Page 1

4530 SERIES

RF POWER METER

INSTRUCTION MANUAL

This manual is applicable to: Revision date: 11/26/2002Revision date: 11/26/2002

Instrument serial numbers: ALL* Manual P/N: 98404800C

Operating Firmware Versions: 20021 1 19 and later* CD P/N: 98404899C

*earlier firmware may not contain all capabilities listed herein

ersions: 20021 1 19 and later* CD P/N: 98404899C

Manual P/N: 98404800C

%

BOONTON ELECTRONICS Web Site: www .boonton.com

A subsidiary of Noise/Com -- A Wireless T elecom Group Company Email: boonton@boonton.com

25 Eastmans Road T elephone: 973-386-9696

Parsippany , NJ 07054-0465 Fax: 973-386-9191

Page 2

& 1998-2001, 2002 Boonton Electronics. All rights reserved.

% is a registered trademark of Boonton Electronics, a subidiary

of Noise/Com, a Wireless T elecom Group Company

Boonton Electronics

25 Eastmans Road

Parsippany , NJ 07054-0465

Information contained in this manual is subject to change without notice. Boonton Electronics makes no warranty of

any kind with regard to this material, including, but not limited to, the implied warraties of merchantability and fitness

for a particular purpose. Boonton Electronics shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishings, performance, or use of this material. No part of this

document may be photocopied, reproduced, or translated to another language without the prior written consent of

Boonton Electronics.

Page 3

Boonton Electronics Contents

4530 Series RF Power Meter

Contents

CHAPTER/SECTION PAGE

List of Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

List of Illustrations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Repair Policy and Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

1. GENERAL INFORMA TION

1.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4.2 Calibration Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4.3 Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4.4 Sampling Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4.5 Measurement Characteristics . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4.6 Sensor Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4.7 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4.8 Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.4.9 Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2. INST ALLA TION

2.1 Unpacking and Re-Packing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 Internal Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.4 Preliminary Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3. OPERA TION

3.1 Operating Controls, Indicators and Connections . . . . . . . . . . . . . . . 3-1

3.2 Key Function Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

i

Page 4

Contents Boonton Electronics

4530 Series RF Power Meter

Contents (Cont)

CHAPTER/SECTION PAGE

3.3 Display Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.1 Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.2 Measurement Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.3 Status Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.4 Channel Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.5 Header / Page Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.4 Operating Mode Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.4.1 Menu Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.4.2 Text Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.4.3 Graph Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.4.4 Edit Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.4.5 Zero/Calibration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.5 Menu Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.5.1 Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.5.2 Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.5.3 Menu Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.5.4 Menu Screen Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.5.5 Menu Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.6 Text Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.6.1 Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.6.2 Measurement Page Selection . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.6.3 Channel Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.6.4 Measurement Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.6.5 Parameter Editing from Text Mode. . . . . . . . . . . . . . . . . . . 3-11

3.7 Graph Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.7.1 Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.7.2 Measurement Page Selection . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.7.2 Channel Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.7.3 Measurement Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.7.4 Parameter Editing from Graph Mode . . . . . . . . . . . . . . . . . 3-12

3.8 Edit Mode Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.8.1 Entry, Exit and Channel Selection . . . . . . . . . . . . . . . . . . . . 3-12

3.8.2 Screen Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.8.3 Parameter Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.8.4 Parameter Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

ii

Page 5

Boonton Electronics Contents

4530 Series RF Power Meter

Contents (Cont)

CHAPTER/SECTION PAGE

3.9 Display Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.9.1 Channel Selection and Paging. . . . . . . . . . . . . . . . . . . . . . . 3-14

3.9.2 Mixed Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Operation . . . . . . . . . . . . . . . . . . . . . . . . .

3.10 Sensor Connection and Calibration . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.10.1 Sensor Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.10.2 Zero Offset Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.10.3 Fixed Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.10.4 Automatic (step) Calibration . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.10.5 Frequency Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.10.6 Calibrator Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.10.7 Calibration Volatility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.10.8 Zero/Cal Menu Navigation. . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.11 Menu Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3.11.1 Measure Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3.11.2 Channel Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.11.3 Markers Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

3.11.4 Trig/Time Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

3.11.5 Statisticl Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

3.11.6 Calibratr Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

3.11.7 Save/Recl Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

3.11.8 Utilities Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

3.11.9 Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

3.11.10Defaults Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

3.11.11 Menu Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

and Calibration . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(step) Calibration . . . . . . . . . . . . . . . . . . . . .

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12 Error Messages and Status Codes . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

3.13 Recorder Output Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

3.14 Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50

4. REMOTE OPERA TION

4.1 GPIB Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Serial Port Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 SCPI Language Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

iii

Page 6

Contents Boonton Electronics

4530 Series RF Power Meter

Contents (Cont)

CHAPTER/SECTION PAGE

4.4 Basic Measurement Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.5 Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.5.1 MEASure Queries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.5.2 INITiate and ABORt Commands . . . . . . . . . . . . . . . . . . . . 4-5

4.5.3 FETCh Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.5.4 READ Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.5.5 Native Mode Queries . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.4.6 SENSe Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.5.7 Calculate Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4.5.8 MARKer Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

4.5.9 DISPlay Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

4.5.10 TRIGger Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

4.5.11 TRACe Data Array Commands . . . . . . . . . . . . . . . . . . . . . 4-36

4.5.12 SENSe:MBUF Data Array Commands . . . . . . . . . . . . . . . 4-37

4.5.13 SENSe:SBUF Data Array Commands . . . . . . . . . . . . . . . . 4-39

4.5.14 SENSe:HIST & SENSe:CAL T AB Data Array Cmnds. . . . 4-40

4.5.15 CALibration Sybsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

4.5.16 MEMory Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

4.5.17 OUTput Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

4.5.18 SYSTem Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

4.5.19 ST AT us Com mands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

4.5.20 IEEE-488.2 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

4.5.21 Remote Interface Command Summary . . . . . . . . . . . . . . . . 4-56

Queries . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . .

Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Array Commands . . . . . . . . . . . . . . . . . . .

Data Array Commands . . . . . . . . . . . . .

Data Array Commands. . . . . . . . . . . . . .

4.6 Remote Sensor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-61

4.6.1 AutoCal . . . . . . . . . . . . . . . . . . . .

4.6.1 AutoCal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-61

4.6.2 Zero and Fixed Cal . . . . . . . . . . . .

4.6.2 Zero and Fixed Cal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-61

Native Mode Programming . . . . . . . . . . . .

4.7 Native Mode Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

4.8 SCPI Example Program Fragments . . . . . . . . . . . . . . . . . . . . . . . . 4-63

SCPI Example Program Fragments . . . . . .

4.8.1 Pulse Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-63

4.8.1 Pulse Mode . . . . . . . . . . . . . . . . . .

4.8.2 Modulated Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-65

4.8.2 Modulated Mode . . . . . . . . . . . . .

4.8.3 CW Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-65

4.8.3 CW Mode

4.8.4 Statistical Mode - CDF, CCDF, DISTRIBUTION . . . . . . 4-66

4.9 Error and Status Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-67

. . . . . . . . . . . . . . . . . . . 4-61

. . . . . . . . . . . . . . . . . . . 4-61

. . . . . . . . . . . . . . . . . . . 4-62

. . . . . . . . . . . . . . . . . . . 4-63

. . . . . . . . . . . . . . . . . . . 4-63

. . . . . . . . . . . . . . . . . . . 4-65

4-65

iv

Page 7

Boonton Electronics Contents

4530 Series RF Power Meter

Contents (Cont)

CHAPTER/SECTION PAGE

5. MAKING MEASUREMENTS

5.1 Sensor Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 Thermal RF Power Sensors . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.2 CW Dual-Diode RF Power Sensors . . . . . . . . . . . . . . . . . 5-1

5.1.3 R F Voltage Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.1.4 Peak Power Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2 Selecting the Right Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.2.1 CW Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.2.2 Modulated Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3 Measurement Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3.1 CW Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3.2 Modulated Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.3.3 Statistical Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.3.4 Pulse Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.4 Selecting the Right Measurement Mode . . . . . . . . . . . . . . . . . . . . . 5-6

5.4.1 CW Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.4.2 Modulated Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.4.3 Pulse Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.4.4 Statistical Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Sensors . . . . . . . . . . . . . . . . . . . . . .

. . . .

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sensors

Measurement Mode . . . . . . . . . . . . . . . . . . .

Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Setting Measurement Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.5.1 What You Need to Know . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.5.2 Channel Parameters Menu Settings . . . . . . . . . . . . . . . . . . 5-7

5.5.3 Trig/Time Menu Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.6 Settings for some Common Signal Types . . . . . . . . . . . . . . . . . . . . 5-9

5.6.1 Measuring GSM and EDGE . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.6.2 Measuring NADC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.6.3 Measuring iDEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.6.4 Measuring Bluetooth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.6.5 Measuring CDMA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.6.6 Measuring HDTV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.7 Measurement Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.7.1 Error Contributions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.7.2 Discussion of Error Terms . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.7.3 Sample Uncertainty Calculations . . . . . . . . . . . . . . . . . . . . 5.17

Parameters . . . . . . . . . . . . . . . . . . . . . . . .

Need to Know

Menu Settings . . . . . . . . . . . . . . . .

v

Page 8

Contents Boonton Electronics

4530 Series RF Power Meter

Contents (Cont)

CHAPTER/SECTION PAGE

APPENDIX A

Available Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX B

Model 2530 1 GHz Calibrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

vi

Page 9

Boonton Electronics Contents

4530 Series RF Power Meter

List of Tables

TABLE PAGE

3-1 Keyboard Controls, Indicators and Connectors . . . . . . . . . . . . . . . . 3-2Indicators and Connectors . . . . . . . . . . . . . . .

3-2 4530 Graph and Text Mode Edit Menus . . . . . . . . . . . . . . . . . . . . . . 3-13

3-3 Measurement Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3-4 Zero/Cal Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3-5 Main Menu Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

3-6 Graph/Text Header Error and Status Messages . . . . . . . . . . . . . . . . . 3-47

3-7 Sensor and Probe Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

3-8 Sensor Zero / Cal Status Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

3-9 Startup Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

4-1 Remote Command Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

4-2 Remote Interface Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-67

4-3 Measurement Result Status Codes . . . . . . . . . . . . . . . . . . . . . . . . . . 4-67

Mode Edit Menus . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 10

Contents Boonton Electronics

4530 Series RF Power Meter

List of Illustrations

ILLUSTRATION PAGE

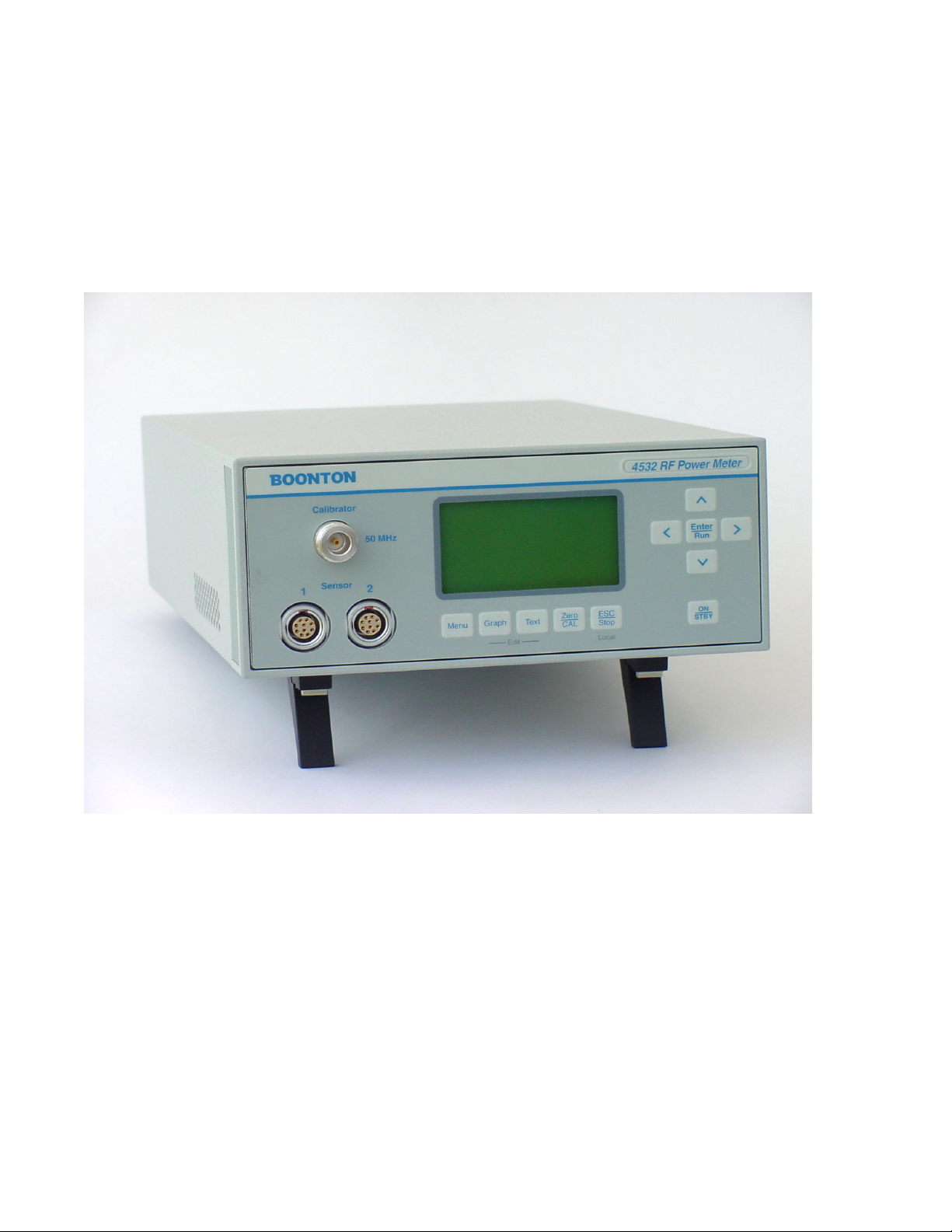

C-1 4530 Series RF Power Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

2-1 Unpacking and Packing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

3-1 4530 Series, Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2 4530 Series, Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-3 Display Areas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-4 Menu Mode Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-5 Text Mode Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-6 Graph Mode Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-7 Edit Mode Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-8 Zero/Cal Mode Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-9 Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-10 Digit Editing Mode Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-11 Menu Mode Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-12 Text Mode Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3-13 Graph Mode Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3-14 Edit Mode Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3-15 Graphic Mixed Mode Measurement Displays . . . . . . . . . . . . . . . . . . 3-15

3-16 Graphic Mixed Mode Edit Displays . . . . . . . . . . . . . . . . . . . . . . . . . 3-15Edit Displays . . . . . . . . . . . . . . . . . . . . . . . .

3-17 Text Mixed Mode Measurement Displays . . . . . . . . . . . . . . . . . . . . . 3-16

Displays . . . . . . . . . . . . . . . . . . . .

3-18 Text Mixed Mode Edit Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3-19 External Calibrator Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3-20 Zero/Calibration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Displays . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

Page 11

Boonton Electronics Contents

4530 Series RF Power Meter

SAFETY SUMMARY

The following general safety precautions must be observed during all phases of operation and maintenance of this

instrument. Failure to comply with these precautions or with specific warnings elsewhere in this manual violates safety

standards of design, manufacture, and intended use of the instrumenmts. Boonton Electronics Corporation assumes

no liability for the customer’s failure to comply with these requirements.

INSTRUMENT MUST BE GROUNDED

T o minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical ground. The instrument is equipped with a three conductor, three prong AC power cable. The power cable must either be plugged into an

approved three-contact electrical outlet or used with a three-contact to a two-contact adapter with the (green) grounding wire firmly connected to an electrical ground at the power outlet.

DO NOT OPERA TE THE INSTRUMENT IN AN EXPLOSIVE A TMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

KEEP A WA Y FROM LIVE CIRCUITS

Operating personnel must not remove instrument covers. Component replacement and internal adjustments must be

made by qaulified maintenance personnel only. Never replace components or operate the instrument with the covers

removed and the power cable connected. Even with the power cable cable removed, dangerous voltages may be

present. Always remove all jewelry (rings, watches, etc.) and discharge circuits before touching them. Never attempt

internal service or adjustment unless another person, capable of rendering first aid and resusitaion, is present.

DO NOT SUBSTITUTE P ARTS OR MODIFY INSTRUMENT

Do not substitute parts or perform any unauthorized modification of the instrument. Return the instrument to

Boonton Electronics for repair to insure that the warrenty and safety features are maintained.

! This safety requirement symbol has been adopted by the International

Electrotechnical Commission. Document 66 (Central Office) 3, Paragraph

5.3, which directs that an instrument be so labeled if, for the correct use of

the instrument, it is necessary to refer to the instruction manual. In this

case it is recommended that reference be made to the instruction manual

when connecting the instrument to the proper power source. Verify that

the correct fuse is installed for the power available.

NOTE NOThe appearance of NOTE

CAUTION The CAUTION sign denotes a hazard. It calls attention to an operating

The appearance of TE indicates that clarifying information follows

immediately

immediately. In many cases this information is necessary for proper operation or is a further explanation of important data.

procedure which, if not correctly performed or adhered to, could result in

damage to the instrument or equipment under test. Do not procedeed

beyond a CAUTION sign until the indicated conditions are fully understood and met.

WARNING The WARNING sign denotes a hazard. It calls attention to an operating

procedure, which, if not correctly performed or adhered to could result in

personal injury. Do not procedeed beyond a WARNING sign until the

indicated conditions are fully understood and met.

ix

Page 12

Contents Boonton Electronics

4530 Series RF Power Meter

Figure C-1 4530 Series RF Power Meter

x

Page 13

Boonton Electronics Contents

4530 Series RF Power Meter

Repair Policy

Model 4531 / 4532 Instrument. If the Boonton Model 4531/4532 RF Power Meter is not operating correctly and

requires service, contact the Boonton Electronics Service Department for return authorization. You will be provided

with an RMA number and shipping instructions. Customers outside the USA should contact the authorized Boonton

distributor for your area. The entire instrument must be returned in its original packing container. If the original

container is not available, Boonton Electronics will ship a replacement container and you will be billed for the container

cost and shipping charges.

Boonton Peak Power Sensors. Damaged or defective peak power sensors are repaired as separate accessories.

Note that sensors which have failed due to overloading, improper mating, or connecting to an out-of-tolerance connector are not considered defective and will not be covered by the Boonton Warranty. If repair is needed, contact the

Boonton Electronics Service Department for return authorization. You will be provided with an RMA number and

shipping instructions. Customers outside the USA should contact the authorized Boonton distributor for your area.

Only the defective sensor should be returned to Boonton, not the entire instrument. The sensor must be returned in its

original packing container. If the original container is not available, Boonton Electronics will ship a replacement

container and you will be billed for the container cost and shipping charges. If a new sensor is ordered, note that it

does not include a sensor cable - this item must be ordered separately.

arranty

.

Contacting Boonton. Customers in the United States having questions or equipment problems may contact

Boonton Electronics directly during business hours (8 AM to 5 PM Eastern) by phoning (973) 386-9696. FAX messages may be sent at any time to (973) 386-9191. Email inquiries should be sent to service@boonton.com.

International customers should contact their authorized Boonton Electronics representative for assistance. A current

list of authorized US and international representatives is available on the Boonton website at www.boonton.com.

Limited W arranty

Boonton Electronics warrants its products to the original Purchaser to be free from defects in material and workmanship and to operate within applicable specifications for a period of one year from date of shipment for instruments,

probes, power sensors and accessories. Boonton Electronics further warrants that its instruments will perform within

all current specifications under normal use and service for one year from date of shipment. These warranties do not

cover active devices that have given normal service, sealed assemblies which have been opened, or any item which has

been repaired or altered without Boonton’s authorization.

Boonton’s warranties are limited to either the repair or replacement, at Boonton’s option, of any product found to be

defective under the terms of these warranties.

There will be no charge for parts and labor during the warranty period. The Purchaser shall prepay inbound shipping

charges to Boonton or its designated service facility and shall return the product in its original or an equivalent

shipping container. Boonton or its designated service facility shall pay shipping charges to return the product to the

Purchaser for domestic shipping addresses. For addresses outside the United States, the Purchaser is responsible for

prepaying

all shipping charges, duties and taxes (both inbound and outbound).

THE FOREGOING W ARRANTIES ARE IN LIEU OF ALL OTHER W ARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED W ARRANTIES OF MERCHANT ABILITY AND FITNESS FOR A P ARTICULAR PURPOSE. Boonton will not be liable for any incidental damages or for any consequential damages, as

defined in Section 2-715 of the Uniform Commercial Code, in connection with products covered by the foregoing

warranties.

xi

Page 14

Contents Boonton Electronics

4530 Series RF Power Meter

xii

Page 15

Boonton Electronics Chapter 1

4530 Series RF Power Meter General Information

GENERAL INFORMATION 1

1.1 DESCRIPTION

The 4530 Series RF Power Meter is a new generation of instruments. It allows high-resolution power measurement of

a wide range of CW and modulated RF signals over a dynamic range of up to 90dB depending on sensor. The power

meter is available configured as the single-channel Model 4531, or as the dual-channel Model 4532. For the remainder

of this manual, the series designation of 4530 will be used to indicate either model, except when otherwise stated.

The 4530 is really several instruments in one, and can function as a CW Power Meter, a Peak Power Meter , a Statistical

Power Analyzer, and an RF Voltmeter. It accepts the full series of Boonton RF power and voltage sensors, which

includes coaxial dual-diode sensors and thermal sensors. Sensor data and calibration information is automatically

downloaded from the sensor or “smart adapter” whenever a new sensor is connected, eliminating the need to manually

enter calibration factors.

When used as a CW power meter, the 4530 provides seamless measurement performance due to the extremely wide

dynamic range of its input stage. Thermal and peak power sensors require no range switching under any conditions,

and even CW diode sensors spanning a 90dB dynamic range require only two widely overlapping ranges. This means

that practically any measurement can be performed without the interruptions and non-linearities associated with the

range changes of conventional power meters.

For modulated signals, the 4530 can make accurate average and peak power measurements with modulation bandwidths as high as 20MHz, making it ideal for high-speed digitally modulated carriers such as CDMA, W-CDMA, GSM,

TDMA, HDTV and UMT . Periodic and pulse waveforms can be displayed in graphical format, and a host of automatic

measurements are available which characterize the time and power profiles of the pulse. Effective sampling rates up to

50MSa/sec and user programmable cursors allow instantaneous power measurements at precise time delays from the

pulse edge or an external trigger as well as time gated or power gated peak and average power.

For spread-spectrum or randomly modulated signals such as CDMA, the 4530’s powerful statistical analysis mode

allows full profiling of the power probability at all signal levels. Sustained acquisition rates in excess of one million

readings per second along with rangeless operation insure that a representative population can be acquired and

analyzed in minimum time. By analyzing the probability of occurrence of power levels approaching the absolute peak

power, it is possible to characterize the occasional power peaks that result in amplifier compression and data errors.

Because of the random and very infrequent nature of these events, they are next to impossible to spot with the

conventional techniques used in other universal power meters. In addition, the instrument’s extremely wide video

bandwidth insures that even the fastest peaks will be accurately measured.

The 4530’s powerful dual-processor architecture permits advanced measurement capabilities with unprecedented

speed and performance. A high-speed, floating-point digital signal processor (DSP) performs the measurements. It

gathers and processes the power samples from the sensors, performs time-stamping, linearity correction, gain adjustment and filtering, all in fractions of a microsecond. The processed measurements are then passed to a dedicated,

32-bit I/O processor that monitors the keyboard, updates the LCD display and responds to RS-232 and GPIB requests

for formatted measurements. This design eliminates the speed tradeoffs between measurement data input (acquisition)

and output (over the GPIB) that are so common among other power meters.

, the 4530 provides seamless measurement performance due to the extremely wide

Instrument operating firmware is stored in flash memory that may be field reprogrammed with any PC via the onboard

RS-232 port. Free firmware upgrades permit the easy addition of new features or capabilities that may become available

in the future. Visit the Boonton website at WWW.BOONTON.COM for upgrade information and to download the

latest firmware version.

1-1

Page 16

Chapter 1 Boonton Electronics

General Information 4530 Series RF Power Meter

1.2 FEATURES

Multi-mode capability Utilizes CW sensors, Peak Power sensors and V oltage probes with automatic sens-

ing and setup for each type. Measures conventional CW power and voltage,

power versus time for pulse analysis, and statistical power distributions for spread

spectrum signals.

Text and Graphics The backlit LCD display shows numerical results as well as graphical results for all

measurements. Measurements are displayed using a large, easy-to-read numerical

format, or in graph mode with a fast-updating, oscilloscope-like trace.

Dual Independent ChannelsDual Independent Channels Model 4532 is equipped with two identical independent measurement channels

with the capability to display two pulse measurements, two statistical measurements or two CW measurements at the same time.

Remote Programming All functions except power on/off can be controlled by a GPIB interface or via an

RS-232 serial connection. The programming language follows the SCPI model with

added non-SCPI commands for special applications.

1.3 ACCESSORIES

Supplied accessories: 1 – NEMA type power cable

1 – Fuse Kit

1 – 4530 Series Operators Instruction Manual

Other accessories: Rack Mounting Kit

See Boonton Electronics Power Sensor Manual for power sensors available.

Options: Model 4531 Single Channel RF Power Meter

Model 4532 Dual Channel RF Power Meter

Rear panel sensor inputs

Rear panel calibrator output

1.4 SPECIFICATIONS MODTIONS MODEL 4531 and 4532 4531 and 4532

1.4.1 General.

Sensor Inputs (Performance depends upon sensor model selected)

Channels: Single Input: Model 4531

Dual Input: Model 4532

RF Frequency Range: 10 kHz to 110 GHz ( Sensor dependent )

Peak Power Measurement Range: -40 to +20 dBm ( Sensor dependent )

CW Measurement Range: -70 to +44 dBm ( Sensor dependent )

Relative Offset Range: ±99.99 dB

V ideo Bandwidth: 20 MHz (Sensor dependent)

Single Shot Bandwidth: 250 kHz (based on 10 samples per pulse)

Pulse Repetition Rate: 1.8 MHz maximum for stable, internal trigger

1-2

Page 17

Boonton Electronics Chapter 1

4530 Series RF Power Meter General Information

1.4.2 Calibration Sources

Internal Calibrator

Output Frequency: 50 MHz ± 0.005%

Level: -60 to +20 dBm

Resolution: 0.1 dB steps

Source SWR: 1.05 (reflection coefficient = 0.024)

Accuracy, 0° to 20°C, NIST traceable: At 0 dBm: ±0.055 dB (1.27%)

+20 to -39 dBm: ±0.075 dB (1.74%)

-40 to -60 dBm: ±0.105 dB (2.45%)

RF Connector: T ype N

External Calibrator (See Appendix B)

Model 2530 1 GHz Calibrator (Purchased separately if required)

1.4.3 T rigger ( Peak power modes only . )

Modes: Pre-trigger and post-trigger

Trigger Time Resolution: 20 ns

Trigger Delay: ±900µs for timespans 5µs and faster

±4ms for timespans 10µs to 50µs

± (80 x TimeSpan) for timespans 50µs to 2ms

± (30 x TimeSpan) for timespans 5ms and slower

Trigger Holdoff: 0 µs to 1 sec, resolution 1µs

Internal Trigger Range: Equivalent to -30 to +20 dBm pulse amplitude range.

External Trigger Range: ±5 volts, ±50 volts with 10:1 divider probe.

External Trigger Input: 1 megohm in parallel with approximately 15pF , dc coupled.

External Trigger Connector: Rear-panel BNC input

1.4.4 Sampling Characteristics

Effective sampling rate: 50 Megasamples per second (each channel, pulse mode)

Sustained sampling rate: 2.5 Megasamples per second (each channel, pulse mode)

Measurement Technique: Continuous and triggered (burst) sampling

1-3

Page 18

Chapter 1 Boonton Electronics

General Information 4530 Series RF Power Meter

1.4.5 Measurement Characteristics

Measurements: Average Power*

Maximum A verage Power*

Minimum A verage Power*

Maximum Instantaneous (“Peak”) Power*

Minimum Instantaneous Power*

Peak to A verage Power Ratio*

Cumulative Distribution Functions: CDF , 1- CDF ,

Probability Distribution (histogram)

Power at a percent statistical probability

Statistical probability at a power level

CW Power

RF V oltage

* All measurements marked with an asterisk (*) may be performed con-

tinuously, or in a synchronous, triggered mode. When triggered, these

measurements may be made at a single time offset relative to the trigger ,

or over a defined time interval. The time offset or interval may be before

or after, or may span the trigger interval.

Channel Math: Displays the ratio, sum (power sensors) or difference (voltage sensors)

between channels or between a channel and a reference measurement

(Modulated and CW modes only).

Trace A veraging: 1 to 4096 samples per data point.

Panel setup storage: 4 complete setups.

Measurement rate (via GPIB): Greater than 200 two-channel measurements per second, neglecting bus

master overhead, or 500 single-channel measurements per sec.

1.4.6 Sensor Characteristics

CW Power Sensors

Power Detection Technique: Dual diode, single diode or thermo-electric.

Internal Data: Frequency and linearity calibration tables, frequency range, power range,

sensor type, serial number and other sensor dependent information are

stored in EEPROM within the sensor cable or in a cable-adapter for use

with existing CW sensors.

Peak Power Sensors

Power Detection Technique: Dual diode with selectable detector bandwidth.

Signal compression: The use of logarithmic signal compression circuitry in the sensor enables

the instrument to measure and analyze changes in power exceeding 60

dB in a single range.

Internal Data: Frequency, linearity and temperature calibration tables, frequency range,

power range, sensor type, serial number and other sensor dependent

information are stored in EEPROM within the peak power sensor.

Sensor Cable: The sensor cable is detachable from both sensor and instrument. The

standard cable length is 5 feet. Optional cable lengths are 10, 20, 25, and

50 feet. Additional cable length will affect measurement bandwidth.

RF V oltage Sensors Dual diode detector.

1-4

Page 19

Boonton Electronics Chapter 1

4530 Series RF Power Meter General Information

1.4.7 Interface

Video Output: Compressed representation of detected RF envelope of peak channel(s)

envelope for external oscilloscope monitor or external device synchronization. This output is roughly logarithmic with input power, is not

calibrated, and can not be used for making any measurements.

Recorder Output: Programmable voltage output which may be used for monitoring mea-

surements or status of either channel, or for outputting a fixed,

programmable voltage. When used as a measurement monitor, the output is proportial to displayed signal level with programmable or automatic

scaling.

Output range: 0 to 10V (unipolar), or -10V to +10V (bipolar)

Output resolution: 5.0mV

Output impedance: 9 K

Absolute accuracy: ±100mV typical, ±200mV max, uncalibrated

±20mV after user calibration

Linearity: 0.1% typical

GPIB Interface: Complies with IEEE-488.1. Implements AH1, SH1,T6, LE0, SR1, RL1, PP0,

DC1, DT1, C0, and E1.

RS-232 Interface: Accepts GPIB commands (except bus dependent commands). Provides

for user software updates.

Remote Programming: SCPI (1990) compliant and Native Mode commands via GPIB or RS-232

interfaces.

Software Drivers: LABVIEW drivers available.

1.4.8 Environmental Specifications

General: Manufactured to the intent of MIL-T 28800E, T ype III, Class 5, Style E

CE Mark: Conforms to EU specifications:

EN 61010-1(90)(+A1/92)(+A2/95)

EN 61010-2-031

EN 61326-1(97)

EN 55022(94)(A2/97)Class B

Display: Graphic type LCD, with LED backlight. T ext and trace displays.

Operating Temperature: 0 to 5 0° C

Ventilation: Fan cooledFan cooled

Altitude: Operation up to 15,000 feet.

Storage Temperature: -40 to 75° C

Humidity: 95% ±5% maximum (non-condensing).

Operation up to 15,000 feet.

-40 to 75° C

95% ±5% maximum (non-condensing).

Shock: Withstands ±20G, 42ms impulse in X, Y , and Z axes, as per MIL-STD-810.

V ibration: Conforms to MIL-STD-167-1.

Power Requirements: 90 to 260 V AC, 47 to 63 Hz, <50 VA , <30 Watts. No voltage switching

Battery: One Lithium coin cell for maintaining non-volatile memory information.

Withstands ±20G, 42ms impulse in X, Y ,

Conforms to MIL-STD-167-1.

90 to 260 V AC, 47 to 63 Hz, <50 VA

required.

Not user replaceable. Typical battery life: 10 years.

1-5

Page 20

Chapter 1 Boonton Electronics

General Information 4530 Series RF Power Meter

1.4.9 Physical Specifications

Dimensions: 3.5 inches (8.9 cm) high,

8.4 inches (21.3 cm) wide,

13.5 inches (34.3 cm) deep,

All dimensions are approximate, and exclude clearance for feet and

connectors. Feet may be removed for rack mounting.

Weight: 7 lbs. (3.2kg)

Connector location option: Sensor input(s) and calibrator connector: Front or rear panel.

Construction: Surface mount, multilayer printed circuit boards mounted to rigid alumi-

num frame and front extrusion/casting with aluminum sheet metal

enclosure.

Note: All specifications are subject to change without notice.

1-6

Page 21

Boonton Electronics Chapter 2

4530 Series RF Power Meter Installation

INSTALLATION 2

2.1 UNP ACKING & REP ACKING

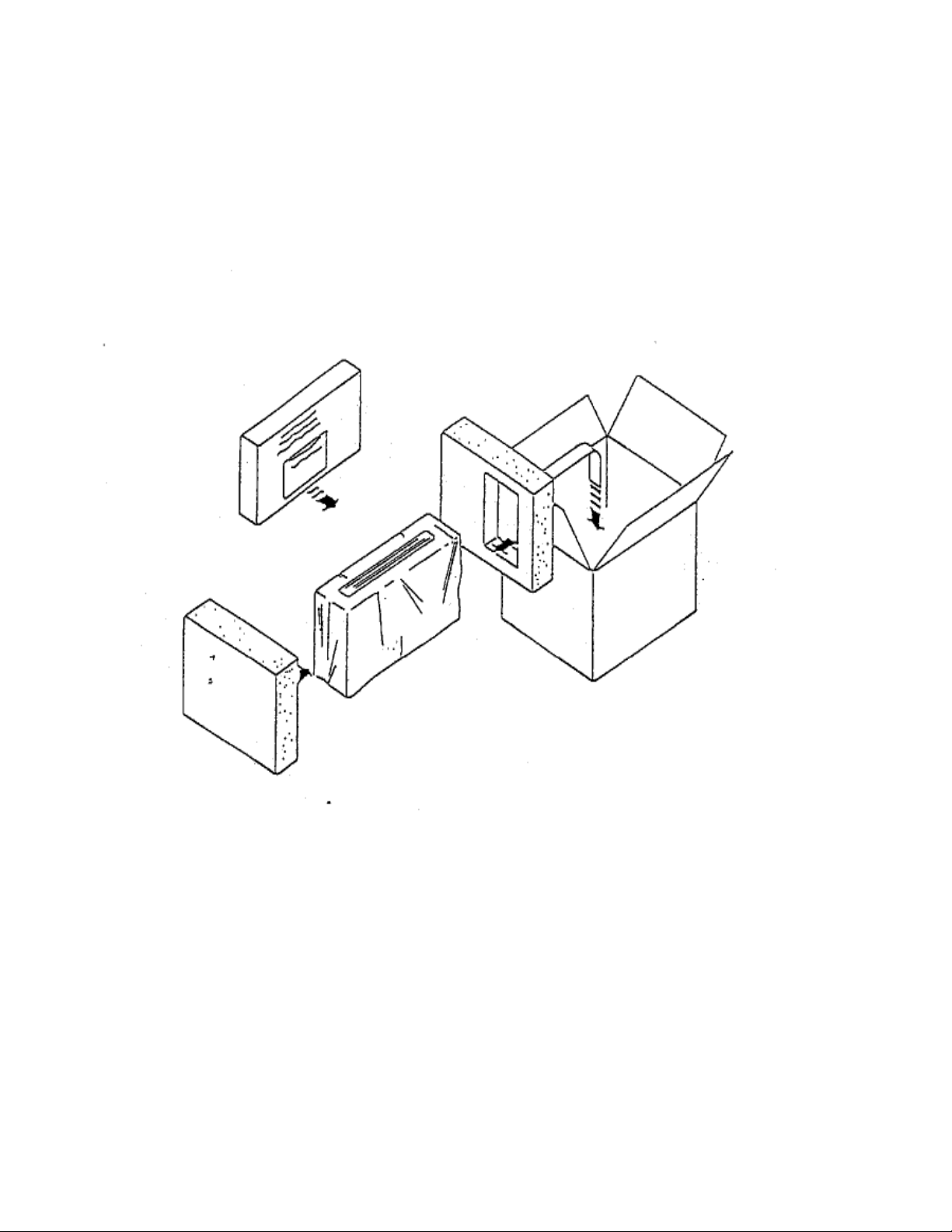

The 4530 Series RF Power Meter is shipped complete and ready to use upon receipt. Figure 2-1 shows the packaging

material. Save the packing material and container to ship the instrument if necessary . If the original materials are not

available, contact Boonton Electronics to purchase replacements. Store materials in a dry environment.

2.2 POWER REQUIREMENTS

The 4530 Series is equipped with a switching power supply that permits operation from a 90 to 260 volt, 47 to 63 Hz,

single-phase AC power source. Power consumption is 50 VA maximum. For replacement fuses, use the fuse kit

supplied.

CAUTION

Before connecting the instrument to the power source, make certain that the correct

fuse(s) are installed in the power entry module on the rear panel.

W ARNING

Before removing the instrument cover for any reason, place the entry module power

switch in the OFF (0=Off) position and remove the line cord from the entry module.

2.3 INTERNAL BA TTERY

The 4530 Series contains a coin cell Lithium battery to provide memory backup when the power source is off. The

battery has an expected life of ten years and is not user replaceable.

2.4 PRELIMINARY CHECK

The following preliminary check verifies that the instrument is operational and has the correct software installed. It

should be performed before the instrument is placed into service. T o perform the preliminary check, proceed as follows:

1. Connect the AC power cord to a suitable AC power source.

2. Press the upper half of the rocker type power switch located in the power entry module on the rear panel.

3. If the instrument does not start up, press the ON/STBY key on the front panel.

4. A banner message should appear on the LCD display, followed by a self-check display and sensor detection

messages. If any fatal errors occur during the startup, the process will terminate with a failure message on the

display. Any marginal conditions detected will be indicated with a cautionary message, but the startup process

will be allowed to proceed.

5 . When the startup process is complete, press the Menu key twice to force the Main Menu to be displayed. Using

the arrow keys to move through the list of menu items and the Enter key to select Utilities > Sys-Tests >

SystemInf display. Verify that the Serial Number matches the number on the rear panel tag. If the numbers do not

match, contact Boonton Electronics technical support.

2-1

Page 22

Chapter 2 Boonton Electronics

Installation 4530 Series RF Power Meter

6. The sensors supplied with the instrument may vary widely in model number and type. Refer to Section 3-9 for

information on connecting and calibrating sensors.

7. Upon successful calibration of the supplied sensors, the instrument is ready for use.

Figure 2-1. Packing and Unpacking Diagram

2-2

Page 23

Boonton Electronics Chapter 3

4530 Series RF Power Meter Operation

OPERATION 3

3.1 OPERATING CONTROLS, INDICA TORS AND CONNECTIONS

Controls, indicators and connectors for the 4530 Series RF Power Meter are shown in figures 3-1 and 3-2. The front

panel is illustrated in figure 3-1 and the rear panel in figure 3-2.

12345

12 11 10 9 8 7 6

Figure 3-1. 4530 Series, Front Panel

12 13 1

18 17 16 15 14 19

Figure 3-2. 4530 Series, Rear Panel

3-1

Page 24

Chapter 3 Boonton Electronics

Operation 4530 Series RF Power Meter

3.2 KEY FUNCTION SUMMARY

Table 3-1 references each operating key or connector to a callout in Figure 3-1or 3-2 and briefly describes the key

function

Table 3-1. Keyboard Controls and Connectors

Item Figure 3-1 Function

50 MHz Calibrator 1 The output of the built-in 50MHz programmable calibrator is available

from a Type-N connector located on the front or optionally on the rear

panel of the instrument. This calibrator is used to automatically calibrate

sensor offset and linearity, and can also be used as a general purpose

calibration signal source.

Display 2 The 4530 Series RF Power Meter uses a 160x80 pixel graphic liquid crystal

display module with a switchable LED backlight. The display contrast

may be adjusted by holding down the ESC key while pressing the

keys.

∧∧

∧

or

∧∧

∨∨

∨

∨

∨

< and > Keys 3 Used to navigate between levels of the menu structure while in Menu

Mode or Zero/Cal Mode and to select individual editing numeric parameters. In Text Mode and Graph mode these keys can be used to switch

the display between channels. In T ext or Graph Edit Modes, the < and >

keys scroll the header line left or right through a list of editable parameters.

∧∧

∨∨

and ∨ Keys 4 Used to scroll up and down through a list of items when in Menu Mode

∧

∨

∧

∧

∨

or Zero/Cal Mode. They are also used to increment and decrement parameter values or individual digits when editing. In certain Text Modes,

these keys can be used to page up or down through a series of measurement screens.

∧∧

(Key Repeat) -- - Note - If the ∧ or ∨ key is pressed and held when incrementing or

decrementing a variable, it enters auto-repeat mode. At first, there is a

short delay, and then the number begins to increment at a slow rate. The

increment rate accelerates to a medium rate after 2 seconds, and to a high

rate after 7 seconds. To select and hold the medium repeat rate, doubleclick the key - releasing and immediately pressing the key will inhibit the

high-speed auto-repeat rate so the value doesn’t “run away” just as the

desired number is being approached.

Enter/Run Key 5 Activates a menu selection or completes update of a parameter in Menu

Mode or Zero/Cal Mode. Pressing Enter/Run while stopped in Text

Mode or Graph Mode will start (or restart) the measurement process.

∨∨

∧

∨

∧

∨

ON/STBY Key 6 Switches the power meter between on and standby modes. When in

standby, some circuitry remains powered to reduce drain on the battery

used to maintain the non-volatile memory.

3-2

Page 25

Boonton Electronics Chapter 3

4530 Series RF Power Meter Operation

Table 3-1. Keyboard Controls and Connectors (Cont)

Item Figure 3-1 Function

ESC/Stop K ey 7 Aborts any operation in progress when in Menu Mode or Zero/Cal Mode.

Pressing ESC/Stop while running in T ext Mode or Graph Mode first causes

the measurement process to stop. Pressing it when already stopped will

clear the screen and reset all measurement values. Pressing ESC/Stop

when the instrument is in remote mode (the GPIB has control of the

instrument and keyboard entry is disabled) will return it to local mode

(the instrument is under keyboard control) unless the local lockout command, LLO, has been issued by the controller.

Zero/CAL Key 8 Places the instrument in Sensor Zero/Calibration Mode and displays a

menu to allow automatic sensor offset and gain adjustments using the

built-in 50MHz calibrator or an external calibrator.

Text Ke y 9 Places the instrument in Text Mode to display the current measurements

in a numeric format. Pressing Text while already in Text Mode toggles the

top portion of the display between the normal T ext Mode header and Edit

Mode for each active channel.

Graph K ey 1 0 Places the instrument in Graph Mode to display the current measurement

waveforms in a graphical format. Pressing Graph while already in Graph

Mode toggles the top portion (header) of the display between the normal

Graph Mode header and Edit Mode for the active channel.

Menu Key 11 Places the instrument in Menu Mode to allow navigation of the menu

structure. Pressing Menu while already in Menu Mode returns the user

to the top-level Main Menu.

Sensor 1 - 2 12 One or two sensor inputs are located on the front, or optionally on the

rear panel of the instrument. These are 10-pin precision connectors designed to accept only Boonton Peak or CW power sensors and Boonton

voltage sensors. The sensor inputs are not measurement terminals and

cannot be used for other than the intended purpose.

CAUTION

Do not attempt to connect anything other than a

Boonton sensor or sensor adapter to the Sensor inputs!

GPIB 13 A rear-panel 24-pin GPIB (IEEE-488) connector is available for connect-

ing the power meter to the remote control General Purpose Instrument

Bus. GPIB parameters can be configured through the menu.

3-3

Page 26

Chapter 3 Boonton Electronics

Operation 4530 Series RF Power Meter

Table 3-1. Keyboard Controls and Connectors (Cont)

Item Figure 3-1 Function

EXT CAL CONTROL 14 An RJ-11 type modular telephone jack is used to connect the instrument

to a Boonton Model 2530 1GHz Programmable Calibrator. This feature

must be used to calibrate peak power sensors that cannot be calibrated at

50MHz, the operating frequency of the built-in calibrator.

CAUTION

Do not attempt to connect the External Calibrator

Control RJ-11 port to a telephone line or to any device

other than a Boonton Model 2530, 1 GHz Calibrator!

RECORDER OUT 15 A rear-panel BNC programmable analog output is available for connec-

tion to an external chart recorder or other device. The output voltage

range is unipolar or bipolar 10 volts, and a 9K output impedance allows

for simple scaling using a single external load resistor. The output can be

programmed to produce a voltage proportional to signal level, or a logiclevel status voltage for signaling when the RF power is above or below

preset “alarm limit” thresholds. Recorder output parameters can be configured through the menu.

VIDEO OUT 1-2 1 6 Two rear-panel video BNC outputs are used to view the demodulated RF

envelope for each channel on an external oscilloscope when using peak

sensors. The output voltage is 0 to 2.5 volts, and is approximately proportional to the logarithm of the sensor power. These outputs are

uncalibrated, and should not be used for making any type of external

measurement.

EXT TRIGGER 17 A rear-panel BNC input is available for connecting an external trigger

source to the power meter. The input impedance is 1 megohm to allow

triggering from a common 10x oscilloscope probe, and the input voltage

range is +5 to -5 volts to simplify triggering from logic-level signals.

RS-232 18 A rear-panel 9-pin female “D” connector is used to connect the instru-

ment to a PC or other serial device. The power meter will directly interface

with most PC serial ports

RS-232 parameters can be configured through the menu.

AC Line Input 19 A multi-function power input module (lower right of rear panel) is used to

house the AC line input, main power switch, and safety fuse. The module

accepts a standard AC line cord, included with the power meter. The

power switch is used to shut off main instrument power . The safety fuse

may also be accessed once the line cord is removed. The instrument’s

power supply accepts 90 to 260VAC, so no line voltage selection switch

is necessary.

using a straight-through type RS-232 cable.

CAUTION

Replace fuse only with specified type and rating!

3-4

Page 27

Boonton Electronics Chapter 3

4530 Series RF Power Meter Operation

3.3 DISPLAY FUNCTIONS

The screen display of the 4530 is divided into three sections: the header, the measurement window and the status

window. Because these functions apply to all modes of operation, it is very important to understand them thoroughly.

∧∧

∨∨

∧

Note that the display contrast may be adjusted by holding down the ESC key while pressing the

Header Status Window

Measurement Window

Figure 3-3. Display Functions

∧

∧

∨ or ∨ keys.

∨

3.3.1

Header. The header appears at the top of the screen. It displays a title line and a line of text describing the

status of the currently highlighted item (sensor status, measurement status or auxiliary measurement values).

If the item is a submenu, a short description of the menu’s function will appear . If it is a parameter , the present

value for that parameter is shown. If it is an action item, the action will be described, and upon activation, the

message will change to indicate that the action has occurred. The header is also used as a two-line parameter

editing window when in the Edit mode.

3.3.2 Measurement Window. The major portion of the screen displays the current measurement results in a single

(4531) or split-channel (4532) format. The text display shows a trace for the primary measurement of the

channel(s) (usually average power), which updates as samples are acquired. In addition, while in the text mode,

the channel source (sensor, reference, or math function) is displayed along with measurement units. While in

the Graph mode, at slower display timebases, the trace will roll from right to left in chart recorder format, while

faster timebases use an oscilloscope-like sweep.

3.3.3 Status Window. The right-hand portion of the screen displays six annunciators that indicate status for the

GPIB, calibrator and measurement. The first four indicate GPIB status: REM, TLK, LSN, and SRQ. Position five

is a measurement status indicator, that can display: STOP, RUN, AUTO, ARMD, or SNGL. Position six displays

CAL when the calibrator output is active.

3.3.4 Channel Selection. Pressing the < or > keys while in text or graph mode toggles the measurement window

between channels. If Channel 1 is active, pressing < from a split-channel display will display only Channel 1,

and pressing > at that point returns to the split channel display. Similarly, pressing > from the split-channel

screen switches to the Channel 2 only display and < returns to the split-channel format. Note that in the singlechannel Model 4531, there is no “Channel 2 only” display , and while the split-channel display is present, there

are no measurements for Channel 2.

3.3.5 Header / Page Selection. Pressing the

a series of three “measurement pages”, each displaying a different set of measurements or status indicators. In

single-channel text mode, the entire measurement window may change, while in graph mode or split-channel

format, only the “auxiliary” measurements shown in the header will change.

∧∧

∨∨

∧

∨ and ∨ Keys while in text or graph mode scrolls the display through

∧∧

∨

3-5

Page 28

Chapter 3 Boonton Electronics

Operation 4530 Series RF Power Meter

3.4 OPERATING MODE SUMMARY

The 4530 can operate in several modes. It is possible to move between these modes without interrupting the measurements currently being performed, even though the measurement display may not always be present.

3.4.1 Menu Mode. The Menu Mode and is used to set operating parameters and start or stop measurements. A

series of displayed menus may be navigated using the front-panel arrow keys to access any instrument

function. The menu is an inverted tree, which begins at the top-level Main Menu, and branches downwards

through several levels of menu items and submenus. Refer to Table 3-5 for a summary of the instrument’s

entire menu structure. The first time the Menu key is pressed after power-up, the instrument enters the Menu

Mode and displays the Main Menu. Subsequent entries into Menu Mode will return the user to the same

position in the menu tree that was last used. Pressing the Menu key twice (or pressing it at any time when

already in Menu Mode) will always return to the Main Menu.

Figure 3-4. Menu Mode

3.4.2 Text Mode. In T ext Mode, the measurements are presented in a numerical format. A summary split-channel

(4532) display which shows the key measurement values for each channel in a large font may be selected, or

detailed single-channel (4531) display that presents a number of different measurements in a tabular format.

In the dual-channel text display, a programmable bargraph can be displayed to aid in viewing fluctuating

signals.

Dual Channel (Example) Single Channel (Example)

Figure 3-5. Text Mode

3-6

Page 29

Boonton Electronics Chapter 3

4530 Series RF Power Meter Operation

3.4.3 Graph Mode. The Graph Mode can present an oscilloscope style trace of power versus time or power

versus percent probability in statistical mode. Each channel may be viewed individually, or both can be

overlaid to make channel-to-channel comparisons. User programmable cursors can be moved back and forth

or up and down on the trace to define measurement regions of interest.

Figure 3-6. Graph Mode (Example)

3.4.4

Edit Mode. Edit Mode is an extension of the basic Graph Mode or Text Mode operation. The screen’s

measurement window continues to display and update the active measurement, but the two-line header area

at the top of the screen is used as an edit window. The arrow keys scroll through a list of commonly accessed

parameters, and allow these parameters to be updated “on the fly” without the need to return to Menu Mode.

Channel Edit Parameter List

Selected Parameter and current V alue

Figure 3-7. Edit Mode (Example)

3.4.5

Zero/Calibration Mode. When the 4530 is placed in Zero/Calibration Mode, a special menu is displayed

that allows quick, single-key access to the instrument’s sensor zeroing and linearity calibration functions. A

configuration submenu is available for each channel to set up certain calibration parameters.

3-7

Page 30

Chapter 3 Boonton Electronics

Operation 4530 Series RF Power Meter

Figure 3-8. Zero/Cal Mode (Example)

3.5 MENU MODE OPERA TION

3.5.1

Entry. When the Menu key is pressed, the instrument enters Menu Mode (See Figure 3-9). The first time the

Menu key is pressed after power-up, the instrument will always enter Menu Mode displaying the Main Menu.

Subsequent entries into Menu Mode will return the user to the same position in the menu tree that was last

used.

Figure 3-9. Main Menu Screen

3.5.2 Navigation. The menu tree is navigated using the arrow keys until the desired menu is highlighted, and then

∧∧

that item may be activated. The

menu’s item list. Pressing > or Enter/Run will activate the highlighted item and move to a subordinate menu

item associated with the selected item. Pressing < or ESC will return to the parent menu. Pressing Graph, Text

or Zero/Cal will exit Menu mode and abort any parameter editing in progress.

∨ ∨

∧

∨ and ∨ keys are used to move the cursor up and down through the current

∧∧

∨

3.5.3 Menu Items. Menu items may be one of four types: Submenu, Numerical Value, Picklist , or Action.

a. Submenus. A submenu is simply a menu at a lower level containing more items. Activating a submenu item

will cause the current menu to become the parent menu, and the submenu will then be opened and become the

current menu.

b. Numerical Values. A numerical value is an operating parameter that can be edited. When a numerical value

item is activated, that item name (parameter) is displayed along with the highlighted current value of the

parameter. Editing is performed with the arrow keys. The default edit mode is increment/decrement mode.

∧∧

∨∨

∧

Only the

∨ and ∨ keys are used to increment or decrement the parameter’s value by a preset amount.

∧

∨

∧

3-8

Page 31

Boonton Electronics Chapter 3

4530 Series RF Power Meter Operation

If a precise value is required, a special digit editing mode (Figure 3-10) may be selected. This mode is entered

from increment/decrement mode by pressing the > key. When > is pressed, a digit pointer will be displayed

∧∧

∨∨

∧

below the leftmost digit field, and the

Pressing > or < will move the digit pointer right or left so any digit of the numeric parameter may be selected.

Pressing < when the leftmost digit is selected will return to increment/decrement mode.

Figure 3-10. Digit Editing Mode (Example)

∨ and ∨ keys will change that digit of the parameter by one count.

∧

∨

∧

In either editing mode, the parameter’s value is always clamped to valid limits, and cannot be advanced

beyond these limits. When editing is complete, press Enter/Run to save the new value and return to the

previous level menu. Press ESC to abort the edit and restore the original value before returning.

c. Picklist. A picklist is used to select a parameter’s value from a list of two or more fixed entries. When a picklist

∧∧

is activated, the list of available values is displayed with the current value highlighted. Use the

to move the cursor up and down through the list until the desired value is highlighted. Press Enter/Run to

save the new value and return to the previous level menu, or press ESC to abort the edit and restore the

original value before returning. If the number of items in the picklist exceeds what can be displayed on the

↓↓

↑ ↑

or ↑ will appear to the left of the top or bottom item to indicate that there are more list items that

↓

screen, a

are scrolled off the top or bottom of the display.

d. Action Item. An action item is a menu selection that causes an event to occur or be initiated immediately when

the item is activated. In some cases (such as AutoSetup), the user will first be prompted to confirm the action

before continuing.

↑

↓

↑

↓

∨∨

∧

∨

and ∨ keys

∧∧

∨

3.5.4 Menu Screen Display. The menu screen is divided into three sections: the header, the path, and the list

of menu items (see figure 3-11).

Menu Path Header Menu Items

Figure 3-1 1. T ypical Menu Screen

3-9

Page 32

Chapter 3 Boonton Electronics

Operation 4530 Series RF Power Meter

a. Header. The header displays a title line and a line of text describing the currently highlighted item (sensor or

measurement status, or auxiliary measurement values). A short description of a selected submenu, or action

item, is listed or the value of a selected parameter is displayed.

b. Path. The path appears on the left side of the screen, and is a list of each branch of the menu tree used to get

to the current position. Each time a new menu item is opened, that item is highlighted, and then that item may

be activated. Pressing > or Enter will activate the highlighted item and move to a subordinate menu item

associated with the selected item. Pressing < or ESC will return to the parent menu. Pressing Graph, Text or

Zero/CAL will exit Menu Mode, and abort any parameter editing in progress. T able 3-5 shows the complete

menu structure of the 4530.

c. Menu items. The list of menu items appears on the right side of the screen, where individual selections maybe

highlighted and activated. The menu is always entered with the top item highlighted, and the ∧ and ∨ keys

may be used to move the cursor up and down through the list. If a ↓ or ↑ appears to the left of the top or

bottom menu item, it means that the list extends above or below what is currently displayed on the screen. In

this case, the list can be scrolled up or down to allow access to these additional items.

As each item is highlighted, the header will show a brief description of that item or its current value. If the item

is a submenu, numeric value or picklist, a → will be shown to the right of the item to indicate that activating

that item moves you down another menu level or an edit screen. Action items have nothing displayed to the

right of the item since there is no “next level” associated with them.

3.5.5 Menu Syntax. When referring to item locations within the menu hierarchy, it is convenient to describe them

by their path. Each menu level will be separated by a “>” (indicating the > or Enter/Run key must be pressed

at this point to move down a level). Since Menu Mode always remains within the Main Menu, this manual will

always show the path beginning with the first item picked from the Main Menu level. For example, to set the

IEEE-488 bus address to 13, the following path string will be used:

Utilities > IEEE-488 > Bus Setup > Address > 13

To execute this function, you must first enter Menu Mode by pressing the Menu key.

3.6 TEXT MODE OPERA TION

In Text Mode, the current measurements are displayed in a numeric format with optional fast-responding bargraph

readouts. Since the 4530 can measure more than just average power, most modes have a number of measurements

associated with them. The flexible text presentation allows you to view key average power measurements in a traditional format or a tabular format to show a larger number of items on the screen.

Figure 3-12. T ext Mode (Example)

3-10

Page 33

Boonton Electronics Chapter 3

4530 Series RF Power Meter Operation

3.6.1 Entry. When the Text key is pressed, the 4530 enters Text Mode.

∧∧

3.6.2 Measurement Page Selection. Pressing the

series of pages that contain all the measurements being performed in the current mode. See paragraph 3.9

(Display Formats) for a list of what measurements are displayed in each format.

3.6.3 Channel Selection. Pressing the < or > keys while in Text mode switches the display between channels.

The keys toggle the display between “CH1 < > BOTH < > CH2”. In addition to the primary measurement, the

CH1 and CH2 displays may show a number of secondary measurements for that channel. The BOTH display

format shows the primary measurements only in the main display window, along with an optional bar graph. In

some cases, secondary measurements for each channel may appear in the header. Single-channel units

(Model 4531) can only page between the CH1 and BOTH display formats. See paragraph 3.9 (Display

Formats) for a list of what measurements are displayed in each format.

3.6.4 Measurement Control. Pressing Enter/Run while in Text Mode starts the measurement if it is stopped, or

arms the trigger if single-sweep mode is active. Pressing ESC/Stop stops the measurement if it is running and

holds the current measurement values. Once stopped, pressing ESC/Stop again clears the measurement

result, and resets for a new measurement. Anytime measurement is stopped, you can change display settings

or certain measurement parameters, and the current measurements displayed are updated accordingly.

∨∨

∧

∨ or ∨ keys while in T ext Mode pages up or down through a

∧∧

∨

3.6.5 Parameter Editing from Text Mode. Pressing Text while already in Text Mode will enter Edit mode for the

first active channel. The screen’s measurement window continues to display and update the active measurement, but the two-line header area at the top of the screen is used as an edit window. Pressing Text again

switches to Edit Mode for the second channel, if active. Another press of the Text key will return to normal

T ext Mode. See paragraph 3.8 (Edit Mode Operation) for more details.

3.7 GRAPH MODE OPERA TION

Graph Mode is used to present the current measurements in a real-time graphic or trace-type format. This can be a plot

of signal amplitude (usually power) versus time, similar to an oscilloscope screen, or power versus percent probability.

Power is always presented on the Y-axis, while time or probability is on the X-axis. Both axes can be scaled, and vertical

or horizontal cursors can be positioned on the trace to perform measurements at specific time or percent offsets of each

cursor or in the region between the two cursors.

Figure 3-13. Graph Mode (Example)

3-11

Page 34

Chapter 3 Boonton Electronics

Operation 4530 Series RF Power Meter

3.7.1 Entry. When the Graph key is pressed, the 4530 enters Graph Mode.

3.7.2 Measurement Page Selection. Pressing the ∧ or ∨ keys while in Graph Mode pages the header display up

or down through several commonly used measurements or parameters. See paragraph 3.9 (Display Formats) for

a list of what measurements are displayed in each format.

3.7.3 Channel Selection. Pressing the < or > keys while in Text mode switches the display between channels.

The keys toggle the display between “CH1 < > BOTH < > CH2”. This is helpful to distinguish between traces

when two channels are being viewed, or to concentrate on settings for one of the channels. Single-channel

units (Model 4531) can only page between the CH1 and BOTH display formats.

3.7.4 Measurement Control. Pressing Enter/Run while in Graph Mode starts the measurement, if it is stopped, or

arms the trigger if Single-Sweep Mode is active. Pressing ESC/Stop stops the measurement if it is running and

holds the current measurement values. Once stopped, pressing ESC/Stop again clears the measurement result,

and resets for a new measurement. Any time measurement is stopped, it is possible to change display settings

or certain measurement parameters, and the current measurements displayed will be updated accordingly.

Also, cursors can be moved around to view the power at selected times without the need to restart the

measurement.

3.7.5 Parameter Editing from Graph Mode. Pressing Graph while already in Graph Mode will enter Edit Mode

for the first active channel. The screen’s measurement window continues to display and update the active

measurement, but the two-line header area at the top of the screen is used as an edit window. Pressing Graph

again switches Edit Mode to the second channel, if active. Another press of the Graph key returns to normal

Graph Mode. See paragraph 3.8 (Edit Mode Operation) for more details.

3.8 EDIT MODE OPERA TION

Edit mode is an extension of Graph Mode or T ext Mode operation which allows common measurement parameters to be

edited in the header area while the active measurements continue to update in the measurement window. The arrow

keys scroll through a list of commonly accessed parameters, and allow these parameters to be updated “on the fly”

without the need to return to Menu Mode. This interactive mode allows parameters to be changed in real time while

viewing the effect of these changes as they are made.

3.8.1 Entry, Exit, and Channel Selection. Edit Mode is entered from T ext Mode by pressing the Text key or from

Graph Mode by pressing the Graph key. Edit mode is always entered for the first active channel currently

displayed. If the display is in single-channel mode, only one channel is displayed and Edit Mode is entered

for that channel. If both channels are active and displayed, Channel 1 will be active first. Pressing Text or

Graph again switches to the next active channel, or returns to regular T ext Mode or Graph Mode once both

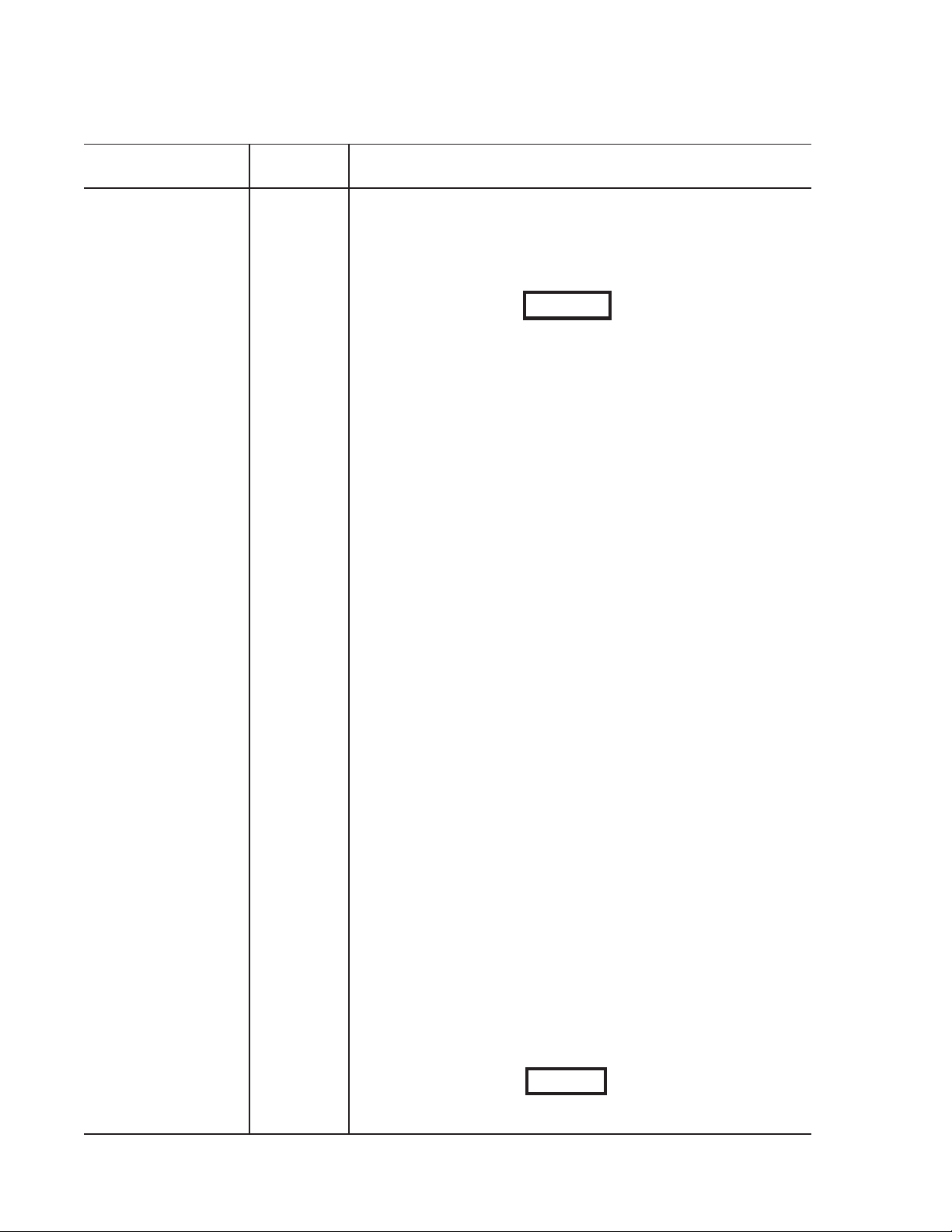

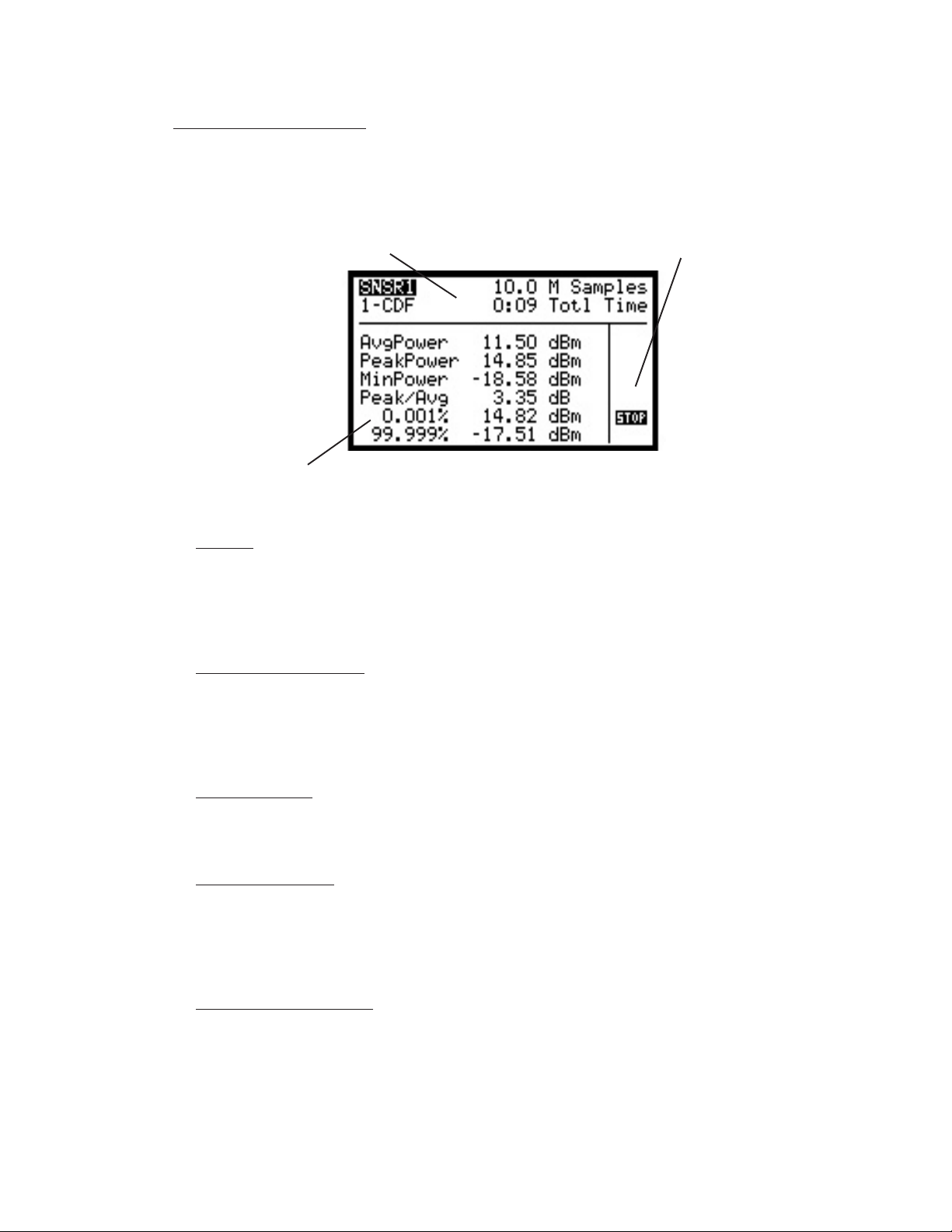

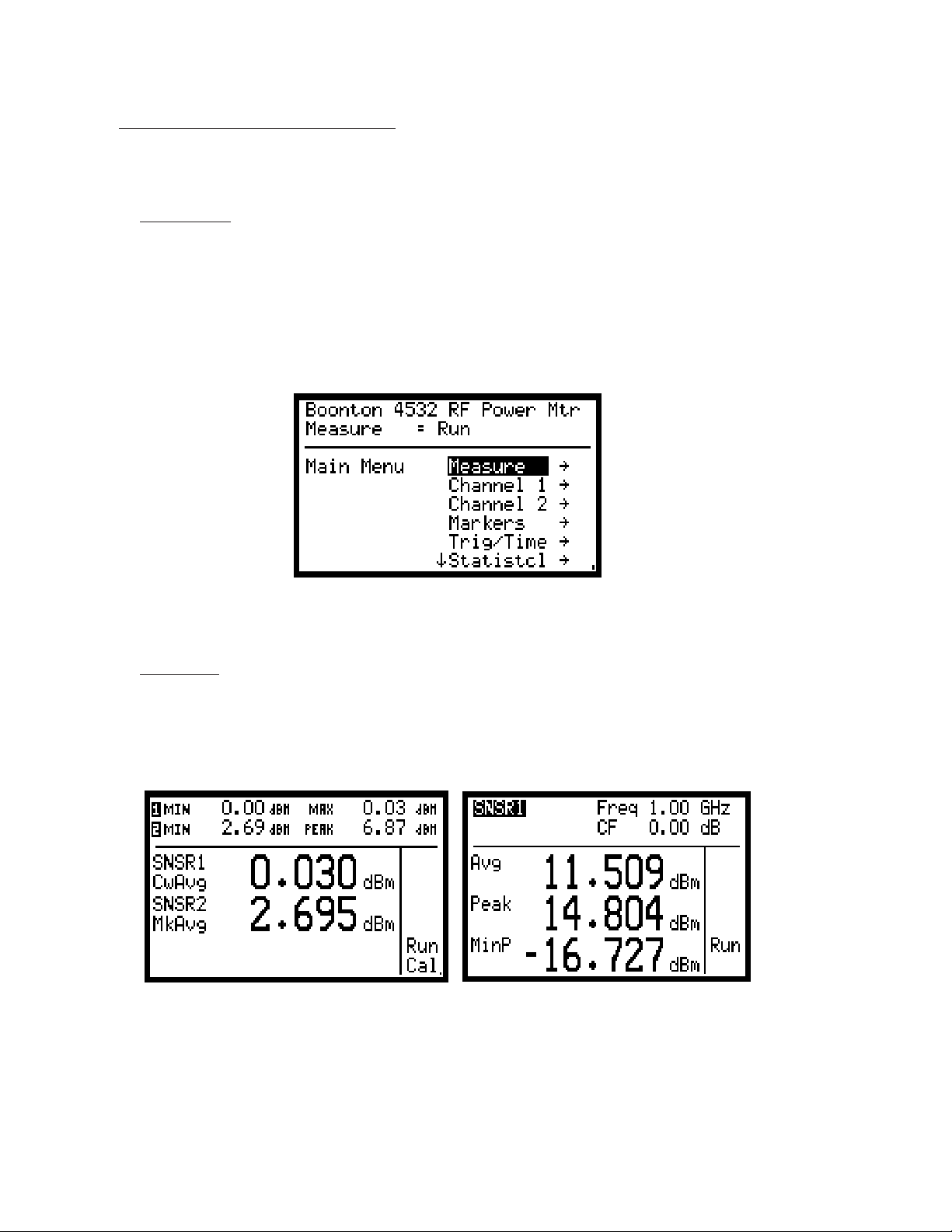

channels have been accessed or if the next channel is not active.