Page 1

MODEL 4230A

RF POWER METER

INSTRUCTION MANUAL

BOONTON ELECTRONICS 25 EASTMANS ROAD PARSIPPANY, NEW JERSEY 07054-0465

TELEPHONE: (973) 386-9696 FAX: (973) 386-9191 E-MAIL: boonton@boonton.com

MANUAL P/N 98102400A

DATE 10/98

Page 2

SAFETY SUMMARY

The following general safety precautions must be observed during all phases of operation and maintenance of this

instrument. Failure to comply with these precautions or with specific warnings elsewhere in this manual violates safety

standards of design, manufacture, and intended use of the instruments. Boonton Electronics assumes no liability for the

customer's failure to comply with these requirements.

THE INSTRUMENT MUST BE GROUNDED.

To minimize shock hazard the instrument chassis and cabinet must be connected to an electrical ground. The instrument

is equipped with a three conductor, three prong AC power cable. The power cable must either be plugged into an approved

three-contact electrical outlet or used with a three-contact to a two-contact adapter with the (green) grounding wire firmly

connected to an electrical ground at the power outlet.

DO NOT OPERATE THE INSTRUMENT IN AN EXPLOSIVE ATMOSPHERE.

Do not operate the instrument in the presence of flammable gases or fumes.

KEEP AWAY FROM LIVE CIRCUITS.

Operating personnel must not remove instrument covers. Component replacement and internal adjustments must be made

by qualified maintenance personnel. Do not replace components with the power cable connected. Under certain conditions

dangerous voltages may exist even though the power cable was removed; therefore, always disconnect power and

discharge circuits before touching them.

DO NOT SERVICE OR ADJUST ALONE.

Do not attempt internal service or adjustment unless another person, capable of rendering first aid and resuscitation, is

present.

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT.

Do not install substitute parts of perform any unauthorized modification of the instrument. Return the instrument to

Boonton Electronics for repair to ensure that the safety features are maintained.

This safety requirement symbol has been adopted by the International Electrotechnical

Commission, Document 66 (Central Office) 3, Paragraph 5.3, which directs that an

instrument be so labeled if, for the correct use of the instrument, it is necessary to refer

to the instruction manual. In this case it is recommended that reference be made to the

instruction manual when connecting the instrument to the proper power source. Verify

that the correct fuse is installed for the power available, and that the switch on the rear

panel is set to the applicable operating voltage.

The CAUTION sign denotes a hazard. It calls attention to an operation procedure,

CAUTION

WARNING

practice, or the like, which, if not correctly performed or adhered to, could result in

damage to or destruction of part or all of the equipment. Do not proceed beyond a

CAUTION sign until the indicated conditions are fully understood and met.

The WARNING sign denotes a hazard. It calls attention to an operation procedure.,

practice, or the like, which, if not correctly performed or adhered to, could result in

injury of loss of life. Do not proceed beyond a warning sign until the indicated conditions

are fully understood and met.

This SAFETY REQUIREMENT symbol has been adopted by the International

Electrotechnical Commission, document 66 (Central Office)3, Paragraph 5.3 which

indicates hazardous voltage may be present in the vicinity of the marking.

Page 3

WARRANTY

Boonton Electronics (Boonton) warrants its products to the original

Purchaser to be free from defects in material and workmanship for a

period of one year from date of shipment for instrument, and for one

year from date of shipment for probes, power sensors and accessories.

Boonton further warrants that its instruments will perform within all

current specifications under normal use and service for one year from

date of shipment. These warranties do not cover active devices that

have given normal service, sealed assemblies which have been opened

or any item which has been repaired or altered without Boonton's

authorization.

Boonton's warranties are limited to either the repair or replacement, at

Boonton's option, of any product found to be defective under the

terms of these warranties.

There will be no charge for parts and labor during the warranty period.

The Purchaser shall prepay shipping charges to Boonton or its

designated service facility and shall return the product in its original or

an equivalent shipping container. Boonton or its designated service

facility shall pay shipping charges to return the product to the Purchaser.

The Purchaser shall pay all shipping charges, duties and taxes if a

product is returned to Boonton from outside of the United States.

THE FOREGOING WARRANTIES ARE IN LIEU OF ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. BE shall not be liable to any incidental or consequential

damages, as defined in Section 2-715 of the Uniform Commercial

Code, in connection with the products covered by the foregoing

warranties.

Page 4

TABLE OF CONTENTS

SECTION I — GENERAL INFORMATION

Paragraph Page

1-1 Introduction ................................................................................................................................................................. 1-1

1-3 Description................................................................................................................................................................... 1-1

1-5 Features ......................................................................................................................................................................... 1-1

1-6 Power Sensors .................................................................................................................................................... 1-1

1-10 Simple Instrument Setup and Operation ...................................................................................................... 1-1

1-11 Alphanumeric Displays.................................................................................................................................... 1-1

1-12 Selectable Ranging ........................................................................................................................................... 1-1

1-13 Selectable Filtering ........................................................................................................................................... 1-1

1-14 Zeroing ................................................................................................................................................................ 1-2

1-15 Built-In Precision Calibration ........................................................................................................................ 1-2

1-16 Chart Recorder Output ..................................................................................................................................... 1-2

1-17 Optional Interface .............................................................................................................................................. 1-2

1-18 Accessories ................................................................................................................................................................... 1-2

1-20 Options ......................................................................................................................................................................... 1-2

1-21 Option -01, Rear Input ................................................................................................................................... 1-2

1-22 Option -02, Rear Calibrator .......................................................................................................................... 1-2

1-23 Option -03, RS-232 ......................................................................................................................................... 1-2

1-24 Option -30, Extended Warranty ...................................................................................................................1-2

1-25 Specifications............................................................................................................................................................... 1-2

SECTION II — INSTALLATION

2-1 Introduction ................................................................................................................................................................. 2-1

2-2 Unpacking................................................................................................................................................................... 2-1

2-3 Mounting ..................................................................................................................................................................... 2-1

2-4 Power Requirements .................................................................................................................................................2-1

2-5 Connections ................................................................................................................................................................ 2-1

2-6 Sensor ................................................................................................................................................................. 2-1

2-7 Recorder............................................................................................................................................................. 2-2

2-8 GPIB.................................................................................................................................................................... 2-2

2-9 RS-232................................................................................................................................................................ 2-2

2-10 Preliminary Check..................................................................................................................................................... 2-2

SECTION III — OPERATION

3-1 Introduction ................................................................................................................................................................. 3-1

3-3 Operating Controls, Indicators and Connectors ................................................................................................... 3-1

3-5 Operating the Instrument .......................................................................................................................................... 3-1

3-7 Measurement Display ................................................................................................................................................ 3-1

3-9 Menu Structure............................................................................................................................................................ 3-1

3-13 Menu Key..................................................................................................................................................................... 3-7

3-16 Channel Menu.................................................................................................................................................... 3-7

3-18 Setup Menu ........................................................................................................................................................ 3-7

3-20 Programming Interfaces .................................................................................................................................... 3-11

3-21a IEEE Menu .......................................................................................................................................................... 3-11

3-21b RS-232 Menu ...................................................................................................................................................... 3-11

3-22 Diagnostics Menu ............................................................................................................................................. 3-13

3-23 Sensor Key ................................................................................................................................................................... 3-13

3-31 Edit Data Menu .................................................................................................................................................. 3-15

3-32 Linearity Factors ................................................................................................................................................ 3-15

3-33 FREQUENCY Calibration Factors ................................................................................................................... 3-16

i

Page 5

3-36 Save ..................................................................................................................................................................... 3-16

3-37 Freq Key ....................................................................................................................................................................... 3-16

3-40 Avg Key ....................................................................................................................................................................... 3-16

3-43 Zero/Cal Key ................................................................................................................................................................ 3-16

3-48 Ref Level Key............................................................................................................................................................... 3-18

SECTION IV — APPLICATION NOTES

4-1 Introduction ................................................................................................................................................................. 4-1

4-3 Sensor Calibration ...................................................................................................................................................... 4-1

4-4 General................................................................................................................................................................ 4-1

4-5 14-Point Linearity Data ................................................................................................................................... 4-1

4-7 High Frequency Calibration Points ............................................................................................................... 4-1

4-9 Zeroing ......................................................................................................................................................................... 4-1

4-16 Dynamic Range ...........................................................................................................................................................4-3

4-18 Filtering ........................................................................................................................................................................ 4-3

4-22 Noise ............................................................................................................................................................................. 4-4

4-23 Noise Reduction ................................................................................................................................................ 4-4

4-25 Error Computation ............................................................................................................................................4-5

4-27 Noise Error Examples ...................................................................................................................................... 4-5

4-28 Integration of Power......................................................................................................................................... 4-5

4-29 Clearing of Filter............................................................................................................................................... 4-5

4-30 Partial Results .................................................................................................................................................... 4-5

4-31 Measurement Time ..................................................................................................................................................... 4-5

4-32 Step Response.................................................................................................................................................... 4-5

4-33 Continuous Response ....................................................................................................................................... 4-5

4-34 Overhead Time .................................................................................................................................................. 4-5

4-36 Digital Filter ...................................................................................................................................................... 4-5

4-37 Default Filter Lengths ...................................................................................................................................... 4-5

4-38 Settled Measurement Time ............................................................................................................................. 4-5

4-39 Fast Mode Measurement Time ...................................................................................................................... 4-5

4-40 High Frequency Accuracy ......................................................................................................................................... 4-10

4-43 Waveform Sensitivity................................................................................................................................................. 4-10

4-48 Chart Recorder Operation .......................................................................................................................................... 4-13

4-50 Bar Graph Operation ................................................................................................................................................. 4-13

4-52 Watts Mode ........................................................................................................................................................ 4-13

4-53 dBm Mode .......................................................................................................................................................... 4-13

4-54 dBr Mode ............................................................................................................................................................ 4-14

4-55 Remote (GPIB) Operation ........................................................................................................................................... 4-14

4-56 Introduction........................................................................................................................................................ 4-14

4-58 Local Operation .................................................................................................................................................4-14

4-59 Remote Operation ............................................................................................................................................. 4-14

4-60 Bus Address ....................................................................................................................................................... 4-14

4-61 Terminating Characters ................................................................................................................................... 4-14

4-62 Listen Operation ................................................................................................................................................ 4-14

4-63 Talk Operation .................................................................................................................................................. 4-14

4-65 IEEE-488 Command Support ......................................................................................................................... 4-14

4-66 Number Formatting............................................................................................................................................ 4-15

4-67 String Format ...................................................................................................................................................... 4-17

4-68 Listen Parameter Commands ............................................................................................................................ 4-17

4-70 Listen Action Commands ................................................................................................................................. 4-17

4-71 Listen Array Commands ................................................................................................................................... 4-17

4-73 Talk Modes ......................................................................................................................................................... 4-18

4-77 Talk Mode 0 (Talk Measurement Floating Point) ...................................................................................... 4-18

4-78 Talk Mode 1 (Talk Measurement With Units) ............................................................................................ 4-18

4-79 Talk Mode 2 (Talk Error) ............................................................................................................................... 4-18

ii

Page 6

4-80 Talk Mode 3 (Talk Both Channels) .............................................................................................................. 4-18

4-81 Talk Mode 4 (Talk Channel Status) ................................................................................................................ 4-19

4-82 Talk Mode 5 (Talk Instrument Status) ......................................................................................................... 4-19

4-83 Talk Mode 6 (Talk Parameter) ....................................................................................................................... 4-19

4-86 Talk Mode 7 (Talk Array) ............................................................................................................................... 4-19

4-87 IEEE-488 Bus Only Commands.................................................................................................................................. 4-20

4-88 General................................................................................................................................................................. 4-20

4-89 Talk Mode (TM) Command.............................................................................................................................. 4-20

4-90 SI Command........................................................................................................................................................ 4-20

4-94 SO Command ...................................................................................................................................................... 4-21

4-98 FI Command ......................................................................................................................................................4-21

4-102 FO Command .................................................................................................................................................... 4-21

4-107 DF Command .................................................................................................................................................... 4-22

4-108 DN Command.................................................................................................................................................... 4-22

4-109 SM (SRQ Mask) Command ........................................................................................................................... 4-22

4-110 Measured and Triggered Operation And Settled Reading ................................................................................. 4-22

4-111 General................................................................................................................................................................ 4-22

4-112 Measure Normal (MN) ................................................................................................................................... 4-23

4-113 Measure Filtered (MF) ...................................................................................................................................... 4-23

4-114 Measure Settled (MS) ....................................................................................................................................... 4-23

4-115 Measure Fast Single (MFS) ............................................................................................................................ 4-23

4-116 Measure Fast Dual (MFD) .............................................................................................................................. 4-23

4-117 Trigger Normal (TN) ....................................................................................................................................... 4-23

4-118 Trigger Filtered (TF) ........................................................................................................................................4-23

4-119 Trigger Settled (TS) ......................................................................................................................................... 4-23

4-120 Trigger Fast Single (TFS) ............................................................................................................................... 4-23

4-121 Trigger Fast Dual (TFD) ................................................................................................................................. 4-23

4-122 IEEE Programming Examples ................................................................................................................................. 4-23

4-125 Example 1........................................................................................................................................................... 4-23

4-126 Example 2........................................................................................................................................................... 4-24

4-127 Error Messages ............................................................................................................................................................ 4-24

4-129 HP Bus Emulation ...................................................................................................................................................... 4-24

4-131 Turn-on Default Conditions ............................................................................................................................ 4-24

4-132 Sending the Data Message ............................................................................................................................ 4-25

4-133 Data Output Format .......................................................................................................................................... 4-24

4-134 Sending the Require Service Message .......................................................................................................... 4-25

4-135 Service Request Mask ...................................................................................................................................... 4-25

4-136 Sending the Service Request Mask Value.................................................................................................... 4-25

4-137 Event Status Register ....................................................................................................................................... 4-25

4-138 HP Emulation Codes .......................................................................................................................................... 4-26

4-139 Remote Operation, RS-232 Interface ...................................................................................................................... 4-26

4-140 General................................................................................................................................................................ 4-26

4-141 Entering the Remote Mode ............................................................................................................................. 4-26

4-142 Returning to Local Mode................................................................................................................................. 4-26

4-143 Talk Operations .................................................................................................................................................4-26

iii

Page 7

LIST OF FIGURES

Figures Page

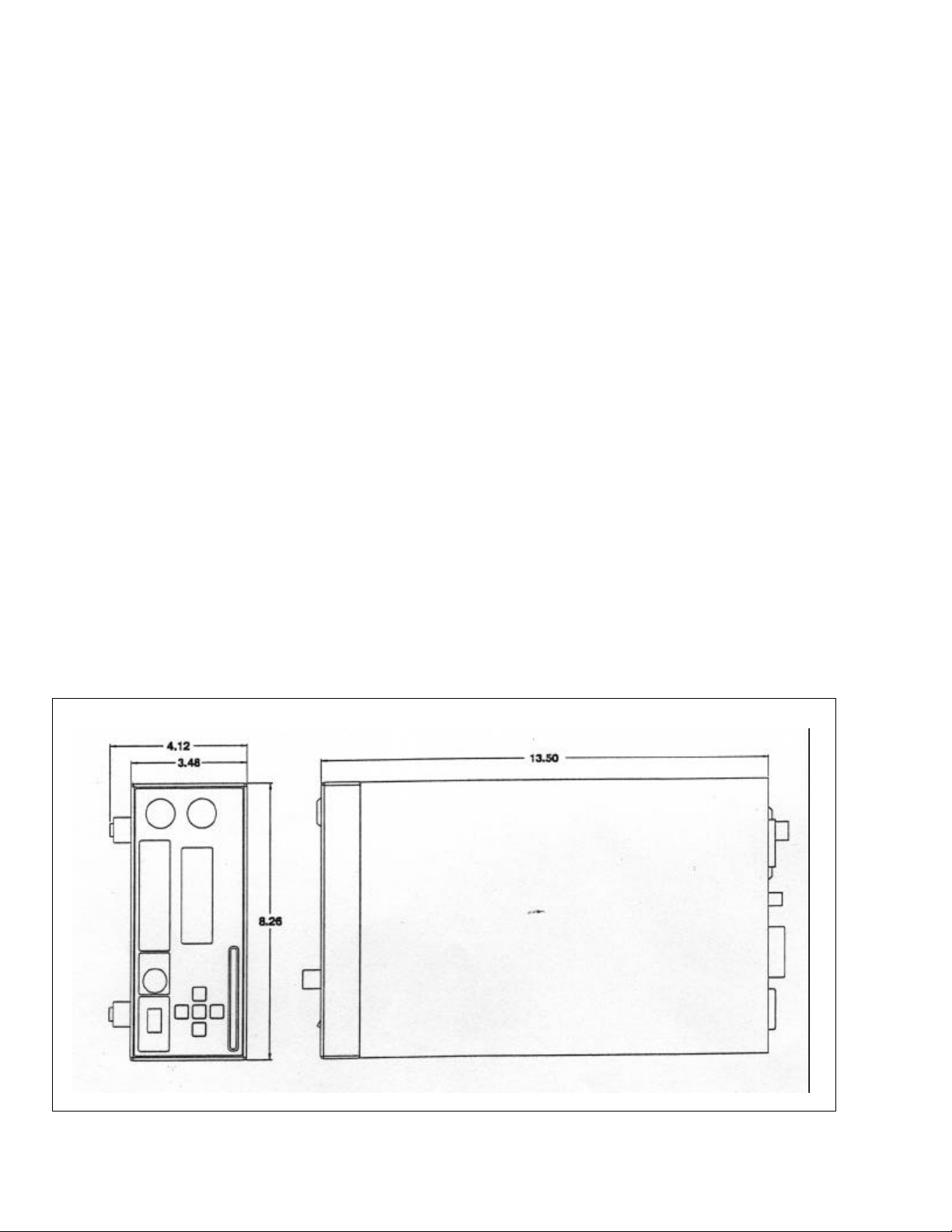

1-1 Model 4230A Series RF Powermeter................................................................................................................... vi

1-2 Outline Dimensions ................................................................................................................................................... 1-2

2-1 Packaging Diagram.................................................................................................................................................... 2-1

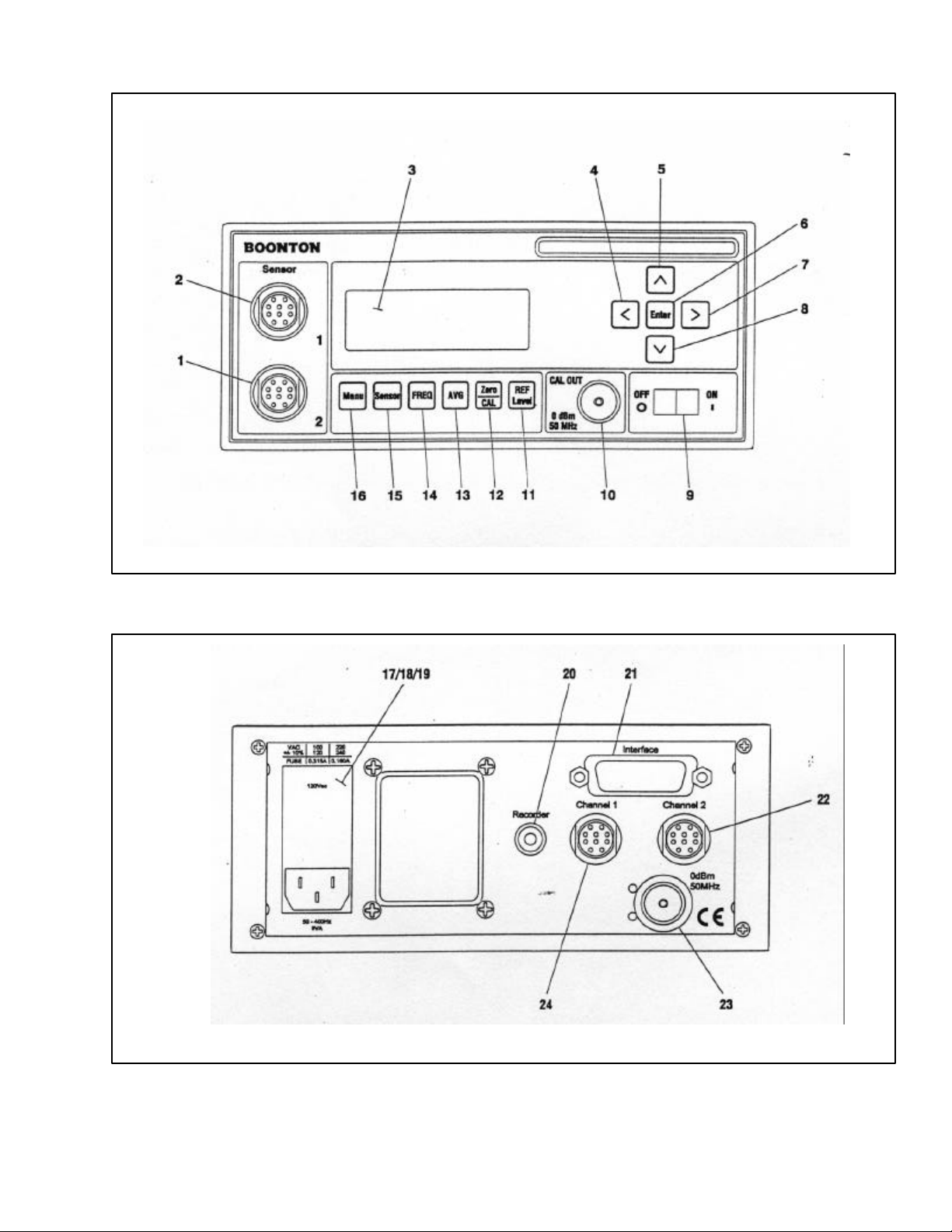

3-1 Model 4230A, Front Panel Controls and Connectors ............................................................................................ 3-3

3-2 Model 4230A, Rear Panel Controls and Connectors ............................................................................................. 3-3

3-3 Measurement Display, Local Mode ......................................................................................................................... 3-5

3-4 Measurement Display, Remote Mode...................................................................................................................... 3-5

3-5 Model 4230A, Command Set ..................................................................................................................................... 3-6

3-6 Main Menu Display .................................................................................................................................................... 3-7

3-7 Channels Menu Display............................................................................................................................................. 3-7

3-8 Setup Menu Display, IEEE Installed ........................................................................................................................ 3-9

3-9 Setup Menu Display, RS-232 Installed .................................................................................................................... 3-10

3-10 IEEE Menu Display ..................................................................................................................................................... 3-11

3-11 RS-232 Menu Display ................................................................................................................................................. 3-12

3-12 Diagnostics Menu Display ........................................................................................................................................ 3-13

3-13 Sensor Display Menu ................................................................................................................................................. 3-13

3-14 Access Code ............................................................................................................................................................... 3-14

3-15 Edit Data Menu Display ............................................................................................................................................. 3-14

3-16 Cal Factor Menu Display ........................................................................................................................................... 3-14

3-17 Calibration Data Example ............................................................................................................................................ 3-16

3-18 Save Display ................................................................................................................................................................ 3-17

3-19 Frequency Display ...................................................................................................................................................... 3-17

3-20 Averaging Time Display ............................................................................................................................................ 3-17

3-21 Zero and Calibration Display..................................................................................................................................... 3-17

3-22 Reference Level Display............................................................................................................................................. 3-17

4-1 14-Point Sensor Calibration ..................................................................................................................................... 4-2

4-2 Diode Sensor Decay ................................................................................................................................................... 4-2

4-3 Thermal Sensor Decay ............................................................................................................................................... 4-3

4-4 Extended Hold Range Mode..................................................................................................................................... 4-4

4-5 Noise Reduction .......................................................................................................................................................... 4-6

4-6 Typical Error Band Specifications .......................................................................................................................... 4-7

4-7 Probability of Falling within an Error Band ......................................................................................................... 4-7

4-8 Confidence Curves, 51013 Sensor with 2.8 Second Filter ................................................................................. 4-8

4-9 Confidence Curves, 51013 Sensor with 10 Second Filter .................................................................................. 4-9

4-10 Integration of Power ................................................................................................................................................... 4-10

4-11 Fast Mode Sampling Rate ......................................................................................................................................... 4-11

4-12 Mismatch Uncertainties Chart ................................................................................................................................. 4-12

4-13 Error Due to AM Modulation (51013 Diode Sensor) ...................................................................................... 4-13

iv

Page 8

LIST OF TABLES

Table Page

1-1 Performance Specifications ................................................................................................................................... 1-3

3-1 Operating Controls, Indicators, and Connectors .............................................................................................. 3-1

3-2 Channel Menu Functions .......................................................................................................................................... 3-8

3-3 Setup Menu Functions .............................................................................................................................................. 3-10

3-4 IEEE Menu Functions ................................................................................................................................................ 3-11

3-5 RS-232 Menu Functions ............................................................................................................................................ 3-12

3-6 Diagnostics Menu Functions ................................................................................................................................... 3-13

3-7 Edit Data Menu Functions ........................................................................................................................................ 3-15

3-8 Sensor Calibration Menu Functions ........................................................................................................................ 3-16

3-9 Reference Level Menu Functions ............................................................................................................................ 3-18

4-1 Listen Parameter Commands ................................................................................................................................... 4-15

4-2 Listen Action Commands ......................................................................................................................................... 4-16

4-3 Listen Array Parameter Commands........................................................................................................................ 4-17

4-4 Talk Array Commands ..............................................................................................................................................4-17

4-5 Talk Modes .................................................................................................................................................................. 4-17

4-6 Error Messages ........................................................................................................................................................... 4-20

4-7 SRQ Masks .................................................................................................................................................................. 4-22

4-8 Status Byte and Service Request Mask................................................................................................................... 4-25

4-9 Event Status Register................................................................................................................................................. 4-25

4-10 HP 437B Emulation GPIB Commands .................................................................................................................. 4-27

4-11 HP 438A Emulation GPIB Commands.................................................................................................................. 4-30

4-12 Boonton 4230A GPIB Commands............................................................................................................................. 4-32

v

Page 9

Figure 1-1. Model 4230A Series RF Powermeter

vi

Page 10

SECTION I

GENERAL INFORMATION

Section I

General Information

1-1. INTRODUCTION.

1-2. This instruction manual provides general information,

installation and operating instructions, and application notes

for the Model 4230A Series of RF power meters. This series

includes Model 4231A with a single measurement channel and

Model 4232A with two measurement channels. The terms

Model 4230A and 4230A used throughout this publication

refer to both models unless otherwise noted. See Figures 1-1

and 1-2.

1-3. DESCRIPTION.

1-4. The Model 4230A Series is a DSP (digital signal processor)

based family of single or dual channel, solid state RF power

meters. They are capable of measuring RF power levels from

-70 dBm to +44 dBm. The RF frequency range and power level

range are sensor dependent. Boonton 51000 series sensors

provide measurement capabilities for frequencies from 10 kHz

to 100 GHz.

1-5. FEATURES.

1-6. Power Sensors. A wide range of diode and thermocouple

power sensors for both coaxial and waveguide applications are

available for use with the Model 4230A. Sensor data adapters

are supplied with the Model 4230A, however, the power sensor

must be ordered separately.

1-7. Diode sensors measure the voltage across a precision

resistor, using specially selected diodes. Detection is square

law (true RMS) over approximately the lower two-thirds of the

sensor's dynamic range, and peak detecting over the upper

portion. Because the instrument is calibrated for sine waves

over the entire range, measurements at the top one-third of the

sensor's dynamic range are valid only for non-modulated

signals. In the RMS region, linearity is excellent, and any signal

type can be measured. The diode range has been extended into

the peak detecting region with the use of real time shaping for

the diode curve. When coupled with the high sensitivity of the

diode, such shaping allows a dynamic range of 90 dB. Diode

sensors are rugged and have an overload headroom of more

than 5 dB for continuous signals. The dynamic range in the

RMS region can be extended further through use of an external

attenuator.

1-8. Thermal sensors measure the voltage developed across

a dissimilar metal junction caused by the thermal gradient

generated by the RF power being measured. Because these

sensors are heat detecting, they provide true RMS response

over their entire range. Very high peak powers (15 to 30 watts)

can be accommodated for very short duty cycles and still

provide valid results. The dynamic range is 50 dB. Thermal

sensors are not as sensitive as diode sensors.

1-9. The sensor data adapter contains non-volatile memory for

storage of the calibration data. In addition, calibration data for

up to four sensors can be stored in the instrument's nonvolatile memory. The user can enter both the linearity and high

frequency sensor calibration correction data which are

supplied with each sensor. For sensors ordered with the Model

4230A, the calibration data is loaded into the sensor data

adapter prior to shipment. When the frequency of the RF signal

to be measured by one of these sensors is entered, the

instrument looks up the appropriate calibration factors,

interpolates as necessary, and automatically applies the

correction to the measured value. Calibration factors for

sensors ordered with the instrument are stored in the plastic

pouch attached to the inside of the instrument's top cover.

1-10. Simple Instrument Setup and Operation. In the

operating mode the functions: Frequency, Averaging Time,

Reference Level, Zeroing/Calibration are selected with a single

keystroke. Values for these parameters are displayed and can

be adjusted by using the arrow and enter keys. Additional

operating parameters can be modified through the menu driven

structure accessible via the <Menu> and <Sensor> keys.

1-11. Alphanumeric Display. The alphanumeric LCD

provides clear, unambiguous readouts of the instrument's

setup and measurement values. Simultaneous display of both

channels is available in dual channel mode. A bar graph

provides a display of the channel's measured value for nulling

and peaking applications.

1-12. Selectable Ranging. Any of seven measurement ranges,

or autoranging, can be selected during instrument setup. The

selection will be held until it is changed, or until the instrument

is turned off. When measuring signals with levels that fall

within a narrow range, selecting one specific instrument range

may reduce measurement time. Autoranging is useful if the RF

signal level is unknown, or if RF signals with widely varying

levels are to be measured.

1-13. Selectable Filtering. Measurement speed and display

stability can be optimized through the use of selectable

filtering. Filter times can be adjusted up to 20 seconds maximum

in 50 millisecond increments.

1-14. Zeroing. Automatic zeroing (nulling of offsets for the

1-1

Page 11

Section I

General Information

sensor and input channel) is done independently on each

range to eliminate zero carryovers.

1-15. Built-In Precision Calibrator. A built-in 50 MHz

calibrator provides an accurate, stable, and convenient power

source for calibration of the instrument to specified tolerances.

The calibrator may be toggled on or off from the Setup menu.

The connector is normally mounted for front panel access,

however option-02 changes this to rear panel access.

1-16. Chart Recorder Output. A 0 to 10 volt dc output,

proportional to the measurement values, is available for

application to a chart recorder.

1-17. Optional Interface. A RS-232 option enables full service

remote control of the Model 4230A. All instrument controls

and values, except power on and off, are accessible to a bus

controller in the remote operating mode.

1-18. ACCESSORIES.

1-19. A sensor data adapter, Model 95109001A, for each

installed channel and an AC line cord are supplied with each

instrument. One or more Boonton 51000 series power sensors

are required. The power sensors are not supplied as part of the

instrument, but must be ordered separately. A five-foot power

sensor cable, Model 41-2A, is supplied with each sensor

ordered. Additional available accessories include the

following:

a. Model 41-2A/10 Sensor/Probe Interconnecting Cable

(10 ft)

b. Model 41-2A/20 Sensor/Probe Interconnecting Cable

(20 ft)

c. Model 41-2A/50 Sensor/Probe Interconnecting Cable

(50 ft)

d. Model 41-2A/100 Sensor/Probe Interconnecting Cable

(100 ft)

e. Model 95004701A F/F Adapter, 41-2A (for connecting

Model 41-2A cables end to end)

f. Model 95004901A Bulkhead Connector F/F, 41-2A (for

connecting Model 41-2A cables end to end)

g. Model 95403001A Rack Mounting Kit

h. Model 95109001A Additional Sensor Data Adapters

1-20. OPTIONS.

1-21. Option-01. Input connectors moved to rear panel.

1-22. Option-02. Calibrator type N connector moved to rear

panel.

1-23. Option-03. Replaces the IEEE-488 Interface with a RS-

232 Interface. The baud rate, data size, stop and parity bits are

programmable.

1-24. Option-30. Warranty extended to 3 years.

1-25. SPECIFICATIONS. Performance specifications of the

Model 4230A are listed in Table 1-1.

1-2

Figure 1-2. Outline Dimensions.

Page 12

Section I

TABLE 1-1. PERFORMANCE SPECIFICATIONS

Parameter Specification

Frequency Range 10 kHz to 100 GHz, sensor dependent

Power Range -70 dBm to +44 dBm, sensor dependent

Power Sensors Accepts sensor data adapter and is compatible with all Boonton diode and

thermal sensors

Dynamic Range Up to 90 dB with diode sensors; up to 50 dB with thermal sensors

Inputs Front or Rear panel sensor connector; rear panel IEEE-488 connector or

optional RS-232 connector

Outputs Front panel or optional Rear panel PWR REF connector, 50 MHz, 0 dBm;

rear panel recorder BNC connector, 9.06 kilohm impedance, 0 to 10 volts

into 1 megohm (may be operated into 1 kilohm for 1V fs).

Display Menu-driven 20 character x 4 line LCD

Display Units MW, kW, W, mW, µW, nW, dBm, dBr, %

Display Resolution 0.001 (db,dBm, dBr) or 5 digits (nW, mW and W)

Display Offset -99.99 dB to +99.99 dB in 0.01 dB steps

Alarm Individual high and low limit thresholds, -99.99 dB to +99.99 dB

Peak Power Mode Programmable duty cycle from 0.01 to 100.00% in 0.01 steps

Ranging Autoranging or manual (7 ranges)

Filtering Filter times to 20.00 seconds in 0.05 second increments

Zeroing Automatic function; calculates, stores, and applies zero corrections to each

range

High Frequency Cal Factors +3 dB to -3 dB in 0.01 dB steps; cal factors for up to four power sensors

with up to 60 frequencies each may be stored in the instrument's non-

volatile memory; cal factors also stored in sensor data adapter

Reference Level -99.99 dB to +99.99 dB in 0.01 dB steps for dBr measurements

Power Reference:

Frequency 50 MHz + 1.5%

Output Level 0 dBm

Level Accuracy +0.7% (+0.03 dB) (23 degrees C) for 90 days; +0.9% (+0.04 dB) RSS,

+1.2% (+0.05 dB) worst case (0 to 55 degrees C) for 1 year

Source Impedance 50 +1 ohm

VSWR < 1.05

Harmonic Output < -50 dBc

Measurement Accuracy Sum of following uncertainties (errors are + worst case): instrument

uncertainty, noise/signal percentage, power reference uncertainty, sensor

shaping, temperature drift, mismatch, and high frequency calibration factors

Instrument Uncertainty .002% at full scale

Noise/signal Percentage Refer to Power Sensor Manual, Table 2-1

Power Reference Uncertainty Refer to Table 1-1 Power Reference: Level Accuracy and for Waveguide

sensors, refer to Power Sensor Manual, Table 2-2 Note 2

Sensor Shaping Refer to Power Sensor Manual, Tables 3-1 and 3-2

Temperature Drift Refer to Power Sensor Manual, Table 2-1

Power Requirements 100, 120, 220, or 240 VAC (±10%), 50-60 Hz or 400 Hz, 15 VA maximum

Ventilation Requirements 1 1/2" clearance after installation, top, side, rear

Temperature

Operating 0 to 55ºC

Non-operating -40 - +75ºC

General Information

1-3

Page 13

Section I

General Information

TABLE 1-1. PERFORMANCE SPECIFICATIONS (CONT.)

Parameter Specification

Altitude

Operating 10,000 ft.

CE Mark: Declares conformity to European Community (EC) Council Directives:

89/336/EEC//93/68/EEC, 73/23/EEC//93/68/

EEC & Standards: EN61326-1, EN55022, EN61000-4/ -2,3,4,5,6,11, ENG1010-1

Humidity 95% non-condensing

Weight 7 lb (3.2 kg)

Dimensions 8.26 in. (21.0 cm) wide 3.48 in. (8.9 cm) high, 13.5 in (34.3 cm) deep

1-4

Page 14

SECTION II

Section II

INSTALLATION

Installation

2-1. INTRODUCTION.

This section contains the installation instructions for the

Model 4230A Series RF Power Meter. It includes unpacking, mounting, power connections, cable connections and

priliminary checkout procedures.

2-2. UNPACKING. The instrument is shipped complete and

ready to use upon receipt. Unpack the instrument from its

shipping container and inspect it for damage that may have

occurred during shipment. Refer to figure 2-1.

NOTE

Save the packing material and container

for possible use in re-shipment of the

instrument.

2-3. MOUNTING. For bench use, choose a clean, dry and

uncluttered surface. For rack mounting, an accessory kit is

available which contains the necessary parts for mounting a

single half-width Model 4230A or two side-by-side halfwidth Model 4230A's (or a compatible product) in a single

19 inch rack.

2-4. POWER REQUIREMENTS. The Model 4230A has

a tapped transformer and a power entry module containing a

line voltage selector switch and two fuses. Operation is permitted from 100, 120, 220 and 240 Volt +-10%, 50 to 60

Hz, single phase AC power supplies.

CAUTION

so that when it is re-inserted into the module, the

desired voltage will appear in the small window in

the cover.

4. To remove the fuses, move the fuseholder tabs in

the direction of the arrow and pull the holder out.

Place a new fuse in the holder and put it back in the

slot, restoring the tab to its original position.

5. After all changes are completed, close the cover.

Make sure the alignment of the selector cylinder and

window is correct and that the cover snaps into place.

VOLTAGE FUSE IEC TYPE

100/120V 0.315A T

220/240V 0.160A T

2-5. CONNECTIONS. An AC power cable is supplied with

the instrument and a standard interconnecting cable or cable/

adapter combination is supplied with each RF Sensor. Longer

RF Sensor cables are available as accessories. All other

cables required must be supplied by the user.

2-6. Sensor. Connect the RF Sensor that is to be used for

measurement to the cable or Data Adapter-Cable combo supplied with the sensor. If the Data Adapter is a separate item,

also connect the cable to the adapter. Make sure that the

serial number on the Data Adapter matches the serial number

of the RF Sensor. Insert the 10-pin adapter plug into one of

the two sensor inputs. For Model 4231, only Sensor input

number 1 is active.

Always make cerain that the setting of the line voltage selector switch most nearly corresponds to the voltage of the AC

power source, and that fuses of the correct rating according

to the chart just above the power entry module, are installed.

To change the line voltage selector switch or the fuses, follow

this procedure:

1. REMOVE the power cable from the power entry

module.

2. To open the power entry module, place a small

screwdriver or coin in the slot at the top of the module and gently pry the cover open.

3. Using a small screwdriver gently pry the voltage

selector cylinder from the module. Turn the cylinder

2-7. Recorder. A data recorder or other similar device can

be connected to the Recorder BNC connector on the rear

panel. The output is a DC voltage proportional to the Channel 1 display value. The voltage range is 0 to 10 volts with an

output impedance of approximately 9 kohms.

2-8. GPIB. The standard instrument is equipped with an

IEEE-488 bus interface for remote operation. The connector is

located on the rear panel.

2-9. RS-232. The optional RS-232 interface can be supplied

in place of the standard IEEE-488 interface. This interface

also provides remote operation using the same command

strings. The DB-25 connector is located on the rear panel.

2-1

Page 15

Section II

Installation

2-10. PRELIMINARY CHECK.

2-11. The following preliminary check verifies that the

Model 4230A is operational. It should be performed before

the instrument is placed in service. Proceed as follows:

a. Ensure that the voltage selector switch and fuses correspond to the AC power source voltage to be used.

b. Connect the AC power cable to the instrument and to the

power source.

c. Connect one or two RF Sensors to the instrument as described above.

d. Set the front panel OFF/ON power switch to the ON position..

e. Verify that BOONTON ELECTRONICS

423XA RF POWER METER

Rev. X.XX

is momentarily displayed.

f. Verify that the measurement display showing "CH 1" only

for Model 4231 or "CH 1" and "CH 2" for Model 4232. Other

data on the display will depend upon previous settings.

g. Press the <MENU> key and select DIAGNOSTICS with the

down arrow key. Press <ENTER>. Verify the following submenu:

DIAGNOSTICS

RTN

SELFTEST <

SWITCHES

RECORDER

j. Use the <Down Arrow> key to select RECORDER and

press <ENTER>. This test will sequentially send a DC voltage in 1 volt steps to the recorder output BNC connector on

the rear panel. The test will continue until <MENU> is pressed.

Use a DC voltmeter to verify correct operation.

k. Press <MENU> to return to the measurement display.

l. Press the <Sensor> key and verify that the RF Sensor

serial number(s) appear under the channel heading(s). An

active channel with no sensor installed will report a table

number.

m. Press the <AVG> key and verify that the filter time and

number of samples appear for each active channel.

n. Press the <REF Level> key and verify that a reference level

and mode is shown for each active channel.

o. With each installed sensor connected to the reference

output, press the <ZERO/CAL> key and select ZERO/CAL

function for the active channel. Verify the ZERO/CAL operation completes successfully. Repeat this operation for

the other channel if installed.

p. For standard instruments equipped with the IEEE-488 interface, connect a GPIB controller to the Model 4230A.

Verify that the instrument can be addressed to Listen at its

IEEE bus address, and set to Remote. The display must show

the correct status on the bottom line of the display. For

message passing, the line terminators for the controller and

the Model 4230A must be compatible for both Listen and

Talk. Use <MAIN> <SETUP> <IEEE> to set address and

terminators for the 4230A. Address the Model 4230A to

Listen/Remote and send the command "?ID" or "*IDN?" EOL.

Then address the Model 4230A to Talk (controller to listen)

and verify that the correct identification string is returned.

h. Press <ENTER> to execute the selftest. The items tested

are:

1. Processor

2. SRAM Memory

3. EEPROM

Each test will display the OK message it it passed. When the

test is completed the menu will reappear.

i. Use the <Down Arrow> key to move the "<" cursor to

SWITCHES and press <ENTER>. Press each front panel key,

avoiding <MENU> until last. Each key press will result in an

identifying message; <MENU> will exit the test and return to

the MENU.

2-2

q. For instruments equipped with the optional RS-232 interface, connect a dumb terminal or PC serial terminal to the

Model 4230A. Use a null modem if the terminal is wired as

DCE. For message communication to take place, the parameters of the serial connection and message strings must

agree between the terminal and the Model 4230A. Use

<MAIN> <SETUP> <RS-232> to set parameters for the

4230A. Send the command "?ID" or "*IDN?" EOL and verify

that the correct identification string is returned.

Page 16

Section II

Installation

Figure 2-1. Packing and Unpacking Diagram

2-3

Page 17

SECTION III

OPERATION

Section III

Operation

3-1. INTRODUCTION.

3-2. This section contains operating instructions for the

Model 4230A. It is strongly recommended that the operator

become familiar with all the material in this section and with

the application notes in Section IV before attempting to

operate the instrument; otherwise, the full capabilities of the

instrument may not be realized.

3-3. OPERATING CONTROLS, INDICATORS, AND

CONNECTORS.

3-4. See Figures 3-1 and 3-2 for the location of the operating

controls and connectors. Refer to Table 3-1 for the function

of each of these items.

3-5. OPERATING THE INSTRUMENT.

3-6. Energize the instrument by setting the POWER switch

to the ON position. The instrument will perform a self test

routine and initialize the operating parameters to the powerup values.

TABLE 3-1. OPERATING CONTROLS, INDICATORS, AND CONNECTORS

Index and

Fig. No. Nomenclature Function

3-7. MEASUREMENT DISPLAY.

3-8. The measurement screen shown in Figure 3-3 can be

configured to display one or two channels along with the

corresponding bar graph. In alarm mode, the ∧ and the ∨

symbols are displayed before the channel mode to indicate

that the measured value is above or below the defined limits.

An asterisk is displayed before the channel mode when in the

manual range mode and the measured value is below the

lower range limit indicating an uncalibrated measurement.

The alarm indicators have precedence over the range limit

display. In peak pulse mode, the

the measurement unit. The ∆ symbol is displayed when the

measurement is associated with an offset. When the

instrument is configured for remote operations over the

IEEE-488 or RS-232 bus, the last line, as shown in Figure 34, is always used for the bus indicators.

3-9. MENU STRUCTURE.

P

symbol is displayed after

K

1, 3-1 Sensor Connector, Channel 2 Provides the means for connecting the power sensor to channel 2

of the instrument.

2 , 3-1 Sensor Connector, Channel 1 Provides the means for connecting the power sensor to channel 1

of the instrument.

3 , 3-1 Display LCD readout of the measurements and user interface for editing

of the instrument's operating parameters.

4 , 3-1 Left Arrow Key In entry mode, advances the cursor to the left.

5 , 3-1 Up Arrow Key In entry mode, advances the cursor upwards. In parameter entry

mode, scrolls forward through the parameter list. In numerical

entry mode, advances the value to the next higher digit.

6 , 3-1 Enter Key In entry mode, initiates the procedure to change a parameter. In

parameter entry mode, terminates the current command and

changes the parameter to the last displayed value.

7 , 3-1 Right Arrow Key In entry mode, advances the cursor to the right.

8 , 3-1 Down Arrow Key In entry mode, advances the cursor downwards. In parameter

entry mode, scrolls backwards through the parameter list. In

numerical entry mode, advances the value to the next lower digit.

9 , 3-1 Power Switch Turns the instrument off and on.

10, 3-1 0 dBm 50 MHz Connector Provides a 50 MHz, 0 dBm output for instrument calibration.

When the calibrator is off, the connector serves as a 50 Ω

termination to zero the instrument.

3-1

Page 18

Section III

Operation

Index and

Fig. No. Nomenclature Function

11, 3-1 <REF Level> Key Selects the reference level menu for relative measurements.

12, 3-1 <Zero/CAL> Key Selects the zeroing and 0 dBm reference level calibration

13, 3-1 <AVG> Key Selects the filter averaging display for the measurement value.

14, 3-1 <FREQ> Key Selects the operating frequency display.

15, 3-1 <Sensor> Key Displays the serial number of the installed sensors and allows

16, 3-1 <Menu> Key Displays and allows editing of the instrument's operating

17, 3-2 Power Receptacle Provides means for connecting the AC power cord to the

18, 3-2 Fuse Protects the power circuits from overload.

19, 3-2 Voltage Selector Switches Switches the power circuits of the instrument to accommodate

20, 3-2 Recorder Connector Provides a DC voltage proportional to the measured values

21, 3-2 GPIB Connector Provides means for connecting the instrument to the IEEE-

22, 3-2 Optional Location of Provides the means of connecting the power sensor to

23, 3-2 Optional Location of Provides 50 MHz, 0 dBm output for instrument calibration.

24, 3-2 Optional Location of Provides the means of connecting the power sensor to

TABLE 3-1. OPERATING CONTROLS, INDICATORS, AND CONNECTORS (CONT)

functions.

for editing of the sensor parameters.

parameters. Returns instrument to local mode when operating

in the bus remote mode. Escapes back to measurement screen

from any menu.

instrument.

100, 120, 220 or 240 volt AC power sources.

for use by an external recorder

or RS-232 Connector 488 or RS-232 bus for remote control

Sensor Connector, Channel 2 channel 2 of the instrument.

0 dBm 50 MHz Connector

Sensor Connector, Channel 1 channel 1 of the instrument.

3-2

Page 19

Section III

Operation

Figure 3-1. Model 4230A, Front Panel Controls and Connectors

Figure 3-2. Model 4230A, Rear Panel Controls and Connectors

3-3

Page 20

Section III

Operation

3-10. The Model 4230A can be configured for operation via the

six switches on the front panel; <Menu>, <Sensor>,

<FREQ>, <AVG>, <Zero/CAL> and <REF Level>.

Pressing a key will bring the instrument to the next submenu.

A flow chart of the instrument's command structure is shown

in Figure 3-5. The <Menu> key also serves as an ESCAPE

key to cancel the current operation from any point and return

to the measurement screen.

3-11. To change a value, use the arrow keys to position the

cursor to the desired parameter. Press the <Enter> key and

then use the up/down arrow keys to scroll through the

parameter list. When a number is to be entered, use the left/

right arrow keys to position the cursor under the number that

is to be changed, then use the up/down arrow keys to

increment/decrement the number. Holding the up/down

arrow key will initiate repeat mode to allow rapid movement

through the selections. The <Enter> key must be pressed to

accept the current selection.

3-12. Within a submenu, the ∧∨ indicators are displayed in

the upper right portion of the display when the current screen

has additional information that can be obtained by scrolling

with the up/down arrow keys. Three conditions are possible:

a.∧ Use the up arrow key to scroll the screen upward for

additional information.

b.∨ Use the down arrow key to scroll the screen downward

for additional information.

c.∧∨ Use the up/down arrow keys to scroll the screen

upward/downward for additional information.

3-4

Page 21

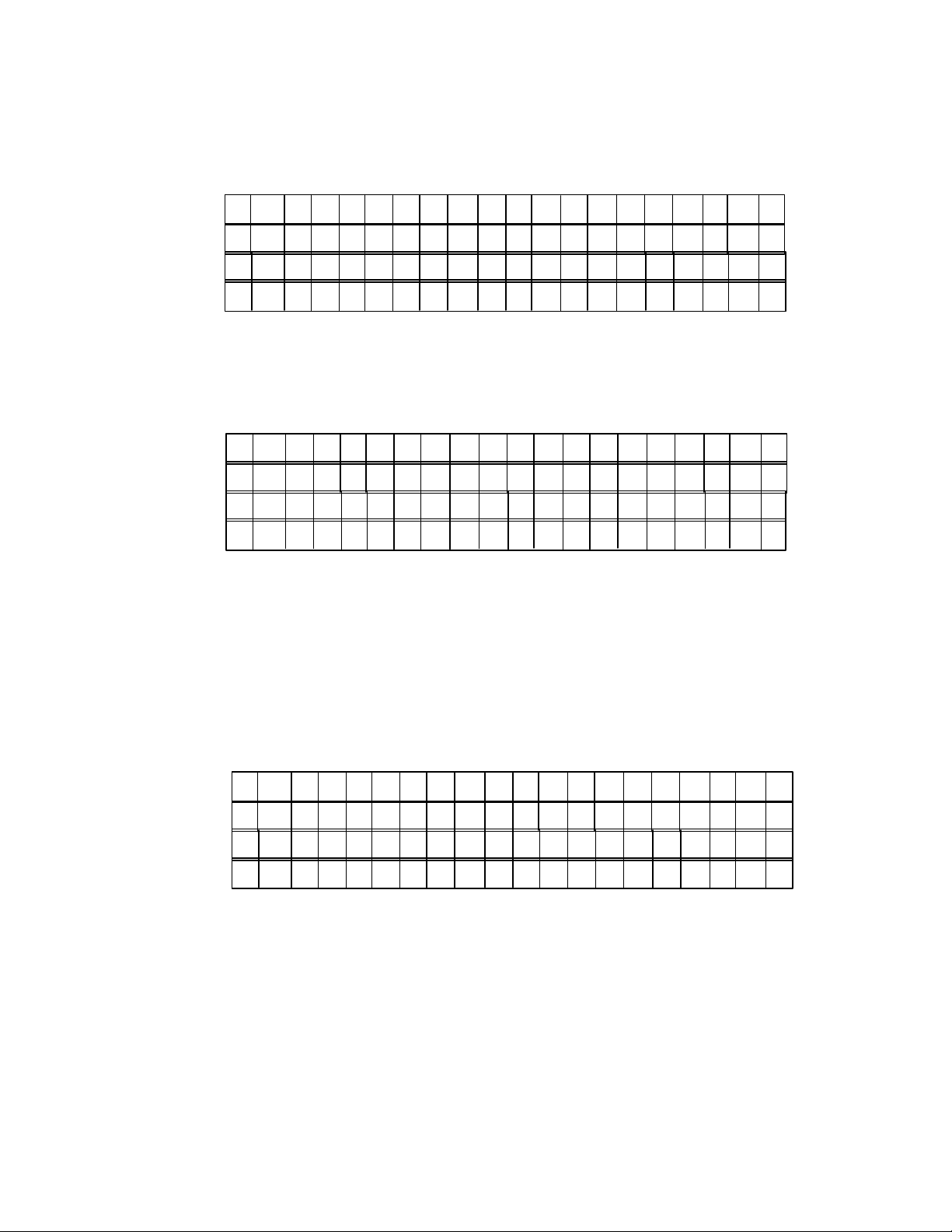

DUAL CHANNEL

Section III

Operation

Key:

L M M M M M ± D D D D D D U U U

( B A R G R A P H )

L M M M M M ± D D D D D D U U U

( B A R G R A P H )

SINGLE CHANNEL

L M M M M M ± D D D D D D U U U

( B A R G R A P H )

O = 0 through 9 or a decimal point

L = ∧ , ∨, (alarm mode), * (range hold-low)

MMMMM = CH1, CH2, CH1+2, CH1/2

UUU = nW, µW, mW, kW, MW, dBm, dBr, %

P

∆

K

P

∆

K

P

∆

K

Key:

Figure 3-3. Measurement Display, Local Mode

L M M M M M ± D D D D D D U U U

( B A R G R A P H )

L M M M M M ± D D D D D D U U U

R E M L S N T L K S R Q

REM = Remote mode enabled

LSN = Listen addressed

TLK = Talker addressed

SRQ = Service request activated

Figure 3-4. Measurement Display, Remote Mode

P

∆

K

P

∆

K

3-5

Page 22

Section III

Operation

3-6

Figure 3-5. Model 4230A, Command Set

Page 23

3-13. MENU Key.

3-14. The instrument's, CHANNELS, SETUP and

DIAGNOSTIC commands are accessed when the <Menu>

key is pressed.

3-15. Using the up/down arrow keys, the cursor can be

positioned to select from the three submenus.

3-16. Channel Menu. An example of the display for the

Channels menu, when two channels are installed in the

Model 4230A, is shown in Figure 3-7. Although the figure

shows eleven lines, the instrument can only display four at a

time. Therefore, it will be necessary to use the up/down arrow

keys to sequence through the commands. When viewing the

commands, the instrument will retain the first line as a header

and use the next three lines to scroll through the remaining

commands.

C H A N N E L S <

S E T U P

Section III

Operation

3-17. Table 3-2 gives a description of the commands

available from the Channels menu. The associated

parameters, and factory default settings are also given.

3-18. Setup Menu. An example of the display for the Setup

menu, when the Model 4230A is configured with an IEEE

interface, is shown in Figure 3-8. Figure 3-9 is an example

of the instrument when equipped with the RS-232 option. It

will be necessary to use the up/down arrow keys to sequence

through the commands since there are more than four lines of

information to be displayed. When sequencing through the

commands, the instrument will retain the first line as a header

and use the next three lines to scroll through the command

list.

D I A G N O S T I C S

Figure 3-6. Main Menu Display

R T N C H 1 C H 2 ∨ ∧

U N I T S > W A T T S d B m

R E S X X X X X . X X

D U T Y 1 0 0 . 0 0 1 0 0 . 0 0

B A R O F F O N

M O D E C H 2

O F F S E T 0 . 0 0 1 0 . 0 0

R A N G E A U T O 4

A L A R M O N O F F

H I L M T 1 0 . 0 0 0 . 0 0

L O L M T 1 . 0 0 0 . 0 0

Figure 3-7. Channels Menu Display

3-7

Page 24

Section III

Operation

TABLE 3-2. CHANNEL MENU FUNCTIONS

Function Description Parameters Default

RTN Returns the instrument to the n/a n/a

previous menu.

UNITS Units used for measurement dBm, WATTS dBm

display.

RES Display resolution X.X, X.XX, X.XXX dBm or/ X.XX

XXX, XXXX, XXXXX Watts

DUTY Duty cycle for pulse power 0.01 to 100.00% 100.00

applications; a value less than

100.00 enables pulse power

mode.

BAR Enables the bar graph on the ON, OFF ON

measurement display.

MODE Sets the display mode for CH2, CH1+2, CH1/2, CH2

channel 2; only available when OFF

two channels are installed. The

units for the sum and ratio

modes track the units selected for

Channel 2.

OFFSET Sets the offset added to the -99.99 to 99.99 dB 0.00

measured value.

RANGE Selects and holds the instrument's Auto, 0,1,2,3,4,5,6 AUTO

measurement range. If

repetitive measurements are to

be made over a narrow range of

levels, selecting the appropriate

instrument range may speed

measurements.

3-8

Page 25

Section III

Operation

TABLE 3-2. CHANNEL COMMANDS (CONT)

Command Description Parameters Default

ALARM Enables alarm mode; the ∨ or ON, OFF OFF

∧ symbol is displayed before

the channel mode designator on

the measurement display to

indicate when the upper or

lower threshold limit is

exceeded.

HI LMT Upper threshold limit for the -99.99 to 99.99 dBm 0.00

alarm function.

LO LMT Lower threshold limit for the -99.99 to 99.99 dBm 0.00

alarm function.

R T N ∨ ∧

R E C A L L > 1

S A V E 2

P O W E R - U P D E F A U L T

C A L I B R A T O R O F F

K E Y B E E P O F F

I E E E

I N S T R C A L

Figure 3-8. Setup Menu Display, IEEE Installed

3-9

Page 26

Section III

Operation

R T N ∨ ∧

R E C A L L 1

S A V E > 2

P O W E R - U P D E F A U L T

C A L I B R A T O R O F F

K E Y B E E P O F F

R S - 2 3 2

I N S T R C A L

Figure 3-9. Setup Menu Display, RS-232 Installed

3-19. Table 3-3 gives a description of the commands, parameters and default settings of the Setup menu.

TABLE 3-3. SETUP MENU FUNCTIONS

Command Description Parameters Default

RTN Returns the instrument to the n/a n/a

previous menu.

RECALL Recalls one of ten user Default, 1-10 Default

defined instrument

configurations or the factory

setup.

SAVE Saves the current instrument 1-10 1

configuration to one of ten

non-volatile memory

locations.

POWER-UP Instructs the instrument to power-up to Default, 1, 2, 3, 4 Default

the specified configuration.

CALIBRATOR Turns on/off the internal 50 ON, OFF ON

MHz 0 dBm calibrator.

KEY BEEP Turns on/off the key beep. ON, OFF ON

IEEE Brings the instrument to the see table 3-4 n/a

IEEE menu. (if installled)

RS-232 Brings the instrument to the see table 3-5 n/a

RS-232 menu. (if installed)

LINEFREQ Select line (mains) 50Hz, 60Hz n/a

frequency.

INSTRCAL Refer to Service Manual. n/a n/a

3-10

Page 27

Section III

Operation

3-20. Programming Interfaces. Either the IEEE-488 or RS-232

interface is installed, but not both. The appropriate setup menu

will appear in the list.

3-21a. IEEE Menu. The IEEE submenu is used to configure the

Model 4230A for communications over the GPIB. An example

of the menu is shown in Figure 3-10 and the description of the

commands, parameters and factory defaults is given in Table

3-4.

R T N ∨ ∧

A D D R E S S 1 5

E M U L A T I O N 4 2 3 0

E O S L S T N L F

E O S T A L K E R C R L F

E O I O F F

S R Q M A S K 0

Figure 3-10. IEEE Menu Display

3-21b. RS-232 Menu. The RS-232 menu is used to configure

the Model 4230A for serial communications over the RS-232

bus. An example of the submenu is shown in Figure 3-11 and

an explanation of the commands, parameters and factory

defaults is given in Table 3-5.

TABLE 3-4. IEEE MENU FUNCTIONS (if installed)

Command Description Parameters Default

RTN Returns the instrument to the n/a n/a

previous menu.

ADDRESS GPIB address assigned to the 0 to 30 n/a

instrument.

EMULATION GPIB emulation mode. NONE, HP437B, HP438A 4230A

EOS LSTN End of string indicator for LF, CR, CRLF, NONE LF

received messages. Where:

LF = Line Feed

CR = Carriage Return

CRLF = Carriage Return

and Line Feed

EOS TALKER End of string character sent LF, CR, CRLF, NONE CRLF

with transmitted messages.

EOI Enables/disables the end or ON, OFF OFF

identify hardware control line.

SRQ MASK Service request interrupt mask. 0 to 255 0

See Table 4-7 for bit Where:

descriptions. 255 enables all interrupts

3-11

Page 28

Section III

Operation

R T N < ∨ ∧

B A U D R A T E 9 6 0 0

D A T A B I T S 8

S T O P S B I T S 1

P A R I T Y N O N E

E O S L I S T E N E R L F

E O S T A L K E R C R L F

S R Q M A S K 0

Figure 3-11. RS-232 Menu Display

TABLE 3-5. RS-232 MENU FUNCTIONS (if installed)

Command Description Parameters Default

RTN Returns the instrument to the n/a n/a

previous menu.

BAUD RATE Rate at which data is 300, 1200, 2400, 9600 9600

transferred over the bus. 19200

DATA BITS Number of data bits in a message. 7, 8 8

STOP BITS Number of stop bits in a message. 1, 2 1

PARITY Parity bit mode in a message. ODD, EVEN, NONE NONE

EOS End of string indicator for LF, CR, CRLF, NONE LF

LISTENER received messages. Where:

LF = Line Feed

CR = Carriage Return

CRLF = Carriage Return

& Line Feed

EOS TALKER End of string character sent LF, CR, CRLF, NONE CRLF

with transmitted messages.

SRQ MASK Service request interrupt mask. 0 to 255 0

See Table 4-7 for bit Where:

descriptions. 255 enables all interrupts

3-12

Page 29

Section III

Operation

3-22. Diagnostics Menu. The Model 4230A can be directed

to perform self-tests from the diagnostics menu. The

Diagnostics menu is shown in Figure 3-12 and a description

of each command is given in Table 3-6.

3-23. SENSOR KEY.

3-24. Pressing the <Sensor> key brings the instrument to the

Sensor menu and facilitates viewing and editing of the power

sensor's parameters. An access code is required to enter the

editing mode (refer to Figure 3-14). A sample display of the

Sensor menu is shown in Figure 3-13.

R T N <

S E L F T E S T <

S W I T C H E S

R E C O R D E R

Figure 3-12. Diagnostics Menu Display

TABLE 3-6. DIAGNOSTICS MENU FUNCTIONS

Command Description Parameters Default

3-25. The instrument is capable of using sensor calibration

data from either the sensor data adapters or from any one of four

internal tables. The sensor calibration data contained within

the sensor data adapter is only accessible to the installed

channel. For example, Channel 1 can use the sensor calibration

data from any of the internal tables or the sensor data adapter

1. Similarly, Channel 2 can use the sensor calibration data from

any of the internal tables or the sensor data adapter 2.

3-26. Referring to Figure 3-13, the cursor can be positioned to