Page 1

Replaces BN-HSWCUTB, December 2009

WATERCOOLED CONDENSING UNITS

Technical Guide

Models HWN | Hermetic • ZWN | Scroll

BNHSWCUTB

March 2011

Page 2

®

TABLE OF CONTENTS

Nomenclature....................................................................................................... ................................................2

Features & Benets. ............................................................................................ ................................................3

Application Data .................................................................................................. ................................................4

Unit Specications .............................................................................................................................................. 5

Performance Data ........................................................................................................................................... 6-8

Physical and Dimensional Data ..................................................................................................................... 9

Electrical Data ............................................................................................................................................. 10-11

NOMENCLATURE

N.Y. MEA

ZW N 030 L 6 B

Compressor Application Equiv. HP Temp. Refrigerant Voltage

HW = Hermetic

ZW = Scroll

N = Indoor 005 = 1/2HP

008 = 3/4HP

010 = 1HP

01* = 1-1/2HP

H = High

L = Low

M = Medium

X = Medium/Low

2 = R-22

6 = R-404A/507

B = 208/230/1/60

C = 208/230/3/60

D = 460/3/60

02* = 2HP

03* = 3HP

04* = 4HP

05* = 5HP

060 = 6HP

2

Page 3

®

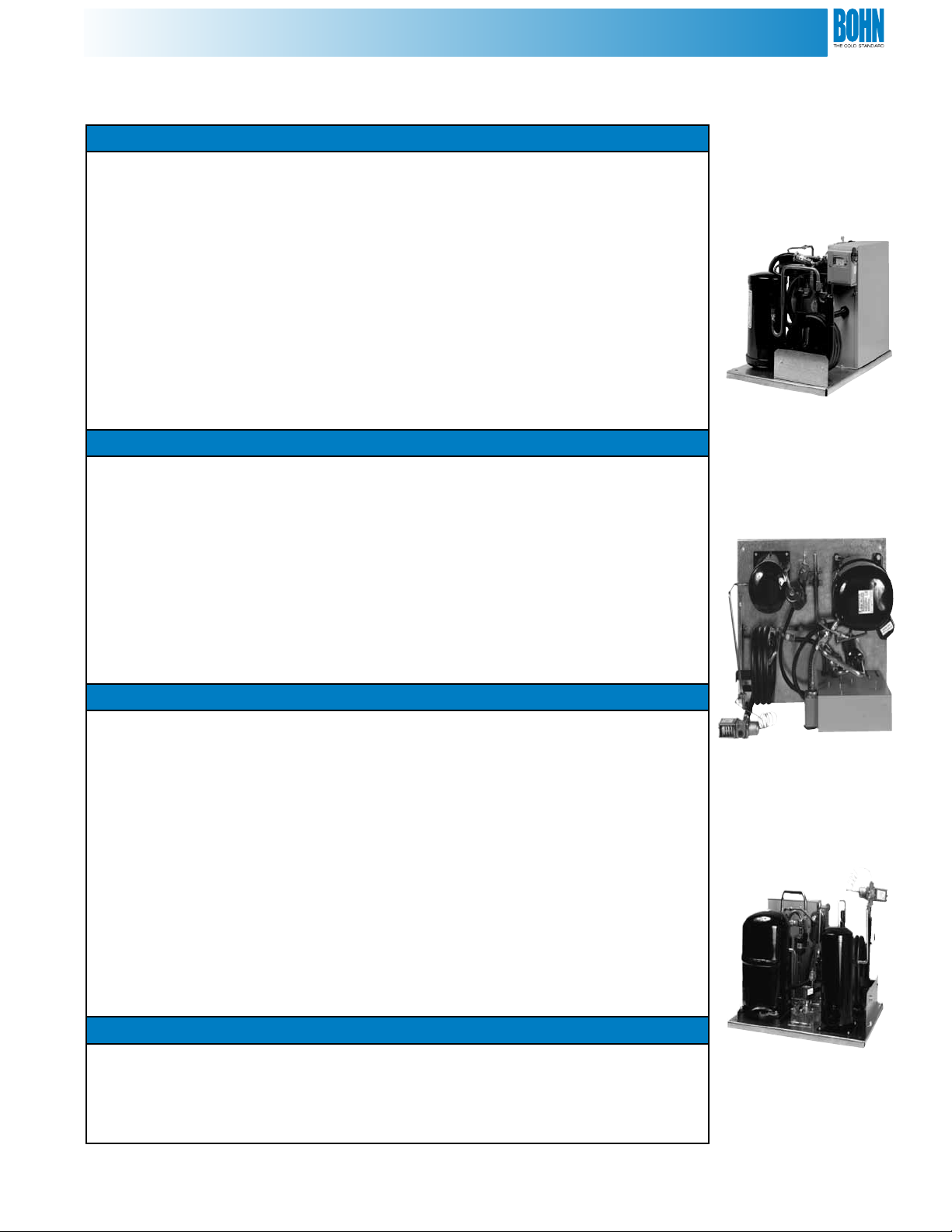

FEATURES & BENEFITS

Construction

• Component location and unit size are all optimized for easy eld

replacements or new installations where space is limited.

• Extra space is provided inside the electrical box for service and installation

of additional components.

• Copeland hermetic and scroll compressors for low and medium temperature

operation using R-22 and R404A.

• All units are provided with a water regulating valve for superior head

pressure control.

• An extra capacity receiver with liquid shut-o valve is provided for

installations with long refrigerant lines.

• A pumpdown switch is provided on all models for eld servicing.

Serviceability

• Easy access to the large electrical panel for service diagnostics or options.

• Color-coded wire harnesses are all labeled and coded for easy identication.

• A suction line rotolock service valve is provided on the compressor

for service.

• An additional shut o valve is mounted in the discharge line of the

compressor for quick and easy compressor to enable the service technician to

isolate the compressor for service.

• Schrader valves permit recovery of refrigerant isolated in compressor for

quick and easy compressor change if ever needed.

Quality

• Piping is laid out to minimize stress and vibration for quieter operation.

• Easy to verify leak-free unit by checking for the nitrogen holding charge

Schrader valve on the discharge or suction service valve.

• Encapsulated, automatic reset, high pressure control, and an adjustable low

pressure control with exible refrigerant hose to reduce possibility for leaks.

• A helix tube in tube water cooled condenser is standard with refrigerant

counter ow for optimum condensing unit eciency.

• Every unit is put into a vacuum and subjected to a rigorous leak test. This

results in a clean, dry and leak free unit every time.

• Electrical circuits are factory tested for functional integrity.

• Every unit is run tested and cycled on both the high and low pressure

controls.

Option

• Sight glass (optional) is easily viewable from the front to monitor the

refrigerant charge.

• Factory-installed suction lter available as option for additional system

protection.

3

Page 4

®

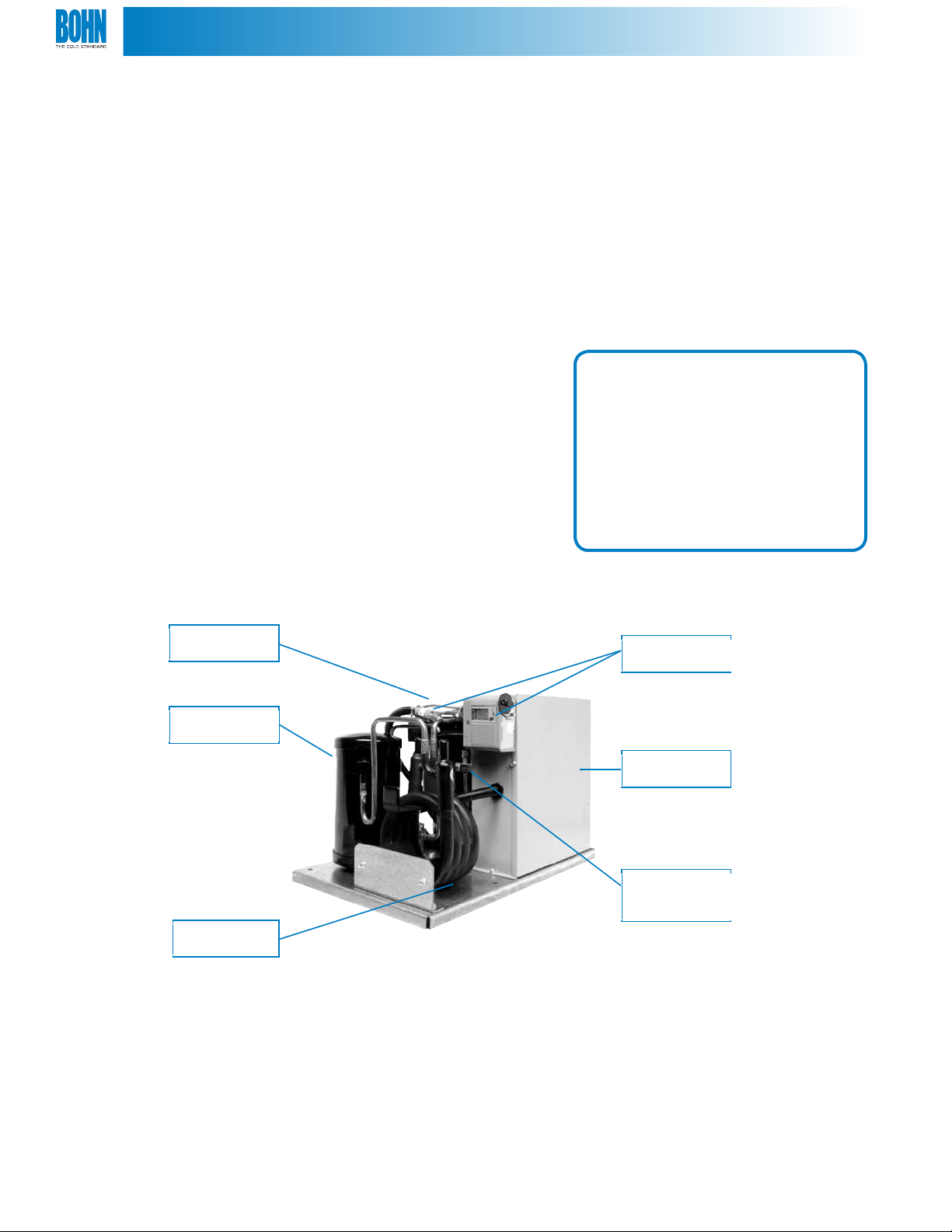

APPLICATION DATA

Installation Precautions

All units are factory charged with dry nitrogen which must be evacuated prior to installation.

Water valves must be adjusted during initial start-up to design condensing pressure for the selected refrigerant.

All HW “X6” models require a suction accumulator. HW “X6” models with RS compressors are not suitable for R-507.

Retrot Installations

If a P.O.E. model is used in a retrot, the old mineral oil must be completely removed from the system or at least

reduced to no more than 5% of the total oil charge. Polyolester oil is very hygroscopic. Take extra precautions to

limit exposure to the atmosphere.

Leveling Units

Unit must be level to insure proper oil return to the compressor.

Condenser Water Temperature

Maximum leaving water temperature is 105°F on all models.

Condenser Water Treatment

The use of untreated or improperly treated water may result in scaling

premature erosion or corrosion. A qualied water treatment specialist is

recommended for proper results.

Engineering Aids

Total Heat of Rejection (THR) all units:

THR = BTUH + (KW x 1000 x 3.4 x 1.0)

Water Temperature Rise (∆T

water cooled condenser:

∆T

= THR ÷ (GPM x 60 x 8.4)

w

) through

w

Hermetic

Compressor

Large

Receiver

Coaxial

Condenser

High & Low

Pressure Controls

Spacious

Control Box

Refrigerant

Isolation Service

Valves (2)

4

Page 5

®

UNIT SPECIFICATIONS

Features & Specications HW ZW

Compressor mounting (rubber grommets) Standard Standard

Compressor discharge service valve (in line brass base valve) Standard Standard

Compressor suction service valve - rotolock Standard Standard

Large capacity refrigerant receiver (up to 100 ft. runs) Standard Standard

Receiver service valve (located on outlet) Standard Standard

Coaxial condenser (counterow tube in tube) Standard Standard

Extra large electric box (encloses all options and capacitors) Standard Standard

Electric conduit (UL recognized, high impact, ame retardant copolymer) Standard Standard

Low pressure control switch (adjustable) Standard Standard

High pressure encapsulated safety switch (xed) Standard Standard

Super hose on low pressure control (higher leak resistance) Standard Standard

Voltage 208-230 - 1ph - 60hz Standard Standard

Voltage 208-230 -3ph - 60hz Standard Standard

Voltage 460 - 3ph - 60hz Standard Standard

Pump down control switch (pre-wired) Standard Standard

Water valve (mounted on condenser inlet) Standard Standard

Agency approvals UL, ULC, N.Y., MEA 106-98-E Standard Standard

Electrical Options HW ZW

Air defrost timer Option Option

Electric defrost timer Option Option

Electric defrost timer with contractor Option Option

Compressor crankcase heater¹ Option Option

Beacon II™ Control Option Option

Mechanical Options HW ZW

Liquid line drier & sight glass assembly (sweat)² Option Option

Liquid line solenoid valve (230V coil) Option Option

Suction lter with bypass Option Option

Suction accumulator Option Option

Suction accumulator & lter Option Option

Two-tiered stacking rack for eld assembly Option Option

¹ Crankcase heaters are not required for indoor operation but are included in all HW models. Field wiring is required. ZW models crankscase heaters are not available.

² Required on ZW “L6” models

The Beacon II system is a pre-assembled, factory installed refrigeration system

featuring an intregrated microcomputer-based electronic control board. System

orders (including matching unit coolers) are now available for all HW & ZW models.

The Beacon II system replaces the expansion valve, solenoid valve, room thermostat,

defrost control timer. It comes factory preset thereby eliminating all of the expensive and time consuming

ne tuning and adjustments necessary for a good system installation. For additional information, see the Beacon II

bulletin or contact your local Sales Representative.

5

Page 6

®

PERFORMANCE DATA

Hermetic Compressors - High & Medium Temperature Models

Model

HWN005H2 ART82C1

HWN008H2 RS64C2

HN010H2 RS70C1

HWN015H2 CR18KQ

HWN020H2 CR24KQ

HWN030H2 CR37KQ

HWN040H2 CR53KQ

HWN050H2 CRN5-0500

Capacity ratings conditions: 85°F entering water, 105°F condensing, 20°F ITD, 0°F subcooling. (ITD = Condensing temperature - entering condenser water temperature)

BTUH = British Thermal Units (All capacities are rated at 60 Hz operation)

GPM = Gallons per Minute (Water ow rate)

PSI = Pounds per Square Inch (Water pressure drop through condenser)

Compressor

R-22

0°F 10°F 20°F 30°F 40°F

BTUH 3,220 4,220 5,390 6,860 8,760

GPM 0.7 1.0 1.3 1.8 3.0

PSI 0.4 0.6 1.0 1.6 2.7

BTUH 3,840 5,530 7,500 9,820 11,990

GPM 0.6 1.1 1.5 2.1 2.7

PSI 0.4 0.6 1.0 1.6 2.7

BTUH 4,550 6,600 8,810 11,350 14,280

GPM 0.5 1.3 1.8 2.7 3.8

PSI 0.4 1.2 2.1 4.1 6.8

BTUH 5,700 8,190 11,240 14,860 19,100

GPM 1.5 1.8 2.6 3.7 6.1

PSI 0.5 0.6 1.1 2.0 4.0

BTUH 7,120 10,330 14,330 19,190 25,100

GPM 1.1 1.8 3.2 4.9 8.0

PSI 0.5 0.8 1.7 3.3 8.0

BTUH 11,950 17,140 23,660 31,640 41,470

GPM 1.4 2.0 4.2 6.8 13.0

PSI 0.6 0.9 1.8 3.7 9.9

BTUH 14,850 23,880 33,740 44,620 56,820

GPM 5.1 5.8 7.5 12 18.0

PSI 1.9 2.2 3.0 6.7 12.7

BTUH 21,510 30,630 40,460 51,570 64,890

GPM 4.0 6.1 9.0 13.5 12.0

PSI 0.9 1.5 3.0 6.1 13.1

Suction Temperature °F

Hermetic Compressors - High Temperature Models

Model

HWN005H6 RST45C1E

HWN009H6 RST64C1E

HWN010H6 RS70C1E

HWN015H6 CS10K6E

HWN025H6 CS14K6E

HWN032H6 CS20K6E

HWN040H6 CS27K6E

HWN050H6 CS33K6E

Compressor

BTU/H 7,370 8,160

GPM 1.3 1.5

PSI 1.0 1.2

BTU/H 11,190 12,310

GPM 1.8 2.1

PSI 2.1 2.6

BTU/H 12,430 13,900

GPM 2.0 2.3

PSI 2.3 2.9

BTU/H 18,510 20,830

GPM 3.3 3.9

PSI 1.6 2.2

BTU/H 25,060 27,910

GPM 4.8 5.7

PSI 3.2 4.2

BTU/H 36,490 40,790

GPM 5.6 6.8

PSI 2.7 3.7

BTU/H 48,220 53,600

GPM 10.3 12.8

PSI 7.5 11.3

BTU/H 53,250 59,150

GPM 8.7 10.3

PSI 2.8 3.8

Suction Temperature °F

35°F 40°F

Capacity ratings conditions: 85°F entering water, 110°F condensing, 25°F ITD, 0°F subcooling

6

Page 7

®

PERFORMANCE DATA

Hermetic Compressors - Extended Temperature Models

Model

HWN005X6 RST45C1E

HWN008X6 RST55C1E

HWN009X6 RST64C1E

HWN010X6 RS70C1E

HWN015X6 CS10K6E

HWN020X6 CS12K6E

HWN025X6 CS14K6E

HWN030X6 CS18K6E

HWN032X6 CS20K6E

HWN040X6 CS27K6E

HWN050X6 CS33K6E

Compressor

R-404A

Suction Temperature

°F

25°F 20°F 10°F 0°F 10°F 20°F 30°F

BTUH 1,280 1,665 2,460 3,290 4,220 5,270 6,480

GPM 0.2 0.2 0.4 0.7 0.9 1.2 1.6

PSI 0.2 0.2 0.2 0.3 0.5 0.9 1.4

BTUH 2,060 2,340 3,070 4,010 5,140 6,460 7,950

GPM 0.4 0.5 0.7 1.0 1.4 1.9 2.6

PSI 0.2 0.3 0.4 0.6 1.1 1.7 3.0

BTUH 2,480 2,880 3,820 4,970 6,320 7,870 9,620

GPM 0.2 0.2 0.5 0.9 1.4 1.8 2.4

PSI 0.2 0.2 0.3 0.7 1.3 2.1 3.2

BTUH 1,600 2,335 3,770 5,200 6,800 8,700 11,200

GPM 0.3 0.3 0.4 1.1 1.5 1.8 2.7

PSI 0.3 0.3 0.3 0.9 1.5 2.1 3.9

BTUH 2,000 2,815 4,580 6,930 9,710 12,900 16,300

GPM 0.6 0.8 1.0 1.5 2.3 3.3 4.8

PSI 0.2 0.3 0.4 0.5 0.9 1.6 3.1

BTUH 2,650 3,615 5,670 8,340 11,490 15,100 19,200

GPM 0.8 0.9 1.6 1.8 2.8 4.3 6.6

PSI 0.4 0.4 0.5 0.6 1.2 2.6 4.3

BTUH 3,840 4,900 7,160 10,140 13,630 17,500 21,800

GPM 0.2 0.5 1.1 1.8 3.2 4.7 7.2

PSI 0.1 0.2 0.5 0.8 1.7 4.2 6.6

BTUH 4,590 5,825 8,570 12,600 17,400 22,700 28,300

GPM 0.5 0.9 1.5 2.9 4.9 8.0 10.5

PSI 0.2 0.4 0.6 1.4 3.3 8.0 10.4

BTUH 4,650 6,505 10,110 14,210 19,220 25,600 34,000

GPM 0.5 0.8 1.3 1.8 2.6 5.0 9.5

PSI 0.2 0.4 0.6 0.8 1.1 2.2 6.6

BTUH 6,819 8,628 12,406 17,547 23,901 31,622 40,740

GPM 0.8 1.3 1.8 2.7 5.5 10.8 15

PSI 0.4 0.6 0.8 1.2 2.6 8.1 13.6

BTUH 8,100 10,515 15,433 21,505 28,838 37,733 48,684

GPM 1.3 2.1 3.1 4.5 6.2 9.0 13.6

PSI 0.1 0.1 0.7 1.0 1.6 3.0 6.2

Hermetic Compressors - Low Temperature Models

Model

HWN011L6 CF04K6E

HWN014L6 CF06K6E

HWN025L6 CF09K6E

HWN031L6 CF12K6E

Capacity ratings conditions: 85°F entering water, 105°F condensing, 20°F ITD, 0°F subcooling. (ITD = Condensing temperature - entering condenser water temperature)

BTUH = British Thermal Units (All capacities are rated at 60 Hz operation)

GPM = Gallons per Minute (Water ow rate)

PSI = Pounds per Square Inch (Water pressure drop through condenser)

Compressor

R-404A

-30 °F 25°F 20°F 10°F 0°F 10°F

BTUH 2,080 2,810 3,570 5,310 7,590 10,680

GPM 0.5 0.7 1.0 1.6 3.0 6.0

PSI 0.2 0.4 0.6 1.4 3.7 7.4

BTUH 3,770 4,810 5,990 8,700 11,780 15,070

GPM 1.0 1.3 1.5 2.5 4.0 5.0

PSI 0.8 1.2 1.5 3.4 7.4 8.0

BTUH 5,560 7,040 8,720 12,590 17,060 21,970

GPM 1.0 1.5 2.0 3.5 5.8 8.5

PSI 0.2 0.6 0.8 2.0 4.4 8.5

BTUH 7,550 9,510 11,570 16,060 21,180 27,140

GPM 1.25 2.5 3.4 5.75 9.5 11.0

PSI 0.6 1.2 1.9 4.4 9.8 12.0

Suction Temperature °F

7

Page 8

®

PERFORMANCE DATA

Scroll Compressors - Extended Temperature Models

Model

ZWN030X6 ZS21K4E

ZWN035X6 ZS26K4E

ZWN045X6 ZS30K4E

ZWN055X6 ZS38K4E

ZWN060X6 ZS45K4E

Compressor

R-404A

-25 °F 20°F 10°F 0°F 10°F 20°F 30°F 40°F

BTUH 9,010 10,230 12,840 16,070 19,740 24,110 29,310 35,200

GPM 1.2 1.3 1.6 2 2.7 4.4 6.8 10.8

PSI 0.6 0.6 0.7 0.9 1.2 1.8 3.7 8.1

BTUH 11,270 12,740 15,910 19,930 24,490 29,950 36,400 43,650

GPM 4.6 5.1 5.2 5.6 6 6.8 8.8 12

PSI 1.9 1.9 1.9 2.1 2.3 2.6 3.9 6.7

BTUH 12,810 14,390 17,960 22,870 28,480 35,030 42,320 50,100

GPM 5.1 5.2 5.5 5.8 6.8 8.5 11.9 15.1

PSI 1.9 1.9 2 2.1 2.6 3.7 6.6 9.8

BTUH 15,920 18,050 22,640 28,420 34,970 42,780 51,980 62,350

GPM 3.1 3.4 4.8 5.8 7.5 10.3 14.5 21

PSI 0.5 0.6 1 1.1 2.2 3.8 7 13.1

BTUH 19,220 21,820 27,360 34,160 41,850 51,090 62,130 74,750

GPM 3.1 3.3 5 6.9 9 12.6 17.7 23.9

PSI 0.8 0.8 1.2 1.2 2 3.7 6.8 10.1

Scroll Compressors - Low Temperature Models

Model

ZWN030L6 ZF09K4E

ZWN035L6 ZF11K4E

ZWN045L6 ZF13K4E

ZWN055L6 ZF15K4E

ZWN060L6 ZF18K4E

Compressor

R-404A

-40°F 30°F 25°F 20°F 10°F 0°F

BTUH 6,380 8,270 9,300 10,500 13,200 16,300

GPM 1.8 2.3 2.6 3.0 4.3 6.5

PSI 0.6 0.9 1.1 1.3 2.6 4.1

BTUH 7,900 10,170 11,500 12,900 16,200 20,200

GPM 1.9 2.7 3.2 4.7 5.2 7.5

PSI 0.8 1.3 1.7 3.1 3.6 7.1

BTUH 8,570 11,480 13,200 15,000 19,100 23,800

GPM 2.6 3.6 4.5 5.2 8.0 10.1

PSI 1.2 2.1 2.9 3.6 8.0 10

BTUH 11,080 14,480 16,400 18,500 23,300 28,900

GPM 2.9 4.3 5.5 6.3 9.0 11.3

PSI 1.5 2.6 3.8 4.7 8.6 12.3

BTUH 13,260 17,260 19,500 22,000 27,700 34,500

GPM 2.5 4.2 4.5 5.5 9.0 13.1

PSI 1.1 1.8 2.1 2.6 6.0 11.1

Suction Temperature °F

Suction Temperature °F

Capacity ratings conditions: 85°F entering water, 105°F condensing, 20°F ITD, 0°F subcooling. (ITD = Condensing temperature - entering condenser water temperature)

BTUH = British Thermal Units (All capacities are rated at 60 Hz operation)

GPM = Gallons per Minute (Water ow rate)

PSI = Pounds per Square Inch (Water pressure drop through condenser)

8

Page 9

®

PHYSICAL AND DIMENSIONAL DATA

Connections (in.)

Model

HWN005H2 ART82C1 1/2 3/8 1/2 1/2 6 22 14 17 77

HWN005X6 RST45C1E 1/2 3/8 1/2 1/2 5.5 22 14 17 98

HWN008H2 RS64C2 1/2 3/8 1/2 1/2 6 22 14 17 92

HWN008X6 RST55C1E 1/2 3/8 1/2 1/2 5.5 22 14 17 98

HWN009X6 RST64C1E 5/8 3/8 1/2 1/2 5.5 22 14 17 103

HWN010H2 RS70C1 5/8 3/8 1/2 1/2 6 22 14 17 91

HWN010X6 RS70C1E 5/8 3/8 1/2 1/2 5.5 22 14 17 107

HWN011L6 CF04K6E 5/8 3/8 1/2 1/2 9 27 22 21 114

HWN014L6 CF06K6E 5/8 3/8 1/2 1/2 9 27 22 21 114

HWN015H2 CR18KQ 5/8 3/8 1/2 1/2 10 27 22 21 136

HWN015X6 CS10K6E 5/8 3/8 1/2 1/2 9 27 22 21 148

HWN020H2 CR24KQ 5/8 3/8 1/2 1/2 10 27 22 21 141

HWN020X6 CS12K6E 7/8 3/8 1/2 1/2 9 27 22 21 148

HWN025L6 CF09K6E 5/8 3/8 1/2 1/2 9 27 22 21 120

HWN025X6 CS14K6E 7/8 3/8 1/2 1/2 9 27 22 21 152

HWN030H2 CR37KQ 7/8 1/2 1/2 1/2 22 29 25 28 174

HWN030X6 CS18K6E 7/8 1/2 1/2 1/2 20 27 22 28 172

HWN031L6 CF12K6E 7/8 1/2 1/2 1/2 20 27 22 21 136

HWN032X6 CS20K6E 7/8 1/2 1/2 1/2 20 27 22 28 182

HWN040H2 CR53KQ 7/8 1/2 1/2 1/2 22 29 25 28 196

HWN040X6 CS27K6E 7/8 1/2 1/2 1/2 20 29 25 28 183

HWN050H2 CRN5-0500 7/8 1/2 3/4 3/4 22 29 25 28 221

HWN050X6 CS33K6E 7/8 1/2 1/2 1/2 20 29 25 28 207

ZWN030L6 ZF09K4E 7/8 1/2 1/2 1/2 20 27 22 28 159

ZWN030X6 ZS21K4E 7/8 1/2 1/2 1/2 20 29 25 28 171

ZWN035L6 ZF11K4E 7/8 1/2 1/2 1/2 20 27 22 28 165

ZWN035X6 ZS26K4E 7/8 1/2 1/2 1/2 20 29 25 28 186

ZWN045L6 ZF13K4E 7/8 1/2 1/2 1/2 20 27 22 28 185

ZWN045X6 ZS30K4E 7/8 1/2 1/2 1/2 20 29 25 28 207

ZWN055L6 ZF15K4E 7/8 1/2 1/2 1/2 20 27 22 28 201

ZWN055X6 ZS38K4E 7/8 1/2 3/4 3/4 20 29 25 28 226

ZWN060L6 ZF18K4E 7/8 1/2 1/2 1/2 20 29 25 28 207

ZWN060X6 ZS45K4E 7/8 1/2 3/4 3/4 20 29 25 28 241

HWN005H6 RST45C1E 1/2 3/8 1/2 1/2 5.5 22 14 17 98

HWN009H6 RST64C1E 5/8 3/8 1/2 1/2 5.5 22 14 17 103

HWN010H6 RS70C1E 5/8 3/8 1/2 1/2 5.5 22 14 17 107

HWN015H6 CS10K6E 5/8 3/8 1/2 1/2 9.0 27 22 21 148

HWN025H6 CS14K6E 7/8 3/8 1/2 1/2 9.0 27 22 21 152

HWN032H6 CS20K6E 7/8 1/2 1/2 1/2 20.0 27 22 28 182

HWN040H6 CS27K6E 7/8 1/2 1/2 1/2 20.0 29 25 28 183

HWN050H6 CS33K6E 7/8 1/2 1/2 1/2 20.0 29 25 28 207

Compressor

Suction Liquid Water In Water Out

(ODS) (ODS) (FPT) (MPT) D W H

Receiver

90% Full

Lbs.

Dimensions (in.)

Net Wt.

(lbs.)

ODS = Outside Diameter Sweat

FPT = Female Pipe Thread

MPT = Male Pipe Thread

H

W

D

9

Page 10

®

ELECTRICAL DATA

Hermetic Compressors

Model

Number

HWN005H2B ART82C1-CAV 208-230 1 60 5.9 30.0 15 15 20.0 20 15 8.0

HWN005X6B RST45C1E-CAV 208-230 1 60 4.6 26.5 15 15 20.0 20 15 8.0

HWN008H2B RS64C2-PAV 208-230 1 60 6.9 37.0 15 15 20.0 20 15 8.0

HWN008X6B RST55C1E-CAV 208-230 1 60 6.1 33.7 15 15 20.0 20 15 8.0

HWN009X6B RST64C1E-CAV 208-230 1 60 8.0 43.0 15 15 20.0 20 15 6.0

HWN010H2B RS70C1-PFV 208-230 1 60 6.3 34.2 15 15 20.0 20 15 7.0

HWN010H2C RS70C1-TFC 208-230 3 60 4.2 31.0 15 15 20.0 20 15 8.6

HWN010X6B RS0C1E-PFV 208-230 1 60 6.3 34.2 15 15 20.0 20 15 7.0

HWN010X6C RS70C1E-TFC 208-230 3 60 4.2 31.0 15 15 20.0 20 15 8.6

HWN011L6B CF04K6E-PFV 208-230 1 60 9.6 59.2 15 15 20.0 20 15 8.0

HWN011L6C CF04K6E-TF5 208-230 3 60 6.4 52.0 15 15 20.0 20 15 8.0

HWN014L6B CF06K6E-PFV 208-230 1 60 11.4 59.2 15 20 20.0 25 23 4.0

HWN014L6C CF06K6E-TF5 208-230 3 60 7.0 52.0 15 15 20.0 20 19 9.0

HWN015H2B CR18KQ-PFV 208-230 1 60 8.1 47.0 15 15 24.0 25 19 6.0

HWN015H2C CR18KQ-TF5 208-230 3 60 4.9 40.0 15 15 24.0 25 19 7.0

HWN015H2D CR18KQ-TFD 460 3 60 2.8 23.0 15 15 20.0 20 15 9.0

HWN015X6B CS10K6E-PFV 208-230 1 60 9.8 56.0 15 20 24.0 25 19 6.0

HWN015X6C CS10K6E-TF5 208-230 3 60 6.7 51.0 15 15 20.0 20 15 7.0

HWN020H2B CR24KQ-PFV 208-230 1 60 12.2 70.5 20 25 29.0 30 23 6.0

HWN020H2C CR24KQ-TF5 208-230 3 60 6.7 40.0 15 15 24.0 25 19 9.0

HWN020H2D CR24KQ-TFD 460 3 60 3.6 28.0 15 15 20.0 20 15 8.5

HWN020X6B CS12K6E-PFV 208-230 1 60 9.8 56.0 15 20 24.0 25 19 6.0

HWN020X6C CS12K6E-TF5 208-230 3 60 6.7 51.0 15 15 25.0 25 19 9.0

HWN025L6B CF09K6E-PFV 208-230 1 60 16.7 87.0 20 30 25.0 35 30 6.0

HWN025L6C CF09K6E-TF5 208-230 3 60 10.2 72.2 15 20 20.0 25 19 7.0

HWN025X6B CS14K6E-PFV 208-230 1 60 11.2 61.0 15 20 29.0 30 23 6.0

HWN025X6C CS14K6E-TF5 208-230 3 60 8.2 55.0 15 15 24.0 25 19 9.0

HWN025X6D CS14K6E-TFD 460 3 60 4.2 28.0 15 15 20.0 20 15 8.3

HWN030H2B CR37KQ-PFV 208-230 1 60 16.7 100.3 21 35

HWN030H2C CR37KQ-TF5 208-230 3 60 9.9 85.0 15 20 38.0 40 30 12.0

HWN030H2D CR37KQ-TFD 460 3 60 5.0 39.0 15 15 24.0 25 19 9.0

HWN030X6B CS18K6E-PFV 208-230 1 60 14.4 82.0 18 30 38.0 40 30 12.0

HWN030X6C CS18K6E-TF5 208-230 3 60 9.4 65.5 15 20 29.0 30 23 7.0

HWN030X6D CS18K6E-TFD 460 3 60 3.9 33.0 15 15 24.0 25 10 19.0

HWN031L6B CF12K6E-PFV 208-230 1 60 19.0 105.0 21 35 38.0 50 30 12.0

HWN031L6C CR12K6E-TF5 208-230 3 60 11.9 85.0 15 20 29.0 30 23 7.0

HWN031L6D CF12K6E-TFD 460 3 60 5.9 42.0 15 15 24.0 25 19 10.0

HWN032X6B CS20K6E-PFV 208-230 1 60 16.7 96.0 21 30 38.0 50 30 12.0

HWN032X6C CS20K6E-TF5 208-230 3 60 10.3 75.0 15 20 29.0 30 23 7.0

HWN032X6D CS20K6E-TFD 460 3 60 4.6 40.0 15 15 24.0 25 19 10.0

HWN040H2B CR53KQ-PFV 208-230 1 60 26.0 140.0 33 50 45.0 60 35 12.0

HWN040H2C CR53KQ-TF5 208-230 3 60 16.3 107.0 20 35 38.0 45 30 12.0

HWN040H2D CR35KQ-TFD 460 3 60 8.1 55.0 15 15 29.0 30 23 11.0

HWN040X6B CS27K6E-PFV 208-230 1 60 21.5 121.0 27 45 44.0 60 35 12.0

HWN040X6C CS27K6E-TF5 208-230 3 60 13.7 105.0 20 30 38.0 40 30 12.0

HWN040X6D CS27K6E-TFD 460 3 60 7.6 52.0 15 15 29.0 30 23 11.0

HWN050H2B CRN5-0500-PFV 208-230 1 60 30.8 142.0 39 50 59.0 60 47 12.0

HWN050H2C CRN5-0500-TF5 208-230 3 60 19.2 130.0 24 40 37.5 50 30 12.0

HWN050H2D CRN5-0500-TFD 460 3 60 8.7 65.0 15 15 29.0 30 23 10.0

HWN050X6B CS33K6E-PFV 208-230 1 60 27.6 1250 35 50 59.0 60 47 12.0

HWN050X6C CS33K6E-TFC 208-230 3 60 16.8 102.0 21 35 38.0 45 30 12.0

HWN050X6D CS33K6E-TFD 460 3 60 8.8 48.0 15 15 29.0 30 23 10.0

HWN005H6B RST45C1E-CAV 208-230 1 60 4.5 26.5 15 15 - - - HWN009H6B RST64C1E-CAV 208-230 1 60 7.6 43 15 15 - - - HWN010H6B RS70C1E-PFV 208-230 1 60 6.9 34.2 15 15 - - - HWN010H6C RS70C1E-TFC 208-230 3 60 4.7 31 15 15 - - - HWN015H6B CS10K6E-PFV 208-230 1 60 11.1 56 15 25 - - - HWN015H6C CS10K6E-TF5 208-230 3 60 7.2 51 15 15 - - - HWN025H6B CS14K6E-PFV 208-230 1 60 12.4 61 20 25 - - - HWN025H6C CS14K6E-TF5 208-230 3 60 8.5 55 15 15 - - - HWN032H6B CS20K6E-PFV 208-230 1 60 17.9 96 22.4 40 - - - HWN032H6C CS20K6E-TFS 208-230 3 60 13.3 75 20 30 - - - HWN040H6K CS27K6E-TF5 230 3 60 14.1 105 20 30 - - - HWN050H6K CS33K6E-TF5 230 3 60 16.5 102 20.7 35 - - - -

Compressor

Number

Power Supply Compressor

Volts Ph Hz+RLA LRA MCA MOPD MCA MOPD Amps Amps

Beacon II™ or

Air Defrost

Electric Defrost

38.0 45 30 12.0

Def.

Htr

Evap.

Fan

+

Consult Factory for 50 hz applications

RLA values have been calculated by dividing the maximum continuous current (MCC) by 1.56, per UL and National Electrical Code Standard.

RLA = Rated Load Amps LRA = Locked Rotor Amps

10

MCA = Minimum Circuit Ampacity MOPD = Maximum Overload Protection Device

Page 11

®

ELECTRICAL DATA

Scroll Compressors

Model

Number

ZWN030L6B ZF09K4E-PFV 208-230 1 60 14.7 88.0 18.0 30 38 45 30 12.0

ZWN030L6C ZF09K4E-TF5 208-230 3 60 9.9 77.0 15.0 20 24 25 19 6.0

ZWN030L6D ZF09K4E-TFD 460 3 60 5.1 39.0 15.0 15 24 25 19 10.0

ZWN030X6B ZS21K4E-PFV 208-230 1 60 14.7 88.0 18.4 30 38 45 30 12.0

ZWN030X6C ZS21K4E-TF5 208-230 3 60 9.9 77.0 15.0 20 38 40 30 12.0

ZWN030X6D ZS21K4E-TFD 460 3 60 5.1 39.0 15.0 15 24 25 19 10.0

ZWN035L6B ZF11K4E-PFV 208-230 1 60 18.6 109.0 23.0 40 38 50 30 12.0

ZWN035L6C ZF11K4E-TF5 208-230 3 60 12.2 88.0 15.0 25 29 30 23 6.0

ZWN035L6D ZF11K4E-TFD 460 3 60 6.4 44.0 15.0 15 24 25 19 10.0

ZWN035X6B ZS26K4E-PFV 208-230 1 60 18.6 109.0 23.2 40 38 50 30 12.0

ZWN035X6C ZS26K4E-TF5 208-230 3 60 12.2 88.0 15.2 25 38 40 30 12.0

ZWN035X6D ZS6K4E-TFD 460 3 60 6.4 44.0 15.0 15 24 25 19 9.0

ZWN045L6B ZF13K4E-PFV 208-230 1 60 24.0 129.0 30.0 50 41 60 30 11.0

ZWN045L6C ZF13K4E-TF5 208-230 3 60 13.5 99.0 17.0 30 38 40 30 11.0

ZWN045L6D ZF13K4E-TFD 460 3 60 7.4 49.5 15.0 15 24 25 19 9.0

ZWN045X6B ZS30K4E-PFV 208-230 1 60 24.0 129.0 30.0 50 59 60 47 11.0

ZWN045X6C ZS30K4E-TF5 208-230 3 60 13.5 99.0 17.0 30 44 45 35 12.0

ZWN045X6D ZS30K4E-TFD 460 3 60 7.4 49.5 15.0 15 29 30 23 11.0

ZWN055L6B ZF15K4E-PFV 208-230 1 60 28.8 169.0 36.0 60 38 60 30 10.0

ZWN055L6C ZF15K4E-TF5 208-230 3 60 19.2 123.0 24.0 40 38 50 30 10.0

ZWN055L6D ZF15K4E-TFD 460 3 60 8.7 62.0 15.0 15 25 25 19 8.0

ZWN055X6B ZS38K4E-PFV 208-230 1 60 28.8 169.0 36.0 60 59 60 47 12.0

ZWN055X6C ZS38K4E-TF5 208-230 3 60 19.2 123.0 24.0 40 44 50 35 12.0

ZWN055X6D ZS38K4E-TFD 460 3 60 8.7 62.0 15.0 15 29 30 23 10.0

ZWN060L6C ZF18K4E-TF5 208-230 3 60 21.5 156.0 27.0 45 44 60 35 12.0

ZWN060L6D ZF18K4E-TFD 460 3 60 8.3 70.0 15.0 15 29 30 23 11.0

ZWN060X6C ZS45K4E-TF5 208-230 3 60 21.5 156.0 27.0 45 38 60 30 12.0

ZWN060X6D ZS45K4E-TFD 460 3 60 8.3 70.0 15.0 15 29 30 23 10.6

+

Consult Factory for 50 hz applications

RLA values have been calculated by dividing the maximum continuous current (MCC) by 1.56, per UL and National Electrical Code Standard.

Compressor

Number

Power Supply Compressor

Volts Ph Hz+RLA LRA MCA MOPD MCA MOPD Amps Amps

Beacon II™ or

Air Defrost

Electric Defrost

Def.

Htr.

Evap.

Fan

RLA = Rated Load Amps

LRA = Locked Rotor Amps

MCA = Minimum Circuit Ampacity

MOPD = Maximum Overload Protection Device

11

Page 12

For more information on Bohn refrigeration products, contact

your sales representative or visit us at www.heatcraftrpd.com.

A Brand of Heatcraft Refrigeration Products LLC

2175 West Park Place Blvd. • Stone Mountain, GA • 30087

800.537.7775

www.heatcraftrpd.com

Since product improvement is a continuing eort, we reserve the right to

make changes in specications without notice.

Loading...

Loading...