Page 1

GREENSTAR HEATSLAVE EXTERNAL

THE APPLIANCE IS FOR USE WITH KEROSENE ( 28 SECOND

OIL) ONLY

INSTRUCTION MANUAL

GB

12/18, 18/25, 25/32kW

FLOOR STANDING EXTERNAL OIL FIRED CONDENSING COMBINATION

BOILER USING BALANCED FLUE SYSTEM

FOR OPEN VENT AND SEALED CENTRAL HEATING SYSTEMS WITH DOMESTIC MAINS FED HOT WATER

THE APPLIANCE IS FOR USE WITH KEROSENE ( 28 SECOND

OIL) ONLY

GB

INSTRUCTION MANUAL

INSTALLATION COMMISSIONING

& SERVICING

Page 2

INSTALLATION &

SERVICING INSTRUCTIONS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

1

Check List Hardware/Literature pack

Item Qty

Greenstar Heatslave External Installation/Servicing Instructions.........1

Users Instructions............................................................................................1

Hardware Pack.................................................................................................1

100mm Ø Services Duct................................................................................1

Condensate Trap Kit........................................................................................1

Warranty Return Envelope.............................................................................1

Cabinet Key.......................................................................................................1

SYMBOLS USED IN THIS MANUAL:

Domestic hot water

Central heating

Room thermostat

Frost thermostat

Wait time period

Programmer/timer OFF

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE STARTING INSTALLATION.

THESE INSTRUCTIONS ARE APPLICABLE TO THE WORCESTER APPLIANCE MODEL(S)

STATED ON THE FRONT COVER OF THIS MANUAL ONLY AND MUST NOT BE USED WITH

ANY OTHER MAKE OR MODEL OF APPLIANCE.

THE INSTRUCTIONS APPLY IN THE UK ONLY AND MUST BE FOLLOWED EXCEPT FOR ANY

STATUTORY OBLIGATION.

THIS APPLIANCE MUST BE INSTALLED BY A COMPETENT PERSON. FAILURE TO INSTALL

CORRECTLY COULD LEAD TO PROSECUTION.

COMPLYING WITH THE BUILDING R EGULATIONS:

This heating appliance forms part of the controlled services for the building. It is law that all controlled

services for buildings must comply with building regulations. You must be able to satisfy your Local

Authority Building Control Body (LABC) that the work carried out concerning the installation and

commissioning of this heating appliance has been carried out to a satisfactory standard.

OFTEC operate a competent persons scheme and registered installers are able to certify that their

work complies with building regulations. Under the scheme;

OFTEC must be informed about every installation.

OFTEC will issue a building regulations compliance certificate to the householder and will

notify the LABC.

OFTEC provide controlled document forms CD10 and CD11 for use during installation and

commissioning respectively.

Other organisations operate self-certification schemes e.g. NAPIT and BESCA Ltd. and it may be

possible for installers who are members of these organisations to self certify their work.

Alternatively you must submit a building control notice to the LABC before installing any boiler. The

LABC will then arrange regular inspection visits during the work to ensure that the installation

complies with the regulations.

IF YOU ARE IN ANY DOUBT CONTACT THE WORCESTER TECHNICAL HELPLIN E.

DISTANCE LEARNING AND TRAI NING COURSES ARE AVAILABLE FROM WORCESTER.

PLEASE LEAVE THESE INSTRUCTIONS WITH THE COMPLETED COMMISSIONING FORM

AND THE USER MANUAL WITH THE OWNER OR WITH THE APPLIANCE AFTER

INSTALLATION OR SERVICING. THE SERVICE INTERVAL RECORD CAN BE FOUND ON

THE BACK PAGE OF THIS MANUAL.

ABBREVIATIONS USED IN THIS MANUAL:

Ø Diameter

CH Central Heating

DHW Domestic Hot Water

TRV Thermostatic Radiator Valve

IP Ingress Protection

CF Conventional flue

BF Balanced flue

N/A Not allowed

SEDBUK Seasonal Efficiency of Domestic Boilers in the United Kingdom

OFTEC Oil Firing Technical Association for the Petrolium Industry

IEE Institute of Electrical Engineers

LABC Local Authority Building Control Body

STORE THE APPLIANCE IN A DRY AREA PRIOR TO INSTALLATION.

INSTALLATION & SERVICING INSTRUCTIONS

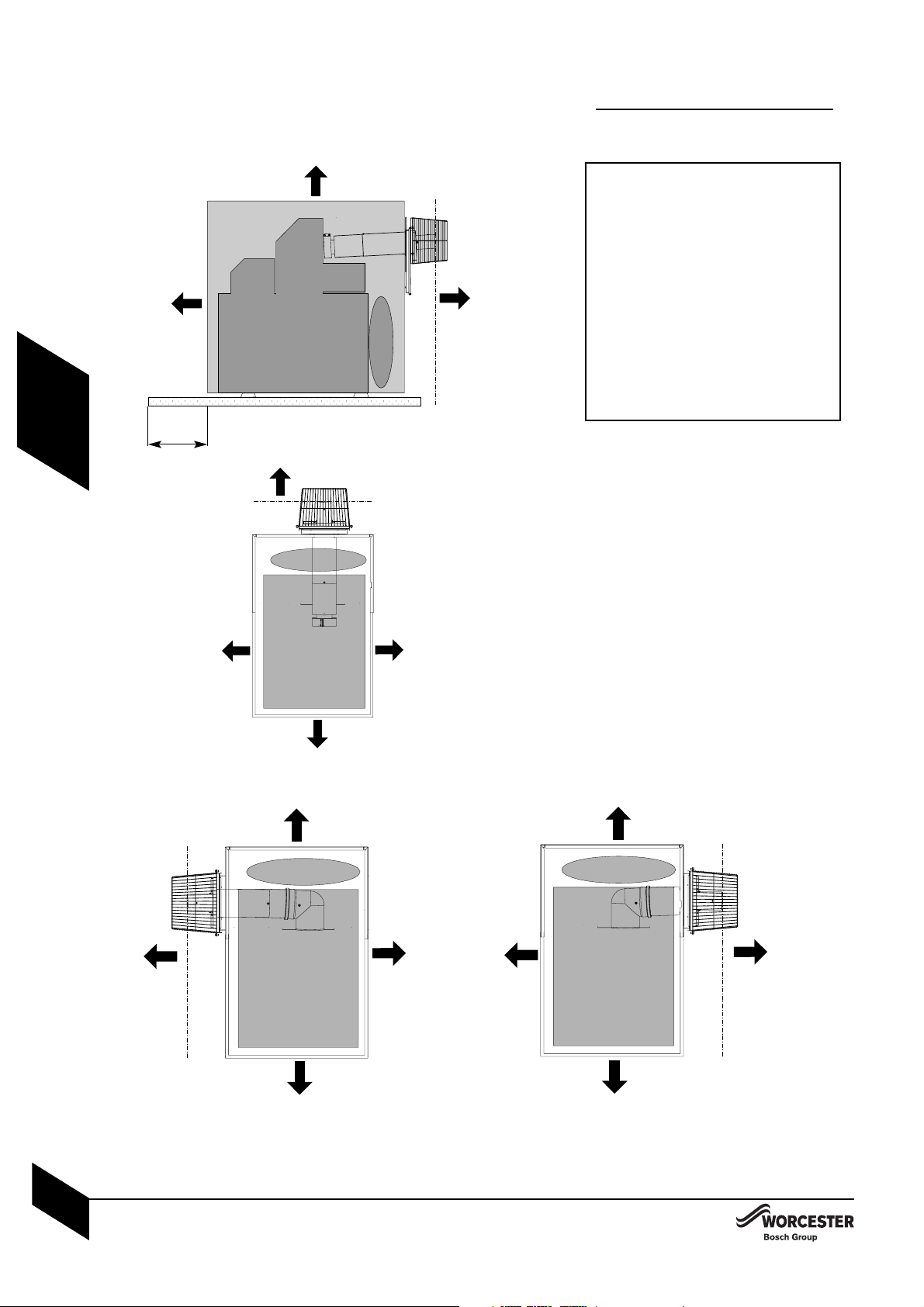

IMPORTANT HANDLING INSTRUCTIONS:

It is advised that more than one person is involved

in the transfer of the packaged appliance from the

van to the point of installation.

It is advised that no attempt should be made to

move the packaged appliance without the use of

a suitable truck.

At all times the correct method for handling

heavy objects should be strictly observed.

GENERAL HANDLING GUIDELINES:

• Lift only a manageable weight, or ask for

help.

• When lifting, bend the knees, and keep the

back straight and feet apart.

• Do not lift and twist at the same time.

• Lift and carry items close to the body.

• Wear protective clothing and gloves to

protect from any sharp edges.

Programmer ON CH only

Programmer ON DHW only

Programmer ON CH and DHW

Cold water main supply

Electricity supply

Page 3

SAFETY & REGULATIONS

IMPORTANT INFORMATION AND SYMBOLS 1

SAFETY PRECAUTIONS AND I NSTALLATION REGULATIONS 3

APPLIANCE INFORMATION

GENERAL INFORMATION 4

TECHNICAL DATA 5

LAYOUT & COMPONENTS 6

PRE-INSTALLATION

CLEANING PRIMARY SYSTEMS 7

MAINS SUPPLIES 8

OIL SUPPLY 9

WATER SYSTEMS & PIPEWORK 10-11

CONDENSATE & PRESSURE RELIEF PIPEWORK 12

BOILER LOCATION & CLEARANCES 13

CABINET MOUNTED LOW LEVEL FLUE TERMINAL POSITIONS 14

HIGH LEVEL FLUE TERMINAL POSITIONS 15

EXTERNAL OILFIT BALANCED FLUE OPTIONS 16

CABINET MOUNTED HORIZONTAL BALANCED FLUE OPTIONS 17

INSTALLATION

UNPACKING THE BOILER 18

PIPEWORK & FLUE POSITIONS 19

BOILER INSTALLATION 20

FLUE INSTALLATION 21

COMBUSTION CHAMBER 22

PIPEWORK CONNECTIONS 23-24

OIL BURNER AND PUMP 25

REFITTING COMPONENTS 26

ELECTRICS 27-28

COMMISSIONING

PRE-COMMISSIONING CHECKS - APPLIANCE 29

FILLING THE SYSTEM 30

STARTING THE APPLIANCE 31-34

WATER TREATMENT 35

FINISHING COMMISSIONING - APPLIANCE 36

SERVICING & SPARES

INSPECTION AND SERVICE 37-40

SHORT PARTS LIST 12/18 41

SHORT PARTS LIST 18/25 42

SHORT PARTS LIST 25/32 43

FAULT FINDING & DIAGNOSIS

FAULT FINDING 44-45

FAULT FINDING LOGIC FOR SATRONIC CONTROL BOX 46

FAULT FINDING LOGIC FOR 535 SE/LD RDB CONTROL BOX 47

ELECTRICAL SCH EMATIC 48

COMMISSIONING & SERVICE RECORDS

COMBUSTION RECORD 49

SERVICE INTERVAL RECORD 50

CONTENTS

CONTENTS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

2

SAFETY &

REGULATIONS

APPLIANCE

INFORMATION

PRE -

INSTALLATION

INSTALLATIONCOMMISSIONING

SERVICING

& SPARES

FAU LT FIND ING

& DIAGRAMS

Page 4

SAFETY PRECAUTIONS

& INSTALLATION REGULATIONS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

3

SAFETY &

REGULATIONS

SAFETY PRECAUTIONS INSTALLATION REGULATIONS

OIL SMELLS, LEAKS OR FUMES FROM THE APPLIANCE:

Extinguish any naked flames.

Isolate the electrical supply.

Isolate the fuel supply to the boiler.

Rectify fault.

HEALTH & SAFETY:

The appliance contains no asbestos and no substances have been used in the construction

process that contravene the COSHH Regulations (Control of Substances Hazardous to Health

Regulations 1988). Where applicable, the CE mark indicates compliance with relative EU

Directives.

COMBUSTIBLE AND CORROSIVE MATERIALS:

Do not store or use any combustible materials (paper, thinners, paints etc.) inside or within the

vicinity of the appliance.

The combustion air must be kept clear of chemically aggressive substances which can corrode

the appliance and invalidate any warranty.

FITTING & MODIFICATIONS:

Fitting the appliance and any controls to the appliance may only be carried out by a competent

engineer in accordance with these instructions and the relevant Installation Regulations.

Flue systems must not be modified in any way other than as described in the fitting instructions.

Any misuse or unauthorised modifications to the appliance, flue or associated components and

systems could invalidate the warranty. The manufacturer accepts no liability arising from any

such actions, excluding statutory rights.

SERVICING:

Advise the user to have the system regularly serviced by a competent, qualified engineer (such

as OFTEC registered personnel) using approved spares, to help maintain the economy, safety

and reliability of the appliance.

Failure to install appliances correctly could lead to

prosecution.

The appliance should be installed by a competent

person. The person installing the appliance should

be aware of the Health and Safety at Work Act and

take appropriate action to ensure that the

regulations are adhered to. In order to give

optimum efficiency and trouble free operation the

appliance must be commissioned by a qualified

OFTEC engineer.

The compliance with a British Standard does not,

in itself, confer immunity from legal obligations. In

particular the installation of this appliance must be

in accordance with the relevant requirements of the

following British Standards and regulations in

respect of the safe installation of equipment:

BS 5410: part 1: Code of practice for Oil Fired

Boilers.

BS 799: part 5: Specification for Oil Storage

Tanks.

BS 7593: Code of Practice for treatment of water

in domestic hot water central heating systems.

BS 5449: part 1: Specification for forced

circulation hot water central heating for domestic

premises.

BS 5955: part 8: Specification for the installation

of thermoplastic pipes and associated fittings for

use in domestic hot and cold water services and

heating systems.

BS 7291: Thermoplastic pipes and associated

fittings for hot and cold water for domestic

purposes and heating installations in buildings.

BS 7074: part 1: Application, selection and

installation of expansion vessels and ancillary

equipment for sealed water systems.

BS 7671: IEE Wiring Regulations, current edition.

BS 1362: Specification for general purpose fuse

links for domestic and similar purposes.

The Building Regulations Part J and L1 England

and Wales; Part F and Part J Section III Scotland;

Part L and Part F Northern Ireland.

Local water company bye-laws.

The Control of Pollution (Oil) Regulations.

OFTEC Standards.

Where no specific instruction is given, reference

should be made to the relevant codes of practice.

Page 5

GENERAL INFORMATION

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

4

APPLIANCE

INFORMATION

GENERAL INFORMATION

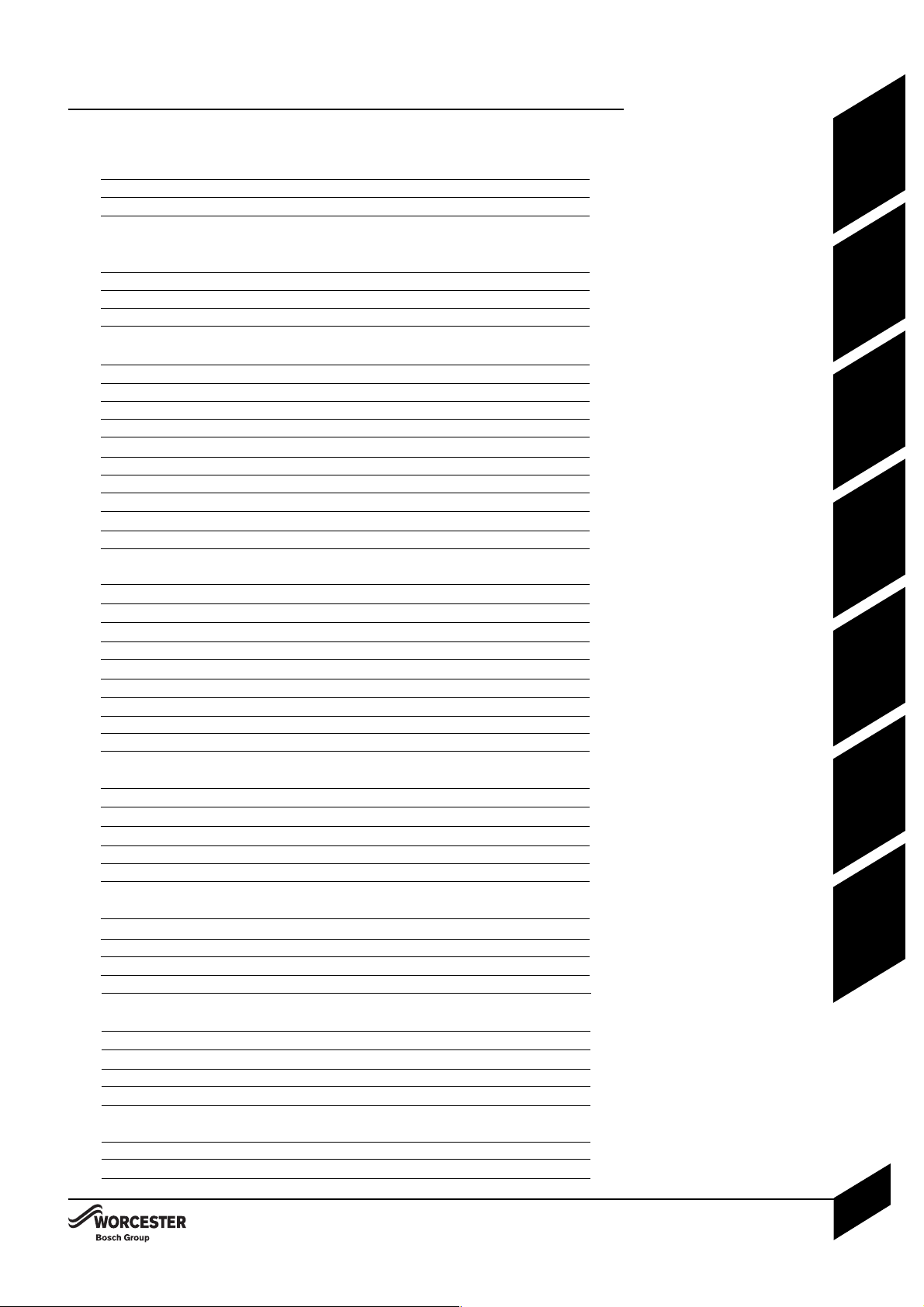

STANDARD PACKAGE:

A - Floor standing oil fired condensing boiler for

open vent and sealed domestic central heating

and mains fed hot water.

B - Literature pack.

C -Condensate trap kit.

D - 100mmØ services duct.

E - Cabinet key

Check List

Item Qty

Greenstar Heatslave External Installation/Servicing Instructions........1

Users Instructions ..........................................................................................1

100mm Ø Services Duct...............................................................................1

Condensate Trap Kit.......................................................................................1

Warranty Return Envelope ............................................................................1

Cabinet Key.......................................................................................................1

770mm

640mm

950mm

A

B

C

D

E

Page 6

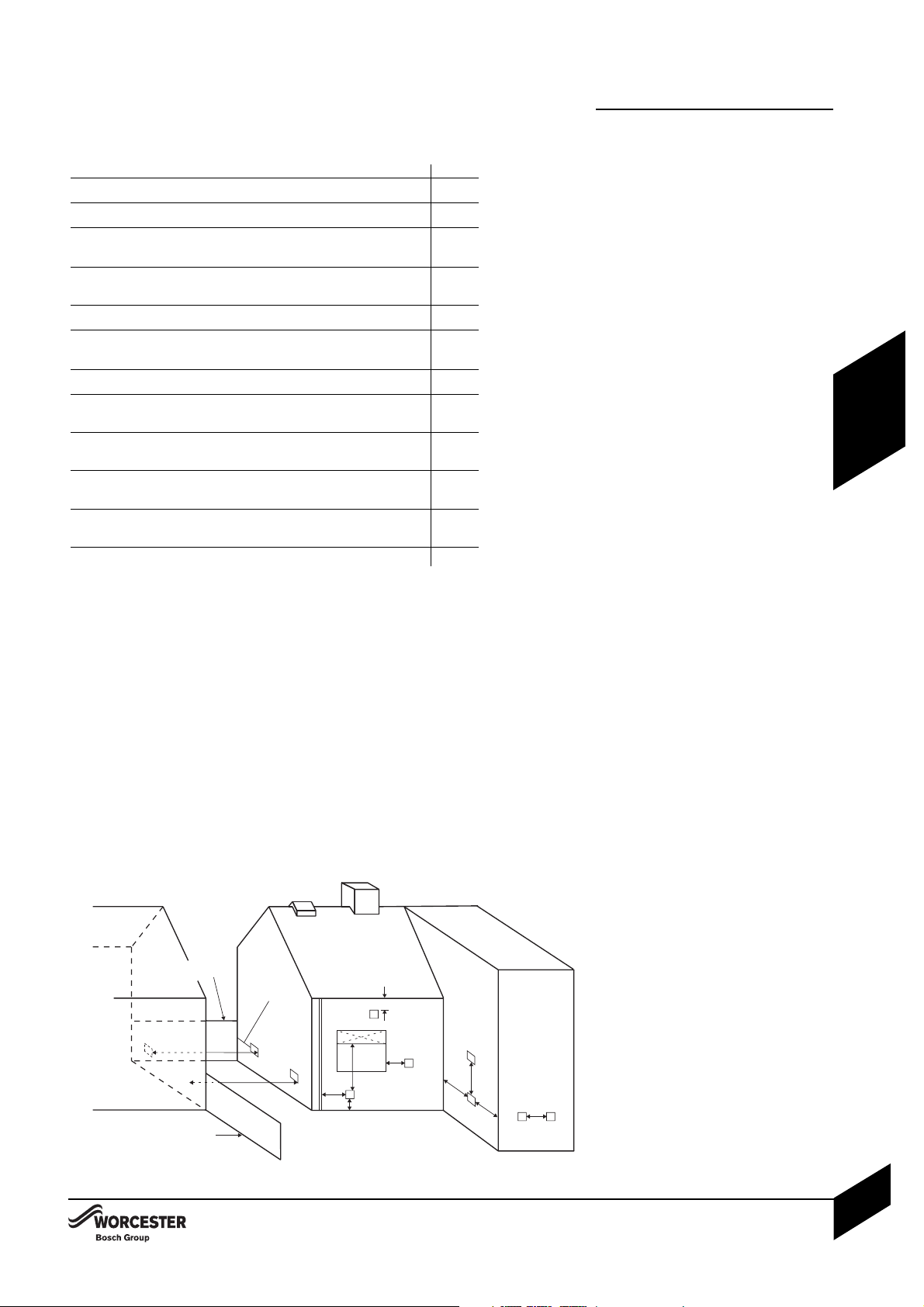

TECHNICAL DATA

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

5

TECHNICAL DATA

Central Heating

Primary water capacity (total) litres

Maximum static head metres

Minimum static head metres

Available pump head (20°C difference) at max. output metres water

Max. permissible sealed system operating pressure bar

in accordance with WRAS guidelines

Flow restrictor colour

Domestic Hot Water

Optimum flow rate (±15%) litres/min

Minimum inlet pressure (dynamic) for optimum flow rate bar

Maximum hot water rise for 90 litres draw off (@optimum flow rate) °C

Flue

Exit flue gas mass flow kg/hr

Pipework connections

Fuel line (compression) mm

CH flow mm

CH return mm

Water main inlet mm

DHW outlet mm

Open vent (optional) BSP

CH drain/optional feed and expansion BSP

Condensate (polypropylene) mm

Electrical

Electrical power supply voltage AC...V

Frequency Hz

Max. power consumption W

Thermostats

CH control thermostat range (cut in/cut out) °C

DHW control thermostat range (cut in/cut out) °C

CH & DHW control thermostat differential °C

Boiler high limit thermostat set point °C

Boiler manual reset overheat thermostat set point °C

Flue reset overheat thermostat set point °C

General Data

Maximum hearth temperature °C

SEDBUK (Band A) %

Appliance protection rating IP

Weight (excluding packaging) kg

Emissions class for NOx and CO class

Typical NOx emissions figure mg/kW hr

DESCRIPTION UNITS 12/18 18/25 25/32

APPLIANCE

INFORMATION

69

30

1

4.7

2.5

Lime

15

1. 5

40

29

10

22

22

15

22

1

3

/

4

21. 5

230

50

240

55/81

55/72

5

92

105

110

<100

90.2

45

19 5

3

75

69

30

1

4.0

2.5

—

18

1. 2

40

40

10

22

22

15

22

1

3

/

4

21. 5

230

50

240

55/81

55/72

5

92

105

110

<100

90.1

45

19 5

3

70

72

30

1

4.2

2.5

—

22

0.9

40

51

10

28

28

15

22

1

3

/

4

21. 5

230

50

263

55/81

55/72

5

92

105

110

<100

90.3

45

206

3

75

Page 7

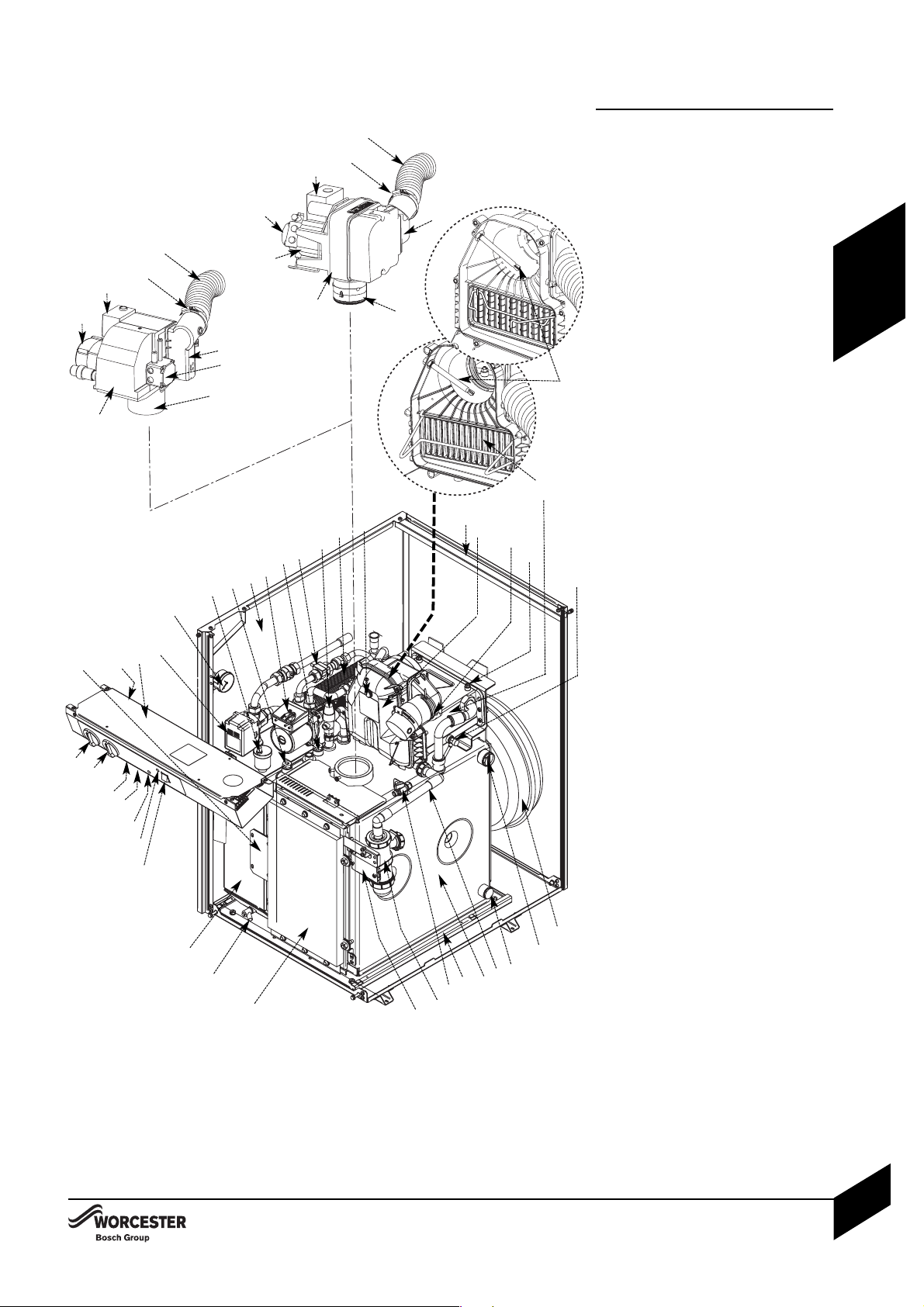

LAYOUT & COMPONENTS

The diagram opposite excludes the top, front

and RH side casing panels.

1. CONTROL BOX ASSEMBLY

2. DIVERTER VALVE

3. PRESSURE GAUGE

4. AUTO AIR VENT

5. CH CONTROL AND MANUAL RESET

OVERHEAT THERMOSTAT PHIAL

6. CASING SIDE PANEL

7. CIRCULATING PUMP

8. AUTO-RESET HIGH LIMIT

THERMOSTAT PHIAL

9. DHW FLOW SWITCH

10. PRESSURE RELIEF VALVE

11. DHW HEAT EXCHANGER

12. FLUE GAS SAMPLING POINT

13. FLUE OVERHEAT THERMOSTAT

PHIAL

14. CASING SUPPORT PANEL

15. FLUE MANIFOLD ACCESS COVER

16. AIR INLET PIPE AND CASING

17. SECONDARY HEAT EXCHANGER

BLEED POINT (ONE ON EITHER SIDE)

18. SECONDARY HEAT EXCHANGER

19. SECONDARY HEAT EXCHANGER

DRAIN

20. EXPANSION VESSEL

21. OPTIONAL OPEN VENT/AIR VENT

22. DRAIN AND OPTIONAL FEED AND

EXPANSION

23. CONDENSATE OUTLET

24. PRIMARY HEAT EXCHANGER

25. TRAY

26. OIL ISOLATION VALVE

27. CONDENSATE TRAP

28. CONDENSATE TRAP BRACKET

29. COMBUSTION CHAMBER ACCESS

DOOR

30. HEATSLAVE TANK DRAIN

31. HEATSLAVE TANK

32. MODE SWITCH

33. BOILER MODE INDICATOR

34. LOCKOUT INDICATOR

35. OVERHEAT RESET BUTTONS (boiler &

flue temperature)

36. LOCKOUT RESET BUTTON

37. SERVICE CONNECTION

38. CH TEMPERATURE CONTROL

39. DHW TEMPERATURE CONTROL

40. DATA LABEL

41. FROST THERMOSTAT SENSORS

42a. BENTONE STERLING BURNER

(12/18 & 18/25)

i) CONTROL BOX

ii) MOTOR

iii) AIR INTAKE CASING

iv) OIL PUMP

v) COMBUSTION HEAD

42b. RIELLO RDB 2.2 BURNER (25/32)

i) CONTROL BOX

ii) MOTOR

iii) AIR INTAKE CASING

iv) OIL PUMP

v) COMBUSTION HEAD

43. CLIP - AIR INTAKE HOSE

44. AIR INTAKE HOSE

LAYOUT & COMPONENTS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

6

APPLIANCE

INFORMATION

1

6

2

4

8

7

5

10

20

11

14

3

13

15

12

16

17

19

21

22

23

18

24

25

29

40

30

31

32

33

9

35/36

39

38

42a

42b

43

44

43

44

v)

iv)

iii)

ii)

i)

v)

iii)

i)

ii)

iv)

41

26

27

28

37

34

Page 8

CLEANING PRIMARY SYSTEMS

BEFORE CLEANING THE SYSTEM:

ENSURE THE SYSTEM AND PIPEWORK IS

IN GOOD WORKING ORDER.

FLUSH THE EXISTING SYSTEM WITH A

POWER FLUSHING MACHINE OR WITH A

CHEMICAL CLEANER BEFORE

INSTALLING NEW COM PONENTS.

CLEANING THE PRIMARY SYSTEM:

Cleanse the system in accodance with

BS 7593.

Fill the system with cold mains water to the

recommended pressure and check for leaks.

Open all drain cocks and drain the system.

Close drain cocks and add a suitable flushing

agent at the correct strength for the system

condition in accordance with the manufacturer's

instructions.

Circulate the flushing agent before the boiler

is fired up.

Run the boiler and system at normal operating

temperature in accordance with the

manufacturer's instructions.

Drain and thoroughly flush the system to

remove the flushing agent and any debris.

IMPORTANT: All the following Pre-Installation sections must be read and

requirements met before starting boiler or flue installation.

CAUTION: ISOLATE THE MAINS SUPPLIES BEFORE STARTING ANY WORK AND

OBSERVE ALL RELEVANT SAFETY PRECAUTIONS.

IMPORTANT: Debris from the system can

damage the boiler and reduce efficiency.

Failure to comply with the guidelines for

the use of water treatment with the

appliance will invalidate the appliance

warranty.

CLEANING PRIMARY SYSTEMS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

7

PRE -

INSTALLATION

Page 9

MAINS SUPPLIES

ELECTRIC SUPPLY:

• Supply: 230V - 50Hz.

• Cable: PVC insulated 0.75mm2(24 x

0.2mm) temperature rated to 90°C.

• Protection IP45.

• External 5A fuse to BS 1362.

• The appliance must be earthed.

• Please refer to IEE regulations for cross

bonding requirements.

• It must be possible to isolate the appliance

from the electric supply with at least a 3mm

contact separation in both poles supplying

the appliance.

• Wiring between the appliance and the

electrical supply must comply with IEE wiring

regulations and any local regulations which

may apply for fixed wiring to a stationary

appliance.

• Any system connected to the boiler must not

have a separate electrical supply.

WATER SUPPLY:

The following are general requirements and if

necessary the advice of the local water company

should be sought before fitting the appliance.

• The appliance cold water supply should be

the first connection off the water main where

possible.

• Maximum mains fed water pressure 10 bar.

If necessary, fit a pressure reducing valve.

IMPORTANT: Non-return, back flow

prevention devices (including those

associated with water meters) fitted to the

mains water supply can cause a pressure

build up which could damage the boiler

and other household appliances.

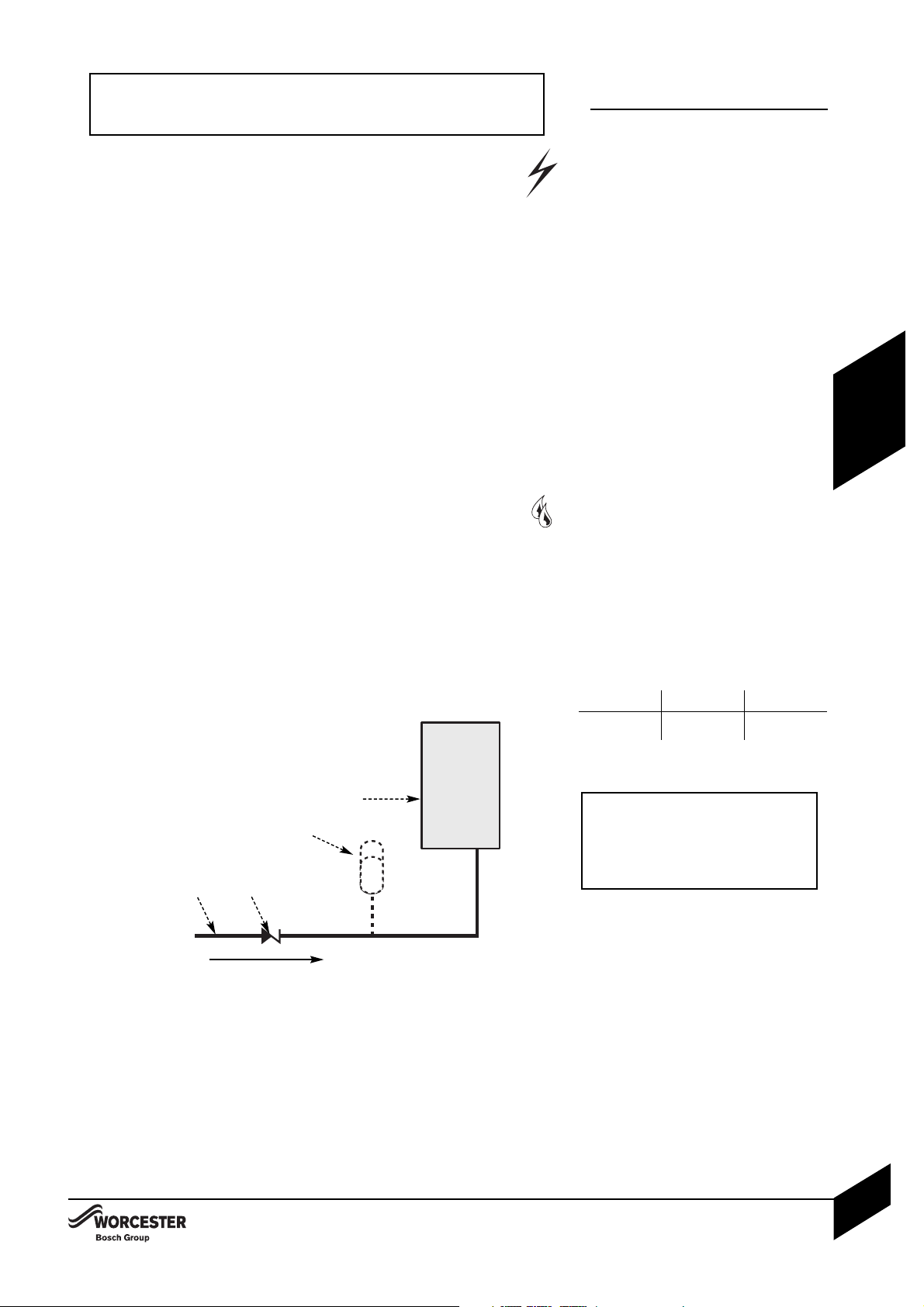

• Where the water main supply has a nonreturn, back flow prevention valve fitted, a

mini expansion vessel (A) must be connected

to the mains water inlet pipe (B) between the

non-return valve (C) and the boiler (D) as

shown opposite.

Use in hard water areas:

Normally there is no need for water treatment to

prevent scale formation as the maximum

temperature of the heat exchanger is limited by

the control circuit.

In areas where the temporary water hardness

exceeds 200ppm, consideration may need to

be given to the fitting of a scale prevention

device. In such circumstances, the advice of

the local water authority should be sought.

MAINS WATER EXPANSION VESSEL:

A - Mini expansion vessel, part No. 7 716 102 105

B - Mains water inlet

C - Non-return valve

D - Boiler

A

B

C

D

MAINS SUPPLIES

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

8

PRE -

INSTALLATION

12/18kW

Water Mains Pressure:

Minimum dynamic mains water pressure for

optimum performance.

1.5 bar 1.2 bar

0.9 bar

18/25kW 25/32kW

IMPORTANT: The appliance provides a permanent external electrical supply

for servicing and must therefore be fed via a circuit breaker incorporating

earth leakage protection.

Page 10

OIL SUPPLY

This appliance is suitable for kerosene (28

second oil) only, no other fuel must be used.

OIL SUPPLY:

• Plastic or steel tanks should be installed to

BS 5410. A steel tank should conform to

BS 799: part 5 and have a slope of 1 in 24

away from the outlet valve with a sludge cock

at its lower end.

• Do not use galvanised steel tanks or

pipework for the oil supply system.

• Do not use soldered joints on the oil

supply pipework.

a) Single pipe gravity feed system:

The oil storage tank (A) must be positioned so

that the oil level does not exceed 4 metres above

the level of the burner oil pump (J) and in addition the oil level must be at least 300mm above

the oil pump (J). Where the maximum oil level in

the oil storage tank exceeds 4 metres, a head

breaking device must be installed between the

tank (A) and the burner oil pump (J).

b) Double pipe sub-gravity feed system:

Maximum suction height 3.5 metres. Non-return

valves must be fitted to the inlet and return oil

line between the oil pump (J) and oil storage

tank (A).

c) Single pipe suction lift with de-aerator

Maximum suction height 3.5 metres. The oil

tank (A) must be positioned below the oil pump

(J). Create an inlet and return loop between the

de-aerator (M) and oil pump (J).

A non-return valve must be incorporated within

the de-aerator or fitted to the oil line between

the oil storage tank (A) and the de-aerator (M).

A top feed oil tank fitted with a de-aerator

using an internal non-return valve should have

any non-return valves fitted in the base of the

tank to the suction line removed to assist

purging air from the oil line.

Pipework

Use copper pipe of the correct diameter

according to the information shown opposite.

Use flexible hoses to connect to the oil pump (J).

Lay the oil supply pipe (H) as straight and

level as possible to avoid air pockets and

unnecessary friction losses. Route away

from the boiler access door or other hot

surfaces.

Install a manual isolating valve (B) to the oil

supply pipe (H), as close to the oil storage

tank (A) as possible.

Fit an oil strainer and water seperator (C) to

the oil supply pipe, near the oil storage tank.

Fit an additional oil filter (N, 16µm max

filtration size) close to the boiler, but not

inside the boiler casing.

Fit a fire valve in accordance with BS 5410.

The fire valve (D) must be fitted externally

at least 1 metre from the appliance with the

fire valve sensor (F) located within the

appliance case.

A capillary type valve provides a neat and

simple installation. Alternatively, a fusible

link or electrical system may be used.

Under no circumstances should a

combination isolating/fire valve be used

as the sole fire protection device.

A

F

BN

GJ

4m (13ft) max.

K

a)

H

300mm

min.

B DB C

MAXIMUM PIPE RUN FOR SINGLE PIPE GRAVITY FEED SYSTEM

B

A

DB

C

E

K

3.5m (11.5ft) max.

L

L

b)

H

F

G

B

MAXIMUM PIPE RUN FOR DOUBLE PIPE SUB-GRAVITY FEED SYSTEM

N

J

B

A

M

B

F

C

G

J

3.5m (11.5ft) max.

E

D

c)

MAXIMUM PIPE RUN FOR SINGLE PIPE SUCTION LIFT WITH DE-AERATOR

H

FUEL FLOW RATE

FUEL FLOW RATE

K

1m

min

.

1m

min

.

1m

min

.

E

OIL SUPPLY

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

9

PRE -

INSTALLATION

A - Oil storage tank

B - Isolating valve

C - Oil strainer & water seperator

D - Fire valve to BS5410

E - External casing

F - Fire valve sensor

G - Oil burner

H - Oil supply pipe

J - Oil pump

K - Full base (plastic tanks)

L - Non-return valve

M - De-aerator

N - Oil filter (16µm max filtration size)

NOTE: All dimensions are in metres unless stated otherwise.

The maximum pipe run figures are based on using copper pipe with an inside diameter of

2mm less than the Ø.

HEAD 10mmØ 12mmØ

0.5 12 30

1. 0 25 69

1. 5 37 91

2.0 49 100

HEAD 10mmØ 12mmØ

2.5 62 100

3.0 74 100

3.5 87 100

4.0 99 100

HEAD 10mmØ 12mmØ

050 100

0.5 44 100

1. 0 3 8 9 5

1. 5 3 2 80

HEAD 10mmØ 12mmØ

2.0 26 66

2.5 20 50

3.0 14 37

3.5 8 22

HEAD 2.5kg/h 5kg/h 10kg/h 10kg/h

8mmØ 8mmØ 8mmØ 10mmØ

0 100 55 26 100

0.5 95 45 23 100

1.0 80 40 20 90

1. 5 70 3 5 17 75

HEAD 2.5kg/h 5kg/h 10kg/h 10kg/h

8mmØ 8mmØ 8mmØ 10mmØ

2.0 60 30 14 65

2.5 45 25 11 50

3.0 35 15 8 35

3.5 25 10 5 20

The table and illustration above is a guide only and does not in any way override the deaerator manufacturers instructions.

Page 11

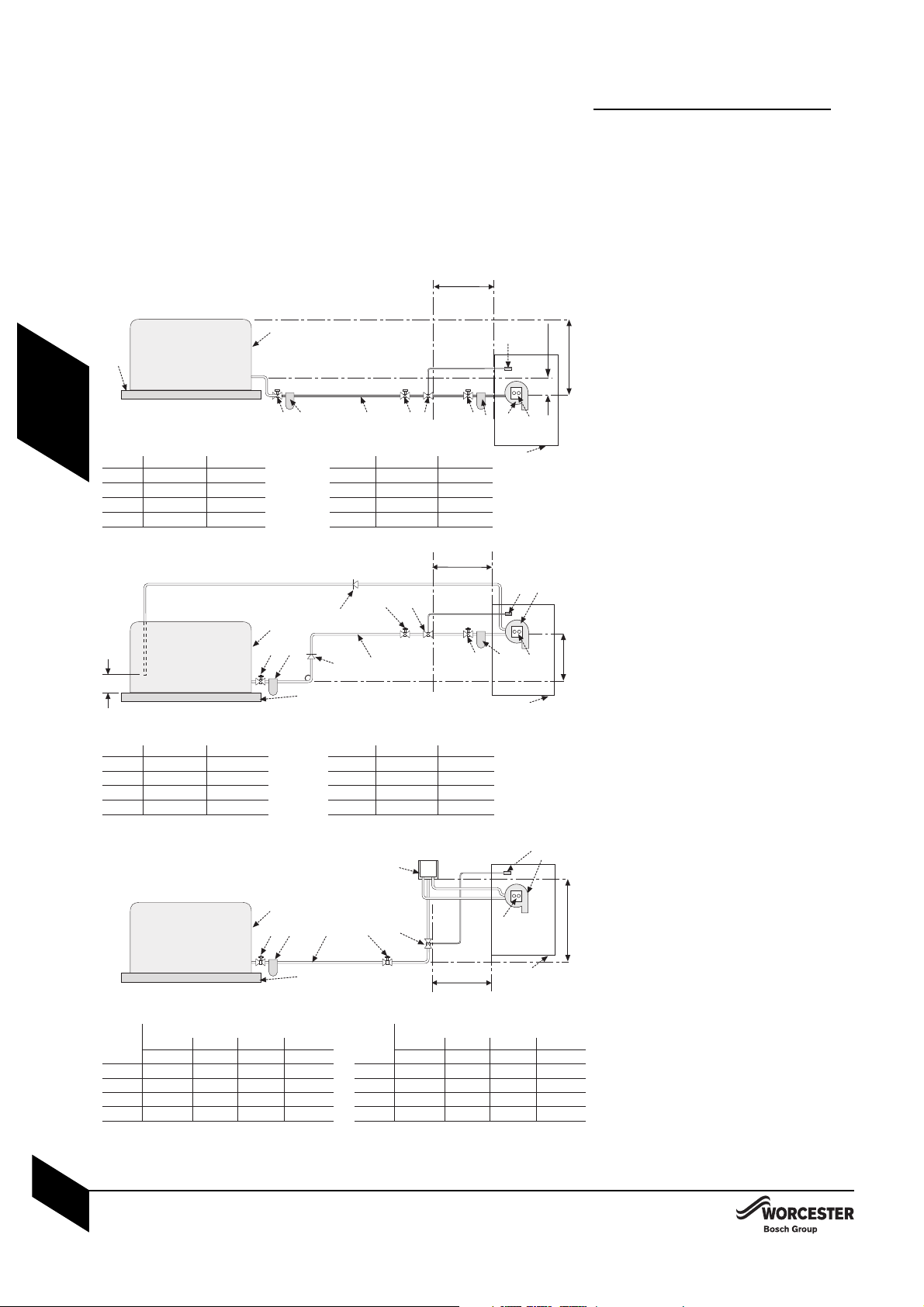

TYPICAL OPEN VENT SYSTEM

INSTALLATIONCOMMISSIONING

A - Appliance expansion vessel

B - Extra expansion vessel

C - Automatic bypass valve

D - Drain cock

E - Feed & expansion cistern

WATER SYSTEMS & PIPEWORK

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

10

PRE -

INSTALLATION

F - Feed & expansion 15mmØ min

G - Appliance

H - Open vent 22mmØ min

L - Lockshield valve

P - Pressure relief discharge

R - Radiators

S - Static head

T - TRV

U - To filling system

WATER SYSTEMS & PIPEWORK

PRIMARY SYSTEM PLASTIC PIPEWORK:

• Plastic pipework must not

be used for

the DHW system.

• Any plastic pipework used for the CH system

must have a polymeric barrier, comply with

BS 7921 and installed to BS 5955 with

1000mm (minimum) length of copper or steel

pipe connected to the boiler.

• Plastic pipework used for underfloor heating

must be correctly controlled with a

thermostatic blending valve limiting the

temperature of the circuits to approx. 50°C

with 1000mm (minimum) length of copper or

steel pipe connected to the boiler.

PRIMARY SYSTEM/CONNECTIONS/VALVES:

• Do not use galvanised pipes or radiators.

• All system connections, taps and mixing

valves must be capable of sustaining a

pressure of 3 bar.

• Radiator valves should conform to

BS 2767:10.

• All other valves should conform to BS 1010.

• On new installations TRVs must be used on

all radiators except the radiator where the

room thermostat is sited, this must be fitted

with lockshield valves and left open. All

installations should have TRVs fitted to

radiators within the sleeping accommodation.

• An automatic bypass valve must be connected

between the heating flow and return where

TRVs are used on all radiators, fitted to give

at least a 3m circuit when activated.

• Drain cocks are required at all the lowest

points on the system.

• Air vents are required at all high points on the

system.

OPEN VENT PRIMARY SYSTEM:

• In order to comply with BS 5449 the feed

and expansion pipe and the open vent pipe,

(or the combined feed and vent pipe), must

be connected to the BSP outlet/s on the

right hand side of the primary heat exchanger.

• The feed and expansion cistern (E) must be

positioned to provide a static head (S) of at

least 1 metre above the highest point in the

heating system to the water level in the feed

and expansion cistern (E).

• Ensure adequate space is left in the expansion

cistern for expansion of the system water.

• No valve shall be fitted in the open vent pipe

(H) or the feed and expansion pipe (F).

• The open vent pipe (H) must be at least 22mmØ.

SEALED PRIMARY SYSTEM:

• Where the system volume is more than 180

litres at 0.5 bar or exceeds 2.65bar at

maximum heating temperature an extra

expansion vessel (B) must be fitted as close

as possible to the appliance in the central

heating return.

• Pressurise the extra expansion vessel (B) to

the same figure as the expansion vessel built

into the appliance.

IMPORTANT: The boiler should not be

allowed to operate with a return

temperature of less than 40°C when the

system is up to operating temperature.

E

F

G

TYPICAL SEALED SYSTEM

A

G

B

U

P

S

1000mm min.

H

C

D

C

D

R R

T

R R

L

R R

T

R R

L

T

L

T

L

T

L

T

L

L

L

L

L

D

D

Page 12

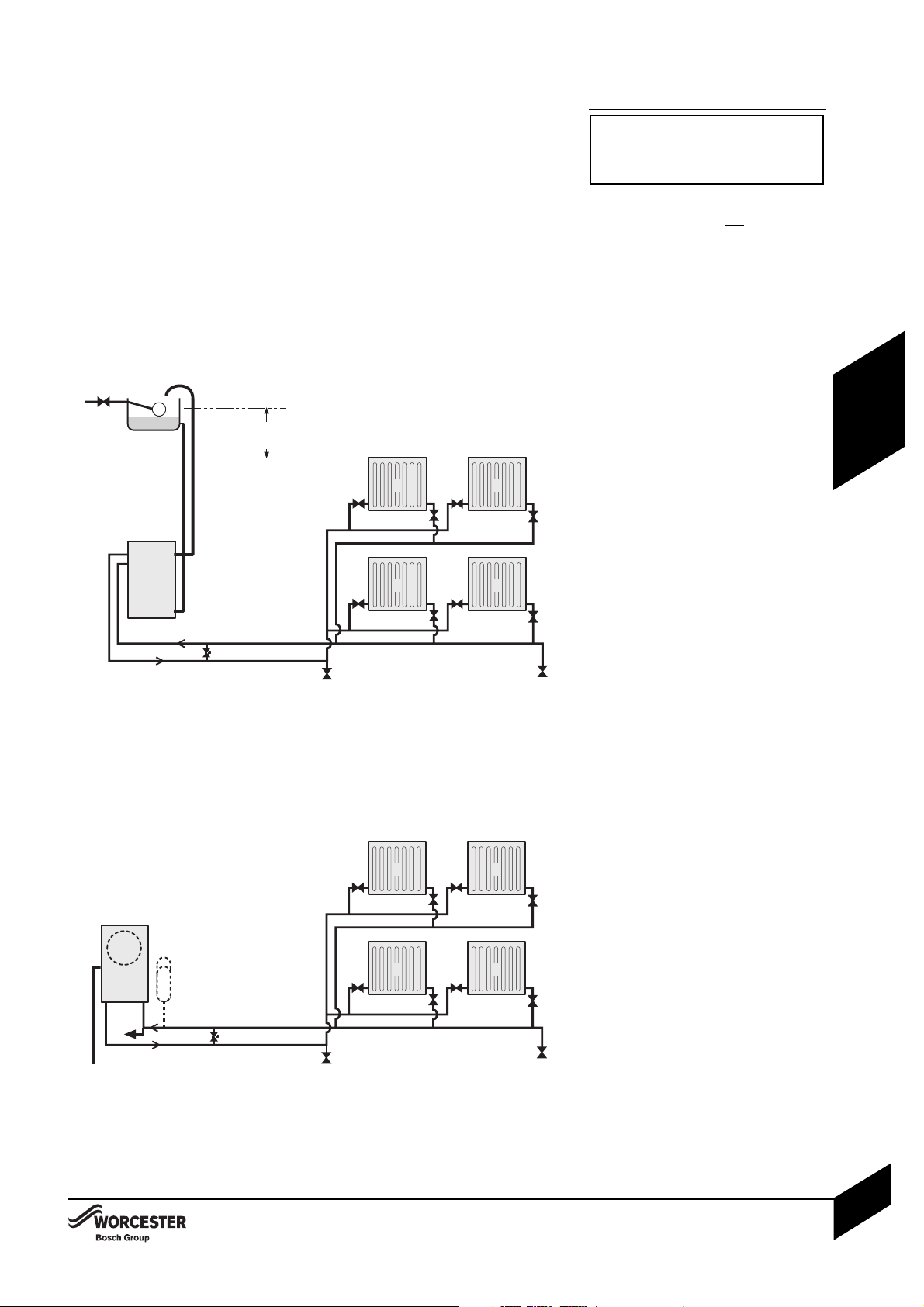

WATER SYSTEMS & PIPEWORK

FILLING PRIMARY SEALED SYSTEMS:

• Filling the system must comply with one of

the methods shown opposite.

• The filling point must be at low level and must

never be a permanent direct fixing to the

mains water supply.

• Filling loops must be WRAS approved.

SHOWERS/BIDETS:

• If a shower head can be immersed in water or

comes closer than 25mm from the top edge

of a bath or shower tray spill over level then

an anti-siphon device must be fitted to the

shower hose.

• Only thermostatically controlled showers are

suitable for use with this appliance.

• Bidets with direct hot & cold mains water can

be used (with the approval of the local water

authority) and must be the over rim flushing

type with shrouded outlets to prevent the

fitting of hand held sprays.

DOMESTIC HOT WATER:

• Plastic pipework must not

be used for

the DHW system.

• Taps and mixing valves must be capable of

sustaining a pressure up to 10 bar in

accordance with the Water Regulations as

they will be operating at mains water

pressure.

• Hot water temperature and flow rate are

affected by the size and insulation of

pipework making up the distribution system

and are controlled by the hot water tap and

the water main inlet pressure. A mixing valve

can be fitted if a more permanent setting is

required.

• If using more than one outlet at once causes

water flow starvation, fit flow balancing valves

or Ball-O-Fix valves to the appropriate outlets.

Heating return

Hose

return

Non return

valve

Non return

valve

Test cock

Stop

cock

Water main

supply

Stop

cock

Temporary hose

Heating return

Auto air

vent

Non return

valve

Stop

cock

Make up

vessel

1000mm above

the highest point

of the system

Fill Point

INSTALLATIONCOMMISSIONING

WATER SYSTEMS & PIPEWORK

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

11

PRE -

INSTALLATION

Page 13

CONDENSATE &

PRESSURE RELIEF PIPEWORK

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

12

PRE -

INSTALLATION

CONDENSATE &

PRESSURE RELIEF PIPEWORK

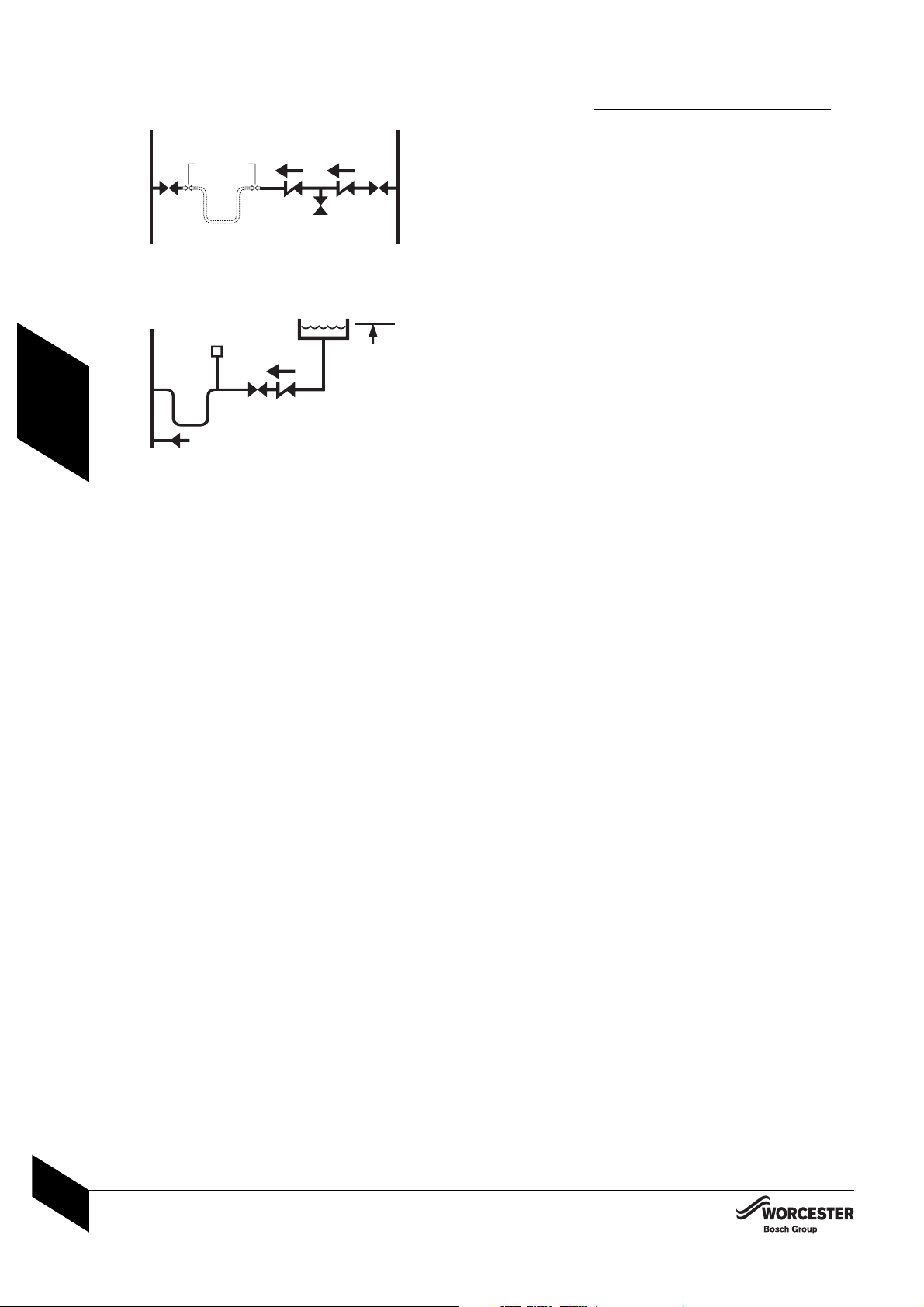

CONDENSATE PIPEWORK:

• All national and, where appropriate, local

regulations for the discharge and

neutralisation of condensate should be

followed.

• The condensate pipe must be a minimum of

21.5mmØ polypropylene pipe.

• The condensate pipework must fall at least

50mm per metre towards the outlet and

should take the shortest practicable route

and not exceed 3 metres outside the building.

If a run greater than 3m is required, 32mmØ

polypropylene pipe must be used.

• The pipework must follow one of the options

shown opposite:

a - Internal waste drainage system

b - Soil/vent stack

c - External drainage system

d - External condensate absorption point

• Condensate pipework must not be connected

to rainwater downpipes.

• Use waterproof pipe insulation in exposed

positions and for external pipework

IMPORTANT: Condensate pipework must not

leak and the condensate trap must be filled

with water before the boiler is started to

prevent the possibility of potentially harmful flue

products escaping via the condensate route.

A - Condensate from the boiler condensate

trap (supplied) which has a 75mm

minimum water seal.

B - Sink.

C - 21.5mm Ø polypropylene condensate pipe.

D - Gully.

E - Internal soil and vent stack.

F - 300mm x 100mm Ø sealed plastic tube.

G - Ground level.

H - Drainage holes 50mm from base of tube

(12mm Ø at 25mm centres) facing away

from building.

I - Limestone chippings.

PRESSURE RELIEF PIPEWORK:

IMPORTANT: The pressure relief valve is a

safety device for the boiler and if activated may

discharge boiling water or steam through the

relief valve drain pipe.

Care should be taken when siting the outlet

pipe so that it does not cause an obstruction or

discharge above a window, entrance or other

public access where it could cause a hazard.

• The pressure relief drain pipe (K) should be

at least 15mm diameter copper pipe and run

downwards away from the boiler and discharge

away from any electrics or other hazard,

preferably to an external drain or soakaway.

• Pipe (K) should be finished with a partial

bend, near the outlet to face the external

boiler casing (as shown) to help prevent

freezing.

J - External boiler casing.

K - Pressure relief pipe.

a

B

75mm

min.

b

C

E

c

A

A

450 min.

Invert

d

C

(Unsuitable for clay soil types)

500mm min.

A

200mm min.

J

K

C

A

D

C

D

F

25mm

min.

G

400mm

I

min.

H

Page 14

BOILER LOCATION &

CLEARANCES

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

13

PRE -

INSTALLATION

BOILER LOCATION &

CLEARANCES

WARN ING:

This appliance should not be installed where

there is a potential for excessive ground

water coverage.

This boiler is only suitable for installing

externally at a suitable location onto a fixed

permanent rigid surface capable of

supporting the boiler weight.

There must be a sufficient hard standing

around the appliance to allow for servicing.

The boiler must be installed on a flat level

surface to ensure that condensate does not

enter the primary heat exchanger.

Tarmac and wood hardstandings are not

recommended.

CLEARANCES: Min service & flue clearances

Above 600mm

Front 600mm

RH/LH flue outlet on opposite side 10mm

RH flue outlet on rear 85mm

LH flue outlet on rear 10mm

Rear = flue outlet on side 150mm**

Rear = rear flue outlet 2500mm*

It is strongly recommended that the flue

terminal faces away from walls to reduce

the possibility of wetting occuring.

*This can be reduced to 1200mm if there is at

least 2500mm clearance on both sides of the

flue.

** 200mm if a high level terminal is used exiting

through the rear panel.

600mm

2500mm*

600mm

BASE

FRONT

FRONT

2500mm*

150mm**

85mm10mm

600mm

10mm

600mm

2500mm*

FRONT

FRONT

2500mm*

10mm

600mm

150mm**

Plan

view

Plan

view

Plan

view

600mm

(min)

Page 15

CABINET MOUNTED LOW LEVEL

FLUE TERMINAL POSITIONS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

14

PRE -

INSTALLATION

Minimum dimensions of flue terminal positions for oil fired appliances:

TERMINAL POSITION B(H)

A

1

Directly below an opening, air brick, opening windows, etc 600mm

B

1

Horizontally to an opening, air brick, opening window, etc 600mm

C Below a plastic/painted gutter, drainage pipe or eaves if 75mm

combustible material protected

D

2

Below a plastic/painted gutter, drainage pipe or eaves without 600mm

protection to combustible material

E From vertical sanitary pipework 300mm

F From an external or internal corner or from a surface or boundry 300mm

alongside the terminal

G Above ground or balcony level 300mm*

H 1From a surface or boundary facing the terminal with 2500mm 1200mm

clearance to both sides of the terminal

H 2From a surface or boundary facing the terminal with less than 2500mm

2500mm clearance to either side of the terminal

I 1From a terminal facing the terminal with 2500mm clearance to 1200mm

clearance to both sides of the terminal

I 2From a terminal facing the terminal with less than 2500mm 2500mm

clearance to either side of the terminal

K Horizontally from a terminal 750mm

B(H) Balanced Horizontal flue

1 An opening means an openable

element, such as an openable

window, or a permanent opening

such as a permanently open air vent.

Notwithstanding the dimensions

above, a terminal should be at least

300mm from combustible material,

e.g. a window frame.

2 A way of providing protection of

combustible material would be to fit

a heat shield at least 750mm wide.

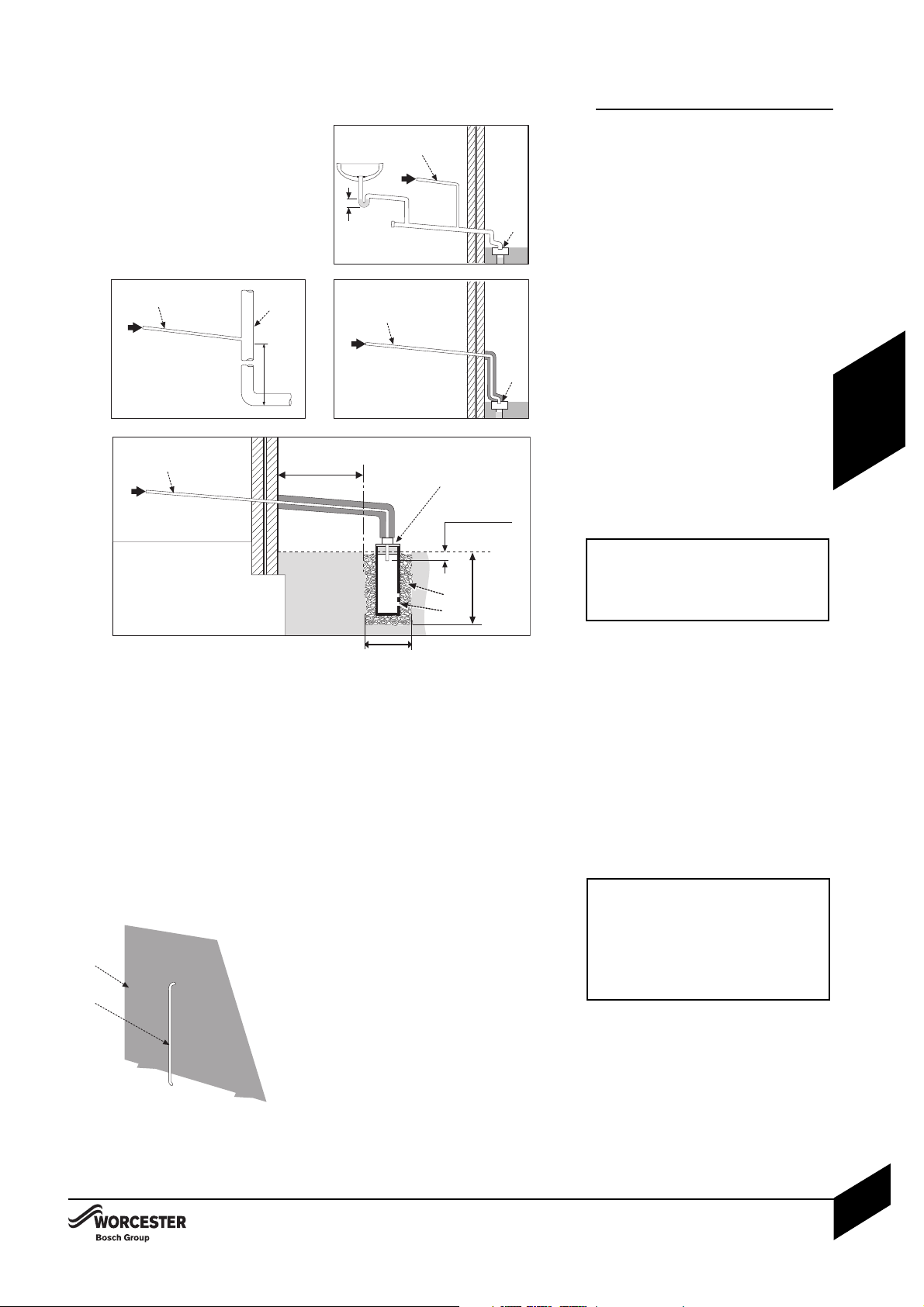

• Flue terminals must be positioned to avoid

combustion products entering into buildings.

• The flue must be fitted and terminated in

accordance with the recommendations of

BS5410.

• The flue must not cause an obstruction.

• Discharge from the flue outlet must not be a

nuisance.

• Flue gases have a tendency to plume and in

certain weather conditions a white plume of

condensation will be discharged from the flue

outlet which could be regarded as a

nuisance, for example, near security lighting.

• There should be no restriction preventing the

clearance of combustion products from the

terminal.

• The air inlet/outlet duct and the terminal of

the boiler must not be closer than 25mm to

any combustible material. Detailed

recommendations on protection of

combustible materials are given in BS 5410:1

• A protective terminal guard must be fitted if

the terminal is 2m or less above a surface

where people have access.

Stainless steel terminal guard.

Part No: 7 716 190 050

• The following additional guidelines (from part

L Exceptions Guidance Document) are

recommended when determining the flue

outlet position:

• Avoid discharging flue gases into car ports

or narrow passageways.

• *Minimum distance of the flue terminal from

above ground is 2100mm where directed to a

public footpath, private access route or a

frequently used area and 2500mm from a

car parking area.

boundary

F

I

H

B

A

G

E

C, D

F

F

J

K

boundary

CABINET MOUNTED LOW LEVEL

FLUE TERMINAL POSITIONS

Page 16

HIGH LEVEL FLUE TERMINAL

POSITIONS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE 12/18-18/25-25/32

8 716 106 252d (08/07)

15

PRE -

INSTALLATION

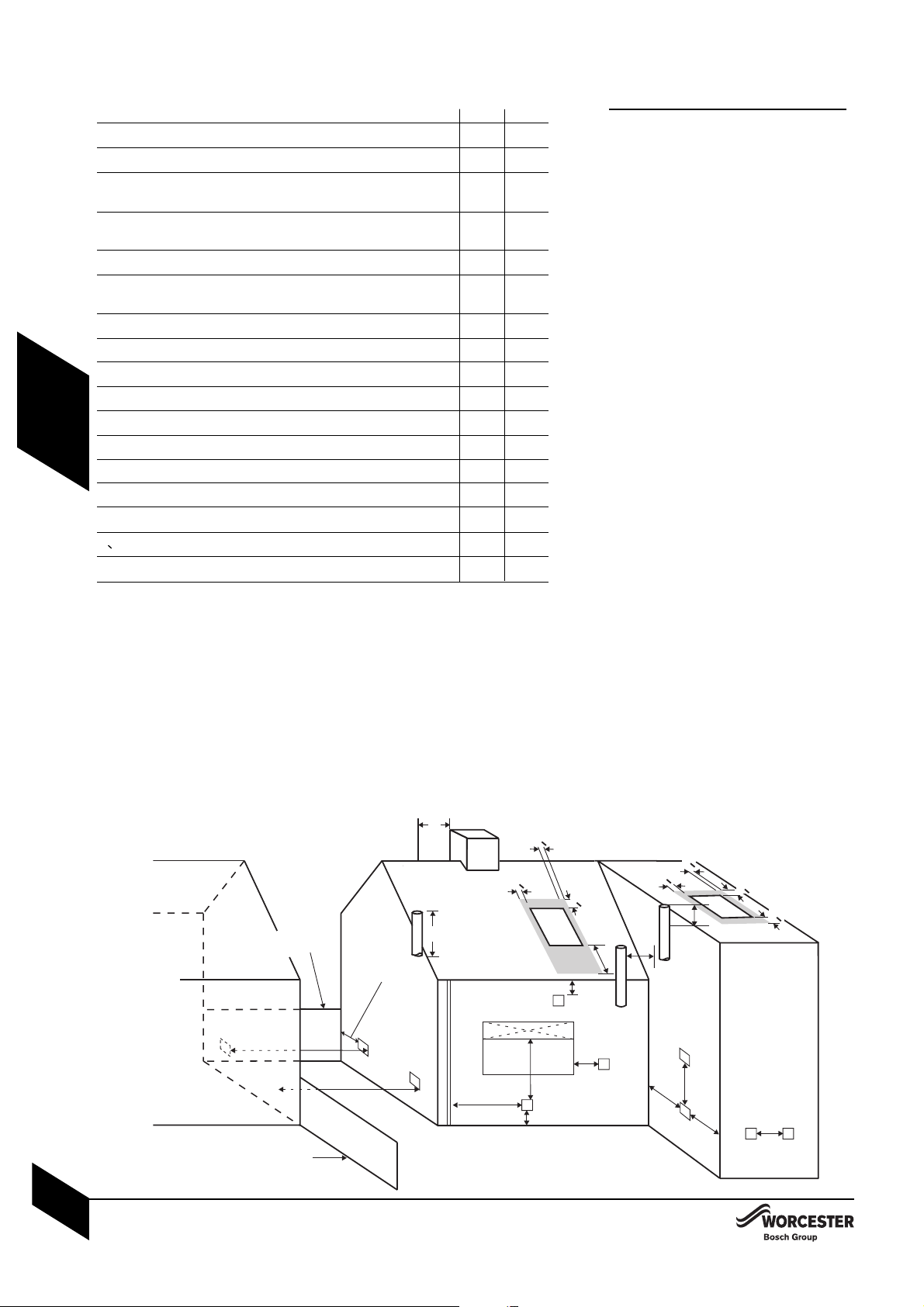

Minimum dimensions of flue terminal positions for oil fired appliances:

TERMINAL POSITION B(H) B(V)

A

1 2

Directly below an opening, air brick, opening window, etc 600mm N/A

B

1 2

Horizontally to an opening, air brick, opening window, etc 600mm N/A

C Below a plastic/painted gutter, drainage pipe or eaves if 75mm N/A

combustible material protected

D3Below a plastic/painted gutter, drainage pipe or eaves without 600mm N/A

protection to combustible material

E From vertical sanitary pipework 300mm N/A

F From an external or internal corner or from a surface or boundry 300mm N/A

alongside the terminal

G Above ground or balcony level 300mm* N/A

H From a surface or boundary facing the terminal 600mm** N /A

J From a terminal facing the terminal 1200**mm —

K Vertically from a terminal on the same wall 1500mm N/A

L Horizontally from a terminal on the same wall 750mm —

M Above the point of highest intersection with the roof — 600mm

N From a vertical structure on the side of the terminal — 750mm

O Above a vertical structure less than 750mm from the side of the terminal — 600mm

P From a ridge terminal to a vertical structure on the roof — —

Q Above or to the side of any opening on a flat or sloping roof — 300mm

R Below any opening on a sloping roof — 1000mm

Key: — Not applicable, N/A Not allowed, B(H) Balanced Horizontal flue, B(V) B alanced Vertical flue.

Notes:

1. Terminals should be positioned so as to avoid products of combustion accumulating in stagnant pockets around the building or

entering into buildings.

2. Vertical structure in N, O and P includes tank or lift rooms, parapets, dormers etc.

3. Terminating positions should be at least 1.8m from an oil storage tank unless a wall with at least 30 min fire resistance and

extending 300mm higher and wider than the tank is provided between the tank and the terminating position.

4. Where a flue is terminated less than 600mm away from a projection above it and the projection consists of plastics or has a

combustible or painted surface, then a heat shield of at least 750mm wide should be fitted.

5. If the lowest part of the terminal is less than 2m above the ground, balcony, flat roof or other place to which any person has

access, the terminal should be protected by a guard.

6. Notwithstanding the dimensions given above, a terminal should not be sited closer than 300mm to combustible material. In the

case of a thatched roof, double this separation distance should be provided. It is also advisable to treat the thatch with a fire

retardant material and close wire in the vicinity of the flue.

7. It is essential that a flue or chimney does not pass through the roof within the shaded area delineated by dimensions Q and R.

8. Where protection is provided for plastic components, such as guttering, it is essential that this is to the standard specified by the

manufacturer of the plastic components.

• Flue terminals must be positioned to avoid

combustion products entering into buildings.

• The flue must be fitted and terminated in

accordance with the recommendations of

BS 5410.

• The flue must not cause an obstruction.

• Discharge from the flue outlet must not be a

nuisance.

• Flue gases have a tendency to plume and in

certain weather conditions a white plume of

condensation will be discharged from the flue

outlet which could be regarded as a

nuisance, for example, near security lighting.

• There should be no restriction preventing the

clearance of combustion products from the

terminal.

• The air inlet/outlet duct and the terminal of

the boiler must not be closer than 25mm to

any combustible material. Detailed

recommendations on protection of

combustible materials are given in BS 5410:1

• A protective terminal guard must be fitted if

the terminal is 2m or less above a surface

where people have access.

The guard must be spaced equally (minimum

50mm) around the flue and fixed to the wall

with plated screws.

Stainless steel terminal guard.

Part No: 7 716 190 050

The following additional guidelines (from part

L Exceptions Guidance Document) are

recommended when determining the flue

outlet position:

• Avoid discharging flue gases into car ports

or narrow passageways.

• *Minimum distance of the flue terminal from

above ground is 2100mm where directed to a

public footpath, private access route or a

frequently used area and 2500mm from a

car parking area.

• **Minimum distance of the flue terminal to a

facing wall, fence, building or property

boundary is 2500mm.

HIGH LEVEL FLUE TERMINAL

POSITIONS

P

boundary

F

M

Pitched roof

Q

Q

Q

Q

Q

Q

O

N

R

Q

Flat roof

C, D

boundary

J

A

B

H

E

G

K

F

F

L

Page 17

BALANCED EXTERNAL OILFIT

FLUE OPTIONS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

16

PRE -

INSTALLATION

IMPORTANT: The weather seal (supplied)

must be fitted to every flue joint to give

the required level of weather protection.

The diagrams (opposite) show the components

used and the maximum flue length (L) for

each flue configuration.

In all cases L is measured from the outside of

the boiler casing.

• To achieve the maximum flue length (L), a flue

section will have to be reduced in length.

• Only the straight flue extensions can be

reduced in length by cutting.

IMPORTANT: All horizontal sections must

rise away from the boiler by 52mm per

metre (3°) to allow the condensate to

drain back to the boiler.

A - Horizontal terminal

B - Straight flue extension

C - Flue bend 90°

D - Flue bend 45°

E - Vertical Terminal Kit (incl. 90° elbow)

F - Horizontal terminal kit (incl. 90° elbow)

Calculating the flue length:

Measure the total flue length required, noting

that the maximum straight flue length including

the terminal is:

Horizontal 80/125mmØ: 4000mm.

Vertical 80/125mmØ / 100/150mmØ (25/32

only): 7000mm.

Then reduce the total straight flue length for

each extra flue bend (excluding the vertical flue

kit 90° elbow) by:

1000mm for 90°

500mm for 45°

Flue Extension lengths:

Horizontal & Vertical: 1000mm overall length.

Effective length when engaged into sockets

within the flue run is 950mm.

Flue Terminal lengths:

Horizontal 80/125mmØ: 720mm

Vertical 80/125mmØ: 1080mm + cage

* Rear exit only.

** Horizontal flue runs should be kept as

short as possible.

L = 2000mm

BALANCED EXTERNAL OILFIT

FLUE OPTIONS

High level horizontal terminal (rear outlet)

*

**

Vertical terminal (rear outlet)

Vertical terminal (rear outlet)

Vertical terminal (side outlet)

**

**

**

F

B

125mmØ x2

L

L = 7000mm

E

B

125mmØ x5

L

A

B

C

D

F

E

L = 6000mm

D

E

D

B

125mmØ x4

L = 6000mm

E

C

B

125mmØ x4

L

L

Page 18

BALANCED FLUE OPTIONS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

17

PRE -

INSTALLATION

CABINET MOUNTED BALANCED

HORIZONTAL FLUE OPTIONS

• The horizontal flue is fitted to the rear or

either side of the cabinet.

IMPORTANT:

It is strongly recommended that the flue

terminal faces away from walls to

minimise the occurance of wetting.

A - External horizontal flue kit

Part No. 7 716 190 052

B - 90° inline elbow 80/125mm

Part No. 7 716 190 034

C - Terminal guard

Part No. 7 716 190 050

FRONT

FRONT

FRONT

Plan

view

Plan

view

Plan

view

REAR FLUE OUTLET

A + C

LEFT HAND FLUE OUTLET

A + B + C

RIGHT HAND FLUE

OUTLET

A + B + C

Page 19

Unpacking:

It is advised that two or more persons are involved

in the transfer of the packaged boiler from the van

to the point of delivery.

1 Once the packaged boiler has been

delivered, the outer carton is removed first.

Care should be taken when releasing the

straps. If a sharp implement is used make sure

the outer carton is not pierced and that the

implement is used in such a way so that it may

not cause personal injury. All sharp objects

must be covered or the blade retracted after

use and put away in a safe place.

2 Lift carton up and away from the boiler.

Remove the plastic bag from the boiler and

place safely aside.

UNPACKING THE BOILER

LIFTING AND CARRYING PRECAUTIONS:

• Lift only a manageable weight, or ask for

help.

• When lifting or putting things down, bend

the knees, and keep the back straight

and feet apart.

• Do not lift and twist at the same time.

• Lift and carry objects close to the body.

• Wear protective clothing and gloves to

protect from any sharp edges.

IIMPORTANT: All the previous Pre-Installation sections must be read

and requirements met before starting boiler or flue installation.

1

2

UNPACKING THE BOILER

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

18

INSTALLATION

Page 20

All dimensions in mm

256

650

58

802

258

81

10 5

171

374

161

650

787

670

518

10 5

94

55

269

658

669

705

715

650

794

670

518

15 8

12 4

89.5

55

658

679

698

718

528

230

INSTALLATIONCOMMISSIONING

SAFETY:

All relevant safety precautions must be undertaken.

Protective clothing, footwear, gloves and safety

goggles must be worn as appropriate.

PIPEWORK CONNECTIONS:

CH flow 22mmØ copper (28mmØ on

25/32kW model)

DHW flow 22mmØ copper

Mains water inlet 15mmØ

CH return 22mmØ copper (28mmØ on

25/32kW model)

Optional open vent 1'' BSP

Services duct 100mmØ

Drain/optional fill/feed & expansion

3

/

4

'' BSP

Pressure relief pipe 15mmØ

Condensate outlet 21.5mmØ

NOTE: For servicing purposes, keep the

condensate and pressure relief discharge

pipes away from components and pipework

connections.

CAUTION: Ensure there are no pipes,

electric cables, damp proof courses or

other hazards before drilling.

PIPEWORK & FLUE POSITIONS

PIPEWORK & FLUE POSITIONS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

19

Condensate

Flue

Services

PRV

Fire valve capillary

& drain access

Flue

Services

Condensate

PRV

Oil

Flue

Services

Condensate

Oil

PRV

LEFT HAND SIDE

RIGHT HAND SIDE

REAR

Fire valve capillary

& drain access

Page 21

BOILER INSTALLATION

Note: The cabinet is not load bearing it

only provides weather protection for the

boiler inside.

1Mark position of the 100mm services

duct on the exterior wall and make a hole

through.

2Remove the key for the door fastners

from its transport position in the left hand

side panel flue outlet aperture.

Undo the screws at the bottom of

the front panel (using the key provided)

and remove the screws from the rear

panel pulling both panels out and down

to remove. Store safely away from the

installation point.

3Remove the screws from the top panel

and lift up to remove, store safely away

from the installation point.

4Slide the pressure gauge up out of its

bracket and carefully rest on top of the

heat exchanger taking care not to snag or

kink the capillary.

5Remove the screws securing the control

box to the side panels and carefully rest

the control box on top of the heat

exchanger taking care not to snag or kink

the capillaries.

6Remove the screws securing the side

panels to the base panel and lift the side

panels off complete with the rear support

bar (shaded grey) and carefully stand the

panels away from the installation point.

7Loosen the flexable air duct clamp (A)

and remove the air duct from the burner.

Depress the locking ears to unplug the

burner lead (B) from the control box (C).

Unscrew the burner retainers (D), then

withdraw the burner (E) from the boiler and

store safely away from the installation point.

8Remove the screws securing the base

panel to the transit pallet and lift the boiler

off the pallet and into its installation

position taking care not to scrape the

base panel across the hard standing. Do

not attempt to lift and position the

boiler on your own. Do not use the

copper pipes to move the boiler.

Fasten the base to the hard standing

using the holes provided. Care should be

taken to ensure that the base is level.

9Refit the side panels and rear support

bar and screw the side panels to the

baseplate and boiler.

Refit the control box and pressure

gauge taking care not to kink the

capillary tubes.

Measure the 100mmØ services duct to

give at least 10mm inside the casing and

to finish flush with the interior wall

surface, cut to size and fit the duct. Fit the

100mm sealing ring where the duct

enters the casing and seal the joint to the

exterior wall and inside the cabinet with a

suitable sealant.

BOILER INSTALLATION

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

20

INSTALLATION

WARNING: THIS APPLIANCE IS SERVICED AND REPAIRED EXTERNALLY.

EXTERNAL EQUIPMENT OPERATED AT 230V SHOULD NOT BE INSTALLED, SERVICED OR

REPAIRED UNDER ADVERSE WEATHER CONDITIONS.

THIS APPLIANCE IS INSTALLED AND SERVICED EXTERNALLY TO THE PROPERTY, BUT

THE ENGINEER MUST HAVE ACCESS TO THE INSIDE OF THE PROPERTY WHEN

INSTALLING OR SERVICING THE APPLIANCE.

7

C

B

3

45

2

6

8

2

E

D

7

A

Page 22

INSTALLATION NOTES:

Ensure all the seals are in good condition

and seated properly.

To ease assembly of flue components,

grease seals lightly with the solvent free

grease supplied.

A terminal guard must be fitted if the

terminal is 2m or less above a surface where

people have access.

All flue options:

1 Lightly grease the flue cowl seal with the

solvent free grease supplied.

2 Carefully remove the blanking plate from

the appropriate flue aperture (if necessary)

and refit the blanking plate in the unused

aperture.

3 Carefully remove the insulation from the

flue aperture in the cabinet that the flue is

to pass through, and fit to the unused

aperture (if necessary).

4 Refer to the flue manual supplied with the

flue kit for flue installation.

FLUE INSTALLATION

FLUE INSTALLATION

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

21

INSTALLATION

Page 23

COMBUSTION CHAMBER

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

22

INSTALLATION

Combustion chamber:

1 Release retaining nuts and washers (B).

Remove combustion chamber access

door (A).

2 Ensure the baffles (C) and baffle retainer

(D) are correctly fitted for the boiler output

as shown in the plan views opposite.

3 Refit combustion chamber door (A).

Secure with nuts and washers (B) and

tighten until the door is firmly secured, do

not over tighten the nuts.

4 Unscrew screws (E) and remove flue

manifold access cover (F).

5 Check that all the baffles (G) and baffle

retainer (H) or ( J ) are correctly fitted to the

secondary heat exchanger.

COMBUSTION CHAMBER

H

F

2

E

4

G

5

A

B

1

3

D

C

12/18 & 18/25kW

Plan sectional view

D

C

25/32kW

Plan sectional view

J

Hook the

retainer ( J )

over the

end two

baffles

or

FRONT FRONT

Page 24

PIPEWORK CONNECTIONS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

23

INSTALLATION

PIPEWORK CONNECTIONS

A - CH flow 22mmØ copper (28mmØ on

25/32 models)

B - DHW flow 22mmØ

C - Water main inlet 15mmØ

D - CH return 22mmØ copper (28mmØ on

25/32 models)

E - 10mmØ oil supply pipe connection

F - Oil isolating valve (10mmØ)

G - Flexible oil hose

N - Optional open vent/air vent

O - Drain/optional feed and expansion

P - Fixing point for optional return oil pipe

WATER CONNECTIONS:

All service pipes into the property must pass

through the services duct.

Insulate all the system/supply pipes where

the pipes pass through the duct with at least

22mm insulation around the pipes.

Remove the transit bungs from the pipework

connections on the boiler.

NOTE: that surplus water may be present due

to factory testing.

Ensure all pipework is clean.

Align water pipework through the 100mm Ø

duct and connect, ensuring that the

expansion tank and control box fit correctly

before permanently connecting the pipework.

Check that all unused sockets have been

capped.

OIL SUPPLY CONNECTIONS:

NOTE: Oil filters and de-aeration devices are

not to be fitted within the casing and the fire

valve body must be at least 1 metre from the

external casing.

Route the oil supply pipe through the

appropriate casing hole as required and

connect to the isolating valve (F) and ensure

the valve is closed.

Connect the flexible oil hose (G) to the

isolating valve (F).

Pass the fire valve sensor through the most

appropriate casing hole and locate the

capillary in the cut out at the bottom of the

hole.

Clip the sensor into the clip provided at the

rear of the control box.

Rotate the cover plate and seal so it does not

cover the capillary, then secure with the screws

provided.

CAUTION: ISOLATE THE OIL & WATER MAINS SUPPLY BEFORE STARTING ANY

WORK AND OBSERVE ALL RELEVANT SAFETY PRECAUTIONS.

Page 25

PIPEWORK CONNECTIONS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

24

INSTALLATION

PIPEWORK CONNECTIONS

H - Flue manifold condensate outlet

J - Condensate outlet (21.5mmØ) - supplied

K - Condensate pipe - not supplied

L - Condensate trap with clamp - supplied

M - Pressure relief (15mmØ)

CONDENSATE CONNECTION:

The condensate trap (L) must be installed

onto the bracket supplied.

Measure condensate pipe (J) mark and cut

square to length required.

Fit sealing washer inside condensate pipe

nut and connect to the flue manifold outlet (H).

Connect 21.5mm polypropylene pipe (K) (not

supplied) to the condensate pipe (J)

and condensate trap (L) before terminating

to waste.

Secure the condensate trap (L) with clamp

supplied.

Ensure that the condensate pipe runs away

from the boiler at a constant fall of 50mm

(min.) for every metre.

Carefully pour 500ml of water into the

condensate collection (R) to fill condensate trap.

Check the water is running away and the

condensate pipework joints are water tight.

Check the flue manifold seal is undamaged

and seated correctly.

Refit flue manifold access cover (Q) and

secure with screws (P).

IMPORTANT: The condensate trap must be

correctly filled to prevent the possibility of

potentially harmful flue products escaping

via the condensate pipework.

PRESSURE RELIEF CONNECTION:

Connect the pressure relief pipe (M) to a

copper discharge pipe (15mmØ min.) and

terminate externally to the appliance casing.

Blank all unused casing holes with the bungs

or cover plates and seals supplied. The

drain/fire valve capillary hole covers should

be rotated so that the unused capillary slot is

covered by the cover plate and seal.

Refit rear panel.

Seal all joints where pipes pass through the

casing, with suitable waterproof sealant.

IMPORTANT: Insulate all

external condensate pipe

work or run in 32mm pipe

work to prevent freezing.

Page 26

OIL BURNER & PUMP

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

25

INSTALLATION

CAUTION: ISOLATE THE OIL & WATER

MAINS SUPPLY BEFORE STARTING ANY

WORK AND OBSERVE ALL RELEVANT

SAFETY PRECAUTIONS.

OIL BURNER:

1 Check the nozzle (A) and electrode (B)

settings are correct for the relevant burner

as shown opposite.

Ensure nozzle (A) is aligned centrally within

the combustion head (C).

Inspect for any visible defects.

IMPORTANT: Whenever replacing the

combustion head, ensure that the photocell

is lined up with the sight hole.

OIL PUMP:

Connecting the oil pump for a single pipe

system:

The pump is factory set for single pipe

operation with the flexible oil hose fitted.

Check connections before use.

Converting the oil pump for a double pipe

system:

1 Check the inlet hose connection.

a) DANFOSS BFP 11 L3:

Remove pump front cover (A) ensuring a

suitable receptacle is used to catch any oil

residue.

Remove changeover screw (B).

Remove horseshoe washer (C).

Refit changeover screw (B).

Refit front cover (A).

Remove oil pump return plug (2).

b) SUNTEC AS47C:

Remove return port plug (2) and insert

grub screw (B).

c) RIELLO RDB:

Unscrew return plug (2).

Screw in by-pass screw (3).

2 Connect the flexible oil return hose

(not supplied) between the oil pump and

the return line connection, and tighten to

secure.

5mm

Electrode gap

2.5 - 3.0mm

7.5mm

B

A

1

C

1

2

B

1

2

B

C

A

5mm

a) DANFOSS BFP 11 L3 OIL PUMP

b) SUNTEC AS47C OIL PUMP

5mm

Electrode gap 4mm

B

A

1

C

5mm

c) RIELLO RDB OIL PUMP

1

2

3

25/32 kW

12/18 & 18/25 kW

OIL BURNER & PUMP

Page 27

REFITTING COMPONENTS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

26

INSTALLATION

REFITTING COMPONENTS

1 Align burner combustion head (A) into boiler

housing tube with gasket (B) correctly fitted.

Push firmly down to compress the gasket (B).

Tighten burner retainers (C) sufficiently to

ensure a good seal.

IMPORTANT: Ensure the gasket is a good

seal between the burner combustion head

and the boiler housing to prevent flue gases

escaping from the combustion chamber

into the cabinet.

Attach the flexible air duct and tighten

clamp(D) to secure to the burner air intake.

2 Plug burner lead (E) into control box (F).

F

A

B

C

D

E

Page 28

ELECTRICS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

27

INSTALLATION

ELECTRICS

1

DANGER - 230V:

ISOLATE THE MAINS ELECTRICITY

SUPPLY BEFORE STARTING ANY

WORK AND OBSERVE ALL RELEVANT

SAFETY PRECAUTIONS.

IMPORTANT: THIS APPLIANCE

PROVIDES A PERMENANT EXTERNAL

ELECTRICAL SUPPLY FOR SERVICING

AND MUST THEREFORE BE FED VIA A

CIRCUIT BREAKER INCORPORATING

EARTH LEAKAGE PROTECTION.

IMPORTANT: OBSERVE ELECTRONIC

STATIC DISCHARGE PRECAUTIONS.

DO NOT TOUCH THE PCB CIRCUITS.

WARNING: EXTERNAL EQUIPMENT

OPERATED AT 230 VOLTS SHOULD NOT

BE SERVICED OR REPAIRED UNDER

ADVERSE WEATHER CONDITIONS.

Access to 230V connections:

1Release screws (B) and remove cover

panel (C) from control box (A).

2Release screws (D) from cable clamp (E).

Pull inner clamp part (F) outwards.

Feed sufficient power cable (G) through the

cable clamp (E) and secure grip with screw (D).

Separate wires from cable end and strip to 6mm.

230V connections (terminal block X1):

3Connect LIVE wire (Brown) to terminal L.

Connect NEUTRAL wire (Blue) to

terminal N.

Connect EARTH wire (Green/Yellow) to

the connector .

Route the power cable down the side panel and

through the service duct to the internal property

connection point avoiding any potentially hot

surfaces.

Any external device connected to the

boiler must take its power supply from

the boiler supply only and must NOT

have a separate supply.

External 230V programmer

(terminal block X4):

4 Remove 4 pin plug (M) from X4.

Remove test links (P) from plug block (M).

Connect wires to plug block (M) as shown.

Fit plug into terminal block X4.

Connect earth to terminal block X1connector

230V room thermostat (terminal block X2):

6 Remove link (K).

Connect LIVE supply to terminal L

S.

Connect SWITCHED LIVE supply to

terminal LR.

NOTE: This is sometimes refered to as ‘call

for heat’ or ‘heating load’.

Connect NEUTRAL to terminal Ns.

NOTE: Some devices do not require this.

Refit electric control panel cover:

Refit panel (C) and secure with screws (B).

NOTE: Both frost thermostats are fitted as

standard to the external appliance to provide

frost protection.

C

B

A

4

P

M

G

D

E

2/3

230V

MAINS

SUPPLY

X2

6

Neutral (if required)

Switched Live

Live

FROST

STAT(1)

FROST

STAT(2)

7 k 7

ROOMSTAT

Accelerator

resistor

(if fitted)

PROG RAMMER (EXTERNAL)

5

clock

CH channel

HW channel

N Supply

L Supply

HW Demand

CH Demand

X4

Fuse

CONTROL

BOARD

.

M

B

G

F

Fs

Ns

L

R

F

R

F

R

Ls

N

L

DHW

CH

Page 29

ELECTRICS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

28

INSTALLATION

X4

X3

X12

X11

X2

X13

X9

X1

X10

X8

X7

X6

gygy bl br

gy

or

bl

br

g

gy

bl

br

gy

bl

br

g

pk

or

y

pk

pk

pk pk

y y

y y

bk r g gy w

123456

r r

r r

r

gor

43

2

3

2

w

2

3

4

or pk y

w w

w

w

987654321

bk r g gy w

g

bk

123456

A

g bk r gy w

bl

br

gy

bl

br

gy

or

bl

br

g

230V

w

1

2

3

4

5

6

7

8

9

11

15

16

17

13

14

12

18

bl

br

w

g

10

1

N

L

Mains

connection

Service

connection

Mode

switch

ELECTRICS

Electrical components:

1 Printed circuit board

2 Thermostat - boiler high limit

3 Thermostat - DHW control

4 Thermostat - CH control

5 Indicator lamp - boiler mode

6 Indicator lamp - lock-out

7 Manual reset - overheat thermostat

8 Manual reset - flue overheat thermostat

9 Manual reset - burner lock-out

10 External programmer (not supplied)

11 Burner socket

12 Burner plug

13 Burner control box (12/18 & 18/25 shown)

14 Flow switch

15 Circulating pump

16 Diverter valve

17 Frost stat

18 Frost stat

Wire colour code:

br - Brown

bl - Blue

gy - Green/Yellow

r - Red

w - White

y - Yellow

g - Grey

bk - Black

or - Orange

pk - Pink

Page 30

PRE-COMMISSIONING

CHECKS - APPLIANCE

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

29

PRE-COMMISSIONING CHECKS -

APPLIANCE

CAUTION: ISOLATE THE MAINS SUPPLIES

BEFORE STARTING ANY WORK AND

OBSERVE ALL RELEVANT SAFETY

PRECAUTIONS.

1 Check that the service and water pipes are

connected correctly.

Check that all unused sockets are capped.

2 Check that the oil supply is kerosene and

that the pipework is connected correctly

to the oil pump via the supplied flexible oil

hose.

Turn on the main oil supply valve at the

tank, check the oil supply pipework and

connections. Rectify any leaks.

3 Check the flue is correctly fitted and the

connections are secure.

4 Check the condensate pipework is

correctly fitted and connected.

Check the condensate trap is filled with

water.

5 Check the CH circulating pump is set to 3.

NOTE: The CH circulating pump is preset to

number 3 and should not be altered. The

diagrams opposite show the pump outputs.

NOTE: The cabinet is not load bearing, it only

provides weather protection for the boiler

inside.

IMPORTANT: If the boiler is not to be

commissioned immediately then:

After successfully completing all of the

checks and any rectification work, close the

water valves, shut off the oil supply and

electrically isolate the boiler.

Complete the installation part of the

Guarantee Registration Card, and complete

a CD10 or its equivalent, to inform the LABC

of the installation.

COMMISSIONING

1

3

2

5

4

12/18 & 18/25

0.6

Bar

Bar

0.5

0.4

0.3

0.2

0.1

0

200

400 600 800 1000 1200 1400 1600

0

Litres per hour

25/32

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

200

400 600 800 1000 1200 1400 1600 1800 2000 2200 2400

0

Litres per hour

Page 31

FILLING THE SYSTEM

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

30

COMMISSIONING

1 Pull lever (C) up and push to the left to

move the diverter valve to the mid-position

between ports A and B.

Push and hold lever (C) down to lock.

2 Loosen the automatic air vent cover.

4 Sealed systems only; check and if required,

adjust the expansion vessel pressure using

the Schraeder type valve (D).

The charge pressure of the built-in 12 Litre

expansion vessel is 0.5 bar as dispatched,

which is equivalent to a static head of 5

metres (16.7 ft).

If an extra expansion vessel is fitted to the

central heating return, adjust this to the same

pressure as the appliance internal expansion

vessel, refer to separate instructions supplied

with the extra expansion vessel.

4 Open all system and radiator valves (E).

Turn on the water main stop cock.

Open vented systems only; turn on the

water to the system feed and expansion

cistern and allow the system to fill.

Sealed systems only; fill the system to

between 1 and 2 bar pressure via a WRAS

approved filling link. Monitor the pressure

gauge during venting and repressurise if

required.

Check air is being discharged from the

automatic air vent.

Vent all radiators, retighten when completed,

check the system and correct any leaks.

Bleed air from both of the secondary heat

exchanger air vents (F).

Bleed air from the pipework using the

pump bleed screw.

5 Sealed systems only; connect a suitable

hose to the Heatslave tank drain. Open the

drain valve to reduce the system to the