Bohn DTSX-IM-120 Installation Manual

DT S X T im e I nitia te d, T e m pe ra ture , P re s s ure or T im e Te rm ina te d 4 0 A De fr os t T im e rs

DTSX-IM-120

Defrost Timer Synchronous}Drive: 40A

Blank: Plastic NEMA 3R

IM: Indoor Metal NEMA 1

M: Mechanism Only  P: Panel Mount w/standoff

P: Panel Mount w/standoff

B: Bracket Mount

120 VAC }

240 VAC

S P E C I F I C A T I O N S |

|

|

E lectrical R atings : |

|

|

[2] & [4] Contacts |

[1] & [3] Contacts |

[1] & [F] Contacts |

30A Resistive |

40A Resistive |

30A Resistive |

@120~240VAC |

@120~240VAC |

@120~240VAC |

1HP @ 120VAC |

1HP @ 120VAC |

1HP @ 120VAC |

2HP @ 240VAC |

2HP @ 240VAC |

2HP @ 240VAC |

E nvironmental R atings : Ambient Temperature: -40F to 130F Humidity: 0-95% non-condensing

Wiring C onnections :

S crew clamp terminals for #22AWG up to #8AWG wire.

Use #8 AWG wire with 90C rating for 40A loads. Use #10 AWG wire with 90C rating for 30A loads.

E nclos ures :

Plastic NE MA 3R R aintight Indoor/Outdoor Metal NE MA 1 Indoor

L E D Indication: G reen LE D when in refrigeration mode R ed LE D when in defrost mode

A P P L I C A T I O N

The DTS X Defrost Timer is identical in function, terminal identifi- c ation, and wiring to the Paragon 8140 and Prec is ion 6140 series Defrost Timers . The DTS X may also be used to replace Paragon 8040 and Precision 6040 series time terminated defrost timers . With the addition of a remote pressure switch, the DTS X can replace the Paragon 8240 series and Precision 6240 series pressure terminated defrost timers .

Defrosts will be initiated at the times set on the timer, which will accept from 1 to over 24 defrost initiation settings per day at 15 minute intervals (8:00AM, 8:15AM, 8:30AM, etc .) Defrost duration is settable in 15 minute intervals from a minimum of 15 minutes up to several hours (15 minutes, 30 minutes, 45 minutes, 1 hour, 1 hour-15 minutes, etc .) The defrost duration determines the termination time.

In standard configuration, the contacts between terminals 1 and 3 are normally open and c los e during a defros t to energize defrost heaters; the contacts between terminals 2 and 4 are normally c los ed (when timer is energized) and open during a defrost to de-energize refrigeration and fans .

DT S X T ime Initiated, R emote T emperature, P res s ure or T ime T erminated: Is used in electric or hot gas defrost applications where the defrost is terminated when the coil is frost free, as sensed by a temperature or pressure switc h, even though the defrost programmed termination time has not been reached. The time termination functions as a fail-safe and will terminate the defrost if the temperature or pressure switch fails to do so. The temperature or pres s ure s witc h on the refrigeration c oil have contacts which close on a temperature or pressure rise to above the freezing level, indicating that frost and ice have melted from the coil. Typically a wide differential S PDT temperature switc h is used, with it's normally c losed c ontac ts wired to the fans, so that the fans are delayed from turning on after defrost termination, until the c oil temperature has dropped bac k to below freezing. In most applications, the contacts at terminals 2-4 are normally closed (when timer is energized) and control the fans and refrigeration equipment or compressor. For hot gas defrost, or for double pole switching, the 2-4 contacts may be c onfigured as normally open by moving jumper S 1 to the "B " position. R efer to wiring diagrams 1 thru 12.

ÒF Ó T erminal: The DTS X c ontains a normally c los ed c ontac t between terminals 1-F. This terminal may be used for switching the fans off during a defrost rather than the 2-4 terminals . For hot gas defrost applications, with S 1 in the "B " position, the fans may be connected to the "F" terminal.

I N S T A L L A T I O N

Note: For outdoor loc ations, R aintight, or wet loc ation c onduit hubs that comply with requirements of UL 514B (standard for fittings for conduit and outlet boxes) are to be used.

1.R emove 2 screws retaining the interior cover panel and remove panel by prying out with a thin blade (NE MA3R ).

2.S elect knockouts to be used. R emove the inner (1/2") knockout by inserting a screwdriver in the slot and carefully punch knockout loose. R emove slug. If the 3/4" knockout is required, remove the outer ring with pliers after removing the 1/2" knockout. S mooth edges with knife if necessary.

3.Place enclosure in desired mounting location and mark the three mounting holes .

4.Drill holes for #10 screws, start screws in holes .

5.Place enclosure over screws and tighten screws .

6.C onnect conduit hubs to conduit before connecting the hubs to the enclosure. After inserting hubs into enclosure, carefully tighten hub lock nut. Do not over-torque.

7.If us ing NE MA1 Metal E nclos ure connect ground wires

to ground lug on bottom of enclos ure.

(Not applicable for NE MA3R plas tic enclos ure). 8. Wire in accordance with National and Local C odes .

9. R eplace interior cover panel and 2 screws (NE MA3R ).

G rounding: NE MA 3R enclosure is of plastic construction and does not require a ground connection or bonding.

N E M A 3 R e nc lo s u r e do e s no t pr o v ide gr o u nding be t w e e n c o ndu it s . W he n u s ing no n -m e t a llic c o ndu it o r c a ble ,

c o nne c t t he gr o u nd w ir e s o f a ll c a ble s t o ge t he r w it h a w i r e n u t . W h e n m e t a l l i c c o n d u i t i s u s e d , u s e gr o u nding t y pe bu s hings a nd a ju m pe r w ir e be t w e e n e a c h c o ndu it .

C A U T I O N : Do not c he c k c irc uits by Òs pa rk ingÓ w ire s to te rm ina ls . Da m a ge to the de fros t tim e r m a y r e s u lt .

P R O G R A M M I N G (S ynchronous and Quartz E lectromechanical Models )

S etting the T ime:

Turn the minute hand clockwise until the time of day (and AM or PM) on the outer dial is aligned with the triangle marker on the inner dial.

DO N O T R O T A T E M I N U T E H A N D C O U N T E R -C L O C K W I S E S etting Defros t Initiation T ime:

Move a white tab (tripper) on the outer dial outward at each des ired initiation time. For example, to s et defros t initiation times at 6:00AM, 11:30AM, 4:30PM and 11:00PM, move the tab adjacent to the "M" in AM on the dial (6:00AM), the tab that lies between 11:30AM and 11:45 AM, the tab between 4 : 3 0 P M a nd 4 : 4 5 P M, a nd the ta b a d ja c e nt to the 11:00-11:15PM marks . (S ee note for 8243/6243 replacement.)

S etting Maximum Defros t Duration:

Different defrost durations may be set for each defrost initiation setting. Each white tab (tripper) provides a 15 minute interval. The tabs that set the initiation time provide a minimum of 15 minutes of defrost. For longer defrost duration, move additional tabs (following in time) from the initiation tab. For example, if a

45 minute defros t is to s tart at 7:00AM, |

|

|

|

|

|

|

|

||

move the tab outward that lies between |

|

|

|

|

7:00 and 7:15 on the AM side of the dial, |

|

|

|

|

and the tabs adjac ent to 7:15-7:30 and |

|

|

|

|

7:30-7:45. (3 tabs moved outward). The |

|

|

|

|

defrost will initiate at 7:00AM and time ter- |

8 |

7 |

|

|

minate at 7:45AM (if temperature termina- |

A |

|||

|

||||

|

|

|||

|

|

|

||

tion does not occur first.) |

|

|

M |

|

|

|

|

F or elec tronic models , refer to s eparate programming ins tructions .

IMP OR T ANT |

INF OR MAT ION: T he |

Normally C los ed |

contacts |

between terminals 2 |

and |

4 are only clos ed |

when the defros t |

||||||||

|

|

|

|

|

|

|

|

||||||||

timer is energized . T he 2-4 contacts |

are the Normally Open contacts |

of |

relay |

K 2. |

(Normal Open relay contacts are more |

||||||||||

reliable than |

Normally C los ed). |

When |

checking |

continuity |

of the |

control |

with no |

voltage applied, |

the 2-4 contacts will |

||||||

appear as open ; this is normal. T he |

1-3 contacts will |

appear |

as |

open and |

the |

1-F contacts will |

appears as clos ed. We |

||||||||

recommend that the control be |

tes ted |

by us ing a |

voltmeter, |

with |

rated |

voltage |

applied. |

|

|

||||||

Note: A definite purpose contactor must be used to switch loads greater than the following maximum loads:

Max. Defrost Heater Load: |

120V: 4800Watts |

Max. Fan & C ompressor Load: |

120V: 1HP |

|

208/240V: 2HP |

||

|

208V: 8320Watts |

|

|

|

Max. Fan Load on Terminal "F" |

120V: 1HP |

|

|

240V: 9600Watts |

||

|

|

|

208/240V: 2HP |

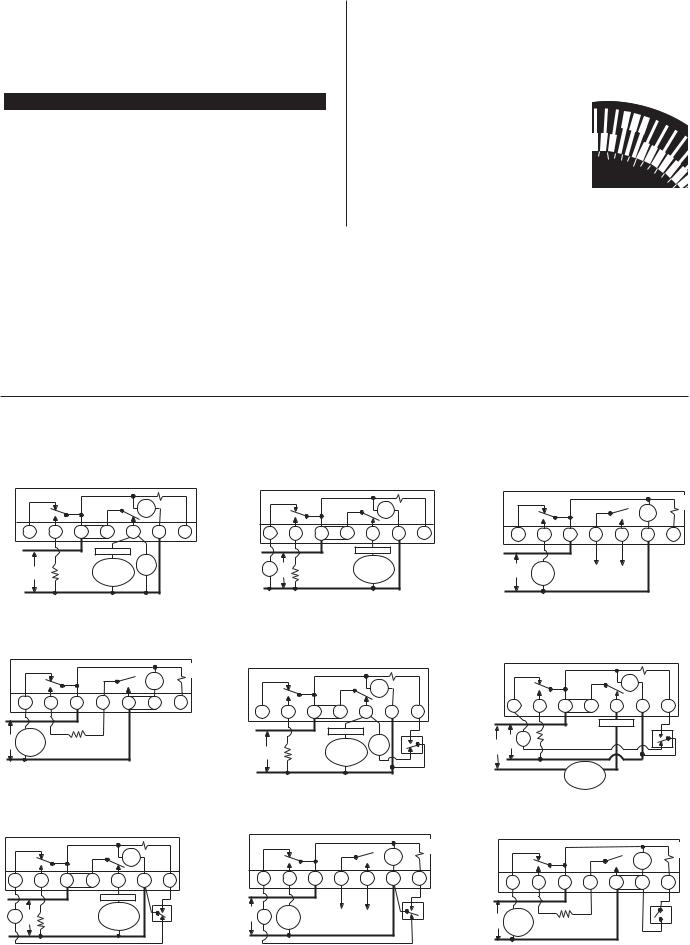

T Y P I C A L W I R I N G DI A G R A M S

All switch positions are shown in refrigeration cycle operation, and change position upon initiation of a defrost.

DT S X T ime/T ime - E lectric Defrost Wiring Diagram |

DT S X T ime/T ime - E lectric Defrost Wiring Diagram |

||

8045 R eplacement |

|||

|

8041 R eplacement |

||

1 S 1 P osition A with 8045 Label Applied |

2 |

||

S 1 P osition A with 8041 Label Applied |

|||

|

|

|

|

|

|

T IME R |

|

|

|

|

|

|

|

T IME R |

|

|

|

|

|

|

R E LE AS E |

|

|

|

|

|

|

|

|

|

|

|

|

|

T IME R |

|

|

|

|

|

|

|

R E LE AS E |

|

|

|

|

|

|

R E LAY |

|

|

|

|

|

T IME R |

|

||

|

|

|

|

|

|

|

|

|

|

|

R E LAY |

|||

F |

3 |

1-N |

2 |

4 |

X |

LABE L |

N |

|

1 |

3 |

2 |

4 |

X |

LABE L |

|

|

|

|

|

|

8045 |

|

|

|

|

|

|

|

8041 |

L1 |

|

|

T HE R MOS TAT |

|

|

|

L1 |

|

|

|

|

T HE R MOS TAT |

|

|

|

|

|

C OMP R E S S OR |

|

FAN |

|

|

|

|

|

|

C OMP R E S S OR |

|

|

|

|

|

|

MOT OR |

|

|

LINE |

|

|

|

OR |

|

|

|

LINE |

|

DE F R OS T |

OR |

|

|

FAN |

|

DE F R OS T |

|

S OLE NOID VALV E |

|

|

||

|

S OLE NOID VALV E |

|

|

|

|

|

OR |

|

|

|||||

|

|

HE AT E R |

OR |

|

|

|

|

|

|

HE AT E R |

|

C ONTAC TOR C OIL |

|

|

|

|

C ONTAC T OR C OIL |

|

|

|

|

|

|

|

|

|

|

||

L2 |

|

|

|

|

|

|

L2 |

|

|

|

|

|

|

|

DT S X T ime/T ime - E lectric Defrost Wiring Diagram 4 8047 R eplacement - Double P ole S witching

S 1 P osition B with 8047 Label Applied

|

|

|

|

|

|

|

T IME R |

|

|

|

|

|

|

|

R E LE AS E |

|

|

|

|

|

|

|

R E LAY |

|

|

|

|

|

|

T IME R |

|

|

N |

1 |

3 |

4 |

2 |

2 |

8047 |

|

LABE L |

||||||

L1 |

|

|

|

|

|

|

|

LINE |

S OLE NOID |

|

|

|

|

|

|

VALVE |

|

DE F R OS T |

|

|

|

|

|

|

OR |

|

|

|

|

|

|

|

C ONTAC T OR |

|

HE AT E R |

|

|

|

|

L2 |

NOT E : Move B ridge to 2-2 |

|

|

|

|||

|

|

|

|

||||

|

NOT E : |

|

|

|

|

|

|

DT S X Time/Temp. - E lectric Defrost Wiring Diagram 7 8141 R eplacement

S 1 P osition A with 8141 Label Applied

|

|

|

|

|

|

T IME R |

|

|

|

|

|

T IME R |

R E LE AS E |

|

|

|

|

|

R E LAY |

|

N |

|

1 |

3 |

2 |

4 |

X |

L1 |

|

|

|

|

T HE R MOS TAT |

|

|

|

|

|

|

|

|

|

|

|

|

|

C OMP R E S S OR |

|

FAN |

LINE |

|

|

|

OR |

|

|

|

|

S OLE NOID VALV E |

|

||

|

|

DE F R OS T |

|

OR |

|

|

|

|

|

C ONTAC TOR C OIL |

|

||

|

|

|

HE AT E R |

|

|

|

|

|

|

|

|

|

|

L2 |

|

|

|

|

|

|

8141 LABE L

TE R MINATION THE R MOS TAT W/FAN DE LAY

DT S X Time/Temp. - E lectric Defrost Wiring Diagram 5 8145 R eplacement

S 1 P osition A - No Label R equired

|

|

|

|

|

|

T IME R |

|

|

|

|

|

T IME R |

R E LE AS E |

|

|

|

|

|

R E LAY |

|

F |

3 |

1 |

2 |

4 |

N |

X |

L1 |

|

|

T HE R MOS TAT |

|

|

|

|

|

|

|

|

FAN |

TE R MINATION |

|

|

|

C OMP R E S S OR |

|

THE R MOS TAT |

|

LINE |

|

DE F R OS T |

OR |

|

MOT OR |

W/FAN DE LAY |

|

S OLE NOID VALV E |

|

|

|

||

|

|

HE AT E R |

OR |

|

|

|

|

|

C ONTAC T OR C OIL |

|

|

|

|

L2 |

|

|

|

|

|

|

DT S X T ime/Temp. - Hot G as Defrost Wiring Diagram 8 8143 R eplacement

S 1 P osition B with 8143 Label Applied

|

1 |

N |

3 |

4 |

2 |

L1 |

|

|

|

|

|

LINE |

|

HOT |

|

C ONNE C T AC R OS S |

|

FAN |

G AS |

|

|||

|

|

VALVE |

|

C OMP R E S S OR |

|

|

|

|

|

T HE R MOS TAT |

|

L2 |

|

|

|

|

|

T IME R

R E LE AS E

R E LAY

T IME R

X |

8143 |

LABE L |

TE R MINATION

THE R MOS TAT

W/FAN DE LAY

NOT E : R emove B ridge B etween 3-4 *S ee Note 1

DT S X T ime/T ime - Hot G as Defrost Wiring Diagram

8043 R eplacement |

|

|

|

|

||

3 S 1 P osition B with 8043 Label Applied |

|

|||||

|

|

|

|

|

|

T IME R |

|

|

|

|

|

|

R E LE AS E |

|

|

|

|

|

|

R E LAY |

|

|

|

|

|

T IME R |

|

F |

3 |

1 |

4 |

2 |

N |

8043 |

LABE L |

||||||

L1 |

|

|

|

|

|

|

LINE |

HOT |

|

C ONNE C T AC R OS S |

|

|

|

G AS |

|

|

|

|||

|

VALVE |

|

C OMP R E S S OR |

|

|

|

|

|

|

T HE R MOS TAT |

|

|

|

L2 |

|

|

|

|

|

|

|

NOT E : R emove B ridge B etween 1-4 |

|

||||

DT S X Time/Temp. - E lectric Defrost Wiring Diagram 6 120V F an & Defrost Heater; 240V C ompressor

S 1 P osition A - No Label R equired

|

|

|

|

|

|

|

T IME R |

|

|

|

|

|

120V |

|

R E LE AS E |

|

|

|

|

|

T IME R |

|

R E LAY |

|

|

|

|

|

|

|

|

|

F |

3 |

1 |

2 |

4 |

N |

X |

L1 |

|

|

|

|

T HE R MOS TAT |

|

|

|

|

|

|

|

|

|

|

|

120V |

|

DE F R OS T |

|

|

TE R MINATION |

|

|

FAN |

|

|

THE R MOS TAT |

|||

240V |

HE AT E R |

|

|

|

|||

|

|

|

|

|

|

W/FAN DE LAY |

|

|

|

|

|

|

|

|

|

L2 |

N |

|

|

|

|

|

|

|

|

|

OR |

|

|

|

|

|

|

|

|

C OMP R E S S OR |

|

|

|

|

|

|

|

S OLE NOID VALV E |

|

|

|

|

|

|

|

OR |

|

|

|

|

|

|

|

C ONTAC TOR C OIL |

|

|

|

DT S X T ime/Temp. - E lectric Defrost Wiring Diagram 9 8143 R eplacement - Double P ole S witching

S 1 P osition B with 8143 Label Applied

T IME R

R E LE AS E

R E LAY

|

|

|

|

|

|

T IME R |

|

1 |

N |

3 |

4 |

2 |

X |

L1 |

|

|

|

|

|

|

LINE |

S OLE NOID |

|

|

|

|

|

VALVE |

|

DE F R OS T |

|

|

|

|

OR |

|

|

|

|

||

C ONTAC T OR |

|

HE AT E R |

|

|

|

|

|

|

|

|

|

||

L2 |

NOT E : R emove B ridge B etween 3-4 |

|||||

|

||||||

|

NOT E : C onnect B ridge B etween 2-X |

|||||

8143 LABE L

TE R MINATION THE R MOS TAT

Loading...

Loading...