Page 1

Typ1 osa / CC 220

Operating Manual

Version

102

Page 2

Typ1 osa / CC 220

Operating Manual

1070 073 303-102 (91.10) GB

(V25)

1991

by Robert Bosch GmbH,

All rights reserved, including applications for protective rights.

Reproduction or handing over to third parties are subject to our written permission.

Discretionary charge 30.– DM

Page 3

Page 4

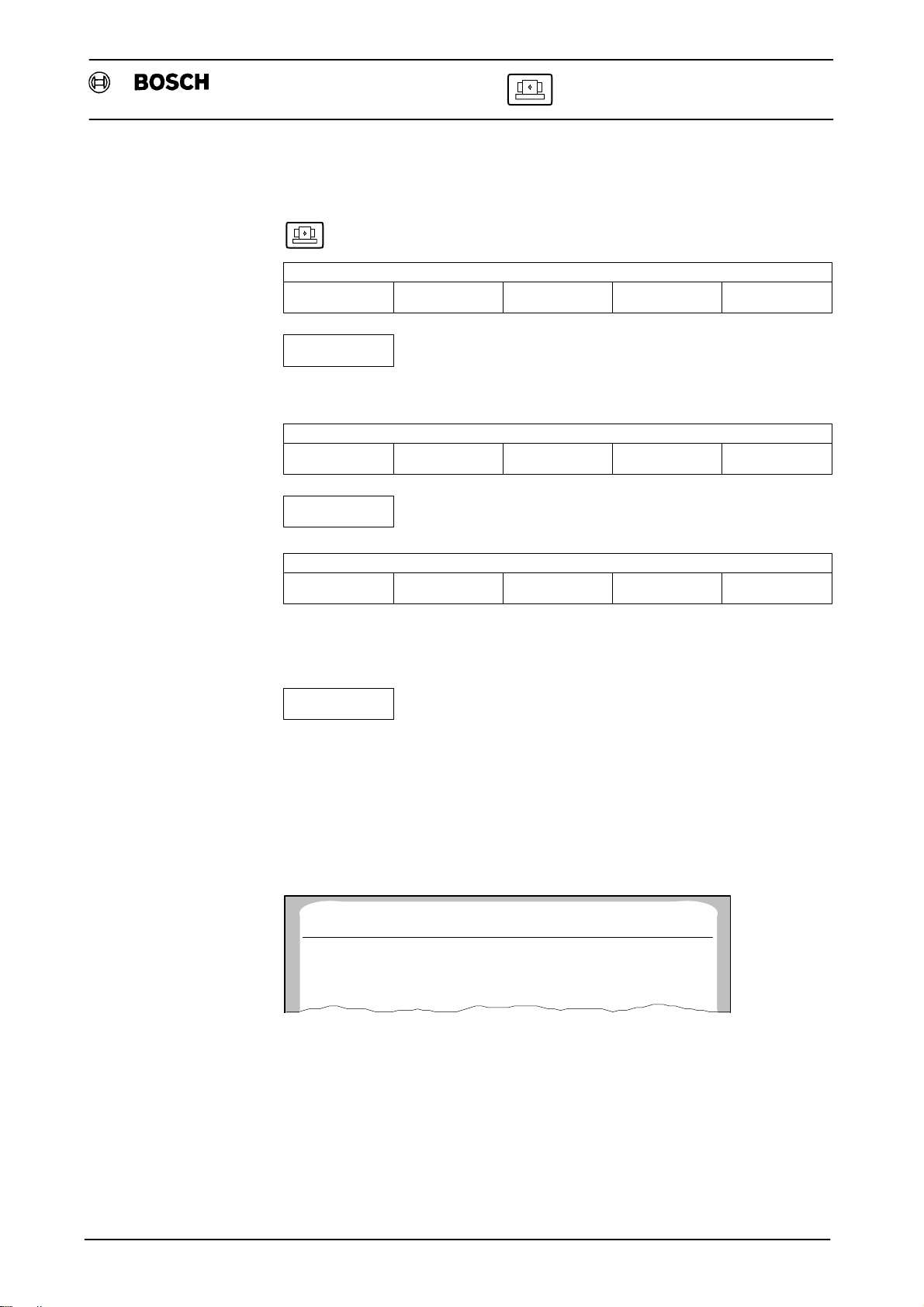

CC 220/320 M

Operating Manual

Flexible Automation

Contents

Contents

Note: An asterisk in front of the page number indicates new and different functions from the CC

300 M.

Sections marked +" are new or revised from Issue D1.

1. Introduction

General 1Ć1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foreword 1Ć2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Configuration and Guidance for Use 1Ć3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control panel 1Ć3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Group modes 1Ć3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Panel control keys 1Ć4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screen layout 1Ć5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ASR 33 ASCII Keyboard 1Ć6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ASCII Keyboard controls 1Ć7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Monitor and Control Functions 1Ć8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notes 1Ć9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions 1Ć10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Information 1Ć11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Group Modes with Typical Display 1Ć12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC 220/320 M Self Test 1Ć15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

2. Machine

Main Screen 2Ć1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 2Ć1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Traverse to Reference Point(s) 2Ć2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GridĆShift (Option) +2Ć3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining GridĆShift values 2Ć4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Traverse to ref. pnt. with GridĆShift 2Ć7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Zero Set 2Ć8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jog Mode 2Ć8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPL/Dialog Call 2Ć9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch Functions F, S, M, T 2Ć9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Switch functions 2Ć9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Include Several Times Switch Functions 2Ć10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Include sev. times switch functions 2Ć11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC 2Ć12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multiple Panels 2Ć12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Screen 2Ć12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

One panel, several control systems 2Ć13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

One control system, several panels 2Ć13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents - 1

Page 5

CC 220/320 M

Operating Manual

Flexible Automation

Contents

3. Manual input

Options 3Ć1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Input at the NC Panel 3Ć2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Manual input 3Ć2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cancelling an active program 3Ć2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Include Several Times 3Ć3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Include several times 3Ć4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ASCII Keyboard Entries (Option) 3Ć6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keyboard connection 3Ć6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering Subprogram Parameters 3Ć7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

New parameter list is generated 3Ć7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delete parameter 3Ć8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Include parameter 3Ć8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Return to entry level 3Ć8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Screen 3Ć1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter list already exists 3Ć9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

4. Data I/O

Main Screen 4Ć1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 4Ć1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editor (SCREEN/WORD) 4Ć2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NC Editor and Word Editor 4Ć4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calling the Word Editor 4Ć5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Important Functions of the NC Editor 4Ć6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block search and insert 4Ć6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delete function / Search function 4Ć6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter in dialog 4Ć7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multiple inclusion of G and M functions 4Ć7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic block number generating 4Ć8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

String define and search 4Ć9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCREEN Editor 4Ć10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calling the Screen Editor 4Ć10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description of SCREEN Editor Functions 4Ć11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delete/Recall functions 4Ć11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Search function 4Ć13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cursor Control 4Ć14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Insert File 4Ć15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quit 4Ć15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generate Auto Line Number 4Ć15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Insert End Mark M30 4Ć16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calculate 4Ć16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section Functions 4Ć17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Other Functions 4Ć18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exit / Switchover in Word Editor 4Ć18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Activate keyboard 4Ć18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Edit command table (ASCII keyboard) 4Ć19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents - 2

Page 6

Flexible Automation

Data In Functions 4Ć20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading in programs 4Ć20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read in through Interface On Control / On Panel" *4Ć20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read in via DNC Channel" interface *4Ć22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data In Error Display *4Ć24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Terminal - Digital Cassette Player 4Ć26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prepare cassette 4Ć26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Program readin without DFS recognize 4Ć27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Read in all programs 4Ć27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Read in a DFS program 4Ć28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Transfer with DCR Ć Procedure 4Ć28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Functions 4Ć29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Program/Files DATA OUT 4Ć30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General key sequences for the DATA OUT function 4Ć30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main and Subprogram OUTPUT 4Ć33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Generate output list 4Ć33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Output list available 4Ć35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Enter CS table 4Ć36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change Selection / New Selection 4Ć37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

New Selection 4Ć38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Managing Programs 4Ć40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change file protection 4Ć40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting permanent file protection 4Ć41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rename, copy program and modify headerfile 4Ć42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deleting files 4Ć43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory assignment 4Ć45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

CC 220/320 M

Operating Manual

Page

5. Compensation

Main Screen 5Ć1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 5Ć1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing an NPV Table 5Ć2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Changing a numeric value 5Ć3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read In NPV Table with DFS Recognize 5Ć4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Read in Zero Offset Table V1 5Ć5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NPV Tables Output 5Ć6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define Output Type 5Ć6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Managing NPV Table 5Ć8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing file protection 5Ć8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rename, copy program and modify headerfile 5Ć9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting file protection permanent 5Ć10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Zero Offset 5Ć11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing a Geometry Compensation Table 5Ć12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Edit a Geo. Comp. Table 5Ć12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying Special Tables 5Ć14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing a CS Table 5Ć16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents - 3

Page 7

CC 220/320 M

Operating Manual

Flexible Automation

Contents

6. NC (Execute)

Main Screen 6Ć1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 6Ć1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program selection and execution 6Ć2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Executing a Program in the AUTOMATIC Mode 6Ć2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Execute Program P1 6Ć2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Executing a Program in the SINGLE BLOCK Mode 6Ć3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Executing in single step 6Ć3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Execute P1 in single step 6Ć3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Executing in single block 6Ć4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Execute P1 in single block 6Ć4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table selection 6Ć5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Link tables 6Ć5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calling link tables 6Ć5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Set link table permanent 6Ć6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deleting link tables 6Ć8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generate Link Table by Program Selection 6Ć9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generating a link table in the background 6Ć10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

More about the GENERATE LINK TABLE" Function

in the background 6Ć11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dialogue program 6Ć13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Messages 6Ć14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Managing Link Table 6Ć15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Simulation (Option) 6Ć16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start simulation 6Ć18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select display 6Ć19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select views 6Ć19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spatial view 6Ć21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Magnifier Function 6Ć22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intervention in Sequence 6Ć25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block slash 6Ć25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional stop 6Ć25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Debug 6Ć26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select breakpoint 6Ć26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screen Displays 6Ć27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before Start 6Ć27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

After Start 6Ć27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

End of Program 6Ć27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dwell time (G04) 6Ć27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

M2 and M30 6Ć27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying Variables 6Ć28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display variable 6Ć28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display program 6Ć29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Mode 6Ć30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Rapid 6Ć30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Range 6Ć30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Axis Inhibit 6Ć30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Aux. Funct. Inhibit 6Ć30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

All Axes Inhibit 6Ć30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rapid Testrun 6Ć31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents - 4

Page 8

Flexible Automation

Without Tool Correction 6Ć31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Entry and Exit 6Ć32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program entry at random points 6Ć32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start block 6Ć32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start block extension *6Ć34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summary of entry options 6Ć35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exit during Program Execution / Parallel Activities 6Ć36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exit from group mode NC 6Ć36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reentry to execution 6Ć36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Search block 6Ć37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Return to Contour 6Ć38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interruption and Reentry 6Ć39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start point 6Ć39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reentry at break point 6Ć39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start block 6Ć39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example: Reentry 6Ć39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

CC 220/320 M

Operating Manual

7. Diagnostic

Main Screen 7Ć1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 7Ć1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Control 7Ć2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lag 7Ć2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switchover language *7Ć3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NC Link Table 7Ć3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software version 7Ć4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test 7Ć6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 7Ć6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving data for EPROM exchange *7Ć7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Other Functions 7Ć9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Machine parameter *7Ć9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output *7Ć9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delete *7Ć9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjust clock 7Ć10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Customer areas *7Ć10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Customer area errors and warnings 7Ć13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Library management *7Ć14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote diagnostic 7Ć15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Machine 7Ć16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Machine error and status display (MSD) 7Ć16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPL/Dialog Call 7Ć17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O status display 7Ć17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC Diagnosis +7Ć19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control 7Ć20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Monitor PLC 7Ć21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

View I/O Force List and Force I/O 7Ć23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference list 7Ć25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC 7Ć27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset Functions 7Ć27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DNC Operation (Option) 7Ć29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Functions 7Ć30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents - 5

Page 9

CC 220/320 M

Operating Manual

Flexible Automation

Contents

8. Overview of Operating Levels

Machine 8Ć1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Input 8Ć2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data I/O 8Ć3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NC Editor 8Ć3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screen Editor 8Ć5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data In 8Ć6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Out 8Ć7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manage 8Ć7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPENSATION 8Ć9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NPV Tables 8Ć9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NC . .

8Ć12

DIAGNOSTIC 8Ć13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Control / Machine / Reset Functions 8Ć13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service functions 8Ć14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. Abbreviations

Index

Contents - 6

Page 10

Flexible Automation

General

Introduction

The Bosch CC 220/320 M is a control concept for machining centres, production

cells and flexible production systems.

Panel and Card Rack of the CC 220 M

CC 220/320 M

Operating Manual

Subject Matter

Panel and Card Rack of the CC 320 M

This manual describes activities performed directly at the control panel and applies

only to the control system.

Special functions that can be selected for specific machines or which relate to the

machine are dealt with by the machine manufacturer.

The order of the chapters reflects the sequence of operations when using the conĆ

trol system and machine.

1 - 1

Page 11

Flexible Automation

Foreword

Introduction

The CC 220/320 M has 6 Group Modes (GBA) that are selected using the symbol

keys found at the top right of the control panel (see Page 1Ć3):

CC 220/320 M

Operating Manual

- MACHINE

- MANUAL INPUT Chapter 3

- DATA I/O

(Program store)

- CORRECTION Chapter 5

- NC (Execute)

- DIAGNOSTIC Chapter 7

These group modes are described and illustrated with examples in the chapters

that follow.

Chapter 1 entitled INTRODUCTION" briefly explains

- the Control Panel,

- the Controls,

- the Screen Layout,

- the ASR 33 ASCII Keyboard,

- the Monitor and Control Functions,

- the Group Modes (GBA)

Chapter 2

Chapter 4

Chapter 6

of the CC 220/320 M, giving guidance and setting out conventions that generally

apply to the following chapters.

Use the Index at the end of this Manual to look up specific terms.

1 - 2

Page 12

Flexible Automation

Introduction

Unit Configuration and Guidance for Use

This section illustrates the front panel of the control unit and the screen layout, and

gives a brief explanation of the key functions.

Control panel (Color)

Cursor and Magnifier Function

Group Modes (GBA)

BOSCH CC 320 M

CC 220/320 M

Operating Manual

Function keys / Softkeys

There are a number of

Softkey levels that can

be accessed in sequence

Group Modes (GBA)

Level return key

Use R" to return from one

Softkey level to the previous

Softkey level

?

. +/-

ENTER

.

.

x

-

+

=

Enter key

confirms entry

7 8 9

4 5 6

1 2 3

0

Numeric and

R

mathematical

keypad

Clear key

Help Key

The keys at the top right of the panel are used to select one of the 6 Group Modes.

The meaning of the symbols is explained below:

NC

(Execute)

Machine

(Setup)

Diagnostic

(Information)

Manual Input

Data I/O

(Program store)

Correction

1 - 3

Page 13

Flexible Automation

Panel control keys

Introduction

Cursor keys

Use the arrow keys to move the cursor (highĆ

lighted) across the screen.

The editing of programs, tables etc.

can be performed wherever the cursor is posiĆ

tioned.

In certain modes holding down the key

initiates an automatic runĆthrough of the options.

Magnifier

Zooms in on details of graphics.

CC 220/320 M

Operating Manual

?

7 8 9

4 5 6

1 2 3

0

. +/-

ENTER

- x

.

+ =

.

Help key

Numeric keypad

Numbers 0 to 9

Decimal point; sign reversal

Delete characters; confirm entry

The four basic mathematical functions are

available for provisional calculations. Use the equals key to

display the result. The result can then be cleared or stored.

1 - 4

Level return

R

Page 14

Flexible Automation

Screen Layout

Introduction

Operating Manual

The figure shows the standard layout for the CC 220/320 M:

Active Control

Prog. No

Block No.

and Status

Active

Panel

STOP

WAITING

RUNNING

LINKING

READY

Error

messages

CC 220/320 M

Mode

and

extra info

B F 0

ACT

N C 0

STOP

- Workpiece geometry

- Graphic NC output

- Machining simulation

- Tool tables

- Program listing

Active

Feed

Prompt line

*) Not displayed for Programmer graphics"

*)

Set

Spindle Speed

MODE

DATE

Actual

Spindle Speed

*)

*)

Function and

Softkey Window

(alternating

readout)

1 - 5

Page 15

Flexible Automation

ASR 33 ASCII Keyboard

The ASCII keyboard can be connected up for simplified operation. Basically all

keyboard functions can also be selected at the panel. The keyboard can be used to

directly activate all valid functions. The keyboard is primarily used to create CPL

programs (usually for programming) in the SCREENĆEDITOR".

Basic Keyboard Functions

Introduction

CC 220/320 M

Operating Manual

Group Modes

F1 F2 F3 F4 F5

!

ESC

CTRL

TAB ?

"

1 2 3 4 5 6 7 8 9 0

Q W E R T Z U I O P

CAPS

A S D F G H J K L

LOCK

SHIFT

Z X C V B N M

#

$ % &

/

Direct selection by key press

NC

(Execute)

Machine

(Setup)

Diagnostic

(Information)

( )

+/-

=

*

_

:

LINE

RETURN

FEED

+

;

> <

.

,

DEL

?

SHIFT

/

@

Manual Input

Data I/O

(Program Store)

Correction

1 - 6

Page 16

Flexible Automation

ASCII Keyboard Controls

The controls consist of Softkeys (function keys), keys for cursor, monitor and conĆ

trol functions and the level return key and magnifier.

Interactive Keys

Introduction

CC 220/320 M

Operating Manual

F1 F2 F3 F4

Cursor Functions / Help / Support

Meaning of Keys:

F5

Softkeys and Function Keys

Level Return

Horizontal / Vertical

movement

Magnifier for Graphics

A - Z, a - z Upper and lower case alphabet, numbers, signs,

Special signs for DIN and CPL programming

1 - 7

Page 17

Flexible Automation

Monitor and Control Functions

The control functions are used for programming (e.g. creating CPL programs).

Introduction

CC 220/320 M

Operating Manual

ESC

CTRL

CAPS

LOCK

SHIFT

TAB

LINE

FEED

Escape

Escape functions such as ESC X etc.

Control

Generating control signs such as CTRL L, CTRL X etc.

Capital Lock, selfĆlatching

latched on: upper case

latched off: lower case

Shift for dual function keys

shift on: upper function active

shift off: lower function active

Tabulator

Horizontal tabulation

Line Feed

DEL

RETURN

Delete

Delete character equivalent to (Clear key on panel)

Return

End of block equivalent to key on panel

ENTER

Space

Blank space between words

Continuous pressing of the standard ASCII keys causes

an automatic repeat after approx. 1 second

Caution!

During programming or while the keyboard drawer is open, ensure that the enviĆ

ronment conforms to keyboard enclosure class IP 40. Particular care should be

taken to prevent ingress of fluids or conductive dust into the keyboard.

1 - 8

Page 18

Flexible Automation

Notes

Introduction

This section contains general operator guidance that applies to the chapters which

follow. The definitions below are not repeated in the individual chapters.

The five function keys (Softkeys) F1 to F5 located beneath the screen of the

CC 220/320 M are not assigned any fixed function. The potential functions

are displayed at the base of the screen depending on the status of the control

system. Once a group mode is selected, subsequent steps are determined

depending on which of the function keys F1 - F5 is operated.

A pressed function key is shown in reverse video - highlighted. This means

that the selected function is active (see page 1Ć11).

If the function key is not shown in reverse video, the function is no longer

active (see page 1Ć11).

Each new function key assignment is known as a function or Softkey level.

Each group mode comprises several function or Softkey levels which can be

accessed in sequence. Operating the relevant function key steps the system

on to the next lower function level display.

CC 220/320 M

Operating Manual

Operating (pressing the Softkey in bold margin) is done line by line (Softkey

lines) from top to bottom and from left to right on each line.

After it has been keyed in, a value must be confirmed by pressing the Enter

key.

R

Press the return key

By selecting a group mode the operator can escape from any function level

directly back to the main screen.

When in the MANUAL INPUT group mode the Sign reverse" key

+/-

must be operated before a negative value is entered.

or to escape to the previous (higher) level.

1 - 9

Page 19

Flexible Automation

Conventions

Introduction

CC 220/320 M

Operating Manual

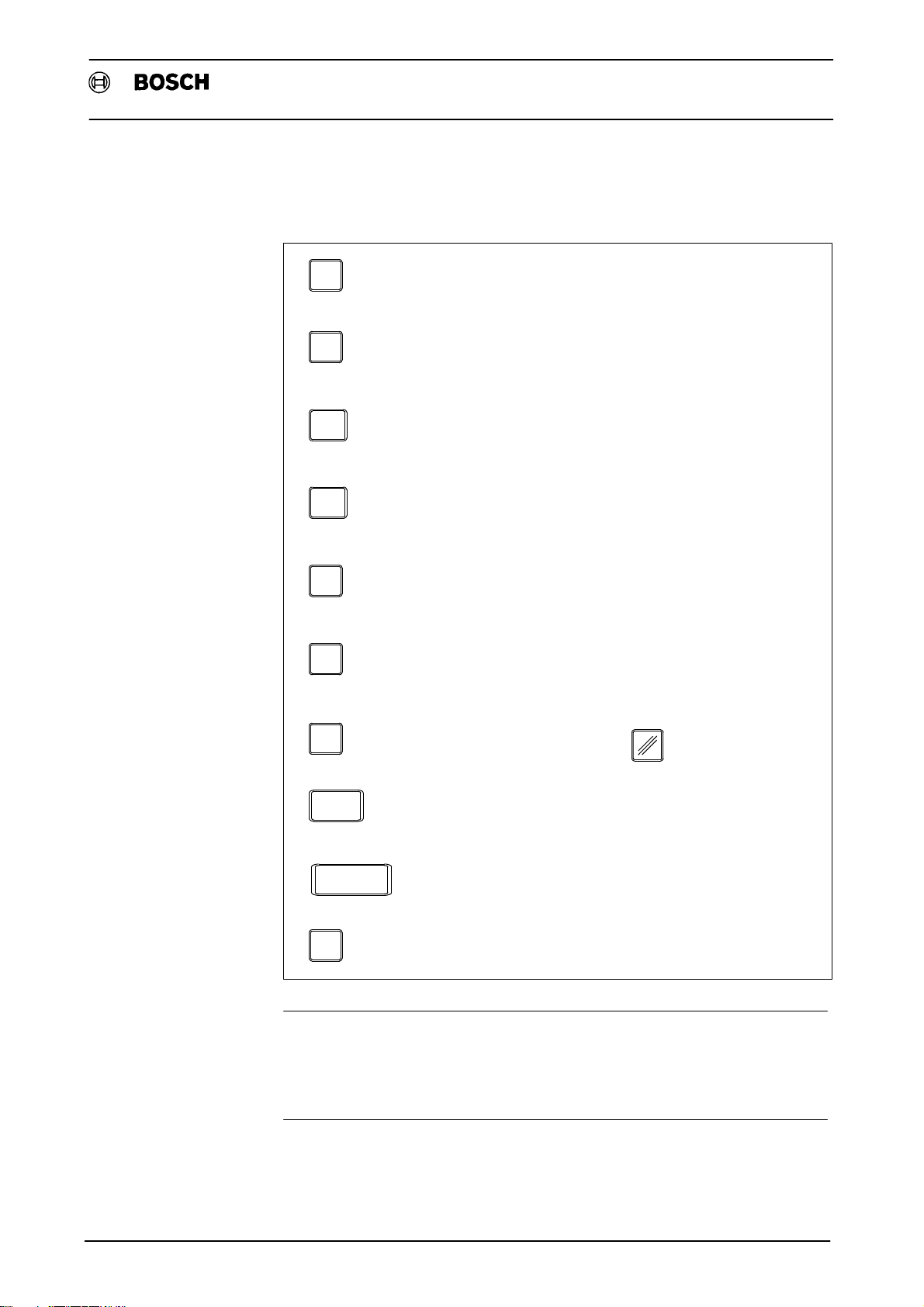

The following conventions apply for the operation of the function keys:

Operate function key

Function key highlighted:

Function is active.

Function key no longer highlighted:

Function is completed and/or not active.

When *-identifying a function key with a

* DEVICE

SELECT

single function only:

The function is permanently preselected

(operating the function key activates

the preselected functions on the next

lower level).

*DELETE

RECALL

R

START

or

NC START

<ENTER>

or

<RETURN>

OPTION

When *-identifying a function key with a

dual function:

Repeated pressing of a function key

that is assigned a dual function will

toggle between the two functions.

Level return

Press NC Start Key

Press ENTER or RETURN KEY

The functions marked Options" are

expansion units (see Figure on page 7Ć5) and

are not part of the basic version. They are

installed at the request of the MTM.

1 - 10

Page 20

Flexible Automation

Safety Information

Introduction

This Manual is for software version V25 of the CC 220 M and CC 320 M control

systems.

Refer to the manual issued by the machine tool manufacturer (MTM) for speĆ

cific machine operating instructions.

The operator is able to considerably influence the relationships between the

CNC and the machine, and operation by semiĆskilled or unskilled operatives

can cause damage to machinery and drives, the loss of software and even

personal injury.

Only skilled persons should therefore be allowed to operate the equipment,

and we can provide comprehensive training to meet this requirement. You

will find a summary of training courses on the inside front cover of this manuĆ

al. Further particulars are obtainable from our Training Centre.

CC 220/320 M

Operating Manual

Ensure that personnel are well clear of hazard areas before traversing maĆ

chine tool axes and that there is no risk of collision within travel ranges.

1 - 11

Page 21

Flexible Automation

Introduction

Group Modes (GBA) with Typical Display

MACHINE

CC 220/320 M

Operating Manual

Essential Functions:

NO BFO NC0 MACHINE

PROGRAM ACT WAITING 19.12 16: 3

X 0.000

Y 0.000

Z 0.000

F 996.1 100% S 0.0 100% SĆACT 82.0

REFERENCE

POINT

JOG

MODE

CPL/DIA LOG

CALL

*

*

*

SWITCH

FUNCTION

MANUAL INPUT

OTHER

COMMANDS

Traverse to reference point(s)

Axes - Jog Mode

CPL / Dialog Call (Option)

Switch functions

Zero set

Panel switchover

MANUAL INPUT BFO NC0 MANUAL INPUT

PROGRAM ACT WAITING 19.12 15:20

MANUAL DATA INPUT

PROGRAM VALUE END POINT POSITION DIFFERENCE

X 0.000 X 0.000 X 0.000 X 0.000 *

Y 0.000 Y 0.000 Y 0.000 Y 0.000 *

Z 0.000 Z 0.000 Z 0.000 Z 0.000 *

F 996.1 100% S 0.0 100% SĆACT 82.0

MANUAL INPUT G

G F M [ ]

S T E

X I A

U R L

Y J B O

V D N P

Z K C

W H Q

FUNCTIONS

Entry and execution of

NC block information

(with Softkeys or ASCIIkeyboard)

Multiple insert

Subroutine parameters

1 - 12

Page 22

Flexible Automation

DATA I/O

Introduction

CC 220/320 M

Operating Manual

P BFO NC0 DATA I/O

N ACT READY 26.12 16:26

NUMBER PROGRAM NAME LENGTH ACCESS

P 999999082 BOHREN 1 V25 28.10 691 E

P 999999082 BOHREN 2 V25 28.10 764 E

P 999999083 TIEFLOCHBOHREN V25 28.10 1559 E

P 999999084 GEWINDEBOHREN V25 11.03 1469 E

P 999999085 AUSBOHREN 1 V25 28.10 788 E

P 999999086 AUSBOHREN 2 V25 28.10 918 E

P 999999999 27.10 711 RWED

P 81 DRILLING 1 V21 VERS.4 05.09 692 RWE

P 82 DRILLING 2 V21 VERS.4 05.09 765 RWE

P 83 DEEP HOLE DRILLING

85 BORE OUT 1 V20 VERS.4 05.09 708 RWE

P 86 BORE OUT 2 V20 VERS.4 05.09 839 RWE

P 84 TAP V21 VERS.6 05.09 1352 RWE

P 5 205 RWED

MEMORY USED BY PROGRAM 68688 OTHERS 25162

MEMORY AVAILABLE: 4454

MANAGE

PROTECTION

V20 VERS.4 05.09 1596 RWE

RENAME DELETE MODIFY

HEADERFILE

COMPENSAĆ

TION

COPY

Input and output of parts

and dialog programs

Edit programs

Copy and rename

programs

Save, clear and manage

programs

NO

PROGRAM

ZERO OFFSETS V 1

G53

G153

G253

G67

GEOMETRY

COMPENSATIONS K 2

D 0 X 0.000 H 0 Z 0.000

TOOL COMPENSATIONS T 1

X 0.000 Z 0.000

ZERO OFFS.

TABLES

BF0

NC0

ACT

WAITING

X 0.000 Y 0.000 Z 0.000

X 0.000 Y 0.000 Z 0.000

X 0.000 Y 0.000 Z 0.000

X 0.000 Y 0.000 Z 0.000

TOOL COMP.

TABLES

SPECIAL

TABLES

CS

TABLES

CORRECTION

5.5 17:00

CPL/DIALOG

CALL

Input and output of tool

compensation, reference point

offset and CS tables

Edit data

Copy and rename

tables

Save and clear

tables

CPL/Dialog Call (Option)

1 - 13

Page 23

Flexible Automation

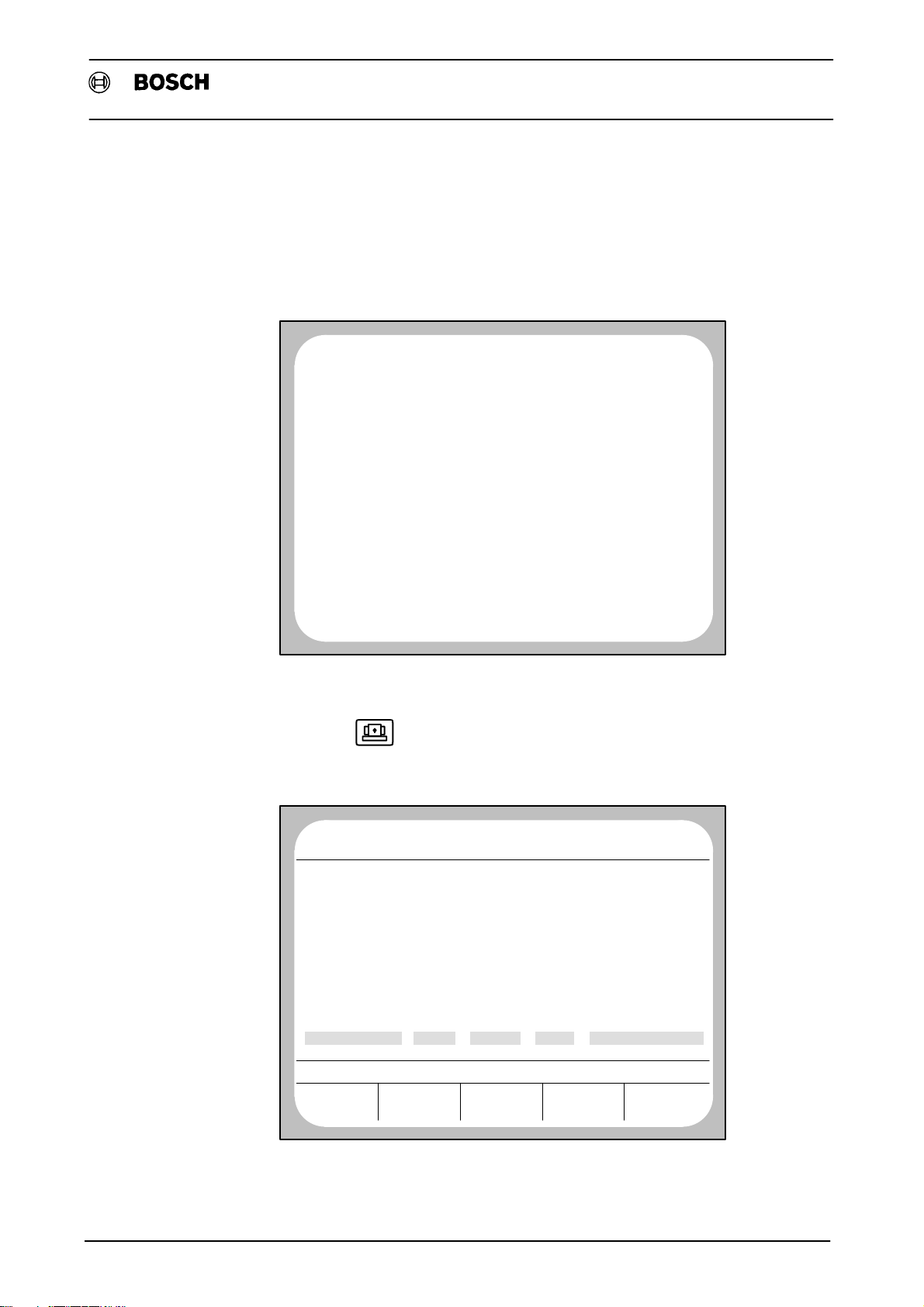

NC

Introduction

CC 220/320 M

Operating Manual

NO BFO NC0 NC

PROGRAM ACT WAITING 19.12 15:20

MANUAL DATA INPUT

PROGRAM VALUE END POINT POSITION DIFFERENCE

X 0.000 X 0.000 X 0.000 X 0.000 *

Y 0.000 Y 0.000 Y 0.000 Y 0.000 *

Z 0.000 Z 0.000 Z 0.000 Z 0.000 *

F 996.1 100% S 0.0 100% SĆACT 82.0

*AUTOMATIC

TABLE

SELECTION

PROGRAM

SELECTION

*STATUS

DIAGNOSTIC

Execute NC programs

Program test with/without

movement

Go block

NC program execution

Single block/Auto

Activate tables

Return to contour

Debug

NO

PROGRAM

ERROR CONDITION ONSTATUS

G 80 G 66

G 43 G 94

G 40 G 18

G 8 G 27

G 15 G 29

G 80 G 53

G 153 G 253

G 67 G 39

G 62 G 97

G 65 G 68

AT LAST PROGR.

F 10.0 M 30 T 101

DIAGNOSTIC

CONTROL

BF0

ACT

DIAGNOSTIC

MACHINE

NC0

STOP

G 1 G 71 DRIVES ON

RESET

FUNCTION

SERVICE

FUNCTION

DIAGNOSTIC

15.07.90 16:35

Display NC basic information

Error and status displays

Machine status and

interface display

Execute delete functions

Activate diagnostic

programs

Machine parameter program

1 - 14

Page 24

Flexible Automation

CC 220/320 M Self Test

Introduction

CC 220/320 M

Operating Manual

The control system is activated when the machine tool is powered up and the CC

220/320 M automatically runs a test. If a problem is detected, startĆup is aborted

and an ERROR" message is displayed. The following screen is built up as the selfĆ

test is run:

TYP2 STARTUP

RAMĆTEST 20 40

EPROMĆTEST 0577E737CC38DE07

CHECKSUMĆTEST 06

SYSTEM INIT

P2INIT

IOĆINIT

P2START Z23H 43

CRTINI

COPYRIGHT 1985Ć90 ROBERT BOSCH GMBH

On completion of the selfĆtest the system automatically switches to the group mode

MACHINE .

The system is now ready for operation.

NO BFO NC0 MASCHINE

PROGRAM ACT WAITING 19.12 16: 3

X 0.000

Y 0.000

Z 0.000

F 996.1 100% S 0.0 100% SĆACT 82.0

REFERENCE

OTHERPOINT

JOG

MODE

CPL/DIALOG

CALL

*

*

*

SWITCH

FUNCTION

WEITERE

FUNCTION

1 - 15

Page 25

Flexible Automation

Introduction

CC 220/320 M

Operating Manual

1 - 16

Page 26

Flexible Automation

Machine

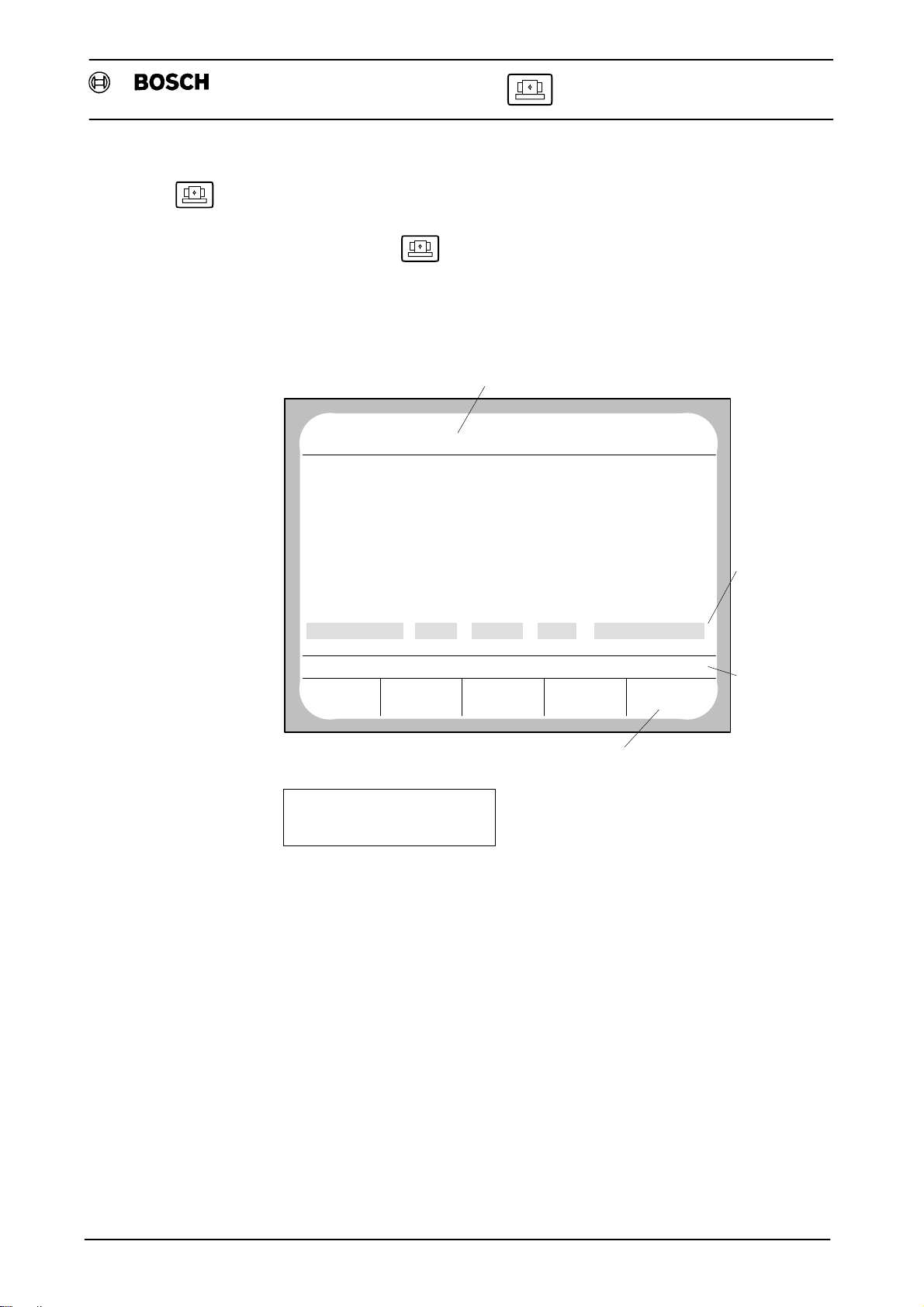

Main Screen

Machine

When you select the system displays the following main screen:

Main screen for the installed axes X, Y and Z

Control system status

NO BFO NC0 MACHINE

PROGRAM ACT WAITING 19.12 15:13

CC 220/320 M

Operating Manual

Options

X 0.007

Y - 0.027

Z - 0.195

F 500.0 100% S 0.0 100% SĆACT 0.0

REFERENCE

POINT

Axis positions:

= Synchr. axis in position

#

= Asynchr. axis in position

Manual setting, switchover functions and preparatory actions e.g.:

- Traverse to reference point(s) Page 2Ć2

- Grid Shift Page 2Ć3

- Zero Set Page 2Ć8

- Manual Mode Page 2Ć8

- CPL/Dialog Call Page 2Ć9

- Switch function F, S, T, M Page 2Ć9

- Include several times Page 2Ć10

- PLC Page 2Ć12

- Multiple panels Page 2Ć13

JOG

MODE

CPL/DIALOG

CALL

SWITCH

FUNCTION

Softkey or function keys

*

*

#

OTHER

FUNCTIONS

Technological

values

Feed and

switch

functions

Notes

(Prompt line)

- 1

2

Page 27

Flexible Automation

Traverse to Reference Point(s)

You must traverse to the reference points when the control is powered up.

The axes can be moved to their reference points either together or individually.

The Softkey is not offered for OVERALL LOCKOUT ACTIVE.

Machine

CC 220/320 M

Operating Manual

REFERENCE

POINT

TRAVERSE TO REFERENCE POINT START AXIS!

REFERENCE

POINT

JOG

MODE

JOG

MODE

CPL/DIALOG

CALL

(Option)

CPL/DIALOG

CALL

(Option)

SWITCH

FUNCTION

SWITCH

FUNCTION

OTHER

FUNCTIONS

OTHER

FUNCTIONS

Further operations at the machine panel as directed by the macine tool manufacĆ

turer:

REFERENCE POINTS REACHED ALL AXES.

REFERENCE

POINT

JOG

MODE

CPL/DIALOG

CALL

SWITCH

FUNCTION

OTHER

FUNCTIONS

The basic screen appears (coordinates are dependent upon machine

parameters). The position is set to zero, for example, as the reference value. All

movements will then relate to the set reference point.

NO BFO NC0 MACHINE

PROGRAM ACT WAITING 19.12 16: 3

X 0.000

*

Y 0.000

Z 0.000

F 996.1 100% S 0.0 100% SĆACT 0.0

REFERENCE

POINT

JOG

MODE

CPL/DIALOG

CALL

*

*

SWITCH

FUNCTION

OTHER

FUNCTIONS

- When the axes reach their reference points, the prompt line displays the text

REFERENCE POINTS REACHED ALL AXES".

- If the reference points cannot be reached, check that the axes have DRIVE ON

or whether the feed potentiometer is on zero.

Traverse to reference point is performed with the standard installed logic. Traverse

to reference point with Grid Shift" is available as an optional expansion unit.

- 2

2

Page 28

Flexible Automation

GridĆShift (Option)

General

Machine

When traversing to reference point with GridĆShift the reference point is not only

assigned to the zero marker defined by the measuring system, it is also assigned to

any random sensor pulse. This value is assigned to a selected zero marker by a

freely definable pulse difference that is less than the sensor impulse number. In this

way the reference point shifts by a selectable number of pulses (GridĆShift).

When traversing to reference point without GridĆShift, the zero marker that is esĆ

sential for reference point evaluation may not be detected at the right time, in which

case different reference points will be approached. When commissioning or resetĆ

ting the system therefore, either the measuring system must be reversed or the

reference point cam moved.

With GridĆShift it is possible to electronically move the evaluated zero marker

and therefore to set the relative position, making mechanical adjustments reĆ

dundant.

CC 220/320 M

Operating Manual

The reference point can be approached in Rapid mode for those axes on

which GridĆShift is active.

The GridĆShift option enables you to define the pulse number and the 1. reduced

reference point feed once only, e.g. on commissioning, for each selected axis.

These values are then automatically stored in the machine parameter program and

recalled for all subsequent traversing to the reference point on the axis that is active

for GridĆShift.

If axes are not active for GridĆShift (see MP 1512), traverse to reference point is still

performed according to the Standard Logic.

Use the IF inputs Reference point E2.xx" at the CNC interface for evaluating the

cam switch signals. Since an optimum time evaluation of the reference point cam

switch signals is not always possible, it may be necessary with GridĆShift to assign

the cam signals from the axes to the highĆspeed inputs on the Servo card to

achieve faster evaluation.

- 3

2

Page 29

Flexible Automation

Defining Grid-Shift Values

Machine Parameter Program

A parameter field is provided in MP Group 9500 for assigning the highĆspeed inputs

(HS I/O) on the ServoĆi card to the axis processors (P9504Ć9506).

- 11: highĆspeed input for GridĆShift 1. axis

- 12: highĆspeed input for GridĆShift 2. axis

.

.

- 18: highĆspeed input for GridĆShift 8. axis

Use interface inputs E2.xx for installed axes (see MPP 1512) not entered here.

MP 502 Reference Point Speed

The speed is active during Traverse to ref. pnt. with GridĆShift".

Machine

CC 220/320 M

Operating Manual

MP 503 1. Reduced Ref. Pnt. Feed

This speed is defined by GridĆShift and stored automatically in this parameter proĆ

vided the speed is less than previously set.

Before defining the GridĆShift values you should therefore enter the value of the refĆ

erence point speed here (MP 502) to achieve the highest possible 1. reduced referĆ

ence point feed.

MP 503 1. Reduced Ref. Pnt. Feed

This speed is active while GridĆShift values are being defined. The lower the speed

setting the greater the value entered for MP 502 (1. reduced ref. pnt. feed).

MP 1511 GridĆShift in Pulses

The defined Grid-Shift values are automatically entered here (see Activate GridĆ

Shift). A 0" is set if no GridĆShift is defined.

Warning!

An edited value can generate an incorrect reference point for an

!

active axis.

MP 1512 Activating Grid-Shift

GridĆShift is activated for a particular axis:

- to define GridĆShift

- to traverse to reference point with GridĆShift

MP 1513 Grid-Shift Cam Slope

You define the slope of the cam switch signal at which the GridĆShift Logic starts

internally defining the pulses.

You will find further details in the CC 220 Machine Parameters" Manual P. No. 4201

and CC 320 Machine Parameters" Manual P. No. 4180.

- 4

2

Page 30

Flexible Automation

Operating

Procedure

Machine

CC 220/320 M

Operating Manual

Calling GridĆShift

REFERENCE

POINT

OTHER

FUNCTIONS

JOG

MODE

The CC 320 M has the following additional level:

PAN EL

PASSIVE

OTHER

FUNCTIONS

GRID

SHIFT

CONTROL

GRID

SHIFT

SWITCH

FUNCTION

OTHER

FUNCTIONS

OTHER

FUNCTIONS

The pulse number and the 1st red. ref. pnt. feed for Grid-Shift are indicated. When

GridĆShift values are defined for the first time, the value 0" (see MPP P1511) is indiĆ

cated as the GridĆShift (pulse number) and the value of MPP P503 follows as the

speed.

The system only displays the axes for which GridĆShift is active (see MPP 1512).

Example: Display in Grid-Shift

NO BFO NC0 MACHINE

PROGRAM ACT WAITING 11 : 45 : 34

AXIS GRID SHIFT MAX.1. RED.REF.PNT.FEED.

X 0 PULSES 3.200 M/MIN

Z 0 PULSES 2.600 M/MIN

- 5

2

Page 31

Flexible Automation

Defining Pulse Number and Speed

START

RECORDING

This activates the logic that defines the Grid-Shift values. The corresponding axis

starts as soon as one of the IF signals 13.0 - 14.7 (Jog) is active. The IF signal Dir.

of Ref." is evaluated for the direction of travel. The axes move in this direction at the

2. reduced reference point feed (see MPP 504) to the reference point cam (evaluĆ

ated with feed pot 100%. Settings > 100% are ignored). The GridĆShift values are

defined.

Within the GridĆShift function itself, the IF signals are generated in the same way as

with a standard traverse to reference point. Certain reaction time limits are defined

for the internal measurement of the GridĆShift values, and these depend on the PLC

coupling:

Bit/word coupling: 250 ms

PIC coupling: 20 ms

Machine

CC 220/320 M

Operating Manual

Saving the Values

With the reference point feeds, the machine parameter program uses the entered

values for the sensor pulse number and the reaction time limit to monitor whether

the entered speed causes a loss of accurate zero marker detection. If it does, then

the approach rate is automatically reduced until the correct pulse number is

properly detected.

ACTIVATE

GRIDĆSHIFT

This saves the internally defined GridĆShift values (pulse number) to MPP P1511

and the 1. reduced ref. pnt. feed to MP 503 provided the measured speed is less

than that already set. The entry is automatic. Use a final RESET to activate the maĆ

chine parameters.

- 6

2

Page 32

Flexible Automation

Traverse to Ref. Pnt. with GridĆShift

Conditions

MPP P1511: GridĆShift (pulse number) must be entered for the desired axis/

MPP P1512: Axis/axes are activated for GridĆShift

MPP P1513: Slope evaluation; what counts is the setting in which the GridĆ

Procedure

TRAVERSE TO REFERENCE POINT START AXIS!

REFERENZCE

POINT

See machine manufacturer's manual for subsequent operations at machine panel.

Machine

axes

Shift was measured.

JOG

MODE

CPL/DIALOG

CALL

CC 220/320 M

Operating Manual

SWITCH

FUNCTION

OTHER

FUNCTIONS

The axes move to the reference point cam (Feed pot=100%) at the speed defined

in MPP P502.

At the reference point cam (axis-specific IF signal E2.xx = high) the approach

speed is reduced to the 1. reduced reference point feed. This must be achieved at

the end of the cam.

The marker search logic including Grid-Shift is initiated as the axis leaves the cam

(signal changes E2.xx = low). The reference point is now no longer exclusively the

zero marker preset by the measuring system but is assigned to a sensor pulse. This

pulse is defined by a pulse difference from the zero marker measured under the

same mechanical conditions (cam position and sensor). The Reference point

position" entered in MPP P1501 is displayed.

Note!

Once the axis has left the reference point cam, the braking distance from the 1. reĆ

duced feed to nil must be less than the distance to the limit.

A programmed reference point offset in MPP P1502 refers to the reference point

moved by GridĆShift. 2Ć13.

- 7

2

Page 33

Flexible Automation

Zero Set

Machine

CC 220/320 M

Operating Manual

The ZERO SET softkey is used to set the current setpoints and actual values within

the axis traverse range to zero:

REFERENCE POINTS REACHED ALL AXES.

REFERENCE

POINT

JOG

MODE

CPL/DIALOG

CALL

(Option)

SWITCH

FUNCTION

OTHER

FUNCTIONS

Jog Mode

PAN EL

PASSIVE

TO ZERO AXES OPERATE AXIS BUTTON

PAN EL

PASSIVE

CONTROL PLC

CONTROL PLC

ZERO

SET

ZERO

SET

Press keys in sequence or

together as directed by

the machine manufacturer.

Once all axes are set to zero the following SK bar is displayed

(ZERO SET softkey is no longer highlighted):

PAN EL

PASSIVE

CONTROL PLC

ZERO

SET

Use the JOG MODE key to inch the axes to any position within their traverse range

either in sequence or simultaneously:

REFERENCE

POINT

JOG

MODE

CPL/DIALOG

CALL

(Option)

SWITCH

FUNCTION

OTHER

FUNCTIONS

JOG (MM/MIN), MANUAL FEED MEDIUM

REFERENCE

POINT

JOG

MODE

CPL/DIALOG

CALL

(Option)

Operate keys as directed by machine tool manuĆfacturer

(after selecting the appropriate manual feed or increĆ

mental).

SWITCH

FUNCTION

OTHER

FUNCTIONS

Other softkey levels can be accessed while Jog Mode is active. This will not interĆ

rupt Jog Mode.

Jog Mode is interrupted when level return is pressed.

- 8

2

Page 34

Flexible Automation

CPL / Dialog Call

Machine

CC 220/320 M

Operating Manual

The CPL/DIALOG CALL softkey is only highlighted when the expansion option

CPL with Progr. Graphics" is installed. This is not part of the basic version.

The CPL/DIALOG CALL softkey allows you to call programs written in the CPL lanĆ

guage:

REFERENCE

POINT

Switch Functions F, S, T, M (*)

The SWITCH FUNCTION softkey allows you to select the following auxiliary and

extra functions

- F (Feed rate)

- S (Speed selection)

- T (Tool selection)

- M (Switch function)

- (*) (Inclusion of machineĆrelated functions)

simply by pressing the appropriate softkeys:

REFERENCE

POINT

JOG

MODE

JOG

MODE

CPL/DIALOG

CALL

CPL/DIALOG

CALL

SWITCH

FUNCTION

Subsequent operations are

described in the machine

manufacturer's manual.

SWITCH

FUNCTION

FUNCTIONS

FUNCTIONS

OTHER

OTHER

SWITCH FUNCTION

F

S T M FUNCTIONS

F

VALUE ... <ENTER>

Each switch function can only be assigned one value (Include Sev. Times is

not possible).

Switch functions can also be entered before traversing to reference point (exĆ

cept for subprogram calls, e. g. M60 P9960).

Every time a switch function of the same type is entered, the previous one is

overwritten (except when INCLUDE SEV. TIMES is activated).

Press

START

to initiate the selected function.

- 9

2

Page 35

Flexible Automation

Machine

Example: Switch functions; Enter F5000 M10

Select

SWITCH

FUNCTION

F 5000 <ENTER>

M 10 <ENTER>

The following screen is now displayed:

NO BFO NC0 MACHINE

PROGRAM ACT WAITING 19.12 16: 3

MANUAL DATA INPUT

F5000 M10

PROGRAM VALUE END POINT POSITION DIFFERENCE

CC 220/320 M

Operating Manual

X 0.000 X 0.000 X 0.000 X 0.000 *

Y 0.000 Y 0.000 Y 0.000 Y 0.000 *

Z 0.000 Z 0.000 Z 0.000 Z 0.000 *

F 1000.0 100% S 0.0 100% S-ACT 0.0

SWITCH FUNCTION M

FST

Include Sev. Times Switch Functions

The INCLUDE SEV. TIMES softkey can be used to enter NC addresses which can

be inserted several times in an NC block. The multiple address is inserted after the

NC address programmed last:

REFERENCE

POINT

JOG

MODE

M

CPL/DIALOG

CALL

FUNCTIONS

SWITCH

FUNCTION

OTHER

FUNCTIONS

SWITCH FUNCTION M

F M

SWITCH FUNCTION

DELETE

S T FUNCTIONS

INCLUDE

SEV.TIMES

R

After pressing the INCLUDE SEV. TIMES softkey (highlighted) and level return, you

return to the input level and insert the NC block by pressing the appropriate keys:

- 10

2

Page 36

Flexible Automation

Machine

F 0.0 100% S 10.0 100% S-ACT 0.0

SWITCH FUNCTION

F T

S M FUNCTIONS

F

CC 220/320 M

Operating Manual

VALUE ... <ENTER>

Example: Include Sev. Times switch functions; Enter M55 M13 T5

Select

SWITCH

FUNCTION

FUNCTIONS

INCLUDE

SEV.TIMES

R

M 55 <ENTER>

M 13 <ENTER>

T 5 <ENTER>

The following screen is now displayed:

NO BFO NC0 MACHINE

PROGRAM ACT WAITING 19.12 16: 3

MANUAL DATA INPUT

M55 M13 T5

PROGRAM VALUE END POINT POSITION DIFFERENCE

X 0.000 X 0.000 X 0.000 X 0.000 *

Y 0.000 Y 0.000 Y 0.000 Y 0.000 *

Z 0.000 Z 0.000 Z 0.000 Z 0.000 *

F 1000.0 100% S 0.0 100% S-ACT 0.0

SWITCH FUNCTION T

FS

MT

FUNCTIONS

2

- 11

Page 37

Flexible Automation

PLC

Machine

This function is only active with PLC connected.

Pressing the PLC softkey initiates subsequent machine operation

by the PLC controller.

CC 220/320 M

Operating Manual

REFERENCE

POINT

PAN EL

PASSIVE

Subsequent operations are described in the machine tool manufacturer's

manual.

Multiple Panels (CC 320 M only)

This function is used when several panels are connected to one NC control system

or when one panel is connected to a number of control systems.

REFERENCE

POINT

NO BF0 NC0 MACHINE

PROGRAM ACT WAITING 19.12 16: 3

JOG

MODE

SELECT

CONTROL

JOG

MODE

CPL/DIALOG

CALL

(Option)

PLC

CPL/DIALOG

CALL

SWITCH

FUNCTION

ZERO

SET

SWITCH

FUNCTION

OTHER

FUNCTIONS

OTHER

FUNCTIONS

X 0.000

Y 0.000

Z 0.000

F 996.1 100% S 0.0 100% S-ACT 0.0

PANEL

PASSIVE

SELECT

CONTROL

2

PLC

- 12

*

*

*

ZERO

SET

Page 38

Flexible Automation

One Panel,

Several Control Systems

Machine

Example: Select Control System

Control 1 is to be selected:

CC 220/320 M

Operating Manual

One Control System,

Several Panels

PAN EL

PASSIVE

WHICH CONTROL?

PAN EL

PASSIVE

SELECT

CONTROL

SELECT

CONTROL

PLC

PLC

S

ZERO

SET

1

ZERO

SET

<ENTER>

Panel is switched to Control 1.

Up to 7 additional panels can be connected to the NC, but only one of them can

transmit and receive actively at any one time.

The other panels are passive, i.e. they may receive only (display). When graphics

are entered only the header is displayed.

Panels can be activated and deactivated by pressing softkeys.

All panels are connected to the soĆcalled Party Line and are permanently adĆ

dressed 0Ć7.

Default: Control system and Panel with the address 0 are active.

Two modes characterize multiplex operation

One panel is active, all others are passive

(no input possible at passive panels)

A passive panel is indicated in the header by BF*.

(display only, no operation)

There are two ways of selecting the panel:

1. Use SELECT PANEL to switch over direct from the currently active panel to

another panel (see Example 1).

2. You can deactivate the active panel using Panel Passive". It is now possible

to activate any panel (see Example 2).

2

- 13

Page 39

Flexible Automation

Machine

Example 1: Select Panel

Panel 1 is to be selected:

CC 220/320 M

Operating Manual

REFERENCE

POINT

PAN EL

PASSIVE

SELECT

PAN EL

WHICH PANEL B

SELECT

PAN EL

JOG

MODE

SELECT

CONTROL

PAN EL

ACTIVE

PAN EL

ACTIVE

CPL/DIALOG

CALL

Option

PLC

Example 2: Select Panel

Panel 0 is active.

REFERENCE

POINT

JOG

MODE

CPL/DIALOG

CALL

Option

SWITCH

FUNCTION

ZERO

SET

SWITCH

FUNCTION

OTHER

FUNCTIONS

1 <ENTER>

OTHER

FUNCTIONS

PAN EL

PASSIVE

CONTROL PLC

ZERO

SET

You have deselected Panel 0.

Now press any key at one of the connected panels to activate that panel.

2

- 14

Page 40

Flexible Automation

Manual Input

Main Screen

Manual Input

CC 220/320 M

Operating Manual

After selecting the system displays the following main screen:

MANUAL INPUT BFO NC0 MANUAL INPUT

N - - - - - - ACT WAITING 19.12 15:20

MANUAL DATA INPUT

PROGRAM VALUE END POINT POSITION DIFFERENCE

X 0.000 X 0.000 X 0.000 X 0.000 *

Y 0.000 Y 0.000 Y 0.000 Y 0.000 *

Z 0.000 Z 0.000 Z 0.000 Z 0.000 *

Options

F 996.1 100% S 0.0 100% SĆACT 0.0

MANUAL INPUT G

G F M [ ]

S T E

X I A

U R L

Y J B O

V D N P

Z K C

W H Q

FUNCTIONS

Entries for direct execution of NC blocks without saving by

- Entry at the panel Page 3Ć2

- Include Sev. Times Page 3Ć4

- Key-in with ASCII Keyboard Page 3Ć7

- Enter subprogram parameters Page 3Ć7

M-Functions that have been assigned a program in the machine parameter can

also be selected. This program is linked before it is run.

Requirements for Manual Input

The mode allows an NC block to be entered for immediate execution. The

following requirements must be satisfied before the Manual Input mode can be

used: