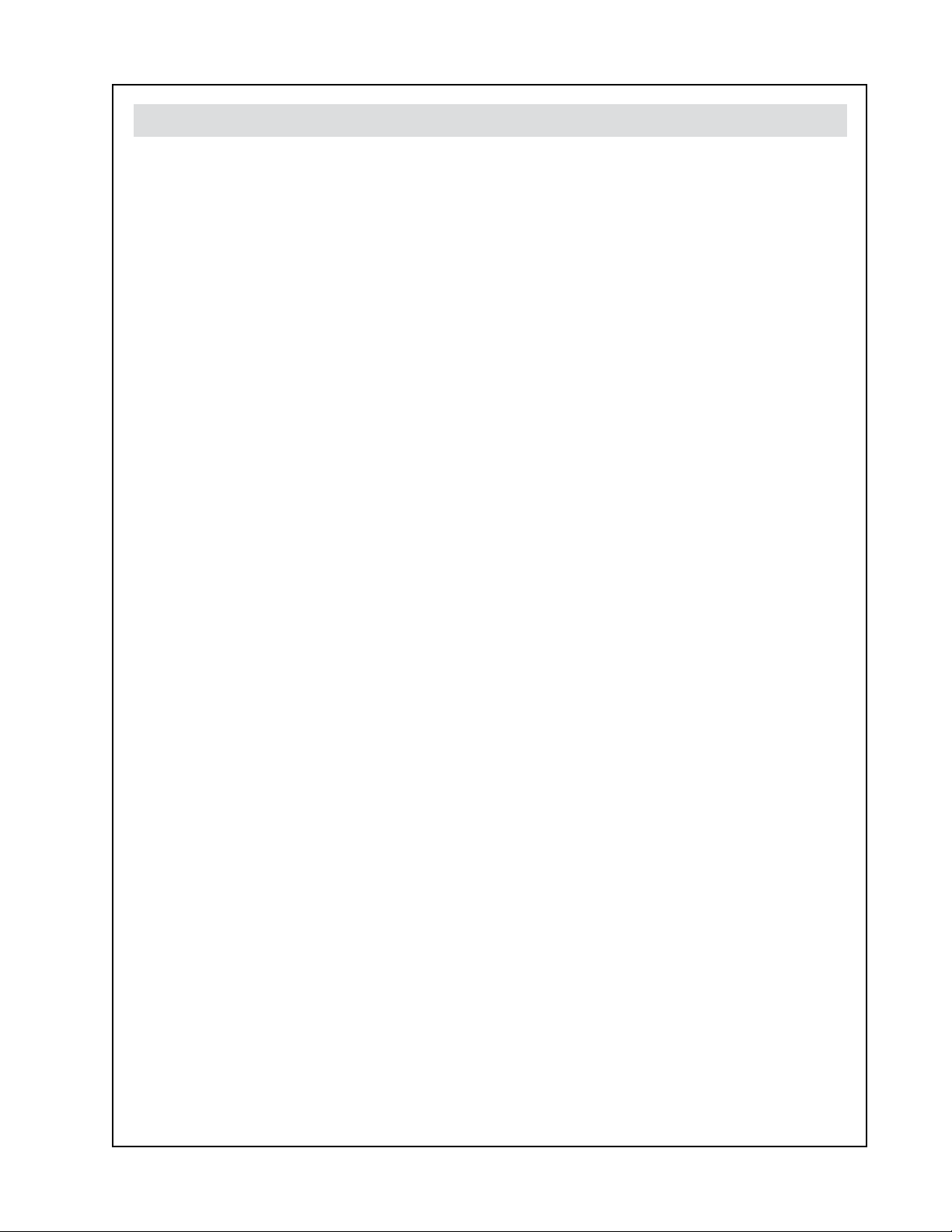

funCtIonAl desCrIPtIon And sPeCIfICAtIons

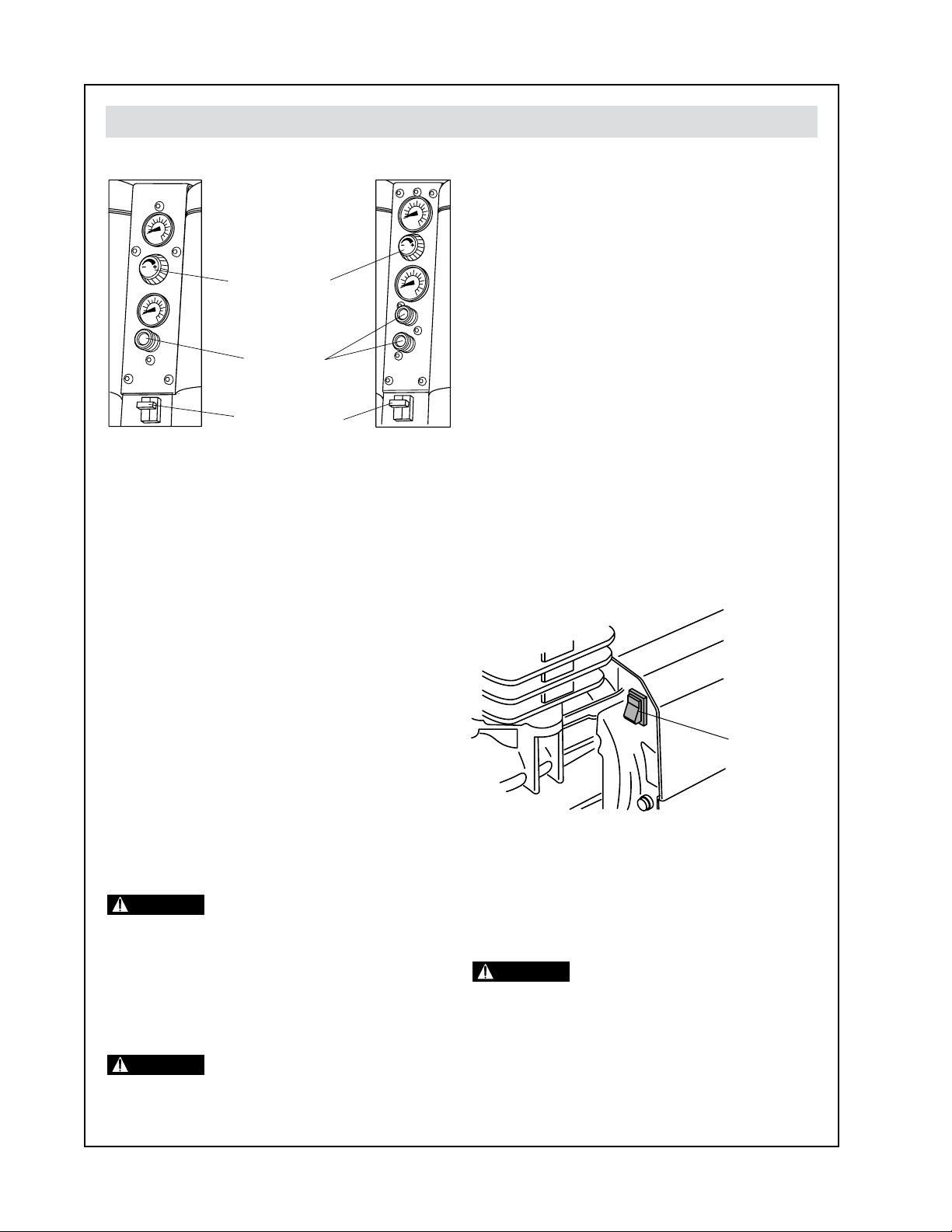

5

8

11

14

16

9

6

17

13

15

2

4

3

12

10

7

1

5

8

11

14

16

3

6

17

13

15

2

4

9

12

10

7

1

Specications: CET3-10

Product Size: 16” x 18” x 16.25”

Weight: 57.3 lbs.

HP: 1

CFM @ 100 psi: 2.6

RPM: 1700

dBA: 72

Recovery Time: 14 seconds

Motor: 4-Pole Induction

Drive Type: Direct

Maintenance: Oil

Specications: CET4-20

Product Size: 16.25” x 17.75” x 19.75”

Weight: 72.7 lbs.

HP: 2

CFM @ 100 psi: 4.2

RPM: 3400

6

dBA: 80

Recovery Time: 12 sec.

Motor: 2-Pole Induction

Drive Type: Direct

Maintenance: Oil

Page 7

5

8

11

14

16

3

6

17

13

15

2

4

9

10

7

1

12

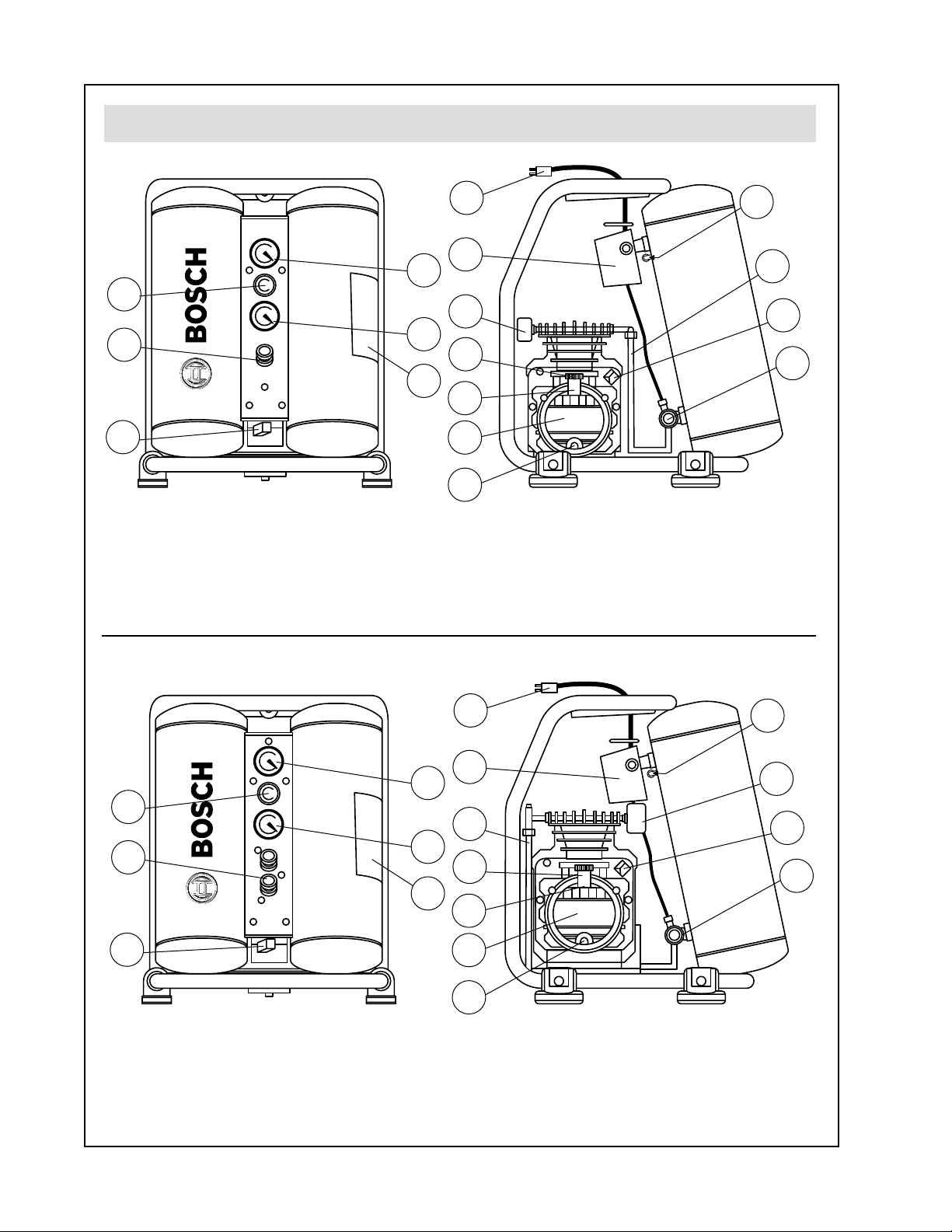

funCtIonAl desCrIPtIon And sPeCIfICAtIons

Specications: CET4-20W

Product Size: 22” x 21.5” x 19.75”

(handle down)

Weight: 84.9 lbs.

HP: 2

CFM @ 100 psi: 4.9

RPM: 3400

1. Warning Label

2. Pressure Switch

3. Pump Discharge Line

4. Oil Dipstick

5. Air Compressor Pump

6. Thermal Overload

7. Pump Oil Fill Port

8. Pump Oil Drain

9. Air Filter

dBA: 80

Recovery Time: 10 sec.

Motor: 2-Pole Induction

Drive Type: Direct

Maintenance: Oil

10. Check Valve

11. Electric Power Cord

12. Safety Release Valve

13. Pressure Gauge - Tank Psi

14. Pressure Regulator

15. Pressure Gauge - Outlet Psi

16. Outlet Fittings

17. Tank Drain Valve

7

Page 8

Assembly / InstAllAtIon

CAUTION

CAUTION

WARNING

CAUTION

MAX

MIN

(A)

(B)

(D)

(C)

GROUNDING

PIN

GROUNDED

OUTLET

GROUNDED

OUTLET BOX

lubrICAtIon And oIl

Do not attempt to operate this air

compressor without first verifying

the oil level in the crankcase. This compressor is

shipped with oil in the crankcase. Serious damage

of the compressor can result from even momentary

operation without proper lubrication.

Prior to each use, verify the crankcase oil level. An

oil sight gauge with minimum and maximum oil level

marks is provided with this compressor.

Always verify that the oil level is at the maximum

mark in the oil sight gauge before operating this

unit. Do not operate the pump with an inadequate or

excessive amount of oil. The cost of failures which

occur due to incorrect oil levels will not be covered

under warranty.

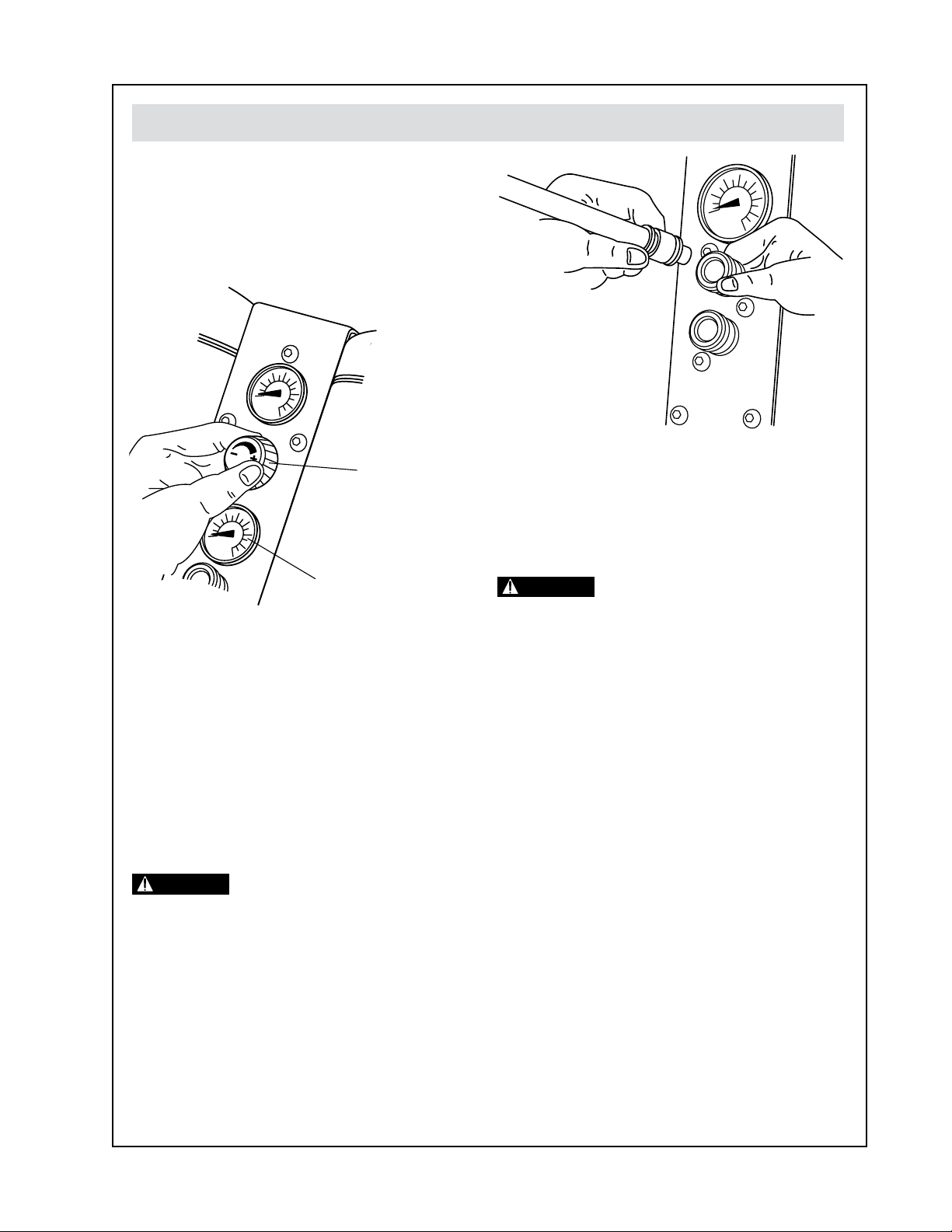

To check the oil level: (see Fig. 1)

1. Place unit on a level surface.

2. Remove dipstick, wipe with a clean rag, replace

in crankcase, then remove dipstick to inspect oil

level.

3. If oil level is low, add as required, but do not exceed

maximum oil level.

frame.

3. Place screw through washer (D) and thread screw

into end of wheel spindle (C). Tighten screw to

secure to spindle.

4. Repeat these steps for second wheel.

Fig. 2

GroundInG

This product must be grounded. In the event of an

electrical short circuit, grounding reduces the risk

of electric shock by providing an escape wire for

the electric current. This product is equipped with

a cord having a grounding wire with an appropriate

grounding plug. The plug must be inserted into an

outlet that is properly installed and grounded in

accordance with all local codes and ordinances (see

Fig. 3).

Improper installation of the

grounding plug is able to result in

a risk of electric shock. When repair or replacement

Fig. 1

crank case is open for inspection. Particulates in oil

may reduce compressor life.

deposits on internal compressor components

reducing compressor life and performance.

dIreCtIons for InstAllInG WHeels

1. Take wheel spindle (A) and thread into wheel

bracket (B), which is welded to compressor frame.

Tighten spindle with wrench to secure to frame.

2. Slide wheel onto wheel spindle. Ination stem for

8

wheel assembly should face toward the compressor

Do not allow particulates such as

sawdust to fall into crank case when

Do not use a detergent oil in

crankcase. Detergent oils will leave

(Cet4-20W only See Fig. 2)

of the cord or plug is required, do not connect the

grounding wire to either flat blade terminal. The wire

with insulation having an outer surface that is green

with or without yellow stripes is the grounding wire.

Check with a qualied electrician or serviceman

when the grounding instructions are not completely

understood, or when in doubt as to whether the

product is properly grounded. Do not modify the plug

provided; if it does not t the outlet, have the proper

outlet installed by a qualied electrician.

Fig. 3

Page 9

WARNING

WARNING

CAUTION

Assembly / InstAllAtIon

This product is for use on a nominal 120-V circuit and

has a grounding plug similar to the plug illustrated on

page 8. Only connect the product to an outlet having

the same conguration as the plug. Do not use an

adapter with this product.

extensIon Cords

Use only a 3-wire extension cord that has a 3-blade

grounding plug, and a 3-slot receptacle that accepts

the plug on the product. Make sure your extension

cord is not damaged. When using an extension cord,

be sure to use one heavy enough to carry the current

your product draws.

Extension Cord Table

0 – 25 ft 25 – 50 ft.

14 ga. 12 ga.

RECOMMENDED SIZES OF EXTENSION CORDS

The maximum recommend cord length is 50 feet with

a 12 gauge cord rating.

PrePArAtIon for use

Use this compressor and all

accessories in accordance with

the instructions. Compressor and accessories

must be used for the purpose for which they are

designed. Use of the compressor for operations

other than what is described in this manual can result

in a hazardous situation.

Fig. 4

If the safety release valve vents

under normal operating

conditions, stop using the compressor

immediately. Send your compressor for service. If

the safety release valve is venting the tanks the

pressure switch may need factory adjustment.

3. Plug the power cord into the correct branch circuit

receptacle.

See the “Grounding Section” for more information on

the correct receptacle.

4. Open the drain valve to permit air to escape the

tank and prevent air pressure build up during the

break-in period.

The drain valve is located on the control panel and

is used to drain condensation from the tanks at the

end of each use. Tank pressure is used to expel the

water.

eleCtrIC motor

Initial Set-Up – Break-in Procedure

Before rst use of this air compressor or after the

compressor pump/motor has been replaced, perform

the following:

1. Ensure the power switch is in the OFF position.

This air compressor has an integrated power and

pressure switch. When the power is ON the pressure

switch will automatically start the compressor motor

any time the tank pressure drops below the factory

set cut-in pressure and stop the motor when the tank

pressure stops at the factory set cut-out pressure.

2. Ensure safety valve is functioning properly by pulling

on the valve ring and allow the valve to reset (see

Fig. 4).

The safety valve is designed to protect against high

pressure by releasing high pressure air from the air

tank when its factory set pressure (slightly higher

than the pressure switch cut-out setting) is exceeded.

5. Move the power switch to the ON position. The

compressor will start.

6. Run the compressor for 20 minutes.

7. After 20 minutes, close the drain valve. The tank

will ll to cut-out pressure and the compressor

motor will stop.

8. Move the power switch to the OFF position and

unplug the compressor.

9. Pull the safety valve and allow to vent until tank

pressure is under 20 psi.

10. Open the drain valve to permit air to escape the

tank and to drain any moisture or particles from

tank. When tank is empty, close drain.

11. Compressor is now ready for rst use.

Change the crankcase oil after the

first 50 hours of operation and as

recommended in the maintenance section of this

manual. Failure to change oil according to

maintenance schedule will reduce compressor life

and performance.

9

Page 10

WARNING

CAUTION

WARNING

oPerAtIon

Reset

Switch (A)

Drain Valve (A)

Regulator (C)

1/4” Outlet

fittings (B)

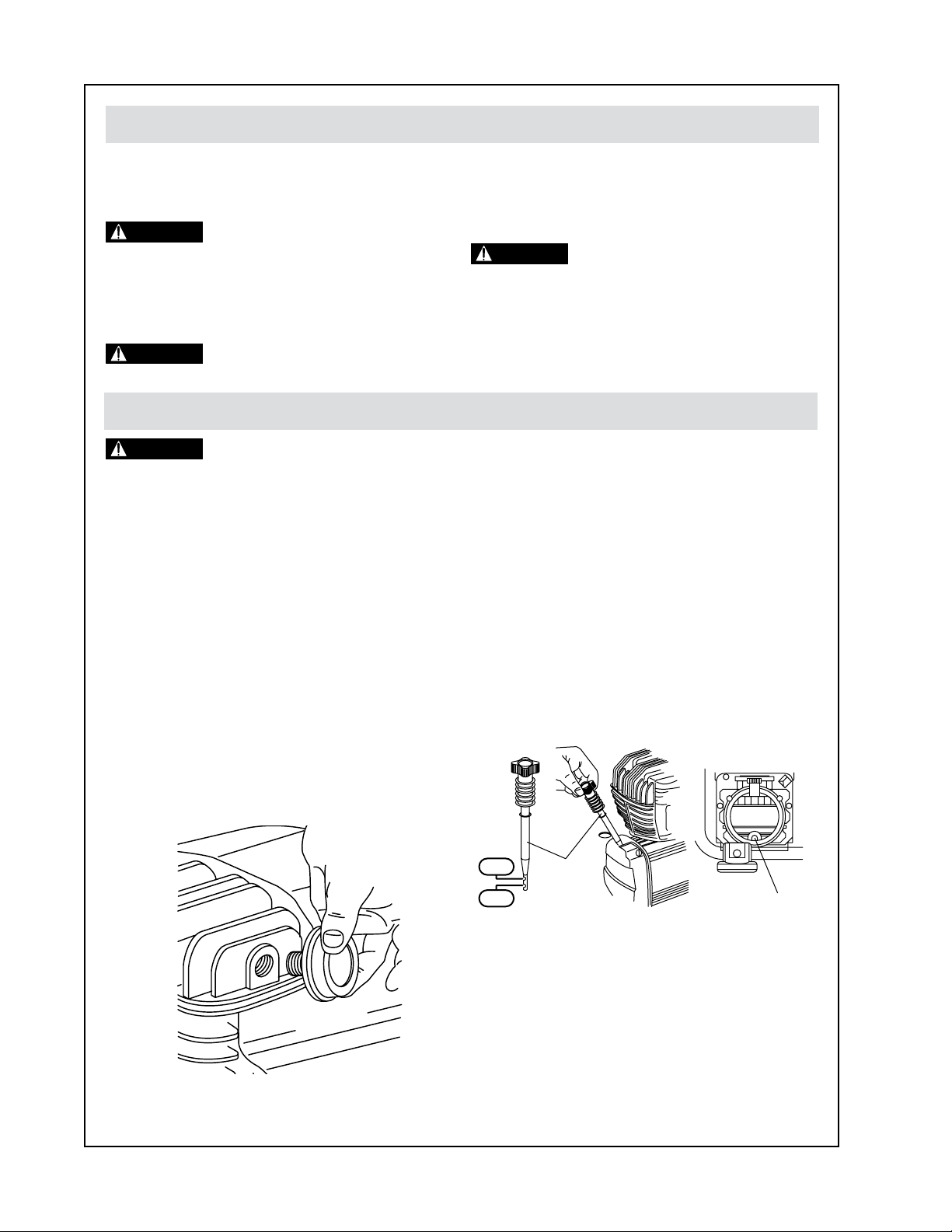

stArtInG tHe ComPressor

CET3-10 CET4-20 and

CET4-20W

Fig. 5

1. Position compressor on a at surface or one with

an inclination of 10° or less, in a well ventilated

area away from vapors.

2. Ensure all covers and labels are in place, legible

(for labels) and securely mounted. Do not use

compressor until all items have been veried.

3. Ensure the power switch is in the OFF position.

4. Plug the power cord into the correct branch circuit

receptacle. See the “Grounding Section” for more

information on the correct receptacle.

5. Ensure drain valve is closed in the horizontal

position (A).

8. Attach hoses to compressor (B).

9. Turn the power to ON, and verify that the compressor

is functioning. Adjust the air pressure the desired

level for the accessory as described in adjusting

regulator (C). Verify that the compressor motor

stops when cut out pressure is reached.

motor tHermAl Cut out

The thermal protector operates to stop the motor

when a problem such as a motor overload, etc.

occurs. If the motor should stop during operation,

proceed as follows:

1. Turn the pressure switch lever to the OFF position

and disconnect the plug from the receptacle.

2. If the extension cord does not conform to the

specications given on page 9, replace with an

extension cord such as that shown on page 9. If the

capacity of the power supply is insufcient, increase

the power supply capacity to remove the cause of

a ow of excessive current (over-current).

3. Wait approximately 5 minutes, then press the reset

switch (A) of the thermal protector (see Fig. 6).

The drain valve is located at the base of the control

panel and is used to drain condensation from the

tanks at the end of each use. Tank pressure is used

to expel the water.

6. Ensure safety valve is functioning properly by pulling

on the valve ring and allow the valve to reset.

If the safety valve vents under

normal operating conditions, stop

using the compressor immediately and send

your compressor for service. If the safety valve is

venting the tanks the pressure switch may need

factory adjustment.

7. Check pump oil level.

Do not operate without oil or with

damage the compressor pump.

10

inadequate oil. Low oil levels may

4. Start the compressor. If the motor still stops during

operation, please contact the service center.

Many components such as compressor head,

engine/motor, and tubing will remain hot even after

the air compressor has been shut down. Allow

compressor to cool before moving or attempting

maintenance.

Fig. 6

Hot surfACes

Use care when touching exposed

metal surfaces of compressor.

Page 11

WARNING

WARNING

oPerAtIon

Regulator (A)

Regulated Pressure

Gauge (B)

AdjustInG reGulAtor

This compressor is provided with an internal regulator

that controls the output pressure of two female quick

connect couplers. Regulated pressure will be equal

to or less than tank pressure depending on user

setting.

Fig. 8

oPerAtInG temPerAtures

Operating temperatures are between 32°F and 104°F

(0°C and 40°C). If operating outside recommended

temperatures, unit may have difculity starting and

will cause additional wear on components.

Fig. 7

To adjust regulated pressure (see Fig. 7):

1. Pull regulator knob out (A).

2. To increase pressure, turn clockwise.

3. To decrease pressure, turn counter clockwise.

4. When desired pressure is set, push regulator knob

in to lock pressure.

5. Regulated pressure gauge is displayed as (B).

ConneCtInG AIr suPPly

Firmly grasp the hose in hand

when installing hoses. If hose is

not held firmly or correctly installed hose may whip

and injure personnel in the operating area.

INSTALLING HOSES (See Fig. 8):

1. Grasp the hose at the quick connect plug and push

the plug into the quick connect body. Coupler will

snap into place.

2. Grasp the hose and pull to ensure coupler is

seated.

Disconnect the compressor from

the power source, drain air tanks

and allow it to cool before making adjustments,

moving the compressor, leaving the work area,

performing maintenance or storing the

compressor. Such precautionary safety measures

reduce the risk of injury.

sHuttInG doWn tHe ComPressor

1. Move On/Off switch to the OFF position.

2. Turn regulator until outlet pressure gauge reads

0 psi.

3. Remove hose and assembly. See disconnecting

air supply below.

4. Drain air from the air tanks by releasing air by pulling

the safety release valve.

5. Once the air tank pressure is under 20 psi, open the

drain valve on the control panel to drain moisture

from the tanks (See draining tanks on page 12).

6. Allow the compressor to cool down before

storing.

dIsConneCtInG AIr suPPly

DISCONNECTING HOSES (See Fig. 8)

1. Ensure regulated pressure gauge reads 0 psi

(0 kPa).

2. Pull coupler on quick connect body back to release

quick connect plug on hose.

11

Page 12

WARNING

WARNING

WARNING

WARNING

oPerAtIon

MAX

MIN

(B)

(A)

drAInInG tAnks

1. Place the compressor on a level surface.

Ensure that the compressor is on

a level surface. If compressor is not

level, water will not drain from tanks causing

corrosion, which may cause the tanks to burst.

2. If pressure is greater than 20 psi, use safety release

valve to reduce tank pressure.

Do not open drain valve with

pressure greater than 20 psi in

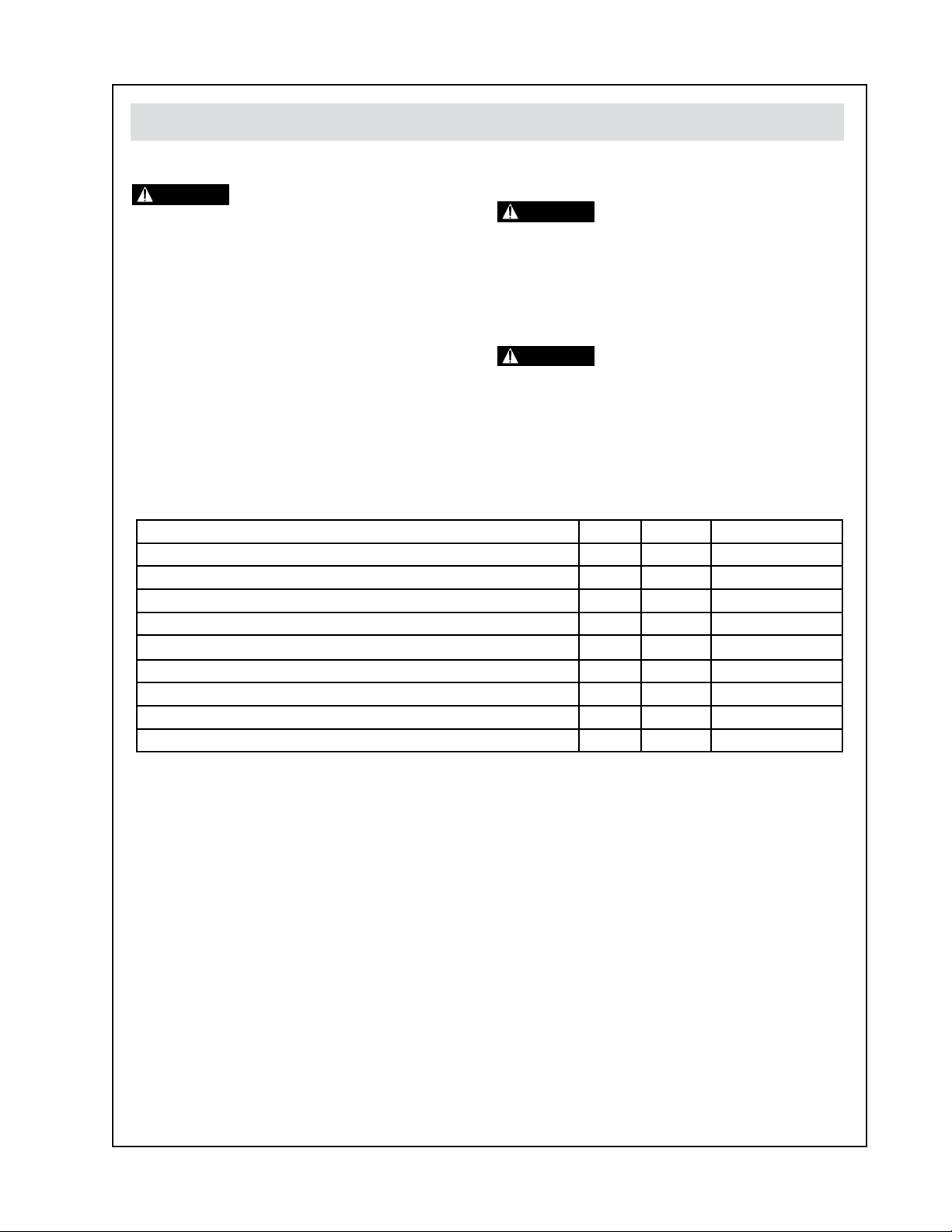

mAIntenAnCe

Maintenance performed by

unauthorized personnel may

result in misplacing of the internal components

which could cause serious hazard. We

recommend that all compressor service be performed

by a BOSCH factory service center or authorized

BOSCH service station.

Your air compressor requires periodic maintenance

according to the maintenance schedule outlined on

the next page, in order to keep your compressor in

peak condition.

Use a soapy water solution to inspect compressor

for leaks. If leaks are found in the compressor pump,

air tanks or tubing, replace compressor immediately.

Never attempt repair leaks, weld or make

modications to the air tank or other uid conning

parts as there is a risk of bursting.

To check the air lter, unscrew the air lter from the

compressor and visually inspect. If the lter appears

to be clogged, replace the lter. After inspection screw

the air lter back on the compressor (See Fig. 9).

tanks. Such precautionary measures reduce the risk

of injury.

3. Ensure that no personnel are in the drain discharge

area in front of compressor.

Do not direct air stream at people

or animals. High pressure air can

propel dust and debris at high speed. Compressor air

from the compressor can contain water, oil, metal

particles, or other contaminants which can cause

serious injury.

4. Turn drain valve on control panel 90°

counterclockwise. When empty, close valve.

serVICe

CHANGING OIL (See Fig. 10):

1. Make sure the pump is cool to avoid burn risk.

2. Take out the oil dipstick (A).

3. Prepare a suitable container to capture the oil from

the crankcase.

4. Remove crankcase drain plug (B) and allow used

oil to drain in the container.

5. Replace drain plug.

6. Return oil to recycling center or dispose of in

accordance with local regulations.

7. Rell crankcase with fresh oil. Fill oil until it reads

to maximum level of oil dipstick.

8. Replace oil dipstick (A).

Fig. 10

Contact your BOSCH service center for instructions

and user replaceable parts. For all other repairs

contact your BOSCH service center.

Fig. 9

12

Page 13

mAIntenAnCe

WARNING

WARNING

WARNING

CleAnInG

When cleaning a compressor be

careful not to disassemble any

portion of the tool since internal components

may be misplaced or safety components may be

improperly mounted.

Certain cleaning agents such as gasoline, carbon

tetrachloride, ammonia, etc. may damage plastic

parts and o-rings.

Periodically clean the compressor tool with soapy

water and a damp cloth.

storAGe

When not in use, the compressor should be

disconnected and stored in a warm and dry place.

If unit is operated in an excessively dirty or dusty area, increase the frequency of all scheduled maintenance

items.

Recommendation Daily Weekly Every 200 hours

Check for proper oil level(s) and oil leaks X

Drain moisture from tanks daily or after each use X

Ensure all safety guards are correctly and securely attached X

Clean the cooling surfaces of the compressor X

Inspect air intake lter X

Check safety valves by pulling on rings X

Check system for air leaks X

Change pump oil X

Replace air lter X

Coil the electric cord and place within frame for

protection.

When not in use, store the

compressor out of reach of

children and other personnel unfamiliar with

compressor operation. Lock the storage area.

Compressor can be dangerous in the hands of users

unfamiliar with its operation.

loAdInG/unloAdInG

Use care when lifting and carrying

the compressor. Some

compressors are too heavy to be lifted by one

person. Get assistance before attempting to liff

compressor to reduce the risk of injury.

13

Page 14

trouble sHootInG

This section provides a list of the more frequently encountered malfunctions, their causes and corrective

actions. The operator or maintenance personnel can perform some corrective actions, and others may

require the assistance of a qualied Bosch technician or your dealer.

PROBLEM SYMPTOMS RESOLUTION

Excessive air tank

pressure – safety

valve pops off

Air leaks Tube fittings are not tight •

Air leaks in air tank or

at air tank welds

Air leaks between

head and valve plate

Air leaks from safety

valve

Knocking noise Defective safety valve•

Pressure switch does not •

shut of motor when compressor reaches cut-out

pressure

Pressure switch cut-out •

too high

enough

Defective air tank• Air tank must be replaced. Do not repair •

Leaking seals• Contact a Bosch factory service center or •

Defective safety valve• Operate safety valve manually by pull-•

Pump oil is low•

Set the On/Off switch to Off, if the unit •

does not shut off contact a Bosch factory service center or a Bosch authorized

service center

Contact a Bosch factory service center or •

a Bosch authorized service center

Tighten fittings where air can be heard •

escaping. Check fittings with soapy water

solution. Do not overtighten.

the leak

Warning:• Risk of bursting. Do not drill

into, weld or otherwise modify air tank or

it will weaken. The air tank can rupture or

explode.

a Bosch authorized service center

ing on ring. If valve still leaks, it must be

replaced.

Operate safety valve manually by pull-•

ing on ring. If valve still leaks, it must be

replaced.

Add no-detergent oil to pump. •

Carbon build-up in pump•

Pressure reading on

the regulated pressure

gauge drops when an

accessory is used

14

Regulator is not adjusted •

correctly for accessory

being used

Contact a Bosch factory service center or •

a Bosch authorized service center

It is normal for some pressure drop to •

occur when an accessory is used, adjust

the regulator.

Note:• Adjust the regulated pressure

under flow conditions while accessory is

being used.

Page 15

trouble sHootInG

Compressor is not

supplying enough

air to operate

accessories

Regulator knob

has continuous air

leak

Regulator will not

shut off air outlet

Moisture in pump

crankcase

Prolonged excessive use of •

air

Compressor is not large •

enough for accessory

Hole in air hose•

Check valve restricted•

Air leaks•

Restricted air intake filter•

Regulator is damaged• Replace.•

Regulator is damaged• Replace.•

Unit operating in damp or •

humid conditions

Detergent type oil being used •

in pump

Decrease amount of air usage.•

Check the accessory air requirement. If •

it is higher than the SCFM or pressure

supplied by your air compressor, a larger

compressor is needed to operate accessory.

Replace air hose.•

Remove, clean or replace•

Tighten fittings.•

Clean or replace air intake filter.•

Move unit to a dry well-ventilated area.•

Drain oil and refill with non detergent oil.•

15

Page 16

trouble sHootInG

Motor will not run Check valve restricted•

Motor overload protection •

switch has tripped

Extension cord is wrong •

length or gauge

Loose electrical connections•

Possible defective motor or •

starting capacitor

Paint spray on internal motor •

parts.

Fuse blown, circuit breaker •

tripped

Remove, clean or replace•

See Motor Overload under Features.•

Check proper gauge wire and cord •

length. See Extension Cords under pg. 9.

Contact a Bosch factory service center •

or a Bosch authorized service center.

Contact a Bosch factory service center •

or a Bosch authorized service center.

Contact a Bosch factory service center •

or a Bosch authorized service center.

Do not operate the compressor in the

paint spray area. See flammable vapor

warning.

1. Check fuse box for blown fuse and replace

as necessary. Reset circuit breaker. Do

not use a fuse or circuit breaker with higher

rating than that specied for your particular

branch circuit.

2. Check for proper fuse. Use only a time delay fuse.

3. Check for low voltage conditions and/or

proper extension cord.

4. Disconnect the other electrical appliances

from circuit or operate the compressor on

its own branch circuit.

Tank pressure exceeds pres-•

sure switch cut-in pressure

Pressure release valve on •

pressure switch has not unloaded head pressure

16

Motor will start automatically when tank •

pressure drops below cut-in pressure of

pressure switch.

Set the On/Off switch to OFF. If the •

valve does not open, replace switch.

Contact a Bosch factory service center

or a Bosch authorized service center.

Page 17

ConsIGnes GénérAles de séCurIté

AVERTISSEMENT

Tous les utilisateurs et employeurs/propriétaires doivent lire et comprendre toutes les

instructions de ce mode d’emploi avant d’utiliser cet compresseur ou de procéder à

son entretien. Le non-respect des instructions indiquées plus bas risque de causer un choc électrique, une

blessure personnelle grave ou même la mort.

ConserVer Ces InstruCtIons

esPACe de trAVAIl

Gardez votre espace de travail propre et bien éclairé.

Les établis encombrés et les zones mal éclairées

augmentent les risques d’accidents, de chocs électriques,

d’incendies et de blessures aux personnes.

N’utilisez pas des compresseurs dans des

atmosphères explosives, comme en présence de

liquides, de gaz ou de poussières inammables.

Maintenez la zone de travail bien ventilée. Installez

toujours le compresseur à au moins 20 pi (6,1 m) de

la zone de travail en cas de pulvérisation de matières

inammables. NE FUMEZ PAS pendant que vous

pulvérisez des matières inammables. Le compresseur

peut produire des étincelles qui risquent d’enammer la

poussière ou les fumées. N’utilisez jamais le compresseur

à des endroits où il y a de la laque, de la peinture, de la

benzine, du diluant, de l’essence, des gaz, des agents

adhésifs ou d’autres matériaux qui sont combustibles

ou explosifs. Un tuyau exible plus long sera peut-être

nécessaire.

Utilisez toujours le compresseur dans un endroit

bien ventilé. Suivez toutes les consignes de

sécurité et utilisez un appareil de protection

respiratoire conformément auxconsignes de sécurité

accompagnant le matériau à vaporiser. Certains

matériaux vaporisés, comme la peinture, les solvants pour

peinture, les décapants pour peinture, les insecticides, les

désherbants, etc. contiennent des poisons et des vapeurs

toxiques.

Ne laissez pas d’autres personnes, des enfants et

autres visiteurs s’approcher d’un compresseur en

marche. Ne permettez pas à des enfants d’utiliser le

compresseur. Des distractions risqueraient de causer la

perte de contrôle des compresseurs, ce qui pourrait causer

des blessures aux personnes se trouvant à proximité.

Ne chahutez jamais avec le compresseur. Respectez le

compresseur comme instrument de travail.

Utilisez toujours le compresseur dans une position

stable et sûre. Ne l’utilisez jamais sur une table ou

sur un toit. Utilisez un tuyau exible à air additionnel

pour permettre aux compresseurs d’atteindre des endroits

élevés.

séCurIté Personnelle

Il ne faut pas retirer ou altérer les commandes de

l’outil, ou les désactiver ou les rendre inutilisables

de quelque façon que ce soit. Ceci causerait un

fonctionnement irrégulier de l’outil et risquerait de causer

des blessures.

Habillez-vous de façon appropriée. Ne portez pas de

vêtements lâches ou de bijoux. Connez les cheveux

longs. Gardez vos cheveux, vêtements et gants à

distance des pièces en mouvement. Les vêtements

lâches, les bijoux et les cheveux longs risqueraient d’être

happés par des pièces en mouvement et augmenter le

risque de blessure.

Portez toujours des équipements de protection des

yeux et des oreilles lorsque vous utilisez cet outil.

Utilisez des équipements de protection individuelle

additionnels suivant les besoins lorsque vous utilisez

cet outil. Les opérateurs et les autres personnes se

trouvant dans la zone de travail doivent porter des lunettes

de sécurité. Une exposition prolongée à des bruits de

grande intensité risquerait de causer une perte auditive. Il

faut utiliser un masque antipoussières, des chaussures de

sécurité à semelle antidérapante, un casque et d’autres

équipements de protection individuelle en fonction des

conditions de travail.

N’utilisez pas le compresseur si vous ne savez pas

parfaitement comment vous en servir. Les utilisateurs

qui ne connaissent pas très bien toutes ses commandes

risquent de se servir du compresseur d’une manière

pouvant être dangereuse et se blesser ou de blesser

d’autres personnes.

Maintenez les commandes et les poignées sèches et

propres, sans résidus d’huile ou de graisse. Des mains

glissantes ne peuvent pas contrôler l’outil de façon sûre.

Restez alerte. Surveillez toujours ce que vous êtes en

train de faire et faites preuve de bon sens quand vous

utilisez un compresseur. N’utilisez pas le compresseur

lorsque vous êtes fatigué ou sous l’inuence de

drogues, d’alcool ou de médicaments. Un moment

d’inattention pendant que vous utilisez le compresseur

pourrait causer des blessures corporelles graves.

Ne dirigez pas un jet d’air vers des gens ou des

animaux. De l’air sous pression peut projeter de la

poussière et des débris à grande vitesse. De l’air comprimé

d’un compresseur peut contenir de l’eau, de l’huile,

des particules de métal ou d’autres contaminants qui

risqueraient de causer de graves blessures.

N’inspirez pas et ne respirez pas d’air comprimé.

N’inhalez jamais d’air directement du compresseur ou

d’un appareil respiratoire connecté au compresseur.

Un jet d’air comprimé peut contenir du monoxyde de

carbone, des vapeurs toxiques ou des particules solides

d’un réservoir d’air qui, en cas d’inhalation, pourraient

causer des lésions graves ou même la mort.

Faites très attention lorsque vous touchez des

surfaces du compresseur en métal. De nombreux

composants tels que la tête du compresseur, son moteur

et ses tuyaux resteront très chauds même après que le

compresseur d’air aura été mis hors tension. Laissez le

compresseur refroidir avant de le déplacer ou d’effec

une opération de maintenance.

tuer

17

Page 18

Ne montez pas sur le compresseur. Soyez toujours

bien stable et équilibré sur vos pieds. La stabilité et un

bon équilibre vous permettent de mieux contrôler l’outil

dans des situations inattendues.

Assurez-vous qu’il n’y a pas d’obstructions ou de

coudes dans le tuyau d’air. N’attachez pas un tuyau

d’air ou un outil à votre corps. Des tuyaux enchevêtrés

ou emmêlés risquent de faire perdre l’équilibre ou de

faire tomber l’opérateur en plus de causer un mouvement

imprévu de l’outil. Attachez le tuyau à la structure pour

réduire le risque de perte d’équilibre en cas de mouvement

du tuyau.

N’utilisez pas le tuyau de façon abusive. Protégez

tous les tuyaux contre les faux plis, les restrictions,

les solvants ou les objets tranchants. Maintenez le

tuyau d’air à distance de la chaleur, de l’huile, des

bords tranchants ou des pièces mobiles. Remplacez

immédiatement un tuyau endommagé. Un tuyau

endommagé risquerait d’éclater ou d’être projeté avec

violence à travers la zone de travail.

Utilisez seulement des tuyaux conçus pour une

pression nominale minimum de 200 psi. L’utilisation de

tuyaux conçus pour une pression nominale élevée réduit

le risque de blessure pouvant résulter de l’éclatement d’un

tuyau.

Saisissez fermement le tuyau dans la main en vue de

l’installation. Si le tuyau n’est pas tenu fermement ou

installé correctement, il risquerait de se libérer de votre

prise et de fouetter et blesser des personnes se trouvant

dans la zone de travail.

Prenez toutes les précautions nécessaires lorsque

vous soulevez et transportez le compresseur. Certains

compresseurs sont trop lourds pour être soulevés par une

seule personne. Demandez de l’assistance avant de tenter

de soulever un compresseur pour réduire le risque de

blessure.

Lorsque vous déplacez ou chargez un compresseur

sur roues, assurez-vous que ce compresseur est

toujours sur une surface plate. Si le compresseur

est placé sur une surface en pente, il risquerait de se

déplacer de façon imprévisible et de causer des blessures

corporelles.

Ce produit contient des produits chimiques,

notamment du plomb, qui, selon les informations

à la disposition de l’État de Californie, causent des

malformations congénitales et d’autres problèmes

affectant la reproduction. Lavez-vous les mains après

avoir utilisé le compresseur.

utIlIsAtIon et entretIen de l’outIl

Utilisez cet compresseur et ses accessoires

conformément aux instructions. Les compresseurs

et leurs accessoires doivent être utilisés dans le but pour

lequel ils sont conçus. L’emploi de les compresseurs pour

des opérations différentes de celles qui sont décrites dans

ce mode d’emploi peut créer une situation dangereuse.

Utilisez seulement des accessoires qui sont

recommandés par BOSCH pour votre modèle

particulier. Des accessoires qui peuvent être

recommandés pour un modèle d’outil particulier ne sont

peut-être pas appropriés pour d’autres modèles d’outils et

pourraient causer des blessures corporelles.

Avant chaque utilisation, inspectez tous les raccords

et tuyaux, ainsi que les boyaux et les connexions,

du compresseur. N’utilisez pas cet compresseur si

une partie quelconque de le compresseur est lâche,

manquante, endommagée, défectueuse, déconnectée

ou altérée. N’utilisez jamais un compresseur qui

semble être endommagé ou qui fonctionne de façon

anormale. Si le compresseur ne semble pas fonctionner

normalement et/ou s’il fait des bruits inhabituels, cessez

immédiatement de l’utiliser et contactez votre centre de

service après-vente BOSCH local. Il existe un risque

d’éclatement si le compresseur est endommagé.

Avant chaque utilisation, inspectez le compresseur

pour vous assurer qu’il n’y a pas de signes de fuites

ou d’autres dommages. Si vous trouvez des fuites

dans la pompe du compresseur, les réservoirs

d’air ou les tuyaux, remplacez immédiatement le

compresseur. Ne tentez jamais de réparer des fuites, de

souder ou d’apporter des modications au réservoir d’air

ou d’autres sections contenant des liquides étant donné

que ceci créerait un risque d’éclatement.

Ne tentez pas d’utiliser ce compresseur d’air sans

avoir vérié au préalable le niveau d’huile dans le

carter du moteur. Ce compresseur est expédié avec

de l’huile dans le carter du moteur. Le compresseur

pourrait être sérieusement endommagé par un

fonctionnement même momentané sans une lubrication

adéquate.

N’utilisez jamais le compresseur sans la valve

de sécurité en place. Vériez quotidiennement le

fonctionnement de la valve de sécurité. Ne vous

servez pas de la valve de sécurité pour compléter la

vidange du réservoir. La valve de sécurité est conçue pour

diminuer la pression du réservoir an de réduire le risque

d’éclatement.

N’utilisez jamais le compresseur si tous les dispositifs

de protection et autres mécanismes de sécurité

ne sont pas à leur place ou s’ils n’exercent pas la

fonction pour laquelle ils ont été conçus. Si une

opération de maintenance ou d’entretien nécessite le

retrait d’un dispositif de protection ou d’un mécanisme

de sécurité, n’oubliez pas de remettre ce dispositif de

protection ou ce mécanisme de sécurité en place avant

de recommencer à utiliser le compresseur. Remplacez

immédiatement tout dispositif de protection ou mécanisme

de sécurité endommagé.

Ne touchez jamais une pièce en mouvement. Ne

placez aucune partie de votre corps à proximité de pièces

en mouvement du compresseur. Ne vous penchez pas

au-dessus des dispositifs de protection an de réduire le

risque de blessure.

N’utilisez pas le compresseur sans le ltre à air. Les

ltres empêchent les grandes particules d’entrer dans le

ux d’air et d’endommager les composants internes du

compresseur.

Ne laissez pas de matières particulaires telles que

de la sciure tomber dans le carter du moteur lorsque

ce dernier est ouvert pour réaliser une inspection. La

présence de matières particulaires dans l’huile risquerait

18

Page 19

de réduire la durée de vie du compresseur.

N’utilisez pas d’huile détergente dans le carter du

moteur. Les huiles détergentes laisseront des dépôts

sur les composants internes du compresseur, ce qui

réduirait la durée de vie du compresseur et affecterait sa

performance.

N’utilisez pas le compresseur dans le cadre d’un

fonctionnement sans surveillance. Restez toujours

à proximité lorsque le compresseur est en marche et

éteignez le compresseur quand il n’est pas utilisé an de

réduire le risque d’incendie.

Ne placez jamais d’objets sur le compresseur ou contre

celui-ci. Installez le compresseur à au moins 12 po

(30 cm) de toutes les obstructions. La restriction de

quelconques orices de ventilation du compresseur

pourrait causer une surchauffe et entraîner un incendie.

N’utilisez pas le compresseur avec une source

d’alimentation électrique différente de ce qui est

indiqué dans les consignes d’utilisation et de sécurité

de le compresseur. L’utilisation de sources d’alimentation

électrique différentes pourrait causer un mauvais

fonctionnement de le compresseur et de la source

d’alimentation électrique, ce qui risquerait de vous blesser

grièvement ou de blesser grièvement d’autres personnes

se trouvant près de vous.

Suivez toutes les recommandations en ce qui

concerne les tailles des tuyaux, des raccords et des

autres accessoires à air du compresseur. Des raccords

ou autres composants de tailles incorrectes pourraient

entraîner des risques de blessures ou de dommages aux

biens.

Ne déplacez jamais le compresseur en tirant sur

un tuyau exible. Le compresseur, les raccords pour

la circulation de l’air et le tuyau à air pourraient être

endommagés et éclater.

Inspectez les conduites d’alimentation en air

pour vous assurer qu’il n’y a pas d’obstacles à la

circulation de l’air avant de procéder à un réglage

de l’outil. Le volume d’air est aussi important que la

pression de l’air. Un débit d’air réduit empêchera l’outil de

fonctionner conformément à ce qui est prévu.

Ne dépassez jamais la pression nominale maximum

permise qui gure sur l’outils et sur ses accessoires.

N’utilisez pas le compresseur pour goner des

objets à basse pression d’air tels que des jouets. Le

dépassement de la pression maximum recommandée des

outils et accessoires risquerait de causer leur éclatement.

La pression correcte est la pression la plus faible qui suft

à faire le travail voulu.

Drainez quotidiennement le condensat des réservoirs

d’air en utilisant la valve de purge. Le drainage de l’eau

du compresseur d’air réduit le risque de corrosion du

réservoir d’air. Les réservoirs d’air corrodés ont un risque

d’éclatement accru.

Arrêtez le compresseur, drainez les réservoirs d’air

et laissez refroidir l’outil avant de procéder à des

réglages, de déplacer le compresseur, de quitter

la zone de travail, d’effectuer une opération de

maintenance ou de ranger le compresseur. De telles

mesures de sécurité à titre de précaution réduisent le

risque de blessure.

Ne modiez pas ce compresseur et ne vous en servez

pas à une pression ou à une vitesse supérieure à la

pression ou la vitesse nominale. Toute altération ou

modication est une utilisation abusive et risquerait de

créer une condition dangereuse telle qu’un incendie ou un

éclatement.

Lorsque vous transportez le compresseur, maintenezle de niveau et placez-le sur un tapis protecteur. Ne

mettez pas le compresseur sur son côté. De telles

précautions réduisent le risque d’incendie ou de danger

d’inhalation de vapeurs d’huile par le personnel

.

serVICe

Toute opération de maintenance réalisée par

du personnel non autorisé risque de causer

un repositionnement erroné de composants

internes et de créer ainsi des dangers graves.

Nous recommandons que toutes les opérations de

maintenance et de réparation soient effectuées dans

un centre de service usine BOSCH ou dans une station

service agréée BOSCH.

Préparez un programme de maintenance périodique

pour votre outil. Lorsque vous nettoyez un

compresseur, faites attention de ne pas démonter

une partie quelconque de l’outil étant donné que

des composants internes risqueraient d’être mal

remis en place ou que des compo sants nécessaires

à la sécurité risqueraient d’être remontés incorrecte-

ment. Certains produits de nettoyage, tels que

l’essence, le tétra chlorure de carbone, l’ammoniac, etc.

risquent d’endommager les composants en plastique et

les joints toriques.

Utilisez seulement des pièces de rechange

recommandées par BOSCH lors de toute opération

de réparation. Suivez les instructions de la rubrique

Maintenance de ce mode d’emploi. L’utilisation de

pièces non autorisées ou le non-respect des instructions

de maintenance pourrait causer un risque de blessure.

Remplacez les étiquettes d’avertissement

manquantes ou endommagées. Reportez-vous aux

schémas pour déterminer le positionnement correct

avec le numéro de pièce.

Effectuez une maintenance soigneuse du

compresseur. Maintenez le compresseur propre

et lubrié. Des outils entretenus de façon soignée

sont moins exposés à des risques de rupture qui

pourraient causer des blessures. Toute altération ou

modication est une utilisation abusive et risquerait de

créer une condition dangereuse.

Lorsque vous ne vous en servez pas, rangez le

compresseur hors de la portée des enfants et des

autres personnes ne maîtrisant pas le fonction-

nement de le compresseur. Quand il n’est pas utilisé,

l’outil doit être déconnecté et rangé dans un endroit sec.

Gardez hors de la portée des enfants. Verrouillez le lieu

de rangement. Les compresseurs sont dangereux s’ils

tombent entre les mains d’utilisateurs ne maîtrisant pas

leur fonctionnement.

19

Page 20

ConsIGnes de séCurIté Pour les ComPresseurs éleCtrIques

Les ches des cordons d’alimentation électrique

doivent être compatibles avec les prises de

courant dans lesquelles elles sont branchées. Ne

modiez jamais une che de quelque façon que

ce soit. N’utilisez pas d’adaptateurs de ches

avec des outils électriques mis à la masse (à la

terre). L’insertion de ches non modiées dans des

prises de courant assorties réduira le risque de choc

électrique.

Évitez tout contact corporel avec des surfaces

mises à la terre ou à la masse telles que celles

de tuyaux, de radiateurs, de cuisinières ou de

réfrigérateurs. Il existe un risque accru de choc

électrique si votre corps est en contact avec la terre

ou mis à la masse.

Ne traitez pas le cordon d’alimentation électrique

de façon abusive. N’utilisez jamais le cordon

pour transporter, tirer ou débrancher l’outil

électrique. Maintenez le cordon à distance de

sources de chaleur, d’huile, de bords tranchants ou

de pièces mobiles. Remplacez immédiatement tout

cordon endommagé. Les cordons enchevêtrés ou

emmêlés augmentent le risque de choc électrique.

N’exposez pas ce compresseur à la pluie. Ne

l’utilisez pas à des endroits humides ou mouillés.

L’humidité augmente le risque de choc électrique

avec cet équipement.

Ne touchez pas la che avec les mains mouillées.

L’humidité augmente le risque de choc électrique

avec cet équipement.

Gardez toutes les connexions électriques

sèches et à distance du sol. Ne laissez pas de

connexions électriques reposer à des endroits

où il y a de l’eau ou dans des positions telles que

de l’eau pourrait entrer en contact avec le cordon

d’alimentation ou une autre connexion électrique.

L’humidité augmente le risque de choc électrique

avec cet équipement.

Lorsque vous utilisez un outil électrique à

l’extérieur, employez une rallonge appropriée

pour un emploi à l’extérieur et avec une intensité

électrique de niveau correct. L’utilisation d’un

cordon conçu pour emploi à l’extérieur réduit le

risque de choc électrique.

Débranchez toujours le compresseur de la prise

de courant, ventilez les réservoirs d’air et laissez

le compresseur refroidir avant d’effectuer une

opération de maintenance. Les compresseurs

pourvus de contrôles de pression automatisés

peuvent se remettre en marche à tout moment.

Arrêtez toujours le moteur quand il n’est pas

utilisé et avant de déplacer le compresseur.

L’arrêt du moteur empêche une mise en marche

accidentelle du compresseur.

Arrêtez et mettez toujours le moteur hors tension

avant de procéder à de quelconques réglages,

de changer des accessoires, de déplacer le

compresseur, quand le compresseur n’est

pas utilisé et avant de ranger le compresseur.

L’arrêt du moteur empêche une mise en marche

accidentelle du compresseur.

Les travaux à la machine tel que ponçage,

sciage, meulage, perçage et autres travaux

du bâtiment peuvent créer des poussières

contenant des produits chimiques qui sont des

causes reconnues de cancer, de malformation

congénitale ou d’autres problèmes reproductifs.

Ces produits chimiques sont, par exemple:

• Le plomb provenant des peintures à base de

plomb,

• Les cristaux de silices provenant des briques et du

ciment et d’autres produits de maçonnerie, et

• L’arsenic et le chrome provenant des bois traités

chimiquement

Le niveau de risque dû à cette exposition varie avec

la fréquence de ces types de travaux. Pour réduire

l’exposition à ces produits chimiques, il faut travailler

dans un lieu bien ventilé et porter un équipement

de sécurité approprié tel que certains masques

à poussière conçus spécialement pour ltrer les

particules microscopiques.

ConserVeZ Ces InstruCtIons

20

Page 21

desCrIPtIon fonCtIonnelle et sPéCIfICAtIons

5

8

11

14

16

9

6

17

13

15

2

4

3

12

10

7

1

5

8

11

14

16

3

6

17

13

15

2

4

9

12

10

7

1

Specications: CET3-10

Dimensions du produit: 16” x 18” x 16.25”

Poids: 57.3 lbs.

HP: 1

pi3/mn à 100 psi: 2.6

tr/mn 1700

dBA: 72

Délai de récupération: 14 sec.

Motor: 4-Pole Induction

Type d’entraînement: Direct

Maintenance: Oil

Specications: CET4-20

Dimensions du produit: 16.25” x 17.75” x 19.75”

Poids: 72.7 lbs.

HP: 2

pi3/mn à 100 psi: 4.2

tr/mn 3400

21

dBA: 80

Délai de récupération: 12 sec.

Motor: 2-Pole Induction

Type d’entraînement: Direct

Maintenance: Oil

Page 22

5

8

11

14

16

3

6

17

13

15

2

4

9

10

7

1

12

desCrIPtIon fonCtIonnelle et sPéCIfICAtIons

Spécications : CET4-20W

Dimensions du produit: 22” x 21,5” x 19.75”

(handle down)

Poids: 84.9 lbs.

HP: 2

pi3/mn à 100 psi: 4.9

tr/mn 3400

1. Autocollant -Avertissement

2. Interrupteur à pression

3. Conduite de décharge de la pompe

4. Jauge d’huile

5. Pompe du compresseur d’air

6. Surcharge thermique

7. Orice de remplissage de la pompe à huile

8. Orice de vidange d’huile de la pompe

9. Filtre à air

dBA: 80

Délai de récupération: 10 sec.

Motor: 2-Pole Induction

Type d’entraînement: Direct

Maintenance: Oil

10. Clapet

11. Cordon d’alimentation électrique

12. Détendeur de pression (valve) de sécurité

13. Manomètre – pression du réservoir

14. Régulateur de pression

15. Manomètre – pression de sortie

16. Garnitures des orices de sortie

17. Valve de drainage du réservoir

22

Page 23

MISE EN GARDE

MISE EN GARDE

MISE EN GARDE

AVERTISSEMENT

AssemblAGe / InstAllAtIon

MAX

MIN

(A)

(B)

(D)

(C)

PRISE DE COURANT

MISE À LA TERRE

FICHE DE MISE À LA TERRE

BOITE PRISE DE

COURANT

MISE À LA TERRE

lubrIfICAtIon et HuIle

Ne tentez pas d’utiliser ce com-

préalable le niveau d’huile dans le carter du moteur.

Ce compresseur est expédié avec de l’huile dans le

carter du moteur. Le com presseur pourrait être

sérieusement endommagé par un fonctionnement

même momentané sans une lubrification adéquate.

Vériez le niveau d’huile dans le carter du moteur avant

chaque utilisation. Un indicateur de niveau d’huile avec

des repères pour le niveau maximum et le niveau

minimum est fourni avec ce compresseur.

Vériez toujours que le niveau d’huile est sur le repère

maximum de l’indicateur de niveau d’huile avant de

mettre cet outil en marche. N’utilisez pas la pompe avec

une quantité d’huile insufsante ou excessive. Le coût

des pannes causées par des niveaux d’huile incorrects

ne sera pas couvert par la garantie.

Pour vérier le niveau d’huile (Voir Fig.1):

1. Placez l’outil sur une surface horizontale.

Enlever la jauge d’huile, essuyer avec un chiffon

2.

presseur d’air sans avoir vérifié au

propre, le remettre dans le carter du moteur, ensuite

retirer la jauge pour inspecter le niveau d’huile.

3. Si le niveau d’huile est bas, ajoutez de l’huile suivant

les besoins, mais ne dépassez pas le niveau d’huile

maximum.

2. Faire glisser la roue sur la broche de la roue. La tige

de gonage pour le montage de la roue devrait être

positionnée vers le châssis du compresseur.

3. Placer la vis au moyen de la rondelle (D) et enler la vis

jusqu’au bout de la broche de la roue (C). Serrer la vis

pour xer à la broche.

4 Répéter ces opérations pour la deuxième roue.

Fig. 2

mIse À lA terre

Ce produit doit être mis à la terre. En cas de court-circuit

électrique, la mise à la terre réduit le risque de choc

électrique en fournissant un l par lequel le courant

électrique peut s’échapper. Ce produit est pourvu d’un

cordon d’alimentation comportant un l de mise à la

terre muni d’une che de mise à la terre appropriée.

La che doit être insérée dans une prise de courant

installée correctement et mise à la terre conformément

à tous les lois et ordonnances applicables (Voir Fig.3).

tomber dans le carter du moteur lorsque ce dernier

est ouvert pour réaliser une inspection. La présence

de matières particulaires dans l’huile risquerait de

réduire la durée de vie du compresseur.

détergentes laisseront des dépôts sur les composants

internes du compresseur, ce qui réduirait la durée de vie

du compresseur et affecterait sa performance.

1. Prendre la broche de la roue (A) et la visser dans le

Fig. 1

Ne laissez pas de matières

particulaires telles que de la sciure

N’utilisez pas d’huile détergente

dans le carter du moteur. Les huiles

InstruCtIons d’InstAllAtIon des roues

(Cet4-20W only Voir Fig.2)

support de la roue (B), qui est soudé au châssis du

compresseur. Serrer la broche au moyen d’une clé pour

la xer au châssis.

Une installation incorrecte de la

fiche de mise à la terre risque de

causer un choc électrique. Quand il est nécessaire de

réparer ou de remplacer le cordon ou la fiche, ne

connectez pas le fil de mise à la terre à l’une des bornes

conçues pour des fiches plates. Le fil avec l’isolation qui

a une surface extérieure verte, avec ou sans bandes

jaunes, est le fil de mise à la terre.

Consultez un électricien professionnel ou un autre

technicien qualié si vous ne comprenez pas bien les

instructions relatives à la mise à la terre, ou si vous avez

des doutes quant au caractère adéquat de la mise à la

terre du produit. Ne modiez pas la che fournie ; si elle

ne rentre pas dans la prise de courant, demandez à un

électricien professionnel d’installer une prise de courant

appropriée.

Fig. 3

23

Page 24

AVERTISSEMENT

AVERTISSEMENT

MISE EN GARDE

AssemblAGe / InstAllAtIon

Ce produit est conçu pour emploi sur un circuit nominal

de 120 volts, et il a une che de mise à la terre qui

est similaire à la che qui est illustrée à la page 23.

Connectez seulement le produit à une prise de courant

ayant la même conguration que la che. N’utilisez pas

d’adaptateur avec ce produit.

Cordons de rAllonGe

Utilisez seulement un cordon de rallonge à trois ls qui

est muni d’une che de mise à la terre à trois lames

de contact, et ne le branchez que dans une prise de

courant à trois orices qui accepte la che du produit.

Assurez-vous que votre cordon de rallonge n’est pas

endommagé. Lorsque vous utilisez un cordon de

rallonge, vériez qu’il est de diamètre sufsant pour

transporter tout le courant dont votre produit a besoin.

Tableau des cordons de rallonge

0 – 25 pi 25 – 50 pi

calibre 14 calibre 12

tAIlle reCommAndées Pour les Cordons de

rAllonGe

La longueur maximum recommandée pour un cordon

de rallonge est de 50 pi, avec un calibre nominal 12.

PréPArAtIon en Vue de l’emPloI

Utilisez ce compresseur et tous ses

accessoires conformément aux

instructions. Le compresseur et ses accessoires

doivent être utilisés dans le but pour lequel ils sont

conçus. Une utilisation du compresseur pour des

opérations autres que celles qui sont décrites dans ce

mode d’emploi risquerait de causer une situation

dangereuse.

moteur éleCtrIque

Montage initial – Procédure de rodage

Faites ce qui suit avant d’utiliser ce compresseur d’air

pour la première fois ou après un remplacement de la

pompe ou du moteur du compresseur :

1. Assurez-vous que l’interrupteur dans la position d’arrêt

(OFF).

Ce compresseur d’air est muni d’un interrupteur

marche/arrêt et d’un interrupteur à pression intégrés.

Quand le compresseur est sous tension (ON),

l’interrupteur à pression met automatiquement le

moteur du compresseur en marche chaque fois que la

pression du réservoir tombe en dessous de la pression

de déclenchement xée à l’usine, et il arrête le moteur

lorsque la pression du réservoir s’arrête à la pression

de coupure xée à l’usine.

2. Assurez-vous que la valve de sécurité fonctionne

correctement en tirant sur l’anneau de la valve et en

permettant ainsi la réinitialisation de la valve (Voir

Fig.4).

La valve de sécurité est conçue pour assurer la

protection contre les hautes pressions en relâchant

de l’air à haute pression du réservoir d’air lorsque sa

pression xée à l’usine (légèrement plus élevée que le

réglage de la pression de coupure de l’interrupteur à

pression) est dépassée.

Fig. 4

Si le détendeur de pression (valve)

de sécurité expulse de l’air dans

des conditions de fonctionnement normales, cessez

immédiatement d’utiliser le compresseur. Faites-le

réparer. Si le détendeur de pression de sécurité expulse

de l’air des réservoirs, cela peut signifier que

l’interrupteur à pression a besoin d’être réglé à l’usine.

3. Branchez le cordon d’alimentation dans une prise de

courant du type approprié.

Référez-vous à la rubrique consacrée à la mise à

la terre pour plus de renseignements sur la prise de

courant appropriée.

4. Ouvrez la valve de drainage pour permettre à l’air

d’échapper du réservoir et pour empêcher une

élévation de la pression d’air pendant la période de

rodage.

La valve de drainage est située sur le panneau de

commande et est utilisée pour drainer la condensation

des réservoirs à l’issue de chaque utilisation. La

pression du réservoir sert à expulser l’eau.

5. Mettez l’interrupteur marche/arrêt dans la position

de marche (ON). Le compresseur se mettra alors en

marche.

6. Faites fonctionner le compresseur pendant 20

minutes.

7. Au bout de 20 minutes, fermez la valve de drainage.

Le réservoir se remplira jusqu’à pression de coupure

et le moteur du compresseur s’arrêtera.

8. Mettez l’interrupteur marche/arrêt dans la position

d’arrêt (OFF) et débranchez le compresseur.

9. Tirez sur la valve de sécurité et laissez sortir de l’air

jusqu’à ce que la pression du réservoir soit

inférieure à 20 psi.

10. Ouvrez la valve de drainage pour laisser échapper

de l’air du réservoir et pour drainer l’humidité ou les

particules du réservoir. Fermez le drain quand le

réservoir sera vide.

11. Le compresseur est maintenant prêt à être utilisé pour

la première fois.

Changez l’huile du carter du moteur

après 50 heures de fonctionnement

initialement et à la fréquence recommandée dans la

rubrique de maintenance de ce mode d’emploi. Si

vous ne changez pas l’huile conformément au calendrier

de maintenance, vous réduirez la durée de vie du

compresseur et affecterez sa performance.

24

Page 25

AVERTISSEMENT

MISE EN GARDE

AVERTISSEMENT

fonCtIonnement

Reset

Switch (A)

Valve de

drainage (A)

1/4” Garnitures

des orifices de

sortie (B)

Régulateur (C)

mIse en mArCHe du ComPresseur

CET3-10 CET4-20 and

CET4-20W

Fig. 5

1. Positionnez le compresseur sur une surface plate

ou sur une surface inclinée de 10° ou moins, dans

un endroit bien ventilé, à une distance sufsante de

toutes vapeurs.

2. Assurez-vous que tous les couvercles et toutes

les étiquettes sont en place, que les étiquettes

sont lisibles et que les couvercles sont solidement

installés. N’utilisez pas le compresseur avant d’avoir

tout vérié.

3. Assurez-vous que l’interrupteur marche/arrêt est dans

la position d’arrêt (OFF).

4. Branchez le cordon d’alimentation dans la prise de

courant d’un circuit de dérivation approprié. Référezvous à la rubrique consacrée à la mise à la terre pour

plus d’informations sur la prise de courant correcte.

5. Assurez-vous que la valve de drainage est fermée

(en position horizontale) (A).

La valve de drainage est située à la base du

panneau de commande et est utilisée pour drainer

la condensation des réservoirs à l’issue de chaque