Page 1

Air-Cooled Condenser

with MiCroChAnnel Coil teChnology

Technical Guide

BNTBACCMCX

April 2011

Page 2

TABLE OF CONTENTS

Features & Benets ........................................................................................................................................................................................... 2-3

Nomenclature .........................................................................................................................................................................................................4

Capacity and Specications ...........................................................................................................................................................................4-6

Condenser Selection ............................................................................................................................................................................................7

Dimensional Diagrams ....................................................................................................................................................................................8-9

Typical Wiring Diagram .....................................................................................................................................................................................10

Overview

Bohn microchannel air-cooled condensers feature

microchannel coil technology. These innovative units

provide signicant refrigerant and energy savings vs.

standard round tube plate n coils.

Key Benefits

Refrigerant Charge Reduction

Microchannel coils oer a very high primary to secondary

surface area ratio. This provides very ecient heat exchange

while maintaining a low internal tube volume. As a result, the

Bohn microchannel condenser reduces condenser refrigerant

charge by over 70% (NRGD02A014 vs. BNED02A015).

Energy Ecient

Bohn microchannel air-cooled condensers feature very

ecient variable speed EC motors. These motors vary speed

based on system requirements to provide optimal energy and

sound performance.

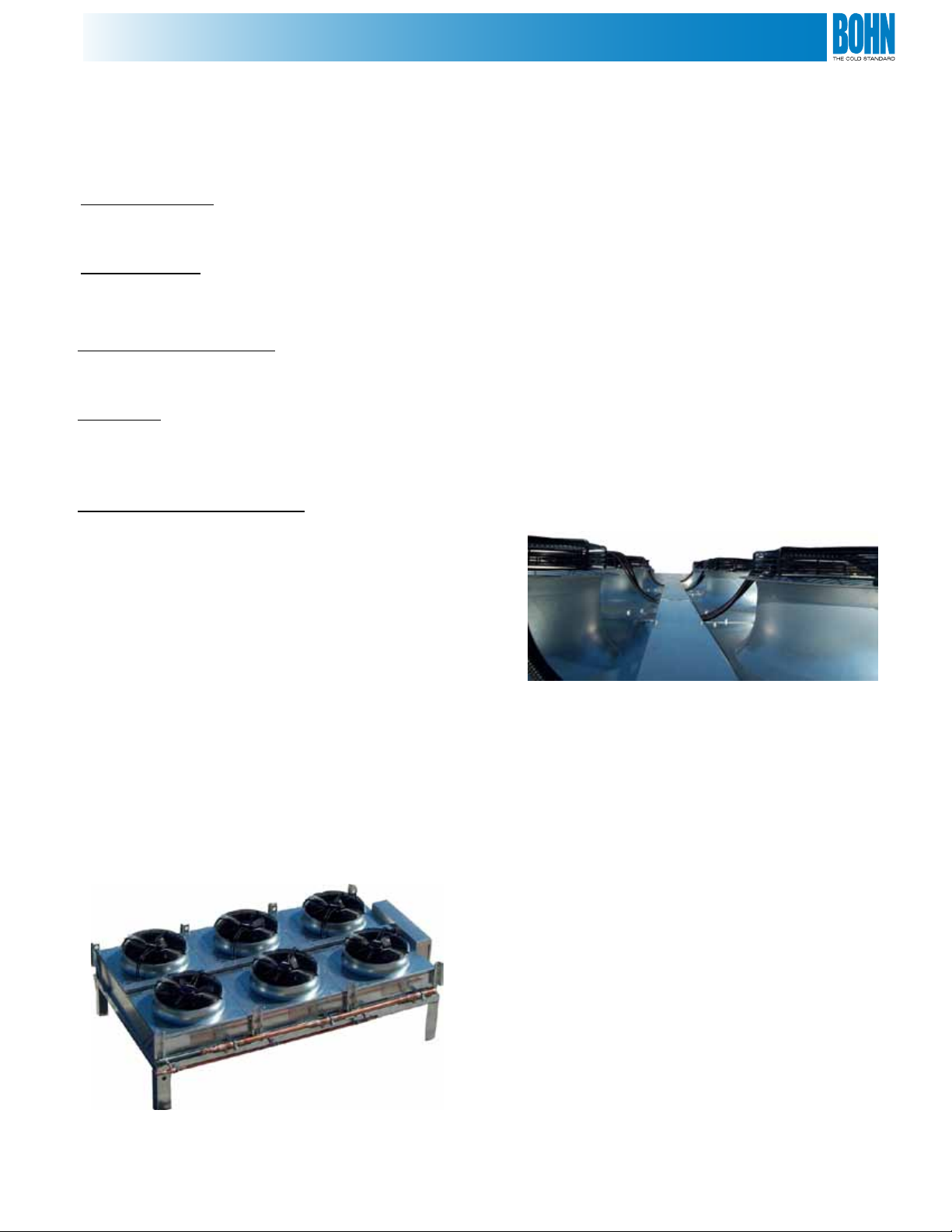

Corrosion Resistance

The mono-metal construction of the microchannel coils

virtually eliminates the risk of galvanic corrosion. A zinc

cladding standard on all coils provides additional corrosion

resistance for harsh environments.

Sound

Microchannel air-cooled condensers feature quiet variable

speed EC fan motors as a standard.

2

© 2011 Heatcraft Refrigeration Products, LLC

Page 3

FEATURES & BENEFITS

Key Benefits Continued

Lighter Weight

Over 30% lighter than comparable round-tube, plate n air-cooled condensers.

Lower Height

Approximately 25% lower cabinet height (with same clearance) than comparable round-tube,

plate n condensers.

Structural Robustness

The coils used in this unit are extremely rigid and resistant to damage.

Warranty

Microchannel air-cooled condensers feature a standard 2 year product warranty, a 2 year

warranty on the microchannel coil and a 3 year warranty on the variable speed EC motors.

Environmentally Friendly

100% recyclable, all -aluminum coil.

Standard Features

• Microchannel Heat Exchanger

• R-404A, R-407C, R-507, R-407A, R-422D,

and R-410A compatible

• 208-230V/3/60Hz or 460V/3/60Hz

• Factory Installed Manifolding*

• 20” clearance legs

• Copper connection points with schrader access valves

• Factory wired for customer supplied analog signal

• Direct acting, series wired motor control

• Through-the-door non-fused disconnect switch

• End access panels for coil-cleaning

• Internal baes between all fan cells

Optional Features

• 40” Clearance legs

• Individual motor fusing

• Individual motor circuit breakers

• Factory installed analog board:

- CPC

- Danfoss

- Novar

• Motor control & wiring

- Direct acting, parallel wired

- Reverse acting, series wired

- Reverse acting, parallel wired

• Export crating

• Proportional pressure control

* Single circuit standard

3

Page 4

NOMENCLATURE

NR G D 04 A 027

Product Line Motor Identier Width # of Fans Model Identier Standard Capacity

NR = Air Cooled

Condenser w/

Microchannel Coil

Technology

G = 710 mm VSEC D = Dual 02 = 2

04 = 4

06 = 6

08 = 8

A = Current

Revision

(MBH/Degree TD,

R404A)

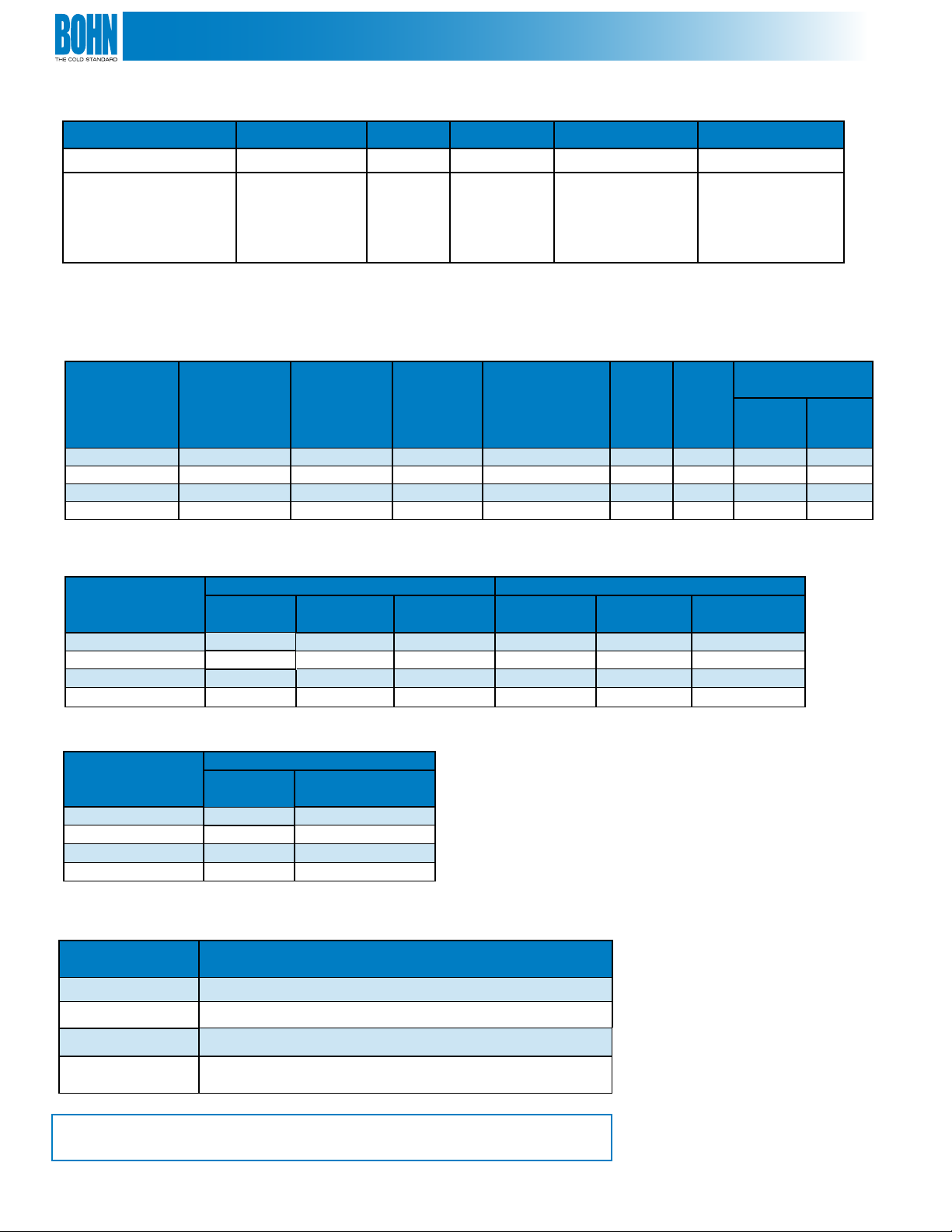

CAPACITY AND SPECIFICATIONS

Condenser Capacities & Specications

R404A

Model Air Mover

NRGD02A014 710 mm VSEC 13.5 13,700 10 470 600 (1) 1-1/8 (1) 7/8

NRGD04A027 710 mm VSEC 27.0 27,400 20 920 1135 (2) 1-1/8 (2) 7/8

NRGD06A041 710 mm VSEC 40.5 41,100 30 1370 1660 (3) 1-1/8 (3) 7/8

NRGD08A054 710 mm VSEC 54.0 54,800 40 1820 2175 (4) 1-1/8 (4) 7/8

* Does not include Manifolding

Capacity

(MBH/1°F

TD)

Full Speed

AirFlow

(ft ³/min)

R404A Flooded

Refrigerant

Charge* (lbs.)

Net

Weight

(lbs.)

Ship

Weight

(lbs.)

Coil Connection

Sizes

Inlet

(in.)

Outlet

(in.)

Condenser Electrical Specications

208-230/3/60 Electrical information 460/3/60 Electrical Information

Model

NRGD02A014

NRGD04A027

NRGD06A041

NRGD08A054

FLA

4.0 15.0 15 2.0 15.0 15

8.0 15.0 15 4.0 15.0 15

12.0 15.0 15 6.0 15.0 15

16.0 20.0 20 8.0 15.0 15

MCA MOPD FLA MCA MOPD

Condenser Manifolding Specications for Single Circuit

Connection Sizes

Model

NRGD02A014 (1) 1-1/8

NRGD04A027 (1) 2-1/8 (1)1-5/8

NRGD06A041 (1) 2-1/8 (1)1-5/8

NRGD08A054 (1) 2-5/8

Note: Contact factory for connection size if not single circuit

Inlet (in.)

Outlet (in.)

(1) 7/8

(1) 2-1/8

Circuiting Options

Model

NRGD02A014

NRGD04A027

Only single circuit available

Single circuit and 50/50 split available

Circuiting

Options Available

NRGD06A041

NRGD08A054

Single circuit, 33/33/33 and 66/33 split available

Single Circuit, 50/50 split and 75/25 split available, also

25/25/25/25 and 50/25/25

Note: These units are optimized for operation at or below 15° T.D.

Operation above 15° T.D. may result in excessive pressure drop.

4

Page 5

CAPACITY AND SPECIFICATIONS

Energy Performance

Condenser Performance Information: Energy Consumption

Unit Energy Consumption (kW)

Typical Operating Range

Model

at 30% Speed

(255 rpm)

NRGD02A014

NRGD04A027

NRGD06A041

NRGD08A054

Power Comparison Chart

0.1 0.3 0.6 1.6

0.2 0.5 1.2 3.2

0.3 0.8 1.8 4.9

0.3 1.0 2.4 6.5

at 50% Speed

(425 rpm)

at 70% Speed

(595 rpm)

at 100% Speed

(850 rpm)

BNHD06A044

BNLD06A042

BNED06A046

NRGD06A041

BNQDO8A041

5

Page 6

CAPACITY AND SPECIFICATIONS

Sound Performance

Condenser Performance Information: Sound Pressure

Sound Pressure (dBA @ 10ft)

Typical Operating Range

at 30% Speed

Model

NRGD02A014 44.3 50.6 57.6 66.5

NRGD04A027

NRGD06A041

NRGD08A054

(255 rpm)

47.3 53.7 60.6 69.5

49.1 55.4 62.4 71.3

50.3 56.7 63.6 72.5

at 50% Speed

(425 rpm)

at 70% Speed

(595 rpm)

at 100% Speed

(850 rpm)

Sound Comparison Chart

Source: http://www.sengpielaudio.com/tableofsoundpressurelevels.htm > Adjusted to 10ft

6

Page 7

CONDENSER SELECTION

Capacity for air-cooled condensers are based on Total Heat of Rejection (THR)

at the condenser. Total heat of rejection is equal to net refrigeration at the

evaporator (compressor capacity) plus the energy input into the refrigerant

by the compressor (heat of compression). The heat of compression will

vary depending on the compressor manufacturer, type of compressor

and the operating conditions of the compressor. Whenever possible, it is

recommended that you obtain the heat of compression value from the

compressor manufacturer.

If this is not available, the THR can be estimated using the following formula:

THR = (Compressor Capacity) * (Heat of Compression Factor, Tables 1 & 2)

Table 1 contains heat of compression factors for suction cooled compressors

and Table 2 contains factors for open drive compressors. For refrigeration

systems beyond the range of Tables 1 and 2, use the following equations to

estimate THR:

Open Compressors:

THR = Compressor Capacity (BTUH) + (2545) * (Break Horsepower, BHP)

Suction Cooled Compressors:

THR = Compressor Capacity (BTUH) + (3413 * KW)

The compressor capacity is aected by its altitude. If the condenser location

is above sea level, an additional correction is required to the THR, as follows:

THR (altitude) = THR * Altitude Correction Factor, Table 3

Selection Example

Compressor capacity: 270,000 BTUH

Evaporator temperature: +25° F

Condensing temperature: 110° F

Ambient temperature 95° F

Refrigerant: R-404A

Compressor type: Semi-hermetic, suction cooled

Condenser type: NRG

Condenser altitude: 1,000 feet

Step 1: Estimate Condenser THR

From Table 1 for suction cooled compressors, at +25° F suction and 115° F

condensing temperature, select a heat of compressor factor of 1.335.

THR = Compressor Capacity * Heat of Compression Factor

= 270,000 * 1.335

= 360,450

Step 2: Correct for Altitude

From Table 3 obtain an altitude correction factor of 1.02 for 1,000 feet.

THR = THR (from step 1) * Altitude Correction Factor (design)

= 360,450 * 1.02

= 367,659

Step 3: Calculate Design Condenser T.D.

Design Condenser T.D. = Condensing Temp — Ambient Temp

= 110°F - 95

= 15° T.D.

Note: These units are optimized for operation at or below 15° T.D.

Operation above 15° T.D. may result in excessive pressure drop.

Step 4: Condenser Selection

Condenser capacitiesare located on page 6. These capacities are given in

MBH/°TD. Convert the THR calculated in step 2 to MBH/°TD by dividing

by 1,000 to get THR in MBH. Then divide the THR by the design TD to get

MBH/°TD.

THR (MBH) = 367,659 / 1,000 = 367.7

THR (MBH/°TD) = 367.7 / 15 = 24.5

Locate the capacity column and read down until you locate a value equal to or

just larger than 24.5. This value is 27.0. Read horizontally to the left to obtain a

condenser model of NRGD04A027

Step 5: Calculate Actual T.D. and Condensing Temperature

The actual condenser T.D. can be calculated by dividing the design THR by

the condenser rating.

Actual T.D. = THR (Design) / (Rating @ 1° T.D.)

= 367.7 / 27.0

= 13.6°F. T.D.

The actual condensing temperature is the actual T.D. plus the ambient

temperature.

Actual Condensing Temperature = (Actual T.D.) + (Ambient)

= 13.6 + 95

= 108.6°F.

Table 1. Heat of Compression Factor for Suction Cooled Compressors.

Suction

Temp. °F

-40° 1.56 1.63 1.72 1.81 1.94

-30° 1.49 1.55 1.62 1.7 1.8

-20° 1.43 1.49 1.55 1.62 1.7

-10° 1.38 1.43 1.49 1.55 1.63

0° 1.34 1.38 1.43 1.49 1.56

5° 1.31 1.36 1.41 1.48 1.55

10° 1.29 1.34 1.39 1.44 1.52

15° 1.26 1.31 1.36 1.41 1.48

20° 1.24 1.28 1.33 1.38 1.44

25° 1.22 1.26 1.31 1.36 1.42

30° 1.2 1.24 1.28 1.33 1.39

40° 1.17 1.2 1.24 1.28 1.33

50° 1.13 1.16 1.2 1.24 1.28

90° 100° 110° 120° 130°

Condensing Temperature °F

Table 2. Heat of Compression Factor for Open Drive Compressors.

Evaporator

Temp. °F

-30° 1.37 1.42 1.47 — — —

-20° 1.33 1.37 1.42 1.47 — —

-10° 1.28 1.32 1.37 1.42 1.47 —

0° 1.24 1.28 1.32 1.37 1.41 1.47

5° 1.23 1.26 1.3 1.35 1.39 1.45

10° 1.21 1.24 1.28 1.32 1.36 1.42

15° 1.19 1.22 1.26 1.3 1.34 1.4

20° 1.17 1.2 1.24 1.28 1.32 1.37

25° 1.16 1.19 1.22 1.26 1.3 1.35

30° 1.14 1.17 1.2 1.24 1.27 1.32

40° 1.12 1.15 1.17 1.2 1.23 1.28

50° 1.09 1.12 1.14 1.17 1.2 1.24

90° 100° 110° 120° 130° 140°

Condensing Temperature °F

Table 3. Altitude Correction Factors.

Altitude Correction Factor

0 1

1,000 1.02

2,000 1.05

3,000 1.07

4,000 1.1

5,000 1.12

6,000 1.15

7,000 1.17

Table 4. Correction Factors.

Correction Factor Capactiy Refrigerant Charge

R-404A

R-22 1.02 1.09

R-410A

R-507 1.00 1.00

50 Hz Power Supply 1.00 --

1.00

1.02

1.00

1.07

7

Page 8

CONDENSER DIMENSIONS

Front View

Note: Drawing shown with standard 20” legs

Side View

2 Fan

4 Fan

6 Fan

8 Fan

* Note:Dimensional drawings include factory manifolding

8

Page 9

CONDENSER DIMENSIONS

Top View

2 Fan

4 Fan

6 Fan

8 Fan

* Note:Dimensional drawings include factory manifolding

9

Page 10

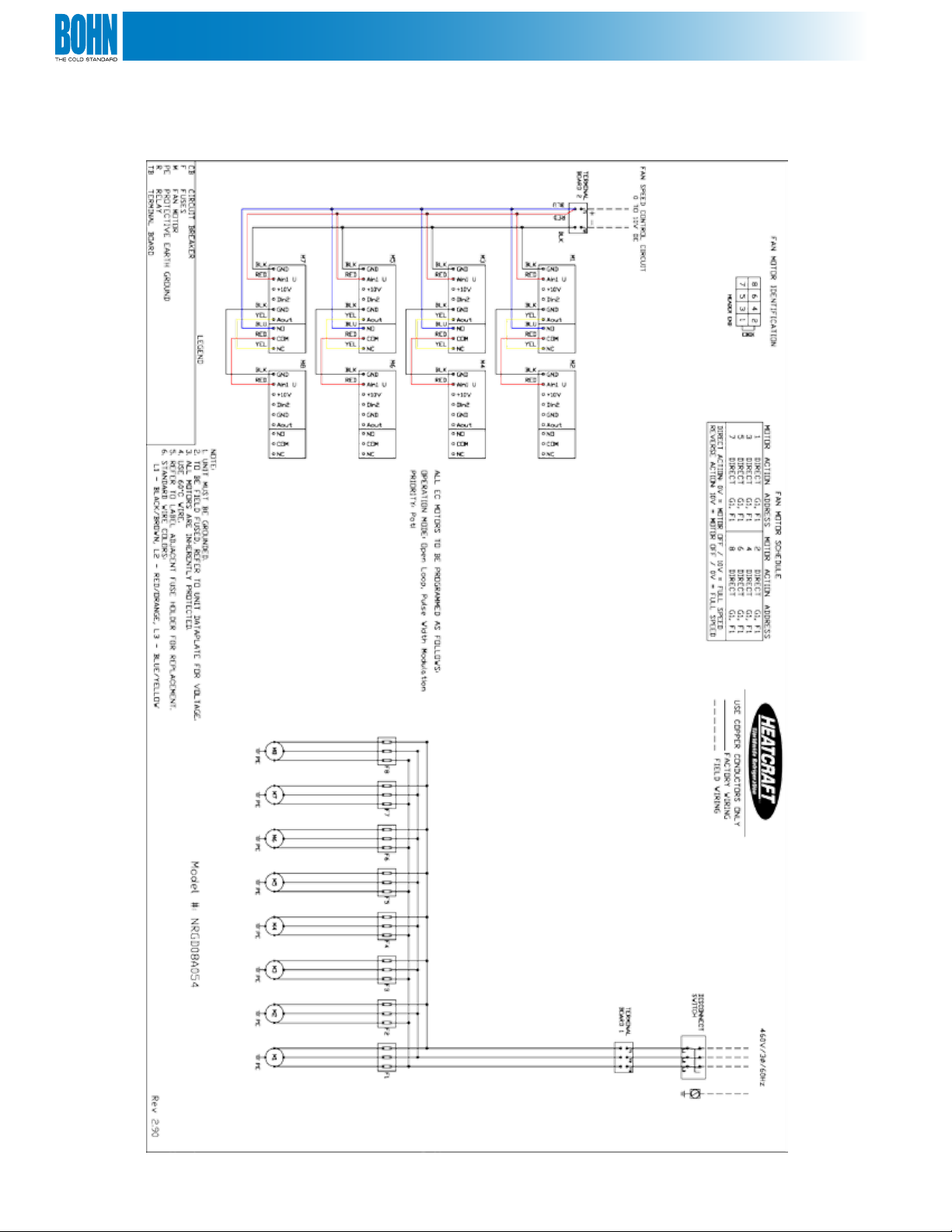

TYPICAL WIRING DIAGRAM

Diagram 1:

10

Page 11

Notes:

11

Page 12

For more information on Bohn refrigeration products, contact

your sales representative or visit us at www.heatcraftrpd.com.

A Brand of Heatcraft Refrigeration Products, LLC

2175 West Park Place Blvd. • Stone Mountain, GA • 30087

800.537.7775

www.heatcraftrpd.com

Since product improvement is a continuing eort, we reserve the right to

make changes in specications without notice.

12

BN-TB-ACCMCX

Loading...

Loading...