Page 1

HUB INSTRUCTIONS

PART NUMBER 231793 SERVICE MANUAL 2003

Page 2

HUB INSTRUCTIONS

STANDARD

Front Hubs

Loose ball . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Loose ball, semi-cartridge; Formula FCM . . . . . . .4-5

Cartridge bearing, alloy axle . . . . . . . . . . . . . . . . .6-7

Cartridge bearing, threaded alloy axle . . . . . . . . . .8-9

Rear hubs

Freehub body information (non-DT Swiss) . . . . . . . 11

Loose ball . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-13

Loose ball, double sealed (Formula FCM) . . . . . .14-15

Cartridge bearing . . . . . . . . . . . . . . . . . . . . . . . . .16-17

DT-SWISS

Comp series hubs

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Comp front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20-21

Comp rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22-24

Pro series hubs

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Pro front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26-27

Pro rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28-31

Please note: Many sections of this manual must be

read in their entirety before performing procedures.

In some cases, revised or updated information may

be available on the Bontrager wheelworks website at

www.bontrager.com.

If you cannot find the information you need to service

Bontrager wheels, please contact a technical service

representative.

Copyright Trek Bicycle Corporation 2002

All rights reserved

2003 Bontrager Service Manual

1

Page 3

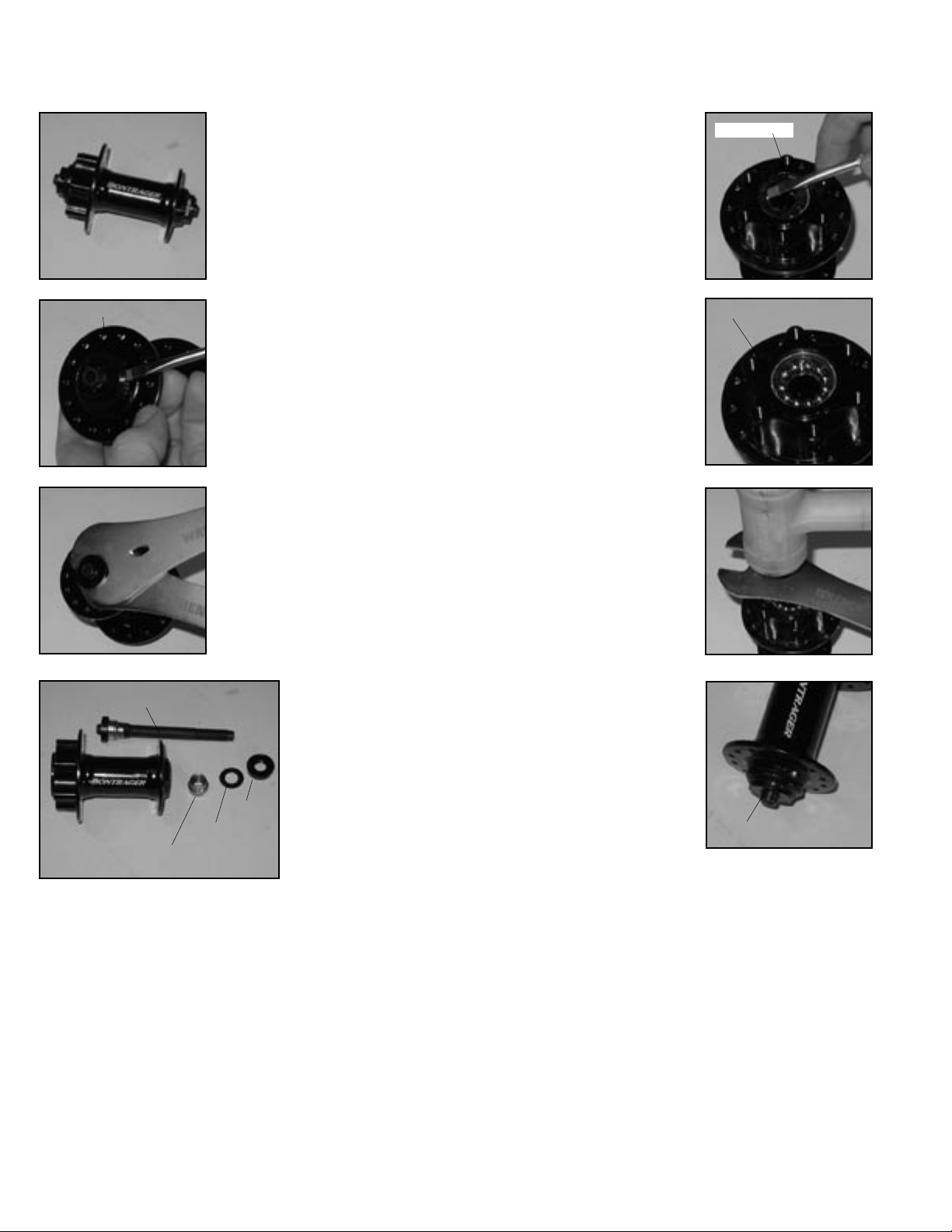

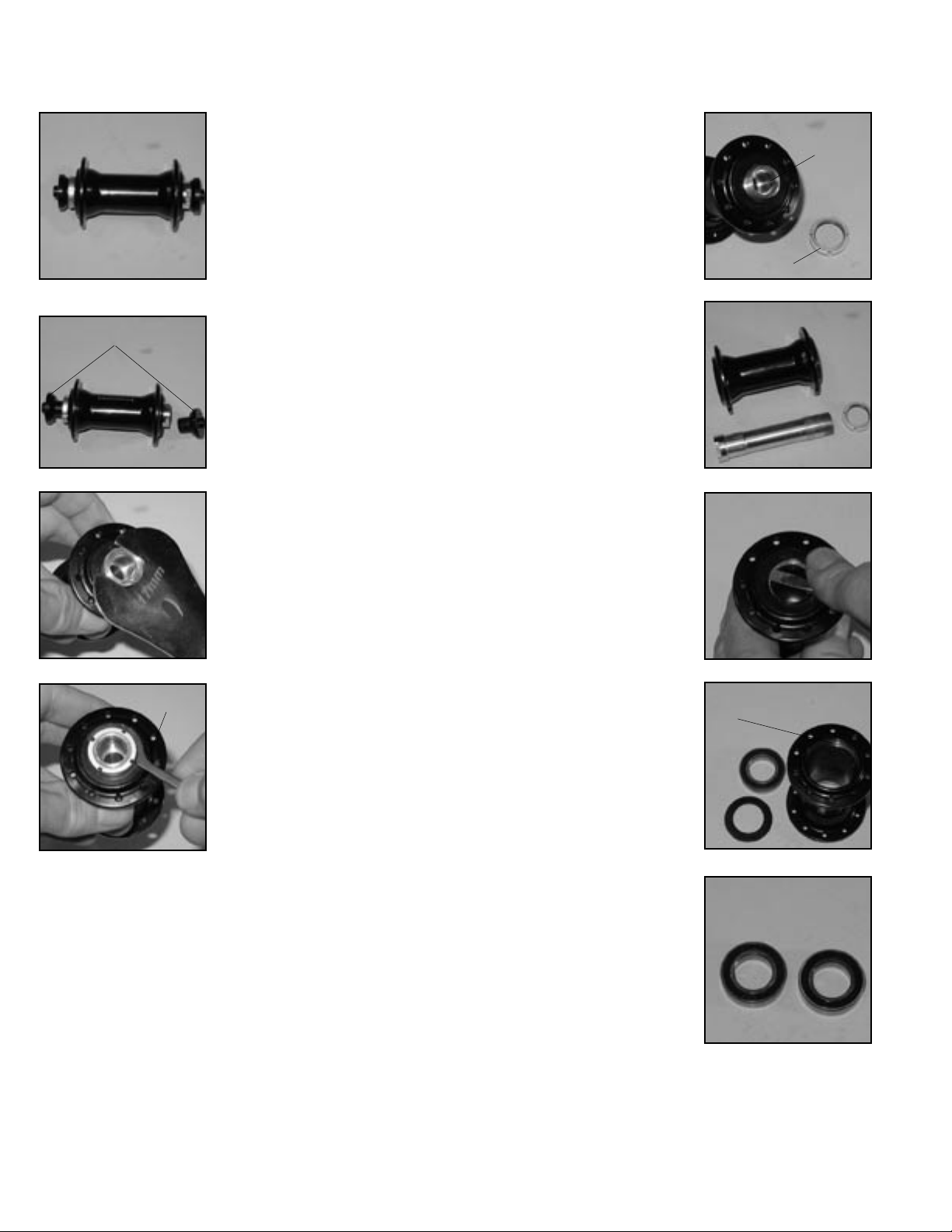

Front hubs- Loose ball

Bontrager Superstock, Superstock Disc, Select ATB, Select ATB Disc, Select Road, and Select Hybrid front wheels;

plus Bontrager Comp II front hub

Recommended tools

13mm cone wrench

17mm cone wrench

Small slot screwdriver

Hammer (soft faced)

DISASSEMBLY

Hub parts and names are referenced on next page.

Remove the axle

Fig. 1A

External seal

Fig. 2A

Fig. 3A

Axle

Ball cone

Fig. 4A

Clean and inspect the parts

1. Use solvent to completely remove all old grease and

debris from the hub, axle, and axle parts.

2. Inspect the bearing running surfaces of both the

ball cones and the ball cups (inside the hub). Replace any

cones. If the cups are worn, replace the hub shell.

1. Remove external seals

(Fig. 2A) with a screwdriver. Be

careful not to tear or mar the

rubber.

2. On one side (either) of the

hub place a 13mm cone wrench

on the ball cone. Place a 17mm

cone wrench on the end nut (Fig.

3A). Loosen the end nut.

3. Remove the end nut,

washer, and ball cone from the

axle (Fig. 4A).

4. Slide the axle, with the

other end nut, washer, and ball

cone still attached, out of the

hub (Fig. 4A).

5. Gently insert a thin

screwdriver blade under the

shell shield (Fig. 5A) and lift to

remove the shield from the hub.

Pry off the shell shields from

both sides of the hub.

6. If inspection

shows it necessary,

remove the other end

nut and ball cone.

End nut

Washer

ASSEMBLY

Shell shield

1. Place eleven 3/16” balls in

the ball cup on one side of the hub.

2. Place the shell shield, with

its sharp edges facing out (Fig.

6A), into the hub. The shell shield

is a press fit, so must be tapped

lightly to fully seat. Lay a cone

wrench over the shell shield and

tap the wrench with a hammer

(Fig. 7A) to protect the shield

and ensure that it is flush with

Bearings in bearing cup

the shell.

3. Repeat Assembly steps 1-2

for the other side of the hub.

4. Tighten the end nut

against the ball cone on the axle.

Hold the ball cone with a 13mm

cone wrench on the axle flats

while turning the end nut with a

17mm cone wrench.

5. Insert the axle through the

hub from either side.

6. Thread the ball cone, washer, and end nut onto the axle in

that order. The serrated surface

of the end nut faces out.

7. Hold the ball cone with a

13mm cone wrench and tighten

the end nut with a 17mm cone

wrench.

8. Check the bearing adjustment by turning the axle with

your fingers. The axle should

spin smoothly without binding or

feeling gritty. There should be no

lateral play of the axle in the hub.

Readjust the hub as necessary,

and re-lock the end nut.

9. Install the external seals,

and apply grease where the seals

Seal not seated

contact the hub shell and axle

parts. Make sure the seals properly seal against both the end nut and the hub shell. There

should be a smooth transition from seal to sealing surface.

An improperly installed seal (Fig. 8A) will allow rapid contamination of the bearings.

After completing assembly of the hub, check its function by spinning the axle with your fingers. It

should rotate freely without irregular friction. A small amount of lateral play is acceptable if the play is

eliminated when the wheel is installed with the quick release properly closed.

Fig. 5A

Fig. 6A

Fig. 7A

Fig. 8A

Lubricate bearings and threads

1. Lubricate the threads on the axle with Wrench

Force™ synthetic grease, or a similar product.

2. Place a bead of grease all the way around each ball

cup, sufficient to hold the balls.

2

2003 Bontrager Service Manual

Page 4

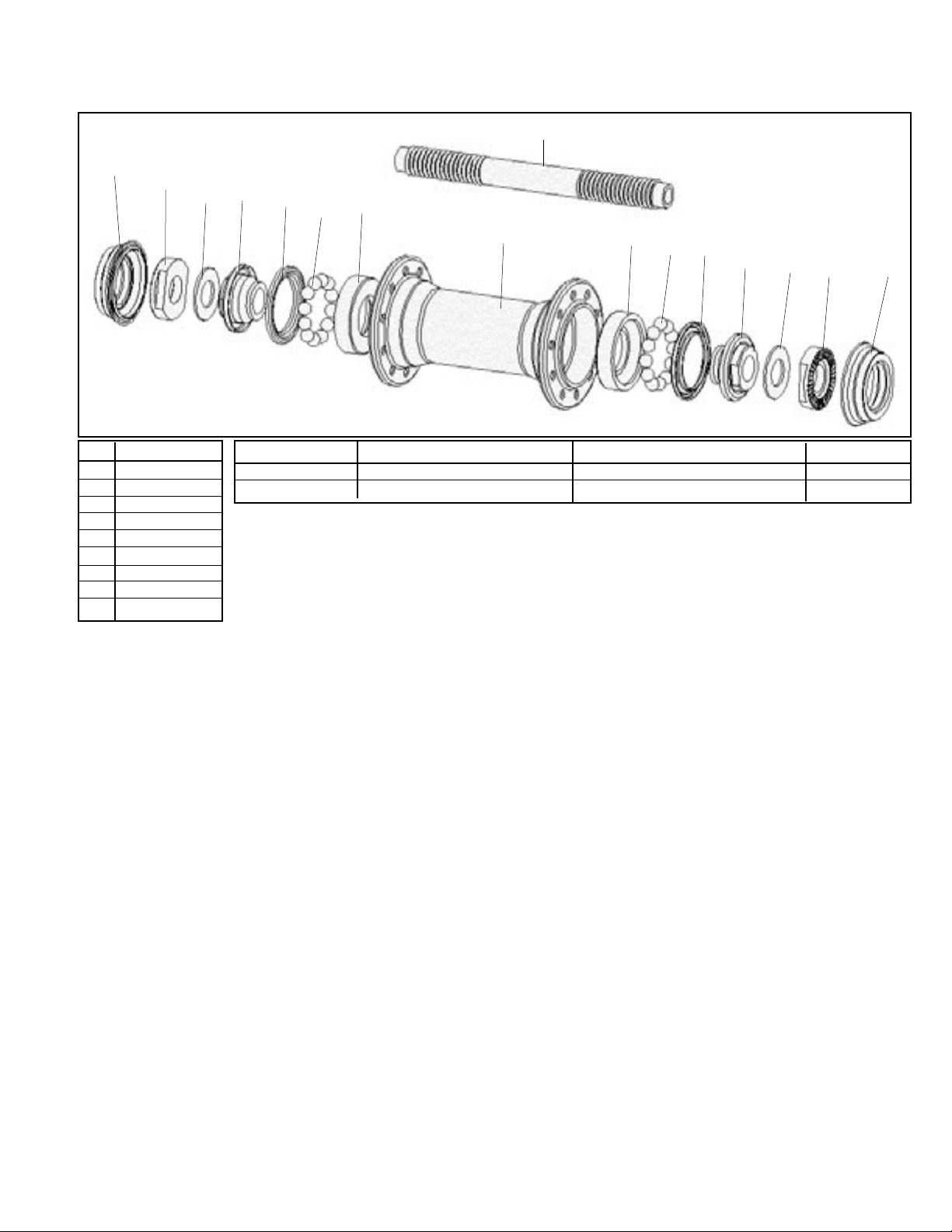

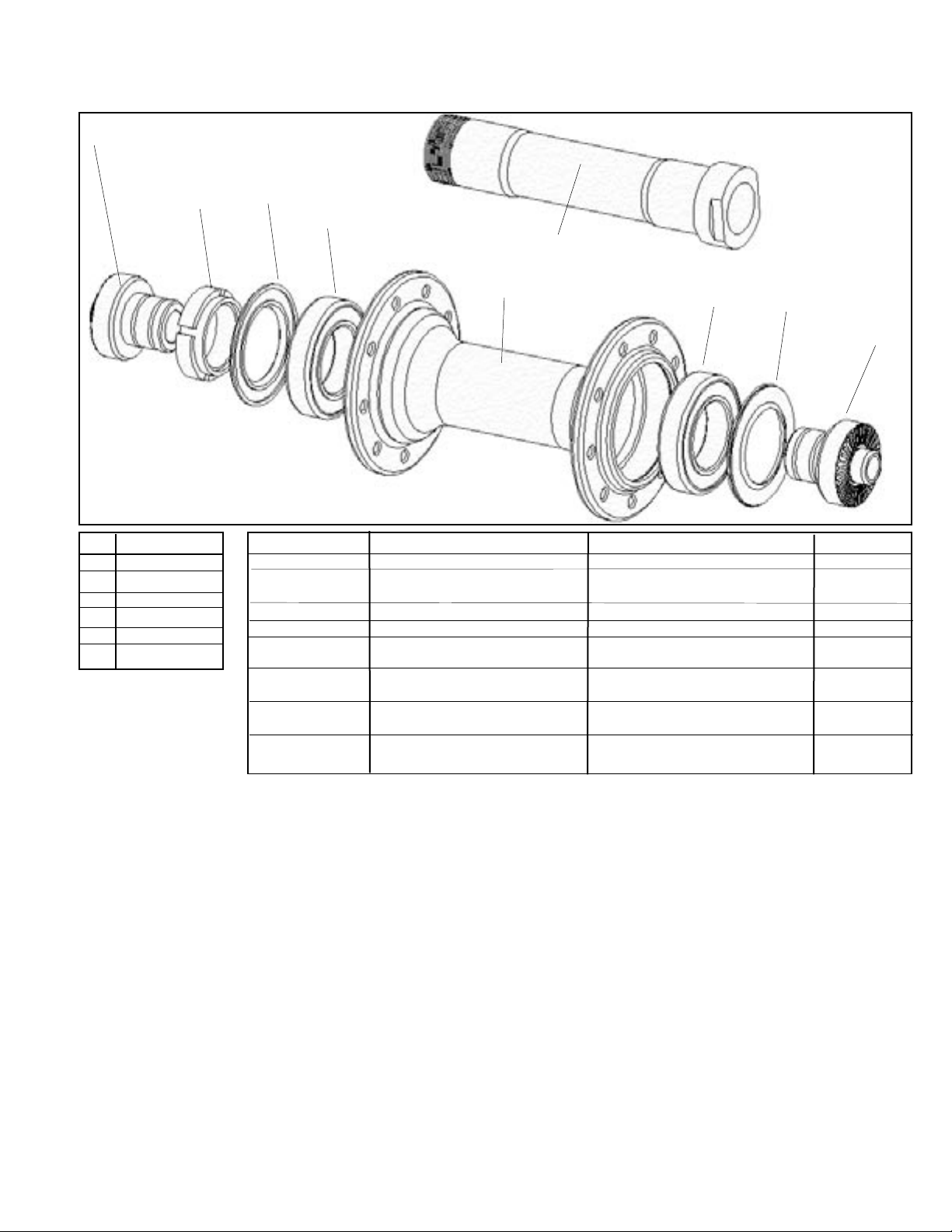

Exploded view and Parts list

9

1

2

4

3

5

7

6

8

7

6

5

4

3

2

1

Pos Description

1 External seal

2 End nut

Description Model year Model for Parts included (qty) TCG Part #

Axle set 99/00/01/02 all 1(2), 4(2), 3(2), 9 68257

Locknut set 99/00/01/02 all 2(2) 68543

3 Washer

4 Ball cone

5 Shell shield

6 Ball bearings

7 Ball cup

8 Hub shell

9 Axle

1999 Bontrager Comp II

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 mm

2000/2001/2002/2003 Superstock

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm

2002/2003 Superstock Disc, Select ATB Disc

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm

Disc rotor spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.5 mm

Rotor BCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.0 mm

2002/2003 Select ATB

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm

2002/2003 Select Road, Hybrid

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm

2003 Bontrager Service Manual

3

Page 5

Front hubs- Loose ball, semi-cartridge; Formula FCM

'99, 2000, 2001 Bontrager Race, Race Disk front wheels

Recommended tools

13mm cone wrench

17mm cone wrench

Adjustable wrench

Hammer (soft faced)

Small slot screwdriver

DISASSEMBLY

Hub parts and names are referenced on next page.

Fig. 1B

External seal

Fig. 2B

Fig. 3B

Collar

Fig. 4B

Shell shield

Fig. 5B

Axle

Ball cone

ning surfaces of both the ball cones and the ball cups

(inside the hub). Replace any worn parts.

Note: If the ‘fixed’ ball cone is worn, the axle assembly (axle and ball cone) must be replaced.

Remove the axle

1. Remove external seals

(Fig. 2B) with a screwdriver. Be

careful not to tear or mar the

rubber.

2. On one side of the hub

(usually left), the cone is locked

against a collar on the axle (Fig.

4B). On the other side, place a

13mm cone wrench on the ball

cone. Place a 17mm cone wrench

on the end nut (Fig. 3B). Loosen

the end nut.

3. Remove the end nut, washer, and ball cone from the axle

(Fig. 4B).

4. Slide the axle, with the

other end nut, washer, and ball

cone still attached, out of the hub.

6. Gently insert a thin

screwdriver blade between the

shell shield (Fig. 5B) and bearing seal (Fig. 6B). Pry off the

shell shields from

both sides of the hub.

Do not attempt to pry

off both shield and

seal at the same time

as you may damage

the bearing seal.

End nut

Washer

7. Gently pry off

the bearing seals (Fig.

6B) from both sides of

the hub.

8. If inspection

shows it necessary,

remove the other end nut. Hold

the axle by the wrench flats

(Fig. 7B) while turning the end

nut with a 17mm cone wrench.

Clean and inspect the parts

1. Use solvent to completely

remove all old grease and debris

from the hub, axle, and axle

parts.

2. Inspect the bearing run-

Lubricate bearings and threads

Bearing seal

1. Lubricate the threads on

the axle with Wrench Force™ synthetic grease, or a similar product.

2. Place a bead of grease all

the way around each ball cup,

sufficient to hold the balls.

ASSEMBLY

1. Place eleven 3/16” balls in

the ball cup on one side of the

hub (Fig. 8B).

2. Place the bearing seal,

with the lettered side facing out,

into the ball cup.

3. Place the shell shield, with

its sharp edges facing out, into

the hub. The shell shield is a press

fit, so must be tapped lightly to

fully seat. Lay a cone wrench

over the shell shield and tap the

wrench with a hammer (Fig. 9B)

Bearings in ball cup

to protect the shield and ensure

that it is flush with the shell.

4. Repeat Assembly steps 1-3

for the other side of the hub.

5. Tighten the end nut

against the fixed ball cone

(attached to axle). Hold the axle

with an adjustable wrench on the

axle flats while turning the end

nut with a 17mm cone wrench.

6. Insert the axle through the

hub from either side.

7. Thread the ball cone, washer, and end nut onto the axle in

that order. The serrated surface

of the end nut faces out.

8. Hold the ball cone with a

13mm cone wrench and tighten

the end nut with a 17mm cone

wrench.

9. Check the bearing adjustment by turning the axle with

your fingers. The axle should

spin smoothly without binding or

feeling gritty. There should be no

lateral play of the axle in the hub.

Readjust the hub as necessary,

and re-lock the end nut.

10. Install the external seals.

Make sure the seals properly seal

Seal not seated

against both the end nut and

the hub shell. There should be a

smooth transition from seal to sealing surface. An improperly installed seal (Fig. 10B) will allow rapid contamination of the bearings.

After completing assembly of the hub, check its function by spinning the axle with your fingers. It

should rotate freely without irregular friction. A small amount of lateral play is acceptable if the play is

eliminated when the wheel is installed with the quick release properly closed.

Fig. 6B

Fig. 7B

Fig. 8B

Fig. 9B

Fig. 10B

4

2003 Bontrager Service Manual

Page 6

Exploded view and Parts list

1

Note:

Rotor adapter for disc hubs not shown

Rotor spacing varies by model year, see details below.

2

3

4

5

6

10

7

8

9

8

7

6

5

12

11

3

2

1

Pos Description

1 External seal

2 End nut

3 Washer

4 Adjust cone

5 Shell shield

Description Model year Model for Parts included (qty) TCG Part #

Axle set 99/00/01 all 10, 4, 2, 5(2), 11, 6(2), 3(2) 68524

Locknut set 99/00/01 all 2(2) 68527

Rotor adapter 99/00 Hayes, RST Not shown 991083

w/screws

Disc bolt set 99/00 all Not shown 991153

6 Bearing seal

7 Ball bearings

8 Ball cup

9 Hub shell

10 Axle

11 Spacer

12 Ball cone

1999 Race

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 mm

1999/2000 Race Disk

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°

Spoke hole P.C.D., right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.0 mm

Spoke hole P.C.D., left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 mm

Disc rotor spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16.0 mm

Rotor BCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.0 mm

2001 Race Disk

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°

Spoke hole P.C.D., right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.0 mm

Spoke hole P.C.D., left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 mm

Disc rotor spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.5 mm

Rotor BCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.0 mm

2000/2001 Race

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm

2003 Bontrager Service Manual

5

Page 7

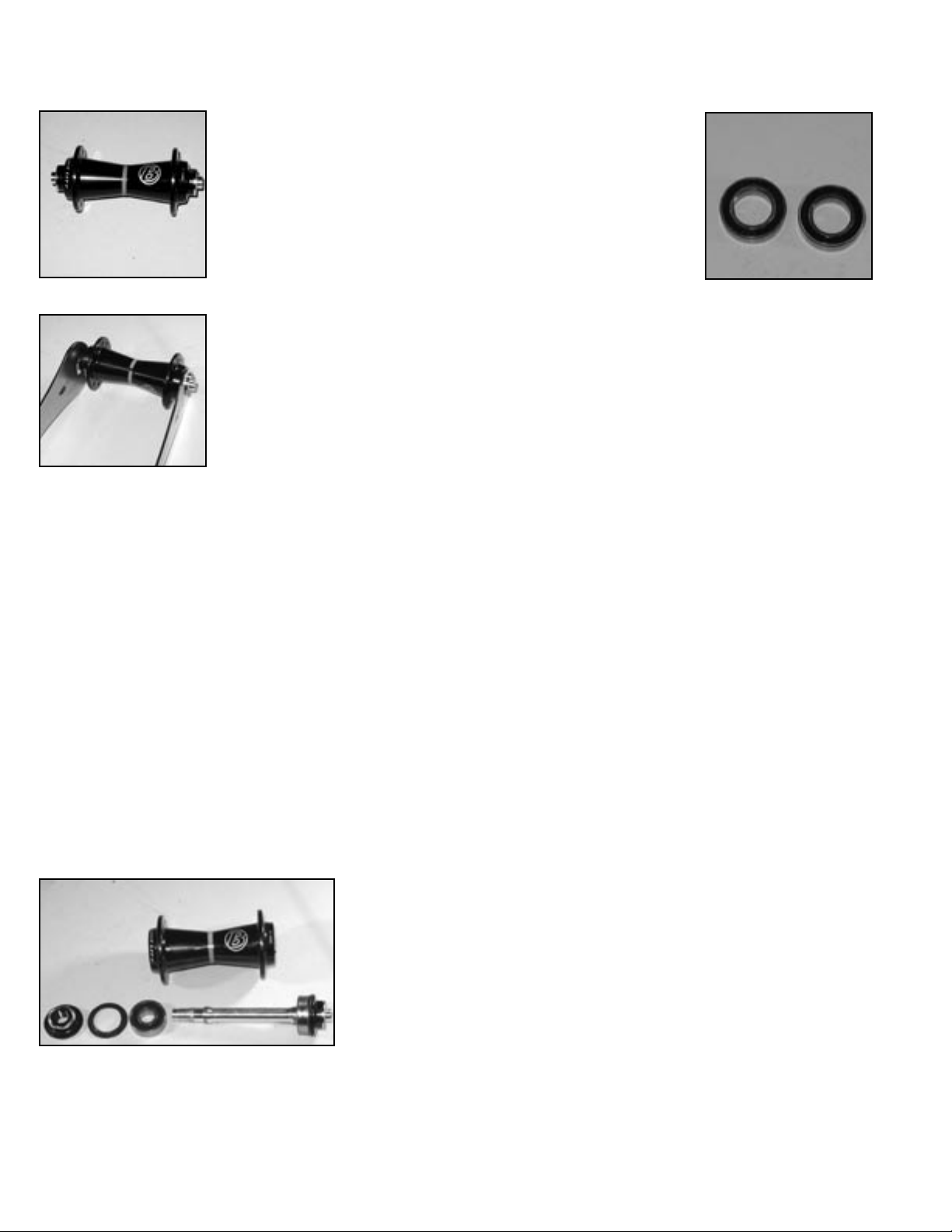

Front hubs- Cartridge bearing, alloy axle

2002/2003 Bontrager Race, Race Disc front wheels

Fig. 1C

Fig. 2C

Fig. 3C

Fig. 4C

End caps

Axle nut

Recommended tools

17mm cone wrench

Special hook spanner

Hammer and broad punch

Bearing removal tool

Bearing press

DISASSEMBLY

Hub parts and names are referenced on next page.

Remove the axle

1. Remove axle end caps

(Fig. 2C) by sliding them out of

the axle with your fingers.

2. Hold the axle with a

17mm cone wrench (Fig. 3C)

while loosening the axle nut

with the special hook spanner

(Fig. 4C).

3. Partially unthread the

axle nut (Fig. 5C) until it

slightly protrudes past the end

of the axle.

4. Tap the axle nut with a

soft-faced hammer until the axle

slides through the opposite bearing. Once loose, the axle should

come out with your fingers.

5. Remove the axle nut, and

extract the axle (Fig. 6C).

6. Gently insert a thin screwdriver blade between the bearing

seal (Fig. 7C) and bearing. Pry

off the bearing seals from both

sides of the hub.

7. Insert a bearing removal

tool into the bearing. Place a

blunt punch through the hub

and against the bearing removal

tool. Tap the punch with the

hammer to drive the bearing out

of the hub (Fig. 8C). Repeat for

the other bearing.

ASSEMBLY

1. Press a bearing into the

hub with a bearing press.

Note: the black seal faces out (Fig. 9C).

2. Press the second bearing

with the bearing press.

3. Place the bearing seals

into the hub with the lettered

surface facing out.

6. Insert the axle through the

hub from either side.

7. Thread the axle nut onto

the axle.

8. Hold the axle with a 17mm

cone wrench and tighten the axle

nut with the special hook spanner until finger tight.

Do not over-tighten the axle nut. The axle should turn freely

with no lateral play in the hub shell.

9. Press the axle end caps

into both ends of the axle.

After completing assembly of the hub, check its function by

spinning the axle with your fingers. It should rotate freely

without irregular friction. A small amount of lateral play

is acceptable if the play is eliminated when the wheel is

installed with the quick release properly closed.

Axle

Axle nut

Fig. 5C

Fig. 6C

Fig. 7C

Bearing

seat

Fig. 8C

Clean and inspect the parts

1. Wipe old grease or debris from the hub bearing

seats.

2. Normally, bearings are not re-used. If you are reinstalling an old bearing, wipe off any grease or debris

from both the inner and outer surfaces.

Do not use solvent on the bearing, as the solvent will

contaminate the grease. This may cause bearing failure.

Lubricate bearings and threads

1. Lubricate the threads on the axle with Wrench

Force™ synthetic grease, or a similar product.

2. Lightly grease the inner and outer surfaces of

each bearing.

6

2003 Bontrager Service Manual

Fig. 9C

Page 8

Exploded view and Parts list

1

2

Note:

Rotor adapter for disc hubs not shown

Rotor spacing varies by model year, see details below.

Pos Description

1 End cap

2 Adjustable nut

3 Seal

4 Bearing

5 Hub shell

6 Axle

3

Description Model year Model for Parts included (qty) TCG Part #

Seal 99/00/01 all 3(2) 68261

Bearing 99/00/01 all 4(2) 68262

#6903

Axle set 99/00/01 all 6, 4(2) 68263

Adjustable nut 99/00/01 all 2 68264

End cap, 99/00/01/02 all 1(2) 211645

20.5mm O..D.

Rotor adapter 99/00 Hayes, RST Not shown 991083

w/screws

Disc bolt set 99/00 all Not shown 991153

4

6

5

4

3

1

Special 99/00/01/02 all Not shown, see Fig. 4C 68259

hook spanner

2002 Race

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm

2002 Race Disk

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°

Spoke hole P.C.D., right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.0 mm

Spoke hole P.C.D., left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm

Disc rotor spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.5 mm

Rotor BCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.0 mm

2003 Bontrager Service Manual

7

Page 9

2003 Bontrager Service Manual

Needs photos and text

Front hubs- Cartridge bearing, threaded alloy axle

2002/2003 Bontrager Race Lite Road front wheels

Recommended tools

17mm cone wrench (2)

Hammer and broad punch

Bearing press

DISASSEMBLY

Hub parts and names are referenced on next page.

Remove the axle

1. Remove one of the thread-

Fig. 1H

Fig. 2H

second bearing from the axle. To do this, clamp the

middle of the axle, loosen the end cap, and remove it.

Support the bearing and tap the axle out with a softfaced hammer.

ed axle end caps (Fig. 2H) by

loosening with the pair of 17mm

cone wrenches.

2. With one end cap

removed, drive the axle from

the hub shell with a soft-faced

hammer.

3. Place a broad punch

through the hub, and tap the

punch with a hammer to drive

the second bearing (Fig. 3H),

with its seal, from the hub.

4. If needed, remove the

ASSEMBLY

1. Press a new bearing onto

the axle with a bearing press.

Note: the black seal faces out (Fig. 4H).

2. Place the hub seal onto the

axle, and thread on the axle end

cap. Clamp the middle of the axle

and tighten the axle end cap with

the 17mm cone wrench.

3. Press the bearing, with the

axle attached, into the hub.

4. Press the second bearing into the hub.

Note: the black seal faces out (Fig. 4H).

5. Place the hub seal over the bearing, and press into

the hub shell.

6. Thread on the second axle end cap, and tighten with

the 17mm cone wrench.

Do not over-tighten the axle nut. The axle should turn freely with no lateral play in the hub shell.

Fig. 4H

Clean and inspect the parts

1. Wipe old grease or debris from the hub bearing

seats.

2. Normally, bearings are not re-used. If you are reinstalling an old bearing, wipe off any grease or debris

from both the inner and outer surfaces.

Do not use solvent on the bearing, as the solvent will

contaminate the grease. This may cause bearing failure.

Lubricate bearings and threads

1. Lubricate the threads on the axle with Wrench

Force™ synthetic grease, or a similar product.

2. Lightly grease the inner and outer surfaces of

each bearing.

8

Fig. 3H

2003 Bontrager Service Manual

Page 10

Exploded view and Parts list

1

Pos Description

1 End nut

2 Seal

3 Bearing

4 Hub shell

5 Axle

2

3

5

4

Description Model year Model for Parts included (qty) TCG Part #

Seal 02 all 2(2) 221468

Bearing 02 all 3(2) 73335

#6000

Axle set 02 all 1(2), 2(2), 3(2), 5 221470

End nut 02 all 1(2) 221467

Axle 02 all 5 221469

3

2

1

2002/2003 Race Lite Road

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm

2003 Bontrager Service Manual

9

Page 11

Freehub body information (non-DT Swiss)

FREEHUB BODY RUNNING CHANGE

Bontrager rear hubs use an unique freehub body that

in some cases has encountered removal issues. In these

cases, a high amount of torque is necessary to remove or

install the freehub body attachment bolt.

To resolve this problem a running change was made

to the 2001 product line. The older, direct contact style

of freehub body has been replaced with a splined freehub

body attachment. This splined attachment requires less

bolt torque. Since it is a running change, the following

information is necessary to identify which freehub body

is on a wheel.

If there is a date code stamped on the freehub body

it probably uses a splined attachment. If there is no date,

it is a threaded attachment. After May 2000, both styles

of freehub bodies (both attachment types) will have this

date mark.

These different styles of freehub bodies are not interchangeable.

Identification of freehub bodies

Threaded freehub body

CNC line

Fig. 1

With the older, threaded

freehub body, there are two

identifiers. First, there is a

CNC machine line approximately

10mm from the outside end of

the freehub body (Fig. 1).

Second, the thread-attached

freehub body is designed to be

removed with a 12mm allen

wrench.

INSTALLATION AND REMOVAL

If the freehub body is worn or damaged, replace it.

Removing the freehub body

1. Follow the Disassembly

instructions for the hub. Remove

the axle, and then the right side

bearings.

2. Determine the correct size

of allen wrench to engage the

freehub body attachment bolt.

3. Unthread the bolt in a

counter-clockwise direction

(standard threading).

Installing the freehub body

1. Carefully clean the mating surfaces and threads of

the freehub body, hub shell, and attachment bolt.

2. Lubricate the threads of the attachment bolt with

Wrench Force™ synthetic grease, or a similar product.

3. Carefully engage the threads of the freehub body

attachment bolt into the hub shell. The bolt is steel, and

the hub is aluminum, so cross-threading the bolt will

result in destruction of the hub shell.

4. With the new splined freehub engagement, make

sure the splines are aligned as you tighten the attachment

bolt.

For the older, threaded style freehub body, tighten the

freehub attachment bolt to 350 lb•in (40Nm).

For the newer, splined design, tighten the freehub

attachment bolt to 400 lb•in (45.2 Nm).

Fig. 4

Splined freehub body

The newer, splined attachment (Fig. 2) freehub body has

no CNC line. Further, it is

designed to use an 11mm allen

wrench for removal. A special

adapter (TCG #211338) is made

which attaches to an 8mm allen

wrench to fit the 11mm allen

head of the freehub attachment

Fig. 2

bolt (Fig. 3).

In addition, as a running

change the new hub bodies will

include a 6-digit part number

embossed on the outside of the

hub shell where it is plainly visible. All hubs with the part number visible use the splined freehub body.

Fig. 3

Description TCG Part #

Freehub tool, 211338

11mm adapter

2003 Bontrager Service Manual

11

Page 12

Rear hubs- Loose ball

Bontrager Superstock, Superstock Disc, Select ATB, Select Road, Select Hybrid wheels, plus Bontrager Comp II rear hub

Recommended tools

(2) 15mm cone wrench

Adjustable wrench

Hammer (soft faced)

Small slot screwdriver

DISASSEMBLY

Fig. 1D

Fig. 2D

Fig. 3D

Axle

End

nut

Small

washer

Large

washer

Fig. 4D

Spacer

removal and installation instructions.

When overhauling the hub bearings, it is usually not necessary to remove the freehub body.

Fig. 5D

12

Hub parts and names are referenced on next page.

Remove the axle

1. Remove external seals

with your fingers or a screwdriver (Fig. 2D). Be careful not

to tear or mar the rubber.

2. On the left side (non-drive)

of the hub place a 15mm cone

wrench on the ball cone. Place a

15mm cone wrench on the end

nut (Fig. 3D). Loosen the end

nut.

4. Remove the end nut, large

washer, spacer, small washer,

and ball cone from the axle (Fig.

4D).

5. Slide the axle, with the

other end nut, washer, and ball

cone still attached, out of the hub.

6. Insert a thin screwdriver

blade under the shell shield (Fig.

5D) and pry off the shell shield

from the left side of the hub.

8. If inspection shows it

necessary, remove the ball cone,

washers, and end

nut from the right

side of the axle.

9. Remove the

ball bearings (Fig.

6D) from both

sides of the hub.

10. If it is

necessary to

Ball cone

remove the freehub body, refer

to the Freehub

Body section,

pages Freehub 1

and Freehub 2, for

Clean and inspect the parts

1. Use solvent to completely

remove all old grease and debris

from the hub, axle, and axle

parts. Avoid getting solvent

into the freehub, and be sure to

remove all solvent thoroughly

before proceeding.

2. Inspect the bearing running surfaces of both the ball

cones and the ball cups (inside

the hub). Replace any worn parts.

ASSEMBLY

Lubricate bearings and threads

the axle with Wrench Force™ synthetic grease, or a similar product.

the way around each ball cup,

sufficient to hold the balls.

Assemble the hub

ball cup on one side of the hub

(Fig. 6D).

with its sharp edges facing out,

into the hub. The shell shield is

a press fit, so must be tapped

lightly to fully seat. Lay a cone

wrench over the shell shield and

tap the wrench with a hammer

(Fig. 7D) to protect the shield and

ensure that it is flush with the

shell.

for the other side of the hub.

against the fixed ball cone

(attached to axle) by holding

the ball cone with a 15mm cone

wrench and turn the end nut with

another 15mm cone wrench.

hub from the right hand (drive) side.

washer, and end nut onto the axle in that order. The

serrated surface of the end nut faces out.

with a 15mm cone wrench and tighten the end nut with

a 15mm cone wrench.

with your fingers. The axle should spin smoothly without

binding or feeling gritty. There should be no lateral play

of the axle in the hub. Readjust the hub as necessary, and

re-lock the end nut.

erly seals against both the end nut and the hub shell.

There should be a smooth transition from seal to sealing

surface. An improperly installed seal (Fig. 8D) will allow

rapid contamination of the bearings.

After completing assembly of the hub, check its function by spinning the axle with your fingers. It

should rotate freely without irregular friction. A small amount of lateral play is acceptable if the play is

eliminated when the wheel is installed with the quick release properly closed.

2003 Bontrager Service Manual

1. Lubricate the threads on

2. Place a bead of grease all

Fig. 6D

1. Place nine 1/4” balls in the

2. Place the shell shield,

Fig. 7D

3. Repeat Assembly steps 1-2

4. Tighten the end nut

Seal not seated

Fig. 8D

5. Insert the axle through the

7. Thread the ball cone, small washer, spacer, large

8. From the left side of the hub, hold the ball cone

9. Check the bearing adjustment by turning the axle

10. Install the external seal. Make sure the seal prop-

Page 13

Exploded view and Parts list

1

2

3

4

5

6

7

Splined

11a

Note:

There are two types of freehub body attachments; see below for specifi-

cations, and page 9 from more information

Pos Description

1 External seal

2 End nut

3 Washer

4 Spacer

5 Ball cone

6 Shell shield

7 Bearings

8 Ball cup

9 Hub shell

10 Axle

11 Freehub body

12 Cone seal

Description Model year Model for Parts included (qty) TCG Part #

Washer 99/00/01/02 all 3 990008

Freehub body, 99/00 all 11, 6 68541

threaded

Freehub body, 01/02 all 11a, 6, removal tool 211341

splined

Rotor adapter 99/00 Hayes, RST Not shown 991075

rear

Rotor adapter 99/00 Magura Gustav, Not shown 69156

Louise rear

Axle set 99/00/01 all road, 130mm 2, 3, 4, 5(2), 10 68542

Axle set 99/00/01 all atb, 135mm 2, 3, 4, 5(2), 10 68531

Disc bolt set 99/00 Not shown 991153

Note:

Rotor adapter for disc hubs not shown

Rotor spacing varies by model year, see details below.

8

9

10

11

7

6

5

3

12

2

Threaded

1999 Bontrager Comp II

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.0 mm

Cassette body type . . . . . . . . . . . . . . . . . . . . . . . . . Shimano 8/9 speed

Cassette body attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . threaded

2001/2002 Bontrager Superstock

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.0 mm

Cassette body type . . . . . . . . . . . . . . . . . . . . . . . . . Shimano 8/9 speed

Cassette body attachment . . . . . . . . . . . . . . . . . . . . . . running change

2002/2003 Bontrager Superstock Disc, Select ATB Disc

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58.0 mm

Disc rotor spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15.25 mm

Rotor BCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.0 mm

Cassette body type . . . . . . . . . . . . . . . . . . . . . . . . . Shimano 8/9 speed

Cassette body attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . splined

2003 Bontrager Service Manual

2002/2003 Bontrager Superstock

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.0 mm

Cassette body type . . . . . . . . . . . . . . . . . . . . . . . . . Shimano 8/9 speed

Cassette body attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . splined

2002/2003 Bontrager Select ATB

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.0 mm

Cassette body type . . . . . . . . . . . . . . . . . . . . . . . . . Shimano 8/9 speed

Cassette body attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . splined

2002/2003 Bontrager Select Road

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.0 mm

Cassette body type . . . . . . . . . . . . . . . . . . . . . . . . . Shimano 8/9 speed

Cassette body attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . splined

2002/2003 Bontrager Select Hybrid

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.0 mm

Cassette body type . . . . . . . . . . . . . . . . . . . . . . . . . Shimano 8/9 speed

Cassette body attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . splined

13

Page 14

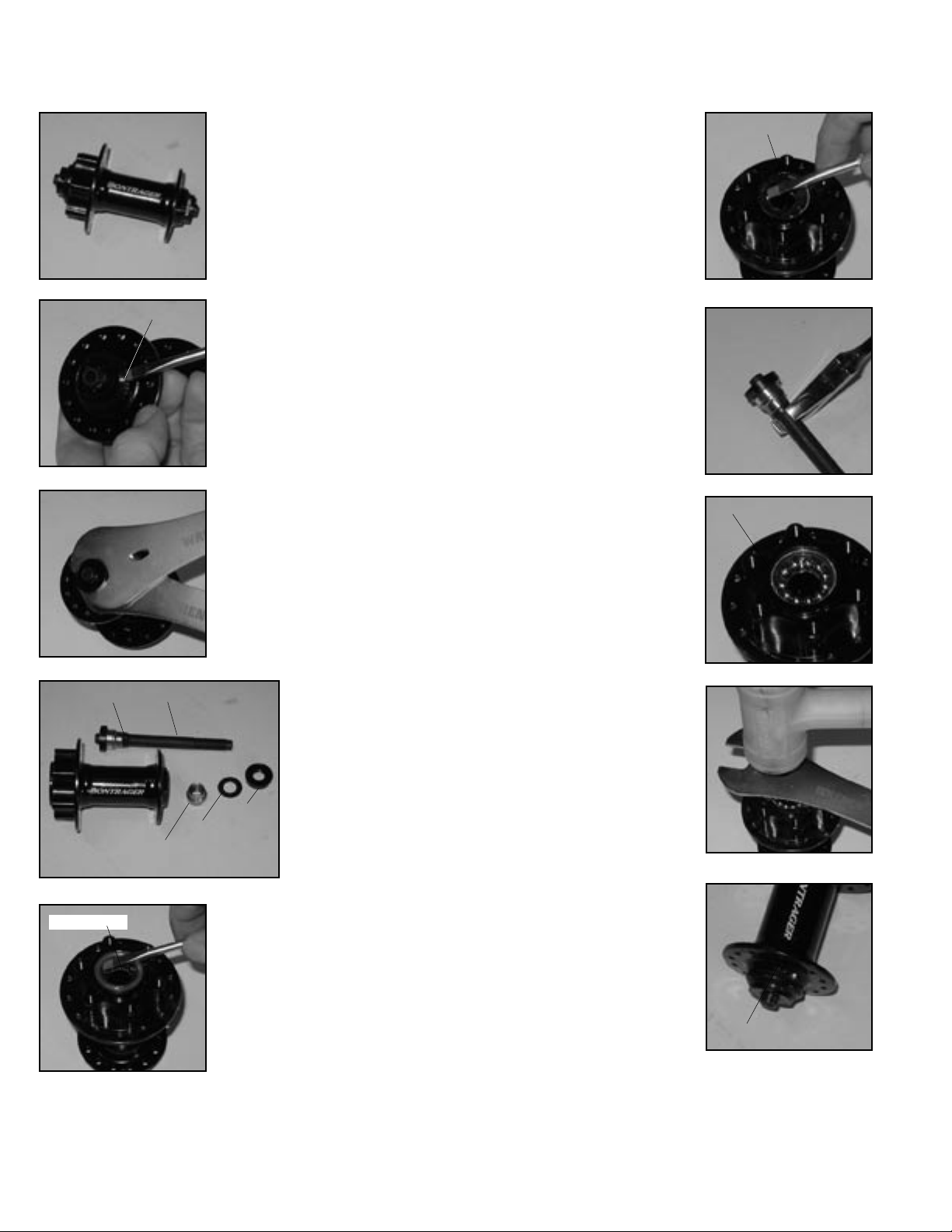

Rear hubs- Loose ball, double sealed (Formula FCM)

'99, 2000, 2001 Bontrager Race and Race Disk rear wheels

Recommended tools

(2) 15mm cone wrench

12mm allen wrench

Adjustable wrench

Hammer

Small slot screwdriver

DISASSEMBLY

Fig. 1E

Fig. 2E

Fig. 3E

Axle

End

nut

Small

washer

Large

washer

Fig. 4E

Spacer

the freehub body, refer to the Freehub Body section,

pages Freehub 1 and Freehub 2, for removal and installation instructions.

When overhauling the hub bearings, it is usually not necessary to remove the freehub body.

Fig. 5E

14

Hub parts and names are referenced on next page.

Remove the axle

1. Remove external seals

(Fig. 2E) with your fingers or

a screwdriver. Be careful not to

tear or mar the rubber.

2. On the left side (non-drive)

of the hub place a 15mm cone

wrench on the bearing cone (Fig.

3E).

3. Place a 15mm cone

wrench on the end nut (Fig. 4E).

Loosen the end nut.

4. Remove the end nut, large

washer, spacer, small washer,

and cone from the axle (Fig. 4E).

5. Slide the axle (Fig. 4E),

with the other end nut, washer,

and cone still attached, out of the

hub.

6. Insert a thin screwdriver

blade under the shell shield (Fig.

5E) and pry off the shell shields

from both sides of the hub.

8. If inspection

shows it necessary, remove the

cone, washers, and

end nut from the

right side of the

axle.

9. Remove the

ball bearings (Fig.

Ball cone

6E) from both

sides of the hub.

7. If it is necessary to remove

Clean and inspect the parts

1. Use solvent to completely

remove all old grease and debris

from the hub, axle, and axle

parts.

2. Inspect the bearing running surfaces of both the cones

and the ball cups (inside the

hub). Replace any worn parts.

2003 Bontrager Service Manual

ASSEMBLY

Lubricate bearings and threads

1. Lubricate the threads on

the axle with Wrench Force™

synthetic grease, or a similar

product.

2. Place a bead of grease all

the way around each ball cup,

sufficient to hold the balls.

Assemble the hub

1. Place nine 1/4” balls in the

ball cup on one side of the hub

(Fig. 6E).

2. Place the shell shield, with

its sharp edges facing out (Fig.

6E), into the hub. The shell shield

is a press fit, so must be tapped

lightly to fully seat (Fig. 7E).

Lay a cone wrench over the shell

shield and tap the wrench with a

hammer to protect the shield and

ensure that it is flush with the

shell.

3. Repeat steps 1-2 for the

other side of the hub.

4. Tighten the end nut

against the fixed cone (attached

to axle) by holding the cone with

a 15mm cone wrench and turn

Seal not seated

the end nut with another 15mm

cone wrench.

5. Insert the axle through the

hub from the right hand (drive) side.

7. Thread the cone, small washer, spacer, large washer,

and end nut onto the axle in that order. The serrated

surface of the end nut faces out.

8. From the left side of the hub, hold the cone with a

15mm cone wrench and tighten the end nut with a 15mm

cone wrench.

9. Check the bearing adjustment by turning the axle

with your fingers. The axle should spin smoothly without

binding or feeling gritty. There should be no lateral play

of the axle in the hub. Readjust the hub as necessary, and

re-lock the end nut.

10. Install the external seal. Make sure the seal properly seals against both the end nut and the hub shell.

There should be a smooth transition from seal to sealing

surface. An improperly installed seal (Fig. 8E) will allow

rapid contamination of the bearings.

After completing assembly of the hub, check its function by spinning the axle with your fingers. It

should rotate freely without irregular friction. A small amount of lateral play is acceptable if the play is

eliminated when the wheel is installed with the quick release properly closed.

Fig. 6E

Fig. 7E

Fig. 8E

Page 15

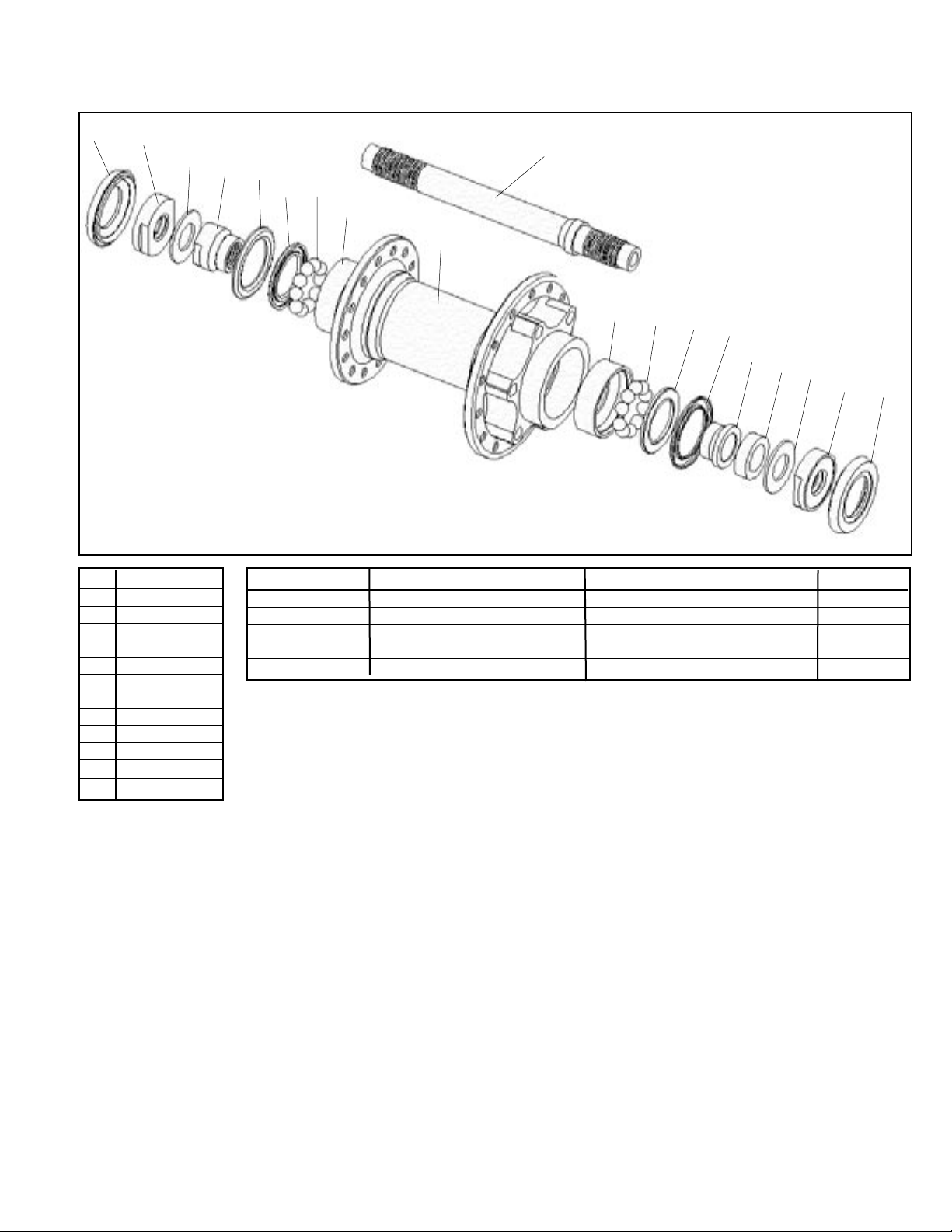

Exploded view and Parts list

Note:

1

2

3

4

5

13

6

7

8

Rotor adapter for disc hubs not shown

Rotor spacing varies by model year, see details below.

Splined

11a

Note:

There are two types of freehub body attachments; see below for specifi-

cations, and page 9 for more information

Pos Description

1 External seal

2 End nut

3 Washer

4 Spacer

5 Adj. cone

6 Shell shield

7 Bearings

8 Ball cup

9 Hub shell

10 Axle

11 Freehub body

12 Ball cone

13 Cone seal

Description Model year Model for Parts included (qty) TCG Part #

Axle set 99/00 all 10 68533

End nut set 99/00 all 2(2) 68536

External seal, 99/00 all 1, 13 68534

yellow

External seal, 99/00 all 1, 13 68535

red

Freehub body, 99/00 all 11 68540

threaded

Freehub body 01 all 11a, 6, removal tool 211340

splined

Rotor adapter 99/00 Hayes, RST Not shown 991075

rear

Rotor adapter 99/00 Magura Gustav, Not shown 69156

Louise rear

Disc bolt set 99/00 all Not shown 991153

9

Threaded

10

11

6

7

12

4

3

13

2

2000 Race

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°

Spoke hole P.C.D., right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58.0 mm

Spoke hole P.C.D., left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.0 mm

Cassette body type . . . . . . . . . . . . . . . . . . . . . . . . . Shimano 8/9 speed

Cassette body attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . threaded

2000 Race Disk

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58.0 mm

Disc rotor spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19.9 mm

Rotor BCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.0 mm

Cassette body type . . . . . . . . . . . . . . . . . . . . . . . . . Shimano 8/9 speed

Cassette body attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . threaded

2003 Bontrager Service Manual

2001 Race

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°

Spoke hole P.C.D., right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58.0 mm

Spoke hole P.C.D., left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.0 mm

Cassette body type . . . . . . . . . . . . . . . . . . . . . . . . . Shimano 8/9 speed

Cassette body attachment . . . . . . . . . . . . . . . . . . . . . . running change

2001 Race Disk

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58.0 mm

Disc rotor spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15.25 mm

Rotor BCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.0 mm

Cassette body type . . . . . . . . . . . . . . . . . . . . . . . . . Shimano 8/9 speed

Cassette body attachment . . . . . . . . . . . . . . . . . . . . . . running change

15

Page 16

Rear hub- Cartridge bearing

2002/2003 Bontrager Race, Race Disc rear wheels

Recommended tools

15mm cone wrench

19mm cone wrench

Small slot screwdriver

Hammer (soft faced)

Cartridge bearing remover

Bearing press

DISASSEMBLY

Fig. 1F

Axle spacer

Fig. 2F

End

nut

Fig. 3F

Fig. 4F

End nut

Axle spacer

the freehub body, refer to the Freehub Body

section, pages Freehub 1 and Freehub 2, for removal and

installation instructions.

When overhauling the hub bearings, it is usually not necessary to remove the freehub body.

Hub parts and names are referenced on next page.

1. Hold the left side (nondrive) axle spacer with a 19mm

cone wrench and loosen the end

nut (Fig. 2F) with a 15mm cone

wrench.

2. Remove the end nut,

washer, and axle spacer (Fig. 3F)

from the axle.

3. Insert a thin screwdriver

blade under the bearing seal

(Fig. 4F) and pry off the seals

from both sides of the hub.

4. Tap the left end of the

axle with a hammer to drive

the axle out of the hub.

5. If inspection shows it

necessary, remove the washers

and end nut from the right side

of the axle.

To loosen the end nut, reinstall the left side axle spacer

and locknut, and lock the end

nut against the axle spacer.

Hold the axle spacer with a cone

wrench while you loosen the

right side end nut. Alternately,

hold the axle with vise grips.

6. Place a bearing removal

tool on the left bearing. With a

punch on the bearing tool, drive

the left bearing out of the hub

with a hammer.

7. If it is necessary to remove

ASSEMBLY

Inside

Lubricate bearings and threads

1. Lubricate the threads on

the axle with Wrench Force™

synthetic grease, or a similar

product.

2. Lightly grease the inner

and outer surfaces of each bearing where they contact the hub

shell and axle.

Outside

Fig. 5F

Assemble the hub

1. Press the right bearing onto the right side of the

axle, denoted by the smooth, non-threaded area with a

shoulder.

Note: the black seal of the bearing faces out (Fig. 5F).

2. Place the axle through the freehub body.

3. Press the bearing into the hub shell with the bearing press.

4. Slide the left bearing onto the axle with the black

seal facing out. Thread the axle spacer onto the axle, and

use the bearing press to press the left bearing into the

hub. The axle should turn freely with no lateral play in

the hub shell.

5. Place the bearing seals into the hub with the lettered surface facing out.

6. Thread the axle spacer onto the axle. Place a 17mm

cone wrench on the axle spacer and a 15mm cone wrench

on the end nut. Tighten the end nut against the axle spacer.

After completing assembly of the hub, check its function by spinning the axle with your fingers. It

should rotate freely without irregular friction. A small amount of lateral play is acceptable if the play is

eliminated when the wheel is installed with the quick release properly closed.

Clean and inspect the parts

1. Wipe old grease or debris from the hub bearing

seats.

2. Normally, bearings are not re-used. If you are reinstalling an old bearing, wipe off any grease or debris

from both the inner and out surfaces.

Do not use solvent on the bearing, as the solvent will

contaminate the grease. This may cause bearing failure.

16

2003 Bontrager Service Manual

Page 17

Exploded view and Parts list

1

2

3

4

5

Pos Description

1 End nut

2 Washer

3 Spacer

4 Seal

5 Bearings

6 Hub shell

7 Axle

8 Freehub body

9 Freehub seal

6

7

8

3

5

9

2

1

Description Model year Model for Parts included (qty) TCG Part #

Axle set 01/02 all 1(2), 2(2), 3(2), 4, 7, 9 211351

Bearing 01/02 all 5 73335

Freehub body 01/02 all 8, 9, removal tool 211339

splined

Bearing press 01/02 all DT Comp/Onyx (not shown) 211416

DT Pro/240 (not shown) 211415

Removal tool Not shown 211338

2002/2003 Race

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°

Cassette body type . . . . . . . . . . . . . . . . . . . . . . . . . Shimano 8/9 speed

Spoke hole P.C.D., right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58.0 mm

Spoke hole P.C.D., left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.0 mm

Cassette body type . . . . . . . . . . . . . . . . . . . . . . . . . Shimano 8/9 speed

Cassette body attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . splined

2002/2003 Race Disc

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58.0 mm

Disc rotor spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15.25 mm

Rotor BCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.0 mm

Cassette body type . . . . . . . . . . . . . . . . . . . . . . . . . Shimano 8/9 speed

Cassette body attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . splined

2003 Bontrager Service Manual

17

Page 18

DT-Swiss Comp series hubs

Important information before you begin with Comp series hubs

Some Bontrager front hubs utilize DT Swiss internal

parts. This manual is intended for retailers with the

appropriate skills and knowledge to work on these hubs.

Please read the entire section before carrying out any

kind of maintenance work.

This manual details the principle design features of

DT Swiss front hubs and also provides instructions as

to maintenance and repair work. Please take special care

to use only original DT Swiss special tools in order to

undertake the work details in this manual. Use only DT

Swiss replacement parts.

In this manual, the hubs are shown installed in

a complete wheel. Maintenance work should be carried

out on complete wheels where possible. Otherwise, some

steps can not be carried out correctly.

This manual provides technical and spare parts information for these hubs. If you have further questions

about these hubs regarding technical information, support, or warranty, they should be directed to Bontrager

Technical Support via phone or on the Bontrager web site

at www.bontrager.com.

In the event of improper servicing of the hubs,

Bontrager has the right to refuse any warranty.

Special information before you begin

Bearing resistance: New or newly re-built hubs have

a higher rolling resistance than used hubs because the

grease in the freehub has not yet been evenly distributed

and the seals have not yet bedded in.

Check your work: Before use, always check the hub

for proper functioning.

Tool list for DT Swiss front hubs

The following tools may be necessary to perform

maintenance work on DT Swiss

Comp series hubs:

Long bearing press

Short bearing press

DT 17mm cone wrench

Comp front hub bearing press

Multi-purpose DT grease

Long

bearing

press

These maintenance items are

available as TCG part #211416.

Short

bearing

press

Special screwdriver

Front hub bearing press

Regular Maintenance

Maintenance of the front hubs should be performed at

least once a year. This maintenance schedule is based on

normal usage. If you ride your bike more than average,

or in rain, snow, or off road conditions, service your

bicycle more often than the schedule suggests. If any

part appears to be malfunctioning, inspect and service it

immediately.

Things to avoid

Avoid high pressure washing systems, like those at

most car washes. The high pressure can bypass bearing

seals, letting water into the bearings. Do not use any kind

of solvents or tensides- this can damage the hub.

2003 Bontrager Service Manual

19

Page 19

Comp front hub

Bontrager Race Modified, Race Modified Disc front wheel, 2003 Race Lite ATB, Race Lite ATB Disc front

wheel

End cap

Fig. 1K

Fig. 2K

Fig. 3K

Bearing

press

Recommended tools

Comp bearing press, front hub

Short bearing press

17mm cone wrench

Multi-purpose grease

Bench vise

Axle vise

Hammer, soft faced

Thin-bladed slot screwdriver

DISASSEMBLY

Hub parts and names are referenced on next page.

Disassemble the hub

1. Tap the axle (either end)

with the hammer until the axle

is flush with the surface of the

end cap.

2. Remove the opposite end

cap (Fig. 1K).

3. Tap the axle end without

the end cap with the hammer

(Fig. 2K) and remove the axle.

4. Slide the end cap, seal, and

bearing from the axle (Fig. 3K).

5. Re-insert the axle through

the hub and tap out the second

bearing.

Clean and inspect the parts

Thoroughly clean and

inspect all components with a

dry cloth. If cracks or any other

damage is visible, replace the

part.

Bearing

ASSEMBLY

1. Place the Comp bearing

press on the workbench or other

solid surface. Push a new bearing onto the axle, and push the

axle into the bearing press (Fig.

4K).

2. Place the hub over the

axle.

3. Place the second Comp

bearing press over the axle. Tap

the upper bearing press with the

hammer (Fig. 5K) to press the

bearing into the hub.

4. Remove the upper bearing

press.

5. Pull the axle out about

10mm (3/8in). Press the second

bearing over the axle (Fig. 6K).

6. Place the second bearing press over the axle. Tap the

upper bearing press with the

hammer (Fig. 7K) to press the

second bearing into the hub.

Check the bearing installation be spinning the axle. It

should rotate freely without irregular friction.

7. Lightly grease the surface

of both bearings.

8. Pull the V-seal off the end

cap (Fig. 8K). Clean it thoroughly

with a cloth, lightly grease it,

and reinstall it on the end cap

with the open ‘V’ facing the hub.

9. Position the completed end cap over the axle, and

press into place with your fingers.

After completing assembly of the hub, check its function by spinning the axle with your fingers. It

should rotate freely without irregular friction. A small amount of lateral play is acceptable if the play is

eliminated when the wheel is installed with the quick release properly closed.

End cap

Fig. 6K

Fig. 7K

V-seal

Fig. 8K

20

Fig. 4K

Fig. 5K

2003 Bontrager Service Manual

Page 20

Exploded view and Parts list

1

2

Pos Description

1 End cap

2 V-seal

3 Bearing

4 Axle

5 Hub shell

4

3

5

3

2

1

Description Model year Model for Parts included (qty) TCG Part #

Axle kit 99/00/01 All 1(2), 2(2), 3(2), 4 70361

Bearing 99/00/01 All 3 211349

2003 Bontrager Service Manual

21

Page 21

Comp rear hub

Bontrager Race Modified rear wheel, 2003 Race Lite ATB, 2002/2003 Race Lite Road rear wheel

Recommended tools

Long bearing press

Short bearing press

17mm cone wrench

Multi-purpose grease

Bench vise

Axle vise

Hammer, soft faced

Thin-bladed slot screwdriver

Fig. 1G

Spacer

DISASSEMBLY

Hub parts and names are referenced on next page.

1. Place the axle vise in the

bench vise and clamp the lefthand end of the axle.

2. Remove the cassette.

3. Loosen the right end nut

with the 17mm cone wrench and

remove the end nut (Fig. 1G).

4. Pull off the freehub body

Fig. 2G

with your fingers.

The spacer (Fig. 2G) may be stuck to the inside of the freehub body with grease.

5. Remove the spacer (Fig. 2G).

6. With the wheel removed

from the vise, tap the right end

of the axle with the hammer

until loose. Pull the axle from

the left side of the hub shell (Fig.

3G).

7. Place the right end of the

Fig. 3G

Retainer

spring

axle into the axle vise.

8. Loosen the left end nut

with the 17mm cone wrench,

Pawl

and remove it from the axle. Also

remove the bearing.

9. Remove the retainer

spring (Fig. 4G) and pawls from

the hub with the screwdriver.

10. Pull the roller bearing

retainer from the hub (Fig. 5G).

Fig. 4G

11. From the left side of the

wheel, place the axle through

the hub and the bearing. Tap

the axle with the hammer to

drive the right hub bearing out.

Remove the bearing from the

axle.

Clean and inspect the parts

Clean all components and

inspect them thoroughly. If any

Fig. 5G

cracks or other damage are visible, the parts must be replaced.

ASSEMBLY

1. Clamp the long bearing press into the bench vise.

Push the axle, long end first, through the hole in the

press. The short, 33mm end of the axle should be on top

(Fig. 6G).

22

2003 Bontrager Service Manual

2. Place the wheel over the

axle with the drive side facing up.

3. Place a new bearing over

the axle, black side out. Tap the

short bearing press with the hammer to begin pressing the bearing

into the hub (Fig. 7G).

4. Leave the short bearing

press in place, and lift the wheel

from the long bearing press (in

the vise). Remove the axle from

the hub and replace the wheel

over the long bearing press.

5. Again tap the short bearing press with the hammer to

press the bearing into the hub.

This is an important step, which ensures the bearing is correctly pressed in.

6. Turn the wheel over and

place it drive-side down on the

long bearing press. Push the

short 33mm end of the axle

through the hub and bearing.

7. Slide the second hub bearing over the axle, black side on

top.

8. Tap the short bearing

press with the hammer to press

the second bearing into the hub.

9. Turn the wheel over.

Lightly grease the bearing shell.

10. Slide the roller bearing

retainer over the hub bearing

and into the housing (Fig. 8G).

Pawl spring

elbow

Be careful not to dislodge any

roller bearings.

Installing the pawl spring and

pawls

1. Place the pawl spring over

the axle and install the spring

into the retainer body with the

elbow pointing up (Fig. 9G).

2. Push both pawls beneath

the spring with a screwdriver

(Fig. 10G). Make sure they are

placed correctly (Fig. 11G).

3. Lightly grease the roller

bearing retainer, pawls, and hub

bearing.

Install the freehub body

1. Push the spacer (Fig. 2G)

over the axle.

2. Remove the freehub body seal

(Fig. 12G). Clean the seal. If it is faulty or

damaged, replace it.

3. Clean the freehub body teeth (a

toothbrush works well).

4. Lightly grease the seal and freehub

Fig. 6G

Fig. 7G

Fig. 8G

Fig. 9G

Fig. 10G

Pawl

Spring position

Fig. 11G

Page 22

Freehub body seal

teeth.

5. Install the seal into the

freehub body with the lip toward

the outside of the hub (Fig. 13G).

6. Push the pawls in with

a screwdriver as you slide the

complete freehub body onto the

axle (Fig. 14G). Check the alignment to avoid excessive force

Fig. 12G

which could damage the spring.

7. Grease the freehub end

and axle end.

8. Clean and lightly grease

the right end nut and end seal

(Fig. 15G). Replace the end seal

on the end nut with the lip facing the inside.

9. Place the complete end

nut onto the axle and tighten it

by hand.

Fig. 13G

Exploded view and Parts list

1

2

3

5

18

6

7

8

7

9

10

11

12

10. Place the wheel with the

left end of the axle in the axle

vise and tighten the right end

nut to 150 lb•in (17Nm).

11. Turn the wheel over and

clamp the right end nut in the

vise.

12. Grease the bearing.

13. Clean and lightly grease

the left end nut and end seal.

Replace the end seal on the end

nut with the lip facing the inside.

9. Place the complete left

end nut onto the axle and tighten it by hand.

10. Tighten the end nut to

150 lb•in (17Nm).

After completely assembling the hub, check for proper

functioning by spinning the freehub body. If the pawls do

not click into place, the spring may not have been correctly installed, or there could be too much grease in the

freewheel.

4

16

13

14

15

Fig. 14G

Fig. 15G

Pos Description

1 End nut

2 V-seal, left

3 Bearing, left

4 Axle

5 Retaining bolt

6 Driver

7 Pawl

8 Pawl spring

9 Roller retainer

10 Bearing shell

11 Bearing, right

12 Spacer

17

13 Freehub seal

14 Freehub body

15 V-seal, right

16 End nut, right

17 Nut cap

18 Hub shell

2003 Bontrager Service Manual

23

Page 23

Description Model year Model for Parts included (qty) TCG Part #

Freehub kit 2000/01 all 7(2), 8, 12, 13, 14 70358

(Shimano)

Driver kit 2000/01 all 5, 6, 10 72678

Axle set 2002/03 Race Lite Road 1, 2, 3, 4, 15, 16, 17 70359

(130 O.L.D.)

Axle 2000/01 Race Mod 1, 2, 3, 4, 15, 16, 17 70360

(135 O.L.D.) 2003 Race Lite ATB

Bearing kit 00/01/02/03 all 3, 9, 11 72677

Bearing shell 2000/01 all 10, 11 72679

kit

Bearing, left 2000/01 all 3 (6000, 12/26 x 8mm) 211348

Bearing, right 2000/01 all 11 (6900, 10/22 x 6mm) 211349

24

2003 Bontrager Service Manual

Page 24

Pro series hubs

Important information before you begin with Pro series hubs

Some Bontrager hubs utilize DT Swiss internal parts.

This manual is intended for retailers with the appropriate

skills and knowledge to work on these hubs. Please read

the entire section before carrying out any kind of maintenance work.

This manual details the principle design features of

DT Swiss hubs and also provides instructions as to maintenance and repair work. Please take special care to use

only original DT Swiss special tools in order to undertake

the work details in this manual. Use only DT Swiss

replacement parts.

In this manual, the hubs are shown installed in a

complete wheel. Maintenance work should be carried out

on complete wheels where possible. Otherwise, some steps

can not be carried out correctly.

This manual provides technical and spare parts information for these hubs. If you have further questions

about these hubs regarding technical information, support, or warranty, they should be directed to Bontrager

Technical Support via phone or on the Bontrager web site

at www.bontrager.com.

In the event of improper servicing of the hubs,

Bontrager has the right to refuse any warranty.

Special information before you begin

Bearing play: A small amount of play between the freehub body and the hub shell is automatically eliminated when

the wheel is installed and the quick release is tightened.

Bearing resistance: New or newly re-built hubs have

a higher rolling resistance than used hubs because the

grease in the freehub has not yet been evenly distributed

and the seals have not yet bedded in.

Aluminum freehub bodies: For hubs with an aluminum freehub body, we recommend cassettes using a solid,

one piece spider like the Shimano Dura-Ace, Ultegra, XTR,

or Deore XT. Cassettes using loose or bolted sprockets

like Shimano Deore LX can cause notches in the freehub

body. This can cause difficulties when later removing

the cassettes from the freehub body (see “Removing

Cassettes” on this page).

Check your work: Before use, always check the rear

hub for proper functioning. Check the freehub body and

the ratchet mechanism. If they do not function correctly,

the rear hub should not be used until the fault is corrected. If you are unable to correct the fault, consult

Bontrager Technical Support.

letting water into the bearings. Do

not use any kind of solvents or

tensides- this can damage the hub.

Determining the year of hub

There are two styles of rear

hub, with some unique parts and

different instructions for assembly and disassembly. To determine which hub type you will be

working on, it is necessary to

remove the freehub. With the star

ratchet removed, you will be able

to see the right side shell bearing. If the bearing is completely

visible due to its 24mm outer

diameter (Fig. FH5), it’s a year

2000 hub. The 2001 model uses

a larger, 28mm diameter bearing

(Fig. FH6) that is partially covered by the ring nut (requiring

the removal of the ring nut).

Removing the cassette from the

freehub body

The cassette does not need

to be removed from the freehub

body to perform regular maintenance. However, if you decide

to remove it, it should only be

removed after the hub has been

completely re-assembled.

1. Release the lockring using

a lockring tool.

2. Loosen the cassette by lightly

tapping it counter-clockwise with the

hammer.

3. Remove all the sprockets from

the freehub body.

4. Use a fine file to remove

bad notches from the aluminum freehub body (Fig. 14H). The aluminum

freehub body must be cleaned and

inspected. If any cracks or other

damage is visible, the components

must be replaced.

Note: Notches on the freehub body do not have a negative influence

on the functionality of the freewheel.

Fig. FH5

Fig. FH6

Fig. FH7

Freehub seal

installation

tool

Short

bearing

press

Long

bearing

press

Regular Maintenance

Maintenance of the rear and front hubs should be

performed at least once a year. This maintenance schedule

is based on normal usage. If you ride your bike more

than average, or in rain, snow, or off road conditions,

service your bicycle more often than the schedule suggests. If any part appears to be malfunctioning, inspect

and service it immediately.

Things to avoid

Avoid high pressure washing systems, like those at most

car washes. The high pressure can bypass bearing seals,

2003 Bontrager Service Manual

Required tools

Maintenance of Pro level hubs

requires special tools, available as TCG

part #211415:

Freehub seal installation tool

Long bearing press

Short bearing press

Special screwdriver

DT Swiss special freehub grease

DT Swiss multi-purpose grease

Spline tool

Special screwdriver

Spline

tool

25

Page 25

Pro front hub

2002 Bontrager Race Lite ATB, Race Lite 29, Race X Lite and Race X Lite Carbon front wheels, 2003 Race X Lite Aero

Fig. 1J

Fig. 2J

Fig. 3J

Recommended tools

Long bearing press

Short bearing press

Multi-purpose grease

Bench vise

Axle vise

Hammer, soft faced

DISASSEMBLY

1. Loosen both end caps by

rotating them in opposite directions with your fingers.

2. Clamp the axle end cap

(either side) in the axle vise

(avoid over tightening).

3. Pull the wheel upward

(Fig. 1J) to remove the end cap

held by the vise.

4. Tap the axle out of the

hub with the hammer (Fig. 2J).

5. Slide the bearing off the

axle (Fig. 3J).

6. Re-insert the axle into

the hub from the side opposite

the remaining bearing. With the

axle end resting on the inside of

the bearing, tap the bearing out

of the shell with the hammer.

Clean and inspect all components. If any cracks or other

damage are visible, replace the

part.

5. Grease both the outer sur-

face of both bearings.

End cap

V-seal

6. Pull the V-seal off the both

end caps (Fig. 13I). Clean each

seal thoroughly with a cloth,

lightly grease it, and reinstall it

on the end cap with the open ‘V’

facing the hub.

7. Push the completed

adapters into place with your

fingers.

After completing assembly of the hub, check its function by spinning the axle with your fingers. It should rotate freely without irregular friction. A small

amount of lateral play is acceptable if the play is eliminated when the wheel is installed with the

quick release properly closed.

Fig. 6J

2002 Race Lite, ATB, Race Lite 29, 2003 Race X Lite ATB

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.5 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm

2002/2003 Race X Lite

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm

2002/2003 Race X Lite Carbon, Race X Lite Aero

O.L.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm

Spoke hole quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16°

Spoke hole P.C.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.0 mm

Q.R. rod outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 mm

Fig. 4J

Fig. 5J

ASSEMBLY

1. Clamp the long bearing

press into the vise.

2. Push the new bearing over

the front axle. Insert the axle

into the bearing press (Fig. 4J).

2. Place the wheel over the

axle and pull the axle out by

about 10 mm (1/2 inch). Push

the second bearing over the axle

and into the hub.

3. Center the axle using the

short bearing press.

4. Tap both bearings into

place with the hammer (Fig. 5J)

at the same time.

Turn the axle to check the bearings. You should not be

able to feel any irregular friction. Make sure that there is

no play in the axle.

26

2003 Bontrager Service Manual

Page 26

Exploded view and Parts list

Pos Description

1 End nut

2 V-seal

4

1

2

3

5

3

2

1

3 Bearing

4 Axle

5 Hub shell

Description Model year Model for Parts included (qty) TCG Part #

Axle kit 00/01/02/03 all 1(2), 2(2), 3(2), 4 70357

V-seal 00/01/02/03 all 2 211342

Bearing 00/01/02/03 all 3(6802, 15/24 x 5mm) 211344

End cap kit 00/01/02/03 all 1(2) 221803

2003 Bontrager Service Manual

27

Page 27

Pro rear hub

Bontrager Race Lite ATB, Race Lite 29, Race X Lite, Race X Lite Carbon rear wheels, Race Lite Aero

A running change to hubs was made in 2001; the newer hub has a part number embossed in the shell. See exploded dioagrams for differences

Recommended tools

Long bearing press

Short bearing press

17mm cone wrench

Multi-purpose grease

Bench vise

Axle vise

Hammer, soft faced

Thin-bladed slot screwdriver

Fig. 1I

DISASSEMBLY

Hub parts and names are referenced on next page.

Disassemble the freehub

Spacer

1. Place the axle vise in the

bench vise and clamp the lefthand end of the axle.

Star

ratchet

2. Pull sharply with your

fingers to remove the cassette,

with the freehub body attached

(Fig. 1I).

Fig. 2I

3. Remove the star ratchet,

spacer and spring (under the star

ratchet) from the hub (Fig. 2I).

4. Remove the second star

ratchet and second spring from

the freehub body.

Disassemble the ring nut

1. Clamp the spline tool into

a bench vise (Fig. 3I).

2. Push the right side axle

Fig. 3I

end into the cylinder. With the

splines engaged, turn the wheel

Bearing

firmly in an anti-clockwise direction. The ring nut will be loosened, and the seal between the

hub and freehub body will fall

over the spline tool onto the vise.

3. Thoroughly clean and

inspect all components, including inside the hub, with a dry

Fig. 4I

cloth. If necessary, use a tooth-

brush. If cracks or any other

damage is visible, the parts must

Spacer

be replaced.