Page 1

BNWCCUTB

August 2016

Replaces BN-WCUTB, June 2015

WATERCOOLED CONDENSING UNITS

Technical Guide

Models HWN | Hermetic • ZWN | Scroll • SWN | Semi-Hermetic

Page 2

TABLE OF CONTENTS

HWN & ZWN Models

Nomenclature ........................................................................................................................................................................................... 2

Features & Benets. .................................................................................................................................................................................3

Application Data ...................................................................................................................................................................................... 4

Specications & Options ....................................................................................................................................................................... 5

Hermetic Compressors ....................................................................................................................................................................6-10

Performance Data ......................................................................................................................................................................... 6-8

Unit Specications ........................................................................................................................................................................... 9

Electrical Data .................................................................................................................................................................................. 10

Scroll Compressors .......................................................................................................................................................................... 11-13

Performance Data .................................................................................................................................................................... 11-12

Unit Specications ......................................................................................................................................................................... 13

Electrical Data .................................................................................................................................................................................. 13

SWN Models

Nomenclature ........................................................................................................................................................................................... 2

Features & Benets. ...............................................................................................................................................................................14

Options ......................................................................................................................................................................................................15

Semi-Hermetic Compressors ...................................................................................................................................................... 16-23

Performance Data .................................................................................................................................................................... 16-20

Unit Specications ......................................................................................................................................................................... 21

Electrical Data ........................................................................................................................................................................... 22-23

Dimensional Drawings ........................................................................................................................................................................22

NOMENCLATURE HWN & ZWN MODELS

ZW N 030 L 6 B

Compressor Application Equiv. HP Temp. Refrigerant Voltage

HW = Hermetic

ZW = Scroll

N = Indoor 005 = 1/2HP

008 = 3/4HP

010 = 1HP

01* = 1-1/2HP

02* = 2HP

03* = 3HP

04* = 4HP

05* = 5HP

060 = 6HP

H = High

L = Low

X = Medium/Low

6 = R-404A/507/

R407A/R407C,

R448A/R449A

B = 208/230/1/60

C = 208/230/3/60

D = 460/3/60

NOMENCLATURE SWN MODELS

S W N 0500 H 6 C

Compressor Model Application Model Size Temp. Refrigerant Electrical Code

S = Semi-Hermetic

Reciprocating

W = Water-Cooled N = Indoor 0075 - 2200 L = Low

M = Medium

E = Extra Low

6 = R–404A/507/

R407A/

R407C/407F,

R448A/R449A

B = 208/230/1/60

C = 208/230/3/60

D = 460/3/60

E = 575/3/60

G = 230/1/60

2

Page 3

FEATURES & BENEFITS - HWN & ZWN Models

Construction

• Component location and unit size are all optimized for easy eld replacements or

new installations where space is limited.

• Extra space is provided inside the electrical box for service and installation of

additional components.

• Copeland® hermetic and scroll compressors for low and medium temperature

operation using R404A.

• All units are provided with a water regulating valve for superior head pressure

control.

• An extra capacity receiver with liquid shut-o valve is provided for installations with

long refrigerant lines.

• A pumpdown switch is provided on all models for eld servicing.

Serviceability

• Easy access to the large electrical panel for service diagnostics or options.

• Color-coded wire harnesses are all labeled and coded for easy identication.

• A suction line rotolock service valve is provided on the compressor for service.

• An additional shut o valve is mounted in the discharge line of the compressor for

quick and easy isolation of the compressor for service.

• Schrader® valves permit recovery of refrigerant isolated in compressor for quick and

easy compressor change if ever needed.

Quality

• Piping is laid out to minimize stress and vibration for quieter operation.

• Easy to verify leak-free unit by checking for the nitrogen holding charge with the

Schrader valve on the discharge or suction service valve.

• Encapsulated, automatic reset, high pressure control, and an adjustable low

pressure control with exible refrigerant hose to reduce possibility for leaks.

• A helix tube in tube water-cooled condenser is standard with refrigerant counter

ow for optimum condensing unit eciency.

• Every unit is put into a vacuum and subjected to a rigorous leak test. This results

in a clean, dry and leak free unit every time.

• Electrical circuits are factory tested for functional integrity.

• Every unit is run tested and cycled on both the high and low pressure controls.

Option

• Sight glass (optional) is easily viewable from the front to monitor the refrigerant

charge.

• Factory-installed suction lter available as option for additional system protection.

3

Page 4

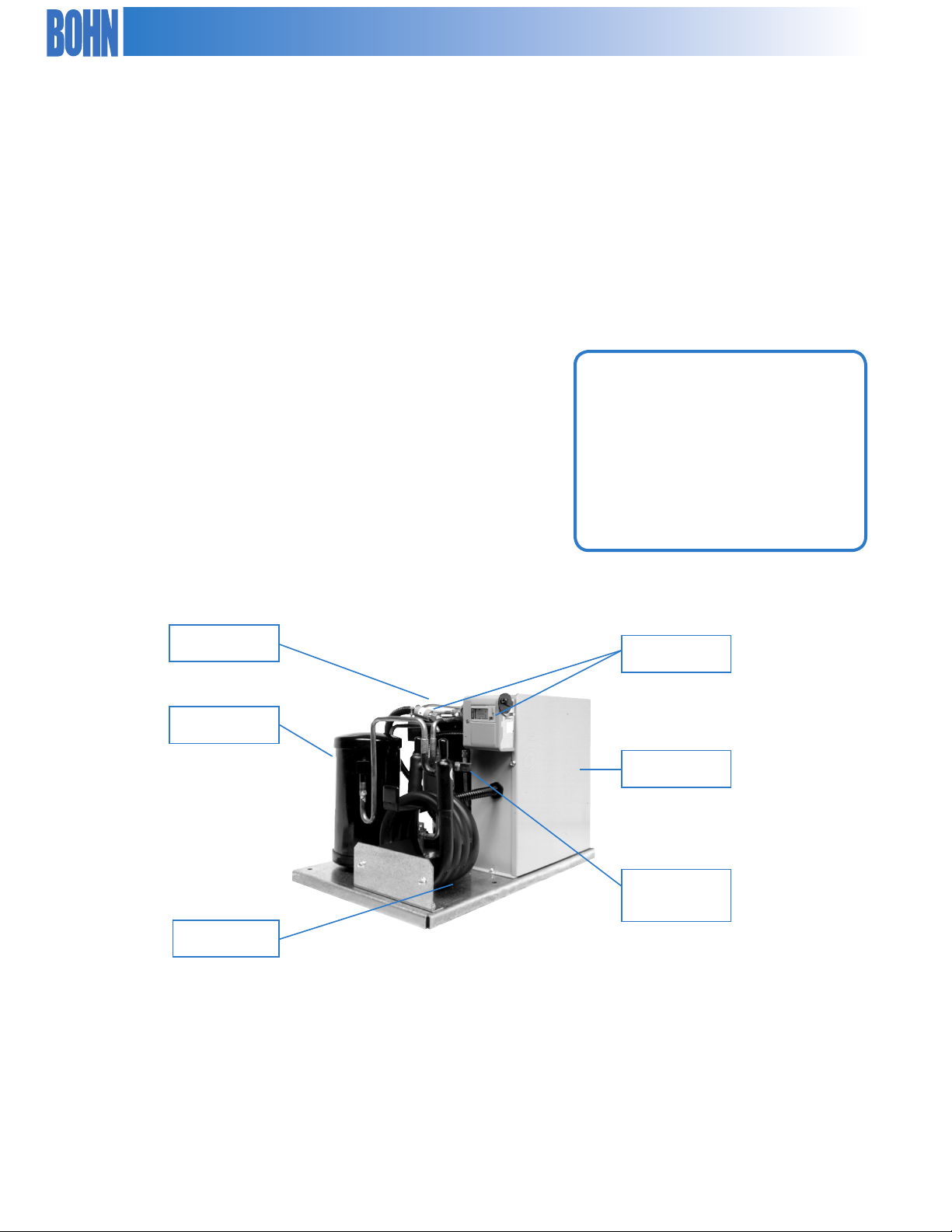

APPLICATION DATA - HWN & ZWN

Installation Precautions

All units are factory charged with dry nitrogen which must be evacuated prior to installation.

Water valves must be adjusted during initial start-up to design condensing pressure for the selected refrigerant.

HW “X6” models with RS compressors are not suitable for R-507.

Retrot Installations

If a P.O.E. model is used in a retrot, the old mineral oil must be completely removed from the system or at least

reduced to no more than 5% of the total oil charge. Polyolester oil is very hygroscopic. Take extra precautions to

limit exposure to the atmosphere.

Leveling Units

Unit must be level to insure proper oil return to the compressor.

Condenser Water Temperature

Maximum leaving water temperature is 105°F on all models.

Condenser Water Treatment

The use of untreated or improperly treated water may result in scaling

premature erosion or corrosion. A qualied water treatment specialist is

recommended for proper results.

Engineering Aids

Total Heat of Rejection (THR) all units:

THR = BTUH + (KW x 1000 x 3.4 x 1.0)

Water Temperature Rise (∆Tw) through

water cooled condenser:

∆Tw = THR ÷ (GPM x 60 x 8.4)

Hermetic

Compressor

Large

Receiver

Coaxial

Condenser

High & Low

Pressure Controls

Spacious

Control Box

Refrigerant

Isolation Service

Valves (2)

4

Page 5

SPECIFICATIONS & OPTIONS HWN & ZWN

Features & Specications HW ZW

Compressor mounting (rubber grommets) Standard Standard

Compressor discharge service valve (in line brass base valve) Standard Standard

Compressor suction service valve - rotolock Standard Standard

Large capacity refrigerant receiver (up to 100 ft. runs) Standard Standard

Receiver service valve (located on outlet) Standard Standard

Coaxial condenser (counterow tube in tube) Standard Standard

Extra large electric box (encloses all options and capacitors) Standard Standard

Electric conduit (UL recognized, high impact, ame retardant copolymer) Standard Standard

Low pressure control switch (adjustable) Standard Standard

High pressure encapsulated safety switch (xed) Standard Standard

Super hose on low pressure control (higher leak resistance) Standard Standard

Voltage 208-230 - 1ph - 60hz Standard Standard

Voltage 208-230 -3ph - 60hz Standard Standard

Voltage 460 - 3ph - 60hz Standard Standard

Pump down control switch (pre-wired) Standard Standard

Water valve (mounted on condenser inlet) Standard Standard

Agency approvals UL, ULC, N.Y., MEA 106-98-E Standard Standard

Electrical Options HW ZW

Air defrost timer Option Option

Electric defrost timer Option Option

Electric defrost timer with contactor Option Option

Compressor crankcase heater¹ Option Option

Beacon II™ Control Option Option

Mechanical Options HW ZW

Liquid line drier & sight glass assembly (sweat)² Option Option

Liquid line solenoid valve (230V coil) Option Option

Suction lter with bypass Option Option

Suction accumulator Option Option

Suction accumulator & lter Option Option

Two-tiered stacking rack for eld assembly Option Option

¹ Crankcase heaters are not required for indoor operation but are included in all HW models. Field wiring is required. ZW models crankcase

heaters are not available.

² Required on ZW “L6” models

The Beacon II system is a pre-assembled, factory installed refrigeration system

featuring an intregrated microcomputer-based electronic control board. System

orders (including matching unit coolers) are now available for all HW & ZW models.

The Beacon II system replaces the expansion valve, solenoid valve, room thermostat,

defrost control timer. It comes factory preset thereby eliminating all of the expensive and time consuming

ne tuning and adjustments necessary for a good system installation. For additional information, see the Beacon II

bulletin or contact your local Sales Representative.

5

Page 6

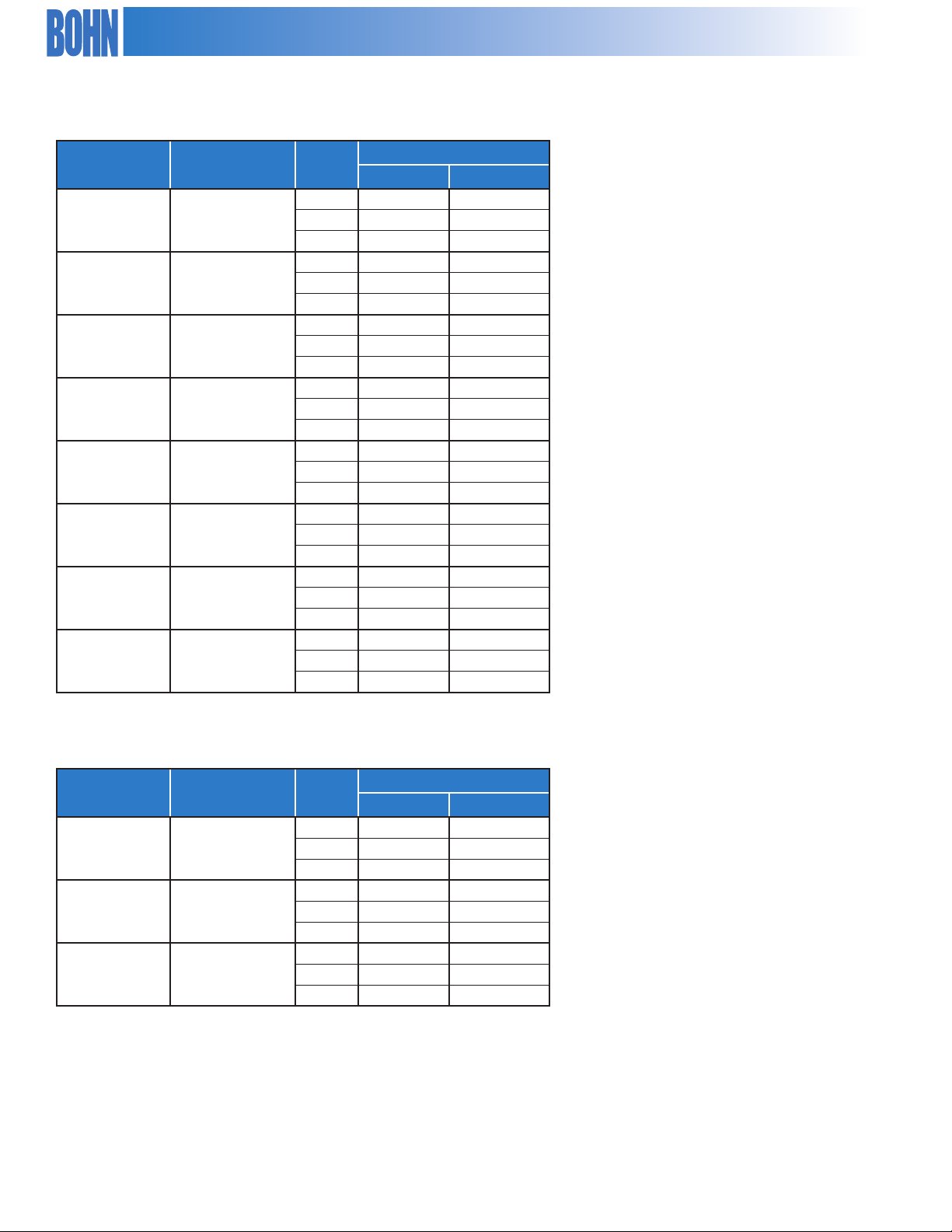

PERFORMANCE DATA HWN MODELS

High Temperature Models - R-404A

Model

HWN005H6 RST45C1E

HWN009H6 RST64C1E

HWN010H6 RST70C1E

HWN015H6 CS10K6E

HWN025H6 CS14K6E

HWN032H6 CS20K6E

HWN040H6 CS27K6E

HWN050H6 CS33K6E

Compressor

Suction Temperature °F

35°F 40°F

BTU/H 7,370 8,160

GPM 1.3 1.5

PSI 1.0 1.2

BTU/H 11,190 12,310

GPM 1.8 2.1

PSI 2.1 2.6

BTU/H 12,430 13,900

GPM 2.0 2.3

PSI 2.3 2.9

BTU/H 18,510 20,830

GPM 3.3 3.9

PSI 1.6 2.2

BTU/H 25,060 27,910

GPM 4.8 5.7

PSI 3.2 4.2

BTU/H 36,490 40,790

GPM 5.6 6.8

PSI 2.7 3.7

BTU/H 48,220 53,600

GPM 10.3 12.8

PSI 7.5 11.3

BTU/H 53,250 59,150

GPM 8.7 10.3

PSI 2.8 3.8

Capacity ratings conditions: 85°F entering water, 110°F condensing, 25°F ITD, 0°F subcooling

High Temperature Models - R-407C

Model

HWN005H6 RST45C1E

HWN009H6 RST64C1E

HWN010H6 RST70C1E

Capacity ratings conditions: 85°F entering water, 110°F condensing, 25°F ITD, 0°F subcooling

Compressor

BTU/H 7,160 8,050

GPM 3.6 4.6

PSI 4.9 7.0

BTU/H 11,320 12,720

GPM 4.9 5.9

PSI 10.0 13.1

BTU/H 11,400 12,760

GPM 4.8 5.7

PSI 9.7 12.5

Suction Temperature °F

35°F 40°F

6

Page 7

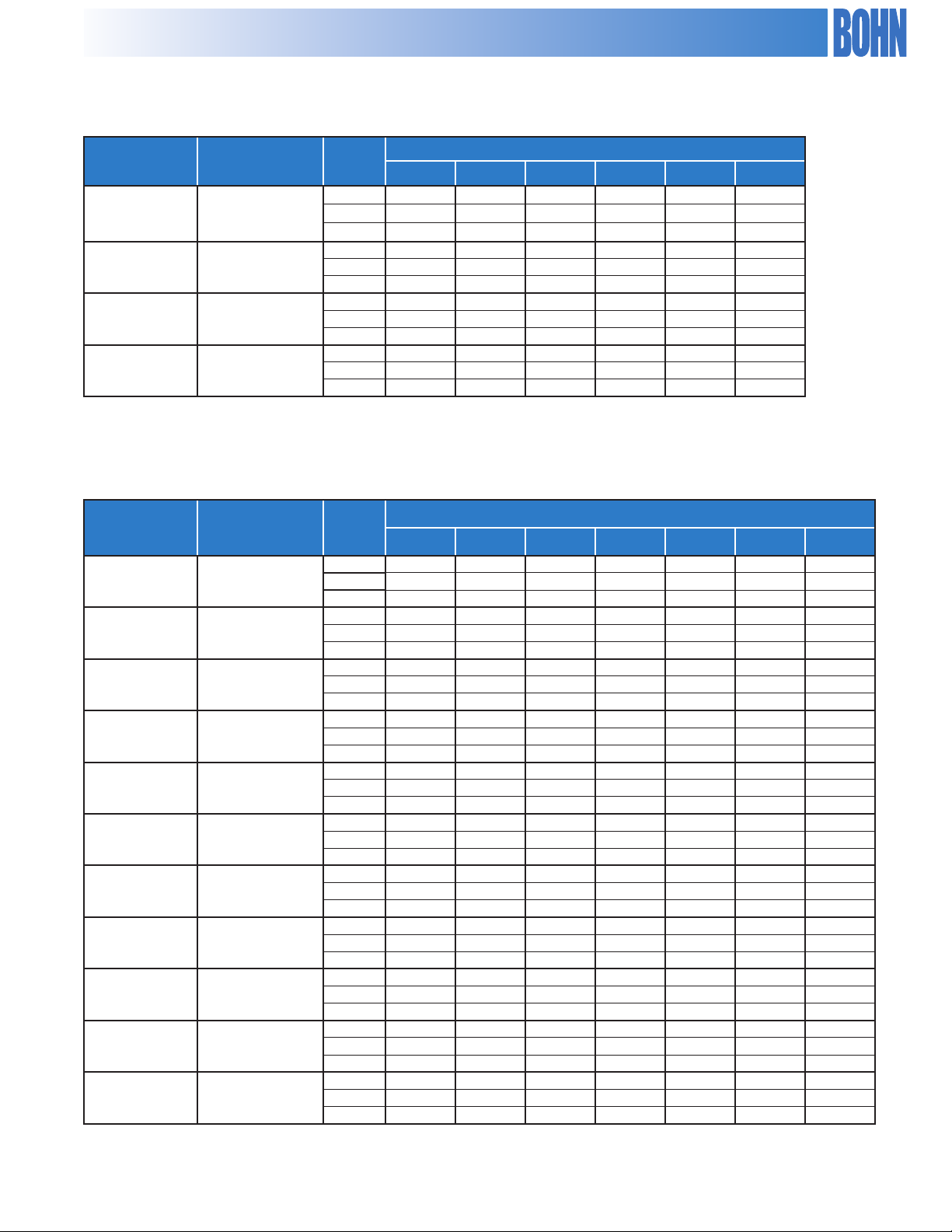

PERFORMANCE DATA HWN MODELS

Low Temperature Models - R-404A

Model

HWN011L6 CF04K6E

HWN014L6 CF06K6E

HWN025L6 CF09K6E

HWN031L6 CF12K6E

Capacity ratings conditions: 85°F entering water, 105°F condensing, 20°F ITD, 0°F subcooling. (ITD = Condensing temperature - entering condenser water temperature)

BTUH = British Thermal Units (All capacities are rated at 60 Hz operation)

GPM = Gallons per Minute (Water flow rate)

PSI = Pounds per Square Inch (Water pressure drop through condenser)

Compressor

-30 °F 25°F 20°F 10°F 0°F 10°F

BTUH 2,080 2,810 3,570 5,310 7,590 10,680

GPM 0.5 0.7 1.0 1.6 3.0 6.0

PSI 0.2 0.4 0.6 1.4 3.7 7.4

BTUH 3,770 4,810 5,990 8,700 11,780 15,070

GPM 1.0 1.3 1.5 2.5 4.0 5.0

PSI 0.8 1.2 1.5 3.4 7.4 8.0

BTUH 5,560 7,040 8,720 12,590 17,060 21,970

GPM 1.0 1.5 2.0 3.5 5.8 8.5

PSI 0.2 0.6 0.8 2.0 4.4 8.5

BTUH 7,550 9,510 11,570 16,060 21,180 27,140

GPM 1.25 2.5 3.4 5.75 9.5 11.0

PSI 0.6 1.2 1.9 4.4 9.8 12.0

Extended Temperature Models - R-404A

Model

HWN005X6 RST45C1E

HWN008X6 RST55C1E

HWN009X6 RST64C1E

HWN010X6 RST70C1E

HWN015X6 CS10K6E

HWN020X6 CS12K6E

HWN025X6 CS14K6E

HWN030X6 CS18K6E

HWN032X6 CS20K6E

HWN040X6 CS27K6E

HWN050X6 CS33K6E

Capacity ratings conditions: 85°F entering water, 105°F condensing, 20°F ITD, 0°F subcooling. (ITD = Condensing temperature - entering condenser water temperature)

BTUH = British Thermal Units (All capacities are rated at 60 Hz operation)

GPM = Gallons per Minute (Water flow rate)

PSI = Pounds per Square Inch (Water pressure drop through condenser)

Compressor

25°F 20°F 10°F 0°F 10°F 20°F 30°F

BTUH 1,280 1,665 2,460 3,290 4,220 5,270 6,480

GPM 0.2 0.2 0.4 0.7 0.9 1.2 1.6

PSI 0.2 0.2 0.2 0.3 0.5 0.9 1.4

BTUH 2,060 2,340 3,070 4,010 5,140 6,460 7,950

GPM 0.4 0.5 0.7 1.0 1.4 1.9 2.6

PSI 0.2 0.3 0.4 0.6 1.1 1.7 3.0

BTUH 2,480 2,880 3,820 4,970 6,320 7,870 9,620

GPM 0.2 0.2 0.5 0.9 1.4 1.8 2.4

PSI 0.2 0.2 0.3 0.7 1.3 2.1 3.2

BTUH 1,600 2,335 3,770 5,200 6,800 8,700 11,200

GPM 0.3 0.3 0.4 1.1 1.5 1.8 2.7

PSI 0.3 0.3 0.3 0.9 1.5 2.1 3.9

BTUH 2,000 2,815 4,580 6,930 9,710 12,900 16,300

GPM 0.6 0.8 1.0 1.5 2.3 3.3 4.8

PSI 0.2 0.3 0.4 0.5 0.9 1.6 3.1

BTUH 2,650 3,615 5,670 8,340 11,490 15,100 19,200

GPM 0.8 0.9 1.6 1.8 2.8 4.3 6.6

PSI 0.4 0.4 0.5 0.6 1.2 2.6 4.3

BTUH 3,840 4,900 7,160 10,140 13,630 17,500 21,800

GPM 0.2 0.5 1.1 1.8 3.2 4.7 7.2

PSI 0.1 0.2 0.5 0.8 1.7 4.2 6.6

BTUH 4,590 5,825 8,570 12,600 17,400 22,700 28,300

GPM 0.5 0.9 1.5 2.9 4.9 8.0 10.5

PSI 0.2 0.4 0.6 1.4 3.3 8.0 10.4

BTUH 4,650 6,505 10,110 14,210 19,220 25,600 34,000

GPM 0.5 0.8 1.3 1.8 2.6 5.0 9.5

PSI 0.2 0.4 0.6 0.8 1.1 2.2 6.6

BTUH 6,819 8,628 12,406 17,547 23,901 31,622 40,740

GPM 0.8 1.3 1.8 2.7 5.5 10.8 15

PSI 0.4 0.6 0.8 1.2 2.6 8.1 13.6

BTUH 8,100 10,515 15,433 21,505 28,838 37,733 48,684

GPM 1.3 2.1 3.1 4.5 6.2 9.0 13.6

PSI 0.1 0.1 0.7 1.0 1.6 3.0 6.2

Suction Temperature °F

Suction Temperature °F

7

Page 8

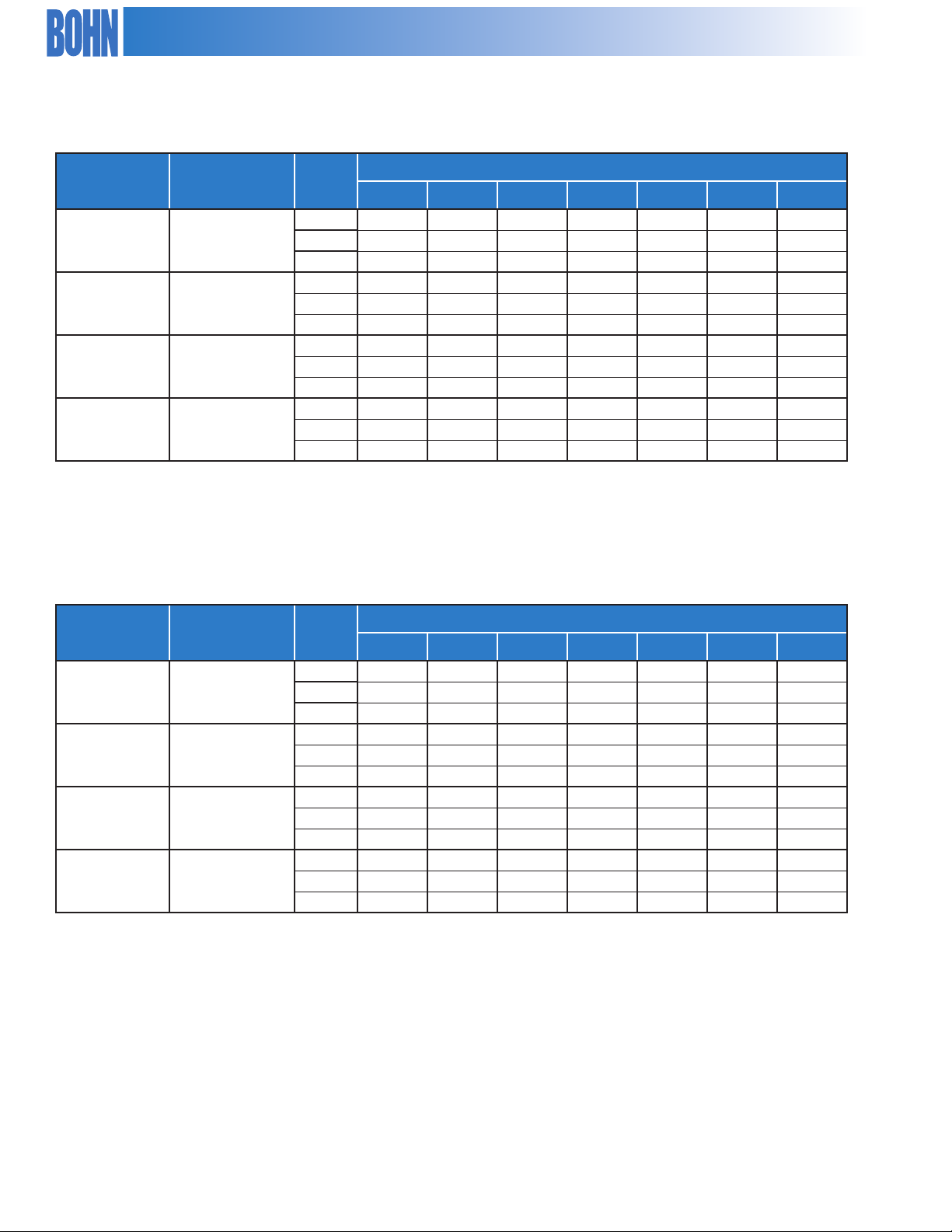

PERFORMANCE DATA HWN MODELS

Extended Temperature Models- R-407C

Model

HWN005X6 RST45C1E

HWN008X6 RST55C1E

HWN009X6 RST64C1E

HWN010X6 RST70C1E

Capacity ratings conditions: 85°F entering water, 105°F condensing, 20°F ITD, 0°F subcooling.

Compressor

25°F 20°F 10°F 0°F 10°F 20°F 30°F

BTUH 1,650 1,780 2,220 2,920 3,890 5,120 6,630

GPM 0.3 0.4 0.6 0.9 1.3 1.8 2.8

PSI 0.1 0.2 0.3 0.5 0.9 1.6 3.4

BTUH 1,300 1,690 2,560 3,570 4,780 6,240 8,010

GPM 0.2 0.4 0.8 1.2 1.7 2.7 4.8

PSI 0 0.2 0.4 0.8 1.5 3.1 7.3

BTUH 1,710 2,220 3,350 4,670 6,260 8,170 10,490

GPM 0.5 0.5 0.6 1.2 1.9 2.7 4.1

PSI 0.25 0.3 0.3 1.1 2.1 3.8 7.8

BTUH 1,310 2,010 3,400 4,850 6,460 8,340 10,590

GPM 0.5 0.5 0.7 1.3 1.9 2.7 4.1

PSI 0.4 0.4 0.4 1.2 2.3 3.8 7.6

Suction Temperature °F

Extended Temperature Models - R-448A/R-449A

Model

HWN005X6 RST45C1E

HWN008X6 RST55C1E

HWN009X6 RST64C1E

HWN010X6 RST70C1E

Capacity ratings conditions: 85°F entering water, 105°F condensing, 20°F ITD, 0°F subcooling.

Compressor

25°F 20°F 10°F 0°F 10°F 20°F 30°F

BTUH - - 2,170 2,970 3,990 5,270 6,850

GPM - - 0.6 0.9 1.3 1.9 3.3

PSI - - 0.3 0.5 1.0 1.8 4.3

BTUH - - 2,820 3,740 5,040 6,690 8,700

GPM - - 0.9 1.3 1.9 3.5 8.9

PSI - - 0.5 1.0 1.8 4.8 16.8

BTUH - - 3,590 4,820 6,440 8,440 10,820

GPM - - 0.9 1.4 2.1 3.0 4.8

PSI - - 0.7 1.4 2.6 4.6 10.2

BTUH - - 3,710 5,060 6,610 8,380 10,390

GPM - - 0.9 1.4 2.0 2.8 4.1

PSI - - 0.6 1.4 2.5 4.1 7.6

Suction Temperature °F

8

Page 9

UNIT SPECIFICATIONS HWN MODELS

Connections (in.)

Receiver

90% Full

Lbs.

Model

Compressor

Water InWater

Suction Liquid

(ODS) (ODS) (FPT) (MPT) D W H

Out

High Temperature Models

HWN005H6 RST45C1E 1/2 3/8 1/2 1/2 5.5 22 14 17 98

HWN009H6 RST64C1E 5/8 3/8 1/2 1/2 5.5 22 14 17 103

HWN010H6 RST70C1E 5/8 3/8 1/2 1/2 5.5 22 14 17 107

HWN015H6 CS10K6E 5/8 3/8 1/2 1/2 9.0 27 22 21 148

HWN025H6 CS14K6E 7/8 3/8 1/2 1/2 9.0 27 22 21 152

HWN032H6 CS20K6E 7/8 1/2 1/2 1/2 20.0 27 22 28 182

HWN040H6 CS27K6E 7/8 1/2 1/2 1/2 20.0 29 25 28 183

HWN050H6 CS33K6E 7/8 1/2 1/2 1/2 20.0 29 25 28 207

Extended Temperature Models

HWN005X6 RST45C1E 1/2 3/8 1/2 1/2 5.5 22 14 17 98

HWN008X6 RST55C1E 1/2 3/8 1/2 1/2 5.5 22 14 17 98

HWN009X6 RST64C1E 5/8 3/8 1/2 1/2 5.5 22 14 17 103

HWN010X6 RST70C1E 5/8 3/8 1/2 1/2 5.5 22 14 17 107

HWN015X6 CS10K6E 5/8 3/8 1/2 1/2 9 27 22 21 148

HWN020X6 CS12K6E 7/8 3/8 1/2 1/2 9 27 22 21 148

HWN025X6 CS14K6E 7/8 3/8 1/2 1/2 9 27 22 21 152

HWN030X6 CS18K6E 7/8 1/2 1/2 1/2 20 27 22 28 172

HWN032X6 CS20K6E 7/8 1/2 1/2 1/2 20 27 22 28 182

HWN040X6 CS27K6E 7/8 1/2 1/2 1/2 20 29 25 28 183

HWN050X6 CS33K6E 7/8 1/2 1/2 1/2 20 29 25 28 207

Low Temperature Models

HWN011L6 CF04K6E 5/8 3/8 1/2 1/2 9 27 22 21 114

HWN014L6 CF06K6E 5/8 3/8 1/2 1/2 9 27 22 21 114

HWN025L6 CF09K6E 5/8 3/8 1/2 1/2 9 27 22 21 120

HWN031L6 CF12K6E 7/8 1/2 1/2 1/2 20 27 22 21 136

Dimensions (in.)

Net

Wt.

(lbs.)

ODS = Outside Diameter Sweat

FPT = Female Pipe Thread

MPT = Male Pipe Thread

H

D

W

9

Page 10

ELECTRICAL DATA HWN MODELS

Model

Number

Compressor

Number

Power Supply Compressor

Volts Ph Hz+RLA LRA MCA MOPD MCA MOPD Amps Amps

Beacon II™ or

Air Defrost

Electric Defrost

Def.

Htr

High Temperature Models

HWN005H6B RST45C1E-CAV 208-230 1 60 4.5 26.5 15 15 - - - HWN009H6B RST64C1E-CAV 208-230 1 60 7.6 43 15 15 - - - HWN010H6B RST70C1E-PFV 208-230 1 60 6.9 34.2 15 15 - - - HWN010H6C RST70C1E-TFC 208-230 3 60 4.7 31 15 15 - - - HWN015H6B CS10K6E-PFV 208-230 1 60 11.1 56 15 25 - - - HWN015H6C CS10K6E-TF5 208-230 3 60 7.2 51 15 15 - - - HWN025H6B CS14K6E-PFV 208-230 1 60 12.4 61 20 25 - - - HWN025H6C CS14K6E-TF5 208-230 3 60 8.5 55 15 15 - - - HWN032H6B CS20K6E-PFV 208-230 1 60 17.9 96 22.4 40 - - - HWN032H6C CS20K6E-TFS 208-230 3 60 13.3 75 20 30 - - - HWN040H6K CS27K6E-TF5 230 3 60 14.1 105 20 30 - - - HWN050H6K CS33K6E-TF5 230 3 60 16.5 102 20.7 35 - - - -

Extended Temperature Models

HWN005X6B RST45C1E-CAV 208-230 1 60 4.6 26.5 15 15 20.0 20 15 8.0

HWN008X6B RST55C1E-CAV 208-230 1 60 6.1 33.7 15 15 20.0 20 15 8.0

HWN009X6B RST64C1E-CAV 208-230 1 60 8.0 43.0 15 15 20.0 20 15 6.0

HWN010X6B RST70C1E-PFV 208-230 1 60 6.3 34.2 15 15 20.0 20 15 7.0

HWN010X6C RST70C1E-TFC 208-230 3 60 4.2 31.0 15 15 20.0 20 15 8.6

HWN015X6B CS10K6E-PFV 208-230 1 60 9.8 56.0 15 20 24.0 25 19 6.0

HWN015X6C CS10K6E-TF5 208-230 3 60 6.7 51.0 15 15 20.0 20 15 7.0

HWN020X6B CS12K6E-PFV 208-230 1 60 9.8 56.0 15 20 24.0 25 19 6.0

HWN020X6C CS12K6E-TF5 208-230 3 60 6.7 51.0 15 15 25.0 25 19 9.0

HWN025X6B CS14K6E-PFV 208-230 1 60 11.2 61.0 15 20 29.0 30 23 6.0

HWN025X6C CS14K6E-TF5 208-230 3 60 8.2 55.0 15 15 24.0 25 19 9.0

HWN025X6D CS14K6E-TFD 460 3 60 4.2 28.0 15 15 20.0 20 15 8.3

HWN030X6B CS18K6E-PFV 208-230 1 60 14.4 82.0 18 30 38.0 40 30 12.0

HWN030X6C CS18K6E-TF5 208-230 3 60 9.4 65.5 15 20 29.0 30 23 7.0

HWN032X6B CS20K6E-PFV 208-230 1 60 16.7 96.0 21 30 38.0 50 30 12.0

HWN032X6C CS20K6E-TF5 208-230 3 60 10.3 75.0 15 20 29.0 30 23 7.0

HWN032X6D CS20K6E-TFD 460 3 60 4.6 40.0 15 15 24.0 25 19 10.0

HWN040X6B CS27K6E-PFV 208-230 1 60 21.5 121.0 27 45 44.0 60 35 12.0

HWN040X6C CS27K6E-TF5 208-230 3 60 13.7 105.0 20 30 38.0 40 30 12.0

HWN040X6D CS27K6E-TFD 460 3 60 7.6 52.0 15 15 29.0 30 23 11.0

HWN050X6B CS33K6E-PFV 208-230 1 60 27.6 1250 35 50 59.0 60 47 12.0

HWN050X6C CS33K6E-TFC 208-230 3 60 16.8 102.0 21 35 38.0 45 30 12.0

HWN050X6D CS33K6E-TFD 460 3 60 8.8 48.0 15 15 29.0 30 23 10.0

Low Temperature Models

HWN011L6B CF04K6E-PFV 208-230 1 60 9.6 59.2 15 15 20.0 20 15 8.0

HWN011L6C CF04K6E-TF5 208-230 3 60 6.4 52.0 15 15 20.0 20 15 8.0

HWN014L6B CF06K6E-PFV 208-230 1 60 11.4 59.2 15 20 20.0 25 23 4.0

HWN014L6C CF06K6E-TF5 208-230 3 60 7.0 52.0 15 15 20.0 20 19 9.0

HWN025L6B CF09K6E-PFV 208-230 1 60 16.7 87.0 20 30 25.0 35 30 6.0

HWN025L6C CF09K6E-TF5 208-230 3 60 10.2 72.2 15 20 20.0 25 19 7.0

HWN031L6B CF12K6E-PFV 208-230 1 60 19.0 105.0 21 35 38.0 50 30 12.0

HWN031L6C CR12K6E-TF5 208-230 3 60 11.9 85.0 15 20 29.0 30 23 7.0

HWN031L6D CF12K6E-TFD 460 3 60 5.9 42.0 15 15 24.0 25 19 10.0

Evap.

Fan

+

Consult Factory for 50 hz applications

RLA values have been calculated by dividing the maximum continuous current (MCC) by 1.56, per UL and National Electrical Code Standard.

RLA = Rated Load Amps LRA = Locked Rotor Amps

MCA = Minimum Circuit Ampacity MOPD = Maximum Overload Protection Device

10

Page 11

PERFORMANCE DATA ZWN MODELS

Extended Temperature Models - R-404A

Model

Compressor

Suction Temperature °F

-25°F 20°F 10°F 0°F 10°F 20°F 30°F 40°F

BTUH 9,010 10,230 12,840 16,070 19,740 24,110 29,310 35,200

ZWN030X6 ZS21KAE

ZWN035X6 ZS26KAE

ZWN045X6 ZS29KAE

ZWN055X6 ZS38K4E

ZWN060X6 ZS45K4E

Capacity ratings conditions: 85°F entering water, 105°F condensing, 20°F ITD, 0°F subcooling. (ITD = Condensing temperature - entering condenser water temperature)

BTUH = British Thermal Units (All capacities are rated at 60 Hz operation)

GPM = Gallons per Minute (Water flow rate)

PSI = Pounds per Square Inch (Water pressure drop through condenser)

GPM 1.2 1.3 1.6 2 2.7 4.4 6.8 10.8

PSI 0.6 0.6 0.7 0.9 1.2 1.8 3.7 8.1

BTUH 11,270 12,740 15,910 19,930 24,490 29,950 36,400 43,650

GPM 4.6 5.1 5.2 5.6 6 6.8 8.8 12

PSI 1.9 1.9 1.9 2.1 2.3 2.6 3.9 6.7

BTUH 12,810 14,390 17,960 22,870 28,480 35,030 42,320 50,100

GPM 5.1 5.2 5.5 5.8 6.8 8.5 11.9 15.1

PSI 1.9 1.9 2 2.1 2.6 3.7 6.6 9.8

BTUH 15,920 18,050 22,640 28,420 34,970 42,780 51,980 62,350

GPM 3.1 3.4 4.8 5.8 7.5 10.3 14.5 21

PSI 0.5 0.6 1 1.1 2.2 3.8 7 13.1

BTUH 19,220 21,820 27,360 34,160 41,850 51,090 62,130 74,750

GPM 3.1 3.3 5 6.9 9 12.6 17.7 23.9

PSI 0.8 0.8 1.2 1.2 2 3.7 6.8 10.1

Extended Temperature Models - R-407A

Model

ZWN030X6 ZS21KAE

ZWN035X6 ZS26KAE

ZWN045X6 ZS29KAE

Capacity ratings conditions: 85°F entering water, 105°F condensing, 20°F ITD, 0°F subcooling.

Compressor

-25°F 20°F 10°F 0°F 10°F 20°F 30°F 40°F

BTUH 7,530 9,140 12,570 16,450 20,950 26,250 32,510 -

GPM 1 1.1 1.2 3.6 6.3 10.2 18.9 -

PSI 1 1 1 1.1 3.3 7.4 18.6 -

BTUH 8,360 10,140 13,950 18,260 23,260 29,130 36,090 -

GPM 2.3 2.8 4.1 5.5 7.1 9.5 14.2 -

PSI 1 1 1 1.8 2.8 4.4 8.9 -

BTUH 9,370 11,360 15,630 20,460 26,050 32,640 40,430 -

GPM 2.8 3.5 4.9 6.5 8.4 12 18.8 -

PSI 0.5 0.6 1.5 2.4 3.6 6.7 13.5 -

Extended Temperature Models - R-407C

Model

ZWN030X6 ZS21KAE

ZWN035X6 ZS26KAE

ZWN045X6 ZS29KAE

Compressor

-25°F 20°F 10°F 0°F 10°F 20°F 30°F 40°F

BTUH 4,090 6,210 10,520 15,050 19,940 25,340 31,410 -

GPM 1 1 2 2.7 5.5 9.2 16.6 -

PSI 1 1 1 1 2.6 6.2 15.7 -

BTUH 4,530 6,890 11,670 16,690 22,120 28,110 34,840 -

GPM 1.4 2 3.4 4.9 6.6 8.7 12.4 -

PSI 1 1 1 1.5 2.5 3.8 7.1 -

BTUH 5,080 7,720 13,080 18,710 24,790 31,510 39,050 -

GPM 1.9 2.6 4.1 5.8 7.7 11 16.8 -

PSI 0.5 0.5 1 2 3.1 5.7 11.5 -

Suction Temperature °F

Suction Temperature °F

Capacity ratings conditions: 85°F entering water, 105°F condensing, 20°F ITD, 0°F subcooling.

11

Page 12

PERFORMANCE DATA ZWN MODELS

Extended Temperature Models - R-448A/R-449A

Model

ZWN030X6 ZS21KAE

ZWN035X6 ZS26KAE

ZWN045X6 ZS29KAE

Capacity ratings conditions: 85°F entering water, 105°F condensing, 20°F ITD, 0°F subcooling.

Compressor

-25°F 20°F 10°F 0°F 10°F 20°F 30°F 40°F

BTUH 7,860 9,510 13,110 17,200 21,910 27,350 33,650 40,920

GPM 1.5 1.7 2.5 4.2 7.0 12.3 20.8 30.9

PSI 0.6 0.8 1.2 1.6 3.9 10.2 26.0 34.3

BTUH 10,480 11,560 14,440 18,330 23,270 29,320 36,540 44,980

GPM 2.7 3.1 4.1 5.5 7.1 9.6 14.9 22.1

PSI 0.1 0.4 1.0 1.8 2.8 4.5 9.6 16.8

BTUH 9,980 12,070 16,630 21,830 27,800 34,710 42,700 51,920

GPM 2.9 3.6 5.1 6.8 9.1 13.7 20.7 28.6

PSI 0.2 0.7 1.6 2.6 4.1 8.4 15.4 23.3

Suction Temperature °F

12

Page 13

PERFORMANCE DATA ZWN MODELS

Low Temperature Models- R-404A

Model

ZWN030L6

ZWN035L6

ZWN045L6

ZWN055L6

ZWN060L6

Capacity ratings conditions: 85°F entering water, 105°F condensing, 20°F ITD, 0°F subcooling. (ITD = Condensing temperature - entering condenser water temperature)

BTUH = British Thermal Units (All capacities are rated at 60 Hz operation)

GPM = Gallons per Minute (Water flow rate)

PSI = Pounds per Square Inch (Water pressure drop through condenser)

Compressor

R-404A

ZF09K4E

ZF11K4E

ZF13K4E

ZF15K4E

ZF18K4E

BTUH

GPM

PSI

BTUH

GPM

PSI

BTUH

GPM

PSI

BTUH

GPM

PSI

BTUH

GPM

PSI

-40°F 30°F 25°F 20°F 10°F 0°F

6,380 8,270 9,300 10,500 13,200 16,300

1.8 2.3 2.6 3.0 4.3 6.5

0.6 0.9 1.1 1.3 2.6 4.1

7,900 10,170 11,500 12,900 16,200 20,200

1.9 2.7 3.2 4.7 5.2 7.5

0.8 1.3 1.7 3.1 3.6 7.1

8,570 11,480 13,200 15,000 19,100 23,800

2.6 3.6 4.5 5.2 8.0 10.1

1.2 2.1 2.9 3.6 8.0 10

11,080 14,480 16,400 18,500 23,300 28,900

2.9 4.3 5.5 6.3 9.0 11.3

1.5 2.6 3.8 4.7 8.6 12.3

13,260 17,260 19,500 22,000 27,700 34,500

2.5 4.2 4.5 5.5 9.0 13.1

1.1 1.8 2.1 2.6 6.0 11.1

Low Temperature Models - R-407A

Model

ZWN030L6 ZF09K4E

ZWN035L6 ZF11K4E

ZWN045L6 ZF13K4E

ZWN055L6 ZF15K4E

ZWN060L6 ZF18K4E

Capacity ratings conditions: 85°F entering water, 105°F condensing, 20°F ITD, 0°F subcooling.

Compressor

-40°F 30°F 25°F 20°F 10°F 0°F

BTUH 5,520 7,090 8,170 9,400 12,140 15,050

GPM 2.6 3.4 3.9 4.6 9.1 18

PSI 1.1 1.7 2.2 2.9 7.4 16.3

BTUH 6,850 8,800 10,150 11,700 15,170 18,840

GPM 3.1 4 4.8 5.8 8.9 14.6

PSI 1.5 2.4 3.2 4.3 9.7 21.3

BTUH 7,880 9,980 11,460 13,180 17,270 21,990

GPM 3.9 5.2 6.2 7.6 13.4 24.2

PSI 2.3 3.6 4.9 7.3 18.9 41.9

BTUH 10,020 12,530 14,270 16,310 21,210 27,040

GPM 4.8 6.7 8.3 10.1 14.3 19.1

PSI 3 5.2 7.4 10.6 20.4 35.9

BTUH 12,020 15,150 17,280 19,740 25,580 —

GPM 4 5.9 7.5 9.5 27.8 —

PSI 1.5 2.9 4.4 6.5 32.2 —

Low Temperature Models - R-407C

Suction Temperature °F

Suction Temperature °F

Model

Compressor

Suction Temperature °F

-40°F 30°F 25°F 20°F 10°F 0°F

BTUH 5,140 6,710 7,730 8,880 11,480 14,340

ZWN030L6 ZF09K4E

ZWN035L6 ZF11K4E

ZWN045L6 ZF13K4E

ZWN055L6 ZF15K4E

ZWN060L6 ZF18K4E

Capacity ratings conditions: 85°F entering water, 105°F condensing, 20°F ITD, 0°F subcooling.

GPM 2.3 3 3.5 4 6.9 14

PSI 0.9 1.3 1.8 2.3 5.2 12.3

BTUH 6,450 8,260 9,540 11,000 14,320 17,850

GPM 2.6 3.5 4.1 5 7.5 12

PSI 1.2 1.9 2.5 3.4 7.1 15.9

BTUH 7,300 9,200 10,590 12,230 16,110 20,570

GPM 3.3 4.3 5.2 6.3 10.6 19

PSI 1.7 2.7 3.6 5.1 13 30.6

BTUH 9,260 11,550 13,210 15,170 19,820 25,230

GPM 3.9 5.5 6.8 8.5 12.5 17

PSI 2.2 3.8 5.3 7.8 15.8 28.6

BTUH 11,180 14,020 16,020 18,360 23,880 —

GPM 3.2 4.7 6 7.7 16.3 —

PSI 1.2 2 3 4.6 15.7 —

13

Page 14

PERFORMANCE DATA ZWN MODELS

Low Temperature Models - R-448A/R-449A

Model

Compressor

Suction Temperature °F

-40°F 30°F 25°F 20°F 10°F 0°F

BTUH 5,760 7,610 8,670 9,840 12,540 15,790

ZWN030L6 ZF09K4E

ZWN035L6 ZF11K4E

ZWN045L6 ZF13K4E

ZWN055L6 ZF15K4E

ZWN060L6 ZF18K4E

Capacity ratings conditions: 85°F entering water, 105°F condensing, 20°F ITD, 0°F subcooling.

GPM 2.6 3.5 4.0 4.7 9.4 20.5

PSI 1.1 1.8 2.3 3.0 7.7 18.8

BTUH 7,180 9,450 10,770 12,240 15,650 19,740

GPM 3.0 4.1 4.8 5.8 8.8 15.5

PSI 1.5 2.5 3.2 4.3 9.4 23.1

BTUH 8,230 10,840 12,440 14,250 18,460 23,460

GPM 5.2 6.6 7.9 9.8 16.6 29.1

PSI 3.7 5.6 7.8 11.5 25.6 52.8

BTUH 10,440 13,610 15,520 17,680 22,720 28,790

GPM 6.6 8.9 10.4 12.0 16.0 20.8

PSI 5.1 8.4 11.1 14.6 25.3 42.6

BTUH 12,610 16,500 18,810 21,380 27,360 -

GPM 6.0 8.3 9.8 14.2 41.0 -

PSI 3.0 5.2 6.8 12.8 51.3 -

14

Page 15

UNIT SPECIFICATIONS ZWN MODELS

Connections (in.)

Model

Low Temperature Models

ZWN030L6 ZF09K4E 7/8 1/2 1/2 1/2 20 27 22 28 159

ZWN035L6 ZF11K4E 7/8 1/2 1/2 1/2 20 27 22 28 165

ZWN045L6 ZF13K4E 7/8 1/2 1/2 1/2 20 27 22 28 185

ZWN055L6 ZF15K4E 7/8 1/2 1/2 1/2 20 27 22 28 201

ZWN060L6 ZF18K4E 7/8 1/2 1/2 1/2 20 29 25 28 207

Extended Temperature Models

ZWN030X6 ZS21KAE 7/8 1/2 1/2 1/2 20 29 25 28 171

ZWN035X6 ZS26KAE 7/8 1/2 1/2 1/2 20 29 25 28 186

ZWN045X6 ZS29KAE 7/8 1/2 1/2 1/2 20 29 25 28 207

ZWN055X6 ZS38K4E 7/8 1/2 3/4 3/4 20 29 25 28 226

ZWN060X6 ZS45K4E 7/8 1/2 3/4 3/4 20 29 25 28 241

Compressor

Suction Liquid Water In Water Out

(ODS) (ODS) (FPT) (MPT) D W H

Receiver

90% Full

Lbs.

Dimensions (in.)

ELECTRICAL DATA ZWN MODELS

Model

Compressor

Number

Low Temperature Models

ZWN030L6B ZF09K4E-PFV 208-230 1 60 14.7 88.0 18.0 30 38 45 30 12.0

ZWN030L6C ZF09K4E-TF5 208-230 3 60 9.9 77.0 15.0 20 24 25 19 6.0

ZWN030L6D ZF09K4E-TFD 460 3 60 5.1 39.0 15.0 15 24 25 19 10.0

ZWN035L6B ZF11K4E-PFV 208-230 1 60 18.6 109.0 23.0 40 38 50 30 12.0

ZWN035L6C ZF11K4E-TF5 208-230 3 60 12.2 88.0 15.0 25 29 30 23 6.0

ZWN035L6D ZF11K4E-TFD 460 3 60 6.4 44.0 15.0 15 24 25 19 10.0

ZWN045L6B ZF13K4E-PFV 208-230 1 60 24.0 129.0 30.0 50 41 60 30 11.0

ZWN045L6C ZF13K4E-TF5 208-230 3 60 13.5 99.0 17.0 30 38 40 30 11.0

ZWN045L6D ZF13K4E-TFD 460 3 60 7.4 49.5 15.0 15 24 25 19 9.0

ZWN055L6B ZF15K4E-PFV 208-230 1 60 28.8 169.0 36.0 60 38 60 30 10.0

ZWN055L6C ZF15K4E-TF5 208-230 3 60 19.2 123.0 24.0 40 38 50 30 10.0

ZWN055L6D ZF15K4E-TFD 460 3 60 8.7 62.0 15.0 15 25 25 19 8.0

ZWN060L6C ZF18K4E-TF5 208-230 3 60 21.5 156.0 27.0 45 44 60 35 12.0

ZWN060L6D ZF18K4E-TFD 460 3 60 8.3 70.0 15.0 15 29 30 23 11.0

Extended Temperature Models

ZWN030X6B ZS21KAE-PFV 208-230 1 60 20.8 112.0 26.0 45 38 50 30 12.0

ZWN030X6C ZS21KAE-TF5 208-230 3 60 13.7 93.0 20.0 30 38 40 30 12.0

ZWN030X6D ZS21KAE-TFD 460 3 60 6.2 48.0 15.0 15 24 25 19 10.0

ZWN035X6B ZS26KAE-PFV 208-230 1 60 21.2 104.0 26.5 45 38 50 30 12.0

ZWN035X6C ZS26KAE-TF5 208-230 3 60 13.9 93.0 20.0 30 38 40 30 12.0

ZWN035X6D ZS26KAE-TFD 460 3 60 6.2 48.0 15.0 15 24 25 19 9.0

ZWN045X6B ZS29KAE-PFV 208-230 1 60 23.4 137.0 29.3 50 59 60 47 11.0

ZWN045X6C ZS29KAE-TF5 208-230 3 60 18.4 114.0 23.0 40 44 50 35 12.0

ZWN045X6D ZS29KAE-TFD 460 3 60 8.4 58.0 15.0 15 29 30 23 11.0

ZWN055X6B ZS38K4E-PFV 208-230 1 60 28.8 169.0 36.0 60 59 60 47 12.0

ZWN055X6C ZS38K4E-TF5 208-230 3 60 19.2 123.0 24.0 40 44 50 35 12.0

ZWN055X6D ZS38K4E-TFD 460 3 60 8.7 62.0 15.0 15 29 30 23 10.0

ZWN060X6C ZS45K4E-TF5 208-230 3 60 21.5 156.0 27.0 45 38 60 30 12.0

ZWN060X6D ZS45K4E-TFD 460 3 60 8.3 70.0 15.0 15 29 30 23 10.6

+

Consult Factory for 50 hz applications

RLA values have been calculated by dividing the maximum continuous current (MCC) by 1.56, per UL and National Electrical Code Standard.

Power Supply Compressor

Volts Ph Hz+RLA LRA MCA MOPD MCA MOPD Amps Amps

Beacon II™ or

Air Defrost

Electric Defrost

Def.

Htr.

Evap.

Net Wt.

(lbs.)

Fan

RLA = Rated Load Amps MCA = Minimum Circuit Ampacity

LRA = Locked Rotor Amps MOPD = Maximum Overload Protection Device

15

Page 16

FEATURES & BENEFITS - SWN MODELS

The indoor SWN water-cooled condensing unit is specically designed for use in supermarket, restaurant, warehouse

and other commercial and industrial applications. The design focuses on ease of installation and maintenance

along with the exibility to t most application requirements.

Construction

• Spacious, pre-painted electrical box

• Fixed low pressure switch (adjustable on low temp models)

• Fixed high pressure switch

• Pump down switch

• 230V control circuit transformer on 460V units

• Standard 16-3/4" tall box - (large 29 - 1/4" tall box is standard when defrost

components are selected)

• Sealed liquid line lter drier and sight glass

Serviceability

• Easy access refrigerant piping

• Captive door fasteners

• Single electrical connection location

• Removable electrical box provides convenient front access to the oil pump

and compressor

• Shell and tube cleanable condenser with outlet shut-o valve, charging port

and pressure relief device

Quality

• Pre-bent tubing reduces the possibility of leaks

• Shipped with dry nitrogen charge

• Heavy duty base plate

• Non-metallic conduit on all wiring runs

Components

• Semi-hermetic reciprocating compressors

• Compressor contactor and control circuit fusing

• Oil pressure switch (when required)

• Rigid mounted compressors (models 0075-0400)

• Spring mounted compressors with suction and discharge vibration

eliminators (models 0499 and above)

• Compressor head cooling fan or water jacket (when required)

• Compressor solid state protection model (on units with 4D compressors)

NOTE: SWN pictured with optional replaceable core

liquid lter, oil separator, replaceable core

suction lter and liquid solenoid valve

16

Page 17

OPTIONS - SWN MODELS

Factory-Installed Options

Dual pressure switch

Oil separator with discharge check valve and oil return hand valve

Compressor and control circuit breaker

Two tier rack

Suction accumulator

Sealed suction lter

Replaceable core suction lter (0300-2200)

Replaceable core liquid lter (0300-2200)

Liquid line solenoid valve

Spring mounted compressors with suction and discharge vibration eliminators (models 0075 to 0400)

Water regulating valve (shipped loose)

Crankcase heater

Air defrost timer

Electric defrost kit. Kit includes timer, evaporator fan contactor, defrost heater contactor(s), lockout relay and

terminal block

Remote load fusing for electric defrost kit. Includes evaporator fan motor and defrost heater fuses

Beacon II™ compatible (contact factory)

17

Page 18

PERFORMANCE DATA - SWN MODELS

Medium Temperature Models- R-404A/R-507

Model Compressor

SWN0090M6 KARA-010E

SWN0199M6 KAKA-020E

SWN0200M6 ERCA-021E

SWN0310M6 ERF1-031E

SWN0500M6 2DC3R53KE

BTUH

GPM

PSIG

BTUH

GPM

PSIG

BTUH

GPM

PSIG

BTUH

GPM

PSIG

BTUH

GPM

PSIG

85°F Entering Water, 105°F Condensing Temperature, 5°F Subcooling

Medium Temperature Models - R-407A

Model Compressor

15°F 20°F 25°F 30°F 35°F 40°F

8,140

1.8

1.0

13,490

3.5

3.7

17,220

4.8

0.8

24,990

6.2

1.4

38,480

9.7

2.4

9,140

2.1

1.3

15,120

4.2

5.0

19,430

5.6

1.1

28,090

7.3

1.8

43,470

11.5

3.4

15°F 20°F 25°F 30°F 35°F 40°F

Suction Temperature °F

10,340

2.4

1.6

16,750

4.8

6.7

21,790

6.5

1.4

31,450

8.5

2.5

48,930

13.7

4.8

-

-

-

-

-

-

-

-

-

-

-

-

54,810

16.5

6.8

Suction Temperature °F

-

-

-

-

-

-

-

-

-

-

-

-

61,160

20.0

9.9

-

-

-

-

-

-

-

-

-

-

-

-

68,040

24.6

14.9

BTUH 35,920 41,000 46,640 - - -

SWN0500M6 2DC3R53KE

GPM 14.1 17.5 22.3 - - -

PSI 5.1 7.7 12.3 - - -

85°F Entering Water, 105°F Condensing Temperature, 5°F Subcooling

Medium Temperature Models - R-407C

Model Compressor

BTUH 33,990 38,960 44,540 50,730 - -

SWN0500M6 2DC3R53KE

GPM 12.7 15.7 20.0 26.1 - -

PSI 4.1 6.3 9.9 16.7 - -

85°F Entering Water, 105°F Condensing Temperature, 5°F Subcooling

15°F 20°F 25°F 30°F 35°F 40°F

Medium Temperature Models - R-448A/R-449A

Model Compressor

15°F 20°F 25°F 30°F 35°F 40°F

Suction Temperature °F

Suction Temperature °F

BTUH 36,980 42,080 47,710 53,880 60,580 -

SWN0500M6 2DC3R53KE

GPM 14.6 18.1 22.9 29.7 38.9 -

PSI 5.4 8.2 13.0 21.4 34.7 -

85°F Entering Water, 105°F Condensing Temperature, 5°F Subcooling

18

Page 19

PERFORMANCE DATA - SWN MODELS

Low Temperature - R-404A/R-507 Models

R-404A/R-507

Model

SWN0150L6 KALA-016E

SWN0200L6 EADA-020E

SWN0210L6 EAVA-021E

SWN0310L6 LAHA-032E

SWN0310E6 LACA-032E

SWN0311L6 2DF3F16KE

SWN0400L6 2DL3F20KE

SWN0599L6 2DA3F23KE

Compressor

BTUH

GPM

PSIG

BTUH

GPM

PSIG

BTUH

GPM

PSIG

BTUH

GPM

PSIG

BTUH

GPM

PSIG

BTUH

GPM

PSIG

BTUH

GPM

PSIG

BTUH

GPM

PSIG

Suction Temperature °F

-40°F -30°F -25°F -20°F -10°F 0°F

3,160

0.8

0.2

3,590

1.1

0.2

3,980

1.2

0.2

5,940

1.5

0.1

8,540

2.1

0.2

10,050

2.4

0.2

12,480

3.0

0.3

14,790

3.4

0.3

4,940

1.3

0.5

5,570

1.5

0.1

5,990

1.6

0.1

9,560

2.3

0.2

12,810

3.2

0.4

14,600

3.5

0.5

17,850

4.4

0.7

20,900

4.9

0.7

5,880

1.5

0.7

6,620

1.7

0.1

7,350

1.9

0.2

11,760

2.8

0.3

15,330

3.9

0.6

17,120

4.1

0.6

20,900

5.2

1.0

24,260

5.7

0.9

6,830

1.7

0.9

7,770

2.0

0.2

8,820

2.3

0.2

14,180

3.4

0.4

18,060

4.7

0.8

19,950

4.8

0.9

24,260

6.1

1.3

27,930

6.7

1.2

9,030

2.3

1.6

10,500

2.7

0.3

12,290

3.3

0.4

19,850

5.0

0.9

-

-

-

26,570

6.6

1.6

31,920

8.5

2.5

36,440

9.0

2.1

11,550

3.1

2.9

13,970

3.8

0.5

16,280

4.7

0.8

26,360

7.3

1.9

34,440

9.1

2.8

41,160

12.0

4.7

46,520

12.2

3.8

-

-

-

SWN0600L6 2DB3F25KE

SWN0601L6 3DA3F28KE

SWN0750L6 3DB3F33KE

SWN0900L6 3DF3F40KE

SWN1000L6 3DS3F46KE

SWN1500L6 4DHNF63KE

SWN2200L6 4DJNF76KE

BTUH

GPM

PSIG

BTUH

GPM

PSIG

BTUH

GPM

PSIG

BTUH

GPM

PSIG

BTUH

GPM

PSIG

BTUH

GPM

PSIG

BTUH

GPM

PSIG

15,460

3.6

0.4

18,260

4.5

0.5

21,670

4.3

0.4

26,440

6.1

0.1

30,140

7.1

0.1

41,760

9.5

0.1

48,600

11.3

0.2

22,050

5.2

0.7

25,200

6.3

1.0

30,030

5.9

0.7

36,440

8.4

0.2

41,480

9.8

0.3

57,960

13.2

0.2

68,670

16.2

0.3

85°F Entering Water, 105°F Condensing Temperature, 5°F Subcooling

25,830

6.2

1.0

29,190

7.4

1.4

34,760

6.8

0.9

42,210

9.8

0.2

47,990

11.5

0.3

66,360

15.2

0.3

79,380

18.9

0.5

29,930

7.3

1.4

33,600

8.6

2.0

39,800

7.7

1.1

48,620

11.3

0.3

55,020

13.3

0.4

75,390

17.3

0.4

90,720

22.0

0.6

39,170

9.9

2.6

43,680

11.8

3.6

51,560

10.1

1.9

63,210

15.1

0.6

70,880

17.7

0.8

95,660

22.5

0.6

115,710

29.3

1.0

50,190

13.7

4.8

55,760

16.5

6.8

65,840

13.1

3.1

80,750

20.1

1.0

89,460

23.5

1.3

120,650

29.5

1.1

144,900

39.1

1.8

Demand Cooling is REQUIRED

19

Page 20

PERFORMANCE DATA - SWN MODELS

Low Temperature Models- R-407A

Model Compressor

SWN0311L6 2DF3F16KE

SWN0400L6 2DL3F20KE

SWN0599L6 2DA3F23KE

SWN0600L6 2DB3F25KE

SWN0601L6 3DA3F28KE

SWN0750L6 3DB3F33KE

SWN0900L6 3DF3F40KE

SWN1000L6 3DS3F46KE

SWN1500L6 4DHNF63KE

SWN2200L6 4DJNF76KE

BTUH 6,900 11,120 13,430 15,980 22,180 30,400

GPM 2.4 3.9 4.8 6.0 9.3 15.6

PSI 0.2 0.6 0.9 1.3 2.9 7.7

BTUH 8,330 13,210 16,120 19,350 26,800 —

GPM 3.1 5.0 6.3 8.0 13.2 —

PSI 0.4 0.9 1.4 2.2 5.7 —

BTUH 9,790 15,490 18,840 22,560 31,150 41,450

GPM 3.5 5.6 6.9 8.6 13.4 21.5

PSI 0.3 0.8 1.3 2.0 4.6 11.5

BTUH 11,100 17,090 20,480 24,210 32,940 43,780

GPM 3.9 6.1 7.6 9.4 14.8 24.4

PSI 0.4 1.0 1.5 2.3 5.6 14.6

BTUH 11,990 19,370 23,400 27,780 37,990 —

GPM 4.4 7.5 9.5 12.0 20.0 —

PSI 0.5 1.5 2.3 3.7 10.0 —

BTUH 15,400 24,540 29,340 34,470 46,230 60,860

GPM 4.5 6.9 8.3 10.0 14.3 21.2

PSI 0.4 0.9 1.3 1.8 3.7 7.8

BTUH — 28,730 34,770 41,340 56,250 73,890

GPM — 9.8 12.1 14.8 22.2 33.6

PSI — 0.3 0.4 0.5 1.2 2.6

BTUH 19,560 31,450 37,890 44,830 60,680 79,970

GPM 7.1 11.2 13.8 16.8 25.4 39.9

PSI 0.1 0.3 0.5 0.7 1.5 3.6

BTUH 30,480 45,330 53,890 63,250 84,460 109,180

GPM 10.6 15.6 18.9 22.9 33.7 50.0

PSI 0.2 0.3 0.5 0.7 1.4 2.9

BTUH 41,900 56,260 66,140 77,750 105,910 —

GPM 14.6 20.9 25.5 31.7 50.7 —

PSI 0.3 0.6 0.8 1.2 3.0 —

-40°F -30°F -25°F -20°F -10°F 0°F

Suction Temperature °F

20

Page 21

PERFORMANCE DATA - SWN MODELS

Low Temperature Models- R-407C

Model Compressor

SWN0311L6 2DF3F16KE

SWN0400L6 2DL3F20KE

SWN0599L6 2DA3F23KE

SWN0600L6 2DB3F25KE

SWN0601L6 3DA3F28KE

SWN0750L6 3DB3F33KE

SWN0900L6 3DF3F40KE

SWN1000L6 3DS3F46KE

SWN1500L6 4DHNF63KE

SWN2200L6 4DJNF76KE

BTUH 6,340 10,370 12,530 14,900 20,530 27,880

GPM 2.2 3.6 4.5 5.5 8.3 12.9

PSI 0.2 0.5 0.8 1.1 2.4 5.4

BTUH 7,640 12,310 15,040 18,040 24,830 32,650

GPM 2.8 4.6 5.8 7.3 11.5 18.3

PSI 0.3 0.8 1.2 1.9 4.4 10.3

BTUH 8,970 14,430 17,580 21,030 28,860 38,010

GPM 3.3 5.1 6.4 7.9 11.9 17.8

PSI 0.3 0.7 1.1 1.6 3.6 7.9

BTUH 10,160 15,890 19,090 22,570 30,530 40,130

GPM 3.6 5.6 7.0 8.6 13.1 19.9

PSI 0.3 0.9 1.3 2.0 4.4 9.9

BTUH 10,600 17,240 21,110 25,400 35,330 —

GPM 3.8 6.4 8.2 10.5 17.3 —

PSI 0.4 1.1 1.8 2.9 7.6 —

BTUH 13,690 21,810 26,420 31,460 42,960 56,640

GPM 3.9 6.1 7.4 8.9 12.9 18.7

PSI 0.3 0.7 1.0 1.5 3.0 6.2

BTUH — 25,550 31,370 37,800 52,330 68,750

GPM — 8.6 10.7 13.2 19.9 29.4

PSI — 0.2 0.3 0.4 1.0 2.0

BTUH — 27,980 34,190 41,000 56,450 74,420

GPM — 9.8 12.2 15.0 22.8 34.6

PSI — 0.3 0.4 0.5 1.2 2.8

BTUH 26,290 40,030 47,990 56,800 77,340 102,370

GPM 9.0 13.5 16.3 19.9 29.4 44.5

PSI 0.1 0.2 0.3 0.5 1.1 2.3

BTUH 32,460 48,710 57,400 66,930 89,830 120,150

GPM 11.5 17.4 21.1 25.4 38.1 62.2

PSI 0.2 0.4 0.6 0.8 1.7 4.4

-40°F -30°F -25°F -20°F -10°F 0°F

Suction Temperature °F

Demand Cooling is REQUIRED

21

Page 22

PERFORMANCE DATA - SWN MODELS

Low Temperature Models- R-407F

Model Compressor

SWN0311L6 2DF3F16KE

SWN0400L6 2DL3F20KE

SWN0599L6 2DA3F23KE

SWN0600L6 2DB3F25KE

SWN0601L6 3DA3F28KE

SWN0750L6 3DB3F33KE

SWN0900L6 3DF3F40KE

SWN1000L6 3DS3F46KE

SWN1500L6 4DHNF63KE

SWN2200L6 4DJNF76KE

BTUH 6,900 11,120 13,430 15,980 22,180 30,400

GPM 2.4 3.9 4.8 6.0 9.3 15.6

PSI 0.2 0.6 0.9 1.3 2.9 7.7

BTUH 8,330 13,210 16,120 19,350 26,800 —

GPM 3.1 5.0 6.3 8.0 13.2 —

PSI 0.4 0.9 1.4 2.2 5.7 —

BTUH 9,790 15,490 18,840 22,560 31,150 41,450

GPM 3.5 5.6 6.9 8.6 13.4 21.5

PSI 0.3 0.8 1.3 2.0 4.6 11.5

BTUH 11,100 17,090 20,480 24,210 32,940 43,780

GPM 3.9 6.1 7.6 9.4 14.8 24.4

PSI 0.4 1.0 1.5 2.3 5.6 14.6

BTUH 11,990 19,370 23,400 27,780 37,990 —

GPM 4.4 7.5 9.5 12.0 20.0 —

PSI 0.5 1.5 2.3 3.7 10.0 —

BTUH 15,400 24,540 29,340 34,470 46,230 60,860

GPM 4.5 6.9 8.3 10.0 14.3 21.2

PSI 0.4 0.9 1.3 1.8 3.7 7.8

BTUH — 28,730 34,770 41,340 56,250 73,890

GPM — 9.8 12.1 14.8 22.2 33.6

PSI — 0.3 0.4 0.5 1.2 2.6

BTUH 19,560 31,450 37,890 44,830 60,680 79,970

GPM 7.1 11.2 13.8 16.8 25.4 39.9

PSI 0.1 0.3 0.5 0.7 1.5 3.6

BTUH 30,480 45,330 53,890 63,250 84,460 109,180

GPM 10.6 15.6 18.9 22.9 33.7 50.0

PSI 0.2 0.3 0.5 0.7 1.4 2.9

BTUH 41,900 56,260 66,140 77,750 105,910 —

GPM 14.6 20.9 25.5 31.7 50.7 —

PSI 0.3 0.6 0.8 1.2 3.0 —

-40°F -30°F -25°F -20°F -10°F 0°F

Suction Temperature °F

Demand Cooling is REQUIRED

22

Page 23

PERFORMANCE DATA - SWN MODELS

Low Temperature Models- R-448A/R-449-A

Model Compressor

SWN0311L6 2DF3F16KE

SWN0400L6 2DL3F20KE

SWN0599L6 2DA3F23KE

SWN0600L6 2DB3F25KE

SWN0601L6 3DA3F28KE

SWN0750L6 3DB3F33KE

SWN0900L6 3DF3F40KE

SWN1000L6 3DS3F46KE

SWN1500L6 4DHNF63KE

SWN2200L6 4DJNF76KE

BTUH 7,610 11,700 14,020 16,620 23,010 31,490

GPM 2.6 4.1 5.1 6.2 9.7 16.3

PSI 0.3 0.6 1.0 1.4 3.2 8.4

BTUH 9,230 13,910 16,830 20,130 27,810 36,920

GPM 3.4 5.3 6.7 8.4 13.8 24.3

PSI 0.4 1.0 1.6 2.4 6.1 17.0

BTUH 10,230 16,240 19,700 23,500 32,290 42,870

GPM 3.8 5.9 7.3 9.0 13.9 22.6

PSI 0.4 0.9 1.4 2.1 5.0 12.7

BTUH 11,130 17,860 21,430 25,260 34,100 45,190

GPM 3.7 6.5 8.1 10.0 15.5 26.0

PSI 0.4 1.1 1.7 2.6 6.1 16.6

BTUH 14,140 20,480 24,380 28,820 39,470 52,750

GPM 5.7 8.2 10.1 12.7 21.5 40.9

PSI 0.9 1.8 2.6 4.1 11.5 37.7

BTUH 16,990 25,830 30,640 35,850 47,940 63,010

GPM 5.0 7.4 8.9 10.6 15.1 22.4

PSI 0.5 1.0 1.5 2.1 4.1 8.7

BTUH 19,630 30,270 36,280 42,900 58,520 78,100

GPM 6.8 10.5 12.8 15.5 23.3 36.3

PSI 0.1 0.3 0.4 0.6 1.3 3.0

BTUH 21,530 33,210 39,800 47,070 64,190 85,680

GPM 7.7 12.0 14.7 18.0 27.5 44.4

PSI 0.2 0.4 0.5 0.8 1.8 4.5

BTUH 25,100 39,450 47,020 55,020 72,790 93,730

GPM 7.9 12.9 15.6 18.6 26.1 36.8

PSI 0.1 0.2 0.3 0.4 0.8 1.6

BTUH 36,620 58,210 69,500 81,550 109,220 143,820

GPM 13.1 22.1 27.6 34.2 53.7 92.0

PSI 0.2 0.6 0.9 1.4 3.3 9.1

-40°F -30°F -25°F -20°F -10°F 0°F

Suction Temperature °F

85°F Entering Water, 105°F Condensing Temperature, 5°F Subcooling

Demand Cooling is REQUIRED

23

Page 24

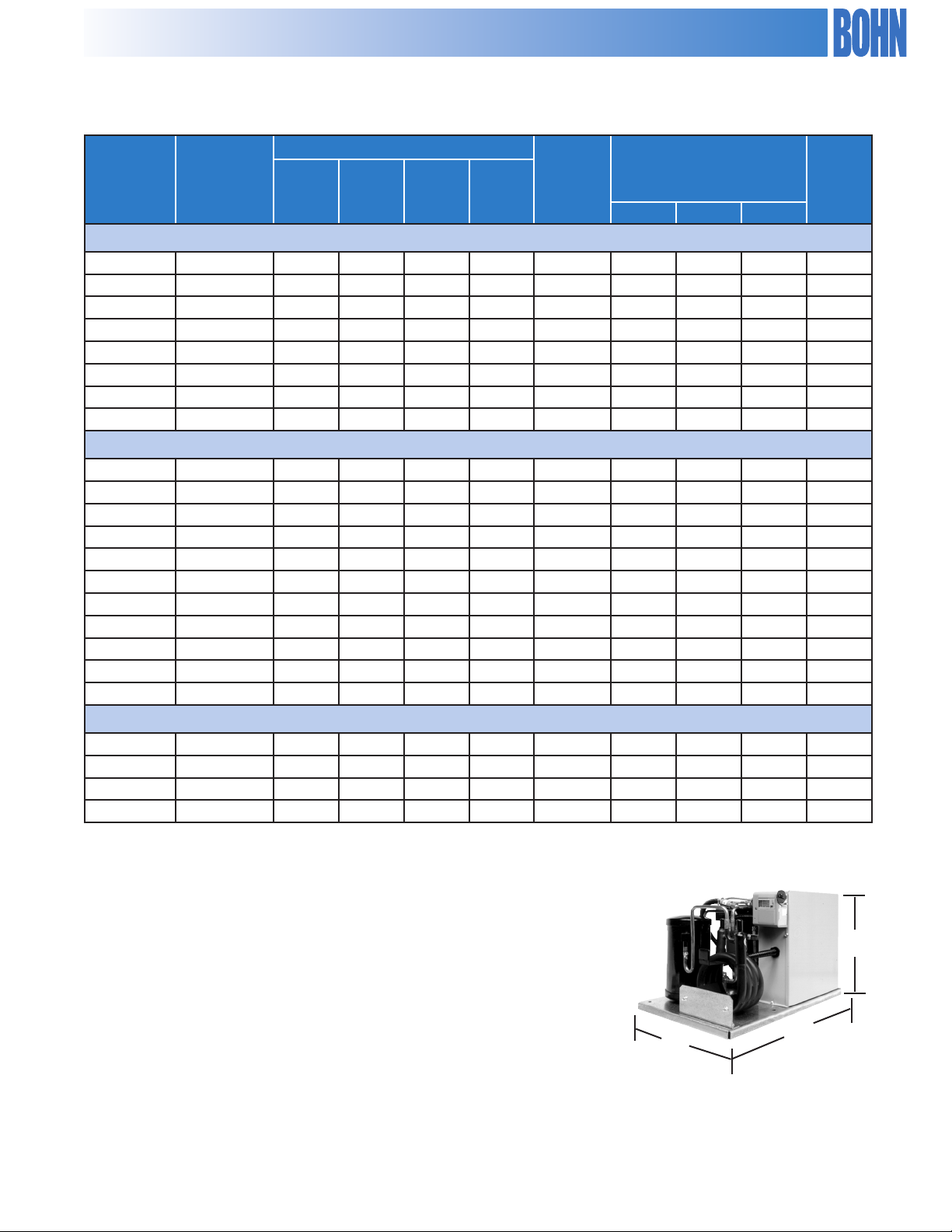

UNIT SPECIFICATIONS - SWN MODELS

Connections (in.)

Model

High & Medium Temperature

SWN0090M6 KARA-010E 7/8 3/8 1/2 1/2 18 37-3/8 23-3/4 35 180

SWN0199M6 KAKA-020E 7/8 3/8 1/2 1/2 18 37-3/8 23-3/4 35 210

SWN0200M6 ERCA-021E 7/8 3/8 1/2 1/2 15 37-3/8 23-3/4 38-3/8 260

SWN0310M6 ERFA-031E 1-1/8 1/2 3/4 3/4 17 36-3/8 26-3/4 38-3/8 325

SWN0500M6 2DC3R53KE 1-3/8 5/8 1-1/4 1-1/4 34 39-1/4 30-3/8 42-1/2 400

Low Temperature

SWN0150L6 KALA-016E 7/8 3/8 1/2 1/2 18 37-3/8 23-3/4 35 195

SWN0200L6 EADA-020E 7/8 3/8 1/2 1/2 15 37-3/8 23-3/4 35 325

SWN0210L6 EAVA-021E 7/8 3/8 1/2 1/2 15 37-3/8 23-3/4 35 325

SWN0310L6 LAHA-032E 1-1/8 1/2 3/4 3/4 17 36-3/8 26-3/4 38-3/8 325

SWN0310E6 LACA-032E 1-1/8 1/2 3/4 3/4 17 36-3/8 26-3/4 38-3/8 325

SWN0311L6 2DF3F16KE 1-3/8 1/2 3/4 3/4 17 36-3/8 26-3/4 38-3/8 340

Compressor

Model

Suction

Liquid

Line

Water

Inlet

Water

Outlet

90%

Cond.

Holding

Capacity

(Lbs.)

Dimensions (in.)

H W D

Approx.

Net Wt.

(Lbs.)

SWN0400L6 2DL3F20KE 1-3/8 1/2 3/4 3/4 17 36-3/8 26-3/4 38-3/8 385

SWN0599L6 2DA3F23KE 1-3/8 5/8 1-1/4 1-1/4 34 39-1/4 30-3/8 42-1/2 415

SWN0600L6 2DB3F25KE 1-3/8 5/8 1-1/4 1-1/4 34 39-1/4 30-3/8 42-1/2 415

SWN0601L6 3DA3F28KE 1-3/8 5/8 1-1/4 1-1/4 34 39-1/4 30-3/8 42-1/2 430

SWN0750L6 3DB3F33KE 1-5/8 5/8 1-1/4 1-1/4 52 41-1/2 35-3/8 55-1/2 465

SWN0900L6 3DF3F40KE 1-5/8 5/8 1-1/4 1-1/4 57 41-1/2 35-3/8 55-1/2 560

SWN1000L6 3DS3F46KE 1-5/8 7/8 1-1/4 1-1/4 57 41-1/2 35- 3/8 55-1/2 715

SWN1500L6 4DHNF63KE 2-1/8 7/8 1-1/2 1-1/2 109 41-1/2 35-3/8 55-1/2 780

SWN2200L6 4DJNF76KE 2-1/8 7/8 1-1/2 1-1/2 109 41-1/2 35- 3/8 55-1/2 865

NOTES: Condenser refrigerant holding capacity refers to the weight of the type of refrigerant indicated by the model number

(i.e. M6, L6, E6 = R-404A/R-507)

Dimensions are maximum dimensions with options. Please refer to submittal drawings for specic model dimensions

24

Page 25

ELECTRICAL DATA - SWN MODELS

Medium Temperature Models

Power

Model

Number

SWN0090M6B KARB-010E 208-230 1 60 6.4 40.0 15.0 15 15.0 15 10 (1) 3 - - - -

SWN0090M6C KARA-010E 208-230 3 60 3.8 27.0 15.0 15 15.0 15 10 (1) 3 - - - -

SWN0199M6B KAKB-021E 208-230 1 60 9.1 55.0 15.0 20 25.0 25 20 (1) 6 50.0 50 40 (1) 12

SWN0199M6C KAKA-020E 208-230 3 60 5.8 50.0 15.0 15 25.0 25 20 (1) 6 - - - -

SWN0200M6C ERCA-021E 208-230 3 60 7.9 46.0 15.0 15 25.0 25 20 (1) 6 - - - -

SWN0310M6G ERFB-031E 230 1 60 15.3 86.0 20.0 30 25.1 40 20 (1) 6 50.0 50 40 (1) 12

SWN0310M6C ERFA-031E 208-230 3 60 11.2 82.0 15.0 25 25.0 30 20 (1) 6 50.0 50 40 (1) 12

SWN0310M6D ERFA-031E 460 3 60 5.2 41.0 15.0 15 15.0 15 10 (1) 3 25.0 25 20 (1) 6

SWN0310M6E ERFA-031E 575 3 60 4.5 30.0 15.0 15 15.0 15 8 (1) 3 20.0 20 16 (1) 5

SWN0500M6C 2DC3R53KE 208-230 3 60 20.0 120.0 25.0 45 31.0 50 20 (1) 6 50.0 50 40 (1) 12

SWN0500M6D 2DC3R53KE 460 3 60 9.4 60.0 15.0 20 15.0 20 10 (1) 3 25.0 25 20 (1) 6

SWN0500M6E 2DC3R53KE 575 3 60 6.9 49.0 15.0 15 15.0 15 8 (1) 3 20.0 20 16 (1) 5

Compressor

Model

Supply

Volts Ph Hz RLA LRA MCA MOPD MCA MOPD Amps Amps MCA MOPD Amps Amps

Compressor

Beacon II™ or

Air Defrost

Low Amps High Amps

Electric

Defrost

Def.

Htr.*

Evap.

Fan

Electric

Defrost

Def.

Htr.*

Evap.

Fan

*Number of defrost heater contactors in parentheses

RLA - Rated Load Amps MCA - Minimum Circuit Ampacity

LRA - Locked Rotor Amps MOPD - Maximum Overcurrent Protection Device

DIMENSIONAL DATA SWN MODELS

Maximum Dimensions with Options

Horsepower A B C D E

3/4 to 2 35" 23-3/4" 37-3/8" 10-5/8" 12"

3 to 4 38-3/8" 26-3/4" 36-3/8" 13-1/2" 12"

5 to 6 42-1/2" 30-3/8" 39-1/4" 14" 12"

7-1/2 to 22 55-1/2" 35-3/8" 41-1/2" 36" 12"

NOTES: Please refer to submittal drawings for exact model dimensions

25

Page 26

ELECTRICAL DATA - SWN MODELS

Low Temperature Models

Model

Number

SWN0150L6B KALB-015E 208-230 1 60 8.9 55.0 15.0 20 25.0 25 20 (1) 6 - - - SWN0150L6C KALA-016E 208-230 3 60 5.0 50.0 15.0 15 25.0 25 20 (1) 6 - - - SWN0150L6D KALA-016E 460 3 60 3.1 25.0 15.0 15 15.0 15 10 (1) 3 - - - SWN0200L6G EADB-021E 230 1 60 9.0 58.0 15.0 20 25.0 25 20 (1) 6 - - - SWN0200L6C EADA-020E 208-230 3 60 6.1 46.0 15.0 15 25.0 25 20 (1) 6 - - - SWN0210L6B EAVB-021E 208-230 1 60 13.2 102.0 20.0 25 25.0 35 20 (1) 6 - - - SWN0210L6C EAVA-021E 208-230 3 60 6.6 50.0 15.0 15 25.0 25 20 (1) 6 - - - SWN0210L6D EAVA-021E 460 3 60 2.9 26.6 15.0 15 15.0 15 10 (1) 3 - - - SWN0210L6E EAVA-021E 575 3 60 2.8 20.0 15.0 15 15.0 15 8 (1) 3 - - - SWN0310L6G LAHB-032E 230 1 60 15.0 105.0 20.0 30 25.0 35 20 (1) 6 50.0 50 40 (1) 12

SWN0310L6C LAHA-032E 208-230 3 60 11.5 112.0 15.0 25 25.0 30 20 (1) 6 50.0 50 40 (1) 12

SWN0310L6D LAHA-032E 460 3 60 5.4 56.0 15.0 15 15.0 15 10 (1) 3 25.0 25 20 (1) 6

SWN0310L6E LAHA-032E 575 3 60 3.7 30.0 15.0 15 15.0 15 8 (1) 3 20.0 20 16 (1) 5

SWN0310E6G LACB-032E 230 1 60 13.9 105.0 20.0 30 25.0 35 20 (1) 6 50.0 50 40 (1) 12

SWN0310E6C LACA-032E 208-230 3 60 11.5 112.0 15.0 25 25.0 30 20 (1) 6 50.0 50 40 (1) 12

SWN0310E6D LACA-032E 460 3 60 5.4 56.0 15.0 15 15.0 15 10 (1) 3 25.0 25 20 (1) 6

SWN0311L6G 2DF3F16KE 230 1 60 22.9 125.0 28.7 50 34.7 50 20 (1) 6 50.0 60 40 (1) 12

SWN0311L6C 2DF3F16KE 208-230 3 60 14.4 102.0 20.0 30 25.0 35 20 (1) 6 50.0 50 40 (1) 12

SWN0311L6D 2DF3F16KE 460 3 60 7.1 52.0 15.0 15 15.0 15 10 (1) 3 25.0 25 20 (1) 6

SWN0311L6E 2DF3F16KE 575 3 60 6.0 41.0 15.0 15 15.0 15 8 (1) 3 20.0 20 16 (1) 5

SWN0400L6C 2DL3F20KE 208-230 3 60 23.6 161.0 29.5 50 35.5 50 20 (1) 6 50.0 60 40 (1) 12

SWN0400L6D 2DL3F20KE 460 3 60 9.2 60.0 15.0 20 15.0 20 10 (1) 3 25.0 25 20 (1) 6

SWN0400L6E 2DL3F20KE 575 3 60 6.9 49.0 15.0 15 15.0 15 8 (1) 3 20.0 20 16 (1) 5

SWN0599L6C 2DA3F23KE 208-230 3 60 25.8 161.0 32.3 50 38.3 60 20 (1) 6 50.0 70 40 (1) 12

SWN0599L6D 2DA3F23KE 460 3 60 9.2 60.0 15.0 20 15.0 20 10 (1) 3 25.0 25 20 (1) 6

SWN0599L6E 2DA3F23KE 575 3 60 8.1 49.0 15.0 15 15.0 20 8 (1) 3 20.0 20 16 (1) 5

SWN0600L6C 2DB3F25KE 208-230 3 60 25.3 161.0 31.7 50 37.7 60 20 (1) 6 50.0 60 40 (1) 12

SWN0600L6D 2DB3F25KE 460 3 60 11.9 80.0 15.0 25 20.0 25 10 (1) 3 25.0 30 20 (1) 6

SWN0600L6E 2DB3F25KE 575 3 60 8.6 63.0 15.0 15 15.0 20 8 (1) 3 20.0 20 16 (1) 5

SWN0601L6C 3DA3F28KE 208-230 3 60 24.0 150.0 30.1 50 36.1 60 20 (1) 6 50.0 60 40 (1) 12

SWN0601L6D 3DA3F28KE 460 3 60 10.8 77.0 15.0 20 20.0 25 10 (1) 3 25.0 30 20 (1) 6

SWN0601L6E 3DA3F28KE 575 3 60 9.4 62.0 15.0 20 15.0 20 8 (1) 3 20.0 25 16 (1) 5

SWN0750L6C 3DB3F33KE 208-230 3 60 27.6 161.0 34.5 60 50.0 70 40 (1) 12 87.5 90 70 (2) 16

SWN0750L6D 3DB3F33KE 460 3 60 14.1 83.0 20.0 30 25.0 35 20 (1) 6 50.0 50 40 (1) 12

SWN0750L6E 3DB3F33KE 575 3 60 9.9 67.0 15.0 20 20.0 25 16 (1) 5 40.0 40 32 (1) 10

SWN0900L6C 3DF3F40KE 208-230 3 60 33.2 215.0 41.5 70 53.5 80 40 (1) 12 87.5 90 70 (2) 16

SWN0900L6D 3DF3F40KE 460 3 60 15.0 106.0 20.0 30 25.0 35 20 (1) 6 50.0 50 40 (1) 12

SWN0900L6E 3DF3F40KE 575 3 60 14.1 84.0 20.0 30 22.6 35 16 (1) 5 40.0 40 32 (1) 10

SWN1000L6C 3DS3F46KE 208-230 3 60 37.2 215.0 46.5 80 58.5 90 40 (1) 12 87.5 90 70 (2) 16

SWN1000L6D 3DS3F46KE 460 3 60 16.7 106.0 20.8 35 26.8 40 20 (1) 6 50.0 50 40 (1) 12

SWN1000L6E 3DS3F46KE 575 3 60 14.6 84.0 20.0 30 23.2 35 16 (1) 5 40.0 40 32 (1) 10

SWN1500L6C 4DHNF63KE 208-230 3 60 47.2 278.0 59.0 100 87.5 110 70 (2) 16 120.0 125 96 (2) 25

SWN1500L6D 4DHNF63KE 460 3 60 23.6 139.0 29.5 50 50.0 60 40 (1) 12 87.5 90 70 (2) 16

SWN1500L6E 4DHNF63KE 575 3 60 18.8 113.0 23.5 40 40.0 50 32 (1) 10 70.0 70 56 (2) 12

SWN2200L6C 4DJNF76KE 208-230 3 60 59.2 374.0 74.0 125 90.0 125 70 (2) 16 120.0 150 96 (2) 25

SWN2200L6D 4DJNF76KE 460 3 60 29.6 187.0 37.0 60 50.0 70 40 (1) 12 87.5 90 70 (2) 16

SWN2200L6E 4DJNF76KE 575 3 60 21.7 135.0 27.1 45 40.0 50 32 (1) 10 70.0 70 56 (2) 12

Compressor

Model

Power

Supply

Volts Ph Hz RLA LRA MCA MOPD MCA MOPD Amps Amps MCA MOPD Amps Amps

Compressor

Beacon II™ or

Air Defrost

Low Amps High Amps

Electric

Defrost

Def.

Htr.*

Evap.

Fan

Electric

Defrost

Def.

Htr.*

Evap.

Fan

*Number of defrost heater contactors in parentheses

RLA - Rated Load Amps MCA - Minimum Circuit Ampacity

LRA - Locked Rotor Amps MOPD - Maximum Overcurrent Protection Device

26

Page 27

Notes

Page 28

For more information on Bohn refrigeration products, contact

your sales representative or visit us at heatcraftrpd.com.

A Brand of Heatcraft Refrigeration Products LLC

2175 West Park Place Blvd. • Stone Mountain, GA • 30087

800.537.7775

heatcraftrpd.com

BN-WCCUTB-0816 | Version 000

Since product improvement is a continuing eort, we reserve the right to

make changes in specications without notice.

Loading...

Loading...