Page 1

Refrigeration

Systems

H-IM-64L September 2007 Part No. 25001201

Replaces H-IM-64L (11/05)

Installation and

Operation Manual

H-IM-64L-0907 | Version 002

Table of Contents

General Safety Information...............................................................................2

Inspection ...............................................................................................................2

Warranty Statement ............................................................................................2

Unit Cooler Placement .......................................................................................3

Unit Cooler Mounting .........................................................................................4

Defrost Thermostat ..............................................................................................5

Expansion Valves and Nozzles .....................................................................5-8

Condensate Drain Lines .....................................................................................9

Air Cooled Condensing Unit and Condenser Space and Location

Requirements ..........................................................................................10

Remote and Water Cooled Condensing Units Requirements ........... 11

Condensing Unit Rigging and Mounting ................................................. 12

Condensing Unit Accessories ................................................................13-17

Suction Filters, Driers, Sight Glasses ........................................................... 13

Demand Cooling ...............................................................................................14

Head Pressure Control .....................................................................................15

Refrigerant Oils ...................................................................................................16

Phase Loss Monitor ...........................................................................................17

Recommended Refrigerant Piping Practices ..........................................17

Refrigeration Pipe Supports ......................................................................... 17

Suction Lines ....................................................................................................... 18

Suction Line Risers ............................................................................................ 18

Liquid Lines .........................................................................................................18

Hot Gas Defrost Systems ..........................................................................19-20

Unit Cooler Piping ............................................................................................. 21

Line Sizing Charts ........................................................................................22-29

Weight of Refrigerants in Copper Lines During Operation ................30

City & Tower Water Connections ..................................................................31

Evacuation and Leak Detection ...................................................................31

Refrigerant Charging Instructions ...............................................................32

Field Wiring ..........................................................................................................32

Check Out and Start Up ..................................................................................32

Operational Check Out ....................................................................................33

System Balancing - Compressor Superheat .............................................33

Evaporator Superheat ......................................................................................34

General Sequence of Operation ..................................................................34

Electric Defrost Troubleshooting ................................................................. 35

Unit Cooler Troubleshooting Guide ...........................................................36

System Troubleshooting Guide .................................................................... 37

Preventive Maintenance Guidelines .....................................................38-39

InterLink Replacement Parts ......................................................................... 39

Typical Wiring Diagrams ...........................................................................40-45

Service Record .................................................................................................... 46

Page 2

General Safety Information

1. Installation and maintenance to be performed only by

qualied personnel who are familiar with this type of

equipment.

2. Some units are pressurized with dry air or inert gas.

All units must be evacuated before charging the system

with refrigerant.

WARNING: Refrigerant can be harmful if it is inhaled. Refrigerant must be used and recovered responsibly.

Failure to follow this warning may result in personal injury or death.

Inspection

Responsibility should be assigned to a dependable individual at the

job site to receive material. Each shipment should be carefully checked

against the bill of lading. The shipping receipt should not be signed

until all items listed on the bill of lading have been accounted. Check

carefully for concealed damage. Any shortage or damages should be

reported to the delivering carrier. Damaged material becomes the

delivering carrier’s responsibility, and should not be returned to the

manufacturer unless prior approval is given to do so. When uncrating,

care should be taken to prevent damage. Heavy equipment should be

left on its shipping base until it has been moved to the nal location.

Check the serial tag information with invoice. Report any discrepancies

to your Heatcraft Refrigeration Products Sales Representative.

3. Make sure that all eld wiring conforms to the requirements

of the equipment and all applicable national and local codes.

4. Avoid contact with sharp edges and coil surfaces.

They are a potential injury hazard.

5. Make sure all power sources are disconnected before any

service work is done on units.

area available through the distributor; the second through fth years,

the purchaser must submit a proof-of-purchase of a compressor and

supply it to Heatcraft Refrigeration Products Warranty Claims for

reimbursement.

Seller makes no express warranties except as noted above. All implied

warranties are limited to the duration of the Express Warranty. Liability

for incidental and consequential damages is excluded.

The forgoing is in lieu of all other warranties, express or implied,

notwithstanding the provisions of the uniform commercial code, the

Magnuson-Moss Warranty - Federal Trade Commission Improvement

Act, or any other statutory or common law, federal or state.

Warranty Statement

Seller warrants to its direct purchasers that products, including Service

Parts, manufactured by SELLER shall be of a merchantable quality, free

of defects in material or workmanship, under normal use and service

for a period of one (1) year from date of original installation, or

eighteen (18) months from date of shipmen

first occurs. Any product covered by this order found to Seller’s

satisfaction to be defective upon examination at Seller’s factory will

at SELLER’s option, be repaired or replaced and returned to Buyer

via lowest common carrier, or SELLER may at its option grant Buyer

a credit for the purchase price of the defective article. Upon return

of a defective product to SELLER’s plant, freight prepaid, by Buyer,

correction of such defect by repair or replacement, and return freight

via lowest common carrier, shall constitute full performance by SELLER

of its obligations hereunder.

SELLER shall have no liability for expenses incurred for repairs made by

Buyer except by prior, written authorization. Every claim on account

of breach of warranty shall be made to SELLER in writing within the

warranty period specied above – otherwise such claim shall be

deemed waived. Seller shall have no warranty obligation whatsoever if

its products have been subjected to alteration, misuse, negligence, free

chemicals in system, corrosive atmosphere, accident, or if operation

is contrary to SELLER’s or manufacturer’s recommendations, or if the

serial number has been altered, defaced, or removed.

MOTOR COMPRESSORS:

Motor compressors furnished by SELLER are subject to the standard

warranty terms set forth above, except that motor compressor

replacements or exchanges shall be made through the nearest

authorized wholesaler of the motor compressor manufacturer (not at

SELLER’s factory) and no freight shall be allowed for transportation of

the motor compressor to and from the wholesaler. The replacement

motor compressor shall be identical to the model of the motor

compressor being replaced. Additional charges which may be incurred

throughout the substitution of other than identical replacements

are not covered by this warranty. An optional, non assignable, four

(4) year extended compressor warranty may be purchased within

the boundaries of the United Sates of America, its territories and

possessions, and Canada. With this extended compressor warranty,

replacements are administered by an authorized compressor

distributor only. Replacements within the rst year of the warranty

2

t by SELLER, whichever

SELLER makes no warranty, express or implied, of fitness for any

particular purpose, or of any nature whatsoever, with respect

to products manufactures or sold by seller hereunder, except as

specically set forth above and on the face hereof. It is expressly

understood and agreed that SELLER shall not be liable to buyer,

or any customer of buyer, for direct or indirect, special, incidental,

consequential or penal damages, or for any expenses incurred by

reason of the use or misuse by buyer or third parties of said products.

To the extent said products may be considered "consumer products,"

As dened in Sec. 101 of the Magnuson-Moss Warranty - Federal Trade

Commission Improvement Act, SELLER makes no warranty of any kind,

express or implied, to "consumers," except as specically set forth above

and on the face hereof.

The following conditions should be adhered to when installing this

unit to maintain the manufacturers warranty:

(a) System piping must be in accordance with good

refrigeration practices.

(b) Inert gas must be charged into the piping during

brazing.

(c) The power supply to the unit must meet the

following conditions:

A. Three phase voltages must be +/ 10% of nameplate ratings. Single

phase must be within +10% or

-5% of nameplate ratings.

B. Phase imbalance cannot exceed 2%.

(d) All control and safety switch circuits must be

properly connected according to the wiring diagram.

(e) The factory installed wiring must not be changed

without written factory approval.

(f) All equipment is installed in accordance with

Heatcraft Refrigeration Products specied minimum

clearances.

© 2007, Heatcraft Refrigeration Products LLC

Page 3

Unit Coolers

Recommended Unit Cooler Placement

Some general rules for evaporator placement which must be

followed are:

1. The air pattern must cover the entire room.

2.

NEVER locate evaporators over doors.

3. Location of aisles, racks, etc. must be known.

4. Location relative to compressors for minimum

pipe runs.

5. Location of condensate drains for minimum run.

The size and shape of the storage will generally determine the

type and number of evaporators to be used and their location. The

following are some typical examples:

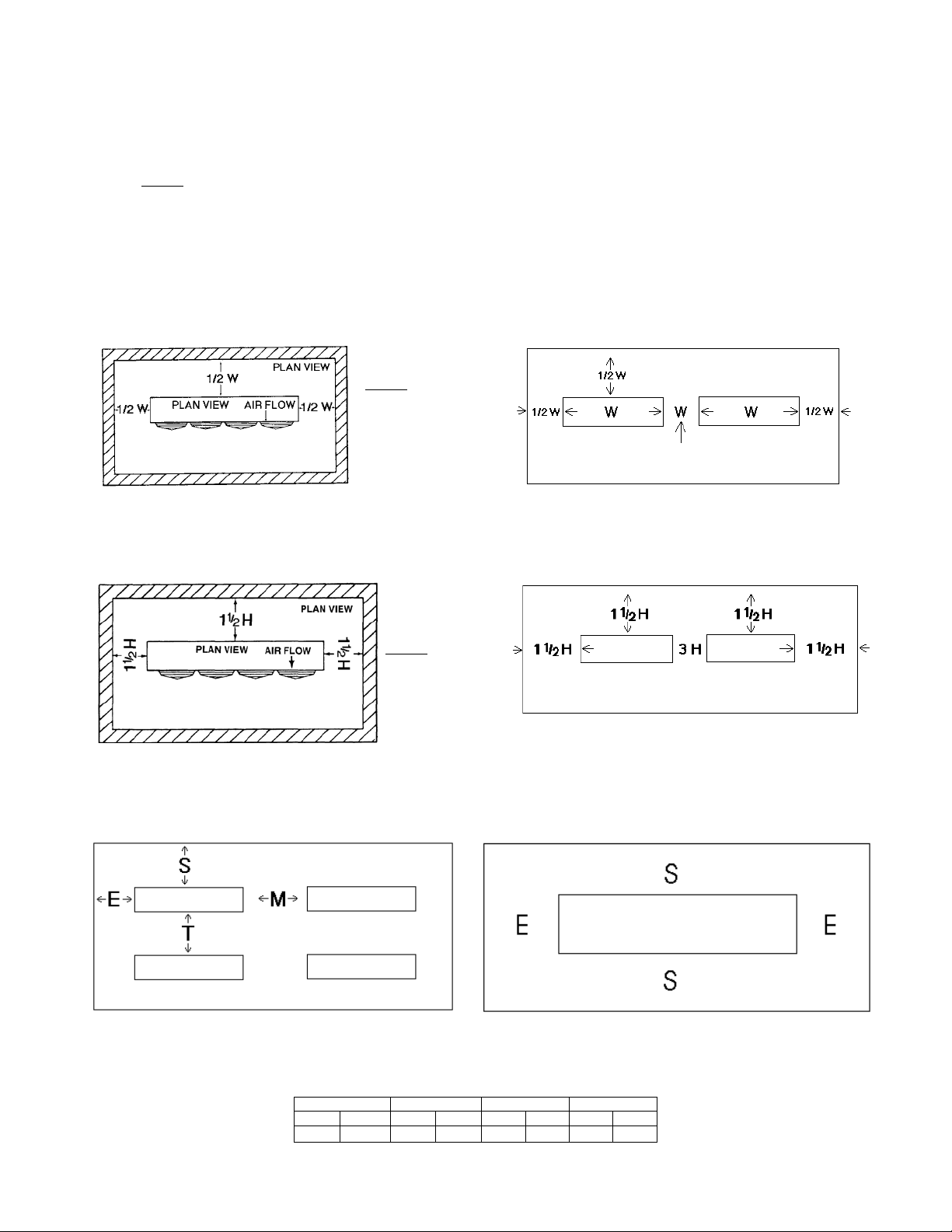

Minimum Unit Clearances

Figure 1. Medium Prole and Large Unit Coolers

NOTE:

W = Total width

of evaporator

coil surface.

One evaporator

Figure 2. Low Prole Unit Coolers

NOTE:

H = Total height

evaporator

coil surface.

NOTE: Leave space equal to unit height between bottom of unit and

product. Do not stack product in front of fans.

Two evaporators

One evaporator

Figure 3. Center Mount Unit Coolers

Recommended Maximum - Minimum Dimensions for

E S M T

Max. Min. Max. Min. Max. Min. Max. Min.

25' 2' 20' 3' 40' 3' 40' 6'

Two evaporators

Center Mount Unit Cooler Installations.

3

Page 4

Unit Cooler Mounting

Most evaporators can be mounted with rod hangers, lag screws, or

bolts. Use 5/16" bolt and washers or rod for up to 250 pounds, 3/8" for

up to 600 pounds and 5/8" for over 600 pounds. Care should be taken

to mount the units level so that condensate drains properly. Note that

some unit cooler designs achieve drain pan slope by using dierent

height mounting brackets. In this situation, the top of the mounting

brackets should be level. Adequate support must be provided to hold

the weight of the unit.

When using rod hangers, allow adequate space between the top of

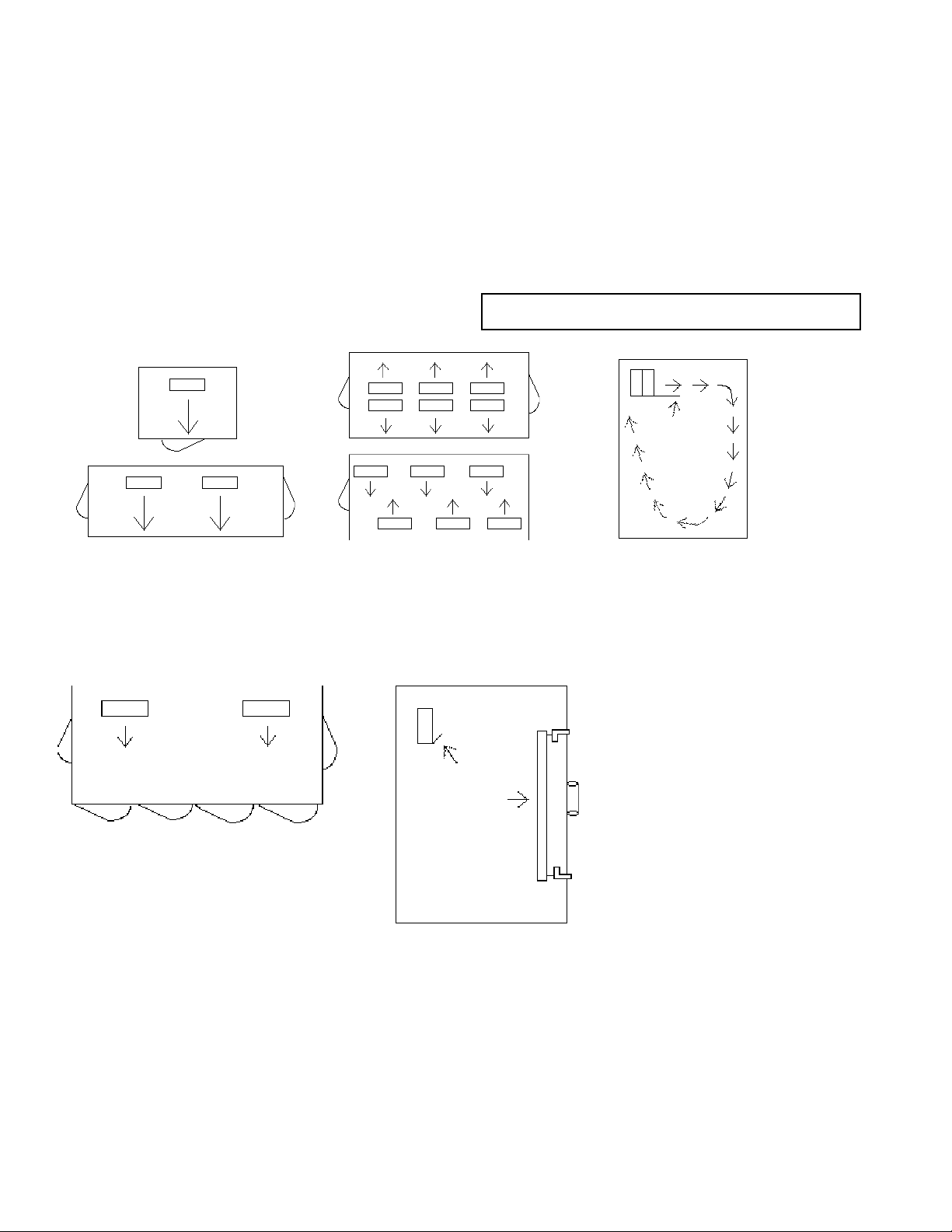

Figure 4. Large Coolers and Freezers Placement.

the unit and the ceiling for cleaning. To comply with NSF Standard 7,

the area above the unit cooler must be sealed or exposed in such a way

to facilitate hand cleaning without the use of tools. When lagging or

bolting the unit ush to the ceiling, seal the joint between the top and

the ceiling with an NSF listed sealant and ends of open hanger channels

must be sealed to prevent accumulation of foreign matter.

When locating unit coolers in a cooler or freezer, refer to Figures 1

through 4 for guidelines.

NOTE: Always avoid placement of Unit Coolers

directly above doors and door openings.

Baed Unit

Whe re o ne wa ll e vap orato r

mounting is satisfactory.

Cooler or Freezer with Glass

Display Doors

Cooler or Freezers where one wall

will not accommodate all required

evaporators or where air throw

distance must be considered.

Bae

Glass

Display

Door

Allow sucient space between

rear of Unit Cooler and wall to

permit free return of air. Refer to

Figures 1 through 3 for proper

space.

Elevation view of glass display door

cooler or freezer. Be sure air discharge

blows above, not directly at doors.

Provide bae if door extends above

blower level.

Defrost

Many types of control arrangements can be used. In some applications,

it may not be necessary to have scheduled defrost periods. The normal

“o cycle” of the compressor may be adequate to keep the evaporator

coil clear of frost. In other applications, a defrost timer may be necessary

to help assure a clear coil. In a medium temperature environment, “air

defrost” is initiated by the timer, but the evaporator fans continue to

operate to facilitate the melting of frost on the n surface. Other types

of defrost schemes require that the fans on the evaporator shut o

4

during the defrost period.

For most applications, two to four defrost cycles per day should be

adequate. The defrost requirements will vary on each installation so

the defrost settings should be determined by observing the system

operation.

Page 5

Defrost Thermostat

Adjustable (F25-209 Series)

The defrost duration is determined by the setting of the defrost

termination thermostat. Initially, the thermostat should be set at midrange. This will terminate the defrost at about a 60°F bulb temperature

which will be satisfactory for most applications. A somewhat longer or

shorter defrost can be obtained by adjusting the control clockwise for a

shorter defrost and counterclockwise for a longer defrost. The fan delay

temperature setting of the thermostat is factory set at 25°F. It can be

adjusted upward by turning the adjusting screw next to the duration

adjustment with a small screwdriver. Each complete clockwise rotation

of this screw raises the setting approximately 3°F. This screw should not

be adjusted more than four turns. Making this adjustment also raises

the defrost termination temperature setting of the thermostat by a

similar amount. For example, with the duration setting at mid-range,

the termination temperature would be approximately 60°F. Turning

the adjusting screw one turn would raise the fan delay temperature to

about 28°F as well as changing the termination temperature from 60°F to

63°F. On medium temperature applications it may be necessary to raise

the setting to assure that the thermostat will reset after a defrost.

Adjustable (060-100-00 Series)

This control has an adjustable defrost termination setpoint and an

adjustable dierential for controlling the fan delay. A typical termination

setting is 60°F with a 25°F dierential. Termination setting may be

adjusted to increase/decrease the length of defrost. The dierential

should be adjusted to turn on the fans at 30 to 35°F (Fan Temperature

= Termination Temperature – Dierential). Actual coil temperature will

be 5 to 10°F below this value. Some unit coolers are preset and labeled

at the factory with special settings.

Note: Defrost controls are positioned as determined

by engineering test. Job conditions may require

the sensing device to be relocated for optimal

defrosting.

Bimetal Disc

A bimetal disc type thermostat is wired to the control circuit to terminate

the defrost cycle when the coil temperature reaches approximately 55°F.

The bimetal disc thermostat provides a fan delay to allow moisture on

the coil to freeze after defrost termination.

Note: On systems where the suction temperature is

above approximately 25°F, the fans may not

start for an extended period of time.

On freezer applications, it may be necessary to apply a jumper to the

fan delay on a warm box. This can be corrected by jumping the fan

switch contacts. This will allow the fans to start immediately after

defrost termination. This will disable the fan delay.

If moisture blow-o is encountered without the fan delay, a higher

temperature defrost thermostat can be ordered. This thermostat

terminates defrost at 60°F and prevents the fans from running when

the coil temperature is above 40°F. Refer to the replacement parts list

for the correct number to order.

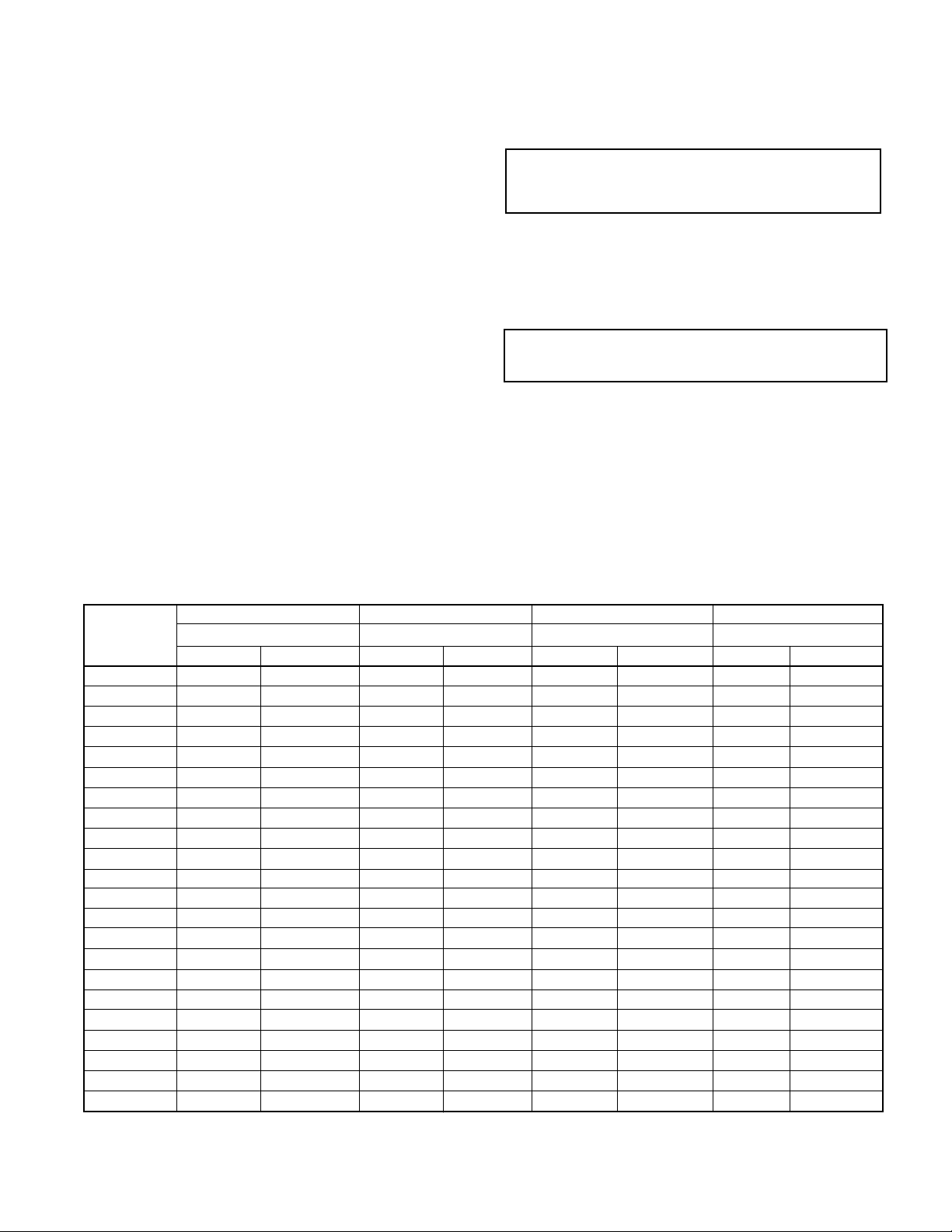

Table 1. Expansion Valve Selection For 100# Head Pressure Valve

BTUH R-507/R404A R-507/R404A R-22 R-22

at about -20

10° T.D. Sporlan ALCO Sporlan ALCO Sporlan ALCO Sporlan ALCO

3,000-5,000 EGSE 1/2 ZP HFESC-1/2-RZ EGSE 1/2 C HFESC-1/2-RC EGVE 1/2 Z HFESC-1-HZ EGVE 1/2 C HFESC-1/2-HC

5,500-7000 EGSE 1/2 ZP HFESC-1/2-RZ EGSE 1 C HFESC-1/2-RC EGVE 1 ZP HFESC-1-HZ EGVE 1 C HFESC-1-HC

7500-8000 EGSE 1 ZP HFESC-1/2-RZ EGSE 1 C HFESC-1-RC EGVE 1 ZP HFESC-1 1/2-HZ EGVE 1 C HFESC-1-HC

8500-10,000 EGSE 1 ZP HFESC-1-RZ EGSE 11/2 C HFESC-1 1/4-RC EGVE 11/2 ZP HFESC-1 1/2-HZ EGVE 1 C HFESC-1-HC

10,500-11,000 EGSE 1 ZP HFESC-1 1/4-RZ EGSE 11/2 C HFESC-1 1/4-RC EGVE 11/2 ZP HFESC-2-HZ EGVE 11/2 C HFESC-1-HC

11,500-13,000 EGSE 11/2 ZP HFESC-1 1/2-RZ EGSE 11/2 C HFESC-1 1/4-RC EGVE 11/2 ZP HFESC-2-HZ EGVE 11/2 C HFESC-1-HC

13,500-15,000 EGSE 11/2 ZP HFESC-2-RZ EGSE 2 C HFESC-1 1/2-RC EGVE 2 ZP HFESC-2 1/2-HZ EGVE 11/2 C HFESC-2-HC

15,500-17,000 EGSE 2 ZP HFESC-2-RZ EGSE 2 C HFESC-2-RC EGVE 2 ZP HFESC-2 1/2-HZ EGVE 2 C HFESC-2-HC

17,500-20,000 EGSE 2 ZP HFESC-3 1/2-RZ SSE 3 C HFESC-2-RC EGVE 3 ZP HFESC-3-HZ EGVE 2 C HFESC-2 1/2-HC

20,500-24,000 SSE 3 ZP HFESC-3 1/2-RZ SSE 3 C HFESC-3-RC SVE 3 ZP HFESC-3-HZ SVE 3 C HFESC-3-HC

24,500-28,000 SSE 3 ZP HFESC-3 1/2-RZ SSE 4 C HFESC-3-RC SVE 4 ZP HFESC-5 1/2-HZ SVE 3 C HFESC-3-HC

28,500-34,000 SSE 4 ZP HFESC-5-RZ SSE 4 C HFESC-3-RC SVE 5 ZP HFESC-5 1/2-HZ SVE 4 C HFESC-5 1/2-HC

34,500-40,000 OSE 6 ZP HFESC-5-RZ SSE 6 C HFESC-5-RC SVE 8 ZP HFESC-5 1/2-HZ SVE 4 C HFESC-5 1/2-HC

40,500-50,000 OSE 8 ZP HFESC-7-RZ OSE 8 C HFESC-5-RC SVE 10 ZP HFESC-8-HZ SVE 5 C HFESC-5 1/2-HC

50,500-60,000 OSE 9 ZP HFESC-10-RZ OSE 9 C HFESC-7-RC SVE 10 ZP HFESC-8-HZ SVE 8 C HFESC-8-HC

60,500-70,000 OSE 9 ZP HFESC-10-RZ OSE 9 C HFESC-10-RC OVE 15 ZP HFESC-10-HZ SVE 8 C HFESC-8-HC

70,500-80,000 OSE 12 ZP HFESC-10-RZ OSE 12 C HFESC-10-RC OVE 15 ZP HFESC-15-HZ SVE 10 C HFESC-10-HC

80,500-90,000 OSE 12 ZP HFESC-13-RZ OSE 12 C HFESC-10-RC OVE 15 ZP HFESC-15-HZ SVE 10 C HFESC-10-HC

90,500-100,000 OSE 12 ZP HFESC-13-RZ OSE 12 C HFESC-13-RC OVE 15 ZP HFESC-15-HZ OVE 15 C HFESC-15-HC

100,500-110,000 OSE 21 ZP TRAE-20-RZ OSE 21 C HFESC-13-RC OVE 20 ZP HFESC-20-HZ OVE 15 C HFESC-15-HC

110,500-120,000 OSE 21 ZP TRAE-20-RZ OSE 21 C HFESC-13-RC OVE 20 ZP HFESC-20-HZ OVE 15 C HFESC-15-HC

120,500-130,000 OSE 21 ZP TRAE-20-RZ OSE 21 C TRAE-20-RC OVE 20 ZP HFESC-20-HZ OVE 15 C HFESC-15-HC

NOTES:

1. Valve selections assume standard conditions and 100°F vapor-free liquid.

2. Equivalent valve may be used in place of selection.

3. For "Medium Temp R-507," valve designation will use “P” for refrigerant code.

˚F/-29˚C Evap. +25˚F/-4˚C Evap. -20˚F/-29˚C Evap. +25˚F/-4˚C Evap.

5

Page 6

Table 2. Expansion Valve Selection 180# Head Pressure Valve

BTUH R-507/R404A R-507/R404A R-22 R-22

at about -20

10˚ T.D. Sporlan ALCO Sporlan ALCO Sporlan ALCO Sporlan ALCO

3,000-5,000 EGSE 1/2 ZP HFESC-1/2-RZ EGSE 1/2 C HFESC-1/2-RC EGVE 1/2 ZP HFESC-1/2-HZ EGVE 1/2 C HFESC-1/2-HC

5,500-7000 EGSE 1/2 ZP HFESC-1-RZ EGSE 1 C HFESC-1/2-RC EGVE 1 ZP HFESC-1-HZ EGVE 1/2 C HFESC-1-HC

7500-8000 EGSE 1 ZP HFESC-1-RZ EGSE 1 C HFESC-1/2-RC EGVE 1 ZP HFESC-1-HZ EGVE 1 C HFESC-1-HC

8500-10,000 EGSE 1 ZP HFESC-1-RZ EGSE 1 C HFESC-1-RC EGVE11/2 ZP HFESC-1 1/2-HZ EGVE 1 C HFESC-1-HC

10,500-11,000 EGSE 1 ZP HFESC-1 1/4-RZ EGSE 11/2 C HFESC-1-RC EGVE 11/2 ZP HFESC-1 1/2-HZ EGVE 1 C HFESC-1-HC

11,500-13,000 EGSE 1 1/2 ZP HFESC-1 1/4-RZ EGSE 11/2 C HFESC-1 1/4-RC EGVE 11/2 ZP HFESC-2-HZ EGVE 1 C HFESC-1 1/2-HC

13,500-15,000 EGSE 2 ZP HFESC-1 1/2-RZ EGSE 11/2 C HFESC-1 1/4-RC EGVE 2 ZP HFESC-2-HZ EGVE 11/2 C HFESC-1 1/2-HC

15,500-17,000 EGSE 2 ZP HFESC-2-RZ EGSE 2 C HFESC-1 1/2-RC EGVE 2 ZP HFESC-2 1/2-HZ EGVE 11/2 C HFESC-1 1/2-HC

17,500-20,000 EGSE 2 ZP HFESC-2-RZ EGSE 2 C HFESC-1 1/2-RC EGVE 3 ZP HFESC-2 1/2-HZ EGVE 11/2 C HFESC-2-HC

20,500-24,000 SSE 3 ZP HFESC-3-RZ SSE 3 C HFESC-2-RC SVE 3 ZP HFESC-3-HZ SVE 2 C HFESC-2-HC

24,500-28,000 SSE 4 ZP HFESC-3-RZ SSE 3 C HFESC-2-RC SVE 4 ZP HFESC-3-HZ SVE 3 C HFESC-2 1/2-HC

28,500-34,000 SSE 4 ZP HFESC-5-RZ SSE 4 C HFESC-3 1/2-RC SVE 4 ZP HFESC-5 1/2-HZ SVE 3 C HFESC-3-HC

34,500-40,000 SSE 6 ZP HFESC-5-RZ SSE 6 C HFESC-3 1/2-RC SVE 5 ZP HFESC-5 1/2-HZ SVE 3 C HFESC-3-HC

40,500-50,000 OSE 9 ZP HFESC-7-RZ SSE 6 C HFESC-3 1/2-RC SVE 8 ZP HFESC-5 1/2-HZ SVE 4 C HFESC-5 1/2-HC

50,500-60,000 OSE 9 ZP HFESC-7-RZ OSE 9 C HFESC-5-RC SVE 10 ZP HFESC-8-HZ SVE 5 C HFESC-5 1/2-HC

60,500-70,000 OSE 9 ZP HFESC-10-RZ OSE 9 C HFESC-7-RC OVE 15 ZP HFESC-8-HZ SVE 5 C HFESC-5 1/2-HC

70,500-80,000 OSE 12 ZP HFESC-10-RZ OSE 12 C HFESC-7-RC OVE 15 ZP HFESC-10-HZ SVE 8 C HFESC-8-HC

80,500-90,000 OSE 12 ZP HFESC-10-RZ OSE 12 C HFESC-10-RC OVE 15 ZP HFESC-10-HZ SVE 8 C HFESC-8-HC

90,500-100,000 OSE 12 ZP HFESC-13-RZ OSE 12 C HFESC-10-RC OVE 15 ZP HFESC-15-HZ SVE 10 C HFESC-8-HC

100,500-110,000 OSE 12 ZP HFESC-13-RZ OSE 12 C HFESC-10-RC OVE 20 ZP HFESC-15-HZ SVE 10 C HFESC-10-HC

110,500-120,000 OSE 12 ZP HFESC-13-RZ OSE 12 C HFESC-10-RC OVE 20 ZP HFESC-15-HZ SVE 10 C HFESC-10-HC

120,500-130,000 OSE 21 ZP HFESC-13-RZ OSE 12 C HFESC-13-RC OVE 20 ZP HFESC-15-HZ OVE 15 C HFESC-10-HC

˚F/-29˚C Evap. +25˚F/-4˚C Evap. -20˚F/-29˚C Evap. +25˚F/-4˚C Evap.

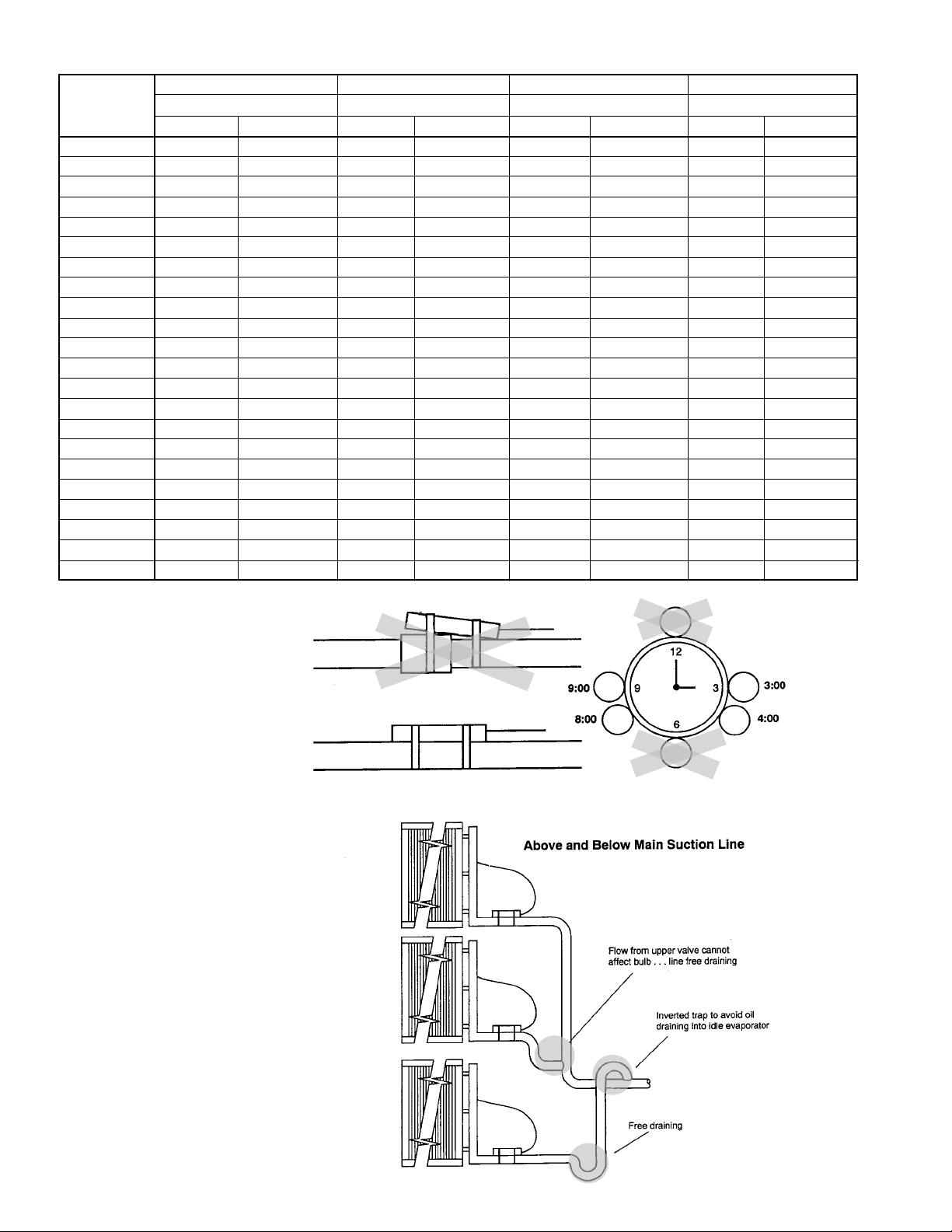

Figure 5. Bulb and Contact Location

Figure 6. Multiple Evaporators

6

Page 7

Distributor Nozzles

Nozzles supplied with unit coolers are selected for numerous

refrigerants at cataloged operating conditions and 95˚F liquid entering

the expansion valve. If mechanical or another method of subcooling

is used, the nozzle and expansion valve selection should be checked.

For conditions outside those cataloged, use the charts to select a

proper nozzle. Nozzle capacity should be within 135% to 180% of

unit operating condition for optimum coil performance. Nozzles are

available from Sporlan Wholesalers or from Heatcraft Refrigeration

Products. A small nozzle can be drilled larger using the I.D. column in

table 3, page 8. The hole must be accurately centered in the nozzle. A

lathe is preferred for accurate drilling.

may occur and poor evaporator operation may be experienced.

For peak performance, it is important to select an expansion valve with

the correct capacity and selective charge. Thermostatic expansion

valves may be mounted in any position, but they should be installed

as close to the evaporator as possible. For best performance, the outlet

of the expansion valve should be installed directly to the distributor

body. If this is not possible, the distance between the valve outlet and

distributor should not exceed 24 inches. Elbows located between the

expansion valve and distributor will hinder proper distribution and

therefore, are not recommended. Some accessories may, however,

necessitate the use of elbows.

Expansion Valves and Distributor Nozzles

Before installing the expansion valve on the distributor of the

evaporator, the proper distributor nozzle must be installed. Two

nozzles are normally shipped with each evaporator for dierent

refrigerants. Select the nozzle for the refrigerant that will be used.

The size of the nozzles shipped with each evaporator is based on

ordinary conditions, usually 95˚F liquid temperature and a maximum

of 15˚F evaporator TD*. If a mechanical subcooler is to be used in

your system, consult the factory or a representative for distributor

nozzle sizing. This is very important as the nominal capacity of the

nozzle increases as the liquid refrigerant temperature is lowered.

If the correct size nozzle is not installed, poor refrigerant distribution

*Temperature Dierence

(design room temperature minus saturated suction temperature)

Selecting Distributor Nozzle at the Job Site

You must know 4 things:

1. Refrigerant

2. Evaporating Temperature

3. Tons or BTUH

4. Highest Liquid Temperature

Locate the expansion valve bulb on a horizontal length of suction

line as close to the suction header as possible. The bulb should be

clamped tightly on the suction line and insulated with a waterproof

type of insulation. The bulb should never be placed on a coupling or

other obstruction so as to not make 100 % contact with the suction line.

The bulb should never be placed in a trap or downstream of a trap in

a suction line. Locating the bulb on the bottom of a suction line is not

recommended. The bulb should be installed at the 3, 4 or 8, 9 o’clock

position on the suction line. See Figure 5 on page 6.

EXAMPLE: Select a nozzle for R404A, -20˚F suction; 9,400

BTUH, 60˚F liquid entering TXV.

9,400

12,000

= .78 Tons

[1.83 Factor

for 60˚F Liquid]

EXAMPLE: Select a nozzle for R22, 20˚F suction; 67,000

BTUH, 100˚F liquid entering TXV.

67,000

12,000

From Table 3 on page 8 select Size 4 rated at 3.84 tons. We prefer

selecting at 135% - 180% of nominal rating. This is typically two sizes

smaller than the closest tonnage in Table 3.

5.58

3.84

= 5.58 Tons

= 145% of Nominal Rating - okay.

0.78

1.83

From Table 3 on page 8 select Size 3/4 rated at 0.29 tons.

0.42

0.29

Typical selections would be between 135% and 180%.

= .42 Corrected Tons

= 145% of Nominal Rating - okay.

7

Page 8

Worksheet:

Given Values

Refrigerant ____________________________

Suction Temperature ___________________˚F

BTUH _______________________________

Liquid Temperature _____________________˚F

Calculations: _____ BTUH ÷ 12,000 = _____ Tons

Liquid Correction Factor:

_____________˚F liquid = _____________ Factor

_____ Tons ÷ _____ Factor = ____Corrected Tons

Nozzle Selections (Table 3)

______ Tons ÷ _______ Nozzle Capacity = ______%

(if within 135% to 180%, it is acceptable)

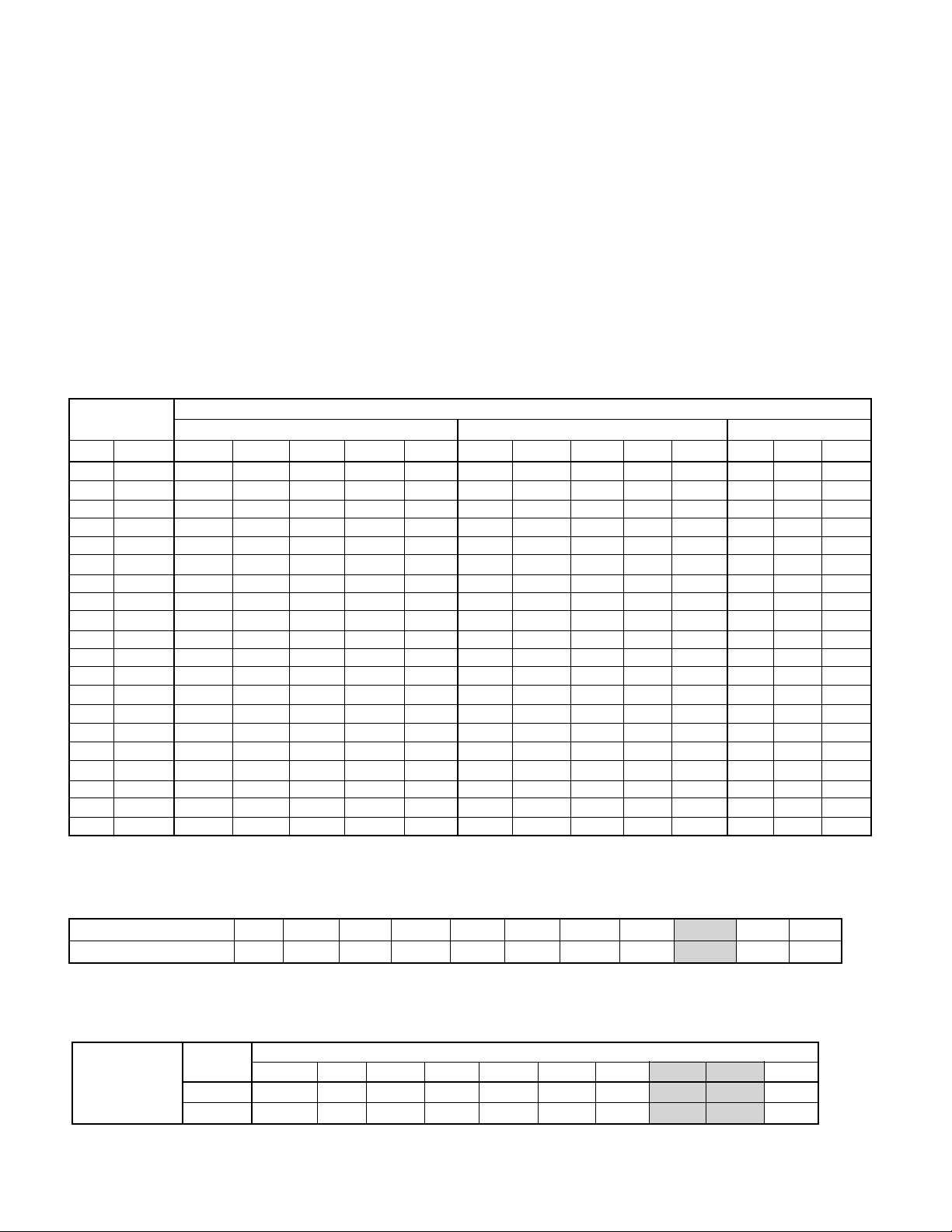

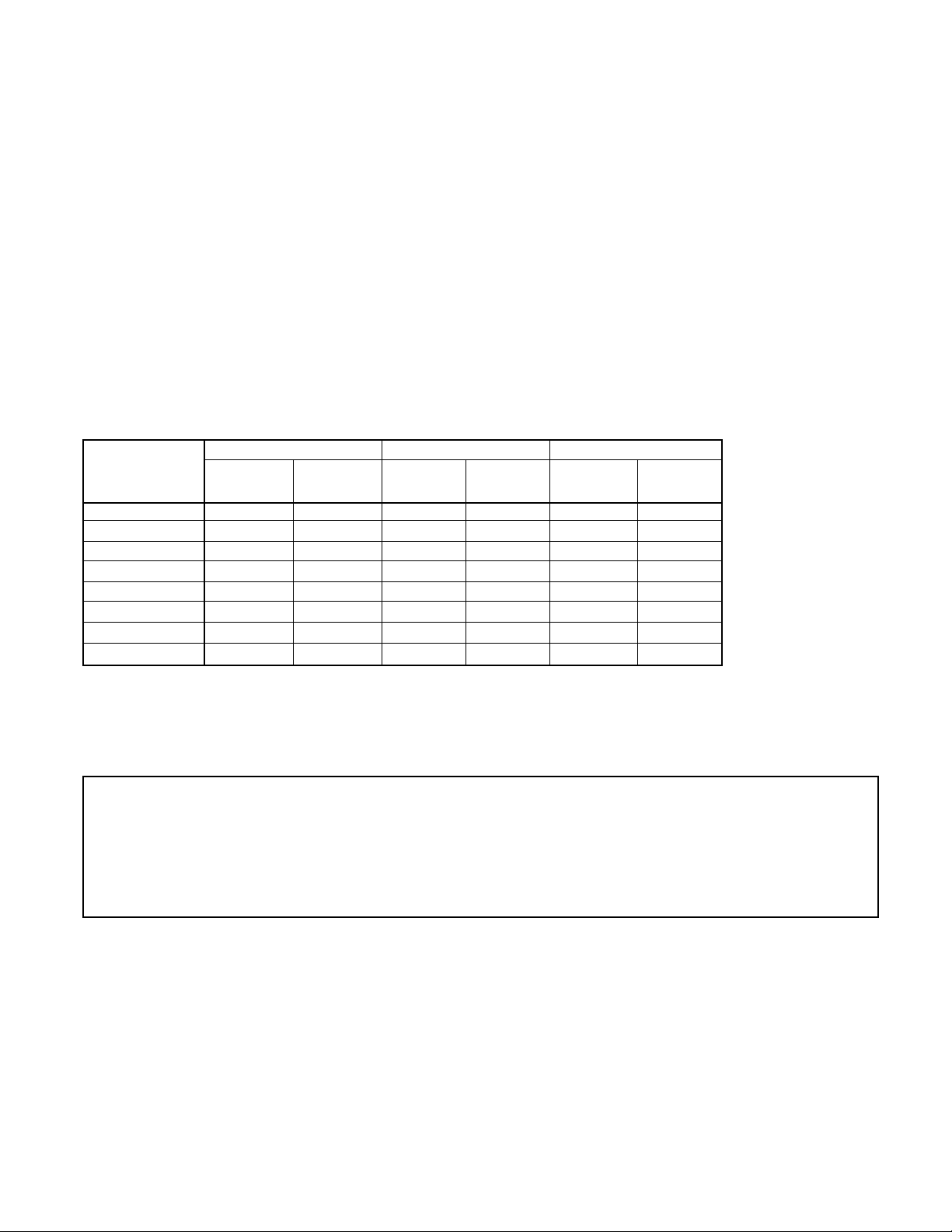

Table 3. Distributor Nozzle Capacities in Tons of Refrigeration

Nozzle Evaporator (Saturated Suction) Temperature °F

Orice R22

No. I.D. (in.) 40° 20° 0° -20° -40° 40° 20° 0° -20° -40° 40° 20° 0°

1/4 0.052 0.34 0.26 0.21 0.18 0.15 0.23 0.17 0.13 0.11 0.09 0.20 0.15 0.12

1/3 0.060 0.44 0.34 0.28 0.23 0.20 0.30 0.23 0.18 0.14 0.11 0.26 0.20 0.15

1/2 0.070 0.61 0.48 0.38 0.32 0.27 0.41 0.31 0.24 0.19 0.16 0.36 0.27 0.21

3/4 0.086 0.92 0.72 0.58 0.48 0.41 0.62 0.47 0.37 0.29 0.24 0.54 0.41 0.32

1 0.100 1.23 0.96 0.78 0.64 0.55 0.83 0.63 0.49 0.39 0.32 0.72 0.54 0.43

1-1/2 0.120 1.79 1.40 1.13 0.94 0.80 1.20 0.92 0.71 0.57 0.46 1.05 0.79 0.63

2 0.141 2.46 1.92 1.55 1.29 1.10 1.65 1.26 0.98 0.78 0.64 1.44 1.09 0.86

2-1/2 0.157 3.07 2.39 1.93 1.60 1.37 2.06 1.57 1.22 0.97 0.79 1.79 1.35 1.07

3 0.172 3.68 2.87 2.32 1.93 1.65 2.47 1.88 1.47 1.17 0.95 2.15 1.63 1.28

4 0.199 4.92 3.84 3.10 2.58 2.20 3.31 2.52 1.96 1.56 1.27 2.88 2.18 1.72

5 0.221 6.07 4.74 3.83 3.18 2.72 4.08 3.11 2.42 1.93 1.57 3.55 2.68 2.12

6 0.242 7.28 5.68 4.59 3.81 3.26 4.89 3.72 2.91 2.31 1.88 4.26 3.22 2.54

8 0.266 8.77 6.84 5.52 4.59 3.93 5.89 4.49 3.50 2.79 2.27 5.13 3.88 3.06

10 0.281 9.83 7.67 6.19 5.15 4.40 6.60 5.03 3.92 3.12 2.54 5.75 4.35 3.43

12 0.313 12.10 9.47 7.65 6.36 5.43 8.16 6.21 4.84 3.86 3.14 7.10 5.37 4.24

15 0.348 15.10 11.70 9.48 7.88 6.74 10.10 7.70 6.01 4.78 3.89 8.81 6.65 5.25

17 0.368 16.80 13.10 10.60 8.81 7.54 11.30 8.61 6.72 5.35 4.35 9.85 7.44 5.87

20 0.404 20.30 15.80 12.80 10.60 9.08 13.60 10.40 8.10 6.45 5.24 11.90 8.97 7.08

25 0.453 25.50 19.90 16.10 13.40 11.40 17.10 13.10 10.20 8.11 6.60 14.90 11.30 8.91

30 0.484 29.20 22.80 18.40 15.30 13.10 19.60 14.90 11.60 9.27 7.54 17.10 12.90 10.20

R404A, R507, R402A R134a, R401A

Note: Based on 100°F liquid entering expansion valve.

(1 ton = 12,000 BTU/H)

Table 4. Liquid Temperature Correction Factor

Liquid Temperature

Correction Factor 3.02 2.55 2.10 1.83 1.59 1.37 1.17

NOTE: Tons X Correction Factor = Nozzle Capacity Nozzle Capacity (Tons) X 12,000 = BTUH Rating

˚F 30˚ 40˚ 50˚ 60˚ 70˚ 80˚ 90˚ 95˚ 100˚ 110˚ 120˚

1.06 1.00 0.85 0.72

Table 5. Pressure Drop vs. Nozzle Loading

Actual Load at a Percent of Above Rating

Group 80% 90% 100% 110% 120% 130% 140% 150% 160% 170%

Nozzle PSI *M 10 12 15 18 20 22 24 27 29 31

Drop

* M Group = R12, MP39, R134a.

†

H 16 20 25 30 35 38 40 43 46 49

†

H Group = R22, R404A, R502, R507, HP80.

8

Page 9

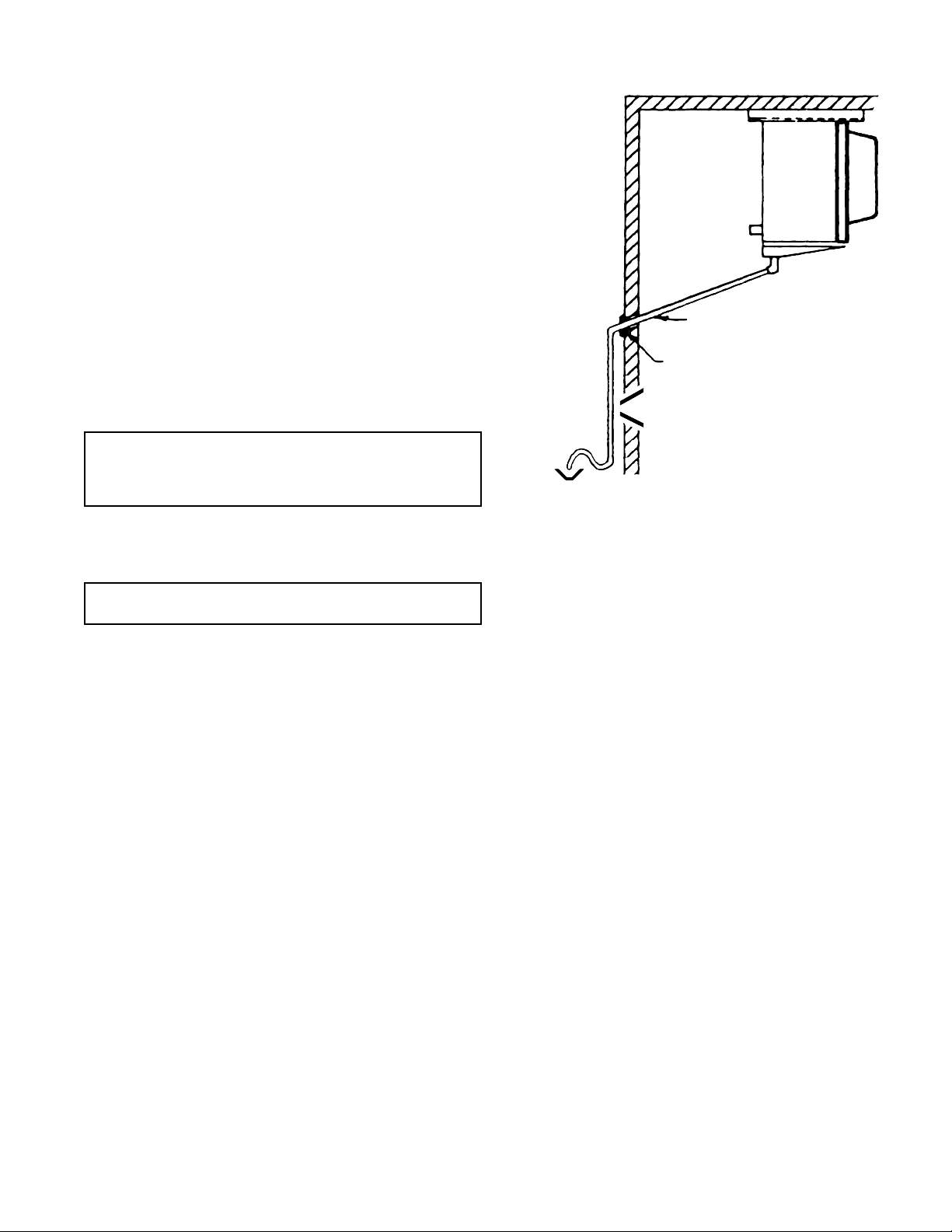

Condensate Drain Lines

DRAIN LINE MIN.

PITCH - 1/4”/ FT.

VAPOR SEAL

TRAP

OPEN

DRAIN

Either copper or steel drain lines should be used and properly protected

from freezing. In running drain lines, provide a minimum 1/4 inch per

foot pitch for proper drainage. Drain lines should be at least as large as

the evaporator drain connection. All plumbing connections should be

made in accordance with local plumbing codes. All condensate drain

lines must be trapped, and run to an open drain. They must never be

connected directly to the sewer system. Traps in the drain line must be

located in a warm ambient. We recommend a trap on each evaporator

drain line prior to any tee connections. Traps located outside, or extensive

outside runs of drain line must be wrapped with a drain line heater.

The heater should be connected so that it operates continuously. It

is recommended that the drain line be insulated to prevent heat loss.

A heat input of 20 watts per linear foot of drain line for 0˚F (-18˚C)

room applications and 30 watts per linear foot for -20˚F (-29˚C) rooms

is satisfactory. In freezers, the evaporator drain pan tting should be

included when heating and insulating the drain line.

Inspect drain pan periodically to insure free drainage of condensate.

If drain pan contains standing water, check for proper installation. The

drain pan should be cleaned regularly with warm soapy water.

Figure 7. Condensate Drain Lines

WARNING: All power must be disconnected before clean-

Traps on low temperature units must be outside of refrigerated

enclosures. Traps subject to freezing temperatures must be wrapped

with heat tape and insulated.

NOTE: Always trap single evaporator system drain

lines individually to prevent humidity migration.

ing. Drain pan also serves as cover of hazardous

moving parts. Operation of unit without drain

pan constitutes a hazard.

9

Page 10

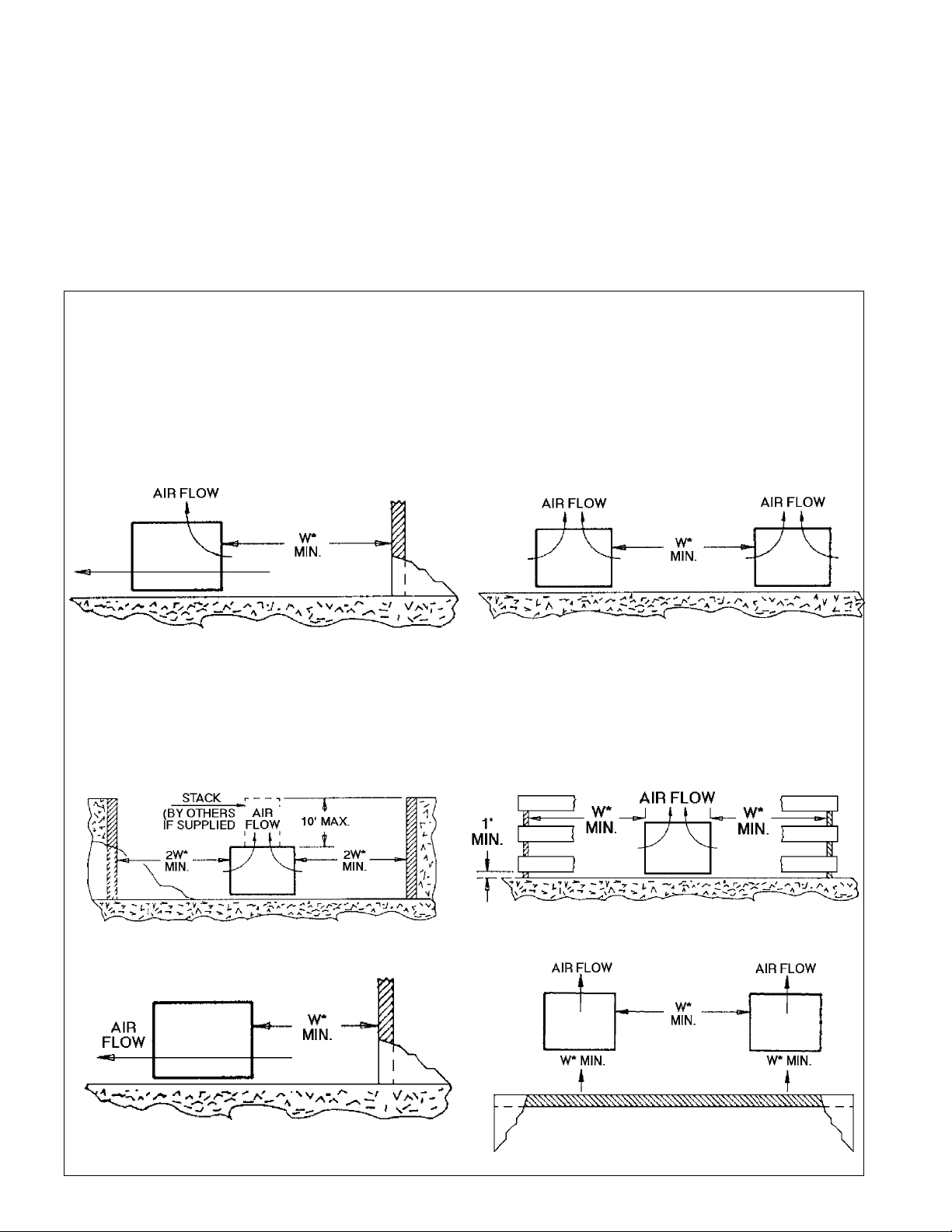

Space and Location Requirements for

Air Cooled Condensing Units and Remote Condensers

The most important consideration which must be taken into account

when deciding upon the location of air-cooled equipment is the

provision for a supply of ambient air to the condenser, and removal of

heated air from the condensing unit or remote condenser area. Where

this essential requirement is not adhered to, it will result in higher

head pressures, which cause poor operation and potential failure of

equipment. Units must not be located in the vicinity of steam, hot air

or fume exhausts. Corrosive atmospheres require custom designed

condensers.

Figure 8. Space and Location Requirements for Condensing Units and Remote Condensers

Another consideration which must be taken is that the unit should be

mounted away from noise sensitive spaces and must have adequate

support to avoid vibration and noise transmission into the building.

Units should be mounted over corridors, utility areas, rest rooms and

other auxiliary areas where high levels of sound are not an important

factor. Sound and structural consultants should be retained for

recommendations.

Walls or Obstructions

The unit should be located so that air may circulate freely and not

be recirculated. For proper air ow and access all sides of the unit

should be a minimum of “W” away from any wall or obstruction. It

is preferred that this distance be increased whenever possible. Care

should be taken to see that ample room is left for maintenance work

through access doors and panels. Overhead obstructions are not

permitted. When the unit is in an area where it is enclosed by three

walls the unit must be installed as indicated for units in a pit.

Units in Pits

The top of the unit should be level with the top of the pit, and

side distance increased to “2W”.

If the top of the unit is not level with the top of pit, discharge

cones or stacks must be used to raise discharge air to the top of

the pit. This is a minimum requirement.

Multiple Units

For units placed side by side, the minimum distance between

units is the width of the largest unit. If units are placed end

to end, the minimum distance between units is 4 feet.

Decorative Fences

Fences must have 50% free area, with 1 foot undercut, a “W”

minimum clearance, and must not exceed the top of unit.

If these requirements are not met, unit must be installed as

indicated for “Units in pits”.

10

Walls or Obstructions for Horizontal Air Flow

* “W” = Total width of the condensing unit or condenser.

Multiple Units with Horizontal Air Flow

Page 11

Requirements for Remote and Water Cooled

Condensing Units

General Installation

The indoor compressor units are designed to be used with a remote

condenser. The water cooled units are similar, except that they have

an integral water cooled condenser. Inlet and outlet water connections

are to be made in the eld. On units having a compressor water jacket,

incoming water shall be routed through the jacket prior to entering

the condenser. For cleaning purposes, condenser end plates can be

removed to give access to the water tubes. Cleaning is accomplished

by a simple spiral tool powered by an ordinary electric drill. During

installation, allow space for cleaning the condenser. Commercial

equipment of this type is intended for installation by qualified

refrigeration mechanics.

Typical Arrangements

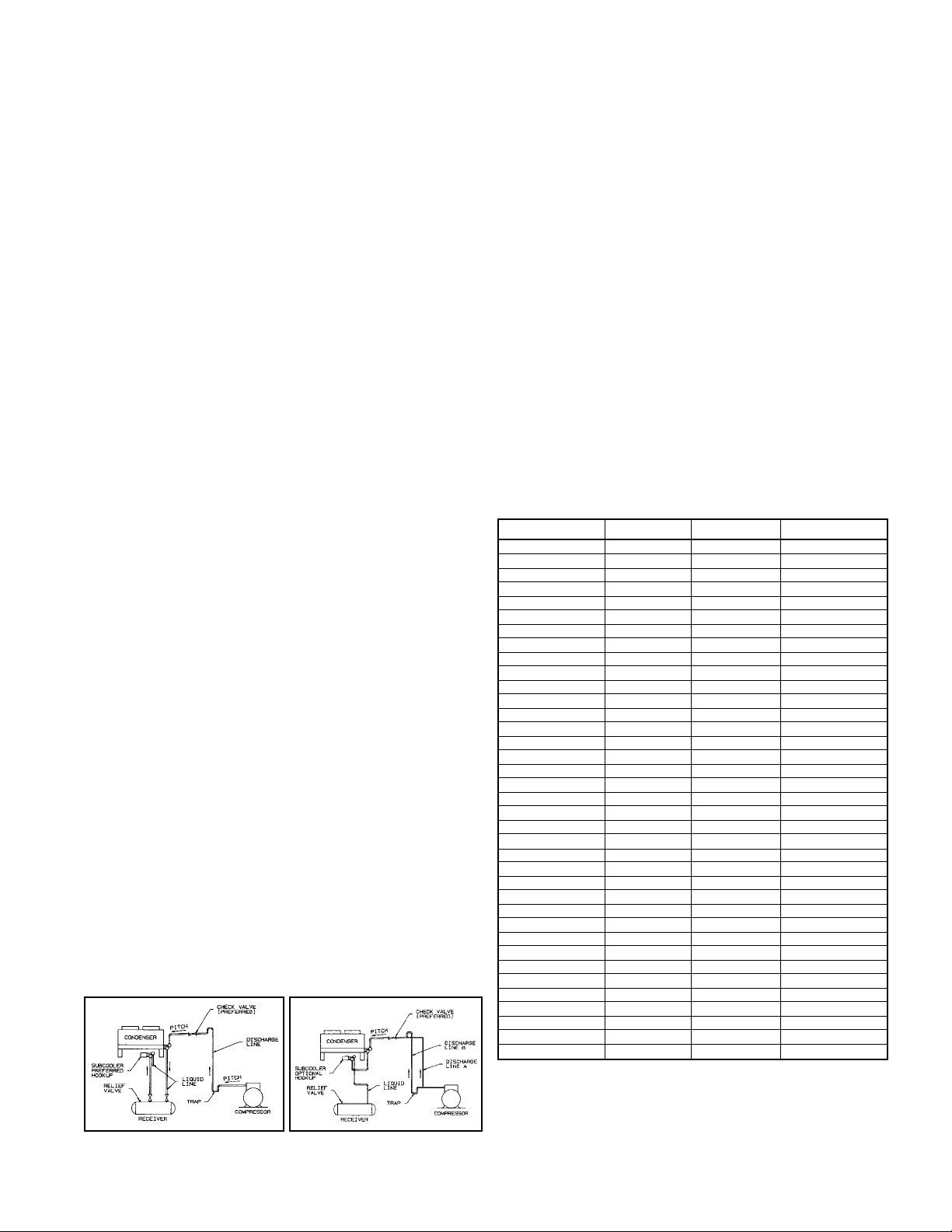

Diagram 1 illustrates a typical piping arrangement involving a remote

condenser located at a higher elevation, as commonly encountered

when the condenser is on a roof and the compressor and receiver are

on grade level or in a basement equipment room.

In this case, the design of the discharge line is very critical. If properly

sized for full load condition, the gas velocity might be too low at

reduced loads to carry oil up through the discharge line and condenser

coil. Reducing the discharge line size would increase the gas velocity

suciently at reduced load conditions; however, when operating at

full load, the line would be greatly undersized, and thereby creating an

excessive refrigerant pressure drop. This condition can be overcome

in one of two of the following ways:

1. The discharge line may be properly sized for the desired pressure

drop at full load conditions and an oil separator installed at the bottom

of the trap in the discharge line from the compressor.

2. A double riser discharge line may be used as shown in Diagram 2.

Line “A” should be sized to carry the oil at minimum load conditions and

the line “B” should be sized so that at the full load conditions both lines

would have sucient ow velocity to carry the oil to the condenser.

Water Regulating Valve

Using this control on the water cooled condensing units, the head

pressure can be maintained by adjusting the ow of water through

the condenser section. This type control is most often located on the

water entering side of the condenser and is regulated by the refrigerant

condensing pressure.

Subcooler

Diagrams 1 and 2 below show typical subcooler piping. Diagram 1

is the preferred connection with receiver as it provides maximum

subcooling. Diagram 2 may be used if the receiver is located far from

the condenser.

Notes:

1. All oil traps are to be as short in radius as possible.

Common practice is to fabricate the trap using three

90 degree ells.

2. Pressure relief valves are recommended at the condenser

for protection of the coil.

3. A pressure valve at the high point in the discharge line is

recommended to aid in removing non-condensables.

4. The placement of a subcooler should be that it does not

interfere with normal airow of the condenser. Increased

static of the unit could cause a decrease in system capacity

and fan motor damage.

GPM Requirements

The GPM Requirements table below can be used as a guide for

determining water ow requirements of the condenser. Operation

below the minimum ow rates may result in excessive fouling and

poor heat transfer. Operation above the maximum ow rates risk

premature impingement corrosion and tube failure.

Water Cooled Condenser GPM Requirements

Model Min GPM Max GPM Rated GPM*

SWN0075H2 0.7 5 1.25

SWN0075M2 0.7 5 1.5

SWN0090H2 0.7 5 2

SWN0090M6 0.7 5 2.25

SWN0100H2 0.7 5 2

SWN0150H2 0.7 5 2.5

SWN0150L6 0.7 5 1.5

SWN0199M6 0.7 5 4

SWN0200H2 2 18 4

SWN0200L6 2 18 2

SWN0200M2 2 18 5

SWN0200M6 2 18 7

SWN0210L6 2 18 3

SWN0310E6 4 18 5

SWN0300H2 4 18 6

SWN0310L6 4 18 4

SWN0310M6 4 18 9

SWN0311L6 4 18 6

SWN0400H2 4 18 11

SWN0400L6 4 18 7

SWN0499H2 7.5 23 10

SWN0500H2 7.5 23 12.5

SWN0500M6 7.5 23 15

SWN0599L6 7.5 23 7.5

SWN0600L6 7.5 23 10

SWN0601L6 7.5 23 10

SWN0750H2 10 25 12.5

SWN0750L6 10 25 10

SWN0760H2 10 25 15

SWN0761H2 10 25 20

SWN0900L6 20 67 20

SWN1000H2 20 67 30

SWN1000L6 20 67 20

SWN1500H2 20 80 35

SWN1500L6 20 80 20

SWN2000H2 20 80 40

SWN2200L6 20 80 25

* Low Temp. Rating Point: -20°F SST, 85°F EWT, 105°F CT, 5°F SC

* Medium/High Temp. Rating Point: 25°F SST, 85°F EWT, 105°F CT,

5°F SC

Diagram 1

Diagram 2

11

Page 12

Condensing Unit Rigging and Mounting

Rigging holes are provided on all units. Caution should be exercised

when moving these units. To prevent damage to the unit housing

during rigging, cables or chains used must be held apart by spacer

bars. The mounting platform or base should be level and located so

as to permit free access of supply air.

Ground Mounting

Concrete slab raised six inches above ground level provides a suitable

base. Raising the base above ground level provides some protection

from ground water and wind blown matter. Before tightening mounting

bolts, recheck level of unit. The unit should in all cases be located with

a clear space in all directions that is at a minimum, equal to the height

of the unit above the mounting surface. A condensing unit mounted in

a corner formed by two walls, may result in discharge air recirculation

with resulting loss of capacity.

Roof Mounting

Due to the weight of the units, a structural analysis by a qualied

engineer may be required before mounting. Roof mounted units should

be installed level on steel channels or an I-beam frame capable of

supporting the weight of the unit. Vibration absorbing pads or springs

should be installed between the condensing unit legs or frame and

the roof mounting assembly.

Access

Provide adequate space at the compressor end of the unit for servicing.

Provide adequate space on the connection side to permit service of

components.

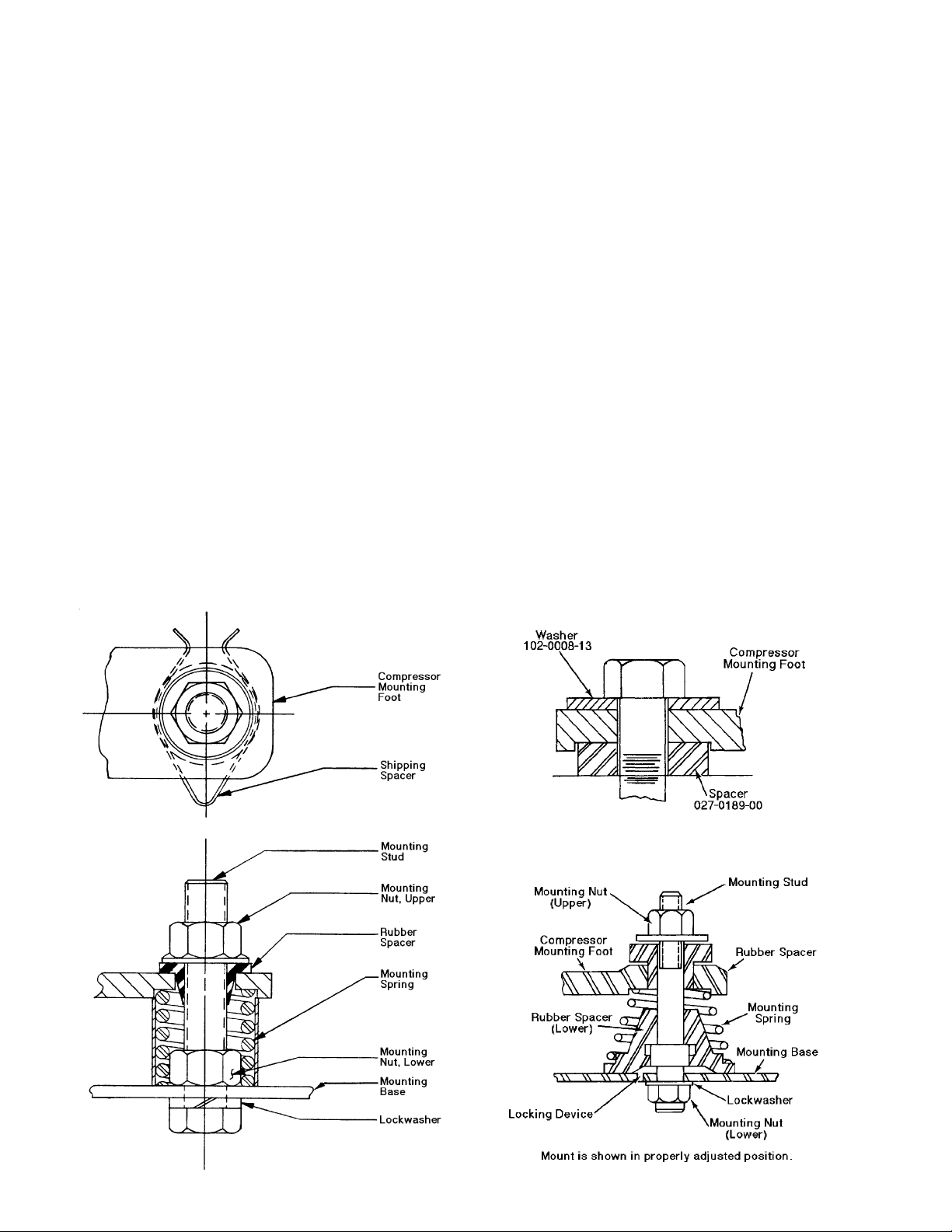

Spring Mounted Compressor

Compressors are secured rigidly to make sure there is no transit damage.

Before operating the unit, it is necessary to follow these steps:

a. Remove the upper nuts and washers.

b. Discard the shipping spacers.

c. Install the neoprene spacers. (Spacers located

in the electrical panel or tied to compressor.)

d. Replace the upper mounting nuts and washers.

e. Allow 1/16 inch space between the mounting nut/

washer and the neoprene spacer. See Figures 9

and 11 below.

Rigid Mounted Compressor

Some products use rigid mounted compressors. Check the compressor

mounting bolts to insure they have not vibrated loose during shipment.

See Figure 10 below.

Figure 9. Spring Mount

Figure 10. Solid Mount for Mobile or Deep

Sump Application.

Figure 11. Spring Mount

12

Page 13

Condensing Unit Accessories

Suction Filters, Driers, Sight Glasses

There are two types of suction and liquid lter/driers used on

Heatcraft Refrigeration Products units. Replaceable core and/or

sealed units are used, dependent upon the option package ordered.

Suction lters, regardless of type, are always installed upstream of

the compressor suction service valve, and any accumulators or other

options that may be installed. Suction lters are equipped with

“Schrader” type access valves to allow eld measurement of pressure

drop across the device. This allows plugged lters and elements to

be identied very quickly and easily so they can be replaced when

the pressure drop is excessive. Refer to the specic manufacturers’

recommendation on servicing these units by make and model.

Liquid lter/driers, regardless of type, are always installed downstream

of the receiver outlet service valve, and upstream of the liquid line

solenoid valve (if supplied). Liquid line driers may or may not have an

access valve, dependent on the size and application.

The basic servicing of these units is similar to suction lters. Liquid

line driers should be replaced whenever there is evidence of excessive

pressure drop across the lter, or the system becomes contaminated

due to system leaks, compressor burnouts, acid formation, or

moisture accumulation as indicated by the liquid line sight glass.

The sight glass is installed in the main liquid line assembly, downstream

from the receiver outlet service valve, and immediately after the liquid

line drier. The sight glass is designed to give a visual indication of

system moisture content with refrigerant owing. Slight color indication

on a new system is common and will be eliminated during system

evacuation. Generally, it requires no eld service. However, in cases of

extreme acid formation in a system after a compressor burnout, the

acid may damage the sensing element or etch the glass. This would

require that the sight glass be replaced, along with the liquid line drier

after any compressor motor burnout.

Table 6. Recommended Low Pressure Control Settings for Outdoor Air Cooled Condensing Units

R-22 R-404A/R-507 R-134a

*Minimum Cut-In Cut-Out Cut-In Cut-Out Cut-In Cut-Out

Temp. ˚F PSI PSI PSI PSI PSI PSI

50 70 20 90 35 45 15

40 55 20 70 35 35 10

30 40 20 55 35 25 10

10 30 10 45 25 13 0

0 15 0 25 7 8 0

-10 15 0 20 1 --- ---

-20 10 0 12 1 --- ---

-30 6 0 8 1"Hg. --- ---

* Minimum ambient or box temperature anticipated, high pressure control setting: R-22, 360 PSI; R-404A, R-507, 400 PSI; R-134a, 225 PSI

* The standard preset low pressure switch used for pumpdown is set for 15 PSI cut in / 4 PSI cut out and is a good setting for most pumpdown systems

* ZB Scroll compressors should be set for 25 PSI cut in / 17 PSI cut out (R-404A / R-507)

CAUTION: Fans closest to the headers should not be

cycled on standard temperature or pressure

controls. Dramatic temperature and pressure

changes at the headers as a result of fan

action can result in possible tube failure.

Fan motors are designed for continuous

duty operation.

Fan cycling controls should be adjusted to maintain a mini

mum of (5) minutes on and (5) minutes o. Short cycling of

fans may result in a premature failure of

motor and/or fan blade.

Compressors operating below +10°F SST must have air

owing over the compressor at all times when the compres

sor is running.

-

-

13

Page 14

Evaporating Temperature (ºF)

Condensin

g

T

emper

atu

r

e (ºF)

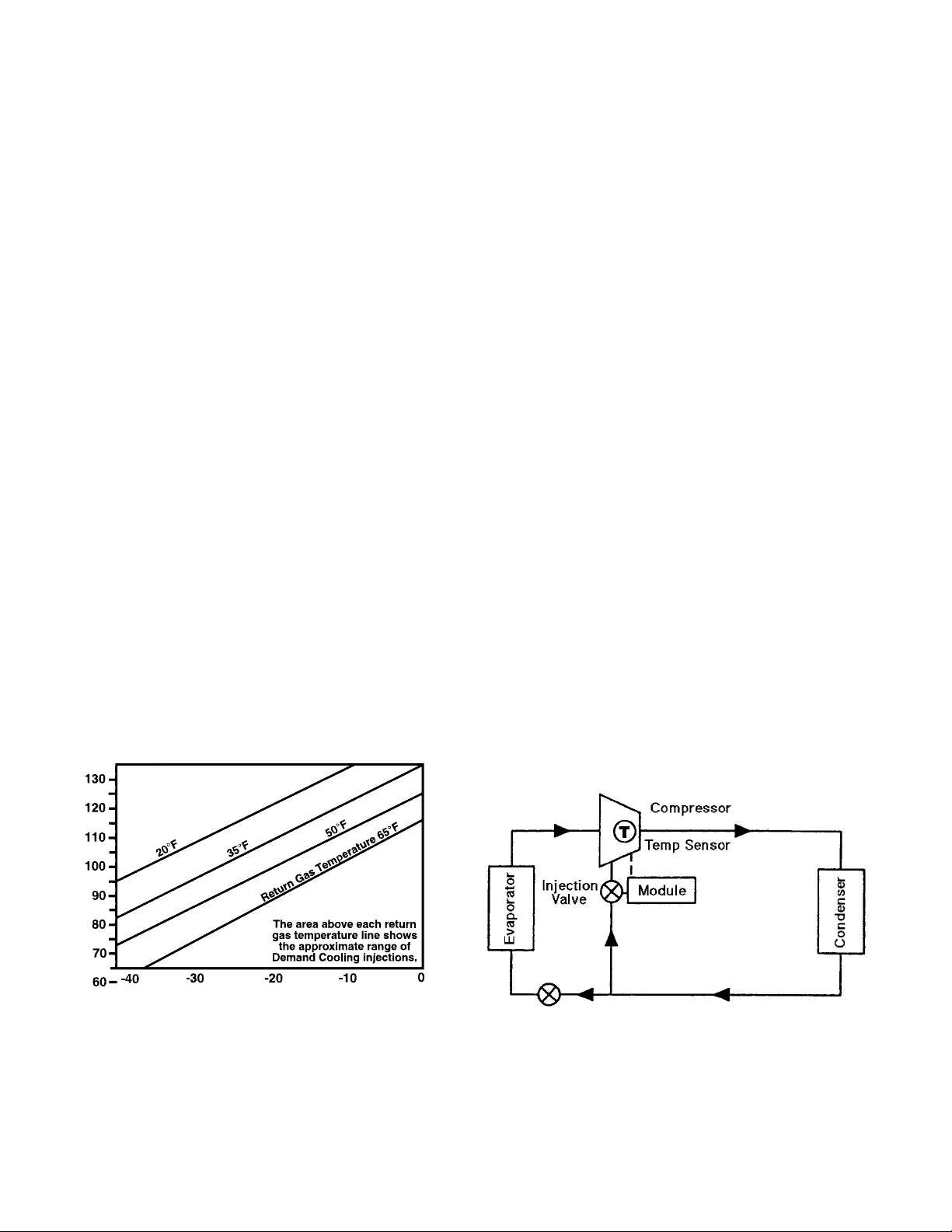

Copeland Demand Cooling for Discus L2 Models

R-22, when used in a properly designed and controlled refrigeration

system, is a realistic low temperature refrigerant alternative to R-502,

which was phased out due to its high ozone depletion potential.

However, experience has shown R-22 can present problems as a low

temperature refrigerant because under some conditions the internal

compressor discharge temperature exceeds the safe temperature limit

for long term stability of refrigeration oil. For this reason suction to liquid

heat exchangers are not recommended unless they are necessary to

prevent another potential problem.

The Copeland Demand Cooling System

Copeland's demand cooling system uses modern electronics to provide a

reliable, cost-eective solution to this problem. It is required for all single

stage R-22 applications with saturated suction temperatures below -10˚F.

The Demand Cooling module uses the signal of a discharge head

temperature sensor to monitor discharge gas temperature. If a critical

temperature is reached, the module energizes a long life injection valve

which meters a controlled amount of saturated refrigerant into the

compressor suction cavity to cool the suction gas. Refer to Figure 13.

This process controls the discharge temperature to a safe level. If, for

some reason, the discharge temperature rises above a preset maximum

level, the Demand Cooling module will turn the compressor o (requiring

a manual reset) and actuate its alarm contact. To minimize the amount

of refrigerant which must be injected, the suction gas cooling process

is performed after the gas has passed around and through the motor.

Operating Range

Demand Cooling is designed to protect the compressor from high

discharge temperatures over the evaporating and condensing

temperature ranges shown in Figure 12 at a maximum return gas

temperature of 65˚F.

When Demand Cooling operates, it “diverts” refrigeration capacity

in the form of injected saturated refrigerant from the evaporator to

the compressor. The eect of this diversion on evaporator capacity is

minimal because the diverted capacity is used to cool the gas entering

the compressor. As the gas is cooled, it naturally becomes more

dense, increasing the mass ow through the compressor, which partly

compensates for the capacity diverted from the evaporator.

1. Compressor Return Gas Temperature: Suction lines

should be well insulated to reduce suction line heat gain.

Return gas superheat should be as low as possible

consistent with safe compressor operation. Minimum 20˚F

superheat at the compressor is required.

2. Condensing Temperatures: It is important when using

R-22 as a low temperature refrigerant that condensing

temperatures be minimized to reduce compression ratios

and compressor discharge temperature.

3. Suction Pressure: Evaporator design and system control

settings should provide the maximum suction pressure

consistent with the application in order to have as low a

compression ratio as possible.

In most cases, with floating head systems where condensing

temperatures are low during most of the year, Demand Cooling will

operate primarily as a compressor protection control much as the

oil failure control protects the compressor during periods of low oil

pressure. Demand Cooling will be allowed to operate only during those

periods when condensing temperatures and return gas temperatures

are high or in periods where a system failure (such as an iced evaporator,

an expansion valve which does not control superheat, blocked

condenser, or a failed condenser fan) raises condensing temperatures

or return gas temperatures to abnormally high levels or lowers suction

pressure to abnormally low levels.

Demand Cooling System Design

Figure 12. Demand Cooling Injection

Figure 13. Single Stage Internal Refrigerant Injection

14

Page 15

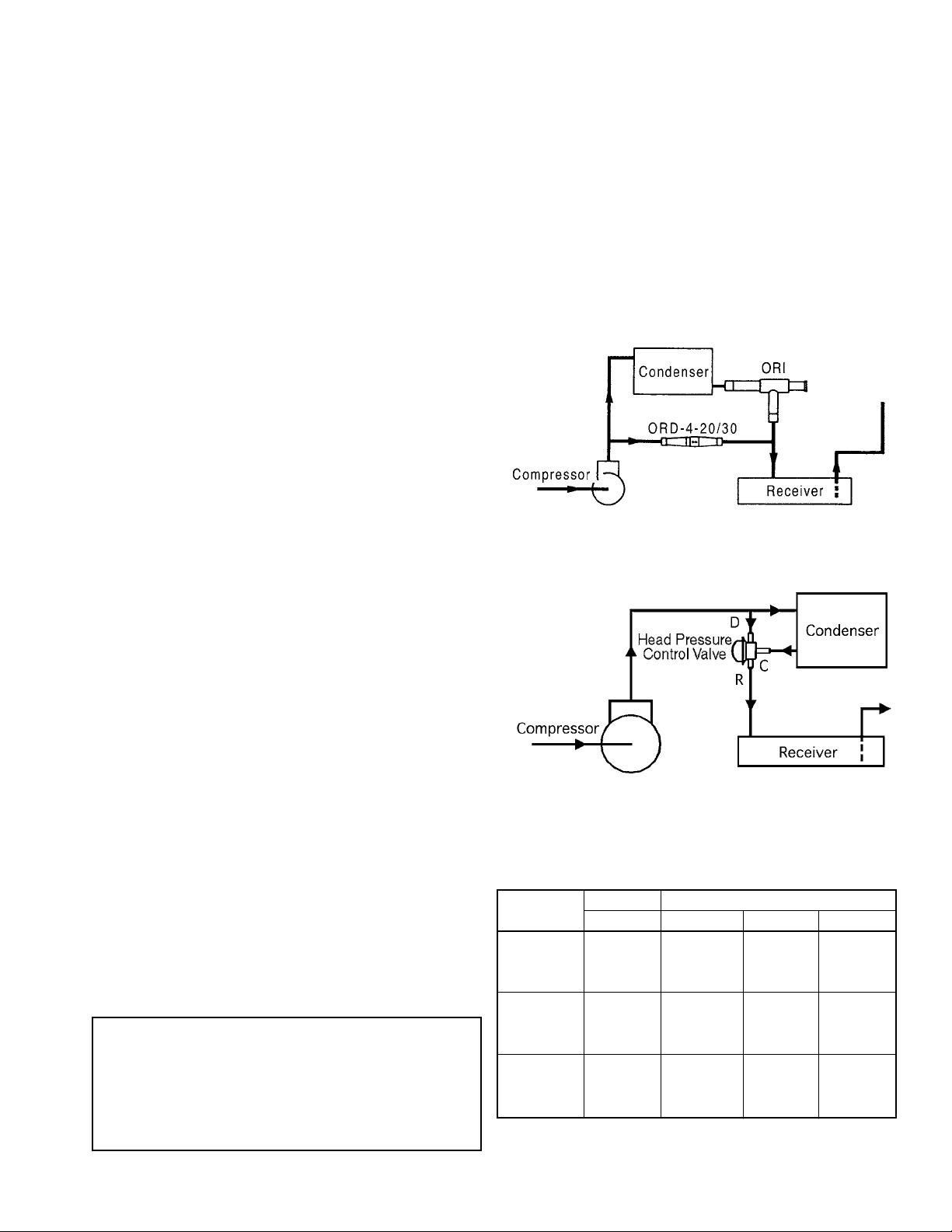

Head Pressure Control

Several types of head pressure control systems are available on

condensing units:

A. Dual Valve System. (See section on operation

and adjustment.)

B. Single Valve system. No adjustments are necessary.

(See section on operation.)

C. Ambient Fan Cycle Control. (See section on operation

and adjustment.)

D. No Control.

A. Dual Valve System

Operation and Adjustment

Condensing units with dual valves require sucient charge to partially

ood the condenser during low ambient conditions.

Valve adjustment should be made with gauges connected to the

discharge port of the compressor. Adjustments should be made during

mild or low ambient conditions. Turning the valve stem “clockwise” on

the ORI valve will increase the discharge pressure, while turning the

valve stem “counterclockwise” will decrease the discharge pressure.

If adjustments are made during warm ambient conditions, it may not be

possible to adjust the regulator valve as low as desired. Readjustment

may be necessary once cooler conditions prevail.

The system employs an ORI (open on rise of inlet pressure) valve and

an ORD ( open on rise of dierential pressure) valve. The high pressure

discharge gas is introduced above the liquid in the receiver tank. The

receiver discharge is regulated by the ORI valve.

The discharge pressure of the ORI valve must be adjusted to regulate

the unit for proper operating conditions. Adjust the ORI valve shown

on the following diagram to maintain a discharge pressure of 160 to

180 PSIG.

B. Single Valve System

The standard valve used on high pressure refrigerant systems controls

the head pressure at approximately 180 PSIG. There is no adjustment

for this valve. On low pressure refrigerant systems the valve controls

pressure at approximately 100 PSIG. For energy eciency, the 100 PSIG

valve is sometimes used on high pressure refrigerant systems. When this

is done, refer to Table 1 on page 5 for expansion valve selections.

At condensing pressures above the valve setting, ow enters Port C

and leaves Port R. When the condensing pressure falls below the valve

setting, the valve modulates to permit discharge gas to enter Port D.

Metering discharge gas into the refrigerant ow leaving the condenser

produces a higher pressure at the condenser outlet, reduces the ow,

and causes the level of liquid refrigerant to rise in the condenser.

This “ooding” of the condenser with liquid refrigerant reduces the

available condensing surface, holding the condensing pressure at

the valve setting.

Figure 14. Dual Valve Piping Arrangement

Figure 15. Single Valve Flooding Valve Piping

Arrangement

C. Ambient Fan Cycle Control

This is an automatic winter control method which will maintain a

condensing pressure within reasonable limits by cycling fan motors

in response to outside air temperature. The thermostat(s) should be

eld adjusted to shut o the fan when the condensing temperature

is reduced to approximately 90˚F. Table 7 lists approximate settings

for several system T.D.’s. These settings are approximate as they do not

take into account variations in load.

CAUTION: Under no circumstance should all condenser

motors be allowed to cycle o on one control.

At least one motor shall be wired to operate

at all times. Under most circumstances, the

condenser motor nearest the inlet header

should remain on whenever the compressor

is operating.

Table 7. Ambient Fan Cycle Thermostat Settings

Design Thermostat Settings

Models T.D. T1 T2 T3

30 60

2-fan units: 25 65

20 70

4-fan units: 15 75

30 60 40

3-fan units: 25 65 55

20 70 60

6-fan units: 15 75 65

30 60 50 30

8-fan units: 25 65 55 40

20 70 65 50

15 75 70 60

NOTE: Cycle pairs of fans on double wide units.

15

Page 16

Refrigeration Oils*

With the changes that have taken place in our industry due to the CFC

issue, we have reevaluated our lubricants to ensure compatibility with

the new HFC refrigerants and HCFC interim blends oered by several

chemical producers. As a secondary criteria, it is also desirable that any

new lubricant be compatible with the traditional refrigerants such as

HCFC-22 or R502. This “backward compatibility” has been achieved

with the introduction of the Polyol ester lubricants.

Table 8 below summarizes which oils/lubricants are approved for use

in Copeland compressors:

Polyol Ester Lubricants

Hygroscopicity

Ester lubricants (POE) have the characteristic of quickly absorbing

moisture from the ambient surroundings. This is shown graphically in

Figure 16 where it can be seen that such lubricants absorb moisture

faster and in greater quantity than conventional mineral oils. Since

moisture levels greater than 100 ppm will results in system corrosion

and ultimate failure, it is imperative that compressors, components,

containers and the entire system be kept sealed as much as possible.

Lubricants will be packaged in specially designed, sealed containers.

After opening, all the lubricant in a container should be used at once

since it will readily absorb moisture if left exposed to the ambient.

Any unused lubricant should be properly disposed of. Similarly, work

on systems and compressors must be carried out with the open time

as short as possible. Leaving the system or compressor open during

breaks or overnight MUST BE AVOIDED!

Color

As received, the POE lubricant will be clear or straw colored. After use,

it may acquire a darker color. This does not indicate a problem as the

darker color merely reects the activity of the lubricant's protective

additive.

Oil Level

During Copeland's testing of Polyol ester oil, it was found that this

lubricant exhibits a greater tendency to introduce oil into the cylinder

during ooded start conditions. If allowed to continue, this condition

will cause mechanical failure of the compressor.

A crankcase heater is required with condensing units and it must be

turned on several hours before start-up.

Oil level must not exceed 1/4 sight glass.

Figure 16.

Table 8. Refrigeration Oils

Interims HFC's

Traditional Refrigerants R401A, R401B, R402A HFC-134a,

Refrigeration Oils HCFC-22 (MP-39, MP-66, HP-80) R404A, R507

POE's Mobil EAL ARCTIC 22 CC A A P

ICI (Virginia KMP) EMKARATE RL 32CF A A P

Suniso 3GS P PM

Mineral Texaco WF32 P PM NOT

Oils Calumet RO15 (Witco) P PM ACCEPTABLE

Sontex 200-LT (White Oil) (BR & Scroll Only)

Witco LP-200 P

A/B Zerol 200TD AM PM NOT

Soltex Type AB-200 PM ACCEPTABLE

P = Preferred Lubricant Choice A = Acceptable Alternative M = Mixture of Mineral Oil and Alkyl Benzene (AB) with minimum 50% AB.

*(Reprinted by permission from Copeland Corporation)

Mineral Oils

The BR and Scroll compressors use Sontex 200, a “white oil”. This oil is

not suitable for low temperature applications nor is it available through

the normal refrigeration wholesalers. For eld “top-o” the use of 3GS

or equivalent, or Zerol 200TD is permissible, as long as at least 50% of

the total oil charge remains Sontex 200.

Suniso 3GS, Texaco WF32 and Calumet R015 (yellow oils) are available

through normal refrigeration wholesalers. These oils are compatible if

mixed and can be used on both high and low temperature systems.

Polyol Ester Lubricants

The Mobil EAL ARCTIC 22 CC is the preferred Polyol ester due to unique

additives included in this lubricant. ICI Emkarate RL 32S is an acceptable

Polyol ester lubricant approved for use when Mobil is not available.

These POE’s must be used if HFC refrigerants are used in the system.

They are also acceptable for use with any of the traditional refrigerants or

interim blends and are compatible with mineral oils. They can therefore

be mixed with mineral oils when used in systems with CFC or HCFC

refrigerants when Copeland compressors are used. These lubricants

are compatible with one another and can be mixed.

Alkyl Benzenes

Zerol 200TD is an alkyl benzene (AB) lubricant. Copeland recommends

this lubricant for use as a mixture with mineral oil (MO) when using the

interim blends such as R-401A, R-401B and R-402A (MP39, MP66 and

HP80). A minimum of 50% AB is required in these mixtures to assure

proper oil return.

Shell MS 2212 is a 70/30 mixture of AB/MO. If this lubricant is used in a

retrot situation virtually all of the existing MO must be drained prior

to relling with the MS 2212 to assure a minimum 50% AB content.

16

Page 17

Phase Loss Monitor

The combination phase sequence and loss monitor relay protects the

system against phase loss (single phasing), phase reversal (improper

sequence) and low voltage (brownout). When phase sequence is

correct and full line voltage is present on all three phases, the relay is

energized as the normal condition indicator light glows.

Note: If compressor fails to operate and the normal condition indicator

light on the phase monitor does not glow, then the supplied electrical

current is not in phase with the monitor. This problem is easily corrected

by the following steps:

1. Turn power o at disconnect switch.

2. Swap any two of the three power input wires.

3. Turn power on. Indicator light should glow and compressor

should start.

4. Observe motors for correct rotation.

Recommended Refrigerant Piping Practices

The system as supplied by Heatcraft Refrigeration Products, was

thoroughly cleaned and dehydrated at the factory. Foreign matter

may enter the system by way of the evaporator to condensing unit

piping. Therefore, care must be used during installation of the piping

to prevent entrance of foreign matter.

Install all refrigeration system components in accordance with

applicable local and national codes and in conformance with good

practice required for the proper operation of the system.

The refrigerant pipe size should be selected from the tables on pages

23-29. The interconnecting pipe size is not necessarily the same size

as the stub-out on the condensing unit or the evaporator.

The following procedures should be followed:

(a) Do not leave dehydrated compressors or lter-

driers on condensing units open to the atmosphere

any longer than is absolutely necessary.

(b) Use only refrigeration grade copper tubing,

properly sealed against contamination.

(c) Suction lines should slope 1/4" per 10 feet

towards the compressor.

(d) Suitable P-type oil traps should be located at

the base of each suction riser of four (4) feet or more

to enhance oil return to the compressor.

(e) For desired method of superheat measurement,

a pressure tap should be installed in each

evaporator suction line in the proximity of the

expansion valve bulb.

(f) When brazing refrigerant lines, an inert gas

should be passed through the line at low

pressure to prevent scaling and oxidation inside

the tubing. Dry nitrogen is preferred.

(g) Use only a suitable silver solder alloy on suction

and liquid lines.

(h) Limit the soldering paste or ux to the minimum

required to prevent contamination of the solder

joint internally. Flux only the male portion of the

connection, never the female. After brazing,

remove excess ux.

(i) See Table 11 on page 23 for discharge and liquid

drain line sizes for remote condenser connections.

(j) If isolation valves are installed at the evaporator,

full port ball valves should be used.

Refrigerant Pipe Support

1. Normally, any straight run of tubing must be supported in at

least two locations near each end of the run. Long

runs require additional supports. The refrigerant lines should

be supported and fastened properly. As a guide, 3/8 to 7/8

should be supported every 5 feet; 1-1/8 and 1-3/8

every 7 feet; and 1-5/8 and 2-1/8 every 9 to 10

feet.

2. When changing directions in a run of tubing, no corner

should be left unsupported. Supports should be placed a

maximum of 2 feet in each direction from the corner.

3. Piping attached to a vibrating object (such as a compressor

or compressor base) must be supported in such a manner

that will not restrict the movement of the vibrating object.

Rigid mounting will fatigue the copper tubing.

4. Do not use short radius ells. Short radius elbows have

points of excessive stress concentration and are subject to

breakage at these points.

5. Thoroughly inspect all piping after the equipment is

in operation and add supports wherever line vibration

is signicantly greater than most of the other piping.

Extra supports are relatively inexpensive as compared to

refrigerant loss.

Figure 17. Example of Pipe Support

Figure 18. Condensing Unit / Compressor to Wall Support.

17

Page 18

Suction Lines

Horizontal suction lines should slope away from the evaporator toward

the compressor at the rate of 1/4 inch per 10 feet for good oil return.

When multiple evaporators are connected in series using a common

suction line, the branch suction lines must enter the top of the common

suction line.

For dual or multiple evaporator systems, the branch lines to each

evaporator should be sized for the evaporator capacity. The main

common line should be sized for the total system capacity.

Suction lines that are outside of refrigerated space must be insulated.

See the Line Insulation section on page 31 for more information.

Figure 19. Suction P-Traps.

Suction Line Risers

Prefabricated wrought copper traps are available, or a trap can be made

by using two street ells and one regular ell. The suction trap must be

the same size as the suction line. For long vertical risers, additional

traps may be necessary. Generally, one trap is recommended for each

length of pipe (approximately 20 feet) to insure proper oil movement.

See Figure 19 below for methods of constructing proper suction line

P-traps.

NOTE: A suction line trap must be installed at the

point where piping changes the direction of

refrigerant ow from any horizontal run to an

upward vertical run.

Slope 1/4"

per 10 ft.

toward

compressor

Figure 20. Double Suction Riser Construction

Sized for

Minimum Load

Sized for

Full

Load

Liquid Lines

Liquid lines should be sized for a minimum pressure drop to prevent

“ashing”. Flashing in the liquid lines would create additional pressure

drop and poor expansion valve operation. If a system requires long

liquid lines from the receiver to the evaporator or if the liquid has to

rise vertically upward any distance, the losses should be calculated to

determine whether or not a heat exchanger is required. The use of a

suction to liquid heat exchanger may be used to subcool the liquid to

prevent ashing. This method of subcooling will normally provide no

more than 20˚F subcooling on high pressure systems. The amount of

Sized for

Minimum

Load

Sized for

Full

Load

subcooling will depend on the design and size of the heat exchanger

and on the operating suction and discharge pressures. An additional

benet from the use of the suction to liquid type heat exchanger

is that it can help raise the superheat in the suction line to prevent

liquid return to the compressor via the suction line. Generally, heat

exchangers are not recommended on R-22 low temperature systems.

However, they have proved necessary on short, well insulated suction

line runs to provide superheat at the compressor.

18

Page 19

Hot Gas Defrost Systems

EVAP. COIL

TXV

PAN LOOP

CHECK VALVE

REVERSE CYCLE DEFROST PIPING

CHECK VALVE

CHECK

VALVE

LIQUID

LINE

SUCTION

LINE

HEAT – X

Hot Gas Defrost systems can be described as reverse cycle, reevap., or alternating evaporator. Please see manual H-IM-HGD for

Mohave™ systems.

Refrigerant Piping

Install all refrigerant components in accordance with applicable

local and national codes and in accordance with good practice

for proper system operation. The thermostatic expansion valve

must be the externally equalized type. It can be mounted inside

the unit end compartment. Mount the expansion valve bulb on

a horizontal run of suction line as close as possible to the suction

header. Use the clamps provided with the valve to fasten the bulb

securely so there is a tight line-to-line contact between the bulb

and the suction line. Suction and hot gas connections are made on

the outside of the unit.

Suction lines should be sloped towards the compressor at the rate

of one (1) inch per ten (10) feet for good oil return. Vertical risers

of more than four (4) feet should be trapped at the bottom with

a P-trap. If a P-trap is used, the expansion valve bulb should be

installed between the unit and the trap.

Reverse Cycle System

The hot gas unit coolers can be used in reverse cycle hot gas

defrost systems using multiple evaporators connected to one

condensing unit. Generally, not more than one-third of the

system defrosts at one time. During the reverse cycle defrost, the

reversing valve, located in the compressor discharge line, diverts

hot gas through the suction line to the evaporator.

See the piping view in the Reverse Cycle Defrost Piping diagram.

The suction line check valve directs the hot gas through the drain

pan loop which prevents condensate in the pan from freezing.

The hot gas exits the loop at the pan loop outlet header and

enters the evaporator through the check valve assembly. As the

hot gas defrosts the coil, heat is removed from the hot gas and

eventually it condenses into a liquid and exits the coil at the

distributor side port. The liquid then ows through the check valve

of the thermostatic expansion valve bypass assembly, around the

thermostatic expansion valve, and into the system liquid line. The

liquid refrigerant then feeds other evaporators on the cooling

cycle, evaporates, and returns to the compressor through their

suction lines.

Three Pipe System

The three pipe system (sometimes called re-evap.) uses three

pipes: one for liquid line, one for suction line, and one for hot gas

line. In addition, a re-evaporator accumulator is used at the suction

outlet of the evaporator. The hot gas is taken from the discharge

line between the compressor and the condenser, through a

hot gas solenoid valve, then to the evaporator drain pan circuit,

distributor tee, through the coil. See the Three-Pipe Defrost Piping

Diagram on p. 20 for typical piping at the evaporator coil.

19

Page 20

Alternating Evaporator System

EVAP. COIL

TXV

PAN LOOP

THREE-PIPE DEFROST PIPING

CHECK

VALVE

HOT GAS LINE

LIQUID LINE

SUCTION LINE

HEAT – X

In the alternating evaporator hot gas defrost system, a third line is

taken o the compressor discharge line as the re-evap system. It

is piped with solenoids at each evaporator, so that hot gas defrost

is accomplished on one or more evaporators while the remaining

IMPORTANT: It is imperative that with the alternating

evaporator hot gas defrost system, no more that 25% of the

operating refrigeration load be in defrost at any time.

evaporators continue to function in a normal manner. The liquid from

defrosting evaporators is reintroduced to the main liquid line and it

is necessary that 75% or greater capacity be retained in the normal

refrigeration cycle to oset the capacity that is being removed by the

units on the hot gas defrost.

Hot gas line sizes for R-22, R404A and R507

System

Capacity

BTU/Hr

4,000 1/2 1/2 1/2 1/2 1/2

5,000 1/2 1/2 1/2 1/2 1/2

6,000 1/2 1/2 1/2 5/8 5/8

7,000 1/2 1/2 5/8 5/8 5/8

8,000 1/2 5/8 5/8 5/8 5/8

9,000 1/2 5/8 5/8 5/8 5/8

10,000 1/2 5/8 5/8 5/8 5/8

12,000 5/8 5/8 5/8 7/8 7/8

14,000 5/8 5/8 7/8 7/8 7/8

16,000 5/8 5/8 7/8 7/8 7/8

18,000 5/8 7/8 7/8 7/8 7/8

20,000 5/8 7/8 7/8 7/8 7/8

25,000 7/8 7/8 7/8 7/8 1 1/8

30,000 7/8 7/8 7/8 1 1/8 1 1/8

35,000 7/8 7/8 1 1/8 1 1/8 1 1/8

40,000 7/8 1 1/8 1 1/8 1 1/8 1 1/8

45,000 7/8 1 1/8 1 1/8 1 1/8 1 1/8

50,000 7/8 1 1/8 1 1/8 1 1/8 1 1/8

60,000 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8

70,000 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8

80,000 1 1/8 1 1/8 1 3/8 1 3/8 1 5/8

90,000 1 1/8 1 3/8 1 3/8 1 5/8 1 5/8

100,000 1 1/8 1 3/8 1 3/8 1 5/8 1 5/8

25 50 75 100 150

Equivalent Discharge Length (Ft.)

Note: Use next larger hot gas line size for -200F. and lower sucton

temperatures.

20

Page 21

Unit Cooler Piping

Pipe size example:

Given: -10°F Freezer with one system having (2) evaporators

• One condensing unit rated at 24,000 BTUH’s @ -20°F SST R404A

refrigerant.

• Two evaporators each rated at 12,000 BTUH’s @ 10°F TD.

• 75 feet of actual line run between condensing unit to rst

evaporator and 20 feet of actual line run between the rst

evaporator and the second evaporator (see gure below).

How to gure line sizes:

1. Determine equivalent line run = actual run + valves and tting

allowances.

2. Use Line Sizing Tables on pages 22-29 to size lines.

3. Note any special considerations.

Evap. 2

Evap. 1

Determine line size 1 (main line from

condensing unit):

1. Main line from the condensing unit to be sized for the total

capacity (balance) of the whole system of 24,000 BTUH’s

(Table 14 and 14A).

2. Refer to 24,000 @75 feet at -20°F SST R404A on the chart.

You will nd the suction line to be 1 1/8" and 1/2" liquid line.

3. Refer to Table 10. For every 1 1/8" 90° elbow you must add

3 equivalent feet of pipe and 2 equivalent feet of pipe for each

1 1/8" tee.

Therefore, total equivalent line run =

Actual line run 75 feet

+ (6) 1 1/8" elbows @ 3' 18 feet

+ (1) 1 1/8" tee @ 2'

Total equivalent line run 95 feet

4. Refer to Table 14A. For 95 total equivalent feet, the suction

line size should be 1 3/8" and the liquid line stays at 1/2" line.

Note: The gray shaded areas on Table 14. For 24,000 BTUH’s, the

maximum suction riser is 1 1/8" to insure proper oil return and pressure

drop from the bottom p-trap to the top p-trap.

2 feet

Fittings in this system:

• (6) 90° elbows in main line plus a 90° turn through

a tee.

• (5) addtional 90° elbows to rst evaporator.

• (4) additional 90° elbows to second evaporator.

Determine line size 2 (evaporators):

1. Line sizing to each evaporator is based on 12,000 BTUH’s and

equivalent run from condensing unit. First evaporator has an 80

ft. run and the second evaporator has a 95 ft. run.

2. Table 14 indicates 7/8" suction for the rst evaporator and Table

14A indicates 1 1/8" suction for the second evaporator.

3. Refer to Table 10. Each 7/8" 90° elbow adds 2 equivalent feet of

pipe. Each 1 1/8" 90° elbow adds 3 equivalent feet and a 90° turn

through a 1 1/8" tee adds 6 equivalent feet.

4. Actual line run (evap 1) 80 feet

+ (5) 7/8" elbows @ 2' 10 feet

+ (1) 90° turn through tee @ 6'

Total equivalent line run 96 feet

Actual line run (evap 2) 95 feet

+ (4) 1 1/8" elbows @ 3'

Total equivalent line run 107 feet

5. Table 14A indicates 1 1/8" suction line and 3/8" liquid line from

main line to both evaporators.

6 feet

12 feet

21

Page 22

Table 9. Pressure Loss of Liquid Refrigerants in Liquid Line Risers (Expressed in Pressure Drop, PSIG,

and Subcooling Loss, ˚F).

Liquid Line Rise in Feet

10' 15' 20' 25' 30' 40' 50' 75' 100'

Refrigerant PSIG ˚F PSIG ˚F PSIG ˚F PSIG ˚F PSIG ˚F PSIG ˚F PSIG ˚F PSIG ˚F PSIG ˚F

R22 4.8 1.6 7.3 2.3 9.7 3.1 12.1 3.8 14.5 4.7 19.4 6.2 24.2 8.0 36.3 12.1 48.4 16.5

R134a 4.9 2.0 7.4 2.9 9.8 4.1 12.3 5.2 14.7 6.3 19.7 8.8 24.6 11.0 36.8 17.0 49.1 23.7

R507, R404A 4.1 1.1 6.1 1.6 8.2 2.1 10.2 2.7 12.2 3.3 16.3 4.1 20.4 5.6 30.6 8.3 40.8 11.8

Based on 110˚F liquid temperature at bottom of riser.

Table 10. Equivalent Feet of Pipe Due to Valve and Fitting Friction

Copper Tube, O.D., Type “L” 1/2 5/8 7/8 1-1/8 1-3/8 1-5/8 2-1/8 2-5/8 3-1/8 3-5/8 4-1/8 5-1/8 6-1/8

Globe Valve (Open) 14 16 22 28 36 42 57 69 83 99 118 138 168