Page 1

AIRCOOLED CONDENSING UNITS

with BITZER COMPRESSORS

Technical Guide

BNCUBZTB

April 2011

Page 2

Table of Contents

Floating Tube™ Coil 3

Options 4-5

Limitizer® 6

Bitzer Compressor

Features and Benets 7-8

Horizontal Air Discharge Condensing Units 4 to 13 HP

Standard and Optional Features 9

Nomenclature 9

Performance Data

Medium Temperature - R-404A/R-507

Low Temperature

Electrical Data

Medium Temperature - R-404A/R-507

Low Temperature

Specications and Dimensional Data

Medium Temperature - R-404A/R-507

Low Temperature

- R-404A/R-507

- R-404A/R-507

- R-404A/R-507

10

10

11

11

12

12

Vertical Air Discharge Condensing Units 13 to 50 HP, Single Compressor

Standard and Optional Features 13

Nomenclature 13

Performance Data

Medium Temperature

Low Temperature

Electrical Data

Medium Temperature

Low Temperature

Specications and Dimensional Data

Medium Temperature

Low Temperature

Vertical Air Discharge Condensing Units 26 to 100 HP, Dual Compressor

Standard and Optional Features 18

Nomenclature 18

Performance Data

Medium Temperature

Low Temperature

Electrical Data

Medium Temperature

Low Temperature

Specications and Dimensional Data

Medium Temperature

Low Temperature

- R-404A/R-507

- R-404A/R-507

- R-404A/R-507

- R-404A/R-507

- R-404A/R-507

- R-404A/R-507

- R-404A/R-507

- R-404A/R-507

- R-404A/R-507

- R-404A/R-507

- R-404A/R-507

- R-404A/R-507

14

15

16

16

17

17

19

20

21

21

22

22

© 2011 Heatcraft Refrigeration Products, LLC

2

Page 3

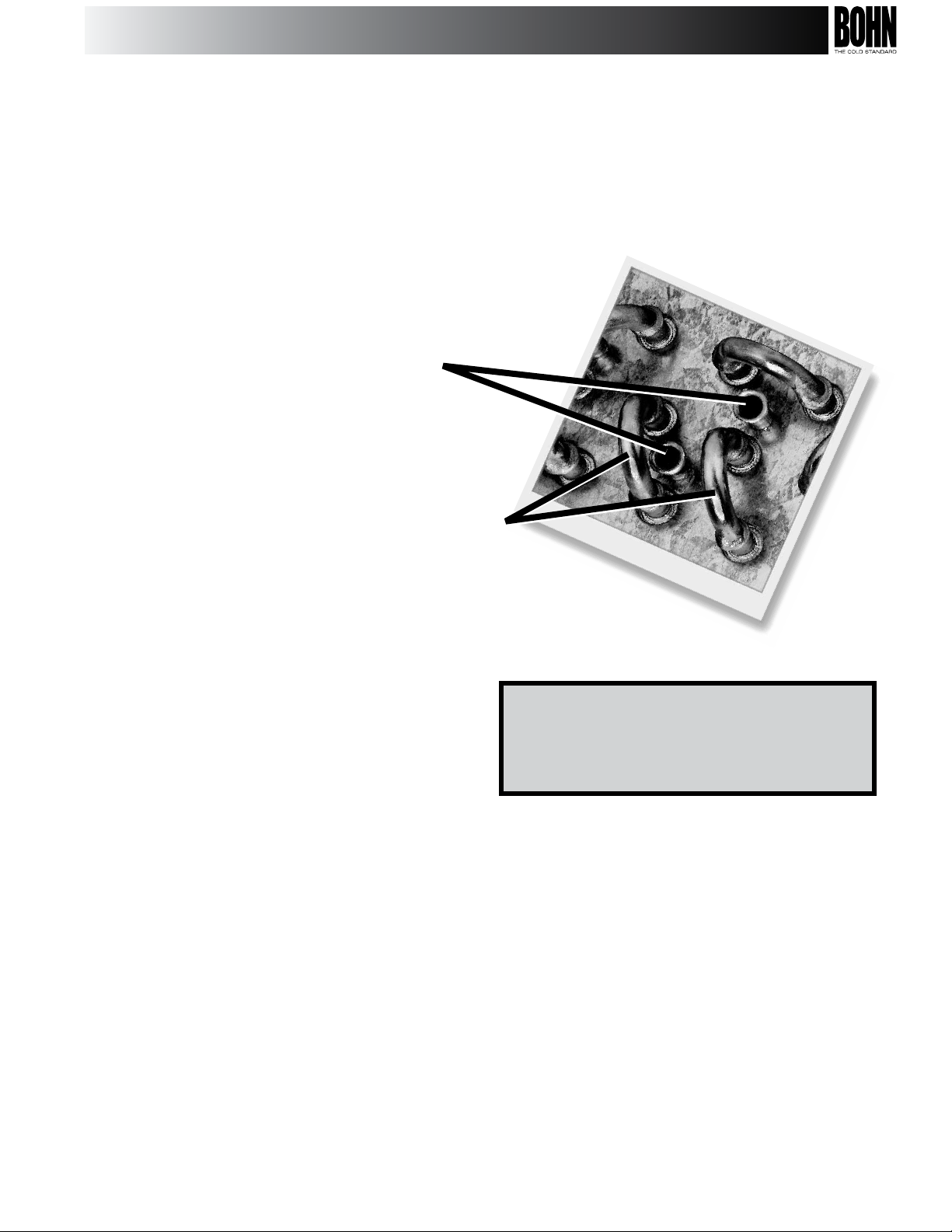

Single And Dual Compressor

Condensing Units

Feature Our Floating Tube™ Coil Design

Expanded (Locked) Auxiliary Tubes:

These tubes support the coil with ns and refrigerant

carrying tubes. They do not carry refrigerant and are

tightly tted on end supports and center supports.

Free Floating Circuited Coil Tubes:

These tubes carry refrigerant and never touch

and sheet metal (end supports and center

supports).

All units include a limited

Five Year Warranty

against condenser leaks at tube sheets and

center supports.

All condensers use the Floating Tube™ coil design to eliminate refrigerant leaks at the tube

sheets. Additional tubes are added to the condenser coil. These tubes are expanded into the

aluminum ns and condenser tube sheets. These anchor tubes support the weight of the coil,

but are not a part of the refrigerant circuit.

The tubes in the refrigerant circuit are expanded into the ns, but “oat” through oversized

holes in the tube sheets. Tube sheet leaks are virtually eliminated, since the tubes which carry

refrigerant never come in contact with the tube sheet.

3

Page 4

Options

E Solutions branded products and options are designed to exceed current energy and environmental

standards. It is our commitment in environmental innovation to dedicate ourselves by delivering energy

ecient eco-conscious choices. Products included in the E Solutions portfolio reduce costs, improve

bottom lines, and enhance equipment performance and service life.

The Beacon II™ Refrigeration System with Smart Defrost, and the factory-installed

Smart Defrost Kit™ are E Solutions options that will optimize your savings and increase

energy eciency.

Available with Beacon II

™

Beacon II™ is the next generation of Bohn’s patented, preassembled, factory installed

refrigeration system featuring an integrated microcomputer-based electronic control

board. The Beacon II™ systems come completely factory installed, wired and tested

saving you time and money.

™

Beacon II™ oers:

• Complete factory installation, wiring and testing which saves time and money

• Simple eld electrical connections and 24 volt wiring between condensing and evaporator units

• Preset factory superheat allowing the system to run more eciently and reducing future adjustments

• Monitors and controls box temperature, evaporator superheat, condenser fan cycling on two fan units,

system status and defrost from outside the box

• Monitor and make system changes remotely via modem and exclusive Beacon II™ Smart II software

• Data logging capabilities with Smart Controller

Beacon II™ Smart Controller

Beacon II™ Smart Controller is an optional system monitoring and

programming control device. It allows for adjustments to be made at the

push of a button from a conveniently mounted location. The Beacon II™ Smart

Controller also allows you to monitor and make changes to the refrigeration

system via modem connection from anywhere in the world. The Beacon II™ has

been updated to allow the user to make even more precise adjustments than the original Beacon’s Smart Controller. One

Smart Controller can program and control up to four separate condensing units with up to four evaporators on each system.

That’s more control in your hands!

4

Page 5

™

Beacon II

Beacon II™ Smart II Software makes it easy to adjust and monitor one or more

refrigeration systems as well as capture minute by minute system conditions. This

Windows-based software allows you to connect to the Beacon II™ Smart Controller

from anywhere in the world to monitor the systems, make adjustments and log

minute by minute system conditions. This data logging capability is critical in the

food service industry.

™

Beacon II

The Beacon II™ Smart Defrost, available only on the Beacon II™ Smart

Controller, enables the Beacon II™ system to sense frost accumulation

and initiates defrost only when it is necessary. To begin, preset defrost

times using the Beacon II™ Smart Controller. At each scheduled defrost

time, Smart Defrost checks system performance to see if a defrost

is necessary. If not, it simply does not defrost, waiting until the next

scheduled defrost time.

Smart Defrost

Smart II Software

Smart Defrost Kit™

The factory installed Smart Defrost Kit (SDK) skips unnecessary defrosts in commercial,

electric defrost walk-in refrigeration systems saving energy, reducing costs and ultimately

improving product integrity. The SDK is available as a factory-installed option on all

condensing units.

5

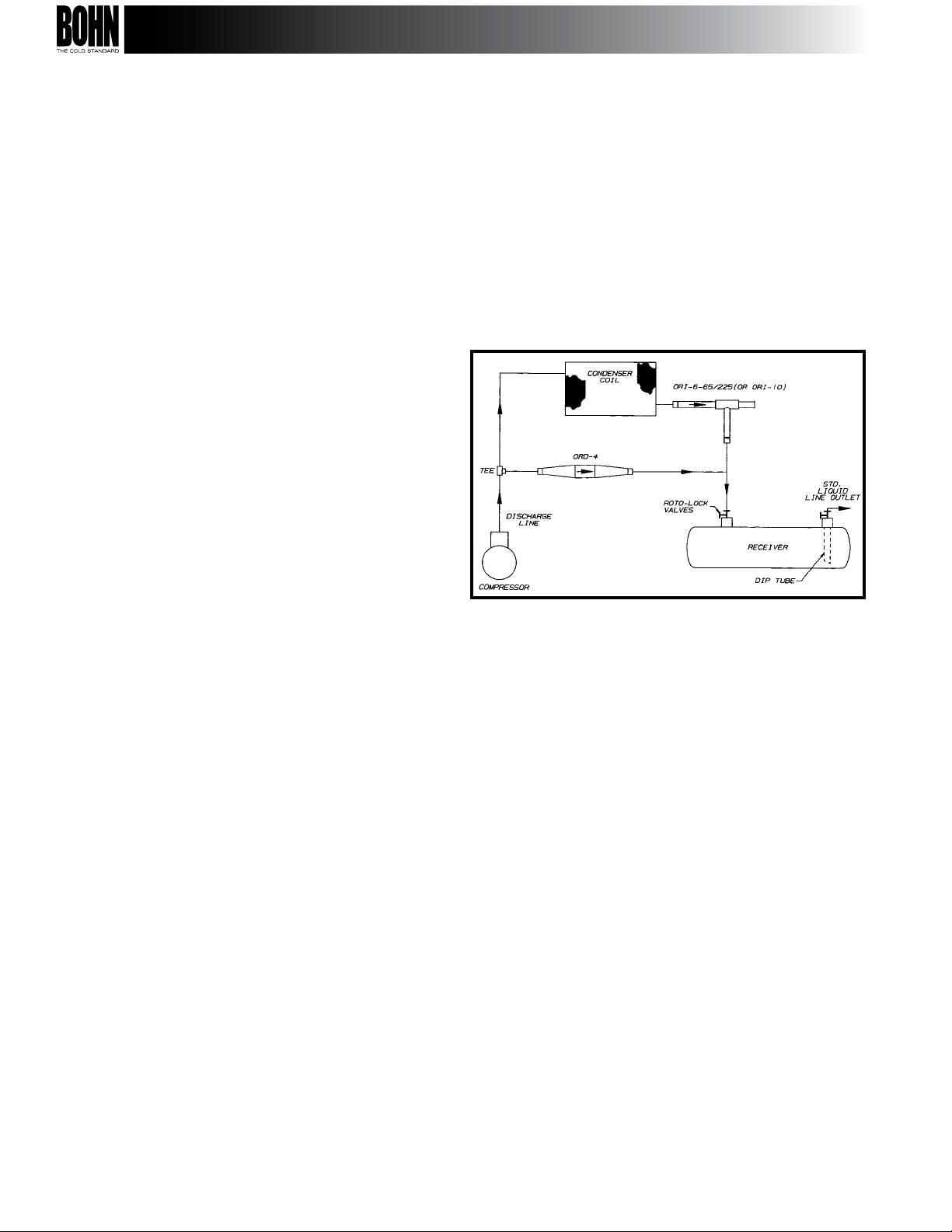

Page 6

LIMITIZER

®

The Need For Head Pressure Control

Refrigeration condensing units must eciently perform at varying

ambient conditions. A properly sized unit will adequately perform

at even the highest summer ambient temperatures. However, in

situations where the system must operate the majority of the time at

less than design temperature, a means of providing adequate head

pressure for refrigerant ow is desirable.

The Bohn Limitizer® System

The Limitizer® system is a factory assembled system utilizing a Limitizer®

control to maintain a constant head pressure at the air cooled

condensing unit during all climatic conditions when the ambient

temperature drops below 75°F (typical).

When the ambient is above 75°F, the condenser pressure is above

the Limitizer® valve setting and therefore, the valve remains in the

full open position.

As the temperature drops below 75°F, the pressure at the condenser

also drops below the setting of the Limitizer

valve, sensing the reduction in condensing pressure, modulates

toward the closed position, thus restricting the ow of liquid from the

condenser. The liquid backs up into the condenser and oods a portion

of the tubes, thus reducing the overall capacity of the condenser. The

Limitizer® valve will continue to ood the condenser until the pressure

setting has been reached, thus providing proper head pressure at all

ambient temperatures.

®

valve. The Limitizer®

While the condenser oods, a second line pressurizes the receiver

through another valve. Therefore, the refrigerant flow from the

condenser to the receiver modulates with conditions. However, the

bypass from the discharge line maintains a minimum receiver pressure.

These valves are adjustable and the minimum receiver pressure may

be reset higher or lower depending upon application situations of a

particular job. The Limitizer

adjustable design.

®

system uses this two-valve,

6

Page 7

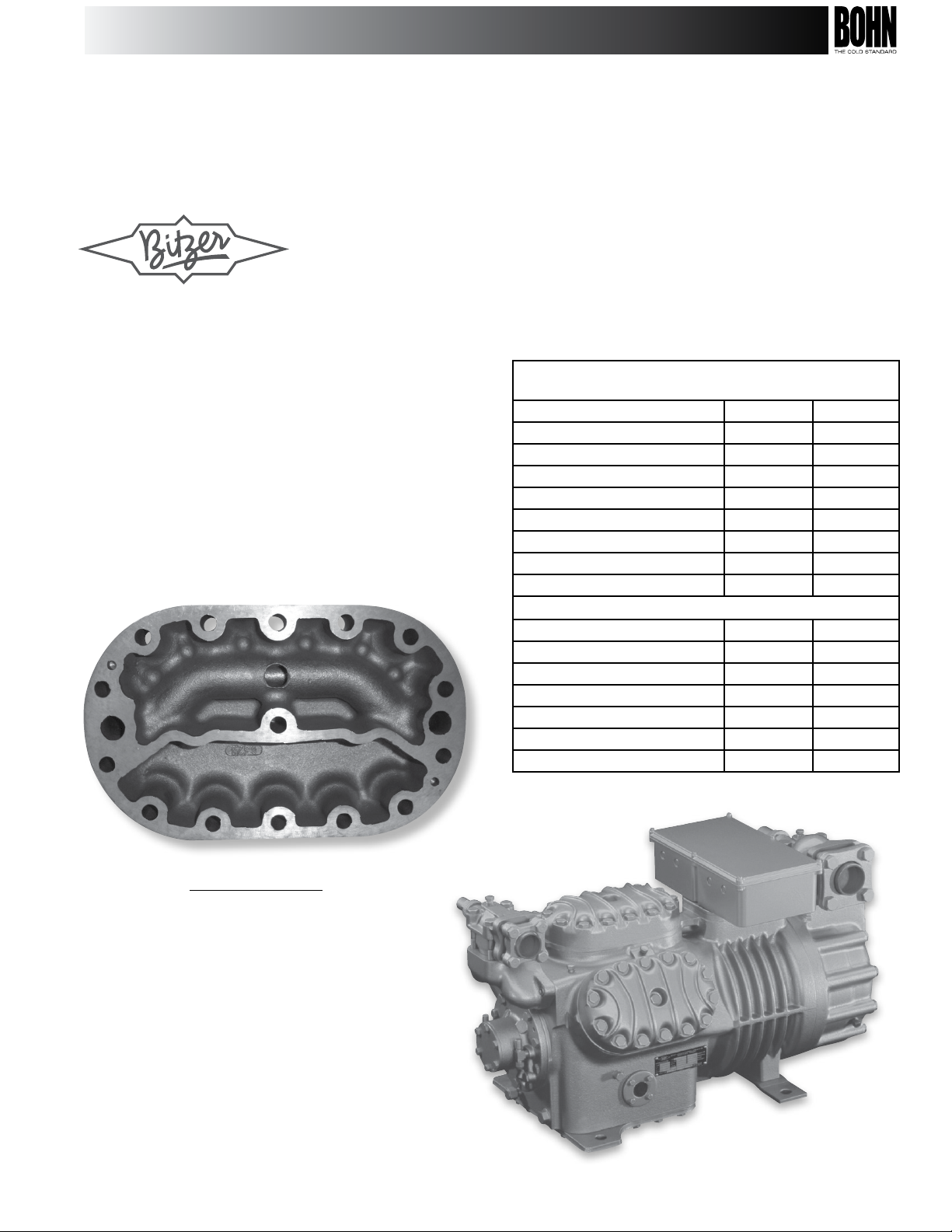

Bitzer Compressors

Features and Benets

Bitzer is the world’s largest manufacturer of semi-hermetic refrigeration compressors

over 3 HP. In business since 1934, Bitzer has manufacturing plants in Germany,

Brazil, Portugal, China and the United States and operates in over 100 countries

around the world. Bitzer’s Georgia plant manufactures a complete range of

semi-hermetic compressors from 3 to 50 HP. Bitzer provides aftermarket support

through wholesalers and also provides 24-hour replacement service from its seven

distribution warehouses located across the U.S.

Bitzer Oers:

• 2-Year Warranty

• Unloader Heads Standard on All 4 & 6-cylinder Models

• Dual Voltage Control Modules on All Models

• Dual Voltage Compressors (6 to 50 HP)

• Lowest Sound Levels in their Class (Built-in Muers)

• Superior Lubrication and Low Oil Circulation Rates

• German Engineering / Built in America

Bitzer Standard Execution

POE Oil Charge √ √

Protective Dry-Nitrogen Charge √ √

Suction & Discharge Service Valves √ √

Dual Voltage INT Protection Modules √ √

Terminal Box Enclosure Class IP65 √ √

Unloader Heads √ √

Patented Internal Muers √ √

Centrifugal Oil System √ √

Conventional Oil Pump √ √

Bitzer Options 4C Models 4B & 6B

Mounting Hardware (Spring Kits) √ √

Hard Mount Kits √ √

Optical Oil Sensor √ √

Crankcase Heaters √ √

Unloader Stems / Coils √ √

Head Fans and Brackets √ √

Delta P II Dierential Oil Pres. Switch √ √

Octagon

4C Models

4B & 6B

Models

Bitzer Quiet!!!

Bitzer compressors are famous for their low sound

levels. We change capacities within a frame size by

changing our bore diameters rather than the length

of the piston strokes. This gives our compressors an

unsurpassed balance and precision that translates

to low decibels. In addition, Bitzer compressors

have a muer built into each head (see photo) that

eliminates pulsations and reduces the sound levels

even further.

7

Page 8

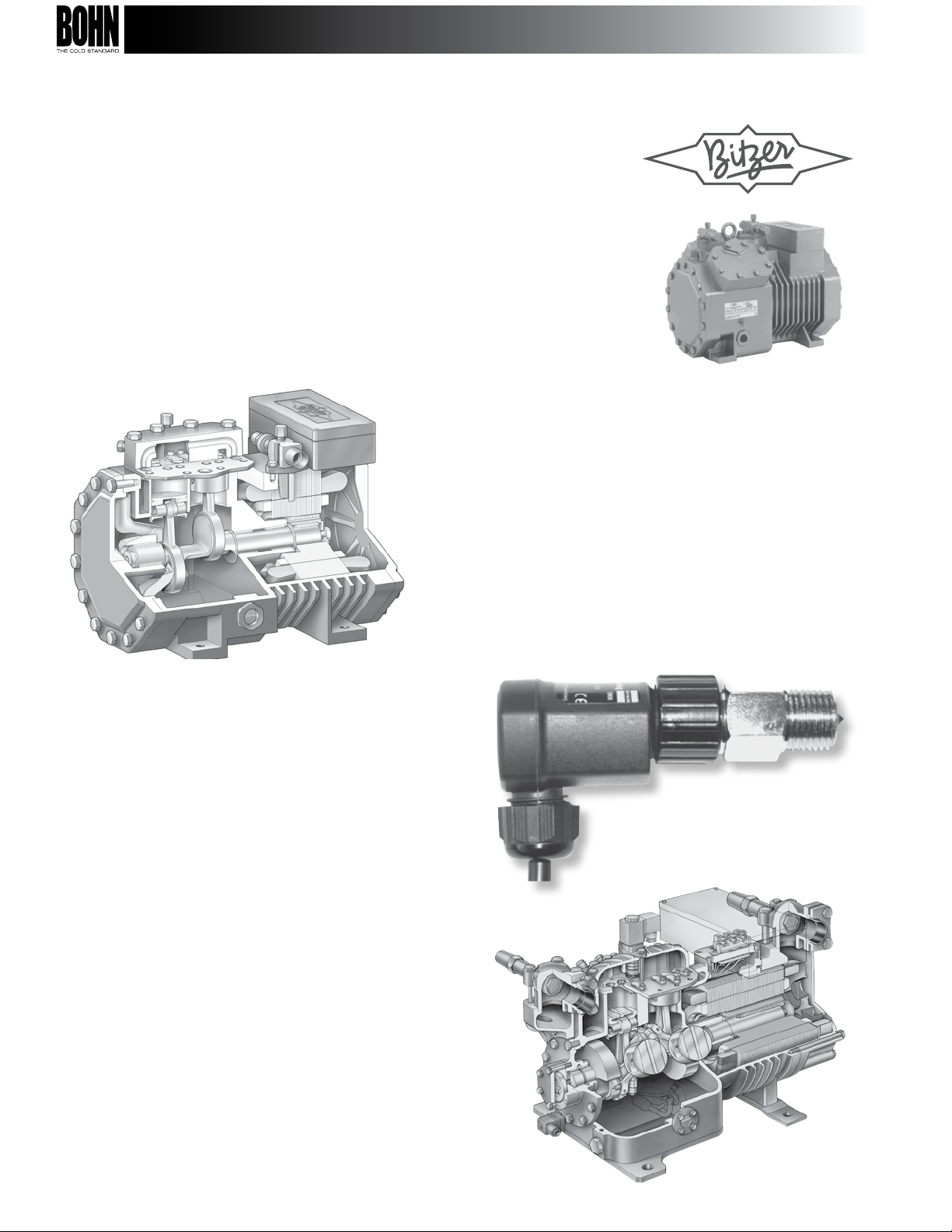

Bitzer Compressors

Features and Benets

Octagon® 4C Models

Bitzer Octagon 4C Models are rated from 3 to 20 HP. This rugged, compact

series utilizes wear resistant drive gear with PTFE coated bearings for especially

low friction, aluminum pistons of optimized geometry, connecting rods with

eccentric straps and generously dimensioned bearing surfaces. Bitzer’s centrifugal

lubrication system eliminates the need for an oil pump and provides optimum oil

supply to the compressor even under extreme operating conditions.

Centrifugal Lubrication

The centrifugal lubrication design employs a solid metal disc

mounted to the crankshaft (see cut-away) that distributes

oil into a reservoir at the end of the shaft. The oil then ows

through the shaft to the bearing surfaces.

OLC-K1 Operating Principle

The OLC-K1 sensing device shines an infrared light into

the oil reservoir. If oil is present, the light is absorbed

and the compressor runs normally. If no oil is present,

the light reects on the sensor, and the compressor

shuts o.

Bitzer 4B & 6B Models

Bitzer 4B through 6B Models are rated from 13 to 50

HP. This series features surface hardened crank shafts,

low friction bearings, aluminum pistons, hard chrome

plated piston rings and special wrist pin bearings.

The 4B & 6B models have a sealed main bearing and

generously sized oil pump. Our patented oil return

system ensures complete lubrication while reducing oil

circulation into the system. Ecient capacity control

is provided by unloader banks that can signicantly

reduce energy consumption.

Bitzer oers an optional Optical Oil Sensor (See OLC-K1 photo

below) that mounts to the outer cover of the compressor

and monitors oil level by means of an infrared light.

8

Page 9

Horizontal Air Discharge Condensing Units 4 to 13 HP

Standard and Optional Features

• Floating Tube™ coil design

• Ried copper condenser tubing

• Designed for use with R-404A, R-507

• Prebent copper tubes minimize welded joints on

internal piping

• Fixed high and adjustable low pressure controls.

• Oil safety control

• Head pressure control valve

• Bitzer compressors with POE oil

• Spring mounted compressor with suction and discharge

vibration eliminators

• Crankcase heater

• Thermally protected, permanently lubricated ball bearing

condenser fan motors

• Separate subcooling circuit in condenser for added capacity

and vapor-free liquid

• Pressure relief valve on receiver

• Sealed liquid line lter drier and sight glass

• Electrical controls, including compressor contactor and

optional defrost control, are located in easily accessible control

box with a hinged cover

• Service Mate

• Pumpdown Switch

• Cabinet is constructed from prepainted galvanized steel

• Base valve and high & low pressure taps on outside

of unit

• Vertical receivers

™

module to assist troubleshooting

Factory-Installed Options

• Oversized receiver

• Replaceable core liquid lter drier

• Liquid line solenoid valve

• Suction lter

• Replaceable core suction lter

• Suction accumulator

• Oil separator

• Air defrost timer

• Electric defrost kits, including timer, evaporator fan contactor

with fusing, defrost heater contactor(s), lockout relay and

terminal strip

• Fusing for defrost kits

• Evaporator holdout relays for systems with multiple electric

defrost evaporators

• Low ambient kit with heated and insulated receiver with

time delay

• Fused disconnect switch

• Non-fused disconnect switch

• Phase-loss monitor

• Manual-reset high pressure switch

• Anti-short cycle timer

• Compressor circuit breakers

• Condenser fan cycling

• Coated condenser coils

• Copper nned coil

• Beacon II

• Hail guards (shipped loose)

• Compressor unloading

• NEMA contactors

• 12" extended legs for snowbelt region (shipped loose)

• Slanted louver for snowbelt regions (shipped loose)

• Dual pressure control

™

compatible

Horizontal Discharge

Nomenclature

B B T

Brand Compressor Application Horsepower Temp. Range

B = Bohn B = Bitzer T = Outdoor

N = Indoor

S = Beacon II

™

0000

0401 - 4

0551 - 5

0601 - 6

0611 -6

0751 - 7.5

0901 - 9

1001 - 10

1201 - 12

1301 - 13

L

M = Med. Temp.

L = Low Temp.

6 C

Refrigerant Voltage

6 = R-404A,

R-507

C = 208-230/3/60

D = 460/3/60

E = 575/3/60

9

Page 10

Performance Data

Medium Temperature R-404A/R-507

3 - 22 HP Condensing UnitsHorizontal Discharge

Unit Model

Number

BB*0551M6 4C0969SH

BB*0751M6 4C1145SH

BB*0901M6 4C1385SH

BB*1001M6 4C1480PH

Compressor

Model

Low Temperature R-404A/R-507

Unit Model

Number

BB*0401L6 4C0969SL

BB*0551L6 4C1145SL

BB*0601L6 4C1385SL

BB*0611L6 4C1480PL

BB*0751L6 4C1761PL

BB*1001L6 4C2067PL

BB*1201L6 4C2397PL

BB*1301L6 4B2707PL

*= T for Outdoors, N for Indoors, S for Beacon II

Consult factory on all models for applications above 110°F ambient.

Compressor

Model

10

Suction Temp.

Suction Temp.

™

90°F

°F

40

30

25

20

15

5

40

30

25

20

15

5

40

30

25

20

15

5

40

30

25

20

15

5

Amb.

89700

75460

68740

62260

56190

45520

105280

88720

80750

72780

65640

53140

129090

108780

99120

89850

81200

65960

137470

115200

104860

94930

85670

69300

90°F

°F

0 35200 33380 31560 28020

-10 27690 26222 24690 21680

-15 24440 23040 21620 18870

-20 21520 20210 18930 16460

-30 17090 16000 14930 12820

-40 15030 14090 13200 11330

0 42930 40770 38600 34290

-10 33890 32073 30230 26620

-15 29880 28200 26510 23190

-20 26310 24770 23230 20270

-30 20960 19650 18370 15830

-40 18450 17320 16240 14010

0 52890 50250 47530 42230

-10 41590 39334 37070 32610

-15 36690 34580 32480 28460

-20 32320 30410 28510 24810

-30 25910 24260 22630 19540

-40 22910 21500 20090 17370

0 56010 52610 49660 43790

-10 43740 41241 38770 33850

-15 38540 36230 33910 29460

-20 33870 31750 29680 25640

-30 26730 24980 23280 19980

-40 23080 21650 20230 17430

0 68040 64570 61090 54180

-10 53710 50780 47800 41660

-15 47320 44580 41840 36480

-20 41590 39080 36600 31870

-30 32760 30720 28700 24750

-40 28200 26530 24910 21590

0 78200 74200 70160 63210

-10 61470 58050 54740 48110

-15 54150 51030 47940 41820

-20 47560 44700 41880 36370

-30 37620 35240 32860 28310

-40 32550 30500 28620 24710

0 93390 88580 83830 74420

-10 74920 69208 65150 57070

-15 64440 60680 56890 49580

-20 56560 53090 49680 43080

-30 44620 41750 38850 33170

-40 38400 36060 33630 28760

0 105360 100530 95590 85790

-10 83410 79221 75110 66870

-15 73740 69890 66030 58590

-20 65040 61530 58040 51230

-30 51830 48880 45950 40350

-40 45050 42600 40250 35390

Amb.

95°F

Amb.

85620

72064

65580

59360

53510

43270

100690

84739

76660

69360

62500

50500

124130

101623

94750

85870

77500

62760

131010

107509

100040

90550

81560

65840

95°F

Amb.

100°F

Amb.

81720

68710

62440

56460

50870

41170

95530

80270

72960

65960

59380

47880

118700

99390

90440

81860

73800

59840

125080

105430

95260

86090

77450

62560

100°F

Amb.

110°F

Amb.

74280

62010

56230

50730

45720

36550

86960

72380

65640

59210

53160

42700

107220

90050

81730

76750

66340

53950

113750

94630

85740

77130

69510

55590

110°F

Amb.

Page 11

Electrical Data

Medium Temperature – R-404A/507

Voltage

Supply ^

Unit Model

Number

BB*0551M6C 4C0969SH 208-230/3 26.5 163.0 2 1/3 5.4 38.5 60

BB*0551M6D 4C0969SH 460/3 12.8 66.5 2 1/3 3.8 19.8 30

BB*0551M6E 4C0969SH 575/3 8.3 48.0 2 1/3 2.4 12.8 20

BB*0751M6C 4C1145SH 208-230/3 29.0 215.0 2 1/3 5.4 41.7 70

BB*0751M6D 4C1145SH 460/3 13.8 88.0 2 1/3 3.8 21.1 35

BB*0751M6E 4C1145SH 575/3 10.3 63.5 2 1/3 2.4 15.3 25

BB*0911M6C 4C1385SH 208-230/3 32.7 215.0 2 3/4 8.8 49.7 80

BB*0911M6D 4C1385SH 460/3 16.3 88.0 2 3/4 4.4 24.8 40

BB*0911M6E 4C1385SH 575/3 13.1 63.5 2 3/4 3.6 20 30

BB*1001M6C 4C1480PH 208-230/3 38.5 222.0 2 3/4 8.8 56.9 90

BB*1001M6D 4C1480PH 460/3 19.2 111.0 2 3/4 4.4 28.4 45

BB*1001M6E 4C1480PH 575/3 15.4 89.0 2 3/4 3.6 22.9 35

Compressor

Model

60 Hz RLA LRA Qty. HP FLA MCA†MOP

Compressor

Condenser

Fan Motors

Beacon II™ or

Air Defrost

Low Temperature – R-404A/R-507

Voltage

Supply ^

Unit Model

Number

BB*0401L6C 4C0969SL 208-230/3 16.7 142.0 1 1/3 2.7 23.6 40.0

BB*0401L6D 4C0969SL 460/3 9.0 58.0 1 1/3 1.9 13.2 20.0

BB*0401L6E 4C0969SL 575/3 7.0 51.5 1 1/3 1.2 10.0 15.0

BB*0551L6C 4C1145SL 208-230/3 19.4 163.0 1 1/3 2.7 27.0 45.0

BB*0551L6D 4C1145SL 460/3 10.6 66.5 1 1/3 1.9 15.2 25.0

BB*0551L6E 4C1145SL 575/3 8.7 48.0 1 1/3 1.2 12.1 20.0

BB*0601L6C 4C1385SL 208-230/3 24.9 215.0 2 1/3 5.4 36.5 60.0

BB*0601L6D 4C1385SL 460/3 14.2 88.0 2 1/3 3.8 21.6 35.0

BB*0601L6E 4C1385SL 575/3 10.8 63.5 2 1/3 2.4 15.9 25.0

BB*0611L6C 4C1480PL 208-230/3 24.4 150.0 2 1/3 5.4 35.9 60.0

BB*0611L6D 4C1480PL 460/3 12.2 75.0 2 1/3 3.8 19.1 30.0

BB*0611L6E 4C1480PL 575/3 9.6 60.0 2 1/3 2.4 14.4 20.0

BB*0751L6C 4C1761PL 208-230/3 28.2 180.0 2 1/3 5.4 40.7 60.0

BB*0751L6D 4C1761PL 460/3 14.1 90.0 2 1/3 3.8 21.4 35.0

BB*0751L6E 4C1761PL 575/3 12.2 72.0 2 1/3 2.4 17.7 30.0

BB*1001L6C 4C2067PL 208-230/3 34.6 222.0 2 1/3 5.4 48.7 80.0

BB*1001L6D 4C2067PL 460/3 17.3 111.0 2 1/3 3.8 25.4 40.0

BB*1001L6E 4C2067PL 575/3 14.4 89.0 2 1/3 2.4 20.4 30.0

BB*1201L6C 4C2397PL 208-230/3 39.7 252.0 2 3/4 8.8 58.4 90.0

BB*1201L6D 4C2397PL 460/3 19.9 126.0 2 3/4 4.4 29.3 45.0

BB*1201L6E 4C2397PL 575/3 15.9 101.0 2 3/4 3.6 22.5 35.0

BB*1301L6C 4B2707PL 208-230/3 43.6 294.0 2 3/4 8.8 63.3 100.0

BB*1301L6D 4B2707PL 460/3 21.8 147.0 2 3/4 4.4 31.7 50.0

BB*1301L6E 4B2707PL 575/3 17.3 117.0 2 3/4 3.6 25.2 40.0

*= T for Outdoors, N for Indoors, S for Beacon II

^ Consult factory for 50Hz applications.

† MCA = Minimum Circuit Ampacity

†† MOP = Maximum Overcurrent Protection

‡ Condensing unit data plate ratings will be based on actual system match.

Compressor

Model

60 Hz RLA LRA Qty. HP FLA MCA†MOP

Compressor

™

Condenser

Fan Motors

Beacon II™ or

Air Defrost

Remote Loads

Electric Defrost

Evap.

††

Defrost

Fan

Heater

Amps

Amps

CONTACT FACTORY FOR SYSTEM

ELECTRICAL RATINGS

System

MCA

Remote Loads

Electric Defrost

Evap.

††

Defrost

Fan

Heater

Amps

Amps

CONTACT FACTORY FOR SYSTEM

ELECTRICAL RATINGS

System

MCA

‡

System

†

‡

System

†

MOP

MOP

††

Horizontal Discharge

††

11

Page 12

Specications and Dimensional Data

Medium & Low Temperature – R-404A/R-507

3 - 22 HP Condensing UnitsHorizontal Discharge

Unit Model

Number

BB*0551M6 4C0969SH 5.5 5/8 1 3/8 67 78 36-3/4 63-3/4 39-1/4 823

BB*0751M6 4C1145SH 7.5 5/8 1 3/8 67 78 36-3/4 63-3/4 39-1/4 862

BB*0901M6 4C1385SH 9.0 7/8 1 5/8 67 87 41-3/4 75-1/8 48-3/4 993

BB*1001M6 4C1480PH 10.0 7/8 1 5/8 67 87 41-3/4 75-1/8 48-3/4 1,101

BB*0401L6 4C0969SL 4.0 1/2 1 1/8 28 52 36-3/4 51-3/4 39-1/4 595

BB*0551L6 4C1145SL 5.5 1/2 1 1/8 28 52 36-3/4 51-3/4 39-1/4 645

BB*0601L6 4C1385SL 6.0 5/8 1 3/8 67 78 36-3/4 63-3/4 39-1/4 775

BB*0611L6 4C1480PL 6.5 5/8 1 3/8 67 78 36-3/4 63-3/4 39-1/4 865

BB*0751L6 4C1761PL 7.5 5/8 1 3/8 67 78 36-3/4 63-3/4 39-1/4 935

BB*1001L6 4C2067PL 10.0 5/8 1 3/8 67 78 36-3/4 63-3/4 39-1/4 1,000

BB*1201L6 4C2397PL 12.0 7/8 1 5/8 67 87 41-3/4 75-1/8 48-3/4 1,082

BB*1301L6 4B2707PL 13.0 7/8 1 5/8 67 87 41-3/4 75-1/8 48-3/4 1,173

*= T for Outdoors, N for Indoors, S for Beacon II

Compressor

Model

HP

Refrigerant Line

Connections (OD)

Liquid Suction STD OPT Length Width Height

™

Receiver Capacity

@ 90% full (lbs.)

Dimensions (inches)

One Fan Condenser

Approx.

Net Wt.

(lbs.)

Two Fan Condenser

12

LEFT SIDE

Length

FRONT

Height

Width

Page 13

Vertical Air Discharge Condensing Units 13 to 50 HP

Single Compressor

Standard and Optional Features

• The Floating Tube™ coil design. Refrigerant-carrying copper

tubes do not contact any metal support sheets; instead,

the coil is constructed with expanded anchor tubes that

support the coil construction and do not carry refrigerant.

The coil design eliminates one of the major causes of leaks in

refrigeration systems

• Limited ve-year warranty against condenser tube sheet and

center support leaks

• Designed for use with R-404A, R-507

• Prebent copper tubes minimize welded joints on

internal piping

• All sweat type connections, no are joints to leak

• Fixed high pressure switch eliminates capillary tubes

• Oil safety control

• Bitzer compressors with POE oil

• Spring mounted compressor with suction and discharge

vibration eliminators

• Crankcase heater

• Thermally protected, permanently lubricated ball bearing

condenser fan motors

• Separate subcooling circuit in condenser for added capacity

and vapor-free liquid

• Receivers are sized for sucient pumpdown capacity with

inlet and outlet service valves

• Pressure relief valve on receiver

• Sealed liquid line lter drier and sight glass

• Electrical controls, including compressor contactor and

optional defrost control, are located in easily accessible

control box with a hinged cover

• Service Mate

• Pumpdown Switch

• Cabinet is constructed from prepainted galvanized steel

• Convenient access panels for easy servicing to internal

components

™

module to assist troubleshooting

Factory-Installed Options

• Compressor unloading

• Replaceable core liquid lter drier

• Liquid line solenoid valve

• Suction lter

• Replaceable core suction lter

• Suction accumulator

• Oil separator with discharge line check valve

• Air defrost timer

• Electric defrost kits, including timer, evaporator fan contactor

with fusing, defrost heater contactor(s), lockout relay and

terminal strip

• Fusing for defrost kits

• Evaporator holdout relays for systems with multiple electric

defrost evaporators

• Low ambient kit with heated and insulated receiver with

time delay

• Fused disconnect switch

• Non-fused disconnect switch

• Phase-loss protection

• Manual-reset high pressure switch

• Anti-short cycle timer

• Compressor circuit breakers

• Condenser fan cycling (standard on BDVS)

• Three-way heat reclaim valve (n/a on BDVS)

• Coated condenser coils for protection against corrosion in

harsh environments

• Beacon II

™

compatible

Single Vertical Air Discharge Condensing Unit

B L V

Brand Head Pressure

Control

B = Bohn L - Limitizer

D - Beacon II

®

™

V = Vertical

VS = Vertical Beacon

Nomenclature

000B

Airow Horsepower Temp. Range

130B - 13

150B - 15

200B - 20

220B - 22

250B - 25

300B - 30

330B - 33

350B - 35

400B - 40

500B -50

L

M = Med. Temp.

L = Low Temp.

6 C

Refrigerant Voltage

6 = R-404A,

R-507

C = 208-230/3/60

D = 460/3/60

E = 575/3/60

13

Page 14

Performance Data

Medium Temperature – R-404A/R-507

Unit Model

Number

B*V*150BM6 4C2067PH

B*V*200BM6 4C2397PH

Compressor

Model

Single Vertical Air Discharge Condensing Unit

B*V*220BM6 4B2707PH

B*V*250BM6 4B3139PH

B*V*300BM6 4B3604PH

B*V*330BM6 6B4060PH

B*V*350BM6 6B4709PH

B*V*400BM6 6B5406PH

B*V*500BM6 6B6462PH

B*V = BLV is Limitizer®, BDVS is Beacon II

Notes: For 50 cycle capacity, multiply values by .86

Suction Temp.

°F

40

30

25

20

15

5

40

30

25

20

15

5

40

30

25

20

15

5

40

30

25

20

15

5

40

30

25

20

15

5

40

30

25

20

15

5

40

30

25

20

15

5

40

30

25

20

15

5

40

30

25

20

15

5

™

90°F

Amb.

197120

165780

150650

136230

122680

98790

230460

192070

174410

157400

141810

113840

254200

212600

193960

175330

157850

127090

291480

245260

222450

201510

181830

146820

339410

284940

259200

235080

211960

171290

385050

321570

292920

263780

237640

190700

438780

369160

335750

303260

273630

220740

505840

425630

388520

352010

317530

256880

592370

501120

457060

414850

375030

304620

95°F

Amb.

188290

157400

143110

129380

116550

93540

219760

183360

166320

150000

134810

107790

244040

204700

185270

167820

150960

121320

279820

234460

213660

193150

173860

140070

324930

273150

248290

225050

202640

163320

368290

308190

279790

252590

227190

181990

421120

353880

321530

290650

261560

210580

483740

408880

371110

336760

303520

245160

567970

479900

437280

396510

357970

290190

100°F

Amb.

178750

150410

132640

123010

110440

88070

209960

175590

158250

142470

127880

101800

232880

195360

177330

160390

144070

115590

268270

225090

203930

184500

165980

133380

311370

261580

237590

214940

193290

155450

352830

296110

267620

241230

216720

173230

401770

338590

306610

277520

249500

200500

463250

391180

354990

321570

289520

233350

543770

485690

417510

378160

341040

275780

110°F

Amb.

162020

134650

121880

109570

98170

77590

191380

157870

142410

127770

113890

89390

213790

177890

161290

145490

130340

103770

243980

204400

185400

167350

150090

119580

285650

238360

215910

194800

174680

139050

323590

268900

243190

218990

195850

155250

368420

307100

278580

251470

225500

179780

424260

355120

322990

291390

261700

209240

494050

415900

378430

341770

307300

246360

14

Page 15

Performance Data

Low Temperature – R-404A/R-507

Unit Model

Number

B*V*130BL6 4B2707PL

B*V*150BL6 4B3139PL

B*V*200BL6 4B3604PL

B*V*220BL6 6B4060PL

B*V*250BL6 6B4709PL

B*V*300BL6 6B5406PL

B*V*400BL6 6B6462PL

B*V = BLV is Limitizer®, BDVS is Beacon II

Notes: For 50 cycle capacity, multiply values by .86

Compressor

Model

™

Suction Temp.

°F

0 105960 100880 95790 85810

-10 81650 77300 72980 64920

-15 70890 66880 62900 55370

-20 61310 57620 53960 46770

-30 46800 43630 40420 33650

-40 39880 37260 34420 29100

0 123250 117250 111270 99750

-10 95940 90740 85500 75940

-15 83810 78930 74120 64930

-20 73030 68530 63970 55110

-30 56580 52580 48520 40050

-40 48750 45290 41760 34500

0 141040 133910 126850 112960

-10 110120 104050 97980 86810

-15 96260 90640 85090 74470

-20 83860 78710 73500 63370

-30 64670 60140 55580 46070

-40 55050 51170 47240 39070

0 156330 148990 141590 127330

-10 120650 114230 107830 96230

-15 104810 98870 92970 81890

-20 90770 85340 79790 69200

-30 69550 64720 59860 49790

-40 59470 55420 51350 43220

0 184510 175840 166300 148750

-10 142790 135120 127430 113350

-15 124340 117270 110260 96980

-20 107930 101510 94950 82350

-30 83040 77430 71770 59880

-40 71140 66410 61560 51750

0 204160 194480 190060 165790

-10 158700 150250 141860 126570

-15 138390 130550 122800 108090

-20 120340 113100 105750 91680

-30 92900 86400 79830 66380

-40 80050 74380 68650 56190

0 245130 232960 220670 196830

-10 189440 178850 168260 148730

-15 164710 154820 144950 126420

-20 142690 133540 124260 106400

-30 109060 100910 92610 74580

-40 93380 86320 79130 63910

90°F

Amb.

95°F

Amb.

100°F

Amb.

110°F

Amb.

Single Vertical Air Discharge Condensing Unit

15

Page 16

Electrical Data

Medium & Low Temperature – R-404A/R-507

Compressor

Unit Model

Number

B*V*150BM6 4C2067PH 48.7 294 2 9.6 70.5 110

B*V*200BM6 4C2397PH 57.7 352 2 14.0 86.1 125

B*V*220BM6 4B2707PH 61.5 352 2 14.0 90.9 150

B*V*250BM6 4B3139PH 75.6 436 2 14.0 108.5 175

B*V*300BM6 4B3604PH 89.7 490 3 21.0 133.1 200

B*V*330BM6 6B4060PH 100.0 550 3 21.0 146.0 225

B*V*350BM6 6B4709PH 105.1 550 3 21.0 152.4 250

B*V*400BM6 6B5406PH 141.0 700 4 28.0 204.3 325

B*V*500BM6 6B6462PH 143.6 950 4 28.0 207.5 350

Single Vertical Air Discharge Condensing Unit

B*V*130BL6 4B2707PL 43.6 294 2 9.6 64.1 100

B*V*150BL6 4B3139PL 46.2 294 2 9.6 67.4 110

B*V*200BL6 4B3604PL 57.7 352 2 9.6 81.7 125

B*V*220BL6 6B4060PL 65.4 436 2 14.0 95.8 150

B*V*250BL6 6B4709PL 69.2 436 2 14.0 100.5 150

B*V*300BL6 6B5406PL 84.6 490 2 14.0 119.8 200

B*V*400BL6 6B6462PL 97.4 700 3 21.0 142.8 225

B*V*150BM6 4C2067PH 24.4 147 2 4.8 35.3 60

B*V*200BM6 4C2397PH 28.8 176 2 7.0 43.0 70

B*V*220BM6 4B2707PH 30.8 176 2 7.0 45.5 70

B*V*250BM6 4B3139PH 37.8 218 2 7.0 54.3 90

B*V*300BM6 4B3604PH 44.9 245 3 10.5 66.6 110

B*V*330BM6 6B4060PH 50.0 275 3 10.5 73.0 110

B*V*350BM6 6B4709PH 52.6 275 3 10.5 76.3 125

B*V*400BM6 6B5406PH 70.5 350 4 14.0 102.1 150

B*V*500BM6 6B6462PH 71.8 425 4 14.0 103.8 175

B*V*130BL6 4B2707PL 21.8 147 2 4.8 32.1 50

B*V*150BL6 4B3139PL 23.1 147 2 4.8 33.7 50

B*V*200BL6 4B3604PL 28.8 176 2 4.8 40.8 70

B*V*220BL6 6B4060PL 32.7 218 2 7.0 47.9 80

B*V*250BL6 6B4709PL 34.6 218 2 7.0 50.3 80

B*V*300BL6 6B5406PL 42.3 245 2 7.0 59.9 100

B*V*400BL6 6B6462PL 48.7 350 3 10.5 71.4 110

B*V*150BM6 4C2067PH 19.6 117 2 4.6 29.1 40

B*V*200BM6 4C2397PH 23.6 140 2 5.6 35.1 50

B*V*220BM6 4B2707PH 24.4 140 2 5.6 36.1 60

B*V*250BM6 4B3139PH 30.1 165 2 5.6 43.2 70

B*V*300BM6 4B3604PH 35.9 196 3 8.4 53.3 80

B*V*330BM6 6B4060PH 39.7 220 3 8.4 58.0 90

B*V*350BM6 6B4709PH 41.7 220 3 8.4 60.5 100

B*V*400BM6 6B5406PH 56.4 280 4 11.2 81.7 125

B*V*500BM6 6B6462PH 57.1 340 4 11.2 82.6 125

B*V*130BL6 4B2707PL 17.3 117 2 4.6 26.2 40

B*V*150BL6 4B3139PL 18.6 117 2 4.6 27.9 45

B*V*200BL6 4B3604PL 23.1 140 2 4.6 33.5 50

B*V*220BL6 6B4060PL 26.9 174 2 5.6 38.5 60

B*V*250BL6 6B4709PL 27.6 174 2 5.6 40.1 60

B*V*300BL6 6B5406PL 33.3 196 2 5.6 47.2 80

B*V*400BL6 6B6462PL 39.1 280 3 8.4 57.3 90

B*V = BLV is Limitizer®, BDVS is Beacon II

† MCA = Minimum Circuit Ampacity

† † MOP = Maximum Overcurrent Protection

‡ Condensing unit data plate ratings will be based on actual system match.

Beacon II™ and Air Defrost Units do not carry any of the evaporator fan or heater loads. Power is

brought directly to the evaporators and does not go through the condensing unit.

An evaporator heater hold out relay (option) is recommended when two or more evaporators are

connected to a single (BLV/ BBV) condensing unit to allow termination on coils that have already

defrosted to prevent unnecessary steaming. This option is not needed on Beacon II™ (BDVS)

systems wired for a Master / Slave operation. Power is brought to each Beacon evaporator. Each coil

terminates its own defrost. Refrigeration will not start until all coils have terminated defrost.

Compressor

Model

RLA LRA Qty. FLA MCA†MOP

™

Condenser Fan

Motors

208-230 Volts

460 Volts

575 Volts

Beacon II™ or

Air Defrost

Remote Loads

‡

Electric Defrost

Evap.

††

Amps

Defrost

Fan

Heaters

Amps

CONTACT FACTORY FOR SYSTEM

ELECTRICAL RATINGS

CONTACT FACTORY FOR SYSTEM

ELECTRICAL RATINGS

CONTACT FACTORY FOR SYSTEM

ELECTRICAL RATINGS

System

†

MCA

System

††

MOP

16

Page 17

Specications and Dimensional Data

Medium & Low Temperature – R-404A/R-507

Unit Model

Number

Compressor

Model

HP

Connections (OD)

Liquid Suction LBS KG (A) (lbs)

B*V*150BM6 4C2067PH 15 7/8 1-5/8 123 56 144 1,400

B*V*200BM6 4C2397PH 20 7/8 1-5/8 123 56 171 1,625

B*V*220BM6 4B2707PH 22 1-1/8 2-1/8 123 56 171 1,690

B*V*250BM6 4B3139PH 25 1-1/8 2-1/8 123 56 171 1,935

B*V*300BM6 4B3604PH 30 1-1/8 2-1/8 188 85 226 1,615

B*V*330BM6 6B4060PH 33 1-1/8 2-1/8 188 85 226 1,785

B*V*350BM6 6B4709PH 35 1-1/8 2-1/8 188 85 226 1,885

B*V*400BM6 6B5406PH 40 1-1/8 2-1/8 188 85 281 2,440

B*V*500BM6 6B6462PH 50 1-1/8 2-1/8 188 85 281 2,835

B*V*130BL6 4B2707PL 13 7/8 1-5/8 81 37 144 1,590

B*V*150BL6 4B3139PL 15 7/8 1-5/8 81 37 144 1,800

B*V*200BL6 4B3604PL 20 7/8 2-1/8 81 37 144 1,870

B*V*220BL6 6B4060PL 22 7/8 2-1/8 123 56 171 2,075

B*V*250BL6 6B4709PL 25 1-1/8 2-1/8 123 56 171 2,170

B*V*300BL6 6B5406PL 30 1-1/8 2-1/8 123 56 171 2,180

B*V*400BL6 6B6462PL 40 1-1/8 2-1/8 188 85 226 1,920

B*V = BLV is Limitizer®, BDVS is Beacon II™

Refrigerant Line

BLV & Beacon II

Receiver Capacity @

90% full (lbs.)

Dimensions

(Inches)

Net

Weight

(Approx)

Dimensions

Side View

(Inches)

End View

Single Vertical Air Discharge Condensing Unit

17

Page 18

Vertical Air Discharge Condensing Units 26 to 100 HP

Dual Compressor

Standard and Optional Features

• Designed for use with R-404A/507

• Bitzer compressors with POE oil

• Thermally protected permanently lubricated ball

bearing condenser fan motors

• Electrical controls, including compressor contactor

and optional defrost control, are located in easily

accessible control box with a hinged cover

• Limitizer® (JLD) head pressure control system

• Receivers are sized for sucient pumpdown

capacity with inlet and outlet service valves

• Cabinet is constructed from prepainted

galvanized steel

• Convenient access panels for easy servicing to

internal components

• Suction and discharge vibration eliminators

• Separate subcooling circuit in condensers for added

capacity and vapor-free liquid

• Sealed liquid line lter drier and sight glass

• Service Mate™ module to assist troubleshooting

• Floating Tube™ coil design

• Prebent copper tubes minimize welded joints on

internal piping

Factory-Installed Options

Additional Standard Features

for Parallel Piped Units

1. Replaceable core liquid line lter drier

2. Replaceable core suction lter

Dual Vertical Air Discharge Condensing Unit

3. Suction accumulator

4. Oil management system

5. Contact Factory for Beacon II

TM

Application

• Replaceable core liquid line lter driers with

sight glasses

• Liquid line solenoid valves

• Suction lters

• Replaceable core suction lters

• Suction accumulators

• Oil separators with discharge line check valves

• Air defrost timers

• Electric defrost kits, including timer, evaporator fan

contactor with fusing, defrost heater contactor(s),

lockout relay and terminal strip

• Low ambient kits with heated and insulated receiver with

time delay

• Compressor unloading

• External discharge line muers

• Phase-loss protection

• Manual-reset high pressure switches

• Anti-short cycling timers

• Compressor circuit breakers

• Condenser fan cycling (standard on JDDS)

• Three way heat reclaim valve with mounted check valves

(n/a on JBD)

• Coated condenser coils for protection against corrosion

in harsh environments

• Beacon II™ compatible

J L D

Brand Head Pressure

Control

J = Bohn L - Limitizer

D - Beacon II

®

™

18

Nomenclature

000B

Airow Horsepower Temp. Range

D = Vertical

DS = Vertical

Beacon

260B - 26

300B - 30

400B - 40

440B - 44

500B - 50

600B - 60

660B - 66

700B - 70

800B - 80

110B -100

M = Med. Temp.

L = Low Temp.

L

6 C

Refrigerant Voltage

6 = R-404A,

R-507

C = 208-230/3/60

D = 460/3/60

E = 575/3/60

Page 19

Performance Data

Medium Temperature – R-404A/R-507

Unit Model

Number

J*D*300BM6 4C2067PH

J*D*400BM6 4C2397PH

J*D*440BM6 4B2707PH

J*D*500BM6 4B3139PH

J*D*600BM6 4B3604PH

J*D*660BM6 6B4060PH

J*D*700BM6 6B4709PH

J*D*800BM6 6B5406PH

J*D*110BM6 6B6462PH

J*D = JLD is Limitizer®, JDDS is Beacon II™, JLD*PP is Parallel Piped

Compressor

Model

(2 Each)

Suction Temp.

90°F

°F

40 394250 376590 357490 324040

30 331570 314800 300810 269290

25 301290 286220 265290 243760

20 272450 258760 246010 219040

15 245360 233090 220890 196340

5 197580 187090 176140 155170

40 460920 439520 419910 382760

30 384140 366730 351180 315740

25 348820 332640 316500 284830

20 314800 299990 284950 255530

15 283620 269620 255760 227790

5 227670 215570 203590 178780

40 508400 488080 465770 427590

30 425210 409390 390720 355770

25 387920 370550 354660 322580

20 350670 335640 320780 290970

15 315710 301920 288130 260680

5 254190 242630 231170 207540

40 582960 559640 536530 487960

30 490520 468920 450170 408790

25 444900 427310 407850 370800

20 403020 386290 369000 334690

15 363660 347710 331970 300180

5 293650 280140 266760 239150

40 678820 649850 622730 571310

30 569890 546290 523150 476730

25 518410 496570 475180 431820

20 470170 450090 429890 389600

15 423920 405270 386590 349370

5 342580 326630 310890 278110

40 770100 736570 705660 647170

30 643130 616390 592210 537790

25 585850 559580 535230 486380

20 527550 505170 482450 437980

15 475270 454380 433450 391700

5 381390 363990 346540 310500

40 877570 842230 803550 736830

30 738320 707760 677170 614200

25 671500 643050 613220 557150

20 606520 581300 555030 502940

15 547270 523130 498990 451000

5 441480 421160 400990 359560

40 1011680 967490 926490 848530

30 851260 817760 782360 710240

25 777050 742220 709980 645990

20 704020 673510 643140 582780

15 635050 607050 579050 523390

5 513760 490320 466700 418470

40 1184730 1135930 1087530 988100

30 1002230 959810 917380 831800

25 914120 874560 835020 756870

20 829690 793020 756310 683550

15 750050 715930 682090 614590

5 609230 580370 551560 492720

Amb.

95°F

Amb.

100°F

Amb.

110°F

Amb.

19

Dual Vertical Air Discharge Condensing Unit

Page 20

Performance Data

Low Temperature – R-404A/R-507

Unit Model

Number

J*D*260BL6 4B2707PL

J*D*300BL6 4B3139PL

J*D*400BL6 4B3604PL

J*D*440BL6 6B4060PL

J*D*500BL6 6B4709PL

J*D*600BL6 6B5406PL

Compressor

Model

(2 Each)

Dual Vertical Air Discharge Condensing Unit

J*D*800BL6 6B6462PL

J*D = , JLD is Limitizer®, JDDS is Beacon II™, JLD*PP is Parallel Piped

Suction Temp.

°F

0 211930 201760 191580 171630

-10 163290 154600 145970 129850

-15 141770 133760 125810 110740

-20 122620 115230 107910 93530

-30 93600 87260 80840 67290

-40 79760 74510 68840 58200

0 246490 234490 222550 199500

-10 191890 181480 170990 151890

-15 167610 157870 148240 129860

-20 146060 137070 129950 110220

-30 113170 105150 97030 80094

-40 97500 90590 83510 68990

0 282080 267830 253710 225910

-10 220240 208090 195590 173620

-15 192520 181280 170180 148940

-20 167720 157420 146990 126740

-30 129340 120290 111160 92150

-40 110090 102350 94480 78130

0 312650 297970 283180 254650

-10 241300 228460 215670 192460

-15 209620 197730 185940 163780

-20 181550 170680 159580 138390

-30 139100 129450 119730 99570

-40 118940 110850 102700 86450

0 369030 350950 332610 297490

-10 285580 270240 254860 226690

-15 248670 234530 220520 193970

-20 215850 203020 189890 164690

-30 166080 154850 143530 119770

-40 142280 132800 123120 103500

0 408320 388960 380130 331580

-10 317410 300490 283720 253140

-15 276770 261100 245600 216170

-20 240670 226200 211500 183350

-30 185790 172800 159650 132760

-40 160100 148770 137310 112380

0 490250 465930 441340 393670

-10 378890 357700 336520 297450

-15 329420 309630 289900 252840

-20 285380 267080 248530 212800

-30 218130 201830 185220 149700

-40 186770 172630 158260 127820

90°F

Amb.

95°F

Amb.

100°F

Amb.

110°F

Amb.

20

Page 21

Electrical Data

Medium & Low Temperature – R-404A/507

Compressor

Unit Model

Number

J*D*300BM6 4C2067PH 48.7 294 4 19.2 128.8 175

J*D*400BM6 4C2397PH 57.7 352 4 28.0 157.8 200

J*D*440BM6 4B2707PH 61.5 352 4 28.0 166.4 225

J*D*500BM6 4B3139PH 75.6 436 4 28.0 198.1 250

J*D*600BM6 4B3604PH 89.7 490 6 42.0 243.8 325

J*D*660BM6 6B4060PH 100.0 550 6 42.0 267.0 350

J*D*700BM6 6B4709PH 105.1 550 6 42.0 278.5 350

J*D*800BM6 6B5406PH 141.0 700 8 56.0 373.3 500

J*D*110BM6 6B6462PH 143.6 950 8 56.0 379.1 500

J*D*260BL6 4B2707PL 43.6 294 4 19.2 117.3 150

J*D*300BL6 4B3139PL 46.2 294 4 19.2 123.2 150

J*D*400BL6 4B3604PL 57.7 352 4 19.2 149.0 200

J*D*440BL6 6B4060PL 65.4 436 4 28.0 175.2 225

J*D*500BL6 6B4709PL 69.2 436 4 28.0 183.7 250

J*D*600BL6 6B5406PL 84.6 490 4 28.0 218.4 300

J*D*800BL6 6B6462PL 97.4 700 6 42.0 261.2 350

J*D*300BM6 4C2067PH 24.4 147 4 9.6 64.5 80

J*D*400BM6 4C2397PH 28.8 176 4 14.0 78.8 100

J*D*440BM6 4B2707PH 30.8 176 4 14.0 83.3 110

J*D*500BM6 4B3139PH 37.8 218 4 14.0 99.1 125

J*D*600BM6 4B3604PH 44.9 245 6 21.0 122.0 150

J*D*660BM6 6B4060PH 50.0 275 6 21.0 133.5 175

J*D*700BM6 6B4709PH 52.6 275 6 21.0 139.4 175

J*D*800BM6 6B5406PH 70.5 350 8 28.0 186.6 250

J*D*110BM6 6B6462PH 71.8 425 8 28.0 189.6 250

J*D*260BL6 4B2707PL 21.8 147 4 9.6 58.7 80

J*D*300BL6 4B3139PL 23.1 147 4 9.6 61.6 80

J*D*400BL6 4B3604PL 28.8 176 4 9.6 74.4 100

J*D*440BL6 6B4060PL 32.7 218 4 14.0 87.6 110

J*D*500BL6 6B4709PL 34.6 218 4 14.0 91.9 125

J*D*600BL6 6B5406PL 42.3 245 4 14.0 109.2 150

J*D*800BL6 6B6462PL 48.7 350 6 21.0 130.6 175

J*D*300BM6 4C2067PH 19.6 117 4 9.2 53.3 70

J*D*400BM6 4C2397PH 23.6 140 4 11.2 64.3 80

J*D*440BM6 4B2707PH 24.4 140 4 11.2 66.1 90

J*D*500BM6 4B3139PH 30.1 165 4 11.2 78.9 100

J*D*600BM6 4B3604PH 35.9 196 6 16.8 97.6 125

J*D*660BM6 6B4060PH 39.7 220 6 16.8 106.1 125

J*D*700BM6 6B4709PH 41.7 220 6 16.8 110.6 150

J*D*800BM6 6B5406PH 56.4 280 8 22.4 149.3 200

J*D*110BM6 6B6462PH 57.1 340 8 22.4 150.9 200

J*D*260BL6 4B2707PL 17.3 117 4 9.2 48.1 60

J*D*300BL6 4B3139PL 18.6 117 4 9.2 51.1 70

J*D*400BL6 4B3604PL 23.1 140 4 9.2 61.2 80

J*D*440BL6 6B4060PL 26.3 174 4

J*D*500BL6 6B4709PL 27.6 174 4 11.2 73.3 100

J*D*600BL6 6B5406PL 33.3 196 4 11.2 86.1 110

J*D*800BL6 6B6462PL 39.1 280 6 16.8 104.8 125

Compressor

Model

(2 Each)

RLA LRA Qty. FLA MCA†MOP

Condenser Fan

Motors

208-230 Volts

460 Volts

575 Volts

11.2 70.4 90

Beacon II™ or

Air Defrost

Remote Loads

‡

Electric Defrost

Evap.

††

Fan

Amps

Defrost

Heaters

Amps

CONTACT FACTORY FOR SYSTEM

ELECTRICAL RATINGS

CONTACT FACTORY FOR SYSTEM

ELECTRICAL RATINGS

CONTACT FACTORY FOR SYSTEM

ELECTRICAL RATINGS

System

MCA

†

System

MOP

††

J*D = JLD is Limitizer®, JDDS is Beacon II™, JLD*PP is Parallel Piped

† MCA = Minimum Circuit Ampacity

†† MOP = Maximum Overcurrent Protection

‡ Condensing unit data plate ratings will be based on actual system match.

Dual Vertical Air Discharge Condensing Unit

21

Page 22

Specications and Dimensional Data

Medium & Low Temperature – R-404A/R-507

Unit Model

Number

J*D*300BM6 4C2067PH 30 7/8 1-5/8 1-1/8 2-1/8 123 56 188 85 144 2,805

J*D*400BM6 4C2397PH 40 7/8 1-5/8 1-1/8 2-1/8 123 56 188 85 171 3,250

J*D*440BM6 4B2707PH 44 1-1/8 2-1/8 1-1/8 2-1/8 123 56 269 122 171 3,380

J*D*500BM6 4B3139PH 50 1-1/8 2-1/8 1-3/8 2-5/8 123 56 269 122 171 3,875

J*D*600BM6 4B3604PH 60 1-1/8 2-1/8 1-3/8 2-5/8 188 85 269 122 226 3,225

J*D*660BM6 6B4060PH 66 1-1/8 2-1/8 1-3/8 2-5/8 188 85 269 122 226 3,570

J*D*700BM6 6B4709PH 70 1-1/8 2-1/8 1-5/8 3-1/8 188 85 363 165 226 3,770

J*D*800BM6 6B5406PH 80 1-1/8 2-1/8 1-5/8 3-1/8 188 85 363 165 281 4,880

J*D*110BM6 6B6462PH 100 1-1/8 2-1/8 1-5/8 3-1/8 188 85 363 165 281 5,670

J*D*260BL6 4B2707PL 26 7/8 1-5/8 1-1/8 2-1/8 81 37 188 85 144 3,175

J*D*300BL6 4B3139PL 30 7/8 1-5/8 1-1/8 2-5/8 81 37 188 85 144 3,605

J*D*400BL6 4B3604PL 40 7/8 2-1/8 1-1/8 2-5/8 81 37 188 85 144 3,735

J*D*440BL6 6B4060PL 44 7/8 2-1/8 1-3/8 3-1/8 123 56 269 122 171 4,145

J*D*500BL6 6B4709PL 50 1-1/8 2-1/8 1-3/8 3-1/8 123 56 269 122 171 4,240

J*D*600BL6 6B5406PL 60 1-1/8 2-1/8 1-3/8 3-1/8 123 56 269 122 171 4,355

J*D*800BL6 6B6462PL 80 1-1/8 2-1/8 1-3/8 3-1/8 188 85 363 165 226 3,835

J*D = JLD is Limitizer®, JDDS is Beacon II™, JLD*PP is Parallel Piped

Compressor

Model

(2 each)

HP

Standard (2 each) Parallel Piped

Liquid Suction Liquid Suction

Connections (in.)

Standard Receiver

Capacity @ 90% full

(lbs.) (2 each)

LBS KG LBS KG A

Paralell Piped

Receiver Capacity @

90% full (lbs.)

Dimensions

(inches)

Approx.

Weight

Net

(lbs.)

Dimensions (Inches)

Dual Vertical Air Discharge Condensing Unit

22

Page 23

23

Page 24

For more information on Bohn refrigeration products, contact your sales

representative or visit us at www.heatcrafrpd.com.

A Brand of Heatcraft Refrigeration Products LLC

2175 West Park Place Blvd. • Stone Mountain, GA • 30087

(800) 537-7775 • FAX (770) 465-5990

www.heatcraftrpd.com

Since product improvement is a continuing eort, we reserve the right to

make changes in specications without notice.

Loading...

Loading...