Bosch BRB-60HWD1N1-M19 Operation Manual

Bosch Inverter Ducted Packaged Heat Pump

19 SEER Series (5 Ton Capacity)

R410A

Installation & Operation Manual

BTC 761701105 A (2019/03) US

|

2

Bosch Inverter Ducted Packaged Heat Pump Installation & Operation Manual

03.2019 | BTC 761701105 AData subject to change

Installation & Operation Manual Bosch Inverter Ducted Packaged Heat Pump | 3

Table of Contents

1 Key to Symbols and Safety Instructions 4

1.1 Key to Symbols 4

1.2 Safety 4

2 Component Location 6

3 Dimensions 7

3.1 Unit Dimensions 7

3.2 Dimensions - Back and Bottom 8

3.3 Dimensions - Right and Top 9

4 Installation 10

4.1 Pre-Installation 10

4.2 Rigging And Lifting 10

4.3 Location Restrictions 10

4.4 Rooftop Installation - Curb Mounting 12

5 Airfl ow Performance 13

6 Indoor Fan Motor Function 14

13 System Operation and Troubleshooting 22

13.1 Control Logic Description 22

13.2 Sensors (Thermistors/Pressure Transducer) 22

13.3 Defrost Description 23

13.4 Compressor Crankcase Heater Description 23

13.5 Reversing Valve Operation 23

13.6 Protection Functions 24

13.7 Fault Code Table 25

13.8 Parameter Point Check Table 26

13.9 Control Board Overview 27

13.10 Error Code Troubleshooting 28

13.11 Temperature and Resistance Relationship Tables (for Sensors) 34

13.12

Temperature and Resistance Relationship Tables (for T5 & Tf Sensors)

13.13 Wiring Diagram 37

35

14 Maintenance 38

14.1 Cleaning Precautions 38

14.2 Regular Maintenance 38

7 Ductwork 14

8 Condensate Drain Connection 16

8.1 Install Drain Pipe 16

9 Air Filter (Not Factory-Installed) 16

10 Electrical Wiring 17

10.1 Power Wiring 17

10.2 Grounding 17

10.3 Control Wiring 17

11 Start Up 19

11.1 System Start Up 19

12 System Charge Adjustment 20

12.1 Charging: Weigh-In Method 20

12.2 S ubc ooli ng C harg ing and Refr iger ant Adju stm ent I n C ooli ng

(Above 55°F Outdoor Temp.) 20

BTC 761701105 A | 03.2019

Data subject to change

|

4

Bosch Inverter Ducted Packaged Heat Pump Installation & Operation Manual

1 Key to Symbols and Safety Instructions

1.1 Key to Symbols

Warnings

Warnings in this document are identifi ed by a

warning triangle printed against a grey background.

Keywords at the start of a warning indicate the type and

seriousness of the ensuing risk if measures to prevent the

risk are not taken.

The following keywords are defi ned and can be used in this document:

DANGER indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided,

could result in minor to moderate injury.

NOTICE is used to address practices not related to personal

injury.

Important information

1.2 Safety

Please read before proceeding

DANGER: HIGH VOLTAGE

Failure to follow this warning could result in property

damage, severe personal injury, or death.

WAIT THREE (3) MINUTES after disconnecting power

prior to touching electrical components as they may

hold a dangerous charge of 380 VDC,then verify DC

Voltage is less than 42VDC at inverter TEST POINTS

P-N.

NOTICE:

This document is customer property and is to remain

with this unit. Please return to service information

pack upon completion of work.

These instructions do not cover all variations in

systems or provide for every possible contingency to

be met in connection with the installation.

Should further information be desired or should

particular problems arise which are not covered

sufficiently for the purchaser’s purposes, the matter

should be referred to your installing dealer or local

distributor.

This symbol indicates important information where

there is no risk to people or property.

This document contains a wiring diagram and service

information. This is customer property and is to remain with this

unit. Please return to service information pack upon completion

of work.

WARNING:

This information is intended for use by individuals

possessing adequate backgrounds of electrical

and mechanical experience. Any attempt to repair

a central air conditioning product may result in

personal injury and/or property damage.

WARNING: ELECTRICAL SHOCK

Failure to follow this warning could result in property

damage, severe personal injury, or death.

Disconnect all electric power, Including remote

disconnects before servicing. Follow proper lockout/

tagout procedures to ensure the power cannot be

inadvertently energized.

03.2019 | BTC 761701105 AData subject to change

Installation & Operation Manual Bosch Inverter Ducted Packaged Heat Pump | 5

WARNING: PERSONAL INJURY/ENVIRONMENTAL HAZARD

Any attempt to repair a central air conditioning

product may result in property damage, severe

personal injury, or death.

These units use R-410A refrigerant which operates

at 50 to 70% higher pressures than R-22. Use only

R-410A approved service equipment. Refrigerant

cylinders are painted a “Rose” color to indicate the

type of refrigerant and may contain a “dip” tube

to allow for charging of liquid refrigerant into the

system. All R-410A systems with variable speed

compressors use a POE oil (VG74 or equivalent )

that readily absorbs moisture from the atmosphere.

To limit this ‘hygroscopic“ action, the system should

remain sealed whenever possible. If a system has

been open to the atmosphere for more than 4 hours,

the compressor oil must be replaced. Never break a

vacuum with air and always change the driers when

opening the system for component replacement.

CAUTION: HOT SURFACE

Do not touch top of compressor. May cause minor to

severe burning. Failure to follow this Caution could

result in property damage or personal injury.

CAUTION: BURN HAZARD

Failure to follow this warning will result in abrupt

release of system charge and may result in personal

injury and/or property damage. Extreme caution

should be exercised when applying gauges to service

ports.

WARNING: ELECTRICAL SHOCK

Failure to follow this warning could result in property

damage, severe personal injury, or death.

Grounding is essential before connecting electrical

supply.

WARNING:

This product can expose you to chemicals including

Lead and Lead components, which are known to the

State of California to cause cancer and birth defects

or other reproductive harm. For more information

go to

www.P65Warnings.ca.gov.

CAUTION: HIGH PRESSURE

Failure to follow proper procedures can result in

personal illness or injury or severe equipment

damage.System contains oil and refrigerant under

high pressure. Recover refrigerant to relieve pressure

before opening system.

WARNING: GROUNDING REQUIRED

Failure to inspect or use proper service tools may

result in equipment damage or personal injury.

Reconnect all grounding devices. All parts of this

product that are capable of conducting electrical

current are grounded. If grounding wires, screws,

straps, clips, nuts, or washers used to complete a

path to ground are removed for service, they must

be returned to their original position and properly

fastened.

BTC 761701105 A | 03.2019

Data subject to change

|

6

Bosch Inverter Ducted Packaged Heat Pump Installation & Operation Manual

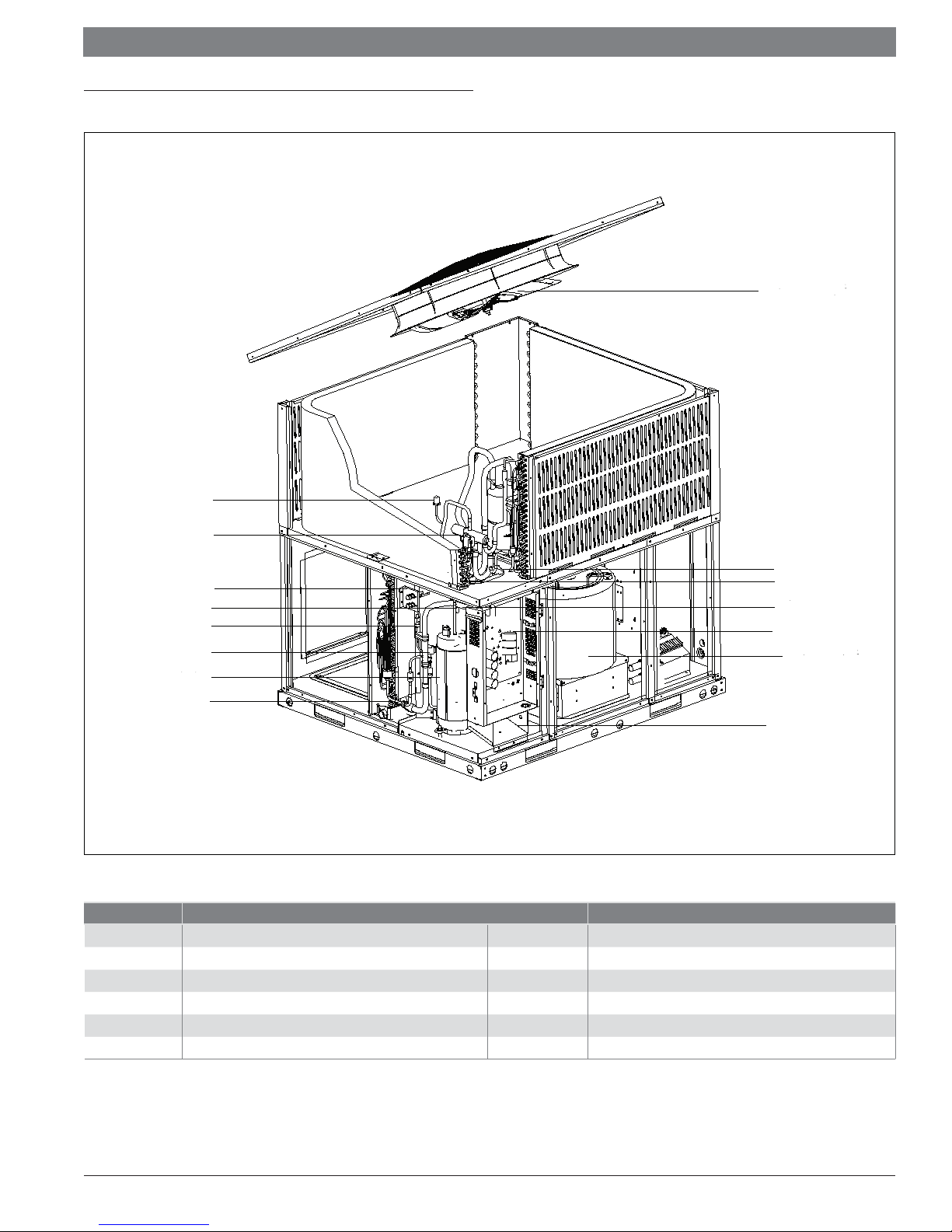

2 Component Location

Outdoor Fan

HPS

RV

Service Valves

T5

PT

EEV

COMP

T2

Figure 1

Component Descriptions Component Descriptions

HPS High pressure switch

PT Pressure transducer Tf Radiator temp. sensor

T2 Indoor coil temp. sensor Th Comp. return temp. sensor

T3 Condenser temp. sensor EEV Electronic expansion valve

T4 Ambient temp. sensor RV Reversing valve

T5 Comp. discharge temp. sensor COMP Compressor

Table 1 Component Descriptions

T3L Condensor outlet temp. sensor

T3L

T3

Th

Tf

Indoor Fan

T4

03.2019 | BTC 761701105 AData subject to change

Installation & Operation Manual Bosch Inverter Ducted Packaged Heat Pump | 7

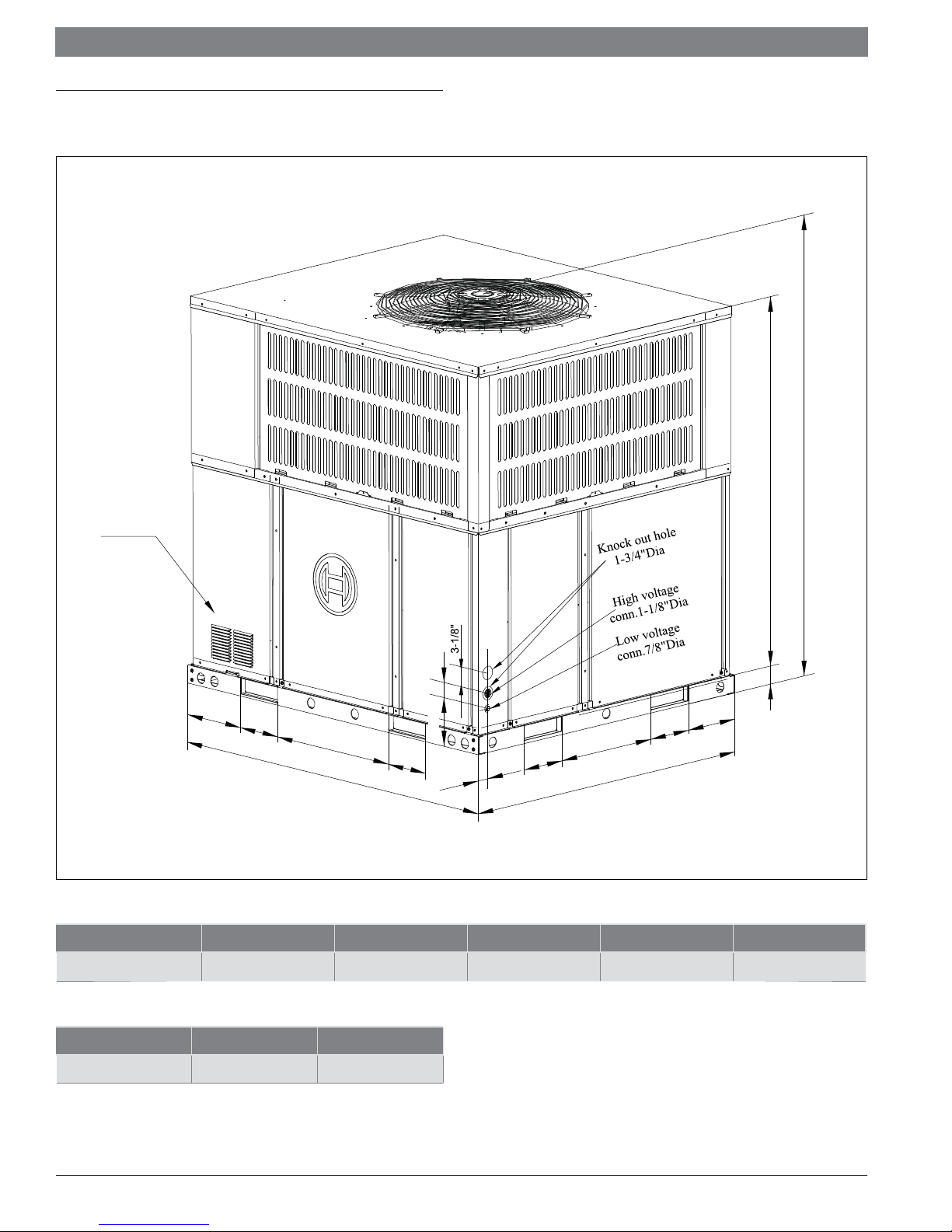

3 Dimensions

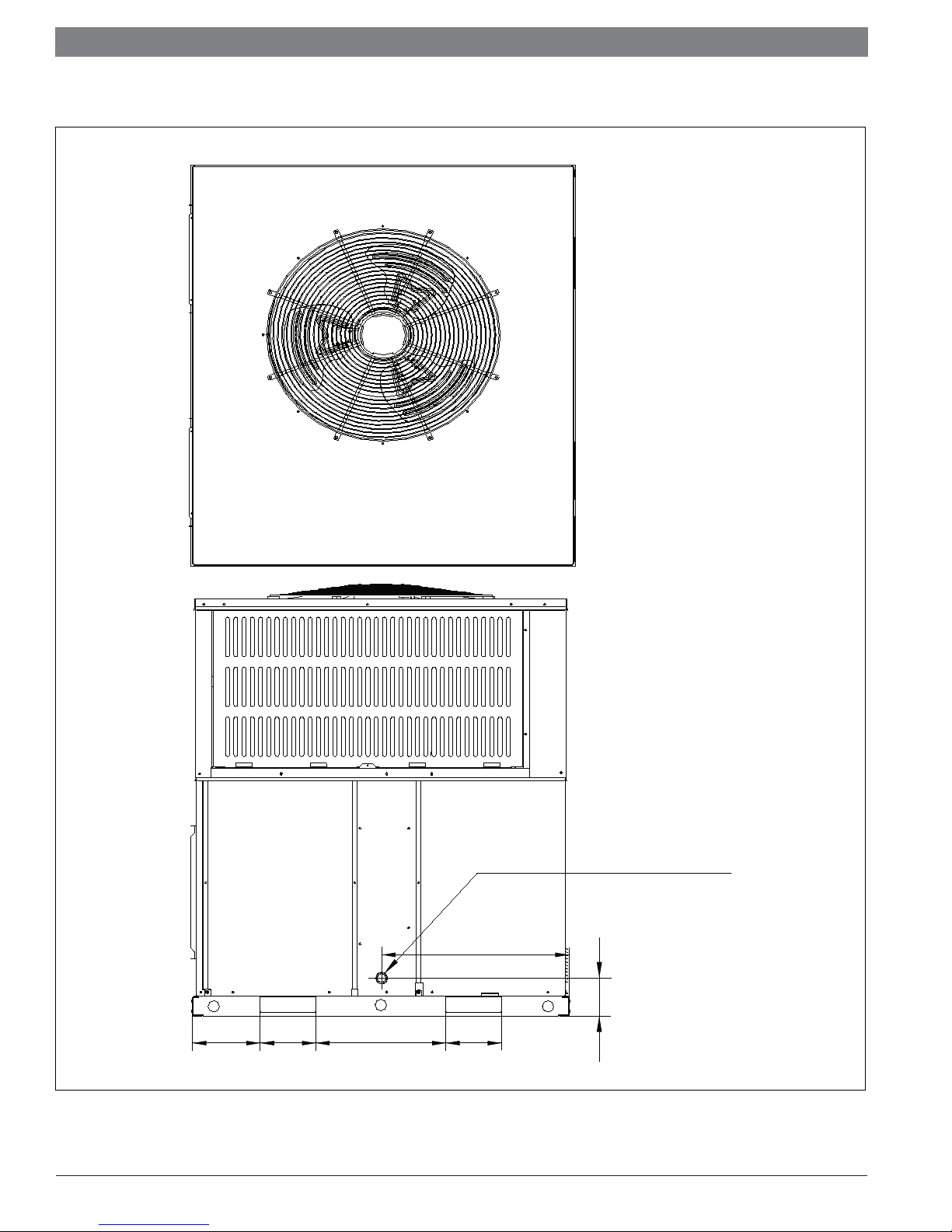

3.1 Unit Dimensions

H

A

Front

.

.

.

2-3/16"

9-5

/16"

6-

5/8"

B

L

Figure 2

6-5/8"

5-1/2"

2-1/

"

15-1/2

/8"

-5

6

"

4

W

Heat Pump Model L W H A B

6

-5/8"

8-1/16"

2-3/8"

BRB-60HWD1N1-M19 51-9/16" 44-13/16" 51-7/16" 47-5/16" 19-11/16"

Table 2 Unit Dimensions

Heat Pump Model Net Weight Gross Weight

BRB-60HWD1N1-M19 561 lbs (255kg) 596 lbs (271kg)

Table 3 Unit Weights

BTC 761701105 A | 03.2019

Data subject to change

|

8

Bosch Inverter Ducted Packaged Heat Pump Installation & Operation Manual

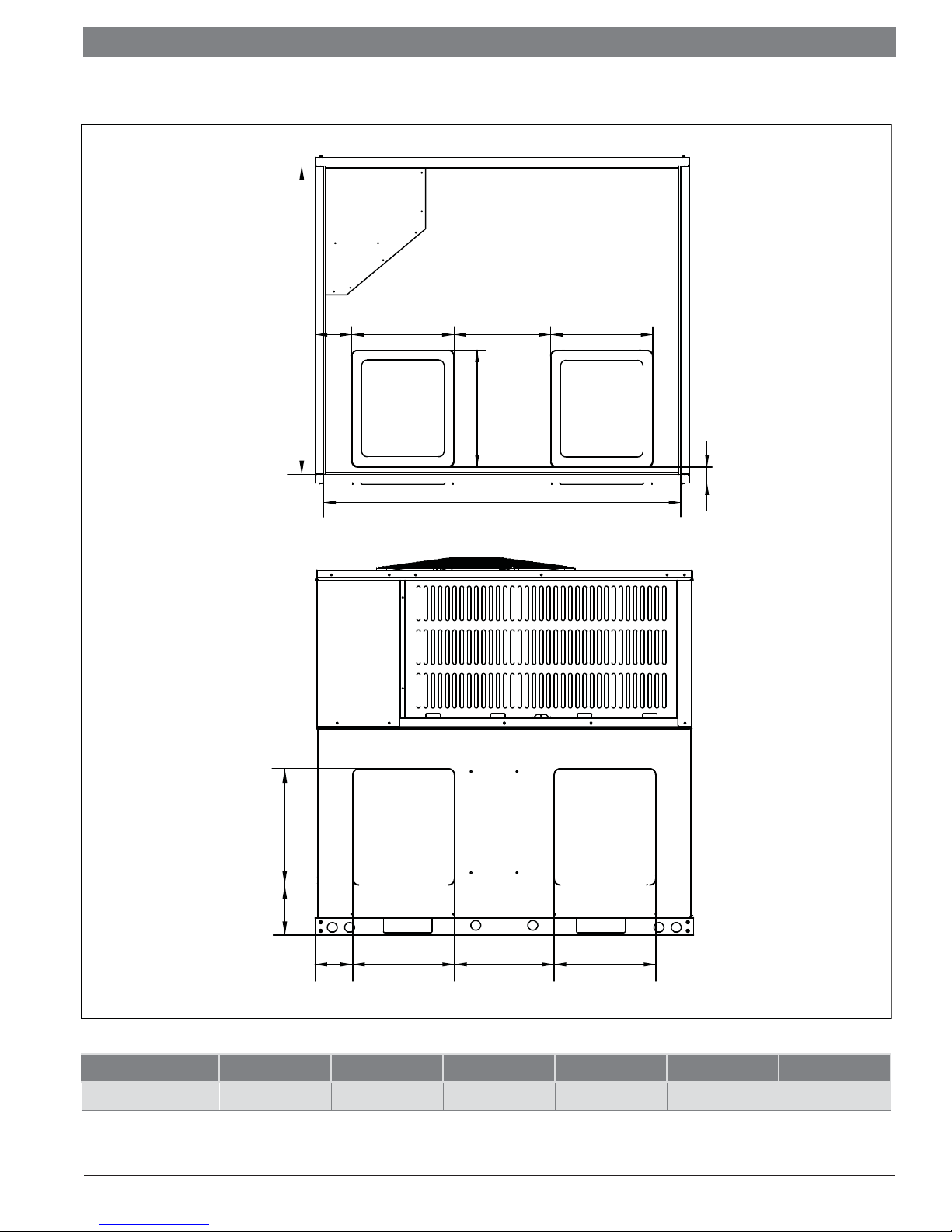

3.2 Dimensions - Back and Bottom

Bottom view

D

4-3/4"

OPTIONAL

RETURN

AIR

Back view

E

OPENING

F

12-15/16"

C

E

OPTIONAL

SUPPLY

OPENING

AIR

2-3/16"

G

6-3/16"

5-3/16"

Figure 3

Heat Pump Model C D E F G H

BRB-60HWD1N1-M19 49-1/4" 42-1/2" 14-1/8" 16-1/8" 15-7/8" 13-7/8"

Table 4 Dimensions - Back and Bottom

SUPPLY

DUCT

OPENING

H

13-9/16"

RETURN

DUCT

OPENING

H

03.2019 | BTC 761701105 AData subject to change

Installation & Operation Manual Bosch Inverter Ducted Packaged Heat Pump | 9

3.3 Dimensions - Right and Top

Top View

Right side view

8-1/16"

Figure 4

BTC 761701105 A | 03.2019

6-5/8"

15-1/2"

Condensate drain connection

3/4" NPT (Trap required)

22-3/8"

4-9/16"

6-5/8"

Data subject to change

|

10

Bosch Inverter Ducted Packaged Heat Pump Installation & Operation Manual

4 Installation

4.1 Pre-Installation

Before installation, carefully check the following:

1. Unit should be installed in accordance with national and local

safety codes, including but not limited to ANSI/NFPS No. 70, local

plumbing and wastewater codes and any other applicable codes.

2. For rooftop installation, be sure the structure has enough strength

to support the weight of unit. Unit must be installed on a fi eld

supplied roof curb or rack and leveled.

3. For ground level installation, a fi eld supplied level slab must be

used.

4. Condenser airfl ow should not be restricted.

5. On applications when a roof curb is used, the unit must be

positioned on the curb so the front of the unit is tight against

the curb. If the unit is to be mounted on a curb in a downfl ow

application, refer to Figure 13, and convert panels prior to rigging

and lifting. The panel removal process may require the unit to be on

the ground.

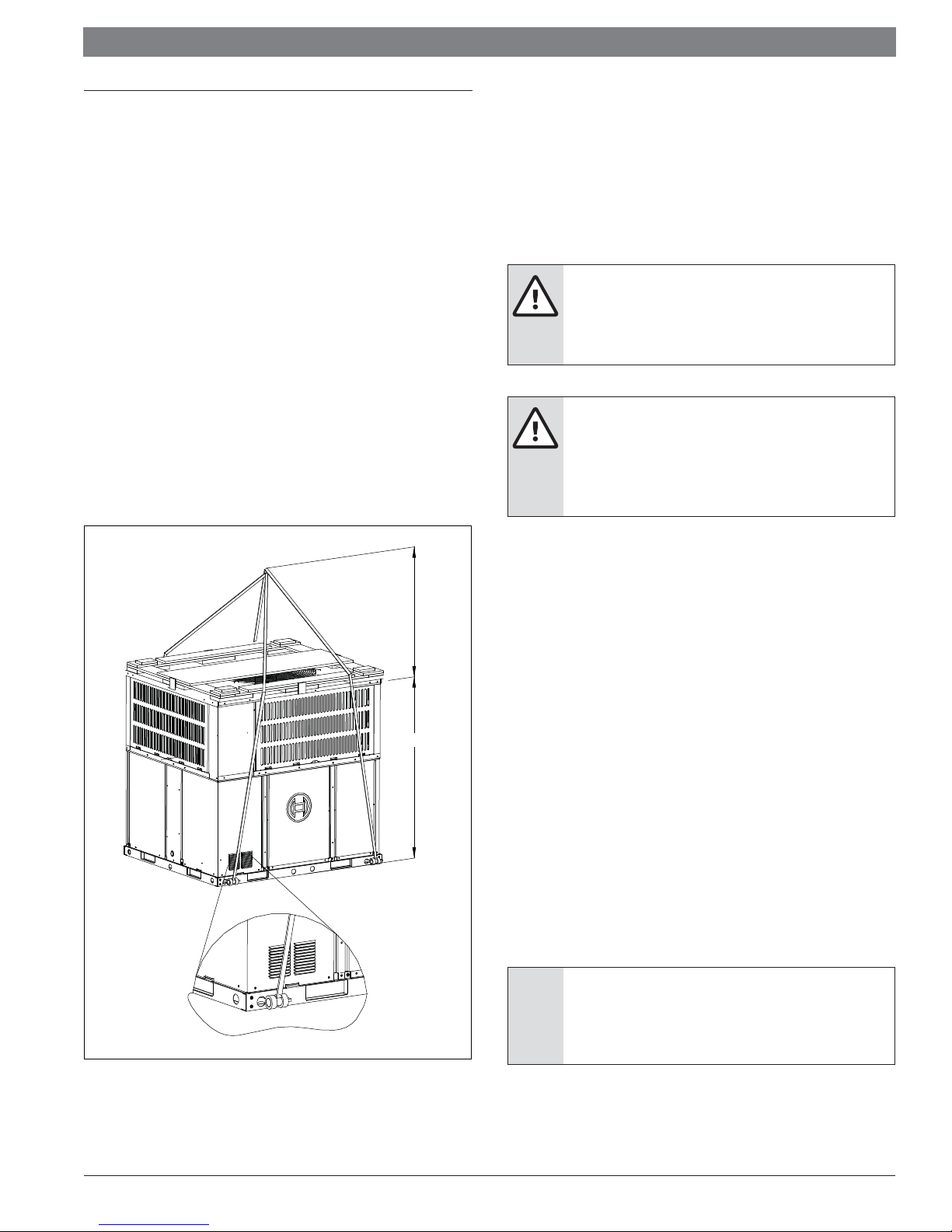

4.2 Rigging And Lifting

Exercise care when moving the unit. Do not remove any packaging until

the unit is near the place of installation. Rig the unit by attaching chain or

cable slings to the lifting holes provided in the base rails. Spreader bars,

whose length exceeds the largest dimension across the unit, MUST be

used across the top of the unit.

When rigging/lifting the unit, the minimum height between the top of the

rigging cables' connection point and top of unit should be 36 in. Refer to

Figure 5.

CAUTION:

Before lifting, make sure the unit weight is

distributed equally on the rigging cables so it will lift

evenly.

CAUTION:

All panels must be secured in place when the unit is

lifted. The condenser coils should be protected from

rigging cable damage with plywood or other suitable

material.

Figure 5

Minimum Height 36"

Unit Height

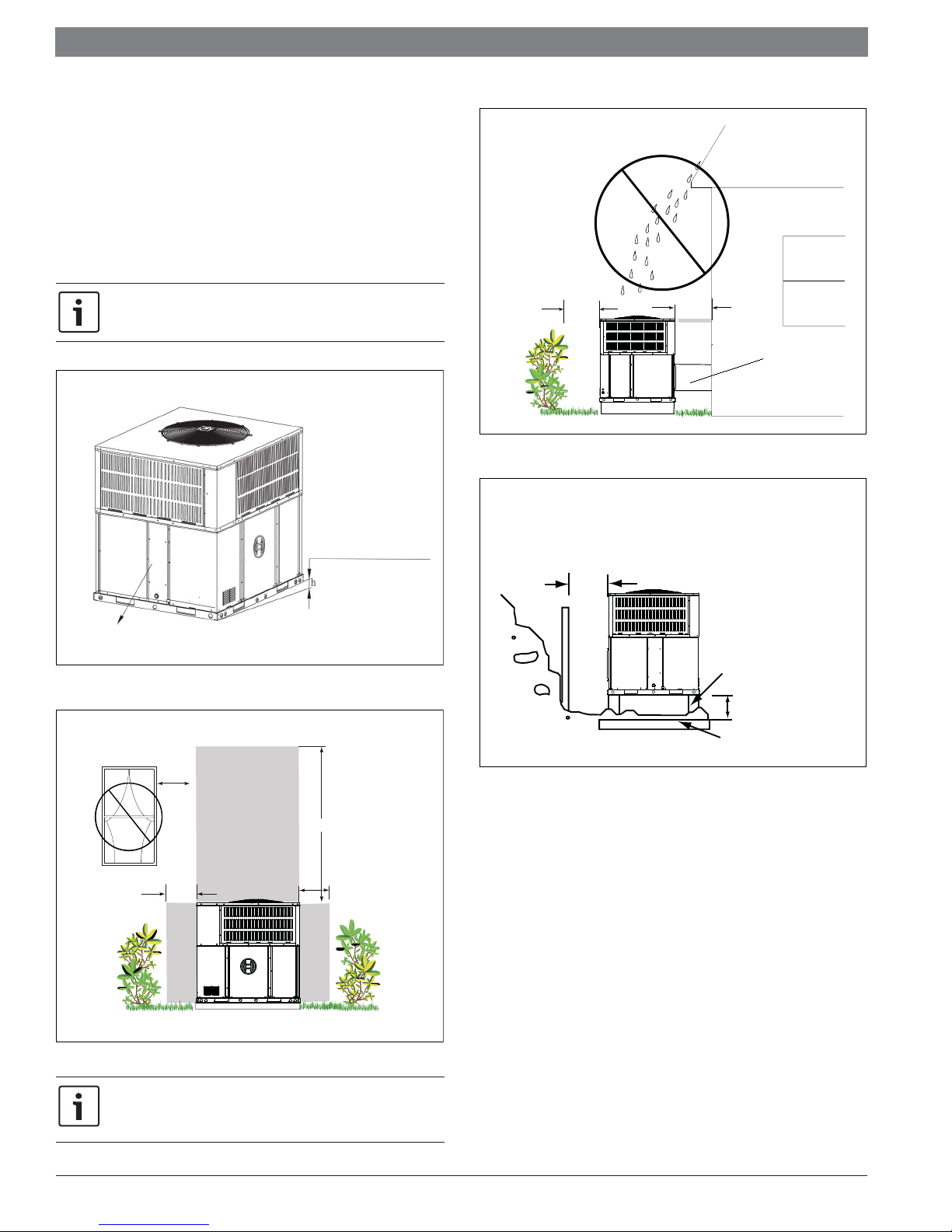

4.3 Location Restrictions

Ensure the top discharge area is unrestricted for at least 60 inches above

the unit.

Do not locate outdoor unit near bedrooms since normal operational noise

levels may be disturbing to building occupants.

Position unit to allow adequate space for unobstructed airfl ow, wiring, and

serviceability.

Do not restrict outdoor airfl ow. An air restriction at either the outdoor air

inlet or the fan discharge may be detrimental to compressor life.

Do not place the unit where water, ice, or snow from an overhang or roof

will damage or fl ood the unit. Do not install the unit on carpeting or other

combustible materials. Slab-mounted units should be at least 2 in. (51

mm) above the highest expected water and runoff levels. Do not use unit if

it has been under water.

Maintain a distance of 24 inches between units. Position unit so water,

snow, or ice from roof or overhang cannot fall directly on unit.

See Fig. 7 and Fig. 8 for minimum clearance requirements.

Cold climate considerations (heat pump only)

NOTICE:

Precautions must be taken for units being installed

in areas where snow accumulation and prolonged

below-freezing temperatures occur.

03.2019 | BTC 761701105 AData subject to change

Installation & Operation Manual Bosch Inverter Ducted Packaged Heat Pump | 11

Units should be elevated 3-12 inches above the pad or rooftop,

depending on local weather. This additional height will allow

drainage of snow and will permit condensate water to drain

when the unit is in defrost mode. Ensure that drain holes in

unit base pan are unobstructed, preventing drainage of defrost

water (See Fig.9).

If possible, avoid locations that are prone to snow drifts. If not

possible, a snow drift barrier should be installed around the

unit to prevent a build-up of snow on the sides of the unit.

Ensure that Condensate Drain side is pitched lower than the

opposite side.

Min. 24"

Access Panel

Figure 8

Min. 12" to

Shrubbery

Supply Air Duct

0˘ h≤ 25mm(

Condensate drain side

1°)

Figure 6

Avoid Install

Near Bedrooms

Min. 60" Unrestricted

Min. 24"

Access Panel

Min. 24"

Access Panel

Figure 7

A minimum clearance of 24" should be maintained adjacent to

all access/service panels. Refer to local code requirements for

additional clearance requirements.

Min 24"

Snow

barrier

Snow legs

pad

3- 12" Elevation

Figure 9

Corrosive Environment

Exposure to a corrosive environment may shorten the life of the

equipment, corrode metal parts, and/or negatively aff ect unit

performance. Corrosive elements include, but are not limited to: sodium

chloride, sodium hydroxide, sodium sulfate, and other compounds

commonly found in ocean water, sulfur, chlorine, fl uorine, fertilizers, and

various chemical contaminants from industry/manufacturing plants. If

installed in areas which may exposed to corrosive environments, special

attention should be given to the equipment placement and maintenance.

Lawn sprinklers/hoses/waste water should not spray directly

on the unit cabinet for prolonged periods of time.

In coastal areas: locate the unit on the side of the building or

roof away from the waterfront.

Fencing or shrubbery may provide some shielding protection

to the unit, however minimum unit clearances must still be

maintained.

Every three months, wash the outdoor coil and any exposed

cabinet surfaces.

BTC 761701105 A | 03.2019

Data subject to change

|

12

Bosch Inverter Ducted Packaged Heat Pump Installation & Operation Manual

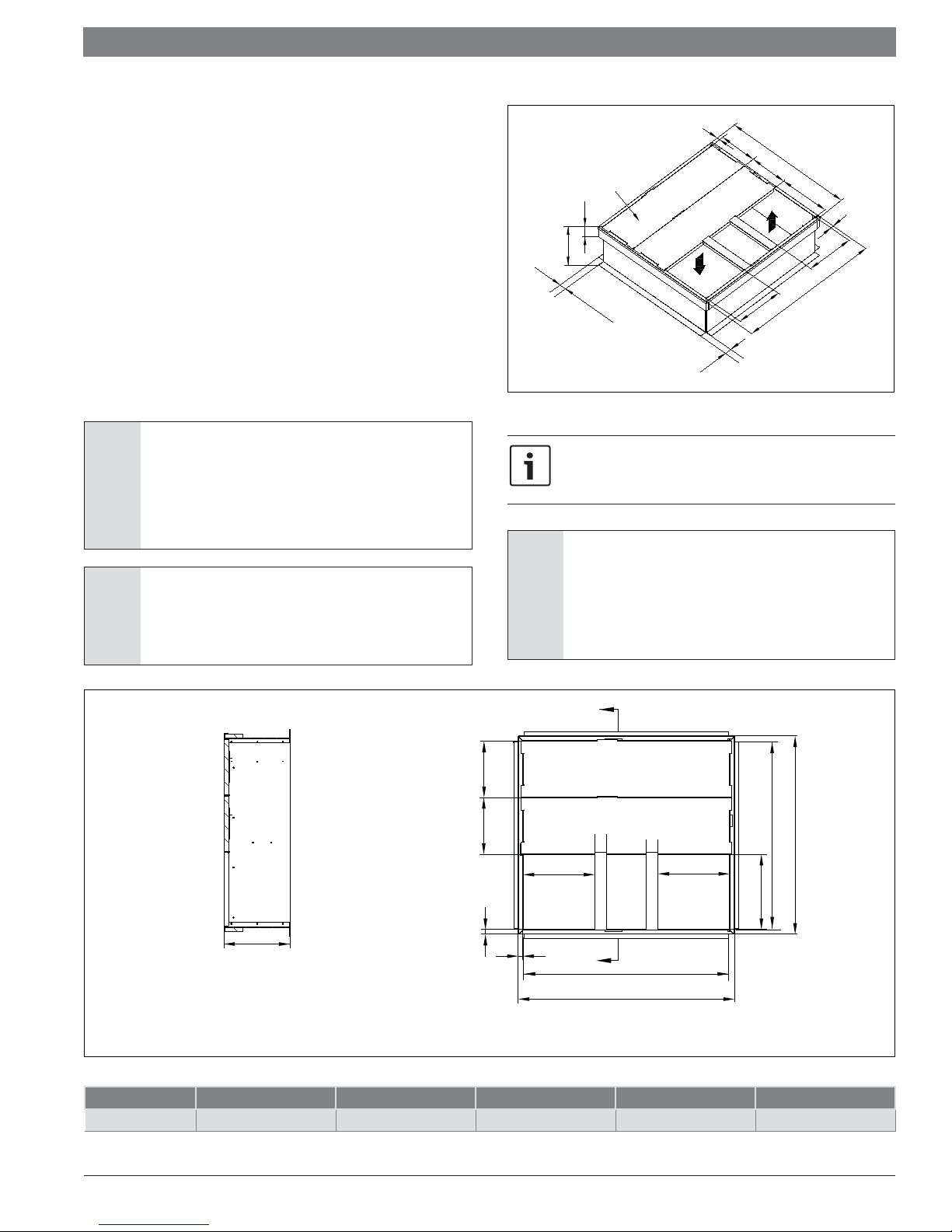

4.4 Rooftop Installation - Curb Mounting

The manufacturer does not supply roof curbs, they must be fi eld supplied.

On applications when a roof curb is used,the unit must be positioned on

the curb so the front of the unit is tight against the curb (see Figure 10

Roof Curb Dimension).

The default orientation from the factory is for horizontal airfl ow. Convert

the unit to downfl ow using the following procedure:

1. Remove the sheet metal screws securing the supply air cover and

the sheet metal screws securing the return air cover from the base

of the unit. Remove the covers from the base. See Figure 13.

2. Place the covers over the horizontal supply and return openings

(painted side out). Align the screw holes, and secure using the

same screws removed in step 1. See Figure 13.

Install the fi eld-supplied roof mounting curb according to the Installation

Instructions supplied with the curb. Install insulation, cant strips, roofi ng,

and fl ashing. Ductwork must be attached to curb.

Figure 11

Insulation layer

4-1/16"

14-1/4"

1-15/16"

Roof Curb Dimensions

1"

1-15/16"

1

2

-1/16"

4

1

2

-1/16"

1/4"

-

5

1

2-3/16"

16"

46-1/

1"

15-1/4"

"

16

NOTICE:

The gasketing of the unit to the roof curb is critical

for a water tight seal. Install gasketing material

supplied with the field supplied roof curb.

Improperly applied gasketing also can result in air

leaks and poor unit performance.

NOTICE:

The unit must be secured to the curb by installing

screws through the bottom of the curb flange and

into the unit base rails.

A-A

B

NOTES:

1. Roof curb must be set up for unit being installed.

2. Seal strip must be applied, as required, to unit being installed.

4. Attach ductwork to curb (flanges of duct rest on curb).

5. Recommended insulated panels: 1 in. (25.4 mm) thick fiberglass 1 lb. density.

For units applied with a roof curb, the minimum clearance

may be reduced from 1 inch to 1/2 inch between combustible

roof curb material and supply air duct.

NOTICE: UNIT/STRUCTURAL DAMAGE HAZARD

Failure to follow this caution may result in property

damage. Ensure there is sufficient clearance for

saw blade when cutting the outer horizontal flange

of the roof curb so there is no damage to the roof or

flashing.

A

F

12-1/16" 12-1/16"

C

C

39-1/2"

E

SUPPLY

1"

AIR

1"

A

43-9/16"

RETURN

AIR

D

Figure 10

Roof Curb Details

BCDEF

CURB 14-1/4" 15-1/4" 46-1/16" 16" 42-3/16"

Table 5 Roof Curb Details -

inches

03.2019 | BTC 761701105 AData subject to change

Loading...

Loading...