Bohn H-IM-AH Installation Manual

Bulletin No� H-IM-AH August 2002 Part Number 4346B001

(Replaces H-IM-71A, August 2002)

Installation &

Operations Manual

Air Handler Unit

Table of Contents

Inspection �������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������2

Shipment of Units

Handling

Suspended Units

Installation

Motors & Drives

Steam Coils

Steam Coils �����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������3

Water Coils

Direct Expansion Coils

Start-up ������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������4

Maintenance

Condensate Drain Traps

Internal Isolation

Section Assembly �����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������5

Coil Stacking

Freezing Temperatures �������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������6

Weights ������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������7

Shipment of Sections

Filter Quantities ���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������8

Replacement Parts

Installation and Operations Manual

Inspection

Shipment should be checked against the bill of lading

to verify that all items listed have been received� All

parts should be carefully inspected to determine if any

damage was incurred in shipment�

Any shortage and/or claims for damage should be

immediately reported to the delivering carrier, followed

by ling a claim for shortages and/or damages�

Shipment of Units

Depending on the unit size and accessories included, the

shipment may be in two or more sections�

Handling

Special care should be taken when handling and

assembling component sections of the unit� Rough

handling at the jobsite can result in damaged bearings,

bent shafts, etc�

All units are shipped on wooden skids� It is recommended

that units not be moved removed from skids until they

are at a place of installation� The mounting legs/rails

provided for isolators should be used when lifting units

into place�

Suspended Units

Sizes 03 through 41 may be ceiling-suspended from

the mounting legs/based rails with 5/8” diameter rods

(not furnished)� These rods will pass through the 11/16”

diameter mounting holes provided� Sizes 50, 65 and 75

cannot be ceiling-suspended�

Installation

It is very important that the unit be installed in a level

position to prevent distortion and to ensure proper

damper operation and coil drainage�

Allow sucient space around the unit for proper

maintenance� Consider factors such as lter removal for

cleaning or replacement, access to all removal panels,

removal of coils and shaft if necessary, lubrication access

or motor belt adjustment� Canvas duct connections

should be used between the unit and supply and return

air ducts�

Units are furnished with 1-1/4” FPT drain connection

on each side of the coil section� The drain line from

the drain pan connection must be adequately pitched

and should have a water seal of sucient depth to

compensate for the air pressure within the units�

(See Condensate Drain Traps on page 4�)

When the unit is located on the roof, it must be mounted

on support beams that span load-bearing walls� If not,

excessive vibration may occur because of the resiliency

of the roof�

2 Part # 4346B001

© 2007, Heatcraft Refrigeration Products LLC

Fan noise is a function of fan design, volume ow,

pressure and fan eciency and could be loud enough

to disturb those in occupied areas� Therefore, on critical

applications we recommend extra sound attention�

Motors and Drives

All units will normally be shipped with motor and drive

installed� When mounting a motor on the adjustable

base (installed on the unit), extreme care should be

taken to ensure proper alignment and belt tension� All

electrical work should be done in strict accordance with

local codes and regulations�

Steam Coils

Type J and NFS coils have supply and return connections

on the same end� Types R, S and RA coils have

supply and return connections on opposite ends�

Type NFD coils have supply connections on each end

of the coil, with a single return connection on one

end only�

All piping should be in accordance with accepted

industry standards and local codes� Support all piping

independent of coil and provide adequate swing joints in

all piping to absorb expansion and contraction strains�

Run return piping the full size of the coil return

connection from the coil to a dirt pocket� (Do not use

reducing ttings�) Install drip traps in steam mains ahead

of coils� Do not drip steam mains through the coils�

Install a vacuum breaker (1/2” 15º check valve) ahead

of the trap on low-pressure, open-gravity return systems

and on high pressure systems� Install a 1/2” 15º swing

check valve in a 1/2” vacuum-equalizing line, bypassing

the condensate trap, on low pressure vacuum systems�

When two or more steam coils are furnished in a unit,

provide separate traps for each coil� Size traps with ample

capacity using the maximum heating load and service

factor recommended by the trap manufacturer�

Select control valves in accordance with the

recommendations of the control manufacturer using

actual heating loads�

Install suitable strainer ahead of all automatic valves and

traps to catch dirt and scale� Provide adequate air vents

to expel air and other non-condensable material�

Control valves used for type J, NFS, RA and NFD coils

must be gradual-acting, modulating type with veeport�

Where a control valve is used for type S or R coils and

the entering air temperature is below 35ºF, use a twoposition valve� Locate control element in the entering air

Air Handler Units

stream so that valve will remain open with a minimum

of ve pounds steam pressure when the entering air

temperature is below 35ºF� At system start-up, the

damper should remain closed for approximately ten

minutes after the steam valve is opened�

Properly locate all temperature sensing elements at a

point of true average air mixture temperature� Refer to

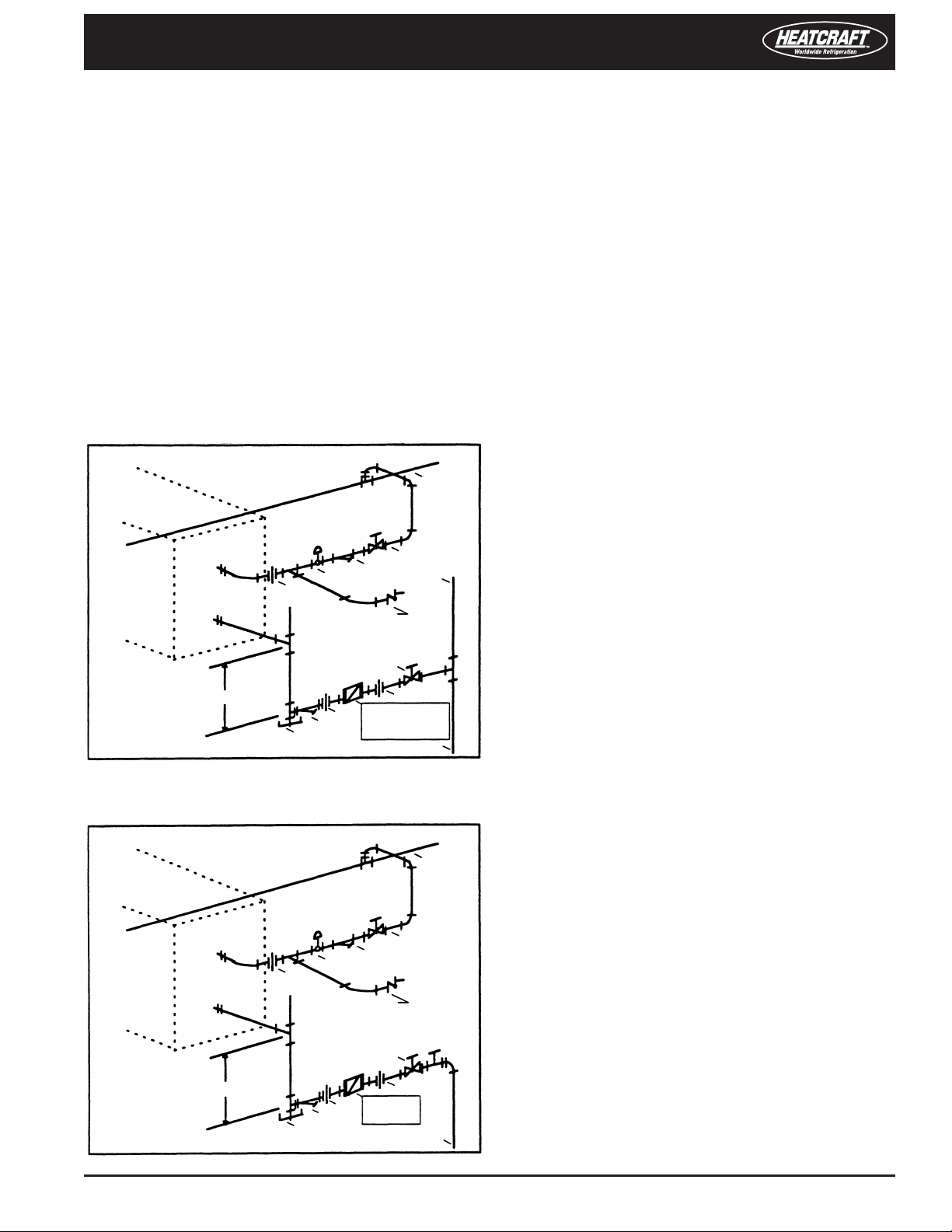

Diagrams 1 and 2 for controls positioning and piping

conguration�

When face and bypass dampers are used, it is good

practice to install a valve that closes with the face damper

to prevent overheating because of damper leakage or

heat from the exposed coil face�

Diagram 1� Typical Steam Coil Piping

Low Pressure, Open Gravity Return System

Steam Main

Water Piping

All piping must be supported independent of coils�

Swing joints or exible ttings must be provided to

absorb expansion and contraction strains� Rigid piping

may also reduce eectiveness of vibration isolators�

The water supply should always be connected to the

bottom inlet of the coil� The coil connections are

identied with stickers�

Water coils (3 through 10 rows) are supplied with a vent

and drain connection (1/4” MPT) that extends through

the unit casing� Coils must be adequately vented in order

to prevent air binding� For protection of coils exposed to

freezing temperatures, refer to page 6�

Direct Expansion

Both the liquid distributor and the suction line extend

through the casting� The expansion valve utilized must

be the external equalizer tube type� The expansion valve

bulb must be placed on the suction line between the

coil and the 1/4” external equalizer tube� Never put the

bulb in a trap�

Gate Valve

Strainer

Control Valve

Union

Vacuum Breaker

1/2”-15” Check Valve

Vent

Gate Valve

12” Minimum

Union

Strainer

Dirt Pocket

Union

Combination Float

and

Thermostatic Trap

Return Main

Diagram 2� Typical Steam Coil Piping

High Pressure System

Gate Valve

Strainer

Control Valve

Union

Vacuum Breaker

Vent

1/2”-15” Check Valve

Open Vent

Steam Main

All refrigerant piping practices should be in accordance

with local codes and latest ANSI Standard B9 Safety Code�

Hard-drawn type L or K copper tubing should be used�

Soft tubing may be used where bending is required,

provided it is in accordance with local codes�

Remember to check for adequate vacuum, clear tubes of

foreign material, etc�

Gate Valve

12” Minimum

Union

Strainer

Dirt Pocket

Union

Float or

Bucket Trap

Return Main

Air Handler Unit Installation & Operations Manual, August 2002 3

Loading...

Loading...