Page 1

ce

120M

Operating Instructions

4 5

--

I

Version 102

BOSCH

Automation

Page 2

Page 3

ce

120M

Operating Instructions

1070 073 435-102 (92.03)

GB

All rights reserved, including applications tor protective rights.

Reproduction

Reg.

Nr.

16149-03

©

1991

by Robert Bosch GmbH,

or

handing overto third parties are subject to our written permission.

Discretionary charge

20.-

DM

Page 4

Page 5

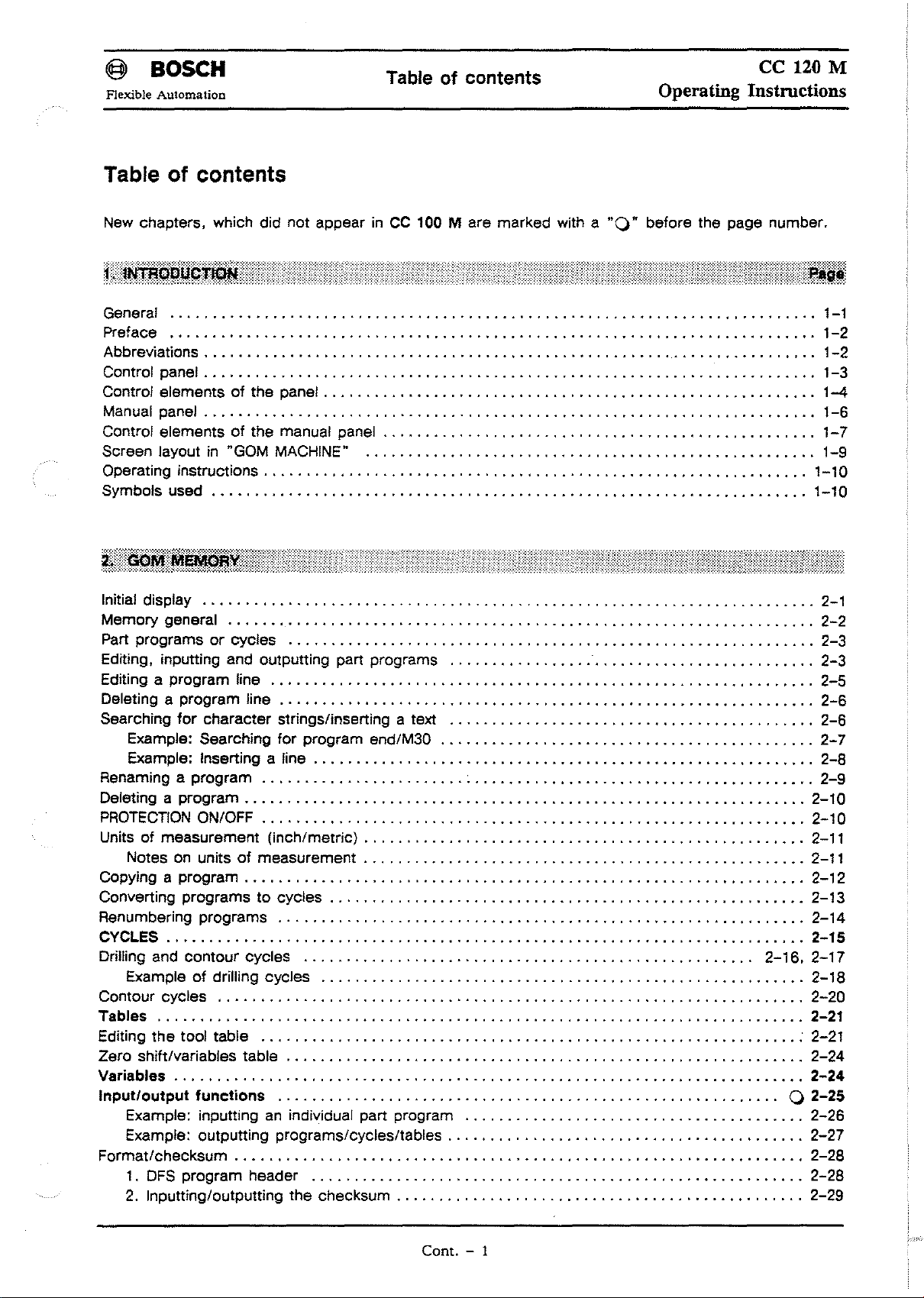

@ BaSCH

Flexible Automation

Table of contents

Table

of

contents

ce

120 M

Operating Instroctions

New ehapters. whieh did not appearinCC

General 1-1

Prelaee

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-2

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contral elements01the

Manual panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-6

Control elements01the

Sereen layoutin"GOM MACHINE"

Operating instruetions ,

Symbols used

Initial display 2-1

Memory general

Part programsorcyeles

Editing. inputting and outputting part programs

Editing a program line

Deleting a program line

Searehing

Example: Searehing

Example: Inserting a !ine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-8

Renaming a program

Deleting a program

PROTECTION

Units01measurement (ineh/metrie) , 2-11

Notes

Copying a program ,

Converting programs to eyeles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-13

Renumbering programs

CYCLES

Drilling and eontour eyeles

Example01drilling eyeles

Contour eyeles

Tables 2-21

Editing

Zero shiltlvariables table "

Variables

Input/output

Example: inputting

Example: outputting programs/eyeles/tables

Formatleheeksum

1.

2. Inputting/outputting the eheeksum

for

eharaeter strings/inserting a text

ON/OFF

on

units01measurement , 2-11

the

tool table : 2-21

functions

DFS

program header

panel.

manual panel... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-7

lor

an

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-4

program end/M30

individual part program

100

'"

Mare

marked with a

"0"

belore the page number.

2-16.

0

...

1-2

1-3

1-9

1-10

1-10

2-2

2-3

2-3

2-5

2-6

2-6

2-7

2-9

2-10

2-10

2-12

2-14

2-15

2-17

2-18

2-20

2-24

2-24

2-25

2-26

2-27

2-28

2-28

2-29

Cont. - 1

Page 6

@ BOSCH

Flexible Automation

Table of contents

ce

120 M

Operating Instructions

Initial display

Basic funetions 3-1

Approaehing

Manual

Exampie: traversing axes manually

Example: entering a block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-6

Teach

Seleeling

Initial display

Basic funetions 4

Automatic

Procedure

Automatie exeeutioninnormal

Seleeting/editing the step size

Aetivating a stop point

Seleeting an

Seleeting the milling eonditions

Calling

Seleeting the start point

Departure/re-entry during automatie

Proeedure

Procedure

Tables 4-11

DRIP

SeleC1ing

Simulation

in

CPC

FEEDING

..........................................•.............................

referenee

mode

the

unitofmeasurement

executionofprograms/cycles

before

NC

block direetly/defining braneh destinations

test

after

NC Start

(automatic

drip feeding

points(s)

NC Start

"

inch/metrie

mode/dry

.................................................•.......

mode

via

run/rapid leed

mode

interface)

3-1

3-2

3-3

3-3

3-7

3-12

4.,.'

4-"

4-2

4-3

4-4

4-5

4-6

4-6

4-8

4-8

4-8

4-9

4-10

4-12

4-12

4-14

Initial display 5-1

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Machine

Meaningofmachine

NC

Errors and mesaages

Axis displays

Status table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PIC/PC displays

Calling up search functians 5-11

Seleeting

I/Ollag8

Calling up trigger functians

Service

Logbook

status

110

status

Meaning

time/counter

lunctions

functions

ofaxis

.....

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

status

display functians : .

functions

tables and

110

f1ags

"

Cant. - 2

'"

5-2

5-4

5-5

5-6

5-7

5-7

5-8

5-10

5-12

5-13

5-14

5-'

5-1

i

Page 7

@ BOSCH

Flexible

Automation

Table of contents

Operating

ce

120 M

Instructions

Displaying logbook

Outputting logbook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . . . . . . . . . . . . .•.5-18

Setting the clock and date display

Selecting the language

Selecting

Interface

DRIP

Buffer size

Block offset

DNC

MTB

Softkey architecture

Reset and delete

Control reset

ON

UNE

.......•.........................•.......................•.•...•.......•...

FEEDING

..............................................•.........................•

..•.•.................................................................•

INTERFACE

service/resetldelete

......................................•........................

........................•...•.....................

............•............................................•.

PIC/ON

with

UNE

PANEL/ON

LSV 2

for

protocol

......................................•......................

machine tool builder

UNE

DNC

..........................•.......................

......•..............•.....................•

....................................•.

Q

5-17

5-19

5-19

5-20

5-20

5-21

5-22

5-22

5-24

5-24

5-25

5-25

5-25

Cont. - 3

Page 8

Page 9

Page 10

Page 11

~

BOSCH

Flexible Automation

General

1 Introduction

ce 120 M

ce 120 M

Operating Instructions

Continuous path controi

centres with 3 - 4 axes and a main spindie.

Continuous path control

Iing applications.

Modular continuous path control

with 4 axes and a main spindie.

Continuous path contral

cellular plastic. flame. stone and glass cutting applications,

drilling / milling / scribing PCBs.

Programming to

functions (CPC) and

ce

CD

DIN

120 M

CD CD

for

driiling and milling machines and small machining

for

wood machining. automatie drilling and surface mil-

for

automated systems with max. 5 axes

for

special

66 025 / expandedtoinclude new graphie and computing

customer-specific

CD

CD

cycles.

0

CD

000000

0

00000

0000

0000

00000

CD

CD

or

{I

BOSCH

CD

00

00

00

00

00

00

1 - 1

Page 12

(@

BOSCH

Flexible Automation

Preface

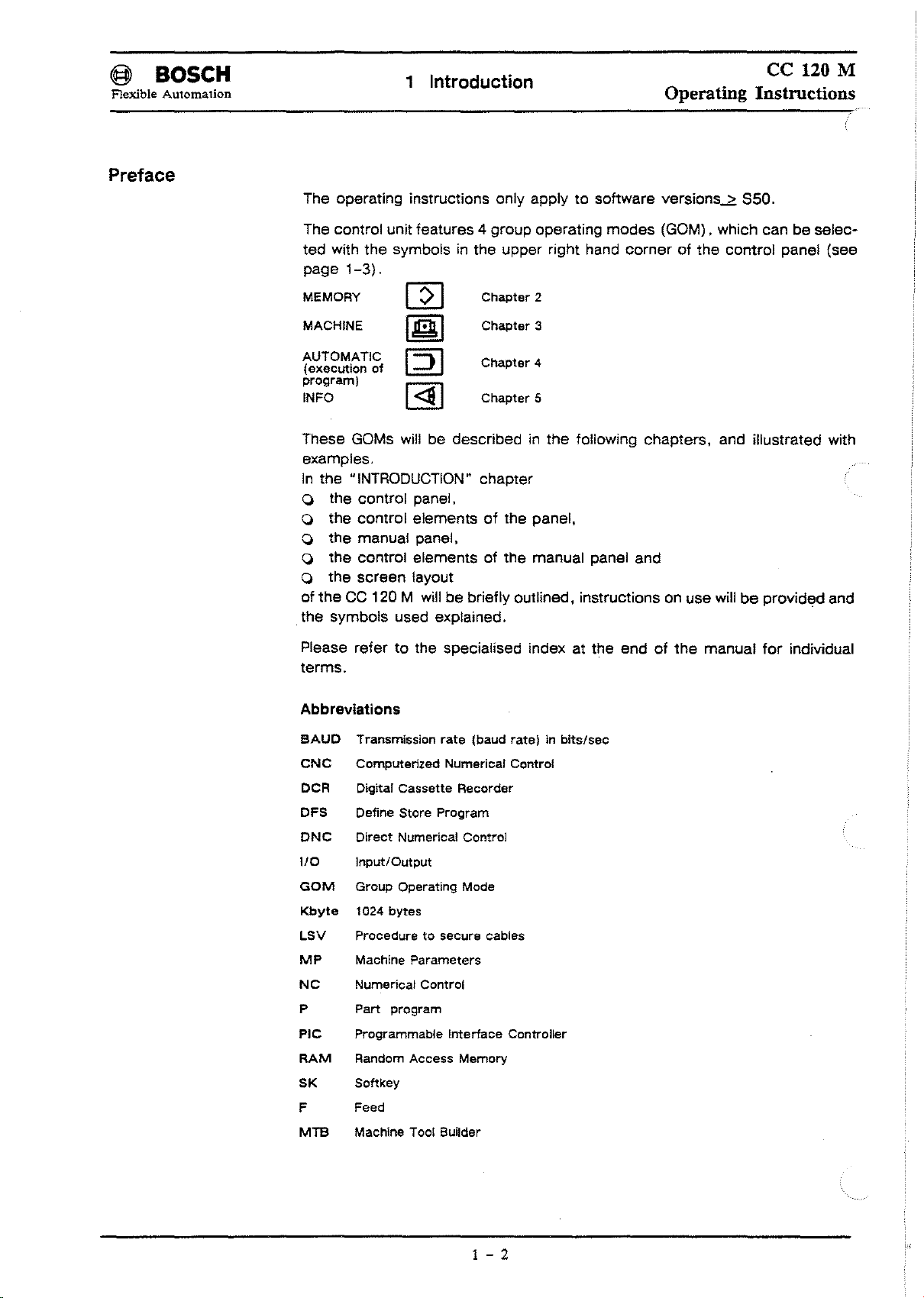

1 Introduction

The operating instructions only apply to software versions.2

Operating Instructions

850.

ce

120 M

The control unit features 4 group operating

the

ted with

page

1-3).

MEMORY

MACHINE

symbolsinthe upper right hand

[2]

Chapter 2

Chapter

3

modes

corner

~

AUTOMATIC

(execution of

prograrn)

INFO

These

examples.

In

GOMs

the "INTRODUCTION" chapter

[2]

@]

will be describedinthe following chapters, and iIIustrated with

o the control panel,

o the control elements

o

the

manual panel,

o the control elements of the manual panel and

o the screen layout

theCC120 M

of

the symbols used explained.

Please refer

terms.

will

to

the specialised index at the endofthe

Chapter

Chapter

of

be briefly outJined, instructions on use willbeprovided and

4

5

the panel,

(GOM).which can be selec-

of the control panel (see

manual

for

individual

Abbreviations

BAUD

CNC

OCR Digital Cassette Recorder

DFS

DNC

110

GOM

Kbyte

LSV

MP

Transmission rate (baud rate)inbits/sec

Computerized Numerical Contral

Define Store Program

Direct Numerical Control

InputlOutput

Group Operating Mode

1024

bytes

Proceduretosecure cables

Machine Parameters

Ne NumericaJ Control

P Part program

Pie

RAM

SK

F Feed

MTB

Programmable Interface Controller

Random

Softkey

Machine T

Access Memory

001

Builder

1 - 2

Page 13

(§

BOSeH

Flexible

Automation

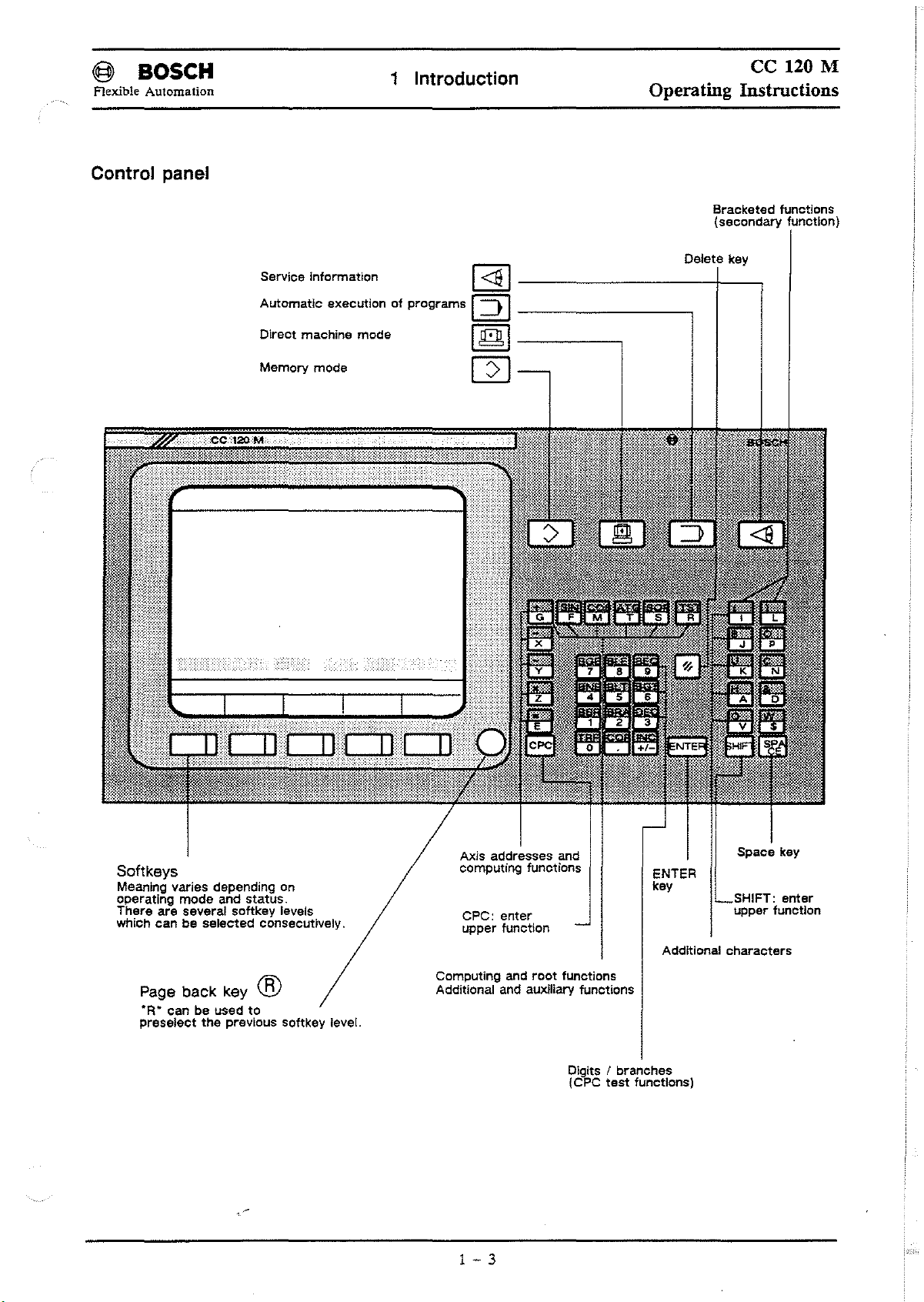

Control panel

Service

Automatie

Dlrect

machine

1 Introduction

Information

executlonofprograms

mode

ce

120 M

Operating Instructions

Bracketed tunetions

(secondary functlon)

Delete key

I

<:a

I-------------+--~

I:JI

I

[[t]

l------~

~

Memory mode

[2]

Softkeys

Meanlng varies depending on

operating mode and status.

There are several softkey levels

which can be selected consecutively,

Page

back

key ®

"R"

can be used

preselect

the

to

previous

softkey

level.

Axis addresses and

computing functions

CPC:

enter

upper function

Computing

Additional and auxiliary functions

and

root

functions

Digits I branches

ICPC

test

1 - 3

ENTER

key

Additional

tunetions )

Space key

SHIFT: enter

upper functlon

characters

Page 14

@ BaSeH

Flexible Automation

1 Introduction

ce

120 M

Operating Instructions

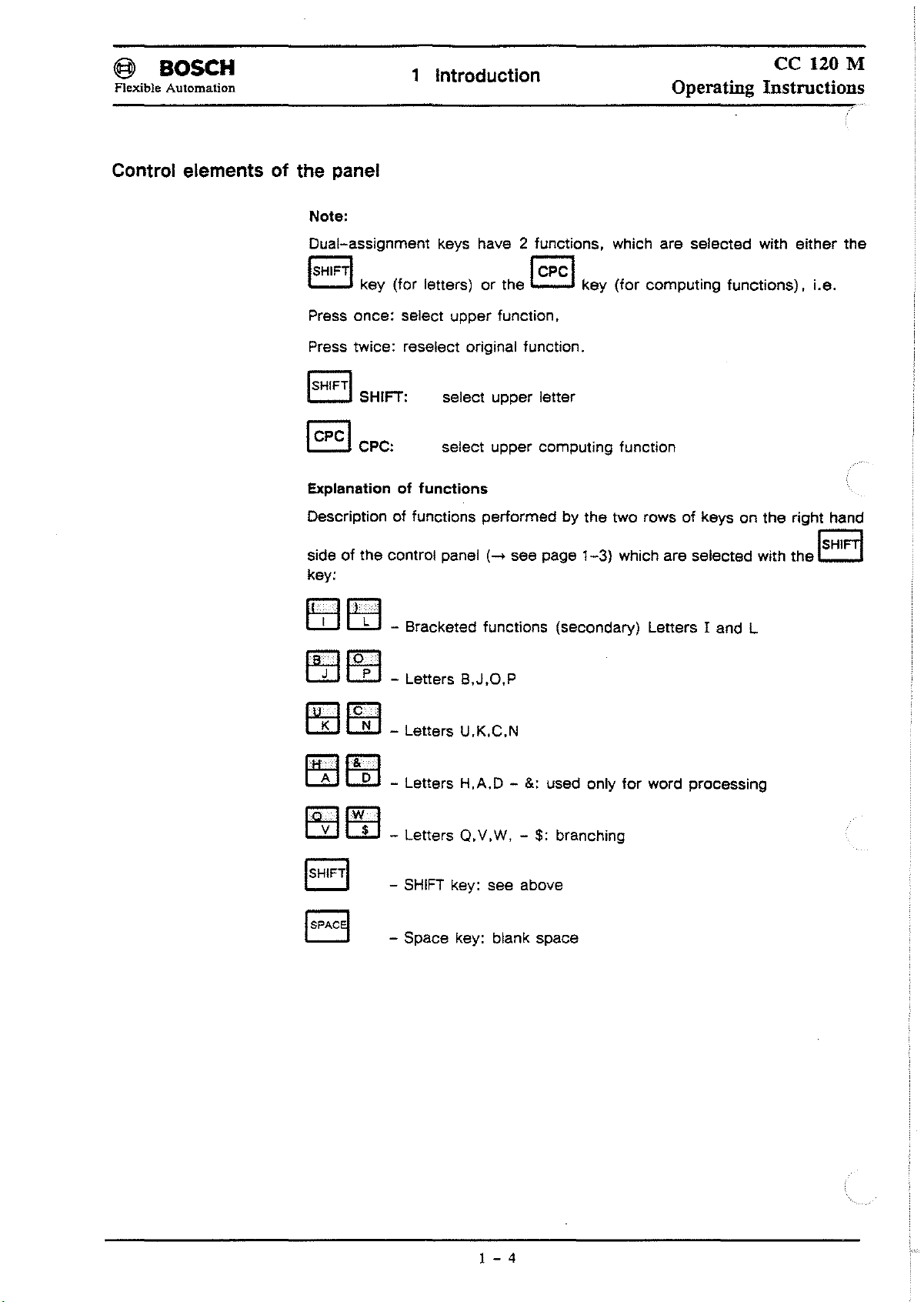

Control elements

of

the panel

Note:

Dual-assignmenl

ISH'FTI

Press

Press

ISH'FTI

I

CPcl

Explanation

Deseriplionoffunelions

sideofIhe

key:

key

(for leiters)orIhe

onee:

Iwiee:

SHIFT:

CPC:

conlral

keys have 2 funelions. whieh

ICPCI

seleel

reselecl

of

upper

original funetion.

seleel

selecl

functions

panel

funelion.

upper

upper

performedbyIhe

(-+

leller

compuling

see

page

are

selecled

key

(for

eompuling

funelion

IwO rowsofkeysonIhe

1-3)

which are

selecled

with

funclions).

with

eilher

Le.

righl

the

Ihe

hand

~

c:::.J

eTI~

EZlEtJ

IUKIIC~1

~~

~~

- Bracketed funclions (secondary)

- Leiters B,J,O,P

_

Leiters

-

Leiters

-

Leiters

SHIFT

-

- Space key: blank spaee

U.K,C,N

H.A,D-&:

Q.

v.

W, -

key:

see

used only

$:

above

branching

for

Leiters

word

land

L

processing

1 - 4

Page 15

@ BOSCH

Flexible Automation

ce

1 Introduction

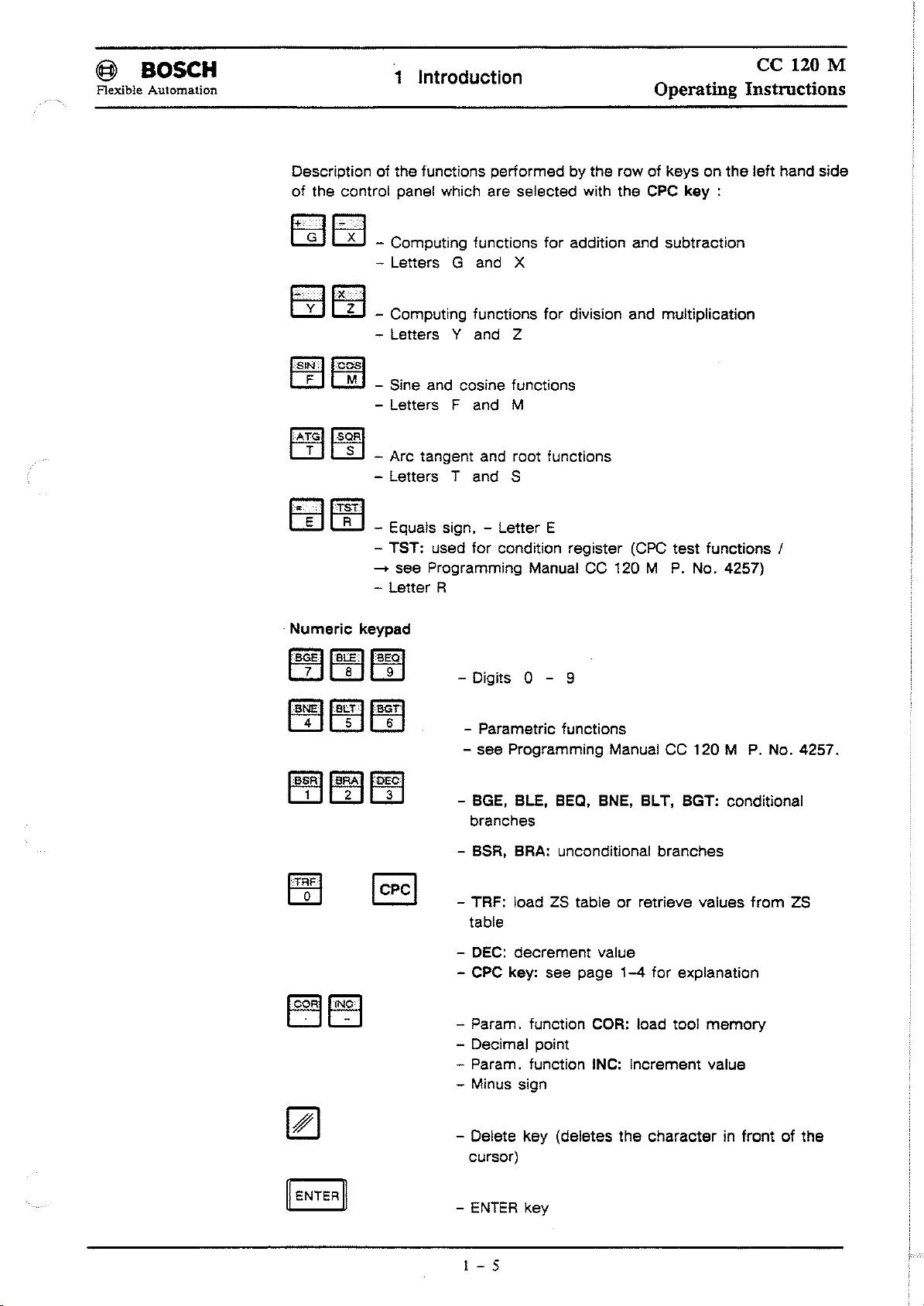

Description of the functions performed by the row of keys on the left hand side

of the control panel which are selected wlth the

- Computing functions for addition and subtraction

- Letters G and X

- Computing functions for division and multiplication

- Letters Y and Z

Operating

CPC

key

:

120 M

Instructions

ISI~llc~1

IA~GIIS~RI

.

Numeric

IB~EIIB~lla~ol

_Sine and eosine funetions

- Letters

_Are tangent and root funetions

- Letters T and S

- Equals sign, - Letter E

- TST: used for eonditlon register (CPC

-+

see Programming Manual

-

letter

keypad

Fand

R

- Digits 0 - 9

- Parametric functions

- see Programming Manual CC 120 M

-

M

BGE.

BlE.

branches

CC

BEQ.

BNE.BlT. BGT: eonditional

t20 M

test

funetions !

P.

No. 4257)

P.

No. 4257.

- BSR. BRA: uneonditional branehes

- TRF: load ZS table

table

-

DEC:

deerement value

-

CPC

key: see page

- Param. funetion

- Decimal point

- Param. funetion INC: Increment value

- Minus sign

- Delete key (dele1es the eharaeter in front of the

cursor)

ENTER

-

1 - 5

key

or

retrieve values

1-4

COR:

load tool

for explanation

memory

from

ZS

Page 16

@ BOSeH

Flexible

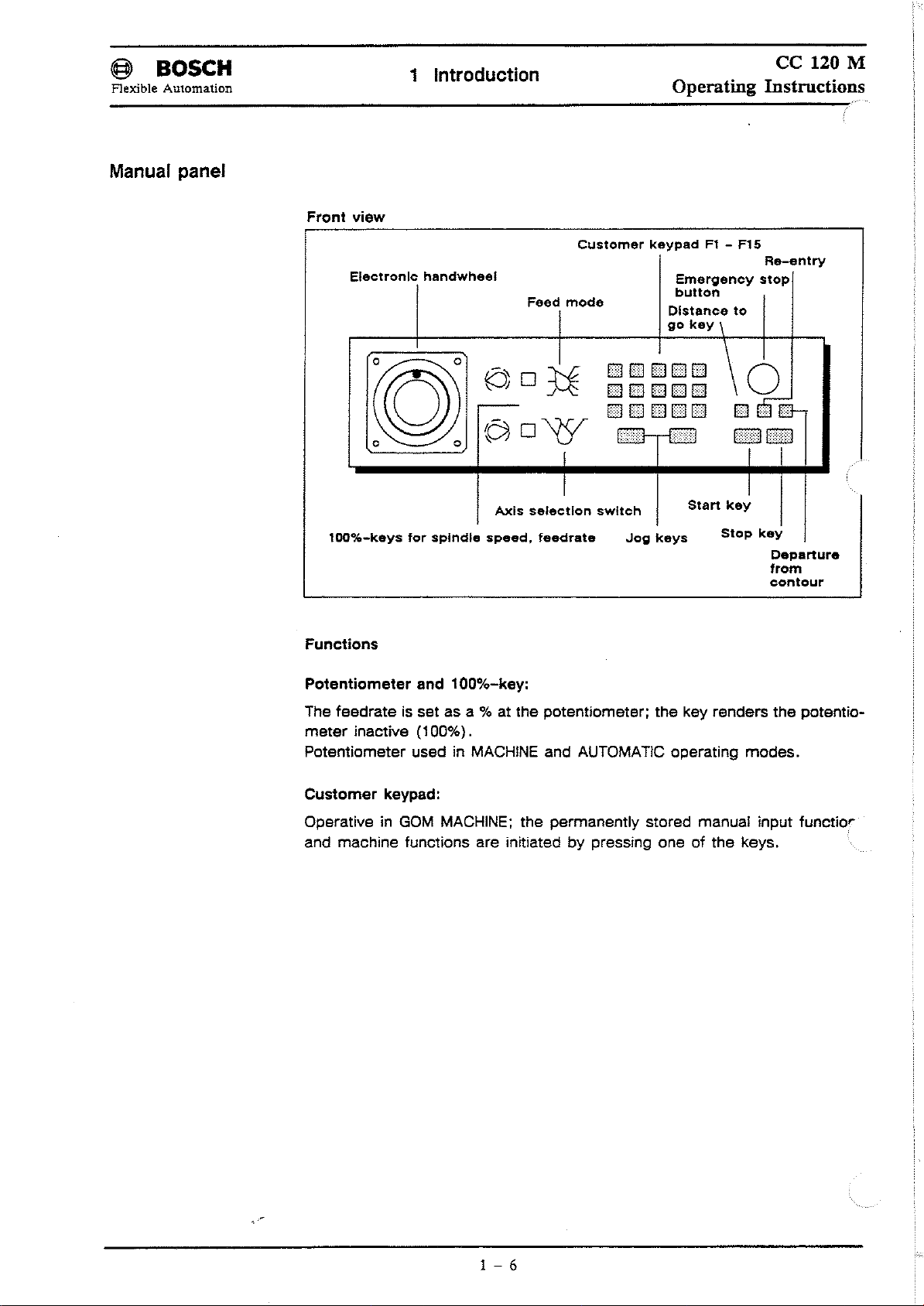

Manual panel

Automation

Front

view

1 Introduction

ce

120 M

Operating Instructions

Electronlc

100%-keys

Functions

Potentiometer

handwheel

Axis

tor

spindie

and 100%-key:

speed,

Feed

mode

selectlon

feedrate

Customer

keypadFI-

E1E1E1E1EJ

E1EJEJDEJ

EJEJEJEJEJ

==

""'"'

swltch

Jog

Emergency

button

Distance

go

key

=

==

Start

keys

FI5

Re-entry

stop

to

\

\0

E11IJ-

Eill:HBIB

key

Stop

key

Departure

trom

contour

The feedrate is set as a % at the potentiometer; the key renders

meter

Potentiometer used in MACHINE and AUTOMATIC operating

Customer

Operative in

and maehine tunetions are initiated by pressing one

inaetive (100%).

keypad:

GOM

MACHINE; the permanently stored manual input funetior

of

the keys.

modes.

the

potentio-

1 - 6

Page 17

(§l

Flexible

BOSCH

Automation

1 Introduction

Operating

ce

120 M

Instructions

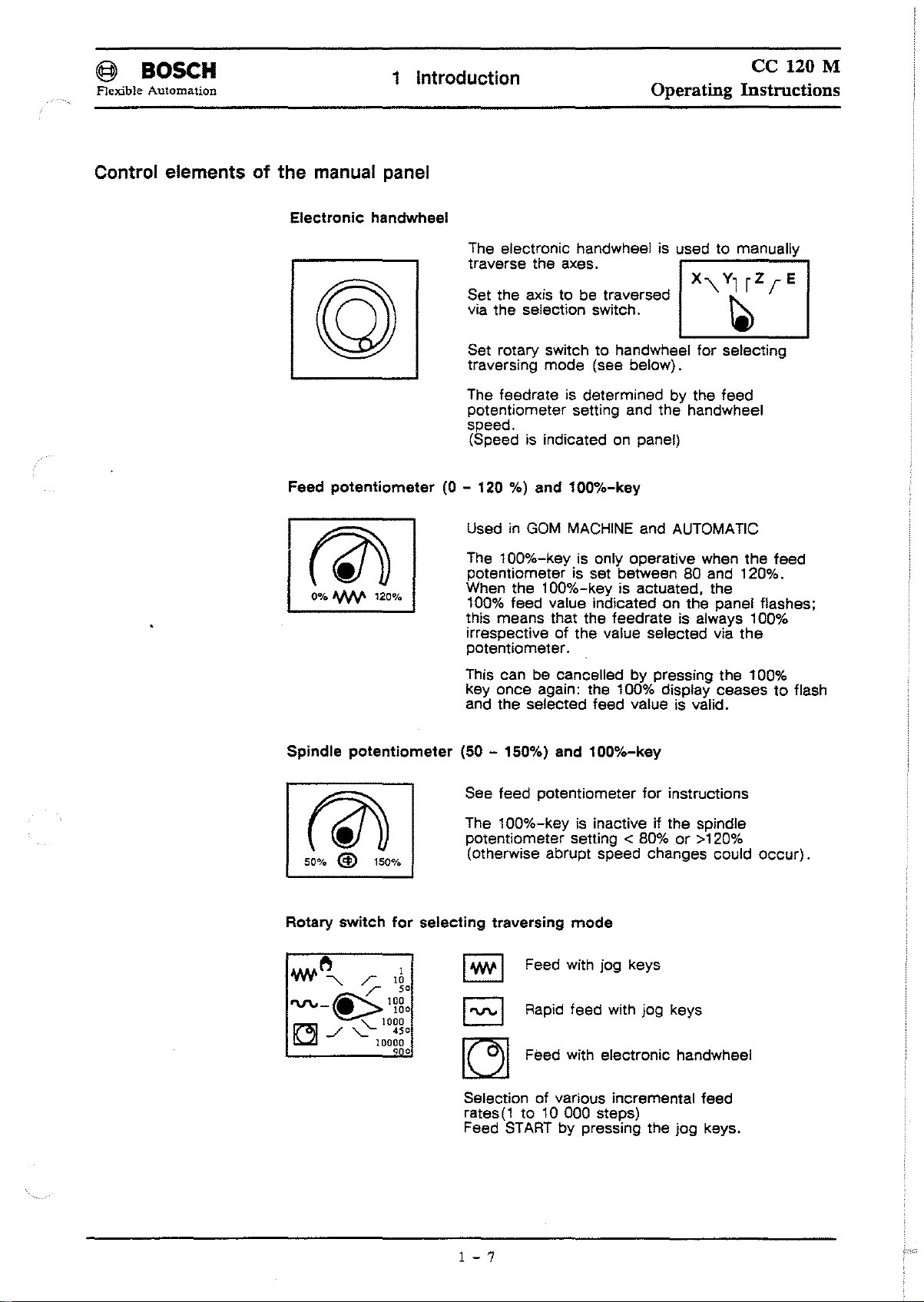

Control elements of

the

manual panel

Electronic

potentiometer

Feed

0%

ANV'

handwheel

120%

The eleetronie handwheel is used to manually

traverse the axes.

Set the axis to be traversed

via the seleetion switch.

Set rotary switch

traversing

The leedrate is determined

potentiometer setting and the handwheel

speed.

(Speed is indicated on panel)

(0 - 120 %) and

Used in

The

potentiometer is set between 80 and 120%.

When the 100%-key is actuated. the

100%

this means that the

irrespective

potentiometer.

mode

GOM

100%-key

leed

to

handwheel

(see below).

100%-key

MACHINE

is only operative when the

value indieated on the panel flashes;

01

the value seleeted via

and AUTOMATie

leedrate

lor

selecting

by

the

leed

is always 100%

leed

the

Spindie

potentiometer

atu

50%

@)

Rotary

switch

150%

lor

This ean be cancelled by pressing the 100%

key

and the selected

(50 - 150%) and

See

The 100%-key is inactive il the spindie

potentiometer setting

(otherwise abrupt speed changes could oeeur).

selecting

I

Wo/'

I

'V'\.o

~

Selection

rates(1to

Feed

once

again: the 100% display ceasestoflash

leed

potentiometer

traversing

leed

100%-key

mode

value is valid.

lor

instructions

< 80%

or

>120%

I Feed with jog keys

I Rapid

STARTbypressing the

leed

with jog keys

Feed with eleetronic handwheel

01

various incremental

10 000 steps)

jog

leed

keys.

1 - 7

Page 18

@ BOSeH

Flexible Automation

1 Introduction

Operating

ce

120 M

Instmctions

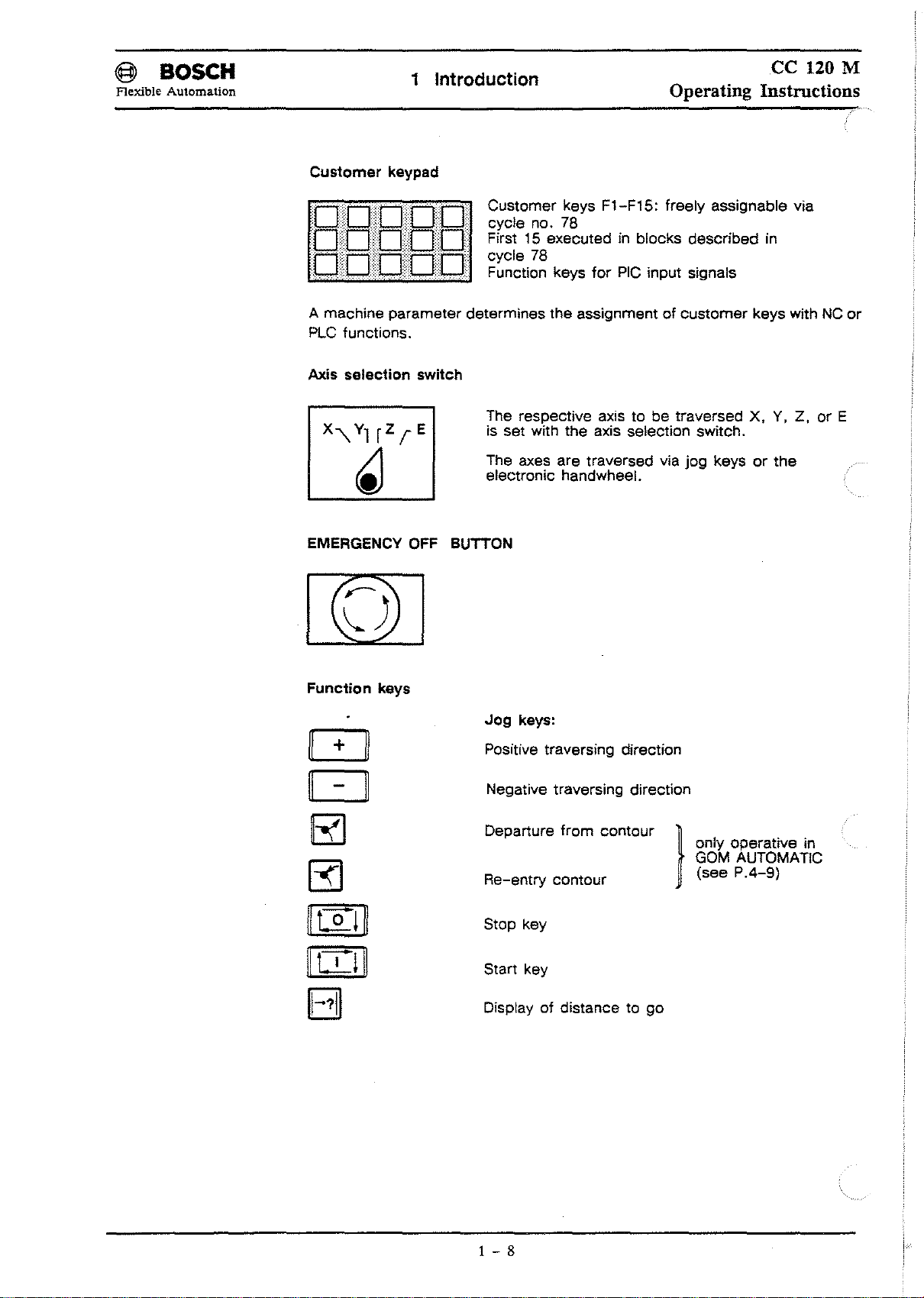

Customer

A machine parameter determines the assignment

PLC

Axls

EMERGENCY OFF BUTTON

keypad

lunctions.

selection

switch

Customer keys F1-F15: Ireely assignable via

cycle no. 78

First

15

executed in blocks described in

78

cycle

FunClion keys

The respective axis to be traversed

is set with the axis selection switch.

The axes are traversed via jog keys

electronic handwheel.

lor

PIC

input signals

01

customer

keys with NC

X.

Y,

Z,orE

or

the

or

Function

keys

[!]

c:J

~

~

~tIjll

II[D~

BI

Jog

keys:

Positive traversing direction

Negative traversing direction

from

Departure

Re-entry contour

Stop key

Start key

Display

01

contour

}

distance to go

only operative in

GOM AUTOMATIC

(see

P.4-9)

1 - 8

Page 19

~

BOSCH

Flexible Automation

1 Introduction

ce

120 M

Operating Instructions

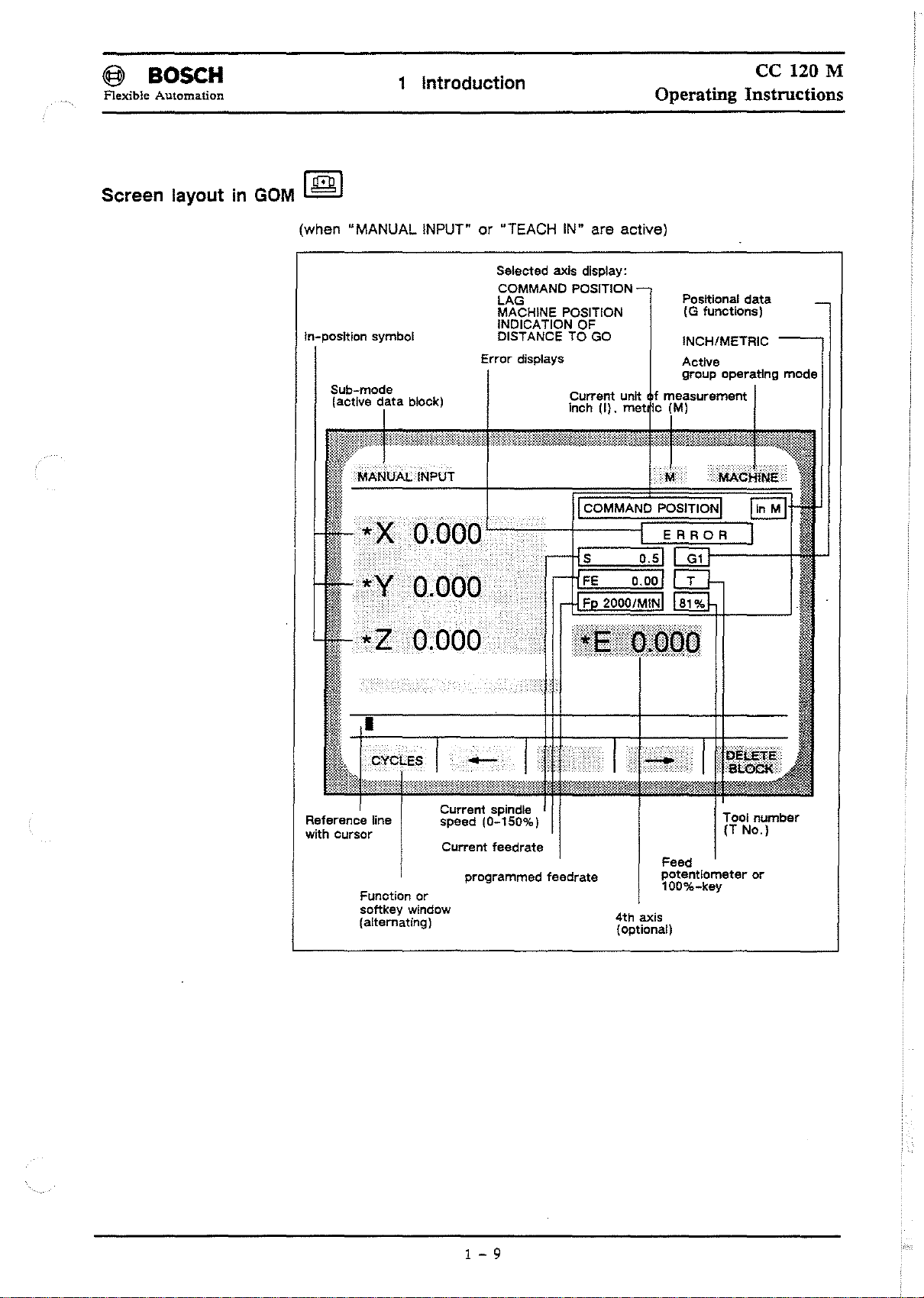

Screen layout in

GOM

I

([iJJ

I

(when "MANUAL INPUT"or"TEACH IN" are active)

Selected axls display:

COMMAND POSITION

LAG

MACHINE POSITION

ln-position symbol

Sub-mode

(actlve

data

block)

OIO()

INDICATION OF

DISTANCE

Error

displays

t

-t:C:o:M::M=A~NrD=P~O~S~I~T~IO~N=;;-_jlln

TO

GO

Current unlt

Inch

(I).

met

S

Posltional

(G lunctlons)

INCH/METRIC

Actlve

group operating

data

mode

MI

Reference line

with

cursor

Function

softkey

(altemating1

Current spindie

speed (0-150%)

Current

cr

window

feedrate

programmed teedrate

4th

axis

(optionai)

Tool

(T

Feed

potentiometer

100%-key

number

No.)

cr

1 - 9

Page 20

@ BOSCH

Flexible Automation

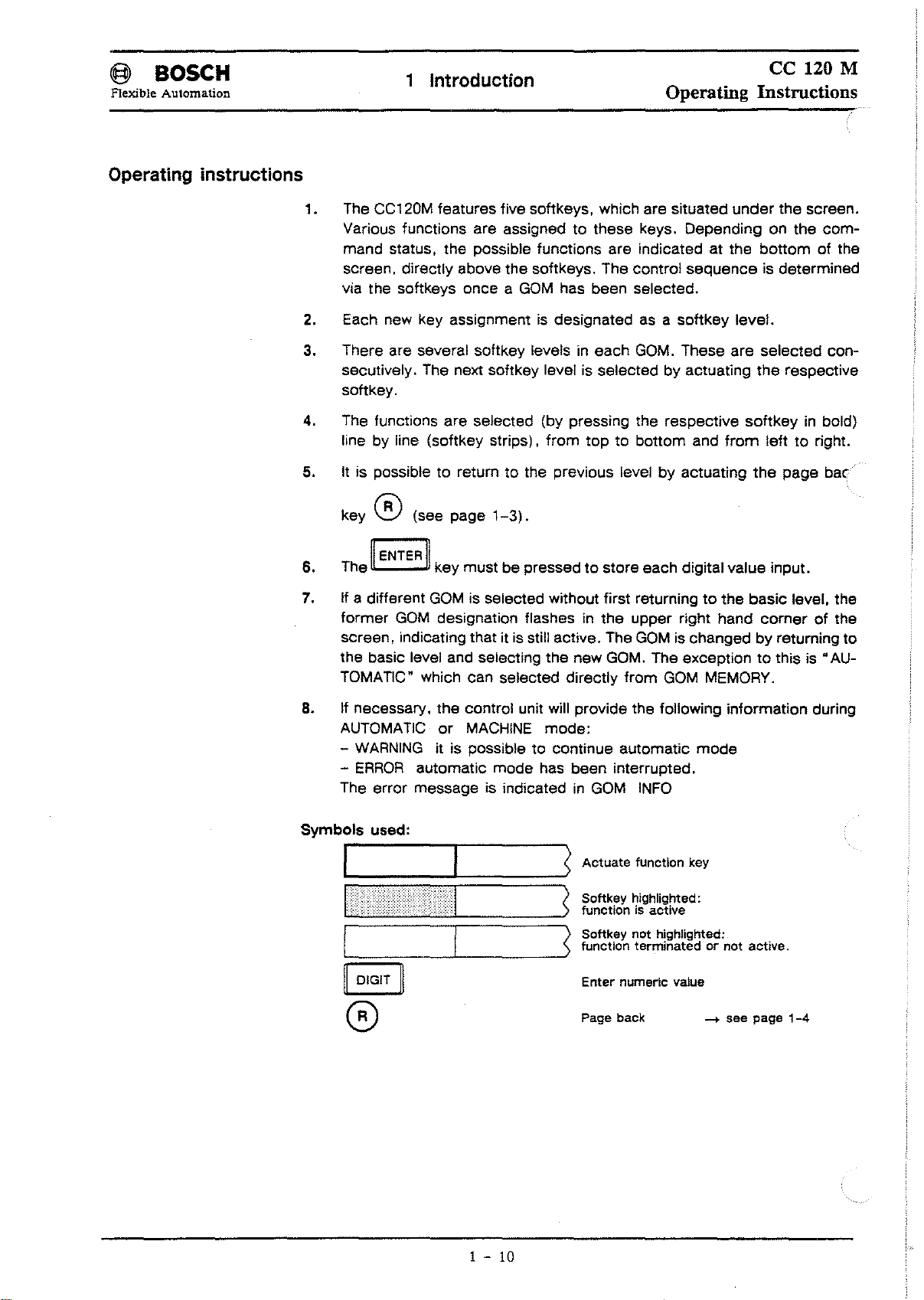

Operating instructions

1 Introduction

ce

120 M

Operating Instructions

1. The CC120M leatures live soltkeys. whieh are situated

Various lunetions are assigned

mand status. the possible lunetions are indieated at the bOllom01the

sereen, direetly above the soltkeys, The eontrol sequenee is determined

via the soltkeys onee a

2.

Eaeh new key assignment is designated as a

3. There are several soltkey levels

seeutively. The next soltkey level is seleeted by aetuating

softkey.

4, The funetions are seleeted (by pressing the respeetive

line by line (soltkey strips).

5.

It

is possible to returntothe previous level

key ® (see page

11

6.

7.

ENTERII

The key must be pressedtostore eaeh digital value input.

II a different

former

sereen, indieating that it is still aetive. The

the basie level and seleeting the new GOM. The exeeption

TOMATIC" whieh ean seleeted direetly

GOM

is seleeted without

GOM

designation Ilashesinthe

GOM

1-3).

to

these keys. Depending on the

has been seleeted,

in

eaeh

GOM,

Irom

toptobOllom and

lirst

returningtothe basie level. the

upper right hand

GOM

from

soltkey

These are seleeted eon-

by

aetuating

is ehangedbyreturning to

GOM

under

level.

the

soltkeyinbold)

lram

the

eorner01the

to

MEMORY.

the sereen.

eom-

respeetive

lefttoright.

page

bat?

this is

"AU-

8.

II

neeessary. the eontrol unit will provide the following information during

AUTOMATIC

-

WARNING

-

ERROR

The error message is indieated

===~======:

'-

or

MACHINE

it is possible to eontinue automatie

automatie mode has been interrupted,

mode:

in

S

Actuate

Softkey highlighted:

functionlsactive

) Softkey not highlighted:

>functlon terminated or not active.

Enter numeric

Page back

GOM

INFO

functlon key

vaiue

mode

-+

see page

1-4

1 -

10

Page 21

Page 22

Page 23

@ BOSCH

Flexible

Automation

Memory

[2]

ce

120 M

Operating Instructions

GOM

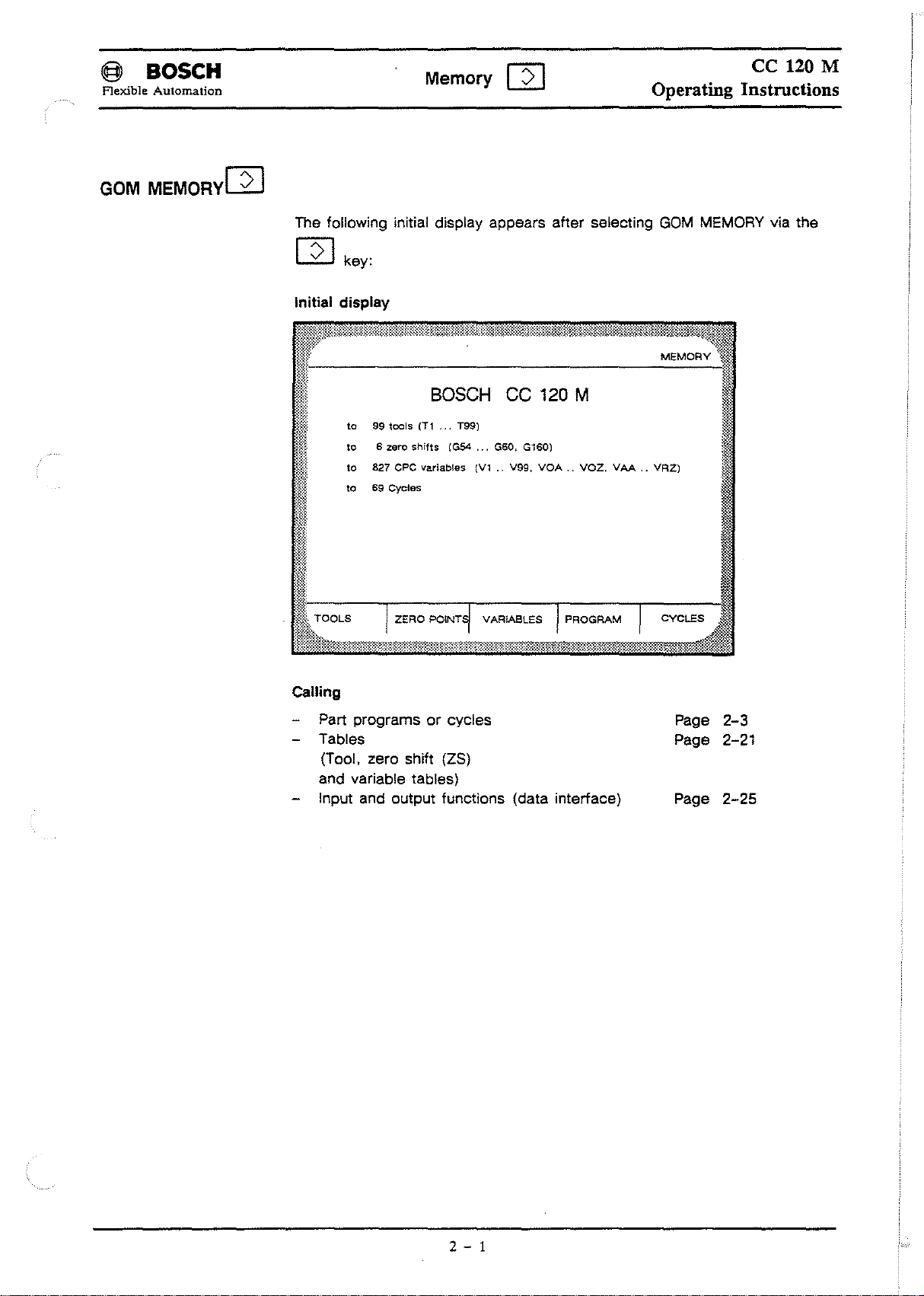

MEMORy[2]

The following initial display appears after selecting

[2]

key:

Initial display

to

99

tools

to6zero

to

827

to

69

Cycles

CPC

BOSCH

(Tl

>

shifts

variables

••

(G54

T99)

CC

...

G60,

(V1..V99,

VARIABLES

120

G160)

VOA..VCZ,

M

VAA..VR2)

GOM

MEMORY via the

MEMORY

Calling

or

Part programs

cycles

Tables

(Tool. zero shift (ZS)

and variable tables)

Input and output functions (data interface)

Page

2-3

Page 2-21

Page

2-25

2 - 1

Page 24

@ BOSCH

Flexible Automation

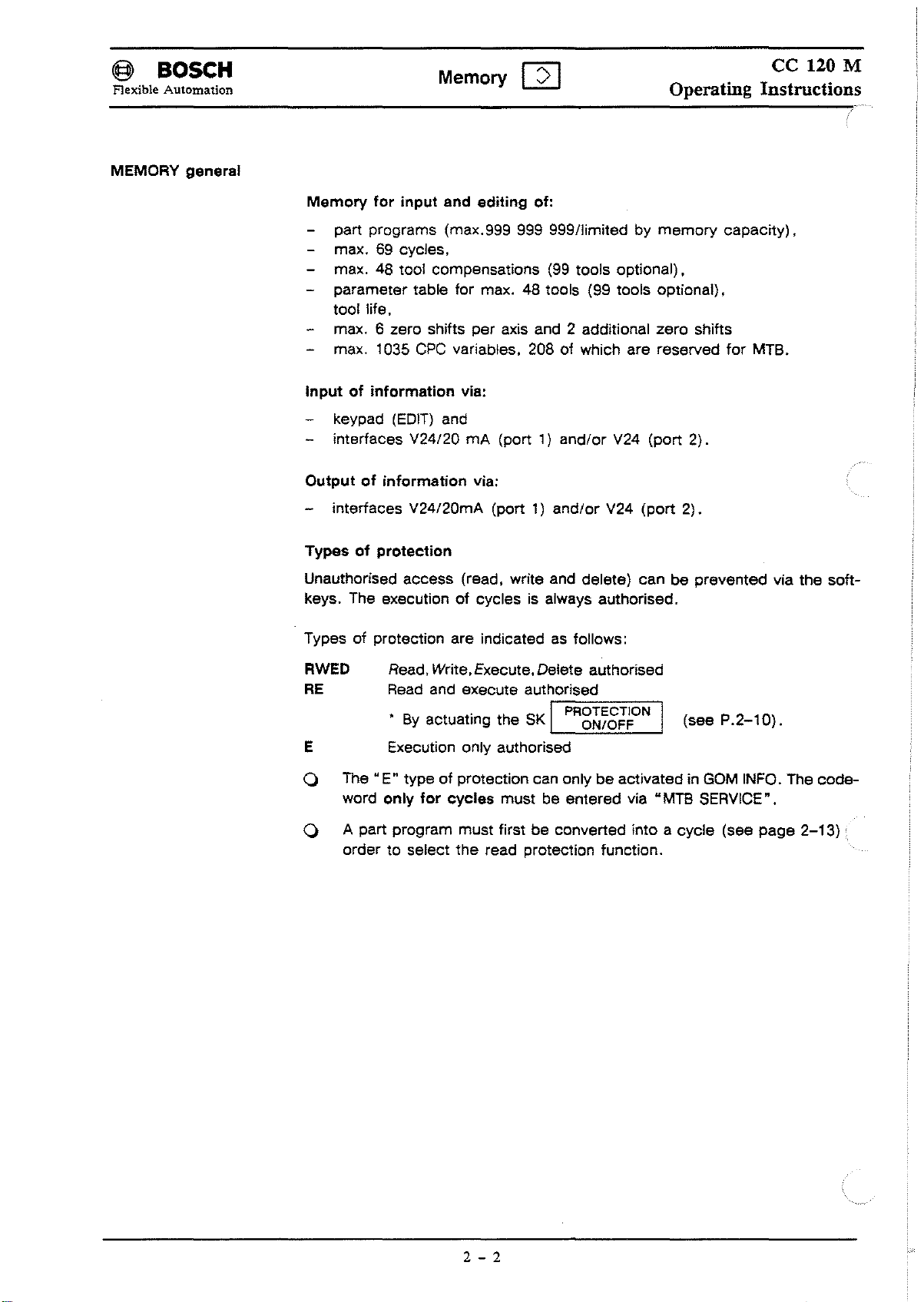

MEMORY general

Memory

[2]

ce

120 M

Operating Instructions

Memory

Inputofinformation

Outputofinformation

Typesofprotection

Unauthorised access (read, write and delete) can be prevented via the

keys. The executionofcycles is always authorised.

Types of protection are indicated as folIows:

for

input

and

editing

part programs (max.999 999 999/limited by

max.

69

cycles,

max. 48 tool compensations

parameter table for max. 48 tools (99 tools optional) ,

tool Iife,

max. 6 zero shifts per axis and 2 additional

1035

CPC

max.

keypad

interfaces V24/20

interfaces V24/20mA (port

(EDIT)

variables, 208 of which are reserved

via:

and

mA

via:

of:

memory

(99

tools optional),

zero

shifts

(port1)and/or V24 (port 2).

1)

and/or

V24 (port 2).

capacity) •

for

MTB.

soft-

RWEO

RE

E Execution only authorised

o The

o

Read, Write,Execute,Delete authorised

Read and execute authorised

,

By

actuating the

"E"

type of protection can onlybeactivated in

word

only

for

cycles

Apart

order to select

program must first be converted into a cycle (see

the

read protection function.

must be entered via "MTB SERVICE" .

~-'---~

SK

PROTECTION

ON/OFF

(see

P.2-10).

GOM

INFO. The

page

2-13)

code-

2 - 2

Page 25

I@

Flexible Automation

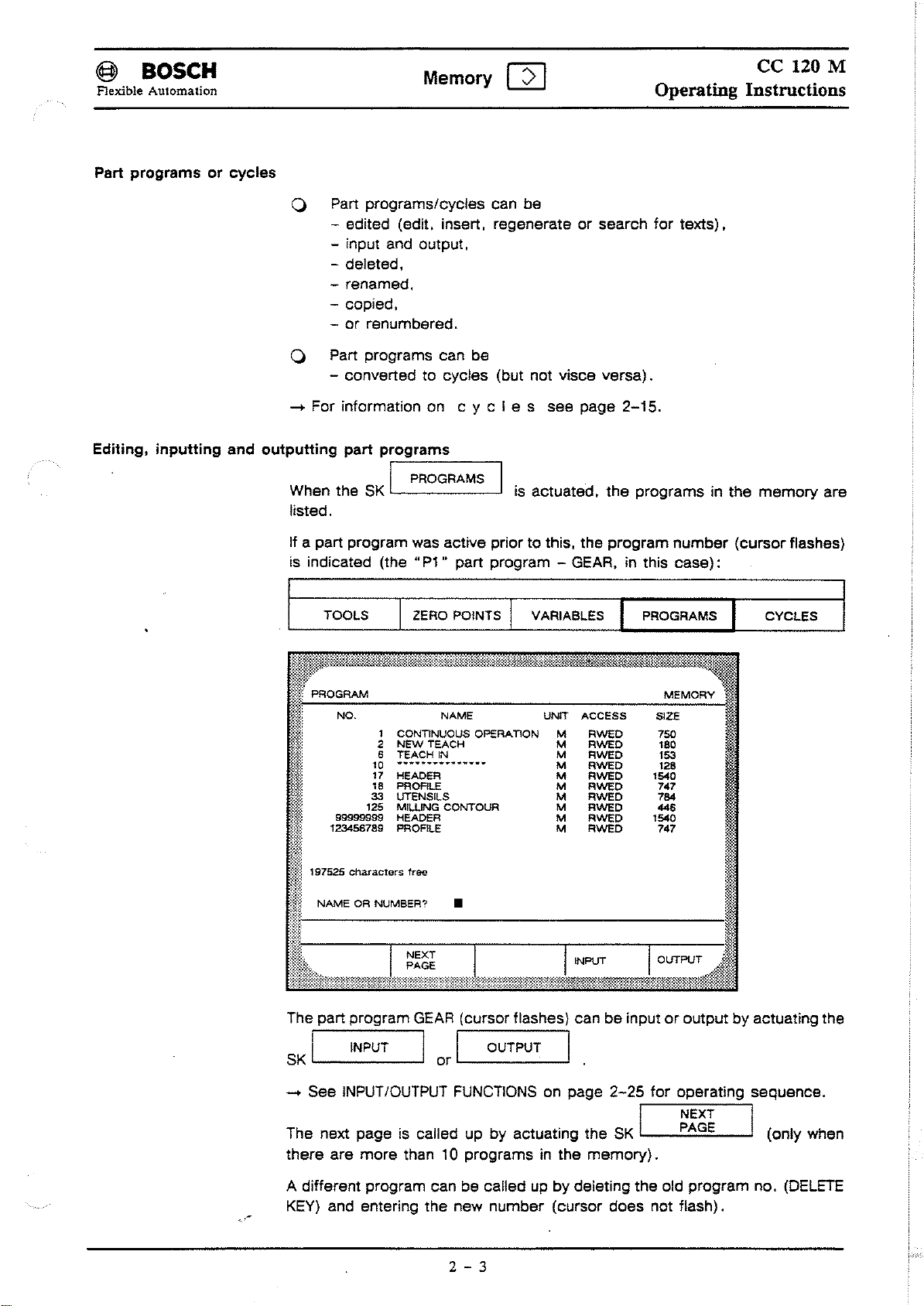

Part programs or cycles

BOSCH

Memory

o Part programs/cycles can be

- edited (edit. insert, regenerate or search for texts),

- input and output.

- deleted,

- renamed,

- copied,

-

or

renumbered.

o Part programs can be

- converted to cycles (but not visce versa).

--+ For information on c y c 1e s see page 2-15.

Editing, inputting and outputting part programs

PROGRAMS I

When the

listed.

SK

I

[2]

is

actuated,

Operating Instructions

the

programs in the

ce

120 M

memory

are

apart

If

is indicated (the

program was active prior to this, the program

"P1"

part program -

TOOLS I ZERO POINTS r VARIABLES I PROGRAMS I CVCLES

GEAR,inthis

number

case):

(cursorflashes)

The part program

SK

I INPUT IorI OUTPUT I.

--+ See

The next page is called up by actuating the

there are more than

A different program can be calied up by deleting the old program no.

KEY)

INPUT/OUTPUT

and entering the new number (cursor does not flash).

GEAR

(cursor flashes) can be inputoroutput by actuating the

FUNCTIONS

10 programs in the

2

- 3

on page

memory).

2-25

for operating sequence.

SK

I

~;~~

I (only when

(DELETE

Page 26

@l

BOSeH

Flexible Automation

Memory

C8

ce

120 M

Operating Instructions

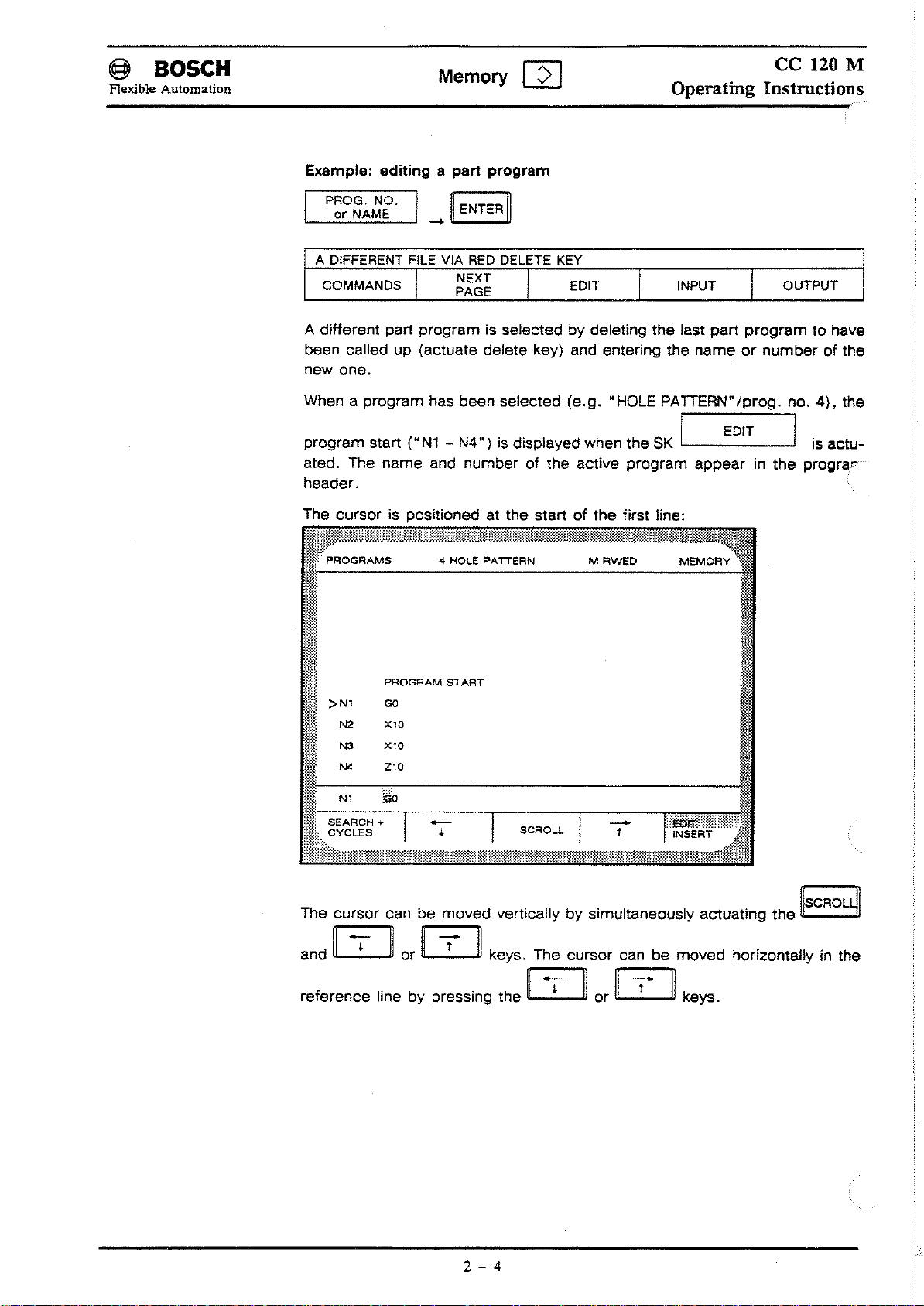

Example: editing

PROG. NO. I

or

NAME .

A DIFFERENT FILE VIA

COMMANDS

A different part programisselected by deletlng

been called up (actuate delete key) and entering the

new

one.

When a program has been selected (e.g. "HOLE PATIERN"/prog. no.

program start

ated, The name and number of the active program appear

header.

The cursor is positloned at the start of

apart

_~

~

T NEXT I EDIT

("N1-N4")

~

ENTER

RED

PAGE

program

~

DELETE KEY

Is

dlsplayed when the SK I EDIT I

the

MRWED

I

the

first line:

INPUT I OUTPUT

last part

nameornumber

MEMORY

program

In

the

to have

of the

4),

the

Is

actu-

prograr

N2

PROGRAM

GO

X10

I

>Nl

I

;:;:~.:

The cursor can be moved vertlcally by simultaneously actuating

and

~

reference line by pressing the

START

or [[Z]] keys. The cursor can be moved horizontally in the

~

or

iC1:J]

keys.

the

IlsCROLyl

2 - 4

Page 27

@ BOSCH

Flexible Automation

Memory

[2]

ce

120 M

Operating Instructions

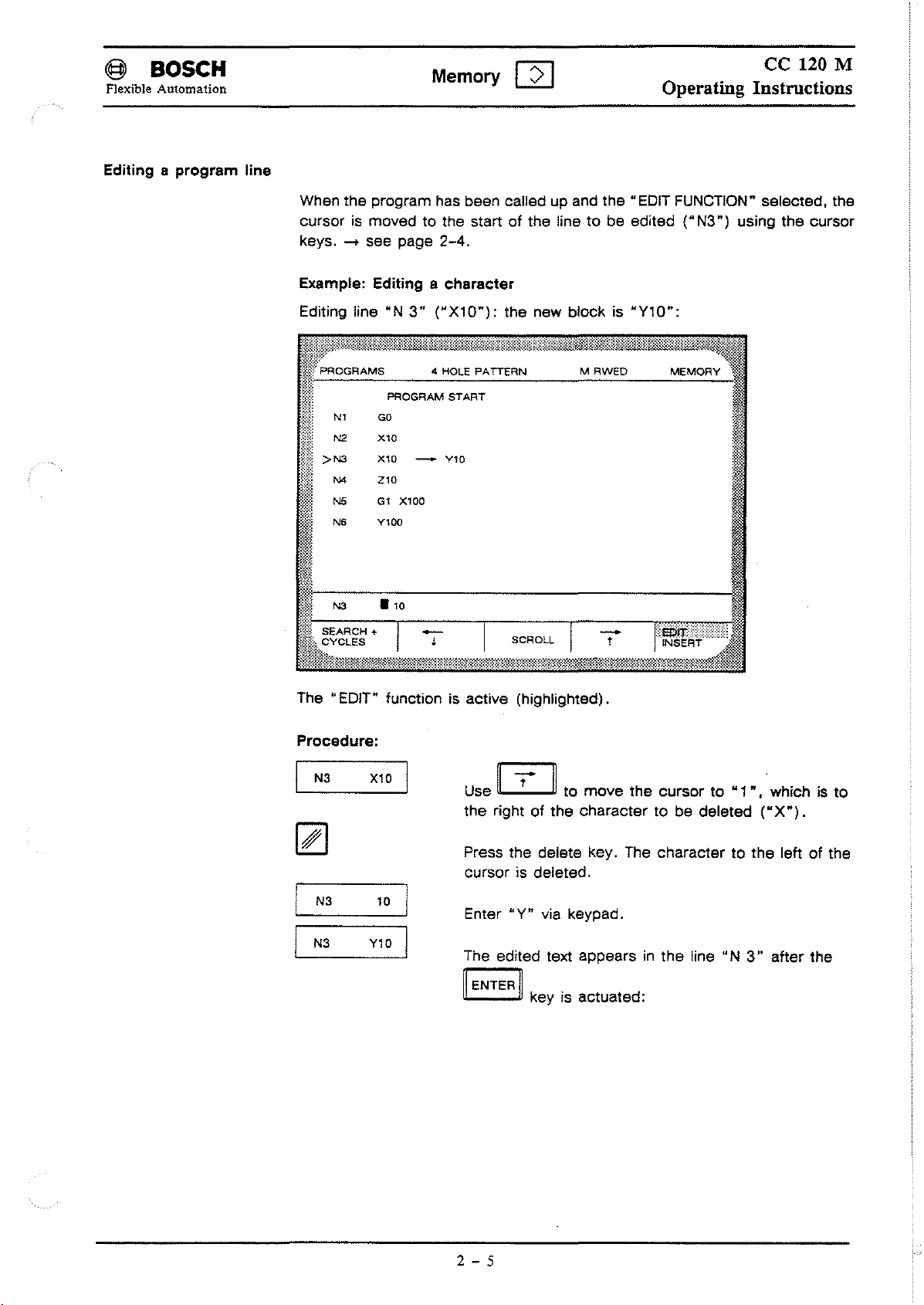

Editing a

program

line

When the program has been called up and the "EDIT FUNCTION" selected, the

cursor is moved to the start

-+

keys.

Example: Editing a

Editing line "N

};:~~

~~j

see page

PROGRAM

Nl

GO

Xl0

N2

N4

N5

N6

Xl0

Z10

Gl

Yl00

>N3

2-4.

character

3"

("X10"):

4 HOLE PATTERN

START

Yl0

-

X100

of

the linetobe edited

the new blockis"Y10":

MRweo

("N3")

MEMORY

using the cursor

I

1--N3---.-,0------------------

The "EDIT" functionisactive (highlighted).

Procedure:

I

N3

N3

N3

X10

10

Y10

Use [I2JI to

the right

Press the delete key. The charactertothe

cursor is deleted.

Enter

The edited text appearsinthe

~

ENTER

of

"Y"

~

key is actuated:

move

the

character to

via keypad.

the

cursorto"1",'

be

deleted

line

"N

which is to

("X").

leftofthe

3"

after the

2 - 5

Page 28

@

BOSCH

Flexible Automation

Memory

[2]

ce

120 M

Operating Instructions

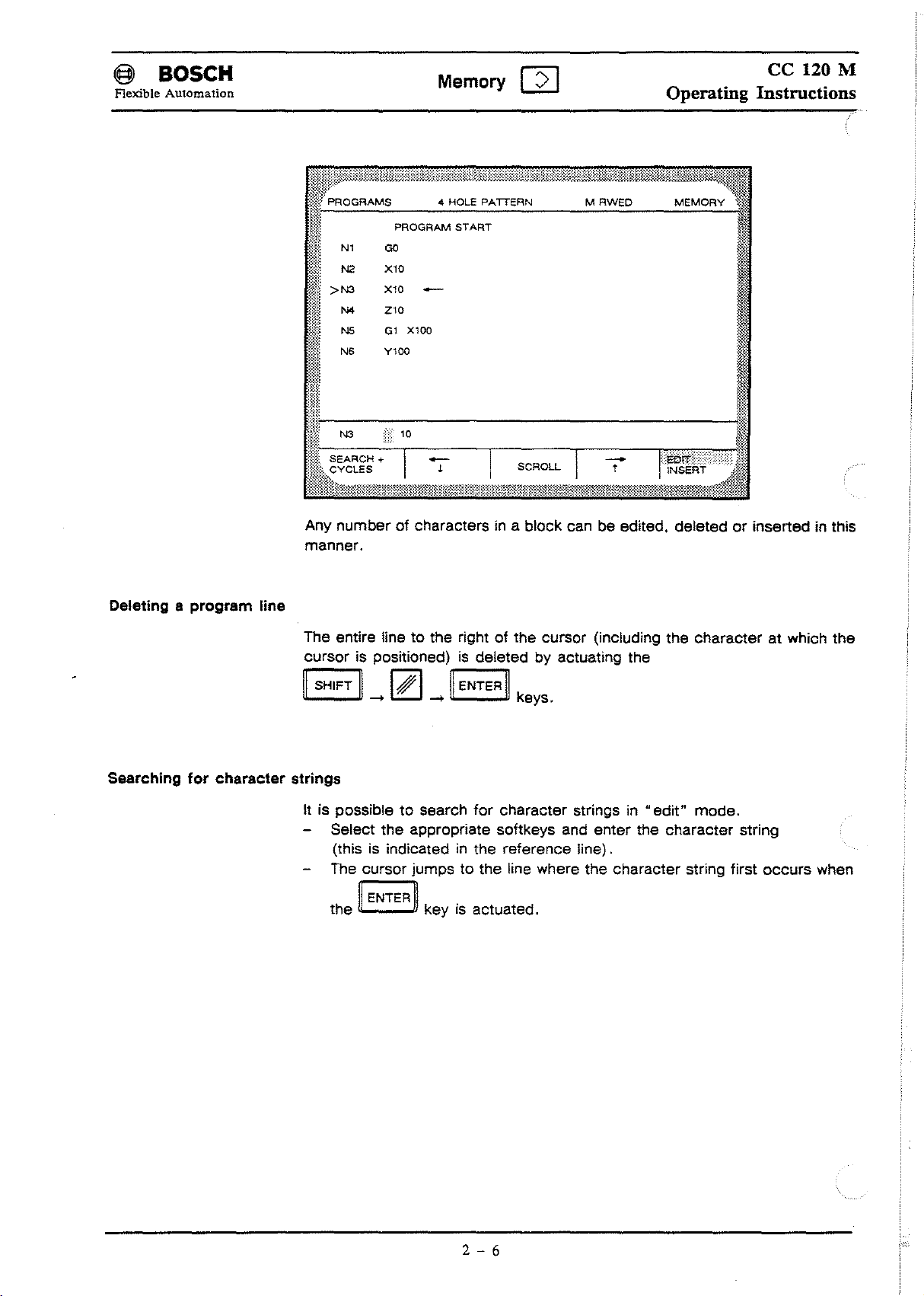

Any

manner.

Deleting a program line

The entire !inetothe rightofthe cursor (including the

cursor

11

SHIFT

Searching for character strings

It is possibletosearch

numberofcharacters in a block can be edited, deletedorinserted in this

character

is positioned)isdeleted by actuating the

~

I# I

-+ -+

Select the appropriate softkeys and enter the

(this is indicated

The cursor jumps to the line where the character strlng first

~

ENTER

the keyisactuated.

~

11

ENTER

in

~

keys.

for

character strings in

the reference !ine).

"edit"

character

mode.

at which the

string

occurs

when

2 - 6

Page 29

@ BOSeH

Flexible Automation

Memory [2]

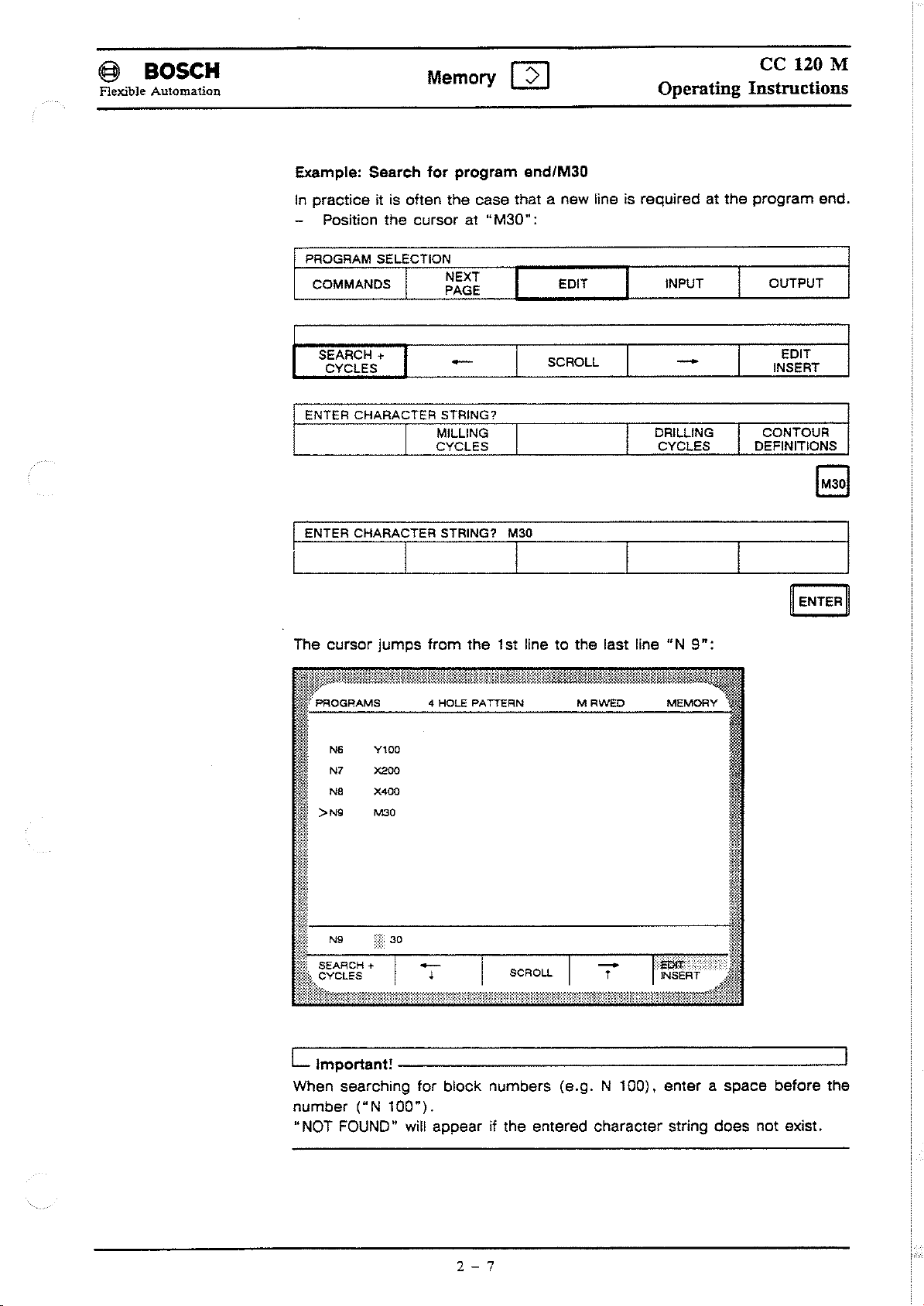

Example: Search tor program end/M30

In

pracliceilis

Position the cursor at

PROGRAM SELECTION

COMMANDS

otlen the case that a new line is required at

"M30":

I NEXT

PAGE

EDIT

I

ce

Operating Instructions

the

program end.

INPUT I OUTPUT

I

120 M

SEARCH

CVCLES

ENTER CHARACTER STRING?

ENTER CHARACTER STRING? M30

__

The cursor

+

MILLING I

I

CVCLES

I 1

jumps

Yl00

><200

X400

MOO

trom

-

the 1st line 10 the last line

SCROLL

I

-

DRILLING

CVCLES

"N

9":

INSERT

CONTOUR

I

DEFINITIONS

,.

EDIT

~!

L Important!

When searching tor block numbers (e.g. N 100).

number

"NOT FOUND" will appear it the entered character string does not exisl.

-----------------------'

("N

100").

2 - 7

enler

aspace

betore the

Page 30

@>

BOSeH

Flexible Automation

Memory

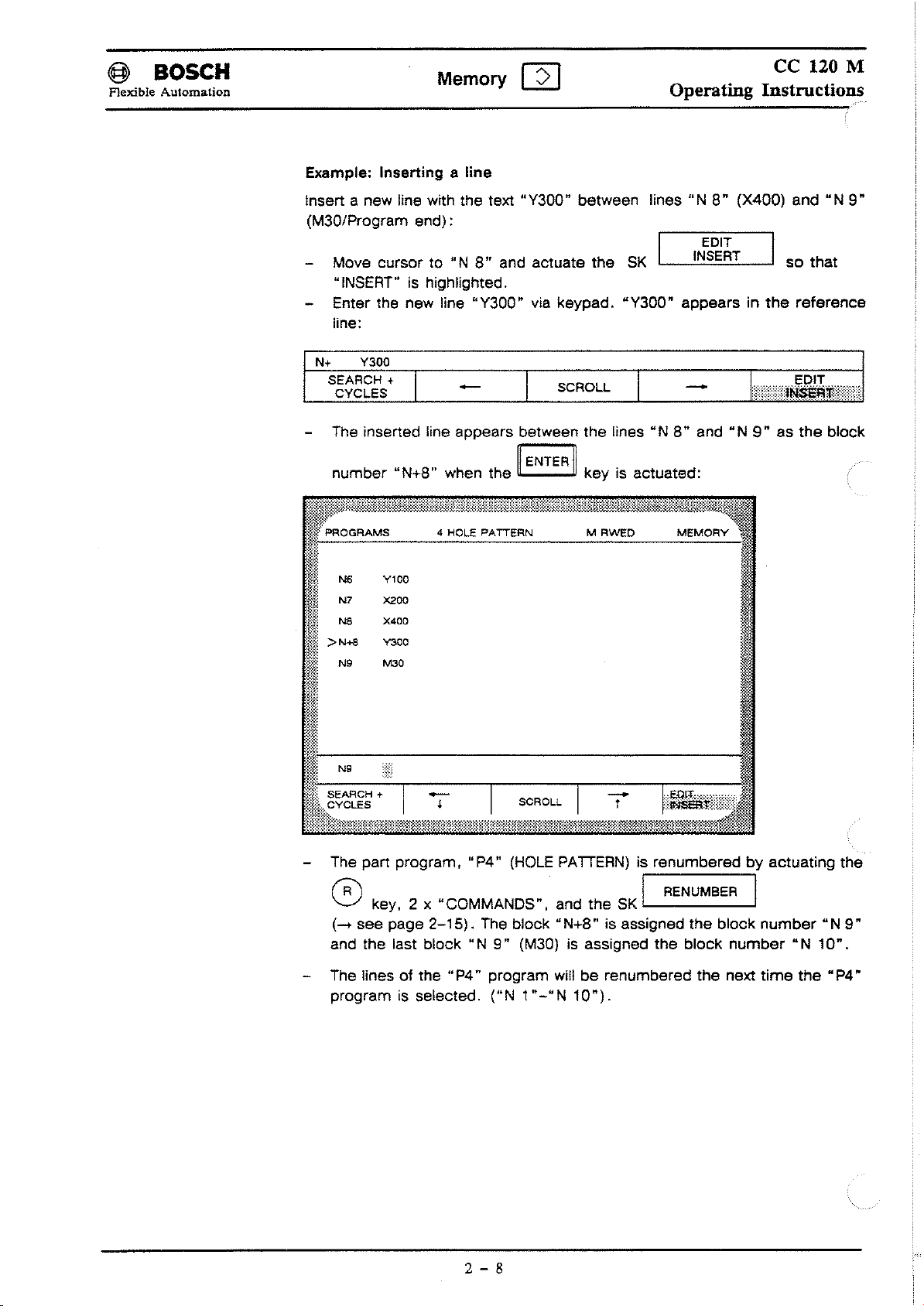

Example: Inserting a line

[2]

ce

120 M

Operating Instructions

Insert a new line with the text "Y300" between

(M30/Program

Move cursor to "NS"and actuate the

"INSERT" is highlighted.

Enter the new fine

fine:

N+

Y300

SEARCH + I

CYCLES

The inserted

number "N+S" when the key is actuated:

end):

"Y300"

-

fine

appears between the fines"NS" and

via keypad. "Y300"

SCROLL I

I

~

ENTER

~

lines"

N S" (X400) and"N9"

SK

I_-,-IN"ES::.~::;I~"T,-_I

appears in

so that

the

relerence

-

"N9"as

the

block

~j!~::~~~i%Wjt'l~jl::~'::~:~~~i!lWMlli~~:@NM&=~'

J:

::

I

F~::

11'-----------------------

lf:~

N9

a SEARCH + I - I I

i:I;li,t:~~~:1wim;;wH1#:m'i!i'wlf:'i!",l

The part program,

fR\ I RENUMBER I

v key, 2 x "COMMANDS", and the

(-+

see page

and the last block

The fines01the

programisselected.

2-15).

"P4"

"il:;::~:<)1#Mm:::1!1!l%;~:::;iM

"P4"

(HOLE

The block "N+S" is assigned

"N

9"

program will be renumbered the next

("N

PATIERN) is renumberedbyactuating the

(M30)isassigned the block

1"-"N

10").

SK

LEOrt

'---------'

the

I

block

number

number"N

"N

10".

time

the

9"

"P4"

2 - 8

Page 31

@ BOSCH

Flexible Automation

Memory

Renaming programs

[2]

ce

120 M

Operating Instructions

Rename the part program

(the prog. no. remains unchanged).

The user is requested

RE

I

SK

Enter the new part program name "CONSOLE" and press the key.

"CONSOLE" now appears (as

NAME I

"P4"

(HOLEPATIERN) as "CONSOLE"

to

enter the new name of "P4 "/CONSOLE when the

has been actuated (highlighted).

~

ENTERII

"P4")inplace of "HOLE PATIERN":-+see page

2-4.

TOOLS

COMMANDS

COMMANDS

IZERO POINTS I VARIABLES I PROGRAMS I

I_.......:~~;:::~~~=-_L-

I PROTECTION I

ON

OFF

__

METRIC

E_D_IT

__

INCH

..L

I

__

I_N_P_UT

DELETE

I

CYCLES

O_U_T_PU_T

RENAME

__

Enter

CONSOLE

NEW

NAME?

COMMANDS

·"'··':@tm!MfttW.1W1WM!WMiliMBI[MMni%'MiMt~illMt~i:K.~W?@it~'~~

NO.

Mi

123456789

I

~I

@~

197525 characters free

..

~'.'.

t.~~.:~

NAME

~

~~!i,-

1

2

6

10

17

1B

33

125

99999999

OR NUMBER'"

CONSOLE

PROTECTION INCH

ON

OFF

4 CONSOLE M

NAME

CONT1NUOUS OPERATION M

NEW

TEACH M

TEACH1N M

.........................

HEADER M

PROFILE

UTENSllS

M1LLlNG

HEADER

PROFILE

CONTOUR

, .

METRIC

UNrT

M

M

M

M

M

M

Rweo

ACCESS

RWEO

RWeD

RWeO

RWED

RWED

RWeO

RWED

RWED

RWED

RWED

DELETE

MEMORY

srZE

750

lBO

153

128

1540

747

784

446

1540

747

~

ENTERII

::tt

rt

r.~

~1

W

~«::.

;::;::

.~.~

.•.

'.~.;

".

~.~

•..

~

..

,~.:t

....';..;'..'..:;..

i.:"·:":':'.""

•••••

:••'..•

,c

....:.•...•...•..•

o

..••...••.•.

M:,

.••••.MA.•.:,.••.••..•

::N

••.•.

:.D

••..

•.•

m.

S RENAME

,.::;:::,:••":""".:.:".,,.

, ".:.,

::::.:.:.:::

••

K;wmll!%.::nw::.;%,@m~@.::m111~i

2 - 9

I.

Page 32

@l

BOSCH

Flexible Automation

Deleting a program

Apart

program ean be deleted by seleeting the

Memory

Q]

ce 120 M

Operating Instructions

PROGRAMS I

I

SK

L . (enter

PROTECTION ON/OFF

prog.

no.),

COMMANDS I I DELETE I

I

and

...J

r===::":':>

First deaetivate the delete proteetlon.-+see

PROGRAM SELECTION

COMMANDS

COMMANDS

The programIsdeleted

aetuated.

I NEXT

PAGE

I PROTECTION I

ON

OFF

from

EDIT

I

INCH

METRIC

the program list when the key is

SK

,-_O=N,.....:O",F",F_..J

I

DELETE

I

L Important!

Only one program ean be deleted at a timeInthe

The write proteetlon is aetlvated or deaetlvated

PROTECTION

INPUT

~

GOM

[2J

by

seleeting

I OUTPUT

RE

I

NAME

ENTER~

---'

the

SK

PROTECTION OFF

PROTECTION

ON

I COMMANDS

The eurrent typeofwrlte proteetion is IndleatedInthe program list via

RWED.

j COMMANDS

COMMANDS

RWED:

RE:

land

I PROTECTION I

ON

READ,

only read and exeeute authorlsed.

-+

see page

P~~TEC6~~N

NEXT

PAGE

OFF

WRITE,EXECUTE,DELETE

2-2,

Types of proteetion

EDIT INPUT

INCH

METRIC

DELETE I RENAME

I

authorlsed.

OUTPUT

RE

or

2 - 10

Page 33

i§

BOSCH

Flexible Automation

Memory [2J

Operating

ce

120 M

Instructions

Unilsofmeasuremenl

(inch/melric)

The unit of measurementofa programora cycle is defined by using the

I

MI~,c~C

ICOMMANDS

COMMANDS I PROTECTION I

When the

measurement M (for metric) or I (for inch)

after each program

L

Noles

1. Default status for

-

GOM

-

GOM

I

l_---'~~;:::~~~=-

ON

OFF

I PROGRAMS I

SK

or

cycle name (in the unit column).

on

unilsofmeasuremenl

MACHINE:

MEMORY

+ AUTOMATIC:

E_D_IT__,--_I_N_P_U_T

INCH

METRIC DELETE RENAME

is actuated, the programorcycle unit of

-------

I I

is

displayedinthe header line and

presetting

presetting

GOM

INFORMATION

GOM

MEMORY

O_U_T_P_U_T_

SK

_

2.

When

GOM

MACHINE

I

<81

GOM

in

-

In

GOM

MACHINE, the unit of measurement can be defined irrespective

of the presetting (in

- When

3.

- The unit of measurement selected in

GOM

preset in

In

GOM

MEMORY

cycle can be set individually.

header.

is the presetting for

(and not

INFO

MACHINEisexited and reselected, the unit of measurement

GOM

INFO

GOM

INFO).

is

seiected I

is active.

GOM

INFO).

is active.

[2J the unit of measurement for every program or

GOM

AUTOMA

"'"

iEb

Ithe unit of measurement preset

or

"M"

is displayedinthe program

GOM

Tici

MEMORY

:=J

I

for

a program/cycle

2 -

11

Page 34

@ BOSCH

Flexible Automation

Memory

[2]

ce

120 M

Operating Instructions

Copying a

program

Apart

Example:

"MILLING":

j

program ean be eopiedbyseleeting

COMMANDS

COMMANDS

NEW

NAME?

COPY

the

copying

the

parl

program

1,--_p:..;NA:..;E~::;~=-

I

PROTECTION

ON

OFF

COPY

I

"P4"

ED_I_T__,-

INCH

METRIC

PRGM

TO

CYCLE

PRGM

TO

CYCLE

(CONSOLE)

I

SK

L

__

IN_P_U_T

DELETE

I

RENUMBER 1

RENUMBER

under

the

I

---L

new

name

O_U_T_PU_T

RE

NAME

of

__

-'

~

Enter new program name: MILUNG

NEW

NAME?

The eopied program "CONSOLE" will be stored in the next available

memory

(the original program "P4/HOLE PATTERN" thus remains unehanged)

New name:

File stored with no. 0

MILLING

loeation underthe new name "MILUNG" - in this ease, under

MILUNG

ENTER

PRGM

CYCLE

TO

~

RENUMBER

I

ENTERI

"PS"

2 - 12

Page 35

@ BOSCH

Flexible Automation

Converting programstocycles

A program can be renamedasa cycle by selecling

"COMMANDS" key and

Memory

lhe

[2]

PRGMTOCYCLE

ce

Operating Instructions

lhe

PROGRAM

key.

softkey, 2 x

120 M

Example: Converting

I

PROGRAM

r

~=======C=O=p=y===:P:R:G:M=T:O===R=E=N=U=M=B=E=R=~=====1

SELECTlONI

~~OO?

'--

lhe

part program "P4"/HOLE

.....

I 2 x

C_O_p_y__llllil_R_E_N_U_M_B_ER_

COMMANDS

CYCLE

PATTERN10cycle 20

I

.

I

----.."""

EI

I

CYCLE

NAME?

_________

NO,20

I

COPY

C_O_P_Y

__

PRGM

TO

CYCLE

RENUMBER

I

L----:P~::.~.:.:~~L~~:...o_1

REN

UMBER

I

0GGJ00000

~~~1:

197525 characters free

~n:

2 -

13

Page 36

@ BOSeH

Flexible Automation

Renumbering

Memory

The block numbersinapart

[2]

program are renumbered consecutively

Operating Instructions

ce

120 M

byactuat-

ing

the

sertedordeleled. The following appears in the reference line when

gram has been renumbered:

"RENUMBERED".

Branch labels and subprogram

Example: inserting a program

The following procedure is used10insert

"Y300" and renumber the part program (

COMMANDS

N+

SEARCH +

CYClES

IRENUMBER

SK

Y300

NEXT

PAGE

-

•

I

. This functlonISused when

call-ups

Une

are also

and renumbering

Ihe

new line "N+B" wilh

.....

see page 2-Bl:

EDIT

SCROll

blocks

re-calculated.

INPUT

-

r

have been in-

apart

Ihe

OUTPUT

pro-

text

®

COMMANDS I PROTECTION I

RENUMBER

ON

OFF METRIC

COPY

COPY

INCH

PRGM

CYClE

PRGM

CYClE

TO

TO

DElETE

I

RENUMBER

RENUMBER

OUTPUT I

RENAME

I

I

I

2 - 14

Page 37

§ BOSCH

Flexible

Cycles

Free

Automation

cycles

ce

Memory

A distinction is made between freely programmable cycles and thosewhich

perform fixed functions.

Machining processes which occur repeatedly are stored in the cycles.

Free cycles are those between 1 and

vided they are notinuse by the

[2]

Operating Instructions

69. These cycles are freely available

MTB.

120 M

pro-

Cycles

with

fixed

functions

Selection in

TOOLS I

PROGRAMS

I

or'-------

SEARCH + I

CYCLES

FREE

Cycle

Cycle

-

Cycle

-

Cycle

-

Cycle

-

Cycle

GOM

MEMORY

ZERO

-

C~STOMER-SPECIFlf

74

75

76

77

78

79

, .

via:

POINTS I VARIABLES I PROGRAMS I CYCLES

-

•

Emergency

»TB

cycle

MTB

cycle

MTB

cycle

Function

on

the

bit

11onNe

-+

see

Reference

SCROLL I

I

CYCLES

routine

assignments

customer

PLC

page

1-8

cycle

(call-up

(call-up

(call-up

keypad and

digital

for

I

with

with

with

t

DRILLING

CYCLES

11122)

11121)

Me)

keys

Fl

bits

interface

0-7

EDIT

INSERT

I

CONTOUR

DEFINITIONS

I

to

F15

cf

output

-+

see Programming Manual ce 120 M P.-No.4257.

2 -

15

Page 38

@ BOSCH

Flexible Automation

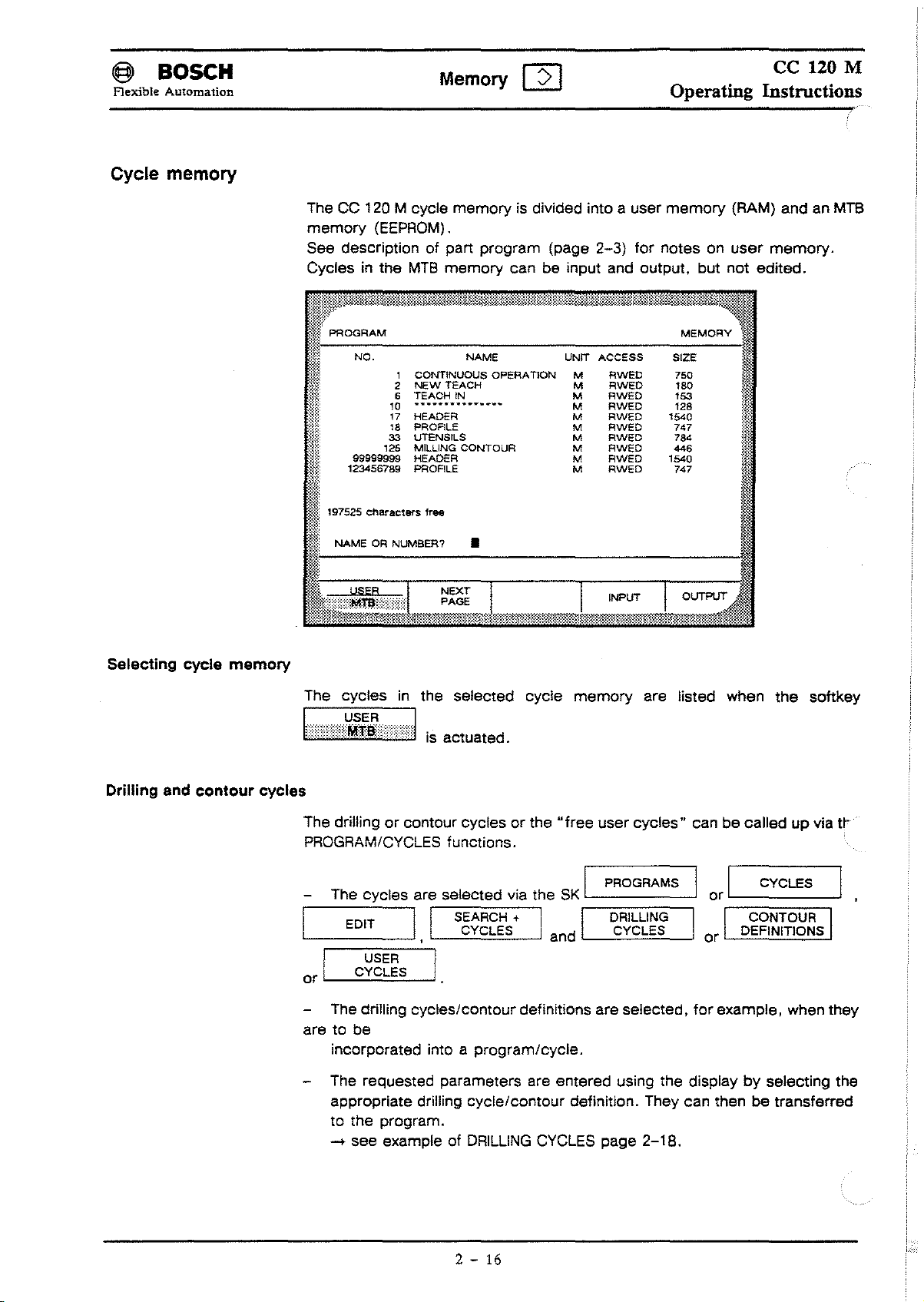

Cycle memory

ce

Memory

The

CC

120 M cycle

memory

See description of

Cycles in the

!1~)i~~wm%:*Im~~~Hl§~@mW~@~~n1~:?1}~WM11~~lli~;~~~m:~:~:i~m~J~l~fllimmllißt.~=t:i~:ililt:i~~%*t~

W

(EEPROM).

PROGRAM

memory

part program (page

MTB

memory

[2]

is divided into a user

2-3)

can be input and output. but

Operating Instructions

memory

for notes on

MEMORY

(RAM) and an

user

not

edited.

120 M

MTB

memory.

Selecting cycle memory

Drilling

end

contour cycles

I

&~f:

M~

a:

~,,~,

I

The cycles in the selected cycle

~-,-,;:((~f~i

NO

~

~~~~';,;:~PERATION

::";~

~~:::;

~~I

123456789 PROFILE M

'97525

NAMEORNUMBER?

6 TEACH IN M

10 M

99009~~

characters free

~~~i~ONTOUR

•

-,-,:1

is

actuated.

u~

A;~;g

RWED

RWED

~

~~II

RWED

memory

~~E

153

128

:E

747

are Iisted when

the

softkey

The drillingorcontour cyclesorthe..free user

PROGRAM/CYCLES functions.

SK

The cycles are selected via the

EDIT

I

USER

J

are to be

CYCLES

The drilling cycles/contour definitions are selected.

incorporated into a program/cycle.

The requested parameters are entered using the display

appropriate drilling cycle/contour definition. They can then be transferred

to

the program.

.... see example of

I I

SEARCH +

CYCLES CYCLES DEFINITIONS

I

DRILLING

2 -

16

I

land

CYCLES page

cycles"

PROGRAMS

DRILLING CONTOUR

2-18.

can becaliedupvia

I or I

or

for

CYCLES

example, when they

by

selecting the

t~

Page 39

@ BOSCH

Flexible Automation

Memory

[2]

ce 120 M

Operating Instructions

Drilling

cycles

Seleet the eyeles as

displayed when

I

EDIT

SEARCH

CYCLES

theSKl--.....:::C..:-YC:::L",E:.::S,--...J

I

+ I

I

I

described

,

-

USER

CYCLES

above.

DRILLING

I

I

I

A selection01the

is

actuated:

SCROLL

I

I

-

t

DRILLING

CYCLES

available

I

I

CONTOUR

DEFINITIONS

cycles

EDIT

INSERT

is

Select the

I

L

Important!

softkey

The

out

in GOM INFO. They willnolonger

internal

erated.

desired

OK

MTB

I

--

DRILLING CYCLES

cycles

eycle via

(GOM

INFO

-+

ONL

the

cursor

and/or

I MTB SERVICE -

Y POSSIBLE WITH CODEWORD ....

keys

and

the

softkey

CONTOUR DEFINITIONS

appearinthe

soltkey

enter

codeword)

strip. Furthermore.

_

canbemasked

canbegen-

2 - 17

Page 40

@ BOSCH

Flexible Automation

Memory [2]

ExampleofDRILLING CYCLES

ce 120 M

Operating Instructions

The following praetieal example illustrates how drilling eyeles

The cyele "GB4/TAPPING" is to be inserted into

number

Before generating the program. aetuate the SK

..

INSERT" is aetive (highlighted).

Enter the following program

NI

N2

N3

N4

N5

N6

N7

NB

N9

Nl0

NIl

N12 M5

N13

N14 M6

N15 T0202

N16 S450

N17

NIB

"N

17".

G90

M6

T010l

S1000

GO

Fl000

GB2VI=0

Xll0

YBO

GO

GBO

TOO

GO

Xll0

M3

Z20

Y40

Z20

M3

Z20

Y40

in

(GOM

MEMORY):

V2=-50

V3=2 V4=0

The "TAPPING CYCLE

iscalied up here and inserted in the

84"

apart

program

1_.....:;.IN;:;:Es":.=~::..~'-'T_--J1

program.

are

called up.

under

the

so

block

that

__

S~~~~~~;;;fE:;:HS;:.+

I

Seleet the"TAPPING" eyele by aetuating the

The nameofthe seleeted drilling eyele then flashesintheseleetion menu (page

2-17)

.

-_"

__

MILLING

CYCLES

2 -

-'-__S_C_R_O_L_L

I I

18

DRILLING

CYCLES

cursor

-_T

key

lC:Z:Jl

~',mf~~}jI

I

CONTOUR

DEFINITIONS

J

.

Page 41

@ BOSeH

Flexible Automation

Memory [2]

ce

120 M

Operating Instructions

The

"tapping"

graphics are displayed when the

SK

IL

ated:

~~~~iMii!lITiMii!lIT~

PROGRAM

TAPPING

G84

V3=3er4 for

spindie

V4=1eed

MM/REV

Nll

M3/M4

in

G84

'6

Ref. level

V1

~

r

V2

1

1

V1= 0 V2=

-10

V3=3

MRWED

•

V5=dweil

V4=

1.5

V5=

Machining-specific values are assignedtothe parameters

~+

G84

Vl=O

V2=-10

V3=3

V4.;.=.;.1"',S.;..;.V'-S_=O"-_.,-

MEMORY

t;me

0

O_K__

"V1-VS":

is actu-

_

L.

__

I

The "tapping

---1.,

cycle"

, TAB -

is translerredtothe program when the key is

actuated:

N17

G84 V1=0 V2=-10

N18

X20 Y20

N19

G80

N20

Z20

N21

M5

N22

TOO

N23

M2

The cycle "G84/T

V3=3

APPING"

V4=1.5 V5=0

appearsinplace01X20/Y20 the next time the

part program (Ior "AUTOMATIC") is called up.

11

ENTER

~

2 - 19

Page 42

(§l

BOSCH

Flexible Automation

Contour cycles

Memory

[2]

ce

120 M

Operating Instructions

The

_

The

contour

CYCLES

COMMANDS

SEARCH

CYCLES

See

"Important"

following contour cycles are available:

cycles

I

I

I

+

I I I

MILLING

CYCLES

@j@llt?MMH~gmtm@]tHM®mMittl@~@ill@fltii1tÜ©llitt.

NEXT

PAGE

,

page

are

selected

EDIT

2-16.

Connection Connection

I

,I

EDIT

SCROLL

via

SEARCH

CYCLES

the

+

DRILLING

CYCLES

SK

land

INPUT

-

t

PROGRAMS

CONTOUR

DEFINITIONS

OUTPUT

EDIT

INSERT

I

CONTOUR

DEFINITION

I

or

%i

WJ.

t:{[.

lnt81'"S.

~ll1

pt. inters. pt. 2 points 1 point +

2 elreles lIne/clrcle 2 angles

Chamfer

I~~~~

lJl

;~~I;,sit;on

When

gene

ming

aid

_

See

Programming

drilling/contour

rating

for

it::

programs,

difficult

cycles.

~~:

~n

the

above

and

complex

Manual ce 120 M

contours.

:~:;;~t

contour

P.-No.4257

definitions

for

detailed

serve

as a

program-

information

on

2 -

20

Page 43

~

Flexible Automation

BOSCH

Tables

The lollowing tables are available: the tool/parameter table (Ior max. 48 tools;

ean be extended up to 99 tools). the zero shilt table(G54

G160) and the variables table.

Tool table / parameter table

The lunetions edit. input and output (see "Input/output lunetions") eanbeseleeted

tables) .

Important: The MT8 may have disabled write aeeess

(edit

the error message "ACCESS DENIED" will appear when the user attempts to

edit the table.

Edltlng the tool table

The tool table is ealled up with

The tables ean then be edited as lollows:

Memory

lor

the tool/parameter table (and also

mode).

TOOLS

either eompletelyorlor

I

r-A-U-T-H-O"""R-IS-E-'-o

. ACCESS

[2]

ce

120 M

Operating Instructions

to

G59. plus G60 and

lor

the zero point and variables

to

the parameter table

speeilie periods01time. II this is the ease.

the lollowing soltkey sequenee:

EDIT

land

I

T~~rS

I

TOOLS

AUTHORISE

j

ACCESS

AUTHORISE

ACCESS METRIC

EDIT EDIT

TOOLS

~IJß:%Ü@it~MMm.r@1i~~~{Hi.iWi@WI;,W:~W&lW}M[ij:M@1001t..{Wl~@J.illlM[~~

~f~(

TOOlS

!ll

~::

Fi~

T4B

j~~~

>

T1

i~:~:~

T2

,~(.;:

T3

:::;~~

IZERO POINTS I VARIABLES I PROGRAMS 1 CVCLES

EDIT

I

::::

A=

0.0

10.0

R=

0.0

R=

0.0

R=

R=

0.0

INCH

~:::

0.0

DA=

DA=

0.0

DA=

0.0

DA=

0.0

0.0

DR=

EDIT

I

I

~:::

0.0

L=

0.0

L=

L=

0.0

0.0

L=

0.0

L=

INPUT

MEMORY

:::

s=

0.0

$=

0.0

s=

0.0

$=

0.0

s=

0.0

I

it

I

*1:

}~

mf

*

i

<~~.

OUTPUT

OUTPUT

PARAMETER

#t

li:-=--..,--.,.-.,---=---~------.;

ii~t

T1

Write

R= 10.0

protection oft

tr

I"

T Tool number

R Radius (in

DR

Radius wear

mm)

(In

mm)

2 - 21

L Length (in mm)

S Cuttlng speed (in

m/min)

Page 44

@>

BOSCH

Flexible Automation

Memory

~

ce

120 M

Operating Instructions

Example: calling

Seleet tool table as deseribed above. First seleet the SK

then enter the tool number 12:

TOOL

NUMBER

The cursorisnow positionedinIront01tool

The parameters

In

tively.

aetivated when

status is indieated

parameter ean then be seleeted

up

tool

no. 12

-

I

ordertodo this, the

I

DR.O.O L.O.O

Unltofmeasurement: Metric

-

I

R,

DR,

L and/or S ean then be enteredoredited eonseeu-

the

edit mode was seleeted (the eurrent write proteetion

inline19- write proteetion: ON/OFF). Eaeh individual

SCROLL

I

SCROLL

AUTHORISE

by

I

ACCESS

aetuating

-

S.O.O

T?

-

number

the

TOOL

I

_-,N~U~M=BE=:R,"-_

r

r

12

soltkey

PARAMETER

I

PARAMETER

(T12).

must

I

and

TABLE

TABLE

have been

[2])

ENTER

A new tool number ean then be seleeted,

There are two ways to seleet a new tool:

1. enter the tool number or

2. press the and

The parameter table ean be seleeted direetly

PARAMETER

This softkey and table are only available when the option • Additional

tool

or

lc:EJ]

key must be pressed when a new input is

~SCROLyl

TABLE:

tables"isaetive.

keys. The

r:::I1

~

lf""=II

or

lL...!......JI

made.

keys simultaneously.

by

aetuating the softkey

2 - 22

Page 45

c§l

Flexible Automation

Editing the parameter table

BOSCH

The

softkey..EDIT

the

option is aetive.

Memory

PARAMETER" and the

[2]

parameter

ce

120 M

Operating Instructions

table

are

only available if

and

sohkey

PARAMETER

The

parameter

TOOlS

TOOlS

AUTHORISE

ACCESS

AUTHORISE

ACCESS

EDIT

TOOlS

~JWlijj~i%WiJi~@i~HW~~~Wi~1$t:1~fti~~ji@illMt.tm1t:@~::~~:~"$%f.i'':''A~~

~~?

TOOlS

~~

T47

TL=

W4=

TL:

T48

W4=

TL:

W4=

TL=

T2

W4=

TS

TL:

W4=

~

table ean be

AUTHORISE

,--,-A:.;:C:.;:C:.::E:.::S",S_..J.

I

ZERO

POINTSIVARIABLES

INCH

I

METRIC

75.0

0.0

75.0

0.0

75.0

0.0

0.0

0.0

0.0

0.0

Wl=

ws=

Wl=

ws=

Wl=

ws=

Wl=

ws=

Wl=

ws:::

edited

I

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

I

W2=

WB:

W2=

W6=

W2=

W6=

W2=

WB=

W2=

WB=

with

EDIT

EDIT

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

EDIT

the

I

I

ws:::

W7=

ws=

W7=

ws=

W7=

ws=

W7=

ws=

W7=

following

I I

PROGRAMS

INPUT

MEMORY

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

sequenee:

EDIT

CYClES

I

OUTPUT

OUTPUT

I

EDIT

PARAMETER

I

lt

TOOLLIFE

T:

Tl:

W1-W7:

Value range:

The tool table ean be seleeted direetly using

See example

and ealling

up

number

Tool

Tool Iife (in

The

MTB

-999999.9to999999.9

under..Editing tool

tools.

min).

determines

2 -

23

value range:

table"

the

meaningofthese

for

ws=

0.0

W7=

0.0

-9999.9to9999.9

parameters.

the

softkey

editing the individual

TOOl

TABlE.

parameters

Page 46

<§

BOSeH

Flexible Automation

Zero

shift

/ variables table

Variables

Memory

Editing zero shift and variables tables:

-+

see..editing tool table"

Input and output:

-+

see chap.

Thereisa total of

The variables are addressed with combinations of letters and digits.

The

following

o

V1

to V99

o

VOAtoVOZ

V9AtoV9Z

o

VAAtoVAZ

INPUT/OUTPUT

1035

variable ranges are available:

C8

FUNCTIONS

variablesinthe

variables

99

260 variables

468 variables

Operating Instructions

variables table.

ce

120 M

o VRA to VRZ

These variables are global.

Note

on

differentiating between system variables and free user variables:

The following variables are used internally by the system

and contour cycles:

o

V1

to V17

10 V99

V90

VA

10 VZ

These syslem variables are used inlernally when

cycles are active. They are Iherefore

These variables muSI not be used by

cycles are active.

Protected

variable range

not

unreslricted. free user variables.

the

user when machining and

Ihe

machining and

o VSA to VSZ 208 variables

VZA 10

These variables can be accessedbyIhe

played if Ihis has been enabled via

management"

funclions. These variables can only be programmed if

lables"

lioned softkey. See Conneclions

quence

VZZ

inlernal cycles. They

Ihe

soflkeys.Inaddition.

mUSI

be active. These variables can be read and written via CPC

oplion is aClive. Programming muSI also be enabled via

CC

120 M part 2, chap.

10 enable Ihese variables.

to

execute machining

conlour

conle

are

only dis-

Ihe

oplion

Ihe..addilional 1001

above-men-

5.4.7

for

..

soflkey

1001

se-

2

- 24

Page 47

@ BOSCH

Flexible Automation

Input I output functions

Memory

[2]

ce

120 M

Operating Instructions

Programsorcycles

number

or

has

TOOLS

TOOLS

been

,-_C_O_M_M_A_N_D_S-l._--,~..:.;.;,:a=~:..-

It is

not

necessarytoactuate

which

have

been

input

the

tables which

I

I

ZERO

ZERO

called

are

input

and

outputasfolIows.

entered:

POINTSIVARIABLES

POINTSIVARIABLES

the

SK

up.

TheSKl..--.::.A:.::C:.::C:.::E",S,,-S_...J

have

been

called

after

the

programorcycle

I

PROGRAMS

I

PROGRAMS

ED_I_T_-...l

AUTHORISE

__

'_N_PU_T_

,-;::::,::A~C~C~E~S~S;::::::-;"'in

AUTHORISE

up:

I

CYCLES

~PROG.

I

CYCLES

~

CYCL.

.....

I..__

o_U_T_PU_T

ordertooutput

must

be

aetivated

NO.~

NO.~

__

tables

to

TOOLS

AUTHORISE

ACCESS

AUTHORISE

ACCESS

Oncethe

meters

or

entered

actuating

Tables /

with/without

with/without

_ See

appropriate

for

the

from

the

programs

page

I

ZERO

INCH

I

METRIC

peripheral

the

input

~

START

and

checksum.

DFS

2-26

for

POINTSIVARIABLES

EDIT

EDIT

I

"INTERFACE" and

device

11

key.

cycles

code.

information

used

devicetotM

can

be

have

program

input /

on

I

I

"transfer

been

output:

"program

PROGRAMS

INPUT

rate/BAUD RATE"

selected.

memoryofthe

header

data

in DFS

I

I

are

control

CYCLES

OUTPUT

OUTPUT

para-

transferred

unit

format".

by

2 -

25

Page 48

@ BOSCH

Flexible Automation

Memory

C8

ce

120 M

Operating Instructions

Example: INPUTTINGanindividual

Start

I

INPUT

"TRANSFER" will

are being

The

SK

"TRANSFER END" will

procedureiscomplete:

__

P_R_O_G_R_A_M_S_...lI_1Input

COMMANDS

INPUT

the

transfer

1

input

STOP

PORT

procedure

1

and

I

appearinthe

transferred

procedure

I

I

__

-,N",E",X::;T=--

PAGE

START

NO:: 1

by

S_T_A_R_T

__

.

can

be

appearinthe

PROG.

I

BAUD

RATE:

I

part

program

actuating

I

reference

abortedatany

NO.

ED_I_T

INTER-

FACE

7

INTER-

FACE

line. indicating

reference

I_~ENTER

__

the

time

line when

INPUT

SK I

by

~

TRANSFER

PROGRAMS

that

the

pressing

the

transfer

OUTPUT

I

data

the

f1ashes

"':':;IN::'P':::Uc:.T

_.

l

~

2. Input several

3.

4. Set

5. II a DNC

__

":'P':::OTRc:.T":N'::O~:",:

__

1 1 1

1:::rt:n:rl-lo-g-ra-m-_+--S-K~I=y~:S;LL=;~;I,;;2;.No=·.·

No.offiles

Enter

procedure

11.

for

input

Checksum

_+

See page

PORT

BAUD

I

requested

numberoffiles

always begins with "FILE1"and

example.

test

NO. and BAUD

RATE

interface

..:1-,B~A:c:U~D

programs

the

number

yes/no

2-29

for

I

_

dependlng

has

RATE:

7

....

=\~I--------:----

_+

SK 1

y~~L

f:;~~,,1

: HOW MANY(1.. 99) ?

from

1-99

which aretobe

"12"

is

entered•the

_+

"CHECK YES/NO".

informationonthe

RATE

via

on data

been

installed. it

checksum.

1

SK

from

canbeselected

INTER- 1

FACE

"'T:.:;RA""NSFER

input. The

continuesinascending.

files 1 -

and

Input

devlce.

using

__

12

END

transfer

will

be

the

softkey

-

I~I~~-

I

. . with no. 3

I

2 - 26

lor

inputting

and

outputting

data.

Page 49

@ BOSeH

Flexible Automation

Memory

Example: OUTPUTTING programs/cycles/lables

[2]

ce

120 M

Operating Instructions

The files

There are six different output options available:

SELECTED

ALL

ALL

FILE+TOOLS

FILE+ZERO

FILE+VARIABLES

Example: Oulpulling a selecled (individual) program

After seleeting

SK

10

be output are seleeted via softkeys and highlighled on the sereen.

FILE

ONLY

PROGRAMsORCYCLES

PROGRAMS+CYCLES

POINTS

GOM

MEMORY

and entering the program number. aetuate the

previously

No

file

Selection

Selected

I OUTPUT I and I START I

PROGRAMS I

....

1 Input

PROG

, NO. 1

selected

selected

via

file

....

11

ENTER

softkey

withatable

L Importani!

No prog. no.isentered if several files are being output:

file

switchover

1I

is

output

is

output

--J

COMMANDS

OTHER

SELECTION

NEXT

PAGE

I

START

EDIT

INTER-

FACE

I

INPUT

I BAUD RATE I

OUTPUT

FORMAT

"TRANSFER END" will appear in the referenee line onee the output pro-

eedure has been eompleted.

2 - 27

Page 50

@>

BOSCH

Flexible Automation

Format/Checksum

Memory

[2]

Operating

FORMAT I

After the

ible to define whether the program header will be output in

("DFS"

I

SK

highlighted)orin

has been selected in output

CC120

format

("CCI20"

mode.

highlighted).

ce

120 M

Instruction~

it is poss-

DFS

format

The program can be transferred, with

I CHECKSUM I

the

SK

YES

I NO

OTHER

SELECTION

OUTPUT

DFS

START

NO CKS PORT: 1 BAUD RATE:

INTER-

FACE

I

See Programming Manual

CHECKSUM

and "

Notes:

OFS

1.

Files can be output with a

specific code. which enables the user

searches for the

(defined

" ,

storage)

DFS

CC

120 MP,No. 4257

program

DFS

program header. These files

codeonthe

header

input

or

without a

to

input the file again (the system

tape).

checksumbyactivating

BAUD RATE FORMAT

12

for

information on "FORMAT"

are

assigned a

Example of standard

DFS'•File.

(

Example: (OFS,P 10,HOLE PATTERN,.M,

See Programming Manual

, type number '

The

suffix

consists of a letter and defines the unit of measurement

(I=INCH/M=METRIC) .

One

or

more blank spaces can be inserted in the program header, of those

positions marked with an••".

File

DFS

header:

.[.

CC

120 M P,No, 4257 for more details and examples.

File

[

name .su

J.

RE)

ff"

]

IX

,'Type

of

protection

)

2 - 28

Page 51

<§>

BOSCH

Flexible Automation

ce

Memory

2.

Inputting/outputting

The checksum is used to test programs. The number of bytes in each program

line and the program header is calculated (except those with

figure

is

then inserted directiyinfront of the "CRLF control

test whether the checksum of a program line is the same before and after the

input and output procedure. If it is not.

the

checksum

[2]

Operating Instroctions

an

error is present.

DFS

character".

120 M

format).

This will

This

Programs can be output with

mat.

OUTPUT

SK

Iygg;grsu~o

I

- Store

or

without the checksum irrespectiveofthe for-

with

checksum

I CHECKSUM I

SK

yES

I!"lid

INPUT (see page 2-24)

SK

1"i!J!!:l§~,~CK

Example:

If a checksum is present. the character

CRLF

control character, followedbythe 2 digit checksum (symbol nn):

NO I _Control unit checks syntax. even when a checksum is

program

- Store

present.

- Control unit checks syntax if a checksum is present.

line

with/without

without

checksum

checksum

":"

appears immediately in tront of the

Block

with

checksum:

Block

without

See Programming Manual

format.

checksum:

-N-15-

-N-15-

CC

-X-21.

-X-21.

120 MP.No. 4257

3-Y-38-Fl200-:

3-Y-38-Fl200-:

tor

more details on

7D

CRLF

CRLF

checksuml

o

2 - 29

Page 52

Page 53

Page 54

Page 55

@ BOSCH

Flexible Automation

Machine

I!GJ

I

ce

120 M

Operating Instructions

GOM

Machine

lai

The lollowing initial dispiay appears

key:

Initial display

x

y

Z

I

'------------------------i\l-.;

0.000

0.000

0.000

MANUAL

INPUT

alter

selecting

COMMAND PO

s

F.

L..-.

GOM

Machine via the I

0.0

===

0.000

_

0.000

Actlve

Axls display

selectlon

Spindie speed

I~

Current

feedrate

AAls positions

position

Softkey

functlon

axes

,8

GOM

In

or

keys

I

The title display indicates

been switched on and started up.

Basic lunclions

Traverse axes manually

Approach relerence point(s)

Manual Input

Block input

Teach

Selecting unit01measurement inch/metric

15

be called up via lunction keys

In

machine-specilic lunctionswhich can

thatthe

system is operative once the control unit has

Page

Page

Page

Page

Page

Page

3-3

3-2

3-3

3-6

3-7

3-12

3 - 1

Page 56

§ BOSCH

Flexible Automation

Approaching reference point(s)

The axes can be traversedtothe relerence points. either individuallyorcollectively.

The

"REFERENCE

IA

Machine

POINT" lunctionisselectedinGOM

I

Operating Instructions

ce 120 M

MACHINE:

REFERENCE I REFERENCE I

POINT CYCLE

X AXIS Y AXIS Z AXIS E AXIS

11

no axes are in use.

~

Approach relerence points

Each axis stops traversing

The coordinates (determined by machine parameters)

screen when

11

a relerence cycle has been selected. the axes approach

in the sequence delined in the cycle

Actuate start key.

the

the

respective

in

once

relerence points have been reached.

MANUAL

INPUT

soltkey

accordance with instructions

the relerence

alter

TEACH

I

can be masked out.

cam

has been reached.

the

SK

L...._C::.Y'-'C::::L:::E=----'

IN

I

lrom

are

displayed on the

the

relerence

REFERENCE

INCH

METRIC

ALL

AXES

MTB

•.

and the

points

~

START

Relerence point approach can be interrupted with the

message will appear: "Interruption: delete block to abortorcontinue".

possible

the user does indeed wish to abort.

It

switched on il soltware limit switches have been setinthe machineparameters.

11

been started up.

~

key have been actuated.

STOP

key. The

to

continue using the

is

essential that the relerence points be approached when

these are not active. the system can be operated normally as soon as it has

START

key. The round page

back

the

followi,.,~

It

key is used il

control unit

is

3 - 2

Page 57

@ BaSeH

Flexible Automation

Manual input

Machine

ce

I

[ß]

I

Operating Instructions

120 M

The purpose ofthe manual modeisto

block. The block is entered by actuating the key.

The foilowing options are available in the manual input mode:

- traverse axes manuaily

- call up cycles

- input block

- delete block

Cail

up

The title display for the "MANUAL MODE" function is displayed when the

MANUAL I

I

MODE

.

Is

actuated (reference points have first been approached):

X 0.000

Y 0.000

Z

0.000

enable the user to directly execute an

11

M

COMMAND

S

Fe

Fp2QOO,OJMIN

.E

0.0

0.000

0.000

START

POSITION in M

11

MACHlNE

G 1

T

87%

Ne

SK

Cursor flashes

Example: traversing axes manually

or

The axes can be traversed individually using the jog keys

wheel. The axis to be traversed must first be selected wlth the axis selection

swilch (see manual panel).

Set

lhe

traversing mode (wlth eleclronic handwheel

feedrale (feed potentiometer) and then acluate

handwheel:

or

jog

the electronic hand-

or

jog keys) and the

keyorrotate eleetronic

3 - 3

Page 58

@ BOSeH

Flexible Automation

Importsnt: