Page 1

CC10.3

Operating, Programming,

Remote Control

Antriebs- und Steuerungstechnik

Version

101

Automationstechnik

Page 2

CC10.3

Operating, Programming,

Remote Control

1070 072 154-101 (95.09) GB

Reg. Nr. 16149-03

E 1995

by Robert Bosch GmbH,

All rights reserved, including applications for protective rights.

Reproduction or handing over to third parties are subject to our written permission.

Discretionary charge 20.– DM

Page 3

Flexible Automation

General

Safety instructions and reading help

Read this instruction manual before you use the CC10.3. Keep this man

ual in a place where it is always accessible to all users.

Standard operation

This instruction manual contains all of the information required for stan

dard operation of the described products.

The products described were developed, manufactured, tested and

documented in accordance with the relevant safety standards. There

should be no risk of danger to personnel or property if the specifications

and safety instructions relating to the project phase and installation and

correct operation of the product are followed.

CC 10

Inerface conditions

Qualified personnel

This instruction manual is designed for specially trained PLC personnel.

The relevant requirements are based on the job specifications as de

scribed by the ZVEI, see:

Anforderungsprofile für SPS-Fachkräfte

I + K SPEKTRUM 19

Hrsg.: ZVEI

Stresemannallee 19

60596 Frankfurt

Federal Republic of Germany

ISSN 0932-5018

This instruction manual is designed for PLC comissioners. These comis

sioners require special knowledge of PLC controllers.

Interventions in the hardware and software of our products which are not

described in this instruction manual may only be performed by our

skilled personnel.

Unqualified interventions in the hardware or software or noncompliance

with the warnings listed in this instruction manual or indicated on the

product may result in serious personal injury or damage to property.

I

Page 4

Flexible Automation

Qualified personnel are persons who

D as planning personnel, are familiar with the safety guidelines

D as operating personnel, are familiar with the equipment used in

D as commissioning personnel, are authorized to commission,

General

used in electrical engineering and automation technology.

the field of automation technology and are thus familiar with the

operating instructions in this manual.

ground and classify electric circuits and devices/systems in ac

cordance with the relevant safety standards.

Safety instructions on the control components

The following warnings and notices may be indicated on the control

components themselves and have the following meaning:

CC 10

Inerface conditions

Danger: High voltage!

Danger: Battery acid!

Electrostatically-sensitive components!

Disconnect at mains before opening!

Pin for connecting PE conductor only!

For screened conductor only!

II

Page 5

Flexible Automation

Safety instructions in this manual

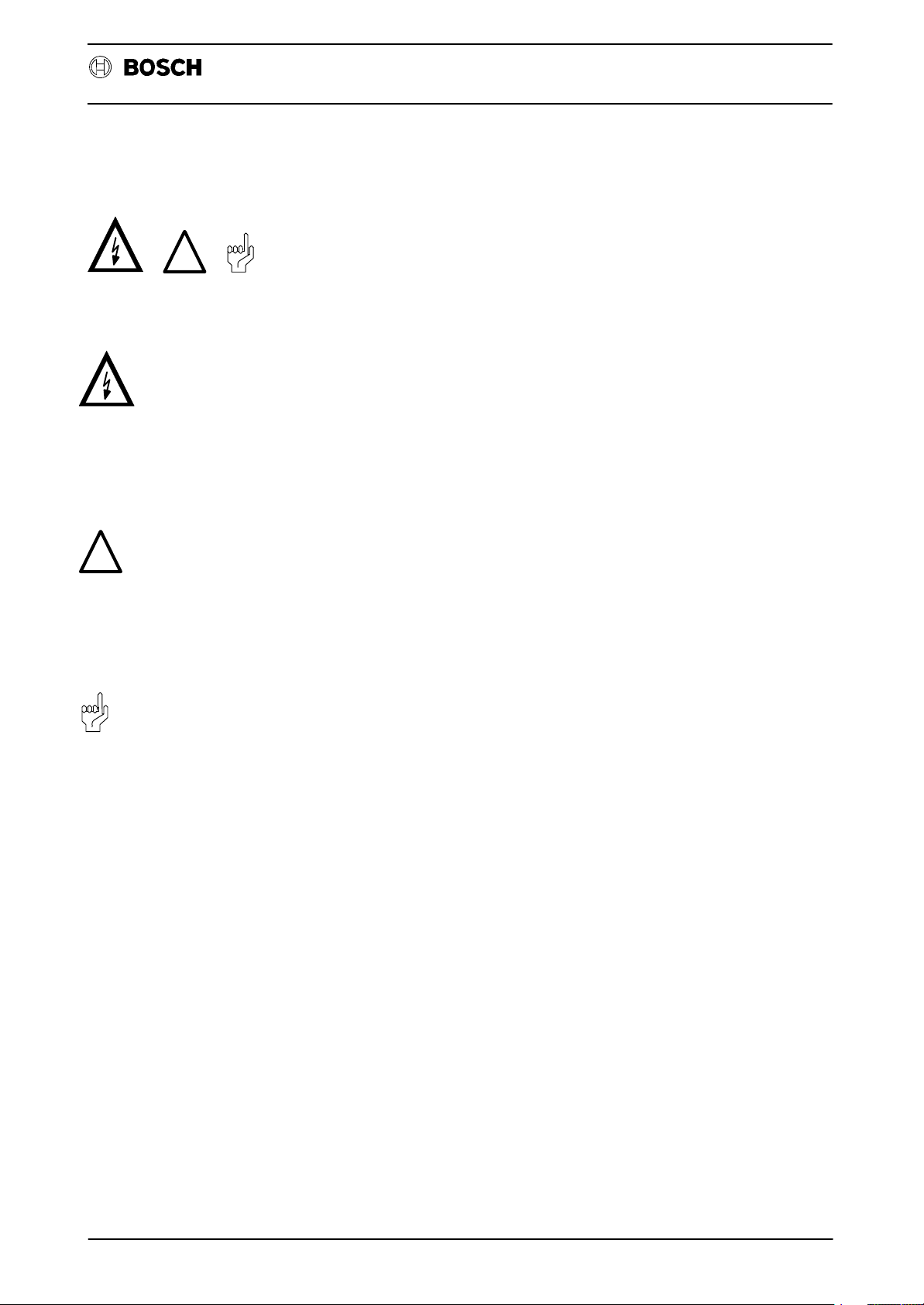

!

DANGER

.

These symbols are used throughout this manual subject to the following

conditions.

This symbol is used to warn of the presence of dangerous electrical

current. Insufficient or lacking compliance with these instructions can

result in personal injury.

Safety instructions accompanied by this symbol are serially numbered,

for example 0.1. The appendix provides translations of the safety notes

shown here in all the official EC languages.

General

CC 10

Inerface conditions

!

.

DANGER

This symbol is used wherever an insufficient or lacking compliance with

instructions can result in personal injury.

Safety instructions accompanied by this symbol are serially numbered,

for example 0.1. The appendix provides translations of the safety notes

shown here in all the official EC languages.

CAUTION

This symbol is used wherever an insufficient or lacking compliance with

instructions can result in damage to equipment or files.

Safety instructions accompanied by this symbol are serially numbered,

for example 0.1. The appendix provides translations of the safety notes

shown here in all the official EC languages.

This symbol is used to inform the user of special features.

III

Page 6

Flexible Automation

Safety instructions

DANGER 0.1

!

CAUTION 0.2

CAUTION 0.3

General

Danger to persons and equipment!

Test every new program before operating the system!

Danger to the module!

Do not insert or remove the module when the control is switched on!

This can destroy the module. Switch off or remove the power supply

module of the control, external power supply and signal voltage be

fore inserting or removing the module!

Danger to the module!

All ESD protection measures must be observed when using the mo

dule! Avoid electrostatic discharges!

Inerface conditions

CC 10

Observe the following protective measures for electrostatically endan

gered modules (EEM)!

D The employees responsible for the storage, transport and handl

ing must be trained in ESD protection.

D EEMs must be stored and transported in the protective packaging

specified.

D EEMs may basically only be handled at special ESD work places

set up specifically for this purpose.

D Employees, work surfaces and all devices and tools, which could

come into contact with EEMs must be same potential (e.g.

earthed).

D Wear an approved earthing strap around your wrist. The ground

ing bracelet must be connected via a cable with integrated 1 M7

resistance with the work surface.

D EEMs may on no account come into contact with chargeable

objects, these include most plastics.

D When inserting EEMs into devices and removing them, the power

source of the device must be switched off.

IV

Page 7

Flexible Automation

Contents

Operating instructions

Contents

Operating instructions

GENERAL 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOREWORD 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Abbreviations 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device description and information for the user 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating and programming panel BPF 10/BPF 10 E 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BPF 10 E/built–in version. 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display unit 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATING ELEMENTS OF THE BPF 10 (E) 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function keys 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Decimal point 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NOTES 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONVENTIONS 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting level 2–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC 10

FUNCTION BLOCK NO.X (Axis selection) 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUNCTION BLOCK MODE 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUNCTION: MACHine 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function: PROGram execution 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MODE: Approach REFerence points

(applies only in conjunction with incremental measuring system) 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MODE: MANual axis displacement 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST part program 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MODE: AUTOmatic part program execution 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MODE: SEMI–automatic part program execution 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NOTES 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUNCTION BLOCK MEM (Memory) 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notes: 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delete a program 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rename a program 5–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPENSATION 5–1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tool length compensation 5–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Zero shift 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Machine parameter program (MPP) 5–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data input and output 5–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XTRANS 5–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading in data 5–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading in part programs 5–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data output 5–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents - 1

Page 8

Flexible Automation

Contents

Operating instructions

FUNCTION BLOCK INFO (Information)

Axis display 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status display 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error display 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software version 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display of control conditions 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display of inputs and outputs 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Softkey trees 7 – 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIGNIFICANCE OF THE SOFTKEYS 7 – 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error codes 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC 10 module

CC 10

Control versions for driving 1 axis, incremental measuring system 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control versions for driving 1–3 axes, incremental measuring system 9–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Control versions for driving 1–3 axes, absolute measuring system 9–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data transfer CC 10.3 $ PG6 9–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading new operating software 9–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initializing the FLASH EPROM 9–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents - 2

Page 9

Flexible Automation

Contents

Programming instructions

Contents

Programming instructions

General

Program creation 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading data in/out 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing programs 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program execution 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part programs 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory allocation 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start of program 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program run 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program end 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program block 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program word 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block number 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program format 10–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC 10

G–FUNCTIONS 1 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioning in rapid traverse mode 11–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Linear interpolation in feed mode 11–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circular interpolation 11–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helical interpolation 11–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dwell time 11–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programmed acceleration ON/OFF 11–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plane selection 11–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conditional/unconditional jump 11–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Zero shifts 11–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exact positioning ON/OFF 11–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set 100 % feedrate 11–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clear G63 11–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic approach to reference point 11–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Absolute dimension input 11–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Incremental dimension input 11–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Miscellaneous functions 12–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Auxiliary functions 12–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 12–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function 12–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(Program stop, program end) 12–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block preparation 12–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function of the WAIT command 12–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read monitoring E–code 12–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents - 3

Page 10

Flexible Automation

Contents

Programming instructions

Compensation tables

Tool length compensation ”Hxx” 13–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Zero shifts ”Gxx” 13–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Zero shift in conjunction with rotary axes 13–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading in the tables 13–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving the tables in the FLASH EPROM 13–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming the rotary axis

Displacement input 14–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC 10

Contents - 4

Page 11

Flexible Automation

Contents

Remote control

Contents

Remote control

General 15–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Machine parameters 16–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface selection 17–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface selection via PLC interface 17–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REQUIRED DATA CHANNEL 18 – 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handshake mode 18 – 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC10.3 receives required data 18 – 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC10.3 transmits required data 18 – 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC 10

Functions 19–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read–in 19–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read–in of part programs 19–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read–in of compensation tables 19–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read–in of zero shifts 19–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read–in of machine parameters 19–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read–out 19–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requesting a part program 19–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requesting the compensation tables 19–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requesting the zero shift table 19–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requesting the machine parameters 19–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deleting files (applicable only to part programs) 19–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Determining memory space 19–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program directory 19–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming files (in the EEPROM) 19–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming part programs 19–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming zero shift tables 19–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming compensation tables 19–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming machine parameters 19–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read-out of any list of errors present 19–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ANNEX

Connection cable PG6 <––> CNC 20–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection via V.24 interface (COM1) 20–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ASCII character set 20–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents - 5

Page 12

Flexible Automation

Contents

CC 10

Remote control

Contents - 6

Page 13

Flexible Automation

GENERAL

General

This description refers to the CC 10 operating system software as from version C40.

Operating instructions

CC 10

CC 10

Computer–assisted positioning control for max. 3 axes

These instructions are intended for the user of the CC 10 control system.

1 - 1

Page 14

Flexible Automation

General

CC 10

Operating instructions

1 - 2

Page 15

Flexible Automation

FOREWORD

Introduction

These instructions describe the operator steps which must be performed on the

CNC itself. They apply only to type CC 10 control systems. Only the described sequences and operations are permitted.

Machine–specific operation through assignment of the function keys F1–F12 is described by the machine tool manufacturer.

All function blocks (FBL) are represented in their overall context, together with all

possible operating sequences. This permits a general overview of all the functions

available in a particular FBL and their selection. The ”arrow notation” (softkey

trees) used for this purpose is intended as a simple and effective memory aid for

experienced operators.

The error messages for the CC 10 are contained in Chapter 8. Chapter 9 contains

further details relating to the function descriptions and examples.

Operating instructions

CC 10

These operating instructions represent a control–specific general ”reference work”

giving the user details and comprehensive information on the available functions

and their selection as well as permitting effective operation of the control system.

The CC 10 is a computer–assisted numerical positioning control (CNC) for use in

the following fields:

` special mechanical engineering

` transfer lines

` handling technology

` assembly technology

` feed units and

` auxiliary axes on machine tools.

The CC 10 is integrated in the programmable logic controllers (PLC) CL 300 or PC

600 (refer to the ”Interface conditions”).

The CC 10 has its own microprocessor and a part program memory with a capacity

of 10 kBytes (for max. 99 part programs). This permits axis positioning parallel to

the PLC cycle without affecting the timing of the latter . Position–controlled axes can

be expanded from 1 axis to 3 axes.

2 - 1

Page 16

Flexible Automation

Introduction

Up to 3 axes can be operated

` as asynchronous, mutually independent axes, each with its own part pro-

gram

or

` as synchronous axes with a common part program.

This specification and any adjustment to the machine–specific requirements are

defined by input of machine parameters.

Operator prompts in all modes ensure that the operator makes the necessary sen-

sible inputs. These prompts also allow the operator to jump to different function and

softkey levels in accordance with the type of information and operation required.

Detailed error messages assist the user in the event of any operator errors.

The CC 10 possesses 4 function blocks (FBL) which can be selected by means

S1 S2 S3 S4

Operating instructions

CC 10

of the function keys or softkeys

board on the operating and programming panel (BPF 10):

S1

` NO.X

Chapter 3

(Axis changeover for asynchronous axes)

S2

` MODE

Chapter 4

(Automatic execution and setting–up mode)

S3

` MEMory

Chapter 5

(Storage)

S4

` INFOrmation

Chapter 6

(Diagnosis)

in the top row of the key-

These function blocks are described in the following chapters and explained with

the aid of examples.

2 - 2

Page 17

Flexible Automation

Introduction

Each FBL has a number of function levels, each of which may contain up to 4 different functions.

The level return key is located on the far right in the second line of the key-

board. This key is pressed in order to jump back to the preceding (higher)

function level. In some levels, operation of this key results in a jump back over two

functions levels. The functions of the individual keys are described in the subsection ”OPERATING ELEMENTS”.

The chapter ”INTRODUCTION” briefly describes the

` operating and programming panel BPF 10 and BPF 10 E

` operating elements

Operating instructions

CC 10

` display unit

of the CC 10, as well as general information of relevance for the subsequent chap-

ters.

The user is advised to read the chapter ”INTRODUCTION” and to note the informa-

tion in the subsections ”NOTES” and ”CONVENTIONS” for subsequent operation.

he chapter ”INTRODUCTION” starts with a list of the abbreviations used in these

operating instructions, before going on to describe the operating and programming

panel (BPF 10).

2 - 3

Page 18

Flexible Automation

Abbreviations

Introduction

ASCII ”American standard code for information interchange”

(data transmission code)

BAUD Baud rate or transmission rate in characters per second

BPF Operating and programming panel

CC Computer control

CL Control logic

CNC Computerized numerical control

DCR Digital cassette recorder

DFS Define store program

EPROM Erasable Programmable Read Only Memory

Operating instructions

CC 10

EEPROM Electrically Erasable Programmable Read Only Memory

FLASH-EPROM Side by side electrically deletable and programmable read

memory

FBL Function block

FU Function

I/O Input/Output

kByte Kilo–Byte (1024 bytes)

LED Light–emitting diode

MP Machine parameter

MPP Machine parameter program

NC Numerical control

P Part program

PG6 PG6 programming device

RAM Random Access Memory

SK Softkey

PCMCIA Personal Computer Memory Card International Association

(international association for standardising PC memory cards)

2 - 4

Page 19

Flexible Automation

Introduction

Device description and information for the user

This subsection contains a general description of the operating and programming

panel and the layout of the display . It also explains the significance of the individual

operating elements.

Operating and programming panel BPF 10/BPF 10 E

The operating and programming panel is available in two versions:

` as BPF 10/hand–held unit and

` as BPF 10 E/built–in version.

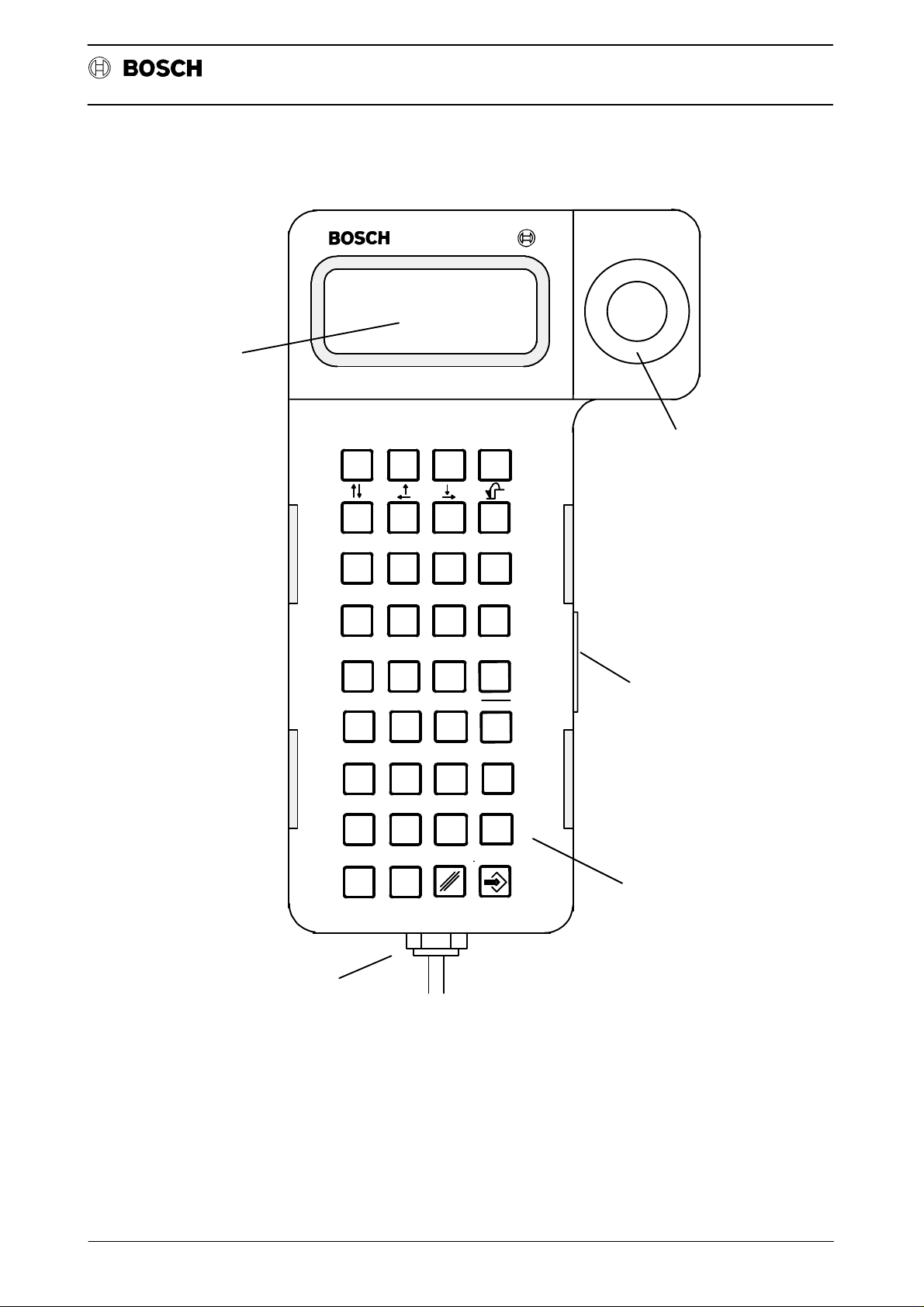

BPF 10 hand–held unit

The BPF 10 hand–held unit is intended for mobile applications. It comprises a

housing accommodating the electronics. The keypad, display unit and EMERGENCY OFF button are located on the front. The BPF 10 is connected to the control system via a cable. The housing is made of black thermoplastic material.

CC 10

Operating instructions

Keypad

Consent key

Display unit

EMERGENCY OFF key

The BPF 10 has a total of 36 keys with different functions (refer to the section OPERATING ELEMENTS of the BPF 10 (E)).

The CONSENT KEY is located on the side panel of the BPF 10. It must be pressed

whenever one of the freely definable function keys F1 – F12 is to be activated. This

key is positioned in such a way that it cannot simply be circumvented (for instance

by jamming the switching element). The contact in the consent key is opened by

spring force.

An LCD display unit (4 x 20 positions) with alphanumeric characters is used as the

display. The character height is approx. 5 mm.

The EMERGENCY OFF key is a slam button with locking switching element and

reliably opening contact. It must be wired to the monitoring circuit of the control cabinet.

2 - 5

Page 20

Flexible Automation

Display unit

Introduction

CC 10

Operating instructions

S1 S2 S3 S4

F1 F2 F3 F4

F5 F6 F7 F8

F9 F10 F11 F12

789

SPACE

456

123

.

0

Shift

EMERGENCY OFF key

+

Consent key

Key field

Cable connection

2 - 6

Page 21

Flexible Automation

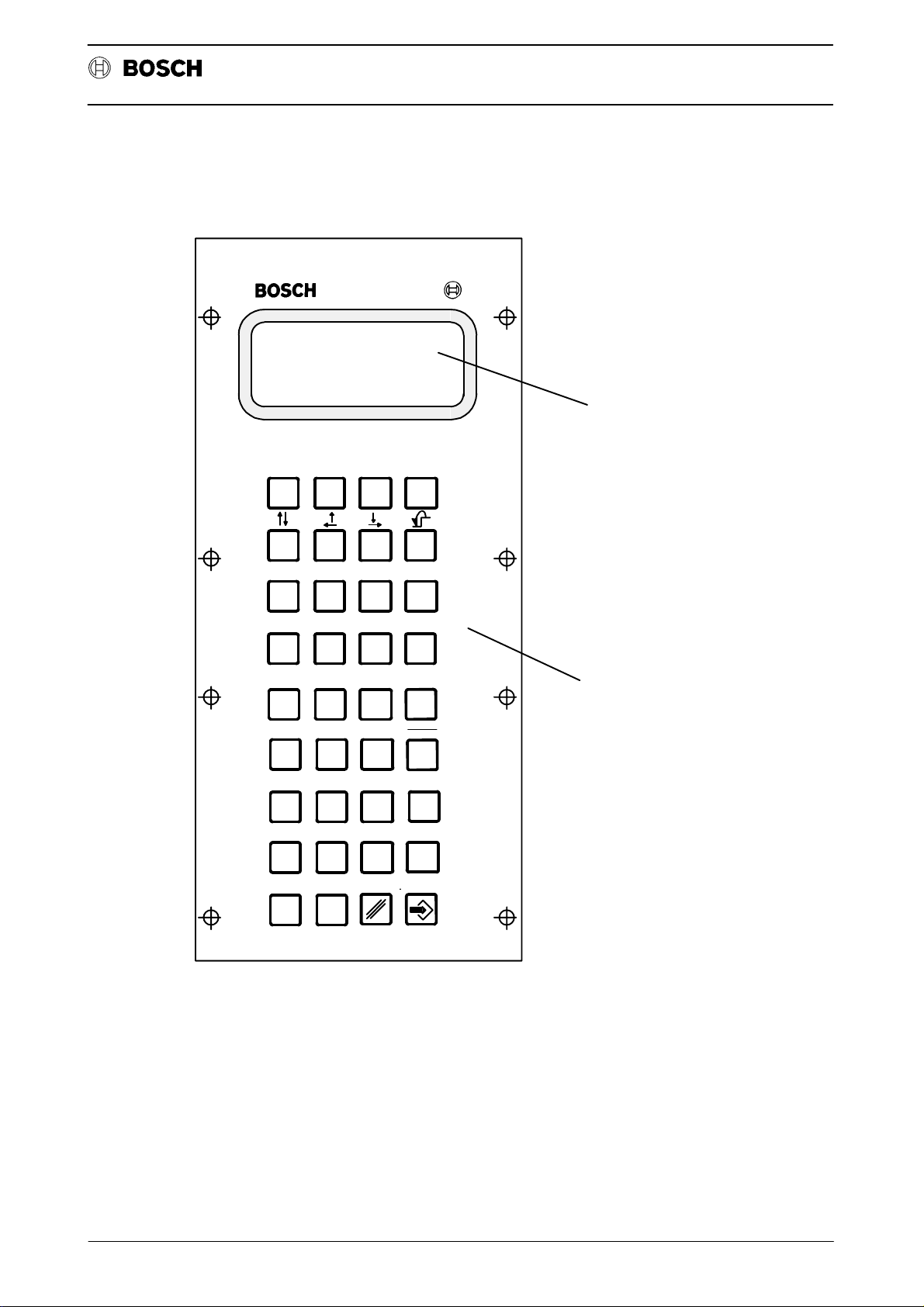

BPF 10 E/built–in version.

Keypad

Display unit

Introduction

The built–in unit is designed for installation in panel cut–outs (e.g. control cabinet

door or operating panel). It consists of a scaled panel to which the electronics of

the BPF 10 is secured.

The unit does not possess either an EMERGENCY OFF button or a consent key .

Otherwise, it is identical with the hand–held unit.

The keypad for the BPF 10 built–in unit is identical with that of the hand–held BPF

10. Refer to the description of the keypad for the BPF 10 hand–held unit for further

details.

A 4 x 20–position LCD display unit with alphanumeric characters is used for display

purposes. All ASCII characters can be represented. The character height is

approx. 5 mm.

Operating instructions

CC 10

2 - 7

Page 22

Flexible Automation

Introduction

S1 S2 S3 S4

CC 10

Operating instructions

Display

F1 F2 F3 F4

F5 F6 F7 F8

F9 F10 F11 F12

789

SPACE

456

123

.

0

Shift

Key field

+

2 - 8

Page 23

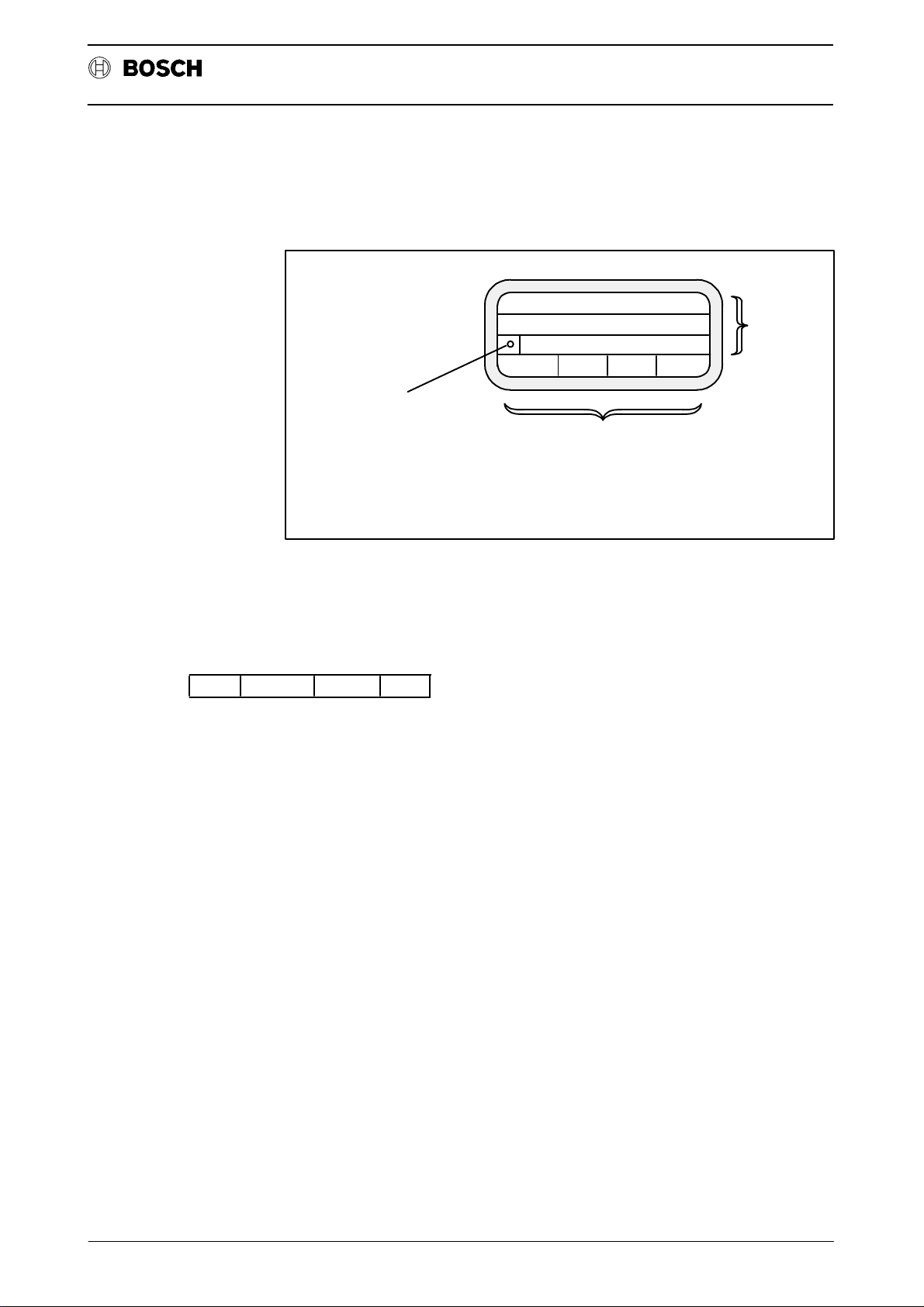

Flexible Automation

Display unit

Introduction

The typical display unit layout for the CC 10 is shown in the figure below:

Error display

Operating instructions

Text lines

and

information

CC 10

(A "Question mark" is shown

in this field if an error occurs.

A plain-text description of

the error is then contained

in the FBL INFO.)

The display consists of a 4 x 20–position display unit with alphanumeric characters.

The character height is approx. 5 mm. When the control system is switched on (refer to the starting display), the available function blocks ”NO.X, MODE, MEM and

INFO” are displayed in the bottom line. The function blocks (FBL) are activated by

pressing softkeys S1–S4:

NO.X MODE MEM INFO

NO.X: Axis changeover

MODE: MODE (automatic/setting–up)

MEM: MEMory (storage)

INFO: INFOrmation (diagnosis)

Function key or softkey

window (changing

significance)

2 - 9

Page 24

Flexible Automation

Introduction

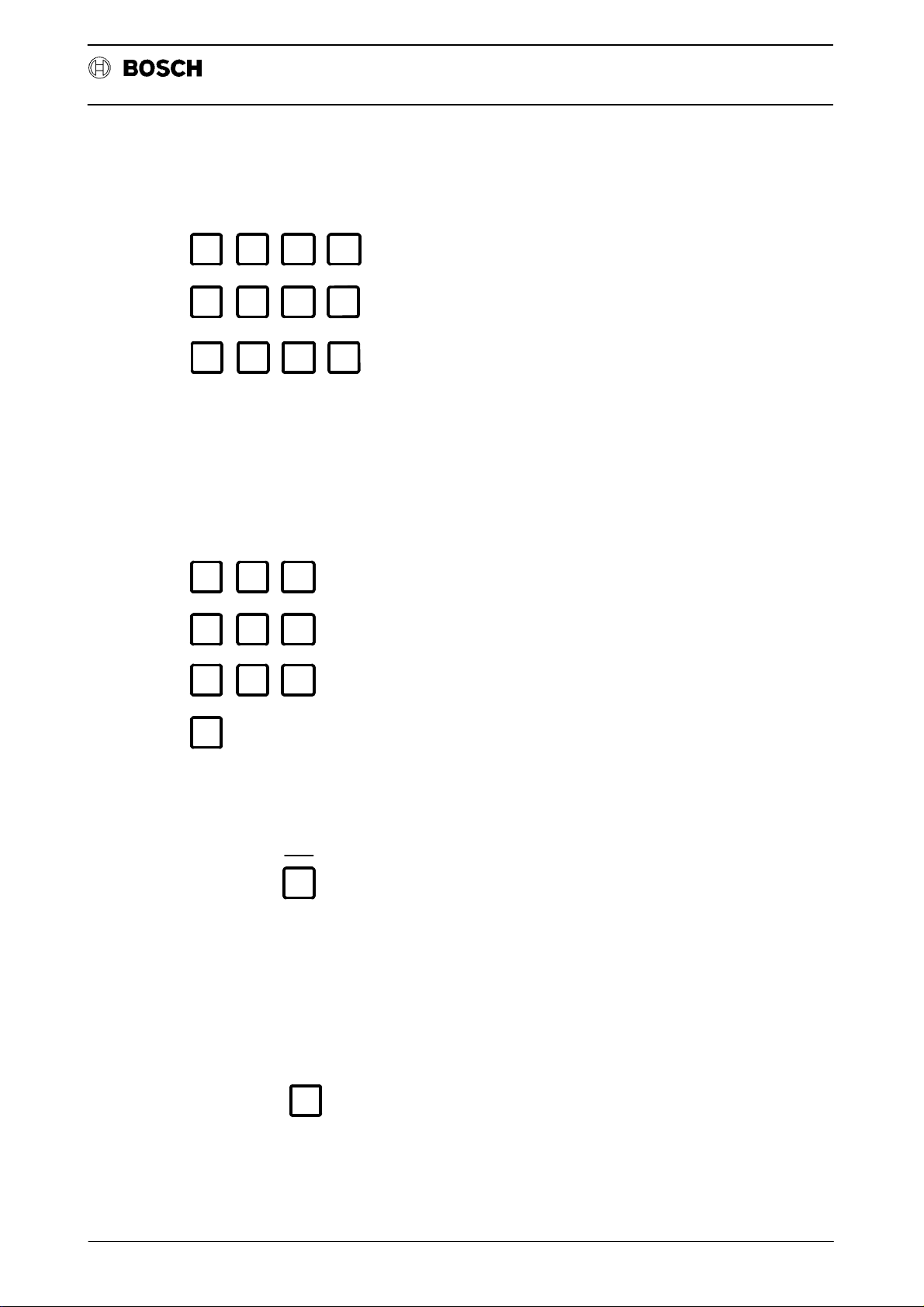

OPERATING ELEMENTS OF THE BPF 10 (E)

Softkeys

S1 S2 S3 S4

These keys are used to call up the individual function blocks:

S1: NO.X (axis selection)

S2: MODE

S3: MEMory

S4: INFOrmation

Cursor keys

CC 10

Operating instructions

Individual function:

The cursor can be moved to the left and right or up and down on the display unit

pressing these cursor keys.

The keys can be used in the program editor and for paging through the program

directory.

Programs and tables can be edited at the point at which the cursor is located.

Double function:

The cursor automatically jumps to the beginning of the preceding line when these

two cursor keys are pressed simultaneously.

Level return key:

The cursor jumps to the start of the next line when these two keys are pressed simultaneously .

By pressing the level return key, it is possible to jump back from one function level

to the previous (next higher) level or all the way back to the starting level.

2 - 10

Page 25

Flexible Automation

Function keys

F1 F2 F3 F4

F5 F6 F7 F8

F9 F10 F11 F12

The function keys F1 – F12 can be freely defined via the MPP and do not have any

predetermined functions.

Note:

No signals affecting safety such as ”STOP” or ”START” must be routed via these

keys.

Introduction

CC 10

Operating instructions

Number keys

Minus sign –

Plus sign +

789

456

123

0

Numbers 0 – 9

+

If the value of an input is negative, a negative sign must be written between the

address letter and the string of digits.

SPACE

Positive signs may be written but need not be.

SPACE

Space between words

2 - 11

Page 26

Flexible Automation

Decimal point

Delete key

SHIFT key

Introduction

.

Shift

Shift for keys with two functions in the program editor.

Pressed: Lower character active.

Released: Upper character active

CC 10

Operating instructions

ENTER key

Confirms and stores the input.

2 - 12

Page 27

Flexible Automation

NOTES

Introduction

This section contains general operating instructions which apply to the subsequent

chapters. No further reference will be made there to the specific significance of the

points listed below.

` Fixed functions are assigned to softkeys on all levels.

` Each FBL has a number of function or softkey levels which can be selected

in succession. The next following (lower) function level is activated when-

ever the corresponding function keys S1–S4 are pressed.

` Each new key assignment is designated as a softkey or function level.

` Each numerical value input must be confirmed by pressing the key .

Operating instructions

CC 10

` The level return key can be used to jump back to the preceding

(higher) level.

` In order to select a different FBL, it is necessary to jump back to the starting

level by pressing .

` When the control system is switched on, the reference points must first be

approached in order to permit execution of a program (exception: the func-

tion ”Approach reference point” is not included in absolute measuring sys-

tems).

` There is a switch on the front panel of the CC 10 module (refer to the chapter

EXPLANATIONS) which allows the EEPROM write protection to be

switched on and off.

` The machine control panel is provided by the machine tool manufacturer.

Operations associated with the machine control panel are therefore not ex-

plicitly described here.

2 - 13

Page 28

Flexible Automation

CONVENTIONS

Introduction

Press the function key

Enter numerical values

Confirm input of numerical values

Return to the next higher level

The following program example (P12) is always used for reference in the subsequent chapters.

N10X01=100G62

Operating instructions

CC 10

N20X02=200

N30X03=300

N40X01=0X02=0X03=0

N50M30

Significance:

Axes X01 – X03 are traversed to the SETPOINT positions 100 mm, 200 mm and

300 mm block–by–block (SEMI) or automatically (AUTO) in the function ”Execute

PROGram” (refer to FBL ”MODE”). All axes are then traversed to position ”0”.

2 - 14

Page 29

Flexible Automation

Starting level

Introduction

The CC 10 performs a self–test when the control system is switched on. When this

self–test has been completed successfully, the control system is in the starting

level and shows the following typical display for the CC 10:

Operating instructions

CC 10

Significance

of the functions

CC10 VERSION C20

SW-V: 63969.101

NO.X MODE MEM INFO

The version number refers to the operating system software and has the following

significance:

I

C40I

alphanumeric code for an existing

for CC 10

Development stage,

here: stage 4

N0.X: FBL AXIS SELECTION

Selection of asynchronous axes.

MODE: FBL MODE

version (internal Bosch code)

Maintenance version of a development

stage 0 = no maintenance version.

` MANUAL (setting–up)

` APPROACH REFERENCE POINT(S)

` SEMI–AUTOMATIC

` AUTOMATIC

` HAND

` TEST

MEM: FBL MEMORY (storage)

` Display, edit and store

part programs,

tool compensation values,

zero shifts,

machine parameters.

` Data input and output from/to external data media.

2 - 15

Page 30

Flexible Automation

Introduction

INFO: FBL INFORMATION (diagnosis)

` Display of

ACTUAL and SETPOINT locations,

difference between SETPOINT and ACTUAL positions,

lag, status (error display, condition, reset) as well as

input and output signals (digital interface CC 10 $ PLC).

` Trip to basic setting (Reset)

The respective FBL can be selected by pressing the softkeys S1 – S4 when the

starting display appears after the self–test. The functions which can be activated

in these FBL are described in the following chapters together with their significance.

Operating instructions

CC 10

2 - 16

Page 31

Flexible Automation

FBL NO.X (axis selection)

FUNCTION BLOCK NO.X (Axis selection)

Softkey S1 ”NO.X” is used to select asynchronous axes (max. 3 axes, e.g. X01 –

X03) if these have been defined in the machine parameter program. The first axis

is activated after switching on. Since each asynchronous axis has its own part program, each axis is controlled separately, i.e. a separate part program is executed

for each asynchronous axis.

Only synchronous axes can be selected if asynchronous axes have not been defined in the MPP. The following message is displayed if softkey ”NO.X” is pressed

nevertheless:

SYNCHRONOUS-AXIS

NO.X MODE MEM INFO

CC 10

Operating instructions

This indicates that only synchronous axes have been defined and that asynchronous axes cannot be selected.

3 - 1

Page 32

Flexible Automation

FBL NO.X (axis selection)

CC 10

Operating instructions

3 - 2

Page 33

Flexible Automation

FUNCTION BLOCK MODE

The modes can be selected via the interface inputs I1.0...1.2 (refer to the description of the digital interface in the ”Interface conditions”) or via the

NO.X MODE MEM INFO

The first menu level reached after pressing the softkey ”MODE” contains the two

function groups

` PROGram execution and

` MACHINE:

FBL Mode

CC 10

Operating instructions

The modes available in FBL ”MODE” are selected by pressing ”PROG” or

”MACH”.

PROG MASCH

4 - 1

Page 34

Flexible Automation

FUNCTION: MACHine

FBL Mode

The following modes can be called up when ”MACH” is pressed:

.

.

PROG MASCH

MANUAL MODE

REF MAN

Significance of these modes:

` REF: Approach REFerence point(s)

Operating instructions

CC 10

` MAN: MANual displacement of the axes (e.g. by means ofthe jog

Function: PROGram execution

The following modes can be selected by pressing ”PROG”:

.

.

PROG MASCH

P11 P12

AUTO SEMI TEST

Significance of these modes

` AUTO: AUTOmatic execution of a part program from the first block to

` SEMI: SEMI–automatic (block–by–block) execution of the program

keys on the machine control panel).

the end of the program.

by pressing the ST ART key on the machine tool control panel.

` TEST : Program check for SYNTAX errors.

4 - 2

Page 35

Flexible Automation

FBL Mode

MODE: Approach REFerence points

(applies only in conjunction with incremental measuring system)

The mode ”Approach reference point” (refer to the Interface conditions, Chapter

6 ”Digital interface”) is output at the digital interface outputs (CC 10 ! PLC) when

”REF” is pressed. The feedback signal from the corresponding inputs I4.2–I4.4

then allows the corresponding axes to approach the reference points.

The procedure for approaching the reference points is represented with the aid of

the various softkey levels. Selection is made by pressing ”MOD”, ”MACH” and

”REF”:

The starting display with selection menu appears when the control system is

switched on (version may differ, here C20I).

CC 10

Operating instructions

CC10 VERSION C20

SW-V: 63969.101

NO.X MODE MEM INFO

CC10 VERSION C20

SW-V:63969.101

PROG MASCH

Select ”MACH”

MANUAL MODE

REF MAN

Select ”REF” (not applicable in the case of absolute measuring systems)

REF

*POS COM DIST LAG

X01 0.000*

X02 0.000*

X03 0.000*

I

I

The axes can now be travelled to the reference point in accordance with the machine manufacturer’s instructions.

4 - 3

Page 36

Flexible Automation

FBL Mode

When the reference point switches have been reached, the axes are synchronized

with the zero pulse of the measuring system and the limit positions are displayed

for each axis.

Operating instructions

CC 10

REF

*POS COM DIST LAG

These are the coordinate values of the respective reference points as defined in

the MPP.

When an axis (e.g axis 1) approaches the reference point (manual or via G74) and

has synchronized with the zero point, the signal REFERENCE POINT APPROACH AXIS 1 is set in the digital interface (refer to the Interface conditions/Digital interface).

The INPOS signal *" is displayed after the corresponding axis to indicate that the

reference points have been reached.

X01 1550.000*

X02 -1885.756*

X03 0.000*

4 - 4

Page 37

Flexible Automation

MODE: MANual axis displacement

The mode ”MANual” is output at the interface outputs of the CC 10 (CC 10 ! PLC)

after selecting FBL ”MODE” and pressing ”MACH” and ”MAN”. The axes can

then be traversed ”manually” in accordance with the machine tool manufacturer’s

instructions. The operating sequence on the BPF 10 is as follows:

NO.X MODE MEM INFO

PROG MASCH

MANUAL MODE

REF MAN

FBL Mode

CC 10

Operating instructions

When the axis to be traversed has been selected, it can be moved to the following

positions, for example, either ”continuously” or ”incrementally” as selected:

or "I"

JOG

*POS COM DIST LAG

C: Continuous displacement

I: Incremental displacement

X01 550.000*

C

X02 885.756*

X03 0.000*

or

4 - 5

Page 38

Flexible Automation

TEST part program

FBL Mode

The part program ”P12” (refer to CONVENTIONS, Page 1–13) is to be executed

after selecting FBL ”MODE” and pressing ”PROG”.

It is advisable to check the program for possible syntax errors before it is executed.

This is done by pressing ”TEST”:

NO.X MODE MEM INFO

PROG MASCH

P11 P12

Operating instructions

CC 10

AUTO SEMI TEST

The displayed programs P11 and P12 are stored in the memory (EPROM).

AUTO SEMI TEST

Program check for SYNTAX errors.

P11 P12

PROG.NO.? -

Enter the program No.:

P11 *P12

12

NO SYNTAX ERROR

AUTO SEMI HAND TEST

(*) indicates that P12 has been activated and that no error has been found during

the syntax check

4 - 6

Page 39

Flexible Automation

FBL Mode

MODE: AUTOmatic part program execution

The entire part program is executed automatically from the first block to M30, for

example, by pressing ”AUTO”, entering the program number and STAR T (via the

interface). The momentary axis positions are indicated on the display screen.

P11 *P12

AUTO SEMI TEST

` When execution of ”P12” has been completed, ”AUTO” can be pressed to

start execution of another program (such as P11) or can be pressed

to return to the starting level.

CC 10

Operating instructions

` If another program is not selected, the START key can be pressed to exe-

cute the same program once more.

MODE: SEMI–automatic part program execution

The program can be executed block–by–block from the first block to M30, for example, in ”SEMI–AUTOMATIC” mode by pressing ”SEMI” and entering the program number. The START key must be pressed after each block has been executed in this case. Softkey S1 can be pressed at any time during execution to

switch over between AUTO and SEMI–automatic.

4 - 7

Page 40

Flexible Automation

NOTES

FBL Mode

1. If program ”P12” has been processed (edited) in FBL ”MEM” before ”Ex-

ecution” and then stored in the part program memory, the information

”P12R” appears in the top display line when the part program is selected

in the FBL ”MODE”:

P12R P11 P12

AUTO SEMI TEST

Significance:

Operating instructions

CC 10

P12: stored in the EEPROM

P12R: was last edited and is additionally stored in the working memory/RAM.

(Refer to the description of FBL ”MEM” for a more detailed explanation).

2. If no reference points have been approached before selecting mode

”PROG”, execution is blocked and a flashing question mark appears on

the screen. This question mark indicates that an error has occurred.

The significance of the error message can be determined in the FBL

INFO as follows.

NO.X MODE MEM INFO

AXIS STAT I/O

ERR COND RESET

The error is now displayed in ”plain text”.

F058 NO REF. POINT

UP DOWN

4 - 8

Page 41

Flexible Automation

FBL Memory

FUNCTION BLOCK MEM (Memory)

The FBL ”MEM” can be used to call up and edit part programs, tool compensations

and zero shifts as well as the machine parameter program (MPP). In addition, it

is also possible to transfer programs, compensation values or the MPP to an external data medium (refer to the control system summary in Chapter 1 of ”Interface

conditions”) or to load these into the memory from there.

NO.X MODE MEM INFO

The first function level of the FBL ”MEM” is reached by pressing ”MEM”.

CC 10

Operating instructions

PROGR. MEMORY:

10080 BYTE FREE

PROG CORR MPP DATA

10080 bytes are still free in the part program memory.

Significance of the functions

PROG: Call, check and edit a part program

CORR: Call, check and edit tool compensation values or zero shifts

MPP: Call the machine parameter program

DATA: Load and output data

5 - 1

Page 42

Flexible Automation

FBL Memory

Example: Create part program P12

The program example described in the subsection ”CONVENTIONS” (refer to

Page 2–14) is to be entered under program No. ”P12”.

Select FBL ”MEM” and then press ”PROG”.

PROG CORR MPP DATA

EDIT DEL REN

Significance:

EDIT: Edit program

DEL: Delete program

Operating instructions

CC 10

REN: Rename program

PROG.NO.?-

EDIT

Call P12

12

Cursor

-

()*_

NGX=-FMST HA

<--- ---> NEW

S1 S2 S3 S4

[]

Program line

Character line; the characters differ

according to axis designation,

auxiliary function etc.

Softkey window

Softkeys

5 - 2

Page 43

Flexible Automation

FBL Memory

Example: Enter the 1st block of P12: (N10X01=100G62)

Press S1 or S3 so that the character line is moved until the character to be programmed is located above the arrow " ". Then enter the character by pressing

the ENTER key or softkey 2. After this, the character appears on the display unit.

Numerical values are input directly via the keyboard (without ENTER).

S3 ! until N is positioned over .

-

NGX=-FMST HA

<--- ---> NEW

S2

Operating instructions

CC 10

or

N_

NGX=-FMST HA

<--- ---> NEW

10

Input:

N10_

NGX=-FMST HA

<--- ---> NEW

The numerical value 10 has been programmed.

[

[

5 - 3

Page 44

Flexible Automation

FBL Memory

S1 z until X is positioned over or

S2 z until = is positioned over or

S3 ! until G is positioned over or

N10X01=100G62_

Operating instructions

S2

1

0

S2

0

1

S2

6

0

2

CC 10

2

3

1

[]

=

=

=

0

2

3

0

X

0

0

0

2

0

=

0

NGX=-FMST HA

<--- ---> NEW

The block programmed in this manner is now completely located in the program

line: Block 1 has been programmed.

NC blocks N20 to N40 can be subsequently input by pressing S4 ”NEW”:

0

N

N

N

S4

S4

2

0

3

0

4

X

X

X

0

0

0

X

S4

N

3

0

5

=

0

M

3

0

0

5 - 4

Page 45

Flexible Automation

FBL Memory

Press the level return key twice after completing input. The program can then

be stored and executed in MODE ”MODE” under ”AUTO” or ”SEMI”.

P12R P11 P12

EDIT DEL REN

Significance:

P12: stored in the PMEM part program memory.

P12R: stored in the edit memory (RAM).

The following query appears if a change is detected when the EDIT mode is left:

Operating instructions

CC 10

Notes:

CHANGE

PART PROGR. MEMORY

TRANSFER TO FLASH

YES NO

The new part program P12 has thus been stored and can be executed in FBL

”MODE” under ”AUTO” or ”SEMI” .

CAUTION 5.1

Programs which have not been stored with ”YES” into the FLASH–EPROM

are no longer available after the supply voltage has been switched off.

Until now the CC10 had access to EEPROM as permanent memory. It was possible to write in individual lines of the EEPROM. The part programs were each

stored separately . This could, depending on the size of the program, be carried out

very quickly.

The CC10.3 now has access to FLASH-EPROMs as permanent memory . FLASHEPROMs are rarely written in or deleted. For this reason, the complete part program memory must be written into the FLASH-EPROM after a part program has

been altered or loaded (independent of the length of the program). This programming process takes a few seconds.

Whereas changes in the CC10.2 were made asynchronously in RAM and EEPROM, the FLASH memory of the CC10.3 functions solely as a resident backup

medium.

When the MEM/PROG level is exited in the CC10.3, the RAM memory is checked

for changes. If changes have been made, the user is informed and must decide

whether to accept the changes into the FLASH-EPROM.

Programming changes to the FLASH-EPROM are carried out in the background.

Further processing of the part programs is not possible during this time.

5 - 5

Page 46

Flexible Automation

FBL Memory

Example: Editing an NC block

The first NC block ”N10” is to be edited:

Old block: N10X01 = 100G62

New block: N10X01 = 200G62

.

.

PROG.NO.?-

EDIT

CC 10

Operating instructions

12

N10X01=100G62

The first NC block is displayed in the program line:

UP DOWN NEW

”NEW”: Assignment of a value

When ”NEW” is pressed, the cursor appears on the screen and can then be posi-

tioned on the ”0” to the right of the ”1” using the cursor keys:

N10X01=100G62

<--- ---> NEW

UP DOWN NEW

_

NGX=-FMST HA

[]

?

Press the delete key

N10X01=00G62

NGX=-FMST HA

<--- --->NEW

Input:

_

2

5 - 6

[]

?

Page 47

Flexible Automation

FBL Memory

CC 10

Operating instructions

N10X01=200G62

NGX=-FMST HA

<--- --->

The new (edited) NC block is displayed.

The next line can be edited by pressing ”UP” and ”NEW” after pressing the level

return key . The same also applies to all subsequent lines. The edited program can then be executed, for example, after storage (refer to ”PROGram execution”).

_

?[]

NEW

5 - 7

Page 48

Flexible Automation

Delete a program

FBL Memory

Programs stored in the part program memory can be deleted by pressing ”DEL”.

1. Deleting the part program in the EDIT or part program memory

.

.

P12R P11 P12

EDIT DEL REN

Call ”Delete”

Operating instructions

CC 10

PROG.NO.?-

DEL

Enter:

Delete the program in the RAM (EDIT, deletion of P12R in the RAM) or EEPROM

(select EEPROM).

After pressing ”EDIT”:

P12(R) is now deleted in the RAM (edit memory) and is no longer listed as ”P12R”

on the display.

12

DEL EDIT OR EEPROM

EDIT EEPROM

P11 P12

EDIT DEL REN

5 - 8

Page 49

Flexible Automation

FBL Memory

2. Deleting a part program which is stored only in the PMEM part program

memory (when, for example, it was previously deleted in the working

memory as in pt. 1)

P11 P12

EDIT DEL REN

Press ”DEL”

PROG.NO.?-

Operating instructions

CC 10

DEL

Enter:

Deleting the part program in the PMEM part program memory

Pressing the level return key triggers recognition of changes to the memory

and prompts the query, whether the deleted part program is also to be deleted in

FLASH.

12

DEL PMEM

YES NO

CHANGE

PART PROGR. MEMORY

TRANSFER TO FLASH

YES NO

YES: Program is also deleted in FLASH memory

NO: Program is not deleted

During the next run-up, the program is automatically copied from

FLASH into the part program memory and is once more at the user’s

disposal.

5 - 9

Page 50

Flexible Automation

Rename a program

FBL Memory

The program name can be changed by pressing ”REN”, e.g. P12 ! P20.

The old program name P12 no longer applies and the program is given the new

designation P20.

The rename function is possible only for part programs stored in the part program

memory. Part programs can thus be copied in this way.

` Select the program to be copied (P12). The program is now located in both

the RAM (P12R) and the PMEM part program memory (P12).

` Rename the PMEM program (P12 after P20).

` Select (P12R) and store (as P12) the RAM program.

` Save the changes in FLASH.

Operating instructions

CC 10

5 - 10

Page 51

Flexible Automation

COMPENSATION

FBL Memory

The function COMPENSA TION can be selected by pressing ”CORR” after selecting the FBL ”MEM” (MEMORY).

NO.X MODE MEM INFO

PROG CORR MEM DATA

HG

There are 2 different types of compensation:

` H: Tool length compensation

Operating instructions

CC 10

` G: Zero shift.

Tool length compensation

A total of 72 length compensation values can be entered in the table and stored

for 3 x 1 asynchronous axis (24 compensation values for each axis) or max. 72

compensation values for 1 axis or max. 24 compensation values for 3 synchronous

axes (the user can define the number of axes in the MPP). If 72 length compensation values are agreed in the machine parameter program for one axis, these compensation values are always of fset in the axis defined as the first axis in the MPP.

For example, if there are 3 synchronous axes (e.g. 2 positioning axes and one machining or feed axis with a tool of variable length), the number of axes to be compensated is defined as ”1” in the MPP. The user can now enter 72 different compensation values in the length compensation table.

The function is called by pressing ”H”.

HG

DATA INPUT

LENGTH OFFSET

GROUP: _

Enter the length compensation (offset) group (e.g. 72):

72

5 - 11

Page 52

Flexible Automation

FBL Memory

H71 X01 0.000

H72 X01 0.000

H01 X01 0.000

.

.

The selected group is always shown in the middle line.

A length compensation value can now be assigned to axis X01 by pressing

”NEW”. The corresponding compensation group can be selected by pressing

”UP” or ”DOWN”. As an example, the compensation value ”1.000 mm” will now

be assigned to the group 01:

Set " > " to group 01 using softkey ”UP” and then press ”NEW”.

>

UP DOWN NEW

Operating instructions

CC 10

H72 X01 0.000

H01 X01

H02 X01 0.000

1

H72 X01 0.000

H01 X01 1.000

H02 X01 0.000

H72 X01 0.000

H01 X01 1.000

H02 X01 0.000

>

UP DOWN

.

>

UP DOWN NEW

>

UP DOWN NEW

NEW

0 0 0

The compensation value 1.000 has now been entered in group 01 and becomes

active immediately, irrespective of whether the compensation value has been

stored in the EEPROM or not.

5 - 12

Page 53

Flexible Automation

FBL Memory

So that the compensation value is still available after switching the control off and

then back on again, the length compensation value input in this way must be stored

in the EEPROM. T o do this, it is necessary to press the level return key twice.

The system then enquires whether the new value is to be stored or not.

Press level return key twice.

STORE PARAMETER?

YES NO

Store: yes

Operating instructions

CC 10

HG

The compensation value has now been stored.

In the same way, it is possible to assign 24 compensation values to each axis. The

corresponding length compensation values are selected by pressing ”UP” or

”DOWN”. Here, for example, it is wished to assign a value to axis X03 in the compensation group ”10”.

HG

Select ”H”

H10 X01 0.000

>

X02 0.000

X03 0.000

UP DOWN NEW AXIS

5 - 13

Page 54

Flexible Automation

FBL Memory

Select ”AXIS” twice

H10 X01 0.000

X02 0.000

>

X03 0.000

UP DOWN NEW AXIS

Press ”NEW” and enter the new value.

Refer to Page 5–12 for a description of the remaining steps.

If it is wished to select a different compensation group, (for example, e.g. group 12),

”UP” must be pressed twice.

.

.

Operating instructions

CC 10

UP DOWN NEW AXIS

Press twice

H12 X01 0.000

Compensation group 12 can now be edited.

A total of 24 compensation groups are available for each axis. If ”UP” is pressed

when group 24 is activated, group 01 is displayed again.

Important:

Compensation values edited during program execution (in SEMI or AUTO mode)

may only become effective 5 blocks later owing to preparatory block processing.

>

X02 0.000

X03 0.000

UP DOWN NEW AXIS

5 - 14

Page 55

Flexible Automation

Zero shift

FBL Memory

A total of 6 zero shifts (axis–specific) G54–G59 can be entered (refer to Programming instructions).

HG

The zero shift table is called by pressing ”G”:

DATA INPUT

ZERO SHIFT

GROUP: _

Operating instructions

CC 10

Select group G54, for example:

5 4

G54 X01 0.000

The other groups G55 – G59 can be selected by pressing ”UP” and ”DOWN”.

Example:

The compensation value 1.000 is to be assigned to axis X02 in group G54.

UP DOWN NEW AXIS

Select an axis (e.g. X02)

>

X02 0.000

X03 0.000

UP DOWN NEW AXIS

G54 X01 0.000

>

X02 0.000

X03 0.000

UP DOWN NEW AXIS

5 - 15

Page 56

Flexible Automation

FBL Memory

Assignment

G54 X01 0.000

>

X02 _

X03 0.000

UP DOWN NEW AXIS

The zero shift value ”1.000” is to be entered

100.0

G54 X01 0.000

>

X02 1.000

X03 0.000

UP DOWN NEW AXIS

CC 10

Operating instructions

G54 X01 0.000

>

X02 1.000

X03 0.000

UP DOWN NEW AXIS

The zero shift has been programmed for X02.

Zero shift values can be assigned to the axes X1, X2 and X3 in all zero shift groups

G54–G59 using the procedure set out above.

The zero shift values must be stored when input has been completed. Proceed as

follows for this purpose:

Press the level return keytwice ( ).

STORE PARAMETER

YES NO

5 - 16

Page 57

Flexible Automation

FBL Memory

The following display appears on the screen when the compensation values have

been stored:

HG

Important:

Compensation values which are edited during program execution (in SEMI or

AUTO mode) may only become effective 5 blocks later due to preparatory block

processing.

Operating instructions

CC 10

Note

It is also possible to program an additive zero point shift(G160). See programming

instructions.

5 - 17

Page 58

Flexible Automation

Machine parameter program (MPP)

The machine parameters can be called up and paged through, edited or stored in

the EEPROM by pressing ”MPP” in FBL ”MEM”.

NO.X MODE MEM INFO

PROG CORR MPP DATA

MACHINE PARAMETER

EDIT DISP. PROG.

FBL Memory

CC 10

Operating instructions

Significance:

EDIT: Edit

DISP: Display

PROG: Program

Example: Display machine parameters

EDIT DISP. PROG.

P0010 NO. OF CC10

OLD = 98765

UP DOWN

The OLD parameter (old value) stored under No. P0010 = 98765 is displayed. All

machine parameters can be displayed by pressing ”UP” or ”DOWN” (refer to the

chapter on machine parameters in ”Interface conditions”).

Press once in order to return.

5 - 18

Page 59

Flexible Automation

FBL Memory

Example: Edit machine parameters

EDIT DISP. PROG.

MPP-EDIT

PASS WO: _

In order to be able to edit the machine parameters, it is necessary to enter a specific

code. This is the number ”337”.

Operating instructions

CC 10

3 3 7

PASS WO:***_

P0010 NO. OF CC10

OLD = 98765

UP DOWN NEW

The machine parameter can now be edited by pressing ”NEW”.

P0010 NO. OF CC10

OLD = 98765

NEW = _

UP DOWN NEW

Old parameter: 98765

New parameter: 99999

9 9 9 9 9

5 - 19

Page 60

Flexible Automation

FBL Memory

P0010 NO. OF CC10

OLD = 98765

NEW = 99999

UP DOWN NEW

P0010 NO. OF CC10

OLD = 99999

UP DOWN NEW

The new parameter has now been entered and can be stored in the EEPROM.

Operating instructions

CC 10

Press once.

EDIT DISP. PROG.

Press PROG.

Example: Programming machine parameters

When machine parameters have been entered or edited, they are stored by

pressing the key and then ”PROG”.

EDIT DISP. PROG.

MP PROGRAMMING OK

RESTART

This display indicates that the new parameters have been stored in the EEPROM.

Press once; the CC 10 performs a system restart (the READY signal is cancelled).

5 - 20

Page 61

Flexible Automation

Data input and output

FBL Memory

After selecting FBL ”MEM” (MEMORY), it is possible to transfer data (programs,

tables, tool compensation values and machine parameters) from the memory to

an external data medium or read this data from there into the memory by pressing

”DA T A”.

Before reading in or outputting data, it is possible to select the external data medium by pressing ”DEV”.

NO.X MODE MEM INFO

PROG CORR MPP DATA

INTERFACE MODE

OFFLINE V24

Operating instructions

CC 10

IN OUT IMOD INIT

Interface selection

The interface defined in machine parameter P0491 is valid when the system is

switched on. The setting can be changed by operation of ”IMOD”.

* OFFLINE V24

* ONLINE V24

* ONLINE PLC

INTERFACE MODE

OFFLINE V24

IN OUT IMOD INIT

The data interface can be configured with ”INIT” before reading data in or out.

The power-up state is defined in parameters P0492...P0497 or P0481...P0486.

5 - 21

Page 62

Flexible Automation

FBL Memory

OFFLINE V24

4800 BAUD

UP DOWN NEW

The following speeds (BAUD rate) can be set with ”NEW”.

110 BAUD

300 BAUD

600 BAUD

1200 BAUD

2400 BAUD

4800 BAUD

It is possible to page through the list of adjustable interface parameters with ”UP”

or ”DOWN”.

Operating instructions

CC 10

OFFLINE V24

7 BIT

UP DOWN NEW

The character length may be

7 bits or

8 bits.

OFFLINE V24

PARITY EVEN

UP DOWN NEW

Each character can be provided with a parity bit. Possible settings:

* Even parity

* Odd parity

* No parity

5 - 22

Page 63

Flexible Automation

FBL Memory

OFFLINE V24

1 STOP BIT

UP DOWN NEW

The number of stop bits can be defined as follows:

1 stop bit

1.5 stop bits

2 stop bits

The start bit cannot be adjusted; one start bit is always sent before the code of the

ASCII character.

OFFLINE V24

HARDWARE HANDSHAKE

Operating instructions

CC 10

UP DOWN NEW

The user must specify for each external input or output device whether it is operated with a ”software handshake”, ”hardware handshake” or without ”handshake”

(control character).

Hardware handshake The following characters are involved here:

DTR Data Terminal Ready

Ready to receive status is output (output signal)

DSR Data Set Ready

Permission to transmit status is recognized

(input signal)

Software handshake The following characters are involved here:

DC2 Start of transmission (XON)

DC4 End of transmission (XOFF)

OFFLINE V24

WITHOUT E-CODE

UP DOWN NEW

Data transmission reliability can be increased by the read monitoring function ”E–

CODE” (refer to Programming Instructions).

Possible parameters: With E–Code

Without E–Code

5 - 23

Page 64

Flexible Automation

XTRANS

Adjusting the XTRANS

interface

FBL Memory

BOSCH offers with XTRANS a comfortable File handling program to tfansfer Data

from PC to CC10 controller an d vice versa. The interface parameters have to be

adjusted according to the CC10 requirements.

F7

SYSTEM

F2

SET UP

F1

INTERFACE

Operating instructions

CC 10

INTERFACE DATA: No. of interface: 1

Baudrate: 4800

Data bits: 7

Stop bits: 1

Patrity: EVEN

Handshake NO

Timeout 20

5 - 24

Page 65

Flexible Automation

Reading in data

FBL Memory

After initializing the interface, it is possible to read part programs, tables and/or machine parameters into the memory of the control system. The selection is made by

pressing ”IN” as well as ”PROG” or ”TAB”. or ”MPP”.

Select ”DATA”

PROG CORR MPP DATA

Select interface, set interface parameters with ”INIT”

IN OUT IMOD INIT

Select ”IN” (reading in).

Operating instructions

CC 10

IN OUT IMOD INIT

READING IN of programs, tables or machine parameters (”PROG, TAB. or MPP”).

The DCR operates with a hardware control character; for this reason, switch to

HARDWARE HANDSHAKE previously with ”INIT”.

INTERFACE MODE

DATA INPUT

PROG TAB. MPP

Select MP (machine parameters)

XTRANS operation

F1

Transfer

Select the file(s) with +

INTERFACE MODE

DATA INPUT

F2

Output

F3

N files

START

Confirmation with ENTER in XTRANS triggers the transfer of data.

PROGR. MEMORY:

10240 BYTE FREE

PROG CORR MPP DATA

After data transfer, the CC 10 returns to the FBL ”MEM”. The free memory space

is reduced during transfer of part programs.

5 - 25

Page 66

Flexible Automation

Reading in part programs

FBL Memory

Read in selection ”Part programs”

INTERFACE MODE

DATA INPUT

PROG TAB MPP

Select ”ONE” part program

CC 10

Operating instructions

ONE MANY ALL

Enter the part program number

PROG.NO.?

6

XTRANS operation

F1

Transfer

Select the file(s) with +

F2

Output

F3

N files

”START” reading in part program

DATA INPUT

START

Confirmation with ENTER in XTRANS triggers the transfer of data.

5 - 26

Page 67

Flexible Automation

FBL Memory

Once the part program has been read in, it can be stored in the part program

memory.

PROGR. MEMORY:

10240 BYTE FREE

PROG CORR MPP DATA

Select PROG

PROGR. MEMORY:

10240 BYTE FREE

PROG CORR MPP DATA

Operating instructions

CC 10

Press YES

PROG.NO.: 6

STORE?

TRANSFER TO FLASH?

YES NO END

Answering the query prompted when leaving the MEM/PROG level with YES

transfers the program into the FLASH memory.

CHANGE

PART PROGR. MEMORY

TRANSFER TO FLASH?

YES NO

5 - 27

Page 68

Flexible Automation

Data output

FBL Memory

Programs, tables or machine parameters can be transferred from the CC 10 to the

previously defined by pressing ”OUT”.

Example: Program output

After selecting the FBL ”MEM” and pressing ”DATA” and ”OFF”, data can be

transferred from the control system memory to an external data medium. As an

example a part program will be output to a PC.

PROG CORR MPP DATA

IN OUT IMOD INIT

(Data output)

Operating instructions

CC 10

PROG TAB MPP

(Part program output)

ONE MANY ALL

(Output of 1 program)

PROG.NO.?

Enter the program number

The part program can now be output.

XTRANS operation

F1

Transfer

F1

Input

F4

Standard

Enter the file name in which your data should be stored

5 - 28

Page 69

Flexible Automation

FBL Memory