Page 1

Installation &

Operations Manual

Supplement

Bulletin No. H-IM-GUC September 2009 Part Number 25007501

Glycol Unit Coolers

NOTE: See H-IM-UC for instructions on Receiving Inspection, Warranty, Unit Cooler

Placement, Electrical Wiring and Routine Maintenance.

Model Prex Product Family

ADTG / LCA6G Low Prole (Air Defrost)

HGTG / LCH6G Low Prole (Warm Fluid Defrost)

WKAG / LWAG Low Velocity (Air Defrost)

WKGG / LWGG Low Velocity (Warm Fluid Defrost)

BMAG / MMT6G Medium Prole (Air Defrost)

LETG / LCE6G Low Prole (Electric Defrost)

WKEG / LWEG Low Velocity (Electric Defrost)

Air Defrost

The air defrost method is for applications where the

room temperature remains above freezing. See HIM-UC for details.

Warm Fluid Defrost

For applications where the room temperature is held

below freezing, an additional heat source must be

employed to periodically clear the unit cooler of frost.

A common method is warm uid defrost. During a

scheduled defrost period, the regular ow of cold

uid is stopped and warm uid is circulated through

the unit cooler to defrost the coil surface.

Unit coolers congured for warm uid defrost include

a control to turn o the fans and turn on electric drain

pan heaters when warm uid is sensed at the inlet

header. After the termination of the defrost period

(generally by a system controller), the ow of cold

uid is restored and the control will re-energize the

fans. See wiring diagram on unit for factory control

settings.

Electric Defrost

For applications where the room temperature is held

below freezing. During a scheduled defrost period,

electric heaters are energized to defrost the coil

surface.

© 2009 Heatcraft Refrigeration Products LLC

Installation, Startup and Operation

1. A heat transfer uid should be selected with

a sucient glycol percentage to ensure freeze

protection. Propylene glycol is usually employed for

applications related to food.

2. In general, the chiller manufacturer’s procedure

for charging and startup should be followed. Unit

capacity, uid ow rate and pressure drop with the

uid to be used should be taken into account during

the system selection and design process.

3. Field piping should comply with applicable codes.

Correct pipe sizing is important and will help reduce

pumping power and operating costs. The system

should be thoroughly leak tested after piping is

complete.

4. To control the ow rate of uid through the unit

cooler, a balance valve is generally installed on the

outlet (top) coil connection during installation. The

valve manufacturer’s adjustment procedure should be

followed during startup.

5. To provide an isolation means, a shut-o valve is

usually installed on the inlet (bottom) coil connection

during installation.

6. Vent and drain valves are provided on each unit

cooler.

Page 2

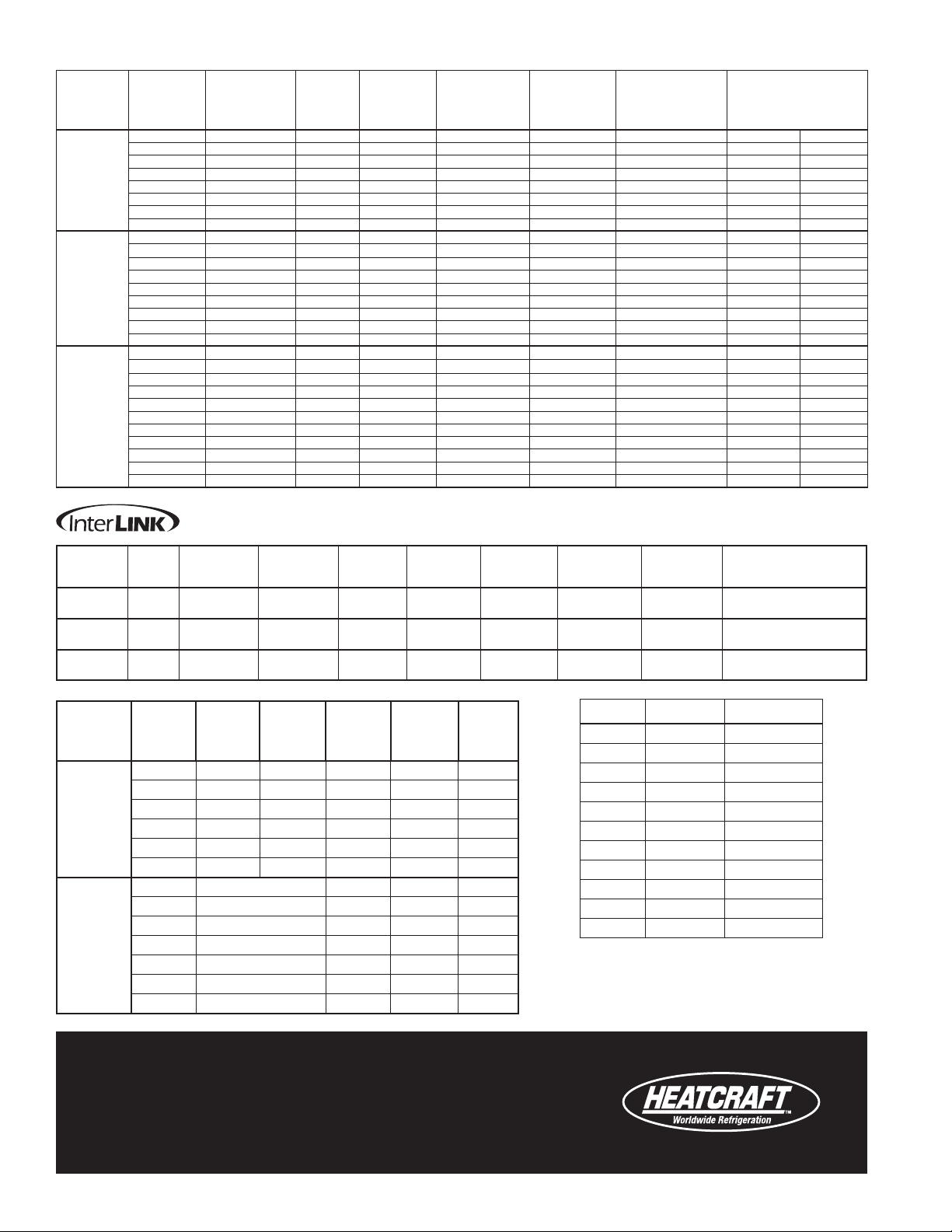

GLYCOL UNIT COOLER WEIGHTS AND FLUID CAPACITIES

AIR

PRODUCT

FAMILY

LOW

PROFILE

LOW

VELOCITY

MEDIUM

PROFILE

*Based on 35% (by volume) Propylene Glycol

DEFROST

MODEL

SIZE

0400 --- 4 7/8 0.06 / 0.002 50 / 23 53 / 24 4 / 2 0.4 / 1.7

0475 0475 5 7/8 0.08 / 0.002 52 / 24 55 / 25 5 / 2 0.6 / 2.3

0525 0525 6 7/8 0.08 / 0.002 55 / 25 58 / 26 5 / 2 0.6 / 2.3

0725 0725 10 7/8 0.12 / 0.003 70 / 32 73 / 33 8 / 4 0.9 / 3.4

0900 0900 10 1-1/8 0.16 / 0.005 83 / 38 86 / 39 10 / 5 1.2 / 4.5

1000 --- 10 1-1/8 0.20 / 0.006 104 / 47 107 / 48 13 / 6 1.5 / 5.7

1300 1300 10 1-3/8 0.35 / 0.010 109 / 49 113 / 51 23 / 10 2.6 / 9.9

1475 1475 10 1-3/8 0.42 / 0.012 134 / 61 139 / 63 27 / 12 3.1 / 11.9

0330 --- 4 7/8 0.08 / 0.002 72 / 33 75 / 34 5 / 2 0.6 / 2.3

0425 --- 6 7/8 0.23 / 0.007 105 / 48 108 / 49 15 / 7 1.7 / 6.5

0700 0700 10 7/8 0.17 / 0.005 108 / 49 111 / 50 11 / 5 1.3 / 4.8

0875 0875 12 1-1/8 0.33 / 0.009 151 / 68 155 / 70 22 / 10 2.5 / 9.3

0975 0975 20 1-1/8 0.33 / 0.009 151 / 68 155 / 70 22 / 10 2.5 / 9.3

1025 1025 12 1-1/8 0.33 / 0.009 163 / 74 167 / 76 22 / 10 2.5 / 9.3

1225 1225 20 1-1/8 0.33 / 0.009 163 / 74 167 / 76 22 / 10 2.5 / 9.3

1450 1450 20 1-1/8 0.44 / 0.012 196 / 89 204 / 93 29 / 13 3.3 / 12.5

1650 1650 20 1-3/8 0.55 / 0.016 247 / 112 254 / 115 36 / 16 4.1 / 15.6

0900 --- 6 7/8 0.23 / 0.007 132 / 60 --- 15 / 7 1.7 / 6.5

1100 --- 5 1-1/8 0.34 / 0.010 150 / 68 --- 22 / 10 2.5 / 9.6

1275 --- 6 7/8 0.45 / 0.013 165 / 75 --- 29 / 13 3.4 / 12.7

1600 --- 9 1-1/8 0.45 / 0.013 165 / 75 --- 29 / 13 3.4 / 12.7

1700 --- 9 1-1/8 0.5 / 0.014 225 / 102 --- 33 / 15 3.7 / 14.2

1900 --- 13 1-1/8 0.5 / 0.014 225 / 102 --- 33 / 15 3.7 / 14.2

2175 --- 12 1-3/8 0.66 / 0.019 247 / 112 --- 43 / 20 4.9 / 18.7

2400 --- 13 1-5/8 0.66 / 0.019 267 / 121 --- 43 / 20 4.9 / 18.7

2425 --- 12 1-3/8 0.88 / 0.025 300 / 136 --- 57 / 26 6.6 / 24.9

2850 --- 18 1-3/8 0.88 / 0.025 300 / 136 --- 57 / 26 6.6 / 24.9

3100 --- 18 1-3/8 1.00 / 0.028 338 / 154 --- 65 / 30 7.5 / 28.3

WARM FLUID

DEFROST

MODEL

SIZE

#

COIL

CIRCUITS

COIL

HEADER

CONN

OD in.

UNIT

INTERNAL

VOLUME

ft³ / m³

AIR DEFR.

NET WT.

(EMPTY)

lbs / kg

ELEC & W.F. DEFR.

NET WT.

(EMPTY)

lbs / kg

UNIT INTERNAL

FLUID CAPACITY

lbs / kg * gal / l

Commercial Refrigeration Parts

PRODUCT

FAMILY FAN

LOW

PROFILE

LOW

VELOCITY

MEDIUM

PROFILE

+ Motor construction is TE (totally enclosed)

PRODUCT

FAMILY

LOW

PROFILE

LOW

VELOCITY

REPLACEMENT PARTS FOR GLYCOL UNIT COOLER 800.686.7278 • www.interlinkparts.com

MOTOR

115V

Shaded Pole

5140C 25300101 25300201 25309501+ 25309801 25308701 25317801 25317701

5110E 5036S 5036T 5036N 5036P --- 25318001 25317901 5055F

5130C --- --- 5020S 5020T 25302201 25317601 25317501

ELEC. & W.F.

DEFROST

MODEL

SIZE

0475 24752102 24752202 24752302 24752002 4267W

0525 24752102 24752202 24752302 24752002 4267W

0725 24752103 24752203 24752303 24752003 4267W

0900 24752104 24752204 24752304 24752004 4267W

1300 24752105 24752205 24752305 24752005 4267W

1475 24752106 24752206 24752306 24752006 4267W

0700 4543B --- 4543B 4267W

0875 4544B --- 4544B 4267W

0975 4544B --- 4544B 4267W

1025 4544B --- 4544B 4267W

1225 4544B --- 4544B 4267W

1450 4545B --- 4545B 4267W

1650 4546B --- 4546B 4267W

DRAIN PAN

HEATER

115V

MOTOR

208-230V

Shaded Pole

DRAIN PAN

HEATER

208-230V

MOTOR

115V

PSC

DRAIN PAN

HEATER

460V

MOTOR

208-230V

PSC

COIL

DEFROST

HEATER

HEATER

AND FAN

CONTROL

MOTOR

460V

PSC

MOTOR

115V

EC TE

P/N CONN SIZE in. DESCRIPTION in.

29315801 1/8 MPT x 1/4 FL Vent / Drain Valve

29320305 5/9 ODF Balance Valve 1/2

29320304 7/8 ODF Balance Valve 3/4

29320301 1-1/8 ODF Balance Valve 1

29320302 1-3/8 ODF Balance Valve 1-1/4

29320303 1-5/8 ODF Balance Valve 1-1/2

29320405 5/8 ODF Shut-O Valve 1/2

29320404 7/8 ODF Shut-O Valve 3/4

29320401 1-1/8 ODF Shut-O Valve 1

29320402 1-3/8 ODF Shut-O Valve 1-1/4

29320403 1-5/8 ODF Shut-O Valve 1-1/2

NOTE: Shipped loose balance and shut-o valves are sized

to match the design uid ow rate, not the coil connection

size. Balance valves include insulation block.

MOTOR

208-230V

EC TE

FAN GUARD

BOHN/LARKIN

37000701 (Molded)

37000601 (Wire)

4339X / 2310022 (Molded)

5036E / 23101802 (Wire)

Visit our website at www.heatcraftrpd.com for technical literature online.

Heatcraft Refrigeration Products LLC

2175 West Park Place Blvd., Stone Mountain, GA 30087

Ph.: 800.321.1881 • www.heatcraftrpd.com

Since product improvement is a continuing eort, we reserve the right to make changes in specications without notice.

H-IM-GUC-0909 | version 000

Loading...

Loading...