Bosch 5412 Operating/safety Instructions Manual

iMPORTANT: iMPORTANT IMPORTANTE:

Read BeforeUsing Lireavantusage Leer antes de usar

Operating/Safetyinstructions

Consignesdefonctionnernent/s6curit6

instruccionesdefuncionarnientoyseguridad

5312

5412

Call ToilFreeforCon-

sumerInformation

& Service Locations

Pourobtenir desinforrnations

et les adresses denoscentres

deserviceapr_s-vente,

appeJezce nurn_rogratuit

Llarnegratispara

obtener information

parael consurnidory

ubicaciones de servicio

For EnglishVersion Versionfran_aise Versi6nenes

Seepage2 Voir page38 Veria p_gina74

_ "READ ALL INSTRUCTIONS" -- Failure to follow the SAFETY RULES identified by

__ BULLET (o)symbol listed BELOW and other safety precautions, may result in serious

personal injury.

General Safety Rules For Bench Top Tools

Work Area • Do not abuse the cord. Never use the cord to

• Keep work area clean and well lit. Cluttered

benches and dark areas invite acdents.

• Do not operate power tools in explosive at-

mospheres, such as in the presence of flam-

mable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

• Keep bystanders, children and visitors away

while operating a power tool. Distractions ca-

cause you to lose control.

• Store idle tools out of reach of children and

other untrained persons. Tools are danger-ous

in the hands of untrained users.

• Do not leave tool running unattended, turn

power off. Do not leave tool until it comes to

acomplete stop.

• MAKE WORKSHOP CHILDPROOF with pad

lock, master switches, or by removing starter

keys.

Electrical Safety

• Before plugging in the tool, be certain the out-

let voltage supplied is compatible with the

voltage marked on the nameplate within 10%.

An outlet voltage incompatible with that specified

on the nameplate can result in serious hazards

and damage to the tool.

• Double insulated tools are equipped with a po- .

larized plug (one blade is wider than the

other). This plug will fit in a polarized outlet

only one way. if the plug does not fit fully in

the outlet, reverse the plug. if it still does not

fit, contact a qualified electrician to install a "

polarized outlet. Do not change the plug in

any way. Double insulation eliminates the need

for the three wire grounded power cord and

grounded power supply.

• Avoid body contact with grounded surfaces

such as pipes, radiators, ranges and refriger-

ators. There is an increased risk of electric shock

if your body is grounded.

• Do not expose power tools to rain or wet con- "

ditions. Water entering a power tool will increase

the risk of electric shock.

"SAVE THESE

carry the tools or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges or

moving parts. Replace damaged cords imme-

diately. Damaged cords increase the risk of elec-

tric shock.

When operating a power tool outside, use an

outdoor extension cord marked "W-A" or "W".

These cords are rated for outdoor use and reduce

the risk of electric shock.

Personal Safety

• Stay alert, watch what you are doing and use

common sense when operating a power tool.

A moment of inattention or use of drugs, alcohol

or medication whileoperating power tools can be

dangerous.

• Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair,

clothing and gloves away from moving parts.

Loose clothes, jewelry or longhair can be caught

in moving parts. Roll long sleeves above elbows.

Rubber gloves and non-skidfootwear are recom-

mended when working outdoors.

• Avoid accidental starting. Be sure switch is

"OFF" before plugging in. Carrying tools with

your finger on the switch or plugging intools that

have the switch "ON" invites accidents.

Remove adjusting keys or wrenches before

turning the tool "ON". A wrench ora key that is

left attached to a rotating part of the tool will be

thrown.

Do not overreach, keep proper footing and

balance at all times. Proper footing and balance

enables better control of the tool in unex-pected

situations.

Do not stand on tool or its stand. Serious injury

may occur if the tool is tipped or if the cutting tool

is accidentally contacted. Do not store materials

on or near the tool such that it is necessary to

stand on the tool or its stand to reachthem.

Use safety equipment. Always wear safety

goggles. Dust mask, safety shoes, hard hat or

hearing protection must be used for appropriate

INSTRUCTIONS"

-2-

conditions. Everyday eyeglasses only have

impact resistant lenses, they are NOT safety

glasses.

Tool Use and Care

• Use clamps or other practical way to secure

and support the wotkpiece to a stable plat-

form. Holding the work by hand or against your

body is unstable. Itallows forwork to shift,causes

binding of the tool and loss of control.

• Donot force tool. Usethe correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed. Do

not use the tool for purpose not intended - for ex-

ample; do not usethe miter sawfor slicing meats.

• Donot use tool if switch does not turn it "ON"

or "OFF". Any tool that cannot be controlled with

the switch is dangerous.

• Disconnect the plug from the power source

before making any adjustments or changing

accessories. Such preventive safety measures

reduce the riskof starting the tool accidentally.

• Keep cutting tools sharp and clean. Properly

maintained tools, with sharp cutting edges, are

less likely to bind and easier to control. When

mounting saw blades be certain that the arrow on

thblade matches the direction of the arrow marked

on the tool andthat the teeth are also pointing in

the same direction.

• Inspect guards before using a tool. Keep

guards in place. Check moving parts for bind-

ing or any other condition that may affect the

normal operation or safety features of the tool.

If damaged, have tool serviced before using

the tool. Many accidents are caused by poorly

maintained tools.

• Do not alter or misuse tool. Any alteration or

modification is a misuse and may result in serious

personal injury.

• The use of any other accessories not speci-

fied in this manual may create a hazard. Ac-

cessories that may besuitable forone type of tool,

may become hazardous when used on an inap-

propriate tool.

Service

• Tool service must be performed only by qual-

ified repair personnel. Service or maintenance

performed by unqualified personnel may result in

misplacing internal wires and components which

could cause serious hazard.

When servicing a tool, use only identical re-

placement parts. Follow instructions in the

Maintenance section of this manual. Use of

unauthorized parts or failure to follow Maintenance

Instructions may create a hazard.

Safety Rules For Miter Saws

• Use clamps to support wotkpiece whenever

possible, if supporting the workpiece by hand,

you must always keep hand outside of "No

Hand" area as marked with a symbol on the

base. Do not use this saw to cut pieces that

are too small to be securely clamped. Your

hand if placed inside the "No Hands"

region can easily slip or be pulled into the blade.

• Do not reach in back of the saw blade behind

the fence with either hand to hold

down or support the workpiece, remove wood

scraps, or for any other reason. The proximity

of the spinning saw blade to your hand may not

be obvious and you may be seriously injured.

• Never cross your hand over intended line of

cutting. Supporting the workpiece "cross handed"

i.e. holding the left side of the workpiece with your

right hand is very dangerous.

• Always disconnect the power cord from the

power source before making any adjustments

or attaching any accessories. You may unin-

tentionally start the saw, leading to serious per-

sonal injury.

• Miter saws are intended to cut wood or wood-

like products, they cannot be used with abra-

sive cutoff wheels for cutting ferrous material

such as bars, rods, studs, etc. However, if cut-

ting materials like aluminum or other non-fer-

rous metals, use only saw blades specifically

recommended for non ferrous metal cutting.

Cutting ferrous materials causes excessive spark-

ing and will damage the lower guard and will over-

load the motor.

(NOTE: Robert BoschTool Corporation does not

offer 12" metal cutting blades.)

Inspect your workpiece before cutting. If

wotkpiece is bowed or warped, clamp it with

the outside bowed face toward the fence. Al-

ways make certain that there is no gap be-

tween the workpiece, fence and table along

the line of the cut. Bent or warped workpieces

can twist or rock and may cause binding on the

spinning saw blade while cutting. Also, make sure

there are no nails or foreign objects in the work-

piece.

"SAVE THESE INSTRUCTIONS"

-3-

• Do not use the saw until the table isclear of all

tools, wood scraps, etc., except the work-

piece. Small debris or loose pieces of wood or

other objects that contact the revolving blade can

bethrown with high speed at the operator.

• Do not feed workpiece into the blade or cut

"freehand" in any way. Workpiece must be

stationary and clamped or braced by your

hand. Saw must be fed through the workpiece

smoothly and at a rate which will not overload the

saw's motor.

• Cut only one workpiece at a time. Multiple

workpieces cannot be adequately clamped or

braced and may bind on the blade or shift during

cutting.

• Be certain the miter saw ismounted or placed

on a level, firm work surface before using. A

leveland firm work surface reduces the riskof the

miter saw becoming unstable.

• Plan your work. Provide adequate support

accessories such as tables, saw horses, table

extension, etc. for workpieces wider or longer

than the table top (see page 20). Workpieces

longer or wider than the miter saw table can tip if

notsecurely supported. If the cutoffpiece or work-

piece tips it can lift the lower guard or be thrown

bythe spinning blade.

• Do not use another person as a substitute for

a table extension or as additional support. Un-

stable support for the workpiece can cause the

blade to bind or the workpiece to shift

during the cutting operation pulling you and the

helper into the spinning blade.

• The cutoff piece must not be jammed against

or pressured by any other means against the

spinning saw blade. Ifconfined, i.e.using length

stops, it could get wedged against the blade and

thrown violently.

• Always use a clamp or a fixture designed to

properly support round material such as

dowel rods, or tubing. Rods have atendency to

rollwhile beingcut, causingthe blade to"bite" and

pullthe work withyour hand into the blade.

• When cutting irregularly shaped work-pieces,

plan your work so itwill not slip and pinch the

blade and be torn from your hand.

A piece of molding, for example, must liefiat or be

held by a fixture or jig that will not let it twist, rock

or slip while being cut.

• Let the blade reach full speed before contact-

ing the workpiece. This will help avoid thrown

workpieces.

"SAVE THESE

• If the workpiece or blade becomes jammed or

bogged down, turn miter saw "OFF" by releas-

ing switch. Wait for all moving parts to stop

and unplug the miter saw, then work to free

the jammed material. Continued sawing with

jammed workpiece could cause loss of control or

damage to miter saw.

• Braking action of the saw causes the saw

head to jerk downward. Be ready for this reac-

tion when making an incomplete cut or when re-

leasing the switch before the head is completely

in the down position.

• After finishing the cut, release the switch, hold

the saw arm down and wait for blade to stop

before removing work or cutoff piece, if blade

does not stop within five (5) seconds, unplug

the saw and follow the instructions in the

Troubleshooting section. REACHING WITH

YOUR HAND UNDER A COASTING BLADE IS

DANGEROUS!

• There are additional safety instructions for

particular operations of the saw in the operat-

ing section. Read the rest of the man-ual for

safe operation.

• For slide action cutting, first PULL saw head

assembly away from the fence, until blade

clears the workpiece or to its maximum exten-

sion if blade cannot clear the workpiece. Make

certain the clamp does not interfere with the

guard and head assembly.

Second, turn saw "ON" and lower the saw to

the table. Then PUSH saw through the work-

piece. Release the switch and wait for the

blade to completely stop before raising the

head assembly and removing the workpiece.

Never "pullcut" since blade may climb the work-

piece causing KICKBACK.

• For chop action cutting, slide the head as-

sembly to the rear as far as it will go and

tighten slide lock knob. Then turn the saw

"ON" and lower the head assembly to make

the cut. Release the switch and wait for the

blade to completely stop before raising the

head assembly and removing the workpiece.

Failure to tighten the slide lock knob can cause

the blade to suddenly climb up on the top of the

workpiece and force itself toward you.

• Do not allow familiarity gained from frequent

use of your miter saw to become common-

place. Always remember that a careless fraction

of a second is sufficient to inflict severe injury.

INSTRUCTIONS"

-4-

_ READ ALL INSTRUCTIONS" -- Failure to follow the SAFETY RULES identified by

BULLET (o)symbol listed BELOW and other safety precautions, may result in serious per-

sonal injury.

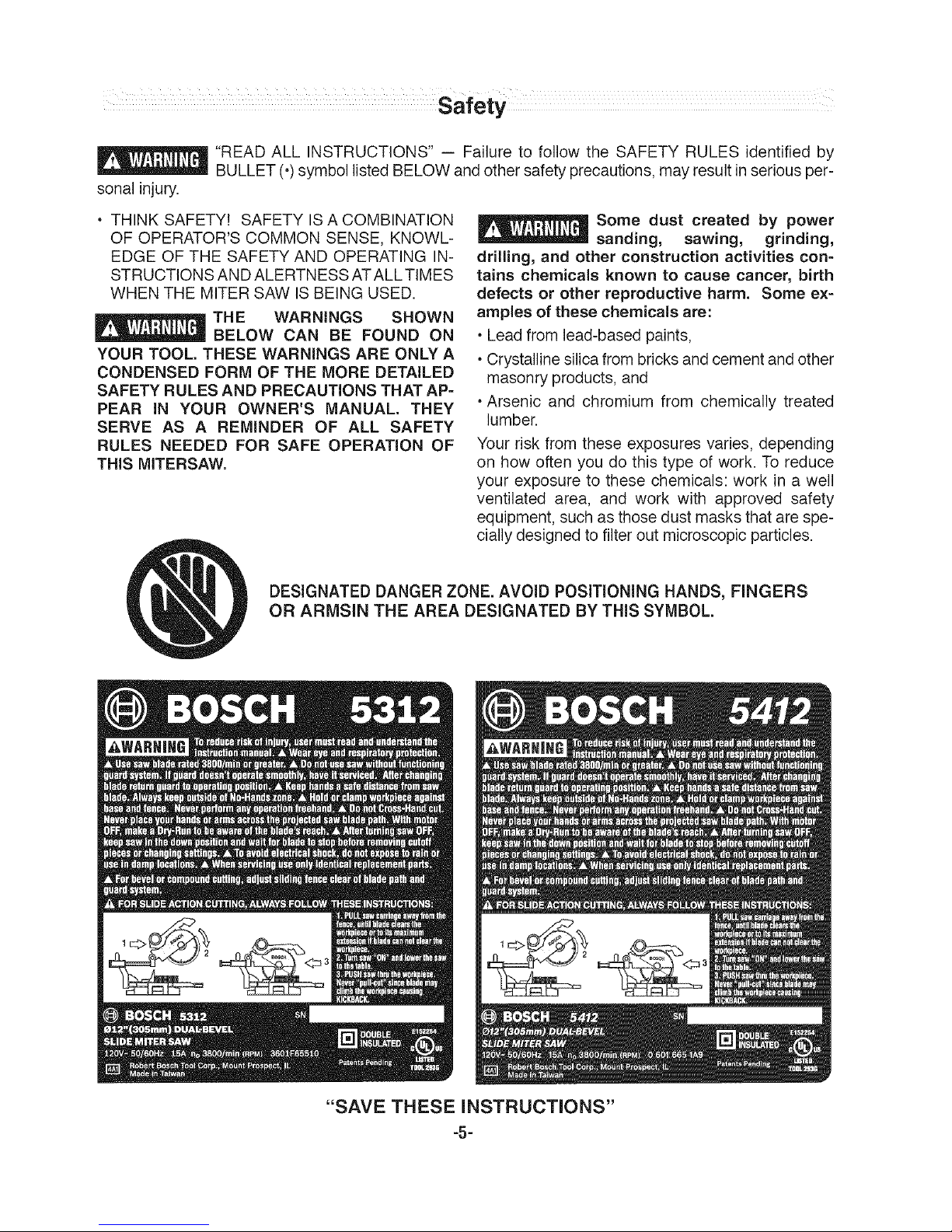

• THINK SAFETY! SAFETY IS A COMBINATION

OF OPERATOR'S COMMON SENSE, KNOWL-

EDGE OF THE SAFETY AND OPERATING IN-

STRUCTIONS AND ALERTNESS AT ALL TIMES

WHEN THE MITER SAW IS BEING USED.

THE WARNINGS SHOWN

BELOW CAN BE FOUND ON

YOUR TOOL. THESE WARNINGS ARE ONLY A

CONDENSED FORM OF THE MORE DETAILED

SAFETY RULES AND PRECAUTIONS THAT AP-

PEAR iN YOUR OWNER'S MANUAL. THEY

SERVE AS A REMINDER OF ALL SAFETY

RULES NEEDED FOR SAFE OPERATION OF

THIS MITERSAW.

Some dust created by power

sanding, sawing, grinding,

drilling, and other construction activities con-

tains chemicals known to cause cancer, birth

defects or other reproductive harm. Some ex-

amples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks andcement and other

masonry products, and

•Arsenic and chromium from chemically treated

lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are spe-

cially designed to filterout microscopic particles.

DESIGNATED DANGER ZONE. AVOID POSiTiONING HANDS, FINGERS

OR ARMSIN THE AREA DESIGNATED BY THIS SYMBOL.

"SAVE THESE INSTRUCTIONS"

"5"

_ READ ALL INSTRUCTIONS" -- Failure to follow the SAFETY RULES identified by

BULLET (,) symbol listed BELOW and other safety precautions, may result in serious

personal injury.

Double insulated Tools

Double insulation [] is a design concept used in

electric power tools which eliminates the need for

the three wire grounded power cord and grounded

power supply system. It is a recognized and ap-

proved system by Underwriter's Laboratories, CSA

and Federal OSHA authorities.

• Servicing of a tool with double insulation requires

care and knowledge of the system and should be

performed only bya qualified service technician.

•WHEN SERVICING, USE ONLY IDENTICAL RE-

PLACEMENT PARTS.

• POLARIZED PLUGS. To reduce the risk of elec-

trical shock, your tool is equipped with a polarized

plug (one blade is wider than the other), this plug

will fit inapolarized outlet only one way. Ifthe plug

does not fit fully in the outlet, reverse the plug. If it

still does not fit, contact a qualified electrician to in-

stall the proper outlet. To reduce the risk of elec-

trical shock, do not change the plug inany way.

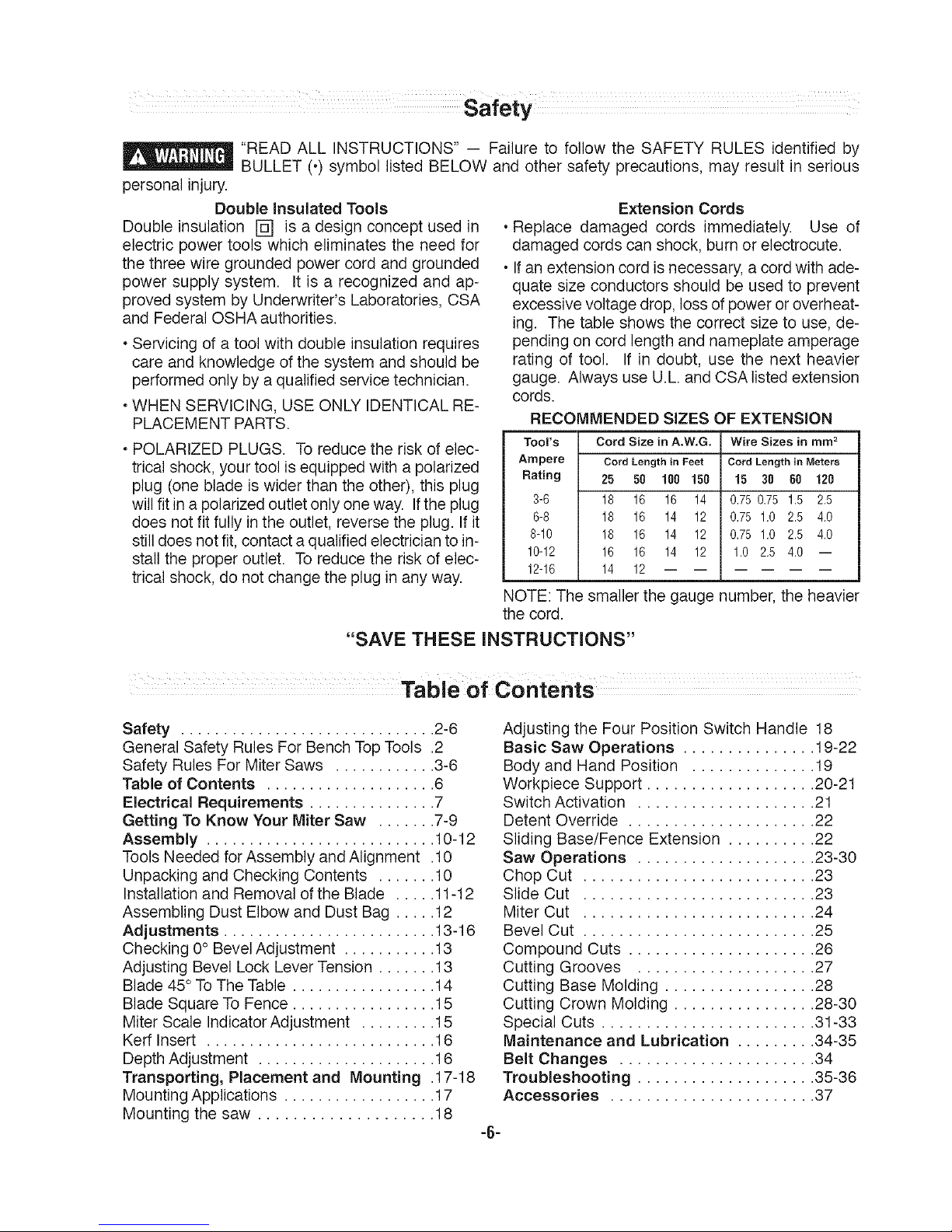

Extension Cords

• Replace damaged cords immediately. Use of

damaged cords can shock, burn or electrocute.

• Ifan extension cord is necessary, a cordwith ade-

quate size conductors should be used to prevent

excessive voltage drop, loss of power or overheat-

ing. The table shows the correct size to use, de-

pending on cord length and nameplate amperage

rating of tool. If in doubt, use the next heavier

gauge. Always use U.L.and CSA listed extension

cords.

RECOMMENDED SIZES

Tool's Cord Size in A.W.G,

Ampere Cord LerBgth in Feet

Rating 25 50 188 150

3-6 18 16 16 14

6-8 18 16 14 12

8-10 18 16 14 12

10-12 16 16 14 12

12-16 14 12

)F EXTENSION

Wire Sizes in mm 2

Cord Length in Meters

15 30 60 120

0.75 0.75 1.5 2.5

0.75 1.0 2.5 4.0

0.75 1.0 2.5 4.0

1.0 2.5 4.0 --

NOTE: The smaller the gauge number, the heavier

the cord.

"SAVE THESE INSTRUCTIONS"

Safety .............................. 2-6

General Safety Rules For Bench TopTools .2

Safety Rules ForMiter Saws ............ 3-6

Table of Contents .................... 6

Electrical Requirements ............... 7

Getting To Know Your Miter Saw ....... 7-9

Assembly ........................... 10-12

Tools Needed forAssembly and Alignment .10

Unpacking and Checking Contents ....... 10

Installation and Removal ofthe Blade ..... 11-12

Assembling Dust Elbow and Dust Bag ..... 12

Adjustments ......................... 13-16

Checking 0° BevelAdjustment ........... 13

Adjusting Bevel Lock Lever Tension ....... 13

Blade 45° To The Table ................. 14

Blade Square To Fence ................. 15

Miter Scale Indicator Adjustment ......... 15

Kerr Insert ........................... 16

DepthAdjustment ..................... 16

Transporting, Placement and Mounting .17-18

Mounting Applications .................. 17

Mounting the saw .................... 18

Adjusting the Four Position Switch Handle 18

Basic Saw Operations ............... 19-22

Body and Hand Position .............. 19

Workpiece Support ................... 20-21

Switch Activation .................... 21

Detent Override ..................... 22

Sliding Base/Fence Extension .......... 22

Saw Operations .................... 23-30

Chop Cut .......................... 23

Slide Cut .......................... 23

Miter Cut .......................... 24

Bevel Cut .......................... 25

Compound Cuts ..................... 26

Cutting Grooves .................... 27

Cutting Base Molding ................. 28

Cutting Crown Molding ................ 28-30

Special Cuts ........................ 31-33

Maintenance and Lubrication ......... 34-35

Belt Changes ...................... 34

Troubleshooting .................... 35-36

Accessories ....................... 37

-6-

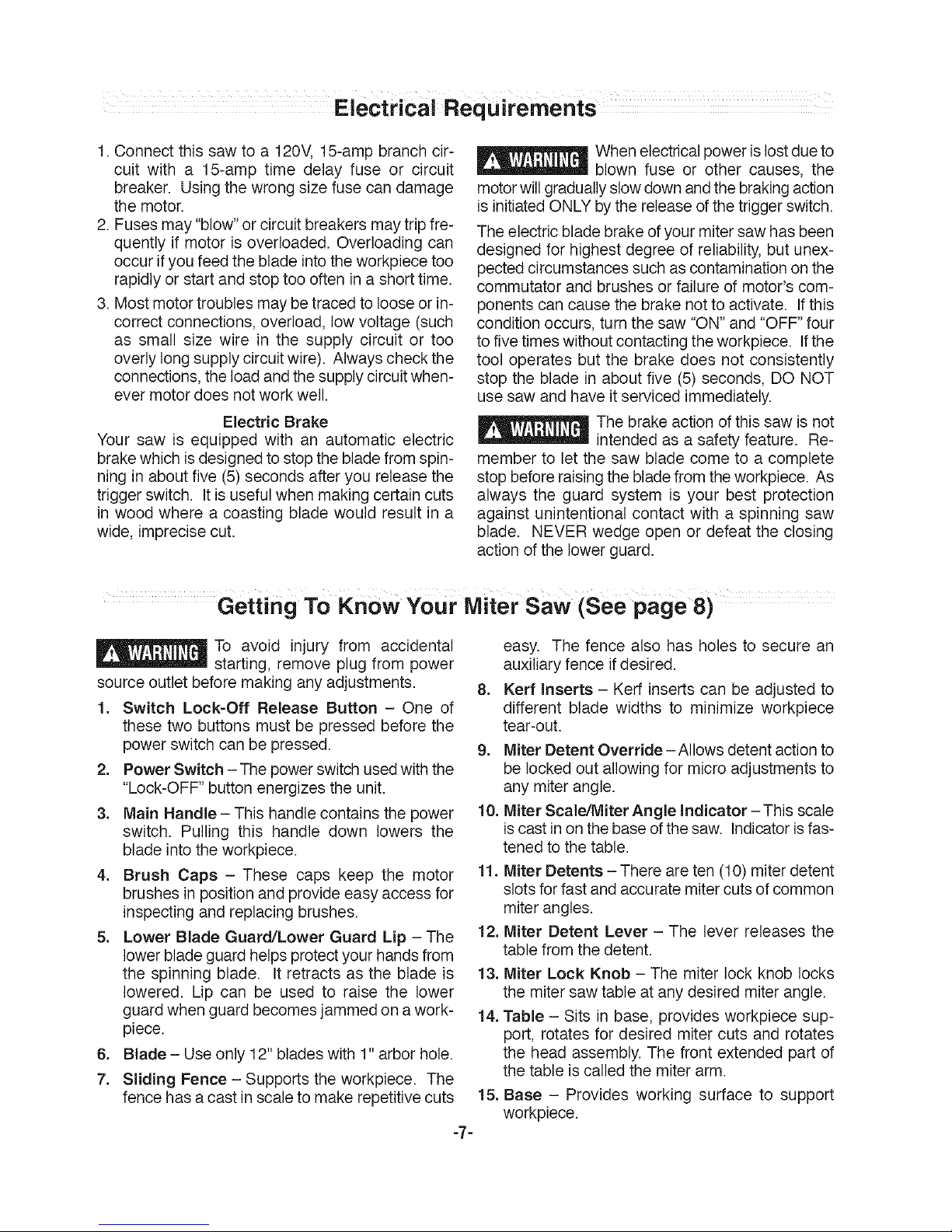

1.Connect this saw to a 120V, 15-amp branch cir-

cuit with a 15-amp time delay fuse or circuit

breaker. Using the wrong size fuse can damage

the motor.

2. Fuses may "blow" or circuitbreakers may trip fre-

quently if motor is overloaded. Overloading can

occur if you feed the blade into the workpiece too

rapidly or start and stop too often ina short time.

3. Most motor troubles may betraced to loose or in-

correct connections, overload, low voltage (such

as small size wire in the supply circuit or too

overly long supply circuit wire). Always check the

connections, the load and the supply circuit when-

ever motor does not work well.

Electric Brake

Your saw is equipped with an automatic electric

brake which is designed to stop the blade from spin-

ning in about five (5) seconds after you release the

trigger switch. It is useful when making certain cuts

in wood where a coasting blade would result in a

wide, imprecise cut.

When electricalpower is lostdue to

__ blown fuse or other causes, the

motorwillgradually slow down and the brakingaction

isinitiated ONLY by the release ofthe trigger switch.

The electric blade brake of your mitersaw has been

designed for highest degree of reliability, but unex-

pected circumstances such as contamination on the

commutator and brushes or failure of motor's com-

ponents can cause the brake not to activate. If this

condition occurs, turn the saw "ON" and "OFF" four

to five times without contacting the workpiece. Ifthe

tool operates but the brake does not consistently

stop the blade in about five (5) seconds, DO NOT

use saw and have it serviced immediately.

The brakeaction ofthis saw is not

intended as a safety feature. Re-

member to let the saw blade come to a complete

stop before raisingthe blade from the workpiece. As

always the guard system is your best protection

against unintentional contact with a spinning saw

blade. NEVER wedge open or defeat the closing

action ofthe lowerguard.

Getting To Know Your IVliter Saw (See page 8)

To avoid injury from accidental

-- starting, remove plug from power

source outlet before making any adjustments.

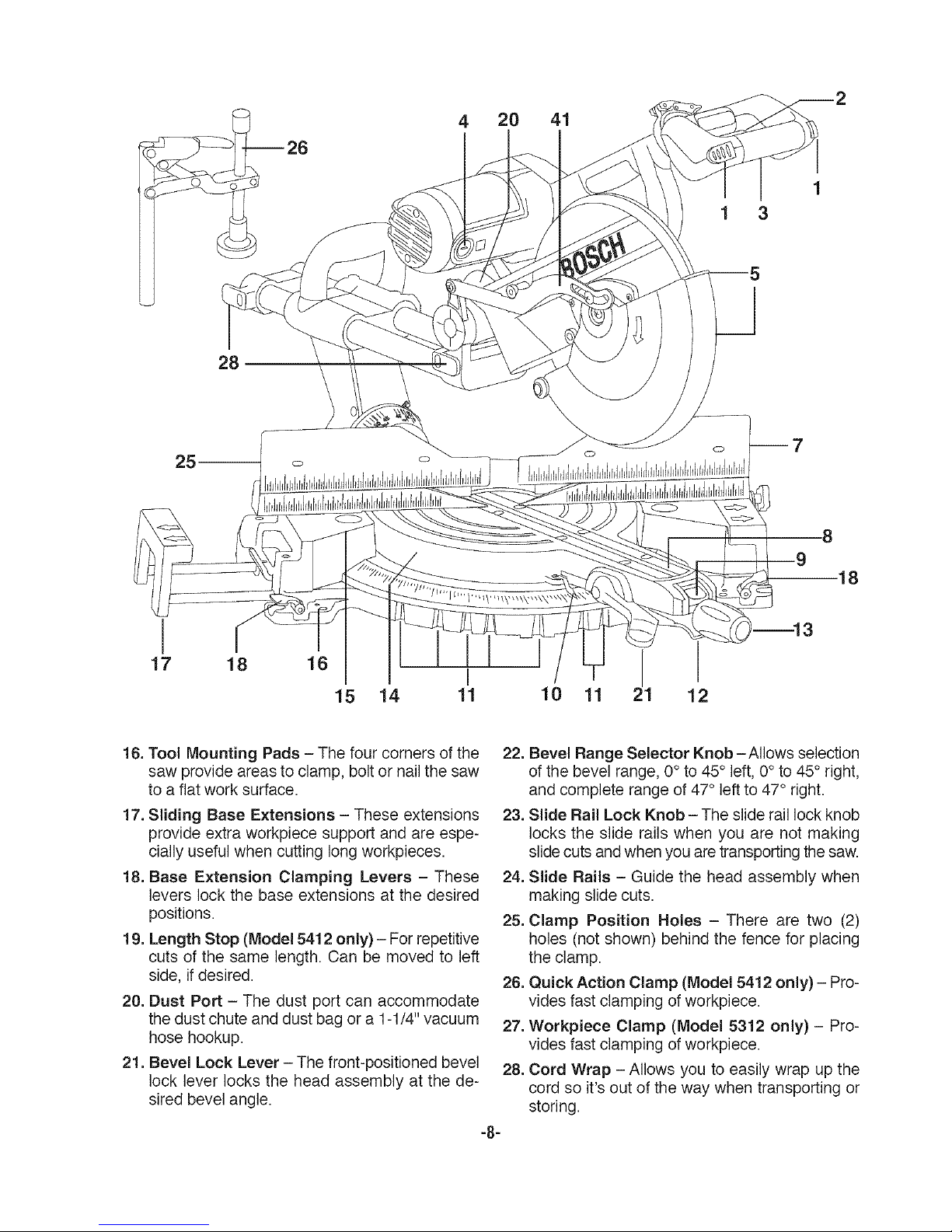

1. Switch Lock-Off Release Button - One of

these two buttons must be pressed before the

power switch can be pressed.

2. Power Switch - The power switch usedwith the

"Lock-OFF" button energizes the unit.

3. Main Handle- This handle contains the power

switch. Pulling this handle down lowers the

blade into the workpiece.

4. Brush Caps - These caps keep the motor

brushes in position and provide easy access for

inspecting and replacing brushes.

5. Lower Blade Guard/Lower Guard Lip - The

lower blade guard helps protectyour hands from

the spinning blade. It retracts as the blade is

lowered. Lip can be used to raise the lower

guard when guard becomes jammed on a work-

piece.

6. Blade- Use only 12" blades with 1" arbor hole.

7. Sliding Fence- Supports the workpiece. The

fence has a cast inscale to make repetitive cuts

-7-

easy. The fence also has holes to secure an

auxiliary fence if desired.

8. Kerr Inserts - Kerf inserts can be adjusted to

different blade widths to minimize workpiece

tear-out.

9. Miter Detent Override -Allows detent action to

be locked out allowing for micro adjustments to

any miter angle.

10. Miter Scale,Jilter Angle indicator - This scale

is castin on the base ofthe saw. Indicatorisfas-

tened to the table.

11. Miter Detents - There are ten (10) miter detent

slots forfast and accurate miter cuts of common

miter angles.

12. Miter Detent Lever - The lever releases the

table from the detent.

13. Miter Lock Knob - The miter lock knob locks

the miter saw table at any desired miter angle.

14. Table - Sits in base, provides workpiece sup-

port, rotates for desired miter cuts and rotates

the head assembly. The front extended part of

the table is called the miter arm.

15. Base - Provides working surface to support

workpiece.

4 20 41

1

1 3

28

17

18 16

I

15 14 11

10 11 11 12

16. Tool Mounting Pads - The four corners of the

saw provide areas to clamp, bolt or nailthe saw

to a fiat work surface.

17. Sliding Base Extensions - These extensions

provide extra workpiece support and are espe-

cially useful when cutting long workpieces.

18. Base Extension Clamping Levers - These

levers lock the base extensions at the desired

positions.

19. Length Stop (Model 5412 only) - For repetitive

cuts of the same length. Can be moved to left

side, if desired.

20. Dust Port - The dust port can accommodate

the dust chute and dust bag or a 1-1/4" vacuum

hose hookup.

21. Bevel Lock Lever - The front-positioned bevel

lock lever locks the head assembly at the de-

sired bevel angle.

-8-

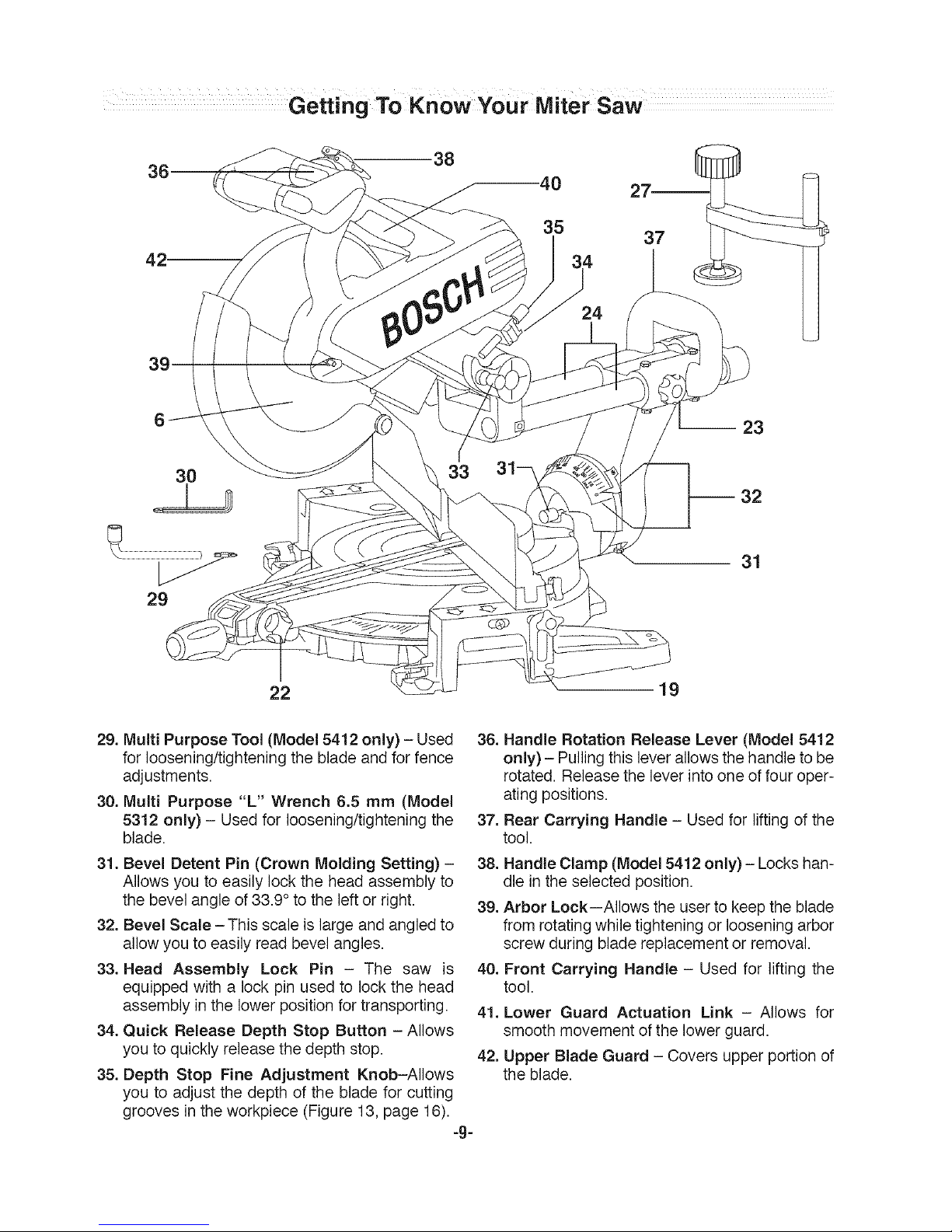

22. Bevel Range Selector Knob- Allows selection

of the bevel range, 0°to 45° left, 0° to 45° right,

and complete range of 47° left to 47° right.

23. Slide Rail Lock Knob -The slide rail lock knob

locks the slide rails when you are not making

slidecuts and when you aretransporting the saw.

24. Slide Rails - Guide the head assembly when

making slide cuts.

25. Clamp Position Holes - There are two (2)

holes (not shown) behind the fence for placing

the clamp.

26. Quick Action Clamp (Model 5412 only) - Pro-

vides fast clamping of workpiece.

27. Workpiece Clamp (Model 5312 only) - Pro-

vides fast clamping of workpiece.

28. Cord Wrap - Allows you to easily wrap up the

cord so it's out of the way when transporting or

storing.

38

30

29

31

22 19

29. Multi Purpose Tool (Model 5412 only) - Used

for loosening/tightening the blade and for fence

adjustments.

30. Multi Purpose "L" Wrench 6.5 mm (Model

5312 only) - Used for loosening/tightening the

blade.

31. Bevel Detent Pin (Crown Molding Setting) -

Allows you to easily lock the head assembly to

the bevel angle of 33.9 ° to the left or right.

32, Bevel Scale -This scale is large and angled to

allow you to easily read bevel angles.

33. Head Assembly Lock Pin - The saw is

equipped with a lock pin used to lock the head

assembly in the lower position for transporting.

34. Quick Release Depth Stop Button - Allows

you to quickly release the depth stop.

35. Depth Stop Fine Adjustment Knob-Allows

you to adjust the depth of the blade for cutting

grooves in the workpiece (Figure 13, page 16).

-g-

36.

37.

38.

39.

Handle Rotation Release Lever (Model 5412

only) - Pullingthis leverallows the handle to be

rotated. Release the lever into one of four oper-

ating positions.

Rear Carrying Handle - Used for lifting of the

tool.

Handle Clamp (Model 5412 only) - Locks han-

dle in the selected position.

Arbor Lock--Allows the userto keepthe blade

from rotating while tightening or loosening arbor

screw during blade replacement or removal.

40. Front Carrying Handle - Used for lifting the

tool.

41. Lower Guard Actuation Link - Allows for

smooth movement of the lower guard.

42, Upper Blade Guard - Covers upper portion of

the blade.

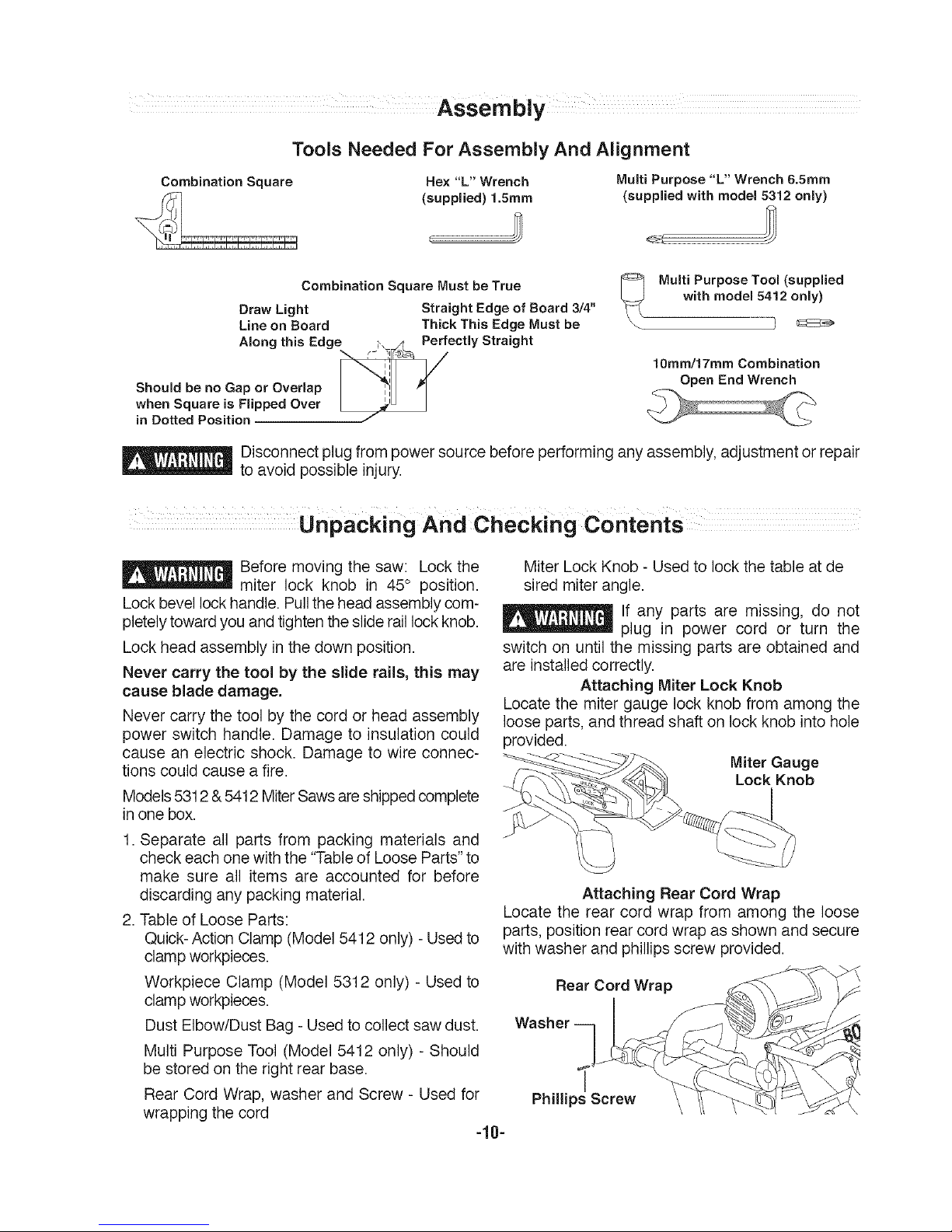

ToolsNeededForAssembly And Alignment

Combination Square Hex "L" Wrench Multi Purpose "L" Wrench 6.5ram

(suppmied) 1.5ram (suppmied with modem 5312 onmy)

Combination Square Must be True

Draw Light Straight Edge of Board 3/4"

Line on Board Thick This Edge Must be

Amongthis Edge _" ,r_ Perfectmy Straight

..oo,00oooo 0o ovo ,a0

when Square is Flipped Over I _'_i

in Dotted Position J

Multi Purpose Tool (supplied

with model 5412 only)

10mm/17mm Combination

Open End Wrench

_ Disconnect plug from power source before performing any assembly, adjustment or repair

__ to avoid possible injury.

Unpacking And Checking Contents

_ efore moving the saw: Lock the

miter lock knob in 45° position.

Lockbevel lock handle. Pull the head assembly com-

pletely toward you andtighten the slideraillock knob.

Lock head assembly in the down position.

Never carry the tool by the slide rails, this may

cause blade damage.

Never carry the tool by the cord or head assembly

power switch handle. Damage to insulation could

cause an electric shock. Damage to wire connec-

tions could cause a fire.

Models5312 & 5412MiterSawsare shippedcomplete

in one box.

1. Separate all parts from packing materials and

check each one with the "Tableof Loose Parts"to

make sure all items are accounted for before

discarding any packing material.

2. Table of Loose Parts:

Quick-Action Clamp (Model 5412 only) - Usedto

clampworkpieces.

Workpiece Clamp (Model 5312 only) - Used to

clampworkpieces.

Dust Elbow/Dust Bag- Used to collect saw dust.

Multi Purpose Tool (Model 5412 only) - Should

be stored onthe right rear base.

Rear Cord Wrap, washer and Screw - Used for

wrapping the cord

-10-

Miter Lock Knob - Used to lock the table at de

sired miter angle.

lf any parts are missing, do not

__ plug in power cord or turn the

switch on until the missing parts are obtained and

are installed correctly.

Attaching Miter Lock Knob

Locate the miter gauge lock knob from among the

loose parts, and thread shaft on lock knob into hole

provided.

Miter Gauge

Lock Knob

Attaching Rear Cord Wrap

Locate the rear cord wrap from among the loose

parts, position rear cord wrap as shown and secure

with washer and phillips screw provided.

Rear Cord Wrap

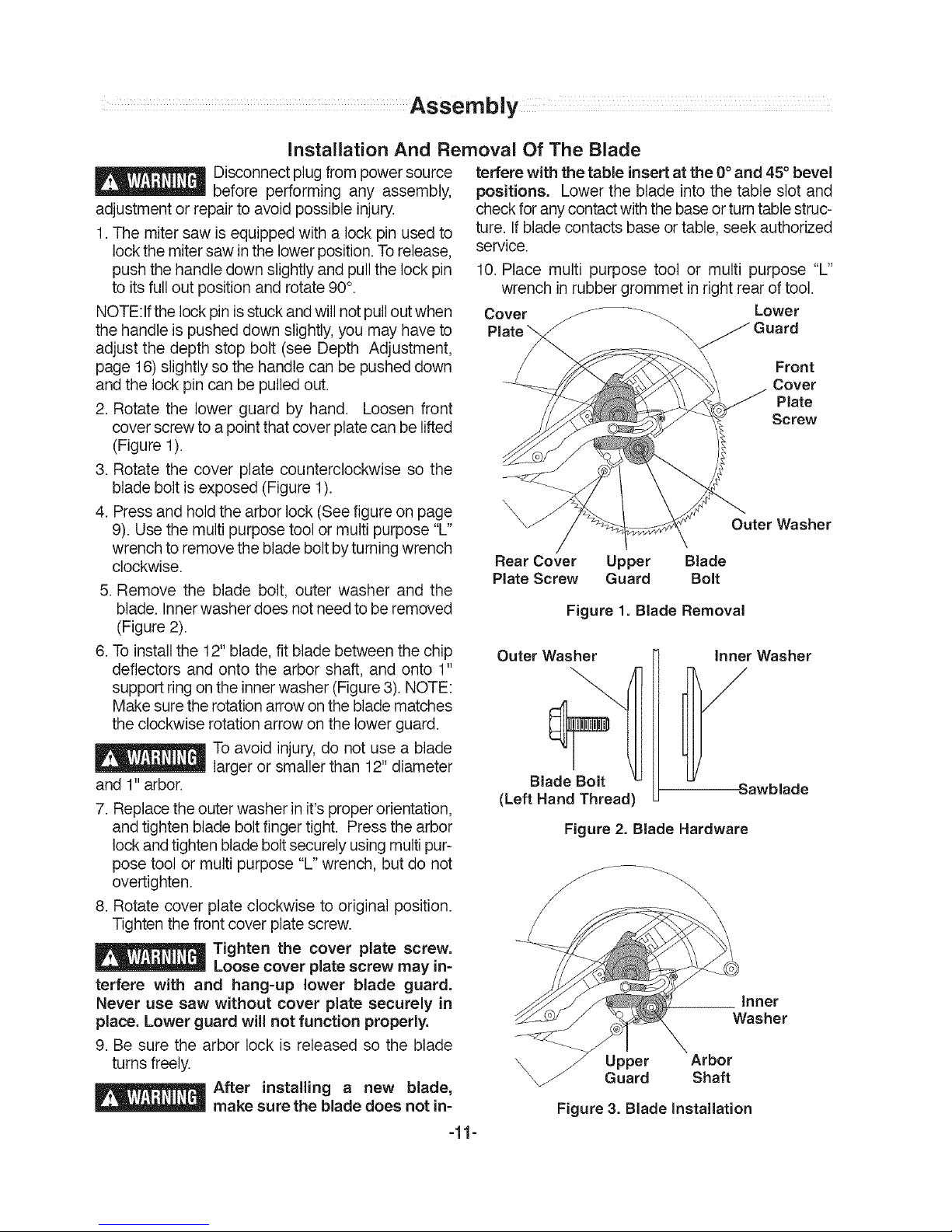

installation And Removal Of The Blade

_ isconnectplug from powersource

before performing any assembly,

adjustment or repair to avoid possible injury.

1.The mitersaw is equipped witha lock pin used to

lock the mitersaw inthe lower position.Torelease,

pushthe handle down slightly and pullthe lock pin

to its full out position and rotate 90°.

NOTE:Ifthe lock pinisstuckand will not pullout when

the handle is pushed downslightly,you may have to

adjust the depth stop bolt (see Depth Adjustment,

page 16)slightly so the handlecan be pusheddown

and the lock pin can be pulled out.

2. Rotate the lower guard by hand. Loosen front

cover screwto a point that cover plate can be lifted

(Figure 1).

3. Rotate the cover plate counterclockwise so the

blade bolt is exposed (Figure 1).

4. Pressand holdthe arbor lock (Seefigure on page

9). Use the multi purpose tool or multi purpose "L"

wrench toremove the blade boltby turningwrench

clockwise.

5. Remove the blade bolt, outer washer and the

blade. Inner washer does not needto be removed

(Figure2).

6. To installthe 12" blade, fit blade between the chip

deflectors and onto the arbor shaft, and onto 1"

support ringon the innerwasher (Figure 3).NOTE:

Make sure the rotation arrowon the bladematches

the clockwise rotation arrow on the lower guard.

Toavoid injury,do not use a blade

largeror smaller than 12" diameter

and 1" arbor.

7. Replacethe outerwasher in it's proper orientation,

andtighten blade boltfinger tight. Press the arbor

lock and tighten bladeboltsecurelyusing multipur-

pose tool or multi purpose "L" wrench, but do not

overtighten.

8. Rotate cover plate clockwise to original position.

Tighten the front cover platescrew.

_ Tighten the cover plate screw.

Loosecover plate screw may in-

terfere with and hang-up lower blade guard.

Never use saw without cover plate securely in

place. Lower guard will not function properly.

9. Be sure the arbor lock is released so the blade

turns freely.

_ After installing a new blade,

make sure the blade does not in-

-11-

terfere with the table insertat the 0° and 45° bevel

positions, Lower the blade into the table slot and

checkfor any contactwiththe baseor turntable struc-

ture. Ifblade contacts base ortable, seek authorized

service.

10. Place multi purpose tool or multi purpose "L"

wrench inrubber grommet in rightrear oftool.

Lower

Cover _ ..... _"_-,, Guard

\

Front

Cover

Plate

Screw

Outer Washer

Rear Cover Upper Blade

Plate Screw Guard Bolt

Figure 1. Blade Removal

Outer Washer

Blade Bolt

(Left Hand Thread

Inner Washer

Sawblade

Figure 2. Blade Hardware

\

Inner

Washer

Upper Arbor

Guard Shaft

Figure 3. Blade Installation

Assembly

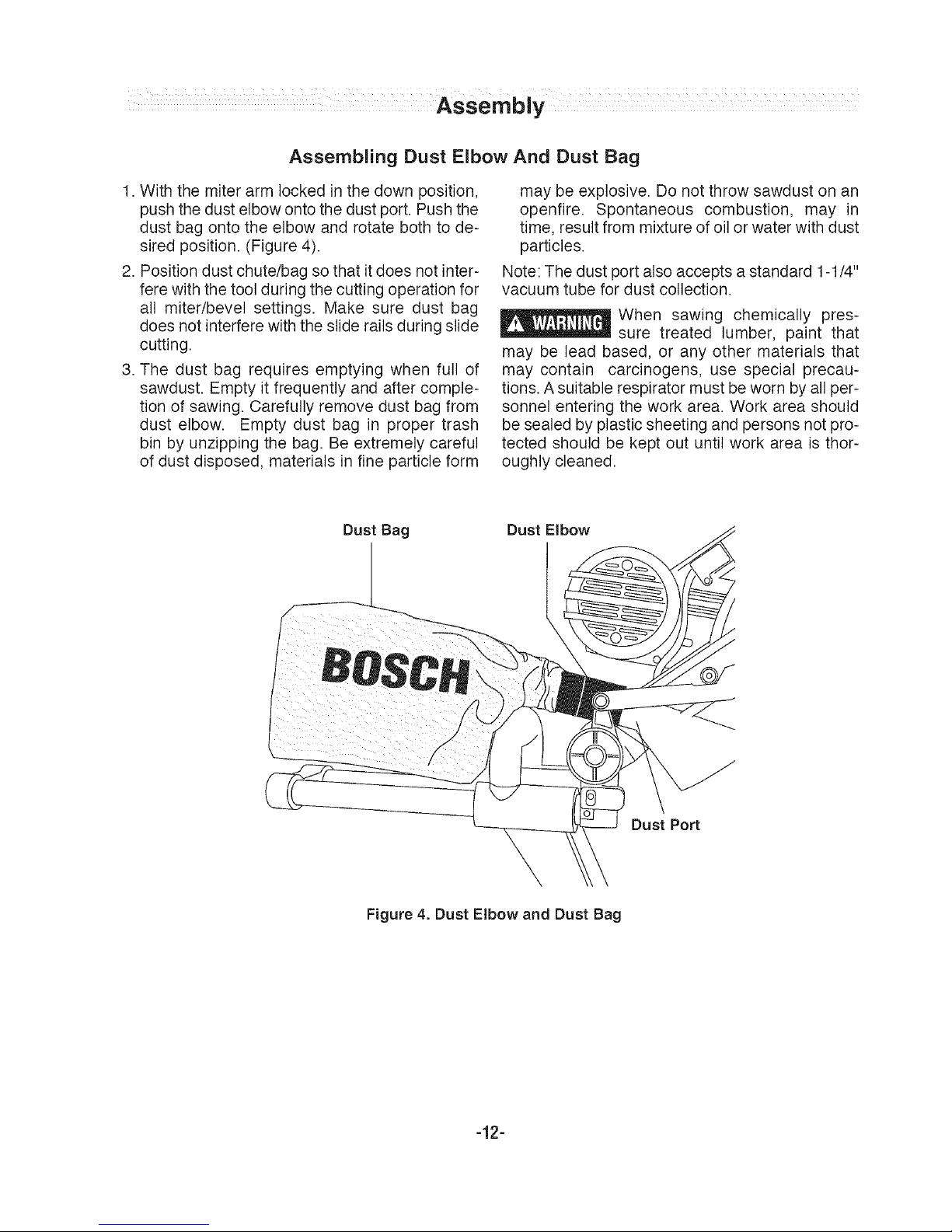

Assembling Dust Elbow And Dust Bag

1. With the miter arm locked in the down position,

pushthe dust elbow onto the dust port. Push the

dust bag onto the elbow and rotate both to de-

sired position. (Figure 4).

2. Position dust chute/bag sothat it does not inter-

fere with the tool during the cutting operation for

all miter/bevel settings. Make sure dust bag

does not interfere with the slide rails during slide

cutting.

3. The dust bag requires emptying when full of

sawdust. Empty it frequently and after comple-

tion of sawing. Carefully remove dust bag from

dust elbow. Empty dust bag in proper trash

bin by unzipping the bag. Be extremely careful

of dust disposed, materials in fine particle form

may be explosive. Do not throw sawdust on an

openfire. Spontaneous combustion, may in

time, result from mixture of oil or water with dust

particles.

Note: The dust port also accepts a standard 1-1/4"

vacuum tube for dust collection.

When sawing chemically pres-

sure treated lumber, paint that

may be lead based, or any other materials that

may contain carcinogens, use special precau-

tions. A suitable respirator must be worn byall per-

sonnel entering the work area. Work area should

be sealed by plastic sheeting and persons not pro-

tected should be kept out until work area is thor-

oughly cleaned.

Dust Bag

Dust Elbow

Dust Port

Figure 4. Dust Elbow and Dust Bag

-12-

Disconnect plug from power

source before performing any as-

sembly, adjustment or repairto avoid possible injury.

NOTE: Your miter saw was completely adjusted at

the factory. However, during shipment, slight mis-

alignment may have occurred. Check the following

settings and adjust if necessary prior to using this

miter saw.

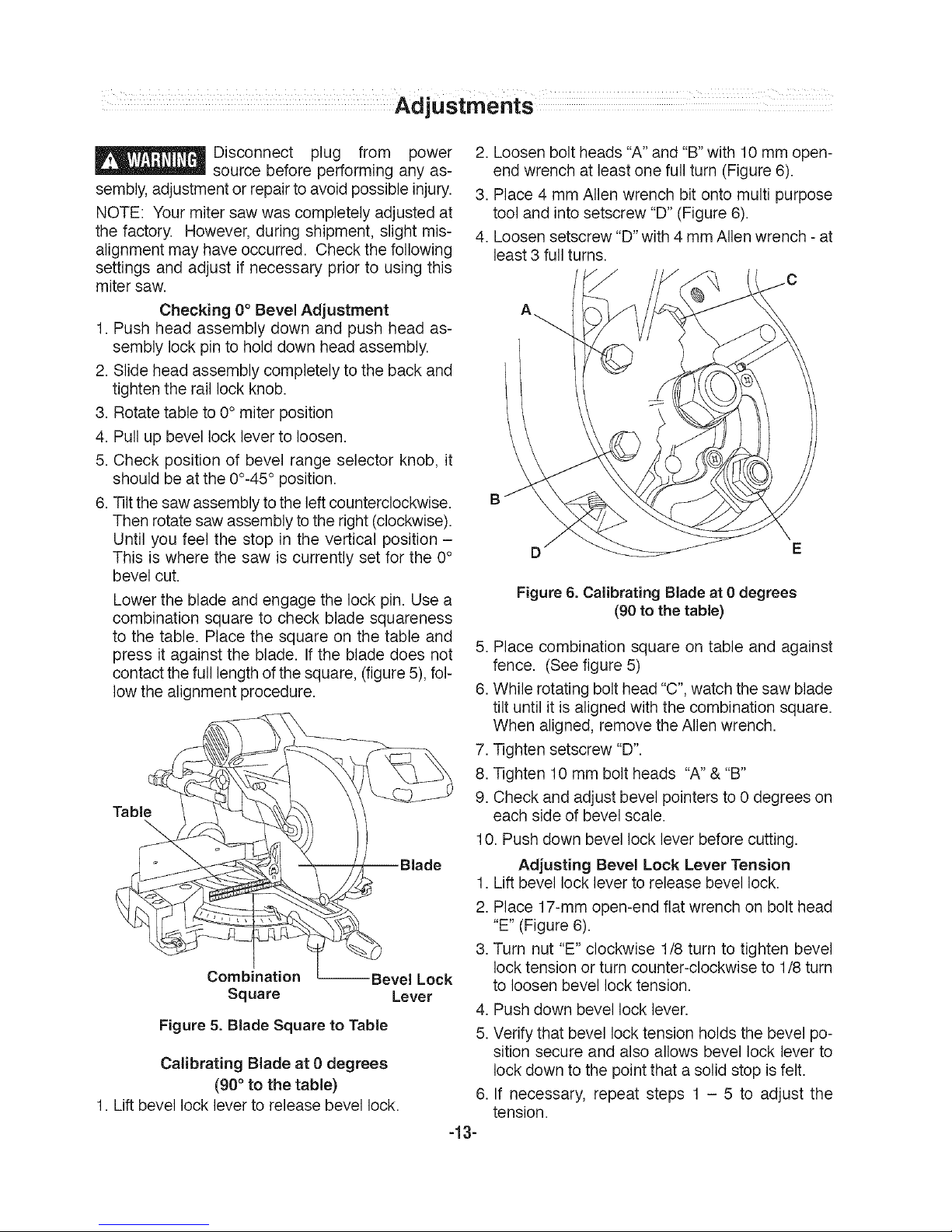

Checking 0°Bevel Adjustment

1. Push head assembly down and push head as-

sembly lock pin to hold down head assembly.

2. Slide head assembly completely to the back and

tighten the rail lock knob.

3. Rotate table to 0° miter position

4. Pull up bevel lock lever to loosen.

5. Check position of bevel range selector knob, it

should be at the 00-45° position.

6. Tiltthe saw assembly to the left counterclockwise.

Then rotatesaw assembly to the right(clockwise).

Until you feel the stop in the vertical position -

This is where the saw is currently set for the 0°

bevel cut.

Lower the blade and engage the lock pin. Use a

combination square to check blade squareness

to the table. Place the square on the table and

press it against the blade. If the blade does not

contact the full length of the square, (figure5), fol-

low the alignment procedure.

Table

Combination --Bevel Lock

Square Lever

Figure 5. Blade Square to Table

Calibrating Blade at 0 degrees

(90 ° to the table)

1. Lift bevel lock lever to release bevel lock.

2. Loosen bolt heads "A" and "B" with 10 mm open-

end wrench at least one full turn (Figure6).

3. Place 4 mm Alien wrench bit onto multi purpose

tool and into setscrew "D" (Figure 6).

4. Loosen setscrew "D" with 4 mm Alien wrench -at

least 3 full turns.

D

Figure 6. Calibrating Blade at 0 degrees

(90 to the table)

5. Place combination square on table and against

fence. (See figure 5)

6. While rotating bolt head "C",watch thesaw blade

tilt until it is aligned with the combination square.

When aligned, remove the Allen wrench.

7. Tighten setscrew "D".

8. Tighten 10 mm bolt heads "A" &"B"

9. Check and adjust bevel pointers to 0 degrees on

each side of bevel scale.

10. Push down bevel lock lever before cutting.

Adjusting Bevel Lock Lever Tension

1. Lift bevel lock lever to release bevel lock.

2. Place 17-mm open-end fiat wrench onbolt head

"E" (Figure 6).

3. Turn nut "E" clockwise 1/8 turn to tighten bevel

lock tension or turn counter-clockwise to 1/8 turn

to loosen bevel lock tension.

4. Push down bevel lock lever.

5. Verify that bevel locktension holdsthe bevel po-

sition secure and also allows bevel lock lever to

lock down to the pointthat a solid stop is felt.

If necessary, repeat steps 1 - 5 to adjust the

tension.

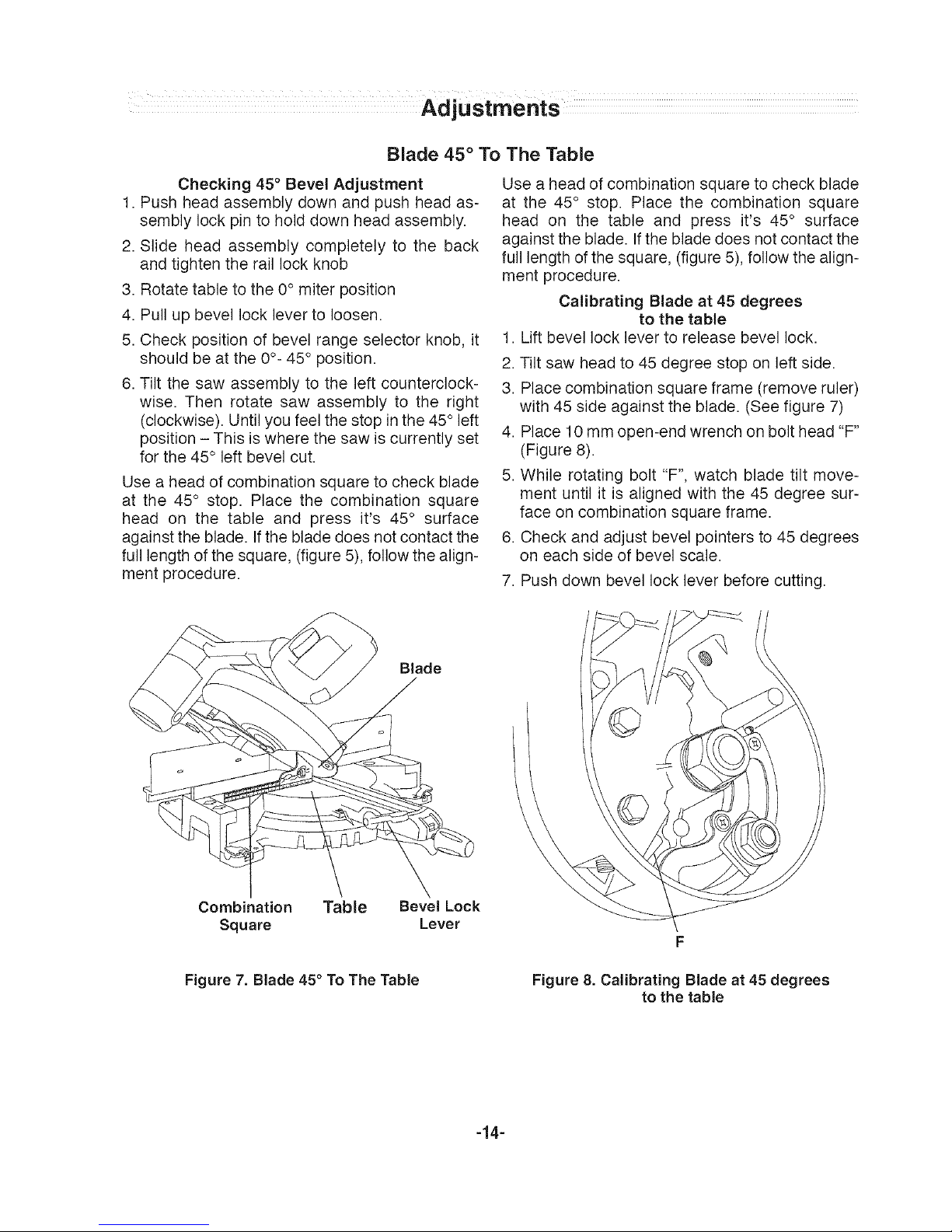

Blade 45° To The Table

Checking 45° Bevel Adjustment

1. Push head assembly down and push head as-

sembly lock pin to hold down head assembly.

2. Slide head assembly completely to the back

and tighten the rail lock knob

3. Rotate table to the 0° miter position

4. Pull up bevel lock lever to loosen.

5. Check position of bevel range selector knob, it

should be at the 0°- 45° position.

6. Tilt the saw assembly to the left counterclock-

wise. Then rotate saw assembly to the right

(clockwise). Untilyou feel the stop in the 45° left

position - This is where the saw is currently set

for the 45° left bevel cut.

Use a head of combination square to check blade

at the 45° stop. Place the combination square

head on the table and press it's 45° surface

against the blade. Ifthe blade does not contact the

full length of the square, (figure 5), follow the align-

ment procedure.

Use a head of combination square to check blade

at the 45° stop. Place the combination square

head on the table and press it's 45° surface

against the blade. Ifthe blade does not contact the

full length of the square, (figure 5), follow the align-

ment procedure.

Calibrating Blade at 45 degrees

to the table

1. Lift bevel lock lever to release bevel lock.

2. Tilt saw head to 45 degree stop on left side.

3. Place combination square frame (remove ruler)

with 45 side against the blade. (See figure 7)

4. Place 10 mm open-end wrench on bolt head "F"

(Figure 8).

5. While rotating bolt "F", watch blade tilt move-

ment until it is aligned with the 45 degree sur-

face on combination square frame.

6. Check and adjust bevel pointers to 45 degrees

on each side of bevel scale.

7. Push down bevel lock lever before cutting.

Blade

Combination Table Bevel Lock

Square Lever

Figure 7. Blade 45° To The Table Figure 8. Calibrating Blade at 45 degrees

to the table

-14-

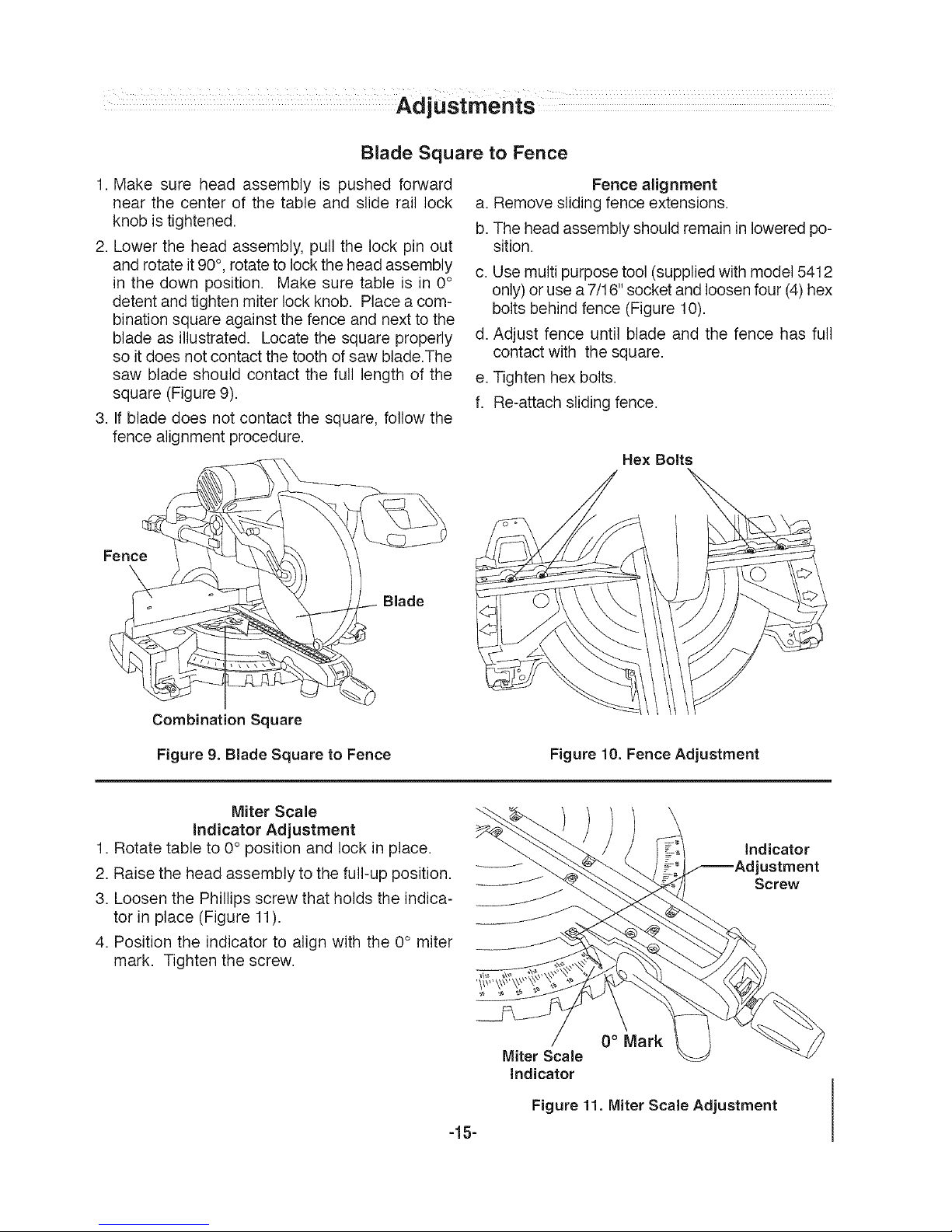

Adjustments

Blade Square to Fence

1. Make sure head assembly is pushed forward

near the center of the table and slide rail lock a.

knob istightened, b.

2. Lower the head assembly, pull the lock pin out

and rotate it90°, rotateto lock the head assembly c.

in the down position. Make sure table is in 0°

detent and tighten miter lock knob. Place a com-

bination square against the fence and next to the

blade as illustrated. Locate the square properly d.

so it does notcontact thetooth of saw blade.The

saw blade should contact the full length of the e.

square (Figure 9). f.

3. If blade does not contact the square, follow the

fence alignment procedure.

Fence alignment

Remove sliding fence extensions.

The head assembly should remainin loweredpo-

sition.

Use multi purpose tool (supplied with model 5412

only)or usea 7/16" socket and loosen four (4)hex

bolts behind fence (Figure 10).

Adjust fence until blade and the fence has full

contact with the square.

Tighten hex bolts.

Re-attach sliding fence.

Hex Bolts

Fence

Blade

Combination Square

Figure 9. Blade Square to Fence Figure 10. Fence Adjustment

Miter Scale

indicator Adjustment

1. Rotate table to 0° position and lock in place.

2. Raise the head assembly to the full-up position.

3. Loosen the Phillips screw that holds the indica-

tor in place (Figure 11).

4. Position the indicator to align with the 0° miter

mark. Tighten the screw.

-15-

indicator

ustment

Screw

0° Mark

Miter Scale

Indicator

Figure 11. Miter Scale Adjustment

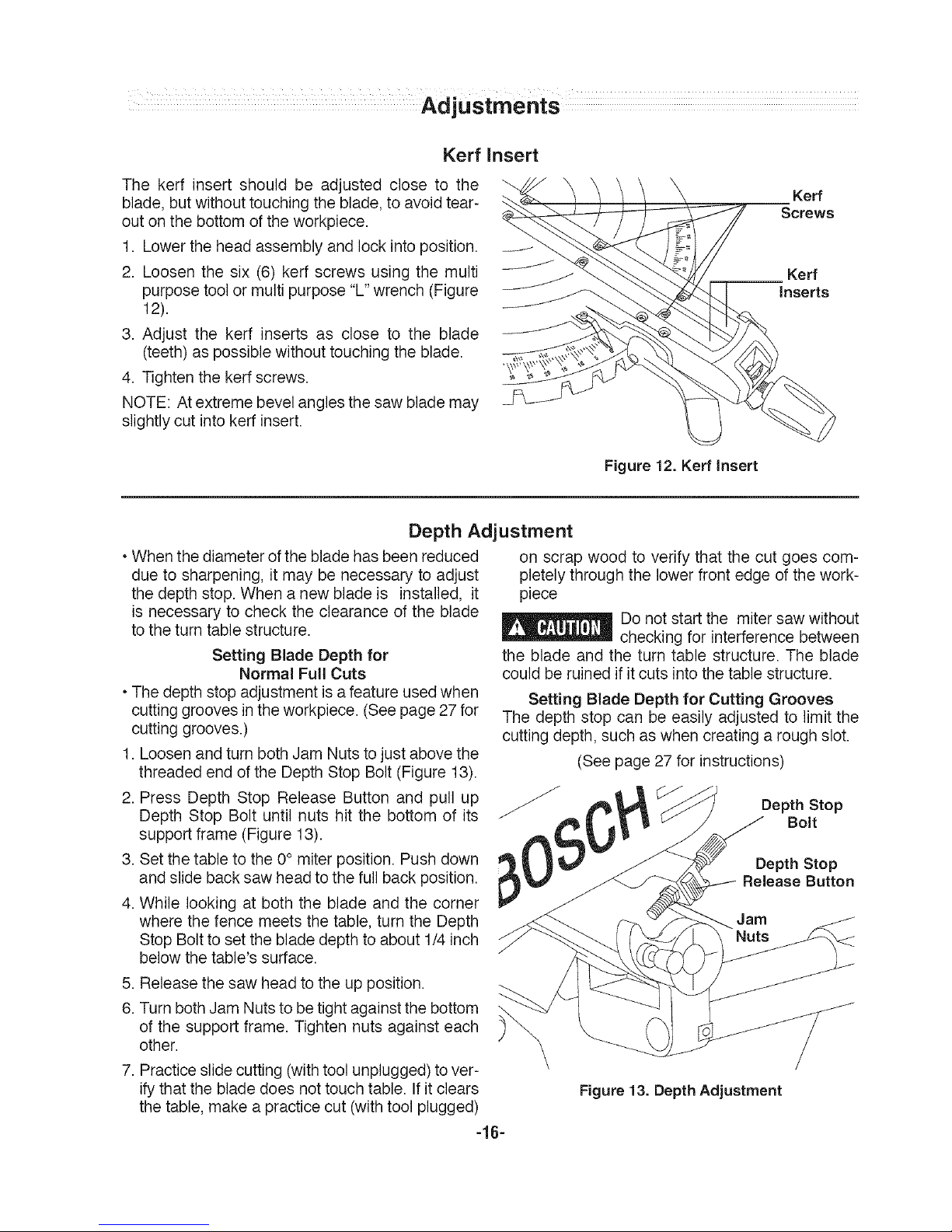

Kerr

The kerf insert should be adjusted close to the

blade, butwithout touching the blade, to avoidtear-

out on the bottom of the workpiece.

1. Lower the head assembly and lock into position.

2. Loosen the six (6) kerr screws using the multi

purpose tool ormulti purpose"L" wrench (Figure

12).

3. Adjust the kerf inserts as close to the blade

(teeth) as possible without touching the blade.

4. Tighten the kerf screws.

NOTE: Atextreme bevel angles the saw blade may

slightly cut intokerr insert.

Insert

Figure 12. Kerf Insert

Kerr

Screws

Kerf

Inserts

Depth Adjustment

• When the diameter of the blade has been reduced

due to sharpening, it may be necessary to adjust

the depth stop.When a new blade is installed, it

is necessary to check the clearance of the blade

to the turn table structure.

Setting Blade Depth for

Normal Full Cuts

• The depth stopadjustment is afeature usedwhen

cutting grooves in the workpiece. (Seepage 27 for

cutting grooves.)

1. Loosenand turn both Jam Nuts to just above the

threaded end of the Depth Stop Bolt (Figure 13).

2. Press Depth Stop Release Button and pull up

Depth Stop Bolt until nuts hit the bottom of its

support frame (Figure 13).

3. Set thetable to the 0° miter position. Push down

and slide back saw head to the full back position.

4. While looking at both the blade and the corner

where the fence meets the table, turn the Depth

Stop Boltto set the blade depth to about 1/4 inch

below the table's surface.

5. Releasethe saw head to the up position.

6. Turn bothJam Nuts to betight against the bottom

of the support frame. Tighten nuts against each

other.

on scrap wood to verify that the cut goes com-

pletely through the lower front edge of the work-

piece

Do not start the miter saw without

checking for interference between

the blade and the turn table structure. The blade

could be ruined if it cuts into the table structure.

Setting Blade Depth for Cutting Grooves

The depth stop can beeasily adjusted to limit the

cutting depth, such as when creating a rough slot.

(See page 27 for instructions)

Depth Stop

Bolt

Depth Step

Release Button

7. Practice slide cutting (withtool unplugged) to ver-

ify that the blade does not touch table. Ifit clears

the table, make a practice cut (with tool plugged)

Figure 13. Depth Adjustment

-16-

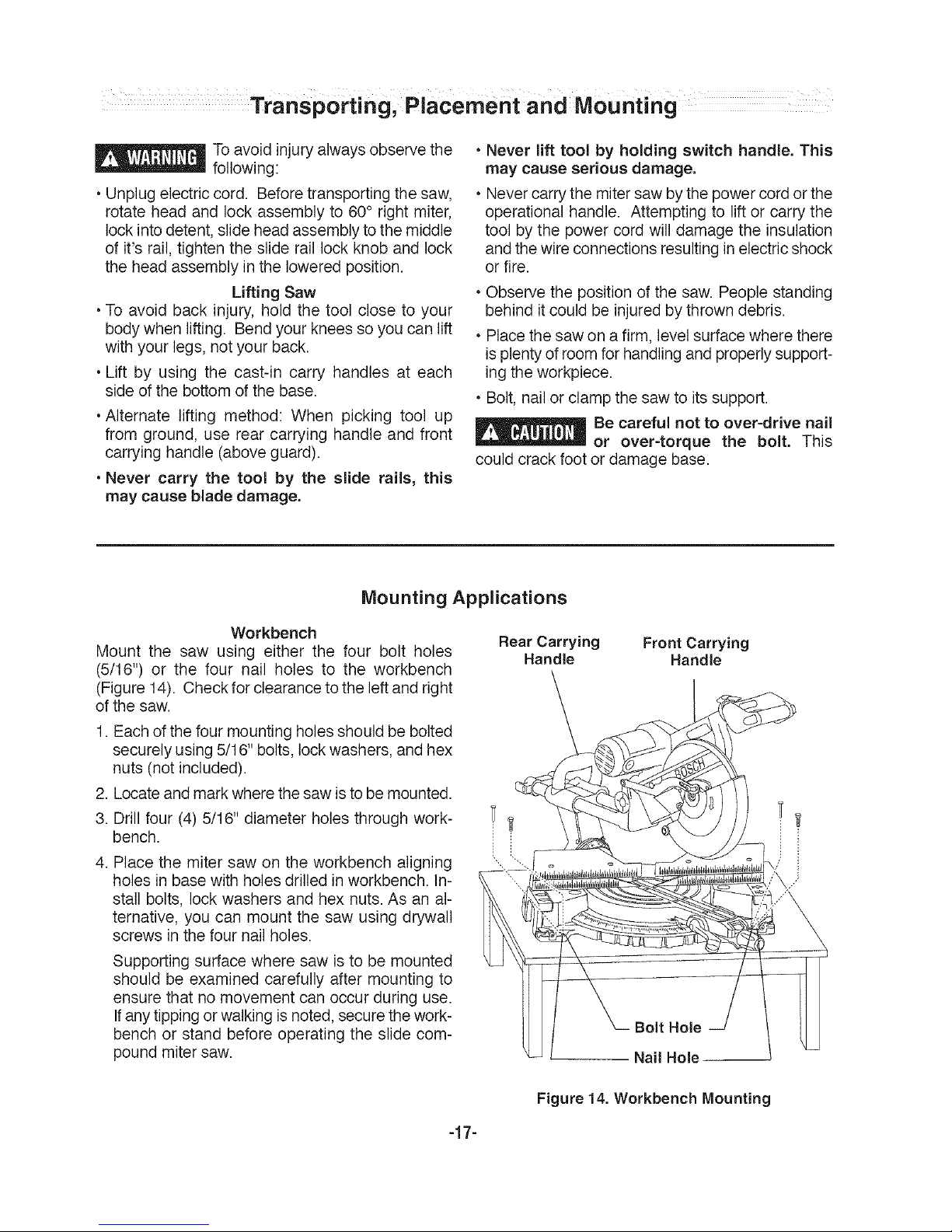

Transportingl Placement and lVlounting

Toavoid injury always observe the

following:

• Unplug electric cord. Before transporting the saw,

rotate head and lock assembly to 60° right miter,

lock into detent, slide head assembly to the middle

of it's rail, tighten the slide rail lock knob and lock

the head assembly in the lowered position.

Lifting Saw

•To avoid back injury, hold the tool close to your

bodywhen lifting. Bend your knees so you can lift

with your legs, not your back.

• Lift by using the cast-in carry handles at each

side of the bottom of the base.

•Alternate lifting method: When picking tool up

from ground, use rear carrying handle and front

carrying handle (above guard).

• Never carry the tool by the slide rails, this

may cause blade damage.

• Never lift tool by holding switch handle. This

may cause serious damage,

• Never carrythe miter saw bythe power cordor the

operational handle. Attempting to lift or carry the

tool by the power cord will damage the insulation

andthe wire connections resulting in electric shock

or fire.

• Observe the position of the saw. People standing

behind it could be injured by thrown debris.

• Place the saw ona firm, level surface where there

is plenty of room forhandling andproperly support-

ing the workpiece.

• Bolt, nailor clamp the saw to its support.

Be careful not to over-drive nail

or over-torque the bolt, This

could crack foot or damage base.

Mounting Applications

Workbench

Mount the saw using either the four bolt holes

(5/16") or the four nail holes to the workbench

(Figure14). Check for clearance to the leftand right

of the saw.

1. Each of the four mounting holes should be bolted

securely using5/16" bolts, lock washers, and hex

nuts (not included).

2. Locateand mark where the saw isto be mounted.

3. Drill four (4) 5/16" diameter holes through work-

bench.

4. Place the miter saw on the workbench aligning

holes in base with holes drilled in workbench. In-

stall bolts, lock washers and hex nuts. As an al-

ternative, you can mount the saw using drywall

screws in the four nail holes.

Supporting surface where saw is to be mounted

should be examined carefully after mounting to

ensure that no movement can occur during use.

Ifanytipping or walking is noted, secure the work-

bench or stand before operating the slide com-

pound miter saw.

Rear Carrying Front Carrying

Handle Handle

Nail Hole-

Figure 14. Workbench Mounting

-17-

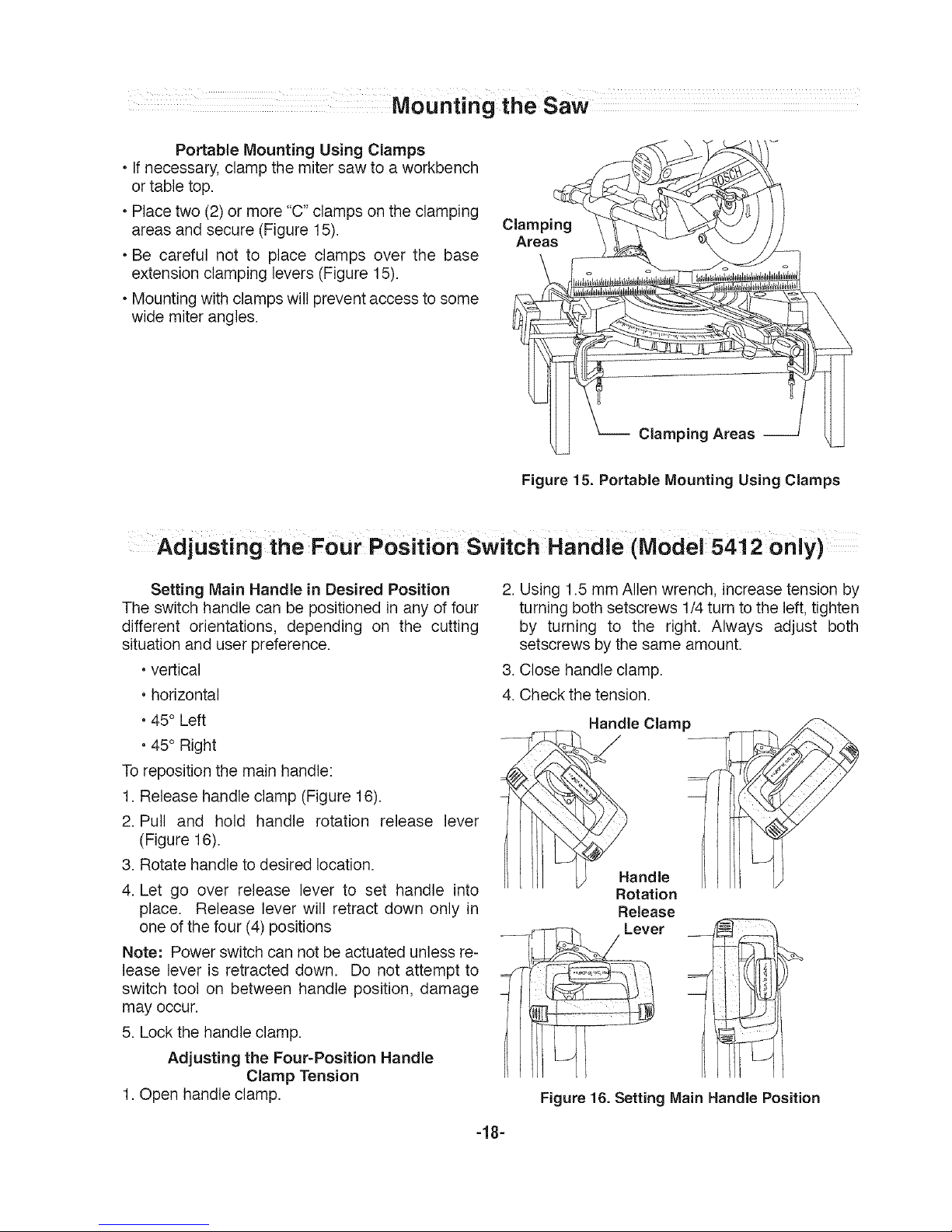

Portable Mounting Using Clamps

• Ifnecessary, clamp the miter saw to a workbench

or table top.

• Placetwo (2) or more"C" clamps on the clamping

areas and secure (Figure 15).

• Be careful not to place clamps over the base

extension clamping levers (Figure 15).

• Mountingwith clamps will prevent access to some

wide miter angles.

Clamping

Areas

Clamping Areas

Figure 15. Portable Mounting Using Clamps

Adjusting the Four Position Switch Handle (Model 5412 only)

Setting Main Handle in Desired Position

The switch handle can be positioned in any of four

different orientations, depending on the cutting

situation and user preference.

• vertical

• horizontal

• 45° Left

• 45° Right

Toreposition the main handle:

1. Release handle clamp (Figure 16).

2. Pull and hold handle rotation release lever

(Figure 16).

3. Rotate handle to desired location.

4. Let go over release lever to set handle into

place. Release lever will retract down only in

one of the four (4) positions

Note: Power switch can not be actuated unless re-

lease lever is retracted down. Do not attempt to

switch tool on between handle position, damage

may occur.

5. Lock the handleclamp.

Adjusting the Four-Position Handle

Clamp Tension

1. Open handle clamp.

2. Using 1.5 mm Alien wrench, increase tension by

turning both setscrews 1/4 turn to the left, tighten

by turning to the right. Always adjust both

setscrews bythe same amount.

3. Close handle clamp.

4. Check the tension.

Handle Clamp /_

Rotation

Release

Lever

Figure 16. Setting Main Handle Position

-18-

BasicSaw Operations

Body and Hand Position

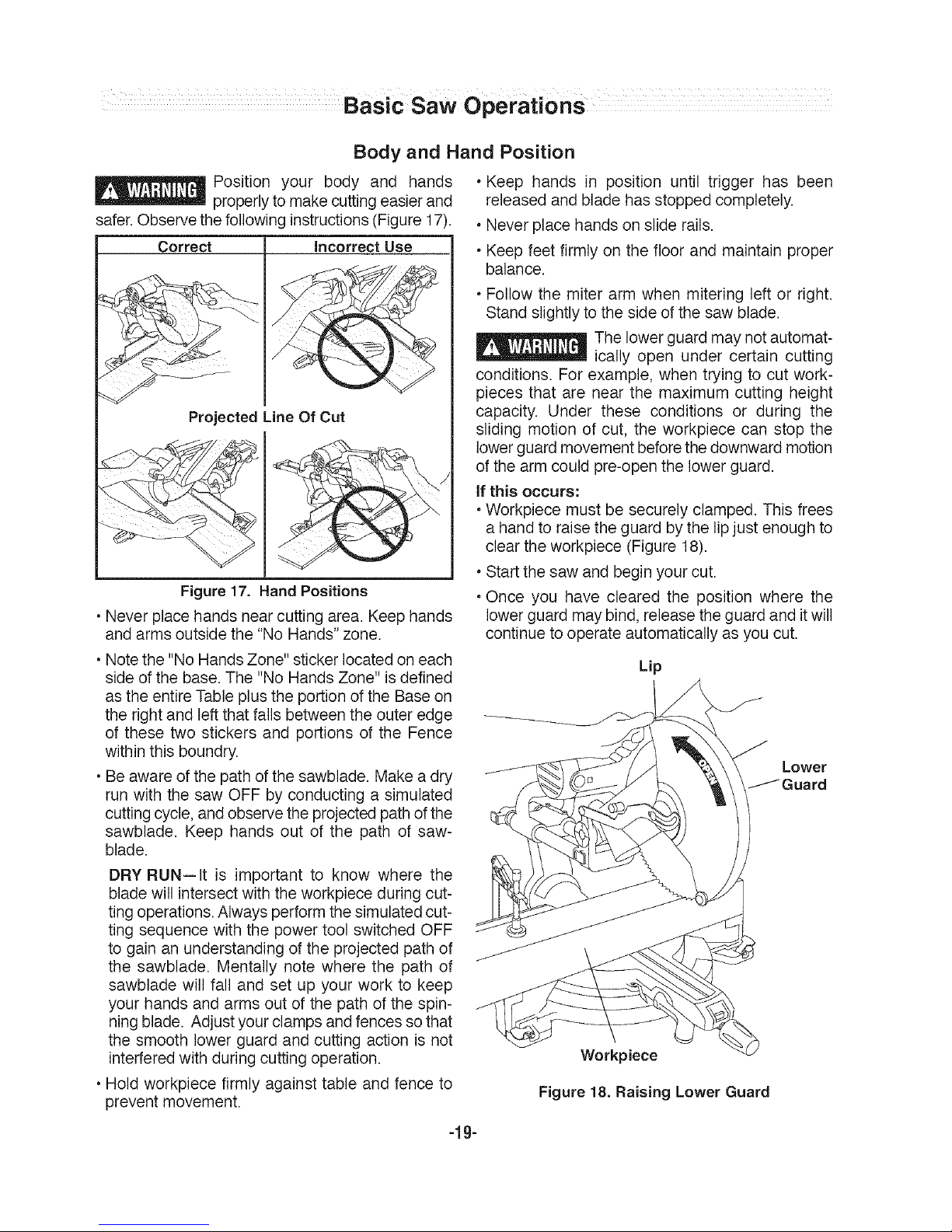

_ osition your body and hands

properlyto make cutting easier and

safer. Observe the followinginstructions (Figure 17).

Correct

Incorreqt ,Use......

Projected Line Of Cut

Figure 17. HandPositions

• Never place hands nearcutting area. Keep hands

and arms outside the "No Hands" zone.

• Keep hands in position until trigger has been

released and blade has stopped completely.

• Never place hands on slide rails.

• Keep feet firmly on the floor and maintain proper

balance.

• Follow the miter arm when mitering left or right.

Stand slightly to the side of the saw blade.

The lowerguard may notautomat-

ically open under certain cutting

conditions. For example, when trying to cut work-

pieces that are near the maximum cutting height

capacity. Under these conditions or during the

sliding motion of cut, the workpiece can stop the

lower guard movement before the downward motion

of the arm could pre-open the lower guard.

If this occurs:

• Workpiece must be securely clamped. This frees

a hand to raisethe guard by the lipjust enough to

clear the workpiece (Figure t8).

• Start the saw and begin your cut.

• Once you have cleared the position where the

lower guard may bind, release the guard and it will

continue to operate automatically as you cut.

• Notethe "No Hands Zone" stickerlocated on each

side of the base. The "No Hands Zone" isdefined

as the entire Table plus the portion ofthe Base on

the right and left that fails between the outer edge

of these two stickers and portions of the Fence

within this boundry.

• Be aware of the path of the sawblade. Makea dry

run with the saw OFF by conducting a simulated

cutting cycle, and observethe projected path ofthe

sawblade. Keep hands out of the path of saw-

blade.

DRY RUN--It is important to know where the

blade will intersect with the workpiece during cut-

ting operations. Always perform the simulated cut-

ting sequence with the power tool switched OFF

to gain an understanding of the projected path of

the sawblade. Mentally note where the path of

sawblade will fall and set up your work to keep

your hands and arms out of the path of the spin-

ning blade. Adjustyour clamps andfences so that

the smooth lower guard and cutting action is not

interfered with during cutting operation.

• Hold workpiece firmly against table and fence to

prevent movement.

Figure 18. Raising Lower Guard

-lg-

BasicSawOperations

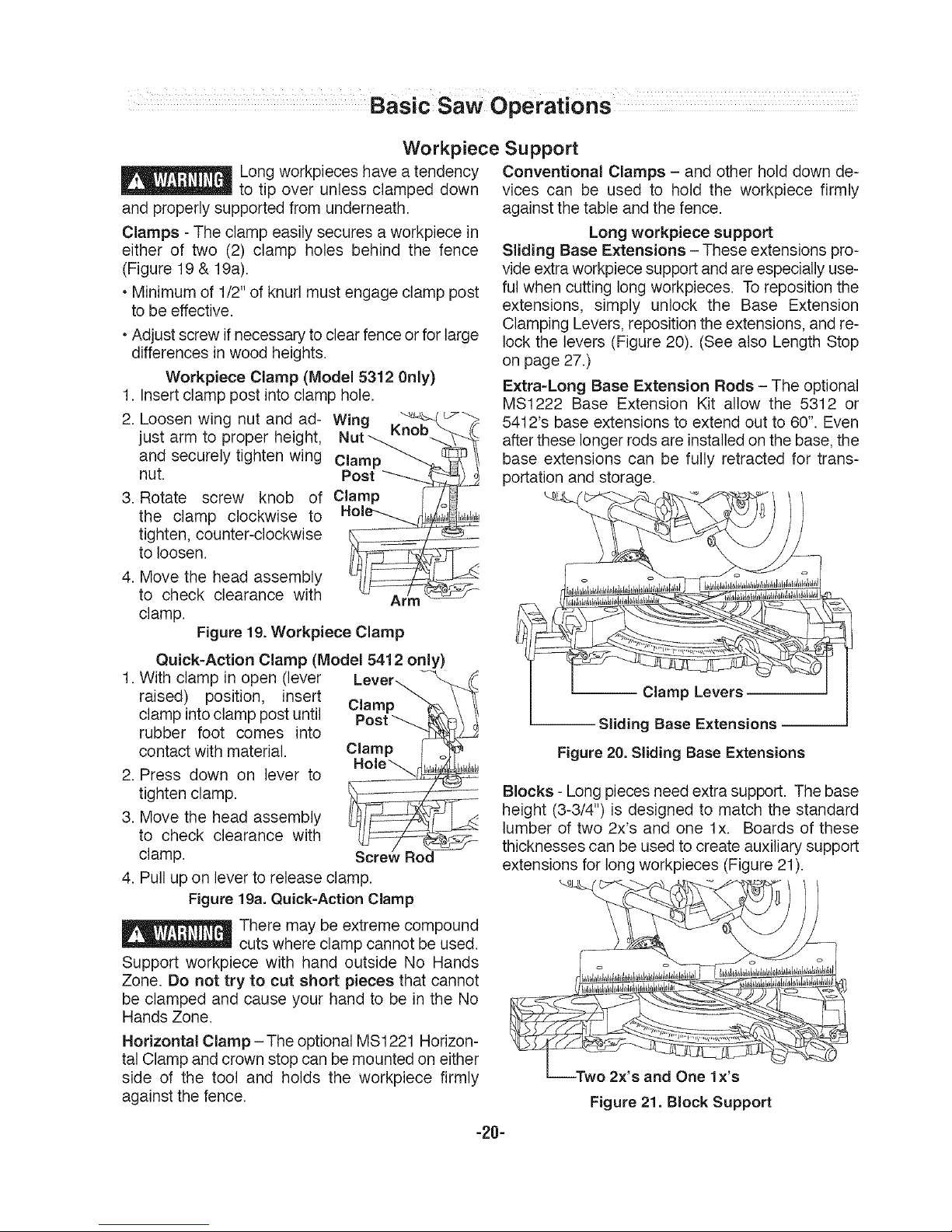

Workpiece Support

Long workpieces have atendency

_to tip over unless clamped down

and properly supported from underneath.

Clamps - The clamp easily secures a workpiece in

either of two (2) clamp holes behind the fence

(Figure 19 & 19a).

• Minimum of 1/2" of knurl must engage clamp post

to be effective.

• Adjust screw if necessary to clear fence or for large

differences in wood heights.

Workpiece Clamp (Model 5312 0nly)

1. Insertclamp post intoclamp hole.

2. Loosen wing nut and ad- Wing

just arm to proper height,

and securely tighten wing

nut.

3. Rotate screw knob of

the clamp clockwise to

tighten, counter-clockwise

to loosen.

4. Move the head assembly

to check clearance with Ar

clamp.

Figure19.Workpiece Clamp

Quick-Action Clamp (Model 5412 only)

1. With clamp in open (lever

raised) position, insert Clamp

clamp into clamp post until Post

rubber foot comes into

contact with material. Clamp

2. Press down on lever to

tighten clamp.

3. Move the head assembly

to check clearance with

clamp.

4. Pullup on lever to release clamp.

Figure19a. Quick-ActionClamp

_ There may be extreme compound

cuts where clamp cannot be used.

Support workpiece with hand outside No Hands

Zone. Do not try to cut short pieces that cannot

be clamped and cause your hand to be in the No

Hands Zone.

Horizontal Clamp - The optional MS1221 Horizon-

tal Clamp and crown stop can be mounted on either

side of the tool and holds the workpiece firmly

against thefence.

Conventional Clamps - and other hold down de-

vices can be used to hold the workpiece firmly

against the table and the fence.

Long workpiece support

Sliding Base Extensions - These extensions pro-

vide extra workpiece support and are especially use-

fulwhen cutting long workpieces. To reposition the

extensions, simply unlock the Base Extension

Clamping Levers, reposition the extensions, and re-

lock the levers (Figure 20). (See also Length Stop

on page 27.)

Extra-Long Base Extension Rods - The optional

MS1222 Base Extension Kit allow the 5312 or

5412's base extensions to extend outto 60". Even

afterthese longer rods are installedon the base,the

base extensions can be fully retracted for trans-

portation and storage.

Figure 20.Sliding Base Extensions

Blocks - Long pieces need extra support. The base

height (3-3/4") is designed to match the standard

lumber of two 2x's and one lx. Boards of these

thicknesses can be used to create auxiliary support

extensions for long workpieces (Figure 21).

Figure 21.Block Support

-20-

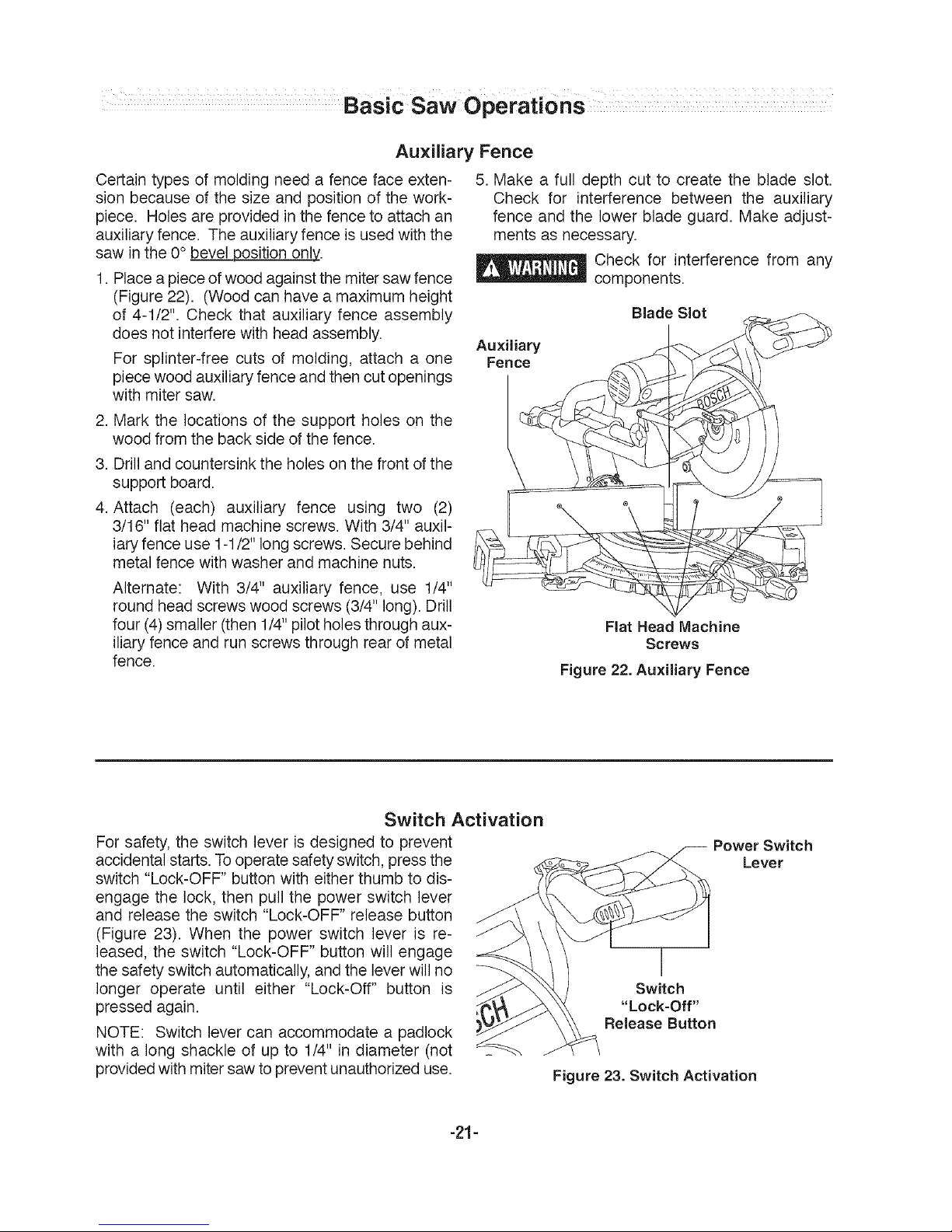

Auxiliary Fence

Certain types of molding need a fence face exten-

sion because of the size and position of the work-

piece. Holes are provided in the fence to attach an

auxiliary fence. The auxiliary fence is usedwith the

saw in the 0° bevel position only..

1. Place a piece of wood againstthe mitersaw fence

(Figure 22). (Wood can have a maximum height

of 4-1/2". Check that auxiliary fence assembly

does not interfere with head assembly.

For splinter-free cuts of molding, attach a one

piece wood auxiliary fence and then cutopenings

with miter saw.

2. Mark the locations of the support holes on the

wood from the back side of the fence.

3. Drill and countersink the holes on the front of the

support board.

4. Attach (each) auxiliary fence using two (2)

3/16" flat head machine screws. With 3/4" auxil-

iary fence use 1-1/2" long screws. Secure behind

metal fence with washer and machine nuts.

Alternate: With 3/4" auxiliary fence, use 1/4"

round head screws wood screws (3/4" long). Drill

four (4)smaller (then1/4" pilot holes through aux-

iliary fence and run screws through rearof metal

fence.

5. Make a full depth cut to create the blade slot.

Check for interference between the auxiliary

fence and the lower blade guard. Make adjust-

ments as necessary.

_ Check for interference from any

components.

Auxiliary

Fence

Blade Slot

Flat Head Machine

Screws

Figure 22. Auxiliary Fence

Switch Activation

For safety, the switch lever is designed to prevent

accidental starts.To operate safety switch, press the

switch "Lock-OFF" button with either thumb to dis-

engage the lock, then pull the power switch lever

and release the switch "Lock-OFF" release button

(Figure 23). When the power switch lever is re-

leased, the switch "Lock-OFF" button will engage

the safety switch automatically, and the leverwill no

longer operate until either "Lock-Off" button is

pressed again.

NOTE: Switch lever can accommodate a padlock

with a long shackle of up to 1/4" in diameter (not

providedwith miter saw to preventunauthorized use.

I

Switch

"Lock-Off"

Release Button

Power Switch

Lever

Figure 23. Switch Activation

-21-

Basic Saw Operations

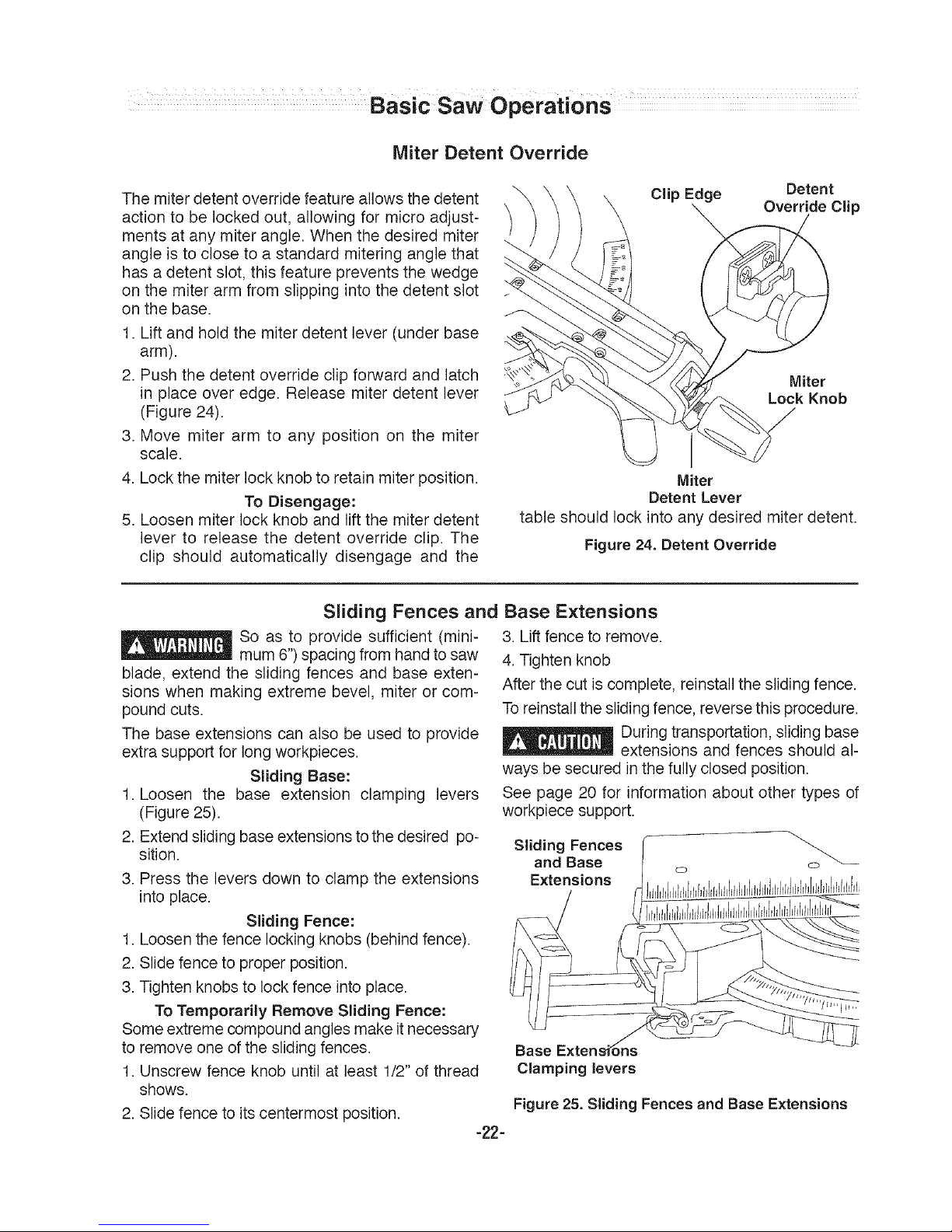

Miter Detent Override

The miter detent override feature allows the detent

action to be locked out, allowing for micro adjust-

ments at any miter angle. When the desired miter

angle is to close to a standard mitering angle that

has a detent slot, this feature prevents the wedge

on the miter arm from slipping into the detent slot

on the base.

1. Lift and hold the miter detent lever (under base

arm).

2. Push the detent override clip forward and latch

in place over edge. Release miter detent lever

(Figure 24).

3. Move miter arm to any position on the miter

scale.

4. Lock the miter lock knob to retain miter position.

To Disengage:

5. Loosen miter lock knob and lift the miter detent

lever to release the detent override clip. The

clip should automatically disengage and the

Clip Edge Detent

Override Clip

Miter

Lock Knob

Miter

Detent Lever

table should lock into any desired miter detent.

Figure 24. Detent Override

Sliding Fences and Base Extensions

So as to provide sufficient (mini- 3. Lift fence to remove.

mum 6") spacing from hand tosaw 4.Tighten knob

blade, extend the sliding fences and base exten-

sions when making extreme bevel, miter or com-

pound cuts.

The base extensions can also be used to provide

extra support for long workpieces.

Sliding Base:

1. Loosen the base extension clamping levers

(Figure 25).

2. Extendsliding base extensions to the desired po-

sition.

3. Press the levers down to clamp the extensions

into place.

Sliding Fence:

1. Loosenthe fence locking knobs (behind fence).

2. Slide fence to proper position.

3. Tighten knobsto lock fence into place.

To Temporarily Remove Sliding Fence:

Some extreme compound angles make itnecessary

to remove one of the sliding fences.

1. Unscrew fence knob until at least 1/2" of thread

shows.

2. Slide fence to its centermost position.

-22-

After the cut is complete, reinstall the sliding fence.

Toreinstall the sliding fence, reverse this procedure.

_ uring transportation, sliding base

extensions and fences should al-

ways be secured in the fully closed position.

See page 20 for information about other types of

workpiece support.

Sliding Fences o'S-

and Base

Extensions

Base

Clamping levers

Figure 25. Sliding Fences and Base Extensions

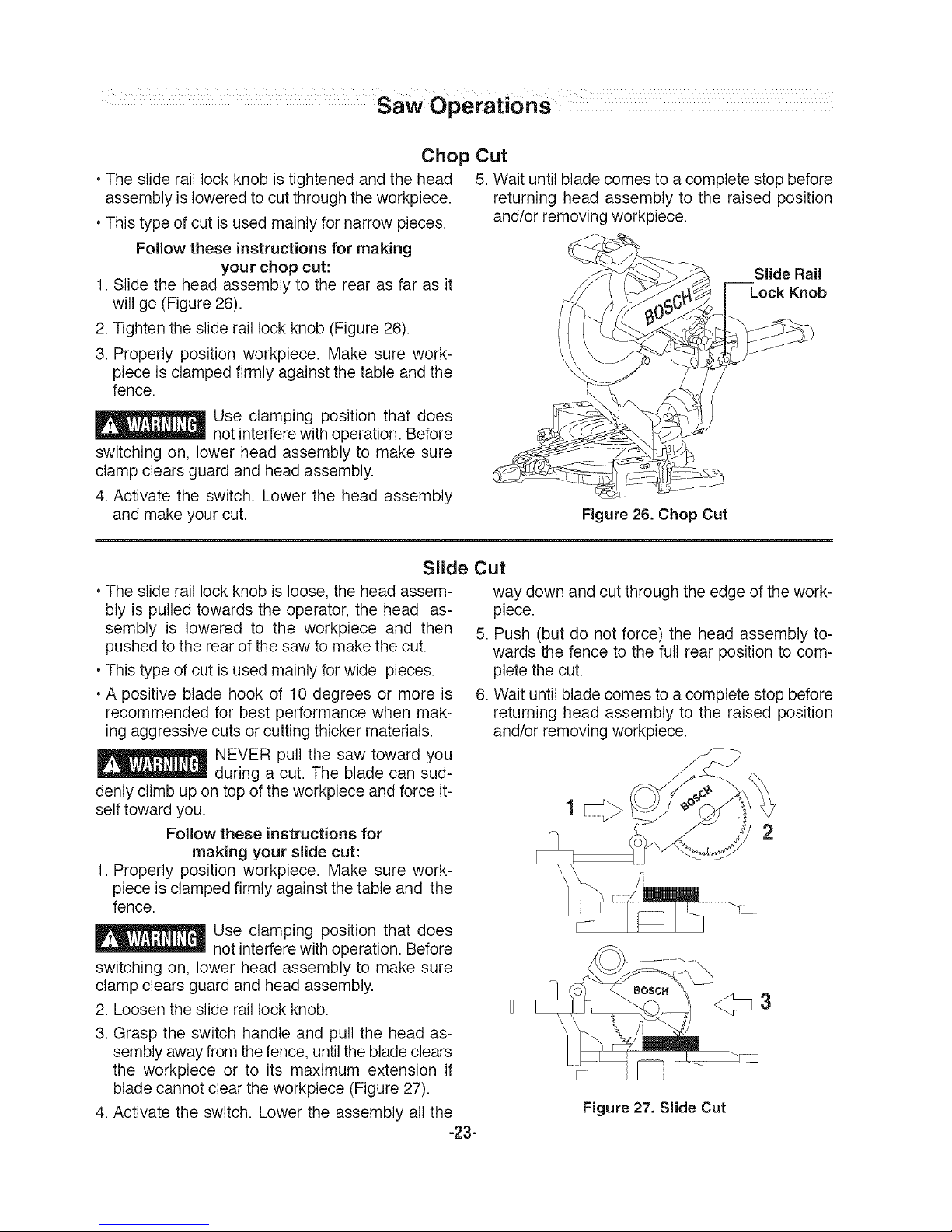

Chop Cut

•The slide rail lock knob is tightened and the head

assembly is lowered to cut through theworkpiece.

•This type of cut is used mainly for narrow pieces.

Follow these instructions for making

your chop cut:

1. Slide the head assembly to the rear as far as it

will go (Figure26).

2. Tighten the slide rail lock knob (Figure 26).

3. Properly position workpiece. Make sure work-

piece is clamped firmly against the table and the

fence.

Use clamping position that does

not interfere with operation. Before

switching on, lower head assembly to make sure

clamp clears guard and head assembly.

4. Activate the switch. Lower the head assembly

and make your cut.

5. Wait until blade comes to a complete stop before

returning head assembly to the raised position

and/or removing workpiece.

Slide Rail

Figure 26. Chop Cut

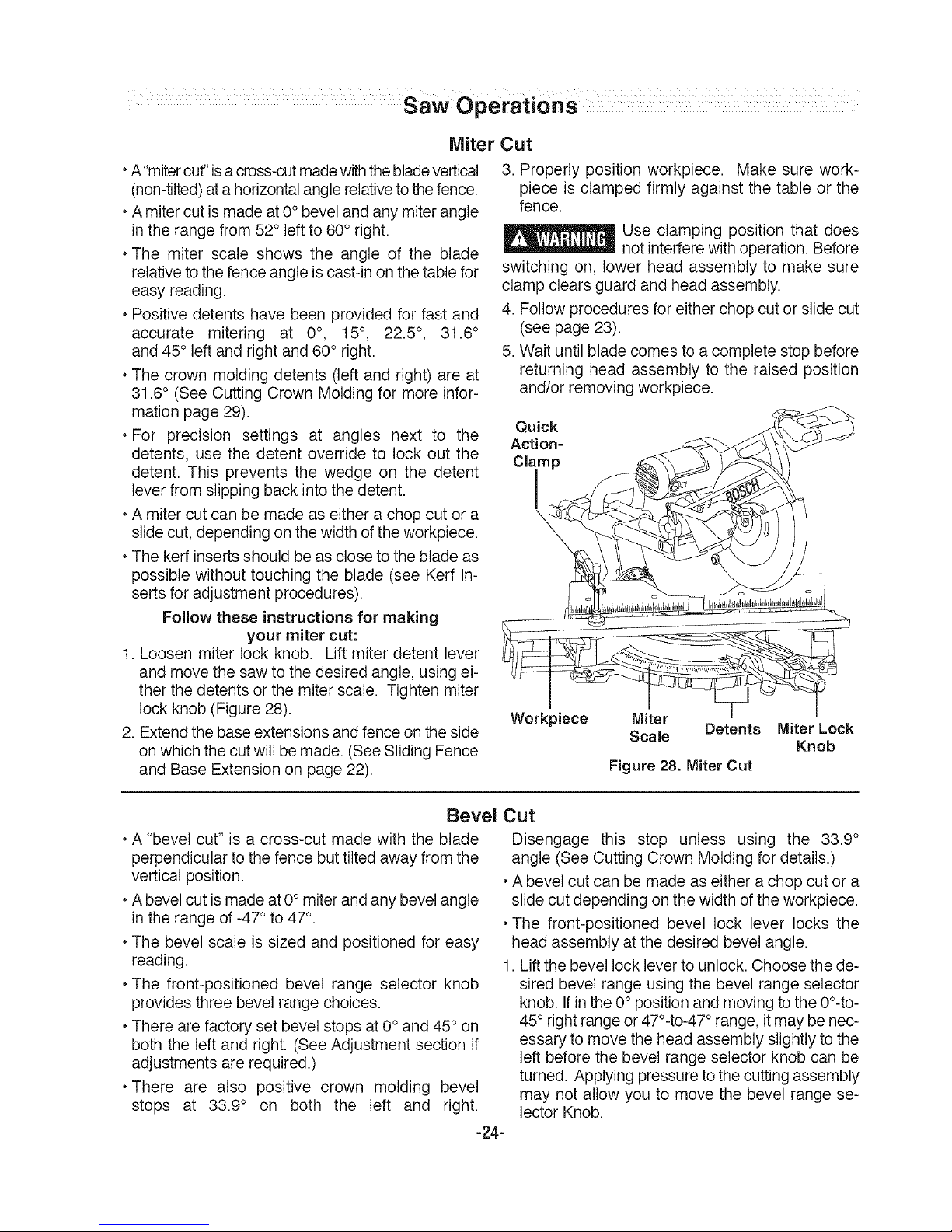

Slide Cut

• The slide rail lock knob is loose, the head assem-

bly is pulled towards the operator, the head as-

sembly is lowered to the workpiece and then

pushed to the rear of the saw to make the cut.

• This type of cut is used mainly for wide pieces.

• A positive blade hook of 10 degrees or more is

recommended for best performance when mak-

ing aggressive cuts or cutting thicker materials.

_ NEVER pull the saw toward you

during a cut. The blade can sud-

denly climb up on top of the workpiece and force it-

self toward you.

Follow these instructions for

making your slide cut:

1. Properly position workpiece. Make sure work-

piece is clamped firmly against the table and the

fence.

way down and cut through the edge of the work-

piece.

5. Push (but do not force) the head assembly to-

wards the fence to the full rear position to com-

plete the cut.

6. Wait until blade comes to a complete stop before

returning head assembly to the raised position

and/or removing workpiece.

2

Use clamping position that does

not interfere with operation. Before

switching on, lower head assembly to make sure

clamp clears guard and head assembly.

2. Loosenthe slide rail lock knob.

3. Grasp the switch handle and pull the head as-

sembly away from the fence, until the bladeclears

the workpiece or to its maximum extension if

blade cannot clear the workpiece (Figure 27).

4. Activate the switch. Lower the assembly all the

-23-

Figure 27. SJJdeCut

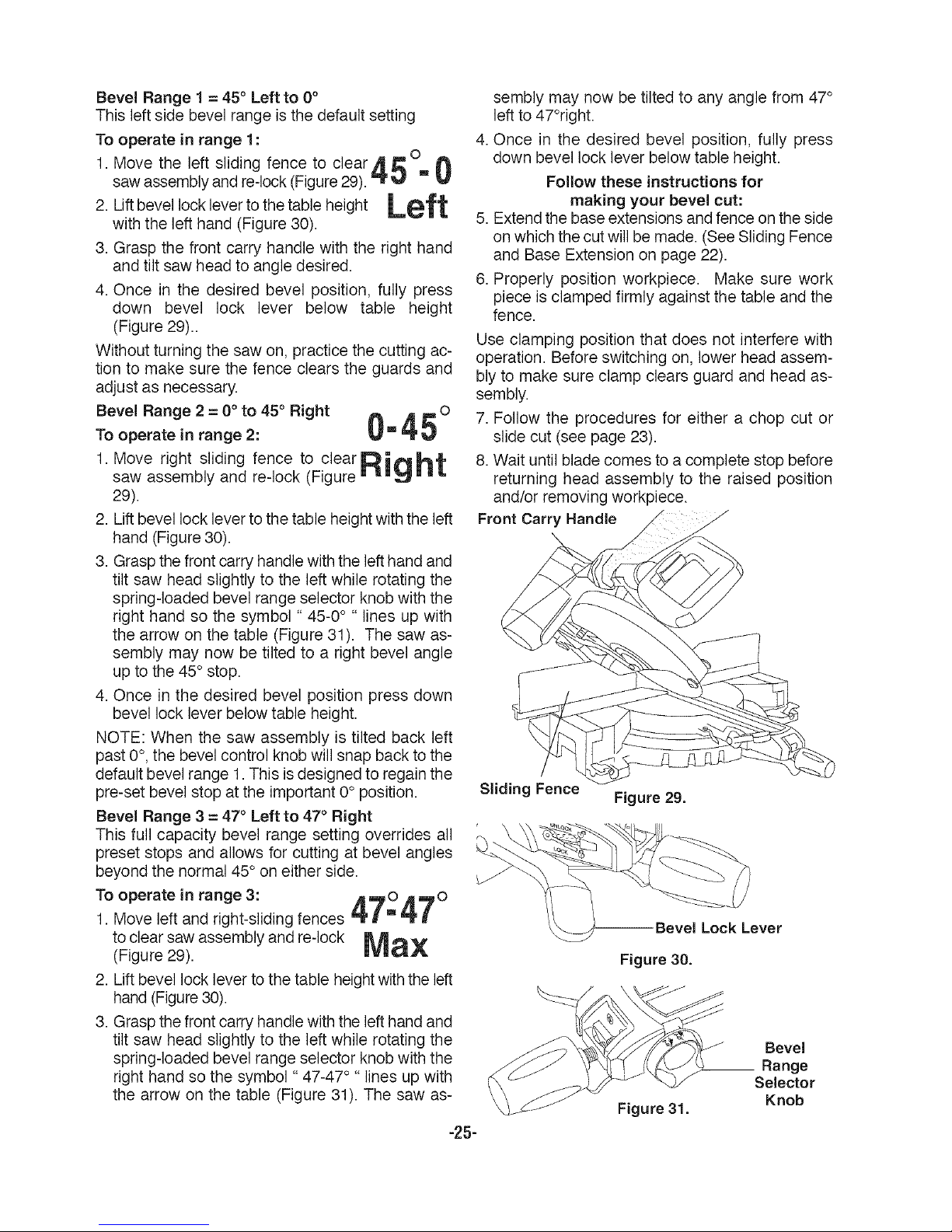

Miter Cut

• A"mitercut" isa cross-cutmadewiththe bladevertical

(non-tilted)ata horizontalangle relativeto the fence.

• A miter cut is made at O° bevel and any miter angle

in the range from 52° left to 60° right.

• The miter scale shows the angle of the blade

relative tothe fence angle iscast-in on the table for

easy reading.

• Positive detents have been provided for fast and

accurate mitering at 0°, 15°, 22.5 °, 31.6°

and 45° left and right and 60° right.

• The crown molding detents (left and right) are at

31.6° (See Cutting Crown Molding for more infor-

mation page 29).

• For precision settings at angles next to the

detents, use the detent override to lock out the

detent. This prevents the wedge on the detent

lever from slipping back intothe detent.

• A miter cut can be made as either a chop cut or a

slide cut, depending on the width ofthe workpiece.

• The kerfinserts should beas close to the blade as

possible without touching the blade (see Kerf In-

serts for adjustment procedures).

Follow these instructions for making

your miter cut:

1. Loosen miter lock knob. Lift miter detent lever

and move the saw to the desired angle, using ei-

ther the detents or the miter scale. Tighten miter

lock knob (Figure 26).

2. Extendthe base extensions and fenceon the side

on whichthe cut will be made. (SeeSliding Fence

and Base Extension on page 22).

3. Properly position workpiece. Make sure work-

piece is clamped firmly against the table or the

fence.

Use clamping position that does

not interfere with operation. Before

switching on, lower head assembly to make sure

clamp clears guard and head assembly.

4. Follow procedures for either chop cut or slide cut

(see page 23).

5.Wait until blade comes to acomplete stop before

returning head assembly to the raised position

and/or removing workpiece.

Quick

Action-

Climp

Workpiece

Miter

Scale Detents

Figure 28. Miter Cut

Miter Lock

Knob

Bevel Cut

• A "bevel cut" is a cross-cut made with the blade

perpendicular to the fence buttilted away from the

vertical position.

• A bevel cut is made at0° miter andany bevel angle

in the range of -47°to 47°.

• The bevel scale is sized and positioned for easy

reading.

• The front-positioned bevel range selector knob

provides three bevel range choices.

• There are factory set bevel stops at 0° and 45° on

both the left and right. (See Adjustment section if

adjustments are required.)

• There are also positive crown molding bevel

stops at 33.9 ° on both the left and right.

-24-

Disengage this stop unless using the 33.9°

angle (See Cutting Crown Molding for details.)

• A bevel cut can be made as either achop cut or a

slide cut depending on the width of the workpiece.

• The front-positioned bevel lock lever locks the

head assembly at the desired bevel angle.

1. Liftthe bevel lock lever to unlock. Choose the de-

sired bevel range using the bevel range selector

knob. If in the 0° position and moving to the 0°-to-

45° rightrange or 47°-to-47° range, it may be nec-

essary to move the head assembly slightly to the

left before the bevel range selector knob can be

turned. Applying pressure tothe cuttingassembly

may not allow you to move the bevel range se-

lector Knob.

BevelRange1=45°Leftto0°

Thisleftsidebevelrangeisthedefaultsetting

Tooperateinrange1:

1.MovetheleftslidingfencetoclearA_°

saw assembly and re-lock (Figure 29). _

2.Li.bevellocklevertothetableheightLeft

with the left hand (Figure 30).

3. Grasp the front carry handle with the right hand

and tilt saw head to angle desired.

4. Once in the desired bevel position, fully press

down bevel lock lever below table height

(Figure 29)..

Without turning the saw on, practice the cutting ac-

tion to make sure the fence clears the guards and

adjust as necessary.

Bevel Range 2 = 0° to 45° Right o

To operate in range 2: 0"45

1. Move right sliding fence to clear_::_itlh, _

saw assembly and re-lock (Figure _ "' _::_' "_"

29).

2. Liftbevel lock lever to the table height with the left

hand (Figure30).

3. Graspthe front carry handle with the lefthand and

tilt saw head slightly to the left while rotating the

spring-loaded bevel range selector knobwith the

right hand so the symbol " 45-0° " lines up with

the arrow on the table (Figure 31). The saw as-

sembly may now be tilted to a right bevel angle

up to the 45° stop.

4. Once in the desired bevel position press down

bevel lock lever below table height.

NOTE: When the saw assembly is tilted back left

past 0°, the bevelcontrol knob will snap back to the

default bevel range 1.This isdesigned to regainthe

pre-set bevel stop at the important 0° position.

Bevel Range 3 = 47° Left to 47° Right

This full capacity bevel range setting overrides all

preset stops and allows for cutting at bevel angles

beyond the normal 45° on either side.

To operate in range 3: 47047°

1. Move left and right-sliding fences

to clear saw assembly and re-lock MaX

(Figure 29).

2. Lift bevel lock lever to the table heightwiththe left

hand(Figure 30).

3. Graspthe front carry handle with the lefthand and

tilt saw head slightly to the left while rotating the

spring-loaded bevel range selector knobwith the

right hand so the symbol "47-47 °" lines up with

the arrow on the table (Figure 31). The saw as-

-25-

sembly may now be tilted to any angle from 47°

left to 47°right.

4. Once in the desired bevel position, fully press

down bevel lock lever below table height.

Follow these instructions for

making your bevel cut:

5. Extend the base extensions and fence on the side

on whichthe cut will be made. (See Sliding Fence

and Base Extension on page 22).

6. Properly position workpiece. Make sure work

piece is clamped firmly against the table and the

fence.

Use clamping position that does not interfere with

operation. Before switching on, lower head assem-

bly to make sure clamp clears guard and head as-

sembly.

7. Follow the procedures for either a chop cut or

slide cut (see page 23).

8. Wait until blade comes to a complete stop before

returning head assembly to the raised position

and/or removing workpiece.

Front Carry Handle

Sliding Fence

Figure 29.

Lock Lever

Figure 30.

Figure 31.

Bevel

__Range

Sele_or

Knob

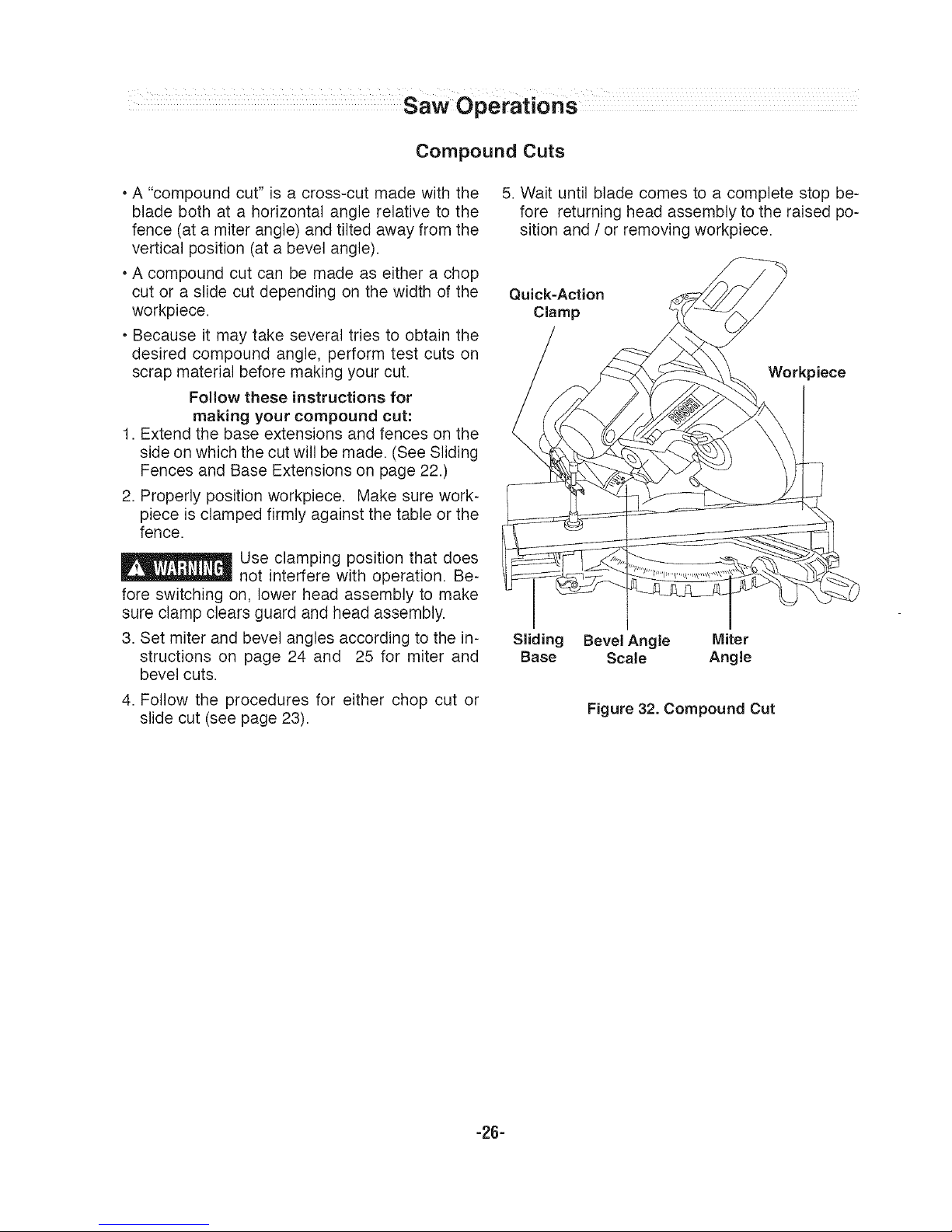

Compound Cuts

• A "compound cut" is a cross-cut made with the

blade both at a horizontal angle relative to the

fence (at a miter angle) and tilted away from the

vertical position (ata bevel angle).

• A compound cut can be made as either a chop

cut or a slide cut depending on the width of the

workpiece.

• Because it may take several tries to obtain the

desired compound angle, perform test cuts on

scrap material before making your cut.

Follow these instructions for

making your compound cut:

1. Extend the base extensions and fences on the

side on which the cut will be made. (See Sliding

Fences and Base Extensions on page 22.)

2. Properly position workpiece. Make sure work-

piece is clamped firmly against the table or the

fence.

Use clamping position that does

not interfere with operation. Be-

fore switching on, lower head assembly to make

sure clamp clears guard and head assembly.

3. Set miter and bevel angles according to the in-

structions on page 24 and 25 for miter and

bevel cuts.

4. Follow the procedures for either chop cut or

slide cut (see page 23).

5. Wait until blade comes to a complete stop be-

fore returning head assembly to the raised po-

sition and / or removing workpiece.

Quick-Action

Clamp

Workpiece

Sliding Bevel Angle Miter

Base Scale Angle

Figure 32. Compound Cut

-26-

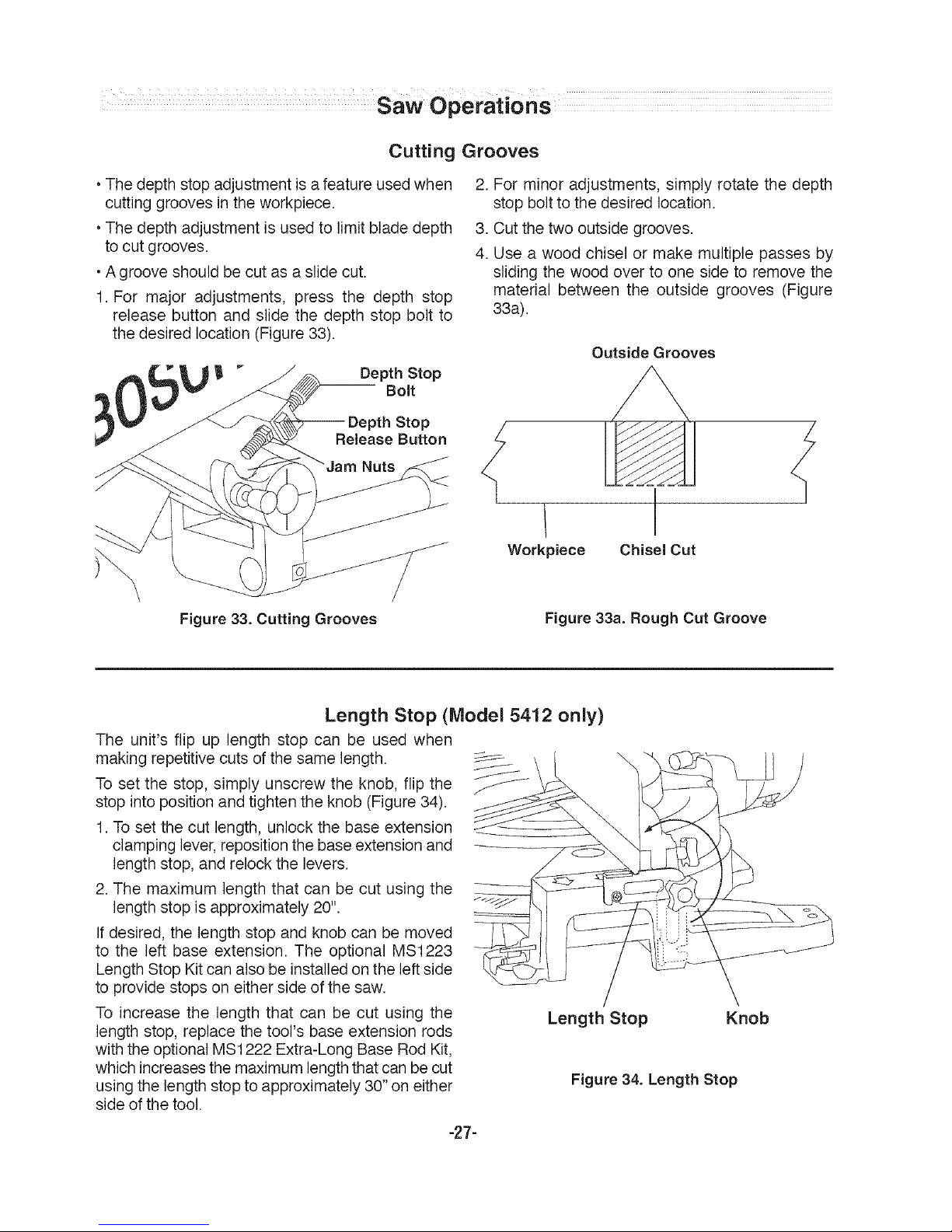

Cutting Grooves

•The depth stop adjustment is afeature usedwhen

cutting grooves in the workpiece.

•The depth adjustment is used to limit blade depth

to cut grooves.

•A groove should be cut as a slide cut.

1. For major adjustments, press the depth stop

release button and slide the depth stop bolt to

the desired location (Figure 33).

Depth Stop

Bolt

Stop

Release Button

2. For minor adjustments, simply rotate the depth

stop bolt to the desired location.

3. Cut the two outside grooves.

4. Use a wood chisel or make multiple passes by

sliding the wood over to one side to remove the

material between the outside grooves (Figure

33a).

Workpiece

Outside Grooves

Chisel Cut

Figure 33. Cutting Grooves

Figure 33a. Rough Cut Groove

Length Stop (Model 5412 only)

The unit's flip up length stop can be used when

making repetitive cuts of the same length.

To set the stop, simply unscrew the knob, flip the _-

stop into position and tighten the knob (Figure 34).

1.To set the cut length, unlock the base extension

clamping lever, reposition the base extension and

length stop, and relock the levers.

2. The maximum length that can be cut using the

length stop is approximately 20". _/_

Ifdesired, the length stop and knob can be moved

to the left base extension. The optional MS1223

Length Stop Kit can also be installed on the leftside

to provide stops on either side of the saw.

To increase the length that can be cut using the

length stop, replace the tool's base extension rods

with the optional MS1222 Extra-Long Base Rod Kit,

which increasesthe maximum lengththat can be cut

using the length stop to approximately 30" on either

side ofthe tool.

Length Stop Knob

Figure 34. Length Stop

-27-

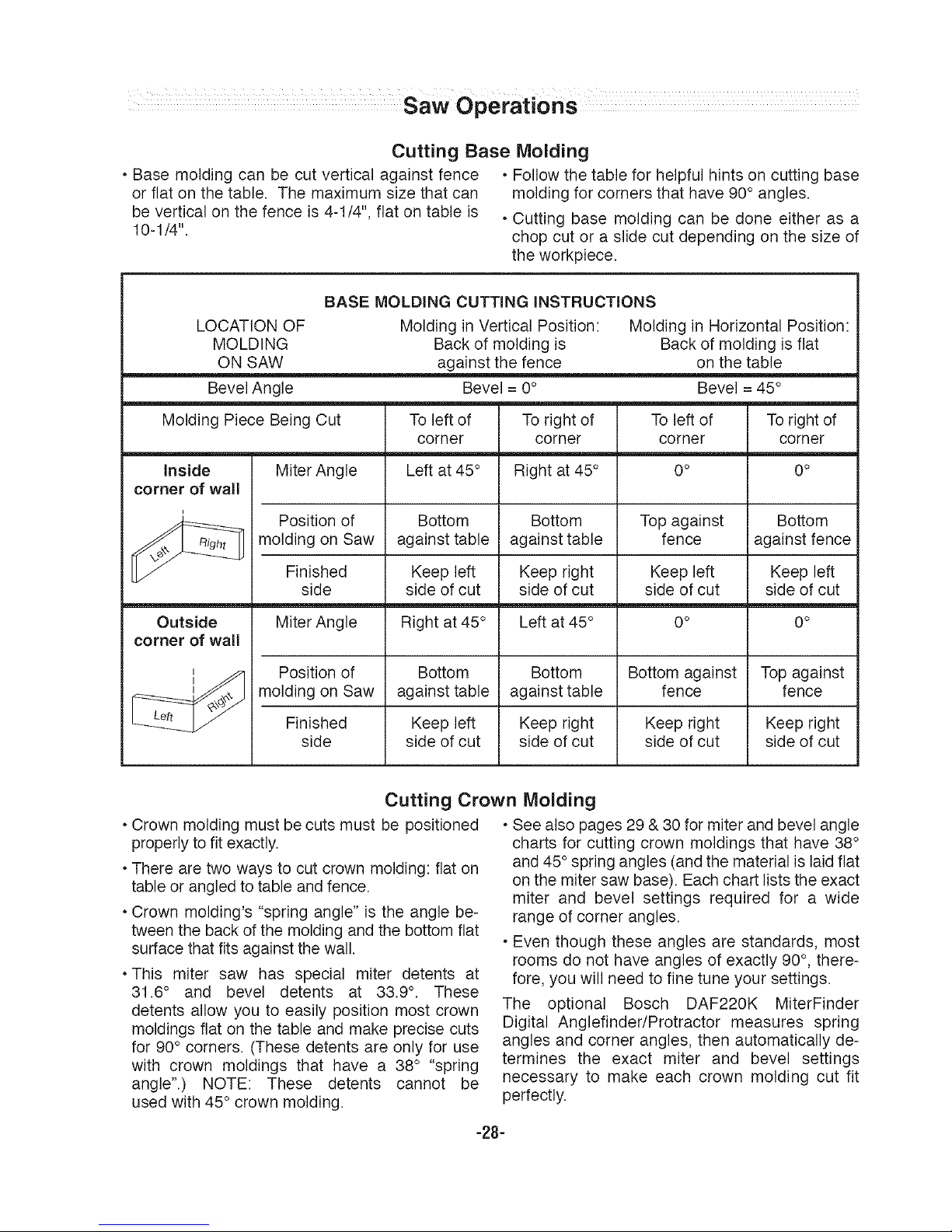

CuttingBaseMolding

•Basemoldingcanbecutverticalagainstfence •Followthetableforhelpfulhintsoncuttingbase

orfiatonthetable.Themaximumsizethatcan moldingforcornersthathave90°angles.

beverticalonthefenceis4-1/4",fiatontableis •Cuttingbasemoldingcanbedoneeitherasa

10-1/4". chopcutoraslidecutdependingonthesizeof

theworkpiece.

LOCATIONOF

MOLDING

ONSAW

BevelAngle

BASE MOLDING CUTTING iNSTRUCTiONS

Molding in Vertical Position: Molding in Horizontal Position:

Back of molding is Back of molding is flat

against the fence on the table

Bevel = 0° Bevel = 45°

Molding Piece Being Cut

To left of

corner

Toright of

corner

Toleft of

corner

Toright of

corner

inside

corner of wall

Outside

corner of wall

Miter Angle

Position of

molding on Saw

Finished

side

Miter Angle

Left at 45 °

Bottom

against table

Keep left

side of cut

Right at 45 °

Right at 45°

Bottom

against table

Keep right

side of cut

Left at 45°

0 o

Top against

fence

Keep left

side of cut

0o

0 o

Bottom

against fence

Keep left

side of cut

0 o

Position of Bottom Bottom Bottom against Top against

molding on Saw against table against table fence fence

Finished Keep left Keep right Keep right Keep right

side side of cut side of cut side of cut side of cut

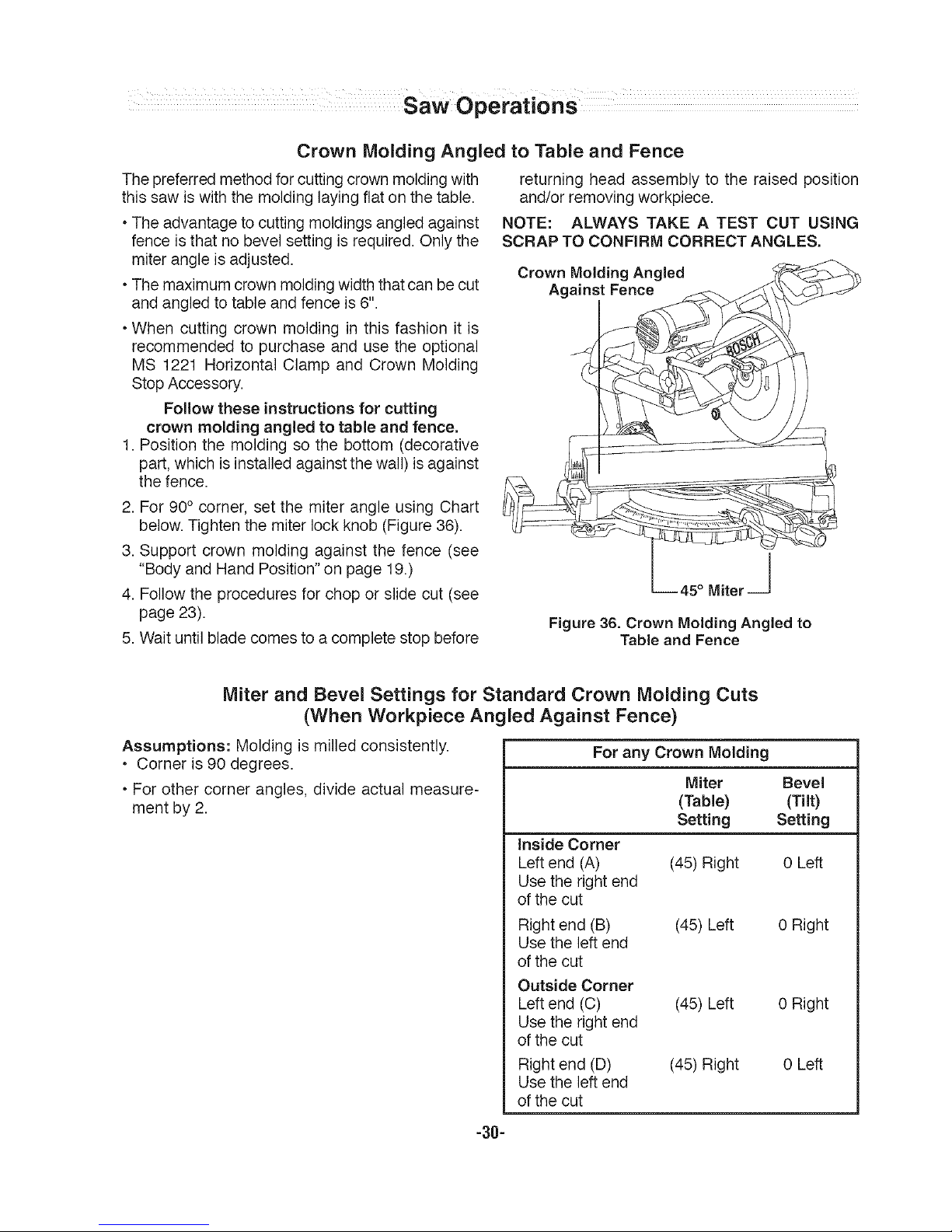

Cutting Crown Molding

• Crown molding must be cuts must be positioned

properly to fit exactly.

• There are two ways to cut crown molding: fiat on

table or angled to table andfence.

• Crown molding's "spring angle" is the angle be-

tween the back of the molding and the bottom fiat

surface that fits against the wall.

• This miter saw has special miter detents at

31.6° and bevel detents at 33.9°. These

detents allow you to easily position most crown

moldings fiat on the table and make precise cuts

for 90° corners. (These detents are only for use

with crown moldings that have a 38° "spring

angle".) NOTE: These detents cannot be

used with 45° crown molding.

• See also pages 29& 30 for miter and bevel angle

charts for cutting crown moldings that have 38°

and 45° spring angles (and the material is laid fiat

on the miter saw base). Each chart lists the exact

miter and bevel settings required for a wide

range of corner angles.

• Even though these angles are standards, most

rooms do not have angles of exactly 90°, there-

fore, you will need to fine tune your settings.

The optional Bosch DAF220K MiterFinder

Digital Anglefinder/Protractor measures spring

angles and corner angles, then automatically de-

termines the exact miter and bevel settings

necessary to make each crown molding cut fit

perfectly.

-28-

Crown Molding Laying Flat on Table

• Notes: Positionworkpiece with itsback fiat on the NOTE: ALWAYS TAKE A TEST CUT USING

saw table. SCRAP TO CONFIRM CORRECT ANGLES.

•Always place top edge of molding against fence

(Decorative edge is at the bottom of crown mold-

ing.)

•"Spring angle" refers to angle between wall and

crown molding.

• Cutting crown molding fiat on the table can be

done eitheras a chop cut or a slide cut depending

on the width of the workpiece.

1. For 90° corner, set the bevel and miter angles

using Charts below. Tighten the miter lock knob

and the bevel lock lever (Figure 35).

2. Position molding on saw table. Clamp workpiece

in place using thequick clamp.

Use clamping position that does

not interfere with operation. Before

switching on, lower head assembly to make sure

clamp clears guard and head assembly.

3. Follow procedures for either chop cut or slide cut

(see page 23).

4. Wait untilblade comes to a complete stop before

returning head assembly to the raised position

and/or removing workpiece.

Quick-Action

Clamp

Crown

Molding

33.9 ° Bevel 31.6 ° Miter

Figure 35. Crown Molding Laying Flat

Miter and Bevel Settings for Standard Crown Molding Cuts

(When Crown Molding is Lying Flat on Table)

Assumptions: Molding is milled consistently. Corner is exactly 90°.

Molding Spring Angle is 38 degrees

Miter Bevel

(Table) (Tilt)

Setting Setting

Inside Corner

Left end (A) (31.6) Right (33.9) Left

Use the left end

of the cut

Right end (B) (31.6) Left (33.9) Right