Page 1

H-IM-68 March 2000 Part No. 25001301

Replaces H-IM-44

Direct Drive

Fluid Coolers

Installation and

Maintenance Data

Table of Contents

Inspection

System Warranty

Installation .........................................2

Rigging Instructions...........................3

Internal Volume and Weight ..............4

Electrical Wiring ............................ 4-6

System Installation

Piping Installation

Glycol Charge ...................................7

Mixing Glycol and Water

Glycol Sludge Prevention

Fluid Circulating Pump ..................................8

Start-up

Space and Location Requirements ..........9-10

Typical Piping

In-Warranty Return Material Procedure........11

Replacement Parts......................................12

Page 2

Inspection

Responsibility should be assigned to a dependable

individual at the job site to receive material. Each shipment

should be carefully checked against the bill of lading. The

shipping receipt should not be signed until all items listed on

the bill of lading have been accounted for.

Check carefully for concealed damage. Any shortage or

damages should be reported to the delivering carrier.

System Warranty

This equipment is designed to operate properly and

produce rated capacity when installed in accordance with

accepted industry standards. Failure to meet the following

conditions may result in voiding of the system warranty:

1. System piping must be installed following industry

standards for good piping practices.

2. System must be thoroughly leak checked before initial

charging.

3. Power supply to system must meet the following

conditions:

Damaged material becomes the delivering carrier's

responsibility, and should not be returned to the manufacturer

unless prior approval is given to do so. When uncrating, care

should be taken to prevent damage. Heavy equipment should

be left on units shipping base until it has been moved to the

final location.

a. Voltage for 208/230 motors not less than

195 volts or more than 253 volts.

b. All other voltages must not exceed +/- 10%

of nameplate ratings.

c. Phase imbalance not to exceed 2%.

4. All controls and safety switch circuits properly

connected per wiring diagram.

5. Factory installed wiring must not be changed

without written factory approval.

Installation

NOTE: Installation and maintenance to be performed only by

qualified personnel who are familiar with local codes

and regulations, and experienced with this type of

equipment.

Unit Location

Units are designed for outdoor application and may be

mounted on a roof or concrete slab (ground level installation).

Roof mounted units should be installed level on steel channels

or an I-beam frame to support the unit above the roof. Use of

vibration pads or isolators is recommended. The roof must be

strong enough to support the weight of the unit. Concrete slabs

used for unit mounting should be installed level and be properly

supported to prevent settling. A one-piece concrete slab with

footings extending below the frost line is recommended.

Sound Vibration

Units should be installed away from occupied spaces and

above or outside of utility areas, corridors and auxiliary spaces

to reduce the transmission of sound and vibration to occupied

spaces. The refrigerant piping should be flexible enough to

prevent the transmission of noise and vibration from the unit

into the building. If the refrigerant lines are to be suspended

from the structure of the building, isolation hangers should be

used to prevent the transmission of vibration. Where piping

passes through a wall, it is advisable to pack fiberglass and

sealing compound around the lines to minimize vibration and

retain flexibility in the lines.

CAUTION: Sharp edges and coil surfaces are a potential

injury hazard. A void contact with them.

The dry cooler should be located far enough away from

any wall or other obstruction to provide sufficient clearance for

air entrance. Do not attach ductwork to the coil inlet or fan

outlet. Care should be taken to avoid air recirculation conditions

that can be caused by sight screening, walls, etc. Also keep

unit fan discharge away from any building air intakes. See

page 10 for space and location requirements.

The unit needs to be secured in its final location. Holes

are provided in the base runner for this purpose.

WARNING: There may be more than one source of

electrical current in this unit. Do not

service before disconnecting all power

supplies.

2

© Heatcraft Inc. 2000.

Page 3

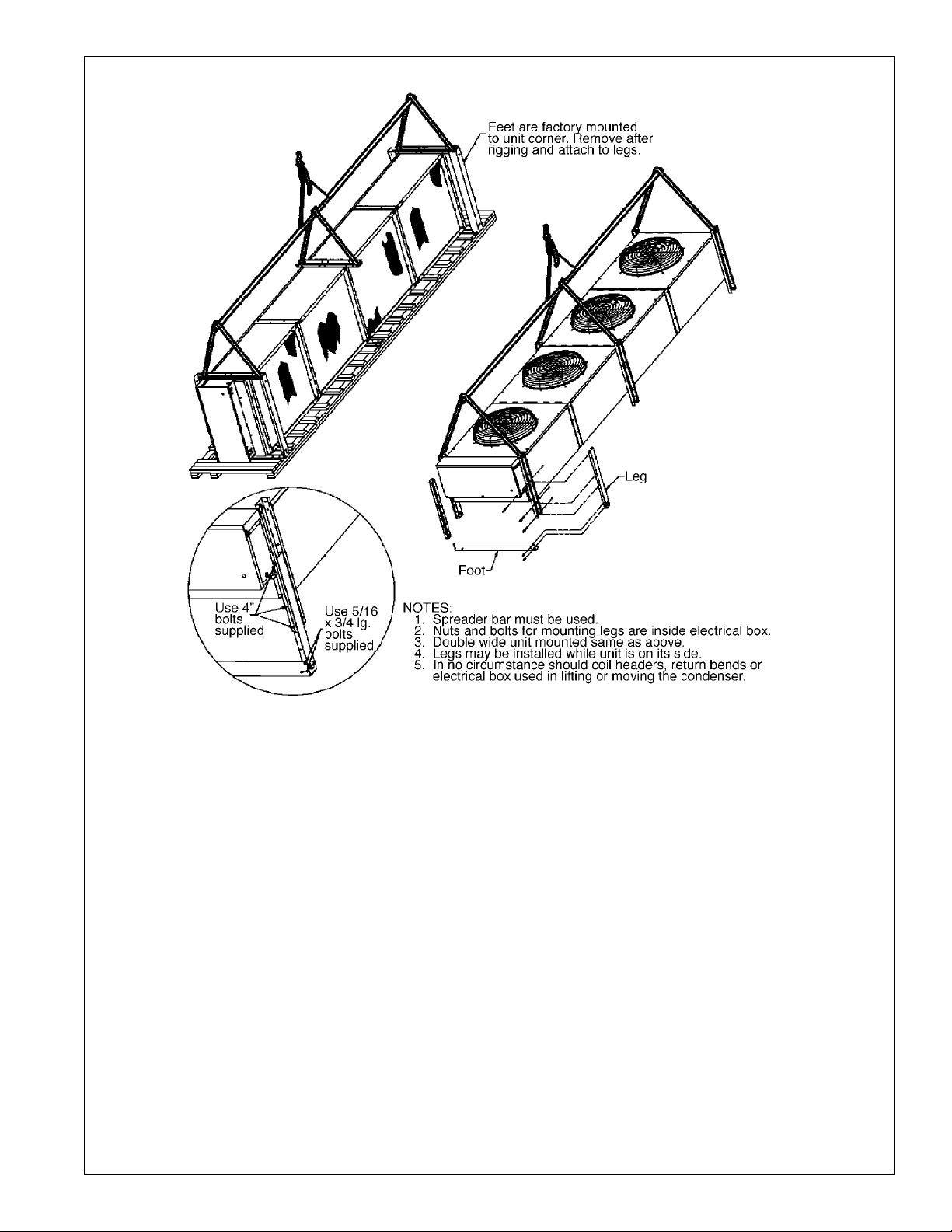

Figure 1. Rigging Instructions.

Vertical airflow type units should be located no closer

than the width of the unit from a wall or other obstruction. It

two or more units are to be positioned in the same area, a

similar distance should be maintained between adjacent units.

Sufficient free area should be left around and below unit to

avoid air restriction to coil.

3

Page 4

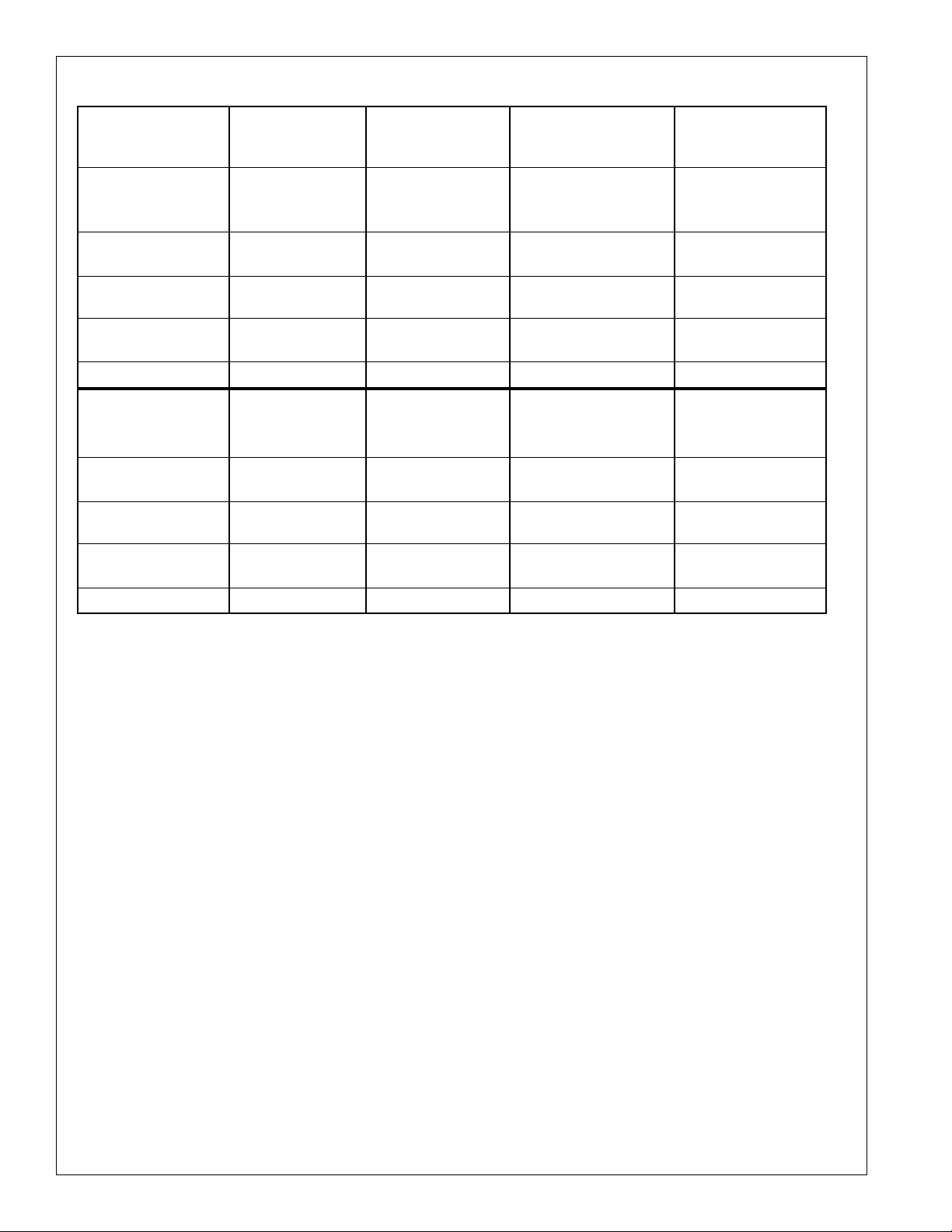

Table 1. Fluid Cooler Internal Volume and Weight

Fluid Number Number Internal Approximate

Cooler of of Volume Net Weight

Fan Configuration Fans Rows Gallons (Lbs.)

1 x 2 2 2 6.7 1540

1 x 2 2 3 9.2 1590

1 x 2 2 4 11.8 1600

1 x 3 3 3 13.0 2360

1 x 3 3 4 16.7 2420

1 x 4 4 3 16.7 3150

1 x 4 4 4 21.7 2190

1 x 5 5 3 20.4 3510

1 x 5 5 4 26.6 3990

1 x 6 6 4 31.6 4790

2 x 2 2 2 13.5 1540

2 x 2 2 3 18.5 1620

2 x 2 2 4 23.5 1760

2 x 3 3 3 25.9 2420

2 x 3 3 4 33.4 2480

2 x 4 4 3 33.3 3230

2 x 4 4 4 43.3 3510

2 x 5 5 3 40.7 4040

2 x 5 5 4 53.1 4390

2 x 6 6 4 63.1 5270

Electrical Wiring

The electrical installation should be in accordance with

National Electrical Code, local codes and regulations. Proper

overcurrent protection should be provided for the fan motors.

Wiring diagrams shown are only basic and do not show fuses,

disconnect switches, etc., which must be provided in the field.

All standard motors have internal inherent overload

protectors. Therefore, contactors can be used instead of

starters requiring thermal protectors, eliminating the problem

of furnishing the proper heating elements.

All dry coolers or units are furnished with either singlephase or three-phase fan motors which are identified by the

unit dataplate.

4

Electrical leads from each motor terminate at the unit

junction box. Field connections must be made from these leads

through a contactor, fuse and disconnect in accordance with

local, state and national codes.

Three-phase motors must be connected to three-phase

power of voltage to agree with motor and unit dataplate.

The motors are wired into a common junction box. The

motors must be checked for proper rotation. Be sure to check

that motor voltage and control connection agree with electric

services furnished.

Page 5

Diagram 1. Typical Fluid Cooler Wiring Diagram Without Fan Cycle Controls.

Single Row of Fans

Double Row of Fans

5

Page 6

Diagram 2. Typical Fluid Cooler Wiring Diagram With Standard Fan Cycle Controls.

Single Row of Fans

Double Row of Fans

6

Page 7

System Installation

NOTE: All installation and maintenance are to be performed

only by qualified personnel who are familiar with local codes

and regulations, and experienced with this type of

equipment. CAUTION: Sharp edges and coil surfaces are

a potential injury hazard. A void contact with them.

General

1. Structure supporting unit must be designed to support both

the unit and the fluid. Table 2 provides weight of fluid per

gallon. Tables 3 and 4 provide unit weight and volume

data. Provide suitable flashing of the roof, if this is a roof

installation. For ground level mounting, a concrete pad is

recommended. Mounting holes permit the unit to be bolted

down to withstand wind pressures. Provide adequate clearance for unobstructed air flow to coils. See page 2 for

Space and Location requirements.

2. Level mounting is necessary to assure proper fluid distri-

Table 2. Fluid Weight Per Gallon

Percent Glycol Pounds Per Gallon

0 (Water) 8.345

10 8.395

20 8.495

30 8.604

40 8.712

50 8.804

bution through the coil as well as flooded suction for the

pump.

3. Water piping must comply with local codes. Correct pipe

sizing will help reduce pumping power and operating costs.

4. In case of doubt, consult the manufacturer for the dry

cooler fluid pressure drop at the specific conditions on

your job.

5. Provide sufficient valves and unions to permit easy access to parts subject to wear and possible repair or replacement.

6. After fluid piping is completed, all joints should be leak

tested.

7. Where city water makeup is required, follow local codes,

making certain that disconnecting provisions are provided.

8. Select wire in accordance wit nameplate data and local

codes.

Piping Installation

The piping system should provide maximum leak prevention. Weld or sweat joints should be used where possible

or tightly drawn T eflon tape threaded pipe joints should be made

if needed. The fact that glycol solutions or other heat transfer

fluids will leak where water will not, must be taken into account.

The glycol system should not employ a pressure reducing valve. This is because a slight leak would lead to dilution

of the mixture. Any refill should be controlled so as to maintain the proper glycol-to-water ratio.

Table 3 shows pressure drops for various pipe sizes at

flow rates commonly used with a typical dry cooler. These

pipe sizes are not necessarily always correct for the run from

the condenser to the dry cooler. Proper pipe size will depend

on available pump head. This can be determined by subtracting from the total available pump head at design flow, the condenser pressure drop and the dry cooler pressure drop. Allow

some safety factor for last minute pipe fittings added to the

system and for eventual fouling of the system.

a. Glycol piping requires no insulation except when fluid tem-

perature will be below ambient dewpoint temperatures.

Dry coolers normally produce about 70° or higher fluid

temperatures.

b. Vents are required at all high points in the piping to bleed

air when filling the system. If fluid coolers are at high

points, vent valves should be installed at each fluid cooler.

c. It is recommended that gate valves be installed on both

sides of the pump to prevent loss of fluid in the event the

pump should require repair or replacement. Shut-off

valves are also recommended at water cooled condens-

Table 3. Pressure Loss in Feet of Water

Pipe

Flow Size O.D. Head Ft./100 Ft. Head Ft./100 Ft.

GPM Steel Copper Equiv. Length Equiv. Length

15 1 1 1/8 17.6 15.0

20 1 1 1/8 30.2 23.1

25 1 1 1/8 — 34.6

25 1 1/4 1 3/8 11.5 12.6

30 1 1/4 1 3/8 16.3 17.4

35 1 1/4 1 3/8 21.8 23.0

40 — 1 3/8 — 26.3

40 1 1/2 1 5/8 13.0 12.9

45 1 1/2 1 5/8 16.5 15.7

60 — 1 5/8 — 26.3

60 2 2 1/8 7.9 7.0

80 2 2 1/8 13.7 12.0

100 2 1/2 2 5/8 8.5 6.1

150 2 1/2 2 5/8 18.6 12.9

200 3 3 1/8 10.7 9.1

250 3 3 1/8 16.5 13.7

300 3 1/2 3 5/8 11.1 9.2

300 4 4 1/8 5.9 4.9

350 4 4 1/8 7.9 6.5

400 4 4 1/8 10.2 8.2

Type "L" Schedule 40 Steel Copper Tube Head

ers in case the condensing unit is to be moved or requires

maintenance involving the coolant system.

Glycol Charge

The amount of ethylene glycol required depends upon

the following:

a. The holding volume of the system which includes the hold-

ing capacity of the condenser, the holding capacity of the

interconnecting piping (Table 3) and the holding capacity

of the dry cooler (see Table 3).

b. Percentage of glycol required by volume to provide pro-

tection at the design minimum outside temperature (see

Table 2).

7

Page 8

Table 4. Percentage of Ethylene Glycol to be Added by

Volume.

Percent % 20% 30% 40% 45% 50%

Minimum Outside Design

Temperature °F

Table 4 is intended to be used as a guide only. Proper precautions need to

be taken to prevent freeze damage during low ambients. Consult glycol vendor recommendations for specific freeze protection for your location.

+15 -3 -14 -23 -38

Fluid Circulating Pump

systems. Gland type pumps would cause glycol waste and, if

used with a pressure reducing valve, will lead to dilution of the

glycol mixture and eventual freeze-up.

sure drop through the dry cooler coil, plus pressure drop

through the heat source.

since in a closed system a counterhead acts on the pump suction.

Mechanical seal type pumps must be used for glycol

Pump is selected for piping friction loss plus fluid pres-

No allowance for vertical lift

is made

Mixing Glycol and Water

Regardless of the strength of the mixture, you MUST

pre-mix the glycol and water prior to adding it to the system.

The chemical reaction between the two will release oxygen,

which is extremely undesirable in a close-loop system.

WARNING: For dry coolers operating without glycol

mixture, adequate freeze protection is

necessary during ambients below 32

° F.

Glycol Sludge Prevention

Glycol systems may be subject to sludge formation in

coils, due to one or more of the following causes:

1. Reaction of the corrosion inhibitor with galvanized piping

(zinc).

2. Reaction of the glycol with chromate type water additives.

3. Reaction of the glycol with pipe dope, cutting oils, solder

flux, and other system dirt.

Glycol manufacturers offer a specially inhibited glycol

(formulated for snow melting systems) which does not react

with zinc. This glycol is also suitable for heat transfer systems. Glycol manufacturers also provide inhibitor check services on a regular basis.

With glycol solution the pump performance curve will

drift to the right from its design point, due to differences in

circuit design, control valve application, pressure drop calculations, etc. The pump should be selected high on the curve

so as to provide for the "drift". The pump curve should be

"flat" so that the pump will compensate for our inability to exactly predict the final operating system flow condition and to

provide sufficient flow for satisfactory heat transfer and maximum protection against freezing at the far end of the circuit.

The pump motor should have sufficient power for operating

over the entire pump curve to prevent motor overload at reduced voltages. Paralleled pumps can also be used for good

power economy and continuous and automatic standby operation. Properly applied parallel pumps will guard against

system breakdown caused by a simple pump failure. Certain

older systems have nonoperating standby pumps of equal

capacity to the operating unit. We recommend parallel pumps

in continuous operation because they provide practically the

same type of standby, in addition to being completely automatic, at lower initial and operating cost.

Consequently, good glycol system design requires the

following precautions:

1. No galvanized piping is to be used.

2. System piping must be thoroughly cleaned and flushed

with a heated trisodium phosphate solution before filling

wit the water/glycol mixture.

3. No chromate inhibitor treatment must be used.

4. The glycol manufacturer should provide inhibitor check

service and supply additional inhibitor as required.

8

Page 9

Start-up

1. Prestart:

Check for correct dry cooler fan rotation. This can be done

by quickly jogging the fan contactor. Be sure that the fans

run freely. The same check is recommended for pumps.

2. Filling and Purging the System

The system should be pressure tested before adding glycol.

The system can be tested with air or water, however if the

ambient temperature is at or below freezing the use of air

is recommended. Test pressure should not exceed 60

PSIG.

a. Roof Mounted Fluid Cooler

To fill the system pour the premixed water and glycol

into the expansion tank. Fill the system until the

expansion tank is half full, then purge the air from

ALL vents. Operate the system for a minute, then

purge ALL vents again, and add glycol as required.

Repeat the purging of all vents after the first hour of

operation and again after several hours of operation.

b. Ground Mounted Fluid Cooler

The fluid cooler may be lowest point in the system,

consequently the premixed water and glycol will have

to be pumped into the system. Close the shut off valve

and open the two hose bibbs installed in the piping

run on the leaving side of the pump, see piping

diagram.

Connect a pump and hose to the hose bibb away

from the pump and a hose to the hose bibb closest

to the pump. Begin pumping the glycol mixture into

the system at FULL PRESSURE. For the return

hose you should close the hose bibb so that you

get only a small flow of fluid or air. This is

necessary so you will build a head of fluid which will

force the air from the system. Once all the air is out

you will have a steady flow of only fluid. At this joint

you should close off the two hose bibbs and open

the shut off valve. See Diagram 3.

3. Flow Adjustment Procedure:

Once the system is completely full of fluid, start the fluid

circulating pump. To assure proper fluid flow, adjust the

shut-off valve for required GPM by checking pump curve

and observing gauge pressure, or by using an in-line flow

meter.

4. Instruction Envelope:

Keep wiring diagrams, instructions, list of spare parts, in

an envelope within easy reach of the installed dry cooler.

Diagram 3.

Space and Location Requirements

The most important consideration which must be taken

into account when deciding upon the location of air-cooled

equipment is the provision for a supply of ambient air to the

condenser, and removal of heated air from the fluid cooler

area. Where this essential requirement is not adhered to, it

will result in higher head pressures, which cause poor operation

and possible eventual failure of equipment. Units must not be

located in the vicinity of steam, hot air or fume exhausts.

Another consideration which must be taken is that the

unit should be mounted away from noise sensitive spaces

and must have adequate support to avoid vibration and noise

transmission into the building. Units should be mounted over

corridors, utility areas, rest rooms and other auxiliary areas

where high levels of sound are not an important factor. Sound

and structural consultants should be retained for

recommendations.

9

Page 10

Walls or Obstructions

The unit should be located so that air may circulate freely

and not be recirculated. For proper air flow and access all

sides of the unit should be a minimum of “W” away from any

wall or obstruction. It is preferred that this distance be increased

whenever possible. Care should be taken to see that ample

Multiple Units

For units placed side by side, the minimum distance

between units is the width of the largest unit. If units are placed

end to end, the minimum distance between units is 4 feet.

room is left for maintenance work through access doors and

panels. Overhead obstructions are not permitted. When the

unit is in an area where it is enclosed by three walls the unit

must be installed as indicated for units in a pit.

Units in Pits

The top of the unit should be level with the top of the pit,

and side distance increased to “2W”.

Decorative Fences

Fences must have 50% free area, with 1 foot undercut,

a “W” minimum clearance, and must not exceed the top of

If the top of the unit is not level with the top of pit, discharge cones or stacks must be used to raise discharge air to

the top of the pit. This is a minimum requirement.

unit. If these requirements are not met, unit must be installed

as indicated for “Units in pits”.

10

* “W” = Total width of the fluid cooler.

Page 11

Diagram 4. Typical Piping

In-Warranty Return Material Procedure

Material may not be returned except by permission of

authorized factory service personnel of Heatcraft Inc.

Refrigeration Products Division in Stone Mountain, Georgia.

A “Return Goods” tag will be sent to be included with the

returned material. Enter the required information on the tag in

order to expedite handling at our factories and prompt issuance

of credits. All parts shall be returned to the factory designated

on the “Return Goods” tag, transportation charges prepaid.

The return of a part does not constitute an order for

replacement. Therefore, a purchase order must be entered

through your nearest Heatcraft Refrigeration Products

representative. The order should include part number, model

number and serial number of the unit involved.

Following our careful inspection of the returned part and if

it is determined that the failure is due to faulty material or

workmanship, credit will be issued on customer's purchase order.

11

Page 12

Replacement Parts

When writing to the factory for service or replacement parts,

refer to the model number and serial number of the unit as stamped

on the serial plate attached to the unit. If replacement parts are

required, mention the date of installation of the unit and date of

failure, along with an explanation of the malfunctions and a

description of the replacement parts required.

Table 5. Replacement Parts List

Part Description

208-230/3/60 460/3/60 575/3/60

Fan Motor, 1 1/2 HP, 1140 RPM 25301801 25301801 25302001

Fan Blade, 30" 22900401 22900401 22900401

Fan Guard, 30" 23100301 23100301 23100301

Contact Customer Service Department for parts to specific fluid cooler models.

Since product improvement is a continuing effort at Heatcraft, we reserve the right to make changes in specifications without notice.

Part Number

12

Heatcraft Refrigeration Products

2175 West Park Place Blvd.

Stone Mountain, GA 30087

(770) 939-4450 • Fax: (770) 908-5480

www.heatcraftrpd.com

Loading...

Loading...