Page 1

MODEL 2400E NG and 2400E LP - INDOOR MODEL

Temperature Modulated with Electronic Ignition

Suitable for heating potable water only

Not approved for space heating purposes

(Intended for variable flow applications)

2400 E NG - Natural Gas

2400 E LP - Liquefied Petroleum (LP) Gas

Warning: If the information in this manual is not

followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

Do not store or use gasoline or other flammable

vapor and liquids in the vicinity of this or any other

appliance.

Improper installation, adjustment, alteration,

service or maintenance can cause injury or

property damage. Refer to this manual. For

assistance or additional information consult a

qualified installer, service agency or the gas

supplier.

In the Commonwealth of Massachusetts this

product must be installed by a licensed plumber or

gas fitter.

Upon completion of the installation, these

instructions should be handed to the user of the

appliance for future reference.

6 720 608 263 US (2007.10) JS

What to do if you smell gas

• Close gas valve. Open windows.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• If you cannot reach your gas supplier, call the fire

department.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions

• Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

Page 2

Index

Index

2.5 Dimensions and Minimum installation clearances 7

1 Warning

2 gninraW1

For your safety

4 sliated ecnailppA2

4 serutaeF1.2

Do not store or use gasoline or other ammable,

4 )atad lacinhceT( snoitacificepS E 00422.2

5 retaeh E 0042 eht gnikcapnU3.2

combustible or corrosive vapors and liquids in the

6 noitarepo efas rof wollof ot selur lareneG4.2

vicinity of this or any other appliance.

3.6.6 Horizontal 51 snoitanimret

4.1 For your safety, read before operating your water heater 24

4.4 Use of optional rem 72 yrossecca lortnoc eto

5 Maintenance 82 ecivres dna

6.2 Burners do not ignite when hot water is turned on 33

9 Interior components diagram and parts list 43

11 Fifteen Year Lim 74 ytnarraW deti

8 snoitcurtsni noitallatsnI3

8 noitcudortnI1.3

8 retaeh ruoy gnillatsni rof noitacol reporP2.3

8 secnaraelc dna tnemecalp retaeH3.3

8 noitallatsni gnitnuoM4.3

9 stnemeriuqer ria noitsubmoC5.3

11 gnitneV6.3

11 snoitacificeps dna lairetam tneV1.6.3

21 snoitcennoc tneV2.6.3

31 stnemeriuqer ebut niard etasnednoC3.6.3

31 )epip niwT( noitallatsni delaes mooR4.6.3

41 snoitanimret lacitreV5.6.3

81 selpmaxe noitarugifnoc tnev tsuahxE7.6.3

91 snoitcennoc & gnipip saG7.3

12 erusserp sag gnirusaeM8.3

22 snoitcennoc retaW9.3

32 snoitcennoc lacirtcelE01.3

32 noitacilppa noitalucriceR21.3

Warning: Carefully plan where you

install the heater. Correct combustion

air supply and ue pipe installation are

very important. If a gas appliance is not

installed correctly, fatal accidents can

result from lack of air, carbon monoxide

poisoning or re.

Warning: Exhaust gas must be vented

to outside using proper vent material

suitable for category III vent systems

and temperatures up to 480°F. Vent

and combustion air piping must be

sealed gas-tight to prevent possibility of

42 snoitcurtsni noitarepO4

42 rewoP2.4

52 noitceles erutarepmeT3.4

72 noitarepO5.4

72 nottub teseR6.4

72 nottub margorP7.4

72 noitidnoc dekcoL8.4

82 ecnanetniam launnA1.5

82 esu lanosaes rof gniziretniW2.5

92 pu-dliub elacs lareniM3.5

92 2OC gnitsujdA4.5

23 scitsongaid draob lortnoC5.5

ue gas spillage, carbon monoxide

emissions and risk of re, resulting in

severe personal injury or death.

Warning: Place the heater in a location

where water leaks will do NO DAMAGE

to adjacent areas or lower oors.

Warning: Field wiring connections and

electrical grounding must comply with

local codes, or in the absence of local

codes, with the latest edition of the

33 gnitoohselbuorT6

33 noitcudortnI1.6

33 toh oot si retaW3.6

33 hguone toh ton si retaW4.6

43 erusserp/wolf retaw woL5.6

43 pat ta setautculf erutarepmet retaw toH6.6

43 noitarepo gnirud retaeh/renrub ysioN7.6

63 scitsongaid edoc rorrE8.6

National Electric Code, ANSI/NFPA 70,

or in Canada, all electrical wiring must

comply with the local codes and the

Canadian Electrical Code, CSA C22.1

Part 1.

Warning: Shock hazard: line voltage is

14 margaid lacirtcelE7

present. Before servicing the water

heater, unplug power supply cord from

24 emehcs lanoitcnuF E 00428

outlet. Failure to do so could result in

severe personal injury or death.

34 stnenopmoc roiretnI1.9

44 margaid stnenopmoC2.9

54 tsil straP3.9

64 tnemnorivne eht gnitcetorP01

Warning: The heater must be

disconnected from the gas supply

piping system during any pressure

testing of that system at test pressures

equal to or more than 0.5 psig.

2

6 720 608 263

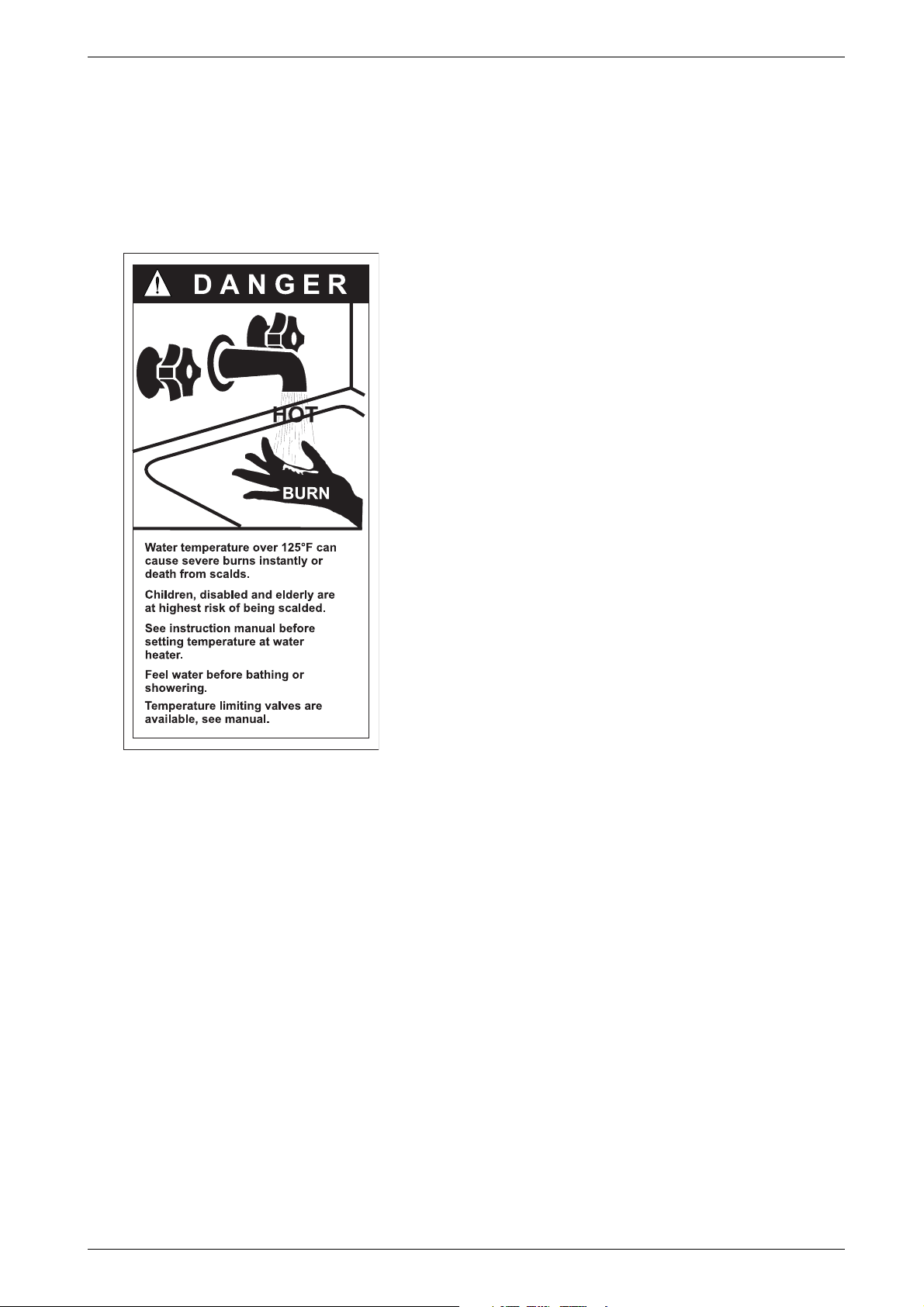

Page 3

FCC:

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2)

this device must accept any interference received,

including interference that may cause undesired operation.

Warning

Fig. 1

6 720 608 263

3

Page 4

Appliance details

2 Appliance details

2.1 Features

Parts

• Touch pad interface control

• High power pre-mix compact burner with low NOx

emissions

• Modulating gas valve with constant gas to air ratio

control

• Modulating water valve for improved comfort and

temperature control.

Safety

• Flame sensor (ionization) rod

• Overheat sensor

• Temperature limiter

• Fan speed monitoring.

High quality materials for long working life

• Copper heat exchanger

• High eciency Ceramat burner

• Compact space saver: mounts on a wall with a

supplied bracket.

• Easily removable one-piece cover.

Features

• LCD Display

• On/O and temperature control switches

• Reset button

• Program key (selectable temperature)

• Failure codes for easy diagnostics and repair

• Diagnostic mode for trou bleshooting/informational

purposes

Accessories

• Optional wireless remote control accessory to

remotely set temperature (Part # TSTAT2) .

• Horizontal vent termination kit (Part # AQ3) .

BOSCH is constantly improving its

products, therefore specications are

i

subject to change without prior notice.

2.2 2400 E Specifications (Technical

data)

Approved in US/Canada

Capacity

Maximum ow rate: 6.35 GP M (24 l/min) at a 45°F

(25°C) rise.

Maximum output

142,968 Btu/h (41.8 kW)

Maximum input

175,000 Btu/h (51.2 kW)

Efficiency in %

Recovery eciency 86.5%

Min. Output

31,131 Btu/h (9.1 kW)

Temperature Control

Selection range: 100°F (38°C) - 140°F (60°C)

Default temperature: 122°F (50°C)

Stability: +/- 2°F (+/- 1°C)

Gas Requirement

Gas connection (inches) - ¾” NPT

Inlet gas pressure under operation (with a high hot

water ow rate)*

• Propane: 11” - 14” water column

• Natural Gas: 5” - 14” water column.

* To measure gas pressure, see Measuring gas

pressure, chapter 3.8.

Venting

A condensate trap is integrated into the exhaust ue

gas collar of the heater, the supplied condensate drain

tube MUST be installed to it for proper removal of

condensate from the trap. Ad ditional condensate traps

and drains may be necessary; see chapter 3.6 for

Venting.

Water

• Hot water connection (inches) - ¾” NPT

• Cold water connection (inches) - ¾” NPT

• Water valve material: Polymer (PPS) (Polypropylene

Suld)

• Minimum water ow for activation: 0.8 gallon/minute

(3 l/m)

• Minimum recommended water pressure: 30 PSI

(2.07 bar)

• Connections:

– Bottom of heater

Combustion

• NOx ≤ 55 ppm

• CO ≤ 300 ppm

4

6 720 608 263

Page 5

Appliance details

•CO

level set from factory, see chapter 5.4.

2

Dimensions

• Depth (in): 8 ½” (220 mm)

• Width (in): 15 ¾” (400 mm)

• Height (in): 23 ½” (600 mm)

• Weight: 47 pounds (21 kg).

Gas types

Natural Gas.

LP Gas.

Converting the gas type can only be done by a certified

gas technician with a calibrated CO

analyzer.

2

Call Bosch Water Heating for conversion information.

Voltage

120 V AC (50/60 Hz)

6 ft power supply cord

Amperage

Idle - 40 mA

Operation - ≤ 2.5 A

Noise

≤ 50 db (A)

Safety devices

• Flame failure device (ionization flame rod sensor)

• Pressure relief valve (supplied with heater)

• Over heat prevention (temperature limiter).

Water resistant

IP X4 (protection against water drops)

2.3 Unpacking the 2400 E heater

Before installing the unit, be certain you have the

correct heater for your type of Gas - Propane or

Natural Gas. Identification labels are found on the

shipping box, and on the rating plate sticker which is

located on the right side panel of the cover.

• Exhaust vent adaptor (with 4 screws and gasket

provided)

• Condensate drain tube kit

• Combustion air inlet adaptor (with 3 screws and gasket provided)

• Plastic decal shields for covering front cover screws

and control panel, installer should affix these decals

to the front of the unit after installation is complete.

See Fig. 3

• Installation manual (replacement manuals can be

downloaded at www.boschhotwater.com

)

• Product registration card

• Energy Guide label.

Please complete and return the enclosed product

registration card.

The 2400 E is not approved or designed for:

• Manufactured (mobile) homes, RV's, boats or any

mobile installation.

• Heating or other recirculating/pumping applications*

• Solar/preheat backup or high temperature booster

use.

* This includes domestic hot water circulator pump loop

systems that may be installed in home hot water system

prior to installing this unit. An approved recirculation

design can be found in chapter 3.9. The use of a small

electric mini-tank water heater (4-6 gallon size) must be

used for this application and designed so the pump will

circulate the hot water in the mini-tank only and through

the building's hot water return loop (timed or

thermostatic controlled operation of the pump is

commonly done). The 2400 E must be plumbed in line

before the mini-tank water heater and supplied with

cold water only. Contact Bosch Water Heating if further

instruction is needed.

To remove front cover

• Loosen the two Philips head screws located on front

panel (beneath plastic decal shields if they are

already attached, see Fig. 3)

• Lift front cover panel upward and remove.

Fig. 2 Rating plate sticker

A Serial number

B Type of gas

The box includes:

• Pressure relief valve (150 psi / 200,000 Btu rating)

• Bracket for wall hanging the heater

6 720 608 263

Plastic decals

Fig. 3 Remove front cover

5

Page 6

Appliance details

2.4 General rules to follow for safe

operation

B 1. You must follow these instructions when you

install your heater. In the United States: The

installation must conform with local codes or, in the

absence of local codes, the National Fuel Gas Code

ANSI Z223.1/NFPA 54.

In Canada: The Installation must conform with CGA

B149.(1,2) INSTALLATION CODES and /or local

installation codes.

B 2. Carefully plan where you install the heater. Correct

combustion air supply and vent pipe installation are

very important. If not installed correctly, fatal

accidents can be caused by lack of air, carbon

monoxide poisoning or fire.

B 3. When the unit is installed indoors with ROOM

SEALED (twin pipe) combustion air and venting, it is

permitted to be located in bathrooms, bedrooms and

occupied rooms that are normally kept closed. See

chapter 3.6. If the unit will be installed indoors and

use indoor combustion air, the place where you

install the heater must have enough ventilation. The

National Fuel Gas Code and National Fire

Codes do not allow UNSEALED gas fired water

heater installations in bathrooms, bedrooms

or any occupied rooms normally kept closed.

See chapter 3.2 and 3.5.

B 4. You must vent your heater. See section on

VENTING.

B 5. The appliance and its gas connection must be leak

tested before placing the appliance in operation.

The appliance must be isolated from the gas supply

piping system by closing its individual manual gas

shutoff valve (not supplied with heater) during any

pressure testing at pressures in excess of ½ Psig

(3.5 kPa).

B 6. Keep water heater area clear and free from

combustibles and flammable liquids. Do not locate

the heater over any material which might burn.

B 7. Correct gas pressure is critical for the optimum

operation of this heater. Gas piping must be sized to

provide the required pressure at the maximum output

of the heater, while all the other gas appliances are in

operation. Check with your local gas supplier and

see Chapter 3.7 Gas piping and connections.

B 8. Should overheating occur or the gas supply fail to

shut off, turn off the gas supply at the manual gas

shut off valve, on the gas line. Note: manual gas

shutoff valve is not supplied with the heater.

B 9. Do not use this appliance if any part has been

underwater. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and any gas control

which has been underwater.

B 11. The heater must not be installed in an unheated

area where temperatures will reach 36°F or lower. If

the heater is left in an area susceptible to such

temperatures, refer to Section 5.4 on Winterizing.

B 12. In areas where water supply has a high mineral

content, a water softener is strongly recommended.

Damage to the water heater resulting from hard

water/scale deposits will not be covered under warranty.

B 13. In areas with warm inlet water (70°F or greater),

increasing flow rate at low flowing fixtures may be

required to prevent outlet temperatures from

exceeding the desired temperature set point.

B 10. Failure to install heater correctly may lead to

unsafe operation and void the warranty.

6

6 720 608 263

Page 7

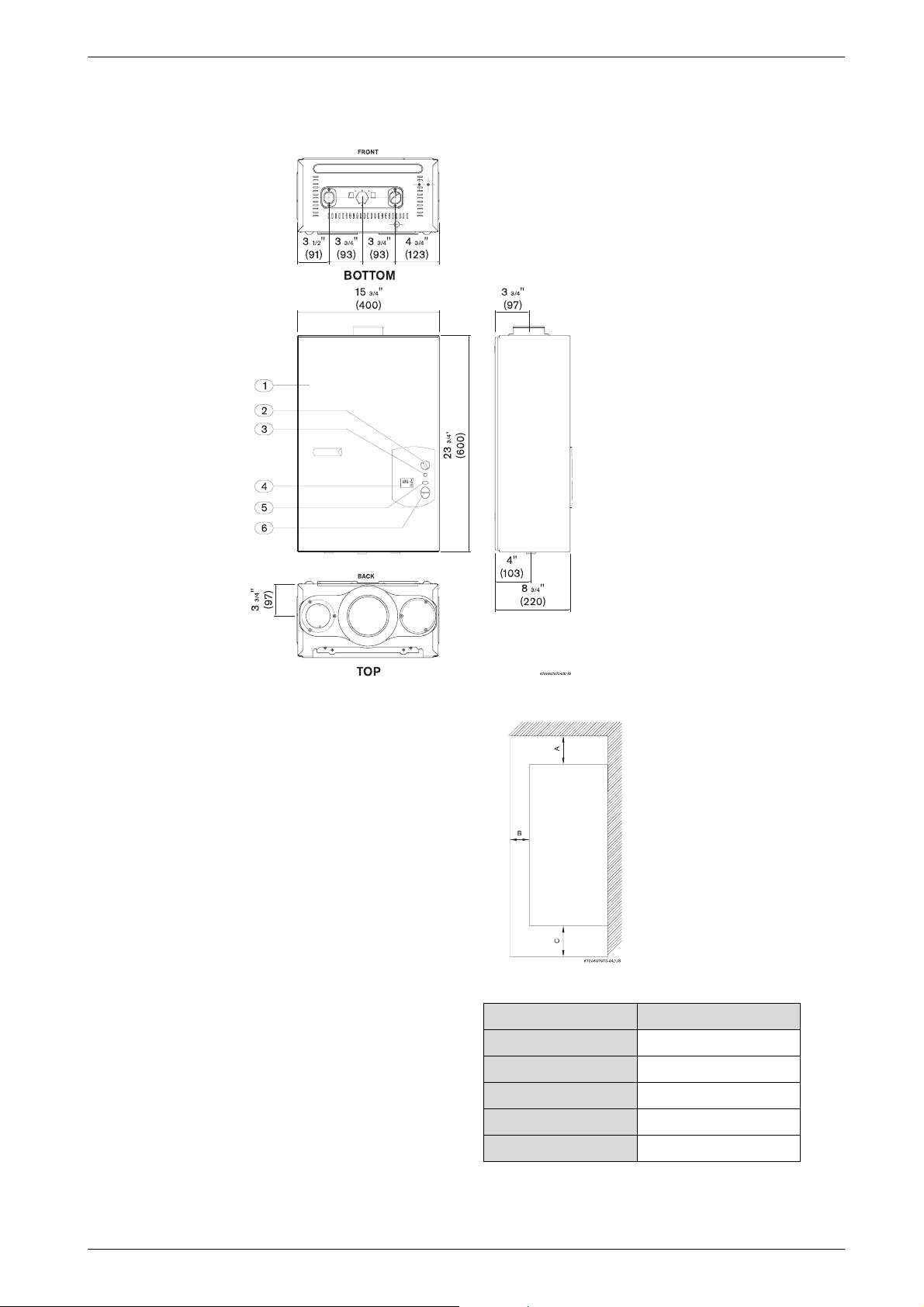

2.5 Dimensions and Minimum installation clearances

Appliance details

Fig. 4 Dimensions

1 Cover

2 On/Off switch

3 Reset button

4 LCD display

5 Program button

6 Temperature buttons

Fig. 5 Minimum clearances

Model 2400 E

TOP (A) 12”

FRONT (B) 1”

BACK 0”

SIDES 1”

6 720 608 263

FLOOR (C) 12”

Table 1 Minimum clearances

7

Page 8

Installation instructions

3 Installation instructions

3.1 Introduction

Please follow these instructions. Failure to follow

instructions may result in:

B Damage or injury.

B Improper operation.

B Loss of warranty.

If you are unable to perform the tasks required to install

this heater properly, please contact a locally licensed

plumber or gas technician.

Please contact Bosch Water Heating with any

questions.

3.2 Proper location for installing your

heater

Carefully select the location of the water heater. For

your safety and for proper heater operation, you must

provide combustion air to the heater and a proper

exhaust vent system.

Follow the guidelines below:

B 1. Locate the heater where venting, gas and

plumbing connections are feasible and convenient.

B 2. The hot water lines should be kept short to save

energy. Centrally locating the water heater is

recommended to keep hot water distribution times

even throughout the structure. It is always best to

have hot water lines insulated.

Warning: The water in this water

heater is cold and always remains cold

except for the times the burners are on.

In the event of power outage during

freezing temperatures, it is

recommended that the heater be

drained.

See chapter 5.5 “Winterizing” for

draining instructions.

Warning: Flammable materials,

gasoline, pressurized containers, or any

other items or articles that are potential

fire hazards must NOT be placed on or

adjacent to the heater. The appliance

area must be kept free of all

combustible materials, gasoline and

other flammable vapors and liquids.

Warning: The water heater must be

installed in a conditioned space where

temperatures will not fall below 36F.

3.3 Heater placement and clearances

The 2400 E is design certified for installation on a

combustible wall (see 3.4 Mounting installation)

provided the floor covering below the heater is

noncombustible. For installations in an alcove or closet,

maintain the minimum clearances to combustible and

non-combustible materials listed below. See also Fig. 5.

A. Top 12 inches (306 mm)

B. Front 1 inches (25 mm)

C. Back 0 inches

D. Sides 1 inches (25 mm)

E. Bottom 12 inches (306 mm)

Clearances from any exhaust vent pipe are dependent

upon the clearance requirements of the stainless steel

vent pipe manufacturer. Single wall stainless steel

(AL29-4C) vent pipe (vent type rated for Category III

appliances) must be used when exhaust venting this

appliance. See 3.6 Venting.

3.4 Mounting installation

Warning: before starting installation:

B check that there are no loose parts

inside the appliance

B check the gas type of the heater

matches the gas supply you will be

connecting the heater

B ensure that gas pipe, gas valve, mixer,

fan and burner have no damage and are

properly fitted.

Front cover should be removed (see

instructions on page 5) in order to inspect

i

components visually.

B Secure the wall mounting bracket provided with the

heater to a wall surface.

Warning: Do not install this appliance

on a carpeted wall. The heater must be

mounted on a wall using appropriate

anchoring materials.

If wall is sheathed with plasterboard, it is recommended

that two support boards, either 1”x4” or 1/2" (minimum)

plywood first be attached across a pair of studs. Then

attach the heater’s bracket to the upper support board.

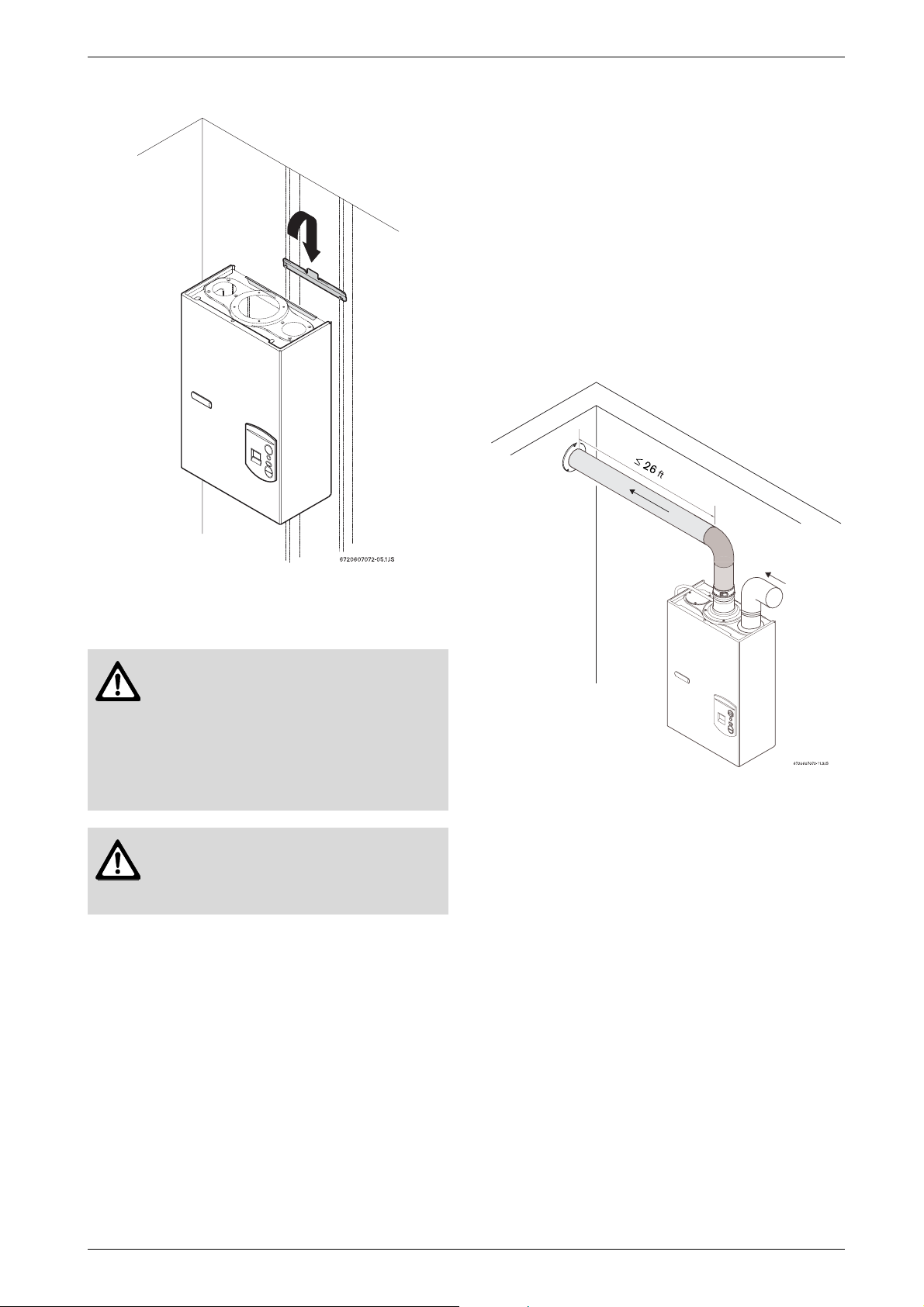

The heater should be kept level on the wall surface. See

Fig. 6.

8

6 720 608 263

Page 9

Installation instructions

pitch down towards termination ¼ inch for every foot of

horizontal length.

Single pipe method:

Although it is permissible to draw combustion air from

the inside, it is not the manufacturer’s recommended

installation method. Always install a 3 inch elbow on the

top of the combustion air inlet adaptor to prevent

foreign objects from falling into the unit.

If a single pipe installation is utilized, follow guidelines

below for providing adequate combustion air for the

water heater as well as any other appliances that may

consume air in the space. Always follow local codes if

they are more stringent.

Fig. 6 Mounting the heater

3.5 Combustion air requirements

Warning: In areas where outside

temperatures commonly fall below

36°F, a twin pipe venting system is

required. Failure to do so may result in

cold outside air being drawn across the

heat exchanger causing it to freeze and

burst. This failure is not covered under

the manufacturer’s warranty.

Warning: When installed in an

environment where corrosive chemicals

or dirty air are present, the twin pipe

system is required.

Twin pipe method:

The 2400 E is designed as a sealed combustion

appliance. It is recommended that the combustion air

be provided by a dedicated 3” or 4” pipe to the outside.

The combustion air pipe may be aluminum flex, PVC or

any other rigid or semi rigid sealed 3” or 4” pipe. The

combustion air inlet, whether terminating vertically or

horizontally, must be located in such a manner as to

provide a minimum 3 foot clearance from the exhaust

vent terminator. See Fig. 17 Letter I.

The maximum length of the combustion air inlet is 26

feet with one elbow. Subtract 2.5 feet for additional

elbows. Maximum number of elbows permitted is 3.

Horizontally terminating combustion air pipes must

Fig. 7 Single pipe installation

The 2400 E water heater holds cold water in its copper

heat exchanger and water valve when not in use.

Because of this, any cold air that comes through the

unit's vent pipe could freeze and damage these

components. This Installation Manual specifies the

minimum vertical vent pipe and the amount of

combustion air required for this unit. When all

requirements are followed, the unit will operate properly

and safely. However, there may still be a risk of freezing

due to negative draft if the other combustion appliances

in the building are not supplied with sufficient

combustion air. A wood stove or furnace can pull its

combustion air from the heater's vent pipe, allowing the

cold incoming air to freeze the cold water in the heat

exchanger. Supplying more combustion air for all

combustion appliances is the solution. A HVAC

specialist should be consulted to design solutions for

providing more combustion air. Observe the following

guidelines:

Installations in structures that have been tightly

constructed (air infiltration rate of 0.40 ACH or less)

must be provided with combustion air per the National

6 720 608 263

9

Page 10

Installation instructions

Fuel Gas Code. Consult a HVAC specialist if your air

infiltration rate is questionable.

The space must have two permanent openings, one

commencing within 12 inches of the top and one

commencing within 12 inches of the bottom of the

enclosure. Each opening must have a minimum free

area of one square inch per:

• 1000 Btu/hr if all air is taken from inside the building

• 2000 Btu/hr if all air is taken from the outside by

horizontal ducts

• 4000 Btu/hr if all air is taken from the outside by

direct openings or vertical ducts.

Or the space must be provided with one permanent

opening or duct that is within 12 inches of the ceiling of

the enclosure. This opening must have a minimum free

area of one square inch per:

• 3000 Btu/hr if all air is taken from the outside by a

direct opening or vertical duct.

Louvers, grills and screens have a blocking effect. If the

effective free area is not known, increase the sizes of

your openings by 300% if your louvers are wood and by

35% if your louvers are metal. Refer to the National Fuel

Gas Code for complete information.

10

6 720 608 263

Page 11

Installation instructions

3.6 Venting

Danger: Do not combination vent this

appliance with any other appliance.

Warning: Do not reduce the vent

(exhaust and combustion) pipe sizes

and do not common vent with any other

vented appliance or stove.

Warning: Failure to vent the exhaust

gases to the outside with sealed

stainless steel vent pipe (AL29-4C)

may result in dangerous flue gases

filling the space in which it is installed.

Warning: Single wall exhaust pipe

MUST be chased through double wall

Type-B vent when passing through an

unconditioned space.

Warning: The vent system must be

installed by a qualified individual in

accordance with these instructions. If

improperly installed a hazardous

condition such as explosion or carbon

monoxide poisoning could result.

Bosch Water Heating will not be

responsible for improperly installed

appliances.

permitted in the total vent length), or subtract 11/4

feet for every 45° elbow used. Horizontal sections of

vent must pitch upwards from heater ¼" for every foot

of horizontal length, to prevent the pooling of

condensate, and be supported at 4 foot intervals with

overhead hangers. See Table 2.

Exhaust Vent

Intake Vent

Diameter Minimum

3 or 4

inches

3 or 4

inches

length

3 feet

1 90° elbow

Maximum

length

26 feet with

1 90°

elbow

26 feet with

1 90°

elbow

Material

Sealed single

wall stainless

steel (AL29-4C)

Sealed

aluminum flex,

PVC or any

other rigid or

semi rigid pipe

Table 2 Venting specifications

Minimum exhaust vent size and length

The minimum exhaust vent length is

3 feet.

The use of a 90 degree elbow is

equivalent to 2 ½ ft in vent length.

The use of 45 degree elbow is

equivalent to 1 ¼ ft in vent length.

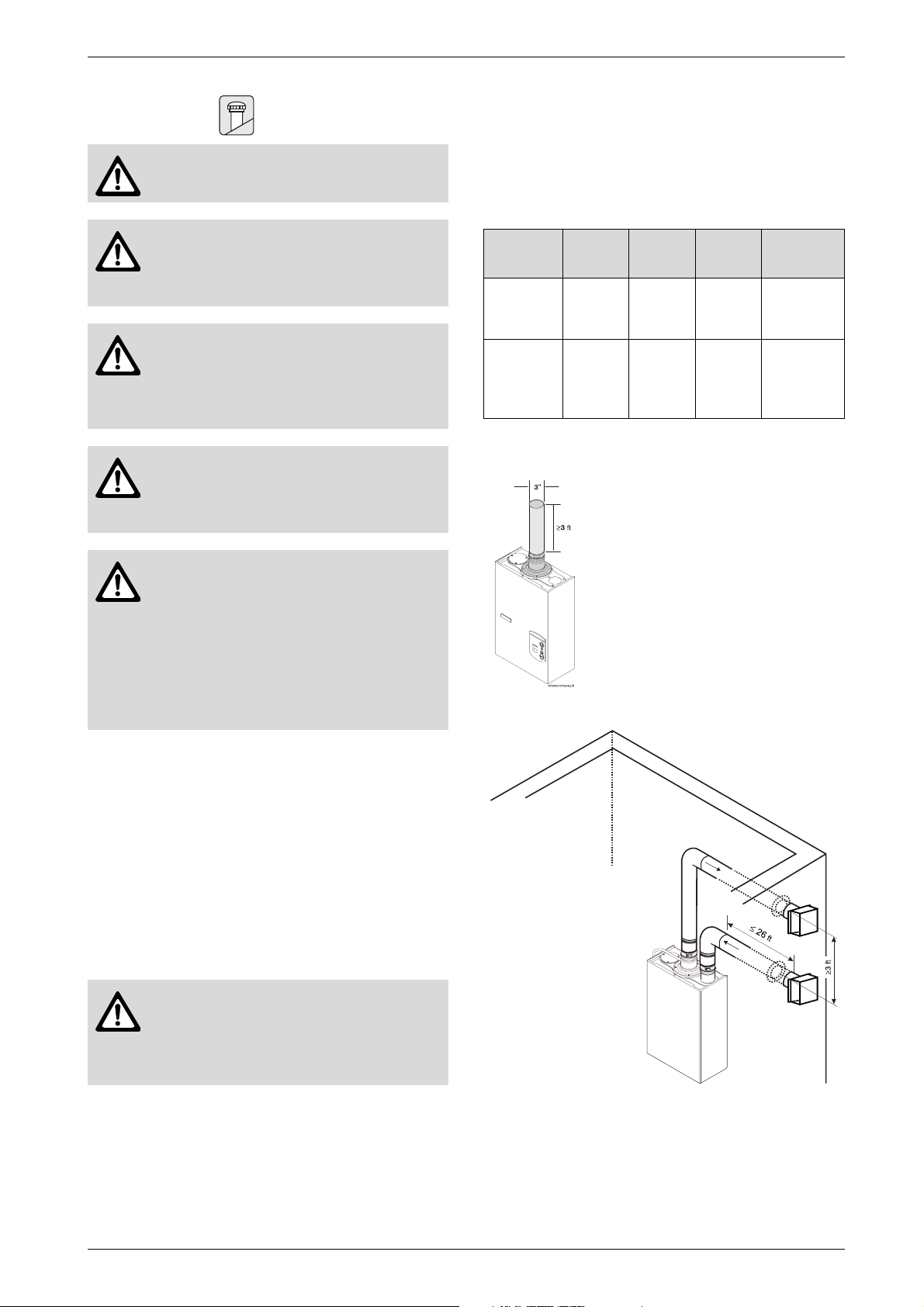

Fig. 8 Minimum exhaust vent length

3.6.1 Vent material and specifications

Establish vent clearances that comply with the vent

manufacturer's specifications. In all cases follow local

codes.

Note: Listed thimbles or collars are necessary to pass

through wall and ceiling partitions. If the vent system

passes through combustible areas where the vent

clearance requirements cannot be maintained, it is

permissible to chase straight sections of sealed 3 inch

single wall vent through 4 inch (or greater) Type-B vent.

The distance to combustibles using this chase

technique is 1 inch (check local codes).

Warning: Type-B vent must never be

used as the actual exhaust vent system

for the appliance, because it is not gas

tight. This will create a serious health

hazard and void the warranty.

Vent lengths

The appliance should be located as close to the point

of termination as possible. The maximum vent length is

26 feet (8 m) with one 90 degree elbow. Subtract 2½

feet from the total vent length for each additional 90°

elbow used (a maximum of three 90° elbows are

Reduce maximum

length 2 ½ ft for

each 90 elbow after

the first one and 1 ¼

ft for each 45 elbow.

Fig. 9 Maximum vent and combustion air lengths

Vent material

The 2400 E requires 3 or 4 inch sealed single wall

stainless steel vent pipe (AL29-4C). Use of any other

vent material will void the manufactures warranty and

6 720 608 263

11

Page 12

Installation instructions

may result in a hazardous condition. For specific

questions concerning vent material, specifications,

usage or installation, contact the vent manufacturer

directly.

Vent manufacturer Contact information

Z-flex www.z-flex.com

800-654-5600

ProTech Industries www.protechinfo.com

800-766-3473

Heat-Fab www.heatfab.com

800-772-0739

Table 3 Vent manufacturer contact information

Z flex ProTech Heat Fab

3” Venting

3” Horizontal

termination

3” Vertical

termination

90°

Condensate

Drain Tee

2SVSTB03 FSTB3 9390 TEE

2SVSRCF03 FSRC3 5300CI

2SVEVWCF03

FST3 &

FSDF3

93PPLSTEE

page 33. Correct the problem and then reset the heater

before operating.

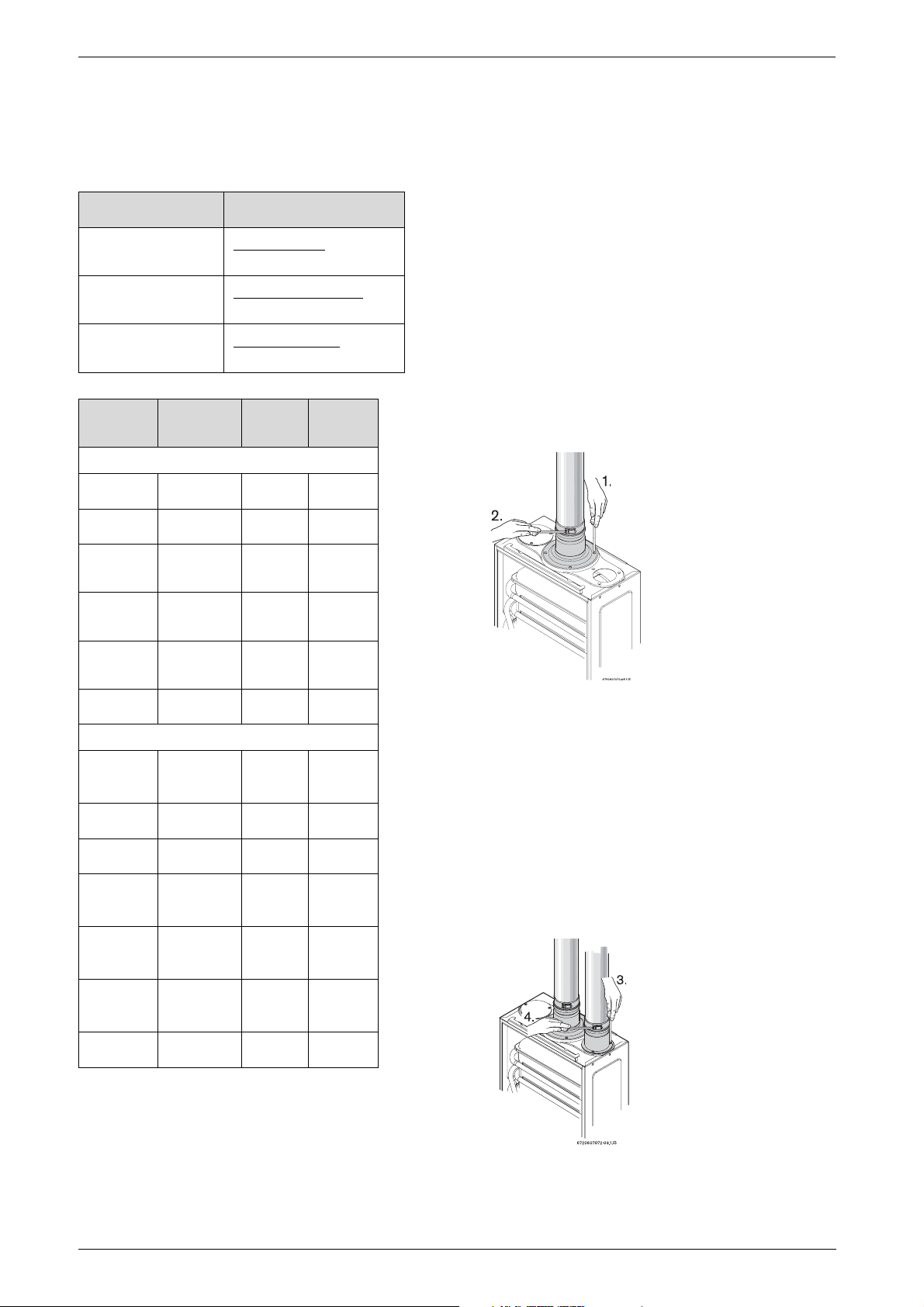

3.6.2 Vent connections

Exhaust vent connection

B Attach the flue gas exhaust accessory (8 705 504

137) to the top of the unit (position 1) using the 4

screws and gasket provided.

B Insert single wall stainless steel vent pipe into the

exhaust vent adapter 1.5” and tighten the clamp ( Fig.

10 position 2).

Note: 3 to 4 inch increaser required when using 4 inch

pipe.

Note: Failure to fully insert vent pipe and tighten clamp

may cause flue gas leakage or condensate damage that

is not covered under the manufacturer's warranty.

Horizontal

Condensate

Drain

Vertical

Condensate

Drain

Condensate

Drain Tube

3” to 4”

Increaser

(Required)

4” Horizontal

termination

4” Vertical

termination

90°

Condensate

Drain Tee

Horizontal

Condensate

Drain

Vertical

Condensate

Drain

Condensate

Drain Tube

2SVEDWCF03 FSHDT3 9321

2SVSEVDP03 N/A N/A

2SVEDTK N/A 7000TUBE

4” Venting

2SVI0304 FS0304TI 9374

2SVSRTF04 FSTB4 9490TEE

2SVSRCF04 FSRC4 5400CI

2SVEVWCF04

2SVEDWCF04 FSHDT4 9421

2SVEVDP04 FSUCD4 N/A

2SVEDTK N/A 7000TUBE

FST4 &

FSDF4

9416 &

9417D

Table 4 Approved vent termination and condensate

drain part numbers (subject to change)

Fig. 10 Exhaust vent connection

Combustion air inlet connection

The combustion air inlet accessory can be connected

either to the top right or left of the appliance. The

unused side must be sealed.

B Attach the combustion air inlet accessory (8 705

504 115) to the top of the unit (position 3) using the

3 screws and gasket provided.

B Install combustion air pipe over the air inlet acces-

sory. If using flexible piping, secure with a clamp

(position 4, not included).

Vent Safety System

The 2400 E will shut down if inadequate exhaust

venting is detected or a lack of combustion air is

provided to the unit. See troubleshooting section on

12

Fig. 11 Combustion air inlet connection

6 720 608 263

Page 13

Installation instructions

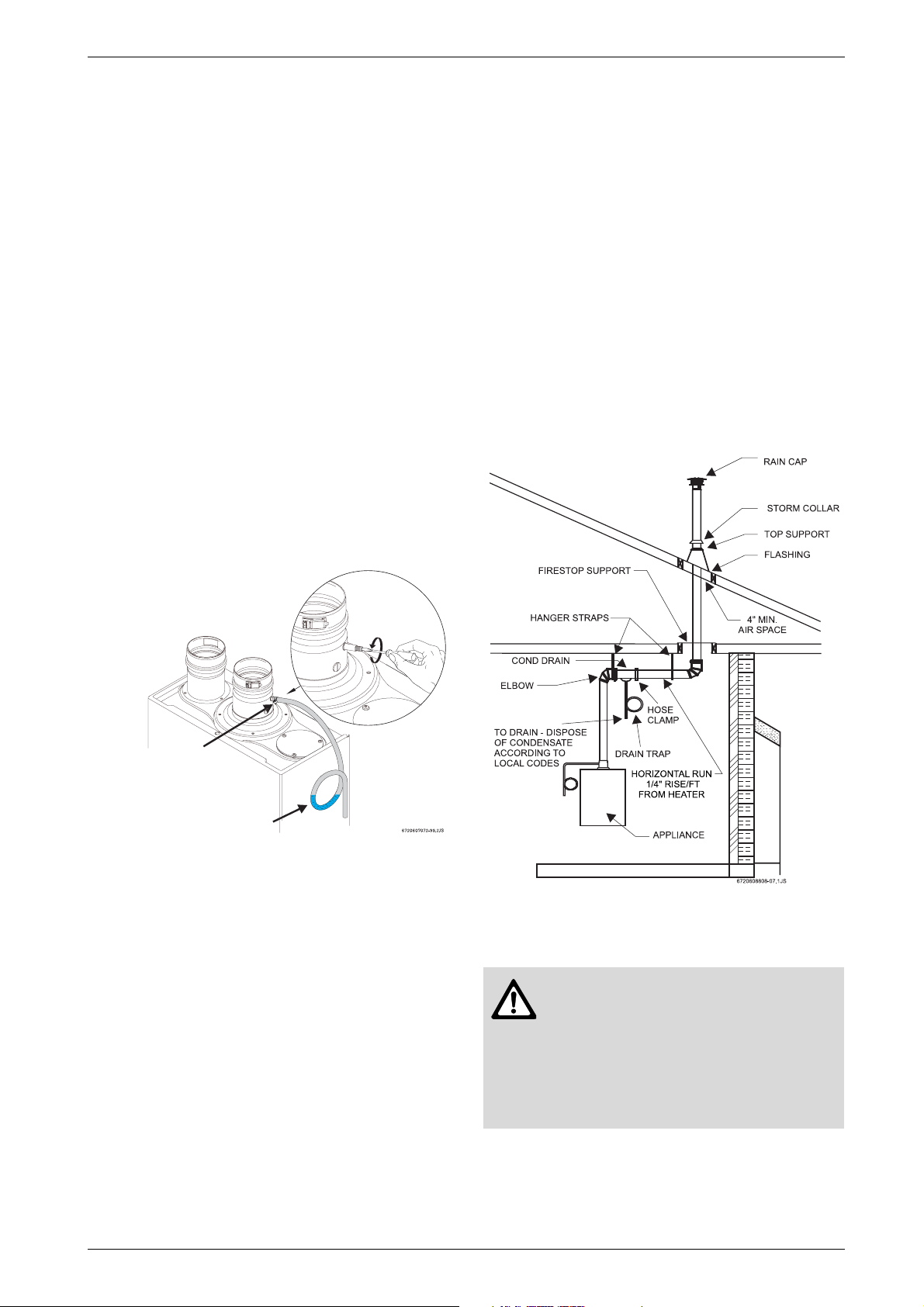

3.6.3 Condensate drain tube requirements

Exhaust collar condensate drain installation

(supplied with heater)

B The condensate drain tube kit must be used for all

installation types. Failure to properly install

condensate drain will void the warranty.

B When installing the condensate drain tube kit on the

exhaust collar (see diagram below), be sure to form a

trap by means of a 3" (76.2 mm) loop partially filled

with water. This loop must be as low as possible to

allow proper drainage of condensate. The supplied

tube is 3/8" ID high temperature silicone and must be

attached to the condensate port on the exhaust collar

with its supplied gear clamp (first remove brass

screw from port).

B To increase tube length, connect vinyl tubing (not

supplied with heater) to the supplied tube. Do not

reduce tubing diameter when using connector or

additional tubing.

B The condensate must be disposed of according to

local regulations.

Condensate port on exhaust collar

Note: Condensate must be disposed of according to

local codes.

Note: Do not install condensate drain in areas where it

may freeze.

1. Install condensate drain as close to heater as

possible.

2. Use 3/8" ID high temperature silicone tubing to

connect to condensate drain port. Do not use copper

piping for any portion of the condensate drain.

3. Form a condensate trap by means of a 3" loop and

fill bottom of loop with water.

4. To increase the tube length, connect to end of the

high temperature silicone tubing with vinyl tubing,

PVC or CPVC pipe. Do not reduce the internal

diameter at any point.

5. Dispose of condensate according to local codes.

1. Remove brass hex head

screw

2. Fit tube with

gear clamp

3. Loop size and location. Coil tube into 3” loop

with nylon tie (don't crimp tubing) and fill bottom

of loop with water

Fig. 12 Exhaust collar condensate drain installation

Note: No part of supplied silicone tube should be

installed above condensate tapping or improper drainage may occur. (see Fig. 12).

External condensate drain installation (not

supplied)

An additional external condensate drain must be

installed under the following conditions:

• Vertical terminating vent installations

• Horizontal terminating vent installations where the

total vent length is greater than 5 feet

• Vent installation where any section of the exhaust

vent pipe passes through an unconditioned space.

Fig. 13 Required condensate drain installation

(Combustion air piping not shown)

3.6.4 Room sealed installation (Twin pipe)

Warning: In areas where outdoor

temperatures commonly fall below

36°F, a twin pipe venting system is

required. Failure to do so may result in

cold outside air being drawn across the

heat exchanger causing it to freeze and

burst. This failure is not covered under

the manufacturer's warranty.

B Although it is permitted to draw combustion air from

inside the structure in warm climates, the recommended method is to provide combustion air through

6 720 608 263

13

Page 14

Installation instructions

a 3" or 4" pipe from the outside. See Chapter 3.5 for

more direction on combustion air.

B To reduce pressure differentials between the exhaust

and combustion air intake, it is recommended that

both terminators exit on the same plane. See Fig. 14

for an example horizontal twin pipe termination and

Fig. 15 for the vertical twin pipe termination example.

Fig. 14 Horizontal twin pipe termination

B Use of two 90° elbows (candy-cane) is an accepta-

ble termination for combustion air intake from the

roof. See Fig. 15 for an example.

B Screening (no smaller than 1/4" mesh) is recom-

mended on candy cane termination.

B Exhaust should terminate above and must be a mini-

mum of 3 feet from must intake termination.

B The exhaust vent must terminate above the roof sur-

face with an approved vent cap not less than 3 feet

(0.6 m) above the highest point where it passes

through the roof and at least 2 feet (0.6 m) higher

than any vertical wall or similar obstruction within 10

feet (3.1m). See Fig. 16 and Table 5.

Fig. 15 Vertical twin pipe termination

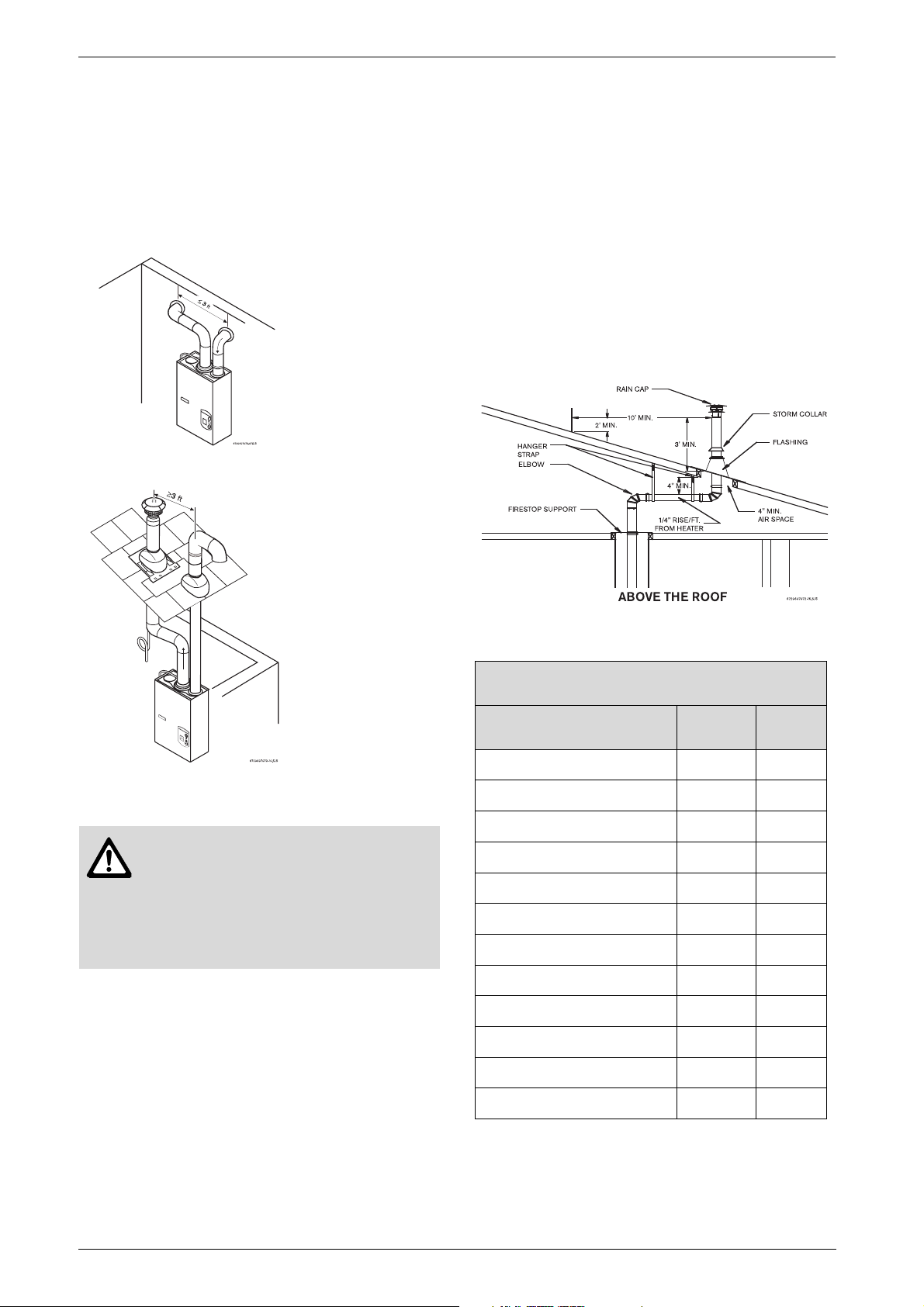

3.6.5 Vertical terminations

Warning: Failure to install a

condensate drain may result in damage

not covered by the manufacturer's

warranty. See chapter 3.6.3.

An approved vent terminator must be

used. See Table 5 for known approved

vertical vent terminations.

Horizontal runs

Any gas vent section that is greater than 45 degrees

from the vertical is considered horizontal. Horizontal

sections must slope upwards from heater at least ¼

inch for every foot of its horizontal length and be properly supported to allow condensate to be collected by

condensate drains.

Vent terminations

B No pipe joints other than the termination connections

should be exposed to the outdoors. See vent manufacturer instructions for details.

Fig. 16 Vertical vent terminations clearances

(Combustion air piping not shown)

GAS VENT TERMINATIONS FOR LISTED VENT

CAPS

Roof pitch H (min.)

feet

Flat to 6/12 1.0 0.30

6/12 to 7/12 1.25 0.38

Over 7/12 to 8/12 1.5 0.46

Over 8/12 to 9/12 2.0 0.61

Over 9/12 to 10/12 2.5 0.76

Over 10/12 to 11/12 3.25 0.99

Over 11/12 to 12/12 4.0 1.22

Over 12/12 to 14/12 5.0 1.52

Over 14/12 to 16/12 6.0 1.83

Over 16/12 to 18/12 7.0 2.13

Over 18/12 to 20/12 7.5 2.27

Over 20/12 to 21/12 8.0 2.44

meters

Table 5 Termination heights at various roof pitches

Interior masonry chimneys

The single wall stainless steel exhaust vent pipe must

be permanently mounted inside the masonry chimney.

14

6 720 608 263

Page 15

Installation instructions

The masonry chimney may have to be tile or metal lined

before the insertion of the gas vent pipe; check local

codes for clarification. You may not vent any other fuel

burning appliances into any free space remaining in the

chimney. The vent terminator must extend at least 3 feet

(0.9 m) above where the chimney meets the roofline and

at least 2 feet (0.6 m) higher than any vertical wall or

similar obstruction within 10 feet (3.1 m). The top of the

chimney must be sealed to prevent rain water or other

elements from entering the chimney.

Exterior masonry chimneys

Refer to the National Fuel Gas Code and consult a local

venting HVAC contractor. Not recommended in cold

climates.

3.6.6 Horizontal terminations

• For horizontal vent runs less than 5 linear feet, the

entire vent run must pitch down to termination 1/4"

per foot to eliminate the danger of rain from entering

the venting system.

• The exhaust vent must terminate immediately once it

penetrates the outside wall.

• An approved vent terminator must be used. See

Table 4 for known approved horizontal vent

terminations.

• Install an additional condensate drain (not supplied)

if the total straight vent length is greater than 5 feet

or if the exhaust vent pipe passes through an

unconditioned space.

• Terminating the intake air piping above the exhaust

termination is not recommended.

• Fig. 17 and table 6 show the required clearances for

the vent termination. Follow local codes if more

stringent.

3.6.6.1 Attention residents of the Commonwealth

of Massachusetts:

In the Commonwealth of Massachusetts the following

regulation went into effect on 12/30/2005:

(a)For all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure

used in whole or in part for residential purposes, including those owned or operated by the Commonwealth

and where the side wall exhaust vent termination is less

than seven (7) feet above finished grade in the area of

the venting, including but not limited to decks and

porches, the following requirements shall be satisfied:

1. INSTALLATION OF CARBON MONOXIDE DETEC-

TORS. At the time of installation of the side wall horizontal vented gas fueled equipment, the installing

plumber or gasfitter shall observe that a hard wired

carbon monoxide detector with an alarm and battery

back-up is installed on the floor level where the gas

equipment is to be installed. In addition, the installing

plumber or gasfitter shall observe that a battery operated or hard wired carbon monoxide detector with an

alarm is installed on each additional level of the dwelling, building or structure served by the side wall horizontal vented gas fueled equipment. It shall be the

responsibility of the property owner to secure the

services of qualified licensed professionals for the

installation of hard wired carbon monoxide detectors.

a. In the event that the side wall horizontally vented

gas fueled equipment is installed in a crawl space or

an at tic, the hard wired carbon monoxide detector

with alarm and battery back-up may be installed on

the next adjacent floor level.

b. In the event that the requirements of this subdivision can not be met at the time of completion of

installation, the owner shall have a period of thirty

(30) days to comply with the above requirements;

provided, however, that during said thirty (30) day

period, a battery operated carbon monoxide detector

with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS.

Each carbon monoxide detector as required in

accordance with the above provisions shall comply

with NFPA 720 and be ANSI/UL 2034 listed and IAS

certified.

3. SIGNAGE. A metal or plastic identification plate shall

be permanently mounted to the exterior of the building at a minimum height of eight (8) feet above grade

directly in line with the exhaust vent terminal for the

horizontally vented gas fueled heating appliance or

equipment. The sign shall read, in print size no less

than one half (1/2) inch in size, "GAS VENT

DIRECTLY BELOW. KEEP CLEAR OF ALL

OBSTRUCTIONS".

4. INSPECTION. The state or local gas inspector of the

side wall horizontally vented gas fueled equipment

shall not approve the installation unless, upon

inspection, the inspector observes carbon monoxide

detectors and signage installed in accordance with

the provisions of 248 CMR 5.08(2)(a)1 through

4.

(b) EXEMPTIONS: The following equipment is

exempt from 248 CMR 5.08(2)(a)1 through

4:

1.The equipment listed in Chapter 10 entitled

"Equipment Not Required To Be Vented" in the most

current edition of NFPA 54 as adopted by the Board;

and

2. Product approved side wall horizontally vented

gas fueled equipment installed in a room or structure

separate from the dwelling, building or structure

used in whole or in part for residential purposes.

(c) MANUFACTURERS REQUIREMENTS - GAS

EQUIPMENT VENTING SYSTEM REQUIRED.

When the manufacturer of Product Approved side

wall horizontally mounted gas equipment provides a

venting system design or venting system components with the equipment, the instructions provided

by the manufacturer for the installation of the equipment and the venting shall include:

6 720 608 263

15

Page 16

Installation instructions

1. Detailed instructions for the installation of the venting system or the venting system components: and

2. A complete parts list for the venting system design

or venting system.

(d) MANUFACTURER REQUIREMENTS - GAS

EQUIPMENT VENTING SYSTEM NOT PROVIDED.

When the manufacturer of a product approved side

wall horizontally vented gas fueled equipment does

not provide the parts for the venting of flue gases, but

identifies "special venting systems," the following

requirements shall be satisfied by the manufacturer:

1. The referenced "special venting system" instructions shall be included with the appliance or equipment installation instructions; and

2. The "special venting systems" shall be product

approved by the Board, and the instructions for that

system shall include a parts list and detailed installation instructions.

(e) A copy of all installation instructions for all products approved side wall horizontally vented gas

fueled equipment, all venting instructions, all parts

lists for venting instructions, and/or all venting design

instructions shall remain with the appliance or equipment at the completion of the installation.

16

6 720 608 263

Page 17

Recommended exhaust vent terminator clearances

Fig. 17

Installation instructions

Ref. Description Minimum distance

A

B

C From any internal corner 12 in

D*

E

F From a terminator facing a terminator 48 in

G Vertically between two exhaust vent terminators on the same wall 60 in

H Horizontally between two exhaust vent terminators on the same wall 12 in

I**

J From any external corner 12 in

K

Directly below an opening; operable windows, doors and any nonmechanical fresh air openings

Below a gutter, sanitary pipework or eaves 24 in

Below a gutter, sanitary pipework or eaves, protected by metal

shielding

Above ground or snow pack 12 in

Above a paved sidewalk 7 ft

From an opposing wall or structure facing the termination 24 in

From the relief valve of a gas regulator 36 in

Horizontally and vertically from combustion air inlet of a twin pipe

system

From the gravity combustion air inlet any other equipment 48 in

Horizontally from an opening; operable windows, doors and any nonmechanical fresh air openings

36 in (twin pipe installation)

48 in (single pipe installation)

12 in

36 in

12 in (twin pipe installation)

48 in (single pipe installation)

L

Vertically from a wall, roof slope, or obstruction (venting through a flat

or pitched roof)

see Chapter

3.6.5

Table 6

* Subject to local codes and anticipated snow level

** Other equipment that operates with a mechanical air inlet may require greater distances, reference manufacturer's instructions

NOTE: terminating exhaust vent under a deck is not recommended

6 720 608 263

17

Page 18

Installation instructions

3.6.7 Exhaust vent configuration examples

Supporting the exhaust vent system

Fig. 18 Horizontal side wall venting installation

(combustion air piping not shown)

Note: Pitch venting up 1/4" per foot to termination and

add additional condensate drain for vent runs longer

than 5 linear feet.

Note: Pitch venting down 1/4" per foot to termination

for vent runs less than 5 linear feet.

Note: For horizontal terminations, venting must

terminate once it penetrates to the outside of the

structure. There should be no sections of vent pipe

exposed to the outdoors.

Fig. 20 Vertical venting installation - Interior masonry

Chimney (combustion air piping not shown)

Fig. 19 Vertical venting installation (combustion air

piping not shown)

18

6 720 608 263

Page 19

Installation instructions

3.7 Gas piping & connections

Before connecting the gas supply, check the rating

plate on the right side of the heater to be sure that the

heater is rated for the same gas to which it will be

connected.

In the United States: The installation must conform with

local codes or, in the absence of local codes, the

National Fuel Gas Code ANSI Z223.1/NFPA 54.

In Canada: The Installation must conform to CGA B149

INSTALLATION CODES and/or local installation

codes.

Warning: DO NOT connect to an

unregulated or high pressure propane

line or to a high pressure commercial

natural gas line.

Warning: The heater must be isolated

from the gas supply piping system

during any pressure testing of that

system at test pressures equal to or

more than 0.5 psig. If overpressure has

occurred, such as through improper

testing of the gas lines or malfunction of

the supply system, the gas valve must

be checked for safe operation.

manufacturer’s sizing tables to determine the pipe

diameter necessary to accommodate the 175,000 BTU

demand of the heater. If there are more gas drawing

appliances on the line, size the gas line according to the

total maximum amount of BTU draw for all appliances.

Note: Under sizing the gas line may result in diminished

output and improper operation. See chapter 3.8 for the

procedure to confirm gas pressure. Proper gas

pressure must be confirmed at time of installation.

Inlet gas particle screen

Gas piping

Fig. 21

GAS CONNECTIONS

B Install a manual gas shut off valve on the gas supply

line.

B Install a union when connecting gas supply.

B The minimum diameter required for any appliance

connector used is ¾” ID.

B National Fuel Gas Code requires that a sediment

trap (drip leg) be installed on gas appliances not so

equipped. The drip leg must be accessible and not

subject to freezing conditions. Install in accordance

with the recommendations of the serving gas

supplier.

Once connections are made, check for gas leaks at all

joints. Apply some gas leak detection solution to all gas

fittings. Bubbles are a sign of a leak. A combustible gas

detector may also be used to detect for leaks.

Danger: If you have a leak, shut off the

gas. Tighten appropriate fittings to stop

leak. Turn the gas on and check again

with a gas leak detection solution.

Never test for gas leaks using a match

or flame.

GAS LINE SIZING

The gas supply piping should be sized for a maximum

draw of 175,000 BTUH. Measure the length of gas

supply line and use the tables in Fig. 22 or the gas line

6 720 608 263

19

Page 20

Installation instructions

D

D

D

D

FOR NATURAL GAS

Maximum Capacity of pipe in Cubic Feet of Gas per Hour for Gas Pressure of 0.5 Psig or less and a Pressure drop

of 0.3” in Water Column (0.75mbar).(Based on a 0.60 Specific Gravity Gas) Btu numbers given in thousands.

Follow boxed numbers for piping just one 2400 E (example: ¾” B.I. Natural Gas pipe for 20 ft (6.1m). will

handle 190,000 btu’s (55.7 kWh). For multiple appliances combine the total btu input load and then refer to

applicable chart below.

Nominal

Iron

Pipe Internal

Size, Diameter

inches inches 10 20 30 40 50 60 70 80 90 100 125 150 175 200

1/4 0.364 32 22 18 15 14 12 11 11 10 9 8 8 7 6

3/8 0.493 72 49 40 34 30 27 25 23 22 21 18 17 15 14

1/2 0.622 132 92 73 63 56 50 46 43 40 38 34 31 28 26

3/4 0.824 278 190 152 130 115 105 96 90 84 79 72 64 59 55

1 1.049 520 350 285 245 215 195 180 170 160 150 130 120 110 100

1 1/4 1.380 1050 730 590 500 440 400 370 350 320 305 275 250 225 210

1 1/2 1.610 1600 1100 890 760 670 610 560 530 490 460 410 380 350 320

2 2.067 3050 2100 1650 1450 1270 1150 1050 990 930 870 780 710 650 610

Length of Black Iron Pipe, Feet

Length of Flexible C orrugated Stainless Steel Tub ing (CSST), Feet

Tube

size,

inches EHD*

1/2 18 EHD 82 58 47 41 37 34

3/4 23 EHD 161 116 96 83 75 68

1 30 EHD 330 231 188 162 144 131

1 1/4 37 EHD 639 456 374 325 292 267

10 20 30 40 50 60

* EHD = Equivalent Hydraulic Diameter. The greater the

value of EHD, the greater the gas capacity of the tubing

.

FOR LP GAS

Maximum Capacity of Pipe in Thousands of BTU per Hour of Undiluted Petroleum Gases (at 11 inches Water Column Inlet

Pressure) (Based on a Pressure Drop of 0.5 Inch Water Column).

* EHD = Equivalent Hydraulic Diameter. The greater the

value of EHD, the greater the gas capacity of the tubing.

Nominal

iron

pipe

Inches

10 20 30 40 50 60 80 100 125 150 200

1/2 291 200 160 137 122 110 94 84 74 67 58

3/4 608 418 336 287 255 231 197 175 155 140 120

1 1145 787 632 541 480 434 372 330 292 265 227

Black Iron Pipe

Length of Pipe, Feet

Length of Flexible Corrugated Stainless Steel Tubing (CSST), Feet

Tube

size

inches EHD*

1/2 18 EH

3/4 23 EH

1 30 EH

1 1/4 37 EH

10 20 30 40 50 60

129 91 74 64 58 53

254 183 151 131 118 107

521 365 297 256 227 207

971 661 528 449 397 359

Maximum Capacity of Semi-Rigid (flexible, non

corrugated) Tubing in Thousands of BTU per Hour of

Undiluted Liquefied Petroleum Gases (at 11 inches

Water Column Inlet Pressure).

(Based on a Pressure Drop of 0.5 Inch Water Column)

* Source National Fuel Gas Code NFPA 54, ANSI

Z223.1 - No Additional Allowance is necessary for an

Outside Length of Tubing, Feet

diameter

Inch 10 20 30 40 50 60 70 80 90 100

3/8 39 26 21 19 _ _____

1/2 9262 50 41 37 3531292726

5/8 199 131 107 90 79 72 67 62 59 55

3/4 329 216 181 145 131 121 112 104 95 90

Copper

ordinary number of fittings

Fig. 22

20

6 720 608 263

Page 21

3.8 Measuring gas pressure

Confirm proper gas pressure upon installation.

Connecting Manometer

B Shut off gas supply at installer supplied shutoff valve.

B Remove front cover and locate inlet gas pressure

measuring point (see Fig. 24).

B Loosen screw inside left test point fitting (do not

remove) and connect manometer tube to test point.

Remove screw completely if correct size adapter is

available.

Installation instructions

Fig. 24 Gas pressure measuring (left tapping)

Static Gas Pressure Reading (see Chapter 3.8)

Static Pressure Test

B Turn gas supply back on.

B Operate all other gas appliances (except heater) on

same gas piping system at maximum output.

B Record static gas pressure reading in table 7.

Operating Pressure Test

B ON/OFF switch in position OFF (0).

B Press and hold "Program" (P) button and turn ON/

OFF switch to ON position.

Fig. 23

B As soon as '188' is displayed, release "Program"

, button and the display should read P2.

enter here: ___________________ Date: ___________

Operating Gas Pressure Reading (see Chapter 3.8)

enter here: ___________________ Date: ___________

Table 7

HIGH ALTITUDE OPERATION

Altitude Natural

0 - 4,000 ft

(0 - 1,219 m)

4,000 ft - 7,000 ft

(1,219 m - 2,134 m)

Above 7,000 ft

(above 2,134 m)

Gas:

no

modification

adjustment with flue

CO

2

gas analyzer required See

section

5.4 for instructions.

Liquid

Propane:

no

modification

Not approved

For operation at

elevations

above 2,000 ft

(610 m) the

equipment

ratings shall be

reduced at the

rate of 4% for

each 1,000 ft

(305 m) above

sea level

Table 8

B Press until P1 appears.

Note: While in this mode the appliance will run

constantly at maximum power and allow maximum water

flow.

B Turn on a high volume of hot water (at least 4 gpm)

and heater will ignite. If heater display reverts to P2,

open more hot water fixtures to allow sufficient flow.

Press until P1 reappears on display.

B Record lowest operating gas pressure reading in

table 7.

Gas pressures lower than 5" W.C. for Natural Gas or

11" W.C. for LPG will result in insufficient degree rise

to the hot water being used, possible error code faults

and must be corrected. See Gas Connections,

chapter 3.7.

6 720 608 263

21

Page 22

Installation instructions

3.9 Water connections

Warning: This heater must be supplied

with cold potable water. It is not

approved for preheated water

applications. See chapter 3.12 for

approved recirculating application.

Warning: In areas where the water

supply has a high mineral content, a

water softener is strongly

recommended. Damage to the water

heater resulting from hard water/scale

deposits will not be covered under

warranty.

B When facing the heater, the ¾” cold inlet connection

is on the bottom right and the hot connection is on

the bottom left. Centrally locating the water heater is

recommended to keep hot water distribution times

even throughout the structure.

or flush the lines before connecting to the water

heater.

B Full port shutoff valves should be installed on both

the cold water supply and hot water outlet lines to

facilitate servicing the heater (see Fig. 26).

Note: If water flow or pressure is low, or heater does

not ignite, check the water inlet filter screen for debris

(see Chapter 5.1).

Connecting the pressure relief valve (PRV)

A listed pressure relief valve supplied with the heater

must be installed at the time of installation. No valve is

to be placed between the PRV and the heater. No

reducing coupling or other restriction may be installed

in the discharge line. The discharge line must be a

minimum of 4” above a drain and installed such that it

allows complete drainage of both the PRV and the line.

The location of the PRV must be readily accessible for

servicing or replacement, and be mounted as close to

the water heater as possible. See Fig. 26. To install the

PRV, a suitable fitting connected to an extension on a

“T” fitting can be sweated to the hot water line.

Support all piping.

INLET

FILTER

UNION

(not supplied with

heater)

HOT

COLD

Fig. 25

B The use of unions when connecting both water pipes

to the cold and hot water connections is required.

This will facilitate any necessary servicing.

B Plastic or PEX type plumbing line materials are not

suitable for connecting directly to the water heater.

B Although water piping throughout the building may

be other than copper, we recommend that copper or

suitably rated stainless steel flex line piping be used

for the water connections for 1.5’ on either side of

the water heater (follow local codes if more stringent).

B Never sweat any rigid piping directly to or beneath

the water connections, as damage can occur to the

internal water valve from heating of the pipe.

B Keep water inlet and outlet pipes to no less than ¾"

(19.05mm) diameter to allow the full flow capacity.

B If the cold and hot connections to the heater are

reversed, the heater will not function. Be certain there

are no loose particles or dirt in the piping. Blow out

Fig. 26 Plumbing connections (with isolation valves)

and pressure relief valve

22

6 720 608 263

Page 23

3.10 Electrical connections

Installation instructions

Warning: For safety reasons,

disconnect the power supply cord to

the heater before any service or testing

is performed.

Warning: This heater must be

electrically grounded in accordance

with the most recent edition of the

National Electrical Code NFPA 70. In

Canada, all electrical wiring to the

heater should be in accordance with

local codes and the Canadian Electrical

Code, CSA C22.1 Part 1. Do not rely

on the gas or water piping to ground the

metal parts of the heater.

The 2400 E requires an electrical power supply from a

120VAC / 60Hz circuit (with a dedicated outlet) and

must be properly grounded.

A means for switching of f the 120VAC power supply

must be provided.

The heater is wired as shown in the wiring diagram

(chapter 7, Fig. 44).

3.12 Recirculation application

Since recirculation through the heater is not

permissible, the following drawing is provided to outline

a proper recirculation application using the Aquastar

water heater with an Ariston minitank water heater. This

schematic is for illustration only and must not be used

for actual installation without appropriate engineering

and technical advice from a properly licensed

professional in the locality where the installation is

made.

2400

E

Ariston Minitank

Fig. 27 Recirculation application

1 Full port isolation valve

2 Circulator

3 Check valve

4 PRV

5 Expansion tank

The use of a small electric mini-tank water heater (4-6

gallon size) should be used for this application and

designed so the pump will circulate the water through

the mini-tank and the building's hot water return loop

only. Timed or thermostatically controlled operation of

the pump is commonly done. The 2400 E must be

supplied with cold water only and plumbed in line

before the mini-tank water heater. Contact Bosch

Water Heating if further information is needed.

6 720 608 263

23

Page 24

Operation instructions

4 Operation instructions

Fig. 28

1 On/Off switch

2 Reset button

3 Program “ “ button

4 Increasing temperature selector

5 Decreasing temperature selector

6 LCD display

4.1 For your safety, read before operating your water heater

Warning: The front cover of this

appliance must be secured and

properly sealed at all times once vent

pipe and water connections are made.

Failure to do so may result in freezing

(not covered under warranty), improper

fuel air mixture or error code faults.

Warning: If you do not follow these

instructions exactly, a fire or explosion

may result causing property damage,

personal injury or loss of life.

A. This appliance is equipped with electronic ignition for

lighting the main burners. When turning the heater on,

follow these instructions exactly.

B. Before operating the unit, set the On/Off switch to

the On ( I ) position.

B Immediately call your gas supplier from a neighbors

phone. Follow the gas supplier’s instructions.

B If you cannot reach your gas supplier, call the fire

department.

C. Use only your hand to turn the on/off control switch.

Never use tools. Follow these instructions exactly. If

control switch is jammed, close the gas supply and call

Bosch Technical Support. Attempted forceful repair

may result in a fire or explosion.

D. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

4.2 Power

On

B To start the appliance move the on/off switch to the

"on" position (I).

LCD will display the default temperature factory

setting 122°F (50°C).

WHAT TO DO IF YOU SMELL GAS

B Do not try to light any appliance.

B Do not touch any electric switch; do not use any

phone in your building.

24

Fig. 29

6 720 608 263

Page 25

Off

B To shut down the appliance move the on/off switch to

the “off” position (0).

4.3 Temperature selection

To select output water temperature:

B Press buttons and in order to reach desired

temperature.

Operation instructions

Fig. 30

If the outlet water temperature is set too high, the heater

can produce temperatures that are too hot. A

temperature balance shower valve will automatically mix

in cold water to reduce such hot water temperature. In

the event of any temperature fluctuation with the use of

a temperature balance shower valve, refer to shower

valve manufacturer's instructions for internal adjustment

setting. Adjustments should be made to the hottest

setting in the shower valve. Additionally the temperature

control of the heater can be lowered to produce a more

comfortable hot water temperature.

6 720 608 263

25

Page 26

Operation instructions

Setting the water temperature

The desired temperature of the hot water can be adjusted on the front control panel of the heater.

The 2400 E has an electronically controlled gas valve that modulates the burner input in response to both varying hot

water flow rates and/or changes in any incoming and outgoing water temperatures.

Note: selected temperature on heater’s display will blink until that temperature has been reached.

Fig. 31 Flow/temperature chart

Note: Low flowing fixtures are the leading cause of

temperature overshoot. To combat this symptom, clean

aerators and shower heads or replace with higher

flowing fixtures if necessary.

26

6 720 608 263

Page 27

Operation instructions

4.4 Use of optional remote control

accessory

Fig. 32 Remote control

The wireless remote control accessory and the

temperature selector buttons on the front of the water

heater operate identically. Contact your installer or

distributor to order the remote control accessory.

Modification of the water heaters interior control unit

(Fig. 48, component 25) is required when installing the

remote control with this heater.

NOTE: up to 6 remote controls can be

programmed for one single water heater,

i

each with a range distance of 98 ft (30 m).

B press reset button in order to return heater to normal

operation.

Fig. 35 Reset button

If the problem persists or error code will not reset,

contact your installer.

4.7 Program button

The program button can be used on the appliance and

on the remote control.

Programming “Program” function

Programming actions are similar for both controls

(appliance control pad and wireless remote control).

4.5 Operation

B When a hot water tap is opened, main burner ignites

and LCD displays indication .

Fig. 33

B LCD blinks until selected temperature is reached.

If display blinks continously, heater cannot maintain

or achieve selected temperature.

4.6 Reset button

If the LCD displays the error symbol and error code

do not shut off power or unplug the heater.

Record the error code displayed on LCD and consult

“Troubleshooting” section (Section 6.8, page 36).

Fig. 36 “Program” button

B Press buttons or to select temperature to be

memorized.

B Hold “Program” button for 3 seconds to save

temperature.

When LCD stops blinking, selected temperature has

been memorized.

Using “Program” function

In order to select memorized temperature

B Press “Program” key.

LCD shows pre-memorized temperature, which is now

the hot water selected temperature.

4.8 Locked condition

This condition is only valid for appliances utilizing one or

more remote controls.

Fig. 34

After following instructions indicated in

“Troubleshooting” section:

6 720 608 263

Fig. 37 Locked condition

Whenever LCD shows the temperature setting

cannot be adjusted because the appliance is in use by

a user which already selected a different temperature.

Appliance will be automatically unlocked after closing

hot water tap.

27

Page 28

Maintenance and service

5 Maintenance and service

Warning: Always turn off the electrical

power supply, turn off the manual gas

valve and turn off the manual water

control valves when servicing heater.

The unit should be checked once a year by a gas

technician. If repairs are needed, the repairs should be

done by a gas technician

5.1 Annual maintenance

(To remove front cover, see page 5.)

Venting System

• Venting system - inspect inside of flue pipe for any

blockage or restriction. Observe burner flames

during heater operation. Verify that the damper inside

flue gas exhaust accessory is able to move freely.

(Vent pipe must be removed in order to access

damper). Inspect the combustion air inlet pipe for

blockage or debris. Inspect combustion air and

exhaust terminations for blockage or debris.

Combustion chamber

• Inspect burner observation window (Fig. 46, #10) for

cracks or leakage of flue gases. Observe burner

flames during heater operation. Flames should be

steady and blue with no signs of yellowing. Yellow

burner flames are an indication of improper

combustion. Refer to Section 3.5 & 3.6 of this

manual to verify exhaust system and combustion air

supply meets manufacturer's specifications.

Pressure relief valve

• Manually open the pressure relief valve to ensure

proper operation.

Inlet water filter

• Verify the inlet filter screen is clean and undamaged.

The inlet water filter is located within the ¾" cold

water inlet on the bottom right side of the appliance

(See Fig. 38). Close installer supplied cold water

shutoff and remove cold water supply pipe. Remove

filter, clean or replace if damaged.

INLET

FILTER

HOT

Fig. 38

COLD

Descaling

• In areas where the water supply has a high mineral

content, the heat exchanger may need to be flushed

with a descaling solution. Scale build up will shorten

the life of the water heater and damage resulting from

scale is not covered under warranty. Refer to

section 5.3 for detailed instructions on descaling the

heat exchanger.

Heat exchanger

• Inspect heat exchanger fincoil for soot build-up or

blockage. To access fincoil, venting must be

removed from flue gas exhaust accessory. With

venting removed, manually hold open damper and

inspect fincoil below with a flashlight. If there is

evidence of soot build-up or blockage, the heat

exchanger should be removed by a professsional and

cleaned thoroughly. To remove the heat exchanger,

consult service bulletin TWH-G2-22 at

www.boschhotwater.com

.

5.2 Winterizing for seasonal use

Please note that installation instructions state that the

water heater must not be installed in a location where it

may be exposed to freezing temperatures. If the heater

must be left in a space which is likely to experience

freezing temperatures (less than 36° F), all water must

be drained from the heater. If precautions are not taken,

resulting damage will not be covered under the

warranty. NOTE: Use of agents such as anti-freeze is

not recommended as they may cause damage to the

water heater's internal components.

1. Turn on/off switch on the water heater to the off (O)

position and unplug power supply cord. The display

should be blank.

2. Shut off gas supply to heater.

3. Shut off the water supply to the water heater using

installer supplied shutoff valve.

4. Open hot water taps to drain and relieve pressure

from the plumbing system. If water continues to flow

after 5 minutes, a plumbing crossover is present and

must be corrected before proceeding.

5. Disconnect inlet and outlet water pipes from the

water heater. Place a small bucket underneath the

water heater to catch residual water remaining inside

the water heater. Save washers for future use.

6. Using an air compressor, blow short bursts of air

(100 PSI Maximum) through the inlet water connection until there is no water coming out of the outlet

water connection of the heater.

7. Reconnect water fittings and return heater to service

when danger of freezing has passed.

28

6 720 608 263

Page 29

Maintenance and service

5.3 Mineral scale build-up

Periodic descaling may be necessary in areas with high

mineral content in the water. Scale buildup in the heat

exchanger may result in lower flow rates, error codes of

A7 and E9 and boiling sounds in the heat exchanger.

Descaling using a pump

1. Disconnect electrical supply from the water heater.

2. Shut off the water supply to the water heater using

(installer supplied) shut-off valve.

3. Open hot water taps to drain and relieve pressure

from the plumbing system.

4. Drain water from the unit's heat exchanger by

disconnecting inlet and outlet water connections

from the heater.

5. Connect a line (A) from the outlet of the circulating

pump (installer supplied) to the inlet water fitting on

the water heater.

6. Connect another line (B) to the water outlet fitting on

the water heater. Route the other end of this line into

a descaling reservoir.

7. Using a 3rd line (C) from the descaling reservoir,

connect to the inlet side of circulating pump. Install a

filter on the end of the line in the descaling reservoir.

8. Make sure all connections are "hand tight.".

9. Fill reservoir with descaling solution so both lines

inside are submersed. We recommend straight white

vinegar. If using a commercial descalant, refer to

manufacturer's instructions on dilution with water.

10.Operate the circulating pump.

11.Make sure there are no leaks and the solution is

flowing from the descaling reservoir through the

heater and returning to the reservoir.

12.Run solution through the heater until the solution

returning to the descaling reservoir comes out clear.

(Changing to a fresh solution may be necessary

during this process).

13.Disconnect all lines and drain all solution from heat

exchanger. Properly discard of solution.

14.Position a container below the hot water outlet and

reconnect cold water supply. Open cold water

supply shut-off valve and flush heat exchanger with

clean water.

15.Shut cold water shut-off valve and reconnect hot

water line to the water heater.

16.Reconnect electrical supply to unit, open water

isolation valves, and return the unit to service.

Fig. 39

5.4 Adjusting CO

2

The CO2 can only be adjusted by a certified gas

technician with a calibrated CO

analyzer.

2

Caution: One factor that may affect

CO

levels is improper gas pressure.

2

Please see Chapter 3.8 for the

procedure to measure gas pressure

and record your findings below:

Static Gas Pressure: “ WC

P1 Operating Pressure: “ WC

The P1 minimum operating gas pressure is 5" WC for

Natural Gas and 11"WC for Propane. Do not proceed

in adjusting CO

until pressure is at or above these

2

levels, but not to exceed 14” WC.

A. Once Gas Pressure is adequate

B Turn ON/OFF switch to the OFF (O) position.

B Remove brass flat head screw on the exhaust collar

as seen in Fig. 40.

B Insert CO

analyzer probe into the measuring port.

2

The tip of the probe should be in the center of the flue

6 720 608 263

29

Page 30

Maintenance and service

pipe (approx 1.5" inserted). Avoid air gaps between

probe and measuring port as it can alter readings.

Fig. 40 Measuring port

B While holding the Program (P) button, turn the ON/

OFF switch to ON (I) position (see Fig. 41). As soon

as ‘188’ flashes on the display, release the Program

button. The display should now read P2. Press

button until “P1” appears on display.

CO2 level

Nat. Gas

max. input P1 9.7 ± 0.3 %

min. input P2 9.5 ± 0.5 %

LP Gas

max. input P1 10.7 ± 0.3 %

min. input P2 10.5 ± 0.5 %

* Final reading must be confirmed with the front cover on,

CO2 levels increase when the cover is installed.

Max CO

level

300 ppm

300 ppm

Table 9

1. If P1 CO

level is off:

2

B Loosen yellow painted philips screw (1) and cover

should rotate down (2) revealing a recessed brass

slotted screw. Fig. 42.

B Turning the slotted screw counter clockwise will

raise P1 CO

CO

levels. Adjustments to the slotted screw will

2

also change P2 CO

B After bringing the P1 CO

levels and clockwise will lower P1

2

levels.

2

readings in range, press

2

the button to enter the P2 mode. Verify CO

readings in P2 mode.

2

Fig. 41

B. Measuring CO

(Cover Installed):

2

B Open all hot water taps to achieve a flow rate of at

least 4 gallons per minute. (1 tub and 2 sinks should

be sufficient).

B Record the CO

reading in P1 below. (Analyzer

2

reading may take several minutes to stabilize).

B Press the ‘ ’ button until P2 appears. Unit will

ramp down to low fire and the water flow should

decrease.

B Record the CO

P1 CO

Reading: % CO

2

P2 CO2 Reading: % CO

reading in P2 below.

2

2

2