Bosch BP007-1HZC-FRS, CP030-1VTN-FRT, BP007-1HZN-FRS, BP007-1HZC-FLS, BP007-1HZN-FLS Installation And Maintenance Manual

...

Installation and Maintenance Manual

CP/BP Series

6 720 220 045

Revised 05-12

©Copyright 2012 Bosch, Inc All rights reserved

Table of Contents

TABLE OF CONTENTS

CP/BP Series

3

Model Nomenclature ............................................. 3

Initial Inspection ................................................... 4

General Description .............................................. 4

Moving and Storage .............................................. 4

Safety Considerations ........................................... 4

Location ................................................................ 4

Installation ............................................................ 5

Mounting Vertical Units ......................................... 5

Mounting Horizontal Units .................................... 5

Condensate Drain ................................................. 6

Duct System .......................................................... 6

Electrical ............................................................... 7

Thermostat Connections ...................................... 8

Safety Devices and the UPM Controller ................. 8

Sequence Of Operation ...................................... 10

Unit Options........................................................ 10

Fluid Differential Pressure Switch ....................... 13

Earth Coupled Systems ....................................... 15

Unit Start-up ....................................................... 15

Heat Recovery Package ....................................... 15

Water Tank Preparation ....................................... 16

HR Water Piping ................................................. 16

Typical Connection Piping ................................... 16

Water Tank Rell ................................................. 17

Initial Start up ..................................................... 17

Maintenance ....................................................... 17

In-warranty Material Return ................................ 18

Unit Specications .............................................. 18

Physical Data ................................................ 18

Dimensions ................................................... 19

Fluid Pressure Drops ..................................... 20

Air Temperature Rise/Fall .............................. 21

Refrigerant Pressure Ranges ......................... 22

Blower Performance ..................................... 23

Water Piping ....................................................... 13

Well Water Systems ............................................. 13

Fresh Water Systems ........................................... 14

MODEL NOMENCLATURE

CP/BP 048 - 1 VT C - F L T

SERIES:

CP/BP

NOMINAL CAPACITY:

MBTUH

VOLTAGE DESIGNATION:

1- 208-230/1/60

CABINET CONFIGURATION:

VT - VERTICAL

HZ - HORIZONTAL

WATER TO REFRIGERANT HEAT EX:

C - COPPER

N - CUPRO-NICKEL

Typical Wiring Diagrams ...................................... 24

Unit Check-out Sheet .......................................... 28

Troubleshooting .................................................. 29

SUPPLY AIR LOCATION:

T - TOP (VT ONLY)

S - STRAIGHT THRU (HZ ONLY)

E - END BLOW (HZ ONLY)

RETURN AIR LOCATION:

L - LEFT

R - RIGHT

WATER CONNECTION LOCATION

F - FRONT

Revised 05-12 Subject to change without prior notice

6 720 220 045

Initial Inspection

4

CP/BP Series

INITIAL INSPECTION

Be certain to inspect all cartons or crates on each

unit as received at the job site before signing the

freight bill. Verify that all items have been received

and that there are no visible damages; note any

shortages or damages on all copies of the freight

bill. In the event of damage or shortage, remember

that the purchaser is responsible for ling the

necessary claims with the carrier. Concealed

damages not discovered until after removing the

units from the packaging must be reported to the

carrier within 24 hours of receipt.

GENERAL DESCRIPTION

These Packaged System Heat Pumps provide the

best combination of performance and ef ciency

available. Safety devices are built into each unit to

provide the maximum system protection possible

when properly installed and maintained.

The CP/BP Water-to-Air Heat Pumps are

Underwriters Laboratories (UL) and (cUL) listed for

safety. The water-to-Air Heat Pumps are designed to

operate with entering uid temperature between

25°F to 80°F in the heating mode and between 50°F

to 110°F in the cooling mode. Ef ciencies and

capacities will vary as entering uid and return air

temperatures vary.

50°F Min. EWT for well water applications

suffi cient water fl ow to prevent freezing.

Antifreeze solution is required for all closed loop

applications where the fl uid temperature may drop

below 50°F. Cooling Tower/Boiler and Earth

Coupled (Geo Thermal) applications should have

suffi cient antifreeze solution to protect against

extreme conditions and equipment failure. Frozen

water coils are not covered under warranty.

This product should not be used for temporarily

heating/cooling during construction. Doing so

may affect the unit’s warranty.

MOVING AND STORAGE

If the equipment is not needed for immediate

installation upon its arrival at the job site, it should

be left in its shipping carton and stored in a clean,

dry area. Units must only be stored or moved in the

normal upright position as indicated by the “UP”

arrows on each carton at all times. If unit stacking is

required, stack units as follows: Vertical units less

than 6 tons, no more than two high; horizontal units

less than 6 tons, no more than three high. Do not

stack units larger than 6 tons.

SAFETY CONSIDERATIONS

Installation and servicing of this equipment can be

hazardous due to system pressure and electrical

components. Only trained and quali ed personnel

should install, repair, or service the equipment. Untrained

personnel can perform basic functions of maintenance

such as cleaning coils and replacing lters.

Before performing service or maintenance

operations on the system, turn off main power to

the unit. Electrical shock could cause personal

injury or death.

When working on equipment, always observe

precautions described in the literature, tags, and

labels attached to the unit. Follow all safety codes.

Wear safety glasses and work gloves. Use a

quenching cloth for brazing, and place a re

extinguisher close to the work area.

The blower motor should only be operated when a

duct is installed and secured to heat pump duct

collar in order to avoid possible injury.

LOCATION

Locate the unit in an indoor area that allows easy

removal of the lter and access panels, and has

enough room for service personnel to perform

maintenance or repair. Provide suf cient room to

make uid, electrical, and duct connection(s). If the

unit is located in a con ned space such as a closet,

provisions must be made for return air to freely

enter the space. On horizontal units, allow

adequate room below the unit for a condensate

drain trap and do not locate the unit above supply

piping. These units are not approved for outdoor

installation; therefore, they must be installed inside

the structure being conditioned.

Do not locate units in areas that are subject to

freezing.

6 720 220 045

Subject to change without prior notice Revised 05-12

VIBRATION

PAD

FULL SIZE

Installation

CP/BP Series

5

INSTALLATION

Remove shipping block under blower housing.

Loosen compressor mounting bolts.

The installer should comply with all local codes

and regulations which govern the installation of

this type of equipment. Local codes and

regulations take precedent over any

recommendations contained in these instructions.

In lieu of local codes, the equipment should be

installed in accordance with the recommendations

made by the National electric code, and in

accordance with the recommendations made by

the National Board of Fire Underwriters. All local

seismic codes for seismic restraint of equipment,

piping, and duct work shall be strictly adhered to.

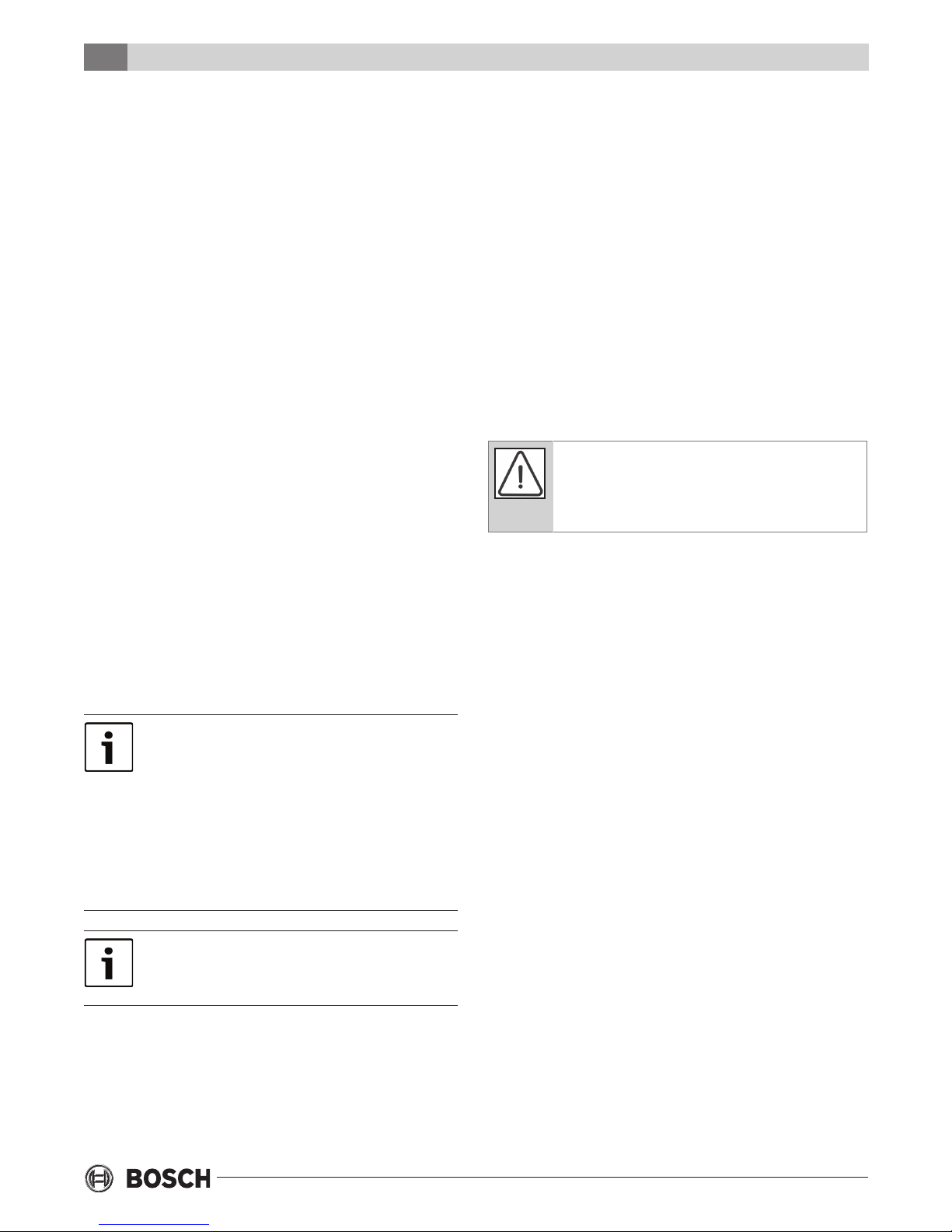

MOUNTING VERTICAL UNITS

Vertical units up to six tons are available in left or

right air return con gurations. Vertical units should

be mounted level on a vibration absorbing pad

slightly larger than the base to minimize vibration

transmission to the building structure. It is not

necessary to anchor the unit to the oor. (See

Figure #1).

MOUNTING HORIZONTAL UNITS

While horizontal units may be installed on any

level surface strong enough to hold their weight,

they are typically suspended above a ceiling by

threaded rods. The rods are usually attached to

the unit corners by hanger bracket kits (P/N

930-008). (See Figure #2). The rods must be

securely anchored to the ceiling. Refer to the

hanging bracket assembly and installation

instructions for details. Horizontal units installed

above the ceiling must conform to all local codes.

An auxiliary drain pan if required by code should

be at least four inches larger than the bottom of

the heat pump. Plumbing connected to the heat

pump must not come in direct contact with joists,

trusses, walls, etc.

If the unit is located in a con ned space such as a

closet, provisions must be made for return air to

freely enter the space.

VIBRATION

PAD

FULL SIZE

Figure #1 – Vertical unit on vibration pad

Figure #2 – Typical horizontal unit hanging bracket

Some applications require an attic oor installa-

tion of the horizontal unit. In this case the unit

should be set in a full size secondary drain pan on

top of a vibration absorbing mesh. The secondary

drain pan prevents possible condensate over ow

or water leakage damage to the ceiling. The

secondary drain pan is usually placed on a plywood base isolated from the ceiling joists by

additional layers of vibration absorbing mesh. In

both cases, a 3/4” drain connected to this secondary pan should be run to an eave and able to drain

to a location that will be noticeable. If the unit is

located in a crawl space, the bottom of the unit

must be at least 4” above grade to prevent ood-

ing of the electrical parts due to heavy rains.

Locate the heat pump unit in an area that provides

suf cient room to make water and electrical

connections, allowing easy removal of the access

Revised 05-12 Subject to change without prior notice

6 720 220 045

6

Condensate Drain

CP/BP Series

panels, and replacement of air lters for routine

maintenance. This will ensure proper work space for

service personnel to perform maintenance or repair.

See Unit Specications for replacement lter sizes

in the back of this manual to ensure proper

clearances are provided during installation. Allow

adequate room below the unit for a condensate

drain trap on horizontal units.

Water freezes at 32°F. Frozen water coils are not

covered under the limited product warranty. It is

the installer’s responsibility to insure that the heat

pump unit is installed in a location or have taken

the proper precautions in order to prevent

rupturing the water coil due to freezing conditions.

The heat pump unit is designed for conditioned

space installation only. If the source water is

subjected to conditions where ambient

temperatures can fall below freezing, some form of

freeze protection should be employed. In an open

loop system this may entail running the water pump

continuously to prevent freezing. An antifreeze

solution wherever possible should be used if water

will be subject to freezing. Consult the factory in

these instances for guidance.

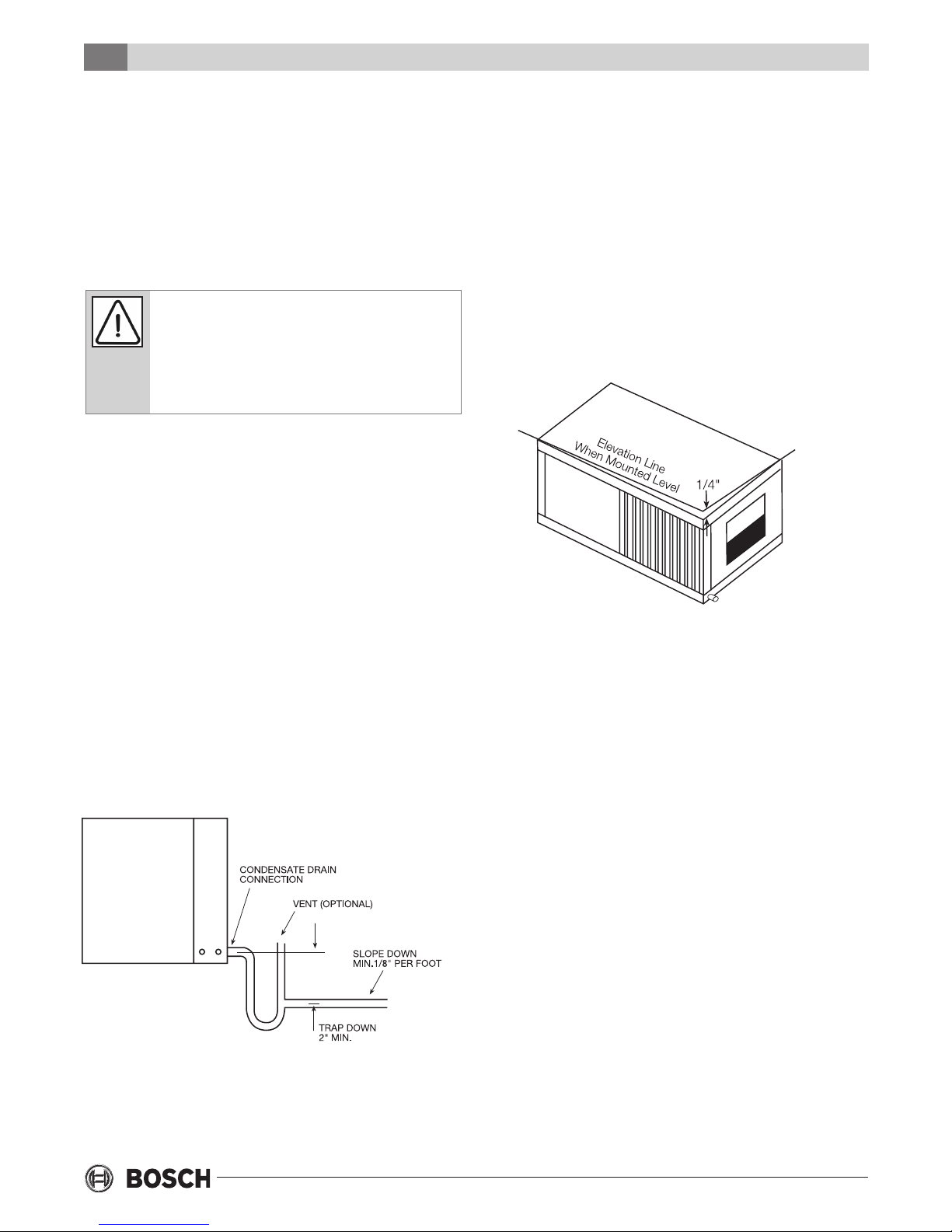

CONDENSATE DRAIN

A drain line must be connected to the heat pump

and pitched away from the unit a minimum of 1/8”

per foot to allow the condensate to ow away from

the unit.

Figure #3 – Heat Pump Condensate Trapping

(Heat Pumps are not internally trapped). A vertical

air vent is sometimes required to avoid air pockets

(See Figure #3). The length of the trap depends on

the amount of positive or negative pressure on the

drain pan. A second trap must not be included.

The horizontal unit should be pitched

approximately 1/4” towards the drain in both

directions, to facilitate condensate removal. See

Figure 4 below.

Figure #4 – Sloped horizontal unit installation

DUCT SYSTEM

A supply air outlet collar and return air duct ange

are provided on all units to facilitate duct

connections. See Unit Specications for duct collar

connection sizes in the back of this manual.

A exible connector is recommended for supply

and return air duct connections on metal duct

systems. All metal ducting should be insulated with

a minimum of one inch duct insulation to avoid heat

loss or gain and prevent condensate forming during

the cooling operation. Application of the unit to

uninsulated duct work is not recommended as the

unit’s performance will be adversely affected. Do

not connect ducts directly to the blower outlet;

factory supplied duct collars should be used for

connection. The factory provided air lter must be

removed when using a lter back return air grill. The

factory lter should be left in place on a free return

system.

This connection must be in conformance with local

plumbing codes. A trap must be installed in the

condensate line to insure free condensate ow.

6 720 220 045

If the unit will be installed in a new installation

which includes new duct work, the installation

should be designed using current ASHRAE

procedures for duct sizing. If the unit is to be

connected to existing ductwork, a check should be

made to assure that the duct system has the

Subject to change without prior notice Revised 05-12

Electrical

CP/BP Series

7

capacity to handle the air required for the unit

application. If the duct system is too small, larger

ductwork should be installed. Check for existing

leaks and repair as necessary to ensure a tight air

seal within duct. The duct system and all diffusers

should be sized to handle the designed air ow

quietly. To maximize sound attenuation of the unit

blower, the supply and return air plenums should

be insulated. There should be no direct straight air

path thru the return air grille into the heat pump.

The return air inlet to the heat pump must have at

least one 90 degree turn away from the space

return air grille. If air noise or excessive air ow are

a problem, the blower speed can be changed to a

lower speed to reduce air ow. (Refer to ECM

motor speeds and settings in Table #1)

Always disconnect power to the unit before

changing motor speed to prevent damage to

the motor, injury or death due to electrical

shock.

ELECTRICAL

Always disconnect power to the unit before

servicing to prevent injury or death due to

electrical shock or contact with moving parts.

All eld wiring must comply with local and national

re, safety and electrical codes. Power to the unit

must be within the operating voltage range

indicated on the unit’s nameplate. On three phase

units, phases must be balanced within 2%.

Operating the unit with improper line voltage

or with excessive phase imbalance is

hazardous to the unit and constitutes abuse

and is not covered under warranty.

Properly sized fuses or HACR circuit breakers must

be installed for branch circuit protection. See

equipment rating plates for proper size.

The heat pump units are provided with a concentric

knock-out in the front right corner post for

attaching common trade sizes of conduit. Route

power supply wiring through this opening. Flexible

wiring and conduit should be used to isolate

vibration and noise from the building structure. Be

certain to connect the ground lead to the ground

lug in the control box. Connect the power leads as

indicated on the unit wiring diagrams.

Table 1: CP/BP Motor CFM Selection (ECM Motor)otor Only)

Units

CP/BP015 450-153 1/3 LOW MED HIGH - -

CP/BP018 450-153 1/3 - LOW - MED HIGH

CP/BP024 450-157 1/3 LOW MED HIGH - -

CP/BP030 450-154 1/3 LOW MED HIGH - -

CP/BP036 450-158 3/4 LOW MED HIGH - -

CP/BP042 450-155 3/4 LOW MED HIGH - -

CP/BP048 450-155 3/4 - LOW MED HIGH -

CP/BP060 450-156 1 LOW MED HIGH - -

CP/BP070 450-156 1 LOW - - MED HIGH

Revised 05-12 Subject to change without prior notice

Motor Part

Number

Motor HP Tap1 Tap2 Tap3 Tap4 Tap5

6 720 220 045

8

Thermostat Connections

CP/BP Series

THERMOSTAT CONNECTIONS

Thermostat wiring is connected to a 7 position low

voltage terminal block in the electrical box. The

thermostat connections and their functions are as

follows:

Y Compressor Operation

G Fan

O Reversing Valve (energized in cooling)

C Transformer 24 VAC Common – 3 Connections

R Transformer 24 VAC Hot

If the unit is being connected to a thermostat with a

malfunction light, this connection is made at the

unit alarm output.

If the thermostat is provided with a malfunction

light powered off of the common (C) side of the

transformer, a jumper between “R” and “COM”

terminal of “ALR” contacts must be made.

below or remains at freeze limit trip for 30

seconds, the controller will shut down the

compressor and enter into a soft lockout

condition. The default freeze limit trip is 30°F,

however this can be changed to 15°F by cutting

the R42 resistor located on top of DIP switch SW1.

• The optional condensate over ow protection

sensor (standard on horizontal units) is located in

the drain pan of the unit and connected to the

‘COND’ terminal on the UPM board.

If the thermostat is provided with a malfunction

light powered off of the hot (R) side of the

transformer, then the thermostat malfunction light

connection should be connected directly to the

(ALR) contact on the unit’s UPM board.

SAFETY DEVICES AND THE

UPM CONTROLLER

Each unit is factory provided with a Unit Protection

Module (UPM) that controls the compressor operation and monitors the safety controls that protect

the unit.

Safety controls include the following:

• High pressure switch located in the refrigerant

discharge line and wired across the HPC

terminals on the UPM

• Low pressure switch located in the unit

refrigerant suction line and wired across

terminals LPC1 and LPC2 on the UPM.

Freeze

Protection

Sensor

• Optional freeze protection sensor, mounted close

to condensing water coil, monitors refrigerant

temperature between condensing water coil and

thermal expansion valve. If temperature drops

6 720 220 045

If freeze protection sensor is not installed, a

jumper between freeze contacts must be installed

on the UPM board otherwise unit will not start.

Subject to change without prior notice Revised 05-12

Safety Devices and the UPM Controller

CP/BP Series

9

The UPM includes the following features:

• ANTI-SHORT CYCLE TIME—5 minute delay on

break timer to prevent compressor short cycling.

• RANDOM START—Each controller has a unique

random start delay ranging from 270 to 300 seconds to

reduce the chances of multiple units simultaneously

starting after initial power up or after a power

interruption, creating a large electrical spike.

• LOW PRESSURE BYPASS TIMER—If the compressor is

running and the low pressure switch opens, then the

control will keep the compressor on for 120 seconds.

After 2 minutes if the low pressure switch remains

open, the control will shut down the compressor and

enter a soft lockout. The compressor will not be

energized until the low pressure switch closes and the

anti-short cycle time delay expires. If the low pressure

switch opens 2–4 times in 1 hour, the unit will enter a

hard lock out and need to be reset.

• BROWNOUT/SURGE/POWER INTERRUPTION

PROTECTION—The brownout protection in the UPM

board will shut down the compressor if the

incoming power falls below 18 VAC. The compressor

will remain off till the voltage goes above 18 VAC and

the anti short cycle timer (300 seconds) times out.

The unit will not go into a hard lockout.

• MALFUNCTION OUTPUT—Alarm output is Normally

Open (NO) dry contact. If 24 VAC output is needed

R must be wired to the ALR-COM terminal; 24VAC

will be available on the ALR-OUT terminal when the

unit is in alarm condition. If pulse is selected the

alarm output will be pulsed. The fault output will

depend on the dip switch setting for “ALARM”. If it

set to “CONST’, a constant signal will be produced

to indicate a fault has occurred and the unit

requires inspection to determine the type of fault. If

it is set to “PULSE”, a pulse signal is produced and a

fault code is detected by a remote device indicating

the fault. See L.E.D. Fault Indication below for blink

code explanations. The remote device must have a

malfunction detection capability when the UPM

board is set to “PULSE”.

• TEST DIP SWITCH—A test dip switch is provided

to reduce all time delay settings to 10 seconds

during troubleshooting or veri cation of unit

operation. Note that operation of the unit while in

test mode can lead to accelerated wear and

premature failure of the unit. The “TEST” switch

must be set back to “NO” for normal operation.

• FREEZE SENSOR—The freeze sensor input is

active all the time, if a freeze option is not selected

the freeze terminals will need a jumper. There are

2 con gurable freeze points, 30°F & 15°F. The unit

will enter a soft lock out until the temperature

climbs above the set point and the anti-short cycle

time delay has expired. The freeze sensor will shut

the compressor output down after 90 seconds of

water ow loss and report a freeze condition. It is

recommended to have a ow switch to prevent the

unit from running if water ow is lost.

If unit is employing a fresh water system (no

anti-freeze protection), it is extremely important to

have the “Freeze” jumper R42 resistor set to 30°F

in order to shut down the unit at the appropriate

leaving water temperature and protect your heat

pump from freezing if a freeze sensor is included.

• L.E.D. FAULT INDICATION—Two L.E.D. indicators

are provided:

• Green: Power L.E.D. indicates 18—30 VAC

present at the board.

• Red: Fault indicator with blink codes as follows:

- One blink—High pressure lockout

- Two blinks—Low pressure lockout

- Three blinks—Freeze sensor lockout

- Four blinks—Condensate over ow

- Five blinks—Brownout

• INTELLIGENT RESET—If a fault condition is initiated,

the 5 minute delay on break time period is initiated

and the unit will restart after these delays expire.

During this period the fault LED will indicate the

cause of the fault. If the fault condition still exists or

occurs 2 or 4 times (depending on 2 or 4 setting for

Lockout dip switch) before 60 minutes, the unit will

go into a hard lockout and requires a manual lockout

reset. A single condensate over ow fault will cause

the unit to go into a hard lockout immediately, and

will require a manual lockout reset.

Revised 05-12 Subject to change without prior notice

6 720 220 045

10

CP/BP Series

Sequence of Operation

• LOCKOUT RESET—A hard lockout can be reset by

turning the unit thermostat off and then back on

when the “RESET” dip switch is set to “Y” or by

shutting off unit power at the circuit breaker

when the “RESET” dip switch is set to “R”.

The blower motor will remain active during a

lockout condition.

• UPM BOARD DEFAULT SETTINGS—Your UPM

board will come from the factory with the

following default settings:

• Freeze—“Terminals not jumped” on all the time

• Temp—30°F

• Lockout—2

• Reset—“Y”

• Alarm—“PULSE”

• Test—“NO”

• Dry Contact—“Normally Open (NO)”

Considerations

1. Always check incoming line voltage power

supply and secondary control voltage for

adequacy. Transformer primaries are dual

tapped for 208 and 230 volts. Connect the

appropriate tap to ensure a minimum of 18 volts

secondary control voltage. 24 volts is ideal for

best operation.

SEQUENCE OF OPERATION

Cooling Mode

See Typical Wiring Diagrams at the end of the

document. Energizing the “O” terminal energizes

the unit reversing valve in the cooling mode. The fan

motor starts when the “G” terminal is energized.

When the thermostat calls for cooling (Y), the loop

pump or solenoid valve if present is energized and

compressor will start.

Once the thermostat is satis ed, the compressor

shuts down accordingly and the fan ramps down to

either fan only mode or off over a span of 30 seconds

(ECM Motors).

Note that a fault condition initiating a lockout will

de-energize the compressor.

Heating Mode

Heating operates in the same manner as cooling,

but with the reversing valve de-energized. The

compressor will run until the desired setpoint

temperature on the thermostat is achieved.

Once the thermostat is satis ed, the compressor

shuts down and the fan ramps down in either fan

only mode or turns off over a span of 30 seconds.

Auxiliary electric heating coils are not available on

the BP/CP product line.

UNIT OPTIONS

HOT GAS REHEAT (HGR)

2. Long length thermostat and control wiring

leads may create voltage drop. Increase wire

gauge or up-size transformers may be required

to insure minimum secondary voltage supply.

3. FHP recommends the following guidelines for

wiring between a thermostat and the unit: 18

GA up to 60 foot, 16 GA up to 100 ft and 14 GA

up to 140 ft.

4. Do not apply additional controlled devices to

the control circuit power supply without

consulting the factory. Doing so may void

equipment warranties.

5. Check with all code authorities on requirements

involving condensate disposal/over ow

protection criteria.

6 720 220 045

Hot gas reheat allows the user to not only control

space temperature, but also humidity levels within

the conditioned space. An excess of moisture in the

space can allow mold growth leading to damage in

the structure or interior surfaces as well as

reducing the air quality and creating an unhealthy

environment.

The typical control of a unit is by a thermostat that

senses the temperature in the space. By utilizing a

humidistat in addition to the thermostat we are

able to monitor the humidity levels in the space as

well. The HGR option allows cooling and

dehumidi cation to satisfy both the thermostat and

humidistat.

Subject to change without prior notice Revised 05-12

Loading...

Loading...