Bosch 24618, 25614, 24614, 25618 Operating Instructions Manual

IMPORTANT: IMPORTANT: IMPORTANTE:

Read BeforeUsing Life avantusage Leer antesdeusar

Operating/SafetyInstructions

Consignesdefonctionnement/s6curit6

Instruccionesdefuncionamientoyseguridad

24614

24618

25614

25618

Call Toll Freefor

ConsumerInformation

& Service Locations

Pour obtenirdesinformations

et lesadressesdenoscentres

deserviceapr_s-vente,

appelezce num_rogratuit

Llame gratispara

obtener informaciOn

para el consumidory

ubicacionesdeservicio

ForEnglishversion Versionfran_azse Versi6n en espafiol

Seepage2 Voirpage17 Verla p_gina32

Read all safety warnings and instructions, Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term "power tool" in all of the warnings refers to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

Work area safety

Keep work area clean and well lit, Cluttered

or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust, Power

tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while

operating a power tool, Distractions can

cause you to lose control.

Electrical safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapter plugs with earthed

(grounded) power tools, Unmodified plugs

and matching outlets will reduce risk of electric

shock.

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges

and refrigerators, There is an increased risk

of electric shock if your body is earthed or

grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damagedor entangled

cords increase the risk of electric shock.

When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

Ifoperating the power tool in damp locations

is unavoidable use a Ground Fault Circuit

Interrupter (GFCI) protected supply, Use of

an GFCI reduce the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of drugs,

alcohol or medication.A moment of inattention

while operating power tools may result in

serious personal injury.

Use personal protective equipment. Always

wear eye protection, Protective equipment

such asdust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the

switch is in the off-position before

connecting to power source and / or battery

pack, picking up or carrying the tool,

Carrying power tools with your finger on the

switch or energizing power tools that have the

switch on invites accidents.

Remove any adjusting key or wrench before

turning the power tool on. A wrench or a

key left attached to a rotating part of the power

tool may result inpersonal injury.

Do not overreach, Keep proper footing and

balance at all times. This enables better

control of the power tool in unexpected

situations.

Dress properly. Do not wear loose clothing

or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in

moving parts.

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

Power tool use and care

Do notforce the power tool. Use the correct

power tool for your application, The correct

power tool will do the job better and safer at

the rate for which it was designed.

Do not use the power tool if the switch does

not turn it on and off. Any power tool that

cannot be controlled with the switch is

dangerous and must be repaired.

-2-

Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools, Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

Maintainpower tools. Check for misalignment

or binding of moving parts, breakage of

parts and any other condition that may

affect the power tools operation. If damaged,

have the power tool repaired before use.

Many accidents are caused by poorly

maintained power tools.

Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

Use the power tool, accessories and tool

bitsetc. in accordancewiththese instructions,

taking into account the working conditions

and the work to be performed, Use of the

power tool for operations different from those

intended could result ina hazardous situation.

Battery tool use and care

Recharge only with the charger specified

by the manufacturer, A charger that is

suitable for one type of battery pack may

create a risk of fire when used with another

battery pack.

Use power tools only with specifically

designated battery packs. Use of any other

battery packs may create a risk of injury and

fire.

When battery pack is not in use, keep it

away from other metal objects like paper

clips, coins, keys, nails, screws, or other

small metal objects that can make a

connection from one terminal to another.

Shorting the battery terminals together may

cause burns or a fire.

Under abusive conditions, liquid may be

ejected from the battery, avoid contact. If

contact accidentally occurs, flush with

water. If liquid contacts eyes, additionally

seek medical help, Liquid ejected from the

battery may cause irritation or burns.

Service

Have your power tool serviced bya qualified

repair person using only identical

replacement parts, This will ensure that the

safety of the power tool is maintained.

-3-

Hold tools by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring.

Contact with a "live" wire will make exposed

metal parts of the tool "live" and shock the

operator.

Use clamps or other practical way to

secure and support the workpiece to a

stable platform, Holding the work by hand

or against your body is unstable and may

lead to loss of control.

Do not drill, fasten or break into existing wails

or other blind areas where electrical wiring

may exist. If this situation is unavoidable,

disconnect all fuses or circuit breakers feeding

this worksite.

Always wear safety goggles or eye

protection when using this tool.

Wear ear protectors when using the tool for

extended periods. Prolonged exposure to

high intensity noise can cause hearing loss.

Use thick cushioned gloves and limit the

exposure time by taking frequent rest

periods. Vibration caused by hammer-drill

action may be harmful to your hands and

arms.

Secure the material being fastened. Never

hold it in your hand or across your legs.

Unstable support can cause loss of control

and injury.

Avoid accidental starting, Be sure the

forward/reverse switch is in the off

position before inserting battery pack,

Carrying appliances with your finger on the

switch or inserting the battery pack into an

appliance with the switch on invites

accidents.

Remove battery pack before changing

accessories. Accidental starting may occur

because battery appliances with a battery

inserted are in the operative condition.

Be prepared for a reaction torque when

"seating" or removing a fastener. The

screwdriver housing may tend to twist in the

opposite direction of bit rotation when

"seating" or removing a fastener depending

on the torque setting of the tool.

Do not use dull or damaged bits and

accessories, When installing an accessory,

insert the shank of the bit well within the

chuck. Be sure the chuck has locked onto

the bit correctly.

Do not run the tool while carrying it at

your side, A spinning bit could become

entangled with clothing and injury may result.

Place the tool onto the fastener only when

the screwdriver is switched off, Rotating

driver tools can slide off the fastener.

Do not use this tool as a drill. Tools

equipped with shut-off clutches are not

designed for drilling applications. The clutch

can shut off automatically and without

warning.

Be careful when driving long screws -

there is a risk of sliding off the fastener

head depending on type of socket or bit

used. First test the run-down of a fastener

and pay attention during the screw driving

process to ensure you do not injure yourself

if the tool bit or socket slides off of the

fastener.

_ ome dust created by

power sanding, sawing,

grinding, drilling and other construction

activities contains chemicals known to

cause cancer, birth defects or other

reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks, cement and

other masonry products.

• Arsenic and chromium from chemically

treated lumber.

Your risk from these exposures varies

depending on how often you do this type of

work. To reduce your exposure to these

chemicals, work in a well-ventilated area and

work with approved safety equipment such

as dust masks designed to filter out

microscopic particles.

-4-

Battery/Charger

Before using battery charger, read all

instructions and cautionary markings on

(1) battery charger, (2) battery pack, and (3)

product using battery.

Use only the charger which accompanied

your product or direct replacement as

listed in the catalog or this manual, Do not

substitute any other charger. Use only Bosch

approved chargers with your product. See

Functional Description and Specifications.

Do not disassemble charger or operate the

charger if it has received a sharp blow,

been dropped or otherwise damaged in any

way. Replace damaged cord or plugs

immediately. Incorrect reassembly or damage

may result in electric shock or fire.

Do not recharge battery in damp or wet

environment. Do not expose charger to rain

or snow. If battery case is cracked or

otherwise damaged, do not insert into

charger. Battery short or fire may result.

Charge only Bosch approved rechargeable

batteries. See Functional Description and

Specifications. Other types of batteries may

burst causing personal injury and damage.

Charge battery pack in temperatures above

+32 degrees F (0 degrees C) and below

+113 degrees F (45 degrees C), Store tool

and battery pack in locations where

temperatures will not exceed 120 degrees F

(49 degrees C). This is important to prevent

serious damage to the battery ceils.

Battery leakage may occur under extreme

usage or temperature conditions. Avoid

contact with skin and eyes. The battery

liquid is caustic and could cause chemical

burns to tissues. If liquid comes in contact with

skin, wash quickly with soap and water. If the

liquid contacts your eyes, flush them with water

for a minimum of 10 minutes and seek medical

attention.

Place charger on flat non-flammable

surfaces and away from flammable

materials when re-charging battery pack,

The charger and battery pack heat during

charging. Carpeting and other heat insulating

surfaces block proper air circulation which may

cause overheating of the charger and battery

pack. If smoke or melting of the case are

observed unplug the charger immediately and

do not use the battery pack or charger.

Use of an attachment not recom-

mended or sold by Bosch will result in a

risk of fire, electric shock or injury to

persons.

Battery Care

When batteries are not in nails, screws, keys, etc. Fire or injury may

tool or charger, keep them result.

away from metal objects. For example, to DO NOT PUT BATTERIES INTO FIRE OR

protect terminals from shorting DO NOT EXPOSE TO HIGH HEAT. They may

place batteries in a tool box or pocket with explode.

-5-

Battery Disposal

Do not attempt to disas-

semble the battery or

remove any component projecting from the

battery terminals, Fire or injury may result.

Prior to disposal, protect exposed terminals

with heavy insulating tape to prevent shorting.

LITHIUM-ION BATTERIES

If equipped with a lithium-ion battery, the

battery must be collected, recycled or disposed

of inan environmentally sound manner.

"The EPA certified RBRC

Battery Recycling Seal on the

lithium-ion (Li-ion) battery

indicates Robert Bosch Tool

Corporation is voluntarily

participating in an industry

program to collect and recycle these batteries

at the end of their useful life, when taken out

of service in the United States or Canada. The

RBRC program provides a convenient

alterative to placing used Li-ion batteries into

the trash or the municipal waste stream, which

may be illegal in your area.

Please call 1-800-8-BATTERY for information

on Li-ion battery recycling and disposal

bans/restrictions in your area, or return your

batteries to a Skil/Bosch/Dremel Service

Center for recycling. Robert Bosch Tool

Corporation's involvement in this program is

part of our commitment to preserving our

environment and conserving our natural

resources."

- WARNING

- User must read instruction manual

- Wear eye protection

-6-

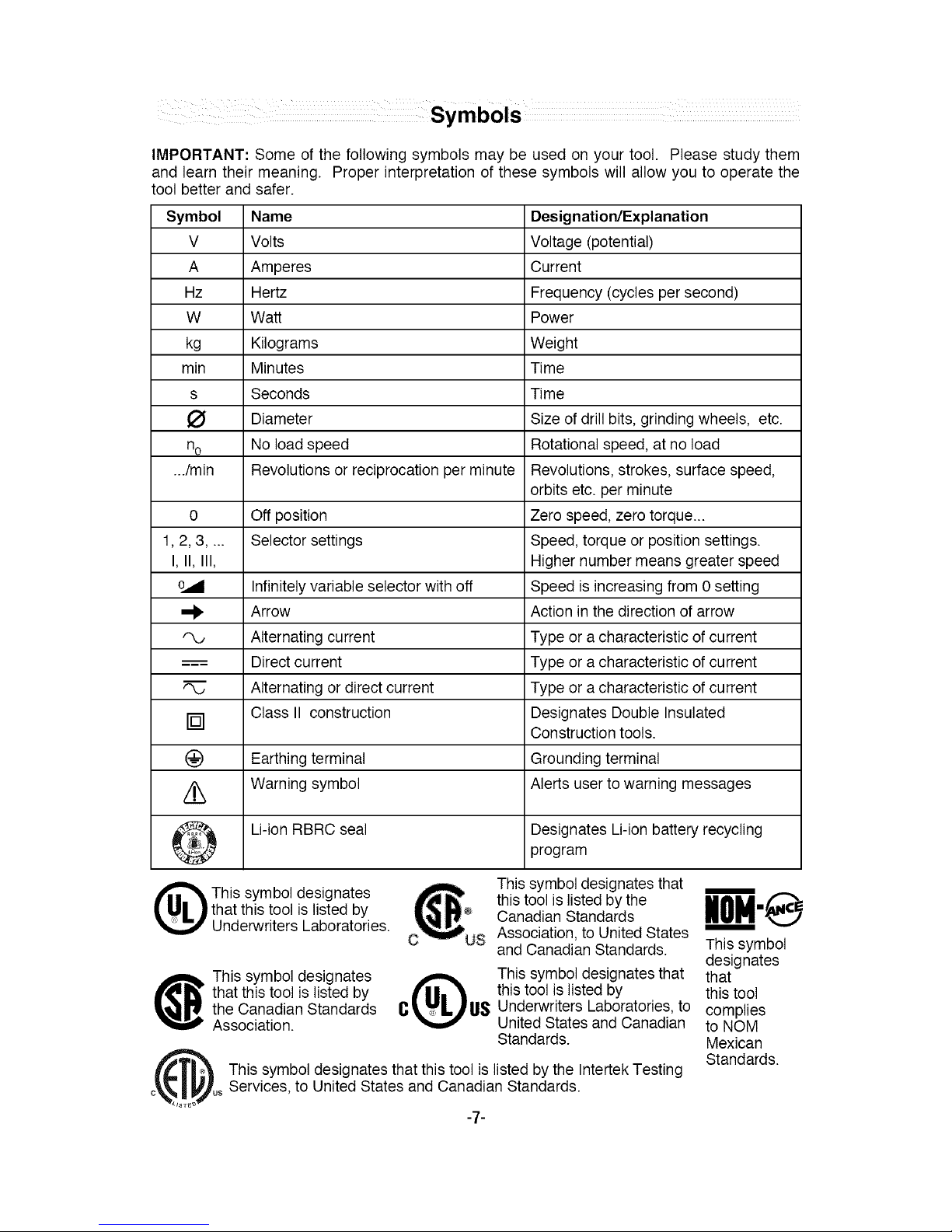

IMPORTANT:

and learn their meaning.

tool better and safer.

Symbol

V

A

Hz

W

kg

min

s

O

no

.../min

Some of the following symbols may be used on your tool. Please study them

Proper interpretation of these symbols will allow you to operate the

Name

Volts

Amperes

Hertz

Watt

Kilograms

Minutes

Seconds

Diameter

No load speed

Revolutions or reciprocation per minute

0 Off position

1,2, 3.... Selector settings

I, II, III,

m_-

[]

(_ Earthing terminal

/,_ Warning symbol

Li-ion RBRC seal

Q his symbol designates

that this tool is listed by

Underwriters Laboratories.

Infinitelyvariable selector with off

Arrow

Alternating current

Direct current

Alternating or direct current

Class II construction

(

This symbol designates

that this tool is listed by

the Canadian Standards C US

Association.

Designation/Explanation

Voltage (potential)

Current

Frequency (cycles per second)

Power

Weight

Time

Time

Size of drill bits, grinding wheels, etc.

Rotational speed, at no load

Revolutions, strokes, surface speed,

orbits etc. per minute

Zero speed, zero torque...

Speed, torque or position settings.

Higher number means greater speed

Speed is increasing from 0 setting

Action in the direction of arrow

Type or a characteristic of current

Type or a characteristic of current

Type or a characteristic of current

Designates Double Insulated

Construction tools.

Grounding terminal

Alerts user to warning messages

Designates Li-ion battery recycling

program

This symbol designates that

this tool is listed by the

Canadian Standards

Association, to United States

and Canadian Standards.

This symbol designates that

this tool is listed by

Underwriters Laboratories, to

United States and Canadian

Standards.

c_o This symbol designates that this tool is listed by the Intertek Testing

s Services, to United States and Canadian Standards.

"7-

This symbol

designates

that

this tool

complies

to NOM

Mexican

Standards.

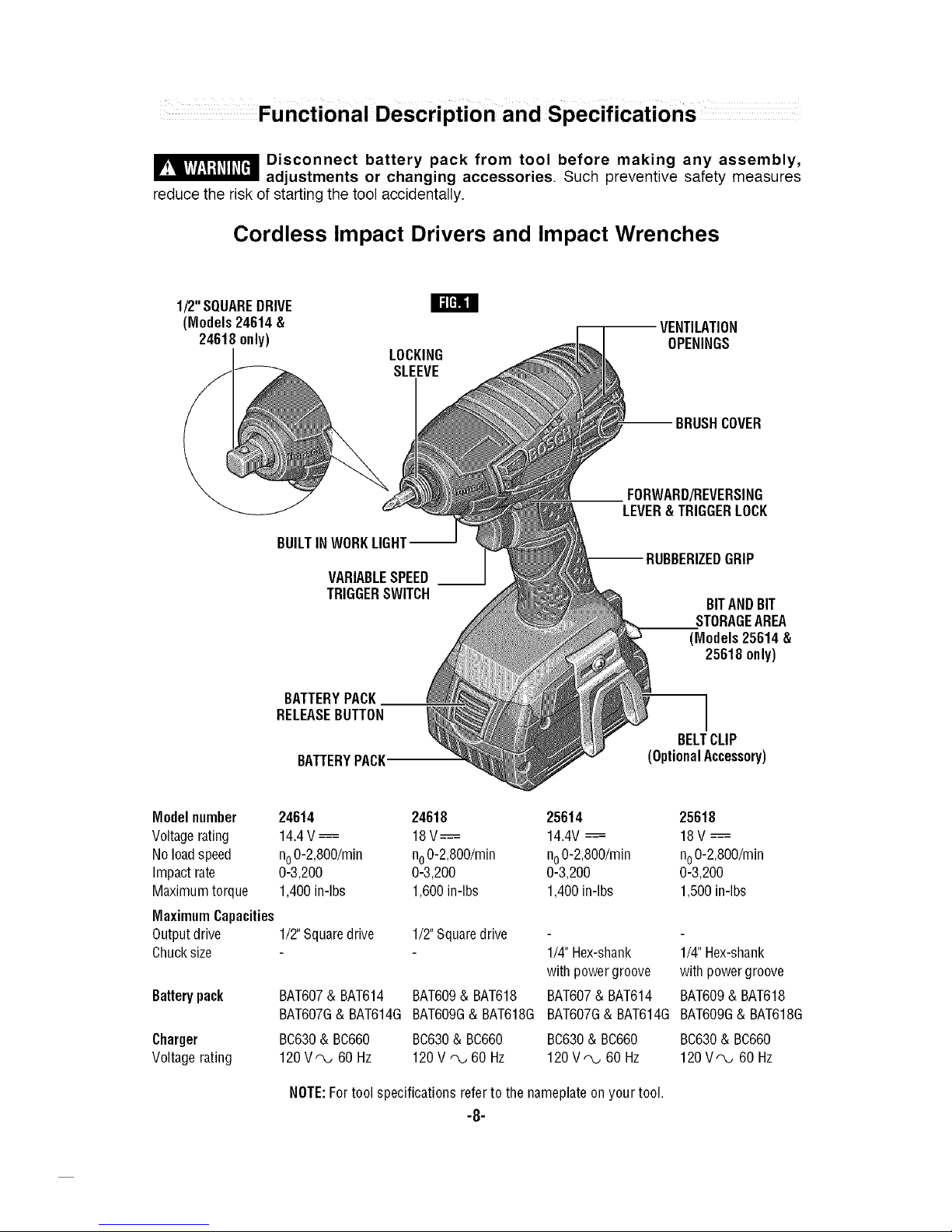

1_I_ Disconnect battery pack from tool before making any assembly,

adjustments or changing accessories. Such preventive safety measures

reduce the risk of starting the tool accidentally.

Cordless Impact Drivers and Impact Wrenches

1/2"SQUAREDRIVE

(Models 24614 & -- VENTILATION

24618 only) OPENINGS

LOCKING

SLEEVE

BUILTIN WORKLIGHT--

VARIABLESPEED

TRIGGERSWITCH

BMTERYPACK

RELEASEBUTTON

BATTERYPACK

COVER

FORWARD/REVERSING

LEVER& TRIGGERLOCK

GRIP

BITANDBIT

STORAGEAREA

(Models 25614 &

25618 only)

BELTCLIP

(OptionalAccessory)

Model number 24614 24618

Voltagerating 14.4V = 18 V=

No loadspeed no0-2,800/min no0-2,800/min

Impact rate 0-3,200 0-3,200

Maximum torque 1,400 in-lbs 1,600in-lbs

Maximum Capacities

Output drive 1/2"Squaredrive 1/2"Squaredrive

Chucksize

Batterypack

Charger

Voltage rating

BAT607& BAT614 BAT609& BAT618

BAT607G& BAT614G BAT609G& BAT618G

B0630 & B0660 B0630 & B0660

120V'_,_60 Hz 120 V'-_60 Hz

25614 25618

14.4V_ 18 V_

no012,800/min no0-2,800/min

0-3,200 0-3,200

1,400in-lbs 1,500in-lbs

1/4"Hex-shank 1/4"Hex-shank

with powergroove with powergroove

BAT607& BAT614 BAT609& BAT618

BAT607G& BAT614G BAT609G& BAT618G

BC630& BC660 BC630& BC660

120V,"_60 Hz 120 V'-_60 Hz

NOTE:Fortool specifications refer to the nameplateon your tool.

"8-

_ isconnect battery pack

from tool before making

any assembly, adjustments or changing

accessories. Such preventive safety

measures reduce the risk of starting the tool

accidentally.

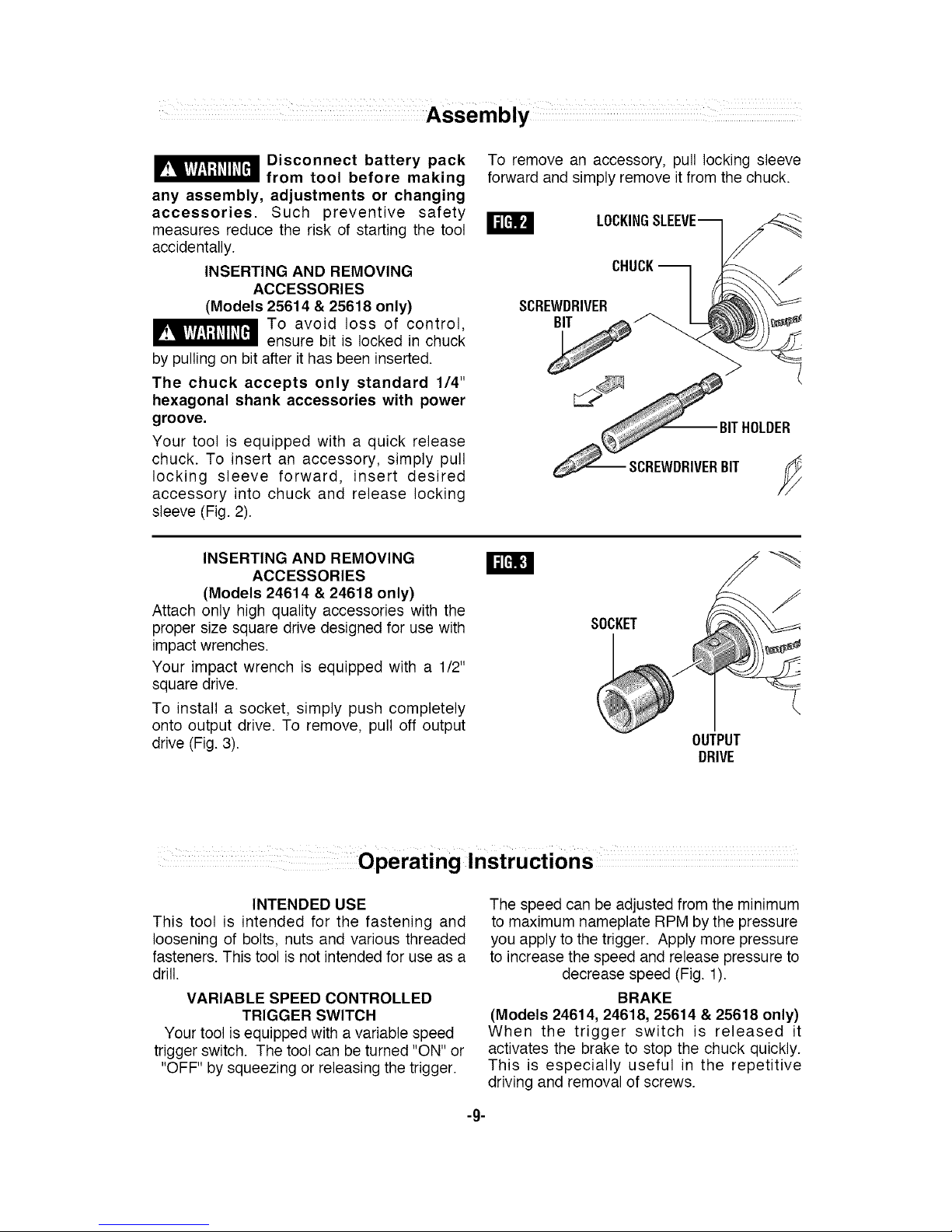

INSERTING AND REMOVING

ACCESSORIES

(Models 25614 & 25618 only)

To avoid loss of control,

ensure bit is locked in chuck

by pulling on bit after it has been inserted.

The chuck accepts only standard 1/4"

hexagonal shank accessories with power

groove.

Your tool is equipped with a quick release

chuck. To insert an accessory, simply pull

locking sleeve forward, insert desired

accessory into chuck and release locking

sleeve (Fig. 2).

To remove an accessory, pull locking sleeve

forward and simply remove it from the chuck.

W

LOCKINGSLEEVE--

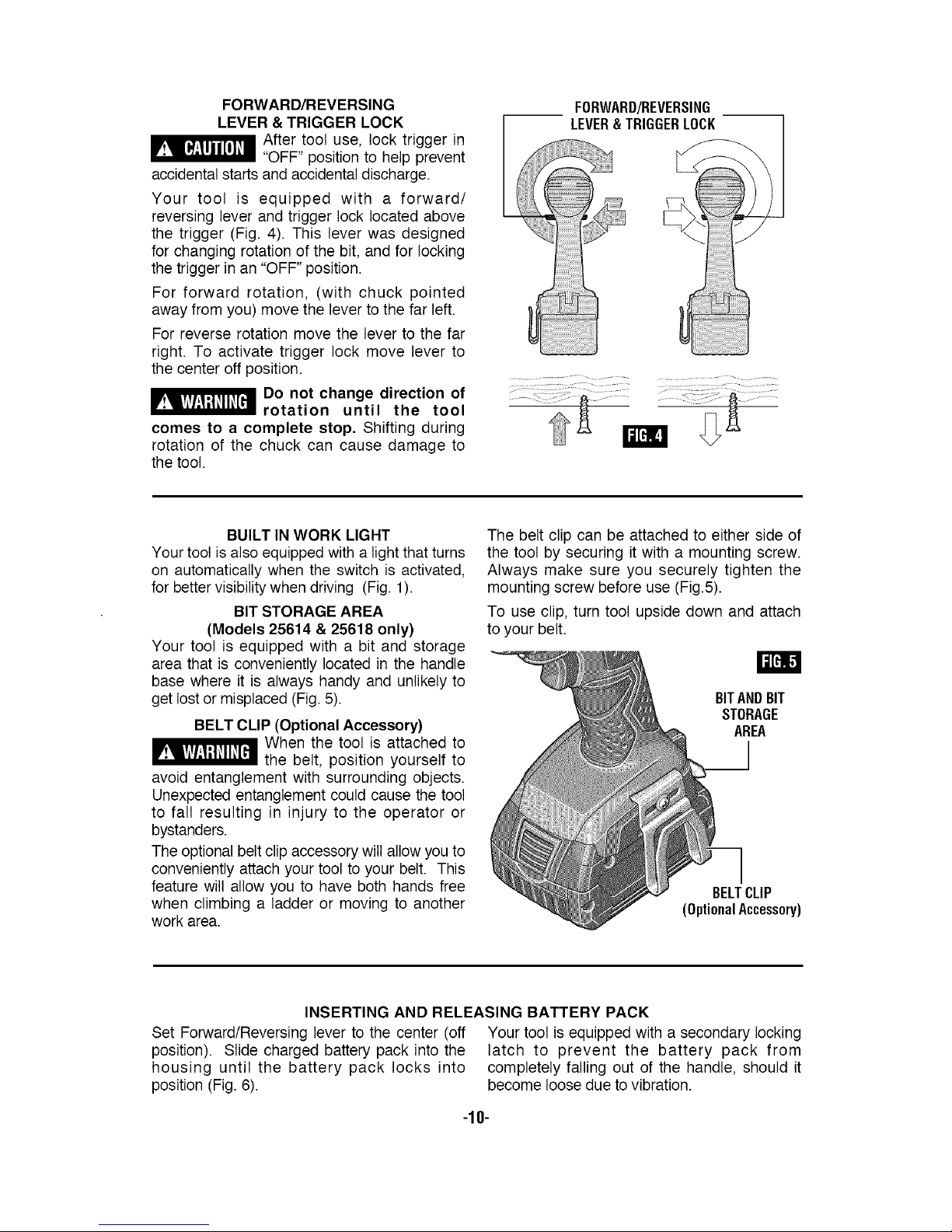

INSERTING AND REMOVING

ACCESSORIES

(Models 24614 & 24618 only)

Attach only high quality accessories with the

proper size square drive designed for use with

impact wrenches.

Your impact wrench is equipped with a 1/2"

square drive.

To install a socket, simply push completely

onto output drive. To remove, pull off output

drive (Fig. 3).

W

OUTPUT

DRIVE

INTENDED USE

This tool is intended for the fastening and

loosening of bolts, nuts and various threaded

fasteners. This tool is not intended for use as a

drill.

VARIABLE SPEED CONTROLLED

TRIGGER SWITCH

Your tool is equipped with a variable speed

trigger switch. The tool can be turned "ON" or

"OFF" by squeezing or releasing the trigger.

The speed can be adjusted from the minimum

to maximum nameplate RPM bythe pressure

you apply to the trigger. Apply more pressure

to increase the speed and release pressure to

decrease speed (Fig. 1).

BRAKE

(Models 24614, 24618, 25614 & 25618 only)

When the trigger switch is released it

activates the brake to stop the chuck quickly.

This is especially useful in the repetitive

driving and removal of screws.

-9-

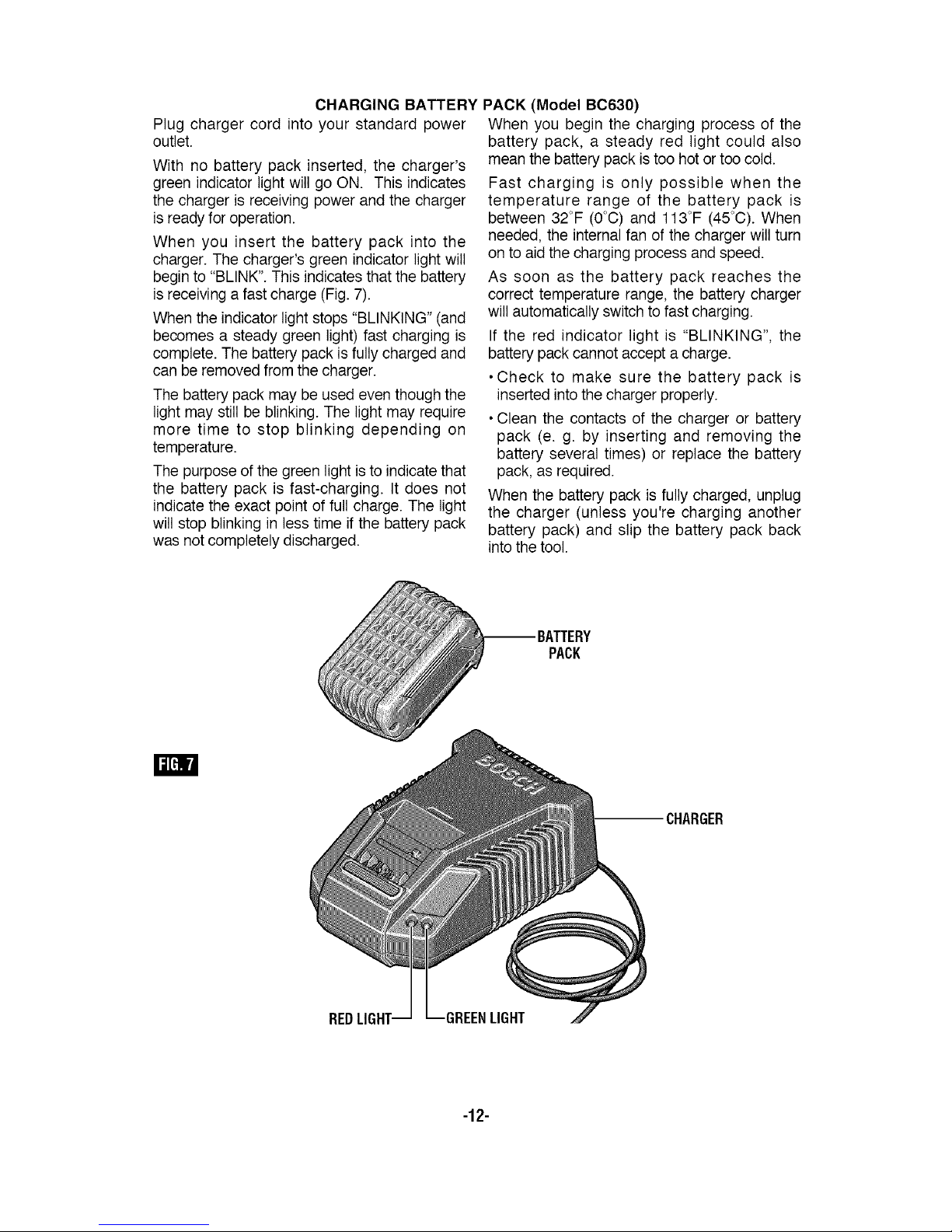

FORWARD/REVERSING

LEVER & TRIGGER LOCK

pl__ After tool use, lock trigger in

"OFF" position to help prevent

accidental starts and accidental discharge.

Your tool is equipped with a forward/

reversing lever and trigger lock located above

the trigger (Fig. 4). This lever was designed

for changing rotation of the bit, and for locking

the trigger in an "OFF" position.

For forward rotation, (with chuck pointed

away from you) move the lever to the far left.

For reverse rotation move the lever to the far

right. To activate trigger lock move lever to

the center off position.

I__ Do not change direction of

rotation until the tool

comes to a complete stop, Shifting during

rotation of the chuck can cause damage to

the tool.

FORWARD/REVERSING

BUILT IN WORK LIGHT

Your tool is also equipped with a light that turns

on automatically when the switch is activated,

for better visibility when driving (Fig. 1).

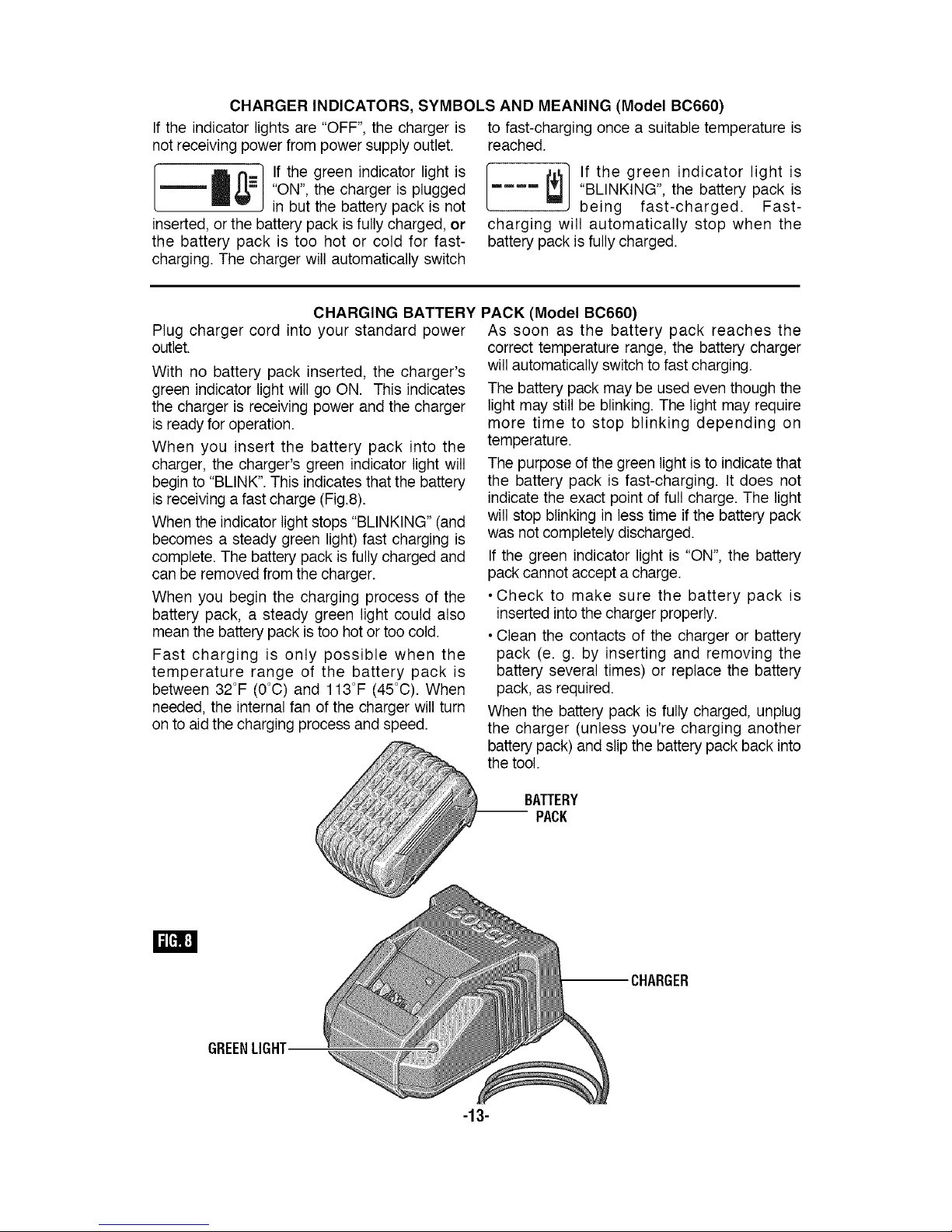

BIT STORAGE AREA

(Models 25614 & 25618 only)

Your tool is equipped with a bit and storage

area that is conveniently located in the handle

base where it is always handy and unlikely to

get lost or misplaced (Fig. 5).

BELT CLIP (Optional Accessory)

When the tool is attached to

the belt, position yourself to

avoid entanglement with surrounding objects.

Unexpected entanglement could cause the tool

to fall resulting in injury to the operator or

bystanders.

The optional belt clip accessory will allow you to

conveniently attach your tool to your belt. This

feature will allow you to have both hands free

when climbing a ladder or moving to another

work area.

The belt clip can be attached to either side of

the tool by securing it with a mounting screw.

Always make sure you securely tighten the

mounting screw before use (Fig.5).

To use clip, turn tool upside down and attach

to your belt.

BITANDBIT

STORAGE

AREA

_l

BELTCLIP

(OptionalAccessory)

INSERTING AND RELEASING BATTERY PACK

Set Forward/Reversing lever to the center (off Your tool is equipped with a secondary locking

position). Slide charged battery pack into the latch to prevent the battery pack from

housing until the battery pack locks into completely failing out of the handle, should it

position (Fig. 6). become loose due to vibration.

-10-

To remove the battery pack, press the battery

pack release button and slide the battery pack

forward.

Press the battery pack release button again

and slide the battery pack completely out of

tool housing (Fig. 6).

IMPORTANT CHARGING NOTES

1. The charger was designed to fast charge

the battery only when the battery temperature

is between 32°F (0°C) and 113°F (45°C). If the

battery pack is too hot or too cold, the charger

will not fast charge the battery. (This may

happen if the battery pack is hot from heavy

use). When the battery temperature returns to

between 32°F (0°C) and 113°F (45°C), the

charger will automatically begin charging.

2. A substantial drop in operating time per

charge may mean that the battery pack is

nearing the end of its life and should be

replaced.

3. Remember to unplug charger during

storage period.

4. Ifbattery does not charge properly:

a. Check for voltage at outlet by plugging in

some other electrical device.

b. Check to see if outlet is connected to a

light switch which turns power "off" when lights

are turned off.

c. Check battery pack terminals for dirt.

Clean with cotton swab and alcohol if

necessary.

d. If you still do not get proper charging,

take or send tool, battery pack and charger to

your local Bosch Service Center. See "Tools,

Electric" in the Yellow Pages for names and

addresses.

Note: Use of chargers or battery packs not

sold by Bosch will void the warranty.

CHARGER INDICATORS, SYMBOLS AND MEANING (Model B0630)

Ifthe indicator lights are "OFF", the charger is

not receiving power from power supply outlet.

l ..$_. ] Ifthe green indicator light is "ON",.. | .. the charger is plugged in but the

battery pack is not inserted, or

the battery pack is fully charged.

[ i''t' eoreer''r'd'cator''oht's

- - "BLINKING", the battery pack is

beingfast-charged. Fast-charging

will automatically stop when the battery pack is

fully charged.

.._._ £1=] If the red indicator light is "ON",

"" I " _- ] the battery pack is too hot or cold

v j for fast-charging. The charger will

automatically switch to fast-charging once a

suitable temperature is reached.

,.[_:. ,4-_]lf the red indicator light is

JX[/"BLINKING", the battery pack

" " " "'-"'/cannot accept a charge or the

contacts of the charger or battery pack are

contaminated. Clean the contacts of the

charger or battery pack only as directed in

these operating instructions or those supplied

with your tool or battery pack.

-11-

CHARGING BATTERY PACK (Model B0630)

Plug charger cord into your standard power

outlet.

With no battery pack inserted, the charger's

green indicator light will go ON. This indicates

the charger is receiving power and the charger

is ready for operation.

When you insert the battery pack into the

charger. The charger's green indicator light will

beginto "BLINK". This indicates that the battery

is receiving a fast charge (Fig. 7).

When the indicator light stops "BLINKING" (and

becomes a steady green light) fast charging is

complete. The battery pack is fully charged and

can be removed from the charger.

The battery pack may be used even though the

light may still be blinking. The light may require

more time to stop blinking depending on

temperature.

The purpose of the green light isto indicatethat

the battery pack is fast-charging. It does not

indicate the exact point of full charge. The light

will stop blinking in less time if the battery pack

was not completely discharged.

When you begin the charging process of the

battery pack, a steady red light could also

mean the battery pack is too hot or too cold.

Fast charging is only possible when the

temperature range of the battery pack is

between 32°F (0°C) and 113°F (45°C). When

needed, the internal fan of the charger will turn

on to aid the charging process and speed.

As soon as the battery pack reaches the

correct temperature range, the battery charger

will automatically switch to fast charging.

If the red indicator light is "BLINKING", the

battery pack cannot accept a charge.

•Check to make sure the battery pack is

inserted into the charger properly.

•Clean the contacts of the charger or battery

pack (e. g. by inserting and removing the

battery several times) or replace the battery

pack, as required.

When the battery pack is fully charged, unplug

the charger (unless you're charging another

battery pack) and slip the battery pack back

into the tool.

PACK

REDLIGHT

-12-

CHARGER INDICATORS, SYMBOLS AND MEANING (Model BC660)

Ifthe indicator lights are "OFF", the charger is

not receiving power from power supply outlet.

i_._ 1 If the green indicator light is

"ON", the charger is plugged

in but the battery pack is not

inserted, or the battery pack is fully charged, or

the battery pack is too hot or cold for fast-

charging. The charger will automatically switch

to fast-charging once a suitable temperature is

reached.

[ _._)/ If the green indicat°r light is

...... BLINKING", the battery pack is

being fast-charged. Fast-

charging will automatically stop when the

battery pack is fully charged.

CHARGING BATTERY PACK (Model BC660)

Plug charger cord into your standard power

outlet.

With no battery pack inserted, the charger's

green indicator light will go ON. This indicates

the charger is receiving power and the charger

is ready for operation.

When you insert the battery pack into the

charger, the charger's green indicator light will

begin to "BLINK". This indicates thatthe battery

is receiving a fast charge (Fig.8).

When the indicator light stops "BLINKING" (and

becomes a steady green light) fast charging is

complete. The battery pack is fullycharged and

can be removed from thecharger.

When you begin the charging process of the

battery pack, a steady green light could also

mean the battery pack istoo hot or too cold.

Fast charging is only possible when the

temperature range of the battery pack is

between 32°F (0°C) and 113°F (45°C). When

needed, the internal fan of the charger will turn

on to aid the charging process and speed.

As soon as the battery pack reaches the

correct temperature range, the battery charger

will automatically switch to fast charging.

The battery pack may be used even though the

light may still be blinking. The light may require

more time to stop blinking depending on

temperature.

The purpose of the green lightis to indicate that

the battery pack is fast-charging. It does not

indicate the exact point of full charge. The light

will stop blinking in less time ifthe battery pack

was not completely discharged.

Ifthe green indicator light is "ON", the battery

pack cannot accept a charge.

• Check to make sure the battery pack is

inserted into the charger properly.

• Clean the contacts of the charger or battery

pack (e. g. by inserting and removing the

battery several times) or replace the battery

pack, as required.

When the battery pack is fully charged, unplug

the charger (unless you're charging another

battery pack)and slip the battery pack back into

the tool.

BATTERY

PACK

I=[_E;!

GREENLIGHT

-13-

Operating Tips

You will extend the life of your bits and do

neater work if you always put the bit in

contact with the work before pulling the

trigger. During the operation, hold the tool

firmly and exert light, steady pressure. Too

much pressure at low speed will stall the tool.

Too little pressure will keep the bit from

cutting and cause excess friction by sliding

over the surface. This can be damaging to

both tool and bit.

DRIVING WITH VARIABLE SPEED

The technique is to start slowly, increasing

the speed as the screw runs down. Set the

screw snugly by slowing to a stop. Prior to

driving screws, pilot and clearance holes

should be drilled.

Always hold the machine straight on the bolt

to be tightened.

The best method to determine the right

impacting/tightening duration is by means of

a trial. For small screws, the right

impacting/tightening duration can be reached

in less then 0.5 Sec. Therefore, work with

low RPM and switch the machine off

immediately when the screw is tight and the

impacting sound can be heard.

For screwing larger, longer wood screws into

hard material, pre-drilling is the best method.

TIGHTENING TORQUE

(Models 24614 & 24618 only)

The tightening torque depends on the

duration of the impacting/tightening action.

The largest tightening torque is achieved

after approx. 6 to 10 Sec. impacting/

tightening action.

The torque build-up depends on the

following factors:

• Hardness of the bolts/nuts.

• Type of washer (disk washer, spring

washer, seal).

• Hardness of the material to be joined.

• Lubricating effect at the surfaces of the

junction.

This leads to the following application cases:

Hard case: The joining of metal to metal with

a disk washer. The maximum torque is

reached after a relative short impacting/

tightening action.

Medium case: The joining of metal to metal

where spring ring washer, disk spring

washer, stud bolts or bolts/nuts with conical

seats are used.

Soft case: The joining of e.g. metal to wood

or insulation material.

For middle or soft joining cases, the

maximum tightening torque is less as for

hard cases. Therefore, a longer impacting/

tightening action is necessary to arrive at the

maximum tightening torque.

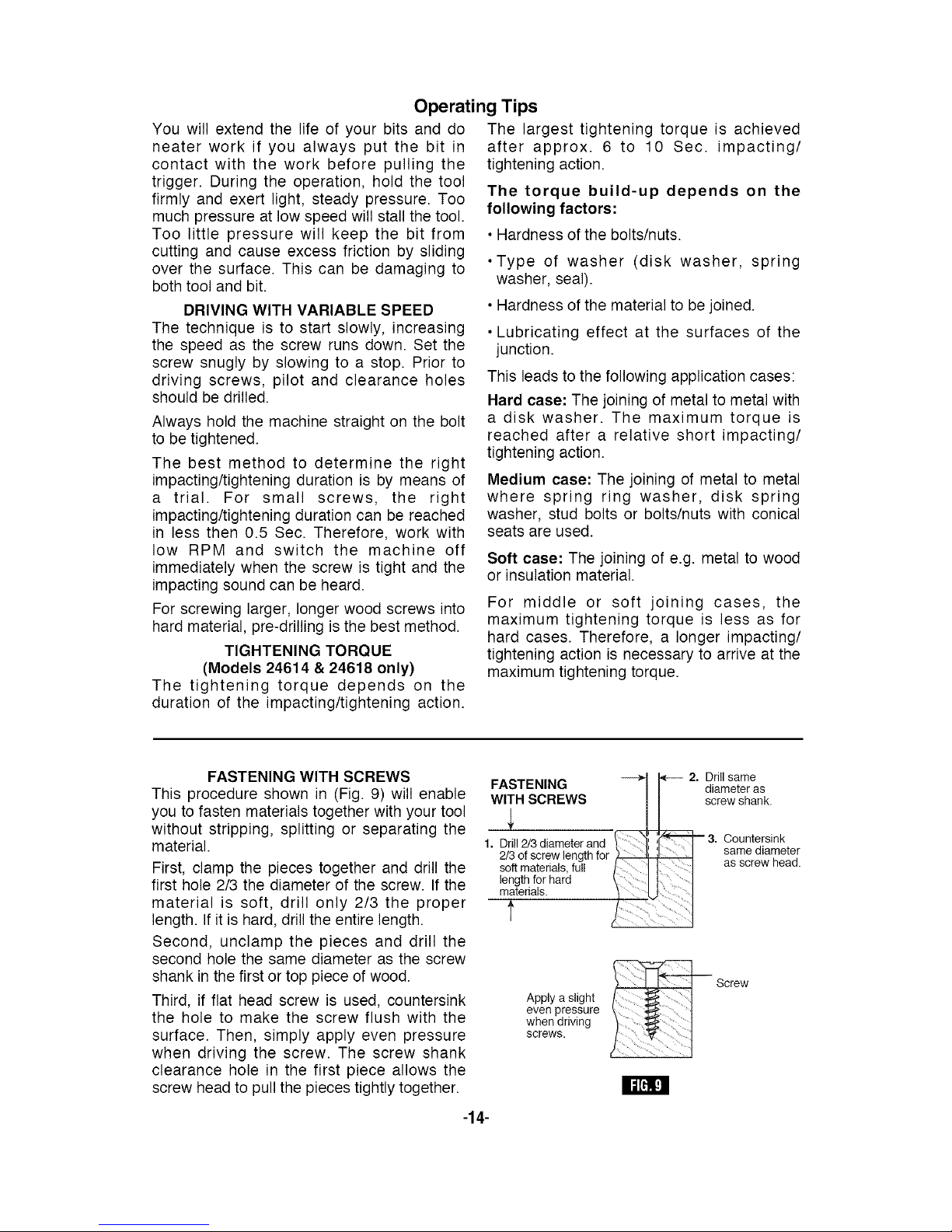

FASTENING WITH SCREWS

This procedure shown in (Fig. 9) will enable

you to fasten materials together with your tool

without stripping, splitting or separating the

material.

First, clamp the pieces together and drill the

first hole 2/3 the diameter of the screw. Ifthe

material is soft, drill only 2/3 the proper

length. If it is hard, drill the entire length.

Second, unclamp the pieces and drill the

second hole the same diameter as the screw

shank in the first or top piece of wood.

Third, if fiat head screw is used, countersink

the hole to make the screw flush with the

surface. Then, simply apply even pressure

when driving the screw. The screw shank

clearance hole in the first piece allows the

screw head to pull the pieces tightly together.

I1=[_1

-14-

FASTENING

WITH SCREWS

(

\ N _ 3

1, Drill2/3diameterand t "

2/3 of screw length for _ _

soft materials, full / ]

length for hard " I

m_terials, t I

2. Drill same

diameter as

screw shank.

Countersink

same diameter

as screw head.

Apply a slight / _: !

even pressure

when driving

screws.

Screw

RUNNING NUTS AND BOLTS

Variable speed control must be used with

caution for driving nuts and bolts with socket

set attachments. The technique is to start

slowly, increasing speed as the nut or bolt runs

down. Set the nut or bolt snugly by slowing the

tool to a stop. Ifthis procedure is not followed,

the tool will have a tendency to torque or twist

in your hands when the nut or bolt seats.

Service

_ NO USER SERVICEABLE

PARTS INSIDE. Preventive

maintenance performed by unauthorized

personnel may result in misplacing of

internal wires and components which

could cause serious hazard. We recom-

mend that all tool service be performed by a

Bosch Factory Service Center or Authorized

Bosch Service Station. SERVICEMEN:

Disconnect tool and/or charger from power

source before servicing.

BATTERIES

Be alert for battery packs that are nearing

their end of life. If you notice decreased

tool performance or significantly shorter

running time between charges then it is time

to replace the battery pack. Failure to do so

can cause the tool to operate improperly or

damage the charger.

TOOL LUBRICATION

Your Bosch tool has been properly lubricated

and is ready for use.

CARBON BRUSHES

The brushes and commutator in your tool have

been engineered for many hours of

dependable service.

If your tool runs sporadically, loses power,

makes unusual noises or runs at a reduced

speed, check the brushes. To continue using

the tool in this condition will permanently

damage your tool.

Check both brushes. Usually the brushes will

not wear out simultaneously. If one brush is

worn out, replace both brushes.

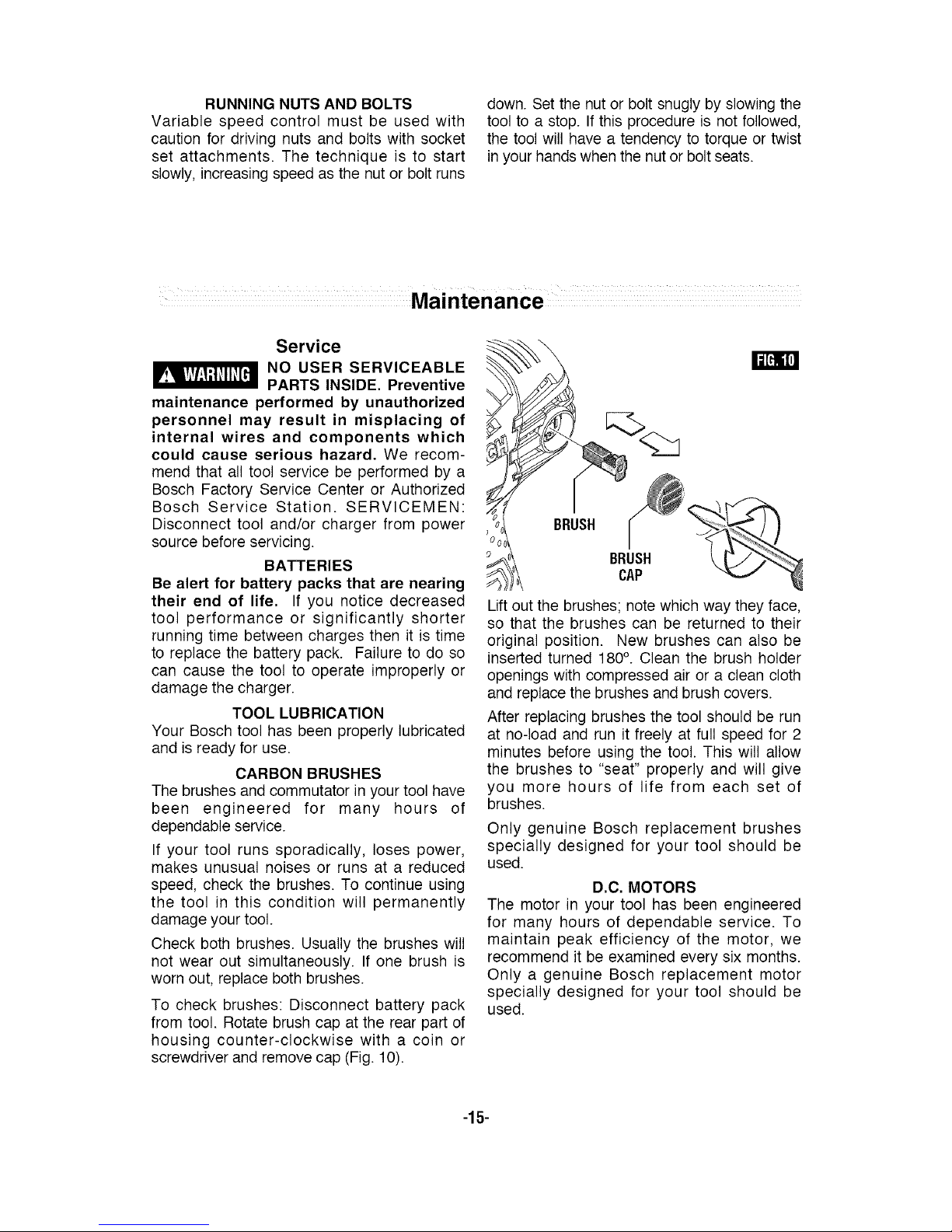

To check brushes: Disconnect battery pack

from tool. Rotate brush cap at the rear part of

housing counter-clockwise with a coin or

screwdriver and remove cap (Fig. 10).

Ii[_Ill]

BRUSH

BRUSH

CAP

Lift out the brushes; note which way they face,

so that the brushes can be returned to their

original position. New brushes can also be

inserted turned 180°. Clean the brush holder

openings with compressed air or a clean cloth

and replace the brushes and brush covers.

After replacing brushes the tool should be run

at no-load and run it freely at full speed for 2

minutes before using the tool. This will allow

the brushes to "seat" properly and will give

you more hours of life from each set of

brushes.

Only genuine Bosch replacement brushes

specially designed for your tool should be

used.

D.C. MOTORS

The motor in your tool has been engineered

for many hours of dependable service. To

maintain peak efficiency of the motor, we

recommend it be examined every six months.

Only a genuine Bosch replacement motor

specially designed for your tool should be

used.

-15-

Loading...

Loading...