Page 1

REACHIN UNIT COOLERS

Technical Guide

Models TA, TL, C, VA, BBM, BBL, KMK, RAMK, BTO & U

BNRITB

January 2004

(Replaces 107.2, 01/04)

Page 2

Table of Contents

Model TA Thin Prole Air Defrost ................................................................................................................... 3

Model TL Thin Prole Electric Defrost ..........................................................................................................

Model C High Prole ..........................................................................................................................................

Model VA Vee-Aire ..............................................................................................................................................

Models BBM/BBL Back Bar ...............................................................................................................................

Model KMK Kompact Mullion .........................................................................................................................

Model RAMK Reverse Air Flow Kompact Mullion ....................................................................................

Model BTO Twin Flow ......................................................................................................................................

Model U ................................................................................................................................................................

4

5

6

7

8

9

10

11

2

©2007 Heatcraft Refrigeration Products LLC

Page 3

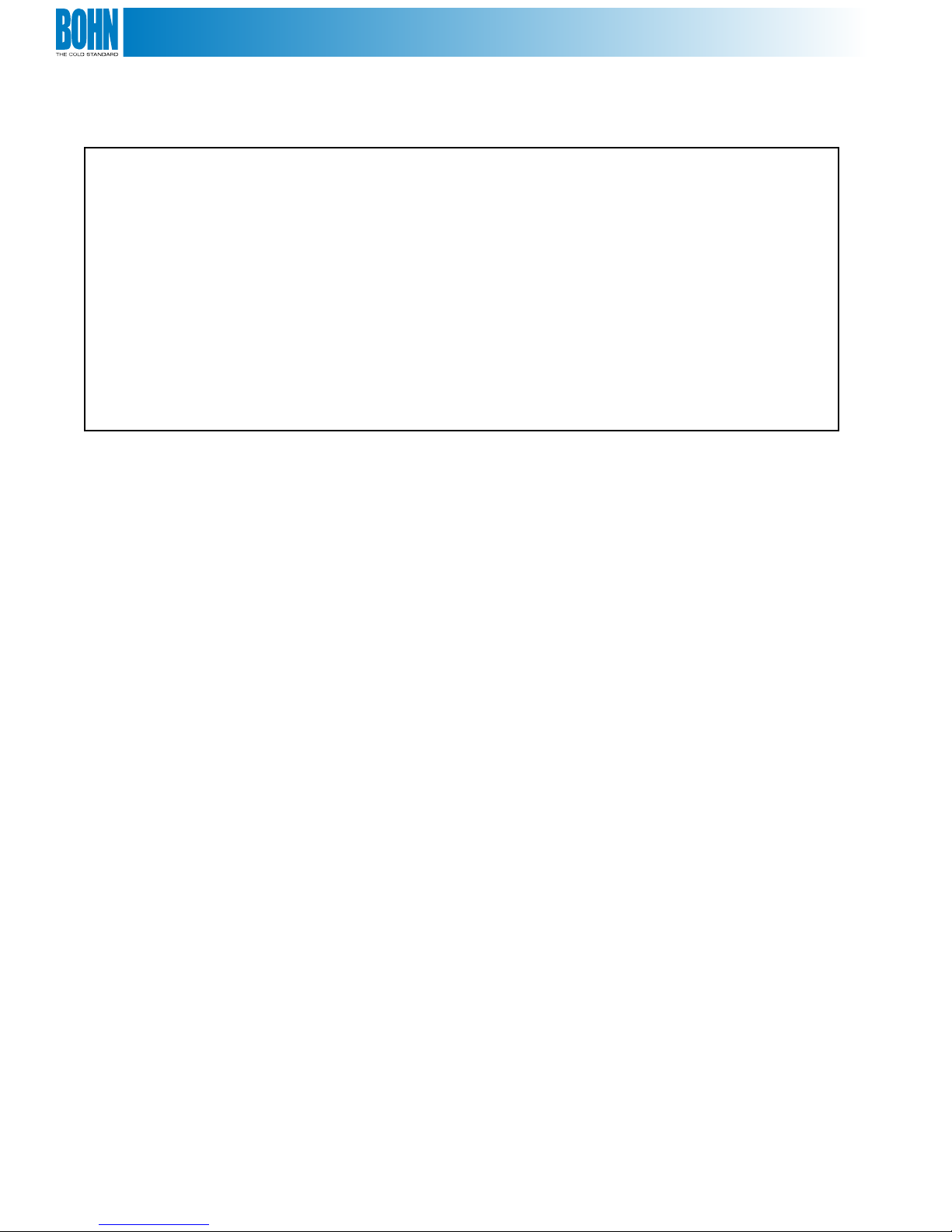

Model TA

Thin Prole Air Defrost Reach-In Unit Cooler

Features

• Textured aluminum cabinet

• Molded Lexan® guards and fans

• Drain tting mounted at 45-degree angle so drain

can be run through back or bottom of refrigerator

• Room for expansion valve inside the unit

• Stainless steel screws

• Motors are thermally protected and

permanently lubricated

• Convenient, moistureproof motor plug

• Compact design! Does a big job in a small space

• Optional Bohn-Kote® coated coil available (Model TAK)

for optimum protection in corrosive environments

• Internal junction box for electrical connection

• All models are UL listed for the US and Canada

• UL classied to NSF standards

Sweat inlet connection to reduce leaks

(are connection available as a ship loose option)

Application

Model TA is a thin prole unit which mounts in the top of

a refrigerator and makes the entire top shelf area usable. The

attractive low silhouette makes the unit particularly desirable

for display type refrigerators. It can also be used in back bars,

under counter cabinets, or wherever space is at a premium.

For 35° to 45°F xtures at 10° to 15° TD applications with 16

hours maximum compressor run time per day.

Nomenclature

Thin Prole Air Defrost

TA (K) 17 B G

Bohn-Kote® Coil

(Optional)

Size

Vintage

Voltage

A = 115/1/60

B = 208-230/1/60

Table 1. Performance and Electrical Data

Model

TA10 1,000 120 1 0.8 0.4 3/8 3/8 1/2 14

TA13 1,300 170 2 1.6 0.8 3/8 3/8 1/2 17

TA17 1,700 210 2 1.6 0.8 3/8 3/8 1/2 21

TA23 2,300 330 3 2.4 1.2 3/8 3/8 1/2 28

TA30 3,000 360 3 2.4 1.2 3/8 1/2 1/2 33

TA43

TA55

†

Models 43 and 55 use external equalized expansion valve

BTUH

10°F TD

†

4,300 540 4 3.2 1.6 1/2 5/8 1/2 44

†

5,500 650 5 4.0 2.0 1/2 5/8 1/2 53

CFM Qty.

Motor Data Connections (in.) Approx.

115/1/60

Total FLA

208-230/1/60

Total FLA

Coil Inlet

OD

SuctionIDDrain

OD

Table 2. Physical Data

Model

TA10 14-5/8 14 15/16 13-1/2 10-1/2 11-3/8 4-1/2 8-7/8 2-1/2 15/16 4-3/8 16-1/2

TA13 18-5/8 14 15/16 13-1/2 10-1/8 10-1/4 4-1/2 8-3/8 9-1/2 15/16 4-3/8 20-1/2

TA17 22-1/8 15 15/16 14-1/2 11-1/8 12 4-1/2 9-3/8 11-1/4 15/16 4-3/8 24

TA23 29-3/4 15 15/16 14-1/2 13 20-7/8 4-1/2 10-3/4 10-1/4 15/16 4-3/8 31-5/8

TA30 38-1/8 15 15/16 14-1/2 13 29-3/4 4-1/2 10-3/4 9-3/4 15/16 4-3/8 40

TA43 51-1/2 15 15/16 14-1/2 13 48-3/4 4-1/2 10-3/4 13-1/4 15/16 4-3/8 53-3/8

TA55 51-1/2 15 15/16 14-1/2 13 49 6-3/4 10-3/4 11 15/16 4-3/8 53-3/8

A B C D E F H J K L M W

Dimensions (in.)

Diagram 1. Dimensions

Ship Wt.

(lbs.)

3

Page 4

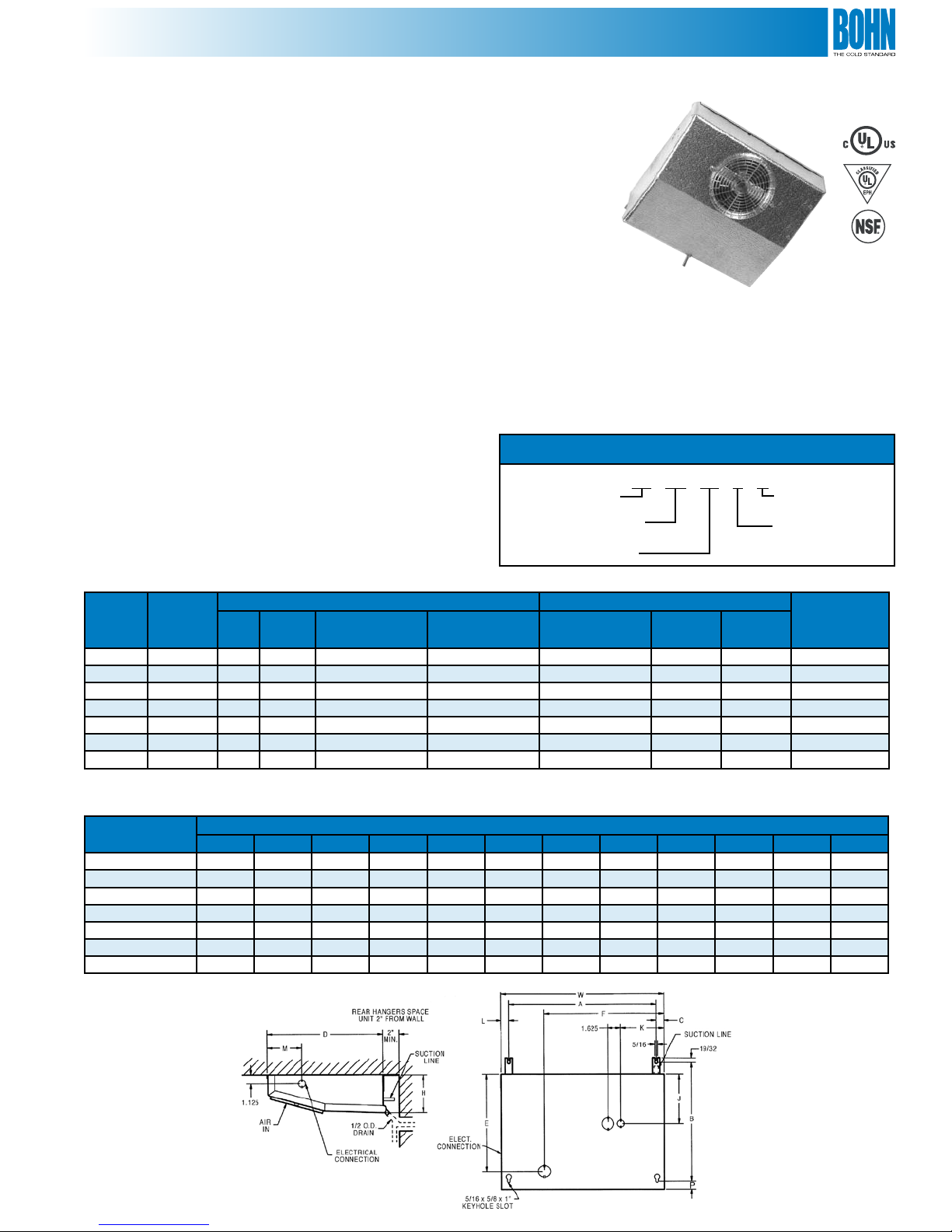

Model TL

Thin Prole Electric Defrost Reach-In Unit Cooler

Features

• Electric defrost insures positive heat source

• Built-in fan delay allows coil to be chilled before returning

to the normal cooling cycle

• Defrost terminates on coil temperature eliminating

excessive defrost period

• Textured aluminum cabinet

• Molded Lexan® guard

• Knockouts provided on sides for electrical

connections - opening in rear for coil connections

• Stainless steel screws

• Motors are thermally protected and

permanently lubricated

• Internal junction box for electrical connection

• Plate type aluminum ns with full collars on expanded

copper tubes

• Coils are dehydrated and sealed

• Easy to install and maintain

• All models UL listed for the US and Canada

• UL classied to NSF standards

Sweat inlet connection to reduce leaks

(are connection available as a ship loose option)

Application

Model TL low temperature unit cooler has a completely

automatic defrost system. Mounted in the top of a refrigerator, its

extremely compact cabinet makes it possible to utilize the entire

top shelf area for storage. Having a normal operating range of

15°F to -20°F, this unit is ideally suited for such applications as

commercial freezers, ice cream boxes and bakery freezers.

Nomenclature

Thin Prole

Electric Defrost

Size

TL 12 B G

Vintage

Voltage

A = 115/1/60

B = 208-230/1/60

Table 3. Performance and Electrical Data

BTUH 10˚F TD Motor Data Heater Data Connections (in.) Approx.

Model

TL09 1,050 900 110 1 0.8 0.4 475 4.1 2.1 3/8 3/8 1/2 14

TL12 1,380 1,200 210 2 1.6 0.8 600 5.2 2.6 3/8 1/2 1/2 19

TL16 1,780 1,600 210 2 1.6 0.8 700 6.1 3.0 3/8 1/2 1/2 23

TL21 2,400 2,100 240 1 1.0 0.5 1,100 9.6 4.8 3/8 1/2 1/2 24

TL28 3,200 2,800 335 3 - 1.2 1,430 - 5.7 3/8 1/2 1/2 27

TL35* 4,000 3,500 420 2 - 1.0 1,600 - 7.0 1/2 5/8 1/2 38

TL53* 6,100 5,300 595 3 - 1.5 1,950 - 8.5 1/2 7/8 1/2 53

* Models 35 and 53 use external equalized expansion valves

20˚F

SST

-10˚F

SST

CFM Qty.

115/1/60

Total FLA

208-230/1/60

Total FLA

Watts

115/1/60

Amps

208-230/1/60

Amps

Coil InletODSuctionIDDrain

OD

Ship Wt.

Table 4. Physical Data

Model

TL09 14-5/8 14 15/16 13-1/2 10-1/2 11-3/8 4-1/2 8-7/8 2-1/2 15/16 4-3/8 - 1 16-1/2

TL12 18-5/8 14 15/16 13-1/2 10-1/8 10-1/4 4-1/2 8-3/8 9-1/2 15/16 4-3/8 - 1 20-1/2

TL16 22-1/8 15 15/16 14-1/2 11-1/8 12 4-1/2 9-3/8 11-1/4 15/16 4-3/8 - 1 24

TL21 22-1/8 16-1/2 15/16 16-1/2 14-1/2 18-7/8 6-3/4 11-7/8 17-1/4 15/16 4-3/8 - 1-1/2 24

TL28 29-3/4 15 15/16 14-1/2 13 20-3/4 6-3/4 9-3/4 9-7/8 15/16 4-3/8 - 1 31-5/8

TL35 35-3/4 16-1/2 15/16 16-1/2 14-1/2 33-1/4 6-3/4 11-5/8 18-3/8 15/16 6 5-1/8 1-1/2 38-3/8

TL53 46-1/2 16-1/2 1-1/8 16-1/2 14-1/2 44 6-3/4 11-5/8 30-3/8 1-1/2 6 5-1/8 1-1/2 49-1/8

A B C D E F H J K L M N P W

Dimensions (in.)

Diagram 2. Dimensions

(lbs.)

4

Page 5

Model C

High Prole Reach-In Unit Cooler

Features

• Textured aluminum cabinet

• Molded Lexan® guard

• Drain tting at 45-degree angle so drain can be run

through bottom or back of refrigerator

• Aluminum hangers automatically space the unit to the

correct distance from the back wall

• Stainless steel screws - prevent rust streaks

• Room for expansion valve inside the unit

• Knockouts in sides and top plus openings in rear provide

maximum exibility for electrical connection

• Full collar aluminum ns on expanded copper tubes

• Internal junction box with pigtail leads for

electrical connection

• Motors are thermally protected and

permanently lubricated

• All models UL listed for US and Canada

• UL classied to NSF standards

• Optional Bohn-Kote® coated coil available (Model CK)

for optimum protection in corrosive environments

Sweat inlet connection to reduce leaks

(are connection available as a ship loose option)

Application

Model C is the ideal unit for refrigerated reach-ins. It mounts

to the top of the refrigerator and discharges cold air against the

back wall. With this air ow pattern, the air is not blasted on

the product but is diused along the back wall and then gently

drawn across the product as it returns to the unit. Thus uniform

temperatures are maintained throughout the refrigerator. In

addition, door sweating and refrigeration loss due to door

opening is greatly reduced because the air is not discharged

against the doors.

Nomenclature

High Prole Unit Cooler

C (K) 43 B G

Bohn-Kote® Coil

(Optional)

Size

Vintage

Voltage

A = 115/1/60

B = 208-230/1/60

Table 5. Performance and Electrical Data

Model

C13 1,300 235 1 1.0 0.5 3/8 3/8 1/2 16

C17 1,700 250 1 1.0 0.5 3/8 1/2 1/2 17

C23 2,300 265 1 1.0 0.5 3/8 1/2 1/2 22

C30 3,000 480 2 2.0 1.0 3/8 1/2 1/2 27

C43

†

Model 43 uses external equalized expansion valve

BTUH

10°F TD

†

4,300 520 2 2.0 1.0 1/2 1/2 1/2 40

CFM Qty.

Motor Data Connections (in.) Approx.

115/1/60

Total FLA

208-230/1/60

Total FLA

Coil Inlet

OD

SuctionIDDrain

OD

Table 6. Physical Data

Model

C13 12-5/8 12-3/8 11-7/16 1-3/8 14-1/4

C17 15-5/8 12-3/8 14-7/16 1-3/8 17-1/4

C23 21-1/8 12-3/8 21-1/16 7/8 22-3/4

C30 26-1/8 12-3/8 25-13/16 1 27-3/4

C43 36-5/16 - - - 38

A B C D W

Dimensions (in.)

Diagram 3. Dimensions

Ship Wt.

(lbs.)

5

Page 6

Model VA

Vee-Aire Reach-In Unit Cooler

Features

• Textured aluminum cabinet

• Molded Lexan® fan guard

• Improved drain pan overlaps coil surface to catch

all condensate

• Stainless steel screws - prevent rust streaks

• Plate-type aluminum ns with full collars on

expanded copper tubes

• Expansion valve mounts inside cabinet

• Internal junction box for electrical connection

• Pigtail leads in junction box

• Motors are thermally protected and

permanently lubricated

• Top quality throughout in a compact size

• All models UL listed for US and Canada

• UL classied to NSF standards

• Optional Bohn-Kote® coated coil available (Model VAK)

for optimum protection in corrosive environments

Sweat inlet connection to reduce leaks

(are connection available as a ship loose option)

Application

Model VA is a deluxe unit designed for use in small reach-

ins, back bar and under counter refrigerators, and many other

applications where a small, compact unit is required. The thermal

expansion valve mounts inside the unit. The unit can be mounted

from the ceiling or o the back wall or end walls.

Nomenclature

V Prole Unit Cooler

VA (K) 08 A G

Bohn-Kote® Coil

(Optional)

Size

Vintage

Voltage

A = 115/1/60

B = 208-230/1/60

Table 7. Performance and Electrical Data

Model

VA06 600 135 1 0.8 0.4 3/8 3/8 1/2 9

VA08 800 130 1 0.8 0.4 3/8 3/8 1/2 9

VA12 1,200 265 2 1.6 0.8 3/8 3/8 1/2 14

VA17 1,700 245 1 1.0 0.5 3/8 3/8 1/2 11

BTUH

10°F TD

CFM Qty.

Motor Data Connections (in.) Approx.

115/1/60

Total FLA

208-230/1/60

Total FLA

Coil Inlet

OD

SuctionIDDrain

OD

Table 8. Physical Data

Model

VA06 4-5/16 13-1/4 4-5/16 - - 3-3/8 6-7/8 5-1/4 8-1/8 12-1/2

VA08 4-5/16 13-1/4 4-5/16 - - 3-3/8 6-7/8 5-1/4 8-1/8 12-1/4

VA12 4-1/2 18-3/4 5-5/16 - - 3-3/8 8 4-7/8 8-1/8 18

VA17 5-1/4 14-3/4 5-1/4 9 2-1/2 4 9-3/4 6-13/16 10-1/2 14

A B C D E F H J K W

Dimensions (in.)

Diagram 4. Dimensions

Ship Wt.

(lbs.)

6

Page 7

Models BBM/BBL

Back Bar Reach-In Unit Cooler

Features

• Molded Lexan® fan guards

• Coils have copper tubes with aluminum ns, mechanicallybonded for ecient heat transfer. The coils are dehydrated

and sealed

• Textured aluminum cabinet

• Knockouts are conveniently located for refrigerant lines

• Screws are hardened, stainless steel with a bright

zinc plating

• Expansion valve mounts inside the cabinet and

connections are sweat-type

• Motors are thermally protected and

permanently lubricated

• Master units include the basic unit plus factory mounted

expansion valve, solenoid, and temperature control. Also

right-hand piping extended 8” - 12” outside the housing,

sealed and pressurized to 20 - 30 PSI. A 1/4” OD liquid feed

to slave is included

• Slave units include the basic unit plus factory mounted

expansion valve with left-hand piping extended 8” - 12”

outside the housing, sealed and pressurized to 20 - 30 PSI

Sweat inlet connection to reduce leaks

(are connection available as a ship loose option)

Table 9. Performance and Electrical Data

BTUH

Model

BBM11 1,100 90 1 1/150 0.8 0.4 - - -

BBM16 1,600 180 2 1/150 1.6 0.8 - - -

10°F

CFM Qty. HP

TD

BBL10 1,000 90 1 1/150 0.8 0.4 275 2.7 1.4

BBL15 1,500 180 2 1/150 1.6 0.8 350 3.5 1.7

Motor Data Defrost Heaters

115/1/60

Total FLA

208230/1/60

Total FLA

Watts

115/1/60

Application

Models BB are compact, wall-mounted units whose low

height makes them ideal for undercounter reach-in or drawertype xtures. The unit draws air in at the bottom and discharges

out the front. An optional air deector is included and can be

mounted over the center of the fan to direct air up and out. The

deector can be eld-formed to direct the air where needed,

usually onto drop-in trays of condiments in salad bar or sandwich

preparation xtures. An S-type mounting angle is included

to position the unit 3/4” o the wall which gives optimum air

circulation and performance.

The BBM (medium temperature) model is designed for 35°

to 40°F xture temperature with o-cycle defrost. The unit

is designed to operate at 10° to 17° TD and 16 hours per day

compressor run time.

The BBL (low temperature) model is designed for 0° to -10°F

xture temperature, and has automatic electric defrost. The

unit is designed to operate at 8° to 15° TD with 18 hours per

day compressor runtime. The BBL has an incoloy sheath heater

embedded in the bottom n surface for ecient and fast

defrosting. A drain pan heater is included to insure complete

condensate drainage. A disc-type sealed defrost termination/

fan delay control is mounted and wired. Field connectors are

located at the terminal board.

Amps

230/1/60

Amps

208-

Back Bar Unit Cooler

L = Low Temp. Unit

M = Med. Temp. Unit

Blank = Standard Unit

S = Slave Unit

M = Master Unit

Nomenclature

BB L S 10 A G

Vintage

Voltage

A = 115/1/60

B = 208-230/1/60

Size

Table 10. Physical Data

Model

BBL10 19-1/8 18 17-1/2 7-1/16 - 16-5/8 19-3/4 17

BBM11 19-1/8 18 17-1/2 7-1/16 - 16-5/8 19-3/4 16

BBL15 25-5/8 24-1/2 24 4-13/16 8-5/8 23-1/8 26-1/4 20

BBM16 25-5/8 24-1/2 24 4-13/16 8-5/8 23-1/8 26-1/4 19

NOTES: All units have 3/8” OD suction, 1/2” OD sweat inlet and 1/2” OD drain

A B C D E F W

Dimensions (in.) Approx.

Diagram 5. Dimensions

Ship Wt. (lbs.)

Typical Section of

Sandwich Station

Model BBM

7

Page 8

Model KMK

Kompact Mullion Reach-In Unit Cooler

Features

• Light grained aluminum cabinets

• PVC coated fan guard

• Stainless steel hardware

• Coils have full collar aluminum ns on expanded

copper tubes

• Bohn-Kote® coated coil for optimum protection in

corrosive environments

• Refrigerant connection knockouts provided on both

ends of unit

• Expansion valve mounts inside the unit

• Motors are thermally protected and

permanently lubricated

• Internal junction box for electrical connection

• Adjustable air deector included provides dierent air

patterns. Air can be directed where its needed

• All models UL listed for the US and Canada

• UL classied to NSF standards

Sweat inlet connection to reduce leaks

(are connection available as a ship loose option)

Application

Model KMK is ideal for under-counter reach-in refrigerators.

The thin line design allows the unit to be mounted behind the

mullion with sucient clearance for tray slides. A down ow fan

arrangement is used with air drawn in at the top and discharged

at the bottom. This design provides superior air circulation and

insures uniform temperature throughout the cabinet.

This versatile design is also adaptable for mounting on the back

wall or ends of a cooler. The method of air circulation insures

minimum box temperature rise when the cabinet doors are

open. Ideal for bottle goods and beverage coolers.

Exclusive Bohn-Kote® Finish is Standard

The nned coil is protected by Bohn-Kote® - a special dip

coating that is baked on. Bohn-Kote® prevents corrosion of the

coil caused by acids that are present in salad dressings, spiced

meats and other food products.

Table 11. Performance and Electrical Data

BTUH

Model

KMK13 1,300 180 2 1.6 0.8 3/8 3/8 5/8 19

KMK17 1,700 170 2 1.6 0.8 3/8 3/8 5/8 20

KMK23 2,300 255 3 2.4 1.2 3/8 1/2 5/8 28

10°F

TD

CFM Qty.

Table 12. Physical Data

Model

KMK13 17-3/4 16-7/8 9 15-5/8 2-3/4 5-1/2 6-15/16

KMK17 19-3/4 16-7/8 10 15-5/8 2-3/4 6-1/2 7-15/16

KMK23 19-3/4 23-1/4 10 22 2-5/16 6-1/2 7-15/16

H L M W X Y Z

Motor Data Connections (in.) Approx.

115/1/60

Total FLA

208-230/1/60

Total FLA

Coil InletODSuctionIDDrain

OD

Nomenclature

Dimensions (in.)

Kompact Mullion

Bohn-Kote® Coil

KM K 13 A G

Size

Diagram 6. Dimensions

Ship Wt.

(lbs.)

Vintage

Voltage

A = 115/1/60

B = 208-230/1/60

8

Page 9

Model RAMK

Reverse Air Flow Kompact Mullion Reach-In Unit Cooler

Features

• Textured aluminum cabinet

• PVC coated fan guard

• Stainless steel hardware

• Coils have full collar aluminum ns on expanded

copper tubes

• Bohn-Kote® coated coil for optimum protection in

corrosive environments

• Refrigerant connection knockouts provided on both

ends of unit

• Expansion valve mounts inside the unit

• Motors are thermally protected and

permanently lubricated

• Internal junction box for electrical connection

• Adjustable air deector included provides dierent

air patterns. Air can be directed where its needed

• All models are UL listed for the US and Canada

• UL classied to NSF standards

Sweat inlet connection to reduce leaks

(are connection available as a ship loose option)

Table 13. Performance and Electrical Data

BTUH

Model

RAMK13 1,300 180 2 1.6 0.8 3/8 3/8 5/8 19

RAMK17 1,700 170 2 1.6 0.8 3/8 3/8 5/8 20

RAMK23 2,300 255 3 2.4 1.2 3/8 1/2 5/8 28

10°F

TD

CFM Qty.

Motor Data Connections (in.) Approx.

115/1/60

Total FLA

208-230/1/60

Total FLA

Application

Model RAMK is ideal for under-counter reach-in refrigerators,

under-counter drawer type refrigerators and salad bars. The

unit is suitable for mounting behind a mullion or on a wall. An

up ow air pattern is used with air drawn in at the bottom and

discharged out the top. This provides optimum temperature for

drop in trays on salad bars or prep tables. It also keep drawer

stored product in premium condition.

An adjustable and detachable air deector/splash protector

is included. The deector can be adjusted to direct the air up

and out at a 45-degree angle. This feature provides excellent

air distribution over drop in trays or containers. Food in the

trays and containers stays colder, lasts longer, and retains the

desired appearance. The deector can be adjusted to distribute

air out both sides when used as a mullion unit.

Exclusive Bohn-Kote® Finish is Standard

The nned coil is protected by Bohn-Kote® - a special dip coating

that is baked on to prevent corrosion of the coil by acids that

are present in salad dressings, spiced meats and other food

products.

Coil InletODSuctionIDDrain

Ship Wt.

OD

(lbs.)

Table 14. Physical Data

Model

RAMK13 17-3/4 16-7/8 9 15-5/8 2-3/4 5-1/2 6-15/16

RAMK17 19-3/4 16-7/8 10 15-5/8 2-3/4 6-1/2 7-15/16

RAMK23 19-3/4 23-1/4 10 22 2-5/16 6-1/2 7-15/16

H L M W X Y Z

Dimensions (in.)

Diagram 7. Dimensions

Reverse Air Flow

Kompact Mullion

Bohn-Kote® Coil

Nomenclature

RAM K 13 A G

Size

Vintage

Voltage

A = 115/1/60

B = 208-230/1/60

9

Page 10

Model BTO

Twin Flow Reach-In Unit Cooler

Features

• Compact two-way design with medium velocity air ow

• Mounts ush to the ceiling and draws air in through the

fan and discharges out both sides

• Air pattern reduces air loss when doors are opened and the

medium velocity reduces product drying

• Textured aluminum cabinet

• Stainless steel fasteners

• Molded Lexan® fan guards

• Drain pan and fan panel is easily removed for

installation and servicing

• Optional Bohn-Kote® coated coil available (Model BTOK)

for optimum protection in corrosive environments

• Coils are constructed of copper tubing with aluminum ns

• Expansion valve mounts inside the cabinet

• Internal junction box is provided for electrical connection

• Motors are thermally protected and

permanently lubricated

• All models are UL listed for the US and Canada

• UL classied to NSF standards

Sweat inlet connection to reduce leaks

(are connection available as a ship loose option)

Table 15. Performance and Electrical Data

Model

BTO09 900 1,350 130 1 0.8 0.4 1/2 1/2 1/2 12

BTO13 1,300 1,950 240 2 1.6 0.8 1/2 1/2 1/2 14

BTO18 1,800 2,700 255 1 1.0 0.5 1/2 1/2 1/2 15

BTO25* 2,500 3,750 460 2 2.0 1.0 1/2 1/2 1/2 23

BTO35* 3,500 5,250 425 2 2.0 1.0 1/2 1/2 1/2 24

BTO45* 4,500 6,750 550 2 2.0 1.0 1/2 1/2 5/8 34

BTO55* 5,500 8,250 730 1 2.1 1.1 1/2 1/2 5/8 34

†

Models 25, 35, 45 and 55 use external equalized expansion valve

BTUH

10°F TD

BTUH

15°F TD

CFM Qty.

Motor Data Connections (in.) Approx.

115/1/60

Total FLA

Table 16. Physical Data

Model

BTO09 16-1/8 19-1/8 7-9/16 4 2-5/16 9-9/16 2-3/4 4-7/8 4-1/2 8-5/8 2-1/2 2-5/8 4-9/16 10 7/8

BTO13 16-1/8 19-1/8 7-9/16 4 2-5/16 9-9/16 2-3/4 5-3/4 4-1/2 8-5/8 2-1/2 2-5/8 4-9/16 10 7/8

BTO18 16-1/8 19-1/8 7-9/16 4 2-5/16 9-9/16 2-3/4 5-3/4 4-1/2 8-5/8 2-1/2 2-5/8 4-9/16 10 7/8

BTO25 18-1/8 26-1/8 11-1/16 4 2-5/16 13-1/16 2-3/4 6-3/4 5-1/2 12-1/8 3-1/2 2-5/8 8-1/16 10 7/8

BTO35 18-1/8 26-1/8 11-1/16 4 2-5/16 13-1/16 2-3/4 6-3/4 5-1/2 12-1/8 3-1/2 2-5/8 8-1/16 10 7/8

BTO45 21-1/8 29-1/8 8-3/16 7-3/4 3-7/16 10-5/8 3-1/2 9-1/4 8 13-5/8 5-15/16 4-1/4 7-9/16 14 1-3/4

BTO55 21-1/8 29-1/8 8-3/16 7-3/4 3-7/16 10-5/8 3-1/2 8-1/2 8 13-5/8 5-15/16 4-1/4 7-9/16 14 1-3/4

A B C D E F G H J K L M N P R

Application

Model BTO is ideal for temperatures of 35°F and higher. Box

temperatures are kept more constant throughout and fresh

products last longer. Seven sizes are available with BTUH from

900 to 5,500 at 10° TD.

Larger BTO sizes are suitable for large reach-in and small step-in

or walk-in coolers.

Nomenclature

Twin Flow Unit Cooler

208-230/1/60

Total FLA

Dimensions (in.)

BTO K 09 A G

Bohn-Kote® Coil

(Optional)

Size

Coil InletODSuctionIDDrain

Vintage

Voltage

A = 115/1/60

B = 208-230/1/60

OD

Ship Wt.

(lbs.)

Diagram 8. Dimensions

10

Page 11

Model U

Reach-In Unit Cooler

Features

• Textured aluminum cabinet

• Full collar aluminum ns on expanded copper tubes

• Detachable drain pan that is easy to clean

• Molded 3-prong motor connector to save installation

time and expense

• Motors are thermally protected and

permanently lubricated

• Optional Bohn-Kote® coated coil available (Model UK)

for optimum protection in corrosive environments

• All models are UL listed for the US and Canada

• UL classied to NSF standards

Sweat inlet connection to reduce leaks

(are connection available as a ship loose option)

Application

Model U is used wherever a small, compact unit is required.

It can be mounted on the ceiling or wall. The model U unit

draws air through the front and discharges it out both sides

to insure proper distribution of cool air and thus maintain a

uniform box temperature.

Nomenclature

Dual Aire Standard Coil

Bohn-Kote® Coil

(Optional)

U K 09 0

Size

Voltage

0 = 115/1/60

1 = 208-230/1/60

Table 17. Performance and Electrical Data

Model

U09 850 1,275 190 0.45 0.55 1/2 3/8 1/2 9

U12 1,150 1,725 250 0.45 0.55 1/2 3/8 1/2 10

U15 1,500 2,250 310 1.10 0.55 1/2 3/8 1/2 14

BTUH

10°F TD

BTUH

15°F TD

CFM

Motor Data Connections (in.) Approx.

115/1/60

Total FLA

208-230/1/60

Total FLA

Coil InletFNSuctionIDDrain

OD

Table 18. Physical Data

Model

U09 8-1/2 11-1/2 8-7/8 6 4 3-1/2

U12 8-1/2 17-1/2 8-7/8 12 4 9-1/2

U15 9-1/2 17-1/2 10-7/8 12 4 9-1/2

H W D A B C

Dimensions (in.)

Diagram 9. Dimensions

Ship Wt.

(lbs.)

11

Page 12

For more information on Bohn refrigeration products, contact

your Sales Representative or visit us at www.thecoldstandard.com.

A Brand of Heatcraft Refrigeration Products LLC

2175 West Park Place Blvd. • Stone Mountain, GA • 30087

(800) 537-7775 • FAX (770) 465-5990

www.thecoldstandard.com

Since product improvement is a continuing eort, we reserve the right to

make changes in specications without notice.

BN-RITB 1107 | version 000

Loading...

Loading...