Page 1

H-IM-80D February, 2004

Replaces H-IM-80C (12/03)

Part No. 25000601

Beacon II Smart Controller

Installation & Operation

Manual

Table of Contents

Features ................................................................2-3

Installation .............................................................4

Wiring ....................................................................5

Power Supply ........................................................6

Initialization of Beacon II Smart Controller ............7

Button Functions ....................................................7

Programming Beacon II Smart Controller..............8

Monitoring Beacon II Smart Controller ..................9

Locking Beacon II Smart Controller ....................... 10

Error Codes ...........................................................10

Wiring Errors ..........................................................11

Alarm Codes .......................................................... 11

Alarm Buzzer .........................................................12

Data Logging .........................................................12

Smart Defrost ........................................................13

PC & Modem Access.............................................14

System Defaults ....................................................15

Parts List ................................................................16

Operational Limits..................................................16

Diagnostics ............................................................17-20

Wiring Diagrams ....................................................21-23

Page 2

Beacon II Smart Controller Features

The Beacon II Smart Controller performs all the

standard Beacon functions with the additional

benefit of:

a) Remote mounting for easy access

b) Remote monitoring and programming

c) Controlling four completely separate

systems

d) Logging data

e) Smart Defrost

f) Access via PC or modem

g) Has buzzer to signal alarms

h) Locking keypad

Beacon II Smart Controller allows complete

monitoring and programming of the system.

The Controller display has the following buttons:

COOLING, DEFROST, PROG REVIEW,

MONITOR, ENTER, CLEAR, SETPOINT AND

TIME.

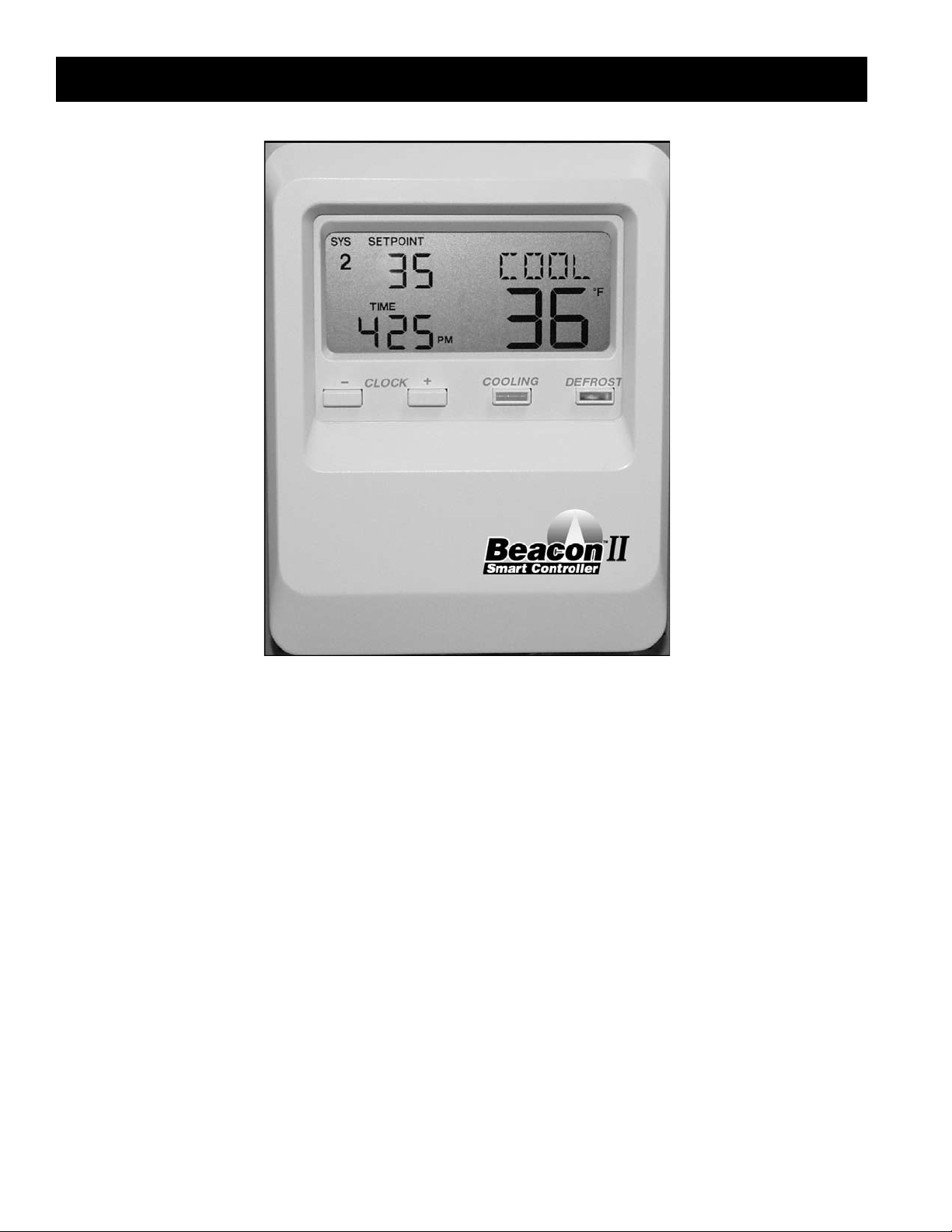

The normal LCD display will show the

Programmed Box Set-point temperature.

Actual Box Temperature, the Current Time

of day and the Mode (i.e. COOL, DEFROST

or OFF). When multiple systems are being

controlled, the system number (i.e. SYS 1, SYS

2, SYS 3, SYS 4) will also be displayed on the

LCD.

© 2004, Heatcraft Refrigeration Products LLC

2

Page 3

Beacon II Smart Controller Features

Features of the Beacon II Smart Controller

• Monitoring of the complete refrigeration system.

• Programming of a variety of parameters for the

optimum control of the refrigeration system.

• The Beacon II Smart Controller has a Liquid

Crystal Display (LCD) which shows: current

time, actual box temperature, box temperature

set-point and if there is an alarm or fault

condition.

• Data Logging.

• Smart Defrost to save energy on defrost.

• Sounds a buzzer to indicate an Alarm condition.

• Can be mounted up to 1000 ft. away from the

system being controlled.

• Each Beacon II Smart Controller can control four

independent systems with up to 4 evaporators

on each system.

• An RS232 port is provided which allows

connection to system via PC or Modem.

• A Backup battery will maintain the clock settings

for 10 years.

• Double E PROM Chip will maintain program

settings indefinitely.

• Password protection system.

• Locking feature to prevent unauthorized access

to program settings.

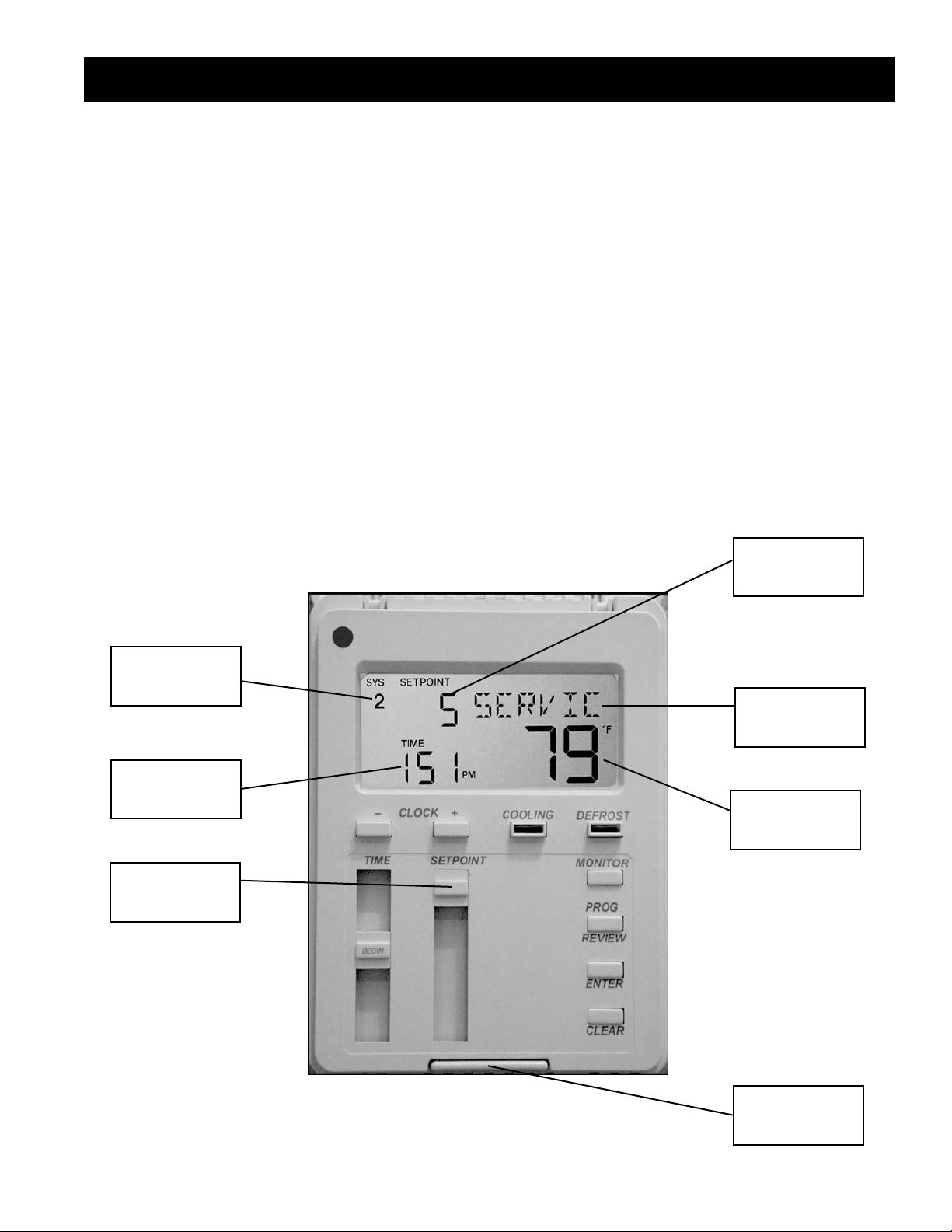

Box Set-point

Temperature

System

Number

Time of Day

Set-point

Slide Bar

Operating

Mode

Box

Temperature

System

Selection Bar

3

Page 4

INSTALLATION

Installation

The Beacon II Smart Controller should be

installed in a location where the large Liquid

Crystal Display (LCD) can be viewed easily,

yet is secure and vibration free. Because of the

LCD screen, the Beacon II Smart Controller

should not be mounted where it will experience

temperatures below 40°F or above 100°F.

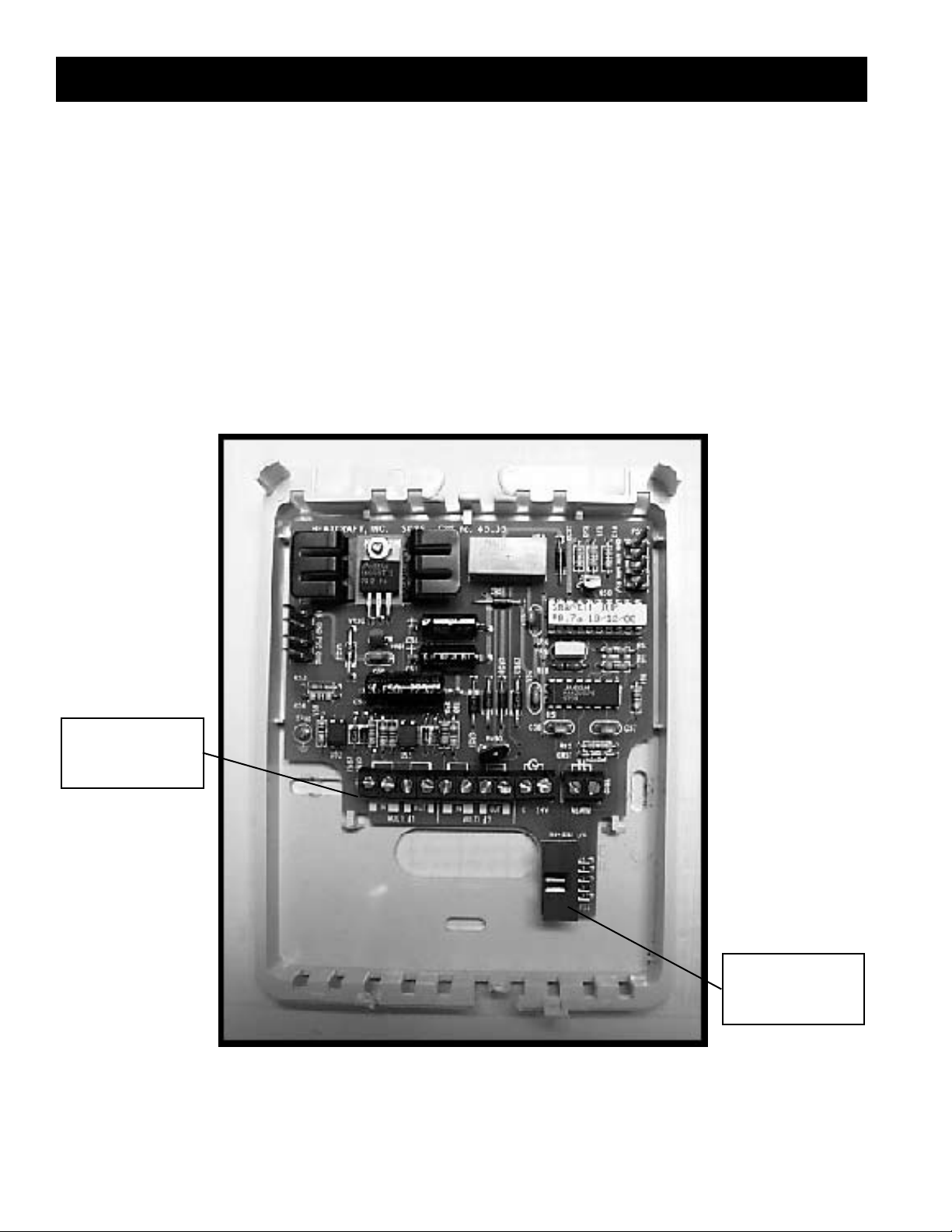

Beacon II Smart Controller Base

A terminal strip for wiring connections is located

on the base of the Beacon II Smart Controller.

To access this terminal strip, pull both halves of

the Beacon II Smart Controller housing apart.

Mounting holes are located in the plastic base.

24 V Terminal

Strip

RS232

Connector

4

Page 5

Wiring

WIRING

All 24 volt wiring must be run separate from the line

voltage wiring.

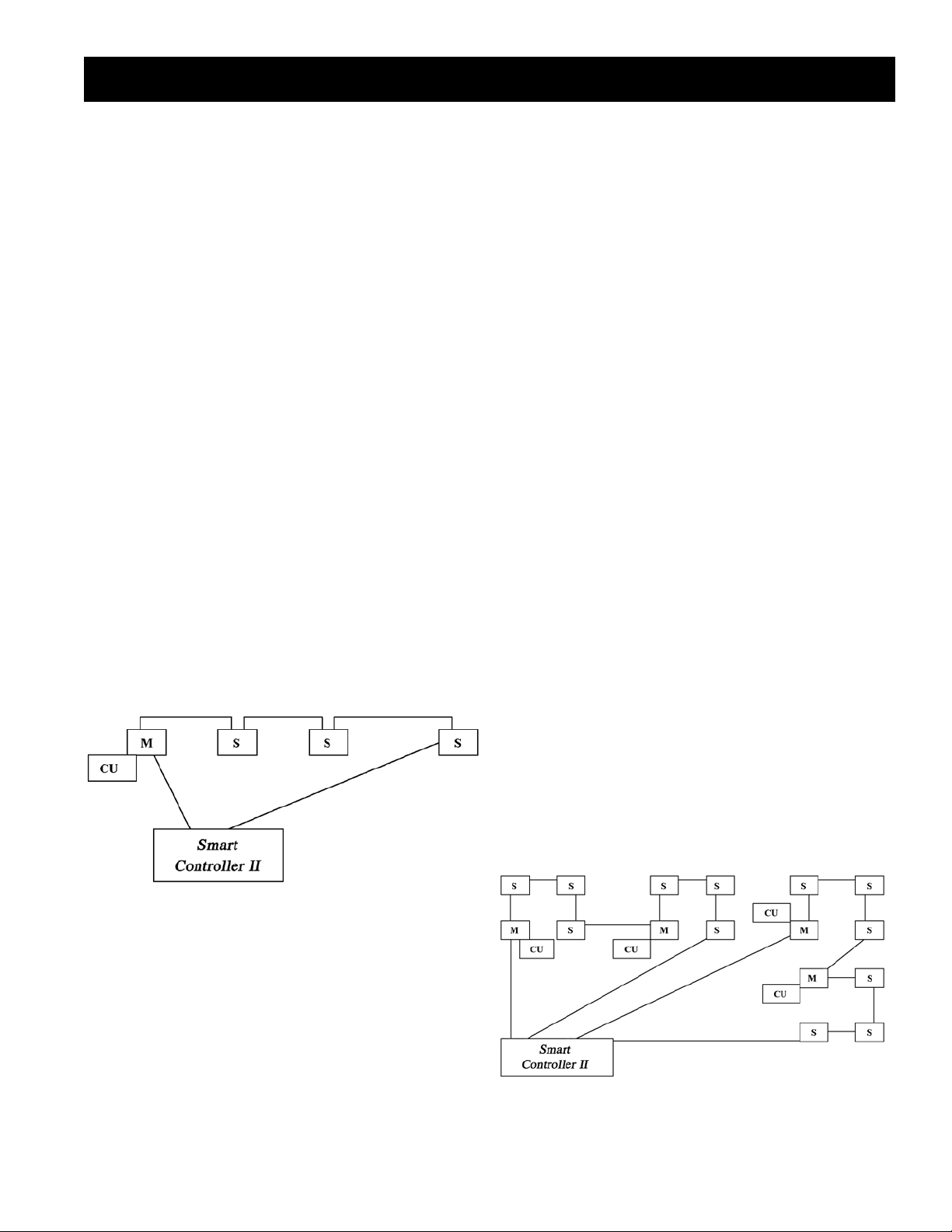

For MULTIPLE

independent Refrigeration systems:

All Low voltage wiring must be 18 gauge minimum

and must be run separate from high voltage wiring.

Themaximum distance from the Beacon II Smart

Controller to the Master Evaporator is 1000 ft.

The terminal strip in the Beacon II Smart Controller is

labeled similarly to that of the Beacon II boards. Connect

the corresponding terminals to those on the Beacon

board.

For single Refrigeration system:

Connect MULTI OUT 1 from the Beacon II Smart

Controller to the MULTI IN on the Beacon board

on the Evaporator. Then connect MULTI IN 1 from

the Beacon II Smart Controller to the MULTI OUT on

the Beacon board on the Evaporator. See typical

wiring diagram at the back of these instructions.

On systems with multiple evaporators the Beacon II

Smart Controller must be wired to the Master

Evaporator first. DO NOT disconnect the Room

sensor from any of the Evaporators.

SINGLE SYSTEM CONNECTION

For the first system, connect MULTI OUT 1 from

the Beacon II Smart Controller to the MULTI IN

on the Beacon II board on the Evaporator in this

first system. Then connect MULTI IN 1 from the

Beacon II Smart Controller to the MULTI OUT on the

Beacon II board on the Evaporator on this first

system. DO NOT disconnect the Room sensor from

any of the Evaporators. See typical wiring diagram at

the back of these instructions.

For the second system, connect MULTI OUT 2 from

the Beacon II Smart Controller to the MULTI IN on

the Beacon II board on the Evaporator in this second

system. Then connect MULTI IN 2 from the Beacon II

Smart Controller to the MULTI OUT on the Beacon II

board on the Evaporator on this second system. See

typical wiring diagram at the back of these instructions.

On systems with multiple evaporators the Beacon II

Smart Controller must be wired to the Master Evaporator

first. DO NOT disconnect the Room sensor from any of

the Evaporators.

DO NOT CONNECT 24V & C BETWEEN

EVAPORATORS.

The Beacon II Smart Controller and the evaporators are

then connected in a daisy–chain fashion.

(See the wiring diagrams in the back of this manual)

M = Master Evaporator S = Slave Evaporator CU = Condensing unit

A minimum 18 gauge wire should be used. All low voltage

wiring must be run separate from high voltage wiring.

MULTIPLE SYSTEM CONNECTION

SYSTEM 1 SYSTEM 2 SYSTEM 3

SYSTEM 4

M = Master Evaporator S = Slave Evaporator CU = Condensing unit

5

Page 6

POWER SUPPLY

Power Supply

The Beacon II Smart Controller gets it’s

24 VAC power supply from the evaporator.

When controlling multiple systems, the

Beacon II Smart Controller is powered from

the evaporator of only one of the systems.

If a power interruption occurs to the system

supplying the Beacon II Smart Controller, the

Beacon II Smart Controller LCD screen will

go blank. The other systems will, however,

continue to operate and maintain their box

temperature.

The Beacon II Smart Controller can be supplied

with it’s own power supply by using a 24

VAC Universal Plug-in Power Source with a

minimum of 300 mA. When powered by an

independent power supply, if power is lost to

the Beacon II Smart Controller the systems

will continue to operate and maintain the box

temperature. This occurs only if an external

power supply is used on the Beacon II

Smart Controller.

If the Beacon II Smart Controller LCD displays

all 88888 this indicates that the power supply

is below 18 VAC. When this occurs the system

will power down and shut off. When the power

supply is corrected to 24 VAC, the system will

restart after the four-minute hold off period and

resume normal operation. The Beacon II Smart

Controller LCD display will then be normal.

6

Page 7

Initialization of Beacon II Smart Controller

INITIALIZATION of BEACON II SMART CONTROLLER

When power is first applied to the Beacon II Smart Controller

it checks the configuration of the system to which it is

connected and stores this in its memory. Beacon II Smart

Controller checks how many condensing units there are and

how many evaporators are connected to each condensing

unit. The order in which the units are wired from the multiout of the Beacon II Smart Controller determines the unit

ID (UNI-4) assigned by the Beacon II Smart Controller.

This is called initialization. Whenever a system is

added, removed or modified (changing the number of

evaporators on a condensing unit), while connected to

the Beacon II Smart Controller, it must be re-initialized.

Place all systems in the service mode before initializing

the Beacon II Smart Controller. Make sure all wiring

changes to the system and the Beacon II Smart Controller

are complete and accurate before initializing the Beacon

II Smart Controller. Each SLAVE Evaporator must also

be programmed as a SLAVE BEFORE the system is

initialized. The “SLA” setpoint must be set from the board

programming. It cannot be done from the Beacon II Smart

Controller.

To initialize the Beacon II Smart Controller (for version 1.2)

• Press and Hold both the ENTER and CLEAR buttons

until the LCD displays EEROM?

• Release the ENTER and CLEAR buttons quickly, then

press the ENTER button

• The LCD will display WAIT”

• COOLING:

in the cooling cycle immediately (The 4 minutes “Hold

Off” is bypassed). This button will illuminate to indicate that

the Cooling function is “ON”. System operation will be as

described under REFRIGERATION MODE in the Beacon

II installation manual.

Pressing the COOLING button while the system is cooling,

and the button illuminated, will pumpdown the system and

turn it off.

• DEFROST:

into defrost immediately (The “Hold Off/Hold On” times

are bypassed). This button will illuminate to indicate that

the Defrost function is “ON”. When in Defrost, pressing this

button a second time will end defrost.

• MONITOR:

the setpoints shown on page 10.

If one Beacon II Smart Controller is controlling two or more

independent systems, you must press the

BAR

monitor. If multiple evaporators are connected to the

system displayed, you must press the “+” or “–” buttons to

display information on the evaporator you want to monitor.

• PROG REVIEW:

of the setpoints for initial setup and to make changes.

Depressing this button will start the system

Depressing this button will force the system

Depressing the MONITOR button will display

SELECTION

to display information on the system you want to

This button allows stepping through each

It may take up to 2 minutes to complete the initialization of

the system after which the normal LCD screen will appear.

BUTTON FUNCTIONS

• SYSTEM SELECTION BAR: If two or more systems are

being controlled from the Beacon II Smart Controller, this

bar allows switching between systems. The display will

show the SYS number and all parameters related to that

system. The cover plate of Beacon II Smart Controller,

when pushed will also change the display between

systems.

• CLOCK (+ -) This is used to set the time of day

on the display.

• Depress the + button to move the clock forward

• Depress the - button to move the clock backward

• When in

through values for setting superheat etc. for each

evaporator of the system(s) attached to the

Beacon II Smart Controller and for different defrost

start time periods.

PROG Mode, these are used to step

If one Beacon II Smart Controller is controlling two or more

independent systems, you must press the

BAR

to display information on the system you want

to make program changes. If multiple evaporators are

connected to the system displayed, you must press the “+”

or “–” buttons to display information on the evaporator you

want to monitor.

• CLEAR:

programming or to return to the System display when

monitoring.

• TIME:

for Defrost times.

• SETPOINT:

while programming.

• ENTER:

NOTE: Settings are recorded in memory even if

power fails.

Used to clear incorrect entries while

Slide-bar is used to set the thermostat clock

Slide-bar is used to change settings

To enter new settings into the program.

SELECTION

7

Page 8

Programming Beacon II Smart Controller

PROGRAMMING BEACON II SMART

CONTROLLER

To make a change, press the PROG REVIEW button until

the setpoint item that needs to be changed is displayed. The

SETPOINT Slide-bar is then used to change to the desired

new setting. When the new desired setting is displayed,

press the “ENTER” button. The new setting is now

programmed into the Beacon II Smart Controller memory.

Press the PROG REVIEW button and follow the steps below

(to back up one step during programming, while pressing the

“MONITOR” button, press the “PROG REVIEW” button):

• DEFTYP

Air Defrost then press “ENTER”. This selection will

automatically set the defaults for Air and Electric Defrost.

Important: This will set the refrigerant type to R22 for

Air and R404A for Electric.

refrigerant you are using in your application if these

are incorrect.

• REFTYP –

display desired value, then press “ENTER.”

• BOXTMP

slide-bar to get desired temp., then press “ENTER.”

– ELE or AIR: Select for Electric Defrostor

You must change to the

22, 404, 507. Use “SETPOINT” slide-bar to

– Box Temp: -30° F to 70° F. Use “SETPOINT”

• DEFSAF – Defrost Fail Safe Time: 10 to 200 minutes.

When this time has elapsed, the defrost cycle will end,

even if the programmed Defrost Termination

temperature was not achieved. Use “SETPOINT” slide-bar

to select desired time, then press “ENTER”.

• DEFTMP

100° F. Use “SETPOINT” slide-bar to select desired temp.,

then press “ENTER”. If multiple evaporators are

connected, use the “+” button to set other evaporators on

this system.

• ALR HI

“SETPOINT” slide-bar to select desired temp., then press

“ENTER”.

• ALR LO

“SETPOINT” slide-bar to select desired temp., then press

“ENTER”.

• ALRMIN

exceed before alarm is indicated: 2 to 120 min. Use

“SETPOINT” slide-bar to select desired time, then press

“ENTER”.

– Defrost Termination Temperature: 40 to

– Alarm High Temperature. -40 to 90° F. Use

– Alarm Low Temperature -40 to 90° F. Use

– Alarm Time, in minutes. Condition must

• SUPRHT

slide-bar to select desired superheat temp., then press

“ENTER.” If multiple evaporators are connected, use the

“+” button to set other evaporators on this system.

• SMT DFT

slide-bar to turn it ON or OFF, then press “ENTER” - (for

version 1.2. When Smart Defrost is turned on, 8 defrost

periods per day will automatically be programmed. These

will be at 12:00 am, 3:00 am, 6:00 am, 9:00 am, 12:00 pm,

3:00 pm, 6:00 pm, and 9:00 pm. Also, the defrost fail safe

time will be set to 60 minutes, and the defrost termination

temperature will be set to 55°F. The user can change

these as needed for the application).

• DEF ST

(For

time, then press “ENTER”. Use + button to scroll to next

defrost period,

defrost time and press “ENTER”. Repeat steps for each

required defrost period). If defrost times are not

programmed the system will use the defaults

Defrost - four per day at 4:00 AM, 10:00 PM, 4:00 PM,

10:00 AM. Air Defrost - two per day at 9:00 AM, 9:00 PM.

– Superheat: 4 to 20 ° F. Use “SETPOINT”

: Smart Defrost: On/Off. Use “SETPOINT”

- Defrost Start time: Up to 12 settings per day

dF 1, use the “TIME” slide-bar to select first defrost

dF 2, use “TIME” slide-bar to select second

: Electric

• ° F / ° C

then press “ENTER”.

• 12/24H

international time. Use “SETPOINT” slide-bar to select,

then press “ENTER”.

• TEST

Use with Caution. This will cycle each output at 10

second intervals. Use “SETPOINT” slide-bar to select,

then press “ENTER”. Return to “OFF” and then press

“ENTER” to end the test.

• SERVIC –

will pump the system down and shut it off. The system will

not restart until SERVIC is placed back in the OFF mode.

When multiple evaporators are connected as master/

slave

information specific to each evaporator. Units in a

master/slave connection are numbered 1 through 4.

The first evaporator connected to the BEACON

II SMART CONTROLLER MULTI-OUT Terminals is

Evaporator # 1.

– ° F or ° C. Use “SETPOINT” slide-bar to select

– Clock: 12H is for standard time. 24H is for

: OFF or ON: Puts all evaporators in TEST mode.

ON or OFF: When placed in the ON mode this

, depressing the + or - button will display

8

Page 9

Monitoring With Beacon II Smart Controller

MONITORING with

BEACON II SMART CONTROLLER

The Monitoring function can be used to monitor live

system data. The information displayed, such as superheat, is the actual superheat of the system as it is

changing.

Press the MONITOR button and follow the steps below

(to back up one step during monitoring, while pressing

the “PROG REVIEW” button, press the “MONITOR”

button):

• SUPRHT – Superheat (use + button to check super heat of other evaporators, if Master/slave)

• EXVSET - Expansion valve step setting (Stepper

Motor setting 0 to 255 steps: use + button to check

other evaporators if Master/slave)

• SUCTMP – Evaporator Suction temperature

(Measured by the Suction Sensor)

• SSVTMP – Saturated Suction temperature at the

Evaporator (Determined by Suction Transducer)

• SUCPRE – Evaporator Suction Pressure

(Measured by Suction Transducer)

When multiple evaporators are connected as master/

slave depressing the + or - button will display information

specific to each evaporator. Units in a master/slave

connection are numbered 1 through 4.

The first evaporator connected to the BEACON II

SMART CONTROLLER MULTI-OUT Terminals is

Evaporator # 1.

• OD TMP – Actual outdoor ambient temperature

(Measured at the Condensing Unit)

• DEFTMP – Evaporator coil temperature

(Used to terminate defrost)

• DEFTIM - Defrost Time: Length of last defrost

• CMPCYC - Comp Cycles:

No of Compressor Cycles since 12:00 midnight

• CMPRUN - Comp run time

(Measured since 12:00 midnight)

• SPRTMP – Spare sensor temperature input

• VERSON – Software Version: For each controller

(use “+” button to check other evaporators, if Master/

slave)

• VERSON - Software Version: for Beacon II Smart

Controller

9

Page 10

Locking Beacon II Smart Controller & Error Codes

LOCKING BEACON II

SMART CONTROLLER

BEACON II SMART CONTROLLER is lockable to

prevent programmed settings changes by unauthorized

personnel. When the Controller is Locked, all the Buttons,

except for the Monitor and Prog Review Buttons, are

disabled.

To LOCK the settings, do the following:

• Press “PROG REVIEW” button.

• Press and hold “MONITOR” button

• While holding “MONITOR” button,

Press “ENTER” button.

• The LCD will display LOCK

This will prevent unauthorized persons from changing

any settings for system displayed.To UNLOCK

the Controller, repeat these steps. LCD will display

“UNLOCK.” Note: Each system must be locked or

unlocked separately.

ERROR CODES

• *BXSEN - Room temperature sensor shorted,

open or not installed

• *DFSEN - Defrost temperature sensor shorted,

open or not installed

• *STSEN - Suction Temperature sensor shorted,

open or not installed

• *SPSEN - Suction pressure transducer shorted,

open or not installed

• *ODSEN - Outdoor temperature sensor shorted

• *SUPLO - Superheat too low

• *SHTDN - Compressor shutdown

(High or low refrigerant pressure or low oil pressure)

The error code will flash alternately with the normal

display information. When the error condition is

corrected, the error code will no longer be displayed and

only the normal information will be displayed.

*All errors for all units connected to the Beacon II Smart

Controller will be displayed with an appropriate indicator

for the unit experiencing the error. The individual boards

will also display the errors.

10

Page 11

WIRING ERROR

Wiring Error & Alarm Codes

If the Beacon II Smart Controller LCD displays +COMM+,

this indicates that there is an error in the communication

wiring or that the wiring is broken or disconnected. Occurrence of this error on the connected unit will indicate

which wires are faulty.

The communication wiring is the MULTI IN and MULTI

OUT connections. Check to make sure the OUT is

connected to IN. Never connect OUT to OUT or IN to IN.

ALARM CODES

• *BOXHI : Box temperature too high

• *BOXLO : Box temperature too low

• *STRUP :System Start-up failure

(Compressor pumps down and tries to restart after

4 minutes.)

• *INFLT : Input fault (Box Temp., Suction Temp.,

Pressure Transducer open or not installed)

• Power failure

When an ALARM condition occurs, the Beacon II Smart

Controller will display “CALL FOR SERVICE”, the ALARM

code, the SYSTEM Number and will sound an internal

buzzer along with the closure of alarm contacts on

controller.

The alarm code will flash alternately with the normal

display information. When the alarm condition is

corrected, the alarm code will no longer be displayed and

only the normal information will be displayed.

The system will pumpdown and cycle off and will

not restart until the fault is cleared for the following

conditions:

Suction sensor shorted, open or not installed Room

temperature sensor shorted, open or not installed

Pressure Transducer open or not installed

The system will pumpdown, cycle off and try to restart

for three consecutive times. Each try will be after

the 4 minutes “Hold Off” period, for the following fault

conditions.

• Oil pressure

• High pressure or low pressure cutout

(or any other compressor safeties)

After the fourth try, the Alarm contacts will be closed and

an alarm message displayed on the LCD screen. To clear

this condition, the system should be cycled through the

“Service” mode after correction is complete.

On Multiple systems the Alarm contacts on each of the

Master Evaporator will also announce Alarms for that

system.

11

Page 12

ALARM BUZZER

Alarm Buzzer & Data Logging

The ALARM buzzer will sound when an Alarm condition

occurs. This buzzer will turn off when the Alarm condition

is cleared. The buzzer can also be silenced at any time

by pressing the “CLEAR” button.

DATA LOGGING

Beacon II Smart Controller logs system data in its

memory every 15 minutes. The length of time it records

data is dependent on how many systems are being

controlled by the Beacon II Smart Controller. It keeps

writing data to its memory until the memory is full. When

the memory is full it will overwrite its oldest stored data in

memory with newly recorded data.

Data recorded:

System Mode, Box Temperature,

AUX Temperature, Superheat, Suction Pressure

and the Number of Compressor cycles since

midnight.

Errors and Alarms recorded:

Date, Time, System #, Unit #, Error type,

Alarm type, Error duration and Alarm duration

On multiple evaporator systems, the data recorded is

from the master evaporator only. This data is available

via connection to a PC through the Beacon II Smart

Controller’s RS232 serial port. The data can be viewed

on a PC using our Windows based SMART II software

and can be imported into an Excel spreadsheet.

Real-time data can also be recorded and stored on a

Desktop PC while the PC is connected to the Beacon

II Smart Controller. The PC will continuously request

information from the Beacon II Smart Controller regarding

system operation and setup and record this data every

minute, in an Excel spreadsheet. This information is

stored to the PC hard drive, which depending on the

size of the hard drive, would allows for many days of

recording. This data may also be periodically saved on a

disk by the user.

The SMART II software is sold separately from the

Beacon II Smart Controller.

Length of data recorded:

One System = 30 days

Two Independent Systems = 15 days

Three Independent Systems = 10 days

Four Independent Systems = 7 days

Recording intervals:

Every 15 minutes

All recorded data will have a date/time stamp.

12

Page 13

Smart Defrost

SMART DEFROST

The Beacon II Smart Controller continuously monitors the

system performance to determine the need for defrost. It

uses a variety of data such as the outdoor ambient and

box temperature in it’s decision making process.

Activating Smart Defrost:

After your system has been running for a week or

two with normal defrost operation and the system has

operated normally with no problems, you may

consider activating Smart Defrost.

You must program multiple defrost times into the

Beacon II Smart Controller to provide flexibility for

the system to defrost the coil properly. Smart Defrost

will only allow the system to defrost at a programmed

defrost time. The system will not defrost in between

programmed defrost times. Hence, we recommend

that a minimum of 8 defrost periods be programmed

when Smart Defrost is turned on. The system will

not defrost eight times per day but with this many

defrost periods it will have better options to keep the

coil clear and to allow the system to operate at

optimum condition.

After programming the minimum 8 defrost periods,

all that’s needed to activate Smart Defrost is to

press the “PROG REVIEW” button until “SMT DFT”

is displayed. Also, it is recommended that the defrost

fail-safe time be increased to 60 minutes.

Deactivating Smart Defrost:

To turn Smart Defrost off move the “SETPOINT”

slid-bar to “OFF” then press “ENTER”.

Press “CLEAR” to return to the main screen.

Move the “SETPOINT” slide-bar to “ON” then press

“ENTER”. Press “CLEAR” to return to the main

screen.

When Smart Defrost is turned on, 8 defrost periods

per day will automatically be programmed. These

will be at 12:00 am, 3:00 am, 6:00 am, 9:00 am,

12:00 pm, 3:00 pm, 6:00 pm, and 9:00 pm. Also,

the defrost fail safe time will be set to 60 minutes,

and the defrost termination temperature will be set to

55°F. The user can change these as needed for the

application (for version 1.2).

13

Page 14

™

PC & MODEM ACCESS

PC And Modem Access

For access to the system from a PC directly or via a

modem, the SMART II Software must be purchased

and installed on your PC. With PC access, ALL system

settings can be monitored, changed or logged from a

remote location. The stored data can be viewed in an

Excel spreadsheet.

Recommended Requirements

PC with a 233 Mhz clock speed or higher

128 MB or higher RAM.

A CD drive.

Hard Drive with 100 MB of Free space.

Requires 20 MB for installation.

(Data logging to a Hard Drive will require additional

storage space).

A VGA monitor.

Windows 95 or later.

When purchased, Heatcraft will supply the software on

a CD, a 6 ft. null modem cable, a 12” ribbon cable and a

detailed instruction booklet. The null modem cable can be

used to connect directly to a PC’s serial port. A modem

cable must be supplied with the modem for connection to

the Beacon II Smart Controller.

Communications Hub

For the connection of multiple Beacon II Smart

Controllers to a single communication device

(PC or modem).

Maximum configuration:

• 4 Beacon II Smart Controllers™ connected to

one Communications Hub (4 systems per Beacon

II Smart Controller™ equals 16 systems with

maximum of 64 evaporators)

• 16 Beacon II Smart Controllers™ connected to

five Communications Hubs (4 systems per Bea

con II Smart Controller™ equals 64 systems with

maximum of 256 evaporators; Communications

Hubs can only be cascaded once)

14

Page 15

System Defaults

SYSTEM DEFAULTS

Following are factory defaults for the parameters which

can be programmed in the Beacon II Smart Controller. If

the user does not select a setting for any of the following

parameters, the default will be used.

It is important the user set ALL parameters based of their needs.

PARAMETERS CODE AIR ELECTRIC

Refrigerant REFTYP R22 R404A

Box Temperature BOXTMP 35°F -10°F

Superheat SUPRHT 8°F 8°F

Smart Defrost SMTDEF N/A Off**

Defrost start times DEF ST 9 AM/9 PM 4 AM, 10 AM, 4 PM, 10 PM

Defrost Fail-safe time DEFSAF 40 min 30 min (60 min. when Smart Defrost is On)

Defrost End Temperature DEFTMP 45°F 60°F (55°F when Smart Defrost is On)

Alarm High Temperature ALR HI 50°F 5°F

Alarm Low Temperature ALR LO 30°F -15°F

Alarm Time ALRMIN 60 min 60 min

Temperature Units °F / °C °F °F

Clock setting 12 / 24H 12 H 12 H

Test mode TEST Off Off

Service mode SERVIC Off Off

**When Smart Defrost is turned on, 8 defrost periods

per day will automatically be programmed. These will

be at 12:00 am, 3:00 am, 6:00 am, 9:00 am, 12:00

pm, 3:00 pm, 6:00 pm, and 9:00 pm. Also, the defrost

fail safe time will be set to 60 minutes, and the defrost

termination temperature will be set to 55°F. The user

can change these as needed for the application (for

version 1.2).

15

Page 16

Parts List

Part Description HRP Part Number

Beacon II Control Board 28910101

Temperature Sensor Kit – White Leads* 89904902

Transformer 120/24 Volt – 40 VA 22529601

Transformer 240/24 Volt – 40 VA 22529602

Transformer 460/24 Volt – 40 VA 22529603

Transformer 575/24 Volt – 40 VA 22529701

Pilot Relay 22511401

Contractor for Compressor 40 Amp with 24 Volt Coil 2252440

Terminal Block – Condensing Unit 2251266

Low Pressure Switch Time Delay Relay 22536801

Electric Expansion Valve

ESB 1 – 3/8” x 3/8” Conn 29320003

ESB 4 – 3/8” x 3/8” Conn 29320004

ESB 10 – 3/8” x 3/8” Conn 29320007

ESB 10 – 1/2” x 1/2” Conn 29320008

ESB 15 – 7/8” x 1 3/8” Conn 29320013

ESB 20 – 7/8” x 1 3/8” Conn 29320014

Expansion Valve Molded Connector (Bipolar Valve) 22515201

Pressure Transducer 28911201

Pressure Transducer Harness 22515101

Beacon II Smart Controller 89704301

Smart Controller Software Package** 89704101

Beacon II Communication Hub 89708001

* Only sensor with White Leads are shipped as a Service Replacement Part.

** Smart Controller Software Package is sold separately.

Parts

16

Page 17

Diagnostics

Beacon II Troubleshooting Guide

PROBLEM Step ACTION ITEM IF OK IF NOT OK

1. Check Primary Power Supply Disconnect 1. Check fuses and circuit breakers

2. Check Voltage to Evaporator Transformer Go to 2. Check field wiring for breaks

LED is not lit. 3. Check Transformer Secondary Output Volts next step 3. Replace if necessary

4. Check Voltage at Control Board (24V and C) 4. Check factory wiring and connections

5. Replace Control Board

1. Check Compressor internal overloads 1. Wait for reset

2. Check Control Power to Condensing Unit 2. Check transformer voltage (secondary and

LED shows Coo, but (24 Volts across “COMP” and “C” at board) Go to primary) and wiring of 208V power taps.

compressor will not run. 3. Check Compressor Contactor Coil Voltage next step 3. Check internal condensing unit wiring

4. Check Compressor Contactor “pulled in” 4. Replace as needed

ERROR CODES:

E1 Room Sensor Check Sensor and Board Connection Replace as needed

E2 Defrost Sensor Check Sensor and Board Connection Replace as needed

E3 Suction Sensor Check Sensor and Board Connection Replace as needed

E4 Suction Transducer Check Transducer and Board Connection Replace as needed

E5 Outdoor Sensor Check Sensor, wiring and Board Connection Replace or remove

1. Check Refrigerant Type 1. Compare board setpoint and refrigerant

2. Check coil for ice 2. Defrost coil and check defrost cycle

settings/setpoints, defrost sensor and

heater amps.

E6 Low Superheat 3. Check Control Board step position from board LED 3. Replace board if EEV steps not at 2.

During Cooling 4. Check Electric Expansion Valve Closure Go to 4. Pumpdown system see if LPS opens or if it

(0°F for 2 minutes) next step times out (EEV is bad or LPS is set

incorrectly, if times out) – See Pumpdown.

5. Compressor Not Operating 5. Check overloads and contactor.

6. Check Suction Temperature Sensor 6. Compare board sensor reading against

actual suction line temperature.

7. Check Suction Pressure Transducer 7. Compare pressure reading against gauges.

17

Page 18

Diagnostics

Beacon II Troubleshooting Guide (continued)

PROBLEM Step ACTION ITEM IF OK IF NOT OK

1. Check wiring connection to the board • Correct field wiring to the board

2. Low Pressure Safety (LPS) Tripped:

• Check for correct refrigerant type • Change setpoint to match refrigerant

• Check refrigerant charge • Add more refrigerant to proper charge

• Check LPS setting • Correct LPS setting

• Check LPS wiring • Correct LSP wiring

• Check EEV operation (stuck?) • Clean or replace EEV

• Check coil for icing • Defrost coil (see E6, step 2)

• Check for correct superheat reading • Check/replace sensor or transducer

• Check for correct nozzle selection • Replace distributor nozzle

• Check for clogged EEV inlet screen • Replace EEV

• Check line sizing • Correct line sizing

• Check LPS time delay relay setting • Reset to 1 minute

• Check operation of LPS • Replace Low Pressure Safety Switch

3. High Pressure Safety (HPS) Tripped:

• Check for system overcharge • Reclaim/recover excess charge

• Check for non-condensables • Remove all non-condensables

• Check condenser fan motor and blade • Repair or replace motor and/or blade

• Check for dirty condenser coil • Clean condenser coil

• Check head pressure controls • Adjust or replace faulty controls

• Check fan cycling controls • Adjust or replace faulty controls

• Check liquid line sizing • Correct line sizing

• Check for liquid line restrictions • Repair line or remove restrictions

• Check operation of HPS • Replace HPS if necessary

E7 Compressor 4. Oil Pressure Safety (OPS) Tripped:

Shutdown • Check oil level in compressor • Add oil to crankcase to minimum level

• Check oil sump screen pickup • Clean or replace pickup screen

• Check oil pump pressure • Replace compressor oil pump

• Check for proper piping practices Go to • Correct piping to minimize oil logging

• Check for low superheat (see E6) next step • Correct per steps in E6

• Check operation of auxiliary relay (R6) • Replace auxiliary relay

• Check OPS sensor • Replace faulty OPS sensor

• Check operation of OPS • Replace faulty OPS

5. Compressor Module Tripped (when supplied):

• Check module • Replace faulty module

• Check superheat at compressor inlet • Reduce superheat (TXV adjust, etc.)

• Check compressor for overheating • Correct overheating problem

• Check suction pressure (too low?) • Consider crankcase pressure regulator or

other measures

6. Phase Loss Monitor (PLM) Tripped:

• Check presence of all phase legs • Correct power phase problem

• Check power supply • Correct power supply problems

• Check operation of PLM • Replace faulty PLM

7. Demand Cooling (when supplied):

• Check auxiliary relay • Replace auxiliary relay

• Check demand cooling device • Replace faulty demand cooling device

8. Check compressor relay on board • Replace board if relay is faulty

18

Page 19

Diagnostics

Beacon II Troubleshooting Guide (continued)

PROBLEM Step ACTION ITEM IF OK IF NOT OK

E9 Multi-out to Multi-in 1. Check for 24 volts power to the board 1. If no voltage, see “LED is not lit” above

Communication Wiring for low voltage, see “88888 LED display”

(only shows after initial 2. Check for crossed communication wiring Go to 2. Correct wiring from “Master” unit Multi-out

successful connection) (multi-out not wired to multi-in terminals) next step to Multi-in of “Slave” unit, etc. to all Slaves

and return to Master. (See wiring diagrams)

3. Check for broken communication wiring 3. Correct wiring between first Slave with

error to previous board in the sequence.

(E9 continued)

Communication Error

Occurrence:

Break in the designated

lines will cause errors

as follows:

Line # Master Slave1 Slave 2 Slave 3

1 E9 E9 E9 E9

2 E9 no error E9 E9

3 E9 no error no error E9

4 E9 no error no error no error

Beacon II Smart

Master

in out

1

in out

1

[With Beacon II Smart

Controller]

Line # SMART Master Slave1 Slave 2 Slave 3

1 +COMM+ E9 no error no error no error

2 +COMM+ no error E9 E9 E9

3 +COMM+ no error no error E9 E9

4 +COMM+ no error no error no error E9

5 +COMM+ no error no error no error no error

Slave 1

in out

Master

in out

2

2

Slave 1

in out

5

Slave 2

in out

4

3

3

Slave 2

in out

Slave 3

in out

Slave 3

in out

4

PROBLEM Step ACTION ITEM IF OK IF NOT OK

88888 LED display 1. Check Voltage to Evaporator Transformer 1. Check field wiring for breaks or shorts

(power is below 18V and 2. Check Transformer Secondary Output Volts Go to 2. Replace if necessary

appears at initial power) 3. Check Voltage at Control Board (24 and C) next step 3. Check factory wiring and connections

4. Check Voltage at Beacon II Smart Controller 4. Check field wiring from board

1. Check for low voltage 1. Check all steps for “88888 LED display”

LED displays dLy Go to Voltage could drop off too fast to show.

then oFF with no 2. Check for short in field wiring from “comp” on next step. 2. Check internal factory wiring to

displayed errors board to condensing unit terminal connection compressor contactor.

3. Replace defective contactor (holding coil)

19

Page 20

Diagnostics

Beacon II Troubleshooting Guide (continued)

PROBLEM Step ACTION ITEM IF OK IF NOT OK

1. Check system operation: Is it running? 1. Check power to condensing unit

Check position of Service Mode switches

Check compressor overloads and contactor

2. Check system charge 2. Add or remove refrigerant to proper charge

3. Check for proper operating superheat 3. Check EEV operation

Check control board EEV signal

Check suction sensor and transducer

4. Check for high superheat and EEV wide open 4. Check EEV inlet screen and restrictions

Check liquid line sizing

Check head pressure controls

5. Check Low Pressure Safety Switch 5. Check everything for E7 LPS above

Cannot get to box 6. Compare equipment capacity with requirements Go to 6. Add or replace with more/larger equipment

temperature 7. Check box temperature setpoint next step 7. Correct setpoint to proper value

8. Check compressor performance 8. Check compressor application limitations

Check integrity of compressor operation

(impaired, worn or damaged components)

9. Check condenser coil for dirt/debris 9. Clean condenser coil

10. Check condenser for non-condensables 10. Remove all non-condensables

11. Check condenser fan operation 11. Replace/repair fan blade, motor, cycling

switch or make corrective adjustments.

12. Check for correct refrigerant type 12. Compare board setpoint and refrigerant

13. Check for iced evaporator coil 13. Defrost coil and check defrost cycle (see E2)

settings/setpoints and defrost sensor

14. Check defrost parameters 14. Correct defrost setpoints in program

(frequency and termination of defrosts)

15. Check superheat setpoint (too high?) 15. Correct setpoint for more cooling surface

16. Check display values (°F or °C) 16. Correct setpoint for proper display values

Placing system into SERVICE MODE Terminating SERVICE MODE

(BOARDS ONLY) (BOARDS ONLY)

1. Use Remote Service Switch in condensing unit 1. Must terminate using same switch

2. Pressing “Force Service” button board* twice 2. Press “Clear” button on board

3. Connection between “Ser” and “C” on board* 3. Open connection between “Ser” and “C”

(all are wired in parallel; all will activate mode) (Note: If multiple switches were placed in Service

Service Mode *ONLY Master board on multiple evaporator systems Mode, all must be “open” to terminate the mode.)

(SEr is displayed)

(with Beacon II Smart Controller) (with Beacon II Smart Controller)

1. Use Remote Service Switch in condensing unit 1. Must terminate using same switch

2. Connection between “Ser” and “C” on board* 2. Open connection between “Ser” and “C”

3. From program menu of Beacon II Smart Controller, 3. From program menu of Beacon II Smart Controller,

Change SERVICE setpoint to “On”. Change SERVICE setpoint to “Off”

[all are wired in parallel; any/all will activate mode.] [Note: If multiple switches were placed in Service

*ONLY Master board on multiple evaporator systems Mode, all must be “open” to terminate the mode.)

20

Page 21

Wiring Diagrams

21

Page 22

Wiring Diagrams

22

Page 23

Wiring Diagrams

23

Page 24

Wiring Diagrams

24

Page 25

Notes

25

Page 26

Notes

26

Page 27

Notes

27

Page 28

Since product improvement is a continuing effort, we reserve the right to make

changes in specifications without notice.

Heatcraft Refrigeration Products, LLC

2175 West Park Place Blvd • Stone Mountain, GA 30087

(800) 321-1881

www.heatcraftrpd.com

Loading...

Loading...